Lancer 82-4437 Installation Manual

LANCER INSTALLATION SHEET

82-4437 MOTHER BAR GUN KIT

FOR QUALIFIED INSTALLER ONLY

! WARNING The dispenser is for indoor use only. This unit is not a toy. Dispenser is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given instruction concerning use of the appliance

by a person responsible for their safety. Unit is not designed to dispense dairy products. The min/max ambient operating temperature for the dispenser

is 40 ºF (4.4 ºC) to 105 ºF (40.5 ºC).

! ADVERTENCIA El dispensador sólo debe usarse en interiores. Esta unidad no es un juguete. Esta unidad no está destinada al uso por parte de

personas (incluso niños) con capacidad física, sensorial o mental reducida, o sin experiencia y conocimientos sucientes, a menos que una persona

responsable de su seguridad les haya dado supervisión o capacitación en el uso de la unidad. Esta unidad no ha sido diseñada para suministrar productos lácteos. La temperatura ambiente operativa mínima / máxima para el dispensador es de 40 ºF (4.4 ºC) a 105 ºF (40.5 ºC).

! AVERTISSEMENT Le distributeur est destiné à un usage à l’intérieur seulement. Cet appareil n’est pas un jouet. Il ne devrait pasêtre utilisé par des

enfants ou des personnes inrmes sans surveillance. Cet appareil n’est pas destiné à un usage par des personnes (y compris les enfants) ayant des

capacités physiques, sensorielles ou mentales réduites, ou manquant d’expérience et de connaissances, à moins qu’elles obtiennent de la surveillance

ou des instructions au sujet de l’utilisation de l’appareil de la part d’une personne chargée de leur sécurité. Cet appareil n’est pas conçu pour distribuer

des produits laitiers. La température de service ambiante minimum/maximum pour le distributeur estde 40ºF (4.4 ºC) à 105 ºF (40.5 ºC).

SPECIFICATIONS

DEMENSIONS WEIGHT VOLTAGE PRESSURE MIN MAX

Height 7.00 inches (177.8 mm) Installed 3.67 lbs (1.66 kg) 24VAC 50/60Hz CARB WATER 70psi (4.82bar) 110psi (7.58bar)

Width 4.77 inches (121.2 mm) SYRUP 20psi (1.37bar) 60psi (4.13bar)

Length 6.10 inches (154.9 mm)

TOOLS REQUIRED: Oetiker Pliers, Needle-nose Pliers, Wrench, Slotted Screwdriver, Tubing Cutters, Cordless Drill

1. INSTALLATION

FIG 1 - KIT

1.1 RECEIVING

Each pre-programmed unit is completely tested under operating conditions

and thoroughly inspected before shipment. At time of shipment, the carrier

accepts the unit and any claim for damage(s) must be made with carrier.

Upon receiving units from the delivering carrier, carefully inspect carton for

visible indication(s) of damage. If damage exists, have carrier note on bill of

lading and le a claim with the carrier.

1.2 UNPACKING

SCREW

A. Remove valve box from corrugated shipping carton.

B. Remove foam inserts from inside valve box

C. Inspect unit and parts for concealed damage. If damage exists,

notify delivering carrier and le claim against same.

1.3 SELECTING THE LOCATION

A. Select a location which is near a properly grounded electrical power

supply. The recommended placement is close proximity to bar gun

manifold. NOTE: It is recommended to leave a clearance of at least 3 inches on the left, right, rear and bottom of the kit.

1.4 OPENING THE KIT

A. Remove front screw (Fig 1) to remove the lid.

1.5 KIT INSTALLATION

A. Inspect the mounting location where the unit is to be installed. Verify the selected location is strong enough to safely support

the weight of the installed unit.

1. The ideal counter for installation should measure at least 1” (25.4 mm) thick.

C O N T I N U E D O N N E X T P A G E

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

“Lancer” is the registered trademark of Lancer • Copyright — 2012 by Lancer, all rights reserved.

DATE: OCT 2012

P.N. 28–0913

MOTHER BAR GUN KIT INSTALLATION MANUAL - PAGE 2

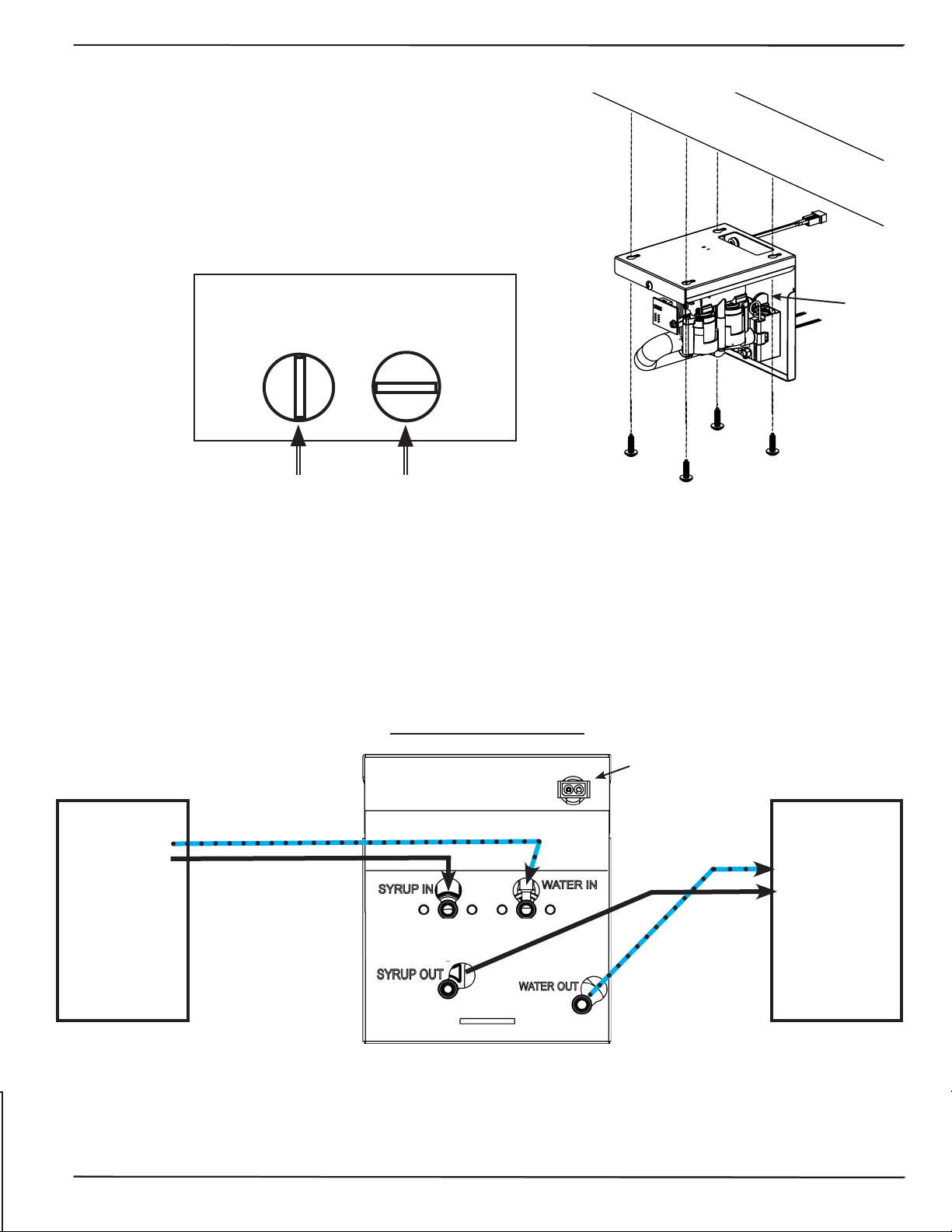

1.5 KIT INSTALLATION - CONTINUED

B. The kit must be installed as shown.

C. Pre-drill (4) holes for valve box and secure.

NOTE: Use the keyholes on the stainless steel as a template.

D. Secure the kit in place using the screws provided. Refer to Fig 2.

NOTE: The kit is shipped with the Valve shutoffs in the ‘open’ position.

To ‘close’ the shutoffs, use needle-nose pliers, turn the valves

counter-clockwise (Fig 3).

FIG 3 - VALVE SHUTOFFS

OPEN CLOSED

FLOW FLOW

FIG 2 - KIT INSTALLATION

COUNTER

T O P

VALVE

SHUTOFFS

1.6 CONNECTING TO WATER SUPPLY

A. Use a tube cutter to cut tubing. Tubing cut with other items will result in plastic shavings that could plug the ow controls in

the dispensing valve.

B. Refer to the Plumbing Diagram (Fig 4) for plumbing line connections.

NOTE: FOR BARGUN FLOW RATE, REFER TO BARGUN MANUFACTURER INSTRUCTIONS. Water pipe connections

and xtures directly connected to a potable water supply must be sized, installed, and maintained according to federal, state,

and local laws. An adequate potable water supply must be provided. It is recommended that the supply shut-off is easily

accessible.

FIG 4 - PLUMBING DIAGRAM

Power

Supply

Connection

CARBONATED WATER

SYRUP

PYTHON

TRUNK

SYRUP

CARBONATED WATER

BARGUN

MANIFOLD

C O N T I N U E D O N N E X T P A G E

Loading...

Loading...