LAARS MagnaTherm MGV Installation Manual

Installation and Operation Instructions Document 1276C

Installation and

Operation Instructions for

®

MAGNATHERM

Modulating Boiler Water Heater

Model MGH2000 Model MGV2000

1,999 MBTU/h 1,999 MBTU/h

Model MGH2500 Model MGV2500

2,499 MBTU/h 2,499 MBTU/h

Model MGH3000 Model MGV3000

3,000 MBTU/h 3,000 MBTU/h

Model MGH3500 Model MGV3500

3,500 MBTU/h 3,500 MBTU/h

Model MGH4000 Model MGV4000

4,000 MBTU/h 4,000 MBTU/h

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in ue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

WARNING

If the information in these instructions is

not followed exactly, a re or explosion

may result causing property damage,

personal injury or death.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute blessure

ou la mort.

Ne pas entreposer ni utiliser d’essence ou ni

d’autres vapeurs ou liquides inammables dans

le à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dans le bâtiment où vous vous trovez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié ou

par le fournisseur de gaz.

H2359200C

Table of Contents

LAARS Heating Systems

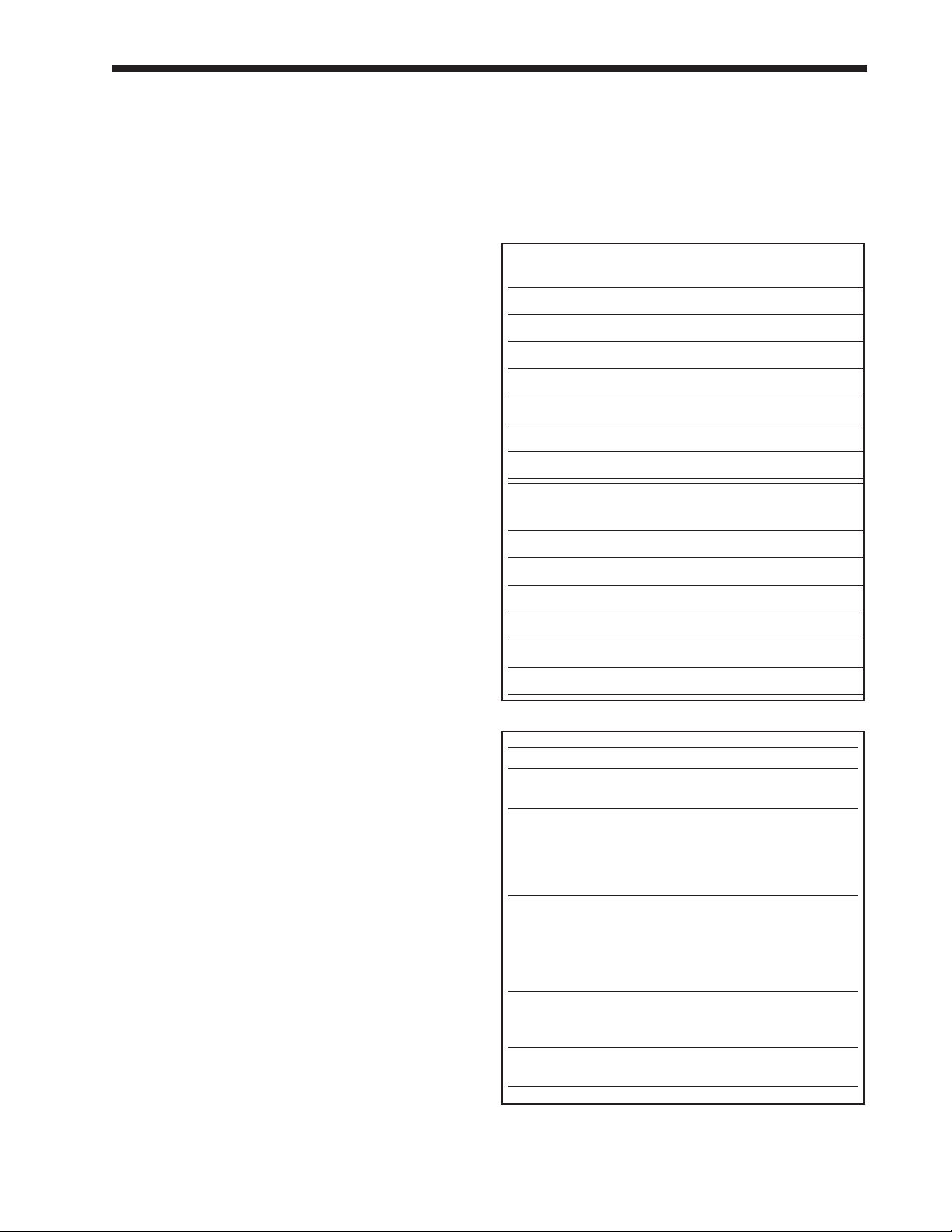

Section 1 - GENERAL INFORMATION

1.1 Introduction ......................................................1

1.2 Safety Notes .....................................................1

1.3 ModelNomenclature/Identication ...............2

1.4 Warranty ...........................................................2

1.5 Unit Overviews ( all sizes ) ...........................3-5

1.6 Dimensions .......................................................6

1.7 Unpacking ........................................................7

Section 2 - LOCA TING THE APPLIANCE

2.1 Locating the Appliance .....................................7

2.2 Correct Vent Distance

from Outside Wall or Roof Termination ...........7

Section 3 - VENTING AND COMBUSTION AIR

3.1 Combustion Air ................................................8

3.1.1 Combustion Air From Room ............................8

3.1.2 Ducted Combustion Air ....................................9

3.2 Venting .............................................................9

3.2.1 Common Venting ............................................10

3.2.3 Venting Requirements Unique to Canada ......10

3.3 Locating the Vent and Combustion Air

Terminals ........................................................11

3.3.1 Side Wall Vent T erminal .................................11

3.3.2 Side Wall Combustion Air Terminal ..............13

3.3.3 V ertical Vent T erminal ....................................14

3.3.4 Vertical Combustion Air Terminal..................14

3.3.5 Installations in the Commonwealth of

Massachusetts .................................................14

3.4 Common Vent Test .........................................15

3.5 Outdoor Installation ........................................16

Section 6 – WATER CONNECTIONS, MGH

6.1 MGH System Piping: Hot Supply

Connections ....................................................19

6.2 MGH Cold Water Make-Up ...........................19

6.3 MGH Freeze Protection..................................19

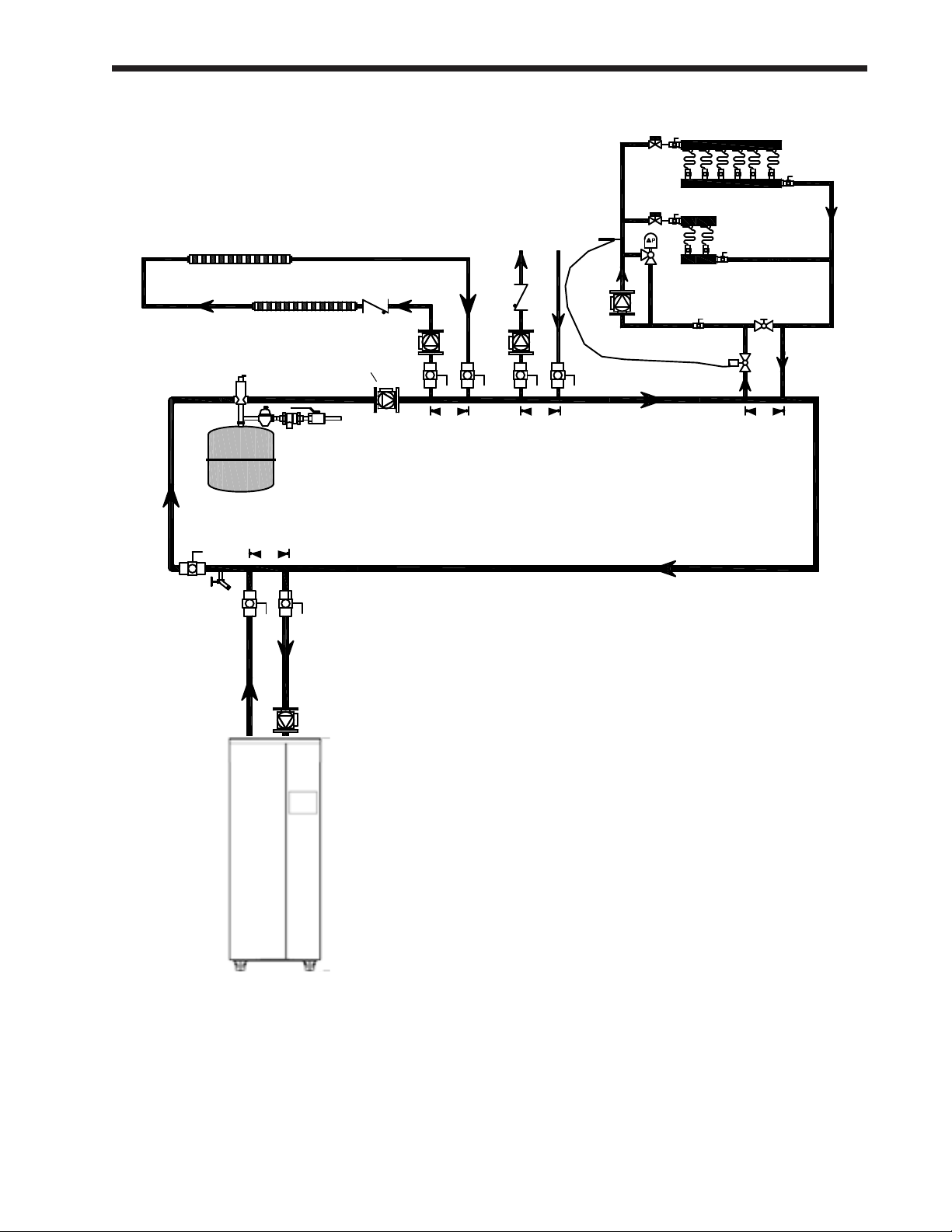

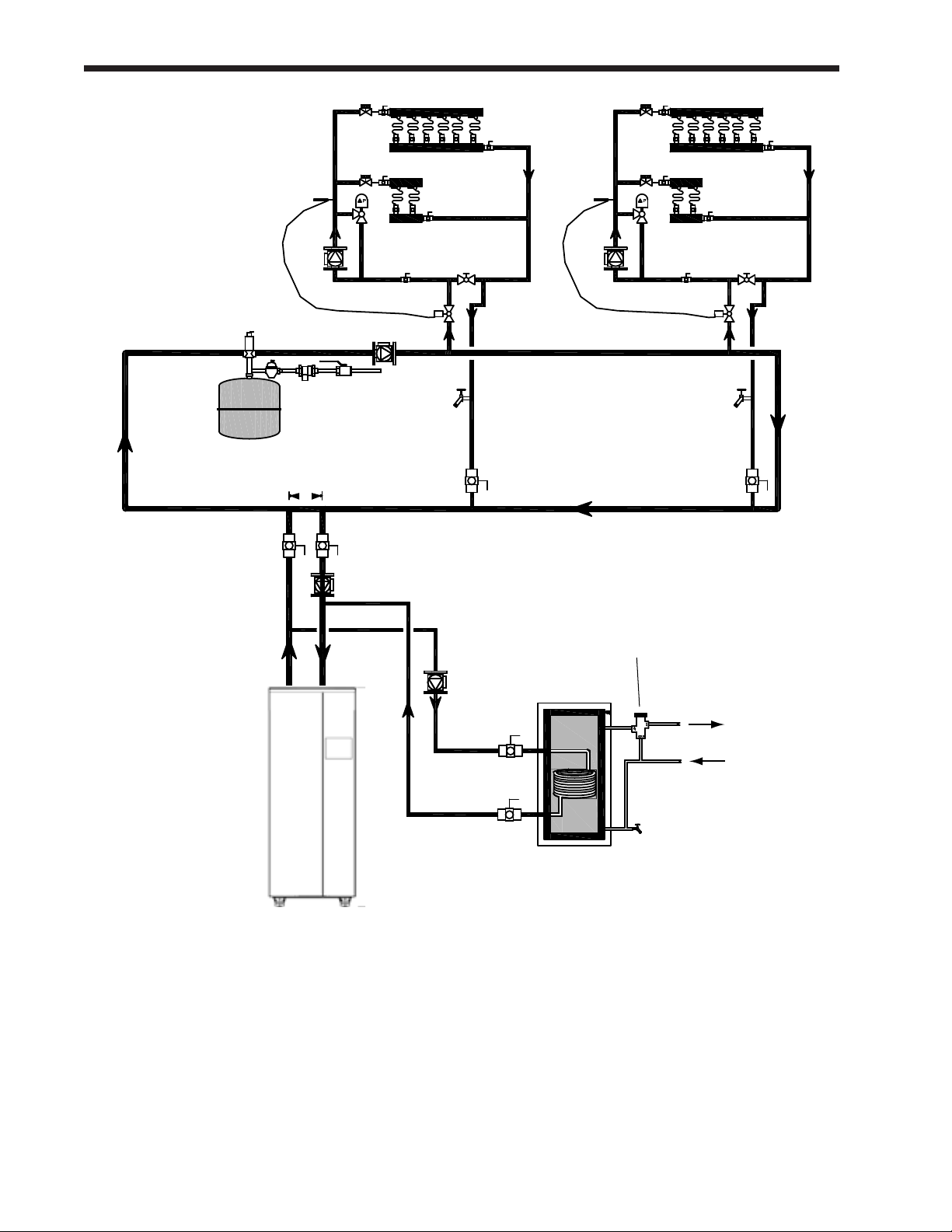

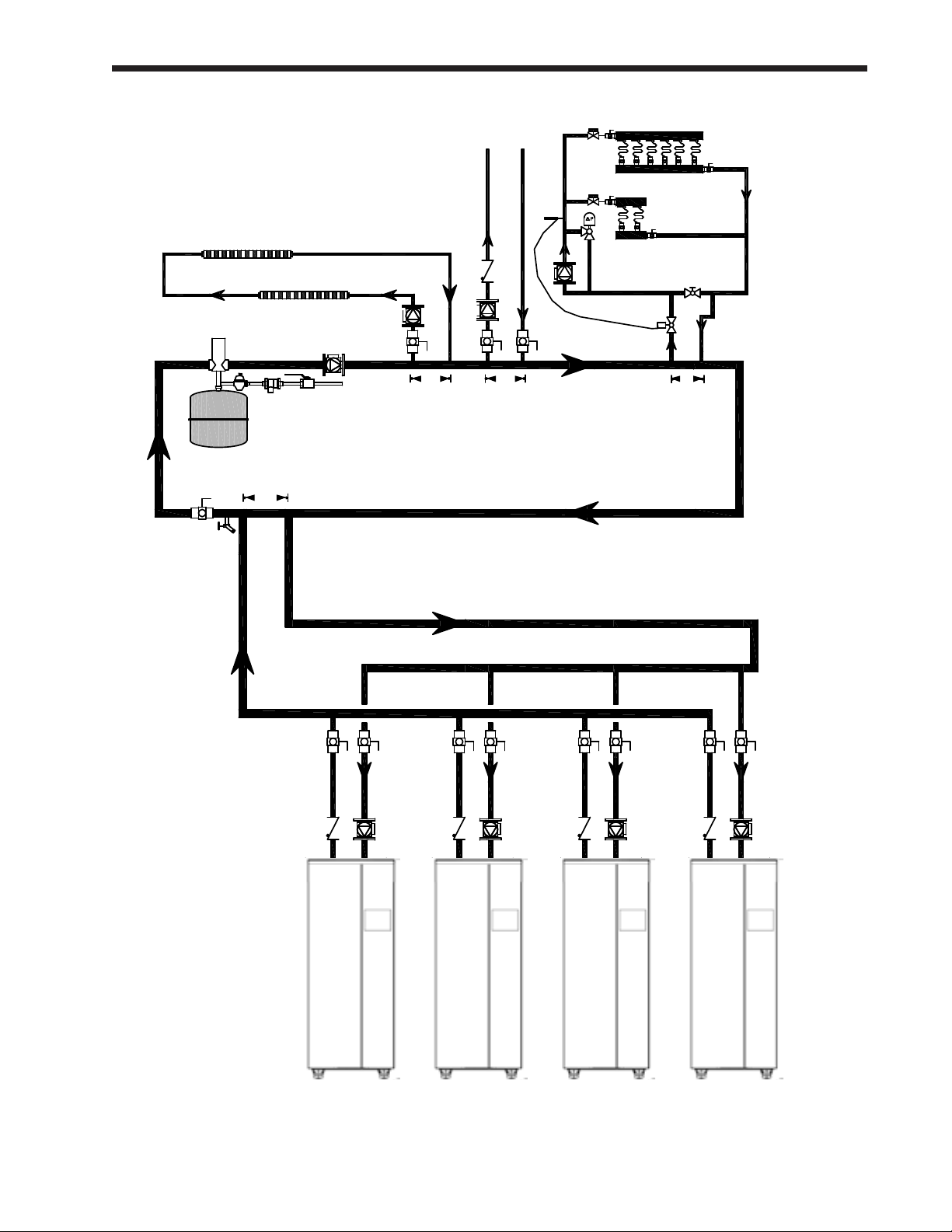

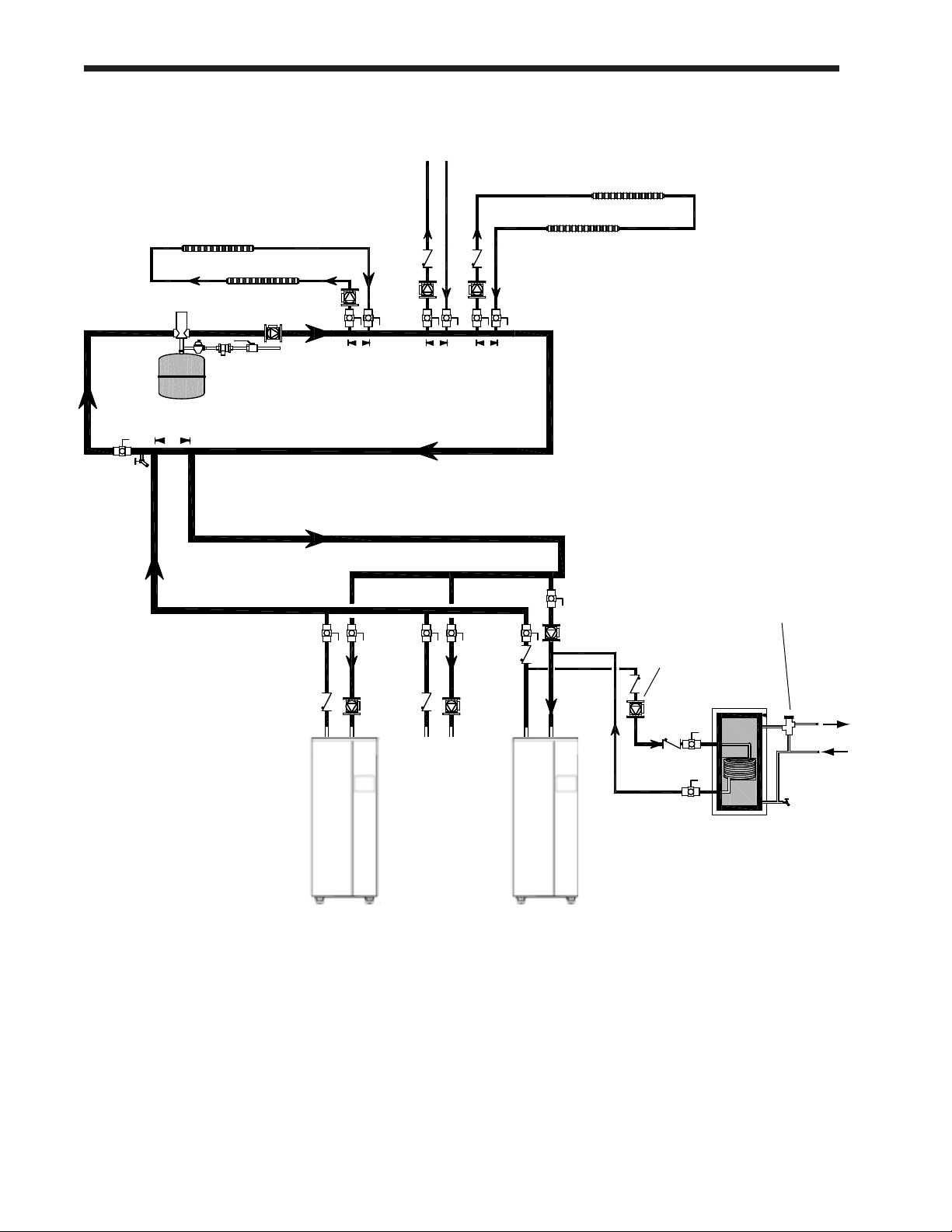

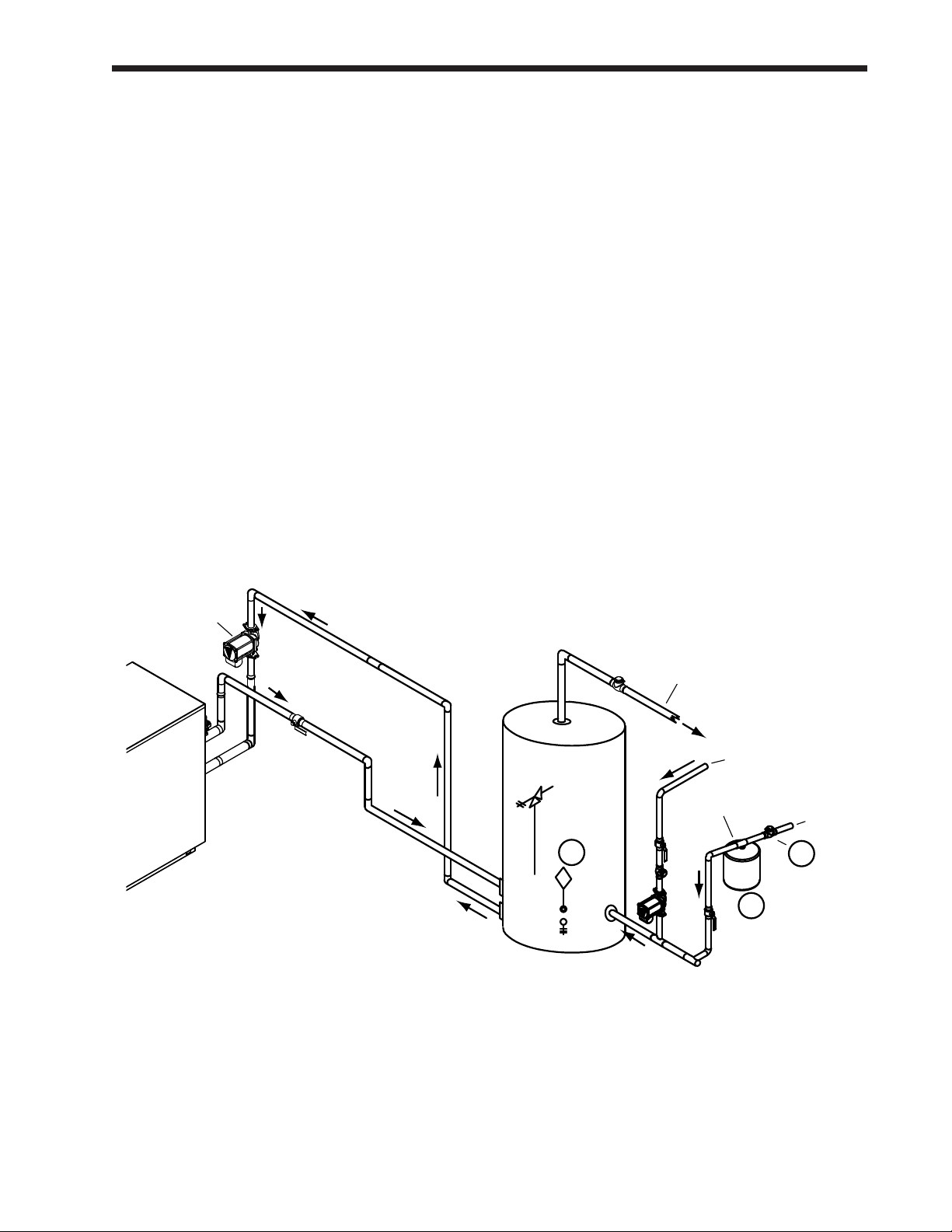

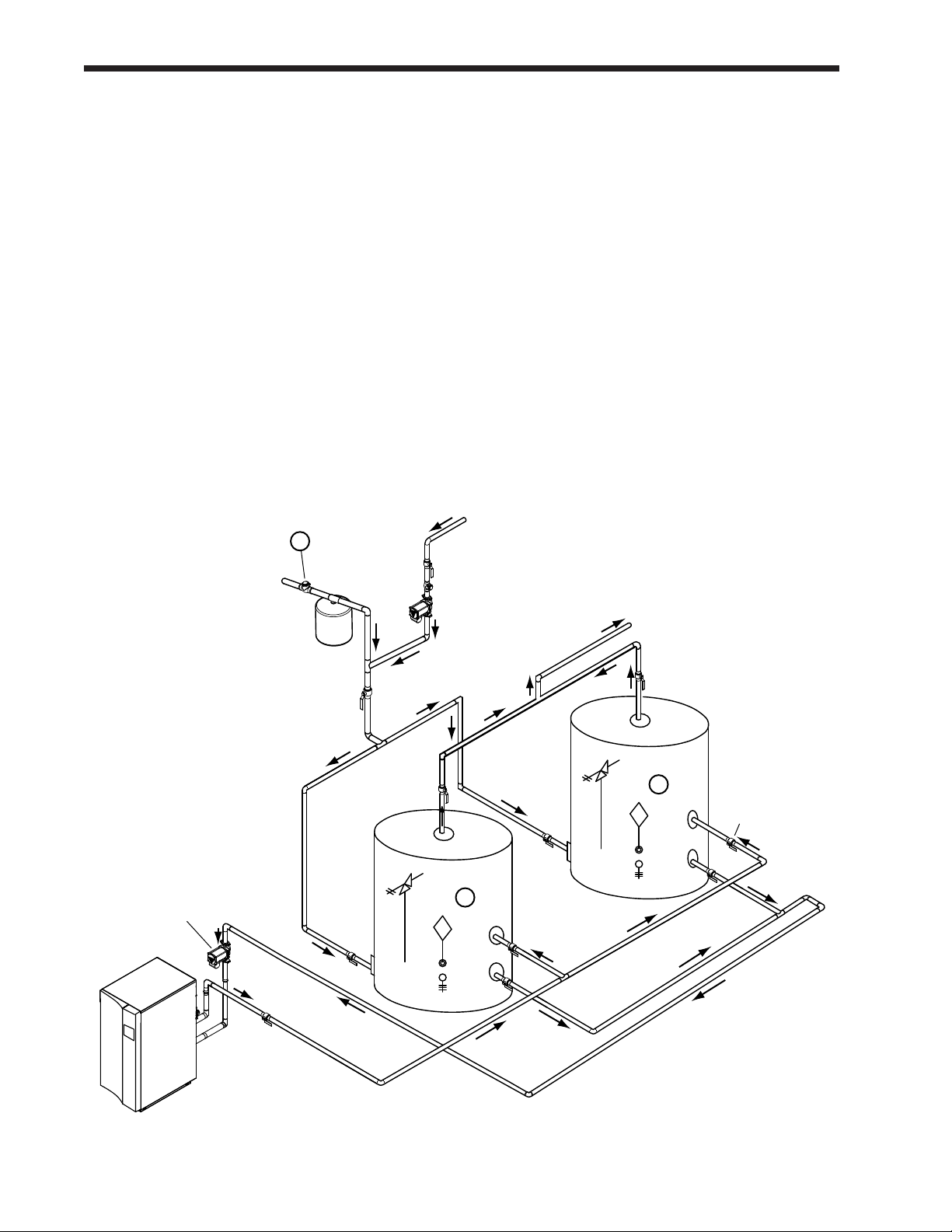

6.4 MGH Suggested Piping Schematics .........20-24

6.5 Condensate Drain Trap ...............................20

Section 7 - WATER CONNECTIONS, MGV

7.1 MGV W ater Quality .......................................25

7.2 MGV Suggested Piping Schematics ...............25

7.3 MGV Piping Requirements ............................25

7.4 MGV Cold Water Make-Up ...........................26

7.5 MGV Freeze Protection ..................................26

7.6 MGV W ater Flow ...........................................27

7.7 Condensate Drain Trap ...................................27

Section 8 – ELECTRICAL CONNECTIONS

8.1 Installation Warnings .....................................28

8.2 Main Power Connections ...............................28

8.3 Pump Connections and Operation ..................29

8.4 Control Panel Layout......................................30

8.5 Wiring Diagram .........................................32-33

8.6 High Voltage Wiring Diagrams .................34-36

8.7 Ladder Diagrams ......................................37-39

Section 4 - GAS SUPPLY AND PIPING

4.0 Gas Supply and Piping ...................................16

Section 5 - WATER FLOW REQUIREMENTS

5.1 MagnaTherm Boiler Flow and Head

Requirements ..................................................18

5.2 MagnaTherm Water Heater Flow and Head

Requirements ..................................................18

i

MagnaTherm Boilers and Water Heaters

Section 9 – NA VIGATING THE TOUCH SCREEN

9.1 The Touch Screen ..........................................40

9.2 Using the Touch Screen ..................................40

9.3 VericationProcessforSafety-Related

Parameters ......................................................42

9.4 While Operating - Checking Individual

Parameters ......................................................43

9.5 ConguringParametersonIndividual

Controllers ......................................................44

9.6 Setting the Date and Time on the

System Display......................45

9.7 CongurationMenus(ALL) ..........................46

9.7.1 SystemIdentication&Access ......................46

9.7.2 CH-CentralHeatConguration....................47

9.7.3 OutdoorResetConguration .........................47

9.7.4 DHW-DomesticHotWaterConguration ...47

9.7.5 WarmWeatherShutdownConguration ........47

9.7.6 DemandPriorityConguration ......................47

9.7.7 ModulationConguration ..............................47

9.7.8 PumpConguration .......................................47

9.7.9 StatisticsConguration ..................................48

9.7.10 High Limits ....................................................48

9.7.11 Stack Limits ....................................................48

9.7.12 Delta T Limits.................................................48

9.7.13 FrostProtectionConguration .......................48

9.7.14 Burner Control Ignition ..................................50

9.7.15 SystemConguration .....................................50

9.7.16 SensorConguration ......................................50

9.7.17 LeadLagSlaveConguration ........................50

9.7.18 LeadLagMasterConguration .....................53

9.8 Parameter Defaults and Ranges ......................53

9.9 Connections to a

Building Automation System .........................57

9.10 Vari-Prime Flow Control System ...................58

9.11 Combustion Setup Procedure .........................59

Section 10 - INITIAL STARTUP INSTRUCTIONS

10.1 Filling the Boiler System ................................62

10.2 Initial Operation .............................................63

10.2.1 Initial Burner Operation .................................63

10.2.2 Combustion Setup Procedure .........................63

10.3 Shutting Down the MagnaTherm ...................63

10.4 Restarting the MagnaTherm ...........................63

Section 11 – MAINTENANCE

11.1 System Maintenance.......................................64

11.2 Maintenance Notes .........................................64

11.2.1 Burner .............................................................64

11.2.2 Modulating Gas Valve/ Venturi ......................64

11.2.3 Controller .......................................................65

11.2.4 Hot Surface Ignitor .........................................65

11.2.5 Flame Sensor ..................................................65

11.2.6 Blower ............................................................65

11.2.7 Heat Exchanger T ubes ....................................66

11.2.8 Gas Pressure Switches ....................................66

Section 12 – TROUBLESHOOTING

12.1 About Lockouts, Holds, and Alerts ................67

12.1.1 Responding to a Lockout, Hold,

or Alert ............................................................67

12.1.2 Viewing the Lockout and Alert

Histories .........................................................67

12.2 Troubleshooting Table ...............................69-83

12.3 Diagnostic Tests and Input/Output

Indicators ........................................................83

12.4 Lead/Lag Slave Diagnostics ...........................84

12.5 Statistics .........................................................84

12.6 Analysis ..........................................................84

12.7 Control Snapshot ............................................85

12.8 Operating Sequence ........................................85

Section 13 – REPLACEMENT PARTS

13.1 General Information .......................................86

13.2 Component Illustrations, Parts Lists,

and Part Numbers ......................................86-99

13.2.1 Frame and Jacket Assembly ...........................87

13.2.2 Final Assembly ...............................................89

13.2.3 Blower Assembly, Model 2000 ......................90

13.2.4 Blower Assembly, Model 2500 ......................91

13.2.5 Blower Assembly, Model 3000 ......................92

13.2.6 Blower Assembly, Model 4000 ......................93

13.2.7 GasTrainAssembly,Models2000&3000 ....94

13.2.8 Gas Train Assembly, Model 2500 ..................96

13.2.9 Gas Train Assembly, Model 4000 ..................97

13.2.10 Waterway Outlet Assembly ...........................98

13.2.11 Control Panel Assembly ..............................100

ii

LAARS Heating Systems

MagnaTherm Boilers and Water Heaters

Section 1

GENERAL INFORMATION

1.1 Introduction

is manual includes information which will

help you to install, operate, and maintain the

Magnaerm 2000, 2500, 3000, 3500 and 4000

systems. Please read this manual completely before

proceeding with the installation. If you have any

questions regarding this equipment, please consult

the LAARS Heating Systems factory, or a local

factory representative. Many operating problems are

caused by improper installation.

1.2 Safety Notes

Page 1

Touch

Screen

DANGER

• Water temperature over 125°F (52°C) can cause

severe burns instantly or death from scalds.

Children, disabled and elderly are at highest risk of

•

being scalded.

See instruction manual before

•

setting temperature at

heating appliance.

•

Feel water before

bathing or showering.

If this appliance is used

•

to produce water that

could scald if too hot,

such as domestic hot water

use, adjust the outlet

control (limit) or use temperature limiting valves

to obtain a maximum water temperature of 125°F

(52°C).

WARNING

Fire or Explosion Hazard

Improper conguration can cause fuel buildup and

explosion. Improper user operation may result in

property loss, severe physical injury, or death.

Any changes to safety-related conguration

parameters must only be done by experienced and/

or licensed burner/boiler operators and mechanics.

If any odor of gas is detected, or if the gas burner

does not appear to be functioning in a normal

manner, close the main gas shuto valve. Do not

shut o the power switch. Contact your heating

contractor, gas company, or factory representative.

Open the

front panel

to access

the Touch

Screen

e Magnaerm Appliance is protected against

over-pressurization. A pressure relief valve is

included with each Magnaerm.

e inlet gas pressure to the appliance must not

exceed 13” W.C. (3.2 kPa).

All installations must be made in accordance with

1) American National Standard Z223.1/NFPA54Latest Edition “National Fuel Gas Code” or 2) CSA

B149.1 “Natural Gas and Propane Installation Code”

and with the requirement of the local utility or other

authorities having jurisdiction. Such applicable

requirements take precedence over the general

instructions contained herein.

WARNING

Carbon Monoxide Hazard

Improper adjustment of the burners may lead to

poor combustion quality, increasing the amount

of carbon monoxide produced. Excessive carbon

monoxide levels may lead to personal injury or

death.

Page 2

LAARS Heating Systems

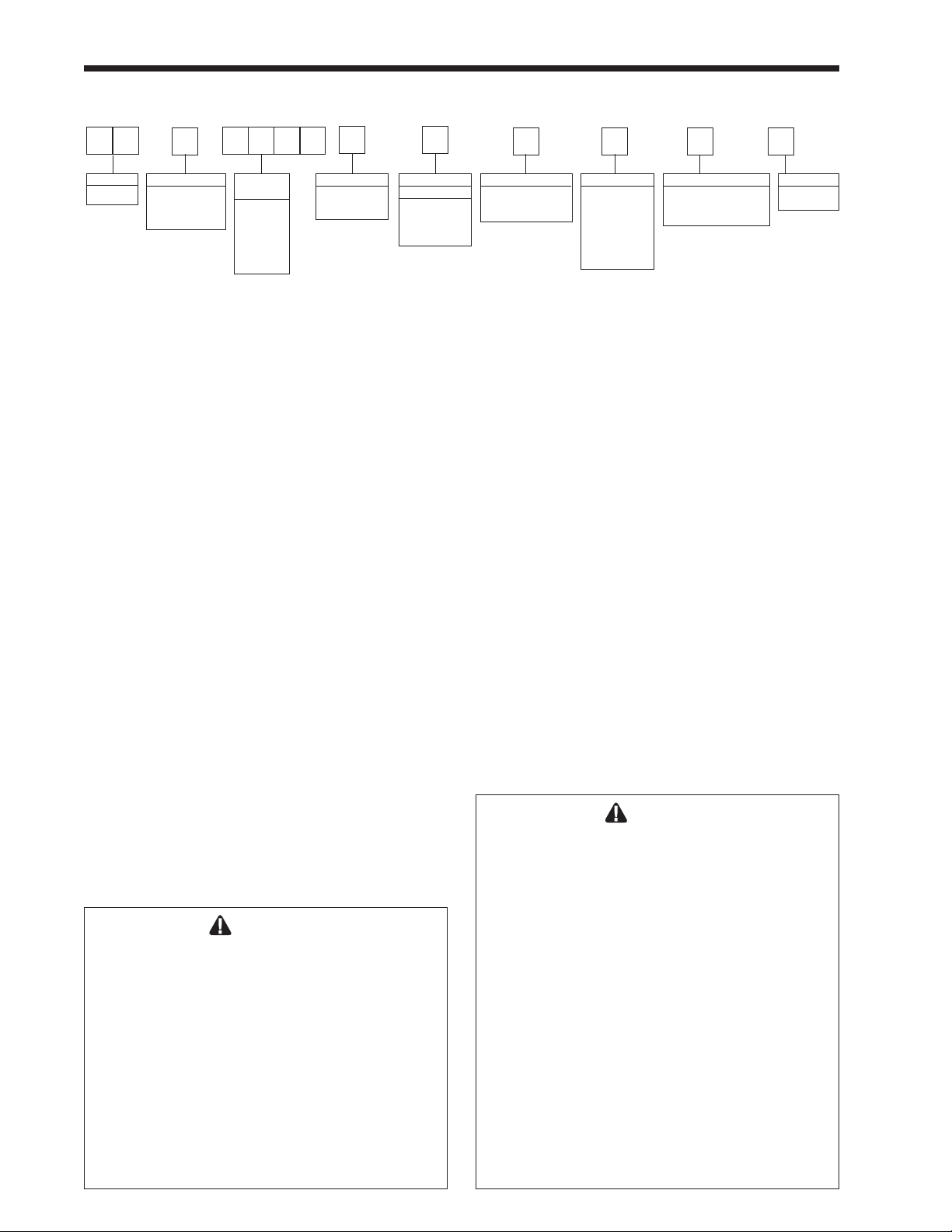

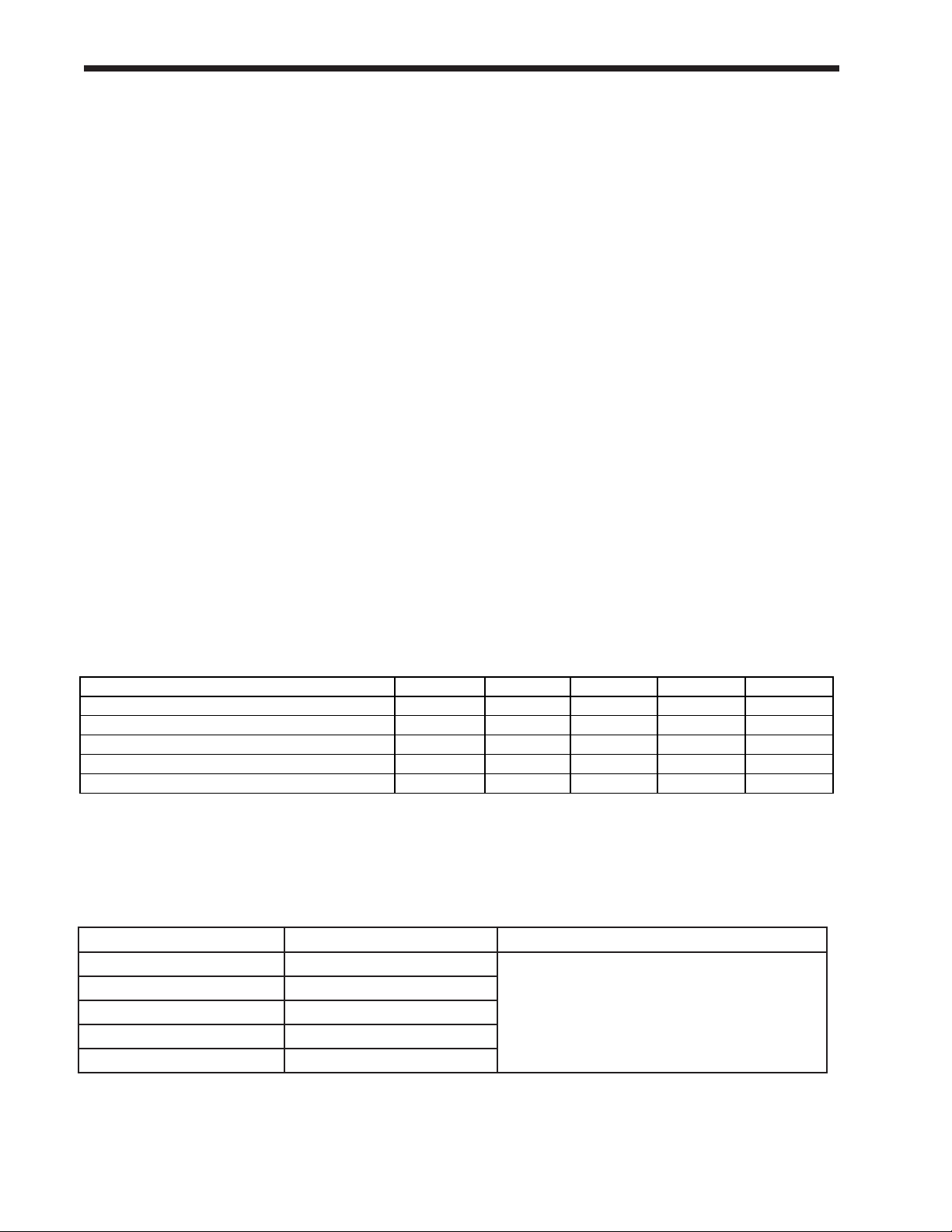

Model Nomenclature

1 2 3 4 5 6 7 8 9 10 11 12 13

M G 1

SERIES

M G

USAGE

H -

HYDRONIC

V - VOLUME

WATER

SIZE

MBTU/h

2000

2500

3000

3500

4000

FUEL

N - NATURAL

P - PROPANE

COUNTRY

CODE

X - USA/

CANADA

E - EXPORT

Not CSA approved

*

*

OPTIONS CODE

X -

STANDARD

J - CSD-1

ELEC SYSTEM

A - 110V, 1Ø

B - 220V, 1Ø

C - 208V, 3Ø

D - 480V, 3Ø

E - 600V, 3Ø

ASME

X - “H” STAMP (MGH)

W - “HLW” STAMP (MGV)

1.3 ModelIdentication

Consult the rating plate on the unit. The following

information describes the model number structure.

(1-2) Model Series Designation

M G = MagnaTherm

(3) Usage

H = Hydronic

V = Volume Water

(4-7) Size

2 0 0 0 = 1,999,000 BTU/hr input

2 5 0 0 = 2,499,000 BTU/hr input

3 0 0 0 = 3,000,000 BTU/hr input

3 5 0 0 = 3,500,000 BTU/hr input

4 0 0 0 = 4,000,000 BTU/hr input

(8) Fuel

N = Natural Gas

P = LP Gas

(9) Country Code

X = USA / CANADA

E - Export (CE - non CSA)

(10) Option Code

X = Standard Unit

J = CSD1 Version

(11) Electrical System

A - 110V, (Single Phase)

B - 220V, (Single Phase)

C - 208V, (Three Phase)

D - 480V, (Three Phase)

E - 600V, (Three Phase)

(12) Additional Options

X - “H” STAMP (MGH)

W - “HLW” STAMP (MGV)

(13) Revision

1 = First

WARNING

Electrical Shock Hazard

Electrical shock can cause severe injury, death or

property damage. Disconnect the power supply

before beginning installation or changing the

wiring to prevent electrical shock or damage to the

equipment. It may be necessary to turn o more than

one power supply disconnect.

All electrical wiring is to be done in accordance with

local codes, or in the absence of local codes, with:

1) e National Electrical Code ANSI/NFPA No.

70 - latest Edition, or 2) CSA STD. C22.1 “Canadian

Electrical Code - Part 1.” is appliance must be

electrically grounded in accordance with these codes.

Altitude:

Gas input rating of the MagnaTherm shall be used for

elevations up to 2000 ft (600 m). The input rating at

elevations above 2000 ft (600 m) shall be reduced at

a rate of 4 percent for each 1000 ft (300 m) above sea

level before selecting the equipment size.

1.4 Warranty

LAARS Heating Systems MagnaTherm boilers are

covered by a limited warranty. The owner should

complete the warranty registration at

http://www.LAARS.com

ALL WARRANTY CLAIMS must be made by an

authorized LAARS Heating Systems representative.

Claims must include the serial number and model

(this information can be found on the rating plate).

All claims must also include the installation date and

name of the installer. Shipping costs are not included

in the warranty coverage.

WARNING

Magnaerm units must be installed in

accordance with the procedures detailed in this

manual, or the LAARS Heating Systems warranty

will be voided. e installation must conform to

the requirements of the local jurisdiction having

authority, and, in the United States, to the latest

edition of the National Fuel Gas Code, ANSI

Z223.1/NFPA54. In Canada, the installation

must conform to the latest edition of CSA

B149.1 Natural Gas and Propane Gas Installation

Code, and/or local codes. Where required by the

authority having jurisdiction, the installation

of Magnaerm boilers must conform to the

Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1.

Any modications to the boiler, its gas controls, or

wiring may void the warranty. If eld conditions

require modications, consult the factory

representative before initiating such modications.

REVISION

1 -FIRST

MagnaTherm Boilers and Water Heaters

1.5 Unit Overviews

The next 3 pages give a visual reference to

the basic component locations of the LAARS

MagnaTherm.

Page 3

Blower

Manual

gas valve

Touch Screen

Heat Exchanger

Power Pack

Model 2000

Perspective from front left corner.

Shown with front doors and left side

panels removed

Condensing Unit

Air Intake and

Filter

Water Outlet

Water Inlet

Vent

Condensate

Trap

Perspective from opposite corner.

Page 4

Blower

Manual

gas valve

Touch Screen

Heat Exchanger

LAARS Heating Systems

Power Pack

Condensing Unit

Air Intake and

Filter

Water Outlet

Water Inlet

Models 2500 and 3000

Vent

Condensate

Trap

MagnaTherm Boilers and Water Heaters

Page 5

Blower

Manual

gas valve

(hidden behind main

gas valve)

Touch Screen

Heat Exchanger

Condensing Unit

Power Pack

Models 3500 and 4000

Air Intake and

Filter

Water Outlet

Water Inlet

Vent

Condensate

Trap

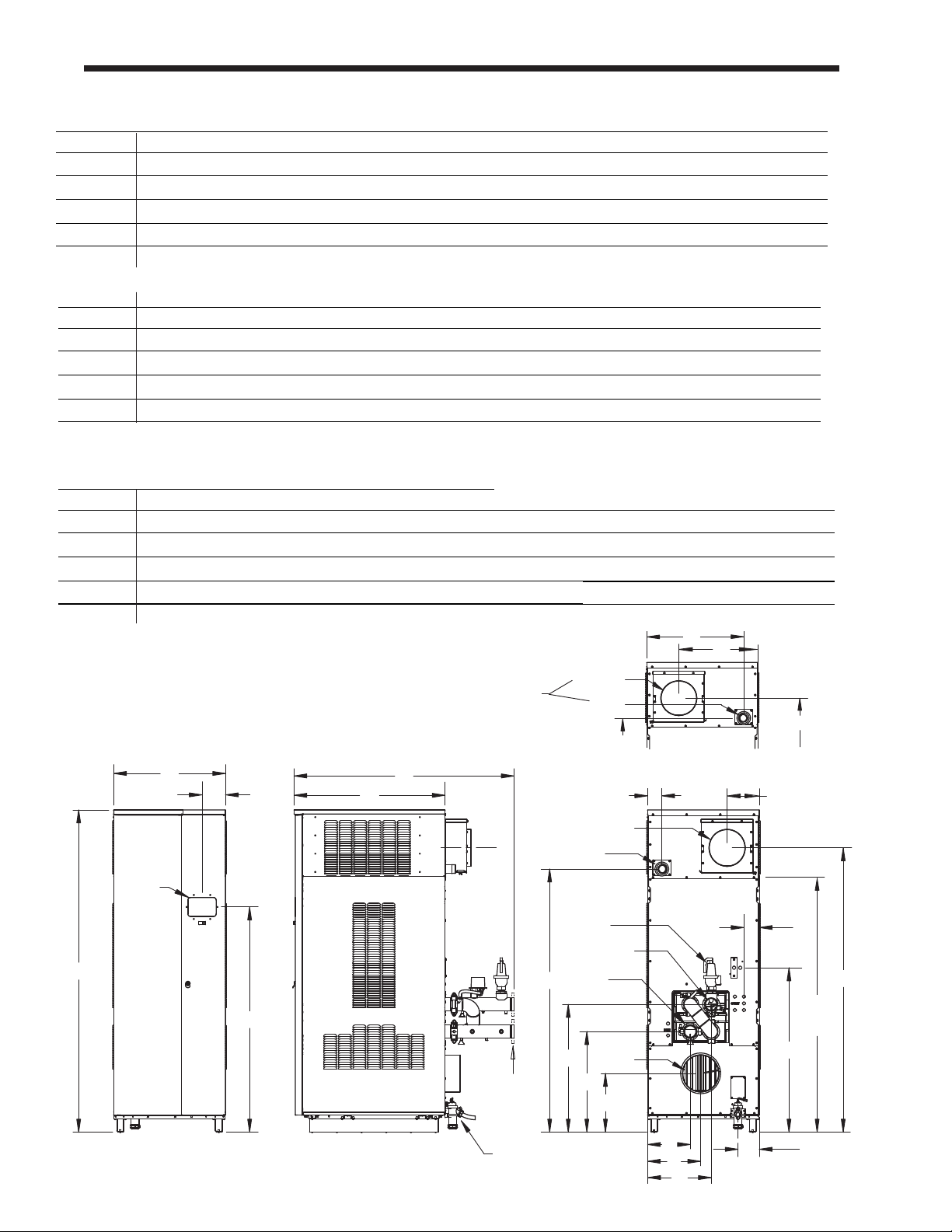

Page 6

E

F

U

B

A

VIEW

REAR

N

Q

S

P

M

R

L

G

H

K

J

T

FRONT

VIEW

SIDE

VIEW

C

D

Condensate Trap

Contact

Factory

Oponal

Flanges,

Vent

Gas

6”x3.5”

Touchscreen

Display

Air Inlet

Pressure

Relief

Valve

Water

Outlet

‘Knock-

down’

Height

Water

Inlet

H

J

Gas

Air Inlet

Model 4000

The Model 4000 varies from other sizes in the locaon of it’s Air Inlet and Gas Supply.

G

K

VIEWREAR

J K L M N P Q R S T U

Inches (cm) Inches (cm) Inches (cm)

29.3 (75) 79 (201) 38 (96) 57.5 (147) 49.8 (126) 4.8 (12) 60.8 (154) 2.6 (7) 8.4 (21) 67.4 (171) 4 (10) 39.2 (100) 30.4 (77) 16 (41) 23 (58) 10.2 (26) 14 (36) 13 (33) 6.3 (16) 8 (20) 8 (20) 60.8 (154)

9.8 (25) 76.4 (194) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30) 18.3 (46) 14.8 (38) 6 (15) 8 (20) 8 (20 ) 71.0 (180)

8.9 (23) 76.8 (195) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30) 18.3 (46) 14.8 (38) 6 (15) 10 (25 ) 10 (25 ) 71.0 (180)

26.5 (67) 85.6 (217) 6.5 (16) 51.3 (130) 40 (102) 21.6 (55) 30.7 (78) 13 (33) 16 (41) 17.4 (44) 6.7 (17 )

34.5 (88) 97 (246) 52 (133) 70 (178) 60.8 (154 ) 6.4 (16) 80.8 (205) 28.8 (73) 26.5 (67) 85.6 (217) 6.5 (16) 51.3 (130) 40 (102) 21.6 (55) 30.7 (78) 13 (33) 16 (41) 17.4 (44) 6.7 (17 ) 12 (30) 12 (30) 80.8 (205)

A B C D E F G H J K L M N P Q R S T U

Inches (cm) Inches (cm) Inches (cm)

29.3 (75) 79 (201) 38 (96) 57.5 (147) 49.8 (126) 4.8 (12) 60.8 (154) 2.6 (7) 8.4 (21 ) 67.4 (171) 4 (10) 39.2 (100) 30.4 (77 ) 16 (41) 23 (58) 10.2 (26) 14 (36) 13 (33) 6.3 (16) 8 (20 ) 8 (20) 60.8 (154)

30.8 (78)

87 (221) 41.5 (105) 60.5 (154) 60.8 (154) 6.5 (16) 71 (180) 4 (10) 9.8 (25 ) 76.4 (194) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30) 18.3 (46) 14.8 (38) 6 (15) 8 (20) 8 (20) 71.0 (180 )

30.8 (78)

87 (221) 41.5 (105) 60.5 (154) 60.8 (154) 6.5 (16) 71 (180) 4 (10) 8.9 (23 ) 76.8 (195) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30) 18.3 (46) 14.8 (38) 6 (15) 10 (25) 10 (25) 71.0 (180)

34.5 (88) 97 (246) 52 (133) 70 (178) 60.8 (154 ) 6.4 (16) 80.8 (205) 28.8 (73) 26.5 (67) 85.6 (217) 6.5 (16) 51.3 (130) 40 (102) 21.6 (55) 30.7 (78) 13 (33) 16 (41) 17.4 (44) 6.7 (17 )

34.5 (88) 97 (246) 52 (133) 70 (178) 60.8 (154 ) 6.4 (16) 80.8 (205) 28.8 (73) 26.5 (67) 85.6 (217) 6.5 (16) 51.3 (130) 40 (102) 21.6 (55) 30.7 (78) 13 (33) 16 (41) 17.4 (44) 6.7 (17 ) 12 (30) 12 (30) 80.8 (205)

S T U

Vent Ø

18.3 (46) 14.8 (38) 6 (15) 8 (20) 8 (20) 71.0 (180)

18.3 (46) 14.8 (38) 6 (15) 10 (25) 10 (25) 71.0 (180)

10 (25) 10 (25)

A B C D E F G H J K L M N P Q R S T U

Inches (cm) Inches (cm) Inches (cm)

29.3 (75) 79 (201) 38 (96) 57.5 (147) 49.8 (126) 4.8 (12) 60.8 (154) 2.6 (7) 8.4 (21 ) 67.4 (171) 4 (10) 39.2 (100) 30.4 (77 ) 16 (41) 23 (58) 10.2 (26) 14 (36) 13 (33) 6.3 (16) 8 (20 ) 8 (20) 60.8 (154)

30.8 (78)

87 (221) 41.5 (105) 60.5 (154) 60.8 (154) 6.5 (16) 71 (180) 4 (10) 9.8 (25 ) 76.4 (194) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30) 18.3 (46) 14.8 (38) 6 (15) 8 (20) 8 (20) 71.0 (180 )

30.8 (78)

87 (221) 41.5 (105) 60.5 (154) 60.8 (154) 6.5 (16) 71 (180) 4 (10) 8.9 (23 ) 76.8 (195) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30) 18.3 (46) 14.8 (38) 6 (15) 10 (25) 10 (25) 71.0 (180)

34.5 (88) 97 (246) 52 (133) 70 (178) 60.8 (154 ) 6.4 (16) 80.8 (205) 28.8 (73) 26.5 (67) 85.6 (217) 6.5 (16) 51.3 (130) 40 (102) 21.6 (55) 30.7 (78) 13 (33) 16 (41) 17.4 (44) 6.7 (17 )

4000

34.5 (88) 97 (246) 52 (133) 70 (178) 60.8 (154 ) 6.4 (16) 80.8 (205) 28.8 (73) 26.5 (67) 85.6 (217) 6.5 (16) 51.3 (130) 40 (102) 21.6 (55) 30.7 (78) 13 (33) 16 (41) 17.4 (44) 6.7 (17 ) 12 (30) 12 (30) 80.8 (205)

Vent Ø

Air Inlet Ø

10 (25) 10 (25)

80.8 (205)

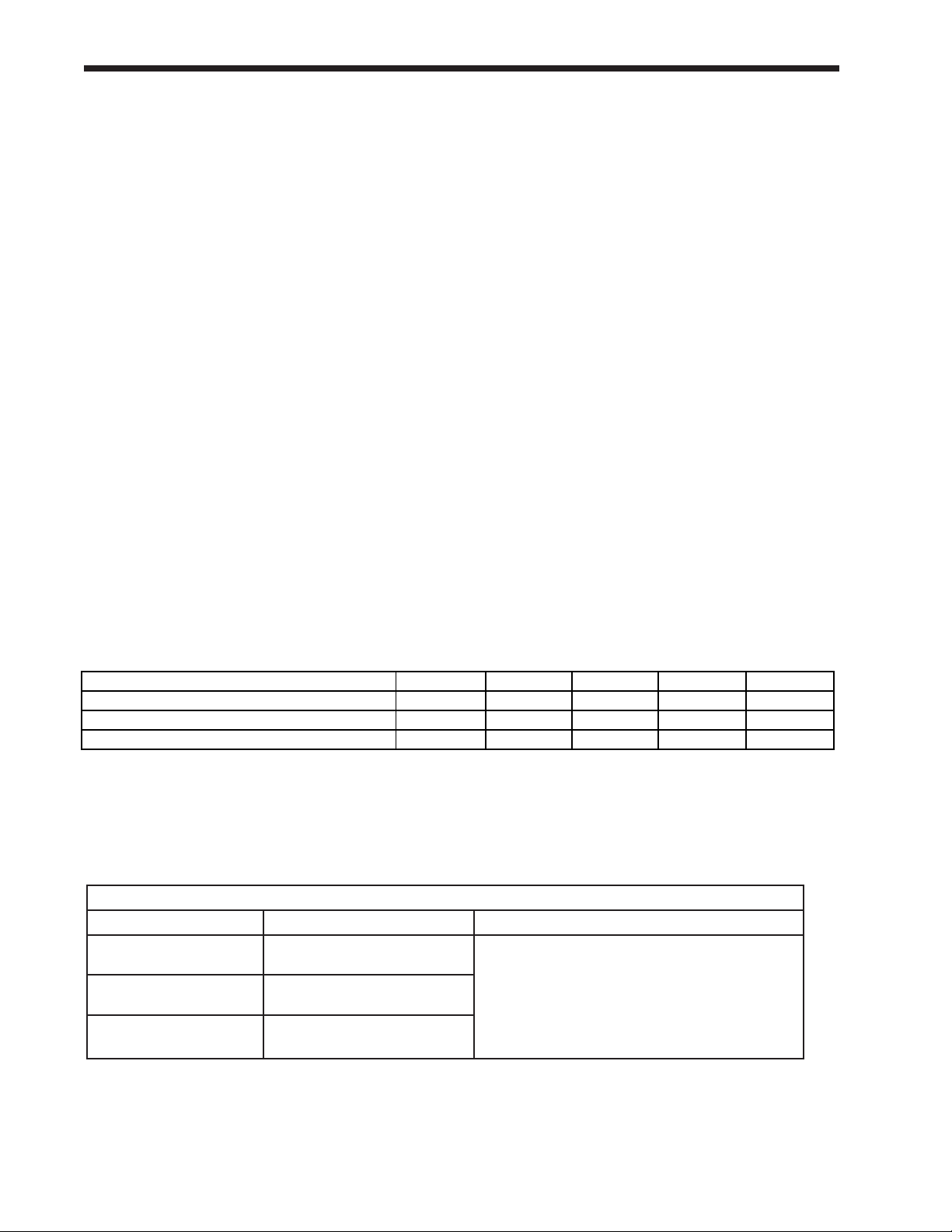

Water Gas

Condensate

Connection Connection Line

3" Groove L ock

(or flange)

2" NPT 1"

3" Groove L ock

(or flange)

2" NPT 1"

3" Groove L ock

(or flange)

2" NPT 1"

4" Groove L ock

(or flange)

2" NPT 1"

4" Groove L ock

(or flange)

2" NPT 1"

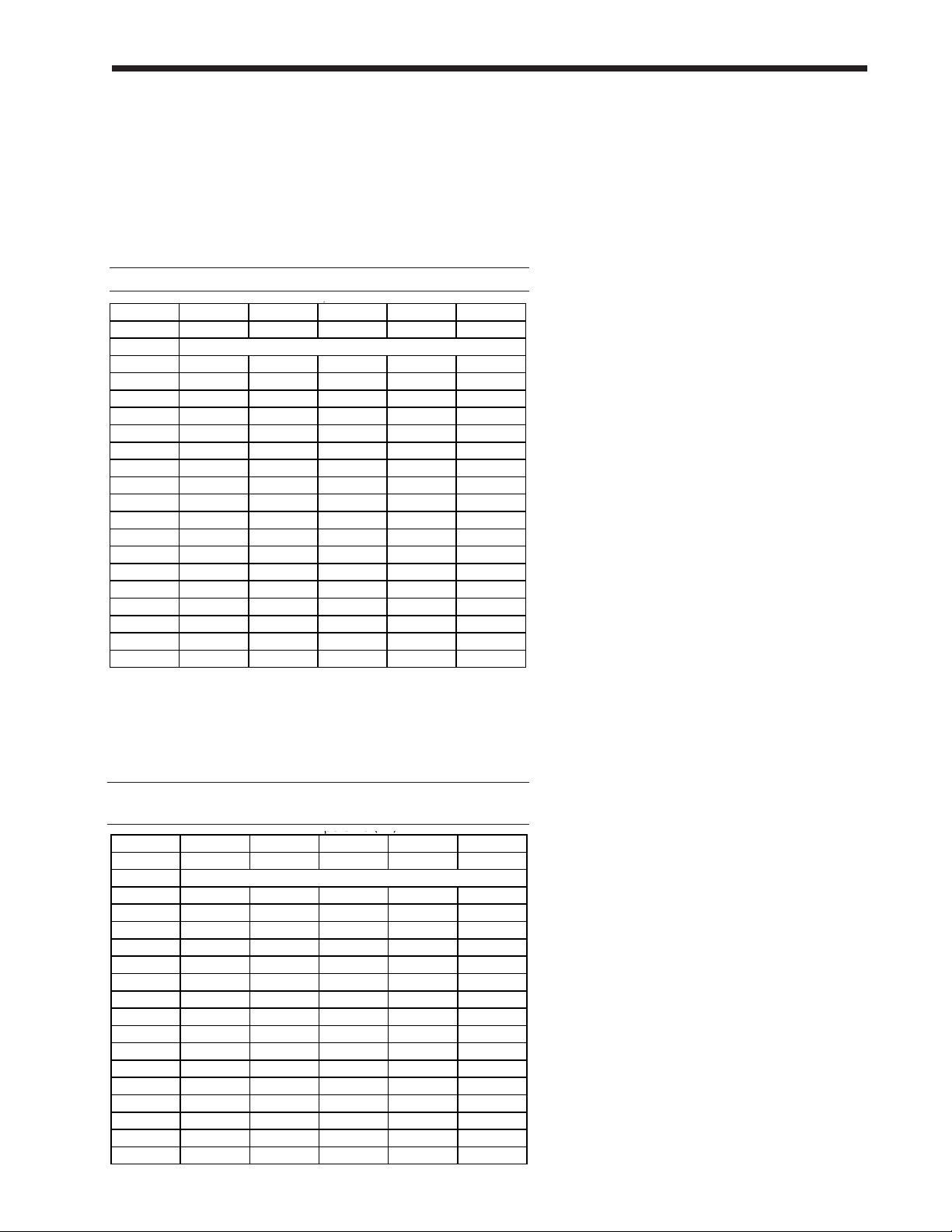

1.6 Dimensions

Model

2000

2500 30.8 (78)

3000 30.8 (78)

3500

4000

A B C D E F G H

34.5 (88) 97 (246) 52 (133) 70 (178) 60.8 (154 ) 6.4 (16) 80.8 (205) 28.8 (73)

87 (221) 41.5 (105) 60.5 (154) 60.8 (154) 6.5 (16) 71 (180) 4 (10)

87 (221) 41.5 (105) 60.5 (154) 60.8 (154) 6.5 (16) 71 (180) 4 (10)

LAARS Heating Systems

Model

2000

2500

3000

3500

4000

Model

2000

2500

3000

3500

Models 3500 and 4000 differ from the other sizes in the location of their Air Inlet and Gas Supply.

J K L M N P Q R

9.8 (25) 76.4 (194) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30)

8.9 (23) 76.8 (195) 4.3 (11) 44.4 (113) 34.5 (88) 17.7 (45) 27.2 (69) 11.8 (30)

'Knock-

down'

Height

Models 3500 / 4000

Figure 1. Dimensions

MagnaTherm Boilers and Water Heaters

Page 7

1.7 Unpacking

The MagnaTherm is shipped in a single crate.

Remove all packing and tie-down materials.

Section 2

LOCA TING THE APPLIANCE

2.1 Locating the Appliance

The MagnaTherm may be installed indoors or

outdoors. If installing outdoors in a location that

may experience freezing temperatures, precautions

must be taken to prevent water in the heat exchanger

and condensate inside and outside of the boiler from

freezing. Damage due to freezing water or condensate

is not covered by the warranty .

Choose a location for the unit which allows clearances

on all sides for maintenance and inspection. See T able 1.

Always install the unit on a rm, level surface.

The unit should not be located in an area where

leakage of any connections will result in damage to

the area adjacent to the appliance, or to lower oors

of the structure.

When this type of location is not available, install

a suitable drain pan, adequately drained, under the

appliance.

The appliance is design-certied by CSA-

International for installation on combustible

ooring; in basements; in utility rooms or alcoves.

MagnaTherm boilers must never be installed on

carpeting. The location for the appliance should

be chosen with regard to the vent pipe lengths and

external plumbing.

The unit shall be installed such that the gas ignition

system components are protected from water (dripping,

spraying, rain, etc.) during operation and service

(circulator replacement, control replacement, etc.).

When vented vertically , the MagnaTherm must be

located as close as practical to the vertical section

of the vent. If the vent terminal and/or combustion

air terminal terminate through a wall, and there is

potential for snow accumulation in the local area, both

terminals should be installed at an appropriate level

above grade or the maximum expected snow line.

The dimensions and requirements that are shown in

Table 1 should be met when choosing the locations

for the appliance.

2.2 Correct Vent Distance from Outside Wall or Roof Termination

The forced draft combustion air blower in the

appliance has sufcient power to vent properly when

the guidelines in Table 2 are followed.

Note - When located on the same wall, the

MagnaTherm combustion air intake terminal must be

installed a minimum of 12” (30cm) below the exhaust

terminal. There must also be a minimum horizontal

distance from intake to the exhaust terminal

of 84” (213cm) See Figure 4

APPLIANCE SUGGESTED SERVICE ACCESS CLEARANCE

SURFACE INCHES CM

Front 24 61

Left Side 8 20

Right Side 8 20

Back 24 61

Top, 2000 12 30

Top, 2500 & 3000 15 38

Top, 4000 24 61

APPLIANCE REQUIRED CLEARANCE TO COMBUSTIBLES

SURFACE INCHES CM

Front 18 45

Left Side 4 15

Right Side 4 15

Back 11 15

Top 1 2.5

Vent 1 2.5

Table 1. Clearances

INTAKE / EXHAUST

MAX EQUIVALENT

SIZE DIAMETER FT. M

2000 & 2500 8” 100 30

3000 & 3500 10” 100 30

4000 12” 100 30

Installations in the U.S. require exhaust vent pipe that is CPVC

complying with ANSI/ASTM D1785 F441, polypropylene

complying with ULC S636, or stainless steel complying with

UL1738. Installations in Canada require exhaust vent pipe that

is certied to ULC S636.

Intake (air) pipe must be PVC or CPVC that complies with

ANSI/ASTM D1785 F441, ABS that complies with ANSI/ASTM

D1527, stainless steel, or galvanized material.

To calculate max equivalent length, measure the linear feet of

the pipe, and add 5 feet (1.5 m) for each elbow used.

Table 2. Vent / Air Pipe Sizes

Page 8

(Place in section 3.1)

Screen for horizontal galvanized air pipe D2012101 D2012101 D2012102 D2012103 D2012103

Screen for horizontal PVC air pipe CA012001 CA012001 CA012002 CA012003 CA012003

Screen for horizontal polypropylene air pipe CA012201 CA012201 CA012202 CA012203 CA012203

Screen for vertical galvanized air pipe D2012201 D2012201 D2012202 D2012203 D2012203

Screen for vertical PVC air pipe CA012401 CA012401 CA012402 CA012403 CA012403

Screen for vertical polypropylene air pipe CA012601 CA012601 CA012602 CA012603 CA012603

Section 3

VENTING AND COMBUSTION AIR

3.1 Combustion Air

MagnaTherm boilers and water heaters must have

provisions for combustion and ventilation air in

accordance with the applicable requirements for

Combustion Air Supply and Ventilation in the

National Fuel Gas Code, ANSI Z223 1; or in Canada,

the Natural Gas and Propane Installation Code, CSA

B149.1. All applicable provisions of local building

codes must also be adhered to.

A MagnaTherms can take combustion air

from the space in which it is installed, or the

combustion air can be ducted directly to the unit.

Ventilation air must be provided in either case.

3.1.1 Combustion Air From Room

In the United States, the most common requirements

specify that the space shall communicate with the

outdoors in accordance with Method 1 or 2. (See the

following descriptions.) Where ducts are used, they

shall be of the same cross-sectional area as the free

area of the openings to which they connect.

Method 1: Two permanent openings, one

LAARS Heating Systems

commencing within 12” (300 mm) of the top and

one commencing within 12” (300 mm) of the

bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts,

with the outdoors or spaces that freely communicate

with the outdoors. When directly communicating

with the outdoors, or when communicating to the

outdoors through vertical ducts, each opening shall

have a minimum free area of 1 square inch per

4000 Btu/hr (550 square mm/kW) of total input

rating of all equipment in the enclosure. When

communicating to the outdoors through horizontal

ducts, each opening shall have a minimum free

area of not less than 1 square inch per 2000 Btu/

hr (1100 square mm/kW) of total input rating of all

equipment in the enclosure.

Method 2: One permanent opening, commencing

within 12” (300 mm) of the top of the enclosure,

shall be permitted. The opening shall directly

communicate with the outdoors or shall

communicate through a vertical or horizontal duct

to the outdoors or spaces that directly communicate

Table 3. Ducted Air Accessories

PVC, sch. 40 ANSI/ASTM D1785 or D2665

CPVC, sch. 40 ANSI/ASTM F441

Single wall galv. steel 26 gauge

Polypropylene ULC S636 Class 2C

Table 4. Required Combustion Air Pipe Material

Model 2000 Model 2500 Model 3000 Model 3500 Model 4000

Material United States Canada

ABS ANSI/ASTM D1527 The air pipe material must be chosen based upon

the intended application of the boiler, and must

be installed according to the vent manufacturer’s

installation instructions.

MagnaTherm Boilers and Water Heaters

with the outdoors and shall have a minimum free

area of 1 square inch per 3000 Btu/hr (734 square

mm/kW) of the total input rating of all equipment

located in the enclosure. This opening must not be

less than the sum of the areas of all vent connectors

in the conned space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they

conform to the requirements in the applicable codes

listed above.

In Canada, consult local building and safety codes

or, in absence of such requirements, follow CAN/

CSA B149.

3.1.2 Ducted Combustion Air

The combustion air can be taken through the wall, or

through the roof. LAARS offers accessories to use

with ducted air systems, as shown in Table 3.

See Table 4 to select the appropriate diameter air

pipe. When taken from the roof, a eld-supplied

rain cap or an elbow arrangement must be used to

prevent entry of rain water. (See Figure 6).

Use ABS, PVC, CPVC, polypropylene, stainless

steel, or galvanized pipe for the combustion air

intake. (See Table 4) The intake must be sized per

Table 2. Route the intake to the boiler as directly

as possible. Seal all joints. Provide adequate

hangers. The unit must not support the weight of

the combustion air intake pipe. The maximum

equivalent pipe length allowed is 100 feet (30 m).

Each elbow is considered to be 5 feet (1.5m)

Page 9

3.2 Venting

WARNING

Selection of improper vent materials for

installations that are installed in closets, or will be

operated in high ambient temperature levels, may

lead to property damage, personal injury, or death.

WARNING

Failure to use the appropriate vent material,

installation techniques, or glues and sealants

could lead to vent failure causing property

damage, personal injury or death.

WARNING

All venting must be installed according to this

manual and any other applicable local codes,

including but not limited to, ANSI Z223.1/NFPA 54,

CSA B149.1, CSAB149.2 and ULC S636. Failure

to follow this manual and applicable codes may

lead to property damage, severe injury, or death.

When using polypropylene or stainless steel

materials in horizontal duct congurations, a single

elbow must be installed on the end of the air inlet

to act as an outdoor terminal. In vertical duct

applications, two elbows must be installed on the

end of the inlet to act as a vent terminal. When

elbows are use as terminals, appropriate screens

must be installed to prevent blockage.

The elbow(s) required for termination are not

included in the kits sown in Table 3

The connection for the intake air pipe is on the back

panel.

In addition to air needed for combustion, air shall

also be supplied for ventilation, including air

required for comfort and proper working conditions

for personnel. Refer to the applicable codes.

Page 10

(Place in section 3.1)

Model 2000 Model 2500 Model 3000 Model 3500 Model 4000

Screen for horizontal galvanized air pipe D2012101 D2012101 D2012102 D2012103 D2012103

Screen for horizontal PVC air pipe CA012001 CA012001 CA012002 CA012003 CA012003

Screen for horizontal polypropylene air pipe CA012201 CA012201 CA012202 CA012203 CA012203

Screen for vertical galvanized air pipe D2012201 D2012201 D2012202 D2012203 D2012203

Screen for vertical PVC air pipe CA012401 CA012401 CA012402 CA012403 CA012403

Screen for vertical polypropylene air pipe CA012601 CA012601 CA012602 CA012603 CA012603

Table 3a - Ducted Air Accessories

(Place in section 3.2)

Model 2000 Model 2500 Model 3000 Model 3500 Model 4000

Horizontal vent terminal for stainless steel D2012001 D2012001 D2012002 D2012003 D2012003

Screen for horizontal CPVC vent CA012101 CA012101 CA012102 CA012103 CA012103

Screen for vertical stainless steel vent D2012301 D2012301 D2012302 D2012303 D2012303

Screen for vertical CPVC vent CA012501 CA012501 CA012502 CA012503 CA012503

LAARS Heating Systems

If the system temperatures are unknown at the

time of installation, class IIC or higher venting

material is recommended.

The MagnaTherm is a Category IV appliance and

may be installed with the standards listed on Table 6.

The unit’s vent can terminate through the roof, or

through an outside wall.

All installations must be done following the vent

supplier’s recommended installation techniques.

If these are not available, refer to the LAARS

recommendations for the material used.

For Category IV boilers, have horizontal runs

sloping upwards not less than 1/4 inch per foot

(21 mm/m) from the boiler to the vent terminal;

be installed so as to prevent accumulation of

condensate; and, where necessary, have means

provided for drainage of condensate.

Pour la catégorie IV, les chaudières ont horizontal

en pente vers le haut au moins 1/4 de pouce par pied

(21 mm/m) à partir de la chaudière pour l’évent

borne; être installé de façon à éviter l’accumulation

de condensats; et, le cas échéant, ont des moyens

prévus pour l’évacuation des condensats.

This will allow the condensate to run back to the

MagnaTherm to drain. Route the vent pipe to the

heater as directly as possible. Seal all joints. Provide

adequate hangers as required in the venting system

manufacturer’s Installation Instructions, or at least

every 4 feet.

The unit must not support the weight of the vent

pipe. The maximum equivalent pipe length allowed

is 100 feet (30m). Each elbow is considered to be 5

feet (1.5m). LAARS offers accessories to use with

horizontal and vertical exhaust vent systems, as

shown in Table 5

3.2.1 Common Venting

The MagnaTherm can be common vented, however,

the common venting must be a professionally

designed and approved system. MagnaTherm

units are never permitted to share a vent with any

Catagory 1 appliances.

3.2.3 Venting Requirements Unique to Canada

MagnaTherm boilers and water heaters are Vent

Table 5. Vent Accessories

Material United States Canada

Stainless steel UL 1738 Venting must be ULC S636 certied for use as

CPVC, sch 40 ANSI/ASTM F441

Polypropylene

Pending APPROV AL

Table 6. Required Exhaust Vent Material

Installation Standards

venting material. The venting material class must

be chosen based upon the intended application

of the boiler, and must be installed according to

ULC S636 Class 2C

the maximum ue gas temperature and the vent

manufacturer’s instructions.

MagnaTherm Boilers and Water Heaters

Category IV appliances. Per the requirements of

CAN/CSA-B149.1, only BH vent systems can be

connected to these units and such vent systems,

either ULC S636 certied stainless steel or other

ULC S636 certied BH vent (eg. plastics) must

be installed per the vent manufacturer’s certied

installation instructions.

It is the responsibility of the appropriately licensed

technician installing this MagnaTherm to use

ULC S636 certied vent material consistent with

the requirements as described in the Venting and

Combustion Air section.

Class I venting systems are suitable for gas-red

appliances producing ue gas temperature of more

than 135°C, but not more than 245°C.

Class II venting systems are suitable for gas-red

appliances producing ue gas temperatures of 135°C

or less.

Page 11

Class II venting systems are further classied into

four temperature ratings as follows:

A Up to and including 65°C / 149°F

B Up to and including 90°C / 194°F

C Up to and including 110°C / 230°F and

D Up to and including 135°C / 275°F

Flue Gas Sampling Port It is also the responsibility of the installer to ensure

that a ue gas sampling port is installed in the vent

system. This ue gas sampling port must be installed

near the ue connection of the MagnaTherm: within

2 feet of the ue connection. There is no ue gas

sampling port internal to the MagnaTherm, so one

must be installed in the vent system external to the

MagnaTherm. A ue gas sampling port available as

a component of the ULC S636 certied vent system

is preferred. However, if one is not available with

the certied vent system, LAARS suggests using

a tee with the branch connection sized to allow for

insertion of a ue gas analyzer probe. The branch

connection must be resealable with a cap or other

means to ensure the vent system remains sealed.

(See Figure 2)

Consideration must be given to the placement

and orientation of the ue gas sampling port to

ensure that condensate is free to ow back into the

MagnaTherm and not collect anywhere in the vent

system - including in the ue gas sampling port.

Exhaust Vent Terminal An exhaust vent terminal must be installed. If an

Figure 2. Test Port

exhaust vent terminal is not available with the

certied vent system, LAARS suggests the use of

a coupler tting from the certied vent system into

which the vent terminal screen can be installed.

Be sure to install and terminate both vent and

combustion air pipes per the instructions in this

section.

3.3 Locating the Vent and Combustion Air Terminals

3.3.1 Side Wall Vent Terminal

The appropriate LAARS side wall vent terminal

must be used. The terminal must be located in

accordance with ANSI Z223.1/NFPA 54 and

applicable local codes. In Canada, the installation

must be in accordance with CSA B149.1 or .2 and

local applicable codes.

Consider the following when installing the terminal:

1. Figure 4 shows the requirements for

mechanical vent terminal clearances for the

U.S. and Canada.

2. Vent terminals for condensing appliances or

appliances with condensing vents are not

permitted to terminate above a public walkway,

or over an area where condensate or vapor

could create a nuisance or hazard.

3. Locate the vent terminal so that vent gases

cannot be drawn into air conditioning system

inlets.

4. Locate the vent terminal so that vent gases

Page 12

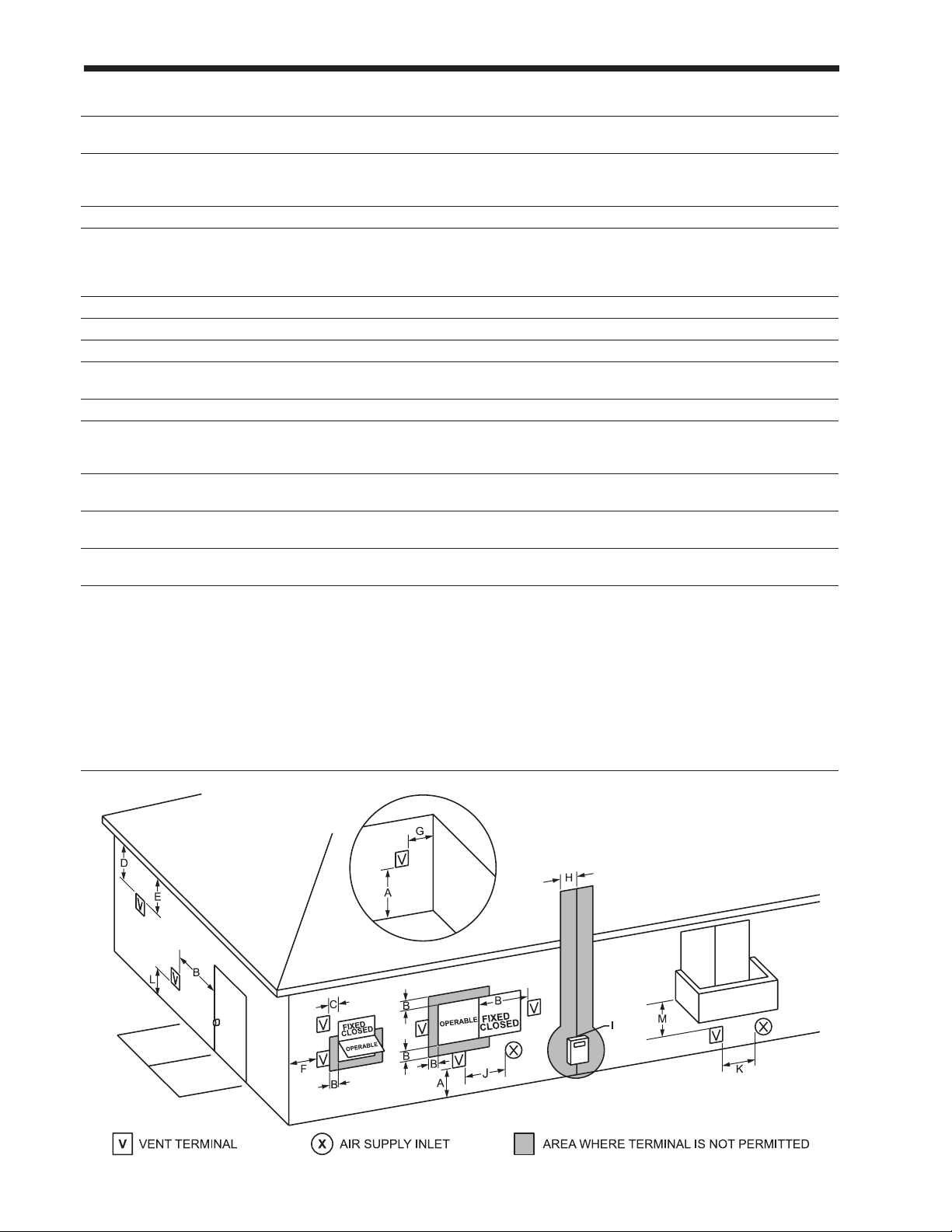

U.S. Installations (see note 1) Canadian Installations (see note 2)

A= Clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm)

deck, or balcony See note 6 See note 6

B= Clearance to window or door that may be Direct vent only: 12 inches (30 cm); 36 inches (91 cm)

opened Other than Direct vent: 4 ft (1.2m) below or to

side of opening; 1 ft (30 cm) above opening

C= Clearance to permanently closed window See note 4 See note 5

D= Vertical clearance to ventilated soft located

above the terminal within a horizontal See note 4 See note 5

distance of 2 feet (61 cm) from the center

line of the terminal

E= Clearance to unventilated soft See note 4 See note 5

F= Clearance to outside corner See note 4 See note 5

G= Clearance to inside corner See note 4 See note 5

H= Clearance to each side of center line 3 feet (91 cm) within a height 15 feet

extended above meter/regulator assembly See note 4 above the meter/regulator assembly

I= Clearance to service regulator vent outlet See note 4 3 feet (91 cm)

J= Clearance to nonmechanical air supply Direct vent only: 36” (91cm)

inlet to building or the combustion air inlet Other than Direct vent: 4 ft (1.2m) below 36 inches (91 cm)

to any other appliance or to side of opening; 1 ft (30 cm) above opening

K= Clearance to a mechanical air supply inlet 3 feet (91 cm) above if within 10 feet (3 m) 6 feet (1.83 m)

horizontally

L= Clearance above paved sidewalk or paved Vent termination not allowed in this location 7 ft (2.1 m)

driveway located on public property for category IV appliances. See note 5

M= Clearance under veranda, porch, deck, See note 4 12 inches (30 cm)

or balcony See note 5

Notes:

1. In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code.

2. In accordance with the current CAN/CSA-B149 Installation Codes.

3. Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

4. For clearances not specied in ANSI Z223.1 / NFPA 54, clearance is in accordance with local installation codes and the

requirements of the gas supplier.

5. For clearances not specied in CAN/CSA-B149, clearance is in accordance with local installation codes and the requirements of the

gas supplier.

6. IMPORTANT: All terminals must be placed so that they remain a minimum 12” above expected snow line. Local codes may have

more specic requirements, and must be consulted.

LAARS Heating Systems

Figure 3. Combustion Air and Vent Through Side Wall

*When vent terminal is less than 10 feet (3 m) horizontally

from a forced air inlet, the terminal must be at least 3 feet

(0.9 m) above the air inlet. (US only)

MagnaTherm Boilers and Water Heaters

84

IMPORTANT: All terminals must be placed so that they remain at least 12”

above the expected snow line. Local codes may have more specic

requirements, and must be consulted. Refer to the NFPA54 National Fuel Gas

Code and your local codes for all required clearances for venting.

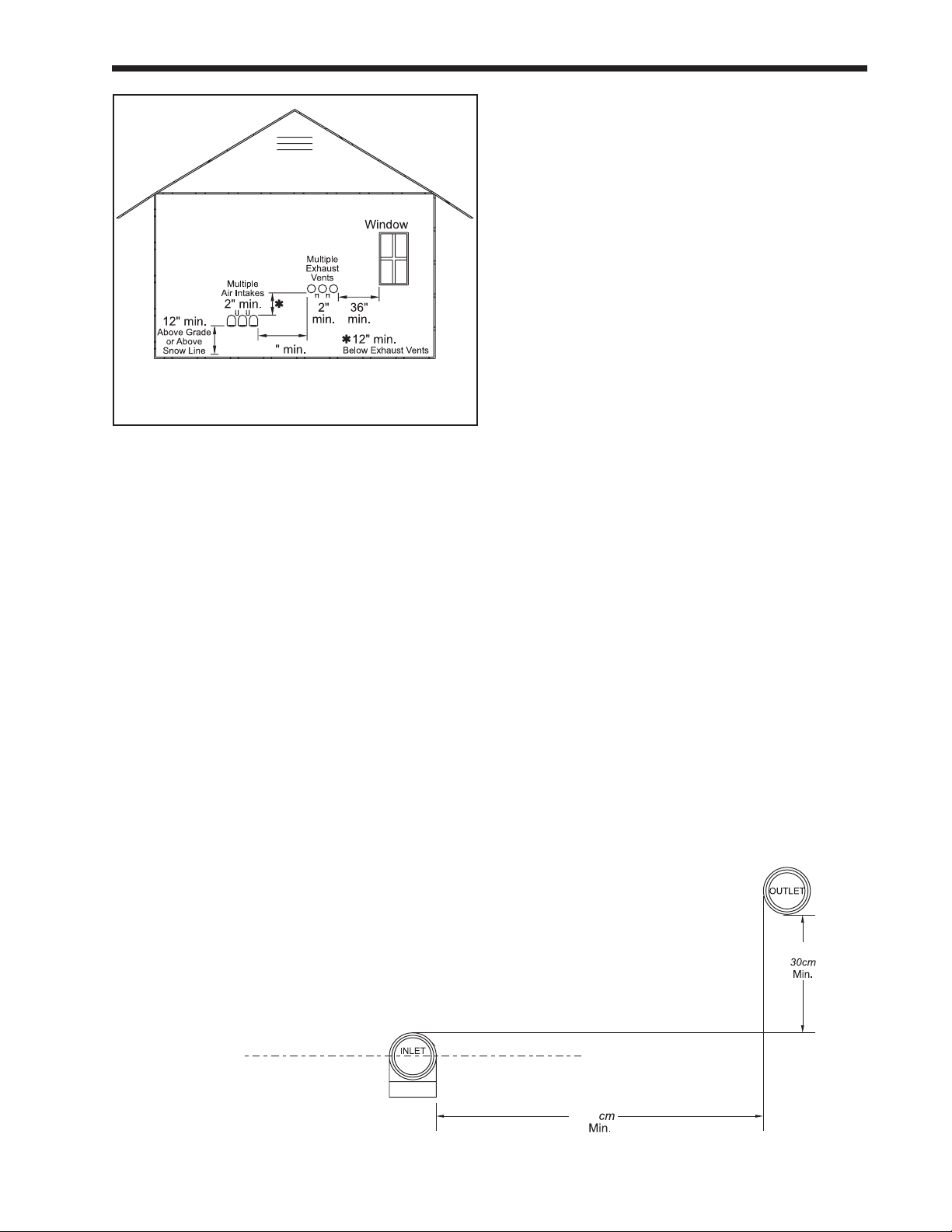

Figure 5. Multiple Side-Wall Terminals, Air and

Vent

cannot enter the building through doors,

windows, gravity inlets or other openings.

Whenever possible, avoid locations under

windows or near doors.

5. Locate the vent terminal so that it cannot

be blocked by snow. The installer may

determine that a vent terminal must be

higher than the minimum shown in codes,

depending upon local conditions.

6. Locate the terminal so the vent exhaust does

not settle on building surfaces or other nearby

objects. Vent products may damage surfaces or

objects.

7. If the boiler or water heater uses ducted

combustion air from an intake terminal located

on the same wall, see See Figure 5 and Figure

4 for proper spacing and orientation.

Page 13

3.3.2 Side Wall Combustion Air Terminal

Consider the following when installing the terminal.

1. Do not locate the air inlet terminal near a

source of corrosive chemical fumes (e.g.,

cleaning uid, chlorine compounds, etc.).

2. Locate the terminal so that it will not be subject

to damage by accident or vandalism. It must be

at least 7 feet ( 2.1 m) above a public walkway.

3. Locate the combustion air terminal so that it

cannot be blocked by snow. The National Fuel

Gas Code requires that it be at least 12 inches

(30 cm) above grade, but the installer may

determine it should be higher, depending upon

local conditions.

4. If the MagnaTherm is side-wall vented to the

same wall, use Figure 4 to determine the proper

mounting locations.

5. Multiple vent kits should be installed such that

the horizontal distance between outlet group

and inlet group is 84” (213 cm). (See Figure 5)

6. The vent outlet must be at least 12” above the top

of the air inlet, and must be at least 84” (213 cm)

horizontally from the air inlet. (See Figure 5).

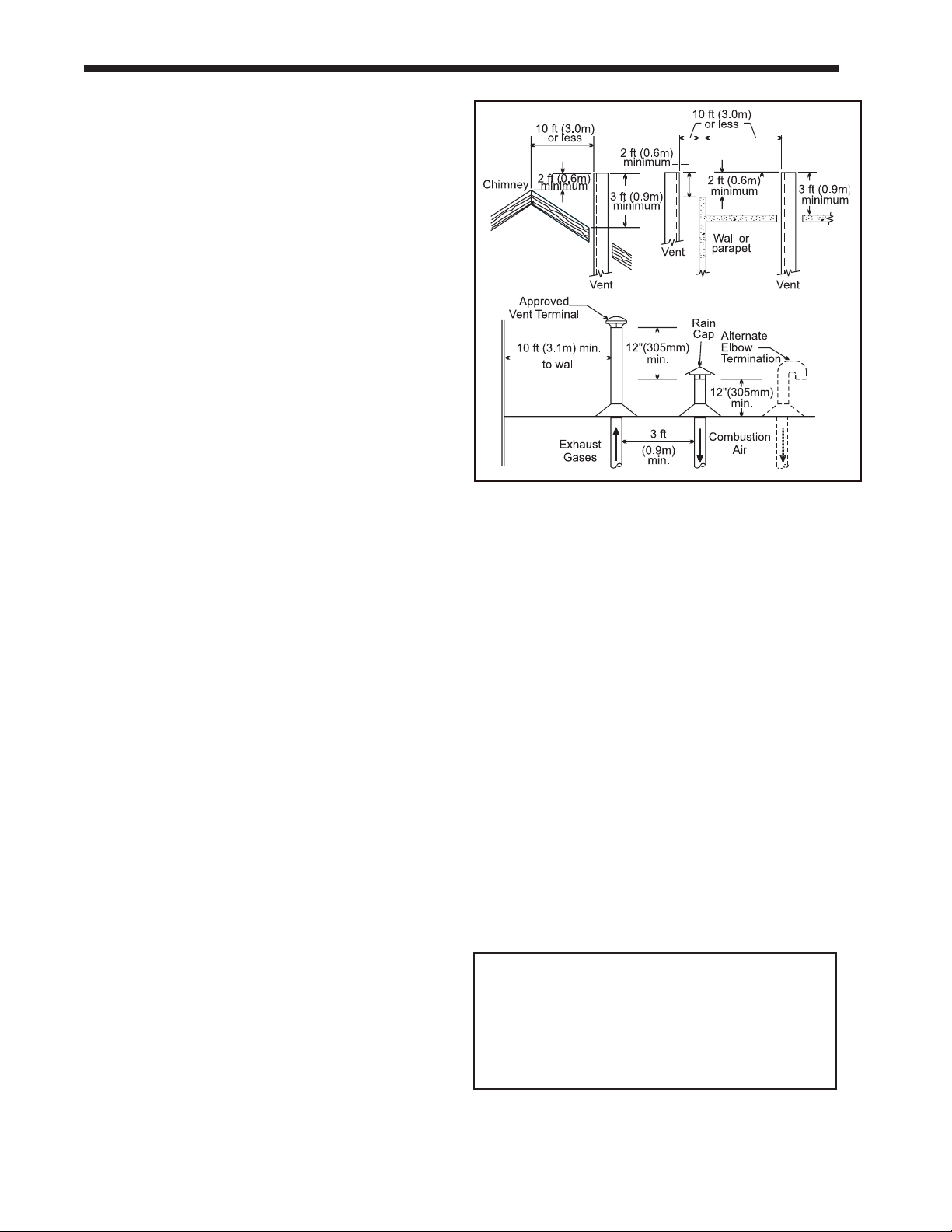

3.3.3 Vertical Vent Terminal

When the unit is vented through the roof, the vent

must extend at least 3 feet (0.9 m) above the point

at which it penetrates the roof. It must extend at

least 2 feet (0.6 m) higher than any portion of a

building within a horizontal distance of 10 feet (3.0

m), and high enough above the roof line to prevent

blockage from snow . The vent terminal offered with

the MagnaTherm can be used in both vertical and

horizontal applications. When the combustion air is

taken from the roof, the combustion air must terminate

at least 12” (30 cm) below the vent terminal.

If the vent termination is located in an area exposed

to high winds, an optional PVC tee (the same

diameter as the vent pipe) may be used. The tee’d

vent termination offers greater protection from wind

related operating issues.

Figure 4. Minimum Venting Distance

12”

84”

213

Page 14

*

3.3.4 Vertical Combustion Air Terminal

When combustion air is taken from the roof, a eld-

supplied rain cap or an elbow arrangement must be

used to prevent entry of rain water. The opening on

the end of the terminal must be at least 12” (30 cm)

above the point at which it penetrates the roof, and

high enough above the roof line to prevent blockage

from snow. When the vent terminates on the roof, the

combustion air must terminate at least 12” (30 cm)

below the vent terminal.

LAARS Heating Systems

*

*

*

In Canada, refer to CAN/CSA B199.1

*

*

3.3.5 Installations in the Commonwealth of Massachusetts

In Massachusetts the following items are required

if the side-wall exhaust vent termination is less than

seven (7) feet above nished grade in the area of

the venting, including but not limited to decks and

porches. (From Massachusetts Rules and regulations

248 CMR 5.08.)

1. Installation of Carbon Monoxide Detectors

At the time of installation of the side wall vented

gas fueled appliance, the installing plumber or

gas-tter shall observe that a hard-wired carbon

monoxide detector with an alarm battery back-

up is installed on the oor level where the gas

appliance is to be installed. In addition, the

installing plumber or gastter shall observe

that a battery operated or hard-wired carbon

monoxide detector with an alarm is installed on

each additional level of the dwelling, building

or structure served by the side-wall horizontally

vented gas fueled equipment. It shall be the

responsibility of the property owner to secure

the services of qualied licensed professionals

for installation of hard-wired carbon monoxide

detectors.

a. In the event that the side-wall horizontally

vented gas fueled equipment is installed in a

crawl space or an attic, the hard-wired carbon

monoxide with alarm and battery back-up may

be installed on the next adjacent oor level.

b. In the event that the requirements of the

subdivision cannot be met at the time of

completion of installation, the owner shall have

a period of thirty (30) days to comply with the

above requirements, provided, however, that

during said thirty (30) day period, a battery

operated carbon monoxide detector with an

alarm be installed.

2. Approved Carbon Monoxide Detectors

Each carbon monoxide detector shall comply

with NFPA 720 and be ANSI/UL 2034 listed and

IAS certied.

*

Figure 6. Combustion Air and Vent Through Roof

3. Signage

A metal or plastic identication plate shall be

permanently mounted to the exterior of the

building at a minimum height of eight (8) feet

above grade directly in line with the exhaust

vent terminal for horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print no less than one-half (1/2) inch in

size: “GAS VENT DIRECTLY BELOW, KEEP

CLEAR OF ALL OBSTRUCTIONS.”

4. Inspection

The state or local gas inspector of the side-

wall horizontally vented gas fueled appliance

shall not approve the installation unless, upon

inspection, the inspector observes carbon

monoxide detectors and signage installed in

accordance with the provisions of 248 CMR

5.08(2)(a) 1-4.

3.4 Common Vent Test

Note -This section does not describe a method

for common venting MagnaTherm’s. It describes

what must be done when a unit is removed from

a common vent system. MagnaTherm’s require

special vent systems and fans for common vent.

Contact the factory if you have questions about

common venting MagnaTherm’s.

MagnaTherm Boilers and Water Heaters

Page 15

When an existing boiler is removed from a common

venting system, the common venting system is likely

to be too large for proper venting of the appliances

remaining connected to it.

At the time of removal of an existing boiler,

the following steps shall be followed with each

appliance remaining connected to the common

venting system placed in operation, while the other

appliances remaining connected to the common

venting system are not in operation.

1. Seal any unused openings in the common

venting system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion or

other deciencies which could cause an unsafe

condition.

3. Insofar as is practical, close all building doors

and windows and all doors between the space

in which the appliances remaining connected

to the common venting system are located

and other spaces of the building. Turn on any

clothes dryers and any appliance not connected

to the common venting system. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan.

Close replace dampers.

4. Place in operation the appliance being

inspected. Follow the lighting instructions.

Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after ve minutes of main burner operation. Use

the ame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return the doors, windows, exhaust fans,

replace dampers and any other gas burning

appliance to their previous conditions of use.

7. Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and/or CAN/CSA

B149.1, National Gas and Propane Installation

Code. When resizing any portion of the common

venting system, the common venting system

should be resized to approach the minimum

size as determined using the appropriate tables

in Appendix F in the National Fuel Gas Code,

ANSI Z223.1 NFPA 54 and/or CAN/CSA

B149.1, National Gas and Propane Installation

Code.

Au moment du retrait d’une chaudiére existante, les

mesures suivantes doivent être prises pour chaque

appareil toujurs raccordé au systéme d’évacuation

commun et qui fonctionne alors que d’autres

appareils toujours raccordés au système d’évacuation

ne fonctionnent pas:

1. Sceller toutes les ouvertures non utilisées du

système d’évacuation.

2. Inspecter de facon visuelle le système

d’évacuation pour déterminer la grosseur

et l’inclinaison horizontale qui conviennent

et s’assurer que le système est exempt

d’obstruction, d’étranglement, de fuite, de

corrosion et autres défaillances qui pourraient

présenter des risques.

3. Dans la mesure du possible, fermer toutes les

portes et les fenêtres du bâtiment et toutes les

portes entre l’espace où les appareils toujours

raccordés au système d’évacuation sont installés

et les autres espaces du bâtiment. Mettre en

march les sécheuses, tous les appareils non

raccordés au système d’évacuation commun

et tous les ventilateurs d’extraction comme

les hottes de cuisinière et les ventilateurs des

salles de bain. S’assurer que ces ventilateurs

fonctionnent à la vitesse maximale. Ne pas faire

fonctionner les ventilateurs d’été. Fermer les

registres des cheminées.

4. Mettre l’appareil inspecté en marche. Suivre les

instructions d’allumage. Régler le thermostat

de facon que l’appareil fonctionne de facon

continue.

5. Faire fonctionner le brûleur principal pendant 5

min ensuite, déterminer si le coup-tirage déborde

à l’ouverture de décharge. Utiliser la amme

d’une allumette ou d’ une chandelle ou la fumée

d’ une cigarette, d’un cigare ou d’une pipe.

6. Une fois qu’il a été détermineé, selon la méthode

indiquée ci-dessus, que chaque appareil raccordé

au système d’évacuation est mis à l’air libre

de facon adéquate. Remettre les portes et

les fenêtres, les vientilateurs, les registre de

cheminées et les appareils au gaz àleur position

originale.

7, Tout mauvais fonctionnement du système

d’évacuation commun devrait être corrigé

de facon que l’installation soit conforme au

National Fuel Gas Code, ANSI Z223.1/NFPA

54 et (ou) aux codes d’installation CAN/

CSA-B149.1. Si la grosseur d’une section du

système d’évacuation doit être modié pour

respecter les valeurs minimales des tableaux

pertinents de l’appendice F du National Fuel Gas

Code, ANSI Z223.1/NFPA 54 et (ou) aux codes

d’installation CAN/CSA-B149.1.

Page 16

(Place in section 3.1)

Model 2000 Model 2500 Model 3000 Model 3500 Model 4000

Screen for horizontal galvanized air pipe D2012101 D2012101 D2012102 D2012103 D2012103

Screen for horizontal PVC air pipe CA012001 CA012001 CA012002 CA012003 CA012003

Screen for horizontal polypropylene air pipe CA012201 CA012201 CA012202 CA012203 CA012203

Screen for vertical galvanized air pipe D2012201 D2012201 D2012202 D2012203 D2012203

Screen for vertical PVC air pipe CA012401 CA012401 CA012402 CA012403 CA012403

Screen for vertical polypropylene air pipe CA012601 CA012601 CA012602 CA012603 CA012603

Table 3a - Ducted Air Accessories

(Place in section 3.2)

Model 2000 Model 2500 Model 3000 Model 3500 Model 4000

Horizontal vent terminal for stainless steel D2012001 D2012001 D2012002 D2012003 D2012003

Screen for horizontal CPVC vent CA012101 CA012101 CA012102 CA012103 CA012103

Screen for vertical stainless steel vent D2012301 D2012301 D2012302 D2012303 D2012303

Screen for vertical CPVC vent CA012501 CA012501 CA012502 CA012503 CA012503

Table 3* - Vent Accessories

(Place in section 3.5)

Air intake screen for unit placed outdoors CA011901 CA011901 CA011902 CA0011903 CA0011903

Vent terminal for unit placed outdoors CA011801 CA011801 CA011802 CA011803 CA011803

Table 7. Air & Vent accessories for Units Placed Outdoors

Model 2000 Model 2500 Model 3000 Model 3500 Model 4000

LAARS Heating Systems

3.5 Outdoor Installation

If installing outdoors in a location that may experience

freezing temperatures, precautions must be taken to

prevent water in the heat exchanger and condensate

inside and outside of the boiler from freezing. Damage

due to freezing water or condensate is not covered by the

warranty.

For proper operation in outdoor installations,

the boiler must be equipped with the inlet air and

exhaust terminal kits listed in Table 7. Additional

instructions are supplied with the terminal kits.

WARNING

Do not use open ame to check for leaks. An

open ame could lead to explosion, which

could result in property damage, serious injury

or death.

Note - The MagnaTherm appliance and all

other gas appliances sharing the gas supply line

must be ring at maximum capacity to properly

measure the inlet supply pressure. The pressure

can be measured at the supply pressure port

on the gas valve. Low gas pressure could be an

indication of an undersized gas meter, undersized

gas supply lines and/or an obstructed gas supply

line. MagnaTherm units may be equipped with

low and high gas pressure switches that are

integrally vent limited. These types of devices do

not require venting to atmosphere.

Section 4

GAS SUPPLY AND PIPING

4.0 Gas Supply and Piping

Gas piping should be supported by suitable hangers

or oor stands, not the appliance. Installers should

refer to local building and safety codes or, in the

absence of such requirements, follow the National

Fuel Gas Code, ANSI Z223.1 NFPA and/or CSA

B149.1 installation codes.

Review the following instructions before proceeding

with the installation.

1. Verify that the appliance is tted for the

proper type of gas by checking the rating

plate. MagnaTherm appliances are normally

equipped to operate at elevations up to 2000

feet (610m).

However, the appliance will function properly

without the use of high altitude modication at

elevations up to 10,000 feet (3050 m).

2. The maximum inlet gas pressure must not

exceed 13” W.C. (3.2kPa). The minimum inlet

gas pressure is 4” W.C. (1.0kPa).

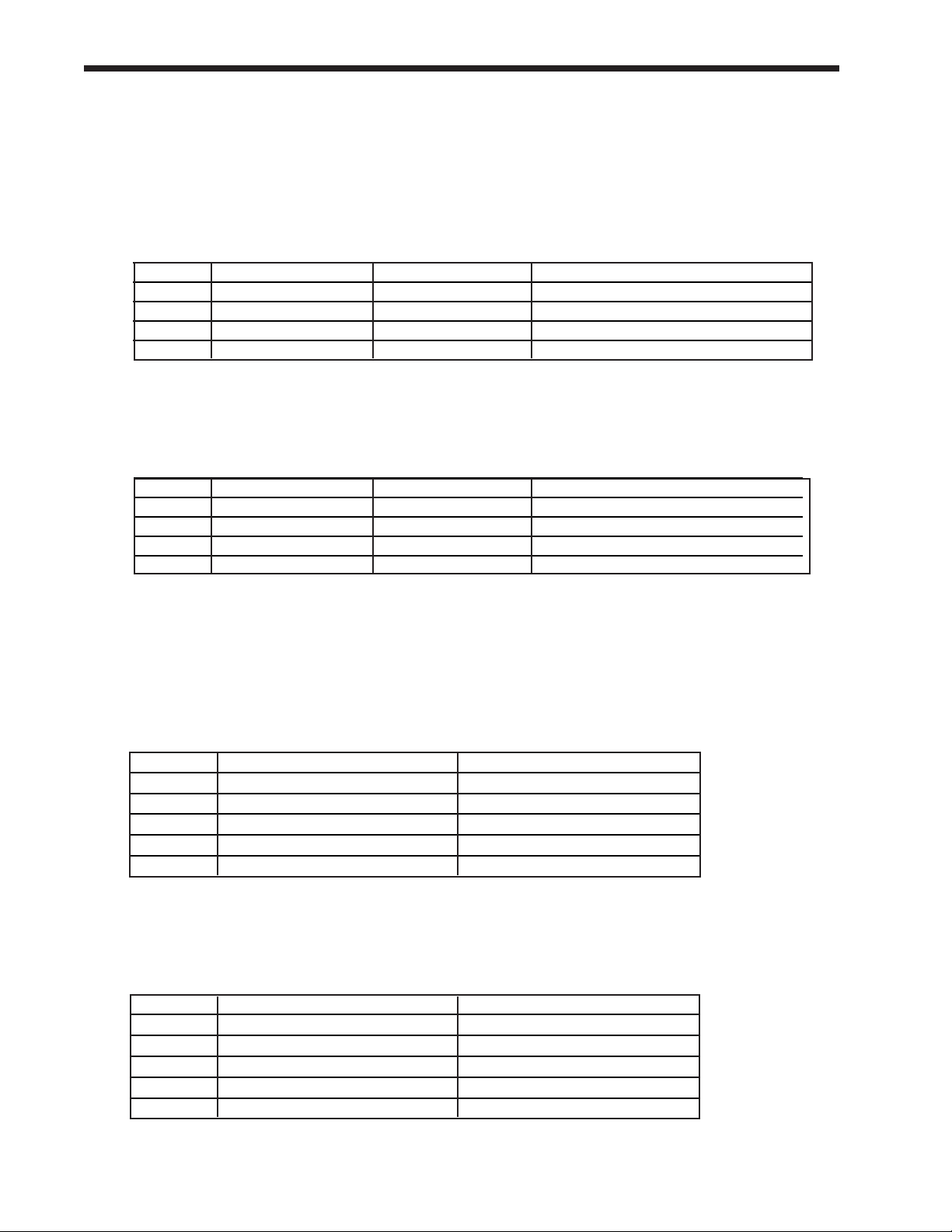

3. Table 8 and Table 9 offer some gas pipe sizing

information. Refer to the applicable gas code

for more detailed sizing information.

4. Run gas supply line in accordance with all

applicable codes.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of

the gas controls.

7. All threaded joints should be coated with

piping compound resistant to action of

liqueed petroleum gas.

8. The appliance and its individual shutoff valve

must be disconnected from the gas supply

piping during any pressure testing of that

system at test pressures in excess of 1/2 PSIG

(3.45kpa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shutoff

valve during any pressure testing of the gas

supply piping system at test pressures equal to

or less than 1/2 PSIG (3.45kpa).

10. The appliance and its gas connection must be

leak tested before placing it in operation.

11. Purge all air from gas lines

MagnaTherm Boilers and Water Heaters

Nominal: 1½ 2 2½ 3 4

Actual ID: 1.61 2.067 2.469 3.068 4.026

Length (ft)

10 3,520 6,790 10,800 19,100 39,000

20 2,420 4,660 7,430 13,100 26,800

30 1,940 3,750 5,970 10,600 21,500

40 1,660 3,210 5,110 9,030 18,400

50 1,480 2,840 4,530 8,000 16,300

60 1,340 2,570 4,100 7,250 14,800

80 1,230 2,370 3,770 6,670 13,600

100 1,140 2,200 3,510 6,210 124,700

125 1,070 2,070 3,290 5,820 11,900

150 1,010 1,950 3,110 5,500 11,200

175 899 1,730 2,760 4,880 9,950

200 814 1,570 2,500 4,420 9,010

250 749 1,440 2,300 4,060 8,290

300 697 1,340 2,140 3,780 7,710

350 618 1,190 1,900 3,350 6,840

400 560 1,080 1,720 3,040 6,190

Notes:

1. Inlet pressure - 11.0 in w.c.

Capacity in Cubic Feet of Gas per Hour

Pipe Size (in.)

Natural Gas

Undiluted Propane

Pipe Size (in.)

Capacity in Cubic Feet of Gas per Hour

Nominal: 2 2½ 3 4 5 Nominal: 1½ 2 2½ 3 4

Actual ID: 2.067 2.469 3.068 4.026 5.047 Actual ID: 1.61 2.067 2.469 3.068 4.026

Length (ft) Length (ft)

10 4,020 6,400 11,300 23,100 41,800 10 3,520 6,790 10,800 19,100 39,000

20 2,760 4,400 7,780 15,900 28,700 20 2,420 4,660 7,430 13,100 26,800

30 2,220 3,530 6,250 12,700 23,000 30 1,940 3,750 5,970 10,600 21,500

40 1,900 3,020 5,350 10,900 19,700 40 1,660 3,210 5,110 9,030 18,400

50 1,680 2,680 4,740 9,660 17,500 50 1,480 2,840 4,530 8,000 16,300

60 1,520 2,430 4,290 8,760 15,800 60 1,340 2,570 4,100 7,250 14,800

70 1,400 2,230 3,950 8,050 14,600 80 1,230 2,370 3,770 6,670 13,600

80 1,300 2,080 3,670 7,490 13,600 100 1,140 2,200 3,510 6,210 124,700

90 1,220 1,950 3,450 7,030 12,700 125 1,070 2,070 3,290 5,820 11,900

100 1,160 1,840 3,260 6,640 12,000 150 1,010 1,950 3,110 5,500 11,200

125 1,020 1,630 2,890 5,890 10,600 175 899 1,730 2,760 4,880 9,950

150 928 1,480 2,610 5,330 9,650 200 814 1,570 2,500 4,420 9,010

175 854 1,360 2,410 4,910 8,880 250 749 1,440 2,300 4,060 8,290

200 794 1,270 2,240 4,560 8,260 300 697 1,340 2,140 3,780 7,710

150 704 1,120 1,980 4,050 7,320 350 618 1,190 1,900 3,350 6,840

300 638 1,020 1,800 3,670 6,630 400 560 1,080 1,720 3,040 6,190

350 587 935 1,650 3,370 6,100 Notes:

400 546 870 1,540 3,140 5,680 1. Inlet pressure - 11.0 in w.c.

Notes: 2. Pressure drop - 0.5 in w.c.

3. Specific gravity - 1.50

4. Schedule 40 metallic pipe

5. Intended use - Pipe sizing between single- or second-stage

4. Schedule 40 metallic pipe (low pressure) regulator and appliance.

Capacity in Cubic Feet of Gas per Hour

Pipe Size (in.)

Natural Gas

Undiluted Propane

Pipe Size (in.)

Capacity in Cubic Feet of Gas per Hour

Undiluted Propane

Pipe Size (in.)

Capacity in Cubic Feet of Gas per Hour

Undiluted Propane

Pipe Size (in.)

Capacity in Cubic Feet of Gas per Hour

The following are gas line sizing examples from the

National Fuel Gas Code. Size your gas lines

properly, based on your installation, and all

applicable codes.

SCH 40 METAL PIPE CAPACITY FOR 0.60 SPECIFIC GRAVITY

NATURAL GAS

NOMINAL PIPE SIZE @ 0.30” W.C. PRESSURE DROP

Nominal: 2 2½ 3 4 5

Actual ID: 2.067 2.469 3.068 4.026 5.047

Length (ft)

10 4,020 6,400 11,300 23,100 41,800

20 2,760 4,400 7,780 15,900 28,700

30 2,220 3,530 6,250 12,700 23,000

40 1,900 3,020 5,350 10,900 19,700

50 1,680 2,680 4,740 9,660 17,500

60 1,520 2,430 4,290 8,760 15,800

70 1,400 2,230 3,950 8,050 14,600

80 1,300 2,080 3,670 7,490 13,600

90 1,220 1,950 3,450 7,030 12,700

100 1,160 1,840 3,260 6,640 12,000

125 1,020 1,630 2,890 5,890 10,600

150 928 1,480 2,610 5,330 9,650

175 854 1,360 2,410 4,910 8,880

200 794 1,270 2,240 4,560 8,260

150 704 1,120 1,980 4,050 7,320

300 638 1,020 1,800 3,670 6,630

350 587 935 1,650 3,370 6,100

400 546 870 1,540 3,140 5,680

Table 8. Pipe Capacity for Natural Gas

Page 17

1. Inlet pressure - Less than 2 psi

2. Pressure drop - 0.5 in w.c.

3. Specific gravity - 0.60

SCHED 40 METAL PIPE CAPACITY FOR 1.50 SPECIFIC GRAVITY

UNDILUTED PROPANE

NOMINAL PIPE SIZE @ 11” W.C. INLET AND 0.5” W.C. PRESSURE

DROP

Nominal: 1½ 2 2½ 3 4

Actual ID: 1.61 2.067 2.469 3.068 4.026

Length (ft)

10 3,520 6,790 10,800 19,100 39,000

20 2,420 4,660 7,430 13,100 26,800

30 1,940 3,750 5,970 10,600 21,500

40 1,660 3,210 5,110 9,030 18,400

50 1,480 2,840 4,530 8,000 16,300

60 1,340 2,570 4,100 7,250 14,800

80 1,230 2,370 3,770 6,670 13,600

100 1,140 2,200 3,510 6,210 124,700

125 1,070 2,070 3,290 5,820 11,900

150 1,010 1,950 3,110 5,500 11,200

175 899 1,730 2,760 4,880 9,950

200 814 1,570 2,500 4,420 9,010

250 749 1,440 2,300 4,060 8,290

300 697 1,340 2,140 3,780 7,710

350 618 1,190 1,900 3,350 6,840

400 560 1,080 1,720 3,040 6,190

Table 9. Pipe Capacity for Propane

Page 18

Gas Pipe

Boiler Thermal

Efficiency

Water Heater Thermal

Efficiency

Water

Content

Vent

Diameter

Vent

Length

Water Heater

Thermal Efficiency

MBH kW %

2000 1999 586 96

2500 2499 732 96

3000 3000 879 95

4000 4000 1172 96

Size

SizeSize

Output Rate

Input Rate

14°C

17°C

19°C

22°C

Dimensional Data Sizing Data

Water Pipe

Gas Pipe

Boiler Thermal

Efficiency

Water Heater Thermal

Efficiency

Water

Content

Vent

Diameter

Vent

Length

Inches cm Inches cm Inches cm Inches cm (NPT) (NPT) MBH kW MBH kW % % lbs kg lbs kg lbs kg Gallons in (cm) ft (m)

2000 29.3 75 77 196 38.0 97 57.0 145 2.5 1.5 2000 1999 586 1883 552 95.0 96 1390 630 1562 709 1590 721 22 8 (20) 100 (30.5)

2500 29.3 75 77 196 38.0 97 57.0 145 2.5 1.5 2500 2499 732 2374 696 95.0 96 1785 810 2039 925 1985 900 31 8 (20) 100 (30.5)

3000 30.8 78 87 221 41.5 105 60.5 154 3 2 3000 3000 879 2814 825 95.0 95 1785 810 2039 925 1985 900 31 10 (25) 100 (30.5)

3500 30.8 78 87 221 41.5 105 60.5 154 3 2 3500 3500 1025 3317 972 95.0 96 2278 1033 2742 1244 2478 1124 56 10 (25) 100 (30.5)

4000

34.5 88 97 246 52.0 132 70.0 178 4 2.5 4000 4000 1172 3724 1091 95.0 96 2278 1033 2742 1244 2478 1124 56 12 (30) 100 (30.5)

Water Heater

Thermal Efficiency

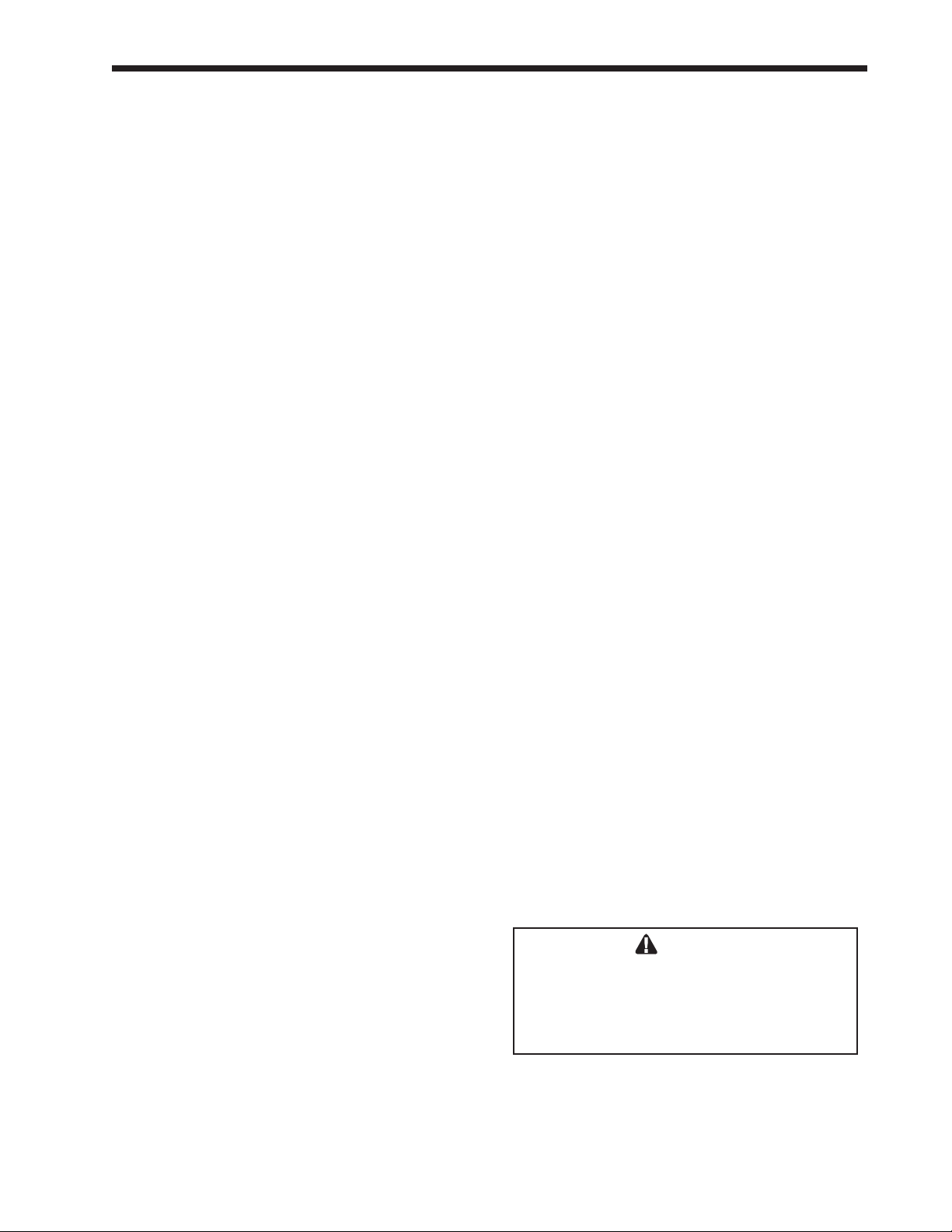

Boiler Water Flow Requirements

Size

Flow

Head Loss

Flow

Head Loss

Flow

Head Loss

Flow

Head Loss

Flow

Head Loss

GPM Feet GPM Feet GPM Feet GPM Feet LPM m LPM m LPM m LPM m

2000 150 30 128 23.5 109 17.1 95 13.6 2000 568 9.2 485 7.2 413 5.2 360 4.2

2500 190 34 158 23.6 136 17.6 119 13.6 2500 719 10.0 599 7.0 514 5.0 449 4.1

3000 226 47 190 34.2 164 25.8 142 18.9 3000 856 14.3 719 10.4 621 7.9 538 5.8

3500 266 41 222 30.6 190 23.6 166 18.6 3500 1007 12.0 839 9.0 719 7.0 629 6.0

4000 300 48 255 38.2 218 28.5 190 22.5 4000 1136 14.6 965 11.6 825 8.7 719 6.9

Size

A B C D

Temperature Rise in °C

30°F

Temperature Rise in °F

25°F

35°F

40°F

14°C

17°C

19°C

22°C

Water Flow Requirements (for water heater submittal)

Model Flow Rate Temp Rise Headloss Flow Rate Temp Rise Headloss Flow Rate Temp Rise Headloss Flow Rate Temp Rise Headloss

GPM °F Ft LPM °C m GPM °F Ft LPM °C m

2000 152 25 33.0 575 14 10.1 177 21 43.9 670 12 13.4

2500 190 25 33.7 719 13.9 10.0 220 21 46.0 833 11.7 14

3000 190 30 36.0 719 17 11.0 220 26 46.0 833 14 14

3500 222 30 30.6 839 17 9.0 266 25 40.6 1007 14 12

4000 224 34 30.0 848 19 9.1 266 29 41.2 1007 16 12.6

Allowable pH: 6.5 to 9.5

Headloss is for the heater only (no piping)

Water Hardness

1-10 grains per gallon

Water Hardness

11-15 grains per gallon

Water Hardness

11-15 grains per gallon

Water Flow Requirements (for water heater submittal)

Model Flow Rate Temp Rise Headloss Flow Rate Temp Rise Headloss Flow Rate Temp Rise Headloss Flow Rate Temp Rise Headloss

GPM °F Ft LPM °C m GPM °F Ft LPM °C m

2000 152 25 33.0 575 14 10.1 177 21 43.9 670 12 13.4

2500 190 25 33.7 719 13.9 10.0 220 21 46.0 833 11.7 14

3000 190 30 36.0 719 17 11.0 220 26 46.0 833 14 14

3500 222 30 30.6 839 17 9.0 266 25 40.6 1007 14 12

4000 224 34 30.0 848 19 9.1 266 29 41.2 1007 16 12.6

Water Hardness

1-10 grains per gallon

Water Hardness

11-15 grains per gallon

Section 5

WATER FLOW REQUIREMENTS

5.1 MagnaTherm Boiler Flow and Head Requirements

LAARS Heating Systems

**

Headloss is for boiler only (no piping)

*

Flow Head Loss Flow Head Loss Flow Head Loss Flow Head Loss

LPM m LPM m LPM m LPM m

2000 568 9.2 485 7.2 413 5.2 360 4.2

2500 719 10.0 599 7.0 514 5.0 449 4.1

3000 856 14.3 719 10.4 621 7.9 538 5.8

3500 1007 12.0 839 9.0 719 7.0 629 6.0

4000 1136 14.6 965 11.6 825 8.7 719 6.9

Table 10. Boiler Flow and Head Requirements

5.2 MagnaTherm Water Heater Flow and Head Requirements

* * *

*

*

*

*

Table 11. Water Heater Flow and Head Requirements

*

*

MagnaTherm Boilers and Water Heaters

Section 6 WATER CONNECTIONS

MGH BOILERS

6.1 MGH System Piping: Hot Supply Connections

Note -This appliance must be installed in a closed

pressure system with a minimum of 12 psi (82.7

kPa) static pressure at the boiler.

Page 19

A boiler installed above radiation level, or as

required by the authority having jurisdiction,

must be provided with a low water cutoff device

either as a part of the boiler or at the time of boiler

installation.

6.3 MGH Freeze Protection

The hot water piping should be supported by

suitable hangers or oor stands. Do not support the

piping with this appliance. The hangers used should

allow for expansion and contraction of pipe. Rigid

hangers may transmit noise through the system

resulting from the piping sliding in the hangers. We

recommend that padding be used when rigid hangers

are installed. Maintain 1” (2.5 cm) clearance to

combustibles for all hot water pipes.

Pipe the discharge of the relief valve (full size) to a

drain or in a manner to prevent injury in the event of

pressure relief. Install an air purger, an air vent, an

expansion tank, a hydronic ow check valve in the

system supply loop, and any other devices required

by local codes. The minimum ll pressure must

be 12 psig (82.7 kPa). Install shutoff valves where

required by code.

Suggested piping diagrams are shown in Figure 7

through Figure 10. These diagrams are meant only as

guides. Components required by local codes must be

properly installed.

The MagnaTherm’s efciency is higher with

lower return water temperatures. Therefore, to

get the best low return temperature with multiple

boilers, pipe as shown in Figure 9 and Figure 10.

6.2 MGH Cold Water Make-Up

1. Connect the cold water supply to the inlet

connection of an automatic ll valve.

2. Install a suitable back ow preventer between

the automatic ll valve and the cold water

supply.

3. Install shut off valves where required.

In some installations, a hot water heating boiler is

connected to heating coils located in an air handling

appliance where the coils may be exposed to

refrigerated air circulation. In these cases, the boiler

piping system must be equipped with ow control

valves or other automatic means to prevent gravity

circulation of the boiler water during the cooling

cycle.

MagnaTherm units may be installed indoors or

outdoors. If installing outdoors in a location that

may experience freezing temperatures, precautions

must be taken to prevent water in the heat exchanger

and condensate inside and outside of the boiler from

freezing. Damage due to freezing water or condensate

is not covered by the warranty .

If installed indoors, and there is an event such as a

power outage, interruption of gas supply, failure of

system components, activation of safety devices,

etc., this may prevent a boiler from ring. Any time

a boiler is subjected to freezing conditions, and

the boiler is not able to re, and/or the water is

not able to circulate, there is a risk of freezing

in the boiler or in the pipes in the system. When

water freezes, it expands. This may result in bursting

of pipes, or damage to the boiler, and this could

result in leaking or ooding conditions.

Do not use automotive antifreeze. To help prevent

freezing, LAARS recommends the use of inhibited

glycol concentrations between 20% and 35% glycol.

Typically, this concentration will serve as burst

protection for temperatures down to approximately

-5°F (-20°C). If temperatures are expected to be

lower than -5°F (-20°C), glycol concentrations up

to 50% can be used. When concentrations greater

than 35% are used, water ow rates must be

increased to maintain a 20°F to 25°F temperature

rise through the boiler.

WARNING

Glycol must not be used in domestic hot

water applications. Refer to Section 7 for

instructions on freeze protection for MGV

units (domestic hot water).

Page 20

LAARS Heating Systems

Different glycol products may provide varying

degrees of protection. Glycol products must

be maintained properly in a heating system, or

they may become ineffective. Consult the glycol

specications, or the glycol manufacturer, for

information about specic products, maintenance

of solutions, and set up according to your particular

conditions.