Page 1

1/01

OPERATION MANUAL

MANUAL NO. 057-561-00

REV. A

LAB-LINE®

AIR-JACKETED COMPACT

AUTOMATIC & FLO-THRU®

CO2 INCUBATORS

MODEL NO. AUTOMATIC:

314, 314-1, 314-1CE

(Stainless Steel Interiors)

316, 316-1

(Copper Interiors)

FLO-THRU:

315, 315-1

(Stainless Steel Interiors)

317, 317-1

Copper Interiors)

1999 North 15th Ave., Melrose Park, IL 60160-1491 USA

PHONE: (319) 556-2241 or (800) 522-5463; FAX: (319) 589-0516

DESIGNERS AND MANUFACTURERS

A SUBSIDIARY of Barnstead|Thermolyne

Page 2

TABLE OF CONTENTS

2

Page 3

SECTION TITLE

1 Introduction

2 Description

3 Specifications

4 Features

5 Installation

6 Operation

7 Maintenance

8 Replacement Parts

Warranty

3

Page 4

BE ADVISED:

IT IS MOST IMPORTANT THAT THE USER FOLLOW INSTALLATION

INSTRUCTIONS EXACTLY AS WRITTEN—FAILURE TO DO SO IS LIKELY TO

LEAD TO IMPROPER OPERATION, ERRONEOUS CALIBRATIONS AND

POSSIBLE DAMAGE TO THE EQUIPMENT. UNDER NO CIRCUMSTANCES

SHOULD THE USER ATTEMPT OPERATION WITHOUT THIS INFORMATION.

THE FOLLOWING EQUIPMENT IS TO BE SUPPLIED BY THE USER:

• Dry CO

• A dual-stage regulator for the CO2 tank.

• ¼" ID Flexible tubing (appropriate length from tank to incubators), and

connected per local codes.

• Fyrite or similar chemical-based CO2 analyzer.

BE ADVISED: INSTALLATION AND PRE-OPERATION PROCEDURE WILL

TAKE AT LEAST 24 HOURS TO COMPLETE. DO NOT ATTEMPT TO RUSH

THE PROCESS WITH SHORT CUTS TO THE PROCEDURES DESCRIBED IN

THIS MANUAL.

2 gas (research grade or better).

4

Page 5

CERTIFICATION OF DECONTAMINATION:

We cannot accept for service or credit a product that has been exposed

to or contaminated with chemically or biologically toxic or infectious substances

or subjected to radioactivity without first being certified as free from said

contamination.

Please have your Medical and/or Safety Officer sign this form certifying

that proper decontamination procedures have been followed to render the

product safe and free from hazards.

Any product forwarded to us, not accompanied by this form and a proper

Return Goods Authorization Number, will be returned to the sender. To obtain a

Return Goods Authorization Number, contact the Customer Relations

Department at (800) 522-5463.

We hereby certify that the LAB-LINE INSTRUMENTS, INC. product:

Model No. and Serial No. ,

which is being forwarded has been properly decontaminated and is free from all toxic

hazards, infectious agents, radioactivity and/or other hazards.

Company/Institution Name:

Street Address:

City: State Zip

Name (please print): Title

Signature:

Phone:

DECONTAMINATION PROCEDURE (Be Specific):

Nature of Hazard That Required Decontamination:

5

Page 6

6

Page 7

SECTION 1

INTRODUCTION

THANK YOU

for selecting Lab-Line Instruments for your equipment needs. For maximum value and

ease of start-up,

PLEASE PROCEED AS FOLLOWS:

• Inspect the carton and contents for shipping damage. Notify the carrier immediately

if damage is found.

• Use the Accessory Checklist when unpacking to verify that the complete unit has

been received. Do not discard packing materials until all is accounted for.

• Read this Operation Manual thoroughly before deciding upon an appropriate location

for the unit: you will want to consider the availability of power and other unit

requirements, as well as user convenience.

• Insist that every operator of this unit becomes familiar with the Operation Section of

this manual.

• Be sure to fill out the Warranty Registration Card and mail it in to Lab-Line

Instruments within seven (7) days after receiving the unit.

IF

after reading this manual you should have any difficulties with the installation or

operation instructions, please call:

Lab-Line Customer Relations Department

(319) 556-2241 or (800) 522-5463

ALL RIGHT RESERVED

The information contained in this manual is the exclusive property of Lab-Line Instruments, Inc., and has been provided solely to enable the users of the equipment described herein to operate and maintain such equipment. Any

other use of this information, or the reproduction or transmission of all or any portion of this manual without prior

written consent of the manufacturer is expressly prohibited. © 2001, Lab-Line Instruments, Inc.

SECTION 2

7

Page 8

DESCRIPTION

314/316 SERIES AUTOMATIC CO2 INCUBATORS:

BASIC COMPONENTS, AN INITIAL OVERVIEW:

1 13

14

2

3

4

5

6

7

8

15 9 10 11 12

1. Control panel

2. CO2 sensor

3. CO

4. Temperature sensor

5. Chamber gasket

6. Chamber shelves

7. Sample port inlet

8. Leveling feet

inlet port

2

9. Inner glass door, handle shaft

10. Inner glass door

11. Inner glass door, handle

12. Outer door gasket

13. CO

14. Fan Cover

15. Humidity Trough

sample port

2

DESCRIPTION: (Con’t)

8

Page 9

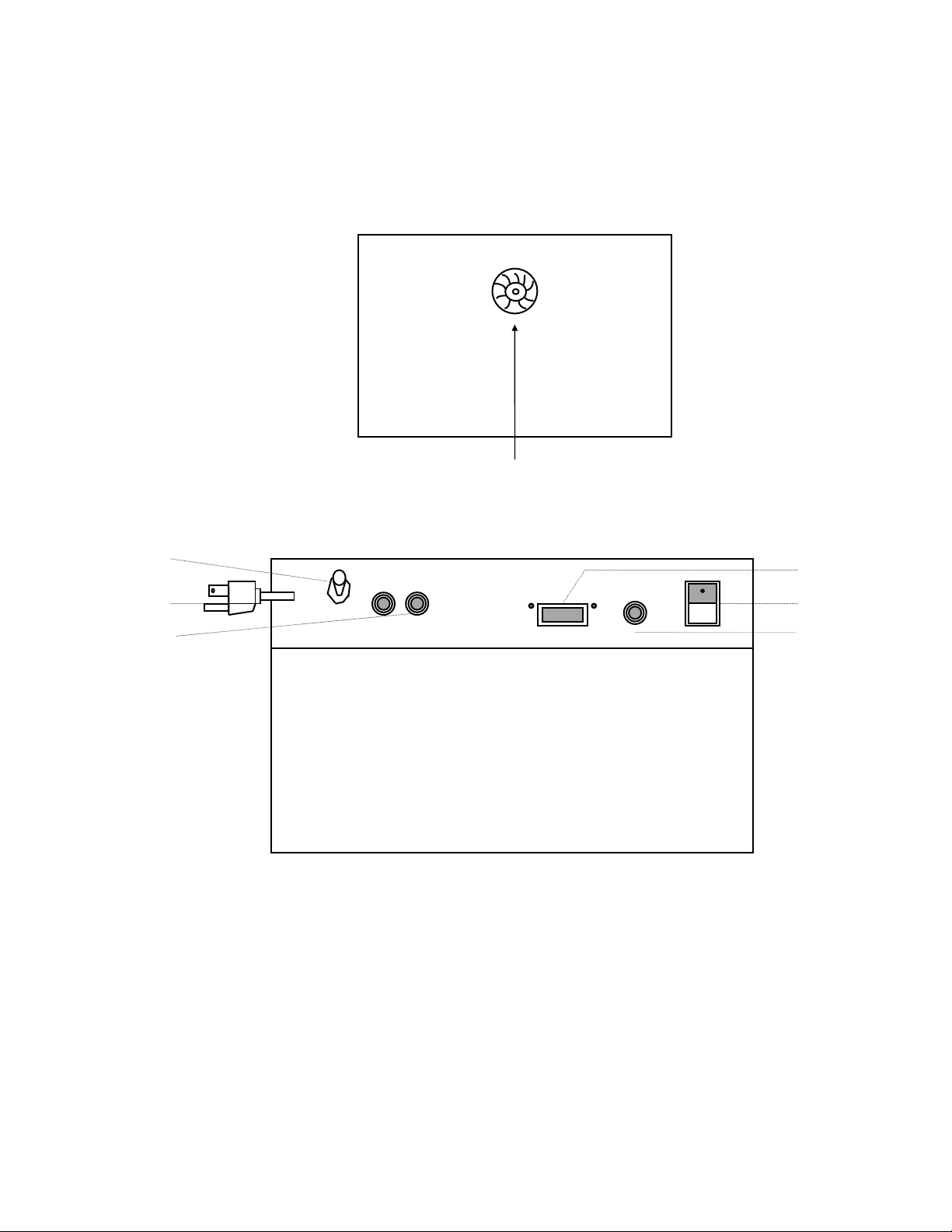

314/316 SERIES AUTOMATIC CO2 INCUBATORS: (Con’t)

BASIC COMPONENTS, AN INITIAL OVERVIEW: (CON’T)

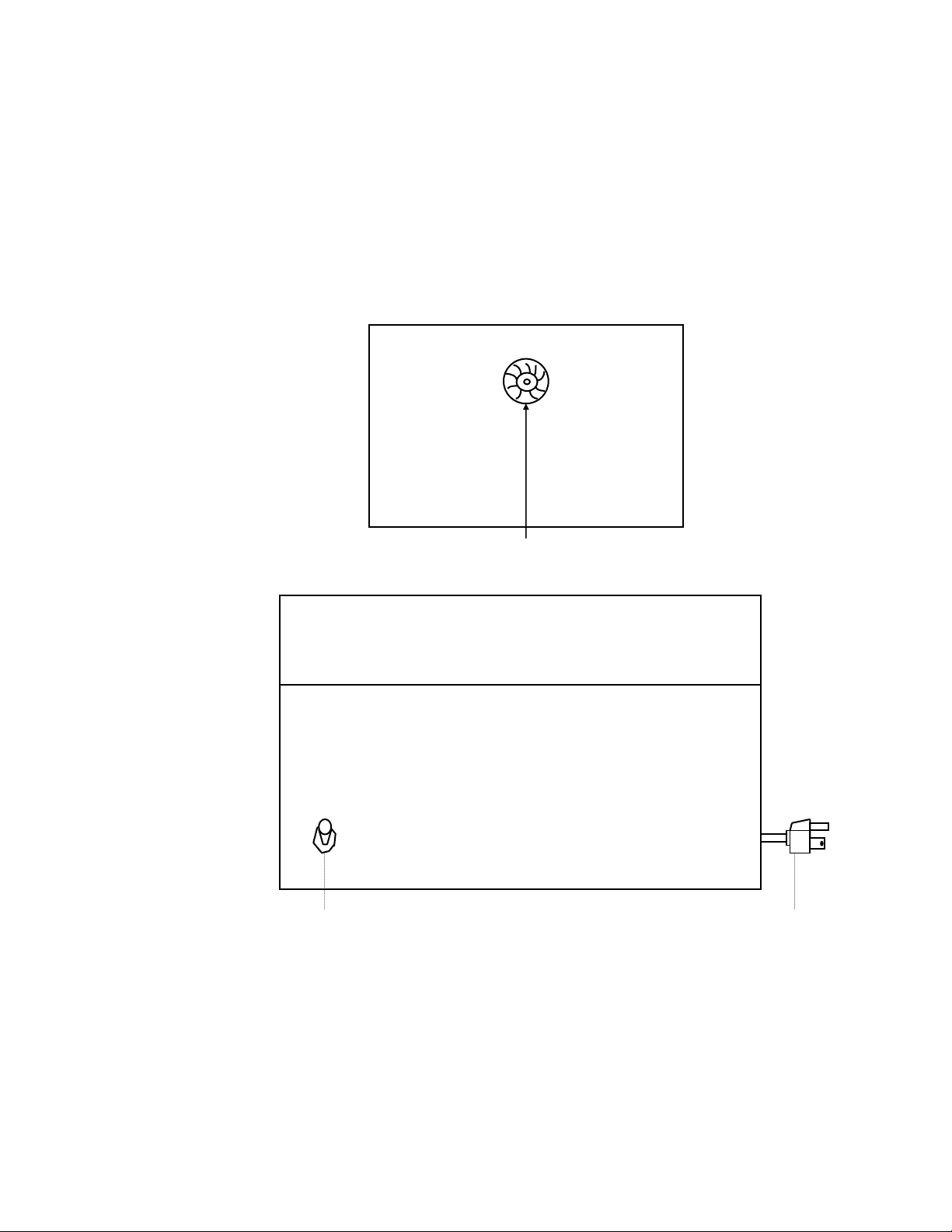

CHAMBER CEILING, INTERIOR

CIRCULATING FAN

REAR PANEL VIEW, EXTERIOR:

1 4

2 5

3 6

1. GAS INLET PORT

2. CORDSET

3. CIRCUIT BREAKERS

4. RS232 DATA PINS CONNECTOR

5. POWER SWITCH

6. OPTIONAL ALARM RELAY OUTPUT

DESCRIPTION: (Con’t)

314/316 SERIES AUTOMATIC CO2 INCUBATORS:

9

Page 10

CO2 levels are automatically set at 5%. These units control CO2

concentrations, as well as temperature, to create a growth environment ideal for

tissue cultures, plants, cells, viruses and related organisms.

Incoming 100%, CO2, from an external source provided by the user,

passes into the gas inlet port located on the rear panel of the unit. Heated air is

moved uniformly throughout the chamber by a circulating fan located in the top of

the chamber. A CO2 access port on the control panel permits sampling of the

chamber atmosphere.

These incubators provide precise and reliable control of carbon dioxide

through the use of a TC, thermal conductivity, sensor coupled with an easy-touse command control console. All required operating commands are

immediately accessible in a functional format on the front of the unit and permit

rapid start-up, close monitoring and efficient control of incubation protocols.

Temperature is measured by a platinum RTD, resistance temperature

detector, producing excellent control within the range, ±0.1ºC. This is combined

with the exclusive SmartGas® algorithm method for controlling CO2 within the

range ±0.1%. The result is a chamber that produces excellent environmental

conditions for the most sensitive of incubations.

Audible and visual alarms provide a signal to the user of any deviation in

the chamber temperature of ±1.0ºC, or carbon dioxide of ±1.0% CO2. In

addition, other signals alert the user to power failures and door openings.

An independent, adjustable hydraulic high limit thermostat will limit the

temperature in the event of a problem with the main temperature controller.

To conserve gas, the unit’s CO2 solenoid valve, as well as the circulating

fan motor, shuts off automatically any time the door is opened.

A double-door system has a tempered glass inner door that provides

unobstructed viewing of the entire chamber.

314 series chambers are constructed of seamless stainless steel for

cleaning ease and maintenance; 2 stainless steel shelves are standard—a total

capacity is 5 shelves. 316 series incubators feature a fungus and bacteria

resistant copper chamber.

Both models have a stainless steel outer cabinet with a powder coated

finish for easy cleaning.

DOUBLE-DOOR CONSTRUCTION WITH INNER DOOR DEFOGGER: 314/316

MODELS:

A tempered glass inner door allows observation of a chamber without

disturbing the chamber environment. Inside the steel outer door are heaters

that can be turned on to defog the glass door when necessary. Each door

seals to a one-piece gasket for a leak-tight environment.

10

Page 11

DESCRIPTION: (Con’t)

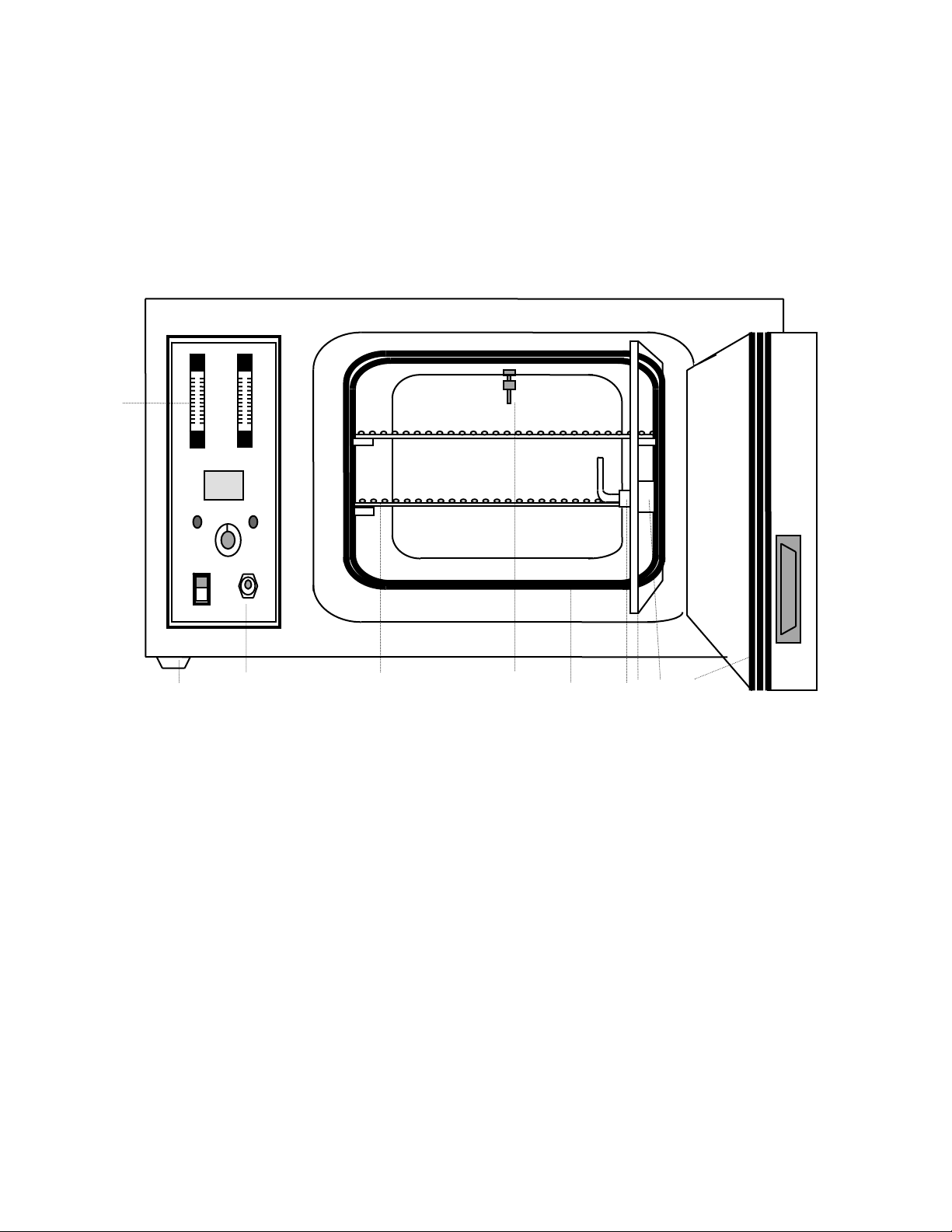

315/317 SERIES FLO-THRU CO2 INCUBATORS:

BASIC COMPONENTS, AN INITIAL OVERVIEW:

1

2 3 4 5 6 7 8 9 10

1. AIR & CO2

FLOWMETERS

2. UNIT FEET

3. CO2 ACCESS PORT

4. CHAMBER SHELVES

5. TEMPERATURE SENSOR

6. CHAMBER GASKET

7. INNER GLASS DOOR, HANDLE SHAFT

8. INNER GLASS DOOR

9. INNER GLASS DOOR, HANDLE

10. OUTER STEEL DOOR/GASKET

11

Page 12

DESCRIPTION: (Con’t)

315/317 SERIES FLO-THRU CO2 INCUBATORS: (Con’t)

BASIC COMPONENTS, AN INITIAL OVERVIEW: (CON’T)

CHAMBER CEILING, INTERIOR

CIRCULATING FAN

REAR PANEL VIEW, EXTERIOR:

CO2

1 2

1. CO2 INLET PORT

2. CORDSET

12

Page 13

DESCRIPTION: (Con’t)

315/317 SERIES FLO-THRU CO2 INCUBATORS:

CO2 levels are manually adjusted utilizing flowmeters. Flo-Thru control of

CO2 concentrations and temperature create a growth environment ideal for tissue

cultures, plants, cells, viruses and related organisms.

An incoming gas mixture passes through the plenum and is gently

circulated throughout the chamber. Separate flowmeters adjust air and CO2

rates and an access port on the control panel permits sampling of the chamber

atmosphere.

2 hydraulic thermostats: one is an adjustable setpoint control unit, the

other is a non-adjustable, over-temperature-limiting unit. It is factory pre-set to

regulate temperature in order to protect the chamber.

Heaters on the outside of the chamber inner walls are positioned for

uniform heat distribution, while high-density fiberglass insulation minimizes heat

loss.

A double-door system has a tempered glass inner door that provides

unobstructed viewing of the entire chamber.

Model 315 and 315-1 interiors are constructed of seamless stainless steel

for cleaning ease and maintenance. 2 stainless steel shelves are standard—a

total capacity is 5 shelves.

Models 317 and 317-1 have a seamless copper interior that acts to reduce

the growth of fungus and bacteria thereby minimizing contamination of

cultures. 2 copper shelves are standard with room for 3 additional shelves.

All models have a steel outer cabinet with a powder coated finish for easy

cleaning.

13

Page 14

SECTION 3

SPECIFICATIONS

314/316 SERIES AUTOMATIC CO

ELECTRICAL REQUIREMENTS:

314, 316: 120 V, 60 Hz, 200 Watts, 1.7 Amps,

314-1, 316-1: 230/240 V, 50 Hz, 200 Watts, 0.8 Amps,

TEMPERATURE:

RANGE: Ambient +5ºC to 60ºC

CONTROL: ±0.1ºC at 37ºC.

UNIFORMITY IN CHAMBER: Within the chamber, ±0.25ºC

ALGORITHM: TEMPERATURE: PID

CO2: SmartGas®

CARBON DIOXIDE TENSION: Range: 0% to 20%

Control: ±0.1%

VOLUME: 1.2 cubic feet (34 liters)

EXTERIOR: 22½" W x 18" D x 19" H

(57 x 46 x 48 cm)

INTERIOR: 14" W x 12" D x 12" H

(36 x 31 x 31 cm)

SHELVES: 2 standard; space for 3 additional shelves.

DIMENSIONS: 13-3/8” (tapering back to) 12-1/8" W x 11½" D

(34~30.7 x 29.2 cm)

SHIPPING WEIGHT: 70 lbs. (32 kg)

2 INCUBATORS:

SPECIFICATIONS: (Con’t)

14

Page 15

315/317 SERIES FLO-THRU CO2 INCUBATORS:

ELECTRICAL REQUIREMENTS:

315, 317: 120 V, 60 Hz, 200 Watts, 1.7 Amps,

315-1, 317-1: 230/240 V, 50 Hz, 200 Watts, 0.8 Amps,

TEMPERATURE:

RANGE: Slightly above ambient to 60ºC.

CONTROL: ±0.5ºC.

UNIFORMITY: ±1.0ºC

CARBON DIOXIDE RANGE: From 0 to 20% of the mixture.

VOLUME: 1.2 cubic feet (34 liters)

DIMENSIONS:

EXTERIOR: 23½" W x 17" D x 15" H

(60 x 43 x 38 cm)

INTERIOR: 14" W x 12" D x 12" H

(36 x 31 x 31 cm)

SHELVES: 2 standard; space for 3 additional shelves.

DIMENSIONS: 11"W x 13½"D x 7"H (28 x 34 x 18 cm)

SHIPPING WEIGHT: 70 lbs. (32 kg)

UNIT’S ENVIRONMENTAL OPERATING CONDITIONS:

POLLUTION DEGREE: 2

INSTALLATION CATEGORY: II

ALTITUDE: 2000 Meters MSL (Mean Sea Level)

HUMIDITY: 80% maximum, non-condensing

ELECTRICAL SUPPLY: 120VAC or 240VAC

VOLTAGE TOLERANCE: ±10% of normal rated line

TEMPERATURE: 15ºC to 40ºC

PRODUCT USAGE: This product is intended for use indoors only

SECTION 4

15

Page 16

FEATURES

314/316 series control panels have a series of command keys that enable

users to enter set point values for temperature, carbon dioxide, door heat and to

calibrate a unit as required. LED readout provides users with current status

information regarding the foregoing parameters.

CONTROL PANEL, 314/316 SERIES AUTOMATIC CO2 INCUBATORS:

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

1. LED READOUT: The LED displays current CO2 tension and temperature

in the Incubator and, in the set mode, displays the set point values

for these two parameters as well as door heat setting. It also enables the

user to enter values necessary to calibrate temperature and CO2.

Indicating lights and legends serve to identify which parameter is being

displayed.

2. SET COMMAND KEY: The SET key is the beginning point for and

initiates subsequent actions of the other keys on the control panel.

3. CAL COMMAND KEY: The CAL key permits calibration of temperature

and CO2 when in this command mode. The Up and Down arrow keys are

used to change the readout to correspond with the readings obtained from

known standards of temperature or CO2 measurement. Both temperature

and CO2 calibration use the zero-point shift method.

1 2 3 4 5 6 7 8 9 10 11 12

FEATURES: (Con’t)

CONTROL PANEL: (Con’t)

16

Page 17

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

1 2 3 4 5 6 7 8 9 10 11 12

4. CO2 COMMAND KEY: Pressing the SET key and then the CO2 key

allows the user with the Up and Down keys to enter the desired carbon

dioxide level in the Incubator.

• High and low limit alarm set points are factory set at ±1% above and

below the user-established set point. In the event CO2 exceeds the

indicated limits, an audible alarm will sound and indicating light above

the key will flash.

• Pressing any key will silence the alarm for a period of one hour. The

user should immediately investigate the reason for the alarm and

take steps to correct the problem. Note that the indicating light

continues to flash. If a problem is not solved the alarm resumes.

• By pressing the CAL (#3) and CO2 (#4) keys sequentially users can

calibrate CO2. The Up and Down arrow keys will change the readout

to correspond with the readings obtained from known standards of

CO2 measurement.

17

Page 18

FEATURES: (Con’t)

CONTROL PANEL: (Con’t)

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

5. TEMP COMMAND KEY: Pressing the SET key and then the TEMP

command key allows the user with the Up and Down arrow keys to

establish the desired set point temperature in the Incubator.

NOTE: DECREASES IN TEMPERATURE AND CO2 DUE TO NORMAL DOOR OPENINGS ARE

TOLERATED WITHOUT INITIATING THE ALARMS.

1 2 3 4 5 6 7 8 9 10 11 12

• High and low limit alarm set points are factory-set at ±1ºC. If the

temperature deviates from these limits, an audible alarm (continuous

beep) will sound.

• While pressing any key will silence the alarm for a one-hour period,

the user should immediately investigate the reason for the alarm and

take steps to correct the problem. Note that indicating light continues

to flash. If problem is not corrected, the alarm will resume after one

hour has passed.

• By pressing the CAL (#3) and TEMP (#5) keys sequentially users can

calibrate temperature. The Up and Down arrow keys will change the

readout to correspond with the readings obtained from known

standards of temperature measurement.

18

Page 19

FEATURES: (Con’t)

CONTROL PANEL: (Con’t)

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

6. DOOR HEAT COMMAND KEY:

7. SCAN/HOLD COMMAND KEY: Permits holding the value of a single

parameter for continued viewing or scans alternately between the values

of the two parameters on a 2-second interval.

8. DOWN ARROW KEY: This key decreases numerical value of the

parameter which has been accessed.

9. UP ARROW KEY: This key increases the numerical value of the

accessed parameter.

NOTE: A 5 SECOND DELAY AFTER ANY FINAL ENTRY RESULTS IN AUTOMATIC ENTRY

OF THAT CHANGE.

1 2 3 4 5 6 7 8 9 10 11 12

• When the SET key is pressed and then the DOOR-HEAT key, enter

the level of heat with the Up and Down keys as a percentage value

being applied to the inner glass door.

• A flashing DOOR-HEAT indicator light above the key indicates that

heat is being applied to the inner glass door.

• A good starting point for the door heat control is 35%; if fogging still

occurs, increase in 10% increments until fogging disappears.

19

Page 20

FEATURES: (Con’t)

CONTROL PANEL: (Con’t)

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

10. HIGH LIMIT THERMOSTAT: This is a back-up high limit temperature

thermostat which functions should the microprocessor fail. The high limit

thermostat will then control the temperature at slightly above the set point.

11. HIGH LIMIT STATUS LAMP: Indicates when the high limit is active.

12. SAMPLE PORT: This access port is available for sampling the

atmosphere in the chamber when executing calibration procedure such as

might be done using a Fyrite or similar chemical-based CO2 analysis

procedure.

1 2 3 4 5 6 7 8 9 10 11 12

FEATURES: (Con’t)

20

Page 21

CONTROL PANEL: (Con’t)

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

1 2 3 4 (5) (6)

PROPER SEQUENCING IMPORTANT IN OPERATING COMMAND KEYS:

To enter commands correctly, it is important to press the keys in

SEQUENCE. Do not hold down one key and press another key—the action will

not be accepted by the system. The following is the proper sequence in which to

press the keys for the indicated actions:

SET(#1), TEMP(#4): View existing value, retain or change set point using Up

and Down keys.

SET(#1), CO2 (#3): View existing value, retain or change set point using Up

and Down keys.

SET(#1), View existing value, retain or change set point using Up

DOOR HEAT(#5): and Down keys.

CAL(#2), TEMP(#4): Calibrate temperature using Up and Down keys.

CAL(#2), CO2 (#3): Calibrate carbon dioxide using Up and Down keys.

CO2 (#3), CAL(#2), Install password using Up and Down keys.

SET(#1):

TEMP(#4), CAL(#2): Disable password using Up and Down keys

SET(#1):

SCAN/HOLD(#6): Each individual contact of key advances to one of 3 options:

A) continuous viewing of temperature; B) continuous

viewing of carbon dioxide; C) an alternating viewing of the

two.

FEATURES: (Con’t)

21

Page 22

ALARMS, 314/316 SERIES AUTOMATIC CO2 INCUBATORS:

POWER OUTAGE: In the event of a power outage, the LED display will flash to

alert the user to take corrective action. If the power outage is of a temporary

nature, pressing any key will restore unit to operating status. Everything operates

normally after a power outage.

DOOR AJAR WARNING: In case the door is inadvertently left open beyond a 5

minute period, an audible beep is sounded and is synchronized with the flashing

of the DOOR-HEAT indicator light to warn the user to correct the condition.

AUDIBLE AND VISUAL ALARMS: The following table summarizes the audible

and visual alarms that are initiated upon the occurrence of various events.

AUDIBLE FLASHING FLASHING

BEEP LIGHT LED

ABOVE KEY DISPLAY

Temp (exceeds limits): YES YES NO

CO2 (exceeds limits): YES YES NO

Door Ajar: YES YES NO

Power Out: NO NO YES

Press any key to silence alarm that will remain silent for a period of one

hour. However, the flashing light will continue. If the condition initiating the alarm

remains uncorrected at the end of that time, the audible alarm will resume.

PASSWORD, CONTROL PANEL, 314/316 SERIES AUTOMATIC CO2 INCUBATORS:

In the event that you want to prevent unauthorized access to the

operation of the unit, a password feature is available

ADDITIONAL INCUBATOR FEATURES, 314/316 SERIES AUTOMATIC CO

2

INCUBATORS:

• CO2 sensor (on thermal-conductivity units only).

• Mechanically convected airflow.

• 1.2 cubic feet, 304-stainless steel chamber; full-view heated glass door;

• 2 shelves

22

Page 23

FEATURES: (Con’t)

OPTIONAL ALARM RELAY OUTPUT: REAR OF UNIT, 314/316 SERIES AUTOMATIC

CO2 INCUBATORS:

The incubator incorporates an output on the rear panel for use as a central

alarm voltage-free (“dry contacts”) connection port. This output may be tied in with

any central alarm system to give notice of any alarm condition: High or Low

Temperature, High or Low CO2, Power Outage or Door Opened.

A standard relay is used and is normally energized while the incubator is in

operation. Common, Normally Open, and Normally Closed pin outputs are routed

to the rear panel for user access. Enclosed with the incubator is a mating

connector that can be customer-wired and used for interfacing with a Central

Alarm. Note the connector is polarized. The rear panel outputs are as shown

here:

RELAY OUTPUTS LOCATED ON REAR PANEL

COMMON

Terminal

“CLOSES” on Fault (Normally Open

WHILE IN OPERATION)

3 1

“OPENS” on Fault (Normally Closed

WHILE IN OPERATION)

4 2

The following ratings are for connection purposes: MAX 5A @ 34VDC or 34VAC

23

Page 24

FEATURES: (Con’t)

CONTROL PANEL, 315/317 SERIES FLO-THRU CO2 INCUBATORS:

AIR CO2

TEMPERATURE ºC

CAL

HI

TEMP SAFETY

POWER SAMPLE

1. AIR FLOWMETER: Controls the amount of

incoming air by rotating its control knob.

2. LED DISPLAY: Displays current

temperature.

3. CALIBRATION POTENTIOMETER: Using a

jeweler’s screwdriver, display can be

adjusted.

4. TEMPERATURE STATUS LAMP: Lit when

heaters are active.

5. TEMPERATURE CONTROL: Rotates to

raise or lower temperatures.

1 7

2

3

4 TEMP CONTROL 8

5

6 9

6. POWER SWITCH: Turns the unit on and off.

7. CO2 FLOWMETER: Controls the amount of

incoming CO2 by rotating its control knob.

8. HIGH SAFETY STATUS LAMP: Lights up

when high limit set point temperature is

exceeded.

9. CO2 SAMPLE INLET PORT: Used to

determine the amount of CO2 inside the

chamber.

24

Page 25

INSTALLATION

SECTION 5

√SHIPPING CARTON:

This should be inspected upon delivery. When received, carefully

examine for any shipping damage before unpacking. If damage is discovered,

the delivering carrier should both specify and sign for the damage on your copy

of the delivery receipt.

Open the carton carefully making certain that all parts are accounted for

before packaging materials are discarded—after unpacking, if damage is found,

promptly report it to the carrier and request a damage inspection promptly.

IMPORTANT: Failure to request an inspection of damage within a few

days after receipt of shipment absolves the carrier from any liability for damage:

you must call for a damage inspection promptly.

LOCATION:

Place the unit where it will be used, away from external vibration sources,

drafts and wide variations in ambient temperature. To prevent damaging the

tubing, allow at least 3” (8 cm) between the back of the incubator and wall.

Choose a location near a power supply that matches the unit nameplate

requirements.

CAUTION: THIS UNIT IS DESIGNED FOR USE WITH CO2 ONLY. DO NOT

USE WITH ANY OTHER GASES. FAILURE TO OBSERVE THESE

PRECAUTIONS CAN RESULT IN EXPLOSION AND/OR FIRE AND SERIOUS

INJURY AND/OR DEATH AND PROPERTY DAMAGE.

ELECTRICAL REQUIREMENTS:

120 VAC models require a 120 VAC, 50/60 Hz power source. They are

supplied with a 3-wire line cord. It should be plugged into an outlet designed for

3-prong plugs. If an extension cord is used, it also should be the 3-wire grounded

type. For an outlet designed to accept 2-prong plugs (ungrounded), it is

required that a qualified electrician replace the outlet with a new grounded type.

240 VAC models require a 240 VAC, 50/60 Hz power source. Because of

the variety of plug configurations in use worldwide for 240 VAC power, the unit is

furnished with the plug removed. The user must install a plug to conform with

local code and configuration requirements.

NOTE: LEAVE UNIT DISCONNECTED WHEN NOT IN USE.

HUMIDIFICATION, 314/316 SERIES AUTOMATIC CO2 INCUBATORS:

The chamber is designed in such a way that a cold spot is formed causing

moisture that is present in the chamber atmosphere to condensate. The

condensation is diverted into a humidity trough that is attached to the rear wall of

the chamber. Distilled water is not necessary to add since this water will be

recirculated throughout the chamber.

WARNING: While the addition of a fungicide to the water will assist in controlling

contaminant, it may also affect the results of experiments conducted with cells,

viruses and other materials. These factors should be taken into account when

deciding whether or not to use a fungicide.

25

Page 26

INSTALLATION: (Con’t)

INSTALLATION OF GAS FILTER INTERFACE ASSEMBLY KIT #018-514-00:

NOTE: Models 315, 315-1, 317, 317-1 require this assembly to be used for both CO2

and air.

KIT #018-514-00 INCLUDES:

• 4, Hose Clamps (#250-331-00)

• 1, In-Line Filter (#525-034-00)

• 1, 10 ft. (4.57m) length of 1/4” (6.35mm) ID PVC tubing (#720-418-00)

INSTALLATION PROCEDURE:

See next page for illustration.

• Turn the unit power switch to the OFF position.

• Connect tubing to tank gas outlet.

• Connect 1/4” (6.35 mm) ID tubing to hose barb on one side of in-line filter

and secure with hose clamp; connect tubing to in-line filter hose barb on

its other side and secure with hose clamp.

• 314/316 series incubators, connect tubing with in-line filter in place to the

appropriate gas inlet fitting on the back of the unit. 315/317 series

incubators require this assembly to be connected to both air and gas inlet

fittings.

• Set the supply regulators at 4 psi.

• Check all of the connections for leaks.

• Turn the unit power switch to the ON position.

WARNING: HIGH CONCENTRATIONS OF CARBON DIOXIDE PRODUCE

METABOLIC ABNORMALITIES, DISTURBANCES OF THE CENTRAL

NERVOUS SYSTEM AND CARDIAC INSTABILITY—UNCONSCIOUSNESS

MAY OCCUR AT CONCENTRATIONS ABOVE 10%.

26

Page 27

INSTALLATION: (Con’t)

INSTALLATION OF GAS FILTER INTERFACE ASSEMBLY KIT #018-514-00: (Con’t)

BACK OF UNIT

REAR PANEL VIEW, EXTERIOR:

IN-LINE FILTER BACK OF UNIT

#525-034-00

HOSE CLAMP HOSE CLAMP

#250-331-00 #250-331-00

1/4” ID TUBING

#720-418-00

HOSE CLAMP 1/4” HOSE BARB

#250-331-00 CONNECTIONS

(CO2 FITTING)

SET PRESSURE AT 4 PSI.

PRESSURE REGULATORS AND GAUGES MUST

BE INSTALLED ON EACH TANK. CHECK LOCAL

GAS SUPPLIER FOR PROPER REGULATORS.

100% CO2 FOR 314/316 MODELS

AIR FOR 315/317 MODELS

27

Page 28

INSTALLATION: (Con’t)

STANDARD AND SIPHON TYPE CO2 GAS CYLINDERS

STANDARD TYPE (CORRECT) SIPHON TYPE (INCORRECT)

2

1 1 3 5

2 4 6

7

3 8

1. Compressed Gas Association 1. Warning tag indicating that

#320 connector. cylinder is siphoning type.

2. Gas head space. 2* Aluminum ring.

3. Liquid CO2 filled to 68% 3* Gold band.

equal weight of water that 4* Stamp or marking on cylinder:

cylinder would hold at 60ºF. "Siphon" or "Eductor Tube".

5* Valve should be of special type for

service.

6* Withdrawal tube draws up the liquid

CO

2.

7* Gas head-space.

8* Liquid CO2 filled to 68% equal weight of

water that cylinder will hold at 60ºF.

*NOTE: SOME GAS SUPPLIERS WILL HAVE NO MARKINGS TO INDICATE AN "EDUCTOR

TUBE" OR "SIPHON" TYPE CYLINDER—BE SURE TO ORDER DRY, LAB-GRADE CO2.

Be sure to obtain a dual-stage regulator from the gas supplier for the CO2

tank that is to be installed according to local codes. Connect ¼" ID (6.35 mm)

flexible tubing to the regulator. Connect the other end of the tubing to the unit's

CO2 inlet (located on the back top panel). Insert tubing over hose barb and

fasten with an appropriate clamp to assure a proper connection. Adjust the

regulator for 5 psi when CO

2 is to be injected into chamber. For optimum results,

do not exceed or reduce this pressure.

28

Page 29

SECTION 6

OPERATION

DANGER: DO NOT USE IN THE PRESENCE OF FLAMMABLE OR

COMBUSTIBLE MATERIALS OR EXPLOSIVE GASES. DO NOT USE IN THE

PRESENCE OF PRESSURIZED OR SEALED CONTAINERS. FIRE OR

EXPLOSION MAY RESULT, CAUSING DEATH OR SEVERE INJURY.

WARNING: DO NOT HEAT ANY SUBSTANCE ABOVE A TEMPERATURE

THAT WILL CAUSE IT TO EMIT TOXIC FUMES—DEATH OR SEVERE

INJURY MAY RESULT.

DANGER: USE ONLY CARBON DIOXIDE IN THE INCUBATOR. DO NOT

UNDER ANY CIRCUMSTANCE INJECT OXYGEN OR OTHER EXPLOSIVE

GAS OR MIXTURE INTO UNIT. FAILURE TO OBSERVE THESE

PRECAUTIONS CAN RESULT IN EXPLOSION AND/OR FIRE AND SERIOUS

INJURY OR DEATH TO PERSONNEL AND PROPERTY DAMAGE

START-UP, 314/316 SERIES AUTOMATIC CO

• Connect unit to power supply meeting the requirements as noted on the

nameplate.

• Turn the power switch ON.

OPERATING BASICS, 314/316 SERIES AUTOMATIC CO2 INCUBATORS:

• Press the SET key first and then the parameter—CO2, TEMP, DOOR

HEAT—which is to be adjusted.

• Use the UP and DOWN arrow keys to enter the desired value.

• Wait 5 seconds and the value is entered automatically into the unit's

nonvolatile memory. Storage is confirmed via two short beeps at the end

of 5 seconds.

• If you access a parameter and initiate no action within the time frame of 10

seconds, the unit times out and returns to the prior state.

• Each press of the SCAN/HOLD key is programmed to follow a sequential

pattern as follows: HOLD Temperature (for continuous viewing), HOLD

2 (for continuous viewing) and alternate scanning of temperature and

CO

CO2.

• To view your previously established set point for any parameter, press

SET and the TEMP, CO2 or DOOR HEAT key(s).

2 INCUBATORS:

29

Page 30

OPERATION: (Con’t)

PASSWORD FEATURE, 314/316 SERIES AUTOMATIC CO2 INCUBATORS:

To prevent unauthorized entry to values which have been set, a password

feature is available with your unit.

• SET, CAL, CO2 and TEMP keys have the numbers 1, 2, 3 and 4 below

that are used to enter or disable a password. Select a 3-digit password

from 001 through 999 (note: 000 is not a valid password). After power up

and after pressing any key, press 3, 2 and 1 in sequence (i.e. CO2, CAL

and SET); enter your numerical password by using the Up or Down arrow

key.

• Once your password is entered, wait 5 seconds and the unit will store this

value in its nonvolatile memory. REMEMBER TO NOTE THE

PASSWORD IN A PLACE FOR SAFEKEEPING AND ACCESSIBLE TO

YOURSELF OR A COLLEAGUE.

• Subsequent access is denied unless the correct password is entered. Any

keystroke will display 00 and YOU HAVE 5 SECONDS within which to

enter the correct password using the Up or Down arrow key.

• To disable the password: enter the password, wait for - - -

• • • •

to appear on the readout, enter 4, 2, 1 (i.e. TEMP, CAL and SET) and the

password is disabled.

SETTING OPERATING TEMPERATURE AND HIGH LIMIT SETPOINT, 314/316

SERIES AUTOMATIC CO2 INCUBATORS:

The unit is factory pre-set at 37ºC and 5.0% CO2. To change these

settings:

• Press the SET and TEMP keys sequentially and using the Up and Down

arrow keys, select the set point temperature.

• Using a jeweler’s screwdriver, rotate the high limit thermostat fully

clockwise.

• Set CO2 set point to zero—accuracy will not be achieved until the

temperature has stabilized.

• Press the SET and CO2 keys sequentially and using the Up and

Down arrow keys, adjust LED readout until a value of 00.0 is

obtained.

• Wait 5 seconds to finalize the selection.

• Allow sufficient time for the unit to reach and stabilize at the set point

temperature, plus an additional hour or two for unit to cycle at the

temperature—4 HOUR TOTAL FOR SETTING 37ºC IS TYPICAL.

30

Page 31

OPERATION: (Con’t)

SETTING OPERATING TEMPERATURE AND HIGH LIMIT SETPOINT, 314/316

SERIES AUTOMATIC CO2 INCUBATORS: (Con’t)

• After sufficient time has elapsed, rotate the high limit thermostat

counterclockwise while watching the red lamp. When the lamp is lit, you

have adjusted the high limit set point to be equal to the operating set point.

• Now rotate the high limit thermostat clockwise 30º of rotation beyond the

point where the lamp goes out. This distance should be similar to the

distance from the twelve o’clock to the one o’clock positions. This

establishes a buffer of a few degrees between the operating set point and

the high limit temperature setpoint allowing PID control to function

normally.

BE ADVISED UNDER NORMAL OPERATING CONDITIONS, THE High

LIMIT LED SHOULD NEVER COME ON. IF IT DOES, ROTATE THE

HIGH LIMIT THERMOSTAT SLIGHTLY CLOCKWISE—MISOPERATION

OF THE TEMPERATURE AND POSSIBLY CO2 CONTROL MAY OCCUR

IF THE HIGH -LIMIT IS SET TOO CLOSE TO THE SETPOINT.

CONDENSATION ON INNER GLASS DOOR, 314/316 SERIES AUTOMATIC CO2

INCUBATORS:

• After the unit has been operating, you can determine what, if any,

condensation is forming on the inner glass door. To dissipate

condensation, press the SET and DOOR HEAT keys to access this

function.

• Using the Up and Down arrow keys, select a value as a percentage of the

heater output. The door heater is about 50 watts; complete control of how

much effective heat will be applied is obtained by setting the door heat

percentage; each 1% translates into 0.5 watts of door heat.

For example: 10 will produce 10% of the available heating capacity.

As experience is gained through trial and error, users are able to select more

precisely the heating value required to remove any condensation.

As a general starting point, 30% at 37ºC may be selected.

• Correct setting of the door heat control depends on varying factors such

as chamber temperature. In general, the setting should produce the

minimal amount of heat necessary to eliminate glass door condensation

and no more. If unsure of the amount of heat to produce, start at a low

value and increment the setting by 5% every couple of hours until

condensation is eliminated. Once set, the door heat percentage need not

be changed again, unless you change the temperature set point

requirements. The setting chosen is stored in nonvolatile RAM memory in

case of power outages.

OPERATION: (Con’t)

31

Page 32

TEMPERATURE CALIBRATION, 314/316 SERIES AUTOMATIC CO2 NCUBATORS:

The Incubator is calibrated at the factory. However, if required, the

temperature readout may be calibrated by pressing the following keys

in sequence: CAL, TEMP.

• Use of a calibrated indicating device positioned in the approximate

geometric center of the chamber is critical to this procedure.

• Use the Up and Down arrow keys to correct the displayed temperature on

the LED readout to match your chamber temperature reading. Wait 5

seconds and the adjustment is self-entering

OPERATION: (Con’t)

32

Page 33

LOADING THE INCUBATOR, 315/317 SERIES FLO-THRU CO2 INCUBATORS:

Load the chamber, spacing the items as far apart as possible (for

maximum air circulation).

AIR/GAS RATIO, 315/317 SERIES FLO-THRU CO2 INCUBATORS:

Set the flowmeters to obtain the required air and CO2 flow—using the

lowest possible CO2 flow rate will help to conserve gas.

Use one of the following formulas to find the desired air-to-gas ratio:

R = % CO2 in the chamber atmosphere

A = Air flow in liters/minute

C = CO2 flow in liters/minute

Equation 1 (to be used if air and CO2 flow rates are known):

R = C x 100

A + C

Equation 2 (to be used if air flow rate and % CO2 are known):

C = RA liters/min.

100 - R

Equation 3 (to be used if CO2 flow rate and % CO2 are known):

A = 100C - RC liters/min.

R

Example 1: If a CO2 percentage of 15% is desired at a flow rate of 0.4

liters/min. of CO2, use Equation 3:

A = 100 (0.4) - 15 (0.4)

= 40 - 6

15 15

= 2.26 liters/min. of air

Example 2: If flow rates are set 0.1 liters/min. of CO2 and 3 liters/min. of

air, use Equation 1 to find percentage of CO2:

B = 0.1 x 100 = 3.2% CO2 in chamber

3.0 + 0.1 atmosphere

33

Page 34

OPERATION: (Con’t)

CO2/AIR FLOW NOMOGRAPH, 315/317 SERIES FLO-THRU CO2 INCUBATORS:

CO2 26 24 22 20 18 16 14 12 10

CO2 10 9.0

L

I 9 8.0

T

E 8 7.0

R

S 7

/

M 6 6.0

I

N 5 5.0

U

T 4 4.0

E

3 3.0

2.5 2.5

2 2.0

1.5 1.5

1.0 1.0

.9

.8 0.8

.7

.6 0.6

.5

.4 0.4

.3

%

CO2

.25

.2

.16

.15

.1

1 1.5 2 2.5 3 4 5 6 7 8 9 10 15 20 25 30 40 50 60 70 80 90 100

LITERS PER MINUTE, AIR

1. DRAW A VERTICAL LINE FROM THE POINT THAT REPRESENTS THE AIR FLOW ON THE HORIZONTAL

AXIS UNTIL IT INTERSECTS A DIAGONAL LINE INDICATING THE REQUIRED VOLUME (%) OF CO2 FLOW; 2.

RUN A HORIZONTAL LINE TO THE VERTICAL AXIS TO FIND REQUIRED FLOW OF CO2 IN LITERS/MINUTE; 3.

TO OBTAIN THE AIR FLOW (IF CO2 FLOW IN LITERS/MINUTE AND % CO2 ARE KNOWN), REVERSE

PROCEDURE.

34

Page 35

OPERATION: (Con’t)

THERMOSTAT CONTROL, 315/317 SERIES FLO-THRU CO2 INCUBATORS:

A hydraulic thermostat is utilized for set point control to protect chamber

from over-temperature conditions.

OPERATING SUGGESTIONS, 315/317 SERIES FLO-THRU CO2 INCUBATORS:

• In order to obtain and maintain the desired CO2 gas pressure, periodically

check the tightness and integrity of the gasket that secures the glass door

to the chamber.

• To be sure of maintaining desired gas pressure, periodically check outflow

pressure from gas supply source.

• If maintaining humidity conditions within the chamber, check level of water

in pan and replenish as necessary.

• After power is disconnected to the unit, do not permit humidity water to

remain in the unit. Remove any pans and/or dry the interior thoroughly.

• Insofar as possible, keep the incubator door closed in order to reduce the

possibility of fungus growth starting from airborne organisms entering the

chamber.

CO2 SAMPLING/MEASUREMENT, 315/317 FLO-THRU CO2 INCUBATORS:

Insert sample probe into the sample access port making sure that a tight

seal is attained. Obtain a sample of CO2 sufficiently large to meet the

requirements of the analytical apparatus or procedure being used. Perform CO

analysis.

CO2 CALIBRATION, 314/316 SERIES AUTOMATIC CO2 INCUBATORS:

In like manner, the CO

standard such as the Fyrite method of analyzing CO2. To access the correct

command mode, press the CAL, CO2 keys sequentially.

Using a Fyrite or similar device, obtain the actual CO2 tension in the

chamber via the front panel CO2 sample port.

If there is a difference between the Fyrite reading and LED display of

CO2, press CAL and CO2 in sequence and use the Up and Down arrow keys to

adjust the displayed CO2 value to match the value obtained with the Fyrite or

device of comparable accuracy and reliability.

All internal CO

2 parameters automatically track this change: FOR

OPTIMUM OPERATION OF YOUR INCUBATOR, CHECK CO2 WITH FYRITE

WEEKLY.

2 reading can be calibrated against a known

2

35

Page 36

OPERATION: (Con’t)

HINTS ON USING THE FYRITE*:

The following information is intended to supplement that found in the

Fyrite manual and is based on experience working with users of our Incubators.

One of the most important aspects of using the Fyrite procedure

and one that is frequently overlooked is the condition of the fluid. The

Fyrite accepts a sample of the Incubator's environment into its own

chamber where it is absorbed by the Fyrite fluid to determine the CO2

percentage or tension. Of special importance is keeping outside air from

the sample drawn from the Incubator. Any outside air contaminating the

sample is detrimental to an accurate reading, and, more importantly, to the

growth of your cells. Inspection of the fluid should be performed only with

the user wearing protective gloves, as the Fyrite fluid is slightly corrosive.

The inspection should review the following:

• THE DATE OF THE LAST FLUID CHANGE: Old fluid will not absorb as

much CO2 and will produce a false reading. This may lead the user to

recalibrate the Incubator to higher CO2 tensions that can prove lethal to

cell cultures. Fyrite fluid should be changed after approximately 350 uses.

This approximates a change of fluid once a year if the Fyrite procedure is

carried out on a daily basis. Keep track of the number of uses and if the

Fyrite is used with more than one Incubator. Experience shows that the

color of the fluid is not as important as the age of fluid.

• CHECK THE CONTAINMENT VESSEL AND HOSES AT LEAST ONCE A

MONTH: Make sure that there are no cracks in the vessel or leakage of

fluid to the outside of the container. This can indicate a leaky seal or

internal crack. Hoses should be stretched slightly and inspected for

cracks or holes. This is critical as cracks and/or holes in the hoses can

draw in outside ambient air and produce a false reading.

• CHECK THE FLUID DAILY AND ADJUST THE SLIDE GAUGE TO READ

ZERO: If you have adjusted the slide gauge all the way down and the fluid

level is still too low, place a couple of drops of distilled water into the

plunger on the top of the Fyrite. Depress the plunger and the water will

transfer into the Fyrite causing the fluid level to rise. Repeat this procedure

until the fluid level reads correctly.

CAUTION: A LITTLE WATER GOES A LONG WAY. USE ONLY A COUPLE

OF DROPS OF DISTILLED WATER AT A TIME.

CAUTION: DO NOT USE FYRITE FLUID TO ADJUST THE LEVEL OF FLUID

USE DISTILLED WATER ONLY. THE ONLY TIME TO USE FRESH FYRITE

FLUID IS WHEN YOU CHANGE IT DUE TO THE AGE OF THE FLUID.

*Trademark of Bacharach Instruments.

36

Page 37

OPERATION: (Con’t)

HINTS ON USING THE FYRITE: (Con’t)

Inspect the Fyrite filter in the clear plastic casing between the hoses for

any contamination or growth. Change it if necessary.

CAUTION: MAKE SURE THE FILTER IS MOIST BEFORE YOU TAKE YOUR

READING. A MOIST FILTER IS A MUST FOR AN ACCURATE READING.

To moisten the filter, remove the end of the short hose without the

squeeze bulb that connects to the Incubator. Add several drops of distilled

water to the filter, replace the hose and squeeze the bulb. Release the bulb and

the water will be drawn into the filter. Squeeze the bulb and quickly release it to

remove any excess water. You will see this water (if any) come out of the end of

hose that is closest to the squeeze bulb. This is the cupped end that is

depressed onto the Fyrite.

TAKING A FYRITE READING:

It is recommended that Fyrite CO2 and independent temperature

tests be performed at intervals to be determined individually or as dictated

by established protocol. Some laboratories conducting critical work may

want to record CO2 and temperature readings on a daily basis.

CAUTION: THE INCUBATOR MUST BE STABLE.

First, clear the Fyrite of any residue CO2. Simply depress the plunger on

the head or the top of the Fyrite taking care not to cover the hole—this

introduces fresh ambient air into the Fyrite chamber. Release the plunger and

turn the Fyrite upside down, holding it at a 45-degree angle until most of the

bubbles surface and the fluid has filled the head. Even the smallest bubbles

may contain CO2, so that it is important to let most of the smaller bubbles

surface.

Now turn it right side up and hold it at 45 degrees. Allow the fluid to fill the

Fyrite and depress the plunger again—this clears the Fyrite of any CO2 that

might cause a false reading.

Next, attach the filter side of the hose to the Incubator's CO2 sample port.

Remove the brass tube, if present, from the Fyrite hose, as it is not needed and

attach the hose to the CO2 sample port. (The brass tube was once used with

older Incubators that utilized a hole in the Incubator wall or door to measure

CO2 but this method proved to cause contamination problems.)

LOOK AT YOUR FYRITE GAUGE AND ADJUST THE ZERO IF

NECESSARY.

Take the squeeze bulb end of the hose and with the hole of the cupped

end facing down, place it onto the plunger of the Fyrite and hold it firmly in

position.

IMPORTANT: ONCE YOU HAVE DEPRESSED THE PLUNGER OF THE

FYRITE, IT IS CRITICAL THAT IT NOT BE RELEASED DURING THE

FOLLOWING PROCEDURE.

37

Page 38

OPERATION: (Con’t)

TAKING A FYRITE READING: (Con’t)

Depress the plunger and hold it down. It is very important not to allow the

plunger to spring up—if this occurs, you will be repeating an already existing

reading. It will not matter how many times you pump the squeeze bulb, as long

as you hold the plunger down you will introduce only one sample to the Fyrite.

But, by releasing the plunger and immediately pushing it back down, you will

then be adding an additional sample to the Fyrite chamber causing the reading

to double or triple. In the event that it is difficult to hold the plunger down while

pumping the squeeze bulb, find a more suitable or comfortable position.

Without releasing the plunger, pump the squeeze bulb at least 20 times—

this assures complete and thorough transfer of the sample to the Fyrite chamber.

Once the bulb has been pumped the required number of times, HOLD THE

SQUEEZE BULB IN THE "SQUEEZED" POSITION and release the pressure on

the cup which will also release the plunger. This traps the sample from the

Incubator in the Fyrite chamber and allows the fluid to absorb the CO2.

With the plunger now released, turn the Fyrite upside down again and

hold at a 45-degree angle to allow the smaller bubbles to surface while the fluid

fills the chamber head. Reverse and turn Fyrite right side up and hold at a 45 degree angle to allow the same thing to happen. Repeat this procedure—hold

upside down at 45-degree angle and right-side up at 45-degree angle. Finish by

shaking the Fyrite slightly while holding at 45-degree angle to allow residue

droplets of fluid to drain into the measuring tube.

Read the gauge: It should match or be close to your CO2 set point. It is

possible that you may be off as much as ±3%. If you read more than 8%, it is

possible that you may have introduced two samples or the Incubator is way out

of calibration. If a wide variation between the reading and CO2 set point exists, it

is recommended that the sampling and measurement procedure be repeated.

Once the possibility of any error in Fyrite reading has been eliminated,

calibrate your Incubator to conform with the reading obtained.

38

Page 39

SECTION 7

MAINTENANCE

BE ADVISED:

NOTE: MAKE NO ATTEMPT TO SERVICE OR REPAIR A LAB-LINE PRODUCT UNDER

WARRANTY BEFORE CONSULTING YOUR LAB-LINE DEALER. AFTER THE WARRANTY

PERIOD, SUCH CONSULTATION IS STILL ADVISED, ESPECIALLY WHEN THE REPAIR

MAY BE TECHNICALLY SOPHISTICATED OR DIFFICULT.

IF ASSISTANCE IS NEEDED BEYOND WHAT THE DISTRIBUTOR CAN PROVIDE, PLEASE

CALL THE LAB-LINE CUSTOMER RELATIONS DEPARTMENT AT (319) 556-2241 OR

(800) 522-5463. NO MERCHANDISE, HOWEVER, SHOULD BE RETURNED DIRECTLY TO

LAB-LINE WITHOUT PRIOR APPROVAL FROM LAB-LINE.

CAUTION: DISCONNECT PLUG FROM ELECTRICAL OUTLET BEFORE

ATTEMPTING ANY MAINTENANCE OR REPAIR OF THIS UNIT.

CLEANING:

Every 6 months inspect the chamber. Clean the stainless steel interior

with any good scale remover or dilute acetic acid and a synthetic scouring pad.

DO NOT USE chlorine-based cleansers or bleach, scouring pads with metallic

content, or harsh abrasives to clean any part of the Incubator.

CARE AND CLEANING OF STAINLESS STEEL:

CAUTION: DISCONNECT UNIT FROM POWER SOURCE PRIOR TO

CLEANING. WE RECOMMEND ALL SERVICE BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

WARNING: ELECTROLYSIS CAN DAMAGE STAINLESS STEEL. THIS

OCCURS WHEN AN OBJECT IS ALLOWED TO REST DIRECTLY ON THE

SURFACE OF STAINLESS STEEL, TRAPPING MOISTURE THAT BECOMES

OXYGEN-STARVED, BUT IS SURROUNDED BY WATER-CONTAINING

OXYGEN.

MAINTENANCE: (Con’t)

39

Page 40

THE ALLOY CALLED STAINLESS:

Stainless steel is an alloy of steel with chromium and nickel that

increase the metal’s resistance to rust and corrosion. Yet, if not properly cared

for, stainless steel can rust and corrode.

Exposure to air provides the passivation, or oxide layer coating, for clean

stainless by producing a thin, durable chromium-oxide film that forms rapidly

on the alloy surface to give stainless its characteristic “stainless” quality. Also

exposure of the surface to other oxidizing environments can produce a

passivating film or coating.

However, if free oxygen is not available due to scale or contamination

buildup the metal surface may become vulnerable to rusting and corrosion as

well as pitting. But by maintaining neutral pH and conducting frequent cleanings

with detergent and water, years of trouble-free service from stainless steel

products can be obtained.

SOME STAINLESS GUIDELINES TO CONSIDER:

Distilled water is recommended. Please note, if this water is very pure, it

may be corrosive to stainless. When filling a bath or incubator, ALWAYS ADD 2

to 40 PPM (20 TO 40 MG/LITER) DISODIUM PHOSPHATE OR SODIUM

BICARBONATE, ADJUSTING DOSAGE TO PROVIDE A pH VALUE OF 7 TO 9.

If not available, use clean, aerated soft tap water provided the total solids

concentration is < 500 PPM.

WE DO NOT RECOMMEND USING 18 MEG OHM DEIONIZED WATER.

If this is the only source of treated water available—mix with regular tap water

at a 50/50 ratio.

THE pH FACTOR:

Check pH regularly. If pH is <6.0, add disodium phosphate to increase pH

to a 7 to 9 value. Sodium carbonate or sodium bicarbonate may be used but

they tend to form scale that must be rinsed out regularly. If pH is >10.0, add

sodium bisulfate to decrease pH to a 7 to 9 value. Avoid adding harsh alkalines

or acids since these may cause localized corrosion and result in unstable pH.

SPECIAL STAINLESS CONSIDERATIONS:

WARNING: IF IT IS NECESSARY TO USE THE FOLLOWING CHEMICALS,

LIMIT EXPOSURE TIME TO A MAXIMUM OF 3 HOURS—ALWAYS CLEAN

SURFACES IMMEDIATELY AFTER USE.

Chemicals which should be limited to a 3 hour maximum exposure time to

stainless steel are:

Aluminum chloride E.D.T.A. Potassium permanganate

Barium chloride Ferrous chloride Potassium thiocyanate

Calcium chloride Lysol Sodium hypochlorite

Chlorinated Lime Mercury salts Stannous chloride

Citric acid (boiling) Phenol Tartaric acid

Dakin’s solution

MAINTENANCE: (Con’t)

40

Page 41

BE ADVISED: NEVER USE THE FOLLOWING ON STAINLESS STEEL:

Aqua regia

Ferric chloride

Iodine

Sodium acid

Sodium azide

Chemical spills, especially those agents listed here, should be removed

as soon as possible and the stainless steel surface cleaned with mild soapy

water followed by a clean water rinse.

CLEANSING AGENTS:

Anti-fungal and anti-bacterial additives are permissible to use as long as

the pH of the aqueous solution is kept within the range of 7 to 9. These are

available through laboratory distributors—but be sure to CONFIRM that they are

not harmful to stainless steel.

STAINLESS CLEANING METHODS:

Do not use any metallic pads. Instead, for stubborn stains, use a plastic

light-duty cleansing pad and rub GENTLY in the direction of the metal grain.

If stains continue to persist, use one of the following chemicals and methods.

CAUTION: EXTREME CARE MUST BE TAKEN WHEN HANDLING THESE

MATERIALS. ALWAYS WORK IN AN AREA WITH ADEQUATE VENTILATION.

USE THE PRECAUTIONS AS OUTLINED IN THE MATERIAL SAFETY DATA

SHEET (MSDS) AND THE MANUFACTURER’S INSTRUCTIONS FOR THE

PRODUCT BEING UTILIZED. ALSO, FOLLOW THE PERSONAL

PROTECTION INDEX FOUND IN THE HAZARDOUS MATERIALS

INFORMATION SYSTEM (HMIS) SECTION OF THE MSDS.

NOTE: THE USE AND DISPOSAL OF THESE CHEMICALS MAY BE REGULATED BY YOUR

LOCAL CITY CODES; CONSULT THOSE REGULATIONS BEFORE OF DISPOSING OF

THESE MATERIALS.

• Any of a variety of “scale removers” available at local supermarkets or

hardware stores used for the cleaning of coffee marks, humidifiers or

vaporizers.

• A 15% to 35% phosphoric acid solution available from laboratory supply

distributors for scale and rust removal. Allow solution to soak the surface

affected until rust and scale is loosened. Immediately follow with a clean

water rise.

• Citric acid based cleaners.

41

Page 42

MAINTENANCE: (Con’t)

STAINLESS CLEANING METHODS: (Con’t)

• Bathroom tub and tile cleaners.

• A mixture of 20% nitric acid and 1.5% hydrofluoric acid (or hyrochloric

acid). Swab solution on surface allowing it to remain until rust is loosened.

Immediately follow with a clean water rise. (This method should ONLY be

used if SEVERE rust and scale stains are present.)

• Oxalic acid 2% to 5% in warm water. Swab solution on surface allowing it

to remain until rust is loosened. Immediately follow with a clean water

rise. (This method should ONLY be used if SEVERE rust and scale stains

are present.)

directions and allow the chemicals to do the cleaning with MINIMAL scrubbing.

Always follow cleanings with a clean water rinse. Air dry.

MATERIALS EFFECTIVE IN DISINFECTING STAINLESS:

• Glutaraldehyde

• Alcohol

BE ADVISED: THIS INFORMATION IS INTENDED AS GUIDELINES ONLY

AND LAB-LINE INSTRUMENTS, INC. MAKES NO CLAIM AS TO THE

SUITABILITY TO ANY PARTICULAR SITUATION. CONSULT YOUR STAFF

CHEMIST TO DETERMINE WHAT WOULD BE BEST FOR YOUR STAINLESS

STEEL PRODUCT AND LABORATORY.

CLEANING COPPER SURFACES: FLO-THRU MODELS, 316/317 SERIES:

Copper surfaces can be cleaned using commercially available detergent

preparations specifically indicated for copper use. Copper surfaces will not

tarnish when washed with detergent solutions that contain small amounts of the

chemical compound 1-, 2- or 3-benzotriazole. It is important, however, before

using the detergents to determine any possible effect the presence of this

compound and any other ingredients might have on the incubation work being

conducted. Contact the manufacturers of the commercially available detergents

and obtain all necessary information on the chemical and physical properties of

the compositions.

TEMPERATURE READOUT CALIBRATION: ALL MODELS:

Place a scientifically accurate thermometer in the chamber, on a center

shelf and allow the incubator to stabilize at some set temperature. If the digital

temperature readout does not agree with the thermometer, take the trimmer pot

tool, insert in calibration pot on control panel and adjust until readout matches

the measured temperature.

UNIT REPAIRS:

In the event that your unit becomes inoperative, consult with your local

dealer for assistance.

Regardless of the approach utilized, ALWAYS follow the manufacturer’s

42

Page 43

SECTION 8

REPLACEMENT PARTS

314/316 SERIES AUTOMATIC CO2 INCUBATORS:

DESCRIPTION PART NUMBER

Printed Circuit Board Assy: 018-478-00

CO2 Sensor Assy: 018-646-00

Axial Fan: 160-136-00

Schematic 314: 228-553-30

Schematic 314-1: 228-553-29

Schematic, 316: 228-553-21

Schematic, 316-1: 228-553-22

Capacitor: 310-082-00

Circuit Breaker, 5 Amp: 330-118-00

Line Filter: 330-347-00

Fuse, 1 Amp (2): 330-369-00

Heater, 120V: 340-377-00

Heater, 120V: 340-377-01

Door Heater: 340-355-00

Tube Heater: 340-356-01

Glass Door: 540-228-00

Door Gasket: 530-248-00

Clear RTV Sealant: 120-024-00

Hi-Limit Status Lamp (red), 120V: 360-272-00

Hi-Limit Status Lamp (red), 240V: 360-290-00

Motor, 120V: 370-278-00

Motor, 240V: 370-279-00

RTD Sensor: 410-632-00

Rocker Switch, 120V: 440-359-00

Switch, 240V: 440-292-00

Transformer, 120V: 460-231-00

Transformer, 240V: 460-287-00

Line Cord: 470-105-00

In Line Filter: 525-034-00

Gasket (4.4 ft): 530-069-00

Leveling Foot With Pad (4): 790-391-00

Shelf, 314 Series (2): 810-424-02

Shelf, 316 Series (2): 810-424-01

Thermostat: 920-301-00

Solenoid Valve: 950-135-00

Dow Corning RTV Sealant: 120-053-00

Circuit Breaker, 10 Amp: 330-119-00

43

Page 44

REPLACEMENT PARTS: (Con’t)

315/317 SERIES FLO-THRU CO2 INCUBATORS:

DESCRIPTION PART NUMBER

Schematic 120V: 229-162-00

Schematic 240V: 229-163-00

Capacitor: 310-082-00

Heater, 120V: 340-372-00

Heater, 240V: 340-373-00

Front Body Heater: 340-376-00

Glass Door: 540-228-00

Door Gasket: 530-226-00

Line Cord: 470-187-00

In Line Filter: 525-034-00

Gasket (4 ft): 530-069-00

Foot (4): 790-225-00

Shelf, 315 series (2): 810-424-02

Shelf, 317 series (2): 810-424-01

Flowmeters

Air: 660-044-00

CO2: 660-043-00

Switch, 120V: 440-359-00

Switch, 240V: 440-292-00

Circuit Breaker: 330-118-00

Lens, Red: 360-234-00

Lens, Amber: 360-235-00

Thermostat: 920-301-00

NEED A PART? CALL THE LAB-LINE PARTS HOTLINE.

CALL: (319) 556-2241 or (800) 522-5463; FAX: (319) 589-0516.

LAB-LINE RESERVES THE RIGHT TO MAKE CHANGES TO SPECIFICATIONS WITHOUT PRIOR NOTICE.

44

Page 45

WARRANTY

Page 1 of 2

LAB-LINE INSTRUMENTS, INC. (“Lab-Line”) warrants that the product manufactured by

Lab-Line shall be free of defects in materials and workmanship for a period of time

defined on the following page from the first to occur of (i) the date the product is sold by

Lab-Line or (ii) the date the product is purchased by the original retail customer (the

“Commencement Date”). Except as expressly stated above,

LAB-LINE MAKES NO OTHER WARRANTY, EXPRESSED OR IMPLIED, WITH

RESPECT TO THE PRODUCTS AND EXPRESSLY DISCLAIMS ANY AND ALL

WARRANTIES, INCLUDING BUT NOT LIMITED TO, WARRANTIES OF DESIGN,

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

An authorized representative of Lab-Line must perform all warranty inspections. In the

event of a defect covered by Lab-Line’s warranty, Lab-Line shall, as its sole obligation

and exclusive remedy, provide free replacement parts to remedy the defective product.

In addition, for products sold by Lab-Line within the continental United States or

Canada, Lab-Line shall provide free labor to repair the products with the replacement

parts, but only for a period of ninety (90) days from the Commencement Date.

Lab-Line’s warranty provided hereunder shall be null and void and without further force

or effect if there is any (i) repair made to the product by a party other than Lab-Line or

its duly authorized service representative, (ii) misuse (including use inconsistent with

written operating instructions for the product), mishandling, contamination, overheating,

modification or alteration of the product by any customer or third party or (iii) use of

replacement parts that are obtained from a party who is not an authorized dealer of LabLine.

IN NO EVENT SHALL LAB-LINE BE LIABLE TO ANY PARTY FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, OR FOR

ANY DAMAGES RESULTING FROM LOSS OF USE OR PROFITS, ANTICIPATED

OR OTHERWISE, ARISING OUT OF OR IN CONNECTION WITH THE SALE, USE

OR PERFORMANCE OF ANY PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, TORT (INCLUDING NEGLIGENCE), ANY THEORY OF STRICT

LIABILITY OR REGULATORY ACTION.

The name of your nearest authorized Lab-Line dealer may be obtained by calling 1800-522-5463.

1999 North 15th Ave., Melrose Park, IL 60160-1491 USA

PHONE: (319) 556-2241 or (800) 522-5463; FAX: (319) 589-0516

DESIGNERS AND MANUFACTURERS

A SUBSIDIARY of Barnstead|Thermolyne

45

Page 46

WARRANTY

Page 2 of 2

12 MONTH PARTS WARRANTY

• All Environmental Chambers

• Low Temperature B. O. D. Incubators

• Animal Study Chamber

• Controlled Environment Centers

• Biological Work Station

• Refrigerators, Freezers

• Chromatography Refrigerators (5 year parts warranty on compressor only)

• Large Capacity Refrigerators and Freezers (5 year parts warranty on compressor

only)

24 MONTH PARTS WARRANTY:

• Frame Clamps, Frame Sets, Lab Jacks

• Saybolt Viscosimeter

• Timers, Samplers, Flasks

• Saf-T-Shield, Safety Tongs

• All Incubators & Ovens

• Dual Action Open Air Shaker

• Reciprocating Shakers (open air and water bath)

• Rockers and Rotators

• Low Cost Shakers

• Environ Blok Shaker

• Titer Plate Shaker

• Multi Wrist Shaker

• Water Baths (excluding Aquabaths), Ultrasonic Cleaners

• Slide Warmers

• Mixers, Stirrers, Hotplates

• Thermal Cyclers

• Blok Heaters

• Aquabaths, lifetime warranty on heaters

LIFETIME PARTS WARRANTY:

• All ORBITAL Shakers (not carrying a 24 month parts warranty) offer a lifetime

parts warranty on the drive mechanism and a 5 year warranty on all other parts

• Refrigerated Orbital Shakers carry a lifetime warranty on the drive mechanism,

1 year parts warranty on the compressor, and a 5 year warranty on all other

parts.

:

46

Page 47

FIRST IN INSTRUMENTS SERVICING SCIENCE, INDUSTRY,

RESEARCH AND EDUCATION

SINCE 1908.

47

Page 48

48

Page 49

ACCESSORY CHECKLIST

packed with this unit. Before discarding any packing materials,

please make sure that nothing has been overlooked.

MODEL NO.: 314, 314-1, 314-1CE, 316, 316-1, 315, 315-1, 317, 317-1

CHECKED BY: ———————

DATE: ____________

PACKED BY: ____________

CHECKED ITEM PART NUMBER QUANTITY

_________

___________ Shelves (316/317 Series) 810-424-01 2

___________ Gas Filter Interface Assy. 018-514-00 1~2

___________ Operation Manual 057-561-00 1

___________ Warranty Card 528-022-00 1

Blue Caution Card

_________

Mating Connector

___________ (314/316 Series) 420-006-00 1

The following loose parts and accessories are

Shelves (314/315 Series) 810-424-02 2

(240 Volt) 528-009-00 1

49

Loading...

Loading...