LAARS XSIG User Manual

4-20 mA EMS

4-20mA INPUT

+

Signal

GND

1

2

3

RS485

EXTENSION

CONNECTORS

XSIG

4-20 mA EMS

4-20mA INPUT

+

Signal

GND

1

2

3

RS485

EXTENSION

CONNECTORS

(-)

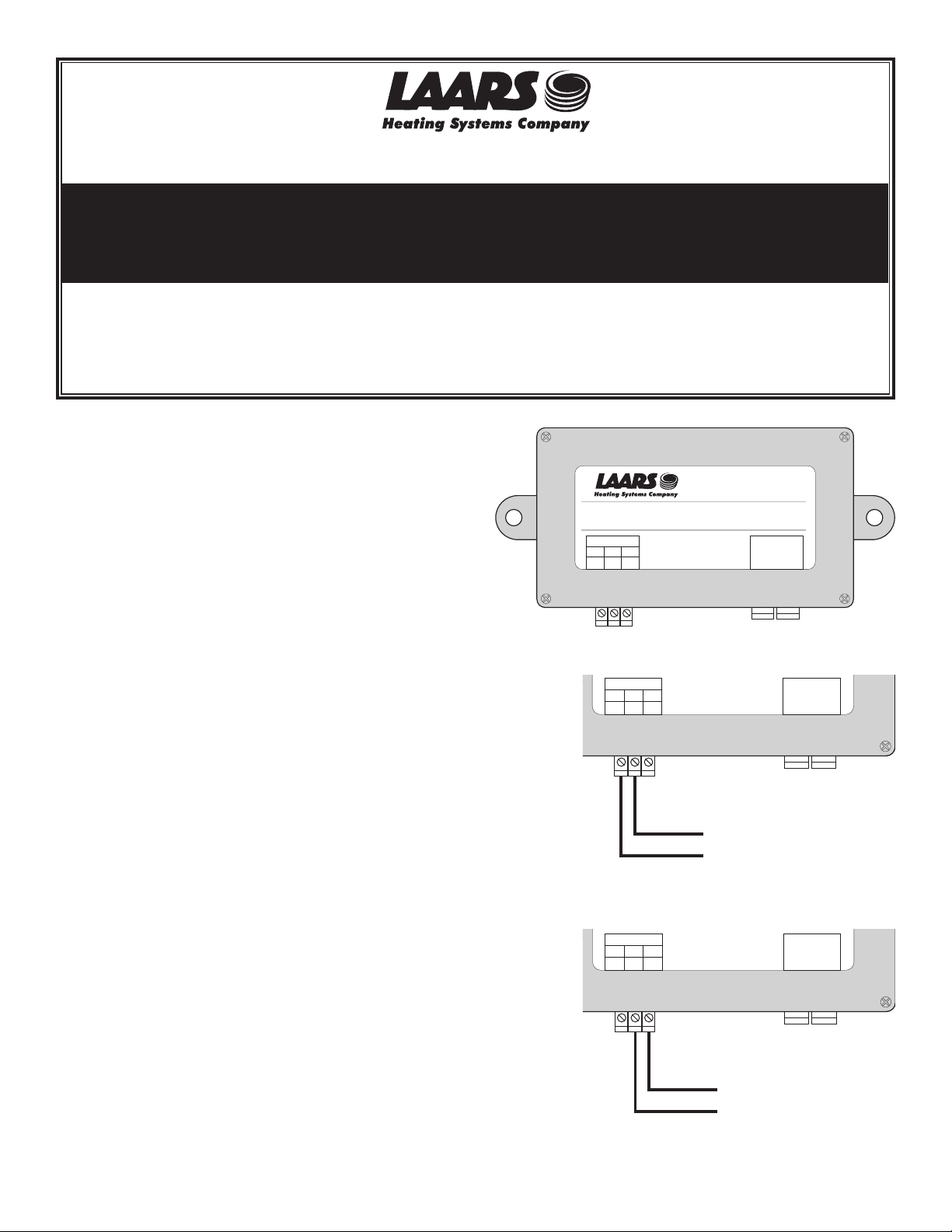

XSIG Interface Sources

DC Excitation Voltage

(+)

EMS/BMS Input

XSIG

4-20 mA EMS

4-20mA INPUT

+

Signal

GND

1

2

3

RS485

EXTENSION

CONNECTORS

(-)

XSIG Interface Sources

DC Excitation Voltage

(+)

EMS/BMS Input

4-20 mA EMS

4-20mA INPUT

+

Signal

GND

1

2

3

RS485

EXTENSION

CONNECTORS

(-)

EMS/BMS Sources

Excitation Voltage

(+)

EMS/BMS Input

XSIG

XSIG

Document 4214

INSTALLATION AND OPERATION INSTRUCTIONS

XSIG

Adds 4-20mA Set point capability to M4 and S8 Controls

The XSIG Interface provides the M4 and S8 series

controls with the capability of receiving an external

Set Point as a 4-20mA signal through an Energy

Management or Building Management Systems (EMS/

BMS). In addition, the M4 and the S8 controls can be

shutdown by the EMS/BMS system.

WIRING

Wiring the EMS Signal

• The signal must be a two-wire 4-20mA.

• A system sensor must be installed to the M4 or S8 control.

• The External Set Point must be set up correctly (See M4 and S8

documentation). These settings will allow the M4 and S8 to read

and monitor the system temperature and also monitor the 4-20mA

input to remotely adjust the set point to the desired value.

• The XSIG Interface can source the current for the 4-20mA input

signal. It provides an excitation DC current. If using the XSIG

Interface to source the power, attach the (+) side of the EMS/BMS

signal to the XSIG Interface terminal marked +. Attach the (-) side

of the EMS/BMS signal to the XSIG Interface terminal marked

SIGNAL.

• If the EMS/BMS or other equipment signal sources the current

(provides the excitation voltage), attach the (+) side of the 4-20mA

input to the XSIG Interface terminal marked SIGNAL. Attach

the (-) side of the 4-20mA input to the XSIG Interface terminal

marked GND.

2 Laars Heating Systems

WARNING

The XSIG interface can either source DC current or accept DC current from and EMS/BMS System. Each configuration

has a different wiring schematic. Wiring the current to the “+” and “Signal” terminals will damage the XSIG interface.

Connecting S8 to Two Extension Panels

and XSIG Interface using RS485

PWR

L N

1 2

Stage A

Stage B

Stage C

Stage D

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

CAUTION:

Stage A7Stage B9Stage C

3

5

6 8 10 12 14

4

Stage E

Stage F

Stage G

Stage H

Risk of Electric Shock.

Use Copper Conductors Only.

Stage D

Stage E15Stage F

11

13

S8

S8

SYSTEM

DHW PUMP

COMB. AIR

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

C US

LISTED

99RA

PROGRAM RUN

SYSTEM

Stage G19Stage H

16 18

17

20 22 28 30 32 34 36

SYS=144F OD=35F

<AB

HI LO -- OFF

STAGE MENU

DHW

COMB.

PUMP

AIR

21

23 24

SEQUENCING CONTROL

> DE GH JK

DO NOT APPLY ANY VOLTAGE TO INPUT TERMINALS

SENSORS MUST BE GOLD SERIES

SYSTEM

OUTDOOR

RETURN

PRESS

TEMP

TEMP

TEMP

+ -

27 29

31

25

26

RS485

SHUTDOWN

DHW

PROVE

/SETBACK

33

35

37

38

XSIG 4-20mA EMS Interface

XSIG

4-20 mA EMS

4-20mA INPUT

Signal GND

+

2

1

3

RS485

EXTENSION

CONNECTORS

S8EXT A

S8EXT

Risk of Electric Shock.

S

U

M

T

11 12

T

L

U

M

V

N

Comm

V

N

13 14

W

O

15 16P17 18

O

P

Power

Ext A

X

Q

I

R

J

S

K

CAUTION:

Use Copper Conductors Only.

Q

PWR

L N

1 2I3 4J5 6K7 8L9 10

R

6 Pin Phone Cable (provided with Extension)

W

X

SEQUENCING CONTROL

Ext B

S8EXT B

Risk of Electric Shock.

S

U

T

M

11 12

T

L

U

M

V

N

Comm

V

N

13 14

W

O

15 16P17 18

W

O

X

P

Power

Ext A

Ext B

X

Q

I

R

J

S

K

CAUTION:

Use Copper Conductors Only.

Q

PWR

L N

1 2I3 4J5 6K7 8L9 10

R

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

EXTENSION

MODULE

RS-485

EXTENSION

MODULE

RS-485

4-20mA

EMS Signal

(+)

(-)

6 Pin Phone Cable (provided with XSIG Interface)

Connecting the XSIG interface to the M4 or S8

• The XSIG Interface connects to the M4 or S8 using an RS485 (phone plug).

• When having to use the RS485 to connect to Extensions, use the extra RS485 (phone plug).

• The control, XSIG Interface and two Extensions can be connected in series using the RS485.

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 0806 Document 4214

HTC#059066-00 Rev.A

Loading...

Loading...