LAKOS PPS User Manual

Pump Protection Separators

Installation Guide

LAKOS Pump Protection Separators come in a variety of

sizes. They can be used with either turbine pumps or large

submersible pumps. They may be shipped in a variety of ways.

Most often, each unit is strapped onto a wooden skid. Before

installation, remove all labels, decals and shipping instructions

from each unit to avoid plugging the inlet slots. LAKOS Pump

Protection Separators are designed to continuously ush

separated particles back into the source water.

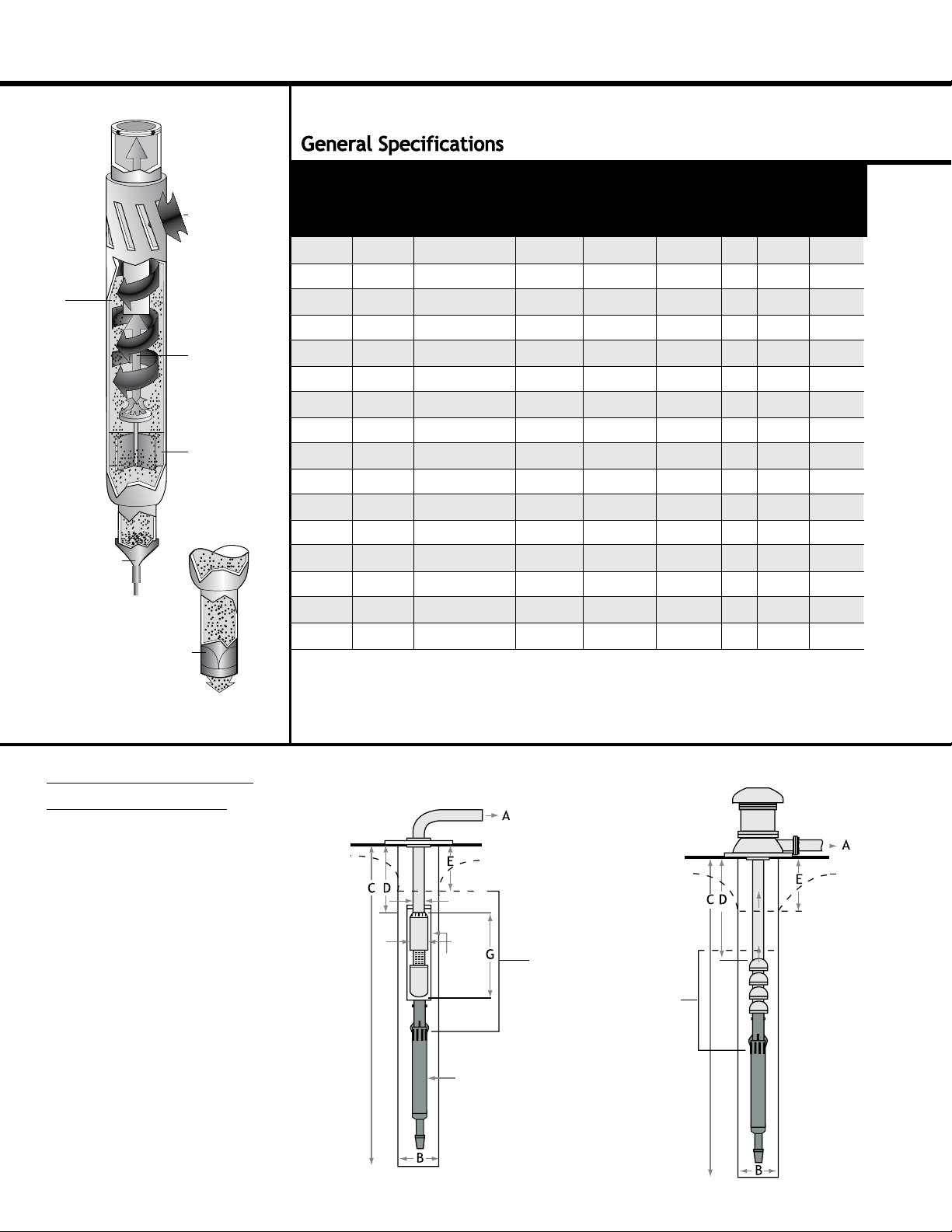

For Turbine pumps:

LAKOS Turbine Separators are manufactured with a standard

M.N.P.T. riser (note General Specications chart on next

page). Should this riser not match the connection to your

pump’s bowl assembly, you’ll need to arrange for the proper

connection (i.e. reducer, etc.). Lifting lugs are provided on the

riser of all models size “E” through “K” for ease of installation.

Connect the separator to the bowl assembly, then install

the apper valve as shown on page 3. At this point, you may

proceed with your customary routine for installing the pump.

FOR

TURBINE

PUMPS

Pump Riser

Pump Bowls

Submersible Pump

Pump Enclosure

Shell

Separator Inlet

Slots

LAKOS Separator

FOR

SUBMERSIBLE

PUMPS

For Submersible pumps:

To allow LAKOS Pump Protection Separators to remove sand

prior to the pump intake, the water must rst be directed

to rst pass through the separator. To achieve this with a

submersible pump, LAKOS provides a pump enclosure shell

or shell kit (see page 4). The submersible pump is positioned

within this shell and then attached directly to the separator

outlet. With the pump properly secured in the shell, the riser

is now attached directly to the column pipe. Installation may

now proceed as normal for submersible pumps.

Once installed, LAKOS Pump Protection Separators require

no routine maintenance. Should you ever need to pull your

pump, always take the opportunity to inspect the separator

and purge assembly.

Flexible Flapper

Valve

Closed when pump is in

operation. Opens when

pump shuts off or

when sand load pushes

the valve open.

Top with Shell Kit

Bottom with

Separator

Connection

Separators and Filtration Solutions

Page 1

Pump Protection Separators Installation Guide

Sand is

centrifugally

separated from

water and tossed

to perimeter

of chamber.

Flapper Valve Closed

Sand accumulates

in separator.

Flapper Valve Open

Sand discharges

deep into well.

Sandy water is

drawn through

tangential inlet

slots into

separation

chamber.

Sand-free water

is drawn to

center of

separator and up

through vortex

outlet to pump’s

suction.

Sand particles

fall downward,

along perimeter,

to bottom

of separator.

143

141

168

219

219

219

270

270

273

273

324

324

356

356

406

406

Length With

Riser &

Flapper Valve

in

88-3/8

106

120-1/4

124

130

132-1/2

141-1/2

145-3/4

147

150-1/2

154

158

163

170

185

204

Minimum

Model

PPS-100-D

PPS-125-E

PPS-150-F

PPS-325-GSA

PPS-520-GGA

PPS-325-G

PPS-600-HSA

PPS-880-HHA

PPS-550-H

PPS-1290-ISA

PPS-825-I

PPS-1460-JSA

PPS-1010-J

PPS-1780-KSA

PPS-1640-K

PPS-2520-KKA

Head Loss: Typically, 9-14 feet (2.74-4.27m), except models with optional tail pipes, which will experience a notably greater head

loss. Consult factory for details.

Maximum Particle Size: 1/4 inch (6.3mm)

Maximum Particle Concentration: 1,000 ppm

*Optional tail pipe in place of the flapper valve

Well I.D.

in mm mmU.S. gpm m

152

6

178

7

203

8

248

9-3/4

248

9-3/4

273

10-3/4

305

12

305

12

337

13-1/4

337

13-1/4

387

15-1/4

387

15-1/4

438

17-1/4

438

17-1/4

489

19-1/4

489

19-1/4

Flow Range

100-175

125-250

150-325

325-520

520-710

325-650

600-910

880-1375

550-1110

1290-1700

825-1450

1460-2040

1010-1800

1780-2420

1640-2560

2520-3180

3

23-40

29-57

34-74

74-118

118-161

74-148

136-207

200-312

125-252

293-386

187-329

332-463

230-409

404-550

373-582

573-723

/ hr

Outside

Diameter

in

5-5/8

5-9/16

6-5/8

8-5/8

8-5/8

8-5/8

10-5/8

10-5/8

10-3/4

10-3/4

12-3/4

12-3/4

14

14

16

16

mm

2245

2692

3054

3150

3302

3366

3594

3702

3734

3823

3912

4013

4140

4318

4699

5182

Length of

Tail Pipe

meters

ft

20

6.1

20

6.1

20

6.1

40

12.2

40

12.2

20

6.1

60

18.3

60

18.3

20

6.1

60

18.3

20

6.1

60

18.3

20

6.1

60

18.3

20

6.1

60

18.3

Riser

Size

2-1/2 "

3"

4"

6"

6"

6"

8"

8"

8"

8"

8"

10"

10"

10"

10"

12"

Weight

lbs M.N.P.T.

93

142

220

191

213

267

281

315

390

393

454

492

526

575

703

754

Submergence

kg

42

64

100

87

97

121

128

143

177

178

206

223

239

261

319

342

Required

Minimum

ft meters

30

30

30

60

60

30

60

60

30

60

30

60

30

60

30

60

9.2

9.2

9.2

18.4

18.4

9.2

18.4

18.4

9.2

18.4

9.2

18.4

9.2

18.4

9.2

18.4

Required Information

Prior to Installation

(Actual Field Conditions)

A. Maximum and minimum

ow rate of pump

B. Minimum inside diameter

(I.D.) of well

C. Depth of well

D. Depth of pump setting

E. Pumping water level

F. Maximum diameter of

pump/motor

G. Overall length of pump

and motor

H. Pump’s riser size

Contact LAKOS so Worksheet LS-423 can be completed.

Page 2

For Submersible Pumps

H

F

Pump

Enclosure

Shell

LAKOS

Separator

For Turbine Pumps

IMPORTANT:

Separator models with

single-letter designations

(i.e. D, E, F, etc.) require a

minimum submergence of

30 ft (9.2m) below the

drawdown water level.

Models with three-letter

designations require 60 ft

(18.3m) submergence.

Minimum clearance below

separator’s purge discharge:

30 ft (9.2m)

Loading...

Loading...