Page 1

COLD CARB ICE COOLED DISPENSER

SERIES 2308 - DROP IN

Installation and Service Manual

PN 28-0720/05

11/10/09

LANCER

6655 Lancer Blvd.

San Antonio, Texas 78219

To order parts, call

Customer Service: 800-729-1500

Warranty/Technical Support: 800-729-1550

Email: custserv@lancercorp.com

www.lancercorp.com

ISO 9001:2000 Quality System Certified

“Lancer” is the registered trademark of Lancer © 2009 by Lancer, all rights reserved.

Page 2

TABLE OF CONTENTS

SPECIFICATIONS..............................................................................................................................................3

1. INSTALLATION OF LANCER ICE COOLED DISPENSER........................................................................3

1.1 RECEIVING........................................................................................................................................3

1.2 UNPACKING ......................................................................................................................................3

1.3 SELECTING A COUNTER LOCATION..............................................................................................3

1.4 WATER SUPPLY................................................................................................................................3

1.5 ELECTRICAL SUPPLY ......................................................................................................................4

1.6 INSTALLATION OF THE DISPENSER AND PUMP DECK ...............................................................4

1.7 CONNECTION OF THE EQUIPMENT ..............................................................................................5

1.8 START UP ..........................................................................................................................................5

1.9 ADJUSTING WATER FLOW..............................................................................................................6

1.10 ADJUSTING WATER TO SYRUP RATIO (BRIX) ..............................................................................7

1.11 CONVERTER BLOCK........................................................................................................................7

2. MVU OPERATION .......................................................................................................................................8

2.1 MVU PLUMBING DIAGRAM - MAKING CONNECTIONS TO THE MVU.........................................8

2.2 SYSTEM STARTUP ...........................................................................................................................8

2.3 PROGRAM MULTI VALVE UNIT (MVU) ............................................................................................9

2.4 SET MVU FOR FLAVOR SHOTS....................................................................................................10

2.5 FLOW RATE CHECK .......................................................................................................................12

2.6 RATIO PROCESS ............................................................................................................................13

2.7 PORTION CONTROL PROGRAMMING (MVU) (NO TOPOFF)......................................................14

2.8 PORTION CONTROL PROGRAMMING WITH TOP-OFF (MVU) ...................................................15

2.9 SHOT SIZE PROGRAMMING .........................................................................................................17

2.10 DISPENSER OPERATION...............................................................................................................18

2.11 FINAL ASSEMBLY ...........................................................................................................................19

3. RECOMMENDED SERVICES AND MAINTENANCE...............................................................................20

3.1 SCHEDULED ...................................................................................................................................20

3.2 CLEANING AND SANITIZING SYSTEMS.......................................................................................20

3.3 CLEANING AND SANITIZING BAG-IN-BOX (BIB) SYSTEMS .......................................................21

3.4 VALVES............................................................................................................................................21

3.5 ICE BIN COMPARTMENT ON ALL ICE CHESTS ...........................................................................22

4. TROUBLESHOOTING...............................................................................................................................23

4.1 NO CARBONATION .........................................................................................................................23

4.2 NOISY CARBONATOR PUMP.........................................................................................................23

4.3 VALVES INOPERABLE....................................................................................................................23

4.4 LED BLINKING 4 BLINKS PER SECOND.......................................................................................24

4.5 LED BLINKING 1 BLINK PER SECOND .........................................................................................24

5. ILLUSTRATIONS, PARTS LISTINGS AND WIRING DIAGRAMS ...........................................................26

5.1 SERIES 2300 DROP-IN..............................................................................................................26-27

5.2 REMOTE PUMP ASSEMBLY .....................................................................................................28-29

5.3 TOWER ASSEMBLY, BEVARIETY MVU ....................................................................................30-31

5.4 MVU ASSY .......................................................................................................................................32

5.5 NOZZLE, HYBRID MULTI-FLAVOR.................................................................................................32

5.6 ICE COOLED UNIVERSAL WIRING DIAGRAM WITH BIN LID SWITCH......................................33

5.7 ICE COOLED UNIVERSAL WIRING DIAGRAM WITH BIN LID SWITCH AND MVU ....................34

5.8 ACCESSORIES................................................................................................................................35

P.N. 28-0720/05

2

Page 3

SPECIFICATIONS

DIMENSIONS

Cabinet 23 inches x 23 inches (58.42 cm x 58.42 cm)

Rim 25 inches x 25 inches (63.50 cm x 63.50 cm)

Height (without legs) 19-1/2 inches (49.53 cm) above counter (to top

of valves)

23 inches (58.42 cm) below counter

WEIGHT

Shipping 296 pounds (134.26 kg)

Empty 253 pounds (114.75 kg)

Operating 365 pounds (165.5 kg)

ICE BIN CAPACITY 100 pounds (45.46 kg)

Pouring coffee, tea, and like substances into the drain can cause clogging.

WARNING!

1. INSTALLATION OF LANCER ICE COOLED DISPENSER

1.1 RECEIVING

Each unit is tested under operating conditions and inspected before shipment. At the time of

shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the

carton for visible damage. If damage exists, have the carrier note the damage on the freight bill and

file a claim with carrier. Responsibility for damage to the unit lies with the carrier.

1.2 UNPACKING

A. The ice cooled dispenser is shipped in a corrugated shipping carton. Remove the corrugated

shipping carton from the unit.

B. Remove the parts from the ice compartment.

C. Inspect the unit and parts for concealed damage. If damage exists, notify delivering carrier and

file a claim.

1.3 SELECTING A COUNTER LOCATION

A. Select a counter location close to a properly grounded electrical outlet and a water supply that

meets the requirements specified in Section 1.4 below.

B. The counter location must be able to safely support a minimum of 365 pounds (165.5 kg) after

the counter cutout is made.

1.4 WATER SUPPLY

A. Provide an adequate potable water supply The water supply line must be at least a 1/2 inches

(12.7 mm) pipe. Water pressure exceeding 50 PSI is regulated by a pressure regulator on the

pump deck. Water pressure below 40 PSI will require a booster pump.

B. Install a shut-off valve in the water line feeding the deck. If a separate water line is run for plain

water, ensure that it also has a shut-off valve.

3

P.N. 28-0720/05

Page 4

Use a filter in the water line to avoid damage to the dispenser.

WARNING!

C. The carbonator pump is equipped with a strainer on the inlet side. A water supply containing any

appreciable quantity of silt, fine sand, or other debris requires a filter ahead of the pump deck.

Clean the filter cartridge periodically, depending on the condition of the water. Failure to do so

may starve the pump of water, causing it to burn out, and voiding the warranty.

1.5 ELECTRICAL SUPPLY

The dispenser must be properly electrically grounded to avoid serious

injury or fatal electrical shock. The power cord has a three-prong grounded

plug. If a three-hole grounded electrical outlet is not available, use an

approved method to ground the unit. Follow all local electrical codes when

making connections. Each dispenser must have a separate electrical circuit.

Do not use extension cords. Do not connect multiple electrical devices on

the same outlet.

ALWAYS disconnect power to the dispenser before attempting any internal

maintenance.

Only qualified personnel should service the internal components of the

dispenser. Avoid any contact with water when plugging in the dispenser.

A. Locate a standard 20 AMP, 110 VAC, 60 Hz single phase electrical power outlet with ground

connectors for the dispenser and pump deck.

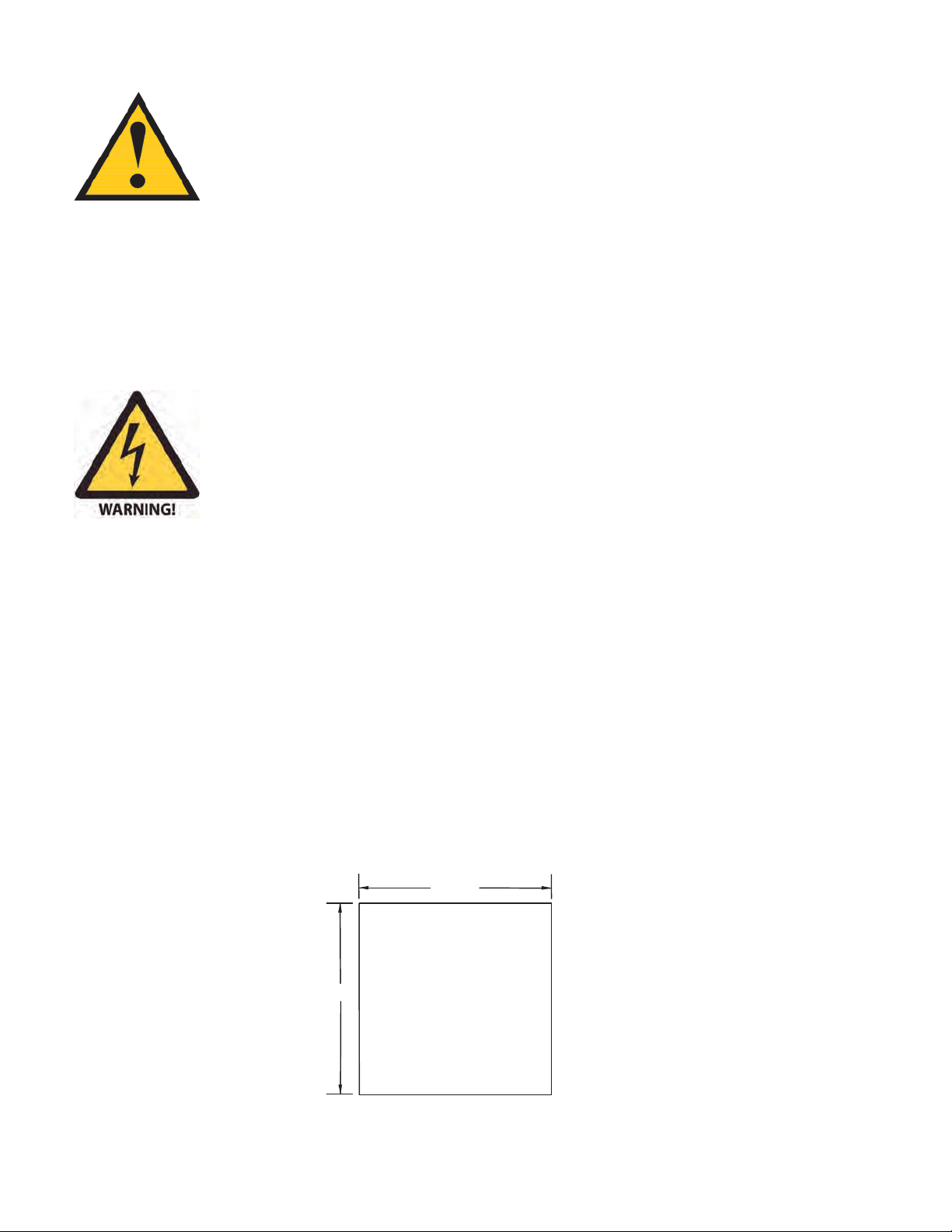

1.6 INSTALLATION OF THE DISPENSER AND PUMP DECK

A Inspect the counter location where the dispenser will be installed. Verify that the counter is

strong enough to safely support a 365 pound (165.5 kg) load, after the counter cutout is made.

B. Verify that the unit will fit in the location. See below for the counter cutout dimensions.

NOTE: The unit can extend up to 23 inches (58.42 cm) below the counter, including the shipping

risers. It is recommended to keep the shipping risers attached to the dispenser. If the

dispenser ever requires removal, the shipping risers will protect the inlet tubes from being

damaged.

23 1/4"

23 1/4"

P.N. 28-0720/05

Counter Cutout for dispenser

4

Page 5

C. After the counter cutout is made, lower the dispenser into the counter.

NOTE: In order to ensure unit drainage and proper carbonation, it is necessary for the dispenser to

be level, front to back and side to side.

D. Position the pump deck under the counter within close proximity to the dispenser. The pump

deck must be on a level surface and have adequate electrical utilities available.

1.7 CONNECTION OF THE EQUIPMENT

A. Position the CO

2 gas tank in the desired location. Assemble the high pressure regulator to the

CO2 gas tank and run the jumper line to the low pressure regulator.

B. Attach the CO2 gas line to the carbonator by attaching the line from the high pressure regulator

to the CO2 inlet. The setting of the high pressure CO2 gas regulator should be 75 PSI.

Do not turn on CO2at this time.

WARNING!

C. Position the syrup pumps in the desired location. Attach the CO

2 gas lines leading from the low

pressure regulator to these pumps.

D. Connect the syrup lines from the pumps to the appropriate inlets at the front of the unit. The

syrup inlets are identified at the bottom of the unit.

E. Connect the water inlet line to the pump. Complete the water line connection between the pump

and the water inlet to the carbonator at the bottom of the dispenser.

F. Provide a suitable drain in the plumbing system and attach the 3/4 inch (1.90 cm) diameter

schedule 40 PVC drains to it. The drip pan drainage outlet is located at the right rear of the unit.

The ice water drainage outlet is located at the right front of the unit.

G. Be sure to place the ice trap in the drain outlet inside the ice bin before filling with ice. This

device holds the ice away from the drain outlet, allowing the ice water to drain properly.

H. Plug in the transformer box to a standard 20 AMP, 110 VAC, single phase outlet. The unit will

internally convert the 110 VAC to 24 VAC.

1.8 START UP

A. After all connections to water, CO

2 gas, electrical power, and syrup pumps are made, check for

leaks.

B. Be sure the Bag-In-Box contains syrup.

Do not operate the carbonator pump deck with the water supply turned off.

WARNING!

C. Turn on water. Open the pressure relief valve on the carbonator tank by flipping up the valve cap

lever, and hold it open until water flows from the relief valve. Close (flip down) the relief valve

and turn on the CO

2 gas.

D. To fill all lines with water, cycle the carbonator several times by operating the dispensing valves.

1. Ensure a good flow of plain water is established from each valve.

2. Turn on CO

at source and ensure that the HP regulator is set at 75 PSIG.

2

3. Operate valves until unit gases out.

4. Plug in carbonator pump motor. Pump Deck will automatically start.

5

P.N. 28-0720/05

Page 6

5. Activate carbonated water valves so that the carbonator pump cycles several times and a

good flow of carbonated water is established.

6. A low pressure gas regulator controls the flow of syrup to each dispensing valve. Connect

BIB connectors to BIB’s. Set LP regulator to 65 PSIG. Activate all valves to purge air from

the syrup lines.

NOTE: The unit will cycle on for 5.5 seconds, shut down, and immmediately start again and run

for additional 5.5 second intervals until the water level reaches the probe.

E. The dispenser bin should now be filled with ice cubes one inch below the level of the door

opening.

1.9 ADJUSTING WATER FLOW

A. The water flow can be adjusted to either 1.25 ounces/second (37 ml/sec) or 2.5 ounces/second

(74 ml/sec) on all dispensing valves, using the following procedure.

NOTE: The unit should have ice on the cold plate for a least one hour before you attempt to brix the

o

valves. The drink temperature should be no higher than 40

F (4.4oC) when the ratio is set. This

is done after the unit has ice in the ice bin.

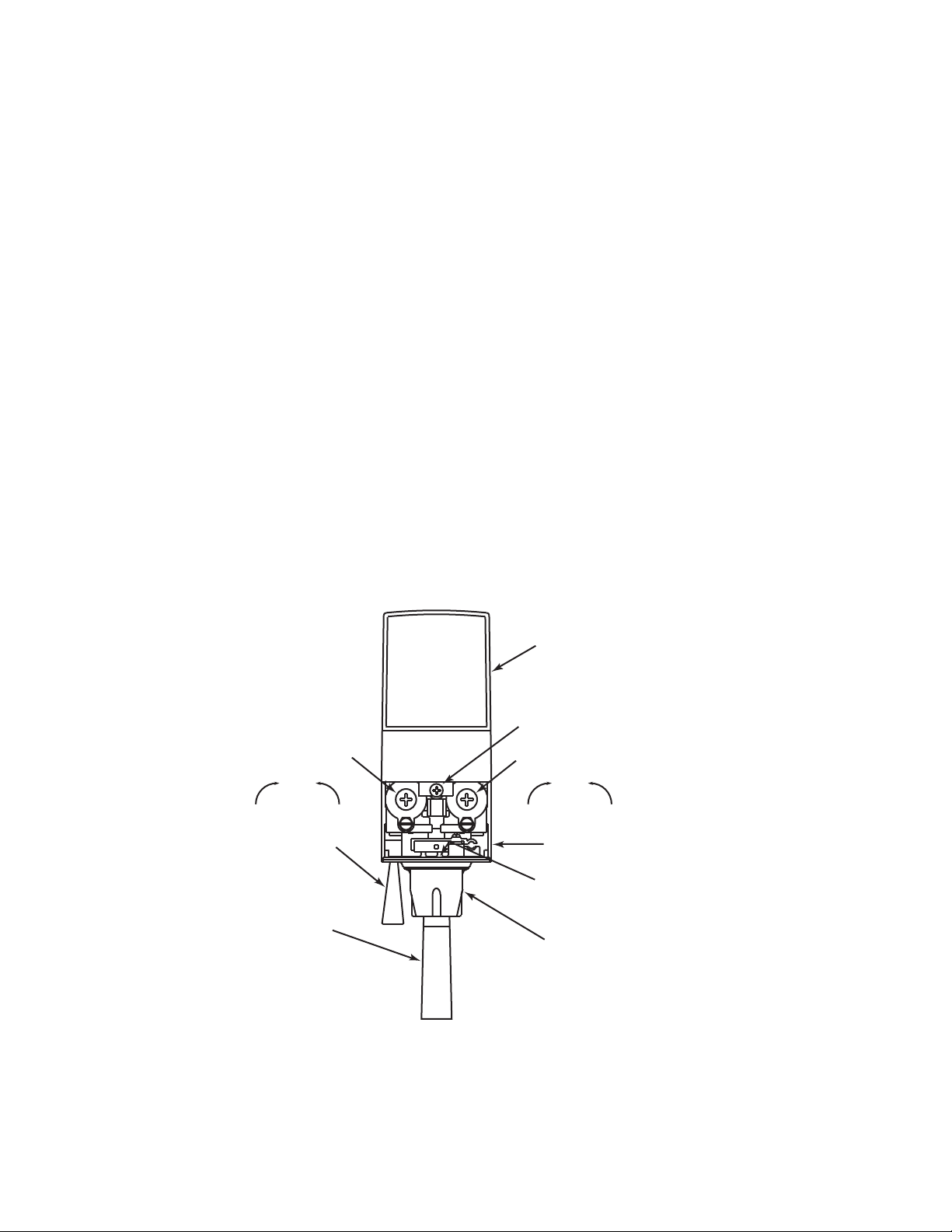

C. Slide the ID panel up until the flow controls are exposed (see below).

D. Remove the nozzle by twisting counterclockwise and pulling down.

E. Remove the diffuser by pulling down.

F. Install Lancer yellow syrup separator (PN 54-0031) in place of the nozzle.

G. Activate the dispensing valve to fill the separator syrup tube.

H. Hold a brix cup under the syrup separator and dispense water and syrup into the cup for four

seconds. Divide the number of ounces (ml) of water in the cup by four to determine the water

flow rate per second.

I. To obtain the proper flow, use a screwdriver to adjust the water flow control.

J. Repeat process for each valve.

FLOW CONTROL

SYRUP

DecreaseIncrease

SODA LEVER

(Optional)

CUP LEVER

I.D. PANEL

(Shown in

open position)

COVER SCREW

FLOW CONTROL

SYRUP

DecreaseIncrease

COVER

DATE OF

MANUFACTURE

SERIES NO.

NOZZLE

Valve Adjustments

P.N. 28-0720/05

6

Page 7

1.10 ADJUSTING WATER TO SYRUP RATIO (BRIX)

A. Hold the brix cup under the syrup separator and activate valve. Check ratio (brix).

B. To obtain the proper ratio, use screwdriver to adjust syrup flow control (see Figure 2).

C. Remove syrup separator.

D. Install diffuser and nozzle.

E. Slide ID panel DOWN.

F. Repeat process for each valve.

NOTE: When re-assembling valves with o-rings, ensure the o-ring is lubricated with an FDAapproved lubricant or water to prevent leakage or damage to the o-ring.

1.11 CONVERTER BLOCK

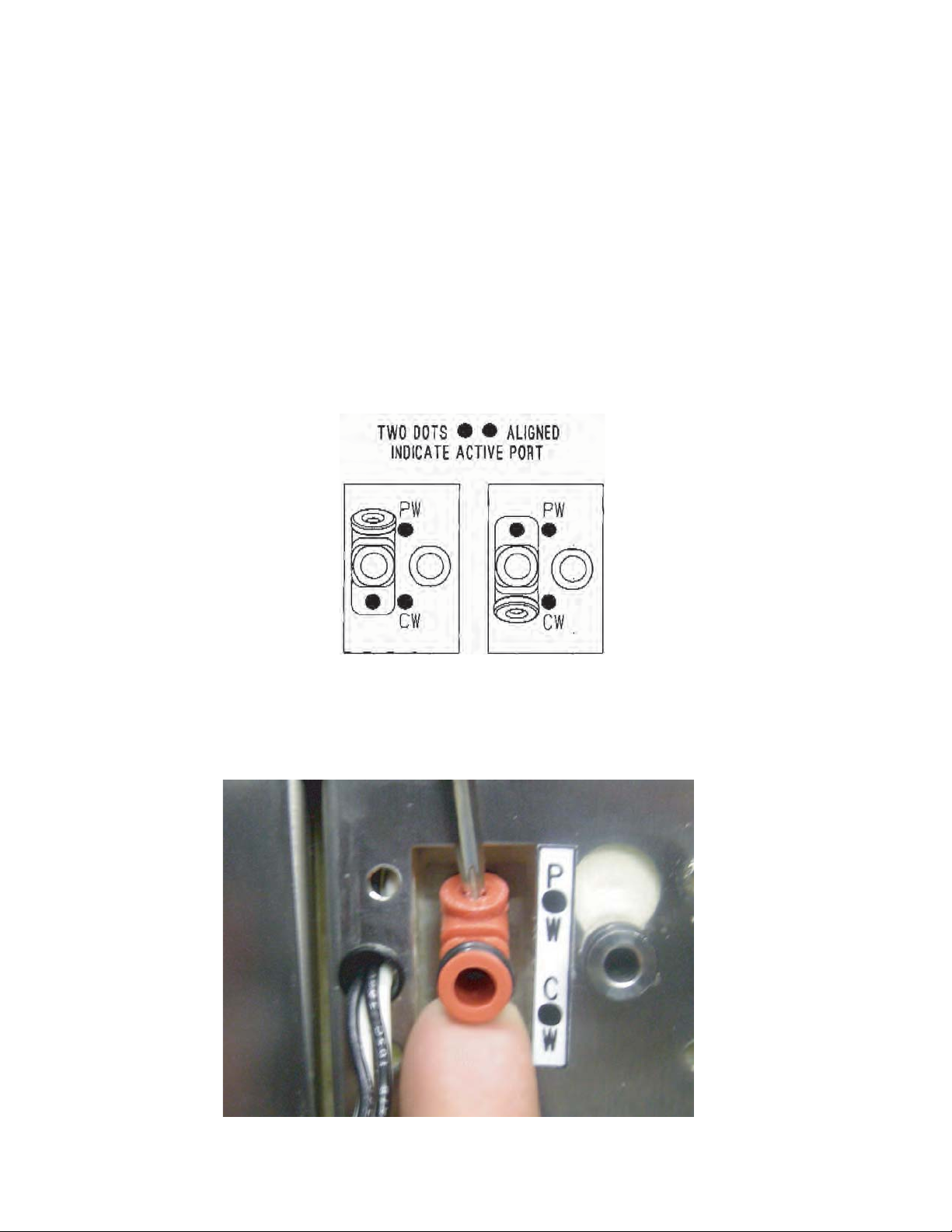

A. Set the converter block to provide either plain or carbonated water, depending on the product.

The alignment of the dot on the converter block signifies the active port (plain water or

carbonated water):

B. To remove the converter block, use a small screwdriver in the blind hole to pry the converter

block out. Applying pressure opposite the blind hole (dot side) will facilitate removing the

converter block:

7

P.N. 28-0720/05

Page 8

2. MVU OPERATION

2.1 MVU PLUMBING DIAGRAM - MAKING CONNECTIONS TO THE MVU

A. Valves 1-3 and 6-8 are in the normal positions on the tower; however, the MVU is plumbed as

shown in the diagram below. Position A is syrup inlet #4 on the cold plate. Position D is syrup

inlet #5. Positions B, C, E, and F on the MVU connect in the positions shown on the illustration

of the Configurator block. These positions (B, C, E, F) are all ambient (bypass the cold plate).

2.2 SYSTEM STARTUP

A. Turn on water and purge lines.

B. Turn on CO2 and gas out dispenser.

C. Plug in carbonator pump.

D. Cycle valves two times.

E. Turn on CO2 to BIB pumps.

F. Pour several drinks.

G. Prime for flavor shots.

H. Prime for beverages.

P.N. 28-0720/05

8

Page 9

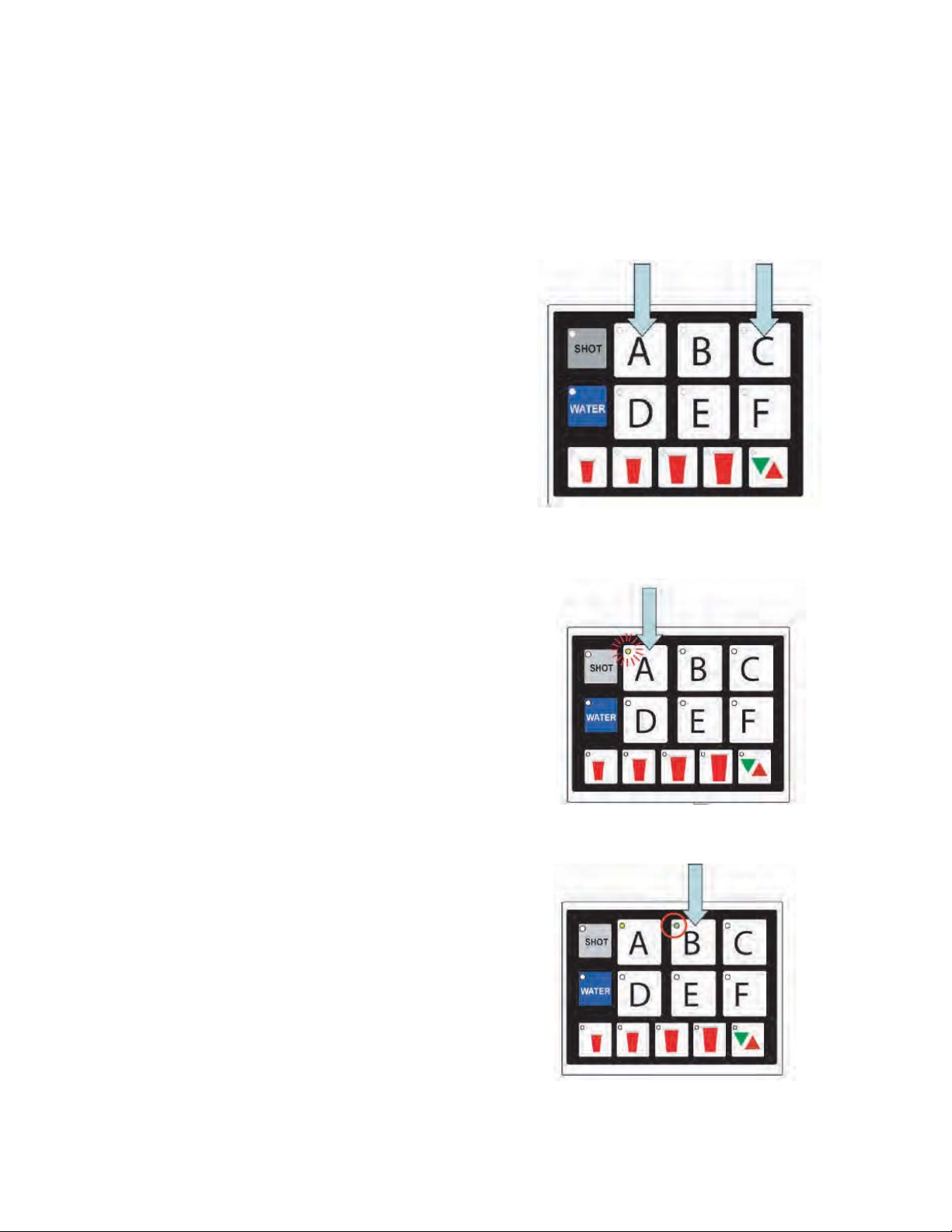

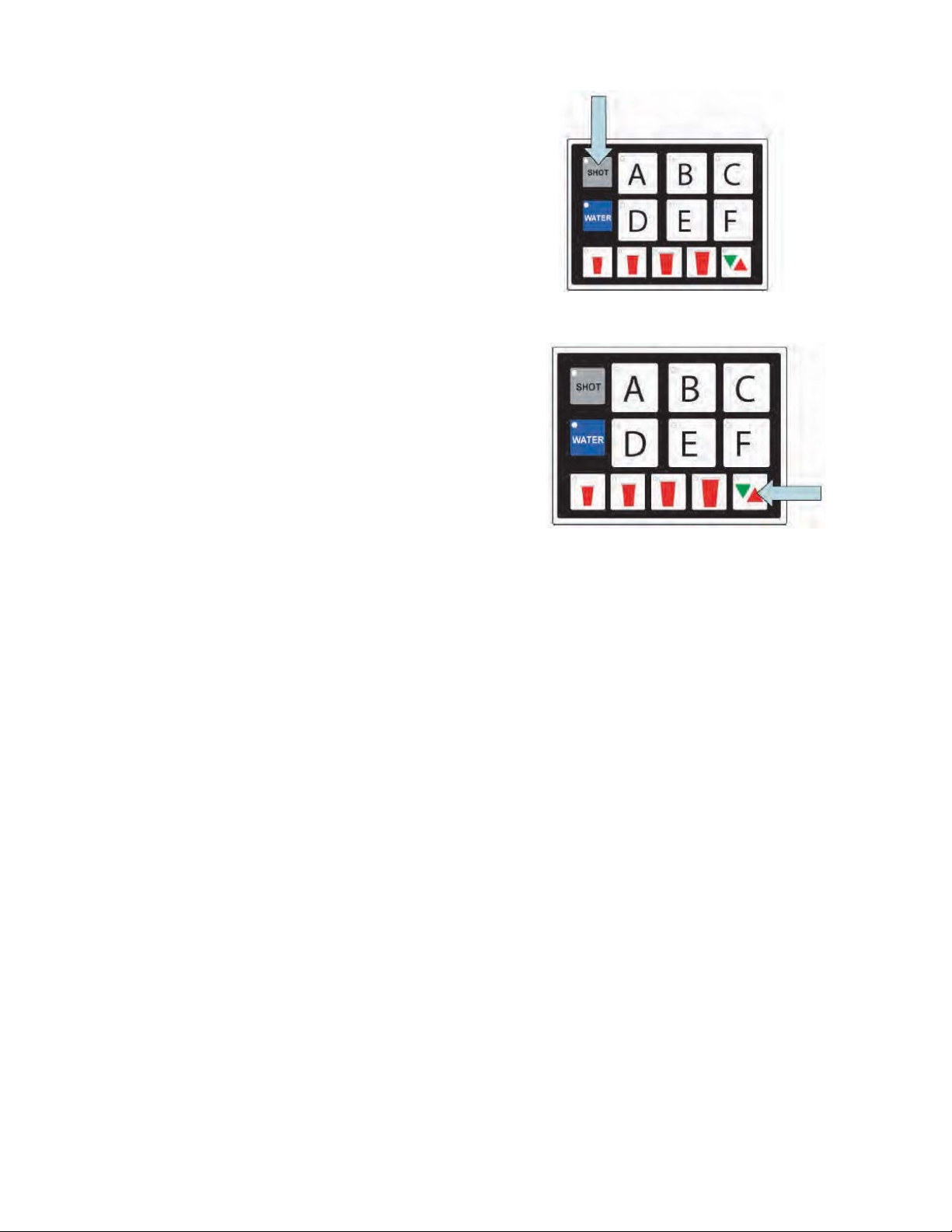

2.3 PROGRAM MULTI VALVE UNIT (MVU)

Set MVU Buttons as Carbonated, Non-Carbonated, or Flavor Shot Only.

The MVU can be programmed to serve soda or plain water beverages as well as a flavor shot from

each of the beverage positions on the valve.

To enter the programming mode on the MVU and assign water type to each individual brand

(Carbonated or Non-carb):

A. Press both A and C brand buttons at the

same time on the MVU panel for five

seconds.

1. The “Pour/Cancel” LED will illuminate. The

“SHOT” LED will blink one time.

2. Brands that are enabled for drinks will

have illuminated LED’s:

Lights on = non-carb

Lights flashing = carb

Lights off = no water (deactivated unless set

for shot)

B. Press a Brand button to change that

beverage from “water off” to “plain water

on”.

1. LED will illuminate and stay on for noncarb beverages.

C. Press the same brand button again to

switch from non-carb to carb.

1. Press the button one more time to turn the

water off for that valve (if position is used

for a flavor shot only).

D. Repeat this process for each brand.

9

P.N. 28-0720/05

Page 10

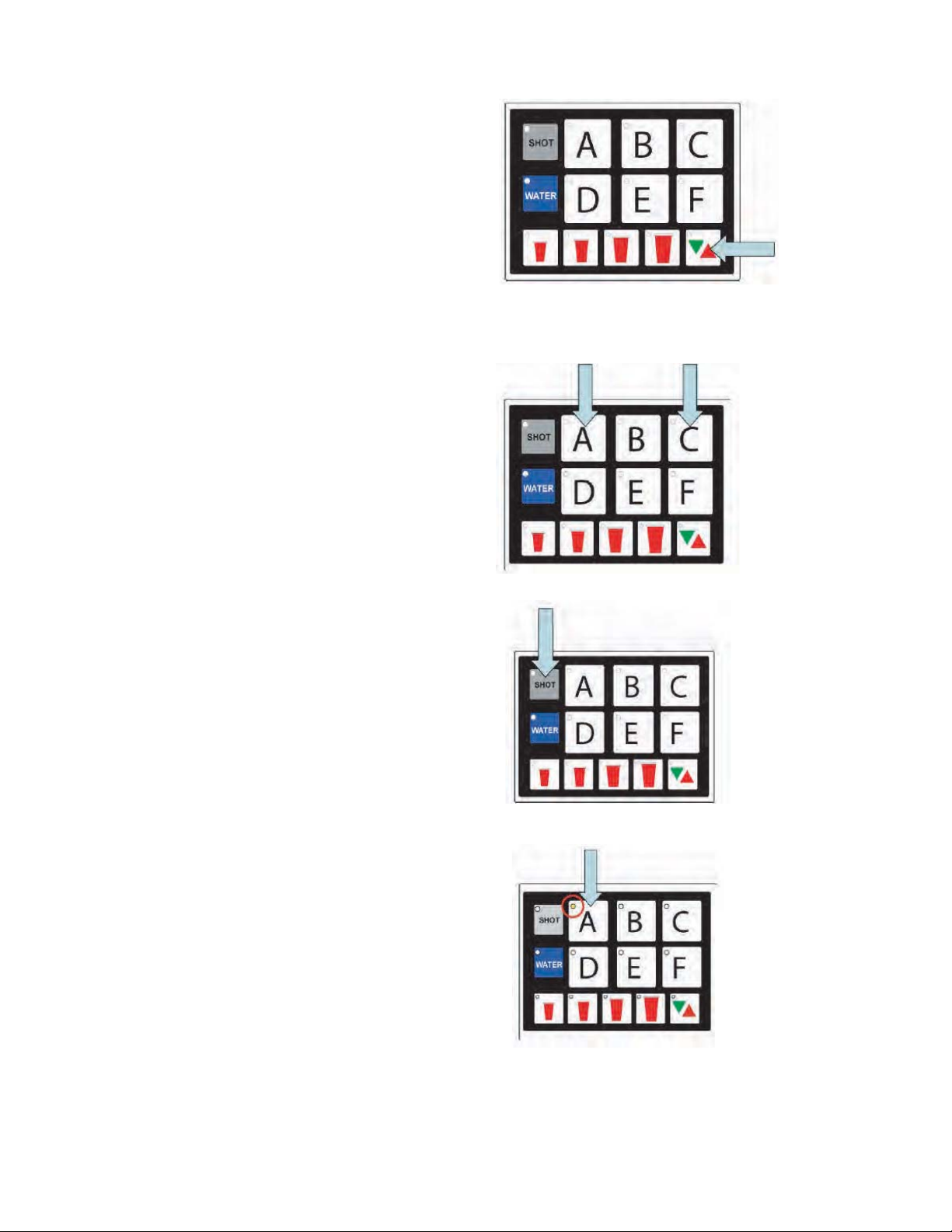

E. Press the Pour/Cancel button to lock the

changes in place and exit the

programming mode.

NOTE: The Program will save automatically

in 60 seconds if no additional changes are

made in that time frame; however, you can

exit any time within the 60 second window

by pressing Pour/Cancel. The changes

you’ve made will be saved.

2.4 SET MVU FOR FLAVOR SHOTS

A. Press both A and C brand buttons (at the

same time) on the MVU panel for five

seconds to get into programming mode.

B. Press the “Shot” button.

1. The “Shot” button will illuminate.

2. Brands enabled for shots will be

illuminated.

C. Press the “Brand” button to turn the shot

mode for that brand on or off.

1. The shot mode is “ON” in the illustration.

P.N. 28-0720/05

10

Page 11

D. Press “Shot” again to return to “Drink Type

Selection”

E. Press the Pour/Cancel Button to lock the

changes in place and exit the

programming mode.

NOTE: The Program will save automatically

in 60 seconds if no additional changes are

made in that time frame; however, you can

exit any time within the 60 second window

by pressing Pour/Cancel. The changes

you’ve made will be saved.

11

P.N. 28-0720/05

Page 12

2.5 FLOW RATE CHECK

The Dispenser’s water flow rate can be checked/calibrated using the on board computer as a

timer. To check/adjust flow rate:

A. Remove splashguard and module cover to expose flow controls and solenoids.

1. All active brands should have their shutoffs in the open position as illustrated below.

CW = Carbonated Water (sparkling)

PW = Plain Water (still)

P.N. 28-0720/05

B. Press the A and B buttons at the same

time for five seconds.

1. The Pour/Cancel button will illuminate and

the shot LED will blink 5 times.

12

Page 13

C. Remove outer nozzle and insert syrup

separator.

1. This is important to do during flow rate

check so you can determine if the

separator has been properly installed.

NOTE: Water will leak through to the syrup

chamber if not properly installed.

D. Place a ratio cup under the nozzle and

press a brand button.

1. The brand’s water module will open and

pour for four seconds.

NOTE: Only water will pour during the flow

rate check.

E. Check for 10 oz of water in the ratio cup.

1. If above or below 10 oz, adjust the water

flow control (shown on previous page)

and recheck.

2.6 RATIO PROCESS

A. Remove outer nozzle and insert MVU separator if not done on previous step.

B. Prime separator by running the valve.

C. Press and fill the ratio cup to the appropriate levels.

D. Check/adjust ratio on each brand.

1. Use flow controls to adjust syrup.

13

P.N. 28-0720/05

Page 14

2.7 PORTION CONTROL PROGRAMMING (MVU) (NO TOP-OFF)

A. Press the S and XL at the same time for

five seconds to enter the portion setting

mode.

1. The Pour/Cancel light will illuminate and

the shot light will blink two times.

Press the Brand button.

1. The selected brand’s LED will illuminate.

2. Multiple brands can be programmed at the same time to pour the same amounts for each

size during this step.

Do this by selecting several brand buttons; however, the first button selected will illuminate

and only its beverage will pour. The other brands selected will flash slowly.

3. If multi-brand programming, do not set carbonated drinks and non-carbonated drinks at the

same time because carbonated drinks will foam.

NOTE: The LED will blink twice and turn off if the brand has been programmed as a flavor shot

instead of a drink. You will need to reprogram the brand as a drink prior to setting the

portion.

C. Fill cup 1/3 full with ice and place it under

the nozzle, push and hold a drink “size”

button until the cup is full.

1. Once the pour is completed, the LED will

blink slowly to indicate that a new pour

duration has been programmed for that

key.

P.N. 28-0720/05

14

Page 15

D. Repeat this step for each of the other size

cups.

E. Select other brands and repeat these

steps for each of them.

F. Press the “Pour/Cancel” button to save

programming.

NOTE: The Program will save automatically

in 60 seconds if no additional changes are

made in that time frame; however, you can

exit any time within the 60 second window

by pressing Pour/Cancel. The changes

you’ve made will be saved.

2.8 PORTION CONTROL PROGRAMMING WITH TOP-OFF (MVU)

A. Press the S, L, and Pour/Cancel buttons

at the same time for two seconds to enter

portion setting mode.

1.The Pour/Cancel light will illuminate and

the shot light will blink three times.

15

P.N. 28-0720/05

Page 16

B. Press the brand button.

1. The selected brand’s LED will illuminate.

2. Multiple brands can be programmed at the

same time to pour the same amounts for

each size during this step. Do this by

selecting several brand buttons;

however, the first button selected will

illuminate and only its beverage will pour.

The other brands selected will flash

slowly.

3. If multi-brand programming, do not set

carbonated drinks and non-carbonated

drinks at the same time because

carbonated drinks tend to pour faster.

C. Fill cup 1/3 full with ice.

D. Place cup under the nozzle, push and

hold a drink “size” button until the cup is

full.

1. Once the pour is completed, the LED will

blink fast to indicate Settle Time

programming mode.

2. If the duration is more than 40 seconds,

the dispense function is stopped and the

portion is not saved.

E. After beverage settles, press the Size button again to top off the drink.

1. If the settle time is more than fifteen seconds, the auto top-off times are cleared for all

selected flavors.

F. Repeat steps B-E for additional brands and cup sizes.

G. Press Pour/Cancel button to save the

portions and exit programming mode.

1. If no button is pressed in 60 seconds, the

system will exit program mode and save

the current programming.

P.N. 28-0720/05

2. The Pour/Cancel will blink until the

program is saved.

16

Page 17

2.9 SHOT SIZE PROGRAMMING

Flavor shot portions can be adjusted using the MVU touchpad and a graduated cylinder. To adjust flavor

shots:

A. While in Portion Control Programming,

press the Shot button.

1. Pressing the Shot button again will exit

Shot Size Programming.

B. Press a “Brand” button. The brand button

will illuminate.

NOTE: If brand is not enabled for shot

mode, the LED light on that brand will blink

twice and turn off.

C. Place a graduated cylinder under the

nozzle.

D. Press and hold the XL portion button until

the portion size is achieved. Target is 30

ml (1 0z) of syrup for an XL portion for

most customers.

1. The XLRG LED will blink slowly to indicate

that a new shot duration has been

programmed.

NOTE: The other size buttons are

proportioned automatically based on the

amount poured in XL mode:

Small = 25% of XL portion

Medium = 50% of XL portion

Large = 75% of XL portion

E. Repeat steps B through D for each of the

other brands.

17

P.N. 28-0720/05

Page 18

F. Press Pour/Cancel to save the settings.

NOTE: The Program will save automatically in 60 seconds if no additional changes are made in

that time frame; however, you can exit any time within the 60 seconds window by pressing

Pour/Cancel. The changes you’ve made will be saved.

2.10 DISPENSER OPERATION

Crew Serve Beverage Dispensing

Flavor Shot Dispensing - Portion Control

A. Place cup under MVU nozzle.

B. Press the “Shot” button.

1. The “Shot” LCD will stay illuminated (active) for 10 seconds.

C. Select Brand Button.

1. Brand will stay illuminated for up to ten seconds.

2. Touch brand again to deactivate.

D. Select portion control size button to begin

dispensing flavor shot.

1. Press “Pour/Cancel” to stop dispense

B

mode.

C

Beverage Dispensing - Portion Controlled

A. Press the brand button.

1. Button stays active for 10 seconds or until

another brand is pressed.

B. Press a portion control size button.

1. Beverage will pour.

2. Press the Pour/Cancel to stop pour prior to

complete dispense.

D

A

A

B

P.N. 28-0720/05

18

Page 19

Beverages - Manual Dispense on Portion Control

A. Press the brand button.

1. Button stays active for ten seconds or until

another brand is pressed.

B. Press and hold the pour/cancel button.

1. The beverage continues to pour until the

button is released.

A

2. The selection will stay in memory for ten

seconds.

3. The valve can pour for a maximum of thirty

seconds.

2.11 FINAL ASSEMBLY

A. Reinstall the front cover plate.

B. Reinstall drip tray, splash plate and cup rest. System is ready for operation.

B

19

P.N. 28-0720/05

Page 20

3. RECOMMENDED SERVICE AND MAINTENANCE

3.1 SCHEDULED

A. Daily – See Section 3.4 for daily cleaning.

B Monthly – See Section 3.5 for monthly cleaning.

C. Periodic Sanitizing - See sections 3.2 and 3.3 for sanitizing requirements.

D. As needed - Keep exterior surfaces of dispenser (including drip tray and cup rest) clean with a

damp, clean cloth.

3.2 CLEANING AND SANITIZING SYSTEMS

A. General Information

(1) Lancer equipment (new or reconditioned) is shipped from the factory cleaned and sanitized

according to NSF guidelines. The operator of the equipment must provide

continuous maintenance as required by this manual and state and local health

department guidelines to maintain proper operation and sanitization.

NOTE: The cleaning and sanitizing procedures below pertain to the Lancer equipment identified

by this manual. If other equipment is being cleaned, follow the guidelines established for that

equipment.

(2) Cleaning and sanitizing should be accomplished only by trained personnel. Use sanitary

gloves during cleaning and sanitizing operations. Observe all safety precautions. Follow

instruction warnings on the cleaning product.

To avoid contamination, do not disconnect water lines when cleaning and

sanitizing syrup lines.

WARNING!

(3) Recommended Preparation of Cleaning Solutions.

(a) Cleaning solutions (for example, Ivory Liquid, Calgon, etc.) mixed with clean, potable

water at a temperature of 90 to 110 degrees Fahrenheit should be used to clean

equipment. The mixture ratio, using Ivory Liquid, is one ounce of cleanser to two gallons

of water. A minimum of four gallons of cleaning mixture should be prepared.

NOTE: Extended lengths of product lines may require that an additional volume of solution be

prepared.

(b) Any equivalent cleanser may be used as long as it provides a caustic-based,

non-perfumed, easily-rinsed mixture containing at least two percent sodium

hydroxide (NaOH).

(4) Recommended Preparation of Sanitizing Solutions.

(a) Sanitizing solutions should be prepared according to the manufacturer’s written

recommendations and safety guidelines. Follow manufacturer’s requirements so that

the solution provides 200 parts per million (PPM) chlorine at a temperature of 90

o

120

F. Prepare a minimum of four gallons of sanitizing solution.

NOTE: Extended lengths of product lines may require that an additional volume of solution be

prepared.

(b) Any sanitizing solution may be used as long as it is prepared according to the

manufacturer’s written recommendations and safety guidelines, and provides 200 parts

per million (PPM) chlorine.

o

F to

P.N. 28-0720/05

20

Page 21

3.3 CLEANING AND SANITIZING BAG-IN-BOX (BIB) SYSTEMS

A. Disconnect syrup quick disconnect coupling from syrup packages and connect coupling to a bag

valve removed from an empty Bag-in-Box package.

B. Place end of syrup inlet line, with bag valve attached, in a clean container filled with clean,

potable, room-temperature water.

C. Place waste container under applicable dispensing valve. Activate valve until water is

dispensed. Flush and rinse line and fittings for a minimum of 60 seconds to remove all traces

of residual product.

NOTE: Extended lengths of product lines may require additional time for flushing and rinsing lines.

D. Prepare cleaning solution as described in Section 3.2 above. Place end of syrup inlet line in

container filled with cleaning solution.

E. Place waste container under applicable dispensing valve. Activate valve and draw cleaning

solution through lines for a minimum of sixty seconds. This will ensure line is flushed and filled

with cleaning solution. Allow line to stand for at least thirty minutes.

F. Place end of syrup inlet line in a clean container filled with clean, potable water at a

temperature of 90 to 110 degrees F.

G. Place waste container under applicable dispensing valve. Activate valve to flush and rinse line

and fittings for a minimum of sixty seconds to remove all traces of cleaning solution. Continue

rinsing until testing with phenolpthalein shows that the rinse water is free of residual detergent.

H. Prepare sanitizing solution as described in Section 3.2 above. Place end of syrup inlet line in

container filled with sanitizing solution which has been prepared.

I. Activate valve and draw sanitizing solution through line for a minimum of sixty seconds. This

will ensure line is flushed and filled with sanitizing solution. Allow line to stand for at least

fifteen minutes.

J. Remove bag valve from quick disconnect coupling and reconnect syrup inlet line to syrup

package. Ready unit for operation.

Flush sanitizing solution completely from syrup systems. Residual sanitizing

solution creates a health hazard.

WARNING!

K. Draw drinks and refill lines with end product to flush sanitizing solution from the dispenser.

NOTE: A fresh water rinse cannot follow sanitization of equipment. Purge only with the end use

product. This is an NSF requirement.

L. Test dispenser in the normal manner for proper operation. Taste dispensed product to ensure

there is no off-taste. If off-taste is found, flush syrup system again.

M. Repeat cleaning, rinsing, and sanitizing procedures for each valve circuit.

3.4 VALVES

A. Valves may be cleaned and sanitized (see preparation in Section 3.2) in the same manner.

1. Remove cover and disconnect power so the valve will not be activated during the cleaning

procedure. Remove nozzle and diffuser. Wash these parts in cleaning solution, then

immerse them in a bath of sanitizing solution for 15 minutes.

2. Visually inspect around nozzle area for syrup residue. This area may be cleaned with warm

water and cloth or with the nozzle brush supplied. Wipe off dispensing lever.

3. Wearing sanitary gloves, remove, drain and air dry the nozzle and diffuser.

4. Wearing sanitary gloves, replace diffuser, twist nozzle in place.

5 Connect power and replace cover. Valve is ready for operation.

21

P.N. 28-0720/05

Page 22

3.5 ICE BIN COMPARTMENT ON ALL ICE CHESTS

A. Clean and sanitize the ice bin compartment of the dispenser thoroughly at least once every

month. Use the following procedure:

B. Prepare cleaning solution and sanitizing solution described in Section 3.2.

C. Using the cleaning solution and a clean soft cloth, wash down the sides of the ice bin and the

surface of the aluminum casting.

D. Using clean, potable water, thoroughly rinse away the cleaning solution from the sides and

surface of the casting.

E. Using plastic sanitary gloves, soak a white cotton gauze cleaning rag in the sanitizing solution

and wipe all surfaces in the ice compartment.

NOTE: A fresh water rinse cannot follow sanitization of equipment. Purge only with the end-use

product. This is an NSF requirement.

F. Sanitizing of the ice compartment is complete. Refill with ice.

P.N. 28-0720/05

22

Page 23

4. TROUBLESHOOTING

TROUBLE CAUSE REMEDY

4.1 No carbonation. A. Carbonator motor not running.

B. Absence of CO

2

gas.

C. Gas only from valves.

D. Carbonator tank air bound.

E. CO

gas pressure below 75

2

PSI.

F. Carbonator motor running

continuously.

A. Check power supply to see if

plugged in. Check if LED light is

blinking. If so, reset by

unplugging and re-plugging

power supply.

B. Replace with full tank of CO

gas.

C. Check for power failure.

Check fuses. Clean strainer on

pump.

D. Relieve gas pressure in tank

by flipping up relief valve until

water spurts out.

E. Reset high pressure CO

2

gas

regulator to 75 PSI. Change CO

tank if required.

F. Inspect check valve for

blockage. Check carbonator

control. Check carbonator pump

for efficiency.

2

2

G. Water pump not moving

water.

H. Ice on cold plate.

4.2 Noisy carbonator pump. A. Insufficient water supply or

water leak allowing air to be

pulled into pump.

B. Loose pump coupling.

4.3 Valves inoperable. A. Loss of power.

B. Faulty bin switch.

CONTINUED ON NEXT PAGE

G. Replace water pump if

necessary.

H. Fill bin with ice.

A. Provide adequate water

supply. Ensure strainer is clean.

B. Tighten set screw on pump

coupling.

A. Check power supply to see if

plugged in. Check transformer

circuit breaker. Check main

power circuit breaker, 110V.

Check keylock switch on side of

tower to ensure it is in the “ON”

position.

B. Ensure proper connection.

23

P.N. 28-0720/05

Page 24

TROUBLE CAUSE REMEDY

4.4 LED blinking 4 blinks per

second.

4.5 LED blinking 1 blink per

second.

A. No water to pump. A. Ensure water supply is on,

carbonator pump motor is

connected, and probe is not

damaged. Reset by unplugging

and re-plugging power supply.

A. Short in probe.

B. Short in harness.

C. Crossed wires in harness or

probe plug.

A. Replace probe.

B. Replace harness.

C. Correct wiring (see CCNA

Bulletin Serv 256).

P.N. 28-0720/05

24

Page 25

NOTES

25

P.N. 28-0720/05

Page 26

5. ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS

5.1 SERIES 2300 DROP-IN

P.N. 28-0720/05

26

Page 27

5.1 SERIES 2300 DROP-IN - PARTS LIST

ITEM PART NO. DESCRIPTION

1 42-0100 Tank Assy, High Performance

- 30-9231 Liner, Tank Wrapper, Back

2 30-10057 Tank Wrapper

3 51-6225 Rim Assy

4 30-9267 Lid, Ice Bin

5 19-0353/02 LEV®, 4.5, Portion Control

6 05-2586 Drip Tray

7 23-0797/02 Cup Rest

8 30-5424 Splash Plate

9 04-1089 Screw, 10 - 32 X 1.000 (for LEV® only)

10 04-1537 Screw, 1/4-20 x .500

11 48-0776 Foamed Manifold (5 Valve, 4-1)

- 48-0767 Foamed Manifold (6 Valve, 5-1)

- 48-0851 Foamed Manifold (5 Valve, 2-1-2)

- 48-0850 Foamed Manifold (6 Valve, 3-1-2)

12 30-5986 Tower Cap

13 04-0148 Screw, 10 - 32 X 0.250

14 12-0097 Key Lock Switch Assy

15 51-6256 Tower Body (Stainless Steel)

16 06-0075-01 Nameplate (8 Valve)

17 51-5541 Base Assy.

18 30-10095 Bracket, Switch

19 11-0015 Housing Socket

20 04-0072 Rivet

21 23-0862 Wire Drain Assy

22 05-2583 Shipping Leg Plastic

23 82-1103 Transformer Assy

24 50-0475 Insulation Gasket LT

- 50-0476 Insulation Gasket RT

25 06-3069 Label, VLU/Probe

26 06-3070 Label WTR/SYR Inlets

27 23-1452 Tower Structure Left

28 23-1453 Tower Structure Right

29 52-3075 Probe Assy

30 30-9871 Cover, Probe

31 23-1200-41 Tower Structure Center

32 54-0066 Relief Valve Sub-Assy, Plastic

- 82-3914 Tower Structure MVU

33 01-2673 Fitting Sub-Assy, CO

34 03-0021 Spring, Check Valve

35 02-0003 O-Ring

36 01-0674 Ball

37 01-0689 Sleeve

38 02-0005 O-Ring

39 01-2647 Body, Check Valve

40 01-2682 Fitting Converter

41 02-0005 O-Ring

-in

2

33

34

35

36

37

38

39

32

Co2 Inlet / Relief

Valve Assy Order

Relief Valve Sub-Assy, Plastic

Fitting, Sub-Assy, Co2-In

Spring, Check Valve

O-Ring, 2-011

Ball

Sleeve

O-Ring, 2-010

Body, Check Valve

27

P.N. 28-0720/05

Page 28

5.2 REMOTE PUMP ASSEMBLY

18

7

3

15

2

6

10

5

19

1

8

17

9

12

11

20

4

16

14

13

5

20

21

P.N. 28-0720/05

28

Page 29

5.2 REMOTE PUMP ASSEMBLY - PARTS LIST

ITEM PART NO. DESCRIPTION

1 01-2700 Adapter, Plastic, 1/2x3/8 Fitting

2 04-0032/01 Nut, Nylock, 1/4-20

3 04-0033/01 Washer, Flat, 1/4 x .062

4 04-0034 Nut, Lock, 1/4-20

5 04-0236 Screw, 10/21 x .375

6 04-0247 Isolator, 1/4-20

7 04-0520/01 Screw, 1/4-20 x .500

8 06-0075-1 Nameplate, Vinyl

9 06-3087 Label, Check Valve

10 07-0582 Clamp, Pump/Motor, SS

11 17-0611 Check Valve, Vented

12 18-0310 Regulator, Water

13 21-0752 Power Cord

14 30-10368 Bracket, Pressure Valve

15 30-10369 Plate, Base Pump

16 52-3062 Harness, Extension, 8 FT

17 82-3808 Enclosure Assy

18 82-3913 Motor Assy, Remote

19 86-0001 Pump, Procon, Brass

20 15-0035 Tape, Teflon

21 01-2701 Adapter, PL

29

P.N. 28-0720/05

Page 30

5.3 TOWER ASSEMBLY, BEVARIETY MVU

12

32

(Female)

to bin switch

(Male)

to power source

white wire

20

8

1

See Detail A

17

8

29

19

34

30

9

14

10

3

4

7

See Detail B

35

33

15

11

16

13

Plug ribbon cable from

Item 13 onto either

connector on Item 8

2

F PW E D C CW B (A)

19

5

6

Diagram

Front Plumbing

5

18

6

31

Detail B

E - Blue 27

F - Brown 28

C - Orange 25

23 A - Yellow

B - Red 24

21 Soda- Black

26 D - Green

22 Water - White

3

Detail A

Harness Connections

P.N. 28-0720/05

30

Page 31

5.3 TOWER ASSEMBLY, BEVARIETY MVU - PARTS LIST

ITEM PART NO. DESCRIPTION

1 30-10098 Structure, MVU Tower

2 51-6259 Weldment Assy, Front Cover

3 17-0622-1 Body Assy, Solenoid, 2-Pack

4 17-0622-2 Body Assy, Shut-off, 2-Pack

5 17-0623-1 Body Assy, FC, 3.0, Syrup

6 17-0623-2 Body Assy, FC, 3.0, SY/WTR

7 04-0481 Scr, 8-32x1.125, PH, PH/SL, RL

8 64-5011/02 PCB Assy, Controller, MVU

9 49-0318/01 Sub-Assy, Nozzle, Bundled MVU

10 05-2687 Plate, Nozzle, MVU

11 05-2682 Bracket, Cover Mount, MVU

12 54-0464 Cover Assy, MVU

13 52-3160 Panel Assy, ID, MVU

14 04-0236 Scr, 10-24 x .375, PHD, PH, MS, S

15 04-0470 Scr, 6-19 x .500 PHD, PH/SL, PL

16 04-0267/02 Scr, 8-16 x .5, PLSTI, HHSW/SW, S

17 42-0161 Config Assy, FMD, 4A/2C, MVU

18 06-3077 Overlay, Button Board, MVU C

19 52-3169 Harness Assy, Solenoid, MVU/Bundle

20 52-3170 Harness Assy, Power, MVU/Bundle

21 06-0111 Label Soda

22 06-0112 Label Water

23 06-3127 Label, “A A A A”

24 06-3128 Label, “B B B B”

25 06-3129 Label, “C C C C”

26 06-3130 Label, “D D D D”

27 06-3131 Label, “E E E E”

28 06-3132 Label, “F F F F”

29 06-3111 Decal, Cover, Back, Bundle, MVU

30 04-0275 Scr, 8-16 x .427, THMD, PH, PLS

31 06-3125 Label, PLMB/Wire Diag, MVU

32 52-3200 Harness Assy, MVU, Bin Switch

33 50-0509/01 Insulation Foam, Nozzle Sonic

34 30-10429 Hose Bracket

35 15-0061 Grommet, Flexible

31

P.N. 28-0720/05

Page 32

5.4 MVU ASSEMBLY

11

10

5

8

6x

4

5

6

9

10

4

5

6x

7

5.5 NOZZLE, HYBRID MULTI-FLAVOR

16x

8x

1

4

6

4

4

6

ITEM PART NO. DESCRIPTION

3

2

1 05-2748 Adaptor, 1/4 Barb x Dole

2 02-0005 O-Ring, 2-010, 97-0999

3 07-0446 Clmp, STPLS, Oetkr, 13/32

4 07-0433 Clp, STPLS, Oetkr, 1/2

5 08-0523/01 MVU, Tube, Formed

6 08-0029 Tubing, Innerbrd, .250ID

7 54-0481 Nozzle, Hybrid MultiFlavor

8 05-2766 Lock, Hose, HMFN

9 01-1280/01 Tee, SS, 1/4 Barb

10 08-0526/01 Tube, Formed, MVU, Inj, 4, 3

11 88-0013 Insul, Tubular, .375ID x .25

12 15-0012 Tape, Blk Duct, 2” (not shown) - wrap

around Item 11 (insulation tube)

junction.

4

3x

ITEM PN DESCRIPTION

1 54-0480 Injector Assy, Syrup, HFMN, 4

2 05-2746/01 Nozzle, Body, Inner, HMFN

3 05-2745 Nozzle, Body, Main, HMFN

4 04-0269 Scr, 8-16x.375, PHD, PH/SL, PL

P.N. 28-0720/05

6

7

5

3

2

ITEM PN DESCRIPTION

5 02-0232 O-Ring, 2-030, 97-0999

6 03-0449 Plate, Nozzle, Locking, HMFN

7 05-2693 Cap, Inlet, Water HMFN

8 05-2699 Outer Nozzle, Overmold, HMFN

32

1

6x

8

Page 33

5.6 ICE COOLED UNIVERSAL WIRING DIAGRAM WITH BIN LID SWITCH

BLACK

WHITE

WHITE

KEY

BLACK

LOCK

WATER SPIGOT

BLACK

F

F

ORIGINAL

POWER SUPPLY

SOLENOID

ICE COOLED UNIVERSAL

F

WIRING DIAGRAM WITH BIN LID SWITCH

F

F

F

SYRUP OUT

LIGHT KIT

PRESSURE SWITCH

3F

3M

ON SPRITE VALV E

REPLACES INTERNAL

CHERRY SWITCH HARNESS

FY

F

F

BLACK

2F

2M

BLACK

1

2F

2

2F

34

2F

2F

2M

5

2F

6

2F

WHITE

VALV E MANIFOLD HARNESS

BLACK

WHITE

WHITE

F

M

F

Y

F

WHITEMWHITE

F

F

2M

2F

IN CONJUNCTION WITH

THIS HARNESS IS NOT USED

2F

2M

2F

ALTERNATE POWER SUPPLY

2F

2M

OR

ALTERNATE

2F

2M

POWER SUPPLY

MARQUEE

BIN

78

2F

SWITCH

MERCHANDISER

: FEMALE BLADE RECEPTACLE

F

: MALE BLADE

M

: "Y" CONNECTOR (2 MALES, 1 FEMALE)

: 2 PIN FEMALE CONNECTOR

: 2 PIN MALE CONNECTOR

: 3 PIN MALE CONNECTOR

: 3 PIN FEMALE CONNECTOR

Y

3F

2F

2M

3M

WATER SPIGOT

BUTTON

2F

33

P.N. 28-0720/05

Page 34

5.7 ICE COOLED UNIVERSAL WIRING DIAGRAM WITH BIN LID SWITCH AND MVU

BLACK

WATER SPIGOT

BLACK

F

F

SOLENOID

WHITE

KEY

LOCK

BLACK

WHITE

ORIGINAL

POWER SUPPLY

ICE COOLED UNIVERSAL

F

WIRING DIAGRAM WITH BIN LID SWITCH

F

F

F

SYRUP OUT

LIGHT KIT

PRESSURE SWITCH

3F

3M

ON SPRITE VALV E

REPLACES INTERNAL

CHERRY SWITCH HARNESS

FY

F

F

BLACK

2F

2M

BLACK

1

2F

2

2F

3

2F

2M

6

2F

WHITE

VALV E MANIFOLD HARNESS

WHITE

MVU

CONTROL BOARD

BLACK

WHITE

WHITE

F

M

F

Y

F

M

WHITE

WHITE

F

F

2M

2F

IN CONJUNCTION WITH

THIS HARNESS IS NOT USED

2F

2M

2F

ALTERNATE POWER SUPPLY

2F

2M

OR

ALTERNATE

2F

2M

POWER SUPPLY

MARQUEE

BIN

78

2F

SWITCH

MERCHANDISER

: FEMALE BLADE RECEPTACLE

F

: MALE BLADE

M

2F

: "Y" CONNECTOR (2 MALES, 1 FEMALE)

: 2 PIN FEMALE CONNECTOR

: 2 PIN MALE CONNECTOR

: 3 PIN MALE CONNECTOR

: 3 PIN FEMALE CONNECTOR

Y

3F

2M

3M

P.N. 28-0720/05

WATER SPIGOT

BUTTON

2F

34

Page 35

5.8 ACCESSORIES

Illuminated Merchandiser

PN 85-2304

Splash Guards Kit

PN 82-3899

Illuminated Marquee

PN 85-2302-20

Water Spigot for Ambient

Temperature Water Kit

PN 82-3903

35

P.N. 28-0720/05

Page 36

LANCER

To order parts, call

Customer Service: 800-729-1500

Warranty: 800-729-1550

Email: custserv@lancercorp.com

www.lancercorp.com

Loading...

Loading...