Page 1

Rev. 3.0.4

Item no. OM–DSERIES–LAKE

D SERIES

High–Power installation platform

Lake Variants:

D 200:4L

D 120:4L

D 80:4L

D 40:4L

D 20:4L

D 10:4L

Incorporating technologies from

Operation Manual

Page 2

1. Important safety instructions

1. Important safety instructions

1. Important safety instructions

Before using the device, be sure to carefully read the Safety Instructions. Keep this document with the device at

all times.

1. Read these instructions.

2. Keep these instructions

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Do not block any ventilation openings. Install in accordance

with the manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, heat

registers, stoves, or other apparatus (including ampliers)

that produce heat.

9. Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades with

one wider than the other. A grounding-type plug has two

blades and a third grounding prong. The wide blade or

the third prong is provided for your safety. If the provided

plug does not t into your outlet, consult an electrician for

replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched,

particularly at plugs, convenience receptacles, and the point

where they exit from the apparatus.

11. Only use attachments/accessories specied by the

manufacturer.

12. Use only with a cart, stand, tripod, bracket, or table specied

by the manufacturer, or sold with the apparatus. When a

cart is used, use caution when moving the cart/apparatus

combination to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when

unused for long periods of time.

14. Refer all servicing to qualied service personnel. Servicing

is required when the apparatus has been damaged in any

way, such as power-supply cord or plug is damaged, liquid

has been spilled or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped.

15. Use the mains plug to disconnect the appartus from the

mains.

16. WARNING: To reduce the risk of re or electric shock, do not

expose this apparatus to rain or moisture.

17. Do not expose this equipment to dripping or splashing and

ensure that no objects lled with liquids, such as vases, are

placed on the equipment.

18. The mains plug of the power supply cord shall remain readily

operable.

19. Do not connect the unit’s output to any other voltage source

such as battery, mains source, or power supply, regardless

of whether the unit is turned on or off.

20. Do not remove the top (or bottom) cover. Removal of the

cover will expose hazardous voltages. There are no user

serviceable parts inside and removal may void the warranty.

21. An experienced user shall always supervise this professional

audio equipment, especially if inexperienced adults or

minors are using the equipment.

22. The US National Differences clause 16.3 requires that

network cables must be ame rated VW-1.

2. Approvals

This equipment conforms to the requirements

of the EMC Directive 2014/30/EU and the

requirements of the Low Voltage Directive

2014/35/EU.

Standards applied: EMC Emission

EN55103-1, E4

EMC Immunity EN55103-2, E5, with S/N

below 1% at normal operation level.

Electrical Safety EN60065, Class I

This equipment is tested and listed according to the

U.S. safety standard ANSI/ UL 60065 and

Canadian safety standard CSA C22.2

NO. 60065. Intertek made the tests and they

are a Nationally Recognized Testing Laboratory

(NRTL).

3. Warnings

3.1. Explanation of warning symbols

The lightning bolt triangle is used to

alert the user to the presence of

un-insulated “dangerous voltages”

within the unit’s chassis that may be

of sufcient magnitude to constitute a

risk of electric shock to humans.

The exclamation point triangle is used to

alert the user to presence of important

operating and service instructions in the

literature accompanying the product.

3.2. Warnings

To prevent electric shock do not remove top or bottom

covers. No user serviceable parts inside, refer servicing to

qualied service personnel.

Français: À prévenir le choc électrique n’enlevez pas les

couvercles. Il n’y a pas des parties serviceable à l’intérieur, tous

reparations doit etre faire par personnel qualié seulment.

D SERIES Lake Operation Manual rev 3.0.4

2

Page 3

3. Warnings

3. Warnings

To completely disconnect this equipment from the AC

mains, disconnect the power supply cord plug from the AC

receptacle. The mains plug of the power supply cord shall

remain readily operable.

Français: Pour démonter complètement l’équipement de

l’alimentation générale, démonter le câble d’alimentation

de son réceptacle. La prise d’alimentation restera aisément

fonctionnelle.

To reduce risk of re or electric shock, do not expose this

apparatus to rain or moisture.

Français: Pour réduire les risques d’incendie ou de choc

électrique, n’exposez pas l’appareil à la pluie ou à l’humidité.

Do not expose this system/apparatus to dripping or splashing

and ensure that no objects lled with liquids, such as vases,

are placed on the apparatus.

Français: N’exposez pas ce système/appareil au

ruissellement ni aux éclaboussures et assurez-vous qu’aucun

objet contenant du liquide tel qu’un vase n’est placé sur

l’appareil.

This apparatus must be connected to a mains socket outlet

with a protective earthing connection.

Français: Cet appareil doit être raccordé à une prise secteur

avec terre de protection.

The mains plug is used as a disconnect device and shall

remain readily operable.

Français: Lorsque la prise du réseau d’alimentation est utilisés

comme dispositif de déconnexion, ce dispositif doit

demeuré aisément accessible.

3.3. Caution

To reduce the risk of re or electric shock, do not remove screws.

No user-serviceable parts inside. Refer servicing to qualied

service personnel.

Français: Pour réduire le risque d’incendie ou de choc

électrique, ne pas retirer les vis. Aucune pièce réparable par

l’utilisateur. Coner l’entretien àpersonnel qualié.

3.4. User responsibility

3.4.1. Mains connection grounding

Your amplier must be connected to a grounded socket outlet.

3.4.2. Speaker output hazard on amplifiers

Ampliers are capable of producing hazardous output

voltages. To avoid electrical shock, do not touch any exposed

speaker wiring while the amplier is operating. The external

wiring connected to the speaker terminals shall be installed

by a qualied person, or ready-made leads or cords of

appropriate capacity shall be used.

As the power output channels on ampliers produce high

voltage, do not connect or disconnect speaker cables when

the mains power is on.

3.4.3. Radio interference

A sample of this product has been tested and complies with

the limits for the European Electro Magnetic Compatibility

(EMC) directive. This equipment has also been tested and

found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful

interference from electrical equipment. This product uses

radio frequency energy and if not used or installed in

accordance with these operating instructions, may cause

interference to other equipment, such as radio receivers.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003

du Canada.

However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which

can be determined by turning the equipment on and off, the

user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment to an outlet on a circuit different

from that to which the receiver is connected.

• Check if the affected unit complies with the EMC limits for

immunity, (CE-labeled). If not, address the problem with

the manufacturer or supplier. All electrical products sold

in the EC must be approved for immunity against

electromagnetic elds, high voltage ashes, and radio

interference.

• Consult the dealer or an experienced radio/TV technician

for help.

3.4.4. Speaker damage

Amplier apparatus is very powerful and can be potentially

dangerous to both loudspeakers and humans alike. Many

loudspeakers can be easily damaged or destroyed by

overpowering them. Always check the speaker’s continuous

and peak power capabilities. Although the ampliers

attenuators can be used to reduce the overall gain, an

increase of the input signal can result in full output power,

which may cause damage to connected speakers.

3.4.5. Maintenance

For safe and reliable operation, the dust lters on both sides

of the front panel, behind the grilles, should be removed and

cleaned regularly to ensure maximum airow through the

device.

If the dust lters are not maintained there will be safety

risks; for example, high internal temperatures could ignite

the dust and start a re. There is also a risk that the unit

will malfunction since it is dependent on constant airow

from front to rear. If the dust lters are not clean and the unit

malfunctions, any resulting problems will not be covered by

the warranty.

D SERIES Lake Operation Manual rev 3.0.4

3

Page 4

4. Table of Contents

4. Table of Contents

4. Table of Contents

1. Important safety instructions 2

2. Approvals 2

3. Warnings 2

3.1. Explanation of warning symbols 2

3.2. Warnings 2

3.3. Caution 3

3.4. User responsibility 3

5. Introduction 6

5.1. Welcome 6

5.2. D Series: Two versions available 6

5.3. Feature summary 7

6. Installation 8

6.1. Unpacking 8

6.2. Mounting 9

6.3. Cooling and fan operation 10

6.4. Operating voltage 10

6.5. Grounding 11

7. Product overview 12

7.1. Front panel 12

7.2. Rear panel 13

14

14

8.2. Level Adjustments & Mute Points 14

9. Front panel interface 15

9.1. Frame status and control 15

9.2. Channel status and control 15

9.3. Frame select and ID 16

9.4. Additional front panel operations and indications 17

D SERIES Lake Operation Manual rev 3.0.4

4

Page 5

4. Table of Contents

4. Table of Contents

10. Rear panel interface 18

11. Operation and performance 19

11.1. Operation precautions 19

11.2. Power output performance 19

21

11.4. Power Supply 28

11.5. Auto power down 29

11.6. LoadPilot Load Monitoring 30

12. Lake Processing and Lake Controller 33

12.1. Introduction 33

12.2. Modules and Frames 33

12.3. Lake LoadLibrary™ and Fingerprints 34

12.4. Loudspeaker Processor Overview 34

34

12.6. Frame and System Presets 34

35

13.1. Network setup 35

36

13.3. System setup 37

13.4. Additional Software Reference Material 40

14. Appendix 41

14.1. Faults and warnings 41

14.2. Current draw and thermal dissipation 43

14.3. Maintenance 49

50

16. Warranty and support 54

16.1. General 54

16.2. Technical assistance and service 54

D SERIES Lake Operation Manual rev 3.0.4

5

Page 6

5. Introduction

5. Introduction

5. Introduction

5.1. Welcome

Thank you for choosing the Lab.gruppen D Series for your sound

offered by this product.

For fast installation and use of this product, your welcome package includes a printed copy of the D Series

Quick Start Guide (QSG). It provides a brief introduction to the features and functionality of the D Series and it

also contains the information required to safely install the product and place it in service. Please read through

recommended that you also review all other product documentation to ensure familiarity with the various

5.2. D Series: Two versions available

D Series is an advanced, high–power installation amplifier platform designed for demanding applications, primarily

in performance venues. For the utmost flexibility in processing and networking, the D Series is available in two

versions: the Lake version, with a full slate of Lake processing algorithms, Dante and AES67 audio networking;

and the Tesira by Biamp version for full integration in a Tesira system and with Ethernet AVB audio transport.

D-series Tesira versions are available in three output power levels, whereas the D-series lake versions are available

in six output models. The six Lake power output models come in two form factors. Three high power models in a

standard form factor and three lower powered models in a slimline, single rack unit, form factor.

This operation manual is for use with Lake processing versions only, and applies to models at all six output

power levels. The models D 200:4L, D 120:4L, D 80:4L, D 40:4L, D 20:4L and D 10:4L will further on only

be referred to as D200, D120, D80, D40, D20 and D10.

D SERIES Lake Operation Manual rev 3.0.4

6

Page 7

5. Introduction

5. Introduction

5.3. Feature summary

5.3.1. Features common to both D Series variants

• Four channels with six levels of total available frame power output: 20000 W, 12000 W, 8000 W, 4000 W,

2000 W and 1000 W

• Rational Power Management (RPM)

• True exibility in allocating power output across each channel to match requirements, for more efcient

use of amplier inventory

• Any channel is capable of being signicantly scaled up to match power requirements.

• Dedicated on–board surveillance and load monitoring for voice alarm applications

• Advanced universal power supply

• Regulated Switch–Mode Power Supply (R.SMPS™) maintains stability through uctuations in mains voltage

• Best–in–class Power Factor Correction (PFC)

• Current Draw Modeling (CDM™) reduces peak mains draw

• Breaker Emulation Limiter (BEL™) responds to available mains distribution

• Under–Voltage Limiting (UVL™) allows continued operation through mains voltage drop

• CAFÉ (Conguring Ampliers For the Environment) software incorporates ESP™ (Equipment Specication

Predictor) to assist in design, equipment specication and commissioning

• Features controlled by on–board DSP

• Amplier gain is set in the digital domain and controlled via the Lake Controller software.

• ISVPL™ – The Inter–Sample Voltage Peak Limiter (ISVPL) tailors each channel’s power output to the

characteristics of the connected load

• Load Verication & Performance Monitoring – A comprehensive set of proprietary DSP–based tools

enables load verication and real–time performance monitoring

NOTE: The D200, D120 and D80 models have the possibility to bridge two power outputs to further

increase scalability. This feature is not available on the D40, D20 and D10 models.

5.3.2. Features unique to Lake variant

• Lake’s exclusive classic/linear–phase/FIR speaker processing platform with four throughputs

• Group control with Raised Cosine™ MESA EQ™ asymmetric lters

• LimiterMax™ peak and RMS limiters

• Extensive loudspeaker preset database (Lake LoadLibrary™)

• Comprehensive clocking management system with low latency sample rate conversion

• Full support for Dante Controller

• Multiple and redundant inputs with programmable failover

• Four “Lake Class” analog inputs with Iso–Float™ ground isolation

• Two AES3 digital inputs (4 audio channels)

• Eight dual–redundant Dante network audio inputs with AES67 support

• Comprehensive 3rd party protocol for integration potential with third party matrix systems via purpose–

developed middleware

D SERIES Lake Operation Manual rev 3.0.4

7

Page 8

6. Installation

6. Installation

5.3.3. Other Documentation

This Operation Manual is intended to serve as a guide and reference to the operation and maintenance of the

D Series Lake hardware platform. Comprehensive information is given regarding installation, connection and

operation of the front panel interface.

D Series Lake ampliers are designed for conguration and operation using the Lake Controller and CAFÉ software

programs. This manual includes a brief tutorial on how to put an amplier into service using Lake Controller, and it

also includes an overview of some features that are implemented via CAFÉ.

For complete information on DSP conguration and operation using Lake Controller, please refer to the Lake

Controller Manual, available online at www.labgruppen.com/support.

For detailed information on conguration and operation of the power platform using CAFÉ, please refer to the guide

embedded in the software or to the CAFÉ Coach video series available on the Lab.gruppen YouTube channel or

via a link on the Lab.gruppen web site.

6. Installation

6.1. Unpacking

Carefully open the shipping carton and check for any damage to the device or the supplied accessories. Every

Lab.gruppen product is tested and inspected before leaving the factory and should arrive in perfect condition. If

any damage is discovered, please notify the shipping company immediately. Only the consignee may initiate a

claim with the carrier or their insurers for damage incurred during shipping. Save the carton and packing materials

for the carrier’s inspection.

6.1.1. Included in the box

In addition to the D Series device, the shipping carton includes the following items:

• D Series Lake Quick Start Guide

• AC mains lead (power cable) with Neutrik powerCON connector (D200, D120 and D80) or IEC connector

(D40, D20 and D10) and AC socket plug according to ordering selection

• Rear brackets for additional rear rack support (pair) along with associated mounting hardware

• Connector kit including all needed connectors

• Front grille and dust lter assembly

NOTE: Depending on the model, the connector kit might include more connectors than applicable for

the product you have. Select those connectors required for your unit and application.

Please keep the original carton and associated packaging to facilitate shipping of the device should the need arise.

D SERIES Lake Operation Manual rev 3.0.4

8

Page 9

6. Installation

6. Installation

6.2. Mounting

D Series is made for mounting in 19 inch racks. Four screw holes are available for attachment of the amplier to

the racks front rack rail. This device has no top or bottom vents; therefore, units may be stacked directly on top of

one another. Sufcient space should be available at the rear to accommodate connectors and cables. In addition,

allowance must be made for cable or loom bends within a rack.

6.2.1. Rear Mounting

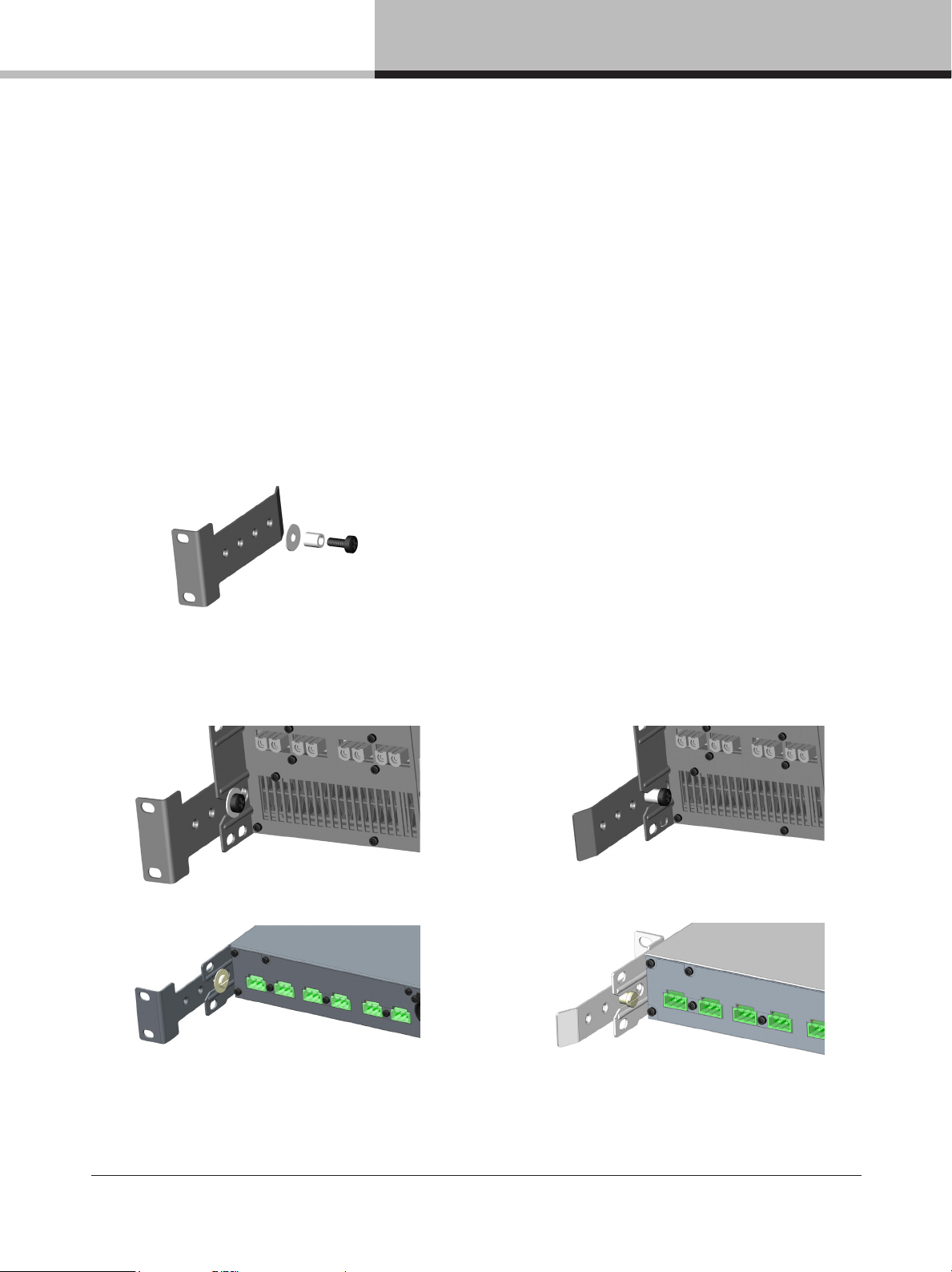

Two rear support brackets, along with associated mounting hardware, are included with the D Series device. It is

strongly recommended that these are used wherever possible. Fit the brackets to the vertical rails at the rear of the

rack. The following diagrams show the tting options for xed and removable installation. The support brackets are

reversible and may be tted to point either to the front or rear of the rack; the proper orientation depends on the

rack depth and position of the rear rack rails.

Figure 6.1: Rear support bracket with

mounting hardware

Figure 6.2: Rear support bracket mounted for Figure 6.3: Rear support bracket mounted for

xed installation and bracket removable installation and bracket

pointing forward pointing towards rear

D SERIES Lake Operation Manual rev 3.0.4

9

Page 10

6. Installation

6. Installation

6.2.2. Mounting front grille

The front grille is shipped on top of the amplier inside the box to protect it during shipping. The front grille adheres

to the amplier with magnets. Hold the front grille with your ngers in each of the side cutouts and slide it gently into

place straight from the front.

6.3. Cooling and fan operation

D Series devices use a forced–air cooling system with airow from front to rear, allowing high continuous power

levels without thermal problems. To facilitate maximum air ow, ensure that no objects such as rack doors or

lids are placed at the front or rear of the rack. Never attempt to reverse the airow. Make sure an adequate air

supply is provided in front of the D Series device, and that the rear of the device has sufcient space to allow

air to escape. It is recommended to keep the ambient temperature around the device as cool as possible. An

increased temperature can have a signicant negative impact on the expected lifetime on the components

inside the D Series device.

NOTE: Always ensure the dust lters behind the detachable front panel are clean to ensure maximum

possible airow. The exterior front panel is held in place by powerful magnets but is easy to detach by

using your ngers in the openings at the each side. To clean the foam lter, detach it from the exterior

front and gently use a vacuum cleaner or gently shake it. Remount with the opposite procedure. Never

operate the amplier without the dust lter installed.

NOTE: Fit solid blanks (not ventilation blanks) to unused rack spaces to ensure effective air circulation. Leaving

gaps in between items of equipment degrades the effectiveness of forced–air cooling.

If installing one or more D Series devices in a rack with other fan–cooled equipment, conrm that all other

equipment also uses front–to–rear airow for cooling. If this precaution is not observed, there is a risk of

overheating, as units with the reverse airow will be drawing in air which has already been heated by the

D Series devices.

The D Series device is equipped with a sophisticated temperature sensing system which protects it from any

overheating which may occur as a result of inadequate ventilation.

6.4. Operating voltage

D Series has a universal power supply and its mains nominal and operating voltages are specied in the Technical

Specications. D Series can be ordered with a variety of mains plugs. If the mains plug (AC plug) tted to the mains

cable (AC cord) is not appropriate for your country it can be removed and a locally–sourced one tted instead. If

you are not 100% condent of your competence to replace the mains plug (AC plug), the task should be carried

out by qualied personnel.

NOTE: In–rush current is controlled and limited during the soft–start sequence. This enables multiple D

Series Devices on the same AC mains circuit to be turned on simultaneously.

D SERIES Lake Operation Manual rev 3.0.4

10

Page 11

6. Installation

6. Installation

6.4.1. Low voltage country considerations

Although the D Series has a wide range of operating mains voltage, some considerations can be applicable for

low voltage regions. D Series performs well throughout the specied nominal voltage range but has slightly better

efciency at higher voltages. For regions with nominal voltage below 140 V, one could consider connecting the

amplier in a three phase delta or two phase split-phase conguration, especially applicable for the bigger models,

(D200, D120 and D80).

NOTE: Following connections applicable only for resulting voltage inside the ampliers nominal voltage

range.

Connecting the amplier in three phase delta conguration

In three–phase conguration where the phases are 120 degrees apart, one can connect three balanced loads in a

delta conguration. The connection is made between the phases instead of between the neutral and a phase.

208V

120V

L1

Amp

L2

Amp

L1 L2

N N

Amp

120V

L3

120V

208V

Amp

Amp

Amp

208V

L3

3 phase Y 120V

3 phase delta 208V

Figure 6:4: Three phase delta conguration

Connecting the amplier in a split phase conguration

In two phase split–phase conguration there are two phases separated by 180 degrees. Connecting between the

phases gives double the line voltage.

100V 100V 200V

Amp

L1

Split phase 100V

Amp

L2N

L1 L2

Amp

N

Split phase 200V

Figure 6.5: Two phase split–phase conguration

6.5. Grounding

D Series must be grounded (earthed) with the safety ground pin to the mains distribution system. NEVER

disconnect the earth (ground) pin on the mains cable (AC power cord). Use correctly-shielded balanced audio

input connections to minimize hum and interference.

D SERIES Lake Operation Manual rev 3.0.4

11

Page 12

7. Product overview

7. Product overview

7. Product overview

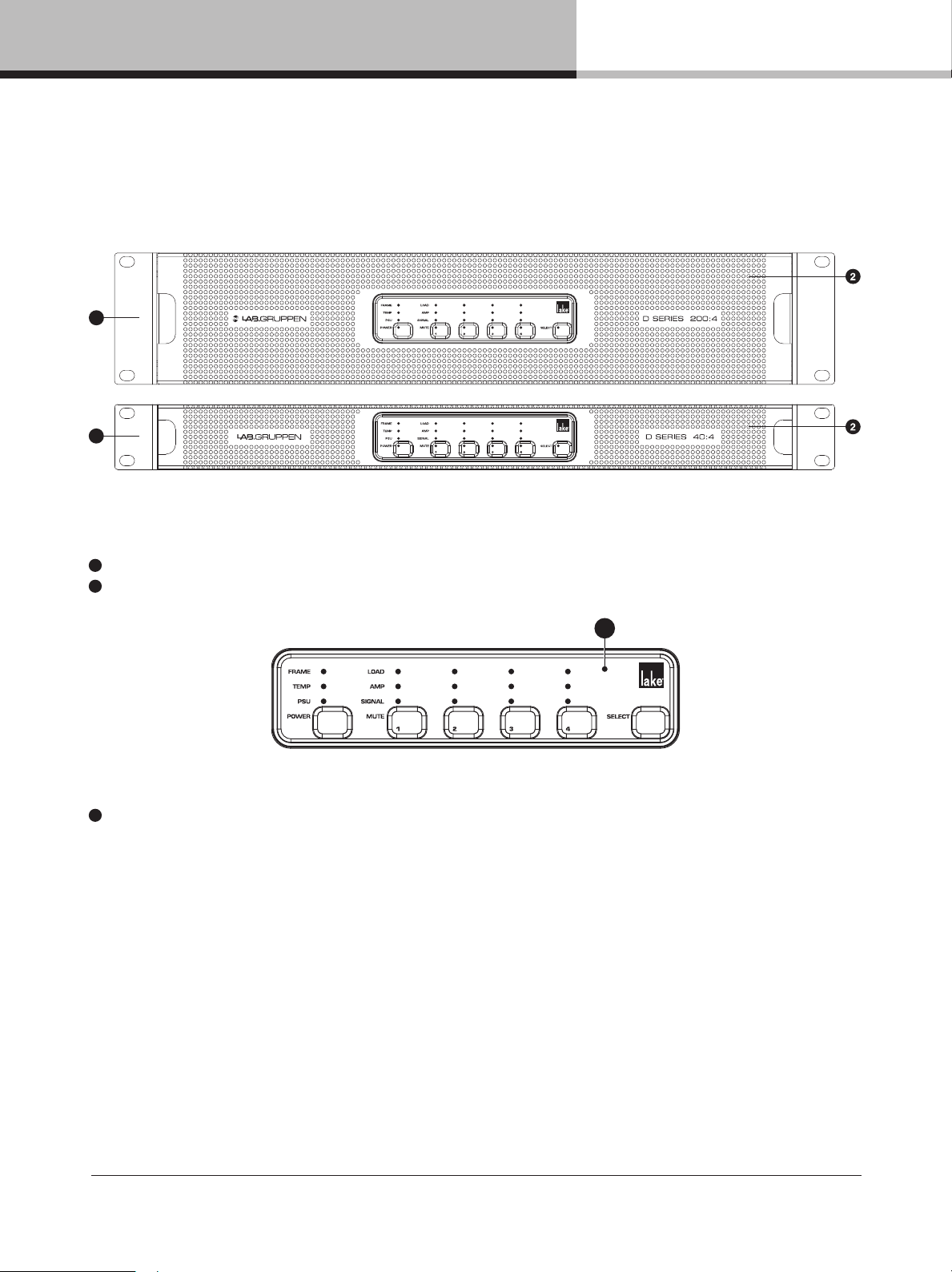

7.1. Front panel

1

1

The front panel consists of an outer front with air intake and a centered user interface. The user interface has LEDs

for monitoring and six recessed touch buttons for control.

1

Rack ears for 19 inch rack mount

2

Exterior front grille (also air intake and dust lter holder)

3

3

Touch and LED panel – See section 9.1 for further information.

D SERIES Lake Operation Manual rev 3.0.4

12

Page 13

7. Product overview

7. Product overview

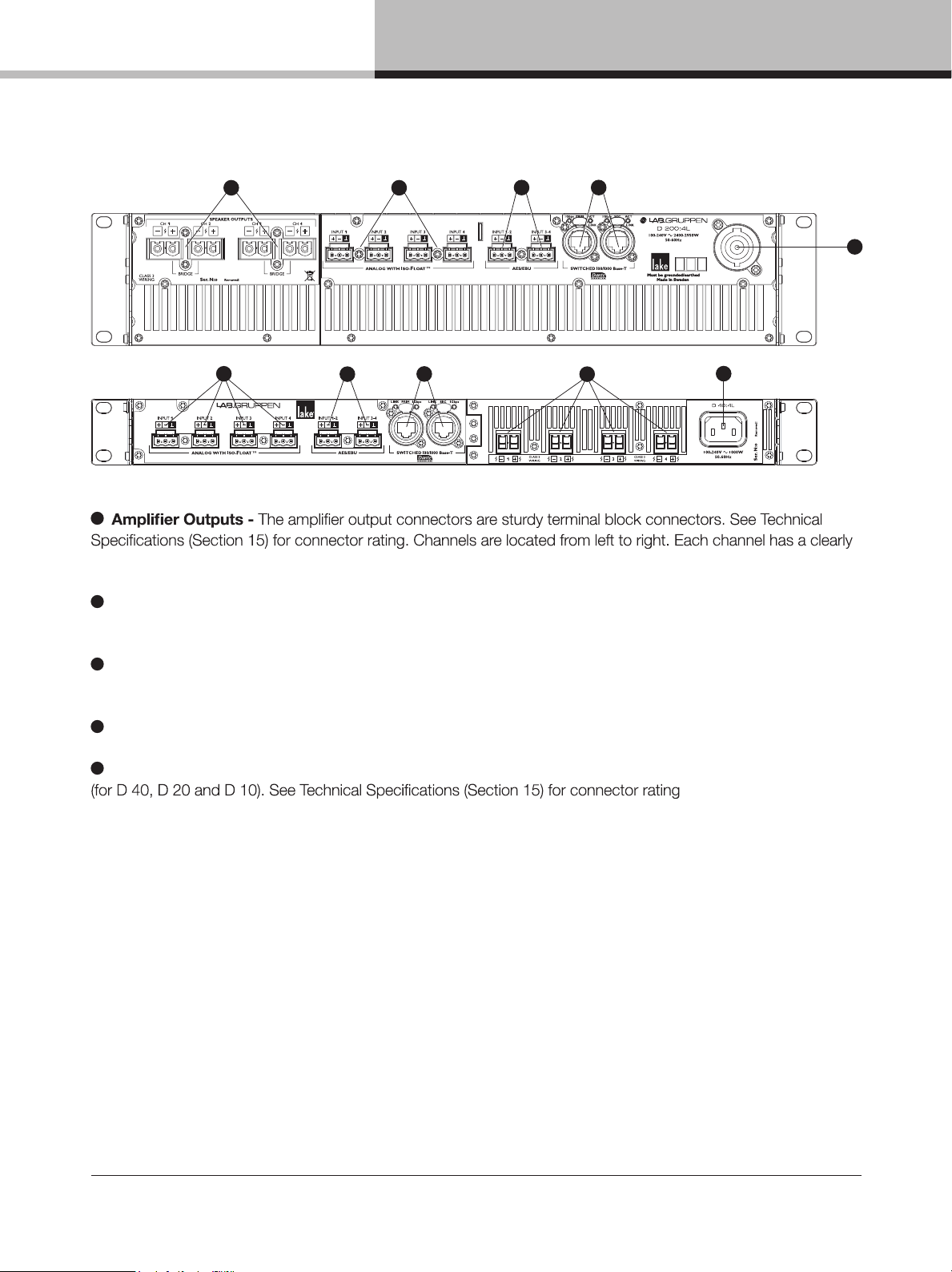

7.2. Rear panel

1

1 2

2

3

3 4

4

1

5

marked hot (+) and cold (-) terminal

2

Analog Inputs - Analog inputs are available on terminal block connectors with clearly marked hot (+), cold (-)

and ground terminals

5

3

AES3 Inputs - AES3 inputs are available on terminal block connectors with clearly marked hot (+), cold (-)

and ground terminals

4

RJ-45 Ethernet connectors for control, Dante and AES67 digital audio network

5

Mains connector - Detachable Neutrik powerCON (for D 200, D 120 and D 80) or locking IEC connector

D SERIES Lake Operation Manual rev 3.0.4

13

Page 14

8. Signal flow, routing and mute points

7. Product overview

8. Signal flow, routing and mute points

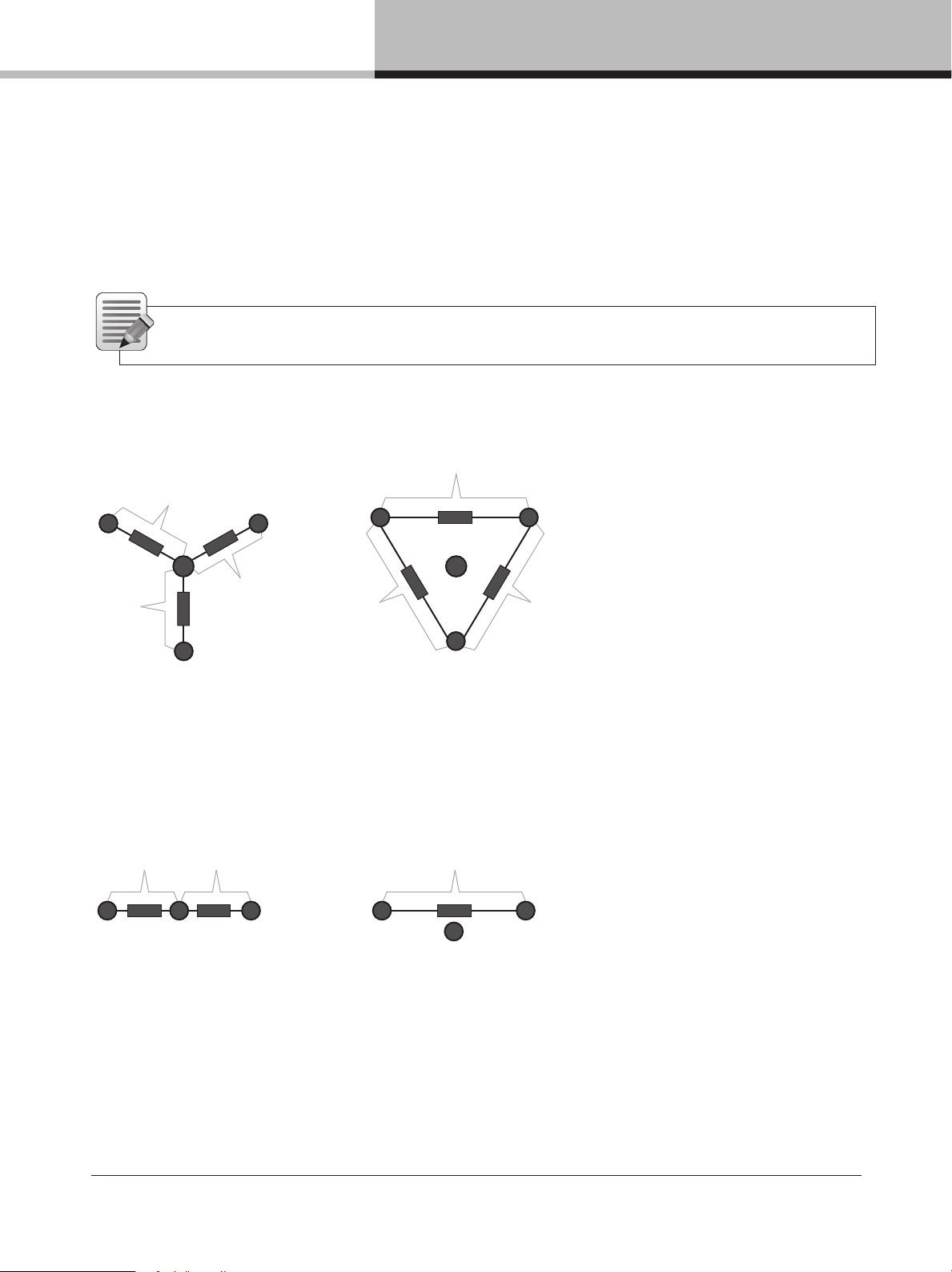

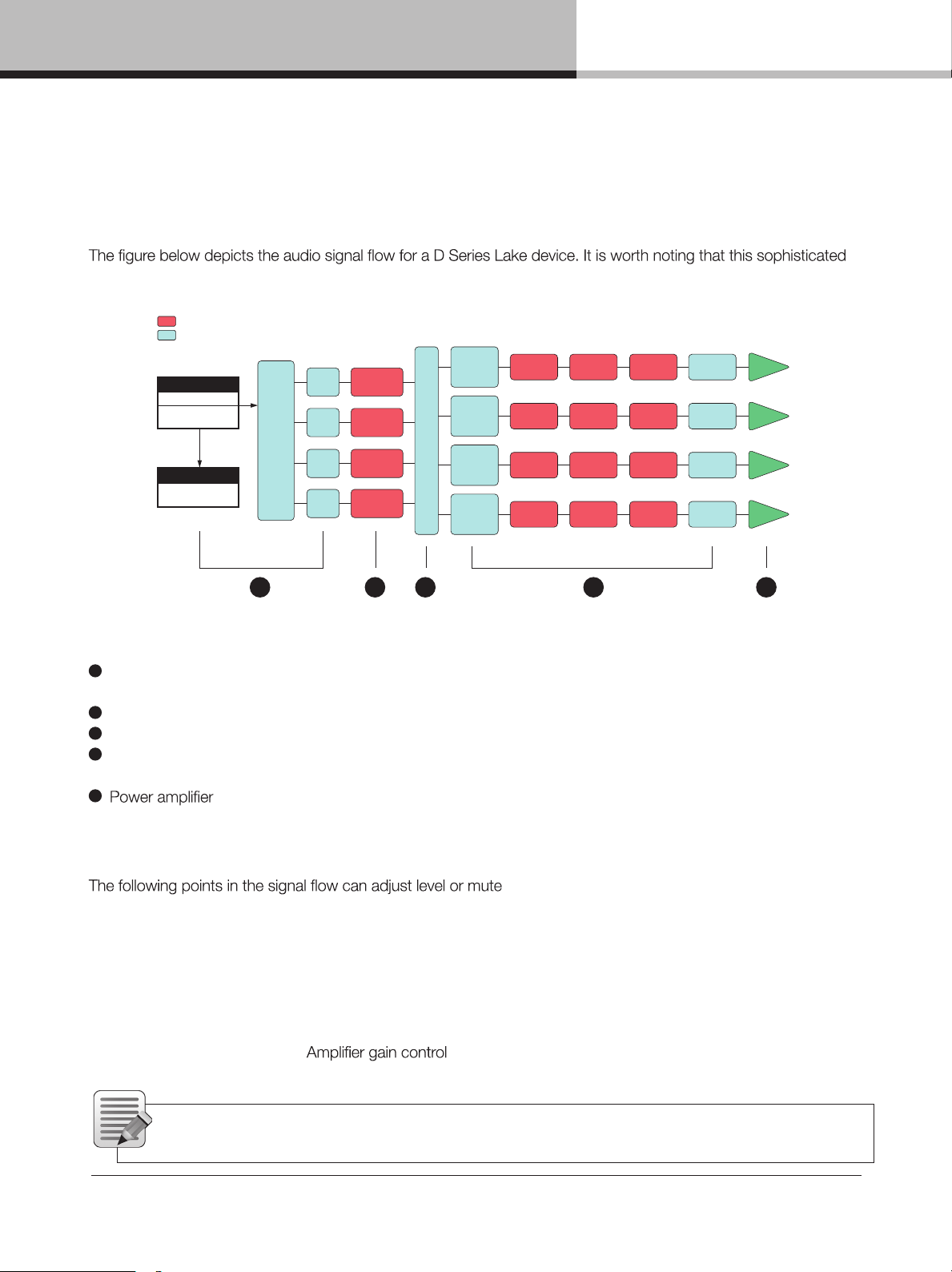

8.1. Signal flow

device provides seven points in the signal chain where the signal level can be adjusted, muted or disconnected.

Module Data stored in Module FIles (Speaker Presets)

Frame Data stored in System Files and Frame Presets

Dante Receivers 1-8

Dante Receivers/AES/

Analog pass through to

Dante/AES67

INPUTS

AES 1-4

Analog 1-4

OUTPUTS

Dante 1-8

(no mutes)

Input

Routers

1-4

WITH

INPUT

MUTES

Input

Mixer A

Input

Mixer B

Input

Mixer C

Input

Mixer D

Lake Contour

Module A

Lake Contour

Module B

Lake Contour

Module C*

Lake Contour

Module D*

Attenuator

Phase Rev

Custom RPM

Attenuator

Phase Rev

Custom RPM

Attenuator

Output Routing

Phase Rev

Custom RPM

Attenuator

Phase Rev

Custom RPM

Mute

Mute

Mute

Mute

ISVPL

Auto RPM

ISVPL

Auto RPM

ISVPL

Auto RPM

ISVPL

Auto RPM

Amp Gain LoadSmart LoadPilot AMP

Amp Gain LoadSmart LoadPilot AMP

Amp Gain LoadSmart LoadPilot AMP

Amp Gain LoadSmart LoadPilot AMP

1 2 43 5

Figure 8.1: D Series Lake Signal Flow Diagram

1

The input section (inputs, input router and input mixer) allows for mixing capabilities as well as redundant and

prioritized inputs with automatic switch-over in case of signal failure

2

Up to four Lake Processing modules provide user EQ and loudspeaker processing, including LimiterMax limiting

3

The Output router allows free routing between module outputs and power output channels

4

Each power output channel provides individual channel processing, including ISVPL limiter, RPM and

load monitoring

5

8.2. Level Adjustments & Mute Points

the signal:

1 Input Router Stage Input selection and MUTE

2 Input Mixer Stage Router on /off connection to mixer and gain settings

3 Module Input Stage Mute and gain settings

4 Module Output Stage Mute and gain settings

5 Output Router Stage Output on /off routing connections

6 Attenuation Stage Power output channel mute and attenuation settings

7 Amp Gain Stage

NOTE: If the required audio signal is not passing correctly, verify the connection, mute and gain settings

at all seven stages.

D SERIES Lake Operation Manual rev 3.0.4

14

Page 15

9. Front panel interface

9. Front panel interface

9. Front panel interface

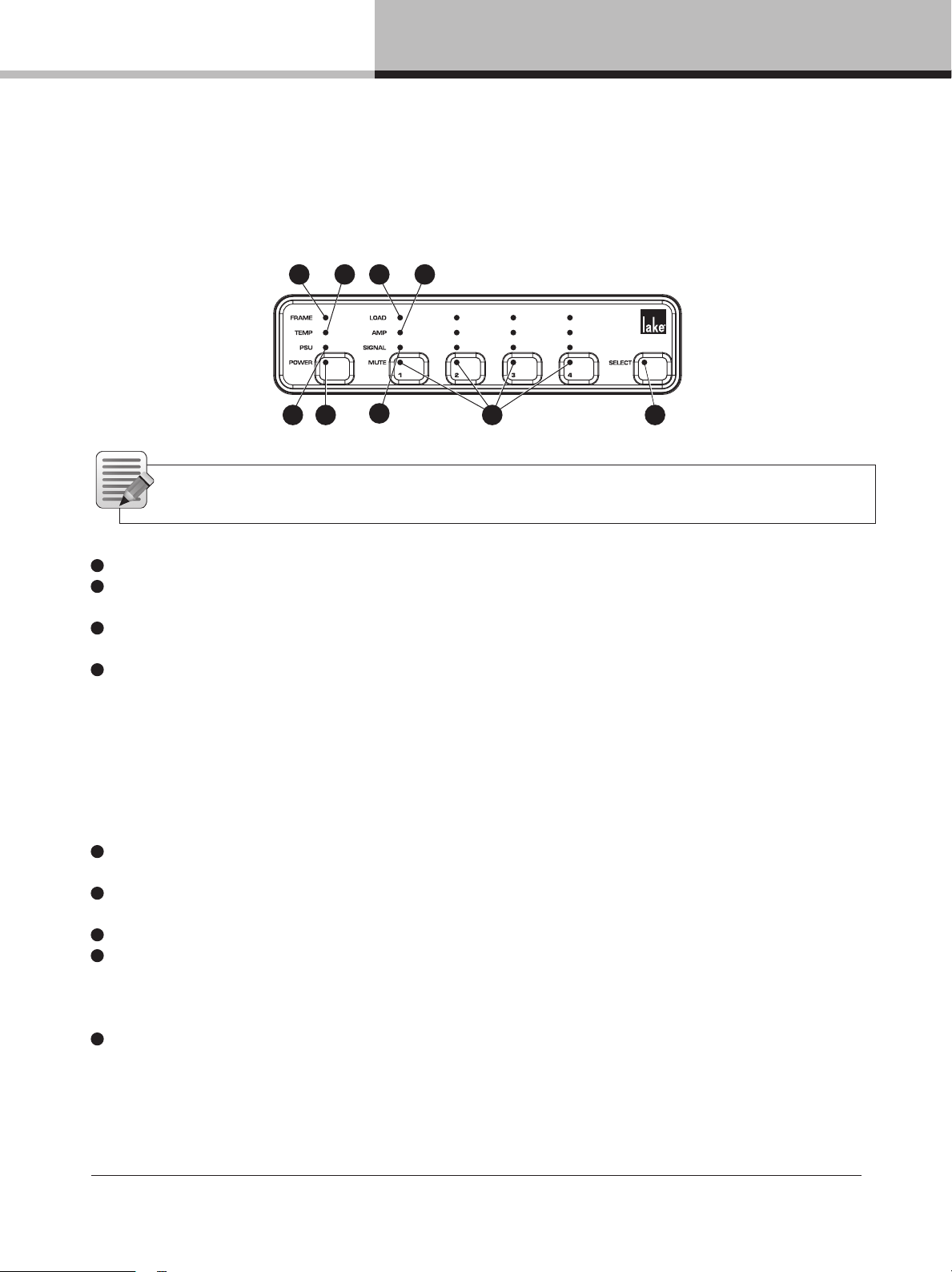

9.1. Frame status and control

1 2 5 6

43

NOTE: General status indication shown in Table 9.1. For detailed information on warning and fault

indication, please refer to the Faults and Warnings table in Section 14.1.

1

FRAME LED – Provides status indication for a number functions affecting the amplier frame

2

TEMP LED – Provides status indication for internal temperatures sensed at multiple points, including power

supply, DSP and output channels

3

PSU LED – Provides status indication on functionality of Power Supply Unit and mains supply, including under–

and over–voltage, power supply faults, and unstable mains supply

4

POWER LED and TOUCH BUTTON – Provides power state indication and control. Press and hold button to

toggle the amplier between ON and STANDBY state. LED indication given in Table 9.1.

7

8

9

9.2. Channel status and control

5

LOAD LED – Provides load related status indication for monitoring functionality of LoadSmart and LoadPilot.

Warnings and faults indicate problems or anomalies detected in the connected loudspeakers and/or cabling

6

AMP LED – Provides amplier related status indication, including faults and warnings related to temperature,

over–current, clipping and very high frequency

7

SIGNAL LED – Provides signal related status indication, including no signal and input signal clipping

8

MUTE LED and TOUCH BUTTON – Provides mute status indication and control. The LED is indicating

both Lake mutes and power channel mute. A single touch on the mute button toggles the power channel mute

between mute and unmuted states

9

SELECT LED and TOUCH BUTTON – for selection and indication control between computer software and unit

D SERIES Lake Operation Manual rev 3.0.4

15

Page 16

9. Front panel interface

9. Front panel interface

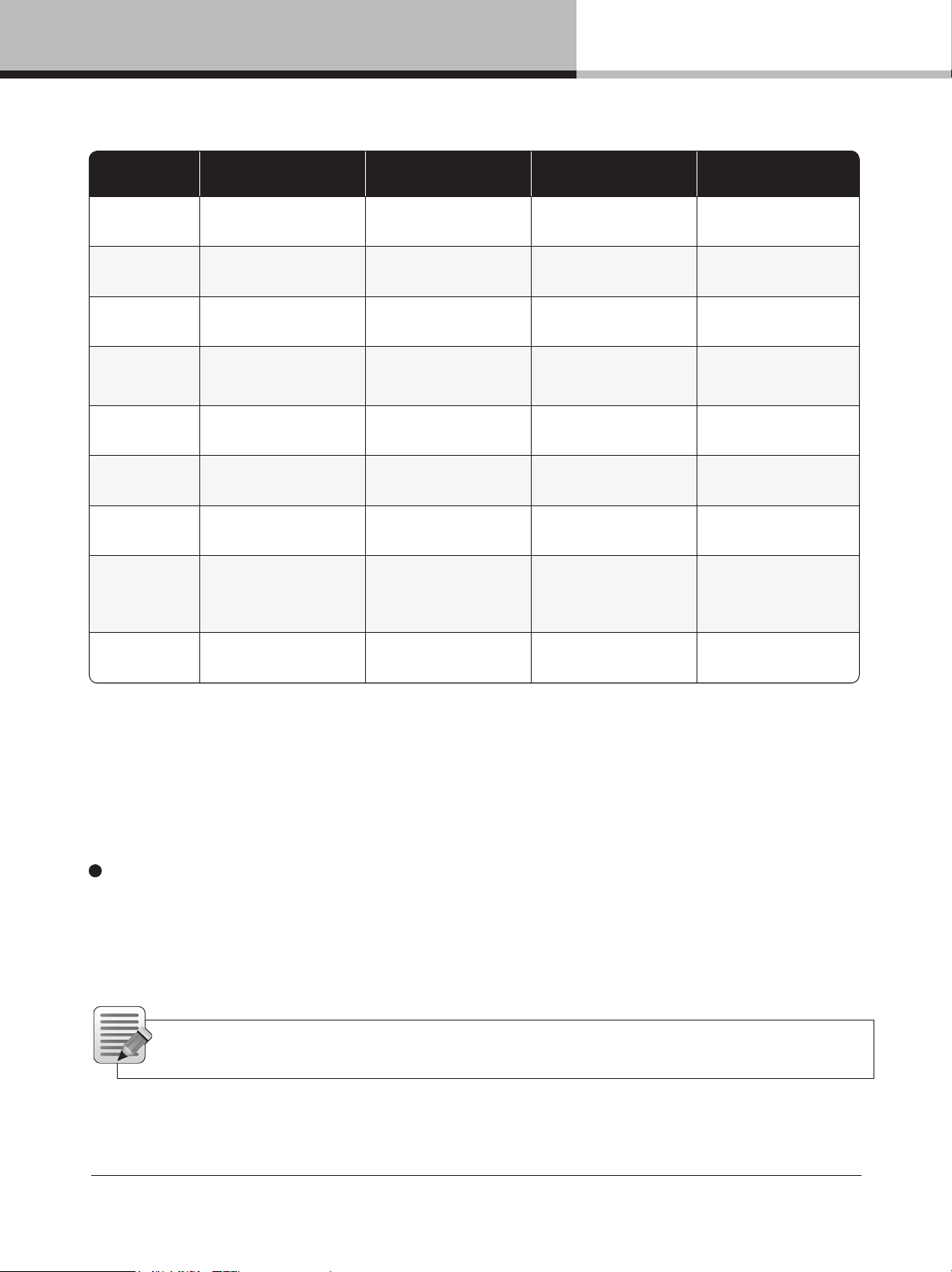

OFF Green Amber Red

Frame

N/A Frame OK Frame warning Frame fault

Tem p

N/A Te mp OK Temp warning Temp fault

PSU

N/A PS U OK

Power supply/

Mains warning

Power supply/

Mains fault

Power

No mains power

Fixed:ON

Blinking: Turning ON

Button pressed.

Hold for transition

Fixed: STANDBY

Blinking: Turning to

STANDBY

Load

No LoadPilot active

LoadPilot active

and LoadOK

Load warning Load fault

Amp

N/A Power channel OK Power channel warning Power channel fault

Signal

Output below signal

present threshold (–60 dB)

Output above signal

present threshold (–60 dB) input clip (–2 dB) or limit/ fault active

Mute

Inactive channel in

bridge operation

Unmuted

Lake module is muting the

signal chain at either input

router, module input or

module output

Power channel muted

Select

Frame not selected Frame selected Waiting for more touches N/A

Input signal approaching Input signal clip

Tabl e 9.1: LED/category chart

9.3. Frame select and ID

9

SELECT LED and TOUCH BUTTON – Selects mode and indicates control between computer software and

unit. A single touch on the button will select the unit in supported computer software views. Multiple consecutive

touches will select the corresponding Lake module (one touch for module A, 2 for module B etc.). In the other

direction, when selecting the unit in a supported computer software view, the LED will indicate the unit is selecte d

with steady green illumination.

NOTE: The touch buttons use capacitive touch technology and might be sensitive to large temperature

and humidity variations.

D SERIES Lake Operation Manual rev 3.0.4

16

Page 17

9. Front panel interface

9. Front panel interface

9.4. Additional front panel operations and indications

9.4.1. Frame reset

A factory reset and soft reset can be performed from the front panel. A factory reset will restore all settings to

original defaults, including network settings, frame presets and current settings. A soft reset reverts only the current

settings to default. Network settings and frame presets are not changed with a soft reset.

6. Place the frame in standby mode.

7. Press and hold Select and channel 3 mute button. Then press the power button.

8. User interface will illuminate available options. Choose from the options below

a. Press channel 1 mute button (red LED) to initiate the factory reset sequence.

b. Press channel 2 mute button (amber LED) to initiate the soft reset sequence.

c. To cancel, press channel 4 mute button (green LED).

9. Wait state indication is present while either reset is performed.

10. To complete the factory reset process, cycle the mains power by completely removing the power plug and

reinserting it.

9.4.2. Wait indication

Wait indication is displayed when the frame is performing an operation. All LEDs except power are unlit and a

circling amber light is displayed on channels 1 and 2.

9.4.3. Power cycle required indication

After an operation that requires a subsequent power cycle to complete, the power LED blinks alternately red and

green. A Power cycle requires that the mains is completely removed from the device and not connected again

until the device has powered off.

9.4.4. Front panel lock

The front panel can be disabled from the Lake Controller. When the front panel is disabled, LEDs 4, 8 and 9

(all buttons on the lowest row) flash in amber when hitting any touch button.

D SERIES Lake Operation Manual rev 3.0.4

17

Page 18

10. Rear panel interface

10. Rear panel interface

10. Rear panel interface

1

nnect loudspeaker

cables to the mating plug–in connectors observing polarity (including bridge mode option for D200, D120

and D80) as marked on the rear panel

2

Analog Inputs – Analog inputs are available on terminal block connectors with clearly marked hot (+), cold (–)

and ground terminals. The inputs are electronically balanced and feature Lake Iso–Float circuitry

3

AES3 Inputs – AES3 inputs are available on terminal block connectors with clearly marked hot (+), cold (–) and

ground terminals

4

RJ–45 Ethernet connectors

accept either mating etherCON connector or a standard RJ–45 connector.

1 2

2

3

for control, Dante and AES67 digital audio network. Neutrik etherCON connectors

3 4

5

4

1

5

Primary Network Connector – The primary connection provides integration into an Ethernet control network

which may include other Lake Processors and the Lake Controller software. Network connection permits full

control of all functions along with real–time metering from a remote position.

This device supports the Dante audio networking protocol, which allows transmission of multichannel, high–

definition digitial audio over the same Ethernet connection. AES67 audio flows are also supported.

Use the primary connector when using a star network topology, consisting of individual Cat–5e connections

between the devices and an Ethernet switch. Alternatively this connection can be used to daisy chain directly

to another Lake Processor. The daisy chain topology should not be used with Dante.

Additional information is also available in the Lake Network Co

NOTE: The Ethernet ports operate at the Ethernet data rate of up to 1 Gbps and allow straight or

crossed network cables. LEDs above each port indicate network activity (ACT) and Gigabit network

connections (Gbps). If Gbps LED is unlit, speed is 100 Mbps.

D SERIES Lake Operation Manual rev 3.0.4

18

Page 19

11. Operation and performance

11. Operation and performance

Secondary Connector – The secondary network connector can be used to create a Dante dual–network

topology by connecting all secondary network connectors to a separate Ethernet switch, ensuring full

redundancy in the event of a network component failure. Alternatively, the secondary network connector can be

used to daisy–chain multiple Lake devices (LM, PLM, PLM+ or D Series), if Dual Redundancy is Disabled from

the Lake Controller. When the device is in Dual Redundancy , it is possible to connect a Lake Controller to the

Secondary Connector as long as the IP address on the computer is on the 172.31.x.x subnet.

If the device has dual redundancy enabled, any AES67 audio must be on the primary network (i.e. AES67

cannot be transmitted or received on the secondary connector).

ed via Lake Controller. See the Lake Controller Operation Manual for further details.

NOTE: When connecting multiple devices to an Ethernet network, care must be taken NOT to create a

closed loop which causes network malfunction.

5

Mains connector – Detachable Neutrik powerCON (for D 200/120/80) or locking I EC c onnector (D 40/20/10).

For more information, please refer to Section 6.4.

11. Operation and performance

11.1. Operation precautions

Make sure that the Standby button on the unit’s f r ont panel is either unlit (OFF), or red ( STANDBY), before making

any input or output connections. Ensure the AC voltage is within the range printed on the label adjacent to the AC

mains connector. Ensure no input signal is present when powering on the unit to reduce the risk of any inadvertent

bursts of high level audio.

11.2. Power output performance

The standard form factor D Series units (D200, D120 and D80) uses Lab.gruppen’s patented Class TD

purity of Class A/B designs. The slimline D Series units (D40, D20 and D10) uses a newly developed Class D:

perfectly under all load conditions and the output maintains it

with very low nominal impedances. Reliability is very high, and there is no interference with nearby RF equipment.

D SERIES Lake Operation Manual rev 3.0.4

19

Page 20

11. Operation and performance

11. Operation and performance

Load Impedance (ohms)

2 ohms

(per channel)

2.67 ohms

(per channel)

4 ohms

(per channel)

8 ohms

(per channel)

16 ohms

(per channel)

Hi-Z 70 V

(per channel)

Hi-Z 100 V

(per channel)

D 200:4L 4400 W 500 0 W 4400 W 2300 W 1150 W 3300 W 4700 W

D 120:4L 300 0 W 3000 W 3000 W 1900 W 950 W 3000 W 3000 W

D 80:4L 2000 W 2000 W 2000 W 1500 W 750 W 2000 W 2000 W

D 40:4L 800 W 1000 W 1000 W 1000 W 700 W 1000 W 1000 W

D 20:4L 500 W 500 W 500 W 500 W 425 W 500 W 250 W

D 10:4L 250 W 250 W 250 W 250 W 250 W 250 W 175 W

11.2.1. Symmetrical power

D Series models can deliver power as shown in Table 11.1 when all channels are driven equally.

Table 11.1: Symmetrical Load Power Ratings

11.2.2. Rational Power Management™

Rational Power Management™ (RPM) is a unique Lab.gruppen feature that allows for exible allocation of power

across channels of a D Series unit. Power that is not used by one output channel is free for use by another output

channel with greater demands. Unique to this series is that all models in the range have amplier channels that can

produce higher outputs than the average 25% of the total power, see the Technical Specications for the maximum

single channel power capacity. RPM automatically allocates power up to the total limits of the specic amplier

model and helps minimize unused power in the installation.

RMS voltage; and also the speaker’s AES power rating. By specifying the nominal impedance of the load, the RPM

algorithms have all input data required to calculate resulting RPM settings. If the desired RPM settings results in a

total power output higher

of delivering the

is performed with the ISVPL limiter algorithm. As default the R

the channels at a voltage (default voltage limitation) given in

in two modes.

er; peak and Via the CAFÉ Software, desired

reduction in dB. Once applied, the RPM functionality will ensure that all channels are capable

D SERIES Lake Operation Manual rev 3.0.4

20

Page 21

11. Operation and performance

2000 W

11. Operation and performance

LOW

Figure 11.2: Amp channels power adjusted to match the loudspeaker requirements on a D 80:4

Auto RPM: The frame will automatically allocate power per output channel according to the ISVPL settings in the

speaker preset (per module output) in Lake Controller. Auto RPM assumes a nominal impedance of the Load and

applies an approximate power allocation. Auto RPM is default for D Series Lake.

MIDSUB

HIGH

Custom RPM: The CAFÉ software allows users to create an advanced custom power allocation scheme.

Switching to Custom mode disables the Automatic mode. Additional information is available in documentation

supplied with the CAFÉ software download.

Custom RPM using CAFÈ with ESP: CAFÉ (Conguring Ampliers For the Environment) is a dedicated software

application for Windows and OSX that provides tools for system planning, specication and commissioning. CAFÉ

incorporates the Equipment Specication Predictor (ESP), a software module that examines SPL and speaker

requirements for a project and generates requirements for output power on an amplier and system level. ESP will

generate a custom RPM conguration optimizing the power allocation within the frame. For more information on

CAFÉ and ESP, please consult the documentation supplied with the CAFÉ software download.

11.3. Amplifier and Load Protection Systems

The D Series is equipped with a comprehensive set of protection circuits. If operating conditions become

sufciently extreme that any of these circuits become active, indication is provided by amber or red LEDs on the

front panel, and by text notications in the Lake Controller and CAFÉ software. Refer to Section 14.1 for more

information on warnings and faults.

D SERIES Lake Operation Manual rev 3.0.4

21

Page 22

11. Operation and performance

11. Operation and performance

11.3.1. Inter–Sample Voltage Peak Limiter (ISVPL)

The ISVPL is a high quality voltage limiter that can deliver seamless limitation to any desired level. It ensures that

the voltage at the output terminals never exceeds the dened threshold. It operates on these principles:

• The signal is delayed slightly to allow the ISVPL to look–ahead and reduce the gain before voltage in excess

of the threshold can appear at the output. This results in zero voltage overshoot at the output with a rounded

limitation up to the threshold.

• The amplitude of the output signal between digital samples is predicted which permits the ISVPL to respond to

analog peaks that may occur at the digital to analog converter.

• The release time of gain reduction is adaptive depending on the dynamics of the signal. It is possible to select

different ISVPL proles for limiting optimization for a specic frequency band and personal preference. The

proles are divided into two categories, with one category optimized for low distortion and the other focusing

on producing high sound pressure level (SPL). Within each category there are proles optimized for the different

frequency bands.

11.3.1.1. Low Distortion Profiles

• Universal – The universal prole is a soft limiter that can be used for all frequencies and is conservative in its

action upon VCL and CPL.

• Sub/LF – The Sub/LF prole is tuned for frequency bands below 600 Hz. It has longer attack and release times

and is less conservative when it comes to acting upon VCL and CPL.

11.3.1.2. High SPL Profiles

High SPL proles do not use the adaptive release time feature. High SPL proles optimized for high frequencies

use less of the look–ahead delay peak–rounding feature; this feature is used most in the Sub prole and least the

HF prole.

• Sub – The Sub prole is optimized for frequencies between 20 – 200 Hz

• LF – The LF prole is optimized for frequencies between 20 – 1200 Hz

• MF – The MF prole is optimized for frequencies between 300 – 6000 Hz

• HF – The HF prole is optimized for frequencies above 1 kHz

11.3.1.3. ISVPL Voltage Settings

The ISVPL threshold may be set at any level between 17.8 V and 600 V in the Lake Controller software. For further

details, please refer to the Lake Controller User Manual.

Lake–enabled amplier devices (D Series Lake, PLM+, PLM) that have a smaller peak output voltage capability still

allow ISVPL speaker threshold settings up to 600 V. When a threshold is set above the current maximum capability

of a power output channel, the actual ISVPL will automatically be set to the maximum ISVPL for that channel.

Therefore, the ISVPL threshold can be set at the Module for the speaker’s maximum capability, and the Module le

remains cross–compatible with all Lake–enabled amplier devices.

Table 11.3 shows the theoretical maximum output power based on only the load impedance and

the ISVPL setting. See the Technical Specications, or use CAFÉ, to nd the available power for a specic

amplier and load.

D SERIES Lake Operation Manual rev 3.0.4

22

Page 23

11. Operation and performance

Max. Sinewave Burst Power (Watts)

LLoad Impedance (ohms)

2 2.67 4 8 16

LISVPL SETTING (V peak)

194 4489 5993 4705 2352 1176

193 4489 5993 4656 2328 116 4

181 4489 5993 4095 2048 1024

167 4489 5223 3486 1743 872

153 4489 4384 2926 1463 732

121 3660 274 2 1830 915 458

101 2550 1910 1275 638 319

83 1722 1290 861 431 215

70 1225 918 613 306 153

56 784 587 392 196 98

47 552 414 276 13 8 69

38 361 270 181 9 0 45

17.8 79 59 40 20 10

Table 11.3: ISVPL–to–output examples

11. Operation and performance

11.3.2. Current Peak Limiter (CPL)

The output Current Peak Limiter (CPL) ensures that the power output section will not be damaged by forcing it to

deliver current levels at the outputs that exceed the maximum current ratings of the output transistors. The CPL

keeps the output transistors within their Safe Operating Area (SOA). The CPL is non–adjustable.

This condition indicates an attempt to draw excessive current at the output. The output is attenuated until the

output current falls below the maximum current rating. Limiting is performed by the ISVPL limiter in conjunction

with the selected ISVPL prole.

CPL activity is shown by amber or red indication on Amp LED of the affected output channel and a corresponding

text description in Lake Controller and CAFÉ software programs. Refer to Section 14.1 for more information on

warnings and faults.

NOTE: If excessive current is indicated, check the output cables and examine the loudspeaker. If

impedance appears normal, you may rectify the condition by altering the ISVPL settings or lowering

input levels. CPL indication can be triggered by excessively low load impedance, possibly the result of

too many loudspeaker cabinets connected in parallel.

11.3.3. Power Average Limiter (PAL)

The Power Average Limiter Active warning (PAL Active) will be displayed when the power supply is operating at the

maximum average input power allowed for the PSU design. When this warning is displayed, gain limiting is being

applied to the signal by a lowering of the ISVPL threshold.

D SERIES Lake Operation Manual rev 3.0.4

23

Page 24

11. Operation and performance

11. Operation and performance

PAL activity is shown by PSU amber LED indication and a corresponding text description in Lake Controller and

CAFÉ software programs. Refer to Section 14.1 for more information on warnings and faults.

11.3.4. Breaker Emulation Limiter (BEL™)

The BEL models the temperature in the external breaker and limits the mains current to prevent the breaker

be selected for Frame Replace support). The desired nominal current value can be set from 1 to 32 Arms. The

resulting

models

the

•

•

allows current above the threshold to pass for a short time, leading to an increased modeled temperature. For

the limiter to disengage, the current must reduce below the threshold to enable the breaker to cool down.

•

momentarily allows current above the threshold for a longer time, leading to an increased modeled temperature.

ed current for the breaker to cool down.

is set above, or bellow, the model’s capabilities, the actual current is automatically adjusted into

:

predict the current consumption, with the exact speaker requirements, and propose a safeguarding

11.3.5. Under Voltage Limiter (UVL™)

The larger D Series devices (not D 20:4L and D 10:4L) are equipped with an under voltage limiter. W ith multiple,

powerful devices on a mains distribution line, heavy current loads risk the reduction of voltage below that

required for devices to function. The UVL reduces the mains current draw when voltage drops below 80 V.

The amount of reduction applied increases as mains voltage drops towards 65 V; at 65 V the power supply is

automatically restarts.

11.3.6. Current Average Limiter (CAL™)

The Current Average Limiter (CAL) monitors the RMS current drawn from each power output channel to ensure

that the power output stages are not overloaded. When activated, it regulates the current to a safe level to

protect the channel. The CAL should not be activated in normal usage. If activated, this is shown by amber or red

indication on the Amp LED of the affected output channel and a corresponding text description in Lake Controller

and CAFÉ software programs. Refer to Section 14.1 for more information on warnings and faults

D SERIES Lake Operation Manual rev 3.0.4

24

Page 25

11. Operation and performance

11. Operation and performance

NOTE: For Slimeline models, to optimize the CAL’s behavior when playing into a low

impedance load, manually set the desired ISVPL to reflect the real peak voltage

output to allow for a higher average current.

11.3.7. Voltage Clip Limiter (VCL)

If current draw from the unit’s power supply is too high, the PSU’s regulation capability may be exceeded and

the internal voltage rails may drop and cause clipping. If this occurs, the VCL acts rapidly to prevent clipping on

the subsequent peaks. Limiting is performed by the ISVPL limite

Indication of this condition is shown on the output LEDs. Refer to Section 14.1 for more information on warnings

and faults.

11.3.8. Temperature Protection

D Series devices are equipped with a sophisticated temperature sensing system that provides protection

from overheating which may occur as a result of inadequate ventilation or excessive power output. Thermal

measurements are made at several points within each power output channel along with measurements in

operate continuously, with the highest possible output, and prevent shutting down. If temperature in any area

reaches a critical level, a warning is displayed. The warning is issued at approximately 80% of the maximum

allowable temperature. If the temperature continues to increase, a limiter (ATL or PTL) is engaged that limits signal

peaks to reduce further heat accumulation. Limiting is accomplished by gradual reduction of the ISVPL thresholds.

In the extreme case where the limiter cannot reduce heat accumulation and temperature reaches a

dangerous level, a fault is displayed and audio is muted.

Each power output channel, the power supply, and DSP area have separate indications. For all temperature faults,

temperature monitoring will continue at 0.5 second intervals, with the output remaining muted. When the area has

cooled below the dangerous threshold, the fault condition is cleared and audio is restored.

11.3.8.1. Power Output Channels

A power output channel temperature warning or fault is indicated by the Amp LED for that channel and the Temp

LED for the frame.

• A warning is indicated by a static amber LED

•

• A fault is indicated with a static red LED

An event report is sent to the Lake Controller software for both the warning and the fault. If a temperature fault

condition arises on a power channel, the output of that channel will be muted.

D SERIES Lake Operation Manual rev 3.0.4

25

Page 26

11. Operation and performance

11. Operation and performance

channel Temperature Limiter (ATL) will engage at approximately 95% of the maximum allowable temperature.

When ATL is engaged, it will try to reduce the power output to avoid that the amp channel goes into temp fault,

i.e. muting. Limiting is removed when temperature falls below the ATL threshold.

11.3.8.2. Power Supply / DSP

A power supply (PSU) or DSP temperature warning or fault is indicated by the Temp LED.

• A warning is indicated by static amber LEDs

• Power supply Temperature Limit (PTL) is indicated by an amber LED

• A fault is indicated with static red LEDs

If the power supply temperature keeps rising after reaching the temperature warning threshold, the Power supply

Temperature Limiter (PTL) will engage at approximately 95% of the maximum allowable temperature. When PTL

i.e. muting of all channels. Limiting is removed when the temperature falls below the PTL threshold.

11.3.9. DC Protection

The DC protection is implemented, individually, on each power output to prevent damage to connected

loudspeakers or any D Series components. DC present at the output will cause the unit’s power output module

breaker to blow, causing a permanent hardware fault that prevents signal throughput. In this instance the channel’s

Amp LED will illuminate red and a service channel fault will be registered in the Lake Controller and CAFÉ status

views (D200, D120, D80 only). For the D40, D20 and D10, no audio will be heard from the outputs.

NOTE: A blown breaker in the power output module is not a user serviceable fault condition and the

unit should be returned for repair.

11.3.10. VHF Protection

The D Series includes protection circuits that detect Very High Frequency (VHF) content in the input signal. The

detection is amplitude–, frequency– and time–dependent. It is initiated from 10 kHz upwards and, if continuous

VHF signals are detected above the threshold for more than the attack time, the output for a D200, D120 and

D80 will attenuate the gain until the signal is below the VHF threshold. When this is done, VHF Warning is

displayed. If the signal is above the VHF threshold and the maximum of -12 dB of gain reduction is not enough

to take the signal below the VHF threshold, the signal will mute after 15 seconds, and retest the signal after

6 seconds. Note that the D40, D20 and D10 will go directly to mute upon VHF detection. When continues

normal operation.

This protection system recognizes only continuous VHF signals at high levels that will not appear in speech or

music. Any such content can therefore be considered as a fault condition. VHF protection is essential to avoid

damage to HF drivers. VHF protection is dependent on a combination of output power level and frequency.

Figure 11.4 shows a decreasing power threshold, from approximately 10 kHz upwards, which illustrates increasing

sensitivity of the protection system with frequency. When continuous output power above the threshold line is

detected, VHF protection becomes active.

D SERIES Lake Operation Manual rev 3.0.4

26

Page 27

11. Operation and performance

11. Operation and performance

100

90

80

70

60

50

40

30

Voltage [Vrms]

20

10

0

0 5

Trigger voltage

10 15 20 25 30

Frequency [kHz]

Fig 11.4: VHF Protection Frequency Sensitivity

The attack time of the VHF protection circuitry also changes with frequency, becoming shorter at higher

frequencies. This is shown in Figure 11.5.

Full output voltage

1400

1200

1000

800

600

Time [ms]

400

20

200

0

0 5

10 15 20 25 30

Frequency [kHz]

Fig 11.5: VHF Protection Attack Time Variations

The VHF pr

solely to detect

continuous VHF content. HF content of normal music or speech signals at peak levels will be passed in full.

Operation of the VHF protection circuits is indicated by the channel’s AMP LED that will illuminate yellow and

display VHF Warning when the max of -12 dB of gain reduction is applied (only applicable for D200, D120

and D80) and light red for a VHF FAULT. Both of these will be registered in the Lake Controller and CAFÉ

status views.

11.3.11. Short Circuit Protection

A low impedance or short circuit at the power output terminals is detected when the output current is high (Current

Peak Limiter is active) and, simultaneously, the peak output voltage is below a predetermined threshold. When this

situation occurs, the output stage is muted to protect it from damage.

Operation of the short circuit protection system is indicated by Amp channel LED showing steady red and a

corresponding text description will register in Lake Controller and CAFÉ software programs. Refer to Section 14.1

for more information on warnings and faults.

D SERIES Lake Operation Manual rev 3.0.4

27

Page 28

11. Operation and performance

11. Operation and performance

The presence of a short circuit (or low impedance) is re–tested every six seconds, and the output remains muted

until the fault clears.

11.3.12. Power supply protection

The power supply is very advanced and has several internal control and monitoring functions. Should any of these

fail, the power supply will shut down to prevent damage or limit severity of the failure. If the power supply shuts

down audio will be muted. Power supply faults, or power supply needs service faults, are indicated by a red LED

and associated error messages registered in Lake Controller and CAFÉ software programs.

In the extreme event of simultaneous low mains voltage supply and high power demand, the amount of incoming

condition is a power protect fault, indicated with a red LED and associated error messages registered in Lake

Controller and CAFÉ software programs.

11.3.12.1. Mains anomaly protection

supply will then be forced to shut down. This

mains service.

Over–voltage – If the power supply detects mains voltage above 400 V peak or 270 V RMS, it will enter protective

associated error messages will register in Lake Controller and CAFÉ software programs.

Under–voltage – If the power supply detects mains voltage of less than 65 V, it will enter protective shut down

mode. The amplifier will auto– restart if the condition clears. Will be indicated by a red LED and associated error

messages will register in Lake Controller and CAFÉ software programs.

Mains instability – If the power supply detects protracted instability in the AC mains, it will enter protective

shut down mode (D 200:4L, D 120:4L and D 80:4L only). The ampli

Will be indicated by a red LED and associated error messages will register in Lake Controller and CAFÉ

software programs.

Mains glitch – If the power supply detects a momentary mains glitch (missing cycles) at the AC inlet, a warning

indication will be reported with a yellow LED and associated error messages will register in Lake Controller and

CAFÉ software programs (D 200:4L, D 120:4L and D 80:4L only). The powers supply and product continue

operation throughout a mains glitch.

11.4. Power Supply

The R.SMPS (Regulated Switch Mode Power Supply) is designed to keep supply voltage rails at optimum levels.

Thus the R.SMPS can deliver full rail voltage to the output sta

consistent transient response and a clean LF response.

D SERIES Lake Operation Manual rev 3.0.4

28

Page 29

11. Operation and performance

11. Operation and performance

D Series features a universal power supply with power factor correction (PFC). The device can accept any mains

voltage, from 65 V to 265 V, allowing it to function worldwide in many different congurations. The PFC reduces

current peaks on the lines and reduces the requirements placed on the mains distribution system. D Series units

offer an unparalleled power factor extremely close to one.

11.4.1. Low Inrush Current

High power ampliers with inadequate inrush current limiting can draw considerable current from the mains at

turn–on, sometimes tripping a fast–acting mains breaker. The D Series, however, has very low inrush current to

prevent tripping of breakers. Several units can, under normal conditions, be powered up simultaneously. If you

do experience problems powering up multiple units simultaneously, they must either be turned on manually in an

ordered manner, or sequenced remotely using the Lake Controller software’s Global Control feature. Alternatively,

the capacity of the mains supply should be increased.

NOTE: If insufcient power is available to allow simultaneous power–up, then there is probably

insufcient capacity for full power output during operation. It is recommended that additional capacity is

added to the mains power distribution system.

11.4.2. Adaptive rail control

The D Series slimline models have Adaptive rail control available in Performance (default) and Green mode.

In Green mode, this feature further increase the slimline models green credentials by lowering the idle

consumption. This is achieved by lowering power supply’s supply voltage, to the

raised,

to allow for full power outtake, as soon as the signal returns. This feature is user controlled via the

Lake Controller, where it can be turned on or off.

11.5. Auto power down

The D Series models have been equipped with a Auto Power Down function. If Auto Power Down is enabled,

user-defined

audio passing and there is no user interaction via the Lake Controller, CAFÉ or 3rd party controllers.

When the

the frame will turn on again.

NOTE: There is no Auto Power On feature on the return of signal, the device will need to be actively

turned on after entering the standby mode via the Auto Power Down feature. This can be done from

the network via the Lake Controller or the 3rd party protocol or via the front panel button.

D SERIES Lake Operation Manual rev 3.0.4

29

Page 30

11. Operation and performance

11. Operation and performance

11.6. LoadPilot Load Monitoring

11.6.1. Introduction

LoadPilot is a feature in D Series ampliers that can continually monitor the integrity of loudspeakers and cables

connected to the outputs to ensure that they are functioning properly and free from major anomalies or faults.

By implementing LoadPilot, systems incorporating D Series ampliers can be certied in compliance with voice

evacuation standards such as EN54–16 and NFPA72.

LoadPilot functions by automatically superimposing low–level pilot tones on the input signal (if any present) to the

amplier. One tone is below the range of human hearing (approximately 10–20 Hz) and the other above (24 kHz),

so the activity of LoadPilot is inaudible regardless of whether the system is currently reproducing program content.

High–resolution current sensing on the outputs can calculate the impedance of the load at the frequency of the

tones. Hence a stable measurement of the impedance of the load can be obtained and potential anomalies or

faults can be detected that would indicate impaired loudspeaker function or total inoperability due to failure of the

loudspeaker or faults in connected wiring. The superimposition of pilot tones and analysis is interleaved across the

amplier’s output channels with a maximum total cycle time of around 20 seconds.

LoadPilot is implemented and congured in the CAFÉ software. Monitoring status and fault indication are displayed

on the front panel and both in CAFÉ and Lake Controller.

LoadPilot may be congured with the automatic calibration or through a manual advanced mode, depending on

monitoring requirements and characteristics of the connected loudspeaker loads.

11.6.2. Automatic calibration

11.6.2.1. Functional description

Automatic calibration is suitable for the following applications and requirements for error detection:

• If one or two low–impedance loudspeakers are connected; if two in parallel is default, it will warn if one is

missing.

• If there are one or two “spurs” with 70V loudspeakers connected; if two in parallel is default, it will warn if one

is missing.

• If there is a short circuit in the load.

• If there is an open circuit (all loudspeakers missing).

• For passive 2– and 3–way loudspeakers, if one or two LF drivers are connected and working; if two in parallel

is default, it will warn if one is missing.

• For some passive 2–way designs, if one HF driver is disconnected. (However, with some loudspeakers the

HF impedance is dominated by a passive component i.e. crossover lter and the anomaly will not be detected.)

NOTE: LoadPilot is enabled only when the amplier is On. It does not function while the amplier is in

Standby.

D SERIES Lake Operation Manual rev 3.0.4

30

Page 31

11. Operation and performance

11. Operation and performance

11.6.3. Manual configuration

11.6.3.1. Functional description

Manual conguration can be used in special cases where proper functioning requires setting of custom

measurement frequencies, custom measurement levels, custom warning thresholds, or combinations of the three.

Manual conguration addresses the following issues:

Speakers with non stable impedance – For the LoadPilot feature to function the load itself needs to have a

stable impedance at the frequency of the tone. Resonances in the speaker or other non linear phenomenons can

make the impedance at a certain frequency unstable. Stability needs to be veried by examining the impedance

response to make sure it is relatively at at the tone frequencies and by verifying LoadPilot readings when playing

signal through the speaker at the most extreme expected level. The frequency of the pilot tones can be changed

within certain ranges and a tone can be disabled. If a frequency where the speaker is stable can not be found one

tone can be disabled and LoadPilot relies solely on the remaining tone.

High noise levels – To obtain accurate impedance measurements, it is necessary to drive a current sufciently

above the noise oor. However, it is important to keep the level low in order to prevent audible artifacts from cone

travel. At very high impedances, the drive current may be insufcient. In the automatic mode, level is set around 60

mV which produces usable results for impedance up to 660 ohms.

Inductance in loudspeaker cables – Loudspeaker cable inductance at higher frequencies is very high relative to

passive resistance, and the inductance increases linearly with length. Consequently, monitoring at the 24 kHz pilot

tone frequency can be problematic with very long cables. The automatic mode will estimate cable impedance for

24 kHz and allow it to be used as long as it is less than 33% of total impedance presented by the load and as long

as the total impedance is below about 440 ohms.

DC blocking capacitors in loudspeakers – Some loudspeakers incorporate a capacitor designed to block

damaging voltages at very low frequencies. This may inhibit accurate measurements when using the 10 Hz pilot

tone. In automatic mode, LoadPilot will disable the 10 Hz tone if total impedance is above about 440 ohms.

Constant voltage loudspeakers – Loudspeakers driven via transformers in 70V/100V solutions are more likely

to exhibit wide variations in measured impedance as music and/or pilot tones are reproduced by the system. Also,

most constant voltage systems operate more than two loudspeakers in parallel. Therefore, in addition to manual

conguration of LoadPilot, additional step may be required. These include:

• Insertion of a series capacitor in each loudspeaker to block the 10 Hz LF tone – This will defeat measuring the

loudspeakers with the LF tone, but will allow the LF tone to propagate through the entire cable run.

• Insertion of EOL (end–of–line) resistors – This enables LoadPilot to detect cable faults in a spur of the system.

• Insertion of EOL (end–of–line) inductor – This is not mandatory, but it will avoid the loss of level at mid and high

frequencies due to the EOL resistor.

NOTE: Manual conguration of LoadPilot is implemented in CAFÉ versions 1.1.0. and later. For detailed

information on manual conguration of LoadPilot, please refer to the integrated guide in the software

program and to the CAFÉ Coach videos posted on the Lab.gruppen web site and on the Lab.gruppen

channel on YouTube.

D SERIES Lake Operation Manual rev 3.0.4

31

Page 32

11. Operation and performance

12. Lake Processing and Lake Controller

11.6.4. Indication

The LoadPilot feature constantly monitors the impedances at the two given pilot tone frequencies and compares to

the measured thresholds. The following faults and warnings can be triggered.

• Speaker shorted warning – Both tones below lower threshold. Corresponds to a distant short circuit that can

either be in the cabling or in the speaker.

• Speaker damaged warning – One of the tones is below or above thresholds. Corresponds to an unexpected

impedance deviation of one of the tones, most likely a damage to the speaker.

• Under speaker count warning – Both tones above upper threshold. Corresponds to an impedance increase

across the impedance response and most likely a loss of speaker(s) in a parallel speaker connection.

•

corresponding to loss of the load.

• Short circuit fault – LoadPilot analysis below short circuit threshold.

11.7. Audio over Ethernet

D Series Lake devices include Dante and AES67 digital audio networking as standard. Utilizing the latest

advances in Ethernet technology, Dante offers simplified system configuration and extremely low latency while

delivering very high quality uncompressed digital audio across the Lake network. The Zen™ automatic configuration feature enables plug-and-play setup without third-party DHCP or DNS servers. Dante is compatible with

high-bandwidth networks, allowing large numbers of audio channels to be distributed alongside control and

analyzer data.

AES67 is a new open standard making it possible connect more devices together and share audio.

The D Series Lake also have a feature to convert between AES67 and Dante, and can accordingly work as a

bridge between the two different network protocols. It can input 8 channels of AES67 and transmit them out

again as 8 Dante channels or vice versa and in any combination of Dante and AES67 channels.

The D Series Lake support 8 x 8 Inputs and Outputs on Dante/AES67. The networked audio channels' inputs are

routed to the Dante receivers and are shared between both Dante and AES67. The total number of networked

audio inputs available is 8 (Dante + AES67).

On the output side, the device has 8 channels in total – and it is possible to configure the channel as Dante only

(Unicast or Multicast) or have it as an AES67 flow as well. Up to 8 channels can be included in an AES67

transmit flow.

In order for the device to be able to input networked audio, “Dante” must be enabled in Lake Controller.

See Lake Controller Operation Manual for further details.

11.7.1. Dante

D Series devices support dual redundant inputs and outputs on Dante, in either 48 or 96 kHz, with receive

latency as low as 0.25 ms and up to 5 ms.

Dante devices and channels can be given “friendly” names, meaning audio can be routed without having to use

or remember complex numbers.

Dante channels can be routed in both Dante Controller or in Lake Controller.

D SERIES Lake Operation Manual rev 3.0.4

32

Page 33

12. Lake Processing and Lake Controller

11.7.2. AES67

When the device is in AES67 enable mode, the device is in 48 kHz only (also for Dante

subscriptions/transmissions). The receiver latency for AES67 subscriptions is 2 ms. Transmission flows are

Multicast only.

AES67 subscriptions can only be configured in Dante Controller. The AES67 transmitter must support the SAP

(Session Announcement Protocol). This is one of four device discovery methods referenced in the AES67

standard. Check if the transmitting non-Dante AES67 device supports SAP. Otherwise Dante Controller cannot

discover the audio flows coming from the device. Dante devices support SAP if their AES67 mode is enabled.

Multicast IP addresses must be in the range of 239.69.0.0 - 239.69.255.255. If dual redundancy is enabled on

the device, the AES67 flow only works on the primary network. It is still possible to utilize Dante on primary and

secondary networks at the same time, as an AES67 flow is present on the primary.

12. Lake Processing and Lake Controller

12. Lake Processing and Lake Controller

12.1. Introduction

D Series Lake integrates seamlessly into the Lake Processing environment, providing all features, functionality and

connectivity associated with all Lake Processors. The internal Lake Processing, which includes programmable

crossovers, EQ, dynamics and other functions, is fully controllable via Lake Controller software with a version

number of v6.3 for D 200:4L, D 120:4L and D 80:4L, v6.5.0 for D 20:4L and D 10:4L and v6.5.1 for D 40:4L.

All models are compatible with newer versions of the Lake Controller.

both available on www.labgruppen.com. Also, additional documentation is available from the Start Menu after

software installation.

12.2. Modules and Frames

A Frame represents one physical Lake Processor device (e.g. a D 200:4L). A maximum of four Modules are

contained within each Frame; these are referred to as Module A, B, C and D. The number of Modules shown in a

ed as a Classic Crossover (Bessel, Butterworth, Linkwitz–Riley), as a Linear Phase

Contour Classic 1 Way (CL1–Way) Output Modules, providing a total of four Module outputs that can be routed

to any of the four power outputs, but default is one to one (input 1 -> output 1 etc.). Please refer to the Lake

Controller Operation Manual for further information.

D SERIES Lake Operation Manual rev 3.0.4

33

Page 34

12. Lake Processing and Lake Controller

12. Lake Processing and Lake Controller