Page 1

Table of Contents

Rotary Cutters

RC5015 & RC6015 (540 RPM) and

RCM5015 & RCM6015 (1000 RPM)

15678

318-047M

Operator’s Manual

Read the Operator’s manual entirely. When

you see this symbol, the subsequent

!

instructions andwarningsare serious - follow

without exception. Your life and the lives of

others depend on it!

© Copyright 2008 Printed

Cover photo may show optional equipment

not supplied with standard unit.

8/28/08

Page 2

Table of Contents

Tab le of Contents

Important Safety Information . . . . . . . . . . .1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look For The Safety Alert Symbol . . . . . . . . . . . . .1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . .10

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . .10

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . 10

Serial Number Plate . . . . . . . . . . . . . . . . . . . . 10

Free Maintenance Video . . . . . . . . . . . . . . . . .10

Further Assistance . . . . . . . . . . . . . . . . . . . . .10

Section 1: Assembly and Set-up . . . . . . .11

Tractor Requirements . . . . . . . . . . . . . . . . . . . . .11

Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hydraulic Outlets . . . . . . . . . . . . . . . . . . . . . . . 11

PTO Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hitch Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Standard Clevis Hitch . . . . . . . . . . . . . . . . . . . 12

Double Swivel Clevis Hitch (Optional) . . . . . . . 12

Bar-Tite Hitch (Optional) . . . . . . . . . . . . . . . . .12

Hitch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wing Axle Assembly . . . . . . . . . . . . . . . . . . . . . .13

Tractor Hook-up to Standard Clevis Hitch . . . . . . 13

Tractor Hook-up to Swivel Clevis Hitch . . . . . . . . 14

Tractor Hook-up to Bar-Tite Hitch . . . . . . . . . . . .14

Driveline Installation . . . . . . . . . . . . . . . . . . . . . . . 15

Check Driveline Length . . . . . . . . . . . . . . . . . .15

Hydraulic Hook-up . . . . . . . . . . . . . . . . . . . . . . . . 16

Unhooking From the Cutter . . . . . . . . . . . . . . . . . 17

Section 2: Operating Instructions . . . . . .18

Pre-start Checklist . . . . . . . . . . . . . . . . . . . . . . . . 18

Cutter Set-up For Transporting . . . . . . . . . . . . . .18

Transporting The Cutter . . . . . . . . . . . . . . . . . . . . 19

Cutter Set-up For Field Operation . . . . . . . . . . . . 19

Operating Speed & Turning Angle . . . . . . . . . . . . 19

General Operating Instructions . . . . . . . . . . . . . .20

Land Pride

Section 3: Adjustments . . . . . . . . . . . . . .22

Center and Wing Section Leveling . . . . . . . . . . . .22

Cutting Height Adjustment . . . . . . . . . . . . . . . . . .22

Section 4: Options . . . . . . . . . . . . . . . . . .23

Safety Guard Options . . . . . . . . . . . . . . . . . . . . . .23

Hydraulic Accessories . . . . . . . . . . . . . . . . . . . . .23

Section 5: Maintenance & Lubrication . . 24

General Maintenance Information . . . . . . . . . . . .24

Cutter Blade Maintenance . . . . . . . . . . . . . . . . . .24

Drivelines With Slip Clutches . . . . . . . . . . . . . . . .25

Type A Clutches . . . . . . . . . . . . . . . . . . . . . . .25

Type B Clutches . . . . . . . . . . . . . . . . . . . . . . .26

Type C Clutches . . . . . . . . . . . . . . . . . . . . . . .27

Skid Shoe Maintenance . . . . . . . . . . . . . . . . . . . .29

Center Skid Shoe . . . . . . . . . . . . . . . . . . . . . .29

Wing Skid Shoe . . . . . . . . . . . . . . . . . . . . . . . .29

Tractor Maintenance . . . . . . . . . . . . . . . . . . . . . .29

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . .31

Axle Hub Bearing . . . . . . . . . . . . . . . . . . . . . .31

Adjustable Turnbuckle . . . . . . . . . . . . . . . . . . .31

Main Hitch . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Double Swivel Clevis Hitch . . . . . . . . . . . . . . .32

Bar-Tite Hitch . . . . . . . . . . . . . . . . . . . . . . . . .32

Divider Box . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Intermediate Driveline Joints . . . . . . . . . . . . . .33

Conventional Driveline Profile Tubes . . . . . . . .34

Conventional Driveline Joints & Shields . . . . .34

Constant Velocity Driveline Profile Tubes . . . .35

Constant Velocity Driveline Joints & Shields . .35

Wing Driveline Profile Tubes . . . . . . . . . . . . . .36

Wing Driveline Joints & Shields . . . . . . . . . . . .36

Section 6: Specifications & Capacities . .37

Section 7: Features and Benefits . . . . . .38

Section 8: Troubleshooting . . . . . . . . . . .40

Section 9: Appendix . . . . . . . . . . . . . . . . .41

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . .41

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

© Copyright 2008 All rights Reserved

Land Pride provides this publication “asis” without warranty ofany kind, either expressedor implied. While every precaution has beentaken in the preparationof this manual, Land

Pride assumesno responsibility forerrors oromissions. Neither isany liability assumedfor damagesresulting from theuse of theinformation contained herein.Land Pride reserves

the rightto revise andimprove itsproducts as it sees fit. This publicationdescribes the stateof this productat the time of its publication,and may notreflect the productin the future.

Land Pride isa registered trademark.

All other brands and product names are trademarksor registered trademarks of their respectiveholders.

Printed in the United States of America.

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

Page 3

Land Pride

▲

Table of Contents

Important Safety Information

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Safety at All Times

Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read

all instructions noted on them.

Do not allow anyone to operate

this equipment who has not fully

read and comprehended this

manual and who has not been

properly trained in the safe

operation of the equipment.

▲ Operator should be familiar with

all functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ Make sure all guards and shields

are in place and secured before

operating the implement.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving

tractor could cause serious injury

or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of

working area.

▲ Turning tractor too tight may

cause implement to ride up on

wheels. This could result in injury

or equipment damage.

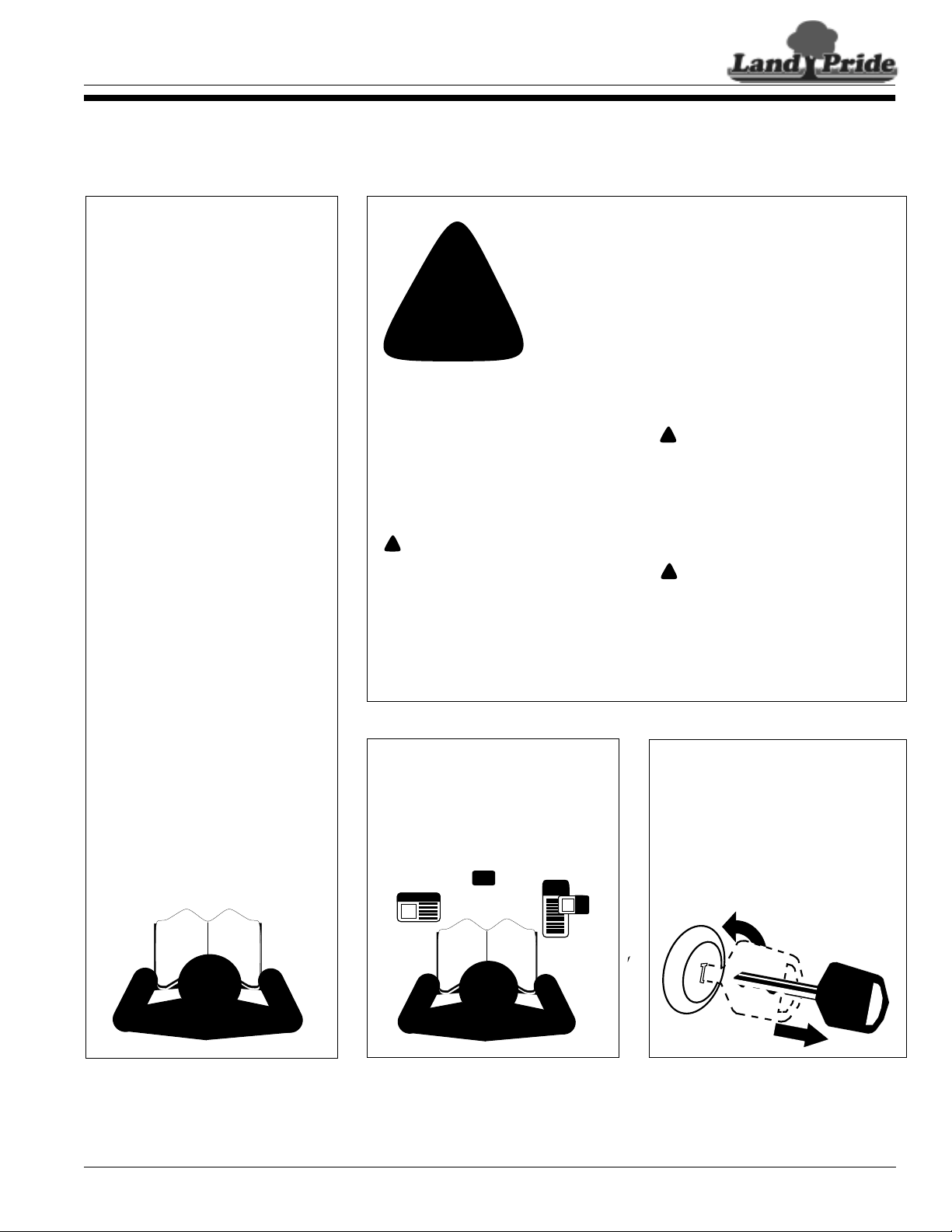

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

!

Be Aware of

Signal Words

A Signal word designates a degree or

level of hazard seriousness. The

signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for

functional purposes, cannot be

guarded.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read all

instructions noted on them.

equipment, hazard control and accident prevention

are dependent upon the awareness, concern,

prudence and proper training of personnelinvolved in

the operation, transport, maintenance and storage of

equipment.

!

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It mayalso

be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine, and

remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

8/28/08

OFF

REMO

VE

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

1

Page 4

Table of Contents

Land Pride

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

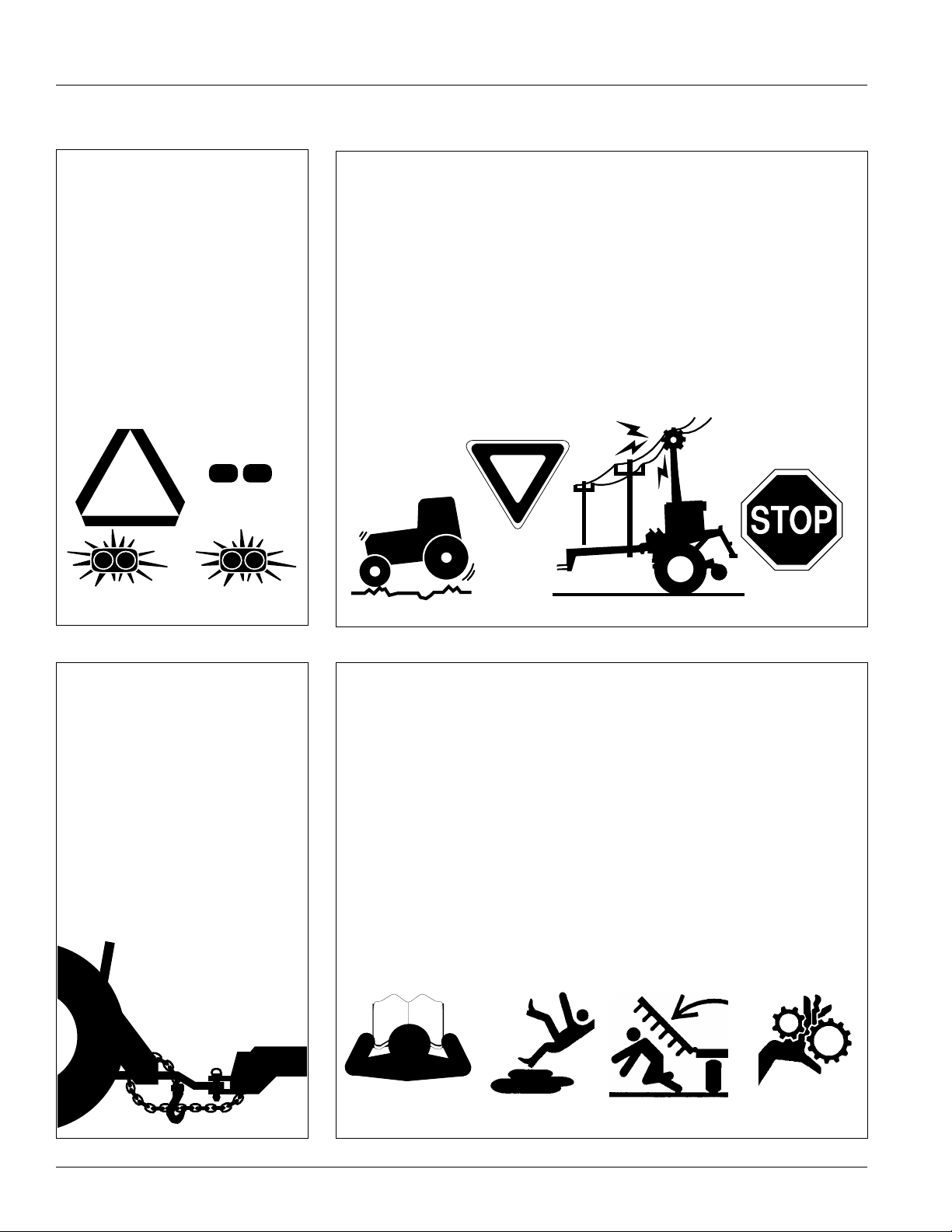

Use Safety

Lights and Devices

▲ Slow moving tractors, self-

propelled equipment, and towed

implements can create a hazard

when driven on public roads. They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended

whenever driving on public roads.

Use lights and devices provided

with implement.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for

implement is 20 mph. DO NOT

EXCEED.Never travel at a speed

which does not allow adequate

control of steering and stopping.

Some rough terrain require a

slower speed.

▲ Sudden braking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with brakes.

▲ Use the following maximum

speed - tow load weight ratios as

a guideline:

20 mph when weight is less

than or equal to the weight of

tractor.

10 mph when weight is double

the weight of tractor.

▲ IMPORTANT: Do not tow a load

that is more than double the

weight of tractor.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it

separate from the tractor

drawbar.

▲ Use a chain with the strength

rating equal to or greater than

the gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other

specified anchor location. Allow

only enough slack in the chain to

permit turning.

▲ Do not use safety chain for

towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower the implement to the

ground, put tractor in park, turn off

engine, and remove key before

performing maintenance.

▲ Allow implement to cool

completely.

▲ Do not grease or oil implement

while it is in operation.

▲ Inspect all parts. Make sure parts

are in good condition & installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before

operation.

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

2

Page 5

Land Pride

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

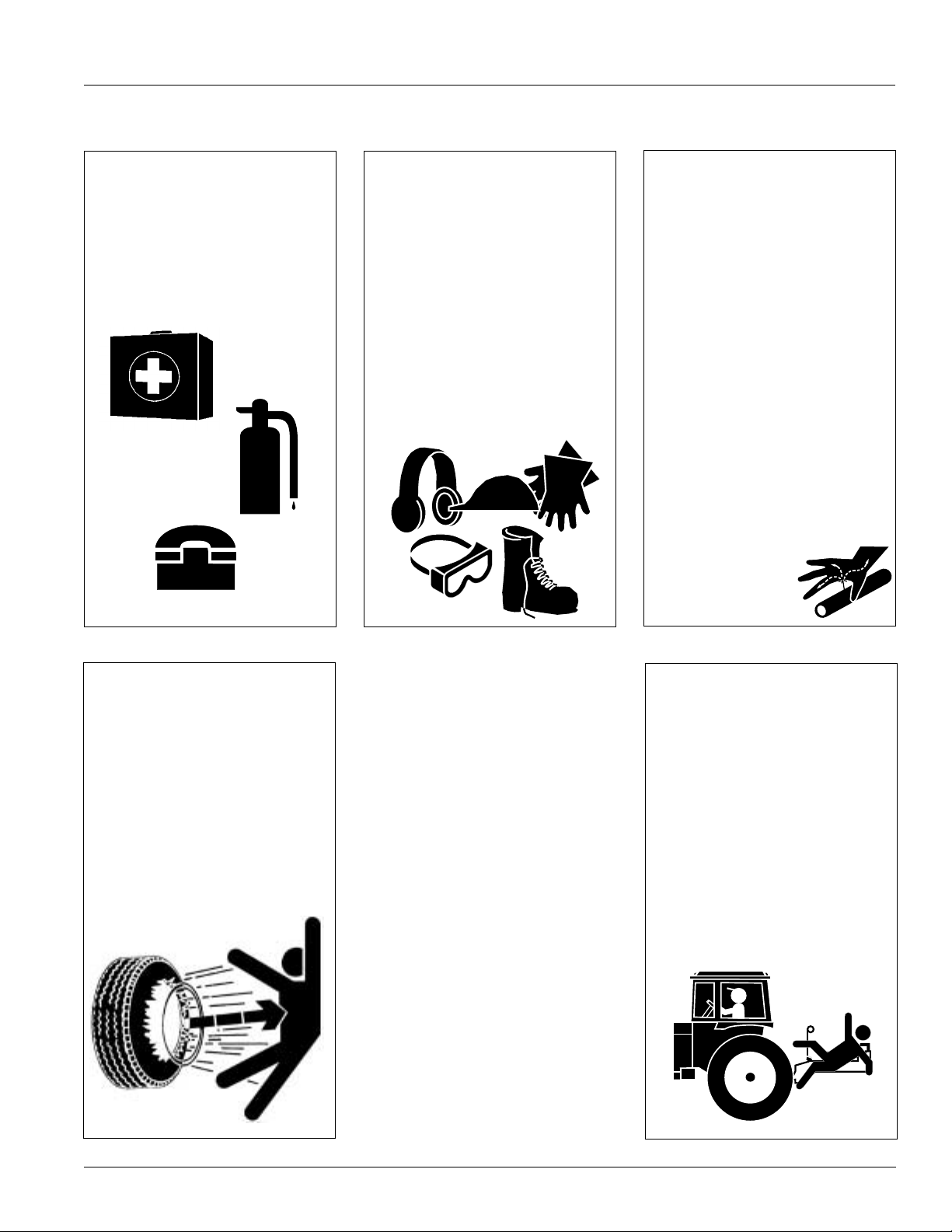

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Protectiveclothingandequipment

should be worn.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable

hearing protection such as

earmuffs or earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid underpressurecan

penetratetheskincausingserious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines or performing work

on the system.

▲ Make sure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to the system.

▲ Use a piece of paper or

cardboard, NOT BODYPARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

treated within a few hours or

gangrene may result.

Tire Safety

▲ Tire changing can be dangerous

and should be preformed by

trained personnel using the

correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel handling

equipment adequate for the

weight involved.

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view, they could be struck by

foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

8/28/08

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

3

Page 6

Important Safety Information

Table of Contents

Land Pride

Safety Labels

Your cutter comes equipped with all safety labels in place. They

were designed to help you safely operate your implement. Read

and follow their directions.

1. Keep all safety labels clean and legible.

2. Replace all damaged or missing labels. To order new

labels go to your nearest Land Pride dealer.

3. Some new equipment installed during repair requires

safety labels to be affixed to the replaced component as

specified by Land Pride. When ordering new components

make sure the correct safety labels are included in the

request.

4. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Spray soapy water on the surface where the label is to

be placed.

c. Peel backing from label.Press firmlyontothesurface.

d. Squeeze out air bubbles with the edge of a credit card.

818-045C

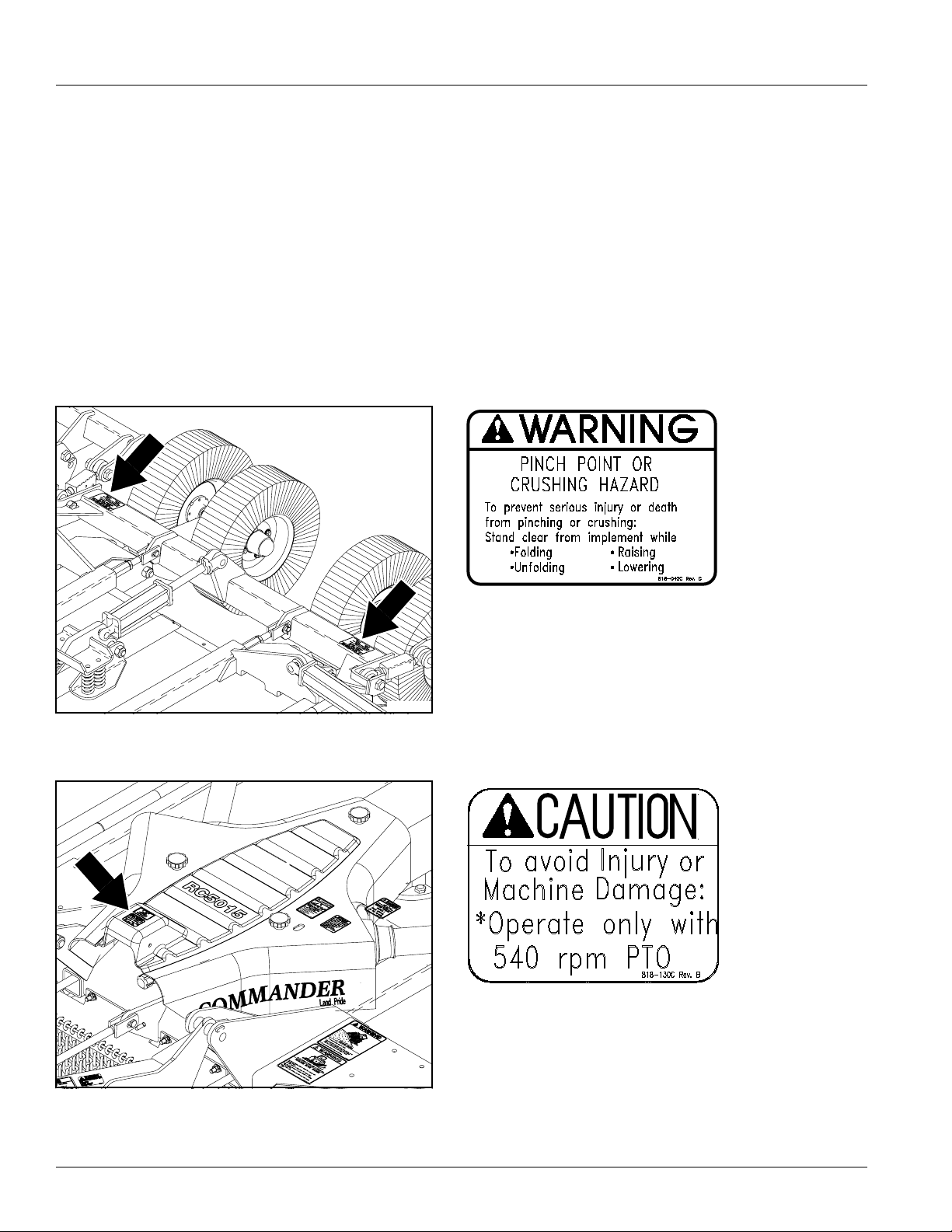

Pinch Point

Warning

23573

23572

818-130C

Caution! Use

540 rpm PTO

only

818-240C

Caution! Use

1000 rpm PTO

only

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

4

Page 7

Land Pride

Important Safety Information

Table of Contents

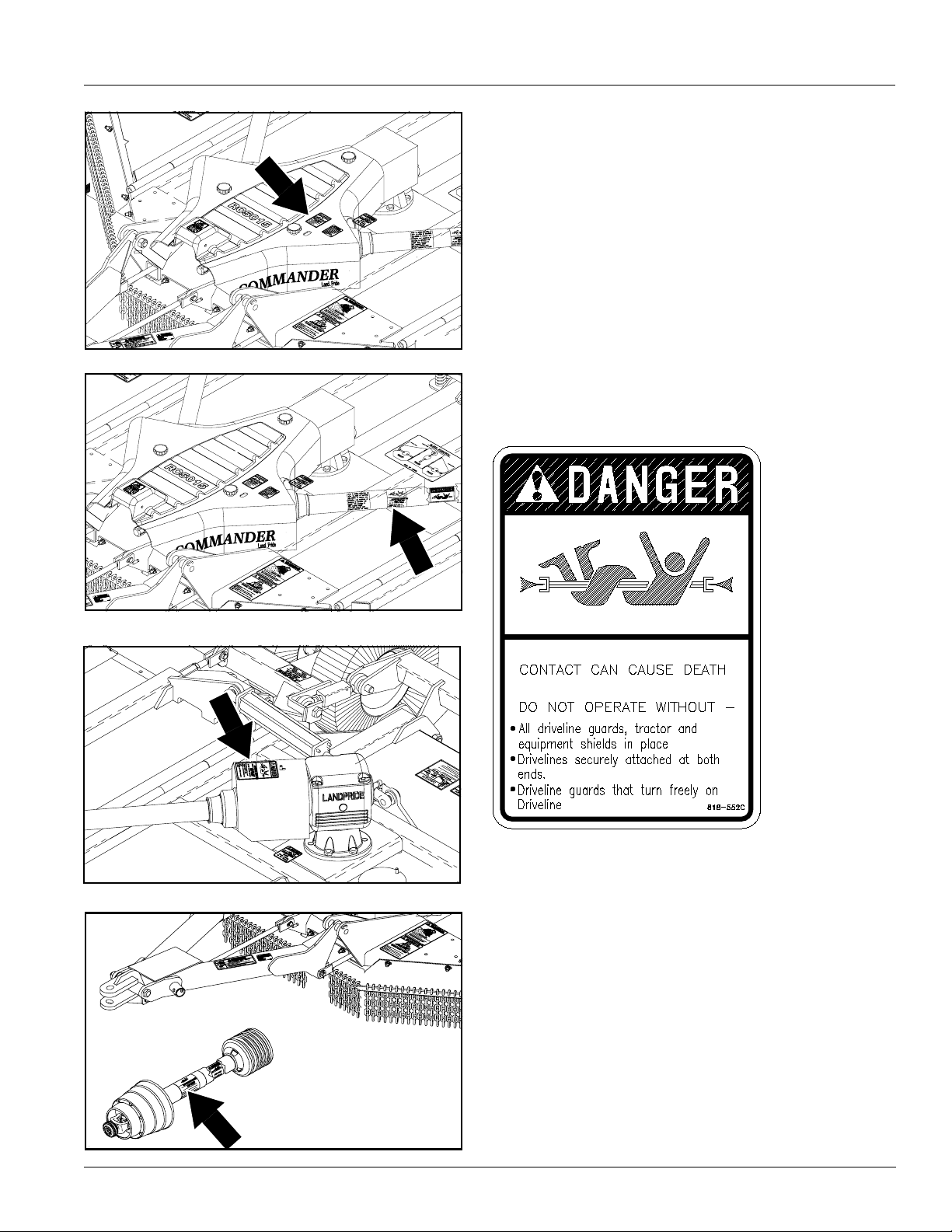

23572

23572

23573

ROTATING DRIVELINE

KEEP AWAY!

818-552C

Danger!Rotating Driveline

Entanglement Hazard

8/28/08

23571

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

5

Page 8

Important Safety Information

Table of Contents

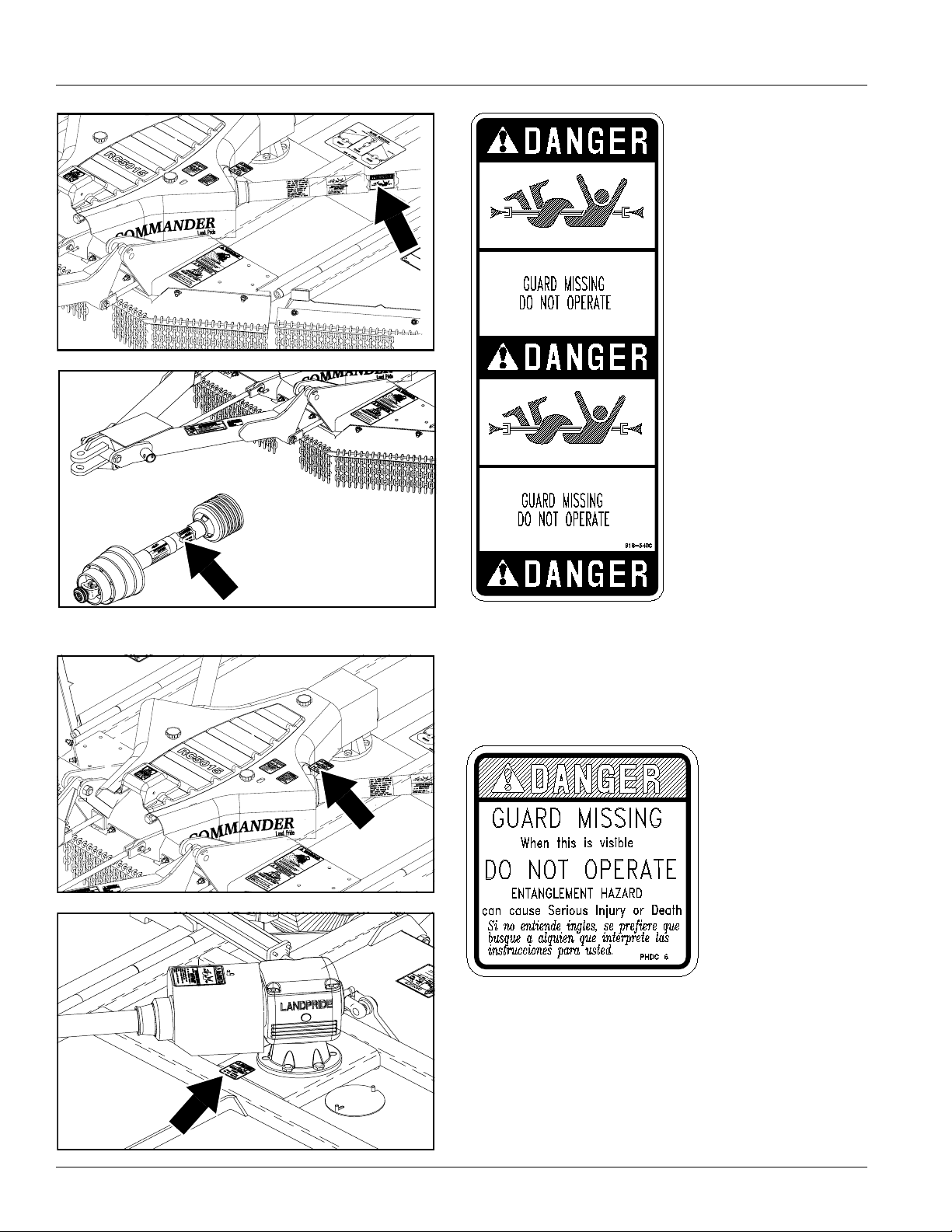

23572

Land Pride

818-540C

Danger! Shield Missing DO NOT Operate

23571

23572

818-543C

Danger! Guard Missing DO NOT Operate

23573

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

6

Page 9

Land Pride

Important Safety Information

Table of Contents

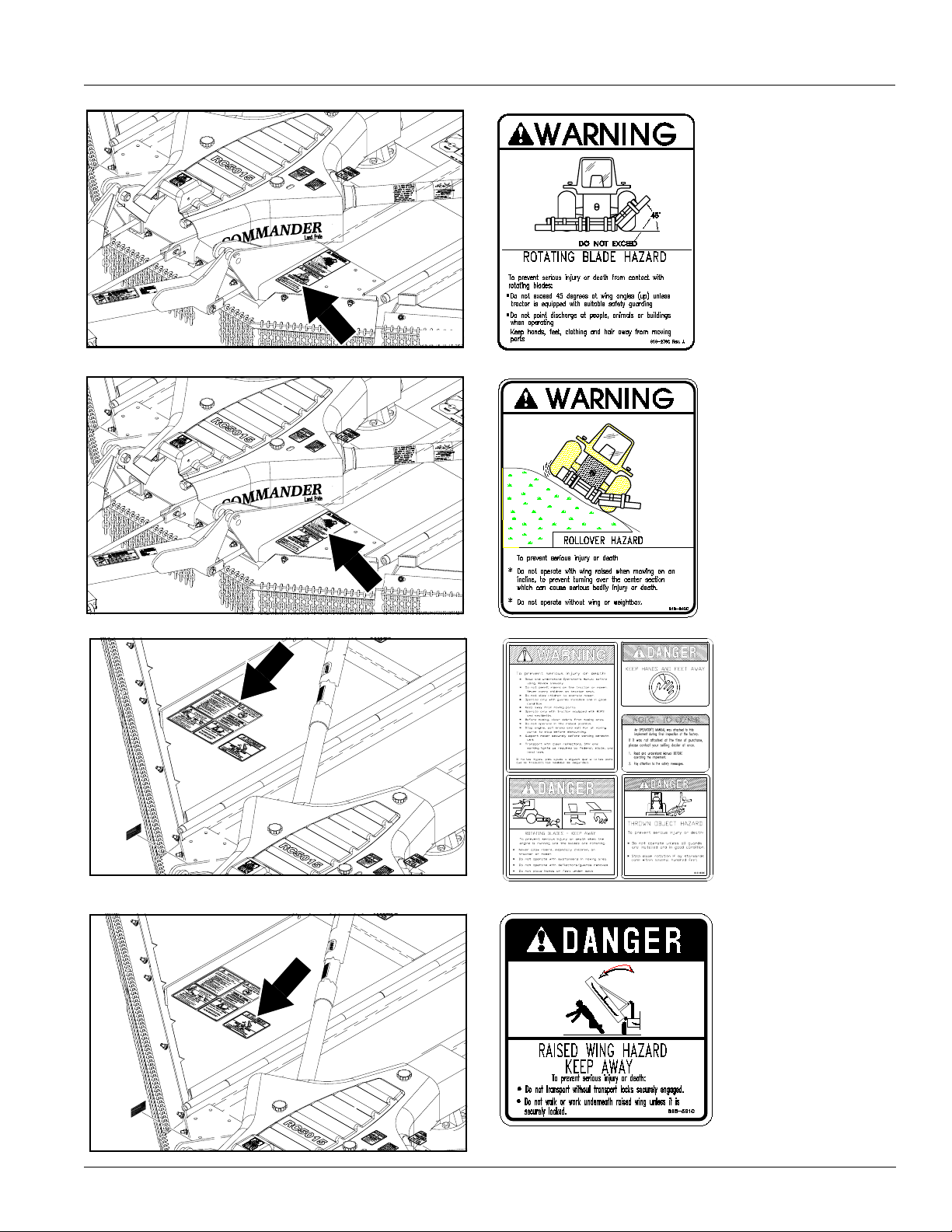

TRACTOR MUST HAVE SAFETY GUARDING

818-276C

Warning!Rotating Blade

Hazard

23572

23572

23572

818-840C

Danger: Rollover Hazard

818-830C

Safety Combo

Located on

Left Wing &

Right Wing

8/28/08

818-561C

Warning! Moving

Parts Hazard

Located on

Left Wing &

23572

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

Right Wing

7

Page 10

Important Safety Information

23572

Standard Clevis Hitch

23572

Double Swivel Clevis Hitch Shown

Table of Contents

Land Pride

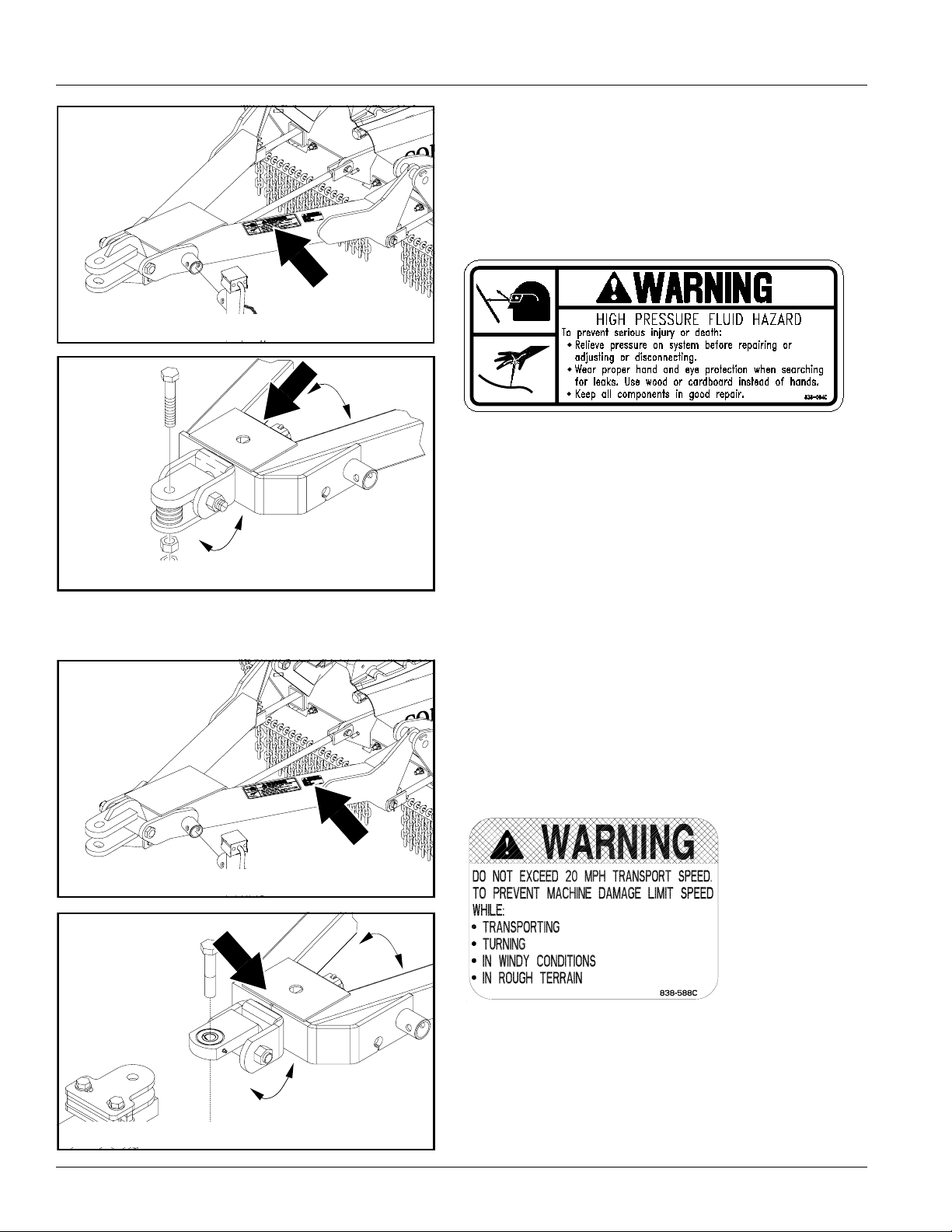

838-094C

Warning: High Pressure

Located on

Standard Clevis Hitch arm,

Double Swivel Clevis Hitch flat plate

and Bar-Tite Hitch flat plate

23572

23572

Standard Clevis Hitch

838-588C

Warning: Folding Cutter Speed Warning

Located on

Standard Clevis Hitch arm,

Double Swivel Clevis Hitch flat plate

and Bar-Tite Hitch flat plate

Bar-Tite Hitch Shown

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

8

Page 11

Land Pride

Important Safety Information

Table of Contents

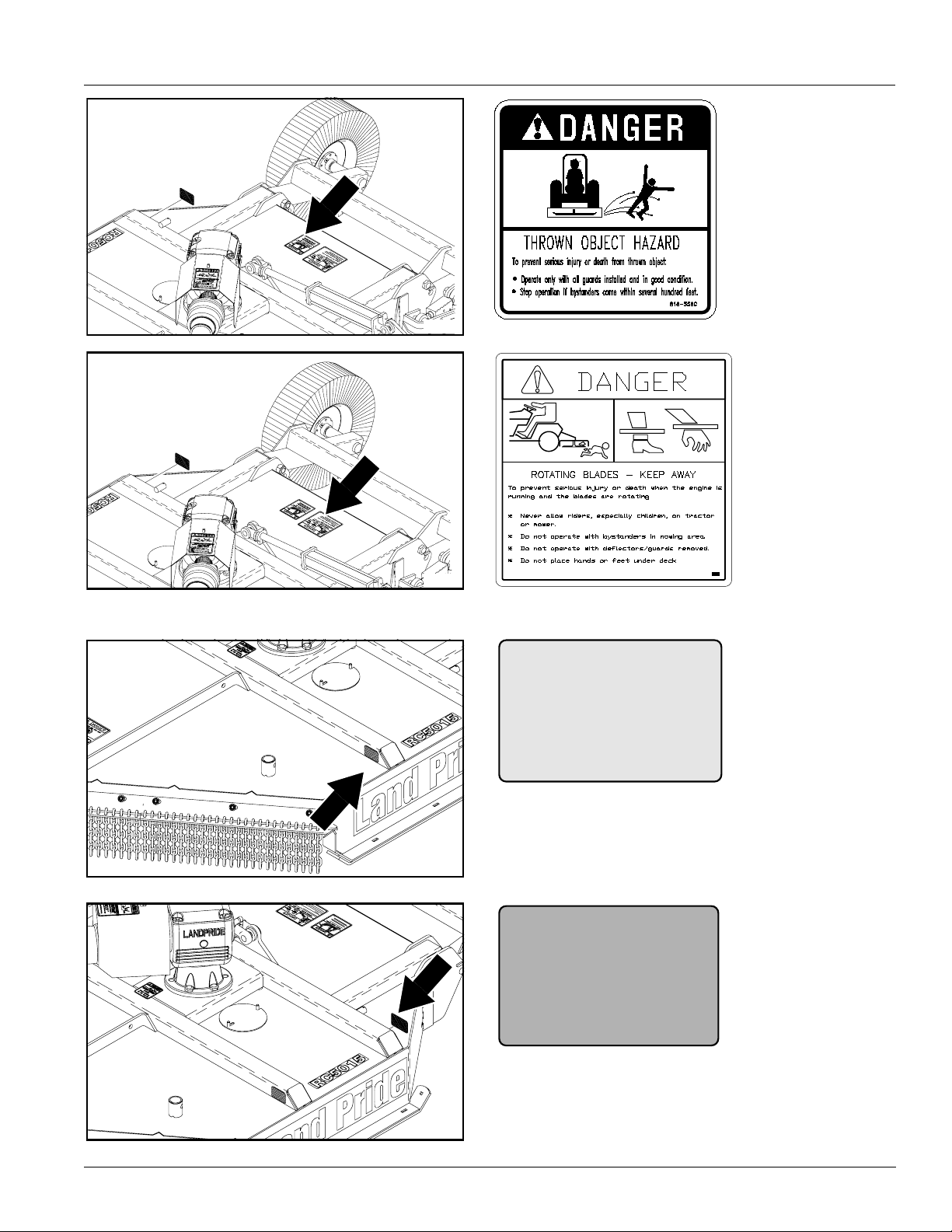

818-556C

Danger! Thrown

Object Hazard

Located on Left Wing

& Right Wing

23572

23572

23571

818-564C

Danger!

Rotating Blade

Located on Left Wing

& Right Wing

818-229C

Amber Reflector

Located on LeftWing

& Right Wing

8/28/08

818-230C

Red Reflector

Located on Left Wing

& Right Wing

23571

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

9

Page 12

Table of Contents

Introduction

Land Pride welcomes you to the growing family of new

Introduction

product owners.

Thisimplement has been designedwithcare and built by

skilledworkersusingqualitymaterials.Properassembly,

maintenance, and safe operating practices will help you

get years of satisfactory use from this machine.

The parts on your Rotary Cutter have been specially

designedandshouldonlybe replaced with genuine Land

Prideparts.Therefore, should your Rotary Cutterrequire

replacement parts go to your Land Pride Dealer.

Application

The heavy duty RC5015, RCM5015, RC6015 and

RCM6015 Series Rotary Cutters are designed and built

by Land Pride to provide excellent cutting performance

on gently sloping or slightly contoured right-of ways,

roadsides, pastures, set-aside-acres, or for residue in

row crop fields. The 15’ cutting width, 2" to 14" cutting

heightandability to cut weeds andbrushmakethemwell

suited for these applications. All listed models offer

pull-type self-leveling clevis hitches for attachment to

50-250 hp tractors. Both 50 & 60 series feature a Cat. 5

main driveline. Both models offer various safety guard

selectionsmaking them anexcellentchoice for state and

municipal mowing applications.

See “Type of Lubrication: Multi-purpose Grease”on

page 36 and “Section 7: Features and Benefits”on

page 38 for additional information and performance

enhancing options.

Using This Manual

This Operator’s Manual is designed to help familiarize

•

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

• The information contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• To orderanew Operator’s or PartsManualcontact your

authorized dealer. Manuals can also be downloaded,

free-of-charge from our website at www.landpride.com

orprintedfromtheLandPride Service & Support Center

by your dealer.

Terminology

“Right” or “Left” as used in this manual is determined by

facing forward in the direction the machine will operate

while in use unless otherwise stated.

Definitions

Land Pride

Owner Assistance

The Warranty Registration card should be filled out by

the dealer at the time of purchase. This information is

necessary to provide you with quality customer service.

If customer service or repairparts are required contact a

LandPridedealer. A dealer has trained personnel, repair

parts and equipment needed to service the cutter.

The parts on your cutter have been specially designed

and should only be replaced with genuine Land Pride

parts. Therefore, shouldyour cutter require replacement

parts go to your Land Pride Dealer.

Serial Number Plate

For prompt service always use the serial number and

modelnumber when ordering partsfromyour Land Pride

dealer.Besuretoincludeyourserialandmodel numbers

incorrespondencealso. Refer to Figure 1forthelocation

of your serial number plate.

23591

Serial Number Plate Location

Figure 1

Free Maintenance Video

Be sure to request your free copy of the 15’ Rotary

Cutter Maintenance Guidelines (alsoapplicable to 10’,

14’& 20’ cutters)videofrom your local Land Pridedealer.

Further Assistance

Your dealer wants you to be satisfied with your new

cutter.Ifforanyreasonyoudonotunderstand any part of

thismanual or are notsatisfied with the servicereceived,

the following actions are suggested:

1. Discuss the matter with your dealership service

manager making sure he is aware of any problems

youmay haveand that he has hadthe opportunity to

assist you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem and request assistance.

3. For further assistance write to:

IMPORTANT: A special point of information related

to its preceding topic. Land Pride’s intention is that

this information should be read and noted before

continuing.

NOTE: A special point of information that the

operator must be aware of before continuing.

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

10

Land Pride Service Department

1525 East North Street

P.O. Box 5060

Salina, Ks. 67402-5060

E-mail address

lpservicedept@landpride.com

Page 13

Land Pride

Section 1: Assembly and Set-up

Table of Contents

Section 1: Assembly and Set-up

Tractor Requirements

Horsepower

The cutter is designed to be used on tractors with 50 to

250 hp.

Hitch

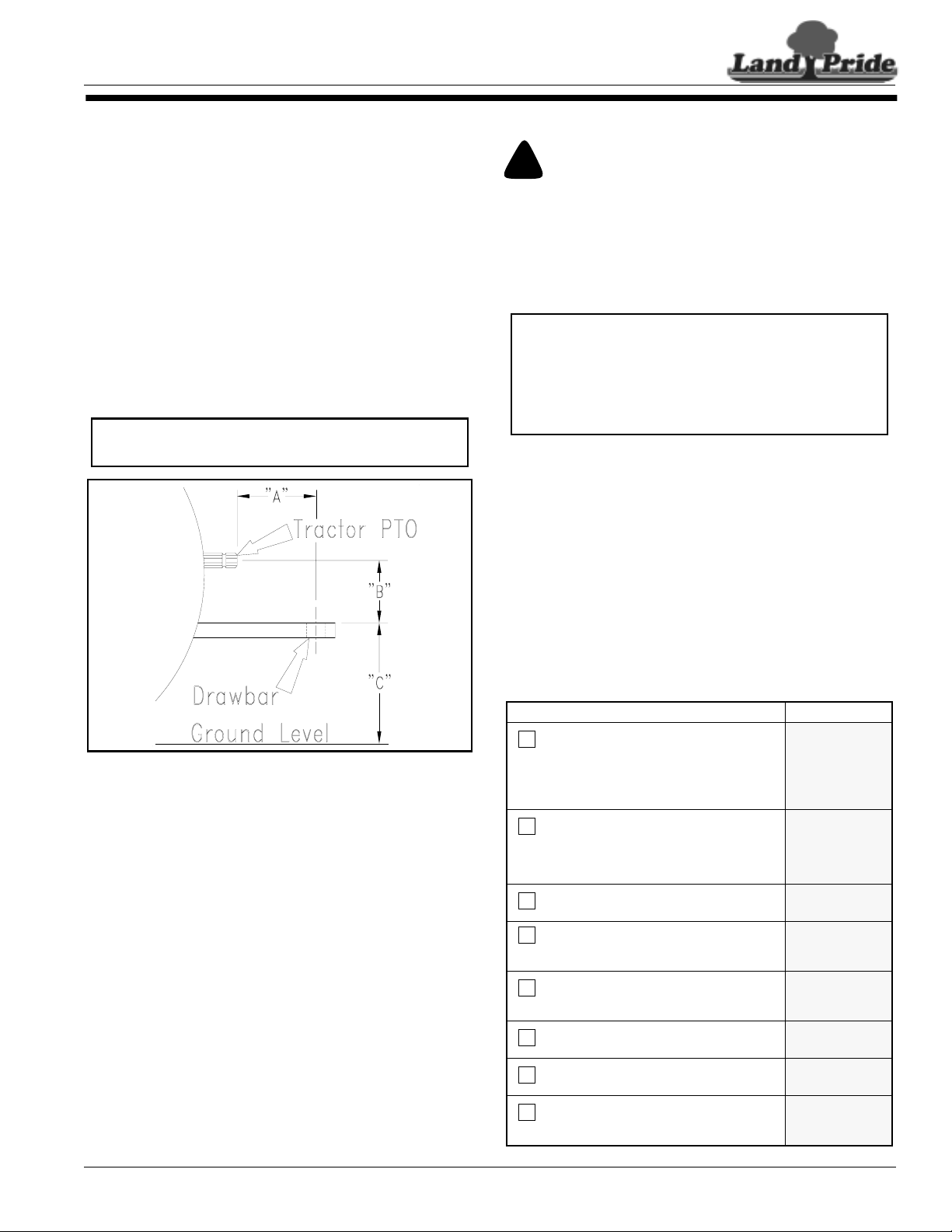

Refer to Figure 1-1:

The cutter uses a drawbar type hitch hook-up. Maintain

proper distance, dimension “A”, between center of

drawbar hitch pin hole and end of tractor PTO shaft.

• “A” = 14" for 540 rpm

• “A” = 16" for 1000 rpm

• “B” = 8" for 540 rpm and 1000 rpm

• “C” = 18” to 21” for 540 rpm and 1000 rpm

IMPORTANT: PTO damage may occur if distance

“A” is not properly maintained.

PTO Speed

!

CAUTION!

Do not over speed PTO. The cutter can be damaged when

operated above its rated PTO RPM.

Either a 540 rpm or 1000 rpm tractor Power Take-Off

(PTO) is required. TheRC5015 and RC6015 cutters are

designed for 540 rpm and the RCM5015 and RCM6015

are designed for 1000 rpm.

IMPORTANT: Do not attempt to operate a 540 RPM

driveline cutter with a 1000 RPM PTO tractor and do

not operate a 1000 RPM driveline cutter with a 540

RPM PTO tractor. Many tractorsprovide both 540 and

1000RPMPTOmodes.Checkyourtractor’smanualto

determine its capabilities.

Before You Start

Read and understand the operator’s manual for your

cutter. An understanding of how it works will aid in the

assembly and set-up of your cutter.

It is best to go through the Pre-Assembly Checklist

before assembling the cutter. Speed up your assembly

task and make the job safer by having all the needed

parts and equipment readily at hand.

This cutter has been partially assembled at the factory.

However,there is still some assemblyrequiredbeforethe

cutter is ready for operation.

22273

PTO to Drawbar Distance

Figure 1-1

Hydraulic Outlets

The number of tractor hydraulic duplex outlets is

dependent upon how the Rotary Cutter is set-up.

• Two duplex outlets are required if the wings are raised

and lowered simultaneously.

• Three duplexoutletsare required if thewingsare raised

and lowered independently.

Control valvekits are available from your local Land

Pride dealer ifthe tractor is notequipped with thecorrect

number of duplex outlets. See “Hydraulic Accessor ies”

on page 23 foravailable hydraulic kits.

Pre-Assembly Checklist

Check Reference

Fasteners and pins that were shipped

with the cutter.

NOTE: All hardware has been factory

installed. If a part or fastener is removed

for assembly, remember where it goes.

Keep parts separated.

Be sure the parts get used in the correct

location. By double checking while you

assemble, you will lessen the chance of

using a bolt incorrectly that may be

needed later.

All grease fittings are in place and

lubricated.

Safety labels are correctly located and

legible. Replace if damaged.

Red and amber reflectors are correctly

located and visible when the cutter is in

transport position.

Inflate tires to specified PSI air pressure.

Tighten wheel bolts to specified torque.

Have a minimum of 2 people at hand

while assembling the cutter.

Have a fork lift or loader with properly

sized chains and safety stands on hand

for the assembly task.

Operator’s

Manual

Operator’s

Manual

Section 5

Page 31

ImportantSafety

Information

Page 1

ImportantSafety

Information

Page 1

Section 9

Page 41

Operator’s

Manual

Operator’s

Manual

8/28/08

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

11

Page 14

Table of Contents

Section 1: Assembly and Set-up

Hitch Types

The cutter is factory supplied with the standard clevis

hitch. Other optional hitches are available. See your

nearest Land Pride dealer should you want to change

your hitch set-up.

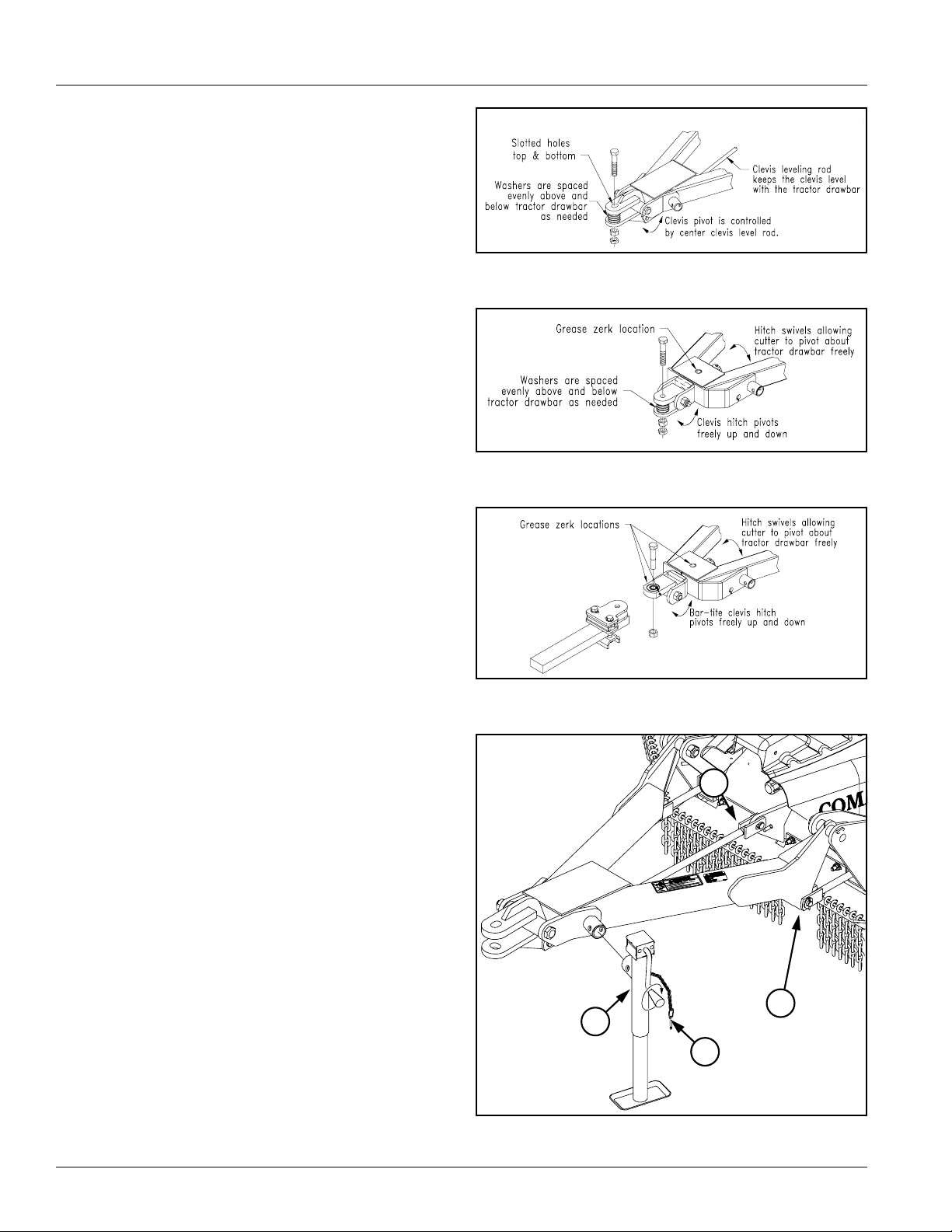

Standard Clevis Hitch

Refer to Figure 1-2:

A level rod attached to the underside of the clevis keeps

the clevis parallel with the tractor drawbar at all cutting

heights. Cutter rotation about the tractor drawbar is

limited to slots located in the clevis’ upper and lower

platesand drawbar holesize.Hitch should besecuredto

the tractor tongue with bolt, washers and nuts to prevent

spreading of clevis.

Double Swivel Clevis Hitch (Optional)

Refer to Figure 1-3:

Theswivelclevishitch allows the cutter to pivotaboutthe

tractor drawbar freely in two directions. It isdesigned for

cutting hillsides, reducing the twisting torque on the

cutter hitch and tractor drawbar. Hitch swivel is

greaseable.

Land Pride

22268

Standard Clevis Hitch

Figure 1-2

22268

Double Swivel Clevis Hitch

Figure 1-3

Bar-Tite Hitch (Optional)

Refer to Figure 1-4:

The Bar-Tite hitch functions the same as the swivel

clevis hitch except it is constructed of case hardened

steel and has abushingin the tonguetoextend hitch life.

Bushing and hitch swivel are greaseable.

Hitch Assembly

Refer to Figure 1-5:

Instructions below are for cutters equipped with a

standard clevis hitch only. See Figure 1-2 on for an

illustration of a standard clevis hitch.

1. Install clevis rod (#1) to the lug on the center deck

weldment using 3/4” x 1 1/2” clevis pin, 3/4” flat

washer and 1/8” x 1 1/4” cotter pin.

2. Install left and r ight leveling rods (#2) to the hitch

frame with 3/4”x 1 1/2” clevis pins, 3/4”flat washers,

and 1/8” x 11/4” cotter pins.Final adjustment should

be made when the cutter is attached to the tractor.

3. Installparking jack(#3) to the hitch frame and secure

with attached pin. Adjust parking jack to preferred

drawbar height.

22268

Bar-Tite Hitch

Figure 1-4

1

2

3

4

Hitch Assembly Illustration

Figure 1-5

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

12

23572

Page 15

Land Pride

Section 1: Assembly and Set-up

Table of Contents

Wing Axle Assembly

!

WARNING!

Connect turnbuckle #3 to wing axle #2 before lowering wing.

Otherwise, personal injury or damage to the turnbuckle can

occur.

NOTE: Donot tighten the hardware until assembly

is complete.

Refer to Figure 1-6

Wing axle locknuts are tightened for shipping purposes.

1. Loosen lock nuts (#1) slightly and rotate wing axles

(#2) to install turnbuckles (#3).

2. Remove cap screws and locknuts (#4).

3. Attach turnbuckles (#3) to the wing axles with

existing cap screws and lock nuts (#4).

4. Tighten locknut (#1) until snug. Do not overtighten.

Allow wing angle to pivot.

5. Tighten locknut (#4) to the correct torque.

23590

Tractor Hookup to Standard Clevis Hitch

Figure 1-7

Refer to Figure 1-7:

IMPORTANT: Jack attachment pin (#8) must be fully

inserted and secured before working on or around a

cutter that is not hooked to the tractor drawbar.

2

1

Turnbuckle(#3)

to be secured

between this

4

flange and the

one below.

3

23703a

Wing Axle - Turnbuckle Assembly

Figure 1-6

Tractor Hook-up to Standard Clevis Hitch

!

DANGER!

A Crushing Hazard exist when hooking-up equipment to a

tractor. Do not allow anyone to stand between the tractor and

implement while backing-up to the implement. Do not operate

hydraulic 3-point lift controls while someone is directly

behind the tractor or near the implement.

NOTE: Items 1, 2, 9and 10 shown in Figure 1-7 are

not furnished by Land Pride.

1. Make certain the parking jack (#3) is properly

attached to the cutter hitch and secured with

attachment pin (#8).

2. Back tractor within close proximity of cutter

clevis (#11).

3. Raise or lower the parking jack (#3) to align clevis

(#11) with the tractor drawbar. Drawbar should fit

between lower and upper plates of clevis.

4. Back tractor up to cutter hitch until holes in the

drawbar and clevis (#11) are aligned.

5. Insert 1" flat washers (#9) equally above and below

tractor drawbar until both spaces between drawbar

and clevis plates are filled.

6. Insert 1" x 5" gr5 hex bolt (#1) through top of clevis

(#11), 1" washers (#9), drawbar, remaining 1"

washers (#9) andout through bottom of clevis(#11).

Secure hex bolt with nut (#2). Tighten nut snugly to

remove all play and then back nut one-quarter turn.

Tighten jamb nut (#10) against nut (#2).

7. Lower jack stand (#3) until hitch weight is removed.

Remove jack stand from hitch and store on left hand

deck wing storage base. Prevent water and freeze

damage by storing it so that the foot is level or lower

than the head, especially when the wing is folded up.

8. Attach hitch safety chain (#4) to the tractor. Adjust

chain length to remove all slack except what is

necessary to permit turning. Lock chain hook

securely to the safety chain.

8/28/08

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

13

Page 16

Section 1: Assembly and Set-up

Table of Contents

Land Pride

Tractor Hook-up to Swivel Clevis Hitc h

!

DANGER!

A Crushing Hazard exist when hooking-up equipment to a

tractor. Do not allow anyone to stand between the tractor and

implement while backing-up to the implement. Do not operate

hydraulic 3-point lift controls while someone is directly

behind the tractor or near the implement.

Refer to Figure 1-8:

IMPORTANT: Jack attachment pin (#8) must be fully

inserted and secured before working on or around a

cutter that is not hooked to the tractor drawbar.

1. Make certain the parking jack (#3) is properly

attached to the cutter hitch and secured with

attachment pin (#8).

2. Back tractor within close proximity of cutter

clevis (#11).

7. Lower jack stand (#3) until hitch weight is removed.

Remove jack stand from hitch and store on left hand

deck wing storage base. Prevent water and freeze

damage by storing it so that the foot is level or lower

than the head, especially when the wing is folded up.

8. Attach hitch safety chain (#4) to the tractor. Adjust

chain length to remove all slack except what is

necessary to permit turning. Lock chain hook

securely to the safety chain.

Tractor Hook-up to Bar-Tite Hitc h

Refer to Figure 1-9:

1. Attach Bar-Tite clevis hitch to tractor drawbar:

a. Insert 1" x 5" hex bolt (#7) through hitch top plate

(#5), hitch weldment with bushing (#4), hitch base

weldment(#2)and tractor drawbar(#13)asshown.

Secure with 1" lock nut (#9). Tighten lock nut

snugly to remove all play and then back nut

one-quarter turn. Do Not torque 1" lock nut.

b. Insert two 3/4" x 5 1/2" gr5 hex bolts (#8) through,

3/4" flat washers (#11), hitch top plate (#5), hitch

base weldment (#2)and formed hitchsupport (#3)

as shown. Secure with 3/4" lock nuts (#10).

c. Tighten 3/4" lock nuts to the correct torque. See

Torque Values Chart on page 41.

d. Remove1"x6 1/2" gr5 hexbolt (#6) and 1" lock nut

(#12) from hitch weldment (#4).

22271

Tractor Hookup to Swivel Clevis Clamp Hitch

Figure 1-8

3. Raise or lower the parking jack (#3) to align clevis

(#11) with the tractor drawbar. Drawbar should fit

between lower and upper plates of clevis.

4. Back tractor up to cutter hitch until holes in the

drawbar and clevis (#11) are aligned.

5. Insert 1" flat washers (#9) equally above and below

tractor drawbar until both spaces between drawbar

and clevis plates are filled.

6. Insert 1" x 5" gr5 hex bolt (#1) through top of clevis

(#11), 1" washers (#9), drawbar, remaining 1"

washers (#9) andout through bottom of clevis(#11).

Secure hex bolt with nut (#2). Tighten nut snugly to

remove all play and then back nut one-quarter turn.

Tighten jamb nut (#10) against nut (#2).

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

14

A Crushing Hazard exist when hooking-up equipment to a

tractor. Do not allow anyone to stand between the tractor and

implement while backing-up to the implement. Do not operate

hydraulic 3-point lift controls while someone is directly

behind the tractor or near the implement.

Bar-Tite Hitch Assembly to Tractor Tongue

Figure 1-9

!

DANGER!

22265

Page 17

Land Pride

Table of Contents

Section 1: Assembly and Set-up

Refer to Figure 1-10:

IMPORTANT: Jack attachment pin (#8) must be fully

inserted and secured before working on or around a

cutter that is not hooked to the tractor drawbar.

2. Make certain the parking jack (#3) is properly

attached to the cutter and secured with attachment

pin (#8).

3. Back tractor within close proximity of cutter hitch.

4. Raise or lower the parking jack (#3) to align hitch

(#10) with bolt hole in swivel clevis (#9).

5. Backtractor up tocutterswivelhitch (#9) untilhole in

hitch weldment with bushing (#10) aligns with holes

in swivel clevis (#9).

6. Insert 1" x 6 1/2" gr5 hex bolt (#1) through the cutter

swivel hitch (#9) and hitch weldment (#10). Secure

hexbolt withlock nut (#2). Tighten locknut snugly to

remove all play. Do Not torque 1" lock nut.

7. Lower jack stand (#3) until hitch weight is removed.

Remove jack stand from hitch and store on left hand

deck wing storage base. Prevent water and freeze

damage by storing it so that the foot is level or lower

than the head, especially when the wing is folded up.

8. Attach hitch safety chain (#4) to the tractor. Adjust

chain length to remove all slack except what is

necessary to permit turning. Lock chain hook

securely to the safety chain.

!

CAUTION!

Always disengage PTO, engage parking brake, shut tractor

engine off, remove switch key and wait for blades to come a

complete stop before dismounting from tractor.

IMPORTANT: The driveline must be lubricated

before putting it into service. Refer to “Lubrication

Points” on page 31.

IMPORTANT: Do notattemptto operate a 540 RPM

driveline at 1,000 RPM or a 1,000 RPM dr iveline at

540RPM. Many tractors provide both540and 1,000

RPM PTO speeds. Check your tractor’s manual to

determine its capabilities.

IMPORTANT: Read and understand “Section 2:

OperatingInstructions” beginning on page 18 before

operating the Rotary Cutter.

The main driveline may be either constant velocity type

or conventional type. Pull-collar couplers and retaining

bolts are used to connect the driveline to the tractor and

implement gearbox.

A driveline that is too long can damage the tractor,

gearbox and/or driveline. Always check driveline length

with cutter hitched to the tractor before engaging the

PTO.

Check Driveline Length

22262

Tractor Hookup to Bar-Tite Hitch

Figure 1-10

Driveline Installation

!

DANGER!

Do not engage tractor PTO while hooking-up and unhooking

the driveline or stand near a rotating driveline.A person’sbody

and/or clothing can become entangled in the driveline resulting

in serious injury or death.

IMPORTANT: The Rotary Cutter must be hitched

with tractor and cutter aligned in a straight line on a

level surface. This arrangement provides correct

alignment between tractor and gearboxPTO shafts.

1. Park tractor and cutter in a straight line on a level

surface. Place gear selector in park, shut tractor

engine off, set park brake and remove switch key.

2. Attach pull-collar coupler to tractor PTO shaft and

boltedcouplertodividergearboxshaft.Skiptostep5

if driveline fits between tractor and implement.

Refer to Figure 1-11:

3. The PTO driveline will require shor tening if it does

not fit between tractor and cutter gearbox. Shorten

driveline as follows:

a. Pull driveline apart as shown in Figure 1-11.

b. Attach pull-collar coupler to the tractor PTO shaft

and bolted coupler to the divider gearbox shaft.

Pull on each dr iveline section to be sure the

universal joints are secured to the shafts.

c. Hold driveline sections parallel to each other to

determine if theyaretoolong. The inner and outer

shieldsoneachsectionshouldendapproximately

1" short of reaching the universal joint shield on

the adjacent section (see “B” dimension). If they

are too long, measure 1" (“B” dimension) back

fromuniversaljointshieldandmakeamark at this

location on the inner and outer driveline shields.

8/28/08

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

15

Page 18

Section 1: Assembly and Set-up

Table of Contents

Land Pride

d. Cut off inner shield at the mark (“X” dimension).

Cut the same amount off the inner shaft (“X1”

dimension). Repeat cut off procedure (“Y”&“Y1”

dimensions) to the outer driveline half.

e. Remove all burrs and cuttings.

f. Apply multi-purpose grease to the inside of the

outer shaft and reassemble driveline.

g. Attach inner driveline yoke end to the divider

gearbox shaft.

h. Attach outer driveline yoke end to the tractor's

shaft.

22165

PTO Driveline Shortening

Figure 1-11

4. Thedriveline should now bemovedbackandforth to

insurebothendsaresecuredtothetractorandcutter

PTO shafts. Reattach any end that is loose.

Each duplex outlet on your tractor can perform only one

operation. One outlet is needed for lifting the cutter and

one for lifting the wings simultaneously. A third outlet is

required if the wings are lifted independently. This will

also require replumbing the hydraulics to the wing

cylinders.

Your Land Pride dealer can help youdetermine the best

configuration that will match your needs and your tractor

capabilities.Optionalcontrolvalvekits are availableifthe

tractor does not have the required number of duplex

outlets.Foradditionalinformation,SeeHydraulicOutlets

on page 11

!

DANGER!

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

Refer to Figure 1-10 on page 15:

1. Route cylinder hoses (#7) through hose support loop

and connect to tractor remote outlets.

2. Cycle hydraulicsystem by raising and lowering center

deck cylinder and wing fold cylinders. It may be

necessarytopurgethehydraulicsystemoftrappedair

if operation is sluggish.

!

WARNING!

Be sure center deck and wings areloweredto the ground and all

hydraulic pressure is relieved before disconnecting any lines or

pipes between the Rotary Cutter and tractor hydraulic system.

IMPORTANT: Two small chains are supplied with

each driveline. These chains must be attached to

theouter and inner drivelineshieldsandto the cutter

deck or hitch to restrict the shields from rotating.

5. Referto Figure 1-10 on page 15. Secure chains (#6)

on driveline (#5) around hitch clevis rod to restrict

driveline outer shield from rotating. Re-latch safety

chain to driveline guard.

6. Attach safety chain located on the other end of the

driveline (#5) to the cutter’s main frame to restrict

driveline inner shield from rotating. Re-latch safety

chain to driveline guard.

Hydraulic Hook-up

The required number of duplex outlets at the tractor is

dependent upon how the cutter is set-up.

The standard cutter is equipped with three hydraulic

cylinders with one in the center for lifting the cutter and

one on each wing for folding the wings simultaneously.

All three cylinders are set-up for single action

(one-way) operation.

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

16

The system may be purged as follows:

a. With wings lowered to the ground and hydraulic

pressure relieved, loosen hydraulic hose fitting at

each wing cylinder slightly to allow fluid to escape.

b. Slowly activate tractor control valveto purge any

trapped air from the system.

c. Tighten each fitting.

3. The center decklift cylinder is purged in the same

manner as the wing cylinders. The cutter must be

resting on the ground and all hydraulic pressure

relieved beforeloosening hose fitting as described in

2a above.

4. Check driveline for adequate clearance under all

ranges of cutterheight. With driveline shaft attached

to the tractor, slowly raise and lower cutter to its

upper and lower limits while observing clearances

between hitch and driveline. Adjust tractor drawbar

height and/or length if driveline interferes. See

Figure 1-1 on page 11 for correct drawbar

dimensions.

Page 19

Land Pride

Table of Contents

Section 1: Assembly and Set-up

Unhooking From the Cutter

1. Parkcutterona levelsolidhardsurface.Place tractor

gear selector in par k and set park brake.

2. Refer to “Transporting The Cutter”, Figure 2-1 &

Figure 2-2 on page 19. Raise wings up in the

transport position and place transport lock bars in

the locked position. Make sure transport bars are

secured in place with lock pins (#2) and hair pins

(#1).

3. Remove stroke control spacers from the center

hydraulic cylinder and lower cutter until front skids

are resting on the ground. Replace stroke control

spacers as needed to support wheels at this

position.

4. With tractor gear selectorin park andpark brake set,

shut tractor engineoff, and removeswitchkey. Move

cylinder lift levers back and forth to releasehydraulic

line pressure.

5. Refer to “Hitch Types” (Figure 1-2) on page 12.

Removetheparking jack (#3) from thelefthand wing

deck and install to cutter hitch. Secure the parking

jack in place with attached jack pin (#4).

6. Adjust the parking jack as needed to remove the

hitch pin.

7. Remove hitch pin and unhook hydraulic hoses from

tractor. Store hose ends in hose support loop.

8. Lowerthe parking jacktorest cutter on itsfront skids.

8/28/08

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

17

Page 20

Table of Contents

Section 2: Operating Instructions

Section 2: Operating Instructions

Pre-start Checklist

Hazard control and accident prevention are dependent

upon the awareness, concern, prudence and proper

traininginvolvedinthe operation, transport, maintenance

and storage of the cutter. Before beginning to operate

your cutter, the following inspections should be made.

• Read and follow the Safety Rules carefully, refer to

“Important Safety Information” starting on page 1.

• Read all of the Tractor Hook Up in the “Assembly and

Set-up” section on page 11, and all preparation

instructions.

• Read the“Operating Instructions” section startingon

page 18.

• Refer to the “Maintenance and Lubrication” section

starting on page 31 to lubricate the cutter as required.

• Check the cutter initially and periodically for loosebolts

and pins, refer to the Torque Values Chart in the

“Appendix” section on page 41.

• Make sure all guards and shields are in place, refer to

“Important Safety Information” starting on page 1.

• Gearbox Gear Lube, refer to the “Maintenance and

Lubrication” section starting on page 33.

Cutter Set-up For Transporting

Refer to Figure 2-1 & Figure 2-2:

IMPORTANT: Always disengage the tractor’s PTO

before raising the cutter wings to transport position.

Drivelines and gearboxes will be damaged if the

wings are raised while PTO is turning.

23592

1

4

3

Transport Bar, Locked Position

Figure 2-1

2

1

Land Pride

NOTE:Thewingsarecontrolled with two hydraulic lift

cylinders. Be certain that the wing hydraulics are

attachedtothetractorand the hydraulic hoses are full

of oil before proceeding.

If the cutter wings are down, they will need to be raised

before transporting on a road and/or through narrow

openings.

1. Disengage tractor PTO and wait for the cutter

bladesto cometo a complete stop beforeraisingthe

wings.

2. Raise the cutter wings fully up with the hydraulics.

3. Place tractor gear selector in park, shut tractor

engine off, set park brake, remove switch key and

dismount from tractor.

4. See Figure 2-2. Remove hairpin clip (#1) from

storage pin (#2).

5. Rotate end of transport lock bar (#3) to cylinder pin

(#4) as shown in Figure 2-1. Secure with hairpin

clip (#1).

6. Repeat steps 4 and 5 for the other wing section.

Cutter is now ready for transporting.

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

18

23593

Transport Bar, Storage Position

3

Figure 2-2

Page 21

Land Pride

Section 2: Operating Instructions

Table of Contents

Transporting The Cutter

!

CAUTION!

When traveling on public roads at night or during the day, use

accessory lights and devices for adequate warningtooperators

of other vehicles. Comply with all federal, state and local laws.

1. Besureto reduce tractor ground speed whenturning

and leave enough clearance so the cutter does not

contact obstacles such as buildings, trees or fences.

2. Select a safe ground speed when transporting from

one area to another. When traveling on roadways,

transport in such a way that faster moving vehicles

may pass you safely.

3. Whentravelingoverrough or hilly terrain, shift tractor

to a lower gear.

Cutter Set-up For Field Operation

!

WARNING!

The following operational procedures should be carried out by

the tractor operator. Other persons should be cleared of the

area even during cutter set-up. Cutter operation should be

stopped when in the vicinity of other persons.

Refer to Figure 2-3:

1. Inspect the wing blade carriers and cutting blades

prior to lowering the wings. The cutting blades may

become locked together (overlapped) when the

wings are raised to transport position. Operating the

cutter under suchcircumstances will result in severe

deck vibration. Inspect the wing decks fora locked

blade condition pr ior to power-on operation. Use a

pry bar or other tool to separate the blades when

necessary.

4. Lower wing sections to the down position.

5. Increase throttle to approximately 1/4 engine speed

and slowly engage driveline. Also see note below.

NOTE: Use tractor’sPTOsoft startoption if available.

6. Ensure that allpowershafts are rotating and thatthe

cutter has no vibration.

7. Continue to increase throttle to full 540 or 1000 PTO

speed before commencing forward operation.

Operating Speed & Turning Angle

Refer to Figure 2-4 & Figure 2-5:

Optimum ground speed depends on the density of the

material being cut, the horsepower rating of the tractor

and terrain. Always operate the tractor at the cutter’s full

rated PTO speed in a gear rangethat allows the cutter to

make a smooth cut without lugging the tractor down,

usually between 2 to 5 mph.

Avoidtractor-to-cutter turning angles exceeding 35

degrees (Figure 2-4) if the main driveline is a standard

conventionalshaft. Turninganglemaybe increased to 80

degrees (Figure 2-5) if the cutter is equipped with a

constant velocity driveline shaft. These extreme angles

are intended for intermittent usage only and not

prolonged usage. Plan your field cutting to minimize the

number of turns as well as extreme turning angles.

!

WARNING!

Do not operate this cutter under any terrain conditions where,

on a continuous cut, the wing angle exceeds 45 degrees up.

Ensure that the wing wheels are in continuous ground contact

at all times. Use the float position of your tractor’s hydraulic

system to provide automatic wing float position for varying

terrain conditions.

Blade Carrier

Wing Deck

Cutting Blades

22169

Wing Deck Blade Positioning

Figure 2-3

NOTE:Thecutterheight is controlled withahydraulic

lift cylinder.

Refer to Figure 2-1 & Figure 2-2 on page 18:

2. Fully raise the wings to release any tension on the

transport lock bar as shown in Figure 2-1. Remove

hairpin clip (#1) from both the left and right cylinder

pins (#4).

3. Rotate end of transport lock bar (#3) to the storage

pin (#2) as shown in Figure 2-2. Secure with hair pin

clips (#1).

8/28/08

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

11934

Conventional U-Joint Driveline

Figure 2-4

20795

Constant Velocity (CV) Driveline

Figure 2-5

19

Page 22

Section 2: Operating Instructions

Table of Contents

Land Pride

General Operating Instructions

!

CAUTION!

To prevent personal injury caused by thrown objects, the use of

front & rear safety guards is strongly recommended! To avoid

injury or death from entanglement in rotating drivelines, the

drive gearbox shields must be in place and secure when

operating.

!

Rotary cutters have the ability to discharge objects at high

speeds; therefore, the use of front & rear safety guards is

strongly recommended when cutting along highways or in an

area where people may be present.

Damage may occur if exceeding the rated cutting capacity of

the cutter!

Do not over speed PTO or machine damage may result.

RC series are designed for a tractor with 540 RPM rear PTO

and RCM series are designed for a tractor with 1000 RPM rear

PTO.

Do not lift deck to use cutting blades as a fan. Cutting blades

are not properly designed or guarded for this use. Using the

deck as a fan can result in injury and/or death.

Do not operate 15 ft. cutters without both wings attached to the

center deck. Removing one wing will expose blades and

increase risk of cutter overturning. Removing both wings will

expose blades on both sides. Exposed blades can result in

serious injury and/or death.

It is important that you familiarize yourself with the

Operator’s Manual, completed the Operators Checklist,

properlyattachedthecuttertoyourtractor,made leveling

adjustments, and preset your cutting height before

beginning a running operational safety check on your

Land Pride RC(M)5015 and RC(M)6015 Series Rotar y

Cutters.

It’s now time to do a running operational safety check. It

is important that at any time during this safety checkyou

detectamalfunction in either the cutter ortractorthatyou

immediately shut the tractor off, remove the key, and

make necessary repairs and/or adjustments before

continuing on.

DANGER!

!

CAUTION!

!

CAUTION!

!

DANGER!

!

DANGER!

Make sure before starting the tractor that the park brake

is engaged, the PTO is disengaged, and the cutter is

resting on the ground with both wings down. Start the

tractor and set the engine throttle speed at a low idle.

Raise the cutter with the tractor’s rear hydraulic lift

control lever to transport position making sure that the

PTO shaft does not bind and does not contact the cutter

frame.Lowerthecutter to the groundandata low engine

speedengage the PTO.Ifeverythingisrunning smoothly

at a low idle, slowly raise the cutter to transport height

checking forbind or chatter in the driveline. Lower the

cutter to the ground and increase the tractor’s engine

rpm untilit reaches the cutter’s full PTOoperating speed

which will be either 540 or 1000rpm. If everything is still

running smoothly,once moreraisethe cutter to transport

height to check for driveline bind or chatter. Lower the

cutter to the ground, return the engine to a low idle, and

disengage the PTO. Position the adjustable stops on the

tractor’s hydraulic lift lever so the cutter can be

consistently returned to the same cutting and transport

height. Make a tight turn to ensure that the rear tractor

tires are not coming into contact with the deck.

You should now be ready to transpor t to your cutting site

at a safe ground speed. On roadways, transport in such

a manner that fastermoving vehicles can easily see you

and pass you safely. Reduce your speed when traveling

overroughandhillyterrain.Avoidquickor sharpsteering

corrections. Take extra care to insure that the mower

doesn’t come into contact with obstacles such as trees,

buildings or fences. Use accessory lights and

appropriate reflective devices to provide adequate

warningtopedestrians and other vehicle operators when

travelingonpublicroads and in thedark of night. Comply

with all local, state and federal laws.

It is important that youinspectthe area whereyouwill be

cutting and clear it of safety hazards and foreignobjects

either beforeor after you arrive at the cutting site. Never

assume the area is clear. Cut only in areas you are

familiar with and are free of debris and unseen objects.

Extremely tall grass should be cut twice to detect

potential hazards. In the event you do strike an object

stop the cutter and tractor immediately to inspect and

make necessary repairs to the cutter before resuming

operation. It really pays to inspect a new area and to

develop a safe plan before cutting.

You will need to maintain either 540 or 1000 rpm PTO

speed and 2 to 5 mph ground speed to produce a clean

cut. Make a tractor gear and range selection that will

enable you to maintain these speed combinations.

Generally the quality of cut is better at lower ground

speeds.Dense ground coverwill create theneed to slow

downevenmore.Incertainconditionstractortireswillroll

grass down resulting in an uneven cut when the grass

fails to rebound. Should this happen you may try

reversingthe direction of cutand/ordoublecut toachieve

the desired finish. Avoid very low cutting heights

especially on extremely uneven terrain. Always cut

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

20

Page 23

Land Pride

Table of Contents

Section 2: Operating Instructions

downwardonslopesandavoidcrossing thefaceof steep

slopes. Avoid sharp drops and cross diagonally through

dips to prevent hanging up the tractor and cutter. Slow

down in turns and avoid sharp turns if at all possible.

Remember to look back often.

Nowthat you’repreparedand well br iefed you may begin

cutting. Begin cutting by doing the following:

• Reducing the tractor’s engine rpm.

• Make surethe wings areon the groundand the cutter is

in cutting position.

• Engage the PTO.

• Raise the engine rpm to the appropriate PTO speed.

• Begin cutting.

Make wide turns when possible. Operators of pull-type

models must plan ahead and choose a cutting pattern

that allows for wider turns. Try increasing or decreasing

ground speed to deter mine the effect on quality of cut.

With a little practice you will be pleased with what you

and your Land Pride Rotar y Cutter can do.

Whether youare done mowing, need to takea break, or

just need to make a few adjustments to the cutter,

remember to always do the following:

• Reduce the tractor’s engine rpm.

• Disengage the PTO.

• Stop on level ground.

• Set the park brake.

• Turn off the engine and remove the key.

• Stay on the tractor until the cutter blades have come to

a complete stop.

8/28/08

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

21

Page 24

Section 3: Adjustments

Table of Contents

Land Pride

Section 3: Adjustments

Center and Wing Section Leveling

These adjustments should be made with the cutter

hooked up to the same tractor that will be used for field

operations or one having the same drawbar height.

Cutter adjusting rods are set at the factory prior to

shipment. The adjustingrods control thedraw bar height

at the hitch clevis.

Refer to Figure 3-1, Figure 3-2 & Figure 3-3:

1. Attach the cutterto the tractorandposition it onlevel

ground.

2. Raise both wings to locked position.

Refer to Figure 3-1:

3. Using tractor’s hydraulics,adjust height of center

deck to 2-3 inch clearance between front skids (#2)

and ground. Check deck levelness by making

measurements from center of hinge rod (#1) to

groundatthe front and back on bothsideofthedeck.

All measurements should be equal if deck is level.

5. Repeat steps 3 and 4 for the right hand leveling rod.

Be sure that both sides of the deck are equal

distance from the ground and that the right and left

leveling rods are equally tight.

6. See Figure 3-3. Lower wings to ground position.

Wing sections may need adjusting now that the

center section is level. Loosen jam nut (#4) and

rotate the adjusting turnbuckle (#5) to desired

position. Re-tighten jam nut (#4).

5

4

1

Jam

15285

Wing Leveling Turnbuckle

Figure 3-3

23574

Front Skid Position

Figure 3-1

Refer to Figure 3-2:

NOTE: Lengthening leveling rods with adjusting

nuts (#3) will lower the front of the cutter.

4. Ifdeckisnotlevel,loosen jamnut(#2)ontheleftside

and rotate leveling rod adjusting nut (#3) until the

deck’s left side is level from front to rear. Re-tighten

jam nut (#2).

Jam

3

Center Section Leveling Rod

2

Figure 3-2

Front Skid

15284

Cutting Height Adjustment

Refer to Figure 3-4:

The cutter comes standard with hydraulic heightcontrol.

Stroke control spacers are supplied to accommodate

various cutting heights.

StrokeControl

Spacers

20792

Hydraulic Cylinder With Stroke Control Spacers

Figure 3-4

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

22

Page 25

Land Pride

Section 4: Options

Section 4: Options

Table of Contents

Safety Guard Options

!

DANGER!

Rotary Cutters have the ability to discharge objects at high

speeds; therefore, the use of front and rear safety guards is

strongly recommended when cutting along highways and in

areas where people may be present.

IMPORTANT: Not all objects will be stopped by the

safety guards. Therefore, Land Pride recommends

using extreme caution when cutting in public areas.

It is best to operate the Rotary Cutter when no one

is around except the operator.

LandPrideoffers three types of safety guards tobestsuit

your application. They arethe rubber guard, singlechain

guard and double chain guard. The rubber guard is

designed for light duty applications. The single chain

guard is designed to handle heavier applications where

the cutter blades contact solid,dense objectscapable of

tearing through therubber. Double chain guards provide

the highest degree of protection against objects being

thrown.

Part Number & Description

Rubber Guards

318-345A Front Rubber Safety Guards

318-701A Rear Rubber Safety Guards

Single Chain Guards

318-344A Front Single Chain Safety Guards

318-630A Rear Single Chain Safety Guards

Double Chain Guards

318-346A Front Double Chain Safety Guards

318-631A Rear Double Chain Safety Guards

Hydraulic Accessories

Independently Controlled Deck Wings

Land Pride offers a kit for raising the deck wings

independentlytoclearsmall obstacles in the field without

maneuveringaround them. Your tractor willrequire three

duplex outlets to raise the wings independently. If

needed, you can add duplex outlets to your tractor by

purchasingLandPride’s3 Spool Control ValveKit or their

Selector Control Valve Kit. See “Duplex outlets” below if

additional outlets are required.

IMPORTANT: Never operate this cutter under any

terrain conditions where, on a continuous cut, the

wing angle exceeds 45 degrees up. Damage to the

wing driveline and gearboxescan occur. Raise wing

only to clear obstacles and then lower the wing

immediately after clearing the obstacles.

Follow all safety precautions in this manual

especiallyinformationregarding raising the wings up

with PTO running.

Part Number & Description

318-316A Hydraulic Wing Control Kit

Duplex outlets

Some tractors do not have enough duplex outlets to

handle the equipment connected the tractor. Land Pride

offers the following kits to add duplex outlets to your

tractor.

3 Spool Control Valve Kit: This kit is for tractors with a

single duplex outlet. It converts the single duplexoutlet

into three duplex outlets with three hydraulic controlled

levers.

Selector Control Valve Kit: This kit is for tractors

needingonlyoneadditionalduplexoutlet.Itconvertsone

of the tractor’s duplex outlets into two duplexoutlets with

a control valve. A selector switch on the control valve

selectswhichof the two duplexoutlets is operational with

the tractor hydraulic control lever.

See your local Land Pride dealer if your tractor is not

properly equipped with the correct number of duplex

outlets.

8/28/08

Part Number & Description

312-315A 3 SPOOL CONTROL VALVE KIT

312-316A SELECTOR CONTROL VALVE KIT

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

23

Page 26

Table of Contents

Section 5: Maintenance & Lubrication

Section 5: Maintenance & Lubrication

General Maintenance Information

Properservicing and adjustmentisthekeytothelonglife

of any implement. With careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

Checkall bolts afterusing the unitforseveralhours to be

sure they are tight.

Replace any worn, damaged or illegible safety labels by

obtaining new labels from your Land Pride Dealer.

Cutter Blade Maintenance

!

DANGER!

Always disconnect main driveline from tractor PTO before

servicing the underside of the cutter deck. Cutter can be

engaged if tractor is started resulting in damage to the cutter,

bodily injury and/or death.

!

WARNING!

Always secure cutter deck in the up positionwith solid supports

before servicing the underside of the cutter. Never work under

equipment supported by hydraulics. Hydraulics can drop

equipment if controls are actuated or if hydraulic lines burst.

Either situation can drop the cutter instantly even when power

to the hydraulics is shut off.

Land Pride

e. Do not sharpen the back side of the blade.

f. Both blades should weigh the same after

sharpening with not more than 1 oz. difference.

IMPORTANT: Unbalanced blades will cause

excessive vibration which can damage gear box

bearings and createstructural cracks incutter housing.

4. Examine blade bolts for excessive wear and replace

if necessary. To replace blade bolts:

a. Order land Pride blade bolt part #802-277C and

lock nut #803-170C.

b. Refer to Figure 5-1: Carefully check the cutting

edges of the blades in relation to the bladecarrier

rotation to ensure correct blade placement.

c. Torque blade lock nut to 450 ft-lbs. An extended

cheater bar may be required.

5. If replacing dishpan, nut on gearbox output shaft

should be torqued to 550 ft-lbs. minimum and cotter

pin installed in nut with legs securely bent around

nut.

IMPORTANT: Blades mustbe ordered and replaced in

pairs. Order only genuine Land Pride blades. Land

Pride blades are made of special heat treated alloy

steel. Substitute blades may not meet Land Pride’s

specifications and may be dangerous to operate.

1. Always disconnect main driveline from tractor PTO

and secure cutter deck in the up position with solid

supports beforeservicing the undersideof the cutter.

2. Alwaysinspect cutting bladesbeforeeachuse.Make

certain they are properly installed and are in good

working condition. Replace any blade that is

damaged, worn, bent, or excessively nicked. Small

nicks can be ground out when sharpening.

3. Both blades shouldbe sharpened at the same angle

as the original cutting edge and must be replaced or

re-ground at the same time to maintain proper

balancein the cuttingunit.The followingprecautions

should be taken when sharpening the blades:

a. Do not remove more material than necessary.

b. Do not heat and pound out a cutting edge.

c. Do not grind blades to a razor edge. Leavea blunt

cutting edge approximately 1/16” thick.

d. Alwaysgrindthecutting edge so that the end ofthe

blade remains square to the cutting edge and not

rounded.

CCW

CC

Blade Rotation

Figure 5-1

CCW

Land Pride Cutter Blade Parts

Part No. Part Description

820-168C CUTTER BLADE 1/2 x 4 x 29 CCW (CTR)

820-169C CUTTERBLADE 1/2x4 x 23 CCW (RH WING)

820-170C CUTTER BLADE 1/2 x 4 x 23 CW (LH WING)

802-277C BLADE BOLT 1 1/8-12 x 3 7/16 WITH KEY

803-170C NUT HEX TOP LOCK 1 1/8-12 PLATE

804-147C WASHER FLAT 1 HARD ASTMF436 PN

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M 8/28/08

24

Page 27

Land Pride

Section 5: Maintenance & Lubrication

Table of Contents

Drivelines With Slip Clutches

!

CAUTION!

Engage parking brake, disengage PTO, shut off tractor, and

remove key before working on or around the driveline and/or

slip clutch.

!

CAUTION!

Slip clutches that have been in use or have been slipped for only

two or three seconds during run-in may be too hot to touch.

Allow a hot clutch to cool before working on it.

Cutter drive componentsare protected fromshock loads

by a friction slip clutch. The clutch must be capable of

slippage during operation to protect the gearbox,

driveline and other drive train parts.

Friction clutches should be “run-in” prior to initial

operation and after long periods of inactivity to remove

any oxidation that may have accumulated on the friction

surfaces. Repeat “run-in” instructionsat the beginningof

each season and when moisture and/or condensation

seizes the inner friction plates.

Refer to Figure 5-2 to determine which friction clutch

your cutter has. Follow “run-in” instructions on the

following pages for your specific clutch type.

2. Carefullyloosen each of the8spring retainer nutsby

exactly2 revolutions. It willbe necessary to hold hex

end of retainer bolt in order to count the exact

number of revolutions.

3. Make sure the area is clear of all bystanders and

machine is safe to operate.

4. Start tractor and engage PTO drive for2-3 seconds

to permit slippage of theclutch surfaces.Disengage

PTO, then re-engagea second timefor2-3 seconds.

Disengage PTO, shut off tractor and remove key.

Wait for all components to stop before dismounting

from tractor.

5. Inspect clutch and ensure that the scribed markings

made on the clutch plates have changed position.

Slippage has not occurred if any two marks on the

friction disk and plate are still aligned. A clutch that

has not slipped must be disassembled to separate

the friction disk plates. See “Clutch Disassembly,

Inspection & Assembly” below.

6. Tighten each of the 8 spring retainer nuts on the

clutch housing exactly2 revolutions to restoreclutch

to original setting pressure.

7. Allow clutch to cool to ambient temperature before

operating again. Clutch is now ready for use.

8. The clutch should be checked during the first hour of

cutting and periodically each week. An additional set

of scribe marks can be added to checkfor slippage.

See Figure 5-5 to adjust spring length.

23560

Type A Clutch Type B Clutch

Clutch Types

Figure 5-2

Type C Clutch

Type A Clutches

Clutch Run-In

Refer to Figure 5-3:

1. Using a pencil or other marker, scribe a line across the

exposed edges of the clutch plates and friction disks.

Clutch Disassembly, Inspection & Assembly

Refer to Figure 5-4 on page 26:

If clutchrun-in procedure aboveindicated that oneor more

friction disks did not slip, then the clutch must be

disassembled to separate the friction disks.

Disassembly

IMPORTANT: Notall Type A clutchcomponents are

arranged as illustrated in Figure 5-4. Also some

havemorecomponentsthan others. Be sure tokeep

track of order and orientation of your clutch

components during disassembly.

Disassemblyof clutch issimplya matter of firstremoving

springretainer nuts (#1),springs(#2) and bolts (#3)from

the assembly. Each friction disk (#4) must then be

separated from the metal surface adjacent to it.

Inspection

Inspect all partsfor excessive wear and condition. Clean

all parts that do not require replacement.The original

friction disk thickness is 1/8" (3.2mm) and should be

replaced if thickness falls below 3/64" (1.1mm). If

clutches have beenslipped to thepoint of “smoking”,the

friction disks may be damaged and should be replaced.

Heat build-up may also affect the yoke joints.

8/28/08

Type A Clutch Run-In

Figure 5-3

RC5015 & RC6015 (540 RPM) and RCM5015 & RCM6015 (1000 RPM) Rotary Cutters 318-047M

13693

Assembly

Reassemble each friction disk (#4) next to the metal

plate it wasseparated from. Installbolts (#3) through the

end plates and intermediate plates as shown. Place

springs (#2) over the bolts and secure with nuts (#1).

25

Page 28

Table of Contents

8

Section 5: Maintenance & Lubrication

14714

IMPORTANT: Keep track of order and orientation of

your clutch components during disassembly

Type A Clutch Disassembly

Figure 5-4

Land Pride

Type B Clutches

Clutch Run-In

Refer to Figure 5-6:

1. Using a pencil or other marker, scribe a line across the

exposed edges of the clutch plates and friction disks.

Refer to Figure 5-5 & Table Below:

Progressively tighten each spring retainer bolt until

correct spring height “A” is reached.

24600

Type A Clutch Adjustment

Figure 5-5