Lancer 85-0087 Service Manual

INSTALLATION AND SERVICE MANUAL

FOR

LANCER LEV

® FILL STATION (LFS)

(PN 85-0087)

REV: 10/15/01

P.N. 28–0507

THIS MANUAL IS AN INITIAL ISSUE.

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

USA -CANADA – 210-310-7250 • LATIN AMERICA – 210-310-7245 • ASIA – 210-310-7242

EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978

FAX ENGINEERING: • 210-310-7096

"Lancer" is the registered trademark of Lancer • Copyright — 2001 by Lancer, all rights reserved.

NOTICE TO USERS:

THIS DISPENSER UNIT IS INTENDED FOR IN-DOOR USE ONLY.

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

TABLE OF CONTENTS

NOTICE TO USERS................................................................................................................................COVER

TABLE OF CONTENTS ......................................................................................................................................i

INTRODUCTION TO THE LANCER LEV® FILL STATION (LFS), PN 85-0087 ...............................................ii

1. SPECIFICATIONS .......................................................................................................................................1

2. INSTALLATION ...........................................................................................................................................1

2.1 RECEIVING........................................................................................................................................1

2.2 UNPACKING ......................................................................................................................................1

2.3 INSTALLATION ..................................................................................................................................1

2.4 CONNECTING TO ELECTRICAL POWER .......................................................................................2

2.5 CONNECTING SUPPLY LINES TO SOURCES................................................................................2

3. SCHEDULED MAINTENANCE ...................................................................................................................2

3.1 DAILY .................................................................................................................................................2

3.2 BIWEEKLY SANITIZING ....................................................................................................................2

3.3 EVERY SIX MONTHS........................................................................................................................2

4. DISPENSER CLEANING AND SANITIZING ..............................................................................................3

4.1 AMBIENT PROCESS.........................................................................................................................3

5. OPERATION OF THE LFS..........................................................................................................................4

5.1 CONNECTIONS.................................................................................................................................4

5.2 INITIAL POWER UP...........................................................................................................................4

5.3 AUTO MODE......................................................................................................................................4

5.4 MANUAL MODE.................................................................................................................................4

5.5 SETTING THE DESIRED RATIO .......................................................................................................4

5.6 CHANGING SYRUP PACKAGE PROCEDURE ................................................................................5

5.7 CHANGING THE BOX OF SYRUP....................................................................................................5

5.8 FUNCTIONS AND ALARMS ..............................................................................................................5

6. TROUBLESHOOTING.................................................................................................................................5

6.1 GREEN POWER LIGHT DOES NOT COME ON..............................................................................5

6.2 UNDER SOLD OUT CONDITION, SOLD OUT ALARM SOUNDS, BUT THE

RED SOLD OUT LED DOES NOT FLASH........................................................................................6

6.3 UNIT WILL NOT GO INTO AUTO MODE ..........................................................................................6

6.4 SOLD OUT ALARM DOES NOT SHUT OFF.....................................................................................6

6.5 WATER NOT DISPENSING FROM VALVE .......................................................................................6

6.6 RED LIGHT ON CIRCUIT COMES ON OR GREEN LIGHT

ON THE CIRCUIT BOARD DOES NOT COME ON..........................................................................6

6.7 WATER LEAKAGE AROUND NOZZLE .............................................................................................6

6.8 LEAKAGE BETWEEN UPPER AND LOWER BODIES.....................................................................6

6.9 MISCELLANEOUS LEAKAGE ...........................................................................................................6

6.10 INSUFFICIENT WATER FLOW..........................................................................................................6

6.11 INSUFFICIENT SYRUP FLOW..........................................................................................................6

6.12 ERRATIC RATIO oBRIX .....................................................................................................................7

6.13 NO PRODUCT DISPENSED .............................................................................................................7

6.14 WATER ONLY DISPENSED, NO SYRUP, OR SYRUP ONLY DISPENSED, NO WATER ...............7

6.15 VALVE WILL NOT SHUT OFF ...........................................................................................................7

6.16 EXCESSIVE FOAMING .....................................................................................................................7

7. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS............................................................8

7.1 CONTROL BOX ASSEMBLY, FRONT VIEW .....................................................................................8

7.2 PLUMBING.........................................................................................................................................9

7.3 WIRING HARNESS DIAGRAM..........................................................................................................9

7.4 INTERNAL COMPONENTS.............................................................................................................10

7.5 WIRING DIAGRAM ..........................................................................................................................11

i

Introduction to the Lancer LEV® Fill Station (LFS), PN 85-0087

ii

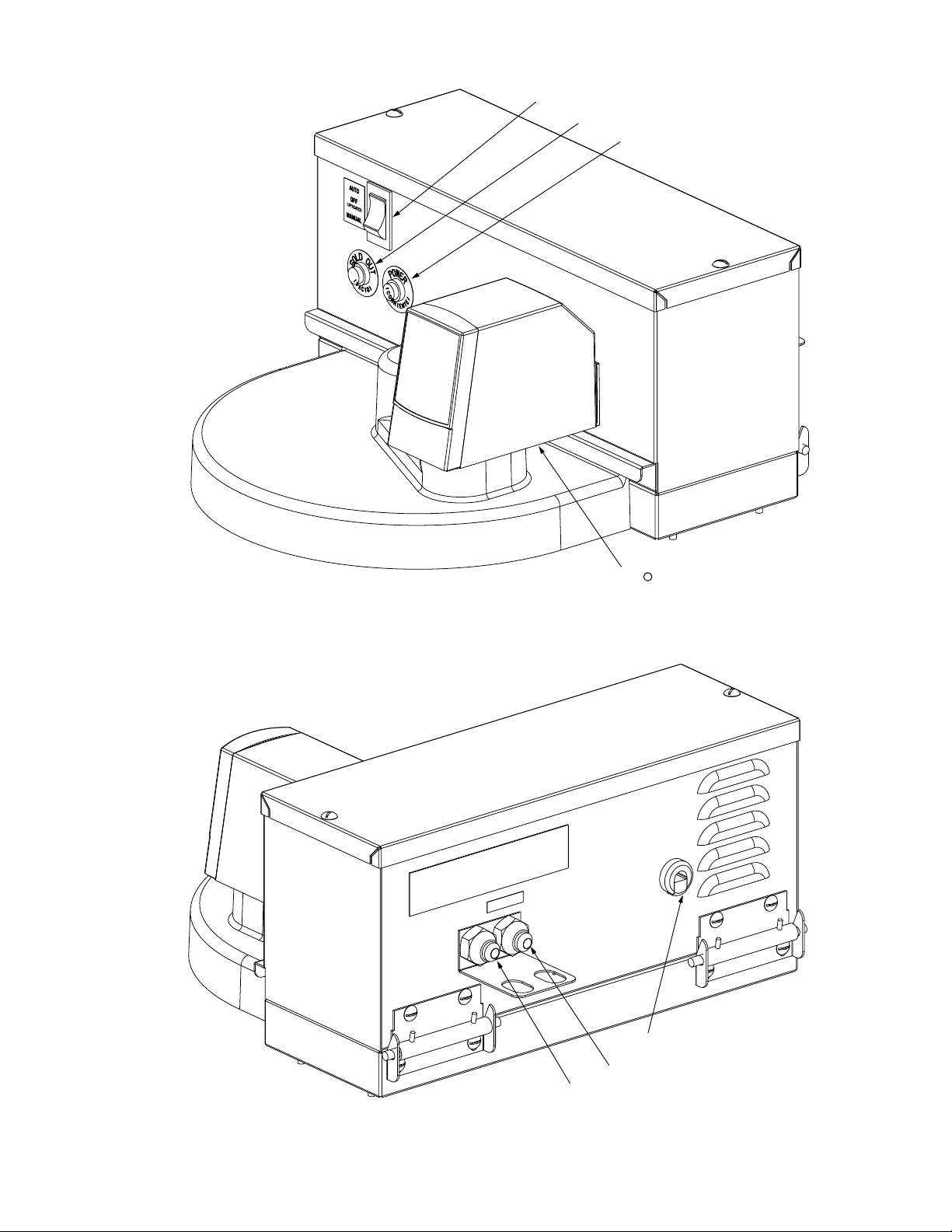

Front View, LFS

Rear View, LFS

Power Switch

LED (Red), Sold Out

LED (Green), Power

LEV

R

3/8" Water Inlet

3/8" Syrup Inlet

Opening for Power Cord,

Three Prong, Grounded

1

Mounting

A. The dispenser is designed for in-door use ONLY and to be mounted on unit, in a well

lighted, visible area.

CAUTION

FAILURE TO MAINTAIN PROPER AIR CLEARANCE WILL CAUSE THE UNIT TO OVERHEAT AND

WILL RESULT IN PREMATURE COMPONENT FAILURE.

B. Locate slush machine with approximately five (5) inches clearance between a wall and the back

of the LFS unit. Follow slush machine manufacturer’s installation instructions for side and rear

ventilation requirements.

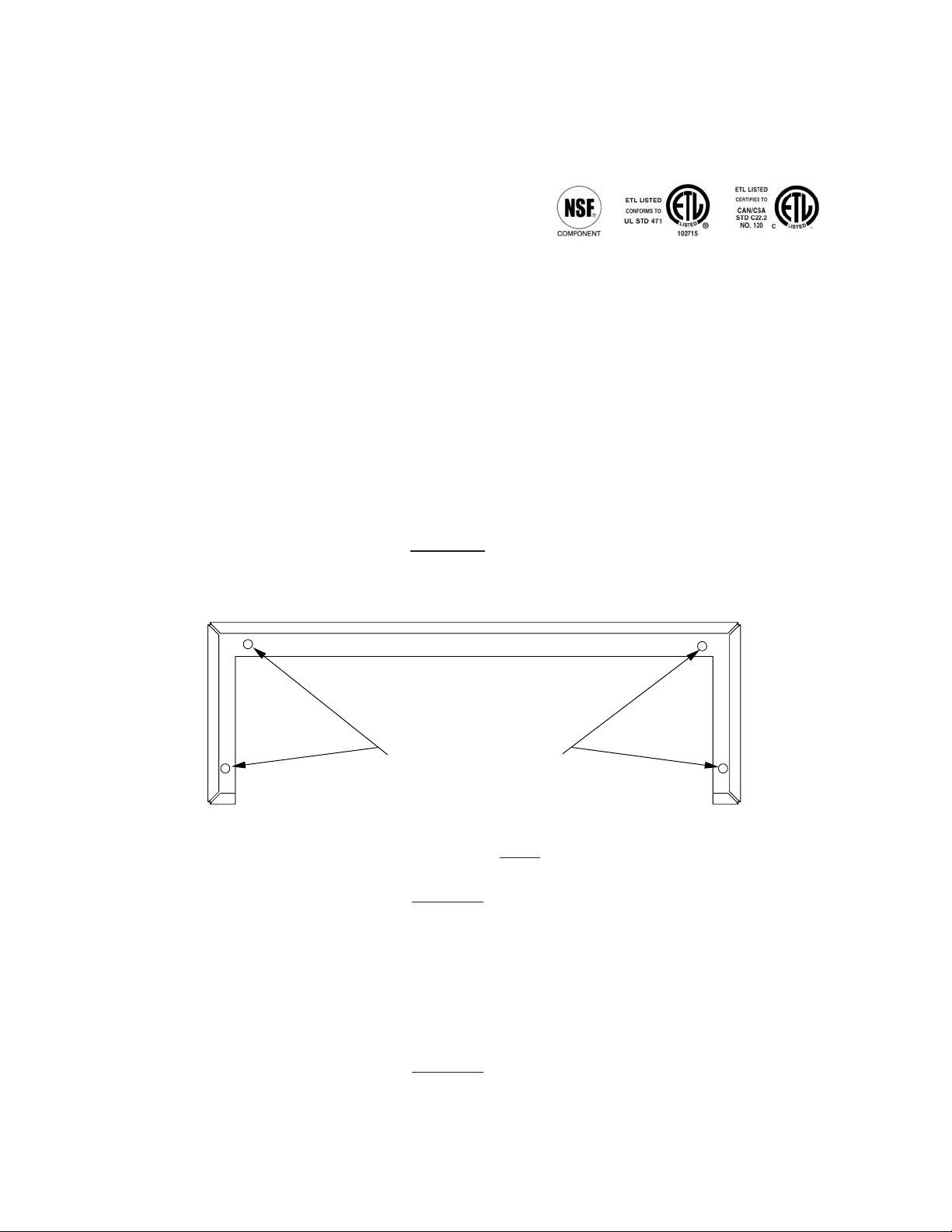

C. If required, locate and mark four (4) holes using base of fill station (see Figure 1).

D. Cover hopper with lid before drilling holes.

CAUTION

ENSURE HOLES ARE CAREFULLY DRILLED TO AVOID DRILLING TOO DEEP AND THEREBY

POSSIBLY DAMAGING REFRIGERATION LINES.

E. Drill four (4) holes using a #19 drill bit (0.166) drill bit.

1. SPECIFICATIONS

SHIPPING WEIGHT Nine (9) pounds (4.1 kg)

DIMENSIONS 14.5" x 5.5" x 7.5" (36.83 cm x 13.97 cm x 19.05 cm)

ELECTRICAL 115V/60Hz/1.0A

(Power Cord is provided with three prong grounded plug)

INLET SYRUP CONNECTIONS 3/8 inch Male Flare

INLET WATER CONNECTIONS 3/8 inch Male Flare

FLOW 4.5 ounces per second

2. INSTALLATION

2.1 RECEIVING

Each unit is completely tested under operating conditions and thoroughly inspected before

shipment. At the time of shipment, the carrier accepts the unit and any claim for damage must be

made with the carrier. Upon receiving unit(s) from the delivering carrier, carefully inspect carton for

visible indication of damage. If damage exists, have carrier note same on bill of lading and file a

claim with the carrier.

2.2 UNPACKING

A. Carefully remove unit from shipping carton.

B. Inspect unit for concealed damage. If damage exists, notify delivering carrier note and file a

claim against the carrier.

2.3 INSTALLATION

W

ARNING

DISCONNECT SLUSH MACHINE FROM POWER SOURCE BEFORE BEGINNING

INSTALLATION OF THE LANCER LEV® FILL STATION (LFS) TO AVOID POSSIBLE FATAL

ELECTRICAL SHOCK OR SERIOUS INJURY.

PN 30-3193

Figure 1

Base Fill Assembly

Screw Mounting, Hole Pattern

F. Using the ROLOC screws provided (PN 04-0558), attach the LFS to the slush machine.

2.4 CONNECTING TO ELECTRICAL POWER

W

ARNING

THIS UNIT MUST BE PROPERLY ELECTRICALLY GROUNDED TO AVOID POSSIBLE FATAL

ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR. THE POWER CORD IS

PROVIDED WITH A THREE PRONG GROUNDED PLUG. IF A THREE-HOLE GROUNDED

ELECTRICAL OUTLET IS NOT AVAILABLE, USE AN APPROVED METHOD TO GROUND THE

UNIT.

DO NOT USE EXTENSION CORDS WITH THIS UNIT. DO NOT "GANG" TOGETHER WITH

OTHER ELECTRICAL DEVICES ON THE SAME OUTLET.

A. Check the dispenser serial number plate for unit's correct electrical requirements. Do not plug

into electrical outlet unless unit electrical configuration, located on serial plate, agrees with local

available power supply.

B. Route the power supply cord to a grounded electrical outlet of the proper voltage and amperage

rating, and plug in the unit.

2.5 CONNECTING SUPPLY LINES TO SOURCES

A. Connect free end of plain water lines to water supply [must be 30-110 PSI (2.1 to 7.6 BAR)].

B. Mark both ends of product and water lines and route to dispenser. Flush lines to be sure each

is clean. Failure to do so may result in clogging of valve(s), resulting in improper operation.

Connect lines to dispenser and secure using Oetiker clamps.

C. Turn on water supply.

D. Open all dispenser valves until air is bled from system.

E. Actuate valve until a smooth flow of water is obtained by holding in Manual Mode.

F. Check for leaks.

G. Connect free ends of product lines to bag-in-box.

H. Activate syrup pump until smooth flow of syrup is obtained by holding in Manual Mode.

I. Check for syrup leaks.

J. Adust the water flow.

K. Adjust water to syrup (ratio) brix (see Section 5.5).

3. SCHEDULED MAINTENANCE

Drain host product unit hopper before starting the sanitization process to prevent overfilling.

The LFS must be sanitized first.

3.1 DAILY CLEANING

A. Nozzle and diffuser must be cleaned daily.

1. Remove nozzle by twisting counter clockwise and pulling down.

2. Remove diffuser by pulling down.

3. Wash nozzle and diffuser with warm water. DO NOT use soap or detergent. This will cause

foaming and off taste in finished product.

4. Reinstall diffuser and nozzle.

5. With a clean cloth and warm water, wipe off all of the unit's exterior surfaces. DO NOT USE

ABRASIVE SOAPS OR STRONG DETERGENTS.

6. Taste each product for off tastes and/or brix changes.

7. Check for leaks.

3.2 BI-WEEKLY SANITIZING

Nozzle and diffuser must be sanitized bi-weekly. Comply with the instructions of the dispenser

manufacturer to properly sanitize the nozzle and diffuser, and ensure no off-taste is present.

3.3 EVERY SIX MONTHS

Clean and sanitize the LFS unit using the appropriate procedures outlined in Section 4 of this

manual.

2

Loading...

Loading...