Page 1

COUNTER ELECTRIC DISPENSER LANCER SERIES 2500

Operation Manual

PN: 28-0089/04

2508

Lancer Corp.

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Manual PN: 28-0089/04

OCTOBER 06, 2004

FOR QUALIFIED INSTALLER ONLY

“Lancer” is the registered trademark of Lancer © 2013 by Lancer, all rights reserved.

Page 2

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product and should be handed over to the operator after the installation and preserved for any further consultation that may be necessary. Please read carefully the guidelines and warnings contained herein as they are intended to provide the user with essential information for the continued safe use

and maintenance of the product. In addition, it provides GUIDACE ONLY to the user on the correct services and site

location of the unit.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with up-to-date

safety and hygiene knowledge and practical experience, in accordance with current regulations.

TABLE OF CONTENTS

SPECIFICATIONS................................................................................................................................4

PRE-INTALLATION CHECKLIST........................................................................................................5

WARNINGS/CAUTIONS...................................................................................................................6-9

1. INSTALLATION............................................................................................................................10

1.1 RECIEVING THE UNIT.......................................................................................................10

1.2 UNPACKING........................................................................................................................10

1.3 SELECTING A COUNER LOCATION.................................................................................10

1.4 CONNECTING THE DRAIN................................................................................................11

1.5 FILLING UNIT WITH WATER..............................................................................................11

1.6 CONNECTING TO ELECTRICAL POWER.........................................................................11

1.7 CONNECTING TO WATER SUPPLY..................................................................................12

1.8 CONNECTING TO CARBONATED WATER SUPPLY.........................................................12

1.9 CONNECTING TO BAG-IN-BOX (BIB) SYRUP SUPPLY TO REMOTE SYRUP PUMPS.13

1.10 PURGING THE CARBONATION SYSTEM........................................................................13

1.11 PURGING THE WATER AND SYRUP SYSTEMS..............................................................13

1.12 ADJUSTING WATER FLOW (LEV®)..................................................................................13

1.13 ADJUSTING WATER TO SYRUP (RATIO) BRIX (LEV®)..................................................14

2. SCHEDULED MAINTANANCE...................................................................................................14

2.1 DAILY...................................................................................................................................14

2.2 WEEKLY..............................................................................................................................14

2.3 MONTHLY............................................................................................................................14

2.4 EVERY SIX MONTHS.........................................................................................................14

2.5 YEARLY...............................................................................................................................14

3. DISPENSER CLEANING AND SANITIZATION..........................................................................14

3.1 GENERAL INFORMATION.................................................................................................14

3.2 CLEANING AND SANITIZING SOLUTIONS.......................................................................15

3.3 AMBIENT PROCESS..........................................................................................................15

3.4 VALVES...............................................................................................................................15

4. TROUBLESHOOTING.................................................................................................................16

4.1 WATER LEAKAGE AROUND NOZZLE...............................................................................16

4.2 LEAKAGE BETWEEN UPPER AND LOWER VALVE BODIES..........................................16

4.3 MISCELLANEOUS LEAKAGE............................................................................................16

4.4 INSUFFICIENT WATER FLOW..........................................................................................16

4.5 INSUFFICIENT SYRUP FLOW...........................................................................................16

4.6 ERRATIC RATIO.................................................................................................................16

4.7 NO PRODUCT DISPENSED..............................................................................................17

4.8 WATER ONLY DISPENSED; NO SYRUP; OR SYRUP ONLY DISPENSED,

NO WATER.........................................................................................................................17

4.9 VALVE DOES NOT SHUT OFF..........................................................................................17

2

Page 3

4.10 EXCESSIVE FOAMING......................................................................................................17

4.11 COMPRESSOR DOES NOT START (NO HUM), BUT CONDENSOR FAN MOTOR

RUNS..................................................................................................................................18

4.12 COMPRESSOR STARTS AND CONTINUES TO RUN UNBTIL FREEZE UP AND WILL

NOT CUT OFF....................................................................................................................18

4.13 COMPRESSOR DOES NOT START BUT HUMS..............................................................18

4.14 COMPRESSOR STARTS BUT DOES NOT SWITCH OFF START WINDING (WILL RUN

FOR ONLY A FEW SECONDS BEFORE INTERNAL OVERLOAD SWITCHES

COMPRESSOR OFF).........................................................................................................18

4.15 COMPRESSOR STARTS AND RUNS A SHORT TIME BUT SHUTS OFF ON

OVERLOAD........................................................................................................................18

4.16 COMPRESSOR AND CONDENSER FAN MOTOR WILL NOT START AFTER FIVE (5)

MINUTE POWER OFF DELAY (LANCER EIBC EXPORT ONLY)....................................19

4.17 WARM DRINKS..................................................................................................................19

5. DISPENSER DISPOSAL.............................................................................................................19

6. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS............................................20

6.1 2500 REFRIGERATION DECK ASSEMBLY, R-134A, LANCER ELECTRONIC ICE BANK

CONTROL (EIBC), USA ONLY, PN 82-2669.................................................................20-21

6.2 2500 REFRIGERATION DECK ASSEMBLY WITH ELECTRONIC ICE BANK CONTROL

(EIBC), R-134A; PN 82-2049E, 230V/50Hz; PN 82-2103E, 115V/60Hz; PN 82-2098E,

240V/60Hz......................................................................................................................22-23

6.3 2500 CONTROL HOUSING ASSEMBLY, ELECTRONIC ICE BANK CONTROL

(EIBC)............................................................................................................................24-25

6.3.A CONTROL HOUSING ASSEMBLY, EIBC, PN 52-2026,

WITHOUT KILL SWITCH........................................................................................25

6.4 2500 CABINET ASSEMBLY...........................................................................................26-27

6.5 2500 WIRING DIAGRAM AND HOUSING CONNECTIONS, LANCER ELECTRONIC ICE

BANK CONTROL, USA ONLY............................................................................................28

6.6 2500 WIRING DIAGRAM, ELECTRONIC ICE BANK CONTROL (EIBC),

INTERNATIONAL ONLY.....................................................................................................29

6.7 INSTALLATION KITS AND OPTIONAL ACCESSORIES....................................................30

3

Page 4

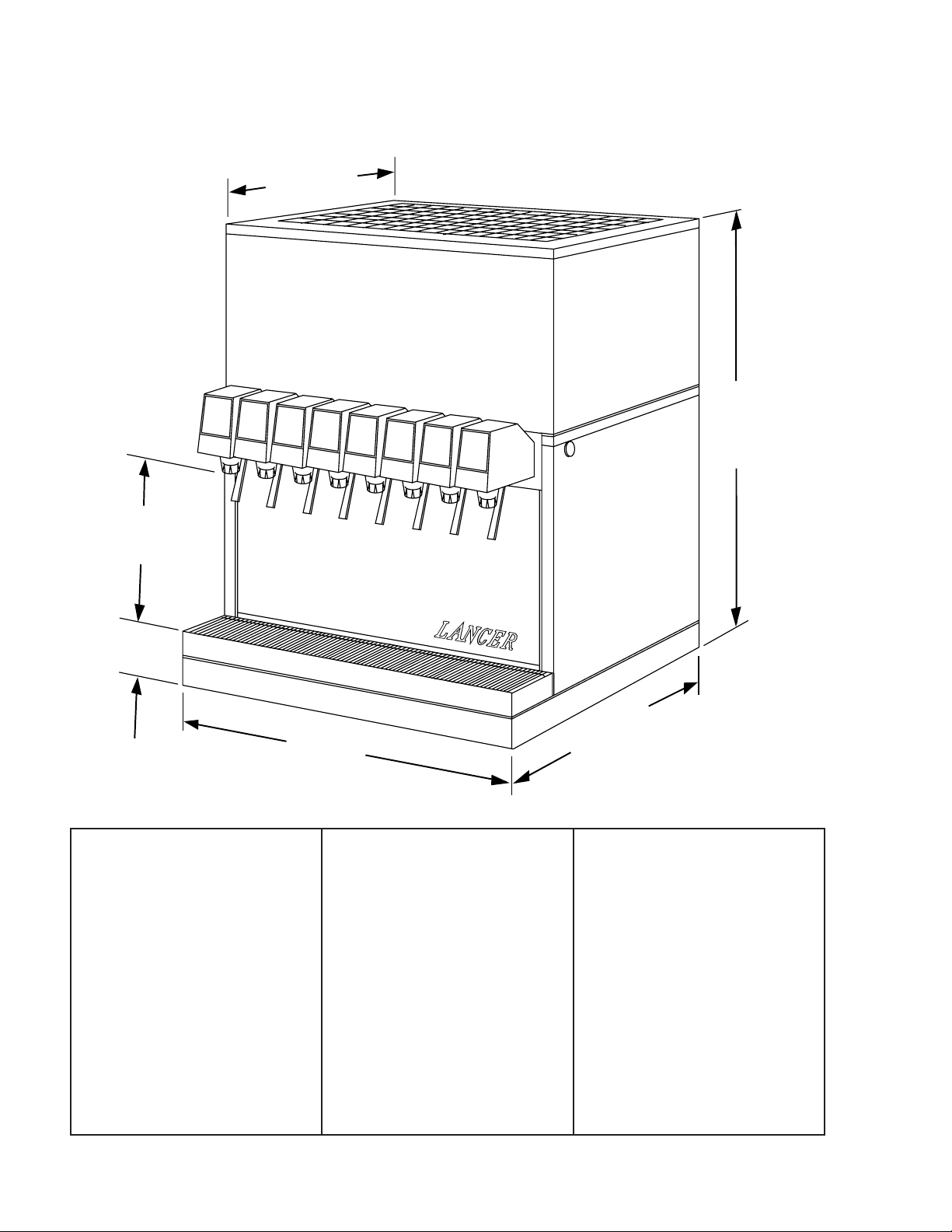

CED 2500 SPECIFICATIONS

21 7/8 "

560 mm

31 1/4 "

790 mm

27 1/8 "

690 mm

26 "

660 mm

3 1/2 "

90 mm

11 1/8 "

280 mm

Æ

DIMENSIONS

Width: 26 in (660 mm)

Depth: 27 1/8 in (690 mm)

Height (w/out legs): 31 1/4 in

(790 mm)

SPACE REQUIRED

Left Side: 4 in (101.6 mm)

Right side: 4 in (101.6 mm)

Back: 4 in (101.6 mm)

Top: 8 in (203.2 mm)

ELECTRICAL

115VAC/60Hz/4.3AMPs

230-240VAC/50-60Hz/2.6AMPs

WEIGHT

Empty: 209 lbs (95 kg)

Operating: 376 lbs (171 kg)

Shipping: 257 lbs (117 kg)

ICE

Capacity: 50 lbs (23 kg)

FITTINGS

Water for carbonator inlet:

3/8” barb

Plain water inlet: 3/8” barb

Brand syrup inlets: 3/8” barb

Injection avor inlets: 1/4” barb

CO2 inlet: 3/8” barb

4

CARBONATOR WATER SUPPLY

Min owing pressure: 35 PSIG

(0.241 BAR)

Max static pressure: 60 PSIG

(0.414 BAR)

CARBON DIOXIDE (CO2)

Min pressure: 70 PSIG

(0.483 BAR)

Max pressure: 80 PSIG

(0.552 BAR)

Page 5

PRE-INSTALLATION CHECKLIST

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly inspected before

shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton for visible damage. If damage exists, have the carrier note the damage on the freight bill and le a claim with carrier. Responsibility for damage to the dispenser lies with the carrier.

TOOLS REQUIRED

Oetiker Pliers Slotted Screwdriver

Tubing Cutters Phillips Screwdriver

Wrench Cordless Drill

POST MIX ACCESSORIES

CO2 Regulator Set CO2 Supply

Beverage Tubing Oetiker Clamps/Fittings

Water Booster Water Regulator

Precision Cutters (if removing/replacing carbonator tank)

BIB SYSTEM

BIB Rack BIB Regulator Set

BIB Syrup Boxes

BIB Connectors - ensure you have the correct connectors for syrup lineup.

CONSIDER LOCATION OF THE FOLLOWING PRIOR TO INSTALL

Water supply lines Drain

Is the countertop level? Heating and air conditioning ducts

Grounded electrical outlet.

Enough space to install the dispenser. Include space for a top-mounted ice machine, if necessary.

Does the top-mounted ice machine have a minimum clearance on all sides?

Located away from direct sunlight or overhead lighting.

Can the countertop support the weight of the dispenser? Be sure to include the weight of an ice

machine (if necessary) plus the weight of the ice.

This unit is not suitable for use in an area where a water jet could be used.

5

Page 6

! !

WARNING/ADVERTENCIA/AVERTISSEMENT

! The dispenser is for indoor use only. This appliance is intended for use in commercial applications such as res-

taurants, stores or similar. This unit is not a toy. It should not be used by children or inrm persons without supervision. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Cleaning and user maintenance shall not be performed

by children without supervision. This unit is not designed to dispense dairy products. The minimum/maximum ambient

operating temperature for the dispenser is 40°F to 90°F (4°C to 32°C). Do not operate unit below minimum ambient

operation conditions. Should freezing occur, cease operation of the unit and contact aurthorized service technician.

Service, cleaning and sanitizing should be accomplished only by trained personnel. Applicable safety precautions

must be observed. Instruction warnings on the product being used must be followed.

! El dispensador sólo debe usarse en interiores. Esta unidad está diseñada para su uso en aplicaciones comer-

ciales tales como restaurantes, tienda o similares. Esta unidad no es un juguete. No la deben usar niños ni personas discapacitadas sin supervisión. Esta unidad no está destinada al uso por parte de personas (incluso niños)

con capacidad física, sensorial o mental reducida, o sin experiencia y conocimientos sucientes, a menos que una

persona responsable de su seguridad les haya dado supervisión o capacitación en el uso de la unidad. Limpieza y

mantenimiento de usuario no deberá ser realizada por los niños sin supervisión. Esta unidad no ha sido diseñada

para suministrar productos lácteos. La temperatura ambiente operativa mínima / máxima para el dispensador es de

40°F a 90°F (4°C a 32°C). No opere la unidad por debajo de las condiciones mínimas de funcionamiento ambiente.

En caso de ocurrir congelación, cesar la operación de la unidad y póngase en contacto con el servicio técnico autorizado. Servicio de limpieza y desinfección debe llevarse a cabo solamente por personal especializado. Precauciones

de seguridad aplicables deben ser observadas. Advertencias de instrucciones en el producto que se use debe ser

seguido.

! Le distributeur est destiné à un usage à l’intérieur seulement. Cet appareil est conçu pour une utilisation dans des

applications commerciales telles que les restaurants, les dépanneurs ou similaires. Cet appareil n’est pas un jouet. Il

ne devrait pas être utilisé par des enfants ou des personnes inrmes sans surveillance. Cet appareil n’est pas destiné

à un usage par des personnes (y compris les enfants) ayant des capacités physiques, sensorielles ou mentales réduites, ou manquant d’expérience et de connaissances, à moins qu’elles obtiennent de la surveillance ou des instruc-

tions au sujet de l’utilisation de l’appareil de la part d’une personne chargée de leur sécurité. Nettoyage et entretien

de l’utilisateur ne doivent pas être effectués par des enfants sans surveillance. Cet appareil n’est pas conçu pour

distribuer des produits laitiers. La température de service ambiante minimum/maximum pour le distributeur est de

40°F à 90°F (4°C à 32°C). Ne pas faire fonctionner l’appareil ci-dessous les conditions minimales de fonctionnement

ambiantes. Faut-gel se produisent, cesser l’exploitation de l’appareil et contactez technicien agréé. Service de net-

toyage et de désinfection doivent être effectuées uniquement par du personnel qualié. Les mesures de sécurité

applicables doivent être respectées. Avertissements Instruction sur le produit utilisé doit être suivie.

6

Page 7

!

This unit has been factory sanitized per Lancer specications.

Listed below are six critical elements which will aid in a successful installation.

1. Fill water bath until water overows from tank overow tube.

2. The carbonator pump motor must be disconnected from the power supply (see Section 1.7) prior to connection to

water .. supply for initial build up of ice bank. Failure to do so will result in automatic shut off of carbonator (see item 6

below) or damage to the pump.

3. If this dispenser is installed in an area that is susceptible to ±10% variation of the nominal line voltage, consider

installing a surge protector or similar protection device.

4. There is a ve (5) minute delay which prevents the compressor and condenser fan from starting until the delay

has lapsed. If electrical current is interrupted, there is always a ve (5) minute delay before the compressor starts.

5. Supply Water Pressure: Minimum - 25 PSI (0.172 MPA); Maximum - 50 PSI (0.345 MPA); If pressure is over 50

PSIG (0.345 MPA), a water pressure regulator must be used.

6. On units with the built in water regulator, the regulator must be removed if inlet water pressure is less than 25

PSIG. (0.172 MPA)

DISPENSER INSTALLATION HIGHLIGHTS

!

!

Esta tin/dad ha sido saneada en fabrica por las especicaciones de Lancer.

A continuacion se relacionan 6 puntos importantes para una connecta instalacion.

1. Llene el bano-Maria hasta que el agua se desborde sobre el tubo que controla la derrama del tanque.

2. El motor de la bomba del carbonatador debe desconectarse electricamente (Ver Manual - Seccion 1.7) antes

de conectar el suministro de agua para la formacion inicial del banco de hielo. De no hacerse esto resultaria en un

bloqueo automatico del carbonatador (ver abajo el punto 6) o en danos a la bomba.

3. Si la unidad va a ser instalada en un area en la que puedan darse variaciones de voltage de + 6 - 10% de su

valor nominal, se debe considerar la conveniencia de instalar un estabilizador de corriente o sistema de proteccion

similar.

4. Hay una demora de 5 minutos que evita que el compresor y el abanico del condensador arranquen hasta pasado

ese tiempo. Si hay algun corte en la corriente electrica siempre se producira esa demora de 5 minutos antes de arrancar el compresor.

5. Presión de suministro del agua de red: Minimo 25 PSI (0.172 MPA); Maximo 50 PSI (0.345 MPA). En unidades

sin regulador de presión incorporado, si la presión del agua es superior a 50 PSIG (0.345 MPA) se debe usar un

regulador de presión.

6. En unidades con regulador de presión incorporado, el regulador debe der eliminado cuando la presión de entrada

de agua sea inferior a 25 PSIG (0.172 MPA).

REGLES DE SECURITE POUR L’NSTALLATION DU DISTRIBUTEUR DE SODAS

!

La proprètè da cet ensamable est assurè à I’usine sulvant les spècications èmis par Lancer .

Il est essentiel de respecter les 6 points suivants pour l’installation de l’appareil:

1. Remplir le bain-Maire jusqu’a ce que l’eau dèborde par le tuyau de trop-plein du rèservoir.

2. Le moteur de la pompe du carbonateur doit etre dèbranchè de l’alimentation èlectrique (Voir le manuel, Section 1.7) avant l’arrivèe de l’eau pour la formation initiale de la glace. Oublier ou nègliger cette opèration provoquera

l’arret automatique du carbonateur (voir le point 6 cidessous) ou causera des dommages à la pompe.

3. Si le distributeur es installè dans une zone ou la tension èlectrique nominale est susceptible de variations de (+)

10%, il est conseillè d’installer un appaeil de protection contre les sautes de courant.

4. Un d’lai de 5 minutes empeche le compresseur et la ventilation du condesateur de se mettre en marche avant

que ce lees de temps ne se soit ècoulè. Lorsque le courant èlectrique es interrompu, il y a toujours un dèlai de 5

minutes avant que le presseur ne se mette en.

5. Pression de l’eau: Minimum 25 PSI (0.172 MPA); Maximo 50 PSI (0.345 MPA). Sur les unitès qui n’ont pas de

règulateur de pression d’eau incorprè, si la pression d’H2O est supèrieure à 50 PSIG (0.345 MPA), un règulateur de

pression d’eau doit etre utilsisè.

6. Sur les unitès avec règulateur d’eau incorporè, le règulateur doit etre enlevè si la pression d’arrivve est inferièure

à 25 PSIG (0.172 MPA)

PUNTOS IMPORTANTES EN LA UNIDAD DISPENSADORA

!

!

7

Page 8

ELECTRICAL WARNING/ADVERTENCIA ELÉCTRICA/

F F

AVERTISSEMENT ÉLECTRIQUE

F Check the dispenser serial number plate for correct electrical requirements of unit. Do not plug into a wall

electrical outlet unless the current shown on the serial number plate agrees with local current available. Follow

all local electrical codes when making connections. Each dispenser must have a separate electrical circuit. Do not

use extension cords with this unit. Do not ‘gang’ together with other electrical devices on the same outlet. The

keyswitch does not disable the line voltage to the transformer primary. Always disconnect electrical power to the unit

to prevent personal injury before attempting any internal maintenance. The resettable breaker switch should not

be used as a substitute for unplugging the dispenser from the power source to service the unit. Only qualied person-

nel should service internal components of electrical control housing. Make sure that all water lines are tight

and units are dry before making any electrical connections!

F Verique la placa con el número de serie del dispensador, donde encontrará los requisitos eléctricos correctos

de la unidad. No enchufe la unidad en un tomacorriente de pared a menos que la corriente indicada en la placa con

el número de serie concuerde con la corriente local disponible. Al hacer las conexiones, respete todos los códi- gos

eléctricos locales. Cada dispensador debe tener un circuito eléctrico independiente. No use extensiones con esta

unidad. No la conecte junto con otros dispositivos eléctricos al mismo tomacorriente. El interruptor de llave no corta

el voltaje de línea al transformador primario desconecte siempre la alimentación eléctrica a la unidad para evitar

lesiones personales antes de tratar de realizar tareas de mantenimiento. El disyuntor de sobrecarga reseteable no se debe usar como sustituto para desenchufar el dispensador de la fuente de alimentación para realizar

tareas de servicio de la unidad. El servicio de los componentes internos de la caja de control eléctrico debe conarse

exclusivamente a personal calicado. Asegúrese de que todas las líneas de agua estén ajustadas y las unidades

estén secas antes de hacer conexiones eléctricas.

F Examinez la plaque de numéro de série du distributeur pour connaître les bonnes exigences en matière

d’électricité pour l’appareil. Ne le branchez pas à une prise électrique murale à moins que le courant indiqué sur la

plaque de numéro de série corresponde au courant local disponible. Respectez tous les codes électriques locaux

lorsque vous faites des connexions. Chaque distributrice doit avoir un circuit électrique séparé. N’utilisez pas

de cordons prolongateurs avec cet appareil. Ne pas le brancher avec d’autres appareils électriques sur la même

prise. L’interrupteur à clé ne coupe pas la tension secteur au transformateur primaire. Débranchez toujours le courant

électrique à l’appareil, an de prévenir des blessures, avant de faire un entretien interne quelconque. Le disjoncteur

réarmable ne devrait pas être utilisé au lieu de débrancher le distributeur de la source d’alimentation en électricité

pour faire de l’entretien/une réparation de l’appareil. Seul le personnel qualié devrait faire l’entretien/la réparation

des composants internes dans le logement des commandes électriques. Assurez-vous que toutes les conduites

d’eau sont étanches et que les appareils sont secs avant de faire des connexions électriques!

CO2/CARBON DIOXIDE /El ANHÍDRIDO CARBÓNICO/

5 5

DIOXYDE DE CARBONE

5 Carbon Dioxide (CO2) is a colorless, noncombustible gas with a light pungent odor. High percentages of CO2 may

displace oxygen in the blood. Prolonged exposure to CO2 can be harmful. Personnel exposed to high concentrations

of CO2 gas will experience tremors which are followed by a loss of consciousness and suffocation. If a CO2 gas leak

is suspected, immediately ventilate the contaminated area before attempting to repair the leak. Strict attention must

be observed in the prevention of CO2 gas leaks in the entire CO2 and soft drink system.

5 El anhídrido carbónico (CO2) es un gas incoloro, no combustible, con un olor pungente ligero. Altos porcentajes

de CO2 en la sangre pueden desplazar el oxígeno en la sangre. La exposición prolongada al CO2 puede ser nociva.

El personal expuesto a concentraciones altas de CO2 sufre temblores seguidos de la pérdida de la consciencia y

sofocación. Si se sospecha que existe una pérdida de CO2, ventile el área contaminada antes de tratar de reparar

la pérdida. Hay que prestar suma atención para evitar pérdidas de CO2 en todo el sistema de CO2 y de bebidas

gaseosas.

5 Le dioxyde de carbone (CO2) est plus lourd que l’air et déplace l'oxygène. Le CO2 est un gaz incolore et incom-

bustible, ayant une odeur un peu âcre. Des concentrations fortes de CO2 peuvent déplacer l'oxygène dans le sang.

Une exposition prolongée au CO2 peut être nocive. Le personnel exposé à de fortes concentrations de CO2 gazeux

éprouvera des tremblements, suivis rapidement d'une perte de conscience et de suffocation. On doit faire très attention de prévenir les fuites de CO2 gazeux dans le système entier de CO2 et de boisson gazeuse. Si on suspecte qu'il

y a une fuite de CO2 gazeux, aérez le secteur contaminé immédiatement avant d'essayer de réparer la fuite.

8

Page 9

AUTOMATIC AGITATION/AGITACIÓN AUTOMÁTICA/

! Units are equipped with an automatic agitation system and will activate unexpectedly. Do not place hands or for-

eign objects in the water bath tank. Unplug the dispenser during servicing, cleaning, and sanitizing. To avoid personal

injury, do not attempt to lift the dispenser without assistance. For heavier dispensers, use a mechanical lift.

! Las unidades están equipadas con un sistema automático de agitación, por lo que se pueden activar repentina-

mente. No ponga las manos ni objetos extraños en el compartimiento donde se guarda el hielo. Durante el servicio,

la limpieza y la esterilización, desenchufe el dispensador. Para evitar lesiones personales, no trate de levantar el

dispensador sin ayuda. Para los dispensadores más pesados, use un elevador mecánico.

! Les appareils sont équipés d’un système d’agitation automatique qui s’activera de manière inattendue. Ne mettez

pas les mains ou des corps étrangers dans le compartiment d’entreposage de glace. Débranchez le distributeur

pendant l’entretien/la réparation, le nettoyage et l’aseptisation. Pour éviter des blessures, n’essayez pas de soulever

le distributeur sans aide. Pour les distributeurs plus lourds, utilisez un chariot élévateur.

! !

WATER NOTICE/AGUA AVISO/ PRÉAVIS DE L’EAU

! Provide an adequate potable water supply. Water pipe connections and xtures directly connected to a potable

water supply must be sized, installed, and maintained according to federal, state, and local laws. The water supply line must be at least a 3/8 inches (9.525 mm) pipe with a minimum of 25 PSI (0.172 MPA) line pressure, but not

exceeding a maximum of 50 PSI (0.345 MPA). Water pressure exceeding 50 PSI (0.345 MPA) must be reduced to

50 PSI (0.345 MPA) with the provided pressure regulator. Use a lter in the water line to avoid equipment damage

and beverage off-taste. Check the water lter periodically, as required by local conditions. The water supply must be

protected by means of an air gap, a backow prevention device (located upstream of the CO2 injection system) or an-

other approved method to comply with NSF standards. A leaking inlet water check valve will allow carbonated water

to ow back through the pump when it is shut off and contaminate the water supply. Ensure the backow prevention

device complies with ASSE and local standards. It is the responsibility of the installer to ensure compliance.

! Proporcione un suministro adecuado de agua potable. La línea de suministro de agua debe ser de una tubería de

por lo menos 3/8 pulgadas (9.525 mm) con una presión de línea mínima de 25 PSI (0.172 MPA) , pero sin superar

el máximo de 50 PSI (0.345 MPA). La presión de agua que supere los 50 PSI se debe reducir a 50 PSI (0.345 MPA)

con un regulador de presión. Use un ltro en la línea de agua para evitar daños al equipo y cierto sabor raro en las

bebidas. Verique periódicamente el ltro de agua de acuerdo con las condiciones imperantes. El suministro de

agua debe estar protegido por una separación de aire, un dispositivo de prevención del contraujo (situado antes del

sistema de inyección de CO2) u otro método aprobado para cumplir las normas NSF. Si la válvula de retención de

entrada de agua tuviera pérdidas, permitiría el contraujo del agua carbonatada a través de la bomba cuando se la

detiene y contaminaría el suministro de agua. Asegúrese de que el dispositivo de prevención del contraujo cumpla

con las normas locales y de ASSE. Es responsabilidad del instalador cumplir con estos requisitos.

! Fournissez une alimentation en eau potable adéquate. Les connexions et les dispositifs de conduite d’eau con-

nectés directement à une alimentation en eau potable doivent être calibrés, installés et maintenus selon les lois

fédérales, provinciales et locales. La conduite d’alimentation en eau doit être un tuyau d’au moins 3/8 pouces (9.525

millimètres) avec une pression de ligne minimum de 25 LPC (0.172 MPA) , mais ne doit pas dépasser un maximum

de 50 LPC (0.345 MPA). Une pression d’eau de plus de 50 LPC (0.345 MPA) doit être réduite à 550 LPC (0.345

MPA) avec le régu- lateur de pression fourni. Utilisez un ltre dans la conduite d’eau pour éviter des dommages à

l’équipement et un goût des boissons qui n’est pas juste. Vériez le ltre à eau périodiquement, selon les exigences

des conditions locales. L’alimentation en eau doit être protégée au moyen d’un intervalle d’air, un disconnecteur

hydraulique (situé en amont du système d’injection de CO2) ou une autre méthode approuvée pour se conformer

aux normes de la NSF. Un clapet antiretour pour l’eau entrante qui fuie permettra à l’eau gazeuse de repasser par

la pompe quand elle est fermée et de contaminer l’alimentation en eau. Assurez-vous que le disjoncteur hydraulique

soit conforme aux normes de l’ASSE et locales. L’installateur est responsable d’assurer la conformité.

9

Page 10

1. INSTALLATION

1.1 RECIEVING THE UNIT

Each unit is completely tested under operating conditions and thoroughly inspected before ship-

ment. At time of shipment, the carrier accepts the unit and any claim for damage(s) must be made

with carrier. Upon receiving units from the delivering carrier, carefully inspect carton for visible

indication(s) of damage. If damage exists, have carrier note same on bill of lading and le a claim

with the carrier.

1.2 UNPACKING

WARNING TO AVOID PERSONAL INJURY OR DAMAGE, DO NOT ATTEMPT TO LIFT A UNIT

WITHOUT HELP. FOR HEAVIER UNITS, USE OF A MECHANICAL LIFT MAY BE APPROPRIATE. UNITS ARE

EQUIPPED WITH AUTOMATIC AGITATION. THE UNIT MAY ACTIVATE UNEXPECTEDLY. DO NOT PLACE HANDS, OR

FOREIGN OBJECTS INTO THE ICE STORAGE COMPARTMENT. UNPLUG

DISPENSER FROM THE POWER SOURCE , WHEN UNIT IS BEING SERVICED, CLEANED, OR

SANITIZED.

ADVERTENCIA EVITE LAS LESIONES PERSONALES, NO TRATE DE LEVANTAR EL DISPENSADOR SIN AYUDA.

PARA LOS DISPENSADORES MÀS PESADOS USE UN ELEVADOR MECÁNICO. LAS UNIDADES EQUIPADAS CON

AGITACIÓN AUTOMÁTICA SE ACTIVAN REPENTINAMENTE. NO PONGA LAS MANOS NI OBJETOS EXTRANOS EN

EL COMPARTIMIENTO DE ALMACENAMIENTO DE HIELO. DESENCHUFE EL DISPENSADOR DURANTE TAREAS

!

A. Cut band and remove.

B. Remove top portion of carton by lifting up.

C. Remove top inner carton pad and corners.

D. Lift Unit up by plywood shipping base and remove lower portion of carton.

E. Inspect unit for concealed damage and if evident, notify delivering carrier and le a claim

F. Remove plywood shipping base from unit by moving unit so that one side is off the counter top

or table, allowing access to screws on the bottom of the plywood shipping base.

NOTE: If unit is to be transported, it is advisable to leave unit secured to plywood shipping base.

G. If Unit is to be installed with optional legs, assemble legs to unit by tilting unit. DO NOT LAY

UNIT ON ITS SIDE OR BACK.

H. Remove accessory kit of loose parts from drip tray.

1.3 SELECTING A COUNER LOCATION

The dispenser is designed to sit on a at, supported surface capable of supporting a minimum

NOTE: NSF listed units must be sealed to the counter or have four (4) inch legs installed.

DE SERVICIO, LIMPIEZA Y ESTERILIZACIÓN.

AVERTISSEMENT POUR ÉVITER DES BLESSURES OU DES DOMMAGES, N’ESSAYEZ PAS DE

SOULEVER UNE UNITÉ SANS AIDE. POUR LES UNITÉS PLUS LOURDES, L’UTILISATION D’UN

ASCENSEUR MÉCANIQUE PEUT ÊTRE APPROPRIÉE. LES UNITÉS SONT ÉQUIPÉES D’UNE

AGITATION AUTOMATIQUE. L’UNITÉ PEUT S’ACTIVER DEMAINÉRE INATTENDUE. NE PLACEZ PAS LES MAINS,

OU DES CORPS ÉTRANGERS DANS LE COMPARTIMENT DE STOCKAGE DE GLACE.

DÉBRANCHEZ LE DISTRIBUTEUR DE LA SOURCE D’ALIMENTATION EN ÉLECTRICITÉ QUAND L’UNITÉ EST ENTRETENUE, NETTOYÉE OU ASEPTISÉE.

against same.

weight of 200 pounds (90.7 kg). It may be either counter or leg mounted. When the dispenser is to

be permanently bolted to the counter top, seal dispenser base to counter top with a silicone sealant

which provides a smooth and easily cleanable bond to the counter.

WARNING FAILURE TO MAINTAIN PROPER AIR CLEARANCE WILL CAUSE THE COMPRESSOR TO

OVERHEAT AND WILL RESULT IN PREMATURE COMPONENT FAILURE

WARNING FALTA DE MANTENIMIENTO DE LIQUIDACIÓN DE AIRE ADECUADO HACEN QUE EL COMPRESOR SE

SOBRECALIENTE Y PODRÁ FALLAR COMPONENTE PREMATURO

!

Locate dispenser to allow approximately 15 inches (380 mm) of unobstructed space above and

six (6) inches (152 mm) of unobstructed space in back of the unit for proper air circulation and

removal of bonnet. Air is drawn in through the back grill and is exhausted out the top grill.

WARNING NON-RESPECT DE LIQUIDATION DE L’AIR BONNE QUE LE COMPRESSEUR À SURCHAUFFER ET À

ENTRAÎNER DE DURER COMPOSANT

10

Page 11

1.4 CONNECTING THE DRAIN

A. Remove cup rest. Lift splash plate up and pull out and down on the bottom to remove.

B. Remove the drip tray from the unit and connect the drain tube to the drain tting located on the

bottom. Secure drain tube with clamp provided in accessory kit.

C. Route the drain tube to a suitable drain and replace the unit’s drip tray.

1.5 FILLING UNIT WITH WATER

A. Remove the bonnet from the unit.

B. Remove the yellow plastic plug from the ll hole.

C. Using a funnel or tube, ll the water bath compartment with water until it ows out of the

overow tube into the drip tray. Use bottled water where a water problem exists.

D. Replace the yellow plug.

1.6 CONNECTING TO ELECTRICAL POWER

NOTE: Adhere to the ELECTRICAL Warnings/Cautions, Page 8.

GROUNDING WARNING THE DISPENSER MUST BE PROPERLY ELECTRICALLY GROUNDED TO AVOID SERI-

OUS INJURY OR FATAL ELECTRICAL SHOCK. THE POWER CORD HAS A THREE-PRONG GROUNDED PLUG. IF A

THREE-HOLE GROUNDED ELECTRICAL OUTLET IS NOT AVAILABLE, USE AN APPROVED METHOD TO GROUND

THE UNIT. FOLLOW ALL LOCAL ELECTRICAL CODES WHEN MAKING CONNECTIONS. EACH

DISPENSER MUST HAVE A SEPARATE ELECTRICAL CIRCUIT. DO NOT USE EXTENSION CORDS. DO NOT

CONNECT MULTIPLE ELECTRICAL DEVICES ON THE SAME OUTLET.

ADVERTENCIA, PUESTA A TIERRA ES NECESARIO PONER A TIERRA ELÉCTRICAMENTE EL

DISPENSADOR PARA EVITAR LESIONES GRAVES E INCLUSO ELECTROCHOQUES FATALES. EL CABLE DE

ALIMENTACIÓN TIENE UN ENCHUFE PUESTO A TIERRA DE 3 CLAVIJAS. SI NO SE DISPONE DE UN TOMA

ELÉCTRICO CONECTADO A TIERRA DE TRES AGUJEROS, USE UN MÉTODO APROBADO PARA PONER A TIERRA

LA UNIDAD. AL HACER LAS CONEXIONES, RESPETE TODOS LOS CÓDIGOS ELÉCTRICOS LOCALES. CADA

F

DISPENSADOR DEBE TENER UN CIRCUITO ELÉCTRICO INDEPENDIENTE. NO USE CABLES DE EXTENSIÓN. NO

CONECTE VARIOS DISPOSITIVOS ELÉCTRICOS AL MISMO TOMACORRIENTE.

EXIGENCES DE MISE À LA TERRE LA DISTRIBUTRICE DOIT ÊTRE MISE À LA TERRE ÉLECTRIQUEMENT

CORRECTEMENT POUR ÉVITER DES BLESSURES GRAVES OU UNE DÉCHARGE ÉLECTRIQUE MORTELLE. LE

CORDON D’ALIMENTATION A UNE FICHE À TROIS BRANCHES MISE À LA TERRE. SI AUCUNE PRISE DE

COURANT ÉLECTRIQUE À TROIS TROUS N’EST DISPONIBLE, UTILISEZ UNE MÉTHODE APPROUVÉE POUR

METTRE L’UNITÉ À LA TERRE. RESPECTEZ TOUS LES CODES ÉLECTRIQUES LOCAUX LORSQUE VOUS FAITES

DES CONNEXIONS. CHAQUE DISTRIBUTRICE DOIT AVOIR UN CIRCUIT ÉLECTRIQUE SÉPARÉ. N’UTILISEZ PAS

DE CORDONS PROLONGATEURS. NE BRANCHEZ PAS PLUSIEURS APPAREILS ÉLECTRIQUES À LA MÊME PRISE

DE COURANT.

1.6 CONNECTING TO ELECTRICAL POWER, CONTINUED

A. If the unit is equipped with a built-in carbonator, disconnect the power supply to the carbonator

motor by disconnecting the designated connector located near the top of the electrical control

box on the refrigeration deck.

B. Check the dispenser serial number plate for correct electrical requirements of unit. Do not plug

into wall electrical outlet unless the current shown on the serial number plate agrees with

local current available.

C. Route the power supply cord to a grounded electrical outlet of the proper voltage and amperage

rating, and plug in the unit. This will turn on the refrigeration system and allow it to start cooling

while completing the rest of the installation. The agitator motor will start immediately, but the

compressor and fan motor will not start until the ve (5) minute delay has elapsed.

CAUTION FAILURE TO DISCONNECT THE MOTOR POWER SUPPLY WILL DAMAGE THE CARBONATOR

MOTOR, THE PUMP AND VOID THE WARRANTY.

PRECAUCIÓN SI NO DESCONECTA LA ALIMENTACIÓN ELÉCTRICA DEL MOTOR PODRÍAN DAÑARSE LA BOMBA

Y EL MOTOR DEL CARBONATADO Y ANULAR LA GARANTÍA.

!

ATTENTION LE FAIT DE NE PAS MAINTENIR LE DÉGAGEMENT SPÉCIFIÉ FERA SURCHAUFFER LE

COMPRESSEUR ET AURA COMME CONSÉQUENCE UNE DÉFAILLANCE DU COMPRESSEUR.

11

Page 12

1.7 CONNECTING TO WATER SUPPLY

INLET VALVE 1, 2, & 3

INLET VALVE 5

6 VALVE

8 VALVE

NOTE: Adhere to the WATER SUPPLY Warnings/Cautions, Page 6.

See Figure 1.

If unit has no plain water circuits, proceed to Section 1.8.

A. Valves 4, 5, and 6 through 8 (on 8 valve units) and valves 3, 4, and 5 (on 6 valve units) have

optional plain water or carbonated water capabilities. Using Figure 1, determine which valves

are to be plumbed with plain water.

B. Using proper beverage tubing and ttings, connect to water source [must be 35 PSI (2.4 bar) or

more].

C. Flush water supply line thoroughly.

D. Route tubing through cutout in counter or through access hole in back of unit.

E. Leave 12 inches (300 mm) of extra tubing length below the counter for servicing and moving

the dispenser.

F. Connect to desired plain water inlet behind splash plate and secure with Oetiker Clamp.

G. Turn on water supply and check for leaks.

H. Actuate each valve until all air is expelled.

87654321

INLET VALVE 4

INLET VALVE 5

INLET VALVE 6, 7, & 8

Plumbing Diagram, Carbonated/Plain Water

Figure 1

1.8 CONNECTING TO CARBONATED WATER SUPPLY

See Figure 1.

A. Install carbonator per manufacturer’s instructions.

B. Using proper beverage tubing and ttings, connect to carbonator tank outlets.

C. Route tubing through cutout in counter or through access hole in back of unit.

D. Leave 12 inches (300 mm) of extra tubing length below the counter for servicing and moving

the dispenser.

E. Connect to soda inlets behind splash plate and secure with Oetiker Clamps.

F. Fill with water and pressurize carbonation system per manufacturer’s instructions.

G. Actuate each valve until a smooth ow of carbonated water is obtained.

H. Check for leaks.

WARNING DO NOT TURN ON THE CO2 SUPPLY AT THIS TIME.

6 45 123

INLET VALVE 3 & 4

INLET VALVE 1, 2, & 6

5

ADVERTENCIA NO CONECTE TODAVÍA LA ALIMENTACIÓN DE CO2.

AVERTISSEMENT N’OUVREZ PAS L’ALIMENTATION EN CO2 À CE MOMENT.

12

Page 13

1.9 CONNECTING TO BAG-IN-BOX (BIB) SYRUP SUPPLY TO REMOTE SYRUP PUMPS

A. To connect CO2 regulator assembly to the CO2 cylinder, see Section 1.9, Steps A - C.

B. Place the remote BIB syrup supply and pumps in a convenient location.

C. Attach the syrup supply tubes to the dispenser’s syrup inlet fittings using an Oetiker clamp for

each syrup flavor.

D. Route the syrup supply tubes to the remote syrup pumps.

E. Complete installation of the remote syrup pump system following the manufacturer’s

instructions.

1.10 PURGING THE CARBONATION SYSTEM

A. Turn on water source. Lift the black lever on the top of the carbonator tank relief valve until

water ows from the holes in the relief valve. Then release the relief valve.

B. Reconnect the power supply to the carbonator pump.

C. Back off on the CO2 regulator pressure adjusting screw all the way. Open the CO2 cylinder

handle slowly. Turn the CO2 pressure regulator up slowly to 75 PSIG (5.1 bar).

D. Press and hold each valve lever until water is owing steadily from each valve.

E. Check all of the unit’s water, syrup, and CO2 connections for leaks and repair if necessary.

NOTE: Tank Method Only - to check for CO2 leaks, close the valve on the CO2 cylinder and

observe if the pressure to the system drops with the cylinder valve closed for ve (5) minutes.

Open the cylinder valve after check.

F. Assemble the unit’s bonnet, splash plate, and rear guard.

NOTE: Ensure a minimum of 5 gallons of water is ushed through each valve prior to use.

1.11 PURGING THE WATER AND SYRUP SYSTEMS

A. Set the adjustable back blocks to deliver plain water

B. Open a dispensing valve until water and syrup are owing steadily from the valve.

C. Repeat procedure “A” for each valve.

D. Check all of the unit’s syrup and water connections for leaks and repair if necessary.

E. Replace the unit’s bonnet, splash plate and cup rest

1.12 ADJUSTING WATER FLOW (LEV®)

A. The water ow can be adjusted between 1.25 oz/

sec (37 ml/sec) and 2.50 oz/sec (74 ml/sec) on

I.D. PANEL

(Shown in

open position)

all dispensing valves using the following

procedures.

B. The refridgeration unit should have been running

for at least one (1) hour before you attempt to

brix the valves. The drink temperature should be

no higher than 40°F (4.4°C) when the brix is

set. This is best done after the unit has made an

ice bank.

C. Slide up ID panel until ow controls are exposed

FLOW CONTROL

WATER

DecreaseIncrease

COVER SCREW

FLOW CONTROL

SYRUP

DecreaseIncrease

(see Figure 2)

D. Remove nozzle by twisting counter clockwise and

pulling down.

E. Remove diffuser by pulling down.

F. Install Lancer (yellow) syrup separator (PN 54-

0031) in place of nozzle.

NOZZLE (WITH

DIFFUSER INSIDE)

G. Activate dispensing valve to ll separator syrup

tube.

H. Hold a Lancer brix cup under the syrup

separator and dispense water and syrup into cup

for four (4) seconds. Divide number of ounces

(ml) of water in cup by four (4) to determine water

ow rate per second

Typical Valve Adjustment, LEV®

Figure 2

I. To obtain the proper ow, use a screwdriver to

adjust water ow control (see Figure 2).

J. Repeat process for each valve.

13

Page 14

1.13 ADJUSTING WATER TO SYRUP (RATIO) BRIX (LEV®)

A. Hold the Lancer brix cup under the syrup separator and activate valve. Check brix.

B. To obtain the proper brix, use screwdriver to adjust syrup ow control (see Figure 1).

C. Once proper ratio is obtained repeat to verify.

D. Remove syrup separator (PN 54-0031 installed in Section 1.10.F above).

E. Install diffuser and nozzle.

F. Slide down ID panel.

G. Repeat process for each valve.

2. SCHEDULED MAINTENANCE

2.1 DAILY

A. Remove the nozzle and diffuser from each valve and rinse well in warm water. Do NOT use

soap or detergent. This will cause foaming and off taste in nished product.

B. Remove the cup rest and wash in warm soapy water.

C. Pour warm soapy water into the drip tray and wipe with a clean cloth.

D. With a clean cloth and warm water, wipe off all of the unit’s exterior surfaces. DO NOT USE

ABRASIVE SOAPS OR STRONG DETERGENTS.

E. Replace the cup rest, valve diffusers, and valve nozzles.

2.2 WEEKLY

A. Taste each product for off tastes and/or brix changes.

B. Remove the bonnet and check the level of water in the water bath. Replenish as required, and

replace the bonnet.

2.3 MONTHLY

A. Unplug the dispenser from power source.

B. Remove the bonnet and clean the dirt from the condenser using a soft brush.

C. Replace the bonnet and plug in the unit.

2.4 EVERY SIX MONTHS

A. Clean and sanitize the unit using the appropriate procedures outlined in Section 3 of this

manual.

2.5 YEARLY

A Clean water bath interior, including evaporator coils and refrigeration components.

B. Clean the entire exterior of the unit.

C. Sanitize syrup lines.

3. DISPENSER CLEANING AND SANITIZATION

3.1 GENERAL INFORMATION

A. Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized

in accordance with NSF guidelines. The operator of the equipment must provide continuous

maintenance as required by this manual and/or state and local health department guidelines to

ensure proper operation and sanitation requirements are maintained.

NOTE: The cleaning procedures provided herein pertain to the Lancer equipment identied by

this manual. If other equipment is being cleaned, follow the guidelines established by the manu

facturer for that equipment.

B. Cleaning should be accomplished only by trained personnel. Sanitary gloves are to be used

during cleaning operations. Applicable safety precautions must be observed. Instruction

warnings on the product being used must be followed.

14

Page 15

3.2 CLEANING AND SANITIZING SOLUTIONS

CLEANING SOLUTION: Mix a mild, non-abrasive detergent (e.g. Sodium Laureth Sulfate, dish

soap) with clean, potable water at a temperature of 90°F to 110°F (32°C to 43°C). The mixture

ratio is one ounce of cleaner to two gallons of water. Prepare a minimum of ve gallons of cleaning

solution. Do not use abrasive cleaners or solvents because they can cause permanent damage to

the unit. Ensure rinsing is thorough, using clean, potable water at a temperature of 90°F to 110°F.

Extended lengths of product lines may require additional cleaning solution.

SANITIZING SOLUTION: Prepare sanitizing solutions in accordance with the manufacturer’s writ-

ten recommendations and safety guidelines. The solution must provide 100 parts per million (PPM)

chlorine (e.g. Sodium Hypochlorite or bleach). A minimum of ve gallons of sanitizing solution

should be prepared. Any sanitizing solution may be used as long as it is prepared in accordance

with the man- ufacturer’s written recommendations and safety guidelines, and provides 50 to 100

parts per million (PPM) chlorine.

3.3 AMBIENT PROCESS

The ambient process is the most common method for cleaning and sanitizing dispenser equipment.

A. Prepare the Cleaning Solution,referred to in Section 3.2.

B. Fill lines at pump inlet with Cleaning Solution ( Section 3.2). The solution should be prepared in

accordance with the manufacturer’s recommendations. Make sure the lines are completely lled

and allow to stand for at least ten (10) minutes.

C. Flush the detergent solution from the lines with clean water.

D. Prepare the Sanitizing Solution, referred to in Section 3.2.

E. Fill the lines with Sanitizing Solution. Make sure that lines are completely lled and allow to

stand for ten (10) minutes.

F. Draw drinks to rell lines and ush solution from the dispenser.

G. Taste the beverage to verify that there is no off taste. If off-taste is found, ush the syrup

system again.

CAUTION FOLLOWING SANITIZATION, RINSE WITH END-USE PRODUCT UNTIL THERE IS NO AFTERTASTE. DO

NOT USE A FRESH WATER RINSE. THIS IS A NSF REQUIREMENT. RESIDUAL SANITIZING SOLUTION LEFT IN THE

SYSTEM CREATES A HEALTH HAZARD.

PRECAUCIÓN DESPUÉS DE LA ESTERILIZACIÓN, ENJUAGUE CON EL PRODUCTO FINAL HASTA QUE

ELIMINAR EL SABOR QUE QUEDA. NO ENJUAGUE CON AGUA FRESCA. ÉSTA ES UNA EXIGENCIA DE NSF. SI

!

3.4 VALVES

A. Valves may be cleaned and sanitized in the same manner

B. Remove cover and disconnect power so not to activate the valve while cleaning. Remove

nozzle and diffuser. Wash these parts in cleaning solution, then immerse them in a bath of

sanitizing solution for 15 minutes.

C. Visually inspect around nozzle area for syrup residue. This area may be cleaned with warm

D. Wearing sanitary gloves, remove, drain and air dry the nozzle and diffuser.

E. Wearing sanitary gloves, replace diffuser and twist nozzle into place.

F. Draw drinks to ush the chlorine solution from the valves.

NOTE: Please note that a fresh water rinse cannot follow sanitization of equipment. Purge only

G. Taste the beverage to verify that there is no off taste.

H. Connect power and replace cover. Valve is ready for operation.

QUEDA SOLUCIÓN DE ESTERILIZACIÓN EN EL SISTEMA, GENERA UN PELIGRO PARA LA SALUD.

ATTENTION DÉFENSE DE RINCER L’OUTIL À L’EAU FRAICHE IMMÉDIATEMENT APRÈS UN TRAITEMENT

SEPTIQUE.EN CAS DE APRÈS-GOÛT, NE PURGER AVEC LE PRODUIT FINAL UNE EXIGENCE NSF.

water and cloth or with the nozzle brush supplied. Wipe off dispensing lever.

with the end use product. This is an NSF requirement.

15

Page 16

4. TROUBLESHOOTING

TROUBLE CAUSE REMEDY

4.1 Water leakage around nozzle. A. Damaged or improperly installed o-ring

above diffuser.

A. if damaged, replace. If imporoperly

installed, adjust.

4.2 Leakae between upper and lower

valve bodies.

4.3 Miscellanease leakage. A. Gap between parts.

4.4 Insufcient water ow. A. insufcient incoming supply water

4.5 Insufcient syrup ow. A. Insufcent CO2 pressure to BIB pumps.

A. Gap between upper and lower valve

bodies.

B. Worn or damaged paddle arm

assemblies.

B. Damaged or improperly installed

o-rings.

pressure.

B. Shutoff on mounting bloack not fully

open.

C. Foreign debris in water ow control.

A. Tighten all six (6) retaining screws.

B. Replace paddle arm assemblies.

A. Tighten appropriate retaining screws

B. Replace or adjust appropriate o-rings

A. Verify incoming supply water pressure

is a minimum of 35 PSI (2.4 BAR).

B. Open shutoff fully.

C. Remove water ow control from upper

body and clean out any foreign material

to ensure smooth free spool movement.

A. Adjust CO2 pressure to 80 PSI (5.5

BAR) [minimum 70 PSI (4.8 BAR)] for

BIB pumps.

B. Shutoff on mounting block not fully

open.

C. Foreign debris in syrup ow control.

4.6 Erratic ratio. A. Incoming water and/or syrup supply

not at minimum owing pressure.

B. Foreign debris in water and/or syrup

ow controls.

B. Open shutoff fully.

C. Remove syrup ow control form upper

body and clean out any foreign material

to ensure smooth free spool movement.

A. Check pressure and adjust

B. Remove ow controls from upper body

and clean out any foreign material to

ensure smooth free spool movement.

16

Page 17

TROUBLE CAUSE REMEDY

4.7 No product dispensed A. Water and syrup shutoffs on mounting

block not fully open.

A. Open shutoff fully.

4.8 Water only dispensed; no syrup; or

syrup only dispensed, no water

B. The key switch on an electric valve is

in the OFF position.

C. Cup lever arm or ID panel actuator on

electric valve is not actuating the switch.

D. Electric current not reaching valve.

E. Improper or inadequate water or syrup

supply.

A. Water or syrup shutoff on mounting

block not fully open.

B. Improper or inadequate water or syrup

ow.

B. Turn key switch to ON position.

C. Repair

D. Check electric current supplied to

valve. If current is adequate, check

solenoid coil and switch, and replace if

necessary.

E. Remove valve from mounting block

and open shutoffs slightly and check

water and syrup ow. If no ow, check

dispenser for freeze-up or other problems

A. Open shutoff fully.

B. Remove valve from mounting block,

open shutoffs slightly and check water

and syrup ow. If no ow, check

dispenser for freeze-up or other

problems. Ensure BIB connection is

engaged.

C. Kinked line.

4.9 Valve will not shut off. A. Cup lever may be sticking or binding.

B. Switch not actuating freely.

C. Solenoid armature not returning to

bottom position.

4.10 Excessive foaming. A. incoming water or syrup temperature

too high.

B. Water ow rate too high.

C. Nozzle and diffuser not properly

installed.

D. Nozzle and diffuser not clean.

E. Air in BIB lines.

F. Poor quality ice.

C. Remove kink or replace line.

A. Correct or replace lever.

B. Check switch fro free actuation.

C. Replace defective armature or spring.

A. Correct prior to dispenser. Consider

larger dispenser or precooler.

B. Readjust and reset ratio. Refer to

Section 1.11

C. Remove and reinstall properly.

D. Remove and clean.

E. Bleed air from BIB lines.

F. Check quality of ice used in drink.

G. High beverage temperature

17

G. Check refrigeration system.

Page 18

TROUBLE CAUSE REMEDY

4.11 Compressor does not start (no hum),

but condenser fan motor runs

A. Compressor relay or overload

malfunctioning.

A. Replace compressor relay or overload.

B. Inadequate voltage.

C. Incorrect wiring.

D. Compressor malfunctioning

4.12 Compressor starts and continues to

run until freeze up and will not cut off

4.13 Compressor does not start but hums A. Inadequate voltage.

A. Ice bank control failure

B. Incorrect wiring.

C. Probe shortened.

B. Incorrect wiring.

C. Starting relay malfunctioning.

B. Measure voltage across common and

run terminal on compressor. Voltage must

not drop below 90% of rated voltage.

C. Refer to wiring diagram and correct.

D. Replace compressor.

A. Replace ice bank control.

B. Refer to wiring diagram and correct.

C. Check probe for foreign material or

damage.

A. Measure voltage across common and

run terminal on compressor. Voltage must

not drop below 90% of rated voltage

B. Refer to wiring diagram and correct

C. Replace starting relay. Be sure to use

correct relay. Failure to use correct relay

will cause compressor failure.

4.14 Compressor starts but does not

switch off start winding (will run for only

a few seconds before internal overload

switches compressor off).

4.15 Compressor starts and runs a short

time but shuts off on overload

D. Compressor malfunctioning

A. Inadequate voltage.

B. Incorrect wiring.

C. Starting relay malfunctioning

A. Dirty condenser

B. Insufcient or blocked air ow.

C. Inadequate voltage.

D. Incorrect wiring.

E. Defective condenser fan.

D. Replace compressor

A. Measure voltage across common and

run terminal on compressor.

B. Refer to wiring diagram and correct

C. Replace starting relay. Be sure to use

correct relay. Failure to use correct relay

will cause compressor failure.

A. Clean the condenser.

B. Remove all obstructions and allow for

minimum clearances of 15 inches (380

mm) over top.

C. Measure voltage across common and

run terminal on compressor. Voltage must

not drop below 90% of rated voltage.

D. Refer to wiring diagram and correct.

E. Replace condenser fan motor.

F. Refrigerant leak.

G. Compressor malfunctioning

18

F. Repair and recharge.

G. Replace compressor

Page 19

TROUBLE CAUSE REMEDY

4.16 Compressor and Condenser Fan

Motor will not start after ve (5) minute

Power Off Delay (Lancer EIBC Export

only)

A. Transformer tripped.

B. Relay will not turn on compressor

C. Probe unplugged

A. Reset transformer.

B. Failed relay. Replace Control Board.

C. Check probe connection at PCB

D. Improper wiring

E. Damaged electronics

4.17 Warm Drinks A. Restricted airow

B. Dispenser connected to hot water

supply.

C. Refrigeration system not running.

D. Refrigeration leak.

E. Condenser fan motor not working.

F. Dirty Condenser.

G. Dispenser capacity exceeded.

5. DISPENSER DISPOSAL

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was pur

chased. Comply with local regulations regarding disposal of the refrigerant and

insulation.

D. Check Power Indicator Lamp; check

wiring per Wiring Diagram

E. Replace Control

A. Check clearances around sides, top,

and inlet of unit. Remove objects blocking

airow through grill.

B. Switch to cold water supply.

C. Refer to Sections 4.11 - 4.15.

D. Repair and recharge.

E. Replace condenser fan motor.

F. Clean condenser.

G. Add pre-chiller.

19

Page 20

6. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS

6.1 2500 REFRIGERATION DECK ASSEMBLY, R-134A, LANCER ELECTRONIC ICE BANK

CONTROL (EIBC), USA ONLY, PN 82-2669

(MANUFACTURED FROM 01/99)

TO

BOX

JUNCTION

45

6

10

9

33

31

46

4

38

14

TO RELAY

17

TO OVERLOAD

13

12

23

BL

BL/W

BL

BL/W

17

20

27

4B

4C

27G

27F

27D

41

30

4A

27A

40

27C

17

35

34

27E

27B

11

24

36

HOLE

ANT -

- IMPORT

WATER BATH FILL

WATER BATH UNTIL

FILL

WATER FLOWS FROM

K OVERFLOW TUBE.

TAN

44

43

5

8

42

7

8

17

21

28C

37

17

3

29

28D

22

17

28G

28A

28F

28

28B

28E

15

31

16

19

20

26

17

2

18

1

39

25

32

Page 21

6.1 2500 REFRIGERATION DECK ASSEMBLY, R-134A, LANCER ELECTRONIC ICE BANK

CONTROL (EIBC), USA ONLY, PN 82-2669 (CONTINUED)

(MANUFACTURED FROM 01/99)

Item Part No. Description

1 23-0986 Condenser

2 51-0349 Shroud Assy

3 25-0047 Transformer, 115V/60Hz

4 83-0101 Compressor, 115V/60Hz

4A 12-0233 Start Capacitor, 115V/60Hz

4B 12-0227 Overload, 115V/60 Hz

4C 12-0232 Relay, 115V/60Hz

- - - - - - - - Refrigerant, R134A Only,

15.5 Ounces

5 23-1205 Evaporator Coil Assy

6 82-0675 Compressor Deck Assy

7 04-0032 Nut, 1/4 - 20

8 04-0063 Washer, 0.260 ID x 0.687

OD, SS

9 07-0268 Deck Handle

10 04-0260 Screw, 10 - 16 x 0.625

11 04-0538 Fill Hole Plug

12 02-0114 Grommet, Compressor

13 04-0537 Washer, Compressor

14 03-0150 Retainer Clip, Compressor

15 23-0999 Dryer/Capillary Tube Assy

16 51-5400 Accumulator

17 04-0504 Screw, 8 -18 x 0.375

18 47-2064 Tube, High Side

19 50-0105 Accumulator Insulator Boot

20 50-0106 Insulation, Low Side

21 50-0107 Insulation, Evaporator Outlet

22 50-0108 Insulation, Evaporator Inlet

23 52-1882 Electronic Ice Bank Control

(EIBC)

24 03-0049 Cord Clip

25 52-0100 Power, Junction Assy

26 06-0031/01 Wiring Diagram, 2500

27 52-1259 Agitator Motor Assy,

115V/60Hz

27A 91-0083 Motor, Agitator, 115V/60Hz

27B 05-0502 Propeller, Agitator

27C 02-0032 Washer, Rubber, 1.000 OD

27D 30-5113/01 Agitator Motor Bracket

27E 04-0059 Screw, 8 - 36 x 0.375

27F 05-0424/01 Agitator Fan

27G 06-0633 Label, 115V/60Hz, 25W

28 52-0740 Fan Motor Assy, 115V/60Hz

28A 91-0017 Fan Motor, 115V/60Hz

28B 07-0257 Fan Blade

28C 30-0043 Bracket, Fan Motor

28D 04-0059 Screw, 8 - 36 x 0.375

28E 04-0060 Nut, Fan Blade

28F 02-0413 Silencer, Fan Blade

28G 06-0667 Label, 115V/60Hz, 35W

29 11-0118 Connector, Ground

30 47-2033/01 Tube, Suction

Item Part No. Description

31 47-0344 Tube, Process

32 04-0070 Screw, 10 - 24 x 1.312

33 01-1713 Reducer, Fitting, Elbow

34 52-0878 Wire, Transformer Lead,

Primary

35 52-0879 Wire, Transformer Lead,

Primary

36 06-0856/01 Fill Hole Label

37 02-0040 Seal, Extrusion

38 06-0663 Label, 115V/60Hz, 3/4 HP

39 21-0085 Power Cord, USA

40 52-1504 Wire Assy, Secondary, White

41 52-1505 Wire Assy, Secondary, Black

42 02-0041 Seal

43 52-1897 Probe Assy

44 04-0394 Screw, 6 - 32 x 0.500, PHP,

SS

45 52-1827 Harness Assy, EIBC

46 13-0059 Bushing, Heyco

21

Page 22

6.2 2500 REFRIGERATION DECK ASSEMBLY WITH ELECTRONIC ICE BANK CONTROL (EIBC),

R-134A; PN 82-2049E, 230V/50Hz; PN 82-2103E, 115V/60Hz; PN 82-2098E, 240V/60Hz

(INTERNATIONAL ONLY)

33

17

34

23

17

31

38

14

4

37

4B

32

12

10

6

9

11

24

27

17

27F

27D

27A

20

4C

27G

17

30

4A

27C

3

27E

27B

16

13

7

17

35

HOLE

ANT-

TER BATH UNTIL

-IMPORT

WATER BATH FILL

FILL WA

WATER FLOWS FROM

TANK OVERFLOW TUBE.

25

26

21

36

8

17

28C

5

29

28A

22

28D

28G

28F

17

28B

19

28

28E

15

22

17

2

18

31

1

Page 23

6.2 2500 REFRIGERATION DECK ASSEMBLY WITH ELECTRONIC ICE BANK CONTROL (EIBC),

R-134A; PN 82-2049E, 230V/50Hz; PN 82-2103E, 115V/60Hz; PN 82-2098E, 240V/60Hz

(CONTINUED)

(INTERNATIONAL ONLY)

Item Part No. Description

1 23-0986 Condenser

2 51-0349 Shroud Assy

3 25-0047 Transformer, 115V/60Hz

- 25-0048 Transformer, 230V/50-60Hz

4 83-0101 Compressor, 115V/60Hz

- 83-0102 Compressor, 230V/50Hz

- 83-0103 Compressor, 240V/60Hz

4A 12-0233 Start Capacitor, 115V/60Hz

- 12-0235 Start Capacitor, 230V/50Hz

- 12-0246 Start Capacitor, 240V/60Hz

4B 12-0227 Overload, 115V/60Hz

- 12-0045 Overload, 230V/50Hz

- 12-0043 Overload, 240V/60Hz

4C 12-0232 Relay, 115V/60Hz

- 12-0236 Relay, 230V/50Hz

- 12-0247 Relay, 240V/60Hz

- - - - - - - Refrigerant, R134A Only;

115V/60Hz and 240V/60Hz,

15.50 Ounces; 230V/50Hz,

15.75 Ounces

5 23-1205 Evaporator Coil Assy

6 82-0675 Compressor Deck Assy

7 04-0032 Nut, 1/4 - 20

8 04-0063 Washer, 0.260 ID x 0.687

OD, SS

9 07-0268 Deck Handle

10 04-0260 Screw, 10 - 16 x 0.625

11 04-0538 Fill Hole Plug

12 02-0114 Grommet, Compressor

13 04-0537 Washer, Compressor

14 03-0150 Retainer Clip, Compressor

15 23-0999 Dryer/Capillary Tube Assy

16 51-5400 Accumulator

17 04-0504 Screw, 8 -18 x 0.375

18 47-2064 Tube, High Side

19 50-0105 Accumulator Insulator Boot

Item Part No. Description

27A 91-0083 Motor, Agitator, 115V/60Hz

- 91-0086 Motor, Agitator, 230V/50Hz

and 240V/60Hz

27B 05-0502 Propeller, Agitator

27C 02-0032 Washer, Rubber, 1.000 OD

27D 30-5113/01 Agitator Motor Bracket

27E 04-0059 Screw, 8 - 36 x 0.375

27F 05-0424/01 Agitator Fan

27G 06-0633 Label, 115V/60Hz, 25W

- 06-0634 Label, 230V/50-60Hz, 25W

28 52-0740 Fan Motor Assy, 115V/60Hz

- 52-0741 Fan Motor Assy, 240V/60Hz

- 52-0742 Fan Motor Assy, 230V/50Hz

28A 91-0017 Fan Motor, 115V/60Hz

- 91-0018 Fan Motor, 230V/50Hz

- 91-0019 Fan Motor, 240V/60Hz

28B 07-0257 Fan Blade

28C 30-0043 Bracket, Fan Motor

28D 04-0059 Screw, 8 - 36 x 0.375

28E 04-0060 Nut, Fan Blade

28F 02-0413 Silencer, Fan Blade

28G 06-0667 Label, 115V/60Hz, 35W

- 06-0668 Label, 230V/50Hz, 35W

- 06-0669 Label, 240V/60Hz, 35W

29 11-0118 Connector, Ground

30 47-2033/01 Tube, Suction

31 47-0344 Tube, Process

32 01-1713 Reducer, Fitting, Elbow

33 52-2027 Harness Assy, EIBC Ground

34 06-1542 Wiring Diagram, Label, EIBC

35 06-0856/01 Fill Hole Label

36 02-0040 Seal, Extrusion

37 06-0663 Label, 115V/60Hz, 3/4HP

- 06-0664 Label, 230V/50Hz, 3/4HP

- 06-0665 Label, 240V/60Hz, 3/4HP

38 02-0041 Seal

20 50-0106 Insulation, Low Side

21 50-0107 Insulation, Evaporator Outlet

22 50-0108 Insulation, Evaporator Inlet

23 52-2026 Control Housing Assy, EIBC

24 03-0049 Cord Clip

25 52-1773 Probe Assy, EIBC

26 04-0394 Screw, 6 -32 x 0.500

27 52-1259 Agitator Motor Assy,

115V/60Hz

- 52-1118 Agitator Motor Assy,

220-240V/50-60Hz

23

Page 24

6.3 2500 CONTROL HOUSING ASSEMBLY, ELECTRONIC ICE BANK CONTROL (EIBC),

INTERNATIONAL ONLY

7

RIGHT SIDE VIEW

20

19

3

3

2

4

5

17

TERM1

1

J4

J3J2

J1

TERM2

TERM3

TERM4

9

23

11 10

4

12

5678

16 15 14 13

8

7

BE FASTENED TO GROUND STUD ON

COMPRESSOR DECK INSIDE OF

AND OPTIONAL MERCHANDISER TO

CONTROL HOUSING.

GROUND WIRES FROM POWER CORD

FRONT VIEW

9

1

8

10

BROWN WIRE FROM

POWER CORD ASSY

BLACK WIRE TO

TERMINAL BLOCK #12

11

12

13

14

16

24

6

TERMINAL PIN #3

WHITE WIRE TO 13

TERMINAL PIN #1

TERMINAL PIN #2

GREEN W/YELLOW

STRIPE WIRE TO

GROUND STUD

BLACK WIRE TO 11

16

LEFT SIDE VIEW

Page 25

6.3 2500 CONTROL HOUSING ASSEMBLY, ELECTRONIC ICE BANK CONTROL (EIBC)

INTERNATIONAL ONLY (CONTINUED)

6.3.A CONTROL HOUSING ASSEMBLY, EIBC, PN 52-2026, WITHOUT KILL SWITCH

Item Part No. Description

1 30-7012 Housing, Control

2 52-1423 PCB Assy

3 13-0047 Stand Off

4 12-0190 Block, Terminal

5 04-0477 Screw, 8 - 32, ROLOK

6 13-0059 Bushing

7 13-0028 Strain Relief

8 52-2057 Power Cord Assy

9 - - - - - - - Not Applicable

10 - - - - - - - Not Applicable

11 52-2021 Lead Assy, Transformer,

Primary, #1

12 52-2022 Lead Assy, Transformer,

Primary, #2

13 52-2023 Lead Assy, Compressor, #1

14 52-2024 Lead Assy, Compressor, #2

15 52-2061 Lead Assy, EIBC

16 52-1210 Harness Assy, Optional

Merchandiser

17 11-0186 Jumper

18 52-1058 Harness, Transformer,

Secondary

19 30-7015 Cover, EIBC, Box Without

Kill Switch

20 04-0504 Screw, 8 -18 x 0.375

WIRING CONNECTION CHART

PART NO. DESCRIPTION TERMINAL

52-1219

with Kill

Switch

52-1218

without Kill

Switch

52-2038 Lead, Kill Switch,

52-2021 Lead, Trans, Pri #1 (BLK) 3

52-2022 Lead, Trans, Pri #2 (BLK/

52-2058 Harness, Trans, Sec

52-2023 Lead, Comp #1 (BLK) Terminal 1

52-2024 Lead, Comp #2 (BLK/

52-1773 IBC Probe Assy J2

52-1259 Lead, Agitator Motor

52-0742 Lead, Agitator Motor

52-1210 Harness, Optional

52-2061 Lead Assy, EIBC, 2500 Terminal 2 to 1

Power Cord (BLU) 15

Power Cord (GRN/YEL) Ground Stud

Power Cord (BRN) Kill Switch (A-A)

Power Cord (BLU) 15

Power Cord (GRN/YEL) Ground Stud

Power Cord (BRN) 12

12

14 GA (BLK)

3

WHT)

J1

(BLK)

Harness, Trans, Sec

(WHT)

6

WHT)

10

(BLK)

14

(BLK-RIDGED)

11

Merchandiser (BLK)

Harness, Optional

Merchandiser (GRN/YEL)

Harness, Optional

Merchandiser (WHT)

Ground Stud

13

25

Page 26

6.4 2500 CABINET ASSEMBLY

29

18

21

15

14

30

13

28

33

8

7

6

4

34

16

35

37

36

5

12

38

6

11

3

2

1

19

20

22

16

23

24

15

17

16

32

31

26

25

26

10

9

27

Page 27

6.4 2500 CABINET ASSEMBLY (CONTINUED)

Item Part No. Description

1 30-0643/01 Wrapper, External

2 51-0547 Trim, Gray

3 04-0067 Rivet

4 50-0175 Insulation, 1/2 inch

5 50-0180 Insulation, 1/2 inch

6 50-0102 Insulation, 1/8 inch

7 50-0184 Insulation, 1/8 inch

8 04-0082 Nut, Hex, 10 - 24, SS

9 30-0612 Back Plate

10 04-0477 Screw, 8 - 32 x 0.375 inch

11 42-0013 Tank, Foamed

12 04-0074 Nut, Clip, 10 - 24

13 30-0649/02 Front Support Plate

14 03-0036 Clip, Drain Tube

15 04-0077 Screw, #4 x 1/4 inch

16 04-0061 Screw, #8 x 1/2 inch

17 03-0115 Clip, Overow Tube

18 04-0443 Screw, 10 - 24 x 0.375

19 13-0005 Bushing, Strain Relief

20 11-0015 Connector Housing

21 23-0391 Faucet Plate, 8-Valve

-- 23-0605 Faucet Plate, 6-Valve

-- 30-6702 Faucet Plate, 6-Valve,

Premix

-- 30-6703 Faucet Plate Stiffener,

6-Valve, Premix

22 30-6640 Splash Plate

23 30-0535 Cup Rest

24 23-0306 Drip Tray

25 12-0097 Key Lock Switch

26 52-0893/01 Harness Assy, 8-Valve

-- 52-1214 Harness Assy, 6-Valve

27 51-0582 Base Assy

28 82-1120 Insulator Plate Assy

29 23-0443/02 Bonnet Assy (Specify

Graphics)

30 30-5314 Shim Plate

31 04-1012 Rivet, Splash Plate Spacer

32 01-1705 Spacer, Splash Plate

33 30-5599/02 Retainer, Cage, 2500

34 30-5143 Clip, Drain

35 01-0450 Tube Support

36 08-0190 Drain Tube

37 01-1483 Elbow Drain Assy

38 04-0072 Rivet

Item Part No. Description

NOTE: Cage Assembly Part Numbers are:

23-1232/01 6-Valve, 3-2-1 Manifold,

3/8 inch Syrup Inlets

23-1236/01 8-Valve, 3-1-1-3 Manifold,

3/8 inch Syrup Inlets

23-0919 4-Circuit Chiller

23-0798/01 9-Circuit Chiller

23-1103 6-Valve Premix

27

Page 28

6.5 2500 WIRING DIAGRAM AND HOUSING CONNECTIONS, LANCER ELECTRONIC ICE BANK

CONTROL, USA ONLY

IMPORTANT

WHEN STARTING UNIT OR IF CURRENT IS INTERRUPTED, THERE IS

A FIVE (5) MINUTE DELAY BEFORE THE COMPRESSOR/FAN STARTS.

GREEN

BLACK

WHITE

120 AC

AGITATOR

MOTOR

24V LEADS

TRANSFORMER

OVERLOAD

JCT.

FAN

MOTOR

COMPRESSOR

RELAY

LANCER

ICE

BANK

CONTROL

PROBE

LABEL, WIRING DIAGRAM, CED, PN 06-0031/01

C

M

L

LABEL, WIRING

500 / 2500, CED

06-0031/01

S

M

S

EIBC PROBE CONNECTION

POWER INDICATOR LAMP

HOT OUT

CONTROL HOUSING CONNECTIONS

POWER

CONNECTIONS

HOT IN

28

Page 29

6.6 2500 WIRING DIAGRAM, ELECTRONIC ICE BANK CONTROL (EIBC), INTERNATIONAL ONLY

A

IMPORTANT

WHEN STARTING UNIT OR IF CURRENT IS INTERRUPTED, THERE IS

A FIVE (5) MINUTE DELAY BEFORE THE COMPRESSOR/FAN STARTS.

KEY

SWITCH

B

B

S1

B

S2

B

S3

V

L

V

E

S

B

S4

B

S5

B

S6

B

S7

B

S8

POWER

CORD

W

W

W

W

W

W

W

W

BLGBR

B

W

J1

LINE

24 V

B/WB

87 65 43 21

BL WB

BBR

RIBBED

KILL

USA

BLK

AGITATOR

MOTOR

B

COMPRESSOR

SWITCH

ONLY

TB1

IN OUT OUTIN

B

B

J2

PCB,IBC

TERM3TERM4

TERM2

BBB/W

B

J3

TERM1

BB

BB/W

910111213141516

B/W

B

J4

W

W OR R

B

G

1

G

3

RIBBED BLK

PLAIN BLK

ICE

PROBE

G

OPTIONAL

B

G

W

MERCHANDISER

FAN

MOTOR

SYM.

DESCRIPTION

CHASSIS GROUND

CONTROL BOX

CHAMFER PIN 1

29

®

LABEL,

WIRING DIAGRAM

06-1542

Page 30

6.7 INSTALLATION KITS AND OPTIONAL ACCESSORIES

Part No. Description

• 82-1796 BIB Installation Kit - For 3/8 Inch Syrup Inlets

• 82-0221-06 FIGAL Installation Kit - 6 Valve - For 1/4 Inch Syrup Inlets

• 82-0221-08 FIGAL Installation Kit - 8 Valve - For 1/4 Inch Syrup Inlets

• 82-2613-06 FIGAL Installation Kit - 6 Valve - For 3/8 Inch Syrup Inlets

• 82-2613-08 FIGAL Installation Kit - 8 Valve - For 3/8 Inch Syrup Inlets

• 82-0344 Leg Kit

• 82-2139 EIBC Retrot Kit - International Only

• 82-2572 ELS Marquee Kit - Graphics Included

• 82-1802 24VAC Lighted Marquee (Graphics Ordered Separately)

Marquee Graphics for PN 82-1802 Only

• 06-1790 Coca-Cola Dynamic Ribbon, Screened

• 06-1789 Coca-Cola Three Cup, “Taste Real Refreshment”, Duratrans

30

Page 31

NOTES

31

Page 32

Lancer Corp.

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Loading...

Loading...