Page 1

Pn

USER'S

AGILENT

Washer : 1600

Serial

Tag

LANCER

30,

31170

INDUSTRIE

_

Zi

de

Pahin

Blvd

de

l'industrie

TOURNEFEUILLE

FRANCE

Number : 62070049

Name : 09-GW-001

MANUAL

TECHNOLOGIES

PRO

DPSS

LANCER

3543

State

WINTER

FLORIDA

USA

Road

SPRINGS

32708

USA

=

INC.

419

ㆍ

00

ISSUE

WRITTEN

07

Dec.

DATE

BY

2006 | Creation

|

TP

TE

MODIFICATIONS

CHECKED

BY

LANCER

PI

一

MIL

AnitlantRR

RIN7NNAO

NO

dine

Pana

41

AR

Page 2

AGILENT

TECHNOLOGIES

|

ae,

の

PRECAUTIONS

Users

must

be

trained

The

staff

that

use

maintenance.

loading

The

staff

washer,

instructions

The

training

the

washer. A written

understanding

This

and

unloading

in

contact

must

have

about

of

of

the

before

or

repair

training

of

the

with

the

knowledge

the

dangers

users

and

register

the

interested

TO

using

the

this

washer

must

include

baskets

and

detergent

of

the

safety

and

the

detection

technicians

of

these

parties.

BE

washer.

must

have

the

selection

the

handling

products.

data

must

training

must

TAKEN

followed a complete

and

of

and

its

sheet

of

of

toxic

product

be

done

be

BEFORE

understanding

the

washing

emanations,

the

used

leaks.

regularly

kept

in

order

training

of

products.

which

products

and

always

to

prove

USE

referring

the

washing

could

be

as

well

before

the

presence

used

as

the

the

its

use

cycle,

in

detailed

first

use

and

and

the

this

of

the

Ex

|

|

NU.

Aailent66..62070049.

00.doc

Paae

2/48

Page 3

AGILENT

TECHNOLOGIES

SUMMARY

a

LANCER

CHAPTER

1.PRO

2.USER'S

CHAPTER

1.PRESENTATION

11

12

2.0PENING

3.SAFETY

31

32

33

4.WASHING

44

You

is

4.2

1

WASHERS

MANUAL

2

LOADING

UNLOADING

OF

ADVICES

PRECAUTIONS

MAXIMUM

USE

PRODUCTS

PRODUCT

will

put the

most

important

INSTRUCTIONS

INTRODUCTION

BEFORE

OF

SIDE

INSTRUMENT

SIDE

THE

DOORS

FOR

CHARGE

TANK

product

tanks

than

the

YOU

THE

CONTROL

INSTRUMENT

USE

AREA

outside

standard.

TO

RESPECT

START

PANEL

PANEL

the

washer

IN

CASE

PANEL

if

the

volume

OF

HANDLING

exceeds

THE

WASHING

the

casing

or

PRODUCTS

the

product

tanks

number

Gi

om

~

co

ο

ο

11

11

11

12

13

13

13

13

u

43

INSTRUCTIONS

44

CHANGE

5.PRINTER

5.1

PRINTER

5.2

CHANGE

5.3

CHANGE

6.USING

CHAPTER

61

6.2

OF

THE

CHOICE

PIECES

3

1.LAUNCHING

TO

RESPECT

OF

THE

TANKS

VERIFICATION

OF

THE

PAPER

OF

THE

RIBBON

ACCESSORIES

OF

ACCESSORIES, BASKETS

TO

BE

WASHED

USING

A

CYCLE

ROLLER

CARTRIDGE

YOUR

IN

CASE

OF

AND

WASHER

CHANGING

RACKS

|

THE

PRODUCT

FORMULA

u

14

15

15

16

17

18

18

18

19

20

NU

Agilent66

62070049

00.doc

Page

3/48

Page 4

AGILENT

TECHNOLOGIES

11

SWITCHING

ON

má

LANCER

|

20

1.2

DESCRIPTION

1.3

EXAMPLE

2.MAIN

3.CYCLE

4.

INFORMATION

5.END

6.WASHING

7.PASSWORDS

MENU

START

3.1.

41

OF

51

5.2

5.3

7.4.

72

How

to

CYCLE

THE

OPENING

END

SWITCHING

PROGRAMS

HOWTO

HOWTO

OF

THE

OF

HOW

TO

MENU

launch a washing

DURING

INFORMATION

CYCLE

OF

THE

DOORS

OF

CYCLE

OFF

CHANGE

CHANGE

YOUR PASSWORD.

YOUR

ACCESS

ENTER

cycle.

THE

WHEN

ID

SCREEN

PROPERLY

CYCLE

THE

CYCLE

ID

AND

PASSWORD

IS

RUNNING

TO

GET

THE

LOG

IN:

21

22

23

24

24

25

26

28

28

28

30

30

34

36

E

デュ

CHAPTER

1.PRINTER

1.1

2.CONDUCTIVITY

24

2.2

4

TRACEABILITY

Print

out,

ticket

size.

METER

USE

AND

ADJUNTMENT

MEASURING

OF

THE

(FINAL

CONDUCTIVITY

RINSE & CHEMICAL

CHAPTER 5 MAINTENANCE

1.DRYING

2.CHAMBER

3.EXTERNAL

4.PREVENTIVE

AIR

FILTERS

FILTERS

MAINTENANCE

MAINTENANCE

OF

THE

CHAPTER 6 ALARMS

1.ALARMS

LIST

OF

THE

WASHER

VERIFICATION)

WASHER

37

38

38

40

40

40

41

42

42

43.

45

46

2.HOW

NU

Agilent66

TO

PROCESS

62070049

00.doc

TO

CLEAR

AN

ALARM

Page

4/48

48

Page 5

AGILENT

TECHNOLOGIES

Sia

LANCER

€

CHAPTER

You

have

in

Its

good

working

You

will

find

have

been

written

Before

This

also

using

manual

find

the

1

your

INTRODUCTION

possession a LANCER

and

your

entire

here.

some

advices

in

your

interest.

your

washer,

has

been

description

learn

conceived

of

the

washer.

satisfaction

about

to

know

with

different

depend

the

use,

it

and use

the

purpose

chapters

on

the

the

loading

it

rightly,

of

introducing

included

in

attention

and

so

this

you

the

maintenance.

as

to

it

can

to

you

utilization

pay

when

develop

the

PRO

manual.

reading

Follow

its

tasks

washer

range,

this

guide.

them,

many

as

they

years.

you

will

fo

1

PRO

WASHERS

2

USER'S

NU_Agilent66_62070049_00.doc

MANUAL

Em

.

Page

5/48

Page 6

em

AGILENT

TECHNOLOGIES

1.

PRO

Your

industry

latest

The

The

WASHERS

PRO

washer

for

high

performance

requirements.

FDA

basic

characteristics

-

the

quality

-

the

quality

-

washing

-

the

~

traceability.

PRO

washers

in

simplicity

has

been

of

of

washing

of

the

construction

various

of

use

are

developed

specially

washing

the

PRO

modulabie

developed

range

(mechanical

and

manufactured

to

and

disinfection

are:

and

microbiological

materials

levels

following

meet

the

systems

3

increasing

which

action)

the

demand

satisfy

and

standards.

E

of

Lancer

of

the

cGMP

drying

pharmaceutical

guidelines

and

the

ED

A

“CE

conformity

declaration”

is

delivered

with

the

machines.

Em

NU_Agilent66_62070049_00.doc

É

Pace

6/48

Page 7

SIR

AGILENT

TECHNOLOGIES

2.

USER’S

The

This

MANUAL

present

only

manual

concerns

is

destined

the

operations

to

facilitate

to

be

done

the

operations

by a level 1 code

of

use,

handle,

owner.

LANCER:

maintenance

and

repair.

att,

Before

and

Respecting

operations

This

You

Chapter 2 will

Chapter 3 describes

Chapter 4 present

Chapter 5 describes

keep

Chapter 6 is a description

using

your

washer

recommendations.

the

described

manual

have

it

just

in

good

is

divided

ended

familiarize

state

Follow

precautionary

in

the

in 6 chapters,

the

reading

yourself

step

your

traceability

the

operations.

as

long

and

manual.

by

step

possible.

of

the

in

order

to

them,

as

they

measures

completed

of-chapter

with

your

the

washing

system

of

internal

different

obtain

the

have

been

of

use,

the:

by

an

1.

washer

process,

available

and

alarms

that

best

service

written

washer

appendix.

in

order

to

use

of

launching. a cycle

in

the

washer.

extemal

you

maintenance

could

read

in

your

must

.

it

find

carefully

interest.

only

be

as

correct

at

of

when

using

the

following

used

for

as

possible.

the

end

your

washer

your

washer.

the

of

this

advices

washing

one.

in

order

to

PEN

All

over

this

manual,

information.

When

you

see

NU_Agilent66_62070049_00.doc

this

icon,

we

have

it

incorporated

means:

:

ATTENTION ! !

brief

comments

PAY

and

SPECIAL

icons

to

help

ATTENTION

you

!!

locate

the

-

Page

important

7/48

Page 8

AGILENT

TECHNOLOGIES

Ea

LANCER

©

CHAPTER2

After

having

with

this

one.

You

will

find

and

avoid

material

1

PRESENTATION

OPENING

N

SAFETY

ο

4

WASHING

5

PRINTER

BEFORE

installed

in

this

chapter

and

OF

THE

ADVICES

PRODUCTS

rightly

your

all

corporal

OF

THE

DOORS

YOU

washer,

the

information

damage.

CONTROL

START

following

PANEL

the

installation

of

indispensable

manual,

knowledge

you

to

can

begin

assure

the

to

familiarize

good

working

6

USING

NU

Agilent66

OF

THE

62070049

ACCESSOIRES

00.doc

Page

8/48

Page 9

AGILENT

TECHNOLOGIES

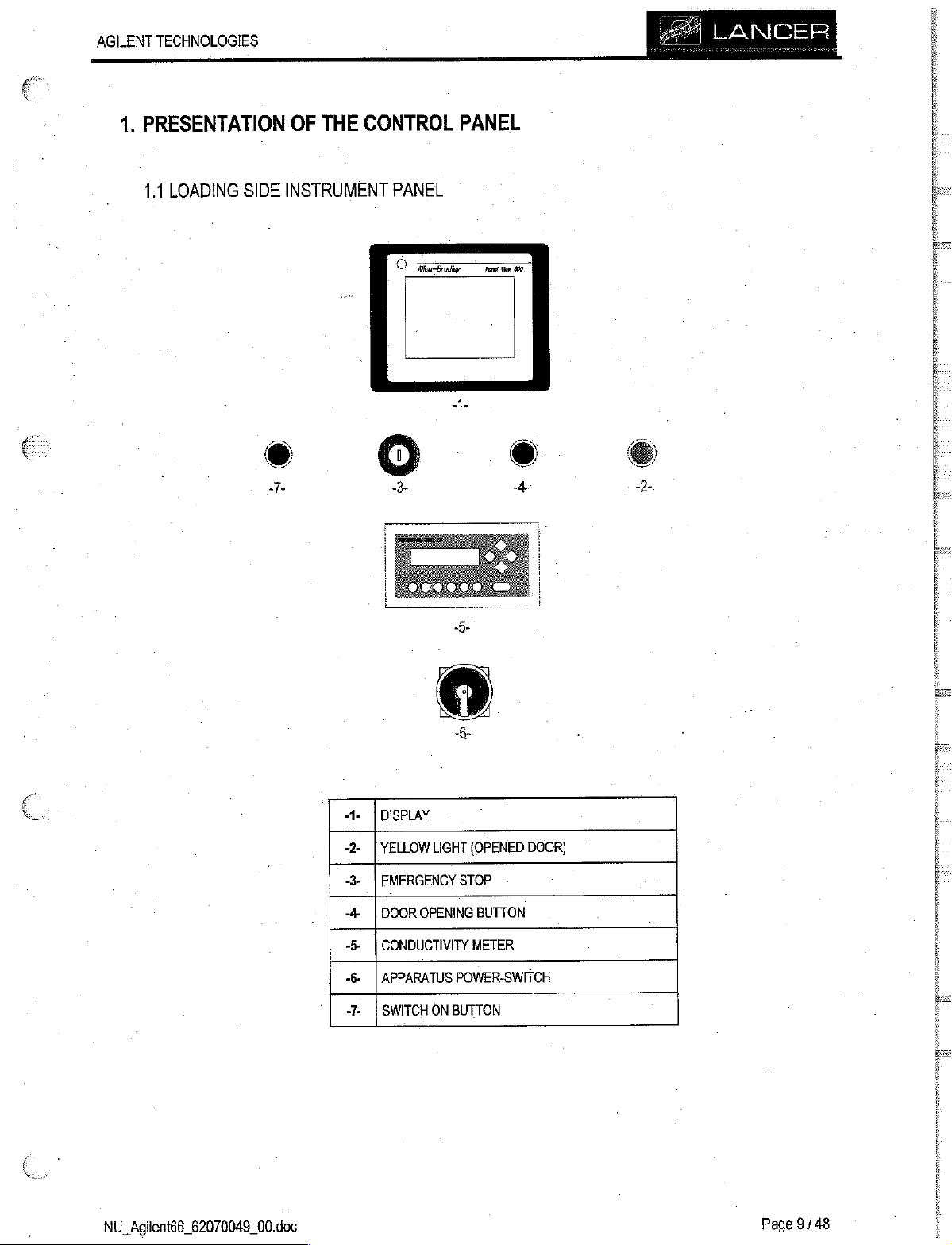

1.

PRESENTATION

1.1

LOADING

OF

SIDE

INSTRUMENT

THE

CONTROL

PANEL

O

му

LANCER

PANEL

aaa

DISPLAY

YELLOW

-- | EMERGENCY

-4 | DOOR

-5 | CONDUCTIVITY

-6- | APPARATUS

-7- | SWITCH

OPENING

-

LIGHT

(OPENED

STOP

BUTTON

METER

POWER-SWITCH

ON

BUTTON

DOOR)

@

Ñ

字

O

Page

NU. Agilent66

62070049

00.doc

9/48

Page 10

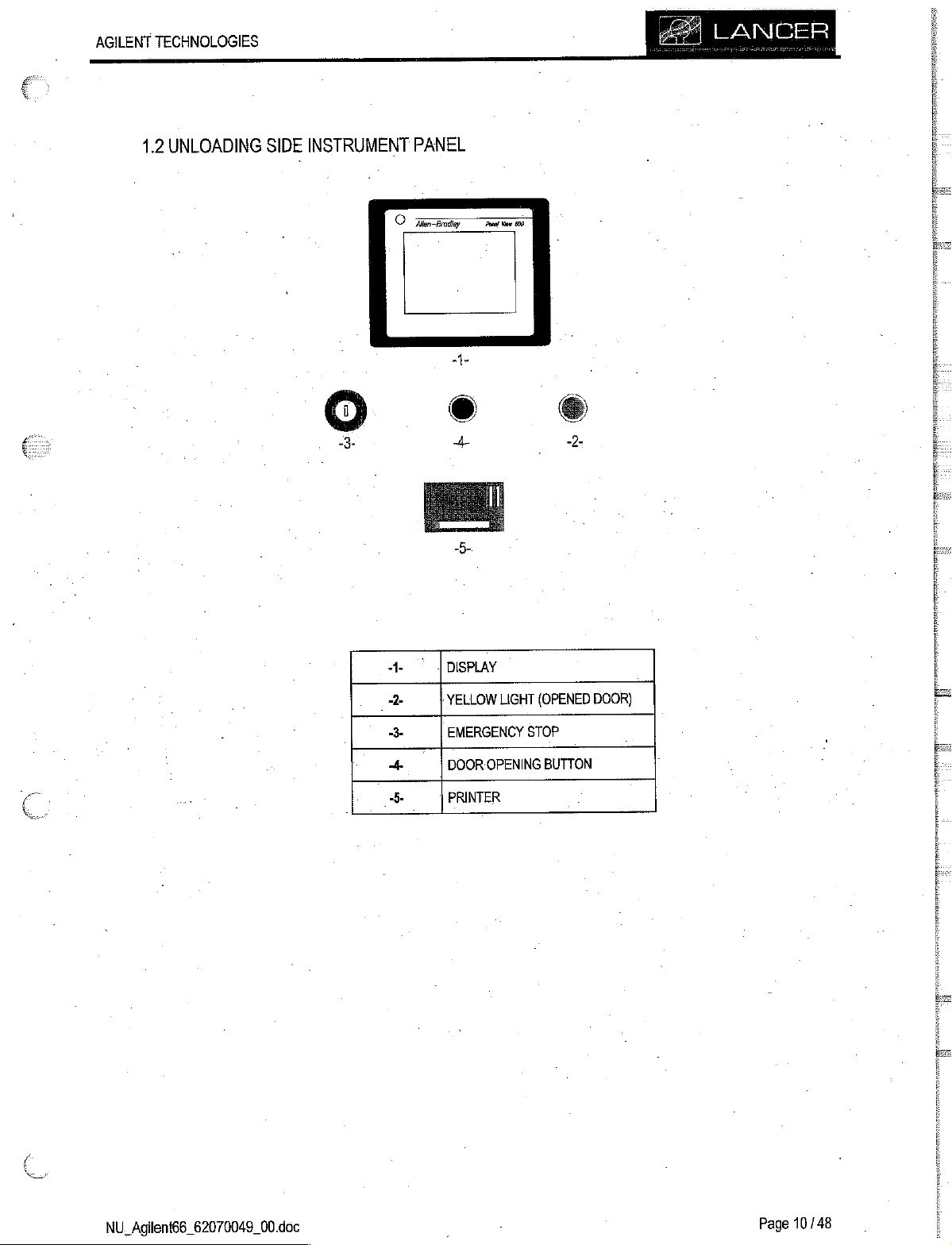

AGILENT

TECHNOLOGIES

1.2

UNLOADING

SIDE

INSTRUMENT

О

PANEL

mamás

Taraf

Var

600

gø"

LANCER

|=

é

C

Xe,

κ.

à

О

3

4.

2

3

4

5

a

oe

4

El

5-

|

DISPLAY

YELLOWLIGHT

|

__

EMERGENCY

|

DOOROPENING

PRINTER

é

2

(OPENED

STOP

BUTTON

DOOR)

|

=

だ

ων

Agilent66_62070049_00.doc

NU.

10/48

|

Раде

Page 11

Aim,

AGILENT

2.

TECHNOLOGIES

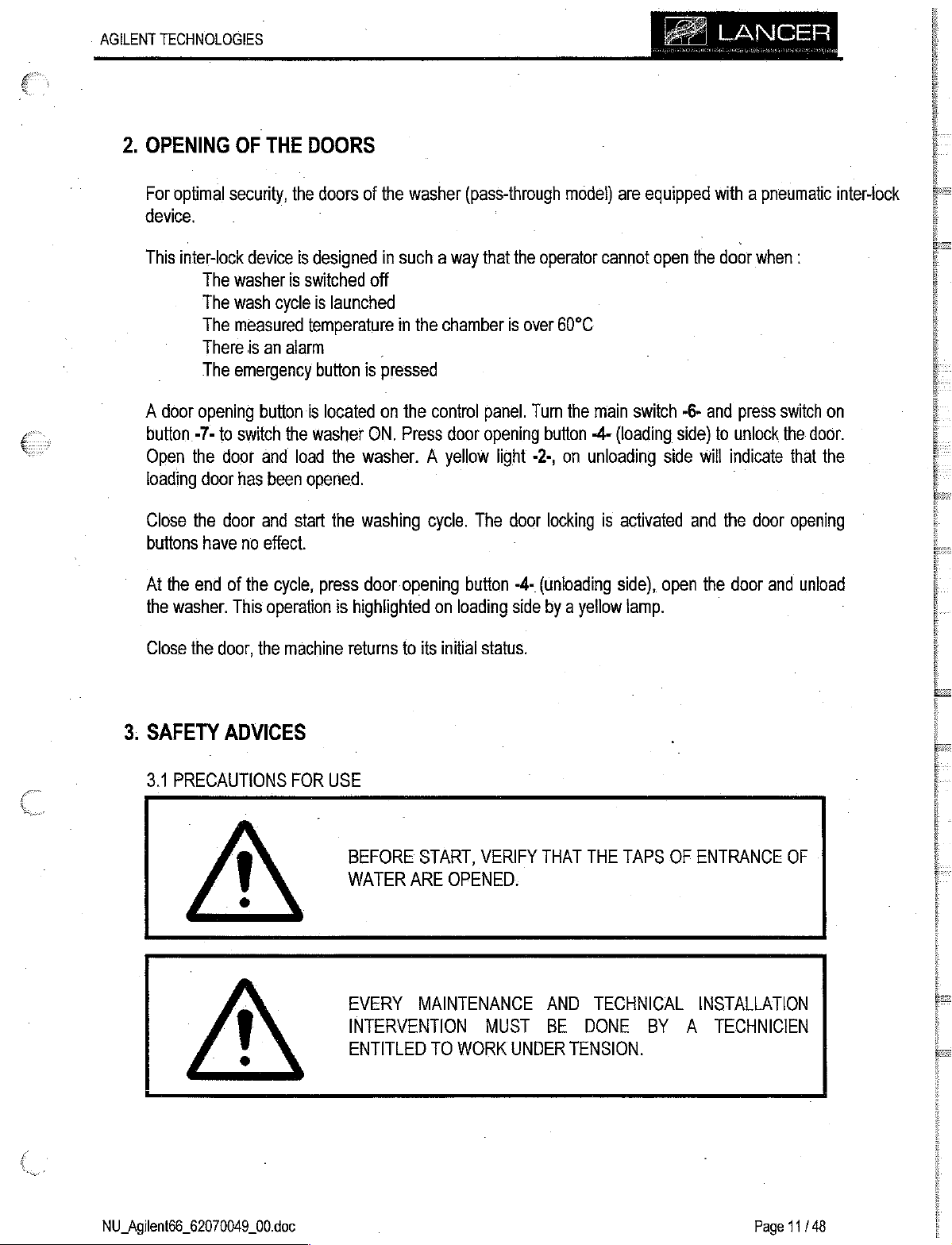

OPENING

For

optimal

device.

This

inter-lock

The

The

The

There

The

A

door

opening

button

Open

loading

-7-

the

door

to

OF

THE

security,

washer

wash

measured

emergency

switch

door

has

the

device

is

is

is

cycle

an

alarm

button

the

and

load

been

DOORS

doors

of

the

designed

switched

is

launched

temperature

button

is

located

washer

the

opened.

in

such a way

off

in

-

is

pressed

on

ON.

washer. A yellow

washer

the

chamber

the

control

Press

door

(pass-through

that

the

is

panel.

opening

light

model)

operator

over

60°C

Turn

the

button

-2-,

on

are

equipped

cannot

main

-4-

unloading

open

switch

(loading

side

with a pneumatic

the

door

when

-6-

and

press

side)

to

unlock

will

indicate

:

switch

on

the

door.

that

the

inter-lock

|

=

Close

buttons

At

the

Close

3.

SAFETY

3.1

the

door

and

have

no

effect.

the

end

of

the

washer.

the

This

door,

the

ADVICES

PRECAUTIONS

start

the

cycle,

press

operation

machine

is

returns

FOR USE

BEFORE

WATER

washing

door

highlighted

cycle.

opening

on

to

its

initial

START,

ARE

OPENED.

The

door

button

loading

-4-

side

status.

VERIFY

locking

(unloading

by a yellow

THAT

is

activated

side),

lamp.

THE

TAPS

and

open

OF

ENTRANCE

the

the

door

door

opening

and

unload

OF

NU

Agilent66

62070049

00.doc

EVERY

INTERVENTION

ENTITLED

MAINTENANCE

TO

WORK

MUST

UNDER

AND

TECHNICAL

BE

DONE

TENSION.

BY

INSTALLATION

A

TECHNICIEN

Page

11/48

Page 12

£m,

AGILENT

TECHNOLOGIES

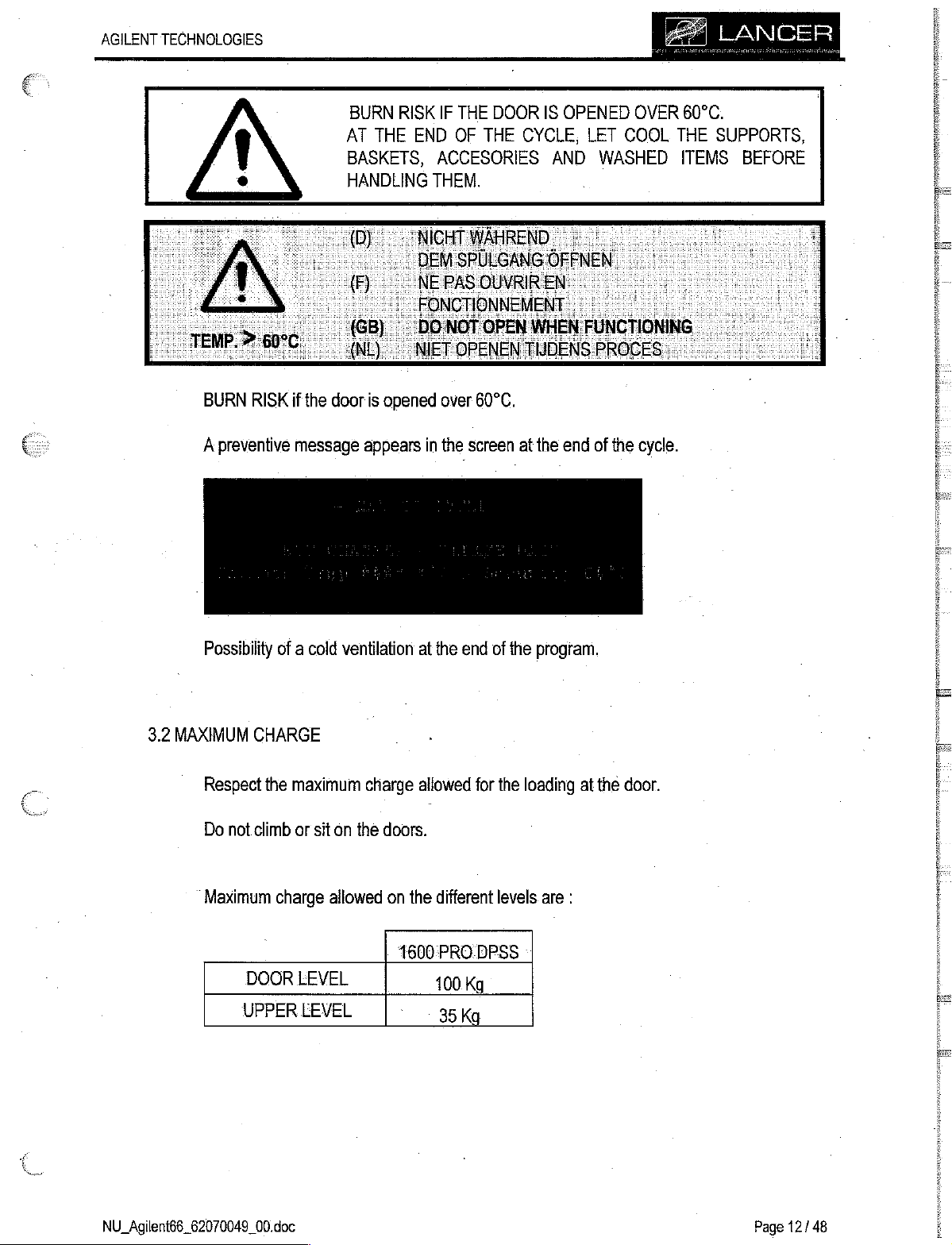

TEMP. > 60°C.

BURN

RISK

A

preventive

AT

BASKETS,

HANDLING

(D)

NL)

if

the

door

message

BURN

RISK

THE

IF

THE

END

OF

THE

ACCESORIES

THEM.

DOOR

MGHTWAHREND

_DEM

SPULGANG

(F)

o

(GB)

is

appears

NEPASOUVRIREN

(OFONCMONNEMENİ

DO

NOT

OPEN

OPENEN

NIET

opened

over

in

the

60°C.

screen

IS

OPENED

CYCLE;

LET

AND

©

OFFNEN

-

o

WHEN

TIJDENS

at

FUNCTIONING

PROCES

the

end

of

OVER

COOL

WASHED

the

cycle.

*|

LANCER

60°C.

THE

SUPPORTS,

ITEMS

|

|.

BEFORE

E

E

3.2

MAXIMUM

Possibility

Respect

Do

not.climb

‘Maximum

of a cold

CHARGE

the

maximum

charge

DOOR

UPPER

ventilation

or

sit

on

the

allowed

LEVEL

LEVEL

charge

doors.

on

the

1600

at

the

end

allowed

for

different

PRO

DPSS

100

Ka

35

Ка

of

the

program.

the

loading

levels

are

:

at

the

door.

NU_Agilent66_62070049_00.doc

Page

12/48

Page 13

AGILENT

TECHNOLOGIES

3.3

USE

The

use

of

the

washer

of

solvents,

these

and

inflammable

Do

not

must

be

locked.

hydrocarbons,-

low

at

are

leave

the

kept

either

in

explosive

acids

concentrations),

strictly

forbidden.

door

half-open.

in

completely

atmosphere

(sulphuric,

alcohols

for

|

safety

open

position

as

well

as

the

nitric,

hydrochloric

derived

and

precautions,

and

the

or

completely

use

any

door

4,

WASHING

4.1

PRODUCT

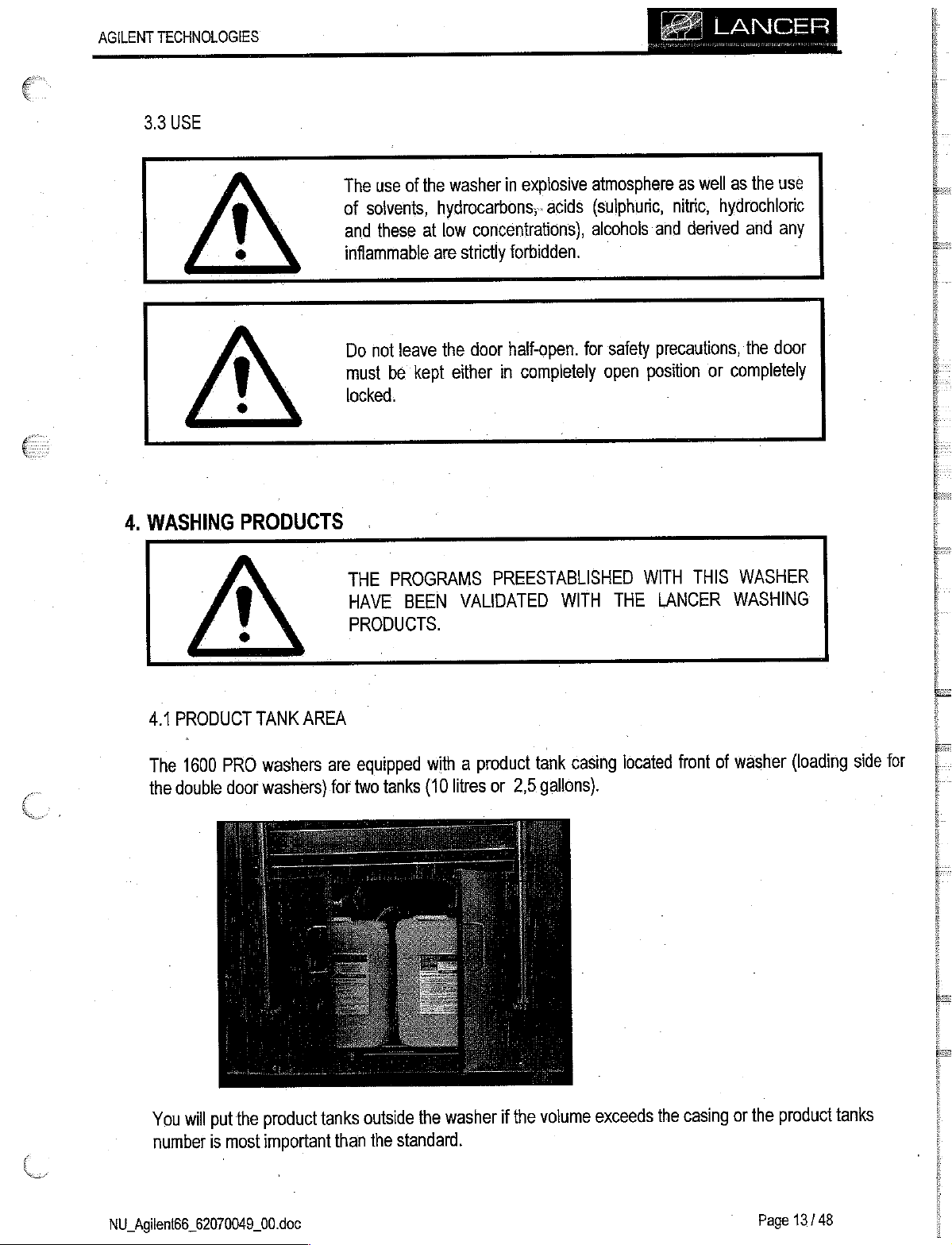

The

the

double

1600

PRODUCTS

TANK

washers

PRO

door

washers)

AREA

are

for

PROGRAMS

THE

HAVE

PRODUCTS.

two

BEEN

tanks

(10

with

equipped

PREESTABLISHED

VALIDATED

or

tank

2,5

gallons).

product

a

litres

WITH

casing

WITH

THE

LANCER

located

THIS

of

front

WASHER

WASHING

washer

(loading

side

for

product

the

put

will

You

number

NU_Agilent66_62070049_00.doc

is

most

important

tanks

than

outside

the

the

standard.

washer

the

if

volume

exceeds

the

casing

or

product

the

Page

19/48

tanks

Page 14

E

Ke

AGILENT

TECHNOLOGIES

4.2

INSTRUCTIONS

TO

RESPECT

IN

CASE

OF

HANDLING

THE

WASHING

es

LANCER

PRODUCTS

Es

ANYBODY

MUST

PRODUCTS...

4.3

INSTRUCTIONS

When a product

“corresponding

Intake

duration

to

level 3 code

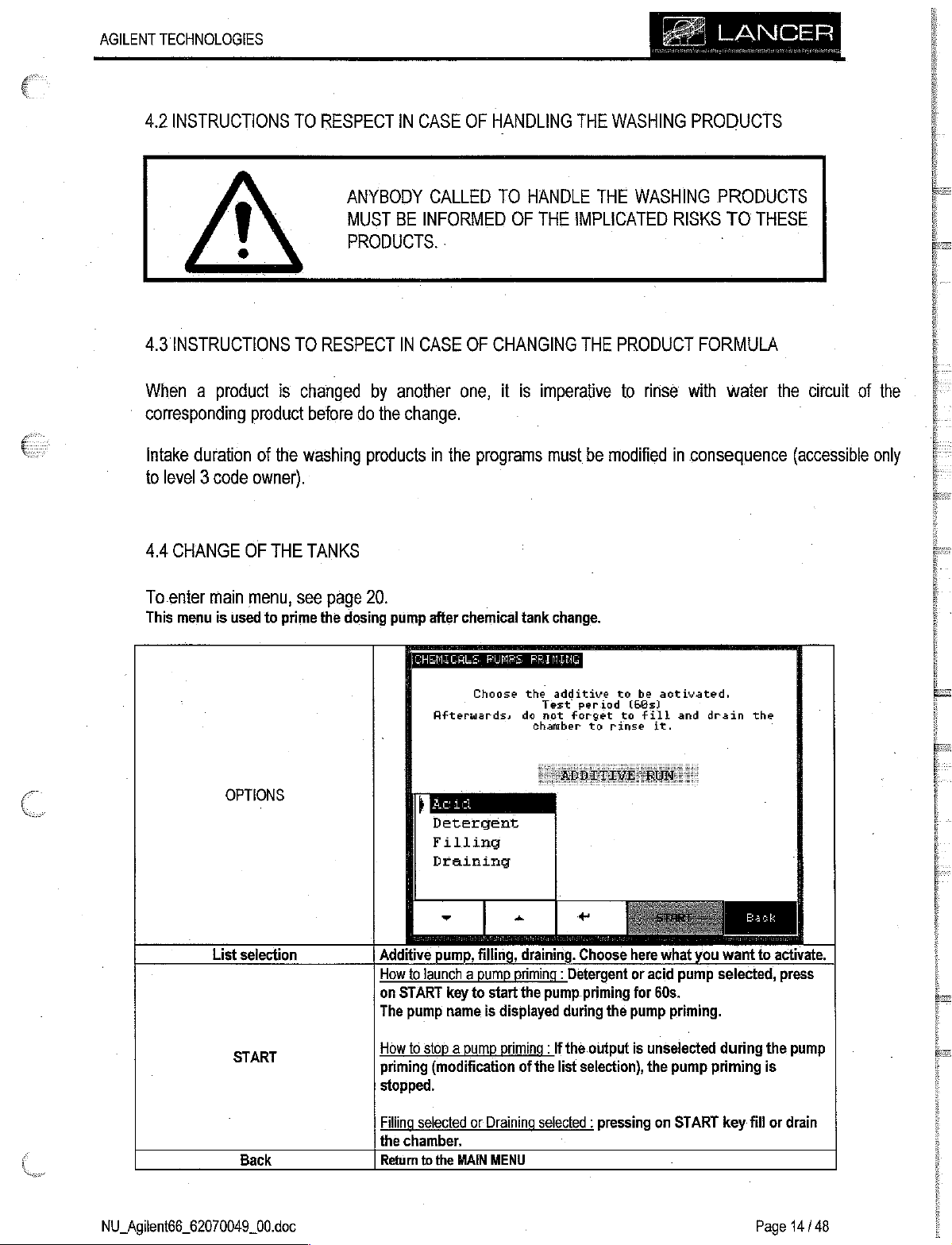

4.4

To

This

CHANGE

enter

menu

main

is

used

OF

TO

is

changed

product

of

the

washing

owner).

THE

menu,

to

see

prime

RESPECT

before

TANKS

page

the

dosing

by

do

the

products

20.

CALLED

BE

INFORMED

IN

CASE

another

change.

in

pump

after

CHEMICALS

OF

one,

thie

programs

chemical

FUMES

TO

HANDLE

OF

THE

CHANGING

it

is

imperative

must

tank

change.

FRINIHOE

THE

WASHING

IMPLICATED

THE

PRODUCT

to

rinse

be

modified

PRODUCTS

RISKS

in

TO

FORMULA

with

waiter

consequence

THESE

the

circuit

(accessible

of

=

|=

the

only

pe

E

=

έ

Nor

OPTIONS

List

selection

START

Back

Choose

Afterwards,

Detergent

Filling

Draining

Additive

How

on

The

How

priming

stopped.

Filling

the

Return

pump,

to

Jaunch a pump

START

key

pump

name

to

stop a pump

(modification

selected

chamber.

to

the

filling,

to

start

is

or

Draining

MAIN

MENU

the

additive

Test

do

draining.

priming : Detergent

the

displayed

priming : If

of

period

not

forget

chamber

the

selected : pressing

to

Choose

pump. priming

during

the.output

list

selection),

to be

to

rinse

the

(665)

here

pump

activated,

fill

and

it.

what

or

acid

pump

for

60s.

priming.

is

unselected

the

pump

on

START

drain

you

want

selected,

during

priming

key

the

to

activate.

press

the

is

fill

or

pump

drain

Ess

læ

fm

NU.

Agilent66

62070049

00.doc

Page

14/48

Page 15

AGILENT

5.

TECHNOLOGIES

PRINTER

9.1

PRINTER

VERIFICATION

#

LANCER

ть

Before

If a continual

If

consider

launching a cycle

red

the

quality

of

changing

trace

the

ink

the

or

printing

appears,

during

ribbon

replace

the

of

the

again

the

ticket,

it

by a new

precedent

printer

impression

(see

check

one

page

the

(see

of

17).

quantity

page

16).

the

ticket

of

paper

in

was-not

enough

the

roller

of

the

printer.

for a good

reading,

NU

Agilent66

62070049

00.doc

Page

15/48

ku

Page 16

AGILENT

TECHNOLOGIES

5.2

CHANGE

OF

THE

PAPER

ROLLER

There

are

printer,

latch,

Door

With

(paper

control

front

(the

towards

forefinger

latch

expose

Paper Feed

With

top

paper

as

One

the

Latch:

the

emerging

buttons

door

outermost

and

PRESS

the

part

feed

long

Figure

printer

the

the

printer

of

as the

2

two

buttons

button

other

of

the

other

(see

the

door

paper

Button.

the

innermost

(see

button

on

operates

controls

mounted

downwards}

are

at

upper

printer,

of

the

two

button,

Figure

can

roll.

in

data

Figure

1).

be

mode

2).

is

the

front

the front

the

paper

in

data

so

left,

press

buttons)

using

This

swung

attitude

button

This

held

down.

r

panel

feed.

mode

that

to

open

the

door

sideways

thumb

will

release

outwards

to

activate

will

continue

of

the

door

attitude

the

two

the

atch

or

the

to

press

the

for

Take a new

from

the

or

gummed

end

squarely

leaving a clean

printer

Figure

Thread

onto

the

an.

anticlockwise

the

open

feed

actuator

until

the

through

5).

roll

of

paper,

rest

of

the

part

of the

with a pair

straight

mechanism.

3

roll.

Remove

paper,

of

edge

/

and

separate

and

scissors

to

any

damaged

cut

the

or a knife,

present

the

free

to

end

the

the

new

roll

past

the

spindie

end.

(See

arm

mechanism

to

the

front

with

the

direction

Figure

(at

upper

grips

of

the

retention

paper

when

4).

Press

left

the

paper

printer.

button

unspooling

viewed

in

the

data

and

(See

from

paper

mode)

pulls

Figure

in

it

LN

en,

PRESS

Paper

Open

swing

if

any

off

against

the

of

the

free

retaining

forefinger

roll.

NU_Agilent66_62070049_00.doc

|

Γ

}

πα

za

|

|

e?

Roll

Replacement:

the

printer

the

door

paper

remains

the

remaining

mechanism

end

emerges.

button

(see

0

door

open

paper

paper

mounting

inwards

figure

as

to

expose

in

the

tear

backwards,

Press

3)

and

N

rn

described

the

printer,

bar

and

chassis,

the

paper

using

the

remove

above

paper

tear

the

carefutly

from

the

until

roll

thumb

the

and

roll.

end

pull

rear

the

and

empty

Turn

wound

door.

More

pressing

.

panel.

the

paper

snugly

paper

the

(see

roll

against

may

now

paper

Figure

so

be

feed

2).

that

any loose

the

rofl.

fed

button.on

Close

through

the

Page

tums

the

printer

by

front

16/48

are

Page 17

απ,

AGILENT

TECHNOLOGIES

5.3

CHANGE

OF

THE

RIBBON

CARTRIDGE

dl

LANCER

oO

Ribbon

Tear

Open

latch

Place

mechanism

against

Caretully

vertically

released.

apart

Swing

open.

and

Press

cartridge

carefully

Cartridge

off

any

the

printer

inwards.

forefinger

the

PRESS

Figure

6

press

opposite

Do

without

the

chassis

This

ink

ribbon

down

marked

remove

paper

door

against

mounting

base

of

the

not

pull

first

releasing

will

expose

cartridge.

on

the

'PUSH'

the

Replacement;

emerging

chassis

the

by

pressing

the

lower

daor

from

and

(see

ir

door

and chassis

directions

the

back,

end

used

door

the

leaving

the

printer

of the

(see

cartridge.

until

and

catch.

ink

Figure

the

printer.

the

door

edge

of

thumb

Figure

6).

in

the

catch

chassis

the

door

mechanism

ribbon

7)

and

the

is

fully

Check

correctly

shaft,

Ensure

paper.

If

faceted

Figure

Turn

turns are

freely,

Consumables

A

two

that

seated

and

that the

necessary

disc

8).

lf

there

is

of

the

printer

pass

clearly

past

the

tear

shut

against

the

paper

wound

Close

the

using

consumables

available

is

recommended,

other

printer

causing

containing

Epson

sources

housing, and

dust

the

ribbon

over

snap

the

ribbon

tighten

clockwise

some

paper

mechanism,

through

bar

before

the

back

roll

snugly

door

and

the

paper

available

pack

ribbon

are

and

cartridge

the

printer

cartridge

is

taut

the

ribbon

using

protruding

ensure

the

guide

snapping

of

the

door.

by

hand

so

against

check.that

feed

button.

(Stock

No.

five

49m

cartridges.

as

most

paper

too

large

to

may

be

wear.

spindle

ribbon

into

and

by

fingernail

channel

that

the

the

A160CBP)

rolls

Use

fit

of

inferior

place.

paralie!

turning

(see

from

the

that

it

the

chassis

any

roll.

paper

of

paper

of

this

rolls

from

within

quality

is

drive

and

loose

the

to

the

front

will

flows

is

and

paper

the

Figure

7

Fit a replacement

paper

lies

between

Printer

NU_Agilent66_62070049_00.doc

platen.

cartridge,

the

ribbon

ensuring

and

the steel

that

the

Page

17

/48

Page 18

AGILENT

6.

USING

6.1

6.2

TECHNOLOGIES

OF

THE

CHOICE

PIECES

OF

ACCESSORIES,

THE

CHOICE

In

the

case

lower

than

during

The

the

washing

mechanical

indispensable

items

with a cover

TO

BE

Place

the

items

other

during

grille

(GC)

ACCESSORIES

BASKETS

OF

ACCESSORIES,

of

flasks

washing,

the

flow

capacity

cycle. A narrow

to

use

WASHED

correctly

the

washing

or

an

injector

action

of

baskets

grille

(GC)

cycle.

cover

on

it

is

of

the

the

jet

with

or

an

or

in

Check

grille

AND

RACKS

BASKETS

very

important

flasks

to

be

neck

hindering

is

absorbed

injectors

injector

the

(GCI).

of

suitable

cover

baskets

that

they

AND

RACKS

that

washed

the

by

grille

or

racks

are

IS

VITAL.

the

flow

rate

in

order

to

fast

draining

the

water

contained

diameter

(GCI).

correctly

and,

so that

they

positioned,

of

the

avoid

of

water

above

do

LAN

injectors

gradual

not

secure

filling

gives

in

the

alll,

to

strike

CER

used

must

of

the

mediocre

glassware.

secure

them

lightweight

one

against

with a cover

be

flasks

results.

It

is

the

~

You

should

into

service,

Close

the

only

use

our

technicians

door,

and

baskets

will

the

washing

IF

THE

KG

THERE

that

are

suitable

give

you

cycle-can

LOADINGS

IS

PLACE

for

the

useful

advice

begin.

TO

BE

HANDLED

TO

USE A HANDLING

parts

to

on

the

be

washed.

best

way

ARE

When

to

load

SUPERIOR

SYSTEM,

your

it.

TO

washer

25

is

put

NU_Agilent66_62070049_00.doc

Page

18/48

Page 19

AGILENT

TECHNOLOGIES

E

LANCER

CHAPTER

This

chapter

You

will

find

the

proposed

1

LAUNCHING

2

MAIN

MENU

3

CYCLE

3

USING

has

been

written

here

the

process

programs,

OF A CYCLE

START

MENU

as

YOUR

in

order

of

launching

well

as

WASHER

to let

the

handling,

you use

of

the

washing

which

your

washer.

cycles

is

necessary

appropriated.

to

make

to

at

the

the

end

materials

of

the

to

cycle.

wash

following

=

wm,

4

INFORMATION

5

END

6

WASHING

7

PASSWORDS

NU

Agilent66

OF

CYCLE

PROGRAMS

62070049

DURING

00.doc

THE

CYCLE

Page

19/48

Page 20

AGILENT

4.

TECHNOLOGIES

LAUNCHING A CYCLE

1.1

SWITCHING

ON

Tum

the

Press

main

switch

switch

on

button

-6-.

-7-.

HA

LANCER

Displayed

Displayed

during

after

ΠΜ

ΠΕ,

the

initialization.

the

initialization.

O

NU_Agilent66_62070049_00.doc

Page

20/48

=

Page 21

an,

AGILENT

TECHNOLOGIES

1.2

DESCRIPTION

OF

THE

ACCESS

NN

SCREEN

LANCER

本

il

<

o

SYSTEM

WARNING

PASSWORD

COUNTER

MESSAGE

WASHER

OPTIONS

BANNER

LOCK

WARNING

1D

DESCRIPTION

Display

interface.

3

When

This

three.

SYSTEM

Identification

Range: 1 to 8 alphanumeric

Password

Range: 1 to

Login

This

2

Technical

the

messages:

.

"ACCESS'

.

ID

.

'ACCESS'

this

message

LOCKED - CALL

attempt

count

e

Awrong

e

Password

Indicate

MODEL

PLC program

Side:

the

messages:

.

.

ENTER

ENTER

AHH

loading

last

error

occurred

ERROR - PLEASE

must

be

entered

ERROR - LAST

message

number.

12

increased

service:

is

is

displayed

number.

alphanumeric

counter,

ID

is

limit

awaited

action.

YOUR

YOUR

188488 - ΘΝΗΗΗΗΗΗΗΗΗ

Phone & Web

version,

or

unloading

before

displayed,

when

THE

characters.

when:

entered.

entry

"ID'

PASSWORDITIME

Panel

side.

during a login

TRY

AGAIN

PASSWORD

TRY

for

ID&PASSWORD

the

login

is

the

login

attempt

ADMINISTRATOR

characters.

timer

elapsed.

REMAINING:

site.

program

version

attempt

possibie

counter

.

at

login

for

60s

on

the

supervisor

is

equal

-

the

operator

or

only.

higher

to

NU_Agilent66_62070049_00.doc

Page

21 / 48

Page 22

AGILENT

TECHNOLOGIES

1.3

EXAMPLE

OF

HOW

TO

ENTER

Press

Enter

Press

fo

valid.

PROPERLY

on

the

ID

the

ID.

ENTER

button.

key

the

ID

AND

PASSWORD

The

message

TO

GET

banner

LANCER

THE

LOG

IN:

Enter

valid.

Press

Press

on

the

the

ID.

the

ENTER

ID

button.

key

to

am,

E%

if

the

Two

The

PASSWORD

failed

attempts

message

is

detected,

The

banner

indicates

not

defined,

wait a password

main

ος

it

is

A

third

menu

the

κο

the

is

to

entry

display

icates

last

try to

error

is

displayed

the

PASSWORD

remains

in

known.

to

entry

the

entry

the

done.

Press

on

the

PASSWORD

Enter

the

PASSWORD.

Press

the

ENTER

to

valid.

number.

Press

on

the

PASSWORD

Enter

the

PASSWORD.

Press

the

to

the

ID

ENTER

valid.

same

state

Ifthe

password

recognized

the

available

then

the

login

counter

is

The

message

'ACCESS'

PLEASE

TRY

displayed.

ID

number

and

the

button.

key

button.

key

and

still

is

but

it

is

not

password

attempt

increased.

ERROR

—

AGAIN

is

PASSWORD.

Blo

The

message

banner

Ifthe

TE

CH

still

ID

is

not

defined

indicates

The

login

attempt

counter

ACCESS

is

displayed.

the

ID

buiton.

ID.

ENTER

attempt

ACCESS'

TRY

key

counter

is

to

entry

the

increases.

The

message

ERROR — PLEASE

AGAIN

ID

number.

Press

on

Enter

the

Press

the

valid.

The

login

is

increased.

The

message

ERROR — LAST

ID&PASSWORD

displayed.

TRY

to

for

|

NU

Agilent66

62070049

00.doc

The

login

attempt

is

equal

Then

the

to

only

can

sysiem.

the

counter

three.

supervisor

unlocked

Page

22/48

Page 23

AGILENT

TECHNOLOGIES

ae

ο.

¿er

2.

MAIN

Through

EMS

CYCLE

MENU

OPTIONS

Config

Back

this

menu,

START

Screen

MENU

the

user

can

have

access

DFTION

SUP/WATER

SUP/FILLING

- e

DESCRIPTIONS.

.

Launching a cycle

This

selector

Use

arrow

This

brings

Brings.

you

list

keys

up

the

back

to

to

to

|

gives

access

scroll

around

PanelView

the

previous

the

functions

HEATING

|

to

the

and

600

screen,

corresponding

[ulss

seen

it)

JEITT

ETTINGS

SETTINGS

+

available

enter

configuration

as

key

which

to

is

in

the

table

display

screen.

always

to

his

access

LANCER

below.

selected

See

section

the

login

level.

Touch

to

screen.

ԤPanelView

screen,

highlight.

600

configuration’

ey

Ho

CHEMICALS

USER

TECIDOSING

TEC/TRANSMITTERS

TECITEMPERATURE

TECICONDUCTIVIMETERS

TECIPRINT & TICKET

TEC/INPUT

TEC/OUTPUTS

TEC/ALARM

SUP/PROGRAM

SUP/TRANSMITTERS

SUP/TEMPERATURE.

SUP/WATER

SUP/FILLING

SUP/DRAINING

SUP/CLOSING

SUP/COUNTERS & TIMERS

SUP/DOOR

SUPIPASSIVATION

ACCESS

STATE

LOCK

PUMPS

CODE

PUMP

CALIBRATION

TEST

HISTORY

SETTINGS

HEATING

SETTINGS

SETTINGS

VALVE

TEMPERATURE

PRIMING

CALIBRATION

PROBES

SIZE

SETTINGS

PROBES

DELAY

|

CALIBRATION

SETTINGS

DESCRIPTIONS

Use

to

change

User

Password,

Volume

measurement

Calibrate

Calibrate

Configure

Print

On

Activation

Alarms

Modification

Transmitter

Probes

Adjust

Configuration

Configure

Chemicals

Follow-up

Doors

Access

the

transmitter

the

temperature

the

option

line

inputs

of

the

history

of

range

alarms.

the

different

draining

valves

of

the

lockup

to

pre-configured

scaling

state

of

temperature

the

additive

ID

and

outputs

the

program

and

value

alarm

function

opening

life

of

tank

name

value

value

parameters

one

settings

alarms.

for

time-outs.

parameters

period

the

machine

set-point

program

B

modification

for

conductivity

by

one

the

water

heating

set-points

13

for

inputs

step

passivation

NU

Agilent66

62070049

00.doc

Page

23 / 48

Page 24

AR

AGILENT

3.

This

TECHNOLOGIES

CYCLE

menu

is

used

OPTIONS

START

to

MENU

launch a washing

program.

LANCER

IASHING

1

1531--ΗΦΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕ

BSS

ΡΒ--44ΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕ

ΕΥ

ΒΕ

SHEE

Gh

GASES

DAS

PROGRAMS

1”-4Η4ΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕ

--Η4ΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕ

-ΗΗ4ΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕΗΗ:

HEHEHE

EEE

ERR

SEE

LIST

EE

SE

AMENER

CURRENT

WASHING

WARNING

INFORMATIONS

PROGRAM

PROGRAM

START

Back

LIST

display

DISPLAYED

Program

Selection

An

Launching a cycle

"START

When

number

of

program

PROGRAM

the

cycle

the

washing

starts,

selected.

program.

displayed

in

is

available

01

(1h25min43s) 7 washing program

the

following

See

‘warning

Displays

When

#1.ACID

#2.DETERGENT

#3.(UN)LOADING

#4.T0.BE

‘User

name

Back

to

display"

information

something

LEVEL

PROGRAMMED

name’ : If a name

is

displayed..

§Main

is

not

(tested

LEVEL

DOOR

menu

next

about

correct,

if

the

(tested

OPEN

(Program

is

defined

the

list

is

not

obligatorily

when

"START

screen

is

line.

problems.detected

one

of

the

following

cycle

need

acid

if

the

cycle

need detergent 1 intake).

(a

door

is

open).

selected

to

the

level

the

current

PROGRAM..

displayed

on

the

washer,

message

intake).

is

not

programmed).

of

access

program.

is

displayed

number + last

:

is

flashing

in

progress,

this

period

:

C

3.1

NU

Agilent66

How

to

1.

On

2.

Press

message

62070049

launch a washing

the

CYCLE

on

00.doc

START

the

START

banner

displays

cycle.

menu,

button

select

only

if

the

WARNING,

the

washing

message

press

banner

on

the

program

WARNING

in

displays

the

'Washing

START

button

program

PROGRAN....

to

have

more

Page

list.

If

the

information.

24/48

Page 25

€

AGILENT

4.

INFORMATION

TECHNOLOGIES

DURING

THE

CYCLE

7|

LANCER

|

e

Ra

ὧν

set

point

Chamber

temperature

E

Displayed

filing

(water

during

name)

Washing

program

number

Step

name

EB

_

the

Water

heater

Displayed

during

the

draining

Recycling

pump

Additive

.

Cycle

Pragram

intake

period

setting

.

É

も

NU

Agilent66

62070049

00.doc

Page

25 / 48

Page 26

AGILENT

From

the

TECHNOLOGIES

4.1

CYCLE

main

screen

INFORMATION

during

the

washing

WHEN

,

the

THE

TIME

CYCLE

key

calls

E

TIME

IS

RUNNING

the

following

screen.

CYCLE

##hOfSminO#s

##nOfminOfs

PERIOD

REMAINING

OPTIONS

CYCLE

INFORMATIONS

PERIOD

REMAINING

STEP

RECYCLING

DISPLAYED

Back

DRAINING

Cycle

Total

time

(memory

The

first

time a program

If

the

program

the

duration

Time

remaining

Remaining

The first

if

the

the

ff

the

remaining

Displays

Displays

‘Cycle

‘Draining’

Return

time = Total

time a program

program

remaining

duration

time

the

the

in

progress’

when

to

the

from

has

been

of

the

previously

for

the

has

been

time

("Last

of

the

program

displays

Prewash

recycling

display

draining

previous

"

in

previous

is

activated,

executed

current

program.

Time - Time

is

activated,

executed

time"

the

program

1/2/3...

timer.

timer

if

itis

part

is

screen.

STEP

HlímivOfs

RECYCL

#fimin0#s

progress...

executed

-time

running

ING

cycle).

the

at

least

program.

elapsed

"Remaining"

at

least

elapsed).

is

duration.

right

activated.

"Cycle

once,

once,

greater

period"

“Cycle

"Remaining"

than

increases.

period"

always

the

displays

previous,

displays

0.

displays

the

y

の

From

the

main

screen

during

the

washing, , the

OPTIONS

WASH

SETTINGS

INFORMATIONS

NU_Agilent66_62070049_00.doc

DISPLAYED

Back

SETTING

Use

the

DRYINGICOOLING : always

Washing

Return

key

calls

FROGRAM

Recycling

Water

Detergent

Rinse

Conductivity

Conductivity

STEP

program

to

the

previous

SETTINGS.

Ambient

:

number

list

selector

the

following

#imin@#s

바고

intake

#öğmi

#

min > #.#mS/om

5.

max

to

displayed.

number

and

screen.

BET

#mS

see

washing

screen.

om

its

settings.

ΒΡΗΕ-ΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕ

DRYING

program

##min

COOLING

name.

min

#HE'C

Page

26 / 48

Page 27

AGILENT

the

From

TECHNOLOGIES

during

screen

main

washing,

the

the

STOP

li

key

A

the

calls

E

following

screen.

O

ES

É

LAN

CER

|

b=

m

{

CYCLE

STOP

LOGIN

Back

BY

THE

USER

yourself

identify

Previous

screen

cycle.

the

stop

to

Ex

f

Ke.

Agilent66

NU

62070049

00.doc

Page

27

/

48

Page 28

AGILENT

5.

TEGHNOLOGIES

END

OF

5.1

OPENING

THE

OF

CYCLE

THE

DOORS

5.2

END

Loading

side

OPTIONS

TEMPERATURE

HIGH

W

ATTHEUN

DOOR

OF

CYCLE

18

OADNG

END.

100

BURN

AT

BASKETS,

HANDLING

RISK

THE

END

IF

THE

DOOR

OF

THE

CYCLE,

ACCESORIES

THEM.

IS

OPENED

LET

COOL

AND

WASHED

DESCRIPTION

NO

SIDE,

NO

SIDE,

ACTION

MESSAGES

ACTION

MESSAGES

OVER

OBJECTS

ARE

ARE

60°C.

THE

SUPPORTS,

POSSIBLE

DISPLAYED

POSSIBLE

DISPLAYED

BEFORE

ON

THIS

ONLY,

ON

THIS.

ONLY.

Unloading

DISPLAY

side

WHEN

THE

IDENTIFY

OPEN

This

side

TEMPERATURE

STEP

1

YOURSELF

STEP

2

THE

DOOR

is

used

IS

CORRECT.

to

unload

At the

Please

ATTENTION : #

When

the

rack,

λα

end

Are

identify

your

of

cycie,

yourself.

the

ini

login

you

have

to

log-in

before

SAM

this

screen

is

displayed.

chamber

temperature

1 ͵

is

recognized,

press

is

higher,

on

the

door

push

identify

opening

ΕΕΞΞΜΗΒΠ

yourself

button

and

the

ANCER

has

open

door.

no

effect.

it.

NU

Agilent66

62070049

00.dac

Page

28 / 48

Page 29

AGILENT

TECHNOLOGIES

LANCER

gn

OTHER

MESSAGES

If

the

chamber

temperature'

button

would

cooling

Press

down

on

the

temperature

set-point,

has

of

door

no

effect.

the

chamber.

push

pressing

button

is

higher

You

and

than

on

the

have

open

open

to

the

wait

it.

‘door

push

the

lock

ET

©

NU_Agilent66_62070049_00.doc

Page

29 / 48

Page 30

AGILENT

5.3

TECHNOLOGIES

SWITCHING

OFF

M

Switch

Clean

COMMENT

In

convenient

execute

6.

WASHING

Cycles 1 to

Estimated

the

the

case

washer

filters

of

an

then

again

PROGRAMS

consumption

45

OFF

of

the

interruption

to

proceed

the

complete

12.

to

50

liters

by

turning

bottom

of

washing

of

water

of

again

the

power-switch

the

chamber

the

electrical

to

cycle.

per

operation

(see

feeding,

the

operations

(depending

-6-.

page

the

of

42).

program

BEGINNING

on

the

used

is

returned

OF A CYCLE

baskets):

to

the

It

initial

point.

is

convenient

It

is

to

Flow-rate

of

970

the

acid

ml/mn

and

detergent

pumps

(depending

on

the

used

products):

NU

Agilent66

62070049

00.doc

Page

30 / 48

Page 31

Е

eo

(

AGILENT

TECHNOLOGIES

FUNCTIONS

PREWASH 1 DURATION

PREWASH 1 TEMPERATURE

PREWASH 1 DETERGENT

PREWASH 1 CONDUCTIVITY

PREWASH 2 DURATION

PREWASH 2 TEMPERATURE

PREWASH 2 DETERGENT

PREWASH 2 CONDUCTIVITY

РВЕМАЗН 3 DURATION

PREWASH 3 TEMPERATURE

PREWASH 3 DETERGENT

PREWASH 3 CONDUCTIVITY CHECK

WASH

DURATION

WASH

TEMPERATURE

WASH

DETERGENT

WASH CONDUCTIVITY

RINSE

ACID

RINSE

DURATION

ACID

RINSE

CONDUCTIVITY

RINSE

RINSE 1 DURATION

RINSE 2 DURATION

RINSE 3 DURATION

RINSE 4 DURATION

FINAL

RINSE

DURATION

FINAL

RINSE

TEMPERATURE

FINAL

RINSE

CONDUCTIVITY

SUPER

DRYING

SUPER

DRYING

COOLING

TEMPERATURE

DOWN

CHECK

CHECK

CHECK

A

CHECK

B

CHECK 0105005.

DURATION

|

4

POSSIBILITY | CYCLEO | CYCLE02 | CYCLE03 | CYCLE04

0

to

30

mn

0095

°С

0to360s

010

2008.

01030

mn

0095

°С

0to

360s

010

2008

010.30

mn

0to95*C

0

to

360

s

010

2008.

0

to

30

mn o

010.95

°C

O

to

360

s

010

2008.

0to9

Oto

30

mn

Oto

20mS.

0to9

Oto

30

mn

0

to

30

mn

0

to

30

mn

0

to

30

mn

0

to

30

mn

0

to

95

°C

0

to

90

mn

Oto

110°C

Oto

30

mn

LANCER

o

o

=

E

C

NU.

Agilent66.

62070049

00.doc

Page

31 / 48

Page 32

€

€

C

©

AGILENT

|

TECHNOLOGIES

FUNCTIONS

PREWASH 1 DURATION

PREWASH 1 TEMPERATURE.

PREWASH 1 DETERGENT

PREWASH 1 CONDUCTIVITY

PREWASH 2 DURATION

PREWASH 2 TEMPERATURE

PREWASH 2 DETERGENT

PREWASH 2 CONDUCTIVITY

,

PREWASH 3 DURATION

PREWASH 3 TEMPERATURE

PREWASH 3 DETERGENT

PREWASH 3 CONDUCTIVITY

WASH

DURATION

WASH

TEMPERATURE

WASH

DETERGENT

WASH

CONDUCTIVITY

RINSE

ACID

RINSE

ACID

RINSE

CONDUCTIVITY

RINSE

RINSE 1 DURATION

RINSE 2 DURATION

RINSE 3 DURATION

RINSE 4 DURATION

FINAL

RINSE

FINAL

RINSE

TEMPERATURE

FINAL

RINSE

CONDUCTIVITY

SUPER

DRYING

SUPER

DRYING

COOLING

TEMPERATURE

CHECK

CHECK

CHECK

CHECK

A

DURATION

CHECK

B

DURATION

CHECK

DURATION

DOWN

POSSIBILITY | CYCLEO5 | CYCLE06 | CYCLEO7 | CYCLE08

01030

mn

01095

°С

0103608

010

2008.

0

t0

30

mn

01095

°С

0103608

010

2078

Oto

30

mn

01095

°С

0103605

010

2008.

0

to

30

mn

0095

°С

0103605

010

2008.

0to9

0to30mn

010

2008.

0109

0

to

30

mn

010.30

mn

Oto

30m

Oto

30

mn

0

to

30

mn

Oto

95

°C

0

to

50018.

0

to

80

mn

Oto

110°C

Oto

30

mn

(し

NU_Aqilent66_62070049

00.doc

Page

32/48

Page 33

€

€

C

|

I

AGILENT

TECHNOLOGIES

FUNCTIONS

PREWASH 1 DURATION

PREWASH 1 TEMPERATURE

PREWASH 1 DETERGENT

PREWASH 1 CONDUCTIVITY

PREWASH 2 DURATION

PREWASH 2 TEMPERATURE

PREWASH 2 DETERGENT

PREWASH 2 CONDUCTIVITY

PREWASH 3 DURATION

PREWASH 3 TEMPERATURE

PREWASH 3 DETERGENT

PREWASH 3 CONDUCTIVITY

WASH

DURATION

WASH

TEMPERATURE

WASH

DETERGENT

WASH

CONDUCTIVITY

RINSE

ACID

RINSE

DURATION

ACID

RINSE

CONDUCTIVITY

RINSE

RINSE 1 DURATION

RINSE 2 DURATION

RINSE 3 DURATION

RINSE 4 DURATION

FINAL

RINSE

DURATION

FINAL

RINSE

TEMPERATURE

FINAL

RINSE

CONDUCTIVITY

SUPER

DRYING

SUPER

DRYING

COOLING

TEMPERATURE

DOWN

CHECK

CHECK

CHECK

CHECK

A

CHECK

B

CHECK

DURATION

POSSIBILITY | CYCLEOS | CYCLE10 | CYCLE11 | CYCLE12

0

to

30

mn

04095

°С

©

°

003603

010

2008.

0

to

30

mn

01095

°C

010

360s

Dto

20m8

010.30

mn

0

to

95

°C

0

to

360.5

010

2008.

010.30

mn

01095

°C

Oto

360

s

010

2008.

0109

Dto

30m

0

to

20m8.

0109

0to

30

mn

Oto

30

mn

Oto

30

m

Oto

30

m

Oto

30

mn

Dto

95

*C

Oto

50018.

0t090

mn

Oto

110°C

0

to

30

mn

LANCER

É

Le

=

<

NU_Agilent66_62070049_00.doc

Page

33 / 48

Page 34

AGILENT

7.

Each

operator

or

the

TECHNOLOGIES

PASSWORDS

interface

users

for

the

loading

7.1

HOW

TO

has

his

side

CHANGE

own

management

and

the

YOUR

of

users

for

the

PASSWORD.

the

passwords & ID.

unloading

side.

The

system

can

have

the

same

users

on

the

two

sides

am,

*

WARMING * Change

(INIT.

USERS

SELECTION

MANE

LIST

1

2

3

fagli:

SUPERVISOR

TECHNICIAN

TECHNICIAN

OPERATOR

OPERATOR

OPERATOR

2

1

2

login

your

detected)

HELP : Find

DISPLAY

PASSWORD & ID

your

Name

registered

the

OP,

ΒΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕ

selected

user

for

DESCRIPTION

Select

your

operator

How

to

find

STEP

1

If

you

list

USER

HHIE

level

:

STEP

STEP

you

Press

2

Enter

When

verify

3

message.

Press

"Enter

When

correct, a message

registered.

Screen

Supervisor

Go

do

at

the

find

on

your

the

your

on the

your

the

back

not

bottom

your

the.

new

used

to

your

NEW

new password.

new

new

verification

Then

only

the

operator

know

your

of

this

name.

PASSWORD

password

password.

VERIFY

PASSWORD

password.

indicates

press

to

modify

ACCESS

level.

(i.e.

SUPERVISEUR

level

?

operator

screen,

is

password

any

the

screen.

level,

Select

button.

entered, a message

Then

press any

bution.

is

entered

that

the

key

to

clear

ID of

the

use

the

key

new

this

user

1).

the

operator

operator

indicates

to

clear

and

if

it

password

message.

login.

until

to

this

is

is

€

NU

Agilent66

62070049

00.doc

Page

34 / 48

Page 35

の

AGILENT

Example

1/Find

la

TECHNOLOGIES

of

changing a password

the

operator

+

MARNING * Change

USERS

LECTIO

ULSUR

SUPERVISOR

TECHNICIAN

OPERATOR

ERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

(INIT.

LIST

2

1

n

2

1

LERİ

CIO

CO

ee

number

login

for

the

for

JEAN

M,

your

PASSWORD € ID

detected)

HELP : Find

Name

registered

the

OP.

ΦΦ4ΗΗΗΗΗΗΗΗΗΗΗΗΗΗΗΕ

selected

user

your

called

USER

user

for

:

JEAN

“Level

*ID*

ME

M.

:

の

LANCER

|

\

ci

nad

E,

n

+

WARNING * Change

(INIT.

USERS

LIST

SUPERUTSOR

SUPERVISOR

TECHNICIAN

TECHNICIAN

M

Pig

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

When

JEAN

2/JEAN

M.

ECS

*

KARNING * Change

SUPERVISOR

SUPERVISOR

TECHNICIAN

TECHNIC. т AN

M.

can

CINIT.

td

ENTRA

JM

CO

LO

pes

tes

is

change

q

your

login

1

2

1

2

HELP - Find

displayed

his

your

login

1

2

1

2

PASSWORD & I0

detected)

Name

registered

the

OP,

on

the

'name

ee

=-

detested)

your

user

selected

in

following

For

registered...',

the

&

ID

:

steps

a:

level

he

1, 2 and3.

A

knows

his

operator

number,

and

in

this

example

it

is : OPERATOR

1.

GPERATOR

OPERATOR

OPERATOR

DPERATOR

OPERATOR

OPERATOR

OPERATOR

OPERATOR

NU.

Agilent66.

62070049

HELP : Find

Name

registered

the

OP.

JERI

00.doc

your

selected

user

for

:

level

Page

35

/48

Page 36

AGILENT

7.2

Use

this

function

Each

user

ERP

TECHNOLOGIES

HOW

TO

CHANGE

to

change

can

only

change

| | emmi

-

NEW

ID to

change

=

INIT

ID

for

NEW

ID.

FOR

Er

PRE

ES]

your

his

own

vour

another

YOUR

login

ID.

login

own

user,

VERIFY

Е

ID;

ID

TD.

ID

he

has

to

be the

current

user.

STEP

1

STEP

2

STEP

3

ani

INIT

ID

PASSWORD

Back

2

Press

on

Enter

your

When

the

verify

your

Press

on

Enter

your

When

the

message

Supervisor

Opens

|

Opens

Back

to

DESGRİPNON

the

NEW

ID

button.

new

ID.

new

ID

is

entered,

new

ID.

the

VERIFY

new

verify

indicates

only.

ID

initialization

Password

the

ACCESS

ID

ID.

ID

is

entered and

that

screen

modification

screen.

LANCER

17

還

you

are

prompted

button.

ifitis

the

new

ID

is

changed.

screen.

fo

correct,

a

o

NU_Agilent66_62070049_00.doc

Page

36 / 48

Page 37

PN

AGILENT

TECHNOLOGIES

er

LANCER

CHAPTER4

These

permanently

TRACEABILITY

filling,

During

on

last

years,

detergent

the

development

data

support.

the

TRACEABILITY

TRACEABILITY

correct

enables

taking,

development

the

effective

of

the

has

of

supervision

temperature,

program

become

the.

washing

of

the

duration

all

the

data

in

the

hospital

cycle

correct

of

must

milieu

and

to

obtain

performance

the

phases.

be

registered,

in a crucial

its

validation.

of

parameters

archived

issue.

in

paper

The

such

support

matter

as

washing,

is

to

control

chamber

and,

optionally,

Or

re,

You

will

find

in

this

chapter

1

THE

PRINTER

2

CONDUCTIVITY

NU_Agilent66_62070049_00.doc

METER

the

system

of

traceability

installed

in

your

washer.

Page

37 / 48

box

Page 38

€

AGILENT

1.

TECHNOLOGIES

PRINTER

ITS

RESULTS:

At

the

end

the

mean

of

of

the

program,

an

horodated

the results

ticket.

are

registered

and

archived,

whether

on a paper

support

by

-

E

—

IMPRESSION

The

in

the

1.1

This

menu

is

WASHING

Machine

configuration

Print

OF A REPORT

date,

the

hour,

ticket,

these

Print

out,

ticket

used

to

select

OPTIONS

PROGRAM

configuration!

Ticket

in

progress

Back

LIST

Cycle

size

-

the

number

durations

size.

the

can

size

of

the

Selection

Press

key

the

Print

Print

Press

valid.

Detailed

Basic

Displayed

Retour

of

phases

vary

from

printout

on

the

the

on the

ticket:

and

of

the

washing

the

cell

valid.

general

machine

configuration

cell

and

ticket:

all

begin

when a print

au

menu

principal

of

one

to

and

use

of

use

parts

of

and

end

is

the

program

cycle

to

print

settings.

program.

the

arrows

parameters.

the

currently

the

arrows

keys

the

cycle

are

of

the

cycle

in

progress

as

well

the

other.

keys

to

selected

cycle.

to

change

printed

are

printed.

as

change

the

their

denomination

the

selection.

selection.

Press

Press

on the

on

the

enter

are

printed

enter

key

the

Ez

f

ων

NU

Agilent66

62070049

00.doc

Page

38 / 48

Bes

=

Page 39

AGILENT

TECHNOLOGIES

#1

MACHINE

へ へ ペペ

ペペ

8"

WASHER

01/6/2002

E

[Chamber

FP

Offset:0.0°C

MA

Chamber

Potset:

"LANCER

PAA

ペペ

CONFIGURATION“

13:32:51

heating:

265°C

Drying : 253°C

0°C

AOA

CYCLE

ο

FUNCTION

ANALYSYS - Complete

Program

N°? - BIG

μμ

-MBy

user:

Hours:

Start:

JPREWASH 1 -

Filing:

Detergent:

°C

prog. : 90°C

Heating : 2min49s

Recycling : OminiOs

[Mn.:

90,19C

Draining : 1min15s

RINE A 1/1

vin.

90,170

SB

Draining : 1mint5s

SBF

INARINSE - Omint5s

‘BM

Recycling : min00s

Μία;

50.2°C

[WaterChack:

MFinaDrain:

Men

JA

Cycle

Al

Cycle

Ack. : 11/05/2002

By

user

Date:

Psignature

LANCER

POO

TOOLS.

—

JOHNM.

Aitámin

Cycles:

11052002

16:42:01

Smin485

Omin32s.

(PM)

OminSGs

Max.:

93.120

-1mw57s

Max

8310

tmint2s

Max:

51.8°C

105.

1.518.

Zmint5s

:11/05/2002

period:

0h17min00s

:KARLS.

:

LEE

CONFIGURATION

ペペ

ヘイン

ペペ

Max

110°C

Max:

150°C

REPORT

ticket

2

02000

16:59:01

17:20:26

ARP

LE

SF

ペン

it

Tite

È

Date

and

time

É

Temperature

probes + Alarm

ИУ

q

Le

|

Title + ticket

size

Program

number + name

|

Washer

model + serial

!

Opérafor

who

has

[Total

(Start

EFiling

‘Detergent intake

yele

‘Acknowiedgement

É

Operator

*

PART

TICKET

Dog

launched

hours + stert

counter

date

and