Lancer 1506 Service Manual

SPECIFICATIONS

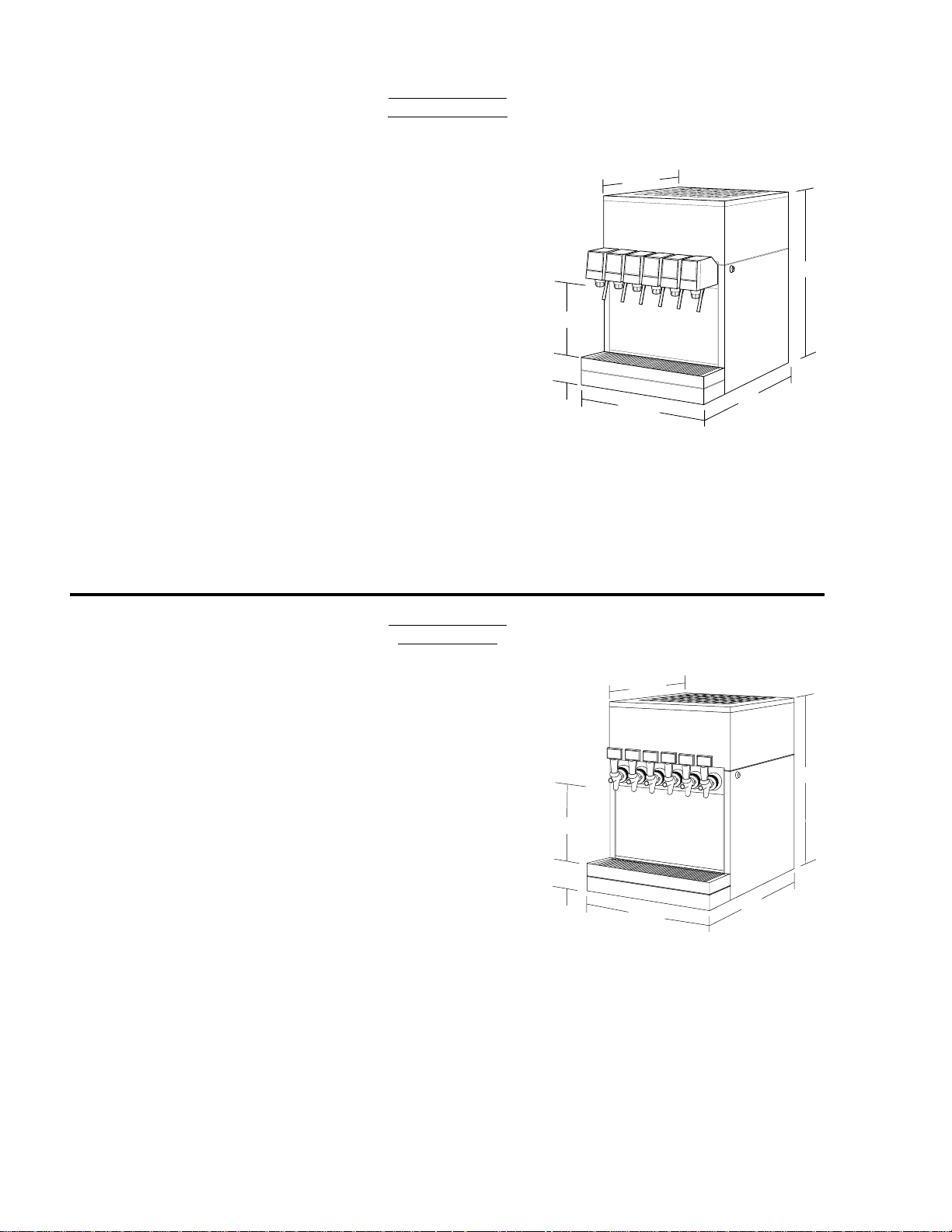

1500 POSTMIX

DIMENSIONS

Width 19 3/16 inches (48.74 cm)

Depth 24 inches (60.96 cm)

Height (without legs) 25 3/8 inches (64.45 cm)

WEIGHT

Shipping 150 pounds (68.2 kg)

Empty 130 pounds (59.0 kg)

Operating 220 pounds (99.8 kg)

ICE BANK WEIGHT 30 pounds (13.6 kg)

WATER BATH CAPACITY 12 gallons (45.4 liters)

COMPRESSOR 1/3 HP, Tecumseh, 115V/60Hz

AGITATOR MOTOR 25 W, 115V

CONDENSER MOTOR 9 W, 115V

ICE BANK CONTROL Lancer Electronic Ice Bank Control (EIBC)

TRANSFORMER Basler, 115V (Primary)/24V (Secondary)

OPTIONS 230V/50Hz and 240V/60Hz systems available

DRINK CAPACITY

395 - 12 ounce (354.8 ml) drinks under 40°F (4.4°C) at four (4) drinks per minute with 75°F (23.9°C)

ambient inlet water and syrup.

INSTALLATION AND SERVICE MANUAL

FOR LANCER DISPENSERS

SERIES 1500 POSTMIX

SERIES 1500E POSTMIX

SERIES 1500 PREMIX

REV. 02/11/00

P.N. 28-0450

This is an initial manual release.

FAX ENGINEERING: • 210-310-7096

"Lancer" is the registered trademark of Lancer • Copyright — 2000 by Lancer, all rights reserved.

Please refer to the Lancer web site (www.lancercorp.com) for

information relating to Lancer Installation and Service Manuals,

Instruction Sheets, Technical Bulletins, Service Bulletins, etc.

6655 LANCER BLVD. • SAN ANTONIO, TEXAS 78219 USA • (210) 310-7000

FAX SALES

• NORTH AMERICA – 210-310-7245 • INTERNATIONAL SALES – 210-310-7242 • CUSTOMER SERVICE – 210-310-7242 •

• LATIN AMERICA – 210-310-7245 • EUROPE – 32-2-755-2399 • PACIFIC – 61-8-8268-1978 •

18 3/4 "

47.63 cm

9 1/2 "

24.13 cm

3 1/2 "

8.89 cm

19 3/16 "

48.74 cm

24 "

60.96 cm

25 3/8 "

64.45 cm

i

SPECIFICATION

1500E POSTMIX

DIMENSIONS

Width 19 3/16 inches (48.74 cm)

Depth 24 inches (60.96 cm)

Height (without legs) 25 3/8 inches (64.45 cm)

WEIGHT

Shipping 150 pounds (68.2 kg)

Empty 130 pounds (59.0 kg)

Operating 220 pounds (99.8 kg)

ICE BANK WEIGHT 30 pounds (13.6 kg)

WATER BATH CAPACITY 12 gallons (45.4 liters)

COMPRESSOR 1/3 HP Tecumseh 115V/60Hz

AGITATOR MOTOR 25 W, 115V

CONDENSER MOTOR 9 W, 115V

ICE BANK CONTROL Lancer Electronic Ice Bank Control (EIBC)

TRANSFORMER Basler, 115V (Primary)/24V (Secondary)

OPTIONS 230V/50Hz and 240V/60Hz systems available

DRINK CAPACITY

350 - 12 ounce (354.8 ml) drinks under 40°F (4.4°C) at four (4) drinks per minute with 75°F (23.9°C)

ambient inlet water and syrup.

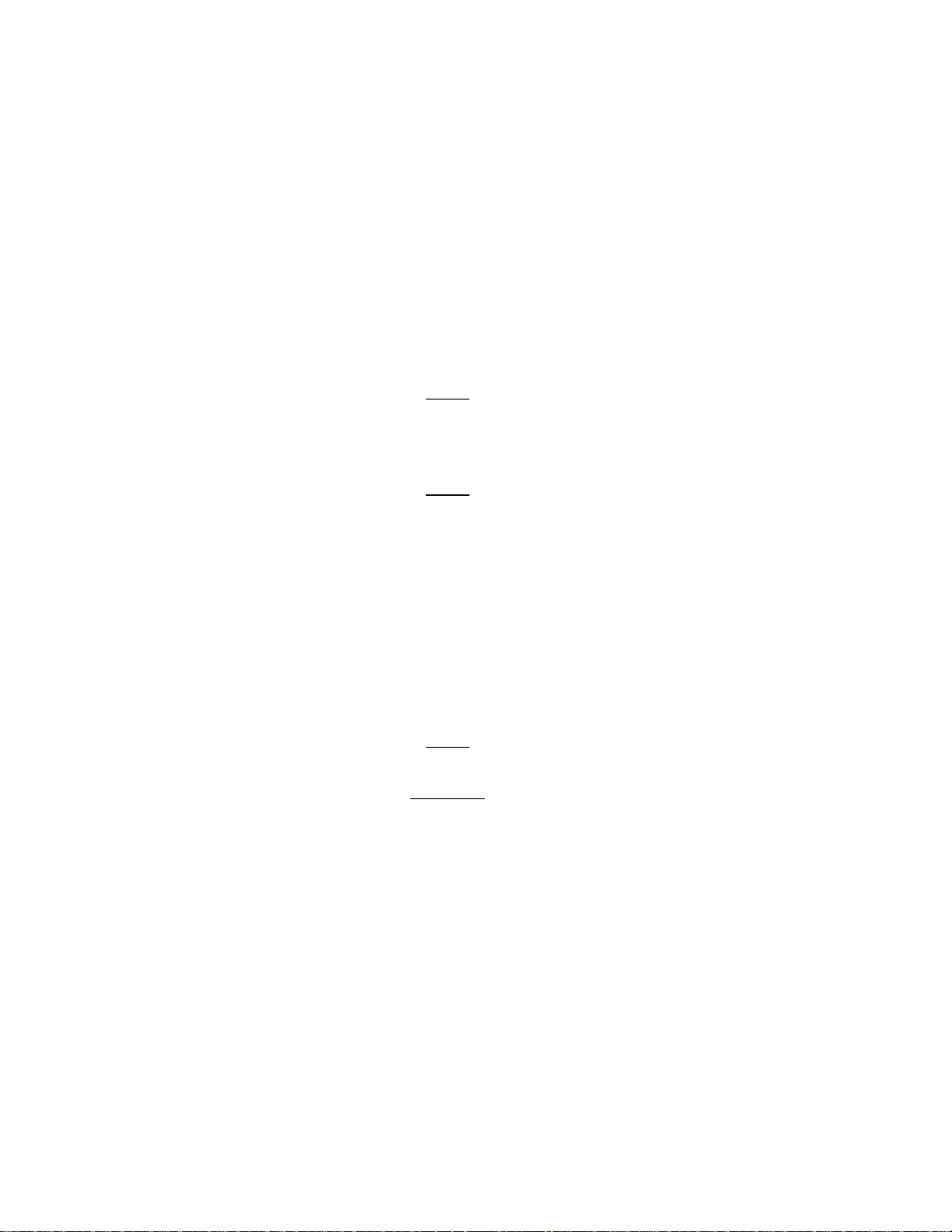

SPECIFICATION

1500 PREMIX

DIMENSIONS

Width 19 3/16 inches (48.74 cm)

Depth 24 inches (60.96 cm)

Height (without legs) 25 3/8 inches (64.45 cm)

WEIGHT

Shipping 150 pounds (68.2 kg)

Empty 130 pounds (59 kg)

Operating 220 pounds (99.8 kg)

ICE BANK WEIGHT 30 pounds (13.6 kg)

WATER BATH CAPACITY 12 gallons (45.4 liters)

COMPRESSOR 1/3 HP, Tecumseh, 115V/60Hz

AGITATOR MOTOR 25 W, 115V

CONDENSER MOTOR 9 W, 115V

ICE BANK CONTROL Lancer Electronic Ice Bank Control (EIBC)

TRANSFORMER Basler, 115V (Primary)/24V (Secondary)

OPTIONS 230V/50Hz and 240V/60Hz systems available

VALVES Cornelius Premix

DRINK CAPACITY

220 - 12 ounce (354.8 ml) drinks under 40°F (4.4°C) at four (4) drinks per minute with 75°F (23.9°C)

ambient inlet water and syrup.

18 3/4 "

47.63 cm

9 1/2 "

24.13 cm

3 1/2 "

8.89 cm

19 3/16 "

48.74 cm

24 "

60.96 cm

25 "

64.45 cm

18 3/4 "

47.63 cm

10 3/4"

27.30 cm

3 1/2 "

8.89 cm

19 3/16 "

48.74 cm

24 "

60.96 cm

25 3/8 "

64.45 cm

TABLE OF CONTENTS

SPECIFICATIONS 1500 POSTMIX ...........................................................................................................Cover

SPECIFICATIONS 1500E POSTMIX ..................................................................................................................i

SPECIFICATIONS 1500 PREMIX.......................................................................................................................i

TABLE OF CONTENTS .....................................................................................................................................ii

1. INSTALLATION ...........................................................................................................................................1

1.1 RECEIVING........................................................................................................................................1

1.2 UNPACKING ......................................................................................................................................1

1.3 SELECTING A COUNTER LOCATION..............................................................................................1

1.4 CONNECTING THE DRAIN...............................................................................................................1

1.5 FILLING UNIT WITH WATER ............................................................................................................1

1.6 CONNECTING TO ELECTRICAL POWER .......................................................................................2

1.7 CONNECTING TO PLAIN WATER SUPPLY .....................................................................................2

1.8 CONNECTING TO CARBONATED WATER SUPPLY.......................................................................2

1.9 CONNECTING TO SYRUP SUPPLY.................................................................................................3

1.10 ADJUSTING WATER AND SYRUP FLOW........................................................................................3

2. SCHEDULED MAINTENANCE ...................................................................................................................3

2.1 DAILY .................................................................................................................................................3

2.2 WEEKLY.............................................................................................................................................3

2.3 MONTHLY ..........................................................................................................................................3

2.4 EVERY SIX MONTHS........................................................................................................................3

2.5 YEARLY..............................................................................................................................................4

3. DISPENSER CLEANING AND SANITIZING ..............................................................................................4

3.1 AMBIENT PROCESS.........................................................................................................................4

3.2 VALVES ..............................................................................................................................................4

4. TROUBLESHOOTING.................................................................................................................................5

4.1 WATER LEAKAGE AROUND NOZZLE .............................................................................................5

4.2 LEAKAGE BETWEEN UPPER AND LOWER VALVE BODIES.........................................................5

4.3 MISCELLANEOUS LEAKAGE ...........................................................................................................5

4.4 INSUFFICIENT WATER FLOW..........................................................................................................5

4.5 INSUFFICIENT SYRUP FLOW..........................................................................................................5

4.6 ERRATIC RATIO ...............................................................................................................................5

4.7 NO PRODUCT DISPENSED .............................................................................................................5

4.8 WATER ONLY DISPENSED; NO SYRUP; OR SYRUP ONLY DISPENSED; NO WATER ...............5

4.9 VALVE WILL NOT SHUT OFF ...........................................................................................................6

4.10 EXCESSIVE FOAMING .....................................................................................................................6

4.11 COMPRESSOR DOES NOT START (NO HUM), BUT CONDENSER FAN MOTOR RUNS............6

4.12 COMPRESSOR STARTS AND CONTINUES TO RUN UNTIL FREEZE UP AND WILL NOT

CUT OFF............................................................................................................................................6

4.13 COMPRESSOR DOES NOT START BUT HUMS .............................................................................6

4.14 COMPRESSOR STARTS BUT DOES NOT SWITCH OFF START WINDING .................................6

4.15 COMPRESSOR STARTS AND RUNS A SHORT TIME BUT SHUTS OFF ON OVERLOAD ...........6

4.16 COMPRESSOR AND CONDENSER FAN MOTOR WILL NOT START AFTER FIVE (5)

MINUTE POWER OFF DELAY (LANCER EIBC EXPORT ONLY) ....................................................7

4.17 COMPRESSOR AND CONDENSER FAN MOTOR WILL NOT START AFTER FIVE (5)

MINUTE POWER OFF DELAY (LANCER EIBC USA ONLY) ...........................................................7

4.18 WARM DRINKS..................................................................................................................................7

5. ILLUSTRATIONS, PARTS LISTS AND WIRING DIAGRAMS ...................................................................8

5.1 WIRING DIAGRAM AND CONTROL HOUSING CONNECTIONS, ELECTRONIC

ICE BANK CONTROL, USA ONLY ....................................................................................................8

5.2 SERIES 1500 REFRIGERATION DECK ASSEMBLY, R-134A, WITH LANCER ICE

BANK CONTROL (EIBC); PN 82-2667; USA ONLY.....................................................................9-10

5.3 SERIES 1500 REFRIGERATION DECK ASSEMBLY, R-134A, WITH LANCER ICE

BANK CONTROL (EIBC); PN 82-2050E, 115V/60HZ; PN 82-2099E, 230V/50HZ;

PN 82-2048E, 240V/60HZ; EXPORT ONLY ...............................................................................11-12

5.4 SERIES 1500 CABINET ASSEMBLY, HIGH PERFORMANCE..................................................13-14

5.5 SERIES 1500E AND 1500 PREMIX CABINET ASSEMBLY ......................................................15-16

ii

1. INSTALLATION

1.1 RECEIVING

Each unit is completely tested under operating conditions and thoroughly inspected before

shipment. At the time of shipment, the carrier accepts the unit and any claim for damages must be

made with the carrier. Upon receiving units from the delivering carrier, carefully inspect carton for

visible indication(s) of damage. If damage(s) exists, have carrier note the same on the bill of lading

and file a claim with the carrier.

1.2 UNPACKING

A. Remove top portion of carton by lifting up.

B. Remove top inner carton pad and corners.

C. Remove accessory kit of loose parts from drip tray.

D. Lift Unit up by plywood shipping base and remove lower portion of carton.

E. Inspect unit for concealed damage(s) and if evident, notify delivering carrier and file a claim

against same.

F. Remove splash plate.

NOTE

Splash plate is located under unit on shipping base for Series 1500E models only.

G. Remove plywood shipping base from unit by moving unit so that one side is off the counter top

or table allowing access to screws on the bottom of the plywood shipping base.

NOTE

If unit is to be transported it is advisable to leave unit secured to plywood shipping base.

H. If Unit is to be installed with optional legs, assemble legs to unit by tilting unit. DO NOT LAY

UNIT ON ITS SIDE OR BACK.

I. Remove accessory kit of loose parts from drip tray.

1.3 SELECTING A COUNTER LOCATION

A. The dispenser is designed to sit on a flat, supported surface capable of supporting a minimum

weight of 400 pounds (182 kg). It may be either counter or leg mounted. A template is

provided to cut and/or drill the necessary holes for mounting.

B. When the dispenser is to be permanently bolted to the counter top, seal dispenser base to

counter top with a bead of clear silicone caulk or sealant which provides a smooth and easily

cleanable bond to the counter.

NOTE

NSF listed units must be sealed to the counter or have four (4) inch legs installed.

WARNING

FAILURE TO MAINTAIN THE PROPER AIR CLEARANCE WILL CAUSE THE COMPRESSOR TO

OVERHEAT AND WILL RESULT IN PREMATURE COMPRESSOR FAILURE.

C. Locate dispenser to allow approximately 15 inches (38 cm) of unobstructed space above and

six (6) inches (16 cm) behind the unit for proper air circulation. Air is drawn in through the back

grill and exhausted out of the top grill.

D. The bonnet may be removed by lifting bonnet upward.

1.4 CONNECTING THE DRAIN

A. Remove cup rest. Lift splash plate up and pull out and down on the bottom to remove.

B. Remove the drip tray from the unit and connect the drain tube to the drain fitting located on the

bottom. Secure drain tube with clamp provided in accessory kit.

C. Route the drain tube to a suitable drain and replace the unit’s drip tray.

1.5 FILLING UNIT WITH WATER

A. Remove the bonnet from the unit.

B. Remove the yellow plastic plug from the unit’s fill hole.

C. Fill the water bath compartment with water until it flows out of the overflow tube into the drip tray.

Use bottled drinking water where hard water problems exist. Do not use distilled water with units

1

equipped with electronic ice bank controls.

D. Replace the yellow plug.

E. Reinstall bonnet on dispenser.

1.6 CONNECTING TO ELECTRICAL POWER

WARNING

THIS UNIT MUST BE PROPERLY ELECTRICALLY GROUNDED TO AVOID POSSIBLE FATAL

ELECTRICAL SHOCK OR SERIOUS INJURY TO THE OPERATOR. THE POWER CORD IS

PROVIDED WITH A THREE PRONG GROUNDED PLUG. IF A THREE-HOLE GROUNDED

ELECTRICAL OUTLET IS NOT AVAILABLE, USE AN APPROVED METHOD TO GROUND THE

UNIT.

DO NOT USE EXTENSION CORDS WITH THIS UNIT. DO NOT “GANG” TOGETHER WITH

OTHER ELECTRICAL DEVICES ON THE SAME OUTLET.

A. Check the dispenser serial number plate for unit's correct electrical requirements. Do not plug

into electrical outlet unless unit electrical configuration, located on serial plate, agrees with local

available power supply.

B. Route the power supply cord to a grounded electrical outlet of the proper voltage and amperage

rating, and plug in the unit. This will turn on the refrigeration system and allow it to start

cooling while completing the rest of the installation. Approximately three (3) hours are required

to form a full ice bank.

NOTE

Units equipped with an electronic ice bank control contain a five (5) minute delay. Compressor

and fan motor will not begin running until five (5) minutes after the unit is energized.

2

Carbonated Water/Plain Water

Plumbing Diagram

Figure 1

1.7 CONNECTING TO PLAIN WATER SUPPLY

NOTE

The water supply must be protected by means of an air gap, a backflow prevention device (located

upstream of the CO2 injection system) or another approved method to comply with NSF standards.

A backflow prevention device must comply with ASSE and local standards. It is the responsibility of

the installer to ensure compliance.

See Figure 1.

If unit has no plain water circuits, proceed to Section 1.8.

A. Valves 2, 3, and 4 (on 5 valve units) and valves 3, 4, and 5 (on 6 valve units) have optional plain

water or carbonated water capabilities. Using Figure 1, determine which valves are to be

plumbed with plain water.

B. Using proper beverage tubing and fittings, connect to water source [must be 35 PSI (2.4 BAR)

or more].

6 VALVE

5 VALVE

6 45 123

INLET VALVE 3 & 4

INLET VALVE 1, 2, & 6

INLET VALVE 5

5 4 3 12

INLET VALVE 2 & 3

INLET VALVE 1 & 5

INLET VALVE 4

C. Flush water supply line thoroughly.

D. Route tubing through cutout in counter or through access hole in back of unit.

E. Leave 12 inches (30 cm) of extra tubing length below the counter for servicing and moving the

dispenser.

F. Connect to desired plain water inlet behind splash plate and secure with Oetiker Clamp.

G. Turn on water supply and check for leaks.

H. Actuate each valve until all air is expelled.

1.8 CONNECTING TO CARBONATED WATER SUPPLY (See Figure 1)

A. Install carbonator per manufacturer’s instructions.

B. Using proper beverage tubing and fittings, connect to carbonator tank outlets.

C. Route tubing through cutout in counter or through access hole in back of unit.

D. Leave 12 inches (30 cm) of extra tubing length below the counter for servicing and moving the

dispenser.

E. Connect to soda inlets behind splash plate and secure with Oetiker Clamps.

F. Fill with water and pressurize carbonation system per manufacturer’s instructions.

G. Actuate each valve until a smooth flow of carbonated water is obtained.

H. Check for leaks.

1.9 CONNECTING TO SYRUP SUPPLY

A. Using proper beverage tubing and fittings, connect to syrup inlets and secure with Oetiker

Clamps.

B. Mark syrup tube assemblies with product ID tape.

C. Route tubing through cutout in counter or through access hole in back of unit.

D. Leave 12 inches (30 cm) of extra tubing length below the counter for servicing and moving the

dispenser.

E. Connect to appropriate five (5) gallon syrup containers or bag-in-box system.

F. Pressurize system.

G. Actuate each valve until product is observed.

H. Check for leaks.

1.10 ADJUSTING WATER AND SYRUP FLOW

Refer to Valve Manufacturer’s product specifications.

2. SCHEDULED MAINTENANCE

2.1 DAILY

A. Remove the nozzle and diffuser from each valve and wash them in warm water. Do NOT use

soap or detergent. This will cause foaming and off taste in finished product.

B. Remove the cup rest and wash in warm soapy water.

C. Pour warm soapy water into the drip tray and wipe with a clean cloth.

D. With a clean cloth and warm water, wipe off all of the unit’s exterior surfaces. DO NOT USE

ABRASIVE SOAPS OR STRONG DETERGENTS.

E. Replace the cup rest, valve diffusers, and valve nozzles.

2.2 WEEKLY

A. Taste each product for off tastes and/or brix changes.

B. Remove the bonnet and check the level of water in the water bath. Replenish as required, and

replace the bonnet.

2.3 MONTHLY

A. Unplug the dispenser from power source.

B. Remove the bonnet and clean the dirt from the condenser using a soft brush.

C. Replace the bonnet and reconnect power.

2.4 EVERY SIX MONTHS

A. Clean and sanitize the unit using the appropriate procedures outlined in Section 3 of this

manual.

3

Loading...

Loading...