Landoll 173531 User Manual

INSTALLATION INSTRUCTIONS FOR

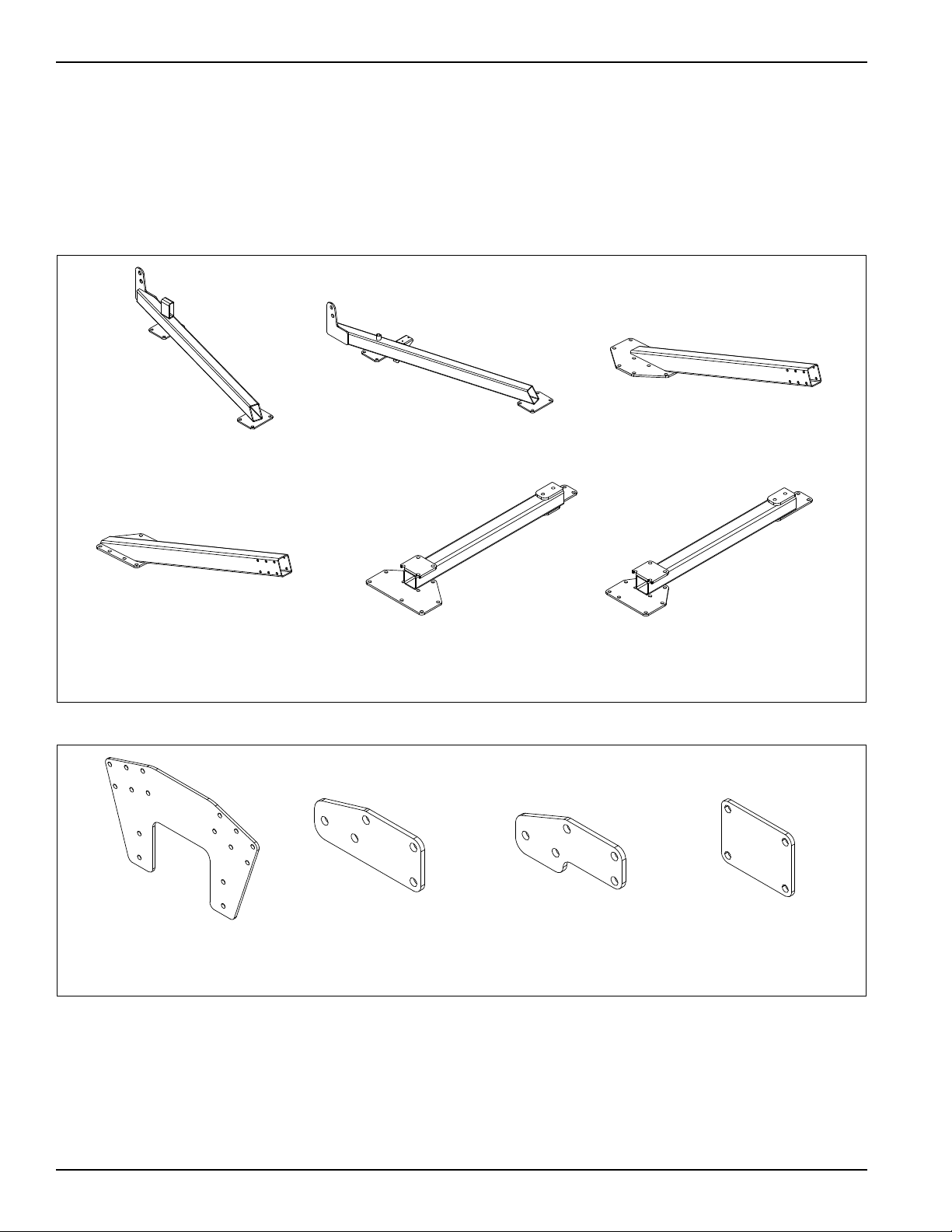

P/N 173167

BRACE-FRAME, LH

P/N 173168

BRACE-FRAME, RH

P/N 173539

TRUSS-FRAME, LH

P/N 173540

TRUSS-FRAME, RH

P/N 173175

BRACE-SIDE, LH

P/N 173174

BRACE-SIDE, RH

required weldments

P/N 171642

PLATE-TRUSS

P/N 173532

PLATE-REAR MOUNT

P/N 173534

PLATE-FOUR BOLT

P/N 173533

PLATE-OFFSET

REAR MOUNT

required piece parts

FRAME STABILIZER KIT (P/N 173531) ON

WING FLOAT PULVERIZER FRAME (P/N 2P416)

1. Identify the six (6) weldments required (See

Figure 1-1):

2. Identify the piece parts (4) required (shipped with the

hardware) (See Figure 1-2):

Figure 1-1: Required Weldments

Figure 1-2: Required Piece Parts

3. Place the Wing Float Pulverizer in a suitable area to

work with the frame while the wings are unfolded.

a. Pneumatic tools will be of benefit during the

installation process.

b. One hydraulic line will need to be opened and

reassembled.

F-694 Edition Brillion Farm Equipment 1-1

rev10-09-2012 Brillion, Wisconsin 54110

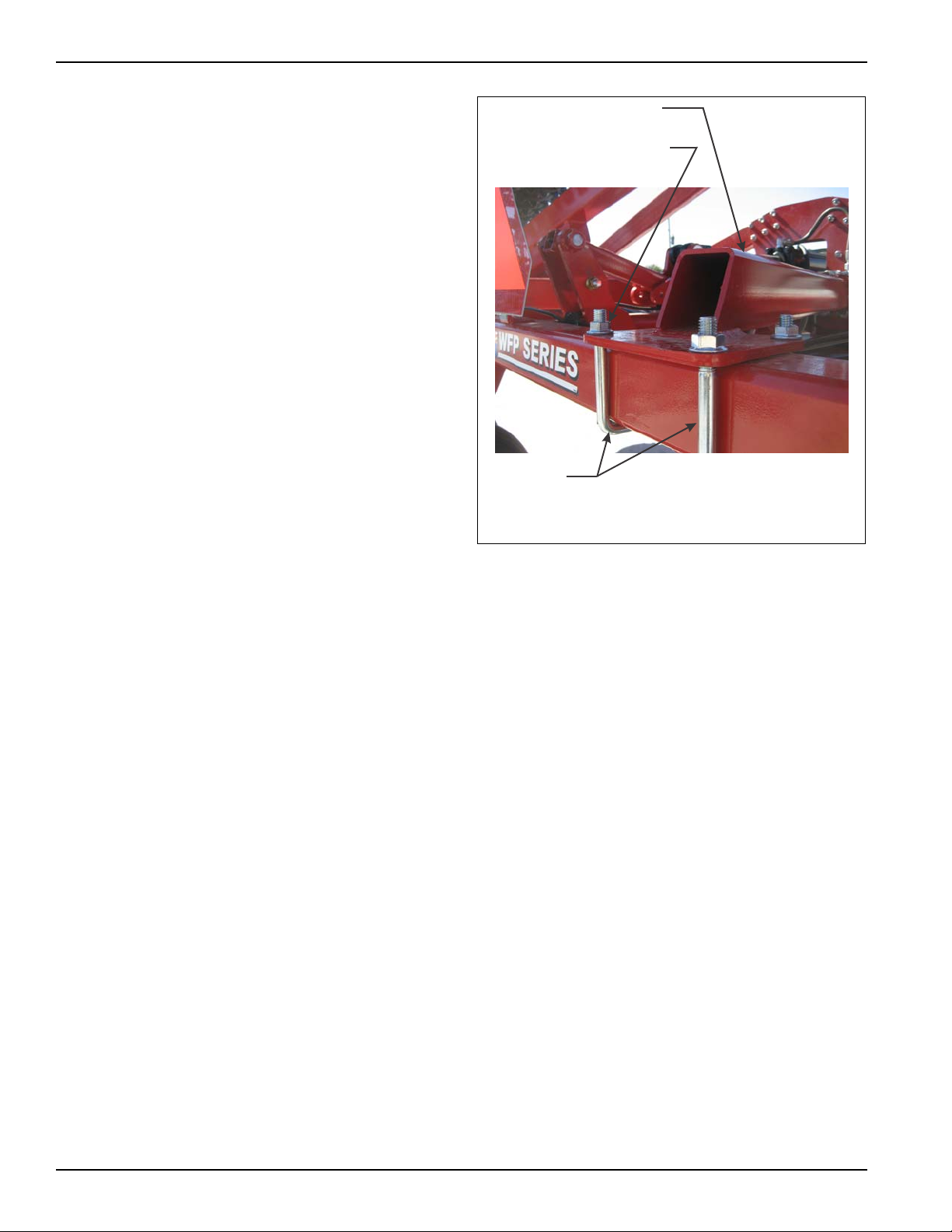

4. Lock the machine in lifted/raised position with the

photo 1

SQUARE TUBULAR LINK

1/2 X 6 CLEVIS PIN

W/ 5/32 HAIR PIN

TOGGLE LINK

photo 2

BRACE, FRAME LH

WELDMENT

1 X 6-3/16 PIN

5/8-11 X 6 HEX HEAD

CAP SCREW

PLATE,

4 BOLT

5/8-11 HEX

LOCK NUT

wings unfolded (the wing tips need to rest on the

ground).

a. Lock the “over the center” lift linkage in the up

position by placing pin P/N 9J437 1/2 X 6

CLEVIS PIN thru the holes provided in the lift

linkage. The pin needs to pass below the square

tubular link to assure that the machine will not fall

when the cylinder pin is removed in a later step

(See Figure 1-3).

b. Make sure all hydraulic pressure is neutralized.

5. Position a jack (ten ton capacity or greater) under th e

rear portion of the hitch, just in front of the frame and

apply enough lifting force to relax the two (2) 1” pins

that secure the base end of the machine lift cylinder

and the upper turn buckle assembly used to level the

machine (the turn buckle may have to be adjusted to

relax both pins simultaneously).

a. Remove the keepers from the pins that secure

the top of the turn buckle and the machine lift

cylinder.

b. Locate the pins P/N 173535, PIN, 1 X 6-3/16 in

the hardware package and replace the pins

allowing equal amounts of the pin to protrude

from either side (See Figure 1-4).

1-2 Brillion Farm Equipment F-694 Edition

Figure 1-3

Figure 1-4

Brillion, Wisconsin 54110 rev10-09-2012

6. Install P/N 173167, BRACE-FRAME, LH to the left of

BRACE - FRAME, LH

5/8-11 HEX LOCK NUT

U-BOLT

photo 2b

center, just above the fra me with the “L” shaped plate

to the front. Fit the holes in the “L” shaped plate over

the pins installed in the previous step.

a. First secure the rear of P/N 173167 with two (2)

“U” bolts P/N 9D989 and four (4) 5/8-11 hex lock

nuts. Position the “U” bolts from below the tube

up into the rear plate of the weldment (See

Figure 1-5).

b. Secure the front of P/N 173167 by placing one

(1) flat washer P/N 1-861-010032-24 and one (1)

cotter pin, P/N 172810 on each pin as seen in

the figure below.

c. Place P/N 173534 below the front tube and

secure with four (4) 5/8-11 x 6 hex head bolts.

Orient the bolts from the bottom upward when

possible. Secure the bolts with 5/8-11 hex lock

nuts.

Figure 1-5

F-694 Edition Brillion Farm Equipment 1-3

rev10-09-2012 Brillion, Wisconsin 54110

Loading...

Loading...