Page 1

A-PDF Merger DEMO : Purchase from www.A-PDF.com to remove the watermark

Page 2

Lada Niva Manual - Maintenance Page 1

Table of Contents

MAINTENANCE............................................................................................................................2

ENGINE LUBRICATION..............................................................................................................2

Oil Sump.................................................................................................................................2

Oil Filter ................................................................................................................................3

VALVE GEAR............................................................................................................................4

Valve Clearances......................................................................................................................4

Tensioning the Valve Gear Chain................................................................................................5

FUEL SYSTEM...........................................................................................................................5

Air Cleaner .............................................................................................................................6

Carburettor.............................................................................................................................7

Idling speed adjustment .............................................................................................................7

CRANKCASE BREATHING SYSTEM...........................................................................................9

COOLING SYSTEM ....................................................................................................................9

Coolant ..................................................................................................................................9

COOLING SYSTEM THERMOSTAT....................................................................................................10

ALTERNATOR DRIVE BELT............................................................................................................ 10

IGNITION SYSTEM...................................................................................................................11

Ignition Distributor ................................................................................................................11

SPARK PLUGS............................................................................................................................. 12

TRANSMISSION.......................................................................................................................12

Clutch Fluid Reservoir ............................................................................................................12

ADJUSTING THE CLUTCH CONTROL MECHANISM .............................................................................. 12

GEARBOX, TRANSFER CASE. ......................................................................................................... 14

Front and Rear Axles ..............................................................................................................14

Propeller Shaft Splined Connections and Crosses ........................................................................14

Joints of Front Wheel Drive Propeller Shafts...............................................................................14

HYDRAULIC SHOCK ABSORBERS AND ANTIROLL BAR .........................................................14

STEERING GEAR AND WHEELS...............................................................................................14

Steering Gear Clearances.........................................................................................................14

Front Wheel Hub Bearings .......................................................................................................15

Examining the Front Suspension Ball Supports and Steering Rod joints...........................................17

Tyres....................................................................................................................................17

Replacing the Wheels...............................................................................................................19

Front-End Alignment...............................................................................................................19

BRAKES.................................................................................................................................. 20

Brake Hydraulic System ...........................................................................................................20

Brake Fluid Reservoir..............................................................................................................21

Flexible brake hoses................................................................................................................21

FRONT BRAKES .......................................................................................................................... 21

REAR BRAKES ............................................................................................................................23

Bleeding the Brake System........................................................................................................24

Adjusting the Free Travel of Brake Pedal....................................................................................25

Brake Vacuum Booster.............................................................................................................25

Parking Brake........................................................................................................................25

ELECTRICAL EQUIPMENT .......................................................................................................25

Wiring diagram...................................................................................................................... 26

Storage Battery ......................................................................................................................27

Alternator .............................................................................................................................27

Starter..................................................................................................................................27

Voltage Regulator...................................................................................................................28

Aiming the Headlight Lower Beam ............................................................................................ 28

Replacing the Bulbs ................................................................................................................28

Tail lights.............................................................................................................................29

Fuses....................................................................................................................................29

Fuse-Protected Circuits ...........................................................................................................29

BODY...................................................................................................................................... 31

Care of Body .........................................................................................................................31

Windshield and Headlight Washers............................................................................................ 33

Windshield and Headlight Wipers.............................................................................................. 33

Fastening of Units and Mechanisms to Car Body......................................................................... 33

MAINTENINCE IN LONG-TERM STORIGE.................................................................................33

Page 3

Lada Niva Manual - Maintenance Page 2

MAINTENANCE

The mechanisms, units and parts subject to scheduled maintenance are indicated by reference

numbers in Figs 25 and 26. Table 1 contains the lubricating instructions and Table 2,

maintenance instructions (cleaning, checking and adjustment).

The car should be serviced every 10,000 Km. However, during the initial period of operation,

when working-in of all the units and mechanisms takes place, the car should be serviced after

covering the first 2,000-3,000 Km. This will ensure superb performance and long service life

of the car.

The list of the tools and accessories delivered with the car for Owner’s services is given in

Appendix 3.

ENGINE LUBRICATION

Oil Sump

Every 500 Km check the oil level in a cold engine and add oil, if

necessary. The oil level should be between marks MIN and MAX on

oil dipstick 1 (Fig. 27).

On a new engine change oil after the first 2,000-3,000 Km, then at

10,000 Km and thereafter every 10,000 Km. Change oil while the

engine is still hot. Drain used oil after removing the plug of the hole

in the bottom of the engine sump. Pour fresh oil through oil filler

neck 2, located on the cylinder head cover.

The seasonal change of oil depends on the change of season as

different temperature conditions call for the employment of different grades of oil (see

Appendix 2).

Every 30,000 Km wash the lubricating system. Wash the system earlier only when sticky

gum deposits accumulate on the camshaft housing.

Perform this operation on a hot engine as follows:

• Drain used oil from the engine sump.

• Fill the engine with a special detergent oil, to the MIN mark and let the engine run idle at a

speed of about 1,000 rpm for 10 minutes.

• Drain the detergent oil, replace the oil filter and pour in fresh oil of the grade recommended

for the season.

note. When using equivalent oils produced by different firms, wash the lubricating system

each time before the oil change.

Page 4

Lada Niva Manual - Maintenance Page 3

Oil Filter

Every 10.000 Km replace the filter. Do it after the first 2,0003,000 Km on a new car. To replace the filter unscrew it from the

cylinder block (pig. 28). Screw the new filter in place only handtight.

Page 5

Lada Niva Manual - Maintenance Page 4

VALVE GEAR

Valve Clearances

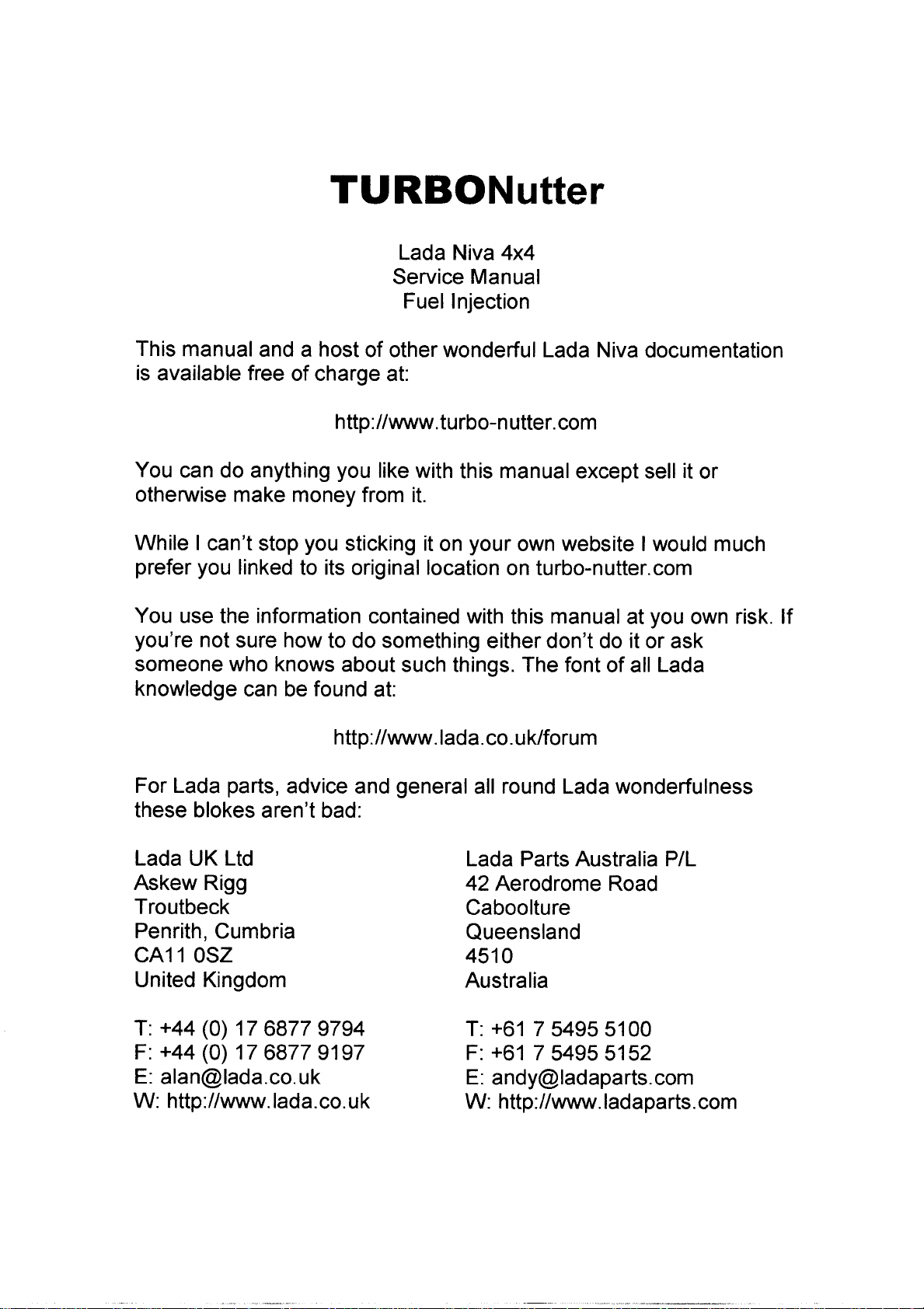

Every 10.000 Km and also in case of abnormal knocking in the

valve mechanism, check clearances A (Fig. 29) between the

cams and valve rockers which should be 0.15 mm on a cold

engine both for the intake and exhaust valves. On a new engine

perform this operation after the first 2,000-3,000 Km upon

checking and tightening the fasteners of the cylinder head,

camshaft bearing housing and intake and exhaust manifolds.

Loosen the cylinder head bolts preliminarily through about

30" each and then tighten them according to the sequence

shown in fig. 30.

A - Valve rocker to cam clearance 1 cam, 2 - valve rocker, 3 - valve oil

deflecting cap, 4 - valve, 5 - rocker

adjusting bolt, 6 - adjust bolt locknut.

Valve Gear

Tighten bolts 1 through 10 to a torque of 115 NÆm (11.5 kg Æ m),

and bolt 11 to a torque of 38 NÆm (3.8 kg Æ m).

Tighten the nuts of the camshaft

Figure 30 - Sequence of tightening

cylinder head bolts

sequence shown in pig. 31.

bearing housing by applying a torque

of 22 NÆm (2.2 kg m) according to the

Fig 31. Sequence of tightening

camshaft bearing housing nuts

To adjust the valve clearances, proceed as follows:

• Remove the cylinder head cover with its gasket; if necessary,

first remove the heater air intake box;

• Rotate the crankshaft clockwise to align mark A (Fig. 32) on

the sprocket with mark B on the camshaft housing; in this case

the piston of the No. 4 cylinder will be on TDC at the end of

the compression stroke, and both valves will be closed

• Adjust the rocker-to-cam clearances of the exhaust valve on

the No. 4 cylinder (8th cam) and of the intake valve on the No.

3 cylinder (6th cam); for this purpose, loosen locknut 2 (Fig.

33) and rotate adjusting bolt 1 to set the required clearance,

using a flat feeler gauge inserted between the cam and the

rocker (the feeler gauge should move in this case with a slight

biting)

• Holding bolt 1 in this position with a wrench, tighten locknut

2 by applying a torque of 52 NÆm (5.2 kg Æ m) and recheck the

clearance

• Turning the crankshaft each time through hall a revolution,

adjust the clearances of other valves, following the sequence

given in Table 3 below.

Fig 32.

Setting No. 4 Cylinder piston in TDC

Fig 33. Adjusting valve clearances:

1- adjusting bolt, 2- adjusting bolt

locknut

Page 6

Lada Niva Manual - Maintenance Page 5

Table 3 - Sequence of Valve Clearance Adjustment.

Crankshaft No of cylinder in which piston is on

Valves under adjustment

TDC

angle at end of compression stroke exhaust intake

degrees

Cylinder

No.

Cam No. Cylinder

No.

Cam No.

0 4 4836

180 2 2447

360 1 1123

560 3 3512

• Reinstall the cylinder head cover with its gasket. Adjustment over, check the tightening

torque of the crankshaft jaws, which should be 122 NÆm (12.2 kg Æ m).

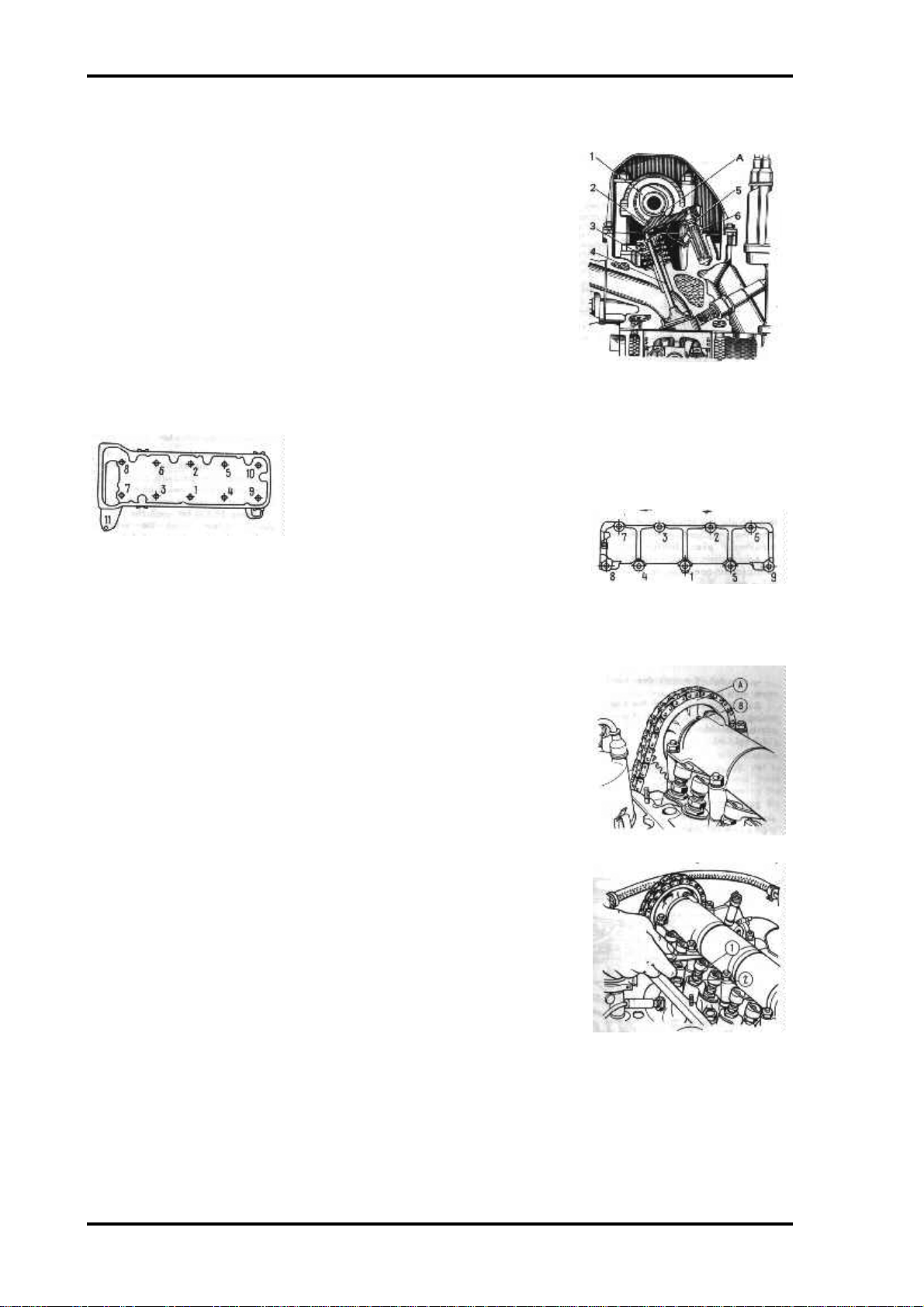

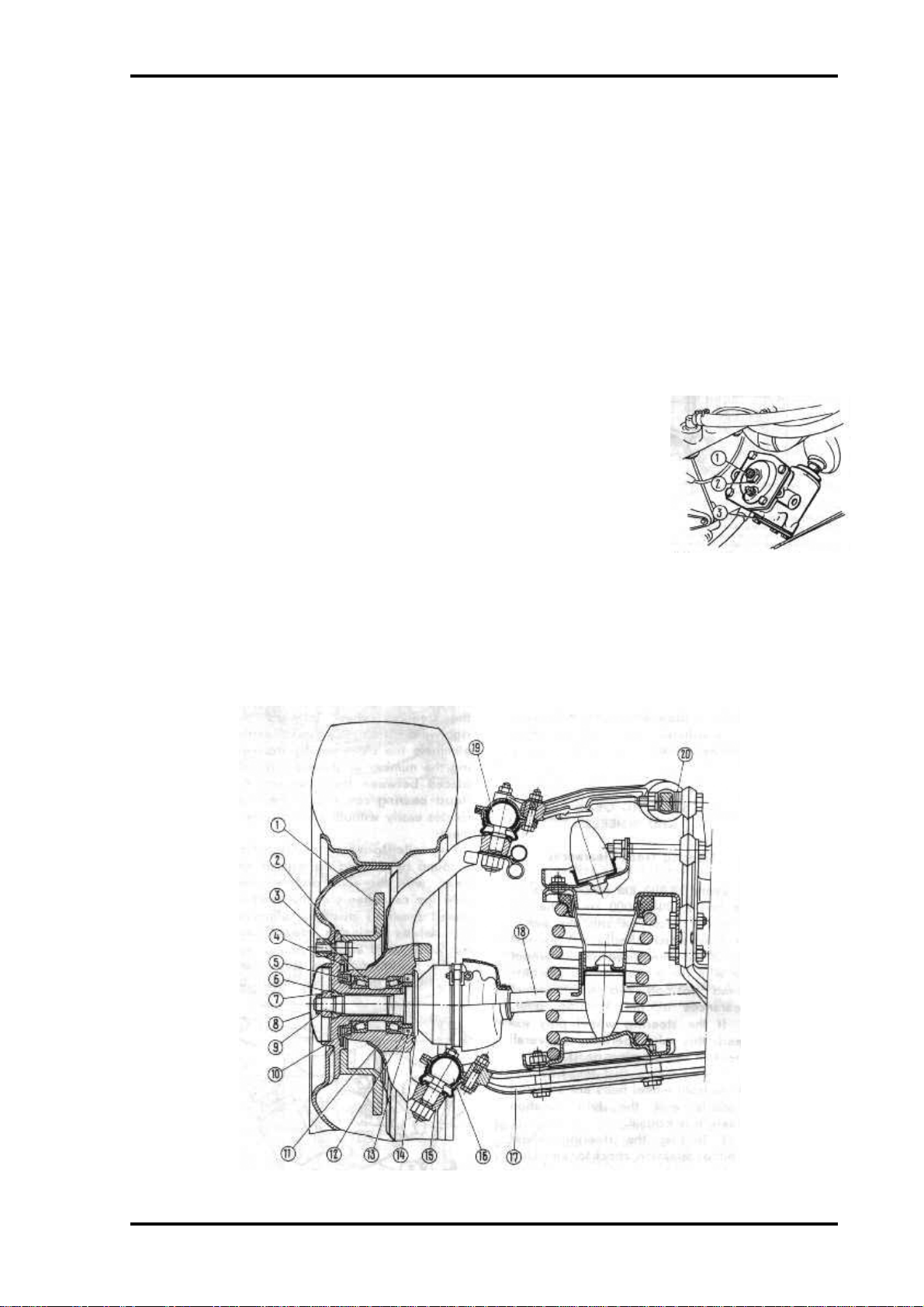

Tensioning the Valve Gear Chain

Every 10.000 Km, adjust the tension of

timing chain 2 (Fig. 34). Do it on a new car

after the first 2,000- 3,000 Km. For this

purpose, loosen retaining nut 7 and turn the

crank- shaft through 1-1~5 revolutions in the

direction of its normal rotation. In this case

spring 10 actuates shoe 6 through plunger 11

and automatically sets the required chain

tension. Adjustment over, tighten nut 7.

Adjust chain tension also in case of excessive

operation noise in the valve gear.

Fig 34. Valve Gear Drive. 1 - camshaft sprocket, 2 - chain, 3 dampener, 4 - oil pump drive shaft sprocket, 5 - crankshaft

sprocket, 6 - chain tensioner shoe, 7 tensioner rod retaining nut, 8 retainer, 9 - tensioner adjusting rod, 10 - plunger spring, 11 tensioner plunger

FUEL SYSTEM

Page 7

Lada Niva Manual - Maintenance Page 6

Air Cleaner

Every 10.000 Km replace filter element 3 (Fig. 35); to this end

unscrew nuts 1 and remove cover 2. When driving on extremely dusty

roads, replace the filter element every 5,000 Km.

Seasonal adjustment of the air cleaner is required for delivery of fresh

or warm air (warmed by the exhaust manifold). If the average ambient

temperature in the season is below 15 "C, slightly pull and then shift

the handle 5 of the gate on the housing of thermo-regulator 4 in the

upper position (HOT) and if the average temperature is above 15 "C,

shift the handle to the lower position (COLD).

Figure 35. Air Cleaner 1- nut, 2cover, 3- filter, 4- thermo-regulator, 5handle

Page 8

Lada Niva Manual - Maintenance Page 7

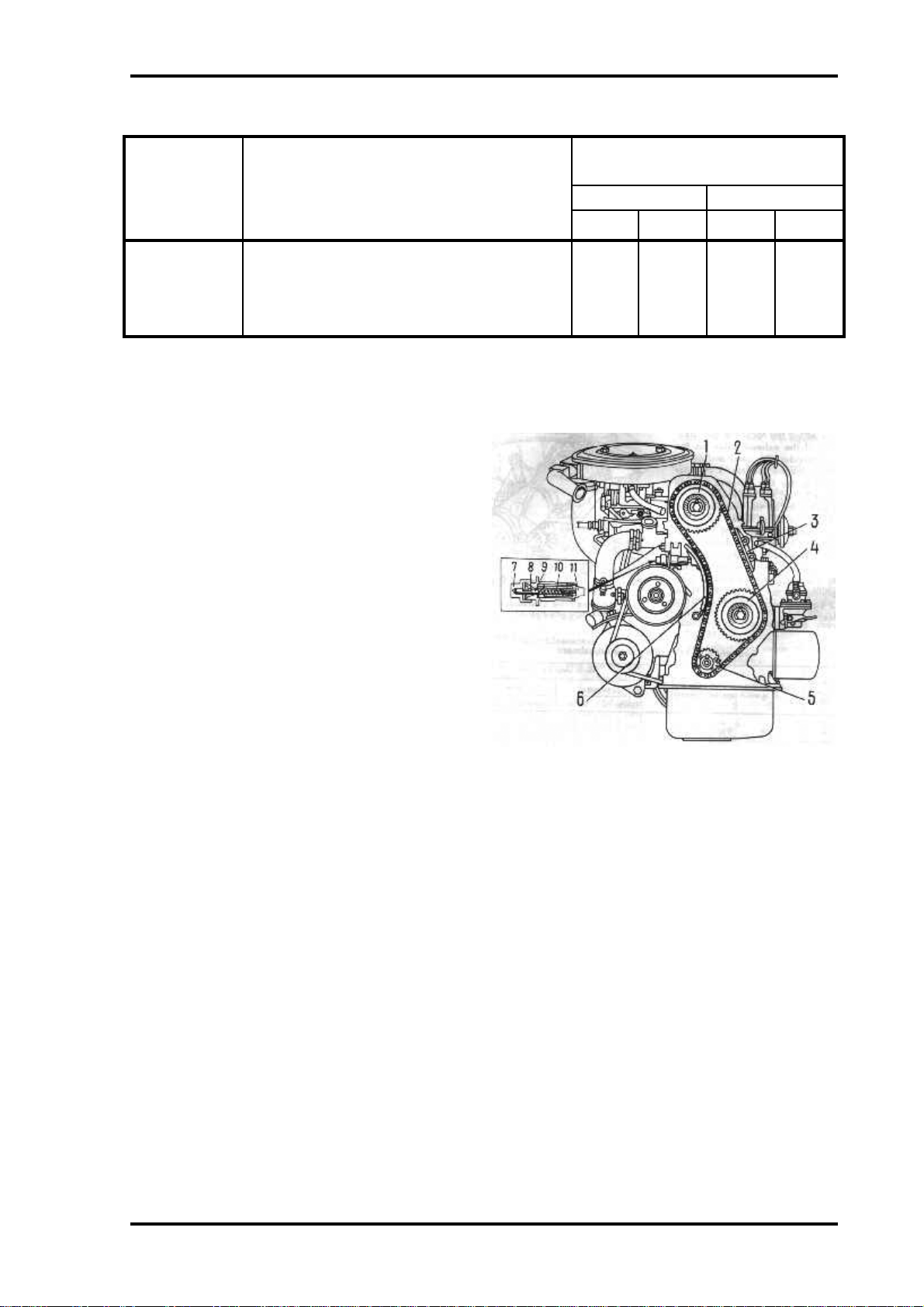

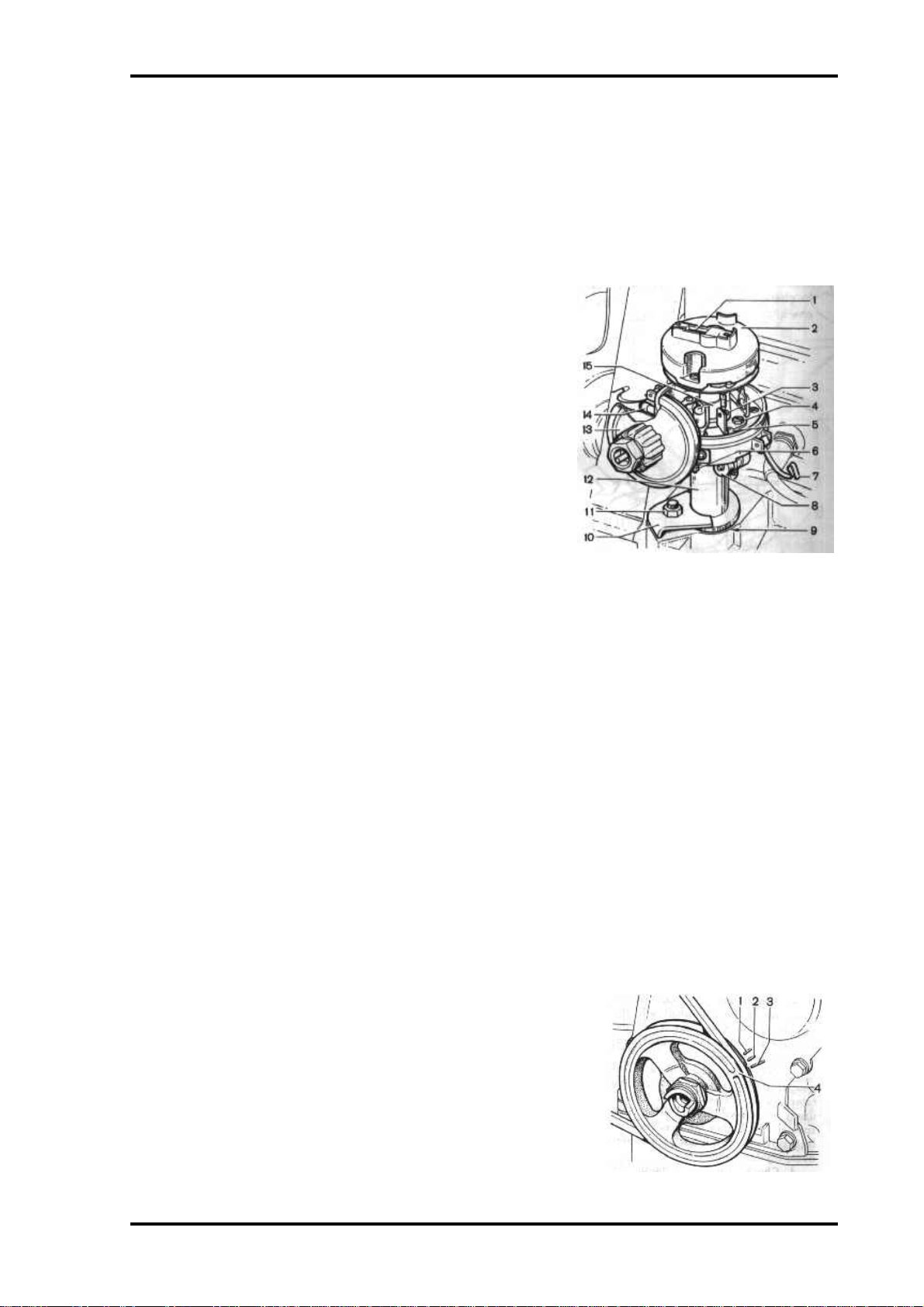

Carburettor

Every 10.000 Km (and also after the first 2,0003,000 Km if the car is new), wash the carburettor

fuel filter and the fuel pump filter with gasoline and

blow them out with compressed air.

Every 20,000 Km clean the carburettor from the

inside, wash it with gasoline or benzene and blow

out with compressed air. When cleaning the

calibrated orifices of the jets, use a wooden stick or

match with a pointed end wetted with acetone. Do

not use wire, even soft, not to disturb the

Fig. 36.Adjusting Fuel Level In Carburettor

Float Chamber: 1- carburettor upper body, 2 -

needle valve rest, 3 - stop, 4 - needle valve, 5ball, 6- pull-back yoke, 7 arm, 8 lounge, 9float, l0- gasket.

dimensions and finish of the orifices. When screwing the jets in or out, avoid damaging the

thread in the holes.

Check and, if necessary, adjust the fuel level in the float chamber and the float travel, for

which purpose.

• Make sure that the mass of float 9 (Fig. 36) complete with arm 7 is 12+1 g, the float has no

holes or dents, and can freely rotate on its pin.

• Make sure that seat 2 of needle valve 4 is tightened reliably and that damper ball 5 built

into needle valve 4 does not stick

• Set upper body 1 vertically so that the fuel inlet union is directed upwards, the needle

valve is closed, and float tongue 8 lightly contacts the needle valve ball.

• With the parts in this position, measure the distance between the float and the surface of

gasket 10 which fits the upper body; the distance should be 6.5 mm

• Change the position of the tongue, if necessary, to obtain the required distance; the tongue

must be perpendicular to the valve axis, and the contacting surface of the tongue should

have no defects that may cause sticking of the valve.

• Check the float travel which should be 8 mm, changing the position of stop 3, if necessary.

• Check that pull-back yoke 6 of the needle valve does not interfere with free travel of the

valve.

• Reinstall the carburettor upper body after making sure that the float is free to move

without brushing against the chamber walls.

Note. When replacing the needle valve, also replace the gasket between the seat and the upper

body.

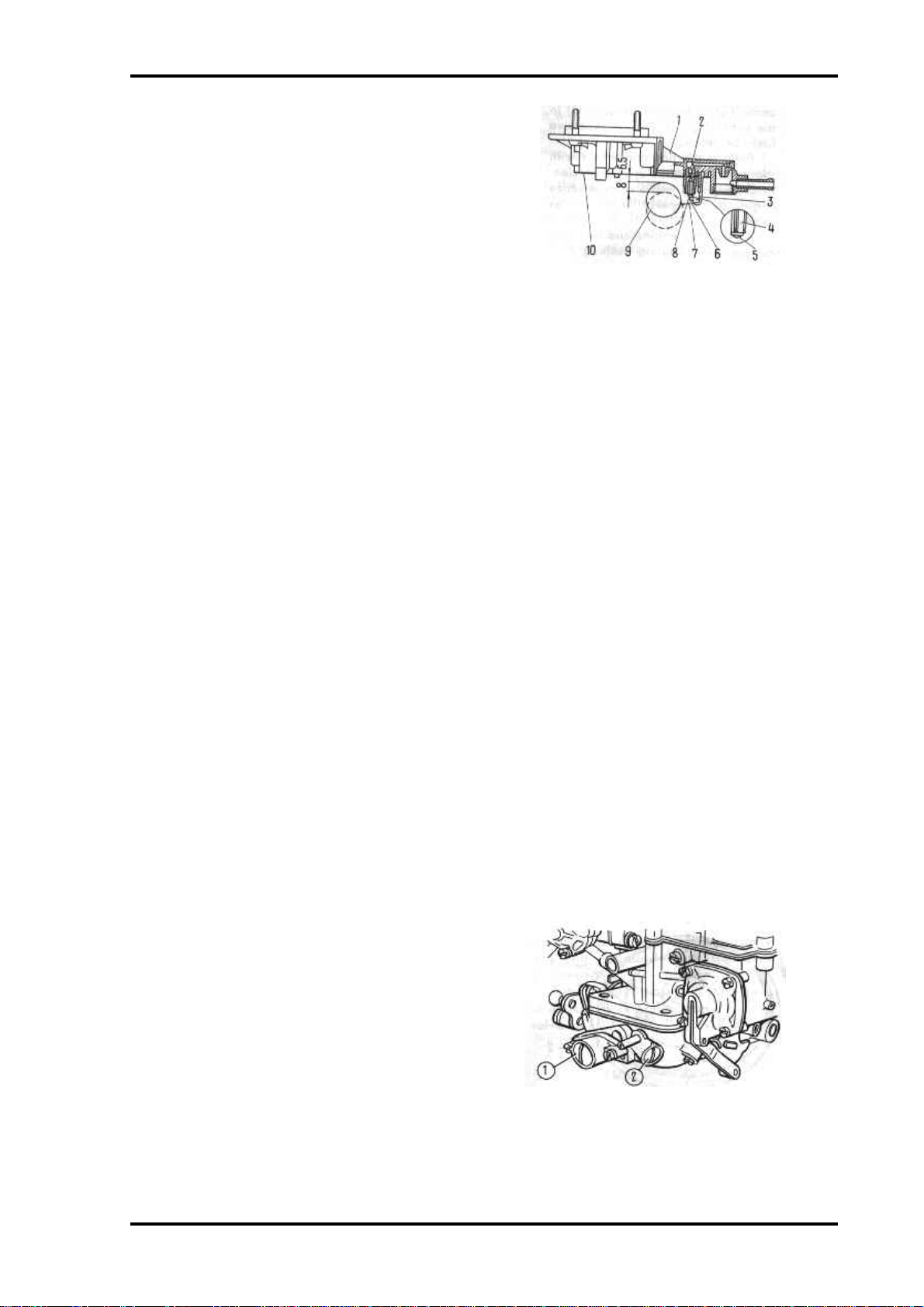

Idling speed adjustment

Every 10.000 Km (and also after the first 2,0003,000 Km if the car is new), adjust the minimum

idling speed of the engine. Have this adjustment

done at a service station. The Owner is allowed

only to carry out fine adjustment of the engine

idling speed within the range permitted by idle

speed screw limiting bushing 1 (Fig. 37) and by

idle mixture screw limiting bushing 2. Attempts to

turn the bushings through a larger angle will

Fig 37. Idling system adjustment screws: 1- Idle

speed screw limiting bushing, 2- idle mixture screw

limiting bushing.

destroy them. In this case the Manufacturer bears

no responsibility for excessive content of carbon monoxide (CO) in the exhaust gases and for

excessive fuel consumption.

Page 9

Lada Niva Manual - Maintenance Page 8

Perform the fine adjustment with the engine warmed-up, valve clearances adjusted, and a

spark advance angle set properly. Proceed as follows.

• Start the engine and turn idle mixture screw limiting bushing 2 all the way out.

• Using idle speed screw limiting bushing 1, set the engine speed within 850-900 rpm

Page 10

Lada Niva Manual - Maintenance Page 9

Check the engine idling performance. For this purpose, abruptly depress and release the

accelerator pedal; in this case the engine speed should increase smoothly without missing. The

engine should not stall when the idling speed is reduced to minimum. If the idling speed fine

adjustment fails to ensure normal running of the engine without missing, apply to a service

station for a qualified help.

CRANKCASE BREATHING SYSTEM

Every 20.000 Km clean and wash with gasoline the hoses of the crank- case breathing

system, the shut-off valve on the carburettor throttle valve shaft, and the flame arrester

located in the exhaust hose running from the engine to the air cleaner.

COOLING SYSTEM

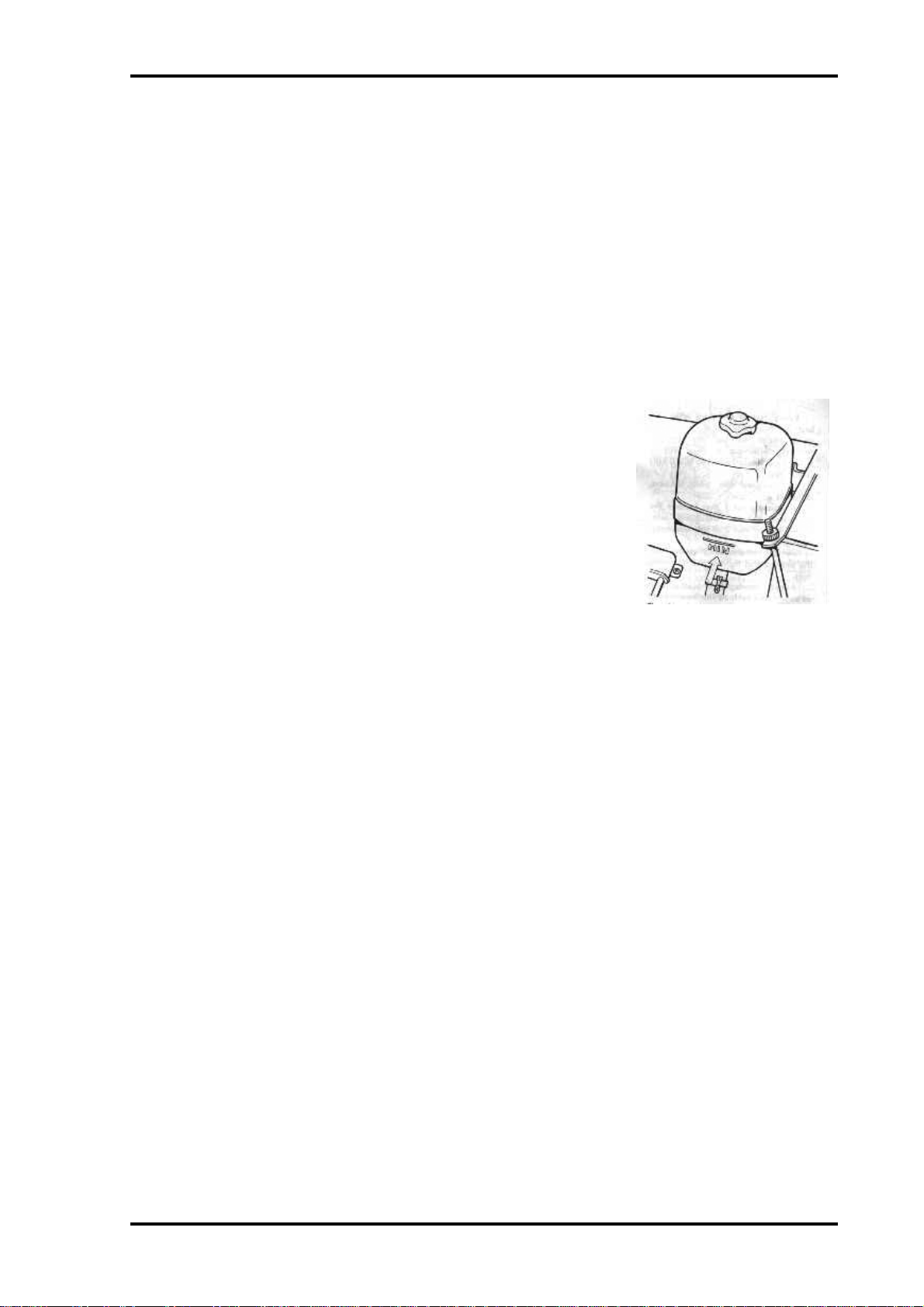

Coolant

The cooling system of the cars leaving the plant is filled with

special fluid A-40M. This fluid is an ethylene glycol mixture with

a freezing point of minus 40"C and anticorrosive, antifoaming and

antiscaling properties. It needs no replacement within a period of

three years. Therefore, care of the cooling system during this

period consists only in checking at regular intervals the fluid level

in the expansion tank.

The fluid level should always be 3-4 cm above the MIN mark

Fig 38 Cooling system expansion tank

(Fig. 38). Check the fluid level on a cold engine only, since when

the engine is hot the level may rise significantly; expansion of the fluid volume may also take

place immediately after engine shutdown.

If the fluid level is below the MIN mark, replenish the expansion tank with fluid of the same

grade. If the coolant level drops constantly and frequent replenishments are required, check the

cooling system for leakage and eliminate the trouble. In an emergency the cooling system may

be filled with clean water. In this case proceed as follows:

• Cool the engine.

• Remove the caps from the radiator and expansion tank.

• Pour water into the radiator (keep pouring water until it starts flowing out of the radiator

filler neck).

• Reinstall the radiator cap.

• Add water into the expansion tank until its level is 3-4 cm above the MIN mark.

• Reinstall the expansion tank cap.

In cold seasons if water has been added into the cooling system and before placing the car in

motion, warm the engine up to 85-90"C to make the fluids mix. Bear in mind that water added

into the cooling system raises the freezing temperature of the mixture; therefore, per- form the

necessary repairs of the cooling system at the first opportunity and fill it with the coolant of

the prescribed grade.

Page 11

Lada Niva Manual - Maintenance Page 10

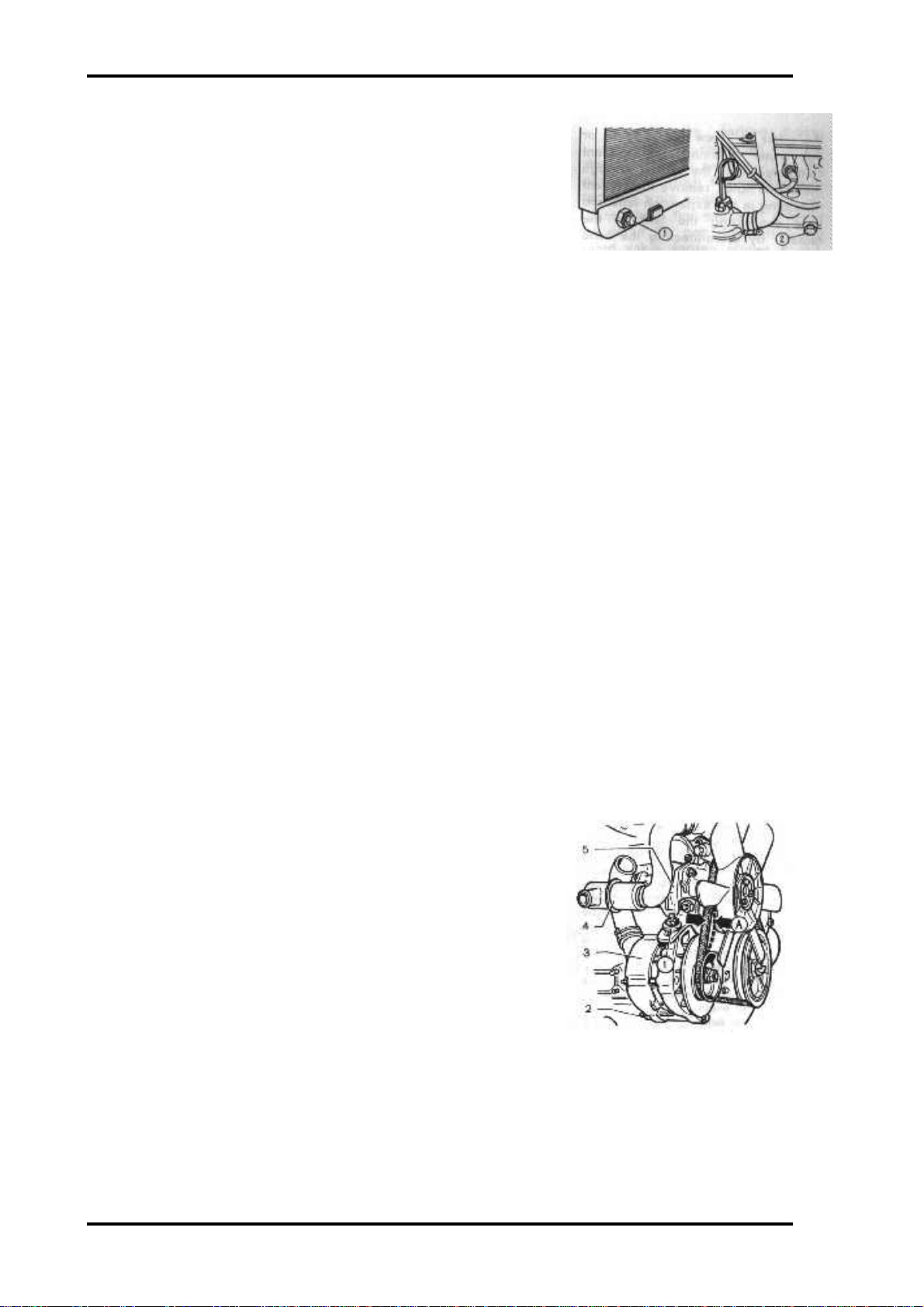

Every three years or every 60,000 Km (whichever comes

first), flush the cooling system and fill it with fresh coolant.

Drain coolant from the system through two drain holes 1 and

2 (Fig. 39), one of which is located in the radiator bottom tank

and the other one in the cylinder block at the left side. In doing

so shift the heater cock control lever to the right most

position.

Fig 39. Cooling system drain holes. 1- drain hole

in radiator bottom, 2- drain hole in cylinder block.

For screwing the radiator drain hole plug in or out, use two wrenches; one to keep in place

the plug union soldered into the radiator tank, and the other to screw the plug in or out. After

draining the coolant completely from the system through the above holes, remove the coolant

remaining in the expansion tank and hose connecting the tank to the radiator by disconnecting

the hose from the expansion tank or by raising the tank proper to a required height.

To flush the cooling system, proceed as follows.

• Fill the system with clean water, start the engine and run it until the bottom tank of the

radiator gets warmed and, with the engine idling, drain water through the radiator and

cylinder block drain holes.

• Let the engine cool down, refill the system with clean water and repeat the above

operation.

After the flushing pour coolant into the cooling system. If the coolant of the specified grade

is not avail- able, it is permissible (at ambient temperatures above zero) to use clean water, as

soft as possible to avoid heavy scale deposition which leads to engine overheating under

normal operating conditions. When using hard water, flush the cooling system twice a year

with special descaling agents.

If an aluminium radiator is in- stalled in the car do not use water in the cooling system as

water affects corrosion resistance of the radiator.

Cooling System Thermostat

Every 20.000 Km and also in case of abnormal temperature

of the engine (overheating under normal operating conditions

or excessively long warm-up period after starting), check

thermostat 4 (Fig. 40) for normal functioning. A simple check

is the hand- feeling of the thermostat directly on the car.

Upon starting the cold engine with the thermostat serviceable, the bottom tank of the radiator starts getting warm as

soon as the coolant temperature is 80-85 "C.

Alternator Drive Belt

Fig 40. Checking tension of Alternator

drive belt. 1- nut, 2- nut of alternator joint

pin, 3- alternator, 4- thermostat, 5- water

pump, A- belt deflection.

Every 10.000 Km (and after the first 2,000-3,000 Km if the car is new), check the belt for

tension. Normal deflection A (Fig. 40) is 10-15 mm if a force of 100 N (10 kg) is applied.

To increase the belt tension, proceed as follows.

• Loosen nut 1 that fastens the alternator to the adjusting arm.

Page 12

Lada Niva Manual - Maintenance Page 11

• Loosen nut 2 of the alternator joint pin.

• Shift alternator 3 away from the engine and tighten the fastening nuts.

Avoid over tightening the belt so as not to overload the bearings of alternator 3 and water

pump 5.

IGNITION SYSTEM

Ignition Distributor

Every 10,000 Km:

1. Check the working surfaces of breaker contacts 3 (Fig.

41). In case of heavy transfer of metal from one

contact point to the other, dress them with a flat

barette file. Do not eliminate completely the crater on

the breaker arm contact point. Check and, if necessary,

dress the contacts in the distributor cap and on the

rotor.

2. Use a piece of clean, gasoline- soaked chamois leather

or some other lint-free material to clean the breaker

contact points, the rotor, and the outer and inner

surfaces of the distributor cap.

3. Check the breaker point gap which should be 0.4+0.05

Figure 41. Ignition distributor. 1- noise resistor

suppressor, 2- rotor, 3- breaker contacts, 4screw, 5- slot, 6- terminal, 7- spring catch, 8capacitor, 9- scale, 10- bracket, 11- nut, 12- body,

13- vacuum spark timer, 14- lubricator, 15- cam

mm, for which purpose.

• Shift the gearshift lever into the neutral.

• Apply the parking brake;

• Rotate the crankshaft with the starting crank to set cam 15 in the position at which the

breaker contacts are wide open.

• Check the gap with a feeler gauge; if the gap differs from the rated value, loosen screws 4

and, using a screwdriver inserted into special slot 5, shift the breaker con- tact post as

required; adjustment eve, tighten screws 4.

4. Check ignition timing, for which purpose

• Connect one end of the wire of a 12-V test lamp to terminal 6, and ground its other end.

• Turn on the ignition and slowly rotate the crankshaft with the starting crank; with the

ignition set properly, the test lamp should come on when mark 4 (Fig. 42) on the

crankshaft pulley is aligned with mark 2 on the timing gear cover, and the contact of rotor 2

(Fig. 41) should be opposite the contact of the No. 1 cylinder on the distributor cap.

5. If the marks are not aligned at the moment the test lamp

comes on, adjust the ignition timing as follows.

• Rotate the crankshaft with the starting crank to set it in

the position at which the rotor contact faces the contact of

the No. 1 cylinder on the distributor cap, and mark 4 (Fig.

42) is aligned with mark 2 (in this position the piston of

the No. 1 cylinder will be 5" before TDC as measured in

crankshaft degrees);

• Loosen nut 11 (Fig. 41) and turn distributor body 12

clockwise until the breaker points are closed.

Fig 42. Timing marks on pulley and valve

gear drive cover. 1- 10o, 2- 5 o, 3-0 o, 4-

mark on pulley

Page 13

Lada Niva Manual - Maintenance Page 12

• Slowly rotate the distributor body counter-clockwise until the test lamp comes on; in doing

so, slightly press the rotor counter- clockwise to take up clearances.

• Stop the distributor body exactly at the moment the test lamp comes on (the breaker

contact points are at the beginning of opening phase).

• Holding the distributor body in this position, tighten nut 11.

• Switch off the ignition, install the distributor cap on its body, and secure it with two spring

catches 7.

On a new car, check the breaker point gap and ignition timing after the first 2,000-3,000 Km.

Every 20.000 Km deliver 2-3 drops of engine oil into the hole of lubricator 14.

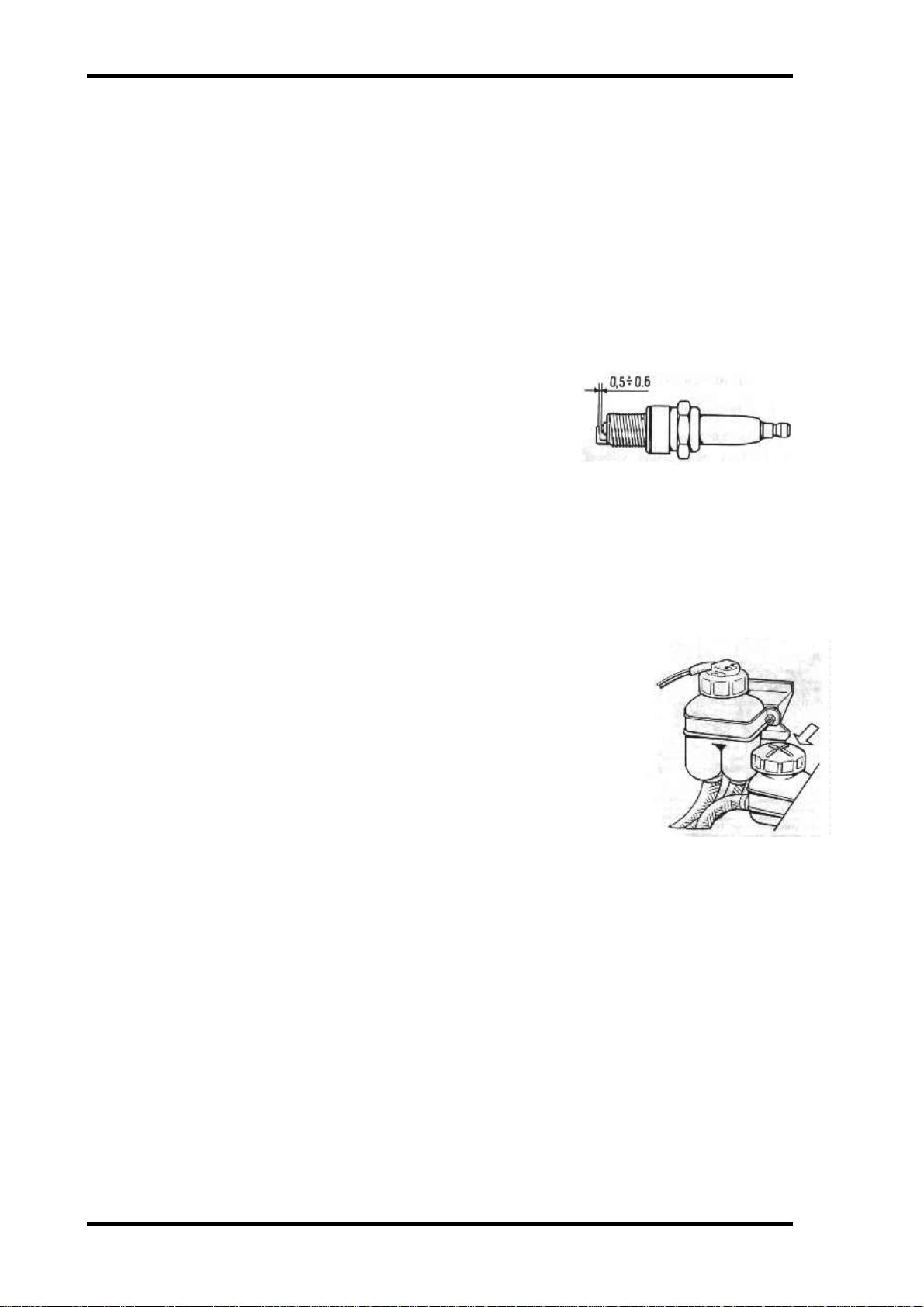

Spark Plugs

Every 10,000 Km proceed as follows:

1. Using gasoline and a stiff brush, remove carbon deposit

from the spark plugs.

2. 2. Check the spark plug gap with a round wire feeler gauge.

The gap should be 0.5-0.6 mm (Fig. 43); the gap must be

Fig 43. Checking spark plug gap

adjusted only by bending the side electrode.

Every 20,000 Km replace the spark plugs with new ones. For re- liable starting of the engine

at low sub-zero temperatures, it is recommended to replace the long-used spark plugs with

new ones, even if the used spark plugs are still serviceable; they can be used again in warm

seasons of the year.

TRANSMISSION

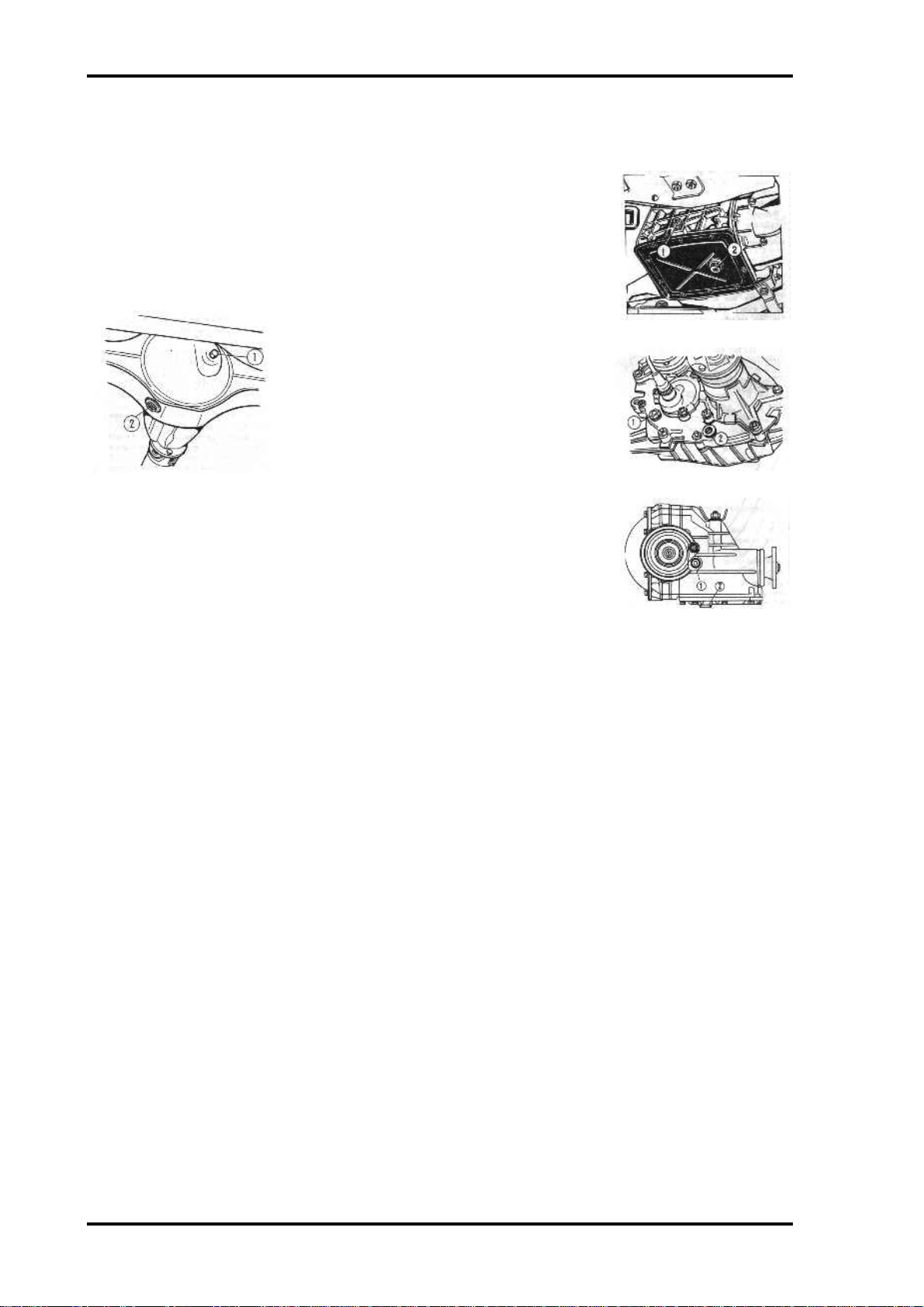

Clutch Fluid Reservoir

Every 10,000 Km check fluid level in the reservoir (Fig. 44) and

replenish, if necessary, to the lower edge of the filler neck.

Add HeBa (Neva) or Tomb (Tom) brake fluid only. It is recommended

to change the brake fluid with fresh one after five years of service.

Adjusting the Clutch Control Mechanism

Every 30,000 Km (and also after the first 2,000-3,000 Km and 10,000 Km if the car is new)

check and, if necessary, adjust the clutch control mechanism for which purpose.

Page 14

Lada Niva Manual - Maintenance Page 13

Check clearance between pushrod 3 (Fig. 45) and piston 2 of master cylinder 1 which should

be 0.1-0.5 mm. The clearance corresponds to the travel of pedal 5 through 0.4-2 mm and it is

adjusted with stop 4.

Check free travel of pushrod 6 of

operating cylinder 10 which should be 4-5

mm. Pushrod free travel is adjusted with

nut 8 after loosening locknut 9.

Adjustment over, tighten locknut 9.

Upon completion of the above

adjustments free travel of the clutch pedal

before the beginning of clutch release

should be 25-35 mm. Check the clutch

pedal free travel also after the bleeding of

the hydraulic control system. Presence of

air in the system is indicated by the

spongy pedal and incomplete release of the

clutch (clutch drags). Bleed the system

through the union of operating cylinder 10

Fig 45. Adjusting Clutch control mechanism. 1- Clutch master

cylinder, 2- pushrod piston, 3- pushrod, 4- pedal travel stop, 5- clutch

pedal, 6- operating cylinder pushrod, 7- clutch release fork, 8- nut, 9locknut, 10- operating cylinder.

in the same way as the brake system.

Page 15

Lada Niva Manual - Maintenance Page 14

Gearbox, Transfer Case.

Front and Rear Axles

After the first 2000-3000 Km and every 30.000 Km, change oil in

the gearbox, transfer case, and front and rear axles. Do it right after

the trip, when oil is still hot. Drain used oil through the holes closed

with plugs 2 (Figs. 46, 47, 48, 49). Pour fresh oil through the level

check holes closed with plugs 1, up to the lower edges of these

holes.

Fig 46. Gearbox. 1- check hole

Every 10,000 Km check oil level which

plug, 2- drain hole plug

should reach the lower edges of the level

check holes. Check be- fore the trip to be

sure that all oil has dripped down from

the walls and gears.

Fig 49. Rear Axle. 1- check hole

plug, 2- drain hole plug.

Propeller Shaft Splined Connections and Crosses

Fig 47. Transfer Case. 1- check

hole plug, 2- drain hole plug

Every 10.000 Km deliver grease to the splined connections through

the grease fittings and grease-gun the crosses with grease No. 158 or

Fig 48. Front Axle. 1- check hole

plug, 2- drain hole plug

cDMOn-ZY till fresh grease shows up under the seals.

Joints of Front Wheel Drive Propeller Shafts

While in service, care of the joints of the front wheel drive propeller shafts is confined only

to regular checking the condition of protective boots. A damaged boot should be immediately

replaced with a new one upon washing the joint and changing the grease. This operation

should be performed at a service station.

HYDRAULIC SHOCK ABSORBERS AND ANTIROLL BAR

Every 30.000 Km check the shock absorbers for serviceability. If the shock absorbers

operation becomes less efficient, which is manifested by slow damping of oscillations (3-4

oscillations) of the car body on crossing a road bump, or by unusual knocking in the shock

absorbers, apply to a service station. Pay attention also to the condition of shock absorber

rubber bushings and rubber cushions of the antiroll bar. If the rubber bushings and cushions

show any signs of damage or age-hardening, replace them with new ones.

STEERING GEAR AND WHEELS

Steering Gear Clearances

Every 20,000 Km (and also after the first 2,000-3,000 Km if the car is new), check the

steering wheel for play which should not exceed 18-20 mm measured on the wheel rim with

the wheels in the straight ahead position and with normal clearances in the steering gear. If the

steering wheel play exceeds this value, perform an overall check of the steering gear:

Page 16

Lada Niva Manual - Maintenance Page 15

1. Make sure that the bearings of the front wheel hubs are adjusted properly and the tyre

inflation pressure is normal.

2. Turning the steering wheel in either direction, check for knocking in the joints, steering

mechanism and connections. Check and tighten, if necessary, the fastenings of the pitman

arm, steering gear case, brackets of the idler arm and steering shaft.

3. Rocking the steering wheel hand-feel the steering rod ball joints for play.

4. Make sure the ball supports and the joints of the front suspension wishbones are in

serviceable condition.

5. Eliminate the faults detected and check steering wheel play. If steering wheel play exceeds

the permissible value, check and adjust the following clearances in the steering mechanism:

Clearance in the worm bearings that is found by axial movement of the

steering shaft while turning the steering wheel leftward and rightward

through a small angle; eliminate the clearance by decreasing the number

of shims 3 (Fig. 50) placed between the case and the thrust bearing

cover until the shaft rotates easily without axial displacement;

Roller-to-worm backlash which is found by rocking the pitman arm

head, with the rods disconnected, with the car wheels in the straight

ahead (neutral) position; eliminate backlash by turning in screw 1,

Fig 50. Adjusting clearances in

steering mechanisms. 1- screw, 2-

nut, 3- shims

with nut 2 loosened and the pitman arm in the neutral position;

adjustment over, tighten nut 2; there should be no backlash between the roller and worm when

the steering wheel is turned through 30" to the right or to the left from the neutral position.

Front Wheel Hub Bearings

Fig. 51. Front Wheel: 1 - brake disc; 2 - hub; 3 - outer roller bearing; 4 - outer seal protective ring; 5 - outer seal; 6 tapered bushing; 7 - hub nut; 8 - hub cap; 9 - propeller shaft drive end; 10 - outer seal demounting ring; 11 - inner

roller bearing; 12 - inner seel demounting ring; 13 - inner seal; 14 - inner real protective ring; 15 - steering knuckle;

Page 17

Lada Niva Manual - Maintenance Page 16

16 - lower wishbone ball support; 17 - lower wishbone; 18-propeller shaft; 19-upper wishbone ball support; 20 shims

Every 10.000 Km (and also after the first 2,000-3,000 Km if the car is new), check and

adjust, if necessary, the clearances in the front wheel hub bearings. For this purpose, proceed

as follows:

• Place the car on a level ground, apply its parking brake, loosen the wheel fastening nuts,

jack up the wheel and remove it, having turned off the wheel nuts

• Remove hub cap 8 (Fig. 51), secure a device with an indicator on steering knuckle 15 so

that the indicator finger contacts the end face of hub 2 near the tapered hole;

• Pull the hub to yourself by hands, and set the indicator pointer to zero;

• Measure the clearances in the hub bearings, for which purpose push the hub axially away

from your- self. If in this case the indicator readings exceed 0.15 mm, adjust clearances in

the bearings in the following way;

• Remove the indicator, screw off nut 7 and replace it with a new one;

• Tighten nut 7 to a torque of 20 NÆm(2 kg m), rotating the hub in both directions;

• Loosen the nut and retighten it to a torque of 7 N Æ m (0.7 kg Æ m); then, screw it off

through 20-25";

• Install the indicator and measure clearances in the bearings. If clearances exceed 0.07 mm,

repeat the adjustment. If clearances are within 0.01-0.07 mm, fix nut 7 by staking the dents

on the nut shoulder into the slots on drive end 9 of the propeller shaft.

• Remove the device with the indicator, install cap 8, fasten the wheel, jack down the car, and

tighten the wheel nuts all the way home.

Every 20.000 Km. replace grease in the bearings of the front wheel hubs. For this purpose

proceed as follows.

• Remove the wheel, disconnect the brake calliper from steering knuckle 15, and take it off

brake disc 1;

• Remove hub cap 8, screw off nut 7, take out tapered bushing 6 and remove hub 2 complete

with brake disc 1;

• Place a support under lower wishbone 17 and screw off the nuts securing ball support 16

to the wishbone;

• Disconnect the shock absorber from the lower wishbone and the side steering rod from the

arm of steering knuckle 15;

• Shift propeller shaft 18 to- wards the front axle as far as it will 90;

• Turning steering knuckle 15 about upper wishbone ball support 19, remove the former

from the propeller shaft drive end;

• Use the puller to remove the cones of bearings 3 and 11 with demounting rings 10 and 12

and seals 5 and 13 from the steering knuckle space. Mark the bearing cones in order to

reinstall the cones in their proper places during the assembly;

• Remove the used grease and wash with kerosene the inner space of the steering knuckle,

outer and inner spaces of the hub, propeller shaft drive end, and bearing cones;

• Pack 40 g of fresh grease nHTon-24 into the bearing cages, apply a uniform layer of grease

to the steering knuckle spaces between the bearings, and lubricate the splines of the

propeller shaft drive end;

• Reinstall the bearing cones and demounting rings, and press- fit the seals;

Page 18

Lada Niva Manual - Maintenance Page 17

• Mount the steering knuckle on the propeller shaft drive end, connect the ball support to

the lower wishbone, secure the shock absorber, and connect the side steering rod to the

steering knuckle arm;

• Install the hub complete with the brake disc on the propeller shaft drive end, and install

tapered bushing 6; screw on new hub nut 7 and adjust bearing clearances, as described

above;

• Fit the hub cap, remove the support, install and secure the brake calliper, and reinstall the

wheel.

• If the car is frequently driven on bad roads (deep mud), change grease every 10,000 Km.

Examining the Front Suspension Ball Supports and Steering Rod joints

If tyre inflation pressure and clearance in the front wheel hub bearings correspond to the

rated values, the joints of the front wheel suspension wishbones are in good condition, the

pitman arm, steering gear case, idler arm brackets and steering shaft are fastened securely, but

adjustment of the steering gear fails to ensure normal play of the steering wheel, check the

following:

1. Clearances in the ball supports. Check the clearances by rocking the hub with the front

wheel suspension jacked up and wheels braked (to exclude the effect of clearances in the hub

bearings). If the steering knuckle displacement at the level of the ball pin sphere relative to the

wishbones exceeds 0.8 mm, replace the ball support.

2. Clearances in the steering rod joints. Determine the clearances by the method of mutual

displacement of the steering rods when turning the steering wheel.

Premature wear of the ball joints is generally caused by damaged protective rubber boots

which allow ingress of water and dust into the joints. If the boot is in good condition, the

service life of the joints is practically unlimited. Therefore, check the protective rubber boots

for condition at regular intervals, and replace them with new ones even if the slightest damage

is detected, after making sure that the ball joints are serviceable and that there is enough grease

U1P6-4in

Tyres

Every 100 Km use a tyre pressure gauge to check tyre inflation pressure, including the spare

wheel. It is advisable to have the pressure gauge periodically checked at a service station.

Whenever tyre inflation pressure is checked, check the tube valve for air leaks (best of all it

may be done by applying soap suds to the valve inlet hole). In case of air leak- age (indicates

by air bubbles) tighten the tube valve core with the valve cap, or replace it with a new one. If

the valve core is in good condition, but-the tyre gets constantly deflated, demount the tyre,

check and repair the tube, or replace it with a new one.

Prior to demounting the tyre, use a piece of chalk to make a mark on the tyre casing opposite

the tube valve with a view to mount the tyre in compliance with this mark. This is necessary

to preserve wheel balance. Demount the tyre from the wheel disc with the tyre tube deflated

completely; see to it that the part of the casing opposite to the zone being demounted is in the

Page 19

Lada Niva Manual - Maintenance Page 18

wheel rim well. Use tyre irons for the de- mounting/mounting jobs. The di- stance between the

tyre irons when catching the tyre bead should not exceed 150 mm.

Upon installation of new tyres, be sure to check the wheel balance at a service station. It is

not advisable to drive the car on new tyres at a speed greater than 100 km/h during the first

500 Km.

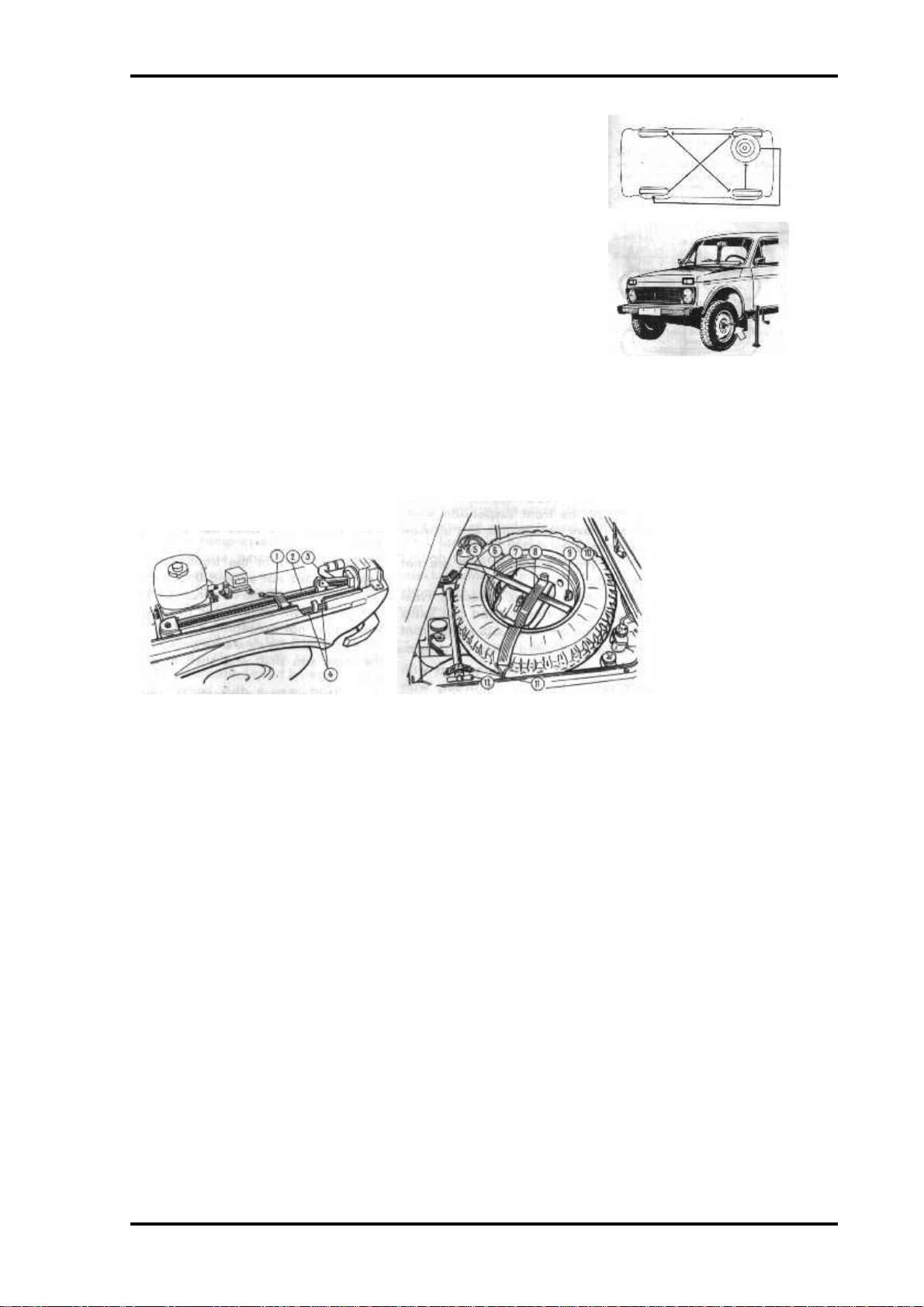

Every 10.000 Km interchange the wheels as shown in Pig. 52 to ensure uniform wear of

tyres. If abnormal vibrations in motion are detected, check wheel balance.

Page 20

Lada Niva Manual - Maintenance Page 19

Replacing the Wheels

To replace a wheel, proceed as follows:

Place the car on a level ground and apply the parking brake;

Prepare the jack, tyre pump, tools bag and spare wheel;

Use the combination wrench to slacken the wheel nuts one

Fig 52. Wheel rotation diagram

revolution;

Insert the jack arm into the socket nearest to the wheel being

replaced (Fig. 53), and rotate the jack handle until the wheel

clears the ground (the jack should not sink in the ground when

the car is being raised);

Unscrew the wheel nuts and remove the wheel. Install the

spare wheel and uniformly tighten the wheel nuts;

Fig 53. Jacking up car for

replacement of wheels.

Lower the car onto the wheels, and withdraw the jack;

Tighten the nuts to a torque of 70-90 NÆm (7-9 kg m), check tyre inflation pressure and bring

it to normal;

Stow the tools and the spare wheel under the hood, and secure them as shown in Fig. 54.

Fig 54. Stowage and

fastening of tools and

accessories. 1, 6, 8, 11-

elastic straps, 2- jack, 3starting crank, 4- tyre irons, 5inspection lamp, 7- tools bag,

9- wing nut, 10 spare wheel,

12 air pump

Front-End Alignment

Every 20,000 Km (and also after the first 2,000-3,000 Km if the car is new) as well as in case

of rapid and irregular wear of the front wheel tyres and impaired steering of the car, check the

front-end alignment. It is advisable that this operation is performed at a service station

equipped with a precision optical stand ensuring high-accuracy checking and front-end

alignment. Given below is a method, though less accurate, of checking only the wheel camber

and toe-in by the Owner himself, on condition that the following requirements are met:

Tyre inflation pressure is normal;

Radial and axial runout of the front wheel rims does not exceed 3 mm;

End play in the front wheel bearings does not exceed 0.15 mm;

Backlash in the steering worm- to-roller mesh ensures a steering wheel play not exceeding 5";

there is no clearance between the idler arm shaft and shaft bushings;

The rubber elements in the joints of the front suspension wish- bones have no ruptures and

ultimate distortions;

Shock absorber rods are not jamming; there are no excessive clearances in the steering rod ball

joints and in the ball supports of the front suspension wishbones.

Check the wheel alignment with the car in the running order, with a load of 3,200 N (320 kg)

which roughly corresponds to the weight of four persons plus 400 N (40 kg) of luggage in the

Page 21

Lada Niva Manual - Maintenance Page 20

luggage compartment. Place the car on a flat level ground and set the front wheels in the

position that corresponds to the straight-ahead motion.

To stabilise the position of the suspension units, exert pressure on them by pushing down

first the rear and then the front bumpers for 2-3 times, applying a force of about 400-500 N

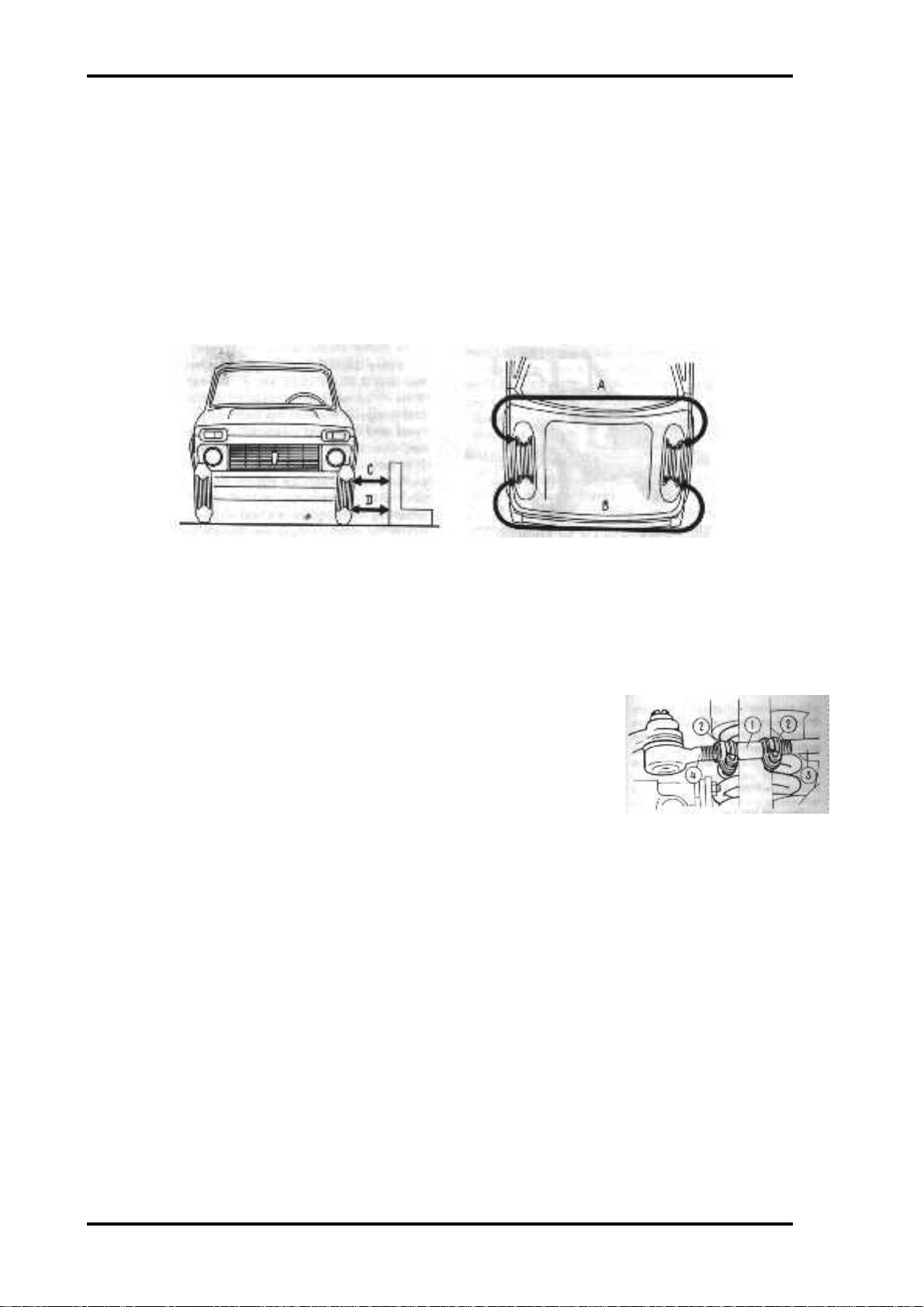

(40-50 kg). To determine wheel camber, measure distance C (Fig. 55) between the wheel rim

and the set square. Then roll the car to turn the wheels through 180", and measure distance D.

Camber is correct if distance D is 1-5 mm greater than distance C. Camber is adjusted by

changing the number of shims 20 (Fig. 51) between the upper wishbone shaft and the cross

member. Check and adjust toe-in only after checking and adjusting the wheel camber.

Fig 55. Checking front end alignment

To determine toe-in, measure distance A (Fig. 55) between the corresponding points on the

front wheel rims. Then roll the car to turn its wheels through 180" and measure distance D is

1-5 mm greater than distance C.

Camber is adjusted by changing the number of shims 20 (Fig 51) between the upper

wishbone shaft and the cross member.

Check and adjust toe-in, measure distance A (Fig 55) between the

corresponding points on the front wheel rims. Then roll the car t o

turn its’ wheels through 180 degrees and measure distance B. Toe-in is

correct, if the first dimension is 2-4 mm greater than the second one.

Toe-in is adjusted by changing the length of side steering rods 3 (Fig.

56). For this purpose loosen clamps 2 and turn adjusting sleeves 1

through the same number of revolutions in the opposite directions,

Fig 56. Adjusting length of side

steering rods. 1- sleeve, 2- clamps, 3

side steering rod, 4- steering rod end.

thus screwing the sleeves on or off and changing the length of the side

steering rods. Adjustment over, tighten clamps 2 to a torque of 19 N Æ m (1.9 kg Æ m) so that

their slots face down and their ends, after tightening, do not touch each other.

Camber and toe-in can be also checked and adjusted, though less accurately, with the car

unloaded. In this case wheel camber D-C should be from -1 to +3 mm, and toe-in A-B should

be 4~1 mm.

BRAKES

Brake Hydraulic System

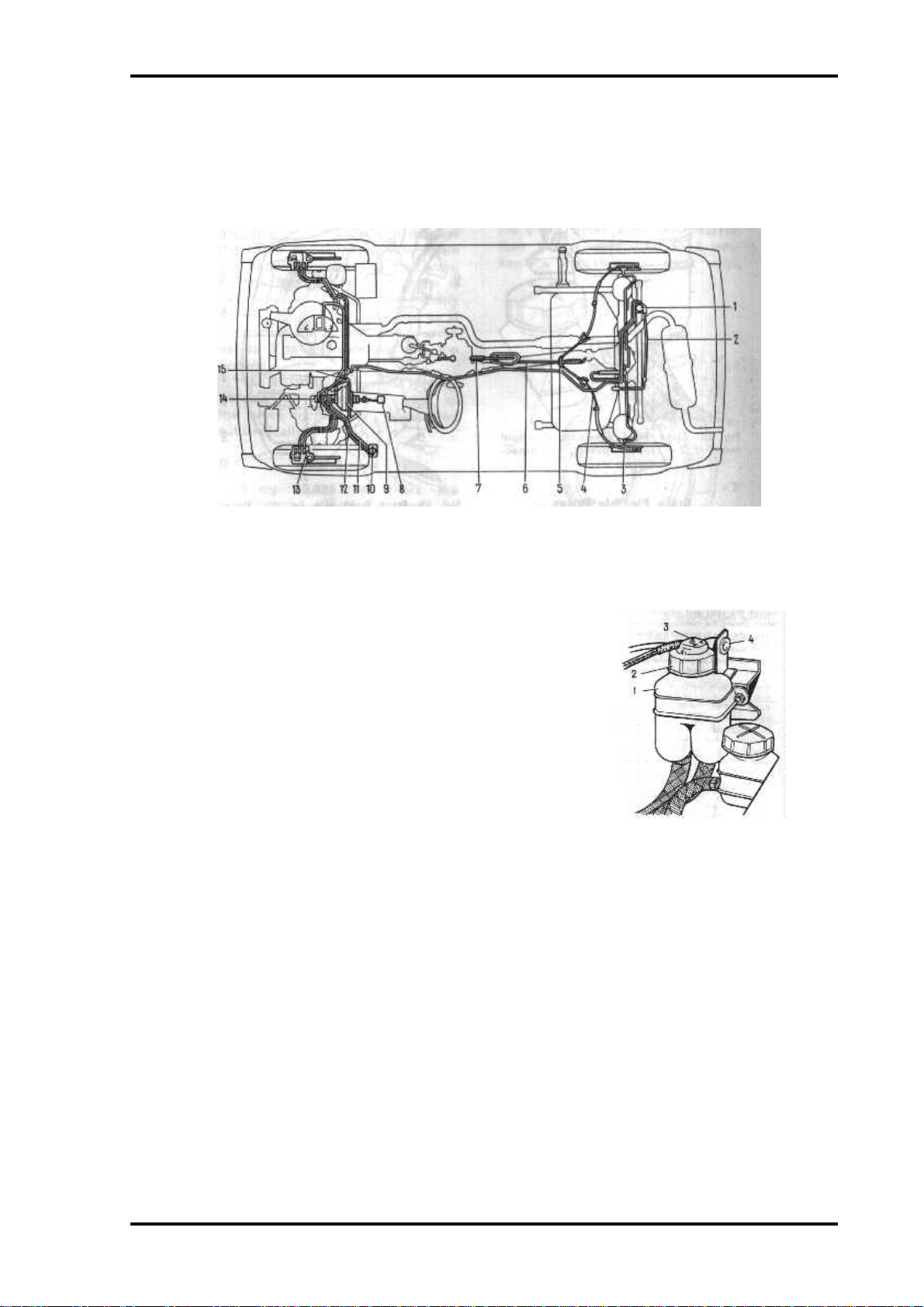

The brake system of the car is given in Pig. 57. Prior to servicing the brake system, clean each

brake of dirt, wash it with warm water and dry with compressed air.

Never use gasoline, diesel fuel, trichloroethylene or other mineral solvents for the purpose

since they attack the cups and seals of the hydraulic cylinders.

The surfaces of the brake linings should be clean, with no traces of dirt or lubricant. Soiled

linings should be cleaned with a wire brush and washed with white spirit. If the pads or linings

Page 22

Lada Niva Manual - Maintenance Page 21

are contaminated with oil, check for oil or brake fluid leakage through the seals and eliminate

the defect. During the maintenance ope- rations take care to protect the brakes from oil.

If free travel of the brake pedal exceeds 5 mm with the engine stopped, or the braking

efficiency of the wheels becomes different, per- form an all-round check of the brake system.

Fig. 57. Brake System Diagram: 1 - pressure regulator; 2 - pressure regulator torsion lever; 3 - rear brake wheel

cylinder; 4 - parking brake rear cable; 5 - rear cable equaliser; 6 - parking brake front cable; 7 - parking brake lever; 8 brake pedal; 9 - vacuum booster; 10 - brake fluid reservoir; 11 - primary brake circuit; 12 - secondary brake circuit; 13

- (rent disc brake cylinder block; 14 - brake master cylinder; (5 - T-piece

Brake Fluid Reservoir

Every 10,000 Km check the fluid level in reservoir 1 (Fig.

58), which should be as high as the lower edge of the filler

neck with cap 2 installed. Add only brake fluid Hesa or

ToML. Depress pusher 3 on the reservoir cap to check the

fluid level transmitter for proper functioning; with the ignition

switched on the warning lamp should be constantly alight. It is

recommended to replace the brake fluid after 5 years of

operation.

Fig 58. Brake fluid reservoir. 1-

Flexible brake hoses

fluid reservoir, 2- cap, 3- pusher,

4- inspection lamp socket

Every 10,000 Km, starting from 30,000 Km check condition of the brake hoses and replace

them with new ones, if minor cracks are detected on the sheathing or bulges appear on the

hose when the brake pedal is pressed.

Front Brakes

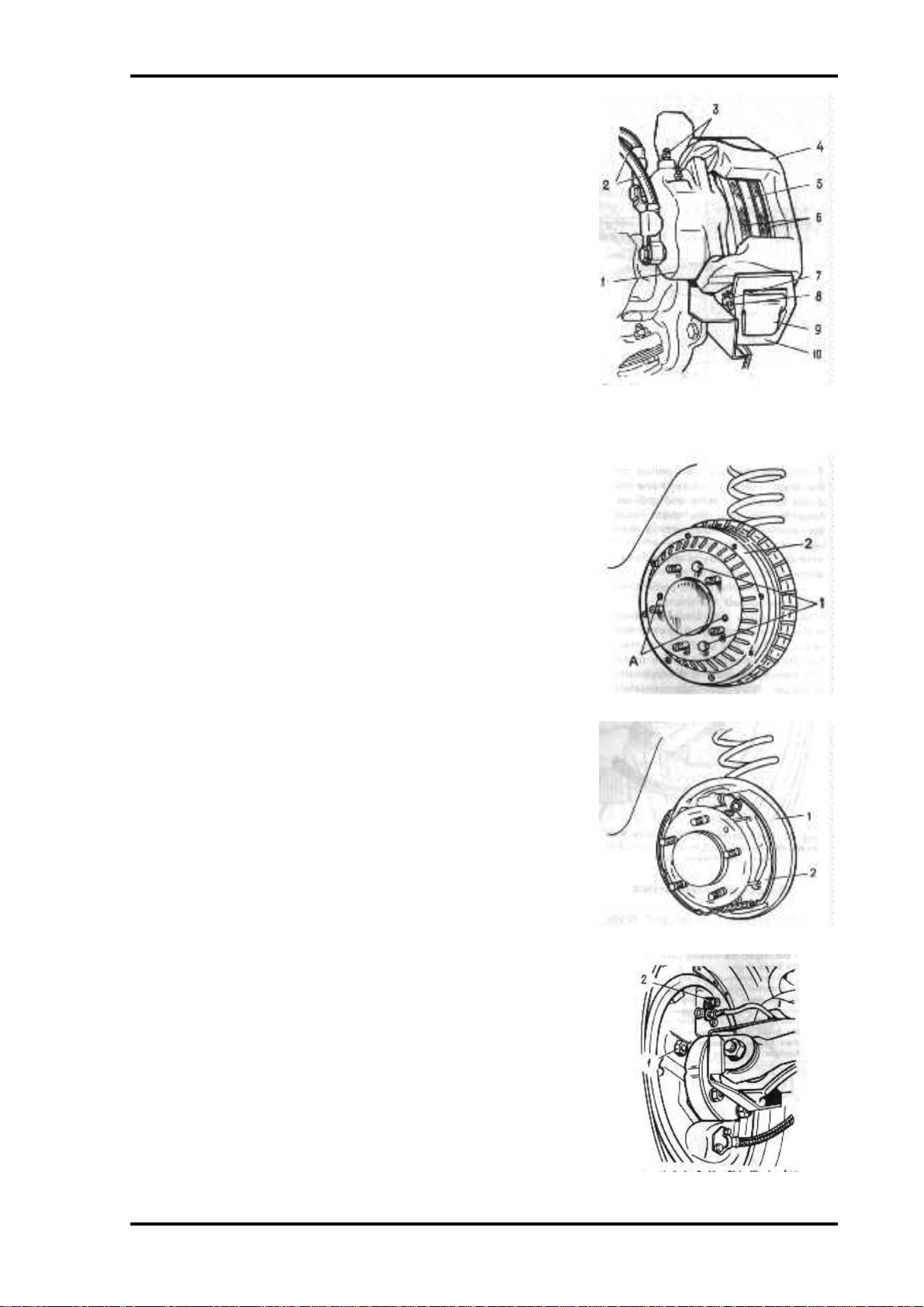

Every 10.000 Km check the condition of brake shoes 6 (Fig. 59). To remove the brake shoes

take out cotter pin 8 in the brake upper part; holding pressure lever 10, take out axle 7 and

remove the lever; shift upwards calliper 4 complete with cylinder block 1 until the lower

pressure lever is released, and remove the calliper with the cylinder block from the brake disc.

Replace the brake shoes if thickness of the friction pads is reduced to 1.5 mm. If the brake

shoes are removed for purposes other than replacement, mark them to reinstall the shoes in

their places.

Page 23

Lada Niva Manual - Maintenance Page 22

Before installation of the brake shoes, make sure that brake disc 5 is not damaged nor deeply

scored. Replace the disc if it is worn to a thickness below 9.5 mm.

To install the brake shoes push the pistons as deep into the cylinders as possible. When

doing so see that the protective rubber seals of the pistons are in their sockets and are not

damaged; replace the seals, if necessary.

When the pistons are pushed into the cylinders, the brake fluid level in the reservoir rises. To

prevent overflowing, remove the reservoir cap and timely remove the required amount of fluid

from the reservoir.

Page 24

Lada Niva Manual - Maintenance Page 23

Then install brake shoes 6, fit the calliper complete with

the cylinder block, and fix it with the pressure levers; for

this purpose press off the lower lever and shift the calliper

so that it is pressed by the lower lever; install the upper

lever, insert axle 7 and fit cotter pin 8.

Upon the installation of the brake shoes the brake system

needs no bleeding. It is sufficient to depress the brake pedal

in order to attain the normal operation of the brake system.

Bleeding of the system is necessary only after disassembly

of the cylinder block, or when air is trapped in the system;

use bleeder valves 3 to evacuate air from the system.

The adjustment required to compensate for the natural

wear of the brake friction pads is effected automatically.

Rear Brakes

Fig 59 front brake. 1- cylinder block, 2flexible hoses, 3- bleeder valves, 4- calliper,

5- brake disc, 6- brake shoes, 7- pressure

lever axle, 8- cotter pin, 9- brake shoe guide,

10 pressure lever.

Every 20.000 Km check the condition of the brake shoes

for which purpose unscrew two bolts 1 (Fig. 60), insert

them into holes A and screw them in until brake drum 2 is

moved off its place.

Check the condition of brake shoes 2 (Fig. 61) with friction

linings 1 and inspect the working surface of the brake drum.

If the brake shoes are broken or distorted which prevents

uniform shoe-to-drum contact and reduces efficiency of

braking, replace the shoes with new ones. Also replace the

brake shoes when thickness of their linings is reduced to 2

Fig 60. Rear Brake. A- holes, 1- bolts, 2brake drum

mm. Replace the shoes in pairs only.

If deep notches are formed on the drum working surface,

have the drums turned in a lathe and ground. Prior to

installing the drum, coat the mounting surface with a thin

layer of graphite grease.

Adjust the shoe-to-drum clearance as follows:

• Depress the brake pedal until the shoes contact the drum;

• Keeping the shoes pressed to the drums, turn adjusting

eccentric heads 1 (Fig. 62) until they contact the shoes;

release the brake pedal and turn the heads in the opposite

Fig 61. Rear brake with drum removed.

1- friction lining, 2- brake shoe

direction through approximately 10";

• Sharply depress the brake pedal 3-4 times and, having

released it, check the brake drum; if it is jammed, repeat

the adjustment.

Fig 62. Brake backing plate viewed from

rear axle. 1- adjusting eccentric head, 2-

rear brake bleeder valve.

Page 25

Lada Niva Manual - Maintenance Page 24

Bleeding the Brake System

An increased travel and sponginess of the brake pedal manifest the presence of air in the

brake system which impairs considerably efficiency of the brakes. Evacuate air from the

system by bleeding in succession; the brake mechanism cylinders of the R.H. rear wheel, then

of the L.H. rear wheel, of the L.H. front wheel and, finally, of the R.H. front wheel through

the upper bleeder valves. In this way the first brake circuit will be bled. To repeat the

procedure for the second brake circuit, make use of the lower bleeder valves of the front wheel

brake mechanisms. It is allowed to start the bleeding procedure from the R.H. or L.H. front

wheel.

Do not jack up the car rear to exclude influence of the pressure regulator.

To perform bleeding, proceed as follows:

1. Unscrew the reservoir cap (Pig. 58) and add some fluid up to the normal level.

2. Remove the protective caps from bleeder valves 3 (Fig. 59) and 2 (Fig. 62) and clean the

latter of dirt and dust.

3. Fit a rubber hose on the bleeder valve head (the hose is available in the set of car

accessories) and dip the hose end into a clean transparent vessel, partly filled with brake

fluid.

4. Press the brake pedal sharply 3-5 times with an interval of 2-3 s and, holding the pedal in

the pressed down position, give the bleeder valve ’/,-3/4 01 a turn out and keep pressing

down the brake pedal to force out the brake fluid together with air into the vessel. When

the brake pedal rests against the stop and escape of the brake fluid ceases, screw in the

bleeder valve. Repeat this operation until air bubbles cease to escape from the hose.

5. Keeping the brake pedal de- pressed, screw the bleeder valve all the way in and remove the

hose. Wipe the bleeder valve end dry and install the protective cap.

In the process of bleeding see that the fluid level in the reservoir is sufficient. The bleeding

over, restore the required maximum fluid level in the reservoir. The fluid discharged from the

brake system during the bleeding should not be reused.

Pressure Regulator

Every 30.000 Km check the pressure regulator

for serviceability, for which purpose:

• Place the car on a lift or an inspection pit;

• Clean the regulator and its boot from dirt;

• Carefully remove the boot, wipe off the

remaining grease, and clean the torsion

lever-to-regulator piston joint;

• Ask an assistant to sharply depress the

brake pedal. With the pressure regulator

serviceable, the protruding portion of the

Fig 63. Brake hydraulic system. 1- brake master cylinder, 2- vacuum

booster, 3- pedal pull-back spring, 4- stop light switch, 5- thrust screw

nut, 6- stop light switch buffer, 7- pushrod, 8- brake pedal.

piston will move relative to the body, thus

twisting the torsion lever.

• Repeat the operation two or three times and, having made sure that the pressure regulator

is serviceable, pack 5-6 g of fresh grease P~T-1 into the regulator, and put on the boot.

• If the piston does not move relative to the body, apply to a service station.

Page 26

Lada Niva Manual - Maintenance Page 25

Adjusting the Free Travel of Brake Pedal

Every 20.000 Km (and also after the first 2,000-3,000 Km if the car is new), check and

adjust, if necessary, the brake pedal free travel. With the brake system serviceable and the

shoe-to-drum clearances of the rear wheels normal, the brake pedal free travel, with the engine

shut down, should be 3-5 mm. Adjust free travel by shifting stop- light switch 4 (Fig. 63)

together with buffer 6 after unscrewing nut 5. Adjustment over, tighten nut 5.

Brake Vacuum Booster

Every 30.000 Km check the vacuum booster for serviceability in the following manner:

depress the brake pedal 5-6 times, with the engine shut down, and holding the brake pedal

pressed, start the engine. With the vacuum booster serviceable, the brake pedal should move

further down upon starting the engine. If the pedal does not move further down, check for

tightness the hose connections to the intake manifold and to the vacuum booster, as loose

connections cause in leakage of air and sharply reduce vacuum booster efficiency. If the

trouble persists apply to a service station.

Parking Brake

Every 20,000 Km (and also after the first 2,000-3,000

Km if the car is new) adjust the parking brake.

Correct adjustment of the parking brake ensures

Fig 64. Adjusting parking brake leaver

travel. 1- adjusting nut, 2- locknut

reliable operation of the whole brake system of the car.

Perform adjustment of the parking brake after adjustment of clearances in the rear brakes and

also when the car cannot be braked on a gradient of up to 30 % with the brake lever shifted

through 4-5 teeth of the quadrant.

Parking brake lever travel is adjusted by means of the tensioning device as follows:

• Shift the lever into the lower- most position and then pull it upwards through two teeth of

the quadrant;

• Loosen locknut 2 (Fig. 64), and turning adjusting nut 1, tighten the cable;

• Tighten locknut 2 and check that the car remains braked after shifting the lever through 4-5

teeth of the quadrant.

To prevent shoe-to-drum freezing after travelling over wet roads at sharp fluctuations of

ambient temperature, do not apply the parking brake when leaving the car in a parking lot or a

non-heated garage, unless the brakes are dried by applying them smoothly while driving to the

parking area.

ELECTRICAL EQUIPMENT

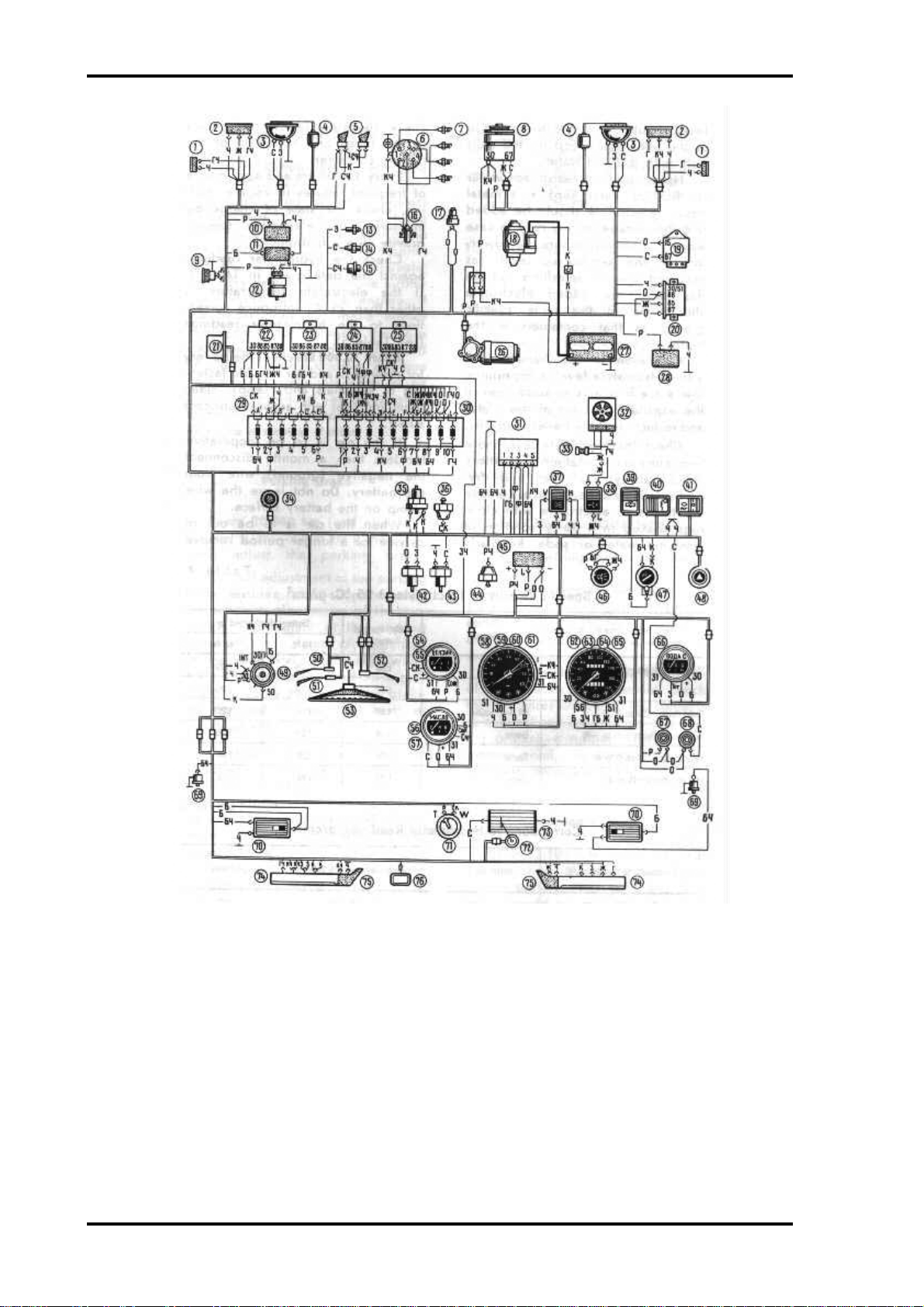

The car wiring diagram is shown in Fig. 65. Do not tamper with the car electric circuits.

Additional power consumers should be connected only by qualified electricians at a service

station. To ensure trouble-free operation of the electrical equipment check that the wires are

clean, the contacts in connections are reliable and that the protective rubber caps on the

ignition coil, ignition distributor and spark plugs are sound.

Page 27

Lada Niva Manual - Maintenance Page 26

Wiring diagram

Fig. 65. Wiring Diagram: 1- ride direction indication; 2- ride lights; 3- headlight; 4 head- light wiper motor; 5- horn; 6- ignition distributor;

7- spark plugs; 8- alternator, 9- Inspection lamp socket; 10- windshield wiper pump; (1- headlight washer pump; (I-k~Æ fluid level

transmitter; 13- coolant temperature transmitter; 14- low oil pressure warning lamp transmitter; 15- oil pressure gauge transmitter; (6-

ignition coil; 17- idling electromagnetic valve; 18- starter; 19- voltage regulator; 20- battery no-charge warning lamp relay 21- windshield

wiper relay; 22-headlighl wiper relay; 23-headlight upper beam relay; 24- headlight lower beam relay; 25- back window hooter relay; 261

windshield wiper P1- storage battery; 28- back window wiper pump; 19- additional furs block; 30-main fuse block; 31- emergency flasher

system and direction indicator (lather unit; 32-aatk) tan; 33- heater fan series resistor; 34- instrument lighting Switch; 35- stop-light switch:

1~- choke warning lamp switch; 37- external lighting switch; 38- heater fan switch; 39-blcL window wiper and washer switch; 40- back

window heater switch; 41- rear fog lamp (witch; 42- backing light switch; 43- transfer differential lock warning lamp switch; 44- parking

brake warning lamp switch; 45- parking brake warning lamp flasher unit; 46- headlight wiper twitch; 47- cigarette lighter with illumination

lamp; 41- emergency flasher system switch and warning lamp; 49- ignition switch; 50- headlight switch: 51- direction indicator switch; 52-

wind- shield wiper and washer switch; 53- horn button; 14- fuel level gauge; 55- low fuel warning lamp; 56- oil pressure gauge; 57- low

oil pressure lamp; 58- tachometer; 59- par- king brake warning lamp; 60- battery no-charge warning lamp; 61- choke warning lamp; 62-

speedometer; 63- marker light warning lamp; 64- direction indicator warning lamp; 65-headlight upper beam warning lamp; 6~-coolÆn~

temperature gauge; 67-lantlor differential lock warning lamp; 68- brake fluid low level warning lamp; 69- interior lamp door switches; 70-

interior lamps and switches; 71- fuel level and low fuel transmitter; 72-brit window wiper; 73- back window heater; 74- tail light; 75-

Wire Colour Code: P- pink; 3- green; Trl blue with black tracer; T- blue; 6-whih; 0- amber; m- yellow; C- grey; K~- brown; ~- black; K-

red; 6~- white with black tracer; mCI-yellow with black tracer; CLi-green with black tracer; 3Lt- green with black tracer; r6- blue with

white tracer; CK-grey with rod tracer; TK- blue with red tracer; 0,- violet; p’i- pink with black tracer; 61- white with blue tracer

number plate lamps: 76-fog lamp

Page 28

Lada Niva Manual - Maintenance Page 27

Storage Battery

Every 2,500 Km or every four months check the electrolyte

level in the battery cells (Fig. 66). The level should be between

the MIN and MAX marks on the semi-trans- parent battery

case; otherwise the level should reach the lower edge of the filler

holes. Top up the cells only with distilled water.

Never add non-distilled water or distilled water kept in a metal

vessel. Electrolyte should be added into the storage battery only

in case when it is known for sure that lowering of the electrolyte

level has occurred due to splashing out. In this case, the added

electrolyte should be of the same specific gravity as that

Fig 66. Holes for checking

electrolyte level in storage battery

cells

contained in the battery.

Operation of the battery with a low electrolyte level is impermissible since it results in

sulphation of the exposed portions of the plates and reduction of the battery capacity.

Check the electrolyte level more frequently in hot weather. The battery should always be

clean and dry, particularly its upper surface. Remove the traces of electrolyte with clean rags

soaked in a 10 % solution of ammonia water or soda. Regularly check cleanness of the vent

holes in the plugs and condition of the battery container.

Every 10,000 Km and also in case of frequent failures in engine starting, check the state of

charge by measuring the electrolyte specific gravity with a hydrometer.

Check the hydrometer readings against the data given in Table 4. (Not included yet) If the

electrolyte temperature is other than 25"C, introduce corrections to the hydrometer readings

(see Table 5).

Every 20,000 Km check the battery for cleanness and for reliable fastening of terminals and

clamps; clean them and coat with aerosol lubricant BTB-l.

If the car is to be inoperative for less than a month, disconnect the negative (ground) wire

from the battery. Do not leave the wire clamp on the battery surface. When the car is to be out

of service for a longer period remove the battery from the car, fully charge it and keep it,

whenever possible, in a dry cool room at a temperature not above O"C. The minimum storage

temperature should not be below minus 50 "C.

Never store the discharged battery since this will lead to sulphation of plates, and finally, to

a complete failure of the battery. Therefore, be sure to check the battery specific gravity every

month, charging it whenever necessary.

Alternator

Every 10.000 Km carefully dress the alternator slip rings with glass cloth, check the brushes

for wear and seating and replace them if necessary. The brushes should move easily in the

holders and should have no chippings. When the car is driven constantly on dusty and dirty

roads perform this operation more frequently.

Starter

Every 40.000 Km carefully dress the commutator, check the brushes for wear and seating

and, whenever necessary, replace them with new ones, having them bedded properly to the

commutator.

Page 29

Lada Niva Manual - Maintenance Page 28

At the same time be sure to clean and lubricate the helical splines of the starter shaft, the

bushings of both end shields and the drive pinion with engine oil, and the pinion shift ring of

the starter drive, with grease.

Voltage Regulator

Any servicing of the voltage regulator must be performed by qualified specialists only.

When installing the voltage regulator on the car or removing it from the car, see to it that the

regulator is not subject to blows which may bring it out of adjustment.

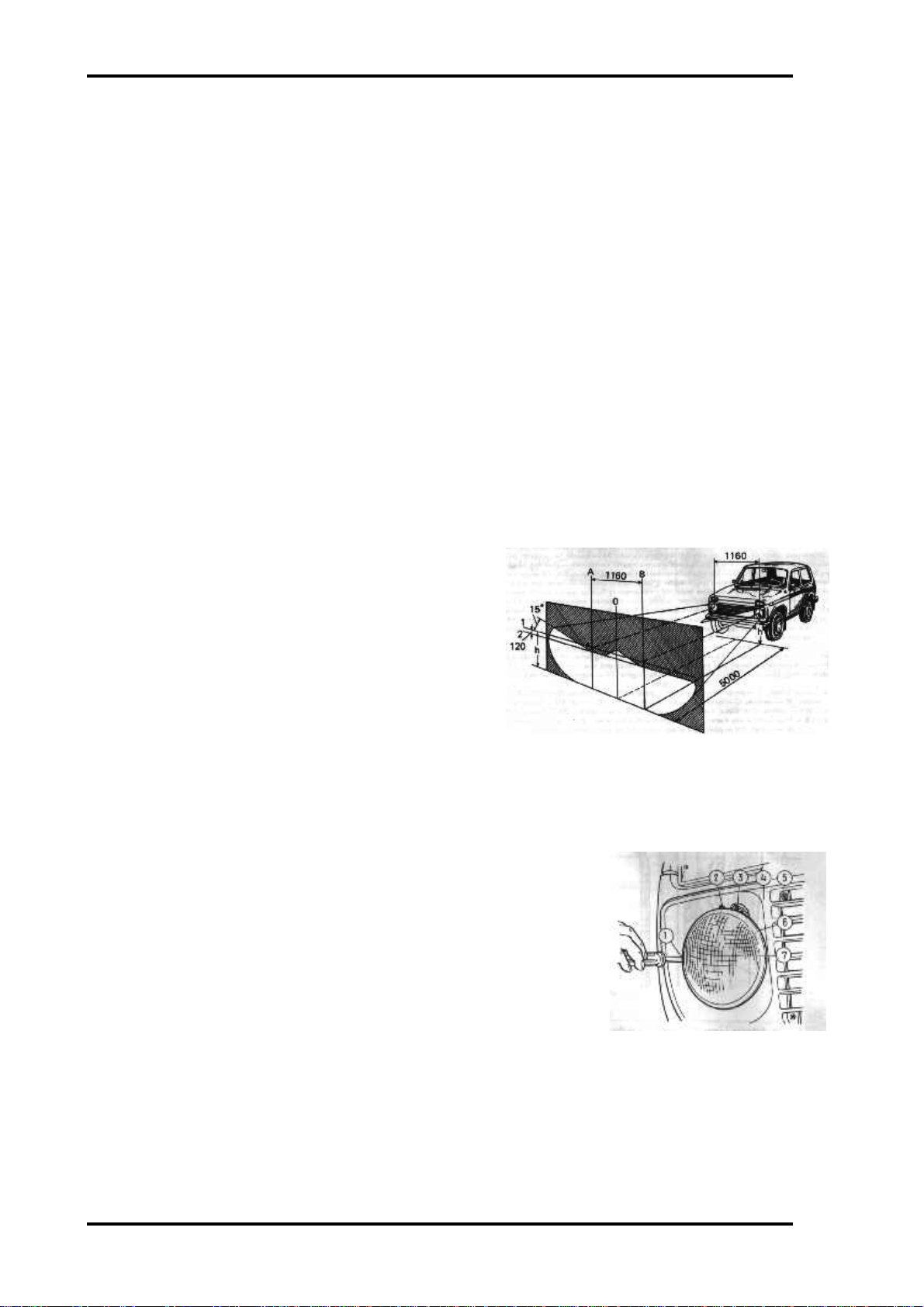

Aiming the Headlight Lower Beam

Every 20.000 Km (end also after the first 2,000-3,000 Km if the car is new) aim the

headlights. The car is equipped with head lights that have an asymmetric light distribution of

the lower beam, with a sharp boundary between the light and dark zones; such light

distribution makes it possible, with the headlight aimed properly, to reduce the dazzling effect

on the drivers of the oncoming vehicles.

To aim the headlight lower beam proceed as follows:

1. Place the car in running order with a load of 750

n (75 kg) on the driver’s seat and with normally

inflated tyres on a level ground (Fig. 67) at a

distance of 5 m from a vertical white screen

located in a shade. A white wall of a building

may serve as a screen.

2. Rock the car sideways to stabilise the car

suspensions.

3. Draw on the screen axial line O located in the car

Fig 67. Aiming headlight lower beam

symmetry plane. Symmetrically to the axial line, draw lines A and B (a distance of 1160

mm between them should correspond to the distance between the headlight centres). Then

draw horizontal line 1 at height h (which is a distance from the headlight centre to the

ground), and line 2 which should be 120 mm below line 1.

1. Switch on the lower beam and rotating screws 1 and 2 (Fig. 68),

set the light units so that the horizontal border-line between the

light and dark zones passes along line 2 (Fig. 67), and the

inclined limiting lines come from the points of intersection of

lines A and B with line 2.

Replacing the Bulbs

To replace a bulb in the headlight, turn out screws 5 (Fig. 68)

which secure decorative grille 4 of the radiator and remove the grille;

loosen screws 3 securing the light unit rim, turn the rim counter-

Fig 68. Headlight. 1- horizontal

adjustment screw, 2- vertical adjustment

screw, 3- headlight rim screw, 4- radiator

decorative grille, 5- radiator grille screw,

6- headlight rim, 7- light unit

clockwise and remove it. Take out light unit 7 and throw off the

bulb spring clamps.

To replace the bulb in the side light or in the rear fog lamp turn out the lens fastening screws,

remove the lens, gently press on the bulb, turn it counter-clockwise, and take it out.

Page 30

Lada Niva Manual - Maintenance Page 29

A burnt-out bulb in the side direction indicator should be replaced after removing the socket

with the bulb on the engine compartment side.

Tail lights

To replace the bulb in the tail light turn off the

upper screws which secure the luggage compartment

lining, screw off nut 2 (Fig. 69) and remove lens 3.

To replace the bulb in number plate lamp 9,

disconnect connector 1 and remove the holder with

the bulb.

To replace the bulb in the body

interior lamp. Carefully pull it out

The lamp is kept in the recess of the

centre pillar by two springs 4 (Fig.

70).

Fig 70. Interior lamp. 1lens, 2- bulb, 3- switch, 4

fastening spring.

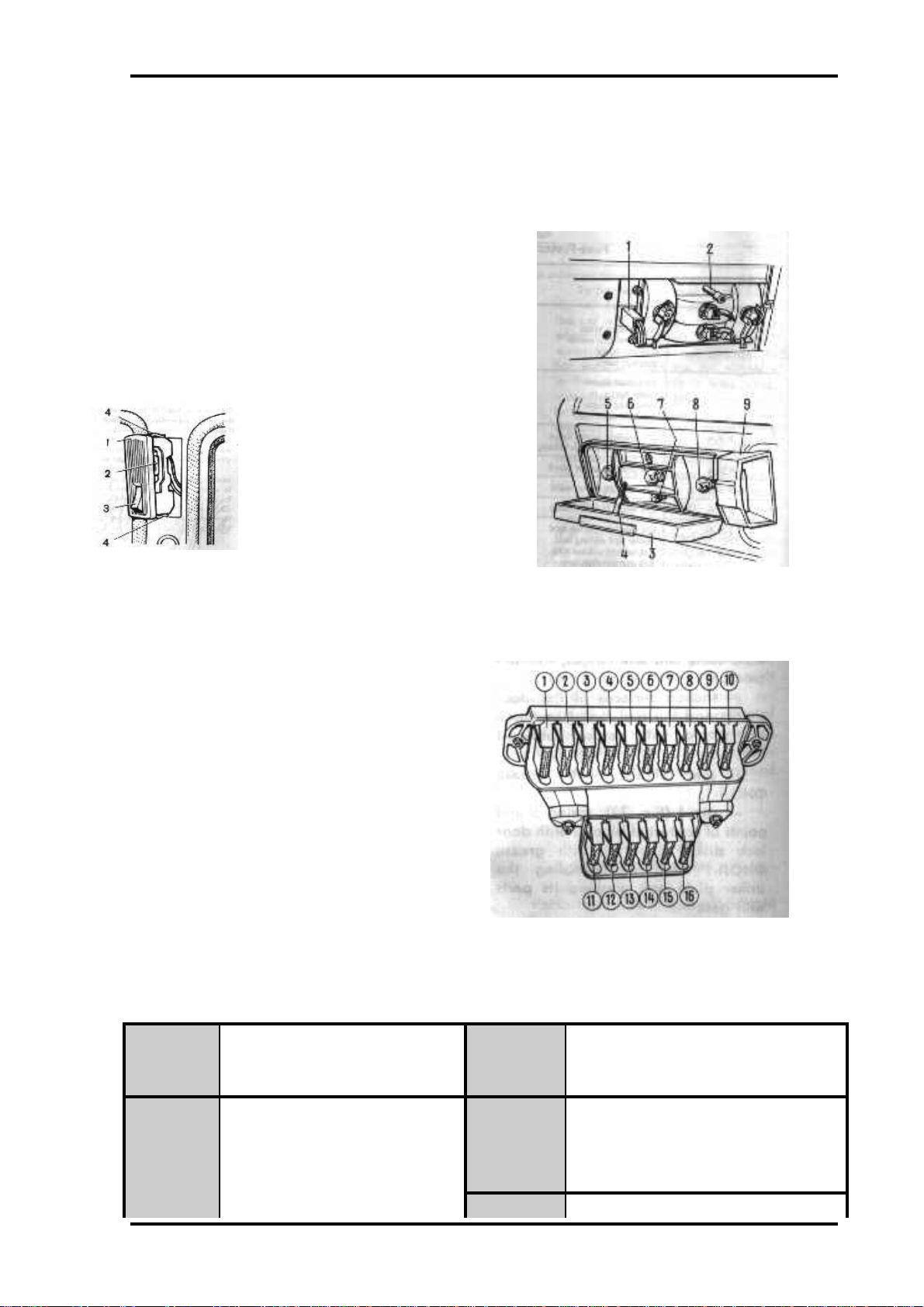

Fuses

Fuses are installed in two blocks. The first

block contains a 16 A fuse (Fig. 71) and nine

8 A fuses. The second block contains four 8

A fuses and two 16 A fuses.

Fuses are held in the blocks by spring

contacts. The circuits protected by fuses are

listed in Table 6.

The electric circuits of ignition, engine

starting, alternator (except for the field

winding), headlight lower beam relay and

headlight upper beam relay are not protected

by fuses.

Prior to replacement of a blown- out fuse, find out and eliminate the cause of trouble.

Fuse-Protected Circuits

Fig 69. Tail light and number plate lamps. 1connector, 2- nut, 3- lens, 4-pin, 5- direction

indicator bulb, 6- reverse light bulb, 6- marker

light bulb, 8- stop light bulb, 9- number plate

lamp.

Fuse No

amperage

in Fig 71

Protected circuit Fuse No

amperage

in Fig 71

Protected circuit

1 (16 A) Horns 2 (8 A) Windshield wiper

Body interior lamps Heater fan

Inspection lamp socket Windshield washer

Cigarette lighter Headlight wiper relay

step-light bulbs 3 (8 A) LH headlight (upper beam)

Page 31

Lada Niva Manual - Maintenance Page 30

Headlight upper beam warning

lamp

Page 32

Lada Niva Manual - Maintenance Page 31

4 (8 A) RH headlight (upper beam) 10 (8 A) Voltage regulator

5 (8 A) LH headlight (lower beam) Alternator field winding

8 (8 A) RH headlight (lower beam) 11 (8 A) Rear fog lamp

7 (8 A) LH side light (marker light) 12 (8 A) Electric motors of headlight wipers

and washer

Marker light warning lamp 13(8A) Back window wiper and washer

RH tail-light (marker light) 14 (I6 A) Back window heater (power

circuit)

RH member plate lamp 15 (16 A) Reserve fuse

8 (8 A) Instrument lighting lamps 16 (8 A) Emergency flasher system switch

RH side light (marker light) end direction indicators operating

LH tail-light (marker light) in emergency mode

Cigarette lighter illumination lamp

LH number plate lamp

9 (8 A) Oil pressure gauge

Low oil pressure warning lamp

Fuel level gauge and low fuel warning lamp

Coolant temperature gauge

Direction indicators with warning lamp

Backing light lamps

Parking brake warning lamp

Brake Fluid low level warning lamp

Differential look warning lamp

Battery no-charge warning lamp

Choke warning lamp

Tachometer

Carburettor electromagnetic valve

Flasher unit of parking brake warning lamp

Direction indicator flasher unit

Back window heater (control circuit)

BODY

Care of Body

To preserve the attractive appearance of the car give constant attention to the car body

surfaces. To prevent scratches on the body do not remove dirt and dust from the car with dry

rags. Wash the car when mud is still wet, using a weak water spray end a soft sponge. In hot

weather wash the car outdoors in the shade. If this is impossible, immediately wipe the

washed surfaces dry, since drops of water that dry under the sun rays leave stains on the

body painted surface. At sub- zero ambient temperatures, having washed the car in a warm

room, wipe the body dry before a trip because frozen drops of water may cause cracks on the

body paint coating. It is not recommended to use soda and alkaline solutions, as they may

tarnish the paint coating.

When using a hose for washing, see that water does not get on the electric units in the engine

compartment.

Page 33

Lada Niva Manual - Maintenance Page 32

Minor chipping of paint on the car body should be timely sanded and coated with the paint

contained in the tin furnished with the car.

In case corrosion of the car body parts is detected (corrosion traces, local paint blisters, etc.),

take necessary measures to eliminate corrosion and prevent its further spreading.

To facilitate examination of boxed spaces of the front fenders, the shields with weatherstrips

are made detachable.

To retain lustre of the body paint- work, particularly of the cars kept outdoors, regularly

polish the paint coating with the use of polishing pastes or wax compounds.

To ensure prolonged shining of the body surfaces, do not leave the car under the sun rays for

a long period of time; prevent acids, soda solutions, brake fluid and gasoline from getting on

the painted surfaces.

To prevent stains on the paint coating under the fuel tank access flap caused by spilled

gasoline, wipe the surface with clean dry rags before and after the fuel servicing.

In the course of operation the car underbody coating is attacked by gravel, sand and salt. As a

result, the anticorrosion compound and primer come off, and the exposed metal gets corroded.

Therefore regularly check the condition of the car underbody coating and timely recondition

the damaged areas.

Clean the chrome-plated parts with soft rags and petrolatum. Wipe the plastic parts with

wet rags. It is not recommended to use gasoline or solvents; otherwise, the plastic parts will be

tarnished.

Use soft linen rags or chamois leather to clean the glasses. To clean heavily soiled glasses first

wash them with water solution of HMMCC-Æ1 liquid or Glass Autocleanser-2 (30 cm3 per

litre of water).

Never use gasoline or solvents to clean the body interior upholstery made of artificial leather.

Use neutral soap with water for the purpose, then wipe the surfaces dry with soft rags or

chamois leather. Simultaneously thoroughly wipe with wet rags the rubber weatherstrips and

the door parts in contact with them.

Periodically, depending on the specific conditions of the operation (very cold climate, dusty

roads, atmospheric effects during long parking periods), lubricate the following parts and

units: - door lock keyholes;

(a) in hot weather with graphite powder;

(b) in cold weather, particularly after washing, with aerosol lubricant BTB-1: as a

preliminary, dry the lock keyholes with compressed air;

Door hinges, hood lock re- lease cable and seat hinges, with engine

oil; friction surfaces of the door checks and the fuel tank flap hinge

and spring, with aerosol lubricant BTB-1; - seat slides, with grease

cDMOn-l ; pin 4 (Fig. 72), spring 5 and points of contact of block

2 with door lock striker plate 1, with grease cDMOn-1 after

disassembling the striker plate and washing its parts with gasoline.

The car body doors should open and close easily. If the door

closes with difficulty or loosely, adjust the position of the door

Fig 72. Door lock striker plate. 1striker plate, 2- block, 3, bolt, 4- pin,

5- spring, 6 bushing.

lock striker plate. Prior to beginning the adjustment, outline the position of striker plate 1 on

the car body pillar with a pencil. If the door is hard to close, loosen bolts 3, move the striker

plate outward and tighten the bolts. If the door closes loosely, move the striker plate inward.

If the door sags in closing, raise the striker plate, and on the contrary, lower it, if the door

Page 34

Lada Niva Manual - Maintenance Page 33

rises. If, for some reason or other, the door lock has been disassembled, wash it to remove old

grease and, prior to assembly, lubricate it with grease. It is not re- commended to use other

grades of grease because at low temperatures the lock may fail to operate, or the door may get