A

Guide

To

Freeze

Drying

for the

Laboratory

An Industry Service Publication

2

Foreword

Introduction

This booklet has been developed to serve as a basic

guide to the freeze drying process. The information

presented is generic in nature and is the result of

research and experience by Labconco personnel and

users of freeze drying equipment. It is our intention to

provide a non-biased review of preparation techniques

and freeze drying methods. The purpose of this booklet is

to help you make an informed choice of equipment for

your laboratory applications.

Our Method

We begin our discussion of freeze drying for the

laboratory by examining the three steps in the process:

prefreezing, primary drying and secondary drying. Next,

we examine a typical freeze drying cycle and the methods

available to facilitate the freeze drying process using

equipment designed for use by laboratories. Finally,

suggestions to optimize successful results are discussed,

including determination of end point, contamination,

backfilling of dried samples and product stability.

A glossary of terms used throughout this booklet to

explain the freeze drying process follows the text, along

with a bibliography.

applications for many years, most commonly in the food

and pharmaceutical industries. There are, however, many

other uses for the process including heat-sensitive

sample preparation, plant material research, the

stabilization of living materials such as microbial

cultures, long term storage of HPLC samples,

preservation of whole animal specimens for museum

display, restoration of books and other items damaged by

water, and the concentration and recovery of reaction

products.

conditions conducive to the freeze drying process. This

equipment is currently available and can accommodate

freeze drying of materials from laboratory scale projects

to industrial production.

solvent from a frozen product by a process called

sublimation. Sublimation occurs when a frozen liquid

goes directly to the gaseous state without passing

through the liquid phase. In contrast, drying at ambient

temperatures from the liquid phase usually results in

changes in the product, and may be suitable only for

some materials. However, in freeze drying, the material

does not go through the liquid phase, and it allows the

preparation of a stable product that is easy to use and

aesthetic in appearance.

freeze dried products do not need refrigeration, and

can be stored at ambient temperatures. Because the cost

of the specialized equipment required for freeze drying

can be substantial, the process may appear to be an

expensive undertaking. However, savings realized by

stabilizing an otherwise unstable product at ambient

temperatures, thus eliminating the need for

refrigeration, more than compensate for the investment

in freeze drying equipment.

Freeze drying has been used in a number of

Specialized equipment is required to create the

Freeze drying involves the removal of water or other

The advantages of freeze drying are obvious. Properly

3

Principles of Freeze Drying

Solid

Phase

Liquid

Phase

Va

por

Phase

F

U

S

I

O

N

L

I

N

E

V

A

P

O

R

I

Z

A

T

I

O

N

L

I

N

E

S

U

B

L

I

M

A

T

I

O

N

L

I

N

E

CRITICAL

POINT

TRIPLE

POINT

A

B

C

D

PRESSURE

TEMPERATURE

prefreezing, primary drying, and secondary drying.

from the solid phase to the gaseous phase, material to be

freeze dried must first be adequately prefrozen. The

method of prefreezing and the final temperature of the

frozen product can affect the ability to successfully freeze

dry the material.

preserving structures to be examined microscopically,

but resulting in a product that is more difficult to

freeze dry. Slower cooling results in larger ice crystals

and less restrictive channels in the matrix during the

drying process.

makeup of the product. The majority of products that are

subjected to freeze drying consist primarily of water, the

solvent, and the materials dissolved or suspended in the

water, the solute. Most samples that are to be freeze dried

are eutectics which are a mixture of substances that

freeze at lower temperatures than the surrounding water.

When the aqueous suspension is cooled, changes occur

in the solute concentrations of the product matrix. And

as cooling proceeds, the water is separated from the

solutes as it changes to ice, creating more concentrated

areas of solute. These pockets of concentrated materials

have a lower freezing temperature than the water.

Although a product may appear to be frozen because of

all the ice present, in actuality it is not completely frozen

until all of the solute in the suspension is frozen. The

mixture of various concentration of solutes with the

solvent constitutes the eutectic of the suspension. Only

when all of the eutectic mixture is frozen is the

suspension properly frozen. This is called the eutectic

temperature.

product to below the eutectic temperature before

beginning the freeze drying process. Small pockets of

unfrozen material remaining in the product expand

and compromise the structural stability of the freeze

dried product.

undergoes glass formation during the freezing process.

Instead of forming eutectics, the entire suspension

becomes increasingly viscous as the temperature is

lowered. Finally the product freezes at the glass

transition point forming a vitreous solid. This type of

product is extremely difficult to freeze dry.

to freeze dry a frozen suspension. While these factors can

be discussed independently, it must be remembered that

they interact in a dynamic system, and it is this delicate

balance between these factors that results in a properly

freeze dried product.

established in which ice can be removed from the frozen

product via sublimation, resulting in a dry, structurally

intact product. This requires very careful control of the

two parameters, temperature and pressure, involved in

the freeze drying system. The rate of sublimation of ice

from a frozen product depends upon the difference in

The freeze drying process consists of three stages:

Prefreezing: Since freeze drying is a change in state

Rapid cooling results in small ice crystals, useful in

Products freeze in two ways, depending on the

It is very important in freeze drying to prefreeze the

The second type of frozen product is a suspension that

Primary drying: Several factors can affect the ability

After prefreezing the product, conditions must be

4

vapor pressure of the product compared to the vapor

pressure of the ice collector. Molecules migrate from the

higher pressure sample to a lower pressure area. Since

vapor pressure is related to temperature, it is necessary

that the product temperature is warmer than the cold

trap (ice collector) temperature. It is extremely

important that the temperature at which a product is

freeze dried is balanced between the temperature that

maintains the frozen integrity of the product and the

temperature that maximizes the vapor pressure of the

product. This balance is key to optimum drying. The

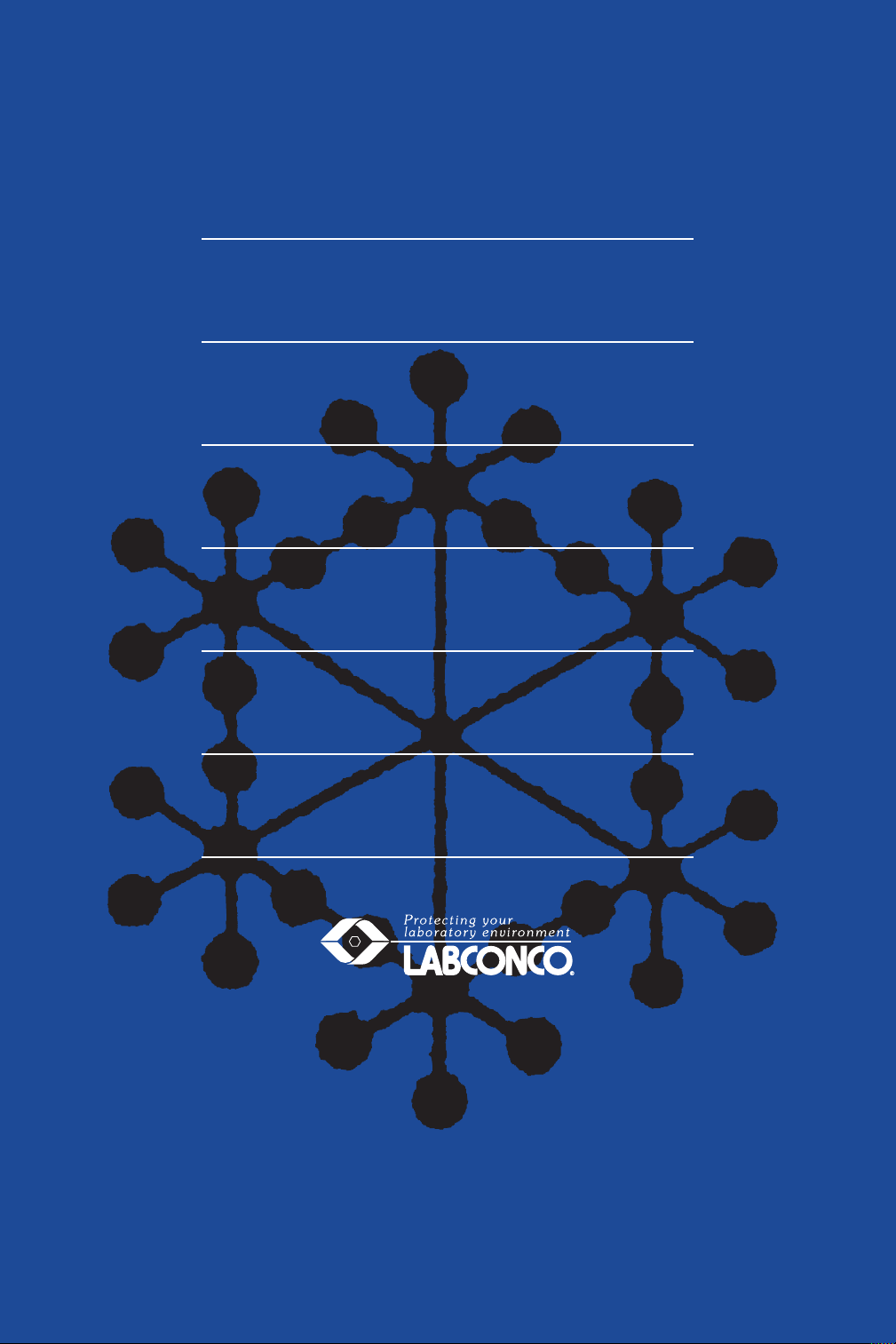

typical phase diagram shown in Figure 1 illustrates this

point. Most products are frozen well below their eutectic

or glass transition point (Point A), and then the

temperature is raised to just below this critical

temperature (Point B) and they are subjected to a

reduced pressure. At this point the freeze drying process

is started.

Figure 1

A typical phase diagram.

Some products such as aqueous sucrose solutions can

undergo structural changes during the drying process

resulting in a phenomenon known as collapse. Although

the product is frozen below its eutectic temperature,

warming during the freeze drying process can affect the

structure of the frozen matrix at the boundary of the

drying front. This results in a collapse of the structural

matrix. To prevent collapse of products containing

A vacuum pump is essential to evacuate the

environment around the product to be freeze dried.

sucrose, the product temperature must remain below a

critical collapse temperature during primary drying. The

collapse temperature for sucrose is -32° C.

No matter what type of freeze drying system is used,

conditions must be created to encourage the free flow of

water molecules from the product. Therefore, a vacuum

pump is an essential component of a freeze drying

system, and is used to lower the pressure of the

environment around the product (to Point C). The other

essential component is a collecting system, which is a

cold trap used to collect the moisture that leaves the

frozen product. The collector condenses out all

condensable gases, i.e; the water molecules, and the

vacuum pump removes all non-condensable gases.

The collecting system acts as a cold trap to collect

moisture leaving the frozen product.

It is important to understand that the vapor pressure

of the product forces the sublimation of the water vapor

molecules from the frozen product matrix to the

collector. The molecules have a natural affinity to move

toward the collector because its vapor pressure is lower

than that of the product. Therefore, the collector

temperature (Point D) must be significantly lower than

the product temperature. As can be noted in Table 1,

raising the product temperature has more effect on

the vapor pressure differential than lowering the

collector temperature.

Table 1

Vapor Pressure (mBar) Temperature (°C)

6.104 0

2.599 -10

1.034 -20

0.381 -30

0.129 -40

0.036 -50

0.011 -60

0.0025 -70

0.0005 -80

Vapor Pressure/Temperature Relationships

A third component essential in a freeze drying system

is energy. Energy is supplied in the form of heat. Almost

ten times as much energy is required to sublime a gram

of water from the frozen to the gaseous state as is

required to freeze a gram of water. Therefore, with all

other conditions being adequate, heat must be applied to

the product to encourage the removal of water in the

form of vapor from the frozen product. The heat must be

very carefully controlled, as applying more heat than the

evaporative cooling in the system can remove warms the

product above its eutectic or collapse temperature.

Heat can be applied by several means. One method is

to apply heat directly through a thermal conductor shelf

such as is used in tray drying. Another method is to use

ambient heat as in manifold drying.

Secondary drying: After primary freeze drying is

complete, and all ice has sublimed, bound moisture is

still present in the product. The product appears dry, but

the residual moisture content may be as high as 7-8%.

Continued drying is necessary at the warmer

temperature to reduce the residual moisture content to

optimum values. This process is called isothermal

desorption as the bound water is desorbed from

the product.

Secondary drying is normally continued at a product

temperature higher than ambient but compatible with

the sensitivity of the product. All other conditions, such

as pressure and collector temperature, remain the same.

Because the process is desorptive, the vacuum should be

as low as possible (no elevated pressure) and the collector

temperature as cold as can be attained. Secondary drying

is usually carried out for approximately 1/3 to 1/2 the

time required for primary drying.

How Freeze Drying Works

Refer to the phase diagram (Figure 1) and a typical

sublimation cycle (Figure 2). The product is first cooled

to below its eutectic temperature (Point A). The collector

is cooled to a temperature approximately 20° C cooler

than the product temperature, generally around -50 to

-105° C. The product should be freeze dried at a

temperature slightly lower than its eutectic or collapse

temperature (Point B) since the colder the product, the

longer the time required to complete primary drying, and

the colder the collector temperature required to

adequately freeze dry the product.

After the product is adequately frozen and the

collector temperature achieved, the system is evacuated

using a vacuum pump (Point C). At this point, primary

drying of the product begins and continues until the

entire frozen matrix appears dry. Heat input to the

product may be achieved by several means such as

increasing the shelf temperature in the case of tray

drying, or using a liquid bath for manifold drying. While

the collector and vacuum pump create the conditions for

allowing sublimation to occur, heat input is really the

driving force behind the whole process.

Heat input to the sample can be enhanced by

controlling the pressure in the system at some level

above the ultimate capability of the vacuum pump. Some

5

freeze dryers incorporate vacuum control systems that

A

B

C

D

As drying proceeds product

temperature remains below

shelf temperature

When primary drying is complete

product temperature equals

shelf temperature

ERUTAREPMETRESNEDNOC

ERUTAREPMETTCUDORP

ERUTAREPMETFLEHS

TIME

PRESSURE

TEMPERATURE

Water

Vapor

Dry Cake

Frozen Sample

Interface

Build-up

of Frozen

Material

automatically regulate the pressure to the preset level.

This allows additional gas molecules to reside in the

system thereby improving the conduction of heat to the

sample. This improves the sublimation rate, reducing

process time and associated energy costs. Care must be

product, drying becomes more and more difficult. The

water molecules must now travel through the dried

portions of the product which impedes their progress. As

the drying front moves farther and farther down the

matrix, the application of heat to the product becomes

more important (Figure 3).

taken to prevent the pressure within the system from

exceeding the ice vapor pressure of the product or

melting of the sample may occur.

can increase the surface area to volume ratio by

spreading out the frozen product inside the vessel

(Figure 4). Shell freezing is accomplished by rotating the

vessel in a low temperature bath causing the product to

Figure 2

freeze in a thin layer on the inside surface of the vessel.

The thickness of the frozen suspension depends on the

volume of the product in comparison to the size of the

vessel. Shell freezing is primarily used in conjunction

with manifold drying.

drying because the pressure must be maintained at a low

level to ensure adequate water vapor flow from the

product to the collector. A pressure gauge (commonly

called a vacuum gauge) is used to monitor the pressure

in the system during the drying process. Pressure can be

expressed in several different units which are compared

in Table 2. Some gauges measure condensable gases,

while others do not. Those gauges that do not measure

the condensable gases give an indication of the total

pressure in the system. Gauges that do sense the

condensable gases indicate a change in pressure during

Typical Sublimation Cycle found in system utilizing Tray

Dryer with shelves.

drying. These sensors can be used as an indication of

the rate of drying, as well as the endpoint of the

drying process.

Heat input to the product must be very carefully

controlled especially during the early stages of drying.

Figure 4

The configuration of the product container and the

volume of the contained product can affect the amount of

heat that can be applied. For small volumes of material,

evaporative cooling compensates for high levels of heat

and drying is accelerated.

The volume and configuration of the suspension to be

freeze dried often determines how the material is freeze

dried. For example, the greater the ratio of the surface

area to the volume of the suspension, the faster drying

occurs. This is because a greater area for the water

molecules to leave the product exists compared to the

distance they have to travel to reach the surface of the

frozen matrix. Drying occurs from the top of the product

and initially the removal of water molecules is efficient.

However, as the drying front moves down through the

Shell freezing as a method of prefreezing the product

The vacuum system is very important during freeze

Figure 3

Ambient room temperature provides heat to encourage

removal of water vapor from frozen samples when

manifold drying.

6

Shell freezing can increase the surface area to volume

ratio by spreading out the frozen product inside the vessel.

Table 2

Microns mm Hg Torr mBar

1000 111.33

100 0.1 0.1 0.133

10 0.01 0.01 0.03

Pressure Relationships

Freeze Drying Methods

Three methods of freeze drying are commonly used:

(1) manifold drying, (2) batch drying, and (3) bulk

drying. Each method has a specific purpose, and the

method used depends on the product and the final

configuration desired.

Manifold Method. In the manifold method, flasks,

ampules or vials are individually attached to the ports of

a manifold or drying chamber. The product is either

frozen in a freezer, by direct submersion in a low

temperature bath, or by shell freezing, depending on the

nature of the product and the volume to be freeze dried.

The prefrozen product is quickly attached to the drying

chamber or manifold to prevent warming. The vacuum

must be created in the product container quickly, and the

operator relies on evaporative cooling to maintain the

low temperature of the product. This procedure can only

be used for relatively small volumes and products with

high eutectic and collapse temperatures.

Manifold drying has several advantages over batch tray

drying. Since the vessels are attached to the manifold

individually, each vial or flask has a direct path to the

collector. This removes some of the competition for

molecular space created in a batch system, and is most

ideally realized in a cylindrical drying chamber where the

distance from the collector to each product vessel is the

same. In a “tee” manifold, the water molecules leaving

the product in vessels farthest from the collector

experience some traffic congestion as they travel past the

ports of other vessels.

vessels to ambient temperature or via a circulating bath.

For some products, where precise temperature control is

required, manifold drying may not be suitable.

system allowing drying of different products at the same

time, in different sized vessels, with a variety of closure

systems. Since the products and their volumes may differ,

each vessel can be removed from the manifold separately

as its drying is completed. The close proximity to the

collector also creates an environment that maximizes

drying efficiency.

similar sized vessels containing like products are placed

together in a tray dryer. The product is usually prefrozen

on the shelf of the tray dryer. Precise control of the

product temperature and the amount of heat applied to

the product during drying can be maintained. Generally

all vials in the batch are treated alike during the drying

process, although some variation in the system can

occur. Slight differences in heat input from the shelf can

be experienced in different areas. Vials located in the

front portion of the shelf may be radiantly heated

through the clear door. These slight variations can result

in small differences in residual moisture.

same time, under the same atmospheric conditions. The

vials can be stoppered in a vacuum, or after backfilling

with inert gas. Stoppering of all vials at the same time

ensures a uniform environment in each vial and uniform

product stability during storage. Batch drying is used to

prepare large numbers of ampules or vials of one

product.

Heat input can be affected by simply exposing the

Several vessels can be accommodated on a manifold

Batch Method. In batch drying, large numbers of

Batch drying allows closure of all vials in a lot at the

In the manifold drying method, flasks are individually

attached to the ports of a drying chamber.

7

Batch drying in a tray dryer permits precise control of

product temperature and heat input.

Bulk Method. Bulk drying is generally carried out in

a tray dryer like batch drying. However, the product is

poured into a bulk pan and dried as a single unit.

Although the product is spread throughout the entire

surface area of the shelf and may be the same thickness

as product dried in vials, the lack of empty spaces within

the product mass changes the rate of heat input. The

heat input is limited primarily to that provided by

contact with the shelf as shown in Figure 5.

Bulk drying does not lend itself to sealing of product

under controlled conditions as does manifold or batch

drying. Usually the product is removed from the freeze

dry system prior to closure, and then packaged in air

tight containers. Bulk drying is generally reserved for

stable products that are not highly sensitive to oxygen

or moisture.

Figure 5

Some heat input at

edges where drying

occurs faster than

in middle

In bulk drying, heat is provided primarily through

conduction from shelf.

Determining Drying Endpoints

Several means can be used to determine the endpoint

of primary drying. The drying boundary in batch drying

containers has moved to the bottom of the product

container and inspection reveals that no ice is visible in

the product. No visible ice indicates only that drying at

the edges of the container is complete and gives no

indication of the conditions in the center of the product.

An electronic vacuum gauge can be used to measure

condensable gases in the system. When the pressure

indicated by the electronic gauge reaches the minimum

pressure attainable by the system, as no more water

vapor is leaving the product.

As the heat input to the product is increased,

evaporative cooling keeps the product temperature well

below the temperature of its surrounding atmosphere.

When primary drying is complete, the product

temperature rises to equal the temperature of its

environment. In manifold systems and tray dryers with

external collectors, the path to the collector can be shut

off with a valve and the pressure above the product

measured with a vacuum gauge. If drying is still

occurring, the pressure in the system increases.

Contamination in a

Freeze Dry System

Two types of contamination can occur in a freeze dry

system. One results from freeze drying microorganisms

and the other results from freeze drying corrosive

materials.

The potential for contamination of a freeze drying

system by microorganisms is real in any system where

microorganisms are freeze dried without a protective

barrier such as a bacteriological filter. Contamination is

most evident in batch tray dryer systems where large

numbers of vials are dried in a single chamber. Evidence

for contamination may be found by sampling the surfaces

of the vials, shelves and collector. The greatest degree of

contamination is usually found on the vials and on the

collector. Although some vial contamination may be due

to sloppiness in dispensing the material originally,

contamination on the collector is due to microorganisms

traveling from the product to the collector through the

vapor stream.

The potential for contamination must be considered

every time microorganisms are freeze dried, and

precautions must be taken in handling material after the

freeze dry process is completed. Recognizing that the

vials are potentially contaminated, the operator should

remove the vials to a safe area such as a laminar flow

hood for decontamination. Decontamination of the freeze

dry system depends upon the type of freeze dry system

used. Some tray dryer systems are designed for

decontamination under pressure using ethylene oxide

sterilization. Ethylene oxide is considered hazardous,

corrosive and detrimental to rubber components. Its use

should be carefully monitored.

Coupled with the risk of contamination in a freeze dry

system is the risk of cross contamination when freeze

drying more than one product at time. It is not good

practice to mix microbiological products in a freeze dry

system unless some type of bacteriological filter is

used to prevent the microbial product from leaving the

vial itself.

While freeze drying of corrosive materials does not

necessarily present a risk to the operator, it does present

a risk of damaging the freeze dry system itself. Although

freeze dry systems are designed using materials that

resist corrosion and prevent the build up of corrosive

materials, care should be taken to clean the system

thoroughly following each use to protect it from damage.

Backfilling

For many freeze dried products, the most ideal system

of closure is while under vacuum. This provides an

environment in which moisture and oxygen, both

detrimental to the freeze dried material, are prevented

from coming in contact with the product. In some cases,

vacuum in a container may be less than ideal, especially

when a syringe is used to recover the product, or when

opening the vessel results in a rush of potentially

contaminating air. In these cases, backfilling the product

container with an inert gas such as argon or nitrogen is

often beneficial. The inert gas must be ultrapure,

containing no oxygen or moisture.

Backfilling of the product container is generally useful

in a batch tray dryer type system. The backfilling should

also be carried out through a bacteriological filter. It is

important that the gas flow during backfilling be slow

enough to allow cooling of the gas to prevent raising the

collector temperature. Backfilling can be carried out to

any desired pressure in those tray dryers that have

internal stoppering capability, and the vials then

stoppered at the desired pressure.

8

Stability of Freeze Dried Products

Several factors can affect the stability of freeze

dried material. Two of the most important are moisture

and oxygen.

All freeze dried products have a small amount of

moisture remaining in them termed residual moisture.

The amount of moisture remaining in the material

depends on the nature of the product and the length of

secondary drying. Residual moisture can be measured by

several means: chemically, chromatographically,

manometrically or gravimetrically. It is expressed as a

weight percentage of the total weight of the dried

product. Residual moisture values range from <1% to 3%

for most products.

By their nature, freeze dried materials are hygroscopic

and exposure to moisture during storage can destabilize

the product. Packaging used for freeze dried materials

must be impermeable to atmospheric moisture. Storing

products in low humidity environments can reduce the

risk of degradation by exposure to moisture. Oxygen is

also detrimental to the stability of most freeze dried

material so the packaging used must also be

impermeable to air.

The detrimental effects of oxygen and moisture are

temperature dependent. The higher the storage

temperature, the faster a product degrades. Most freeze

dried products can be maintained at refrigerator

temperatures, i.e. 4-8° C. Placing freeze dried products at

lower temperatures extends their shelf life. The shelf life

of a freeze dried product can be predicted by measuring

the rate of degradation of the product at an elevated

temperature. This is called accelerated storage. By

choosing the proper time and temperature relationships

at elevated temperatures, the rate of product degradation

can be predicted at lower storage temperatures.

Contact Labconco for a complimentary catalog of Freeze

Dry Systems designed for laboratory use.

about freeze drying equipment. It is available upon

request from your laboratory supply dealer or Labconco

Corporation at (800) 821-5525, (816) 333-8811 or

www.labconco.com.

The Labconco catalog provides additional information

9

Glossary

Accelerated Storage: Exposure of freeze dried products to

elevated temperatures to accelerate the degradation process that

occurs during storage.

Batch Freeze Drying: Freeze drying multiple samples of the

same product in similar sized vessels at the same time in a shelf

tray dryer.

Bulk Freeze Drying: Freeze drying a large sample of a single

product in one vessel such as the bulk drying pans designed for

shelf tray dryers.

Collapse: A phenomenon causing collapse of the structural

integrity of a freeze dried product due to too high a temperature

at the drying front.

Collapse Temperature: The temperature above which

collapse occurs.

Collector: A cold trap designed to condense the water vapor

flowing from a product undergoing freeze drying.

Internal Collector: A collector located in the same area as the

product. All water vapor has a free path to the collector.

External Collector: A collector located outside the product

area connected by a small port through which all water vapor

must pass. Allows isolation of the product from the collector

for drying end point determinations and easier defrosting.

Ethylene Oxide: A colorless, odorless gas used for gas

sterilization of tray dryer systems.

Eutectics: Areas of solute concentration that freeze at a lower

temperature than the surrounding water. Eutectics can occur at

several different temperatures depending on the complexity of

the product.

Eutectic Temperature: The temperature at which all areas of

concentrated solute are frozen.

Evaporative Cooling: Cooling of a liquid at reduced pressures

caused by loss of the latent heat of evaporation.

Freeze Drying: The process of drying a frozen product by

creating conditions for sublimation of ice directly to

water vapor.

Glass Transition Temperature: The temperature at which

certain products go from a liquid to a vitreous solid without ice

crystal formation.

Isothermal Desorption: The process of desorbing water from a

freeze dried product by applying heat under vacuum.

Lyophilization: The freeze drying process.

Manifold Freeze Drying: A freeze drying process where each

vessel is individually attached to a manifold port resulting in a

direct path to the collector for each vessel.

Prefreezing: The process of cooling a product to below its

eutectic temperature prior to freeze drying.

Pressure Gauge (Vacuum Gauge): An instrument used to

measure very low pressures in a freeze drying system.

Thermocouple Gauge: A pressure gauge that measures only

the condensable gases in the system. This gauge can be used

as an indicator of drying end points.

McLeod Gauge: A mercury gauge used to measure total

pressure in the system (i.e. condensable and noncondensable gases.)

Primary Drying: The process of removing all unbound

water that has formed ice crystals in a product undergoing

freeze drying.

Residual Moisture: The small amount of bound water that

remains in a freeze dried product after primary drying. Residual

moisture is expressed as the weight percentage of water

remaining compared to the total weight of the dried product.

The amount of residual moisture in a freeze dried product can

be reduced during secondary drying.

Secondary Drying: The process of reducing the amount of

bound water in a freeze dried product after primary drying is

complete. During secondary drying, heat is applied to the

product under very low pressures.

Shell Freezing: Freezing a product in a thin layer that coats the

inside of the product container. Shell freezing is accomplished

by swirling or rotating the product container in a low

temperature bath.

Sublimation: The conversion of water from the solid state (ice)

directly to the gaseous state (water vapor) without going

through the liquid state.

Vapor Pressure: The pressure of the vapor in equilibrium with

the sample.

10

Bibliography

1. Barbaree, J.M. and A. Sanchez. 1982. Cross-contamination

during lyophilization. Cryobiology 19:443-447.

2. Barbaree, J.M., A. Sanchez and G.N. Sanden. 1985.

Problems in freeze-drying: I. Stability in glass-sealed

rubber stoppered vials. Developments in Industrial

Microbiology 26:397-405.

3. Barbaree, J.M., A. Sanchez and G.N. Sanden. 1985.

Problems in freeze-drying: II. Cross-contamination

during lyophilization. Developments in Industrial

Microbiology 26:407-409.

4. Flink, J.M. and Knudsen, H. 1983. An Introduction to

Freeze Drying. Strandberg Bogtryk/Offset, Denmark.

5. Flosdorf, E.W. 1949. Freeze-Drying. Reinhold Publishing

Corporation, New York.

6. Greiff, D. 1971. Protein structure and freeze-drying: the

effects of residual moisture and gases. Cryobiology 8:145-

152.

7. Greiff, D. and W.A. Rightsel. 1965. An accelerated storage

test for predicting the stability of suspensions of measles

virus dried by sublimation in vacuum. Journal of

Immunology 94:395-400.

8. Greaves, R.I.N., J. Nagington, and T.D. Kellaway. 1963.

Preservation of living cells by freezing and by drying.

Federation Proceedings 22:90-93.

9. Harris, R.J.C., Ed. 1954. Biological Applications of Freezing

and Drying. Academic Press, New York.

10. Heckly, R.J. 1961. Preservation of bacteria by lyophilization.

Advances in Applied Microbiology 3:1-76.

11. Heckly, R.J. 1985. Principles of preserving bacteria

by freeze-drying. Developments in Industrial Microbiology

26:379-395.

12. Jennings, Thomas. 2002. Lyophilization: Introduction and

Basic Principles. CRC Press, Florida.

13. King, C.J. 1971. Freeze-Drying of Foods. CRC Press,

Cleveland.

14. May, M.C. E. Grim, R.M. Wheeler and J. West. 1982.

Determination of residual moisture in freeze-dried

viral vaccines: Karl Fischer, gravimetric, and

thermogravimetric methodologies. Journal of Biological

Standardization 10:249-259.

15. Mellor, J.D. 1978. Fundamentals of Freeze-Drying.

Academic Press, London.

16. Nail, S.L. 1980. The effect of chamber pressure on heat

transfer in the freeze-drying of parental solutions.

Journal of the Parental Drug Association 34:358-368.

17. Nicholson, A.E. 1977. Predicting stability of

lyophilized products. Developments in Biological

Standardization 36:69-75.

18. Parkes, A.S., and A.U. Smith, Eds. 1960. Recent Research

in Freezing and Freeze-Drying. Charles C. Thomas,

Springfield.

19. Rey, L.R., Ed. 1960. Traite de Lyophilization.

Hermann, Paris.

20. Rey, L.R., Ed. 1964. Aspects Theorique et Industriels de la

Lyophilisation. Hermann, Paris.

21. Rowe, T.W.G. 1970. Freeze-drying of biological materials:

some physical and engineering aspects. Current Trends in

Cryobiology: 61-138.

22. Seligman, E.B. and J.F. Farber. 1971. Freeze-drying and

residual moisture. Cryobiology 8:138-144.

11

Labconco Corporation

8811 Prospect Avenue

Kansas City, Missouri 64132-2696

816-333-8811, 800-821-5525

FAX: 816-363-0130

www.labconco.com

© 2010 by Labconco Corporation Printed in the U.S.A. 3-53-8/10-James-3M-R8

Loading...

Loading...