Lada Niva 1700 User Manual

VAZ VEHICLES

VAZ-21213, VAZ-21214, VAZ-21214-20, VAZ-21215

REPAIR MANUAL

Contents |

|

Section 1. General data.......................................................... |

4 |

Section 2. Engine .................................................................. |

7 |

Engine - removal and refitting.......................................... |

12 |

Cylinder block .................................................................. |

19 |

Inspection and repair.................................................. |

19 |

Pistons and connecting rods ........................................... |

21 |

Selecting piston to cylinder ........................................ |

23 |

Dismantling and reassembly ...................................... |

23 |

Crankshaft and flywheel .................................................. |

24 |

Design description...................................................... |

24 |

Inspection and overhaul ............................................. |

24 |

Cylinder head and valve gear.......................................... |

26 |

General description .................................................... |

26 |

Valve clearance adjustment ....................................... |

27 |

Cylinder head - removal and refitting ......................... |

28 |

Cylinder head - dismantling and reassembly............ |

28 |

Camshaft and timing gear ............................................... |

32 |

Cooling system ............................................................... |

34 |

Lubrication system........................................................... |

38 |

Fuel system ..................................................................... |

42 |

Carburettor....................................................................... |

46 |

Exhaust gas recirculation system .................................... |

55 |

Exhaust system ............................................................... |

46 |

Chapter 3. Power train......................................................... |

57 |

Clutch .............................................................................. |

57 |

Gearbox........................................................................... |

64 |

Transfer box .................................................................... |

73 |

Drive line ......................................................................... |

80 |

Rear axle ......................................................................... |

84 |

Front axle ........................................................................ |

96 |

Chapter 4. Wheel suspensions ........................................... |

100 |

Alternator....................................................................... |

140 |

Starter motor ................................................................. |

146 |

Ignition system .............................................................. |

149 |

Lighting and signalling................................................... |

156 |

Windscreen wiper/washer ............................................. |

159 |

Instruments.................................................................... |

163 |

Chapter 8. Bodywork......................................................... |

167 |

Bodywork - repair ......................................................... |

169 |

Paintwork....................................................................... |

172 |

Door............................................................................... |

176 |

Bonnet, bumpers ........................................................... |

179 |

Bodywork glazing and windscreen washers ................. |

180 |

Instrument panel, seats................................................. |

181 |

Heater unit..................................................................... |

183 |

Chapter 9. VAZ-21213 vehicle modifications, alternative and addi-

tional equipment............................................................... |

185 |

VAZ-21214 vehicle ........................................................ |

185 |

Engine repair - description ............................................ |

185 |

Central Injection Unit..................................................... |

186 |

VAZ-21214-20 vehicle ................................................... |

189 |

Engine 21214-10 ........................................................... |

190 |

VAZ-21215-10 vehicle ................................................... |

197 |

Cooling system.............................................................. |

200 |

Lubrication system ........................................................ |

202 |

Fuel system ................................................................... |

202 |

Exhaust emission system.............................................. |

203 |

Electrical system ........................................................... |

203 |

Steering with BREED «SRS-40» |

|

driver’s airbag in the steering wheel ............................ |

209 |

Front suspension........................................................... |

102 |

Attachments |

212 |

|

Rear suspension |

110 |

|||

|

|

|||

Chapter 5. Steering ........................................................... |

115 |

|

|

|

Steering - inspection, check and adjustment ................ |

116 |

|

|

|

Steering mechanism...................................................... |

118 |

|

|

|

Chapter 6 Braking system.................................................. |

121 |

|

|

|

Front brakes .................................................................. |

128 |

|

|

|

Rear brakes................................................................... |

130 |

|

|

|

Handbrake..................................................................... |

134 |

|

|

|

ëhapter 7. Electrical system............................................... |

135 |

|

|

|

Wiring and fuses ........................................................... |

135 |

|

|

|

Battery ........................................................................... |

136 |

|

|

Д‚ЪУПУ·ЛОЛ ЗДб-21213, ЗДб-21214, ЗДб-21214-20, ЗДб-21215 кЫНУ‚У‰ТЪ‚У ФУ ВПУМЪЫ ‡‚ЪУПУ·ЛОВИ

©ЙЦзЦкДгъзхв СЦиДкнДеЦзн кДбЗанаь Д/й ДЗнйЗДб

©Д‚ЪУ ˚- ‡Б ‡·УЪ˜ЛНЛ: ЗУО„ЛМ л. з., дУБОУ‚ и. г., дУТ‡ В‚ л. з.

©иВ В‚У‰ б. ДМЛТУ‚УИ, а. лЪ‡МНУ‚УИ

©å‡ÍÂÚ-Ó Л„ЛМ‡О ЛБ„УЪУ‚ОВМ Еде миДЗк Дй ДЗнйЗДб. дУПФ¸˛ЪВ М‡fl ‚fi ТЪН‡ Л УЩУ ПОВМЛВ - З. ДО‡В‚, З. а‚НУ‚, З. еЛЪ УЩ‡МУ‚. ЪВО. (8482) 22-54-19.

àÁ‰. ‹ 0021311

2

About this manual

This Manual provides information on routine maintenance and servicing and is intended for engineers and mechanics of service outlets, garages and workshops.

The Manual covers the following models:

VAZ-21213 model |

- an off-road vehicle, three-door body of all-steel unitary construction, |

|

with 1.7 litre carburettor engine; |

VAZ-21214 model |

- with 1.7 litre Central Fuel Injection Engine; |

VAZ-21214-20 model - with 1.7 litre Sequential Fuel Injection Engine; |

|

VAZ-21215 model |

- with Turbo Diesel Engine. |

The chapters of the manual give full descriptions of VAZ-21213 vehicle units. For general description, service and repair procedures applicable to other models, refer to Section 9 where you can also find the information on additional and alternative equipment fitted to the vehicles.

The Manual provides a detailed description of service operations on the base of OEM parts, with helpful information on fault diagnosis, along with clear indications on removal and refitting, dismantling and reassembly, adjustment and repair of various vehicle units.

We recommend to use special tools and working facilities as listed in Attachment No 2. Tighten the thread connections to torques specified in Attachment No 1. Basic adjustments and inspection checks are outlined in Attachment No 3. Refer to Attachment 4 for recommended lubricants and fuels.

Due to the on-going process of vehicle improvement aimed to enhance the VAZ vehicle reliability and performance, the manufacturer can make alterations and design changes which may fail to enter this publication. Such changes and alterations will be incorporated into our manuals at the earliest opportunity.

The Manual describes the vehicle design as of October 1999.

3

Section 1. General Data

|

|

|

|

|

|

Table 1-1 |

|

TECHNICAL SPECIFICATION |

|

|

|

||

|

|

|

|

|

|

|

Features |

|

VAZ-21213 |

VAZ-21214 |

|

VAZ-21214-20 |

VAZ-21215 |

|

|

|

|

|

|

|

|

|

General |

|

|

|

|

Number of seats |

5 |

5 |

5 |

5 |

||

Kerb weight, kg |

1210 |

1210 |

1210 |

1240 |

||

Payload, kg |

400 |

400 |

400 |

400 |

||

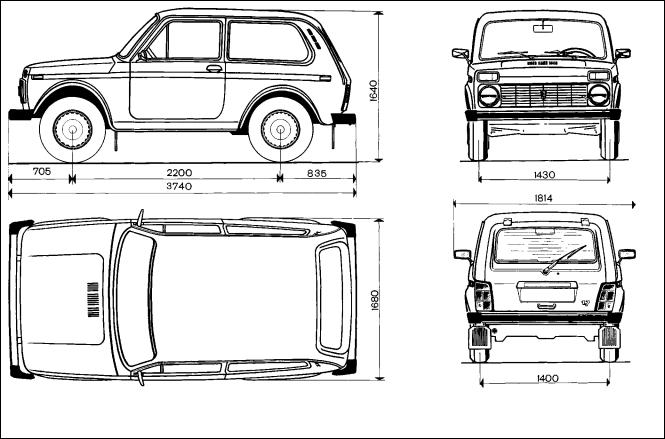

Overall dimensions |

|

|

|

Fig.1-1 |

|

|

Maximum braking distance at GVW and 80 km/h |

|

|

|

|

|

|

on horizontal dry flat asphalt road, not greater, meters: |

|

|

|

|

|

|

• with service braking system applied |

40 |

40 |

40 |

40 |

||

• with emergency system applied (either of two service braking circuits) 90 |

90 |

90 |

90 |

|||

Maximum speed* in top gear, km/h: |

|

|

|

|

|

|

• with driver and passenger |

137 |

137 |

137 |

130 |

||

• at full load |

135 |

135 |

135 |

128 |

||

Acceleration time*, 0 to 100 km/h through gear shifting, seconds: |

|

|

|

|

||

• with driver and passenger |

19 |

19 |

19 |

22 |

||

• at full load |

21 |

21 |

21 |

24 |

||

|

|

Engine |

|

|

|

|

Model |

21213 |

21214 |

21214-10 |

DHW (XUD-9SD) |

||

Type |

|

Four-stroke, |

Four-stroke, |

|

Four-stroke, |

Four-stroke, |

|

|

petrol, carburettor |

petrol, CFI |

|

petrol, sequential injection |

turbo diesel |

No of cylinders |

|

four in-line |

four in-line |

|

four in-line |

four in-line |

Bore x stroke, mm |

|

82ı80 |

82ı80 |

|

82ı80 |

83ı88 |

Capacity, litre |

1.69 |

1.69 |

1.69 |

1.905 |

||

Compression ratio |

9.3:1 |

9.3:1 |

9.3:1 |

21.5:1 |

||

Maximum power: |

|

|

|

|

|

|

as per GOST 14846 (net), at least, ÍW (h.p.) |

58 (78.9) |

58 (78.9) |

58.5 (79.6) |

55 (74.8) |

||

as per ISO 1585, ÍW |

58 |

58 |

58.5 |

55 |

||

Maximum crankshaft speed at maximum power, rpm |

5200 |

5400 |

5000 |

4600 |

||

Firing order |

1-3-4-2 |

1-3-4-2 |

1-3-4-2 |

1-3-4-2 |

||

____________________________________

* Measured using a special procedure

4

Features |

VAZ-21213 |

VAZ-21214 |

|

VAZ-21214-20 |

|

VAZ-21215 |

|

|

|

|

|

|

|

|

Power train |

|

|

|

|

|

Clutch |

|

single dry plate, diaphragm spring |

|

|||

Clutch release mechanism |

|

hydraulic, servo spring |

|

|||

Transmission |

|

5-speed, synchro units on all forward gears |

|

|||

Gear ratio: |

|

|

|

|

|

|

• first gear |

3.67 |

3.67 |

3.67 |

|

3.67 |

|

• second gear |

2.10 |

2.10 |

2.10 |

|

2.10 |

|

• third gear |

1.36 |

1.36 |

1.36 |

|

1.36 |

|

• fourth gear |

1.00 |

1.00 |

1.00 |

|

1.00 |

|

• fifth gear |

0.82 |

0.82 |

0.82 |

|

0.82 |

|

• reverse gear |

3.53 |

3.53 |

3.53 |

|

3.53 |

|

Transfer case |

|

two-gear, lockup differential |

|

|||

Gear ratio: |

|

|

|

|

|

|

• top gear |

1.2 |

1.2 |

1.2 |

|

1.2 |

|

• bottom gear |

2.135 |

2.135 |

2.135 |

|

2.135 |

|

Transfer case differential |

|

bevel gears, |

two pinion gears |

|

||

Drive line: |

|

|

|

|

|

|

• from transmission to transfer case |

|

flexible coupling and CV joints |

|

|||

• from transfer case to front and rear axles |

two universal joints on needle bearings with grease nipples and yokes |

|||||

• from front axle to wheels |

|

open, with CV joints |

|

|||

Final drive ratio, front and rear axles |

|

bevel, hypoid |

|

|||

• gear ratio |

3.9 |

3.9 |

3.9 |

|

3.9 |

|

• differential |

|

bevel, two pinion gears |

|

|||

|

Suspension and wheels |

Front suspension |

independent, lower track control arms (wishbones), coil springs, |

|

hydraulic telescopic shock-absorbers, anti-roll bar |

Rear suspension |

rigid axle beam with Panhard rod and four trailing arms, |

|

coil springs/hydraulic telescopic shock-absorbers |

Wheels |

pressed-steel disc |

• wheel rim |

127J x 406 (5J x 16) |

Tyres |

tubed, cross-ply or radial ply |

size: |

|

• cross-ply tyres |

175 x 406 (6.95 x16), |

• radial-ply tyres |

175/80R16 |

5

Features |

VAZ-21213 |

VAZ-21214 |

VAZ-21214-20 |

VAZ-21215 |

|

|

|

|

|

|

Steering |

Steering mechanism |

globoidal worm, double-crest roller, steering ratio 16.4 |

Steering linkage |

three links, relay rod and two steering rods, |

|

drop arm, idler arm and swing arms |

|

Braking system |

Service braking system: |

|

• front brakes |

disc-type, floating caliper, automatic disc-to-pad clearance adjustment |

• rear brakes |

drum-type, self-applying shoes and automatic shoe-to-drum clearance adjustment |

• brake operation line |

foot-type, hydraulic, dual circuit, split diagonally, vacuum servo unit and pressure regulator |

Handbrake |

cable-operated on rear wheels |

|

Electrical system |

Wiring diagram |

single-wire, negative earth type |

Voltage, volts |

12 |

Battery |

6ëí-55Ä, 55 ampere-hour |

Alternator |

AC, integral diode plate and electronic voltage regulator |

Starter motor |

pre-engaged, solenoid switch and overrun clutch |

|

Body |

Type |

all-steel unitary construction, monocoque, three-door, double-space |

Fig.1-1. Basic overall dimensions of VAZ-21213 vehicle

6

Section 2. Engine

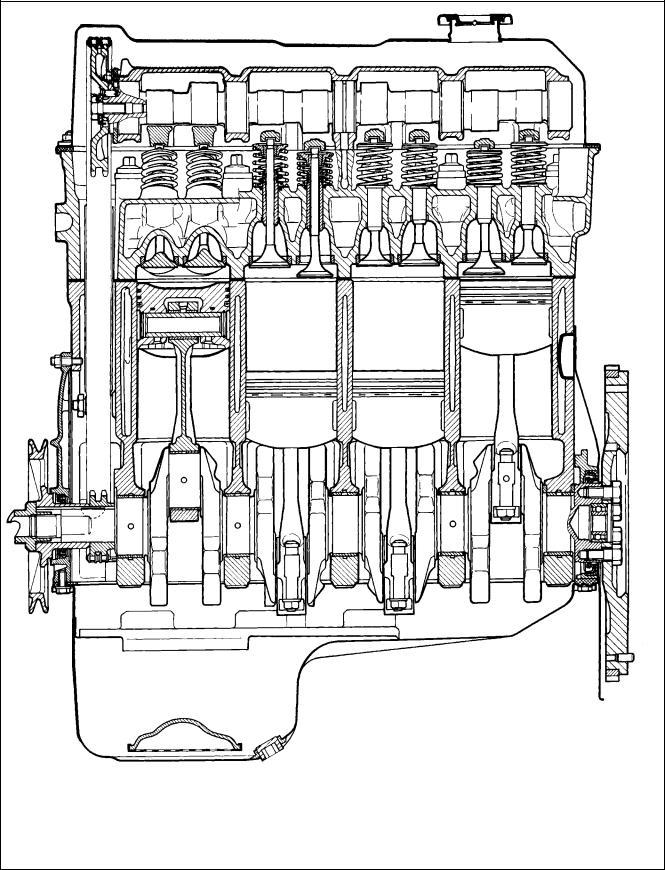

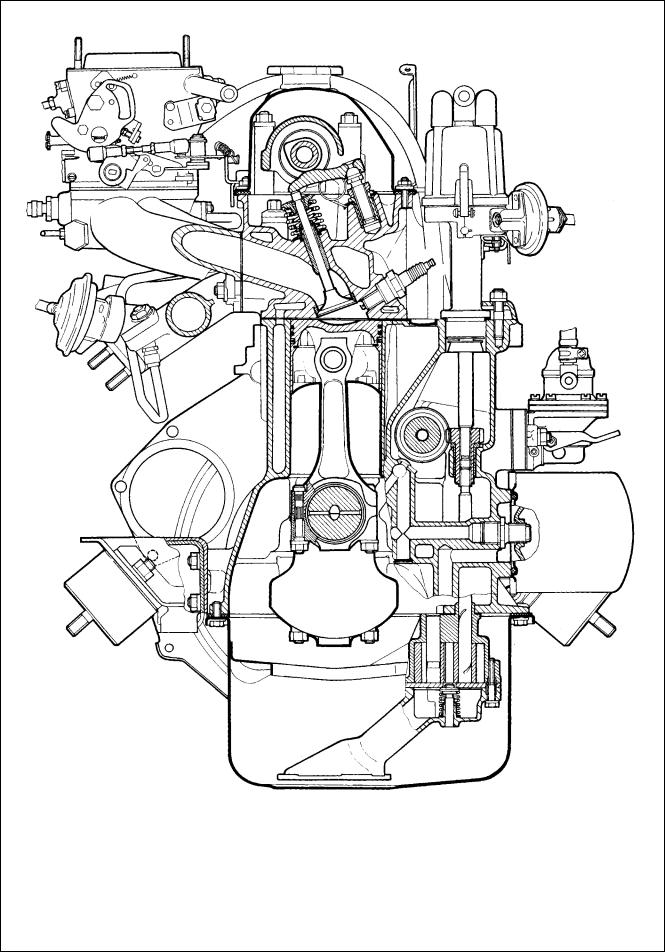

Refer to Fig.2-1 and Fig.2-2 for front and side sectional views of the engine.

Fig.2-1. Side sectional view of the engine

7

Fig.2-2. Front sectional view of the engine

8

Fault diagnosis

Symptom/fault |

Remedy |

|

|

Engine fails to start

1. No fuel to carburettor:

-blocked fuel pipes or fuel filter;

-clogged carburettor or fuel pump filters;

-faulty fuel pump

2.Ignition system fault

3.Carburettor fuel cutoff solenoid fails to open at ignition switch-on:

-disconnected, loose or broken wiring to solenoid or solenoid control unit;

-faulty solenoid control unit;

-defective fuel cutoff solenoid

4. Carburettor choke not opening at first flashes in cylinders

1. Carry out the following operations:

-blow fuel pipes, clean fuel tank, renew fuel filter;

-clean filters;

-check pump operation and renew any damaged components 2. Refer to section «Ignition system»

3. Carry out the following:

-check wiring and connections, renew damaged wires;

-renew control unit;

-replace solenoid with a new one

4. Eliminate any leakage of choke pull-down unit

Engine idles erratically or stalls

1.Incorrectly adjusted idle speed

2.Defective carburettor solenoid control system

3.Faulty carburettor:

-blocked carburettor jets or internal passages;

-water in carburettor;

-broken choke control diaphragm

4.Ignition system fault

5.Vacuum leak through damaged hose between intake pipe and brake servo unit

6.Air leak through gaskets at connections between intake pipe and carburettor/cylinder head

7.Leaking distributor vacuum pipe

1.Adjust idle speed

2.Refer to «Engine fails to start»

3.Carry out the following:

-blow carburettor jets and internal passages;

-remove water from carburettor, drain sludge from fuel tank;

-fit new diagram

4.Refer to section «Ignition system»

5.Replace damaged hose

6.Tighten retaining nuts or renew gaskets; eliminate carburettor flange deformation or fit new carburettor

7.Fit new pipe in place of damaged one

Engine lacks power and has poor acceleration

1.Partly open throttle

2.Choked air cleaner element

3.Ignition system fault

4.Faulty fuel pump

5.Faulty carburettor:

-faulty accelerator pump;

-blocked main jets;

-partly open choke;

-low fuel level in float chamber;

-leaky throttle enrichment diaphragm 6. Restricted fuel tank vent pipe

7. Incorrect valve clearances

8. Misaligned timing marks

9. Insufficient cylinder compression - below 1 åP‡ (10 kgf/Òm2):

-broken or sticking piston rings;

-poor valve-to-seat fitting;

-excessively worn cylinders or piston rings

1.Adjust throttle linkage

2.Change filter element

3.Refer to section «Ignition system»

4.Check pump operation and renew any damaged components

5.Carry out the following:

-check pump operation, renew damaged parts;

-blow jets with compressed air;

-adjust choke operation;

-adjust float;

-replace diaphragm

6.Blow pipe with compressed air

7.Adjust valve clearances

8.Adjust timing belt accordingly, align timing marks

9.Carry out the following:

-clean piston rings or grooves from carbon deposits, renew damaged components;

-replace damaged valves, regrind valve seats;

-replace pistons, rebore and hone cylinders.

9

Main bearing knocking

Typical knocking or thumping noticeable at sudden throttle opening at idle which intensifies with higher crankshaft rate. Excessive endfloat of crankshaft causes sharper irregular knocking, especially noticeable during smooth increase or decrease in crankshaft speed.

1. |

Early ignition |

1. |

Adjust ignition timing |

2. |

Insufficient pressure oil |

2. |

Refer to subsection «Insufficient oil pressure at idle» |

3. |

Loose flywheel securing bolts |

3. |

Tighten bolts to torque specified |

4. |

Excessive main bearing running clearance |

4. |

Grind journals and renew bearing shells |

5. |

Excessive thrust washers-to-crankshaft clearance |

5. |

Fit new thrust washers, check clearance |

|

|

|

|

Big-end bearing knocking

Big-end bearing knocking is sharper than that of main bearings. It is noticeable during engine idle at sudden throttle opening. The origin of knocking can be easily identified through switching off spark plugs one at a time.

1. |

Insufficient oil pressure |

1. |

Refer to «Insufficient oil pressure at idle» |

2. |

Excessive big-end bearing running clearance |

2. |

Fit new bearing shells and regrind journals |

Piston slap

Thumping noise caused by piston «runout» in cylinder. Most noticeable at low crankshaft speed and under load.

1. |

Excessive piston-to-cylinder bore clearance |

1. |

Renew pistons, rebore and hone cylinders |

2. |

Excessive gudgeon pin-to-piston groove clearance |

2. |

Fit new rings or new pistons with rings |

|

|

|

|

Knocking of intake or exhaust valves

Excessive valve clearances cause typical regular noise; its frequency is lower than the frequency of any other engine noise, since the valves are operated by camshaft rotating at half the crankshaft speed.

1. |

Excessive valve clearances |

1. |

Adjust clearances |

2. |

Broken valve spring |

2. |

Renew spring |

3. |

Excessive valve-to-guide clearance |

3. |

Replace worn parts |

4. |

Worn camshaft lobes |

4. |

Renew camshaft and levers |

5. |

Loose locknut of adjuster bolt |

5. |

Adjust clearance between lever and cam, tighten locknut |

|

|

|

|

Excessive noise of camshaft operation line

Noise from camshaft operation line is caused by clearances between engagement elements and becomes noticeable in general engine noise at low crankshaft speed.

1. Tighten chain

1. Loose chain caused by general wear

2. Renew tensioner shoe or damper

2. Broken chain tensioner shoe or damper

3. Eliminate seizure

3. Seized chain tensioner plunger rod

Insufficient oil pressure at warm engine idle

1.Foreign particles entrapped under oil pump relief valve

2.Seized oil pressure relief valve

3.Worn oil pump gears

4.Excessive main bearing running clearance

5.Excessive camshaft bearing journal-to-bearing housing clearance

6.Incorrect oil grade or inappropriate oil quality

1.Clean valve from foreign particles and flash, clean oil pump

2.Renew valve

3.Repair oil pump

4.Turn journals and renew bearing shells

5.Renew camshaft or bearing housing

6.Change oil as recommended in Attachment 4

|

|

Excessive oil pressure on warm engine |

||

1. |

Seized oil pressure relief valve |

|

Renew valve |

|

|

1. |

|||

2. |

Excessively tough spring of oil pressure relief valve |

|

2. |

Renew spring |

|

|

|

|

|

10

Excessive oil consumption

1.Oil leaking through engine gaskets

2.Restricted crankcase ventilation system

3.Worn piston rings

4.Broken piston rings

5.Foul windows of oil scraper rings or foul slots in piston grooves due to wrong oil

6.Worn or damaged valve oil caps

7.Badly worn valve stems or guides

1.Tighten fittings or replace gaskets and oil seals

2.Wash components of crankcase ventilation system

3.Rebore and renew pistons and rings

4.Renew rings

5.Clean windows and slots of carbon, change motor oil as recommended in Attachment 4

6.Renew oil caps

7.Renew valves, repair cylinder head

|

Excessive fuel consumption |

|||

1. |

Choke not fully opened |

|

1. |

Adjust choke linkage |

|

||||

2. |

Excessive resistance to vehicle motion |

|

2. |

Check and adjust pressures in tyres, braking system, wheel alignment |

3. |

Incorrect ignition timing |

|

3. |

Adjust ignition timing |

4. |

Defective distributor vacuum unit |

|

4. |

Renew vacuum unit or ignition distributor |

5. |

High fuel level in carburettor: |

|

5. |

Carry out the following: |

- leaking needle valve or its gasket; |

|

- check for any foreign matter entrapped between needle and valve seat; |

||

|

|

|

renew valve or gasket as applicable; |

|

- seizure or excessive friction hindering normal float operation |

|

- check and when necessary replace floats |

||

|

|

|

||

6. |

Choked carburettor air jets |

|

6. |

Clean jets |

|

|

|

||

7. |

Leaking part throttle enrichment diaphragm |

|

7. |

Replace diaphragm |

|

|

|

||

8. |

Carburettor solenoid failed to shut off fuel at overrun: |

|

8. |

Following to be done: |

|

|

|

||

- no earthing of idle switch sliding contact; |

|

- clean solenoid contact surfaces; |

||

|

|

|

||

- broken wire between control module and carburettor idle switch; |

|

- check wiring and connections, renew damaged wire; |

||

|

|

|

||

- faulty control module |

|

- renew control unit |

||

|

|

|

||

Engine overheating

Coolant temperature gauge needle is in the red sector. Start tracing the failure with checking coolant temperature gauge and its sender (Refer to section «Instrumentation»).

1. |

Slackened pump and alternator drive belt |

1. |

Adjust drive belt tension |

2. |

Insufficient coolant in system |

2. |

Top up coolant to cooling system |

3. |

Incorrect ignition timing |

3. |

Adjust ignition timing |

4. |

Dirty radiator outside |

4. |

Clean radiator outside with water jet |

5. |

Defective thermostat |

5. |

Renew thermostat |

6. |

Faulty radiator cap inlet valve (opening pressure is below 0.07 MPa |

6. |

Renew cap |

(0.7 kgf/cm2) |

|

|

|

7. |

Defective coolant pump |

7. |

Check pump operation, renew or repair pump |

|

|

|

|

Sudden coolant drop in expansion tank

1.Damaged radiator

2.Damaged cooling hoses or pipe gaskets, loose clips

3.Leaking heater tap or heater matrix

4.Leaking water pump seal

5.Damaged radiator cap or cap seal

6.Defective cylinder head gasket

7.Leaks from fissures in cylinder block or cylinder head

8.Leaks from fissures in water pump housing, water jacket return pipe, thermostat, expansion tank or intake pipe

1.Repair or renew radiator

2.Renew damaged hoses or gaskets, tighten hose clips

3.Renew tap or heater matrix

4.Renew seal

5.Renew cap

6.Renew gasket

7.Check cylinder block and cylinder head for leakage; renew damaged components in case of evident cracking

8.Check for leaks; renew components in case of fissures; minor leaks can be cured by adding a radiator sealant such as заалл-1

11

Engine - removal and refitting

Put the vehicle on a lift or over an inspection pit and apply the handbrake. Take out the spare wheel and its supporting pipe. Disconnect the battery leads and withdraw the battery. Unbolt and remove the bonnet.

To remove the air cleaner, disconnect its hoses, remove the cover and filter element. Temporarily plug the carburettor.

Disconnect the throttle linkage and choke cable.

Disconnect the wires from the fuel cutoff solenoid, idle switch, oil pressure sensor, coolant temperature sensor, ignition distributor, alternator and starter motor.

Drain coolant from the radiator, cylinder head and heater unit. To do this, shift the heater tap control lever to the right, undo the caps on the cylinder block left side and radiator right-hand fluid cooler, screw instead the return hoses connectors, then undo the caps of the expansion tank and radiator.

Separate the fan cowl halves and remove the fan blower cowl. Disconnect the coolant supply and return hoses from the engine. Undo two bolts retaining the radiator to the body, release the top catch of the fan cowl, move the top radiator toward the engine and withdraw the radiator from the engine bay complete with the thermostat and associated hoses. Remove the fan cowl.

Undo the nuts holding the downpipe to exhaust manifold. Detach the downpipe from the bracket on the transmission and lower it down.

Slacken the clips, disconnect the hoses from the fuel pump and secure the pump in the position that excludes any fuel leakage. Detach the fuel return hose from the carburettor.

Release the clips and disconnect the hoses from the heater manifolds, detach the brake servo hose from the intake pipe.

Use socket spanner 02.7812.9500 to unbolt the starter motor from the clutch housing. Undo the bolts holding the clutch housing cover to the lower clutch. Using Ä.55035 undo the clutch bellhousing to the cylinder block.

Hoist the beam íëé-3/379 and secure the engine right side to the lifting yoke at the front exhaust manifold stud, while the left side shall be secured through the clutch housing mounting hole.

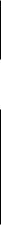

Slightly tension the hoist, undo the nuts that retain front engine mounting rubbers 3 (Fig.2-3) to the side brackets, undo the nut and bolt holding the front axle housing to the engine brackets. Disconnect the engine negative lead.

Lift out the engine, first raise its top in order to take the bolts of the mounting rubber out of the bracket holes, then move the engine forward in order to release the input shaft from the bearing in the crankshaft flange.

Fig. 2-3. Engine mounting unit:

1 - right-hand support bracket with rubber; 2 - left-hand support bracket; 3 - mounting rubber; 4 - cross-piece, rear mounting; 5 - bracket with rear mounting

12

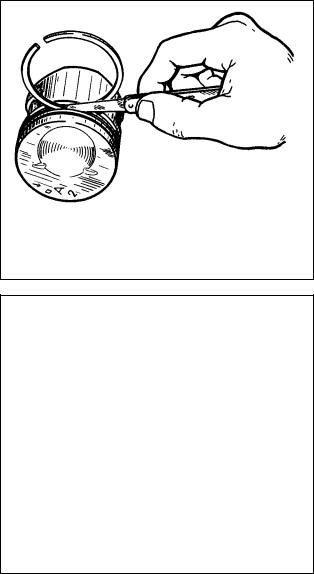

Fig.2-4. Removing the oil filter using tool Ä.60312

Remove the starter motor heat shield, followed by the starter motor, hot air intake complete with the supply hose. Remove from the cylinder head two side brackets together with the front engine mounting rubbers.

Unbolt the clutch and withdraw it.

Refitting is a reversal of the removal procedure. Draw special attention to the engine-to-transmission connection: the input shaft must precisely engage the clutch disc splines. Furthermore, for perfect engine/transfer box centering, the centering washers of the front engine mounting rubbers must be in the respective side brackets holes.

Engine - dismantling

Flush the engine, mount it on a stand for dismantling and drain the oil sump.

Remove the carburettor, for that disconnect the hoses and throttle operating rod.

Remove the fuel pump and ignition distributor. Use spanner 67.7812.9514 to unscrew the spark plugs and coolant temperature sensor.

Remove the alternator and water pump drivebelt. Remove the alternator and its retaining bracket.

On the pump and exhaust manifold disconnect the coolant supply pipe from the heater.

From the pump and exhaust manifold disconnect the coolant supply pipe from the heater.

Use tool Ä.60312 to undo the oil filter with seal, remove the oil filter and seal (Fig.2-4).

Unscrew the oil pressure warning lamp sender. Remove the crankcase vent breather cover, crankcase and oil pump. Remove the oil separator drain pipe catch and take out the oil separator.

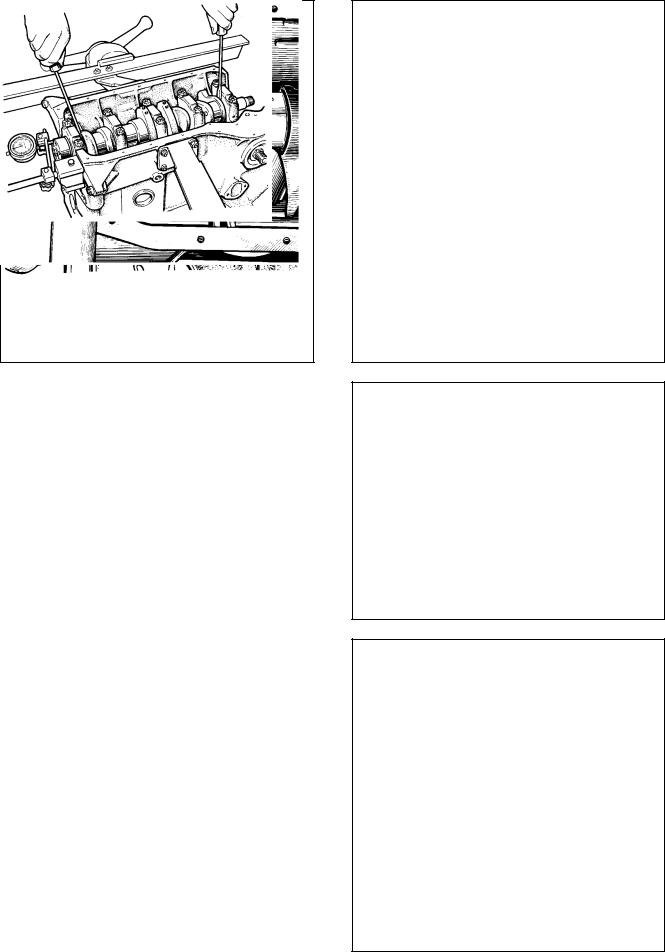

To remove the crankshaft pulley, secure the flywheel using Ä.60330/R (Fig. 2-10) and undo the nut using tool Ä.5012 (Fig. 2- 5). Withdraw the valve cover and timing cover. Unbolt the

Fig.2-5. Releasing the crankshaft nut using tool Ä.50121

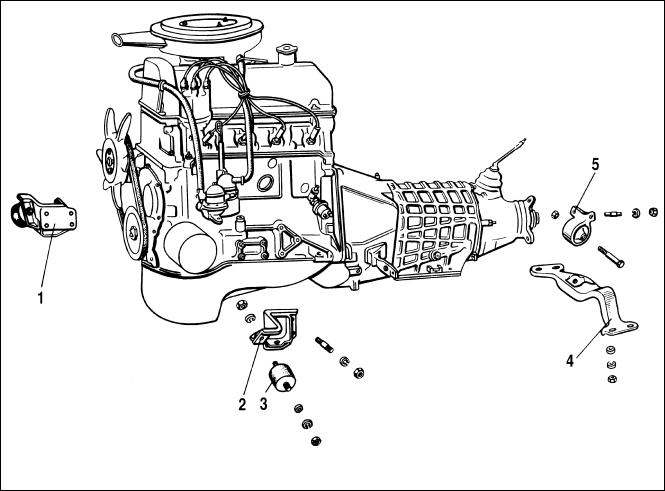

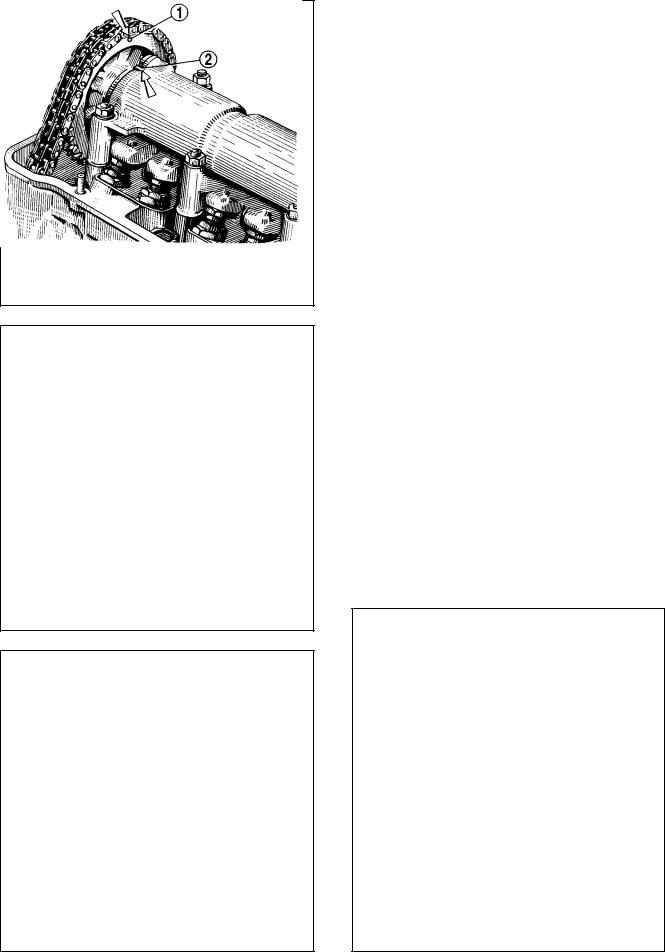

Fig.2-6. Removing the chain tensioner and damper:

1 - camshaft timing chain; 2 - shoe retaining bolt; 3 - tensioner chain; 4 - tensioner retainer nut; 5 - tensioner housing; 6 - tensioner cap nut; 7 - chain damper securing bolts; 8 - oil pump shaft sprocket retaining bolt

camshaft and oil pump drive shaft sprockets.

Slacken chain tensioner cap nut 6 (Fig.2-6), undo nut 4 holding it to the cylinder head, remove the tensioner; then unbolt and remove chain tensioner shoe 3.

Undo the chain stop pin, remove the oil pump and camshaft sprockets, then take off the chain.

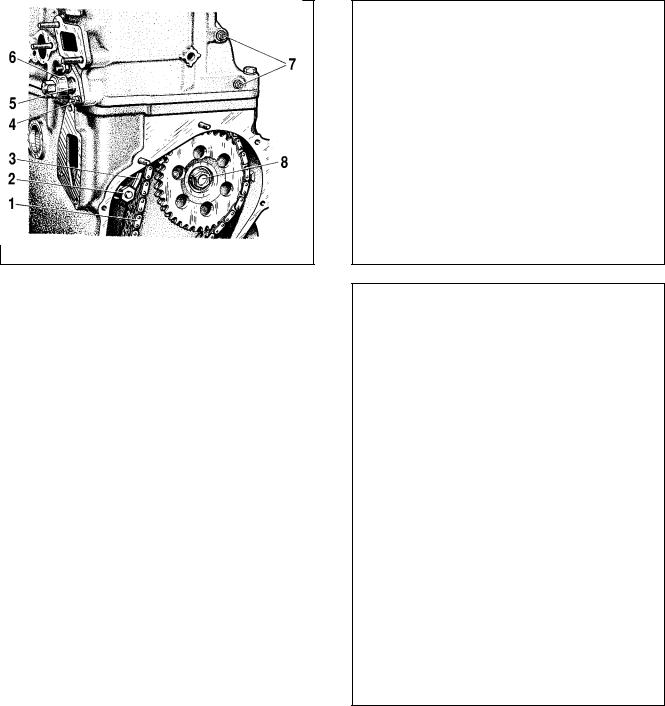

Loosen studs 4 nuts (Fig. 2-7). Remove the camshaft bearing housing. Undo studs 4 nuts, remove thrust flange 1 and withdraw the camshaft exercising maximum care not to damage the camshaft bearing housing surface.

Unbolt the cylinder head and withdraw it complete with the exhaust manifold and intake pipe.

13

Fig.2-7. Removing the camshaft thrust flange:

1 - thrust flange; 2 - camshaft; 3 - bearing housing; 4 - thrust flange securing stud

Remove thrust flange 1 (Fig.2-8) of the oil pump drive shaft and take the shaft out of the cylinder block.

Using picker Ä.40005/1/7 (kit Ä.40005) drive the sprocket off the crankshaft (Fig.2-9).

Undo the connecting rod bolts, remove the big end cap and carefully lift the pistons with the conrods through the cylinders. Mark the piston, connecting rod, main and big-end bearing shells for position to facilitate the reassembly.

WARNING. When removing the pistons and conrods, do not press out the connecting rod bolts.

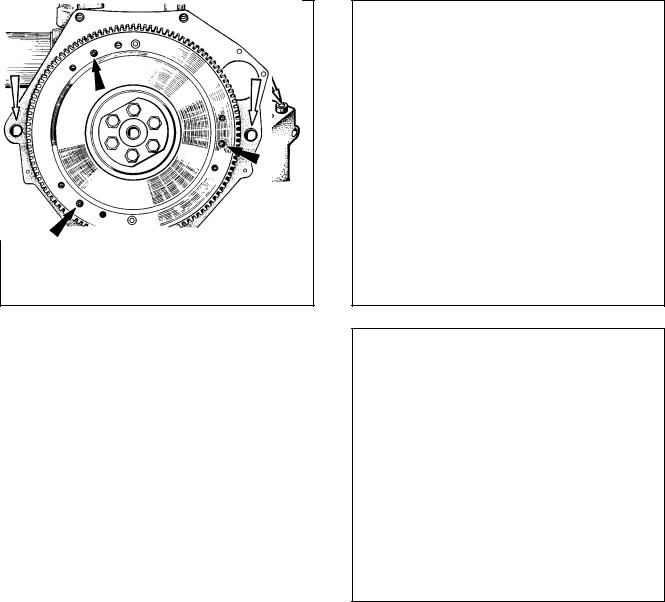

Fit tool 5 (Fig.2-10), undo bolts 3, remove washer 4 and the flywheel from the crankshaft. Remove the front clutch housing cover.

Using tool Ä.40006, take the input shaft bearing out from the crankshaft (Fig.2-11).

Remove the crankshaft oil seal retainer.

Unbolt the main bearing cap bolts, remove them complete with the lower bearing shells, then lift out the crankshaft, top bearing shells and rear bearing thrust washers.

Engine - reassembly

Follow the engine reassembly procedure as below:

Locate a clean cylinder block and screw in any missing dowels. Oil the crankshaft bearing shells, thrust washers, pistons and oil seals. Always fit new crankshaft oil seals when reassembling the engine after overhaul.

Fig.2-8. Removing the oil pump shaft:

1 - thrust flange; 2 - flange securing bolt; 3 - oil pump shaft; 4 - wrench

Fig. 2-9. Removing the crankshaft sprocket using a picker

Fig.2-10. Removing the flywheel:

1 - wrench; 2 - flywheel; 3 - flywheel securing bolt; 4 - washer; 5 - tool Ä.60330/R to lock the flywheel stationary; 6 - front clutch housing cover

14

Fig.2-11. Pressing out the bearing from the crankshaft using tool A.40006

Fit the centre main bearing shells without an oilway into the bearing recesses. Fit into other cylinder bores the bearing shells with an oilway, while into the relevant main bearing caps - the bearing shells without an oilway. Lower the crankshaft into position, then stick two thrust washers into the rear bearing recesses (Fig.2-12).

WARNING. The washers must be fitted so that their oilways face away from the bearings in the block and cap (antifriction coat is applied on the washer surface). At the rear of the rear main bearing there fitted a sintered thrust washer (yellow), while at the front - a steel-aluminium thrust washer.

Locate the main bearing caps according to the marks on their outer surface (Fig.2-13). Tighten the cap securing bolts.

Check the crankshaft endfloat. To do this, turn the cylinder block to have the rear side up and position the dial gauge foot against the crankshaft flange (Refer to Fig.2-14). Moving the crankshaft up and down (using screwdrivers, for instance), check the crankshaft endfloat to be within 0.06-0.26 ÏÏ. If not, adjust accordingly and replace the old thrust washers with new ones or fit thicker thrust washers.

Locate the rear oil seal housing gasket on the crankshaft flange, insert the front clutch housing cover bolts into the respective bores (Fig.2-15). Place the oil seal housing on tool 41.7853.4011 and slide it to on the crankshaft flange; next secure it to the cylinder block with the bolts.

Locate front clutch housing cover 6 (Fig.2-10) over two centering pins (Fig. 2-16). Secure the cover to the rear oil seal housing with nuts.

Fig. 2-12. Refitting the thrust washers to the rear mounting

Fig.2-13. Marks on the main bearing caps (bearing are numbered from the engine front end)

Fig.2-14. Checking the crankshaft endfloat

15

Fig.2-15. Crankshaft rear oil seal housing.

The lugs (arrowed) for centering the housing against the crankshaft flange

Locate the flywheel in position so that the marking (a cut-out) near the rim is against the No 4 cylinder crankpin axis. While holding the flywheel stationary with tool Ä.60330/R, bolt it to the crankshaft flange to the specified torque.

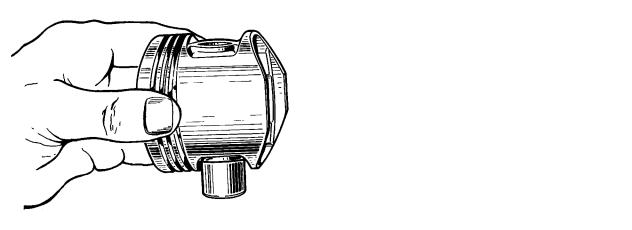

Using a ring compressor (tool 67.8125.9502), fit the pistons and connecting rods to the cylinders (Fig.2-17).

WARNING. The hole for gudgeon pin in the piston is 1.2 mm set off, so the arrows on the piston crown must face the timing belt end of the engine when inserting the pistons into the cylinders.

Press the big-end bearing shells into the connecting rods and caps. Guide the conrods and big-end caps onto the crankshaft journal, then tighten the connecting rod bolts. The big-end caps must be positioned so that the cylinder number on the cap is against the cylinder number on the connecting rod big-end.

Refit the crankshaft sprocket. Locate the oil pump shaft and secure it with the thrust flange.

Insert two centering pins into the cylinder block (Fig.2-17) and locate the cylinder head gasket over them.

WARNING. Always fit the new cylinder head gasket. Never re-use the old gasket.

Before refitting the gasket, remove any oil from the mating surfaces of the block and cylinder head. Make sure the gasket is perfectly clean and dry. Avoid any incidental oiling of the gasket.

Turn the crankshaft so that the pistons are midway in the cylinder bore.

Refit the cylinder head complete with the valves, exhaust manifold and intake pipe over the centering pins.

Fig.2-16. Clutch dowels (arrowed black) and clutch housing centering pins (arrowed white)

Fig.2-17. Fitting the pistons complete with piston rings using ring compressor; centering pins of the cylinder head (arrowed)

Tighten the cylinder head bolts in the established procedure (Fig.2-18) in four steps to ensure a reliable fit and exclude further tightening during vehicle servicing.

1st step - tighten the bolts 1-10 to 20 N•m(2 kgf•m);

2nd step - tighten the bolts 1-10 to 69.4-85.7 N•m

(7.1-8.7 kgf•m), while the bolt 11 to 31.36 -

39.1 N•m (3.2-3.99 kgf•m);

3rd step - turn the bolts 1-10 to 90°;

4th step - turn again all bolts 1-10 to further 90°.

WARNING. The cylinder head bolts can be re-used only when their length is not in excess of 120 mm, otherwise renew the bolt.

Before reassembly, immerse the bolts, thread and head, into engine oil. Allow the excess oil drip for at least 30 minutes. Remove all entrapped oil from the bolt bores in the cylinder head.

16

Fig. 2-18. Cylinder head bolt tightening sequence

Fig. 2-19. Aligning the timing marks on the crankshaft sprocket and cylinder block

Fig.2-20. Centering pins for camshaft bearing housing

Turn the flywheel so that the mark on the crankshaft sprocket is against the cylinder block mark (Fig.2-19).

Check to see the camshaft bearing housing centering pins are in position (Fig.2-20). Refit the sprocket to the camshaft complete with the bearing housing and turn the camshaft so that the timing mark in the sprocket is aligned against the mark on the bearing housing (Fig.2-21). Remove the sprocket and without changing the camshaft position, refit the bearing housing to the cylinder head so that the centering pins are in the respective bores of the bearing housing. Secure the bearing housing, tightening the nuts in the sequence as shown in Fig.2-22.

Refit the chain vibration damper.

Refit the camshaft timing chain:

-fit the chain onto the camshaft sprocket and position the sprocket so its TDC mark is aligned with the respective mark on the bearing housing (Fig.2-21). Do not tighten the sprocket bolt fully;

-fit the sprocket to the oil pump shaft, but do not tighten the retaining bolt fully;

-fit the chain tensioner shoe and tensioner, but do not tighten the cap nut so that the tensioner spring can compress the shoe; screw the chain stop pin into the cylinder block;

-turn the crankshaft two turns forward to ensure the chain tension required; check the indentations in the sprockets are aligned with TDC marks in the cylinder block and bearing housing (Fig.2-19 and Fig.2-21);

-when the marks are aligned, hold the flywheel stationary with tool Ä.60330/R (Fig.2-10), then tighten the sprocket securing bolts and chain tensioner cap nut to the torques specified, bend the sprocket bolt lock washers; should the marks are not aligned, repeat the chain refitting procedure.

Fig.2-21. Aligning the timing mark on the camshaft sprocket against bearing housing mark:

1 - mark in sprocket; 2 - mark on bearing housing

17

Fig.2-22. Camshaft bearing housing nuts tightening sequence

Adjust the clearance between the camshaft lobes and valve levers.

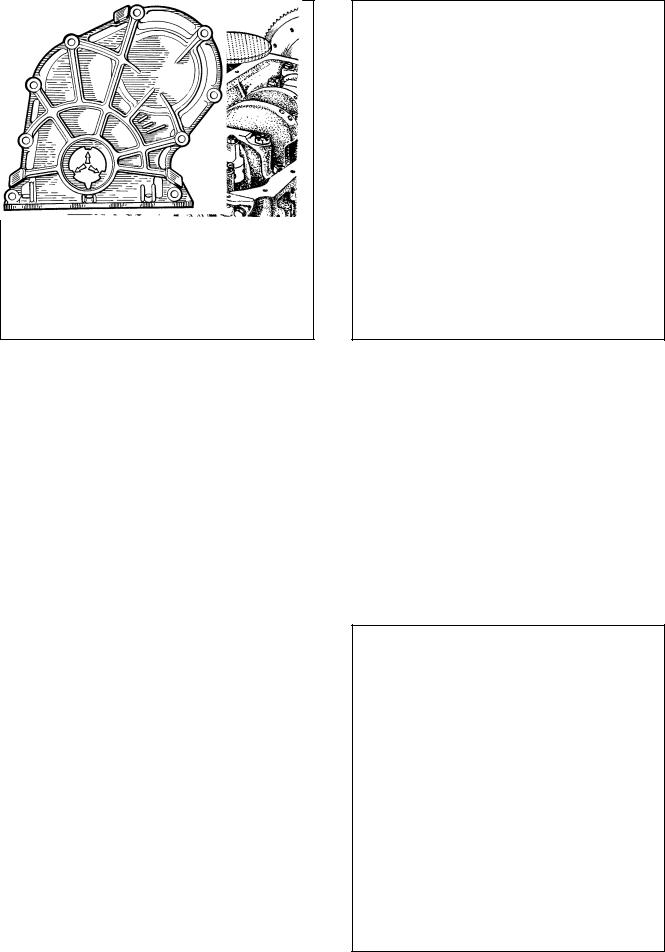

Refit the camshaft cover (Fig.2-23) complete with the gasket and oil seal to the cylinder block, do not tighten the retaining bolts and nuts fully. Using tool 41.7853.4010 centralize the cover against the crankshaft end, then tighten the retaining nuts and bolts to the torques specified.

Fit the alternator and oil pump pulley, then secure it with the

nut.

Fit the oil filter complete with the gasket, manually screw it to the union on the cylinder block. Refit the crankcase vent oil separator, breather cover and secure the oil separator drain pipe with the clip.

Fit oil pump 1(Fig.2-24), then fit the oil sump with the gasket.

Fit the coolant pump, alternator bracket and alternator. Fit the belt around the pulleys and adjust the belt tension.

Fit the heater matrix supply pipe and cooling water jacket outlet pipe to the cylinder block. Secure the heater matrix drain pipe to the coolant pump and outlet pipe.

Fit the instrumentation sensors.

Fit the oil pump / distributor gear, followed by the ignition distributor. Insert the spark plugs, place spanner 67.7812.9515 on the spark plugs and tighten the spark plugs with a torque wrench to the torques specified.

Fit the fuel pump as outlined in section «Fuel system».

Fit the carburettor and reconnect the hoses. Cover the carburettor with a provisional cap.

WARNING. Never secure the carburettor (or tighten its retaining nuts) when it is warm.

Fig.2-23. Timing cover

Projections (arrowed) for cover centering against crankshaft pulley hub

Fit the valve cover complete with the gasket and fuel piping bracket.

Fit the air cleaner, to do this secure the hoses to the air cleaner housing, fit the filter housing complete with the gasket to the carburettor, then fit the mounting plate and secure the housing with nuts. Locate the filter element and secure the air cleaner cover.

Reconnect the HT leads to the distributor and spark plugs.

Fill the engine with motor oil through the oil filler in the valve cover.

Fig.2-24. Refitting the oil pump:

1 - oil pump; 2 - drain pipe lock; 3 - oil separator drain pipe

18

Engine run-in after overhaul

After overhaul the engine is bench tested (run-in) at no loads under the following cycle:

750-800 rpm |

2 minutes |

1000 rpm |

3 minutes |

1500 rpm |

4 minutes |

2000 rpm |

5 minutes |

Locate the engine on the test bench, start the engine and make checks with respect to the following items:

-evidence of coolant or fuel leaks through mating components, pipe connections or gaskets;

-oil pressure and oil leaks through gaskets;

-ignition timing;

-idle speed;

-carburettor / intake pipe tightness;

-abnormal knock.

In case of any malfunctions or unknown rattle, stop the engine, eliminate the faults, then continue the tests.

In case of oil leaks through the gasket between the valve cover and cylinder head or through the gaskets between the oil sump, cylinder block and covers, tighten the securing bolts to the torque specified. If oil leaks persist, check the correct fitting of the gaskets and renew when applicable.

Since the overhauled engine is not fully bed-in and frictions between the working surfaces of renewed parts show significant resistance to the rotation, a certain run-in period is required.

This especially concerns those engines, where the pistons, main / big-end bearing shells have been renewed, or the crankshaft journals have been reground, or the cylinders - honed.

Therefore during run-in after the engine overhaul, never allow the engine to run at maximum loads. When in the vehicle, always run-in the engine at the speeds which are recommended for the run-in periods.

In-vehicle engine inspection after overhaul

Locate the engine in the vehicle, thoroughly check its correct mounting.

Run the engine for a while, then check for:

-coolant or fuel leaks through pipe connections, tighten when necessary;

-full throttle opening and closing by the carburettor cable, adjust accordingly, if necessary;

-alternator drivebelt tension, adjust, when applicable;

-reliable wiring connections and operation of the warning lamps in the instrument cluster.

WARNING. Never check the engine or vehicle on the roller stand without additional rollers for the front wheels.

Cylinder block

General description

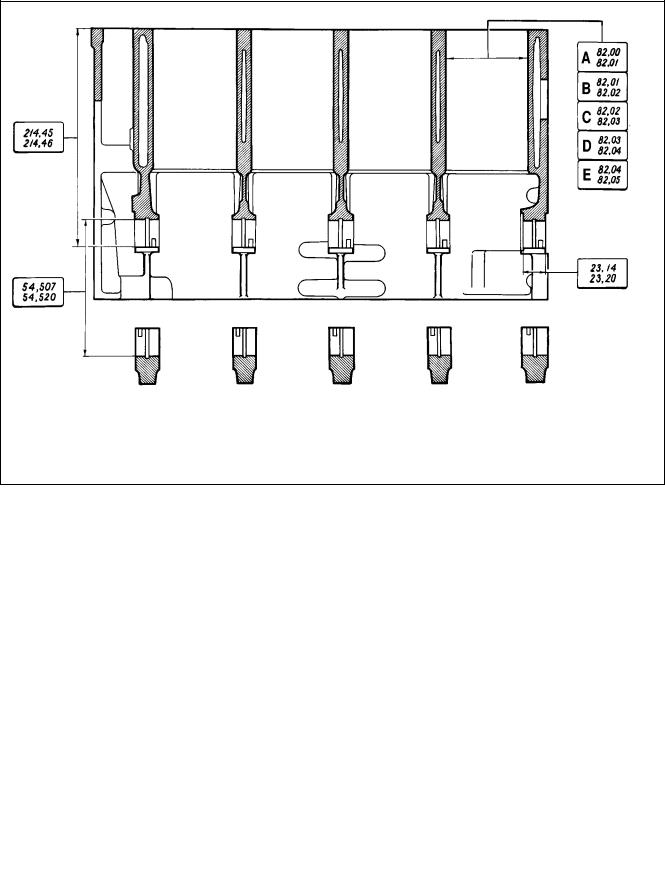

The cylinder block basic sizes are shown in Fig.2-25.

The cylinder block is of a low-alloyed cast iron. The cylinder bores are of five classes in steps of 0.01 mm and are designated by the letters A, B, ë, D, Ö. The cylinder class is engraved on the cylinder block bottom face. (Fig.2-26).

The cylinders can be rebored to accommodate the oversize pistons of 0.4 mm and 0.8 mm bigger diameters.

The main bearing caps are machined complete with the cylinder block; therefore they are not interchangeable and feature distinctive notches on the outside surface (Fig.2-13).

Inspection and repair

Inspection. Wash the cylinder block thoroughly and clear the oilways. Blow dry with compressed air and inspect the cylinder block visually. Make sure there are no cracks in the mountings or elsewhere in the cylinder block.

When cooling water is suspected in the crankcase, use a special test bench to examine the cylinder block for leaks. To do this, plug the cylinder block cooling water jacket ports, force in some room temperature water at 0.3 MPa (3 kgf/sq.cm). There should be no evidence of water leaks from the cylinder block within 2 minutes.

When coolant is found contaminated with oil, do not strip the engine completely, rather check the cylinder block for cracks in the area of the oilways. For that, drain the coolant from the cooling system, remove the cylinder head, refill the cylinder block water jacket with water and apply compressed air to the vertical oilway in the cylinder. If there are any bubbles in the water of the cooling water jacket, renew the cylinder block.

Examine the split face between the cylinder block and cylinder head using a straight-edge and feeler blades. Position the straight-edge diagonally and using a feeler gauge measure at the centre, both transversely and longitudinally. The flatness to be within 0.1 mm tolerance.

Cylinder repair. Check the cylinders for wear to be maximum 0.15 mm.

When available, use a dial inside gauge to measure the bore diameter (Fig.2-27) in four lands, both longitudinally and transversely (Fig.2-28). Use tool 67.8125.9502 to set the inside gauge to zero.

19

Fig.2-25. Basic sizes of the cylinder block

|

|

Fig.2-27. Measuring the cylinder bore with the inside dial gauge: |

Fig.2-26. Cylinder size class engraved on the cylinder block |

|

1 - inside dial gauge; 2 - setting to zero against reference gauge |

|

|

|

20

There is practically no wear in the land 1 area of the cylinders. Compare the values measured on the first and other cylinder lands to see the amount of the cylinder wear.

When the maximum wear is over 0.15 mm, rebore the cylinders to the nearest oversize; provide 0.03 mm honing allowance on the diameter. Hone the cylinder walls so that the difference between the oversize piston diameter and cylinder bore is 0.025 - 0.045 mm.

Pistons and connecting rods

General Description

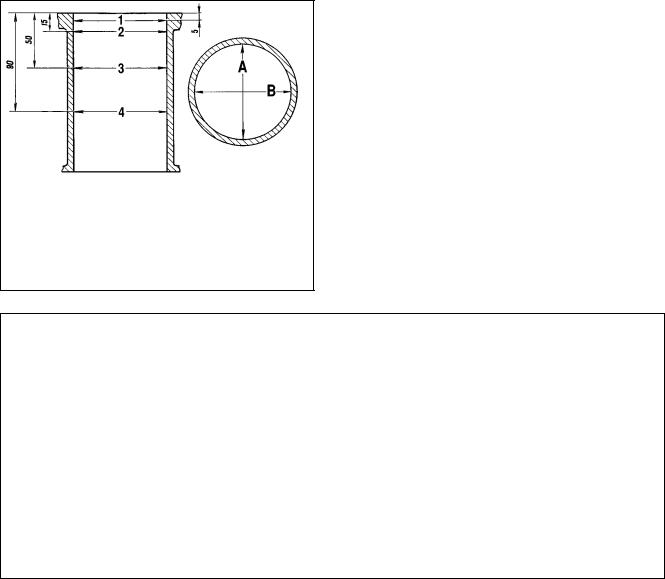

The basic sizes of the pistons and connecting rods are shown in Fig.2-29.

Piston is an aluminium casting. The piston weight is precisely maintained during the manufacturing process. Consequently, there is no need to select the matching piston of the same weight class during the engine assembly.

Fig.2-28. Measuring the cylinder bore:

A and B - direction of measurement; 1, 2, 3 and 4 - No of lands

There are five classes (Ä, Ç, ë, D, Ö) of the piston according to their major diameter, in steps of 0.01 mm. The piston has a complex outside shape: tapered in height and oval in the crosssection area. Therefore, the piston diameter must be measured in the plane normal to the gudgeon pin at 55 mm from the piston crown.

There are three classes (1, 2, 3) of pistons, as to the hole for the gudgeon pin, in step of 0.004 mm. The classes of piston diameters and holes for the gudgeon pin are stamped on the piston crown (Fig.2-30).

The oversize piston major diameter is 0.4 or 0.8 mm bigger. The 0.4 step is marked in the form of a triangle, while the 0.8 mm step is marked as a square.

Use the arrow on the piston crown for correct piston orientation and fitting within the cylinder. The arrow of the piston must face the timing belt end of the engine.

Gudgeon pin is of steel, hollow, floating-type, i.e. freely operates in the piston bosses and connecting rod bush. The gudgeon pin is secured in the hole with two circlips.

As to the outside diameter the gudgeon pin are of three classes in step of 0.004 mm. The class is paint marked on the gudgeon pin face: 1st class - blue paint, 2nd class - green paint, 3rd class - red paint.

Piston rings are of cast iron. The top compression ring has a chromed barrel face. The bottom compression ring is of the scraper type. The oil control piston ring features chromed working edges and has a coil expander (spreader ring).

The oversize rings are marked as 40 or 80, which corresponds respectively to 0.4 or 0.8 mm step in the major diameter.

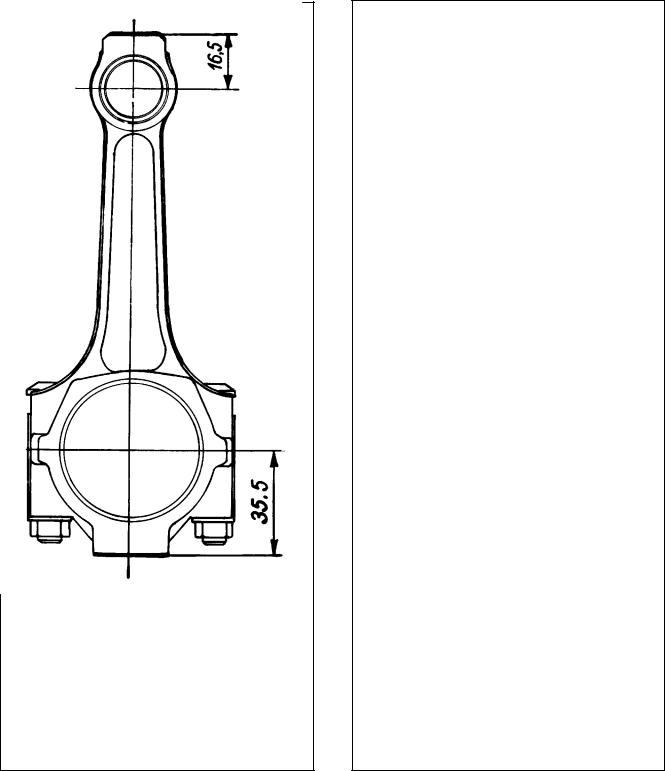

Connecting rod is of forged steel.The connecting rod is machined together with the big end cap, therefore they are interrelated. The cylinder number (6 in Fig.2-30) is stamped on the caps and connecting rods to prevent confusion when refitting into the cylinders. During reassembly the figures on the connecting rod and cap should face the same side.

Fig.2-29. Basic dimensions of pistons and connecting rods

21

The connecting rod small-end features a pressed-in steelbronze bush. As to the diameter of the bush, the connecting rods are divided into three classes in steps of 0.004 mm (similar to the pistons).

The class number (5 in Fig.2-30) is engraved on the big-end cap.

The connecting rod small-end and big-end are classified weight-wise (Table 2-1) and are paint marked on the connecting

rod. The engine must always be fitted with the connecting rods of the same weight class. The connecting rod weight can be adjusted by removing excess metal from the bosses on the small-end or big-end up to the minimum size of 16.5 mm or 35.5 mm (Fig.2- 31).

Fig.2-30. Marking on the piston and connecting rod:

1 - arrow on piston crown for orientation in cylinder; 2 - oversize; 3 - piston class; 4 - class of gudgeon pin hole; 5 - connecting rod class as to gudgeon pin hole; 6 - cylinder No

Fig.2-31. Locations of possible metal removal subject to adjusted connecting rod small-end and big-end weights

22

Table 2-1

Connecting rod classification as to

small-end and big-end weights

Connecting rod weight, g |

|

Class |

Paint mark |

|

|

|

|

|

|

small-end |

big-end |

|

|

|

|

|

|

|

|

|

519±3 |

Ä |

white |

|

186±2 |

525±3 |

Ç |

blue |

|

|

531±3 |

ë |

red |

|

|

519±3 |

|

D |

black |

190±2 |

525±3 |

|

E |

violet |

|

531±3 |

|

F |

green |

|

519±3 |

|

G |

yellow |

194±2 |

525±3 |

ç |

brown |

|

|

531±3 |

|

I |

orange |

|

|

|

|

|

Selecting piston to cylinder

The design clearance between the piston and cylinder bore (for new parts) is 0.025 - 0.045. The condition must be ensured through prior measurements of the associated parts and fitting of the pistons which belong to the same class of cylinders. The maximum permissible gap (for worn parts) is 0.15 mm.

When the engine, in the course of operation, shows a clearance of over 0.15 mm, reselect the pistons to the cylinders to have the clearance as close to the design value as possible.

The pistons of classes Ä, ë, Ö are intended for replacement. These classes can be selected to closely match any cylinder in the event of the engine overhaul, since the pistons and cylinders are classified with small overlapping in the sizes. It means, the piston of class C can match the cylinders of class B and D.

Dismantling and reassembly

Dismantling. Prise out the gudgeon pin circlips from the piston, press out the gudgeon pin and detach the connecting rod from the piston. Remove the piston rings.

The bolts are pressed into the connecting rod and must never be pressed out from the connecting rods during the engine or piston/connecting rod dismantling.

When some components of the piston or connecting rod are not damaged or show little wear, they can be re-used. Identify them accordingly during dismantling to facilitate further reassembly with the respective components and to the original cylinder.

Reassembly. Before reassembly, select the gudgeon pin to match the piston and connecting rod. For new components the class of the holes for the gudgeon pin in the connecting rod and pistons must be identical to the class of the gudgeon pin. In case of used components, for perfect mating, the gudgeon pin when oiled should fit the relevant piston hole by force of the hand thumb (Fig.2-32); it should not drop out while held as shown in Fig.2-33.

If the gudgeon pin drops, replace it with a new one of the next class. When the piston is fitted with the gudgeon pin of the third class, renew the piston, gudgeon pin and connecting rod.

The reassembly of the piston and connecting rod is a reversal of dismantling. After reassembly oil the gudgeon pin through the holes in the piston bosses. Refit the piston rings in the order as detailed below.

Oil the piston rings and grooves in the piston. Arrange the piston rings so that the gap of the first compression ring is at a 45° interval to the gudgeon pin; space the gap of the second compression ring at about 180° interval to the first compression gap, afterwards align the gap of the oil ring at about 90° interval to the first compression ring gap.

Fig.2-32. Fitting the gudgeon pin using the thumb pressure |

|

Fig.2-33. Checking the gudgeon pin fitting |

|

|

|

23

Fig.2-34. Checking the piston ring-to-groove gap

Fig. 2-35. Checking the piston ring gap

Make certain the second compression ring is positioned with the recess facing down (Fig.2-30), while the TOP (or ÇÖêï) mark should face up (the piston crown).

Before refitting the oil ring, check to see the joint of the coil expander (spreader ring) is on the side opposite to the ring gap.

Inspection

Scrape away all traces of carbon from the piston and remove all carbon deposits from the piston/connecting rod oilways.

Thoroughly examine the components. Make sure there are no cracks of any sort on the piston, piston rings, gudgeon pin, connecting rod or big-end cap. Renew the bearing shell if there is obvious scoring or scuffing.

The piston-ring-to-groove wall clearance is checked using feeler blades as shown in Fig.2-34, fitting the ring into the respective groove. For new components the design clearance (rounded off to the nearest 0.01 mm) is 0.04-0.07 mm for the first compression ring; 0.03-0.06 mm for the second compression ring and

0.02-0.05 mm for the oil control ring. When worn, the tolerance must not exceed the specified maximum of 0.15 mm.

The piston ring gap should be checked with a feeler gauge via inserting the rings into the gauge (Fig.2-35), with the bore equal to the piston ring nominal diameter ±0.003 mm. Use gauge 67.8125.9502 for the normal 82 mm rings.

The gap for all new piston rings should be within 0.25 to 0.45 mm. The maximum permitted gap for worn rings is 1 mm.

Crankshaft and flywheel

Design description

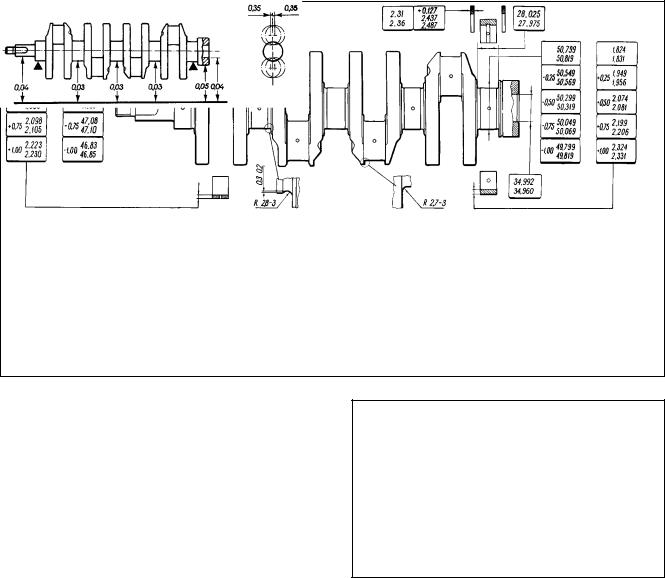

Basic dimensions of the crankshaft are shown in Fig.2-36.

Crankshaft is cast-iron, of five bearings. The crankshaft journals can be reground during the engine overhaul when the diameter is reduced by 0.25 mm, 0.5 mm, 0.75 mm and 1mm.

The crankshaft endfloat is restricted by two thrust washers. The thrust washers are fitted on both sides of the rear main bearing: a sintered one (yellow) at the rear end and a steel-aluminium one at the front end. The thrust washers are of two sizes - standard and 0.127 mm thicker.

Crankshaft bearing shells are thin-walled, aluminium with steel backing. The upper bearing shells of No 1, 2, 4 Ë 5 bearings have inner oil grooves, whilst the lower bearing shells are plain shells. The upper and lower bearing shells of the centre bearing (No 3) are plain, without an oil groove. The big-end bearing shells (both upper and lower ones) are also plain.

The oversize bearing shells are thicker for the crankshaft journals reduced by 0.25 mm, 0.5 mm, 0.75 mm and 1 mm.

Flywheel is cast iron with the pressed-in steel starter ring. The flywheel centering is ensured by a front input shaft bearing which is pressed into the crankshaft.

A taper recess on the rear face of the flywheel near the ring gear is provided as a positioning mark. Adjust it against cylinder No 4 crankpin.

Inspection and overhaul

Crankshaft. Inspect the crankshaft. Make sure there are no cracks. Examine the faces which mate the oil seal working edges for evident cracking, scoring or scuffing.

Mount the crankshaft on two V-blocks as shown in Fig.2-37 and check the run-out with a dial gauge:

•main bearing journals - maximum 0.03 mm;

•mounting surfaces for the input shaft sprocket and bearing

-maximum 0.04 mm;

•surface mating the oil seal - maximum 0.05 mm.

Measure the diameters of the main bearing journals and

24

Fig.2-36. Basic crankshaft dimensions

crankpins. Regrind when the wear is in excess of 0.03 mm, ovality is over 0.03 mm, or when scoring and scuffing is obvious.

Regrind the journals and crankpins through reducing the diameter to the nearest undersize (Fig.2-36).

When regrinding, observe the sizes for the crankshaft fillet as shown in Fig.2-36 for the standard-size crankshaft.

The ovality and taper for the main bearing journals and bigend bearing journals after regrinding must not exceed 0.005 mm.

On a reground crankshaft, the vertical offset of the crankpins axes must be 0.35 mm (Fig.2-37). To check this, place the crankshaft on V-blocks and position the crankshaft so that No1 crankpin axis is in the horizontal plane passing through the main bearing journal axes. Using a dial gauge, check the vertical offset of crankpins No 2, No 3 and No 4 against crankpin No 1.

After regrinding the journals and crankpins, polish them using the diamond paste or special grinding pastes.

After regrinding and followed finishing, unplug the oilways, then machine the plug seats with the mill-cutter Ä.94016/10 and spindle Ä.94016. Thoroughly wash the crankshaft and oilways to flush abrasive residuals and blow dry with compressed air.

Use tool Ä.86010 to press in new plugs and punch each plug in three points with a centre-punch.

On crankshaft web No 1 mark the reduced amount (undersize) of the main bearing journals and big-end journals (eg. M 0.25; B 0.50).

Bearing shells. Remember that no adjustment on the bearing shells is allowed. Renew the shells when there are scratches, scoring or flaking.

Fig.2-37. Permissible runouts for basic crankshaft surfaces

The main and big-end bearing running clearance is checked by measuring the components. It is convenient to check the clearance with the help of «Plastigage» (which consists of a fine thread of perfectly-round plastic, which is compressed between the bearing cap shell and the crankshaft journal) under the following procedure:

-ensure the journals and bearing shells are clean and dry, cut several pieces of the appropriate-size Plastigage (they should be slightly shorter than the width of the bearings) and place one piece on each crankshaft journal axis;

-with the bearing shells in position in the cages, fit the caps to their original locations (depending on the journal checked). Take care not to disturb the Plastigage. Then tighten the securing nuts and bolts to the specified torque. Tighten the connecting rod bolts to 51 ç•Ï (5.2 kgf•m), while the main bearing cap bolts to 80.4 ç•Ï (8.2 kgf•m);

-remove the bearing cap and check the running clearance by comparing the width of the crushed Plastigage on each journal with the scale printed on the card gauge to obtain the bearing running clearance (Fig.2-38).

25

Fig.2-38. Measuring the big-end bearing running clearance:

1 - crushed Plastigage; 2 - bearing shell; 3 - big end cap; 4 - scale for clearance measurement

The nominal design clearance is 0.02-0.07 mm for the crankpins and 0.026-0.073 mm for the main bearing journal. When the running clearance is below the maximum value (0.1 mm for the big-end bearing journals and 0.15 mm for the main bearing journals), the bearing shells can be re-used.

When the running clearance exceeds the specified maximum, replace the respective bearing shells with new ones.

Where the crankshaft journals are worn and are reground to their undersize, change the bearing shells to those oversize.

Thrust washers. Similar to the bearing shells, no adjustments are possible on the thrust washers. Always renew the thrust washers when there is scoring, scuffing or flaking.

The thrust washers must be renewed when the crankshaft endfloat exceeds the specified limit of 0.35 mm. Select new thrust washers of the standard size or 0.127 mm thicker to have the endfloat within 0.06 - 0.26 mm.

The crankshaft endfloat is checked with the help of a dial gauge as outlined in Section «Engine reassembly» (Fig.2-14).

The crankshaft endfloat can be also checked on the engine in the vehicle. The axial shift of the crankshaft occurs at depressing and releasing the clutch pedal, the endfloat value is determined by the front crankshaft end displacement.

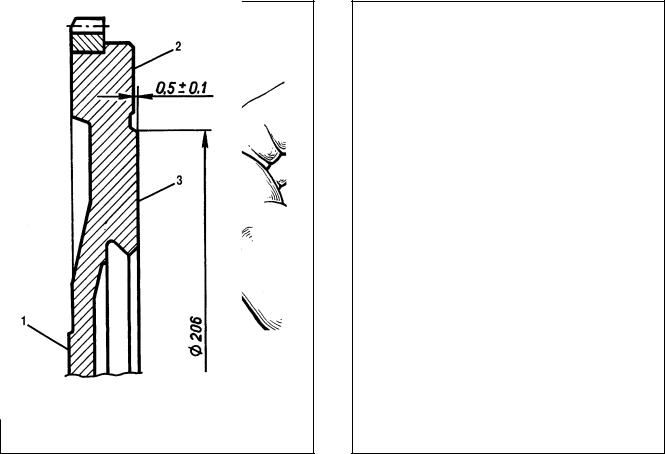

Flywheel. Inspect the teeth of the flywheel starter ring, should they are found deteriorated, renew the flywheel. If there are temper colours on flywheel face 3 (Fig.2-39), check the

Fig.2-39. Flywheel:

1 - surface mating the crankshaft flange; 2 - surface for clutch securing; 3 - clutching surface

starter ring interference on the flywheel. The starter ring should not rotate when applying 590 ç•Ï (60 kgf•m).

Check to see there are no scratches or scores on flywheel face 1 mating the crankshaft flange or on surface 3 mating the clutch disc.

Remove by lathing all scratches or scores on face 3, provided the overall thickness is reduced maximum by 1 mm. Do not forget to lathe surface 2 maintaining the size (0.5±0.1) mm. Ensure surfaces 2 and 3 are parallel to surface 1. The out-of-par- allelism tolerance is 0.1 mm.

Mount the flywheel on the tool, centralize is over the mounting bore against surface 1 and check the run-out of surfaces 2 and 3. The run-out values at the outboard points must not exceed 0.1 mm.

Cylinder head and valve gear

General description

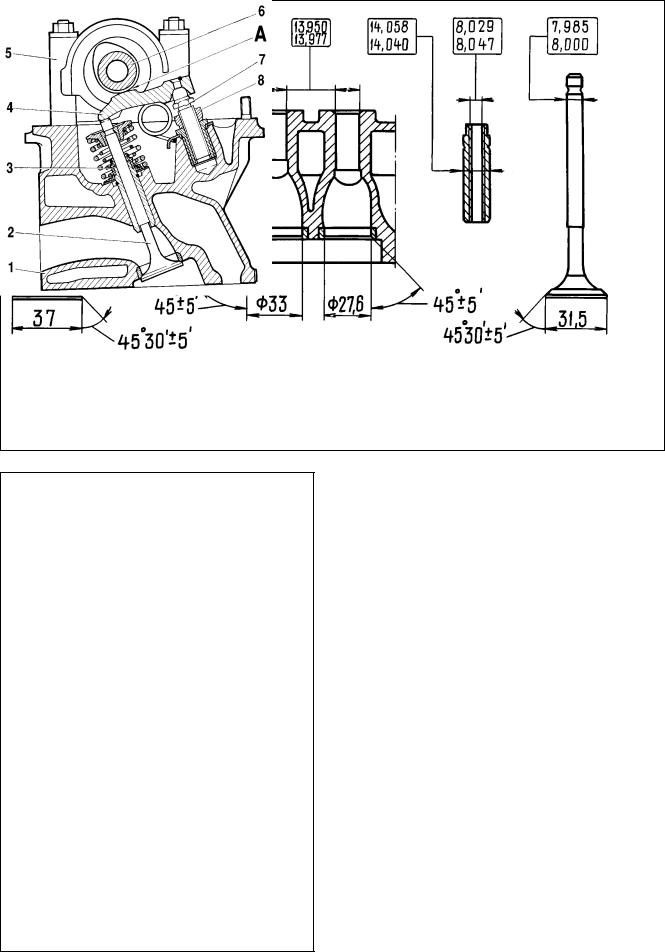

Refer to Fig. 2-40 for basic sizes of the valves, guides and valve seats.

Cylinder head is an aluminium casting with the pressed-in iron valve seats and valve guides.

The top of the valve guides is sealed with metal-rubber oil caps 3 (Fig.2-41).

26

Fig.2-40. Basic dimensions of the valves, valve guides and valve seats

Fig.2-41. Cylinder head cross-sectional view showing the exhaust valve:

1 - cylinder head; 2 - valve; 3 - oil cap; 4 - lever; 5 - bearing housing; 6 - camshaft; 7 - adjuster bolt; 8 - lock nut; Ä - cam-to-lever clearance

The outer diameter of the replacement guides is 0.2 mm bigger. Bearing housing 5 with camshaft 6 is fitted to the cylinder head.

Valve train. Valves 2 are operated by the cams through levers 4. One end of the lever pushes the valve stem, while the other end rests on the spherical head of adjuster bolt 7 which adjusts the clearance A in the valve gear.

Valve clearance adjustment

The clearances are adjusted on the cold engine by means of the chain adequately tensioned. The adjustment should result is 0.15±0.02 mm clearance for the intake valves and 0.2±0.02 mm clearance for the exhaust valves.

While making adjustments, do not to twist the valve lever, since it may result in a bigger final clearance.

The clearance is adjusted as follows:

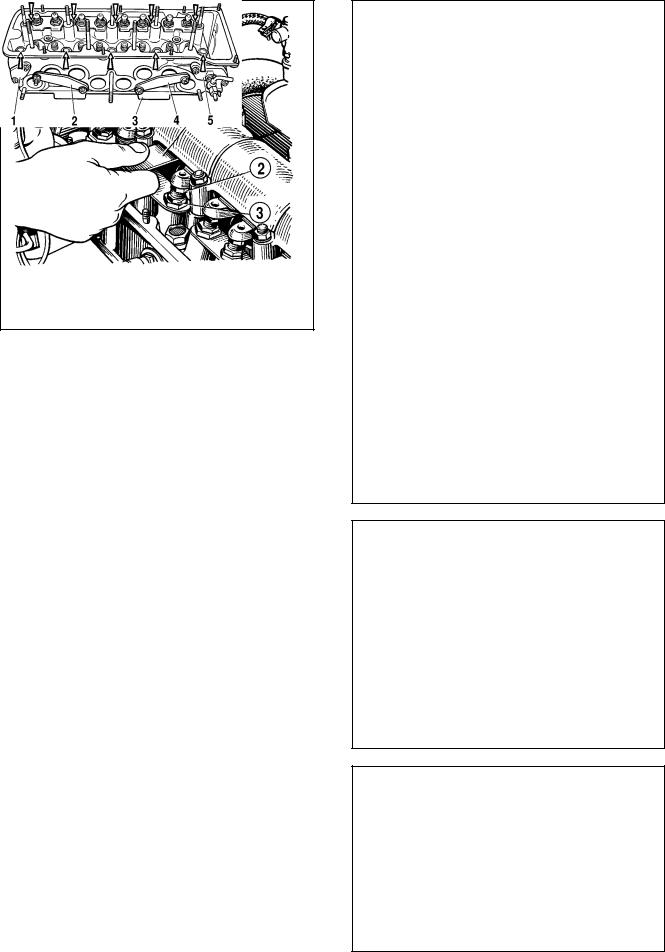

-turn the crankshaft clockwise to align the indentation in the camshaft sprocket with the mark on the bearing housing, which corresponds to the end of the compression stroke of the cylinder No4. Now in this position adjust the clearance at the cylinder No4 exhaust valve (No8 cam) and cylinder No3 intake valve (No6 cam);

-slacken the valve lever adjuster bolt nut;

-between the valve lever and cam place a flat feeler blade (A.95111) of 0.15 mm for the intake valve (0.2 mm for the exhaust valve) and using a spanner tighten or slacken the bolt with further

27

Fig.2-42. Checking the clearance between the rocker levers and cam lobes:

1 - feeler blade Ä.95111; 2 - adjuster bolt; 3 - lock nut

lock nut tightening, until the blade is a firm sliding fit when the lock nut is tightened (Fig.2-42);

- after the clearance is adjusted at the cylinder No4 exhaust valve and cylinder No3 intake valve, turn the crankshaft progressively to the 180° and adjust the clearances, observing the sequence as shown in Table 2-2.

Table 2-2

Valve clearance adjustment

Crankshaft angle, |

|

Cylinder No |

|

Valve (cam) No |

degrees |

|

(end of compression stroke) |

|

|

|

|

|

|

|

0 |

|

4 |

|

8 & 6 |

180 |

|

2 |

|

4 & 7 |

360 |

|

1 |

|

1 & 3 |

540 |

|

3 |

|

5 & 2 |

|

|

Cylinder head - removal and refitting

The cylinder head is removed from the engine in the vehicle, when no complete stripping of the engine is required, or when carbon deposits should only be removed from the combustion chamber and valves. To remove the cylinder head, carry out the following operations.

Apply the handbrake, remove the spare wheel and disconnect the battery negative lead.

Remove the air cleaner and protect the carburettor with the provisional plug. Drain the coolant from the radiator and cylinder block.

Fig.2-43. Valve components:

1 - valve; 2 - circlip; 3 - valve guide; 4 - oil cap; 5 - lower spring seat, outer spring; 6 - locking washer, inner spring; 7 - inner spring; 8 - outer spring; 9 - upper spring seat; 10 - collets; 11 - valve rocker lever; 12 - valve lever spring; 13 - adjuster bolt; 14 - lock nut, adjuster bolt; 15 - bush, adjuster bolt; 16 - locking plate, valve lever spring

Fig.2-44. Removing the valve spring:

1 - tool Ä.60311/R; 2 - mounting base

Fig. 2-45. Checking the leak-proofness of the cylinder head on tool A.60334:

1, 2, 4 - plugs; 3 - tool plate; 5 - flange with water supply connector

28

Disconnect the leads from the spark plugs and coolant temperature sender, from carburettor idle switch and fuel cutoff solenoid.

Disconnect the choke cable; disconnect the throttle linkage from the intermediate lever on the valve cover.

Loosen the clips and disconnect the carburettor supply / return fuel hoses. Secure the hoses in a manner to exclude possible fuel leaks. Detach the vacuum hose from the carburettor.

Disconnect the hoses from the intake pipe, from the outlet pipe of the cooling water jacket and from coolant delivery pipe to the heater. Remove the EGR valve.

Disconnect the starter motor shield from the exhaust manifold, downpipe and detach the bracket securing the coolant pipe (heater return line).

Remove the valve cover complete with the gasket and fuel piping securing bracket.

Turn the crankshaft to align the camshaft sprocket TDC mark against the bearing housing mark (Fig.2-22).

Unbolt the camshaft sprocket. Slacken the chain tensioner cap nut, release the tensioner rod and fix it in position with the cap nut. Remove the camshaft sprocket.

Undo the bolts securing the cylinder head to the cylinder block and remove the cylinder head complete with the gasket.

Refitting of the cylinder head is the reverse order of removal, refer to the procedure described in section «Engine reassembly». Never re-use the gasket between the cylinder head and cylinder block, always replace it with a new one.

While refitting the cylinder head, adjust the timing chain tension and valve clearances. Having refitted the cylinder head, adjust the carburettor linkage and ignition timing.

Cylinder head - dismantling and reassembly

Dismantling. When only a single part is required to be replaced, there is no need to completely dismantle the cylinder head; instead, remove only what is necessary.

Position the cylinder head on the stand, disconnect the hose from the hot air intake, undo the nuts and remove the carburettor complete with the gasket; next withdraw the inlet and exhaust manifolds (the hot air intake is withdrawn at the same time).

Remove the water jacket return pipe and coolant-to-heater return pipe. Unscrew the spark plugs and coolant temperature sender.

Undo the securing nuts and remove the bearing housing complete with the camshaft. Undo the nuts holding the thrust flange to the bearing housing. Remove the flange and lift out the camshaft from the bearing housing.

Release springs 12 and remove valve rocker levers 11 (Fig.2-43). Remove the rocker lever springs.

Slacken lock nuts 14, undo adjuster bolts 13 and bushes 15.

Position tool Ä.60311/R, as shown in Fig.2-44, compress the valve springs and release the collets. A stationary tool 02.7823.9505 can be used instead of tool Ä.60311/R.

Remove the valve springs together with lower and upper seats. Turn the cylinder head over and remove the valves from the underneath. Take off the outer caps from the valve guides.

Reassembly. Reassemble the cylinder head in the reverse order. Before assembly begins, always oil the outer caps and valves with engine oil.

Before refitting the camshaft bearing housing, check the centering pins are in the position (Fin.2-21). Tighten the bearing housing securing nuts in the sequence as shown in Fig.2-23. Ensure the centering pins are positioned in the bearing housing recesses without sheering.

The valve clearances are adjusted only after the cylinder head has been refitted to the engine.

Inspection and overhaul

Cylinder head. Thoroughly wash the cylinder head and clean the oilways. Scrape away all carbon from the combustion chambers and from the exhaust valve ports with a wire brush.

Examine the cylinder head. Look to see there is no cracking in the cylinder head. Check the cylinder head for leakage when suspicious as to possible oil contamination with coolant.

To do this, plug the cooling water jacket holes (using plugs from tool A.60334, Fig.2-45), then pump water into the cylinder head water jacket at 0.5 åP‡ (5 kgf/Òm2). No water leak should be evident within 2 minutes.

The cylinder head tightness can be checked with compressed air. Plug the water jacket holes (using the same plugs from tool Ä.60334), immerse the cylinder head into the bath with water of 60-80°C for 5 minutes. Next pump the compressed air into the cylinder head at 0.15-0.2 åPa (1.5-2 kgf/Òm2). No air bubbles must be seen from the cylinder head within 1-1.5 minutes.

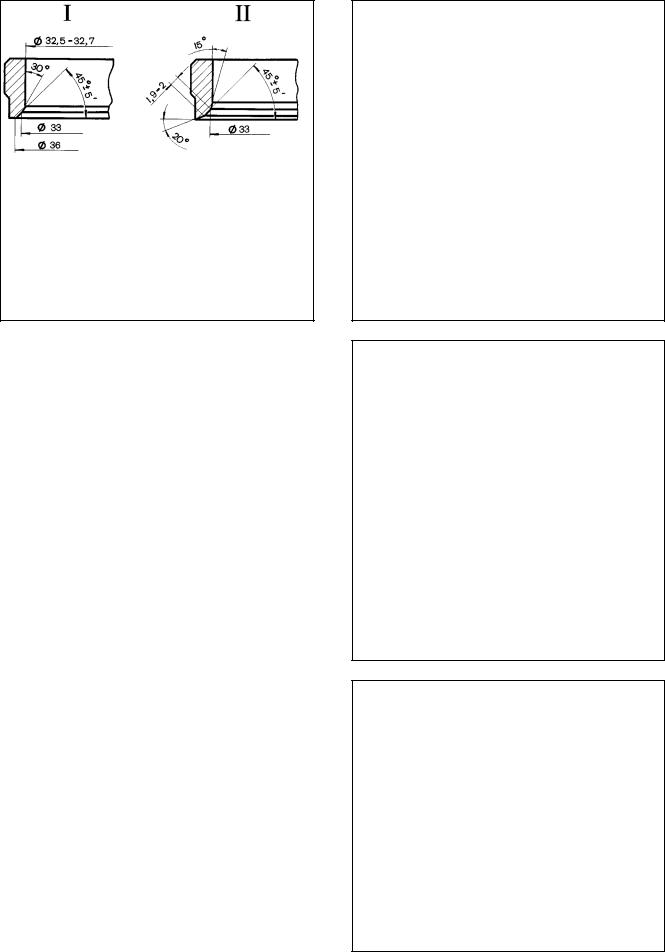

Valve seats. The valve seat chamfer shape is shown in Fig.2-46 and Fig.2-47. Check the working chamfers of the valve seats (valve contact area) for pitting, corrosion or deterioration. Minor irregularities of the seats must be recut. Remove as little metal as possible. Both manual and machine grinding is permitted. Valve regrinding is carried out as follows.

Position the cylinder head on a mounting base. Insert centering tool A.94059 in the valve guide and clean the seat chamfers from carbon using tools Ä.94031 and Ä.94092 for the exhaust valves and Ä.94003 and Ä.94101 for the inlet valves. Use spindle Ä.94058 and centering tool Ä.94059. The centering tools differ in diameters, use tool Ä.94059/1 for the inlet valve guides and Ä.94059/2 for the exhaust valve guides.

29

Fig. 2-46. Intake valve seat profile:

I - new seat; II - reconditioned seat

Put spring A.94069/5 on tool Ä.94059, fit tapered wheel A.94078 on spindle Ä.94069 for the exhaust valve seats or wheel Ä.94100 for the inlet valve seats, secure the spindle in a grinder and recut the valve seat (Fig.2-48).

The grinding wheel must be off at the moment the grinding wheel contacts the valve seat, otherwise vibration ensued will distort the chamfer. Frequent diamond dressing of the wheel is recommended.

The working chamfer width for the exhaust valve seats should be as shown in Fig.2-46 using tools A.94031 (20°) and A.94092 to remove the wear hardening on the minor diameter. The tools should be used with spindle Ä.94058 and are centered with tool Ä.94059.

The working chamfer width for the inlet valve seats should be as shown in Fig.2-47, first machine the inner chamfer with tool Ä.94003 (Fig.2-49) to get the diameter of 33 mm, then machine the 20° chamfer with tool Ä.94101 to achieve the working chamfer width of 1.9-2 mm.

Valves. Scrape away carbon from the valves.

Check the valve stem for deformation; check the valve disc for cracking. Always renew the damaged valve.

Examine the valve working chamfer. Reface the valve in case of minor damages, maintaining the chamfer angle at 45°30' ±5'. Note, that the distance between the bottom valve seat face and base diameter (36 and 30.5) must be as shown in Fig.2-50.

Valve guides. Check the valve guide - to - stem clearance by measuring the valve stem diameter and valve guide bore.

The clearance for new guides is 0.022 - 0.055 mm for the inlet valves and 0.029 - 0.062 mm for the exhaust valves; the maximum permissible clearance (in case of wear) is 0.3 mm provided no excessive noise is produced in the valve train.

Fig. 2-47. Exhaust valve seat profile:

I - new seat; II - reconditioned seat

Fig. 2-48. Regrinding the valve seat working chamfer

Fig. 2-49. Reducing the valve seat working chamfer using the cutting tool with spindle Ä.94058

30

Loading...

Loading...