LAARS VW-PW Installation Manual

Installation, Operation and Maintenance Instructions Document 2051F

Installation, Operation

and Maintenance

Instructions for

Mighty Therm

Volume Water Heaters

Model VW-PW

Sizes 175-400

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly , a fire or explosion may result causing

property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0147500F

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1.1 Introduction.................................................... 3

1.2 Warranty........................................................ 3

1.3 Technical Assistance..................................... 3

SECTION 2.

Installation Instructions

2.1 General Information....................................... 4

2.2 Field Assembly ..............................................4

2.3 Site Location.................................................. 5

2.3.1 Installation Information...................................5

2.3.2 Outdoor Installation (U.S. only)...................... 5

2.3.3 Flooring - Typical Installation ......................... 6

2.4 Combustion and Ventilation Air Supply.......... 6

2.4.1 Outdoor Air Supply ........................................ 7

2.4.2 Indoor Air Supply ........................................... 7

2.4.3 Exhaust Fans or Vents .................................. 7

2.5 Venting of Combustion Products ................... 7

2.5.1 General Information....................................... 7

2.5.2 Replacement of Existing Heater .................... 8

2.6 Water Flow .................................................... 8

2.6.1 Reversible Water Connections ...................... 8

2.6.2 Water Chemistry.......................................... 11

2.6.3 Freeze Protection ........................................ 11

2.6.4 Water Hardness .......................................... 11

2.6.5 Pump Requirements.................................... 14

2.6.6 Pressure Buildup in Water System .............. 14

2.6.7 Pressure Relief Valve .................................. 14

2.6.8 Water Pressure ........................................... 14

2.6.9 Pump Installation ......................................... 14

2.6.10 Storage Tank Installation ............................. 15

2.6.11 Thermal Circulation of Hot Water in

Cold Water Supply Lines ............................. 15

2.7 Gas Supply and Piping ................................ 16

2.7.1 General Instructions..................................... 16

2.7.2 Special Precautions for Propane Gas.......... 16

2.8 Electrical Wiring........................................... 16

2.9 Combined Space Heating/Potable

Water Heating Systems............................... 17

2.9.1 Combined Space Heating............................ 17

SECTION 3.

Operating Instructions

3.1 Normal Operating Sequence ....................... 17

3.2 Start-Up Procedure...................................... 17

3.3 Setting the Temperature Controls................ 20

3.3.1 Remote Water Heater Temperature

Control: ........................................................20

3.3.2 Internal Water Heater Temperature

Control: ........................................................20

3.4 Adjustment for Minimum Input Rate

(models with modulating gas valve)............. 21

3.5 Hi-Limit Switch Checkout............................. 22

3.6 Shut-Down Procedure ................................. 22

SECTION 4.

Maintenance

4.1 General Instructions..................................... 22

4.2 Replacement of Gas Controls...................... 22

4.3 Heat Exchanger........................................... 24

4.3.1 Inspecting the Heat Exchanger.................... 24

4.3.2 Cleaning the Heat Exchanger ...................... 24

SECTION 5.

Troubleshooting

5.1 Gas Pressure Tests..................................... 24

5.1.1 Checking the Main Line Gas Pressure ........ 24

5.1.2 Checking the Manifold

Regulated Gas Pressure ............................. 25

5.2 Electrical Troubleshooting ........................... 25

5.2.1 Heater Does Not Come On.......................... 25

5.2.2 Testing the Transformer .............................. 26

5.2.3 Testing the Electrical Power Supply............. 26

5.2.4 Testing the Manual Reset

Hi-Limit Switch............................................. 26

5.2.5 Testing the Flow Switch ...............................26

5.2.6 Testing the Fusible Link

(Flame roll-out switch) ................................. 26

5.2.7 Testing the Fuse.......................................... 27

5.2.8 Testing the Ignition Control

(for spark ignition)........................................ 27

5.2.9 Testing the Ignition Control

(for standing pilot)........................................ 28

5.2.10 Testing the High Voltage Ignition Lead ........ 28

5.2.11 Testing the Safety Shutoff

(for standing pilot)........................................ 28

5.2.12 Testing the Safety Shutoff

(for automatic pilot)...................................... 28

5.2.13 Testing the Igniter Electrode ........................ 28

5.2.14 Testing the Pilot Thermocouple

(for standing pilot)........................................ 29

5.2.15 Testing for Pilot burner

(for spark ignition)........................................ 29

5.2.16 Testing for Burner Ignition

(for standing pilot)........................................ 30

5.2.17 Heater Will Not Shut Off .............................. 30

5.2.18 On-Off Main Burner Cycling......................... 30

5.2.19 Testing the Terminal Strip/External

Controls ....................................................... 30

SECTION 6.

Parts List

6.1 General Information..................................... 30

6.2 Parts List ..................................................... 30

Mighty Therm Volume Water Heaters

Page 3

SECTION 1.

General Information

1.1 Introduction

This manual provides installation, operating, and

maintenance instructions for Models VW and PW

Volume Water Heaters, Sizes 175 through 400. Review

all application and installation procedures completely

before proceeding with the installation. Experience has

shown that most operating problems are caused by

improper installation.

The VW-PW heaters are offered in a basic

configuration (see Figure 1). On PW heaters the pump

is factory installed. On VW heaters the pump is field

installed.

1.2 Warranty

The VW-PW heaters are sold with a limited

factory warranty.

Make all warranty claims to an authorized Laars

representative or directly to the factory. Claims must

include the heater serial number and model (this

information can be found on the rating plate),

installation date, and name of the installer. Shipping

costs are not included in the warranty coverage.

Some accessory items are shipped in separate

packages. Inspect everything for damage immediately

upon delivery, and advise the transporter of any

shortages or damage. Any such claims should be filed

with the transporter. The transporter will not accept a

claim from the shipper, Laars.

The warranty does not cover damage caused by

improper installation, operation, or field modification.

1.3 T echnical Assist ance

Consult Laars or your local wholesaler with any

questions or problems involving the specification,

installation and operation of Laars equipment. An

experienced technical support staff is ready to assist in

assuring the proper performance and application of

Laars products.

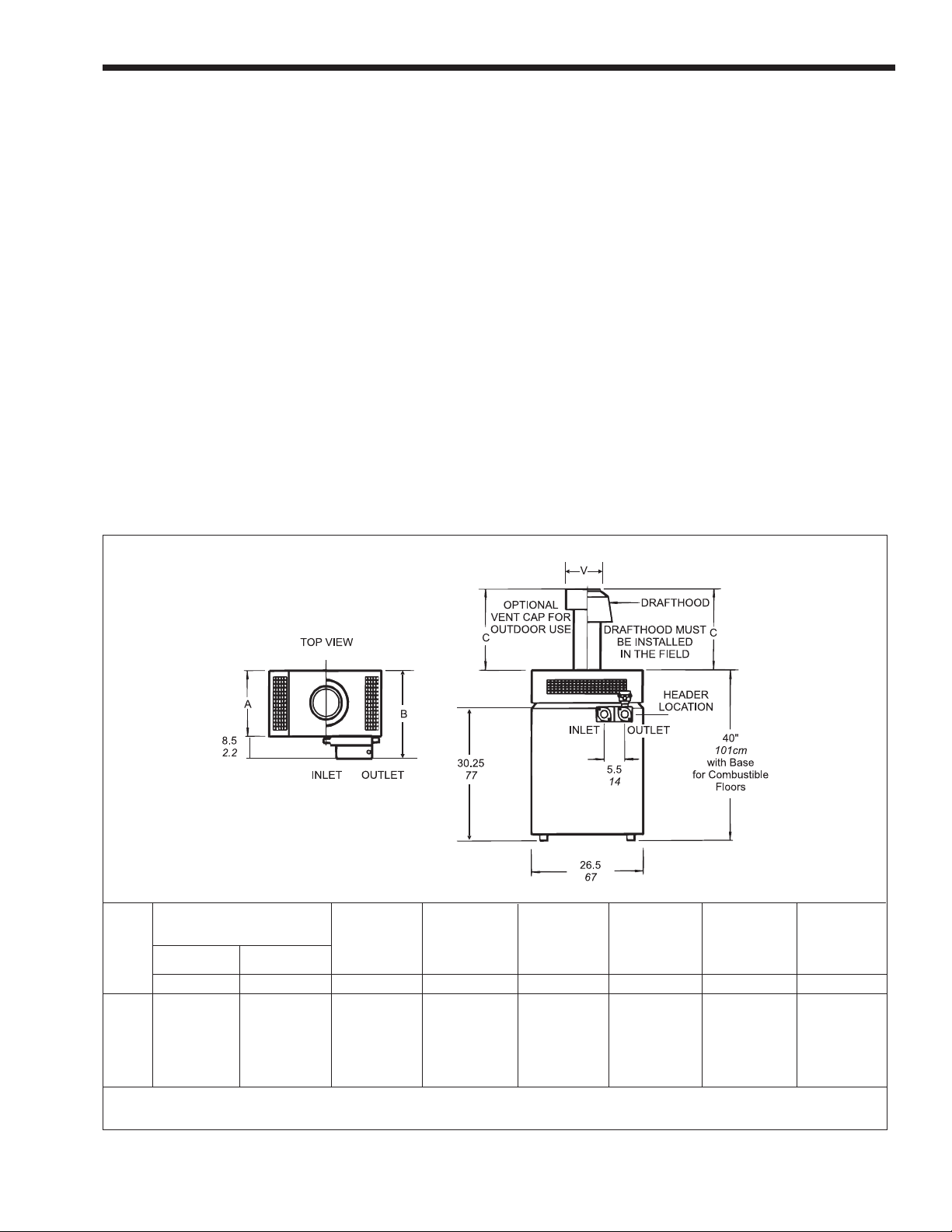

Dimensions shown in inches cm.

Gas Connection

Size Water C C V

Connect. U.S. Only (Indoor) Vent

Nat. Propane Size A B (Outdoor) Dia.

Size in. mm in. mm in. mm in. cm in. cm in. cm in. cm in. mm

175

250

325

400

Figure 1. General configuration.

3

/4 19

3

/4 19

3

/4 19

3

/4 19

Note: Dimensions may vary.

1

/2 13 11/2 38 18 46 261/2 67 141/16 36 23/2 60 6 152

1

/2 13 11/2 38 221/2 57 31 79 181/16 47 243/4 63 7 178

1

/2 13 11/2 38 263/4 68 353/4 91 193/16 49 257/8 66 8 203

1

/2 13 11/2 38 313/4 80 401/4 102 225/8 58 267/8 68 9 229

Page 4

LAARS Heating Systems

SECTION 2.

Installation Instructions

2.1 General Information

WARNING

Follow local regulations with respect to installation of

carbon monoxide (CO) detectors and

manufacturer's maintenance schedule of the heater.

Install the VW-PW heaters in accordance with

the procedures in this manual (or the Laars warranty

may be voided), local codes and ordinances. In the

absence of such codes, install the heaters in

accordance with the latest edition of the National Fuel

Gas Code, ANSI Z223.1. In Canada, the installation

must be in accordance with CAN1-B149.1 or .2 and

local codes. The authority having jurisdiction may

require the installation conform to the Standard for

Controls and Safety Devices for Automatically Fired

Heaters, ANSI/ASME CSD-1. Any changes to the

heater, gas controls, gas orifices, wiring or draft

diverter may void the warranty. If field conditions

require a change to any of the above, consult the

factory.

All gas-fired products require correct installation

to assure safe operation. The requirements for heaters

include the following:

1. Field assembly of drafthood or vent cap (see

Section 2B).

2. Appropriate site location (clearances) and

flooring.

3. Sufficient combustion and ventilation air.

4. Adequate venting of combustion products.

5. Adequate water flow.

6. Properly sized gas meter and piping.

7. Proper electrical wiring.

This manual provides the information needed to

meet these requirements. Review all application and

installation procedures completely before continuing

the installation.

number for the drafthood is on the heater rating plate.

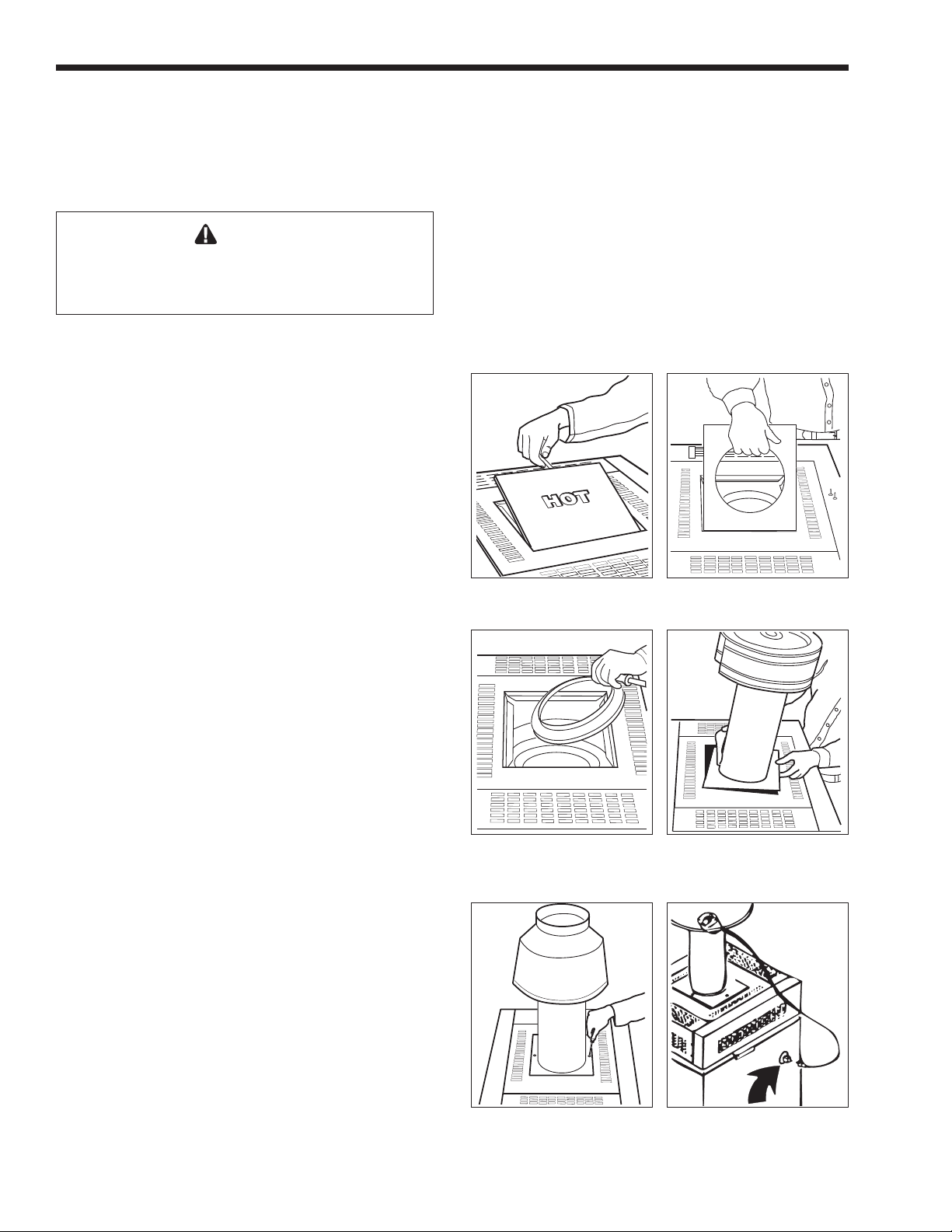

Follow this procedure to make the conversion:

a. Remove the top filler plate, stamped “HOT”, by

slipping a fine-blade screwdriver into the slot at

the rear of the plate and gently prying it up (see

Figure 2).

b. Remove the two screws attaching the adapter

plate to the top assembly and lift it out (see

Figure 3).

c. Remove the vent cap or drafthood from its

package.

Figure 2. Top filler plate. Figure 3. Adapter plate.

Figure 4. Flue transition Figure 5. Vent cap with

ring. adapter plate

(outdoor).

2.2 Field Assembly

The VW-PW heater is shipped from the factory

with the top assembly in the low-profile configuration

for outdoor installations.

The VW-PW heater is design certified for indoor

installation when equipped with a special drafthood,

which must be installed without modification. The part

Figure 6. Drafthood with Figure 7. Drafthood switch

adapter plate receptacle.

(indoor).

Mighty Therm Volume Water Heaters

d. Disengage the flue transition ring from the stack

extension and place it on top of the collector

assembly as shown in Figure 4.

e. Slide the adapter plate over the bottom of the

stack extension as shown in Figure 5. Fit the

stack extension down over the flue transition

ring. Seat the adapter plate on the top assembly

and secure it with two screws (see Figure 6).

f. Indoor models, size 175 and 250 only, require an

adapter cable (included with product). The cable

connects the blocked vent safety switch (BVSS)

on the bell of the external draft hood to the 6position Molex plug on the side of the unit (see

Figure 7). Refer to instruction sheet included

with cable.

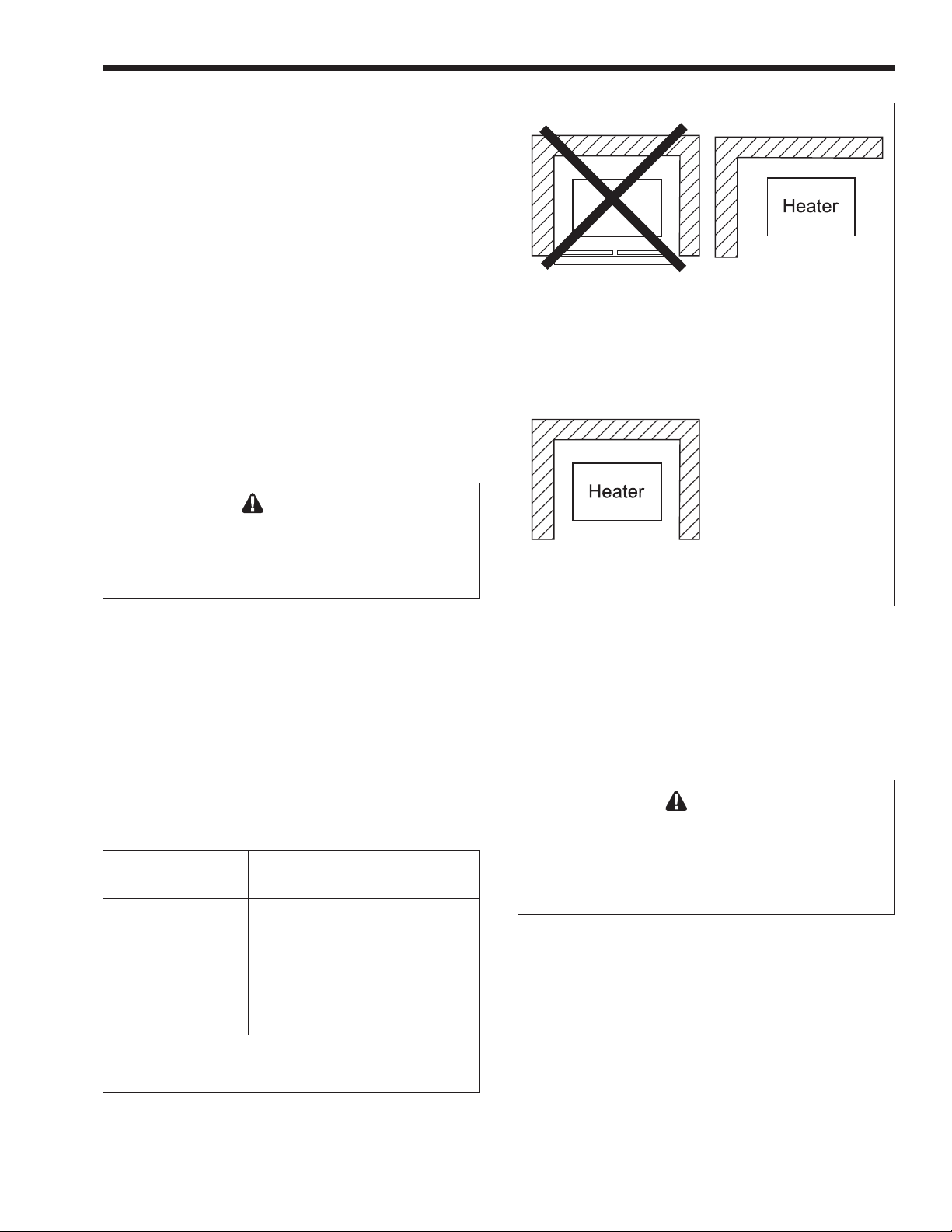

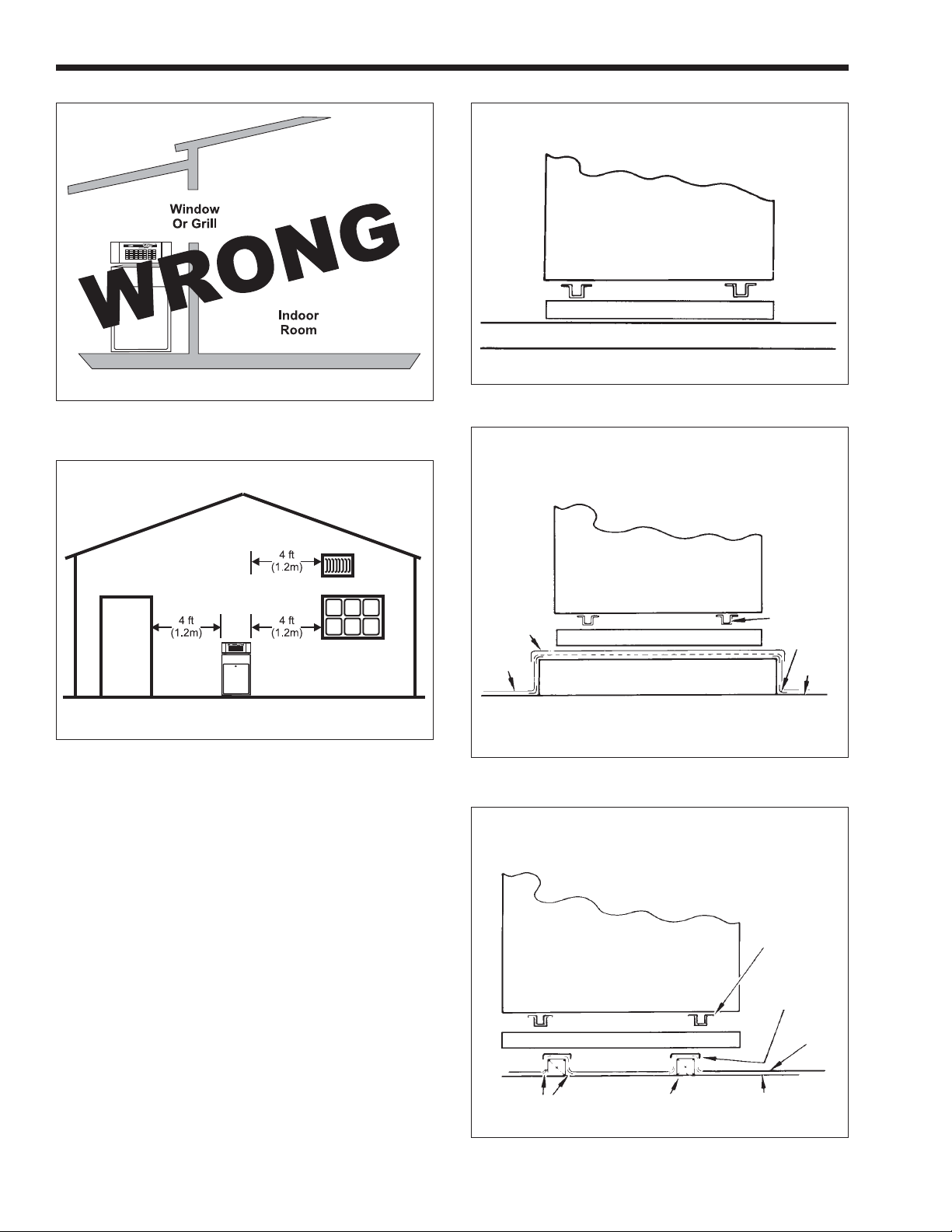

Closet Installation

(unacceptable)

A closet is any 4 sided enclosure

which is less than 16* times the

total volume of all the gas fired

appliances within the enclosure.

Page 5

Room Installation

(acceptable)

A room is any enclosure which is

at least 16* times greater than the

total volume of all the gas fired

appliances within the enclosure

2.3 Site Location

2.3.1 Installation Information

WARNING

Improper installation or maintenance can cause

nausea or asphyxiation from carbon monoxide in

flue gases which could result in severe injury,

property damage, or death.

Avoid placing the heater in locations where it can

be damaged by water or condensate leakage. If this is

not possible, provide a suitable drain pan to catch and

divert any leakage. The pan must not block natural

flow of air around the heater.

Locate the heater to provide adequate clearance

on all sides for inspection, service and to provide

adequate air circulation for proper operation.

Locate the heater so the clearances from

combustible surfaces shown in Table 1 and Figure 8

are met.

Indoors Outdoors

Clearance from: inch mm inch mm

Top 37 940 Unobstructed

Water conn. side 12 305 Unobstructed

Opposite side 6 152 6 152

Front Alcove Unobstructed

Rear 6 152 6 152

Vent* 6 152 —

Flooring Combustible Combustible

Service clearance = 36 inches (914mm) at front of heater,

and 18 inches (457mm) at water connection side.

*1" (25mm) if double wall vent is used.

Table 1. Minimum Boiler Clearances

from Combustible Surfaces.

Alcove Installation

(acceptable)

An alcove suitable for the

installation of a heater is a

restricted section of a room not

separated from the room by a door

or partition and which meets the

minimum clearances specified in

this manual.

* When the ceiling height exceeds 8 feet, you are only allowed to consider

8 feet when calculating the total volume of the enclosure.

Figure 8. Alcove installation.

Locate the heater on a waterproof floor with a

floor drain and a 6 inch (152 mm) minimum curb on

all four sides to protect the building if heater repairs

are needed.

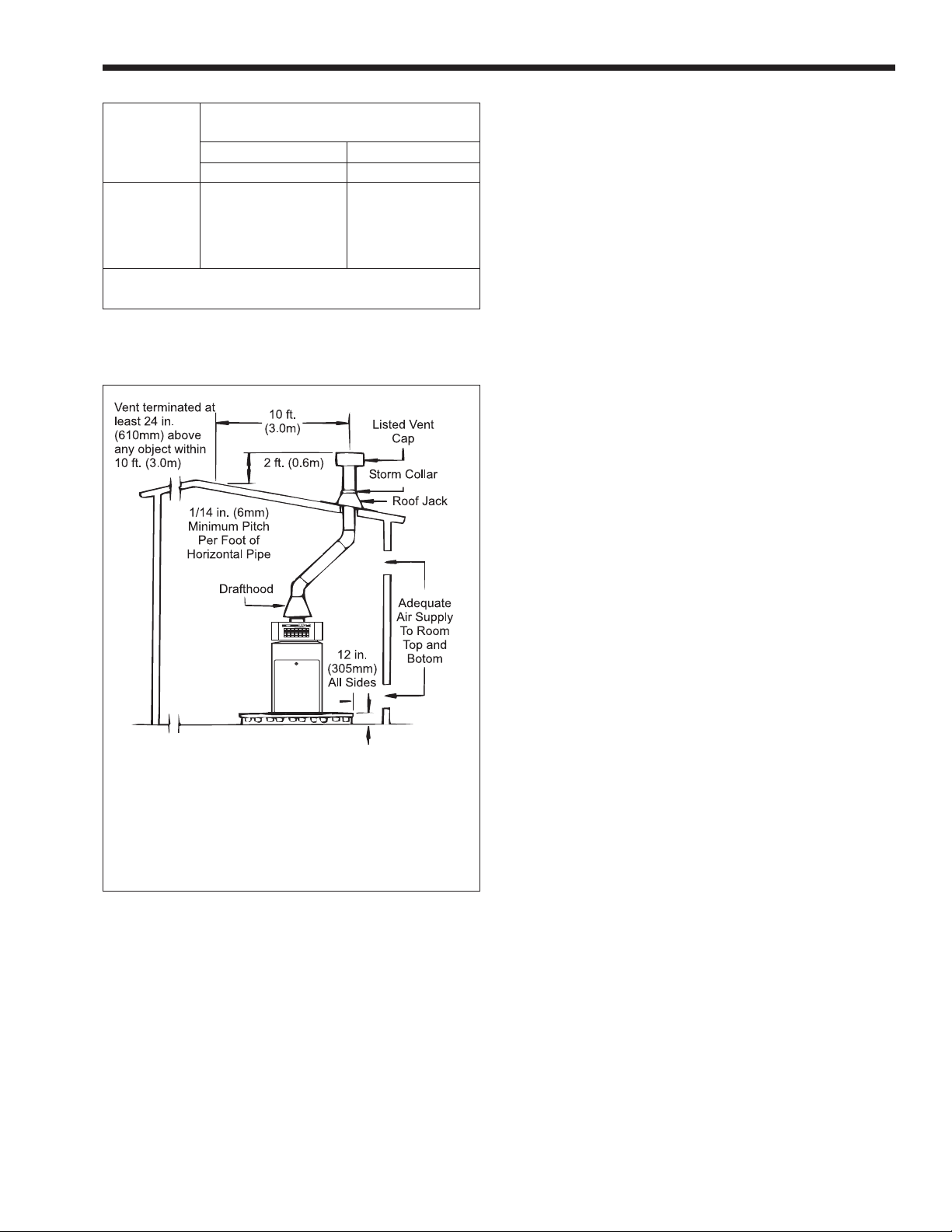

2.3.2 Outdoor Installation (U.S. Only)

Caution

Outdoor installations are not recommended in areas

where the danger of snow blockage exists. VW-PW

heaters can be installed in the standard low-profile,

grate top configuration as received from the factory,

or with an optional vent cap.

Locate the heater in an open, unroofed area. Do

not locate the heater below or adjacent to any doors,

windows, louvers, grills, etc., which connect in any

way with an inhabited area of a building, even though

the access might be through another structure such as a

garage or utility room (see Figure 9 and Table 1).

There must be a minimum of 4 feet (1.22 m)

horizontally and vertically between the heater and any

door, window, or gravity inlet to a building (see

Figure 10).

If the heater is installed close to a structure,

protect it from rain water runoff with rain gutters on

the roof or other measures. Do not locate the heater

near sprinkler systems that could spray water on it.

Page 6

LAARS Heating Systems

Concrete slab must extend out a

minimum of 12 in. (305mm) on

all sides.

LAARS

UNIT

(Side View)

Base For Combustible Floors

Roof - Wood and Steel Construction

Figure 9. Incorrect outdoor installation.

Figure 10. Outdoor location installation.

A void locations where wind deflection off nearby

structures might cause wind loading and downdraft

conditions. Where downdraft conditions exist, locate

the heater at least 3 feet (0.91 m) from the structure.

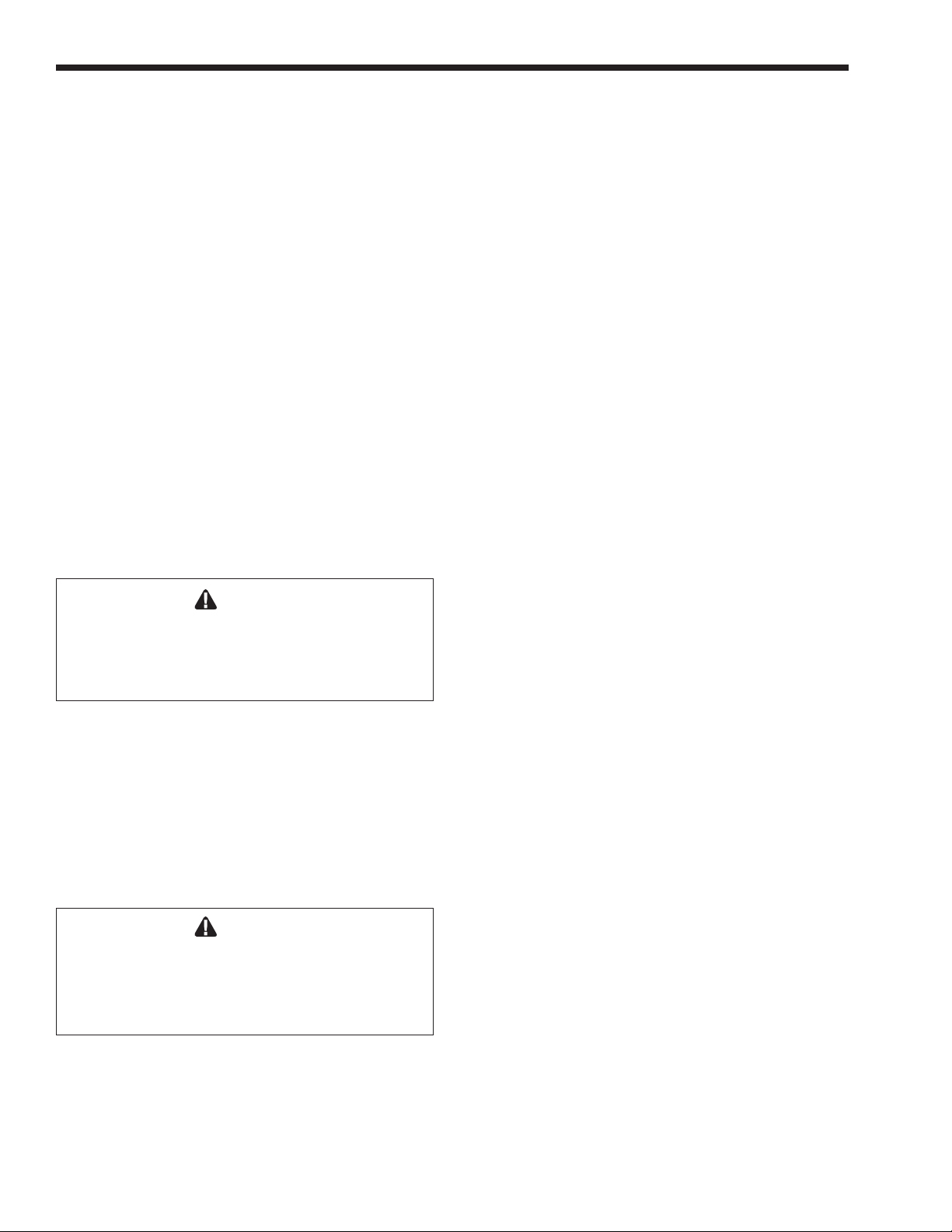

Figure 11. Standard base for combustible floor.

Mounting Platform must extend

out a minimum of 12 in.

(305mm) on all sides.

LAARS

20 Gauge

Galvanized

Sheet Metal

Cap

Roofing

Figure 12. Typical roof mounting.

Base For Combustible Floors

UNIT

(Side View)

Raised Mounting

Platform (Wood)

Base Rail

Flashing

Roof

2.3.3 Flooring - Typical Installation

Do not install the heater directly on carpeting

without placing a non-combustible platform between

the carpeting and the heater. If the heater is installed in

a carpeted alcove, the entire floor of the alcove must

be covered by a non-combustible panel. The panel

must be strong enough to carry the total weight of the

heater and all piping, pumps, and any other equipment

attached to the heater. For rooftop installation, see

Figure 11 through Figure 13.

2.4 Combustion and Ventilation

Air Supply

All indoor installations must have openings to

outside air for combustion, ventilation and dilution of

LAARS

UNIT

(Side View)

Base For Combustible Floors

Flashing 4x4 Stringer Roof

Figure 13. Typical roof mounting with standard

combustible mount base.

Base Rail

20 Gauge

Galvanized

Sheet Metal

Cap

Roofing

Mighty Therm Volume Water Heaters

Page 7

Required Net Free Opening Area

Directly from Outside

At Top At Bottom

Model in.

175 44 284 44 284

250 63 406 63 406

325 82 529 82 529

400 100 645 100 645

Note: For screens or louvers, add 50%.

Table 2. Air Openings to Outside.

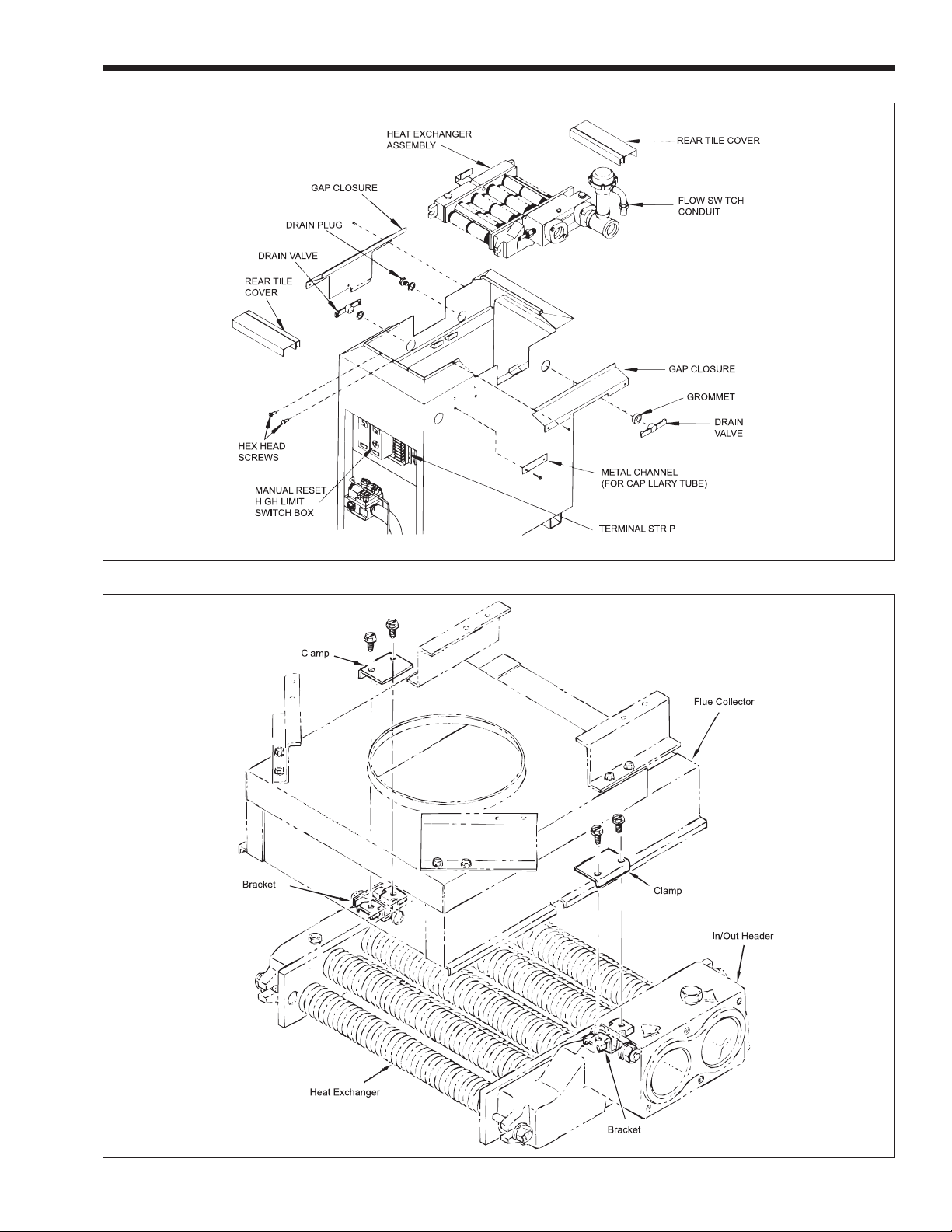

Notes:

1. The drafthood must sit directly on top of the heater

as shown and must not be altered in any manner.

2. An Underwriters' Laboratories listed vent cap is required to eliminate downdraft and allow the heater

to function properly.

3. Use approved roof fitting.

2

cm

2

in.

2

cm

Method 1:

T wo permanent openings, one commencing

within 12" (30 cm) of the top and one commencing

2

within 12" (30 cm) of the bottom of the enclosure shall

be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces that

freely communicate with the outdoors. When directly

communicating with the outdoors directly, or through

vertical ducts, each opening shall have a minimum free

area of 1 square inch per 4000 Btu/hr (550 square mm/

kW) of total input rating of all equipment in the

enclosure. When communicating to the outdoors

through horizontal ducts, each opening shall have a

minimum free area of not less than 1 square inch per

2000 Btu/hr (1100 square mm/kW) of total input

rating of all equipment in the enclosure.

Method 2:

One permanent opening, commencing within

12" (30 cm) of the top of the enclosure shall be

permitted. The opening shall directly communicate

with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces

that directly communicate with the outdoors, and shall

have a minimum free area of 1 square inch per 3000

Btu/hr (734 square mm/kW) of the total input rating of

all equipment located in the enclosure. This opening

must not be less than the sum of the areas of all vent

connectors in the confined space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in ANSI Z223.1, or applicable

codes.

In Canada, Table 2 does not apply. Consult local

building and safety codes or, in absence of such

requirements, follow CAN/CGA B149.

NOTE: Check with louver manufacturers for

net free area of louvers. If screens or louvers are

installed, add 50 percent for each screen/louver to the

net free area Check all local codes applicable to

combustion air.

Figure 14. Indoor installation and venting.

flue gases from inside the building (see Figure 14 and

Table 2 ). Laars does not recommend indoor

installations that do not provide combustion air from

outside the building.

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

2.4.1 Outdoor Air Supply

When combustion air comes directly through an

outside wall, each opening must have a minimum free

area of at least one square inch for each 4,000 BTU/h

input of the total input rating of all appliances in the

enclosed area. (In Canada, refer to CGAB149.1 and .2.)

2.4.2 Indoor Air Supply

Confined and non-confined areas have different

requirements for installation. Consult the latest edition

of the National Gas Code for installation requirements.

2.4.3 Exhaust Fans or Vents

Any equipment which uses air or removes air

from the heater room can use up the combustion air

Page 8

LAARS Heating Systems

supply or reverse the natural draft action of the venting

system. This could cause flue products to build up in

the heater room. More air must be supplied to make up

for the decrease.

2.5 Venting of Combustion Products

2.5.1 General Information

When installed indoors, the drafthood must be

connected to a venting system. The venting system

must be installed by a qualified installer and in

accordance with the latest edition of ANSI Z223.1. In

Canada, the installation must be in accordance with

CAN1-B149.1 or .2, and any local codes that apply.

The vent pipe must have a listed vent cap, and

extend at least 2 feet (0.6 m) above any object within a

10 foot (3.0 m) radius.

NOTE: Do not use sheet metal screws at the

snap lock joints of Type B double-wall gas vents.

Do not weld or bolt the vent pipe to the heater

drafthood. The weight of the stack must not rest on the

heater. The drafthood and heater top must be easily

removable for normal heater service and inspection.

WARNING

Avoid ending heater vents near air conditioning or air

supply fans. The fans can pick up exhaust flue

products from the heater and return them inside the

building, creating a possible health hazard.

Avoid horizontal runs of the vent pipe and 90

degree elbows, reductions, and restrictions. Horizontal

runs should have at least a 1/4 inch (6.3 mm) rise per

foot in the direction of flow. Support a vent connector

for the design and weight of the material used to

maintain clearances and physical damage and separate

of joints.

Always use double-wall or insulated vent pipe

(Type B or equivalent).

WARNING

In cold weather, uninsulated outside vents can chill

the rising flue products, blocking the natural draft

action of the venting system. This can create a

health hazard by spilling flue products into the

heater room.

Avoid oversize vent piping or extremely long

runs of the pipe which may cause too much cooling

and condensation of flue gasses.

When the installation of a power vent or draft fan

in the venting system is necessary, qualified personnel

should design the installation following good

engineering practices and all applicable codes. A

suitable draft switch must be wired into the heater

control circuit at the terminal designated Field

Interlock to keep the heater from firing unless there is

a positive draft.

2.5.2 Replacement of Existing Heater

When a heater is removed from a common

venting system, the venting system may be too large

for proper venting of the other appliances connected

to it.

If replacing an existing heater with a VW or PW

heater and the existing heater was connected to a

common venting system, the common venting system

must comply with ANSI Z223.1/National Fire

Protection Association (NFPA) 54. When resizing any

portion of the common venting system, the common

venting system should be resized to approach the

minimum size as determined using the tables in ANSI

Z223.1/NFPA 54, Appendix G. In Canada, the common

venting system should be resized so the installation

will be in accordance with CAN/CGA B149.1 or .2.

2.6 Water Flow

2.6.1 Reversible Water Connections

NOTE: This procedure is not recommended for

the PW pump-mounted models.

Laars ships the VW heater with the water

connections on the right side. The VW heater can be

installed with the water connections on either side. It

could be necessary, or helpful, to switch the

connections to the left side to improve access for

installation service. Have a professional service

technician perform this modification before installing

the heater using the following procedures:

1. Remove the front cover.

2. If there is a vent cap or drafthood installed, they

must be removed before removing the grate top

assembly. On indoor installations (sizes 175-

250), the drafthood switch must be disconnected

at the left side of the heater.

3. If the unit is in the low-profile outdoor

configuration, remove the hex-head screws

(see Figure 15) and lift the grate top assembly

straight up.

4. Remove the screws that fastens the flue collector

holddown clamps and remove the clamps (see

Figure 16).

5. Remove the flue collector assembly by lifting it

out of the chassis.

6. Remove the screws that fastens the gap closures

and put them aside.

Mighty Therm Volume Water Heaters

Page 9

Figure 15. Heat exchanger reversal.

Figure 16. Flue collector Holddown Clamps.

Page 10

LAARS Heating Systems

7. Remove the three grommets.

8. Remove the drain valves and plug. There is one

hex plug on the left side, near the rear of the

jacket. The drain valves are located on the left

side and right side of the heater (see Figure 9).

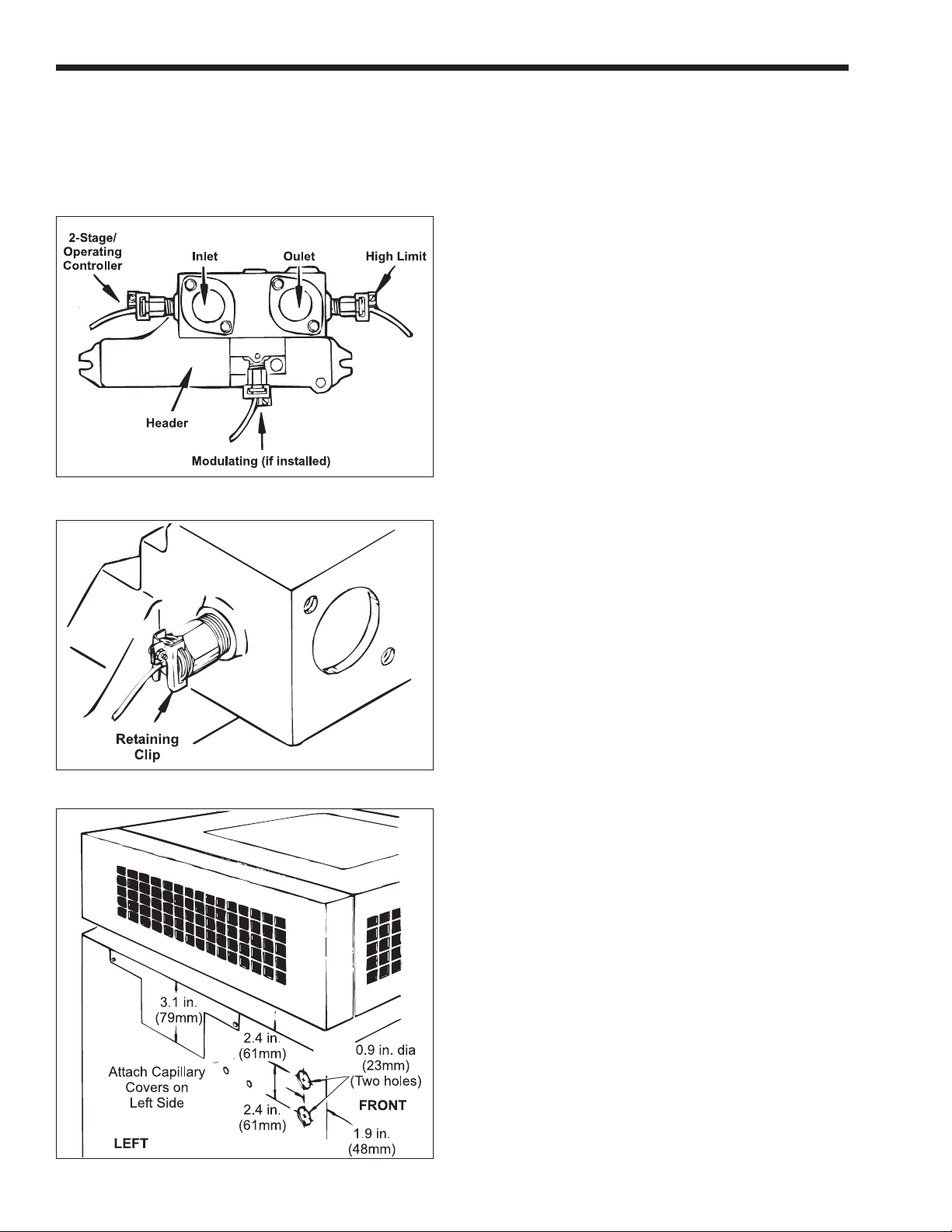

Figure 17. Sensory bulb locations.

Figure 18. Retaining clip removal.

Figure 19. Hole location, left side.

9. Remove the four screws that fastens the metal

channels covering the capillary tube on the right

side of the jacket, and lay the channels aside.

10. In the control compartment, find the manual reset

high-limit switch box (see Figure 15) and loosen

the screw on the top to remove the cover.

11. Loosen the screw that fastens the white wire and

remove it from the terminal. Pull it out through

the top of the case and separate the other white

wire from the red wire coming from the fuse

holder. Gently pull the two white wires out of the

control compartment and coil them on top of the

heat exchanger.

12. A temperature control sensing bulb is located in

the front of the header on the inlet side and a

manual reset hi-limit sensing bulb is located on

the back side of the header on the outlet side (see

Figure 17). Remove these sensing bulbs from the

header. The following steps for removal apply to

all sensing bulbs:

a. If there is more than one capillary tube coming

out of the header, label the capillary tubes.

b. Loosen the screw on the capillary tube

retaining clip, then gently pry the clip apart

until it comes free from the temperature

control (see Figure 18).

c. Pull the sensing bulbs out of the temperature

control.

d. Gently pull the capillary tubes into the control

compartment.

e. Pull the temperature sensing bulb out of the

header, and temporarily route it to the front of

the heater.

13. Use a pair of diagonal cutters to cut the plastic

tie around the wire bundle in the control

compartment.

14. On the terminal strip, disconnect the two brown

wires from No. 5 and No. 6 terminals.

15. Remove the flow switch conduit retaining clip

and the elbow leading into the jacket.

16. Reach inside the control compartment and

release the retaining nut in the upper right corner.

The nut should only be finger-tight.

17. When the conduit is pulled away from the jacket,

pull the two brown wires out of the control

compartment. Coil the conduit and wires on top

of the heat exchanger.

18. Use a chassis punch to put two 7/8 inch (22 mm)

holes in the front left side of the jacket (see

Figure 19).

19. Remove the front and rear tile covers (see

Figure 15).

Loading...

Loading...