LAARS M4-Ext Installation Manual

Laars Modulating Controls

Document 4211A

PWR

PWR

L

L

1

1

N

N

2

2

OUTPUT RATINGS:

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

FOR ALL CIRCUITS

INPUT RATINGS:

INPUT RATINGS:

115VAC 60Hz , 30VA MAX

115VAC 60Hz , 30VA MAX

USE COPPER WIRE,

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CLASS 1 WIRE ONLY.

ENCLOSED

ENCLOSED

ENERGY

ENERGY

MANAGEMENT

MANAGEMENT

EQUIPMENT

EQUIPMENT

LISTED

LISTED

99RA

99RA

A

B

SYS

A

B

SYS

5

3

6

7

8

4

5

3

6

7

8

4

CAUTION: RISK OF ELECTRIC SHOCK

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

More than one disconnect switch may be required

to de-energize the equipment before servicing.

to de-energize the equipment before servicing.

C

D

C

D

9

10

11

12

9

10

11

12

M4

SYSTEM

SYSTEM

A

A

B

B

C

C

D

D

A

A

CUR / VLT

CUR / VLTBCUR / VLTCCUR / VLT

CUR / VLT

CUR / VLT

VLT

mA

GND

GND

mA

VLT

GND

GND

-

-

-

-

+

+

+

+

13

15

16

14

13

16

15

14

FULL MODULATION SEQUENCING

Full Modulation Sequencing Control

RUNPROGRAM

RUNPROGRAM

D

B

D

CUR / VLTCCUR / VLT

mA

VLT

VLT

VLT

mA

mA

GND

GND

mA

mA

mA

mA

VLT

VLT

VLT

GND

GND

mA

-

-

-

-

+

+

+

+

+

+

+

+

+

+

+

+

+

+

18

19

20

23

22

21

17

17

24

23

18

19

20

21

24

22

Mini-MOD

DO NOT APPLY ANY VOLTAGE

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

TO INPUT TERMINALS

OUTDOOR

SYSTEM

OUTDOOR

TEMP

TEMP

O

T

T

O

26

25

27

26

25

27

---

SYSTEM

TEMP

TEMP

T

T

Modulating

---

EXTENSION

EXTENSION

SHUTDOWN

PROVE

SHUTDOWN

PROVE

/DHW

/DHW

O

O

29

28

29

28

MODULE

MODULE

/SETBACK

/SETBACK

RS-485

RS-485

O

O

O

O

30

31

32

30

32

31

Model M4 and M4-Ext

Output panel to Modulate

up to 16 individual

stages with lead-lag and

manual override capabilities

FOR YOUR SAFETY: This product must be installed and serviced by a

professional service technician, qualified in hot water heater/boiler controls

installation and maintenance. This manual is intended for anyone who will

install, operate or maintain the control system. Before you begin installation

and operation of this control, it is important that you thoroughly review this

manual. Improper installation and operation could result in damage to

equipment and possibly even personal injury. Laars Sequencing Controls are

not intended for use as operation safety limit controls. Another control, that is

intended and certified as a high limit control, must be in the water heater/boiler

control circuit.

Page 2 LAARS Heating Systems

Contents

M4 LAYOUT . . . . . . . . . . . . . . . . . 3

M4 OVERVIEW . . . . . . . . . . . . . . . 4

UNDERSTANDING OPERATION CONCEPT 5

Reset Ratio/Outdoor Reset . . . . . . . . . .5

INITIAL PILOT PROGRAM . . . . . . . . . 6

Making Sure You Have the Right Control . 6

Selecting the System Features. . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . 7

Mounting the Enclosure . . . . . . . . . . 7

Install the Sensors . . . . . . . . . . . . . 8

Heating System Sensor (HSS) Installation. . .8

Outdoor Sensor Installation . . . . . . . . . . 8

Wiring. . . . . . . . . . . . . . . . . . . . 9

Wiring the Power (Terminals 1, 2) . . . . . . . 9

Wiring the Sensors . . . . . . . . . . . . . . . 9

Wiring the Shutdown (Terminals 31, 32) . . . .9

Wiring the System Prove (Terminals 29, 30) 10

Wiring the Domestic Hot Water Call DHW

(Terminals 29, 30) . . . . . . . . . . . . . . 10

Wiring the System Output (Terminals 3, 4) . . 10

Wiring the Boilers . . . . . . . . . . . . . . 10

Wiring to Modulating Motors . . . . . . . . . 11

Connecting to the M4-Extension Panels . . . 11

MENU SEQUENCE . . . . . . . . . . . . . 12

Startup Settings . . . . . . . . . . . . . . 14

Program Change Settings . . . . . . . . . . 14

Startup Sequence . . . . . . . . . . . . . . 14

Sensor Type . . . . . . . . . . . . . . . . . 14

EMS Input Mode (Available in Set Point Only) 14

Selecting the Output Type . . . . . . . . . . 14

Selecting the Modulating Mode . . . . . . . 15

Prove/Domestic Hot Water (DHW) . . . . . . 15

Setback Mode . . . . . . . . . . . . . . . . 15

Boost Mode . . . . . . . . . . . . . . . . . 15

Sensor Fault . . . . . . . . . . . . . . . . . 15

Operating Settings . . . . . . . . . . . . . 16

Program Change Settings . . . . . . . . . . 16

Season . . . . . . . . . . . . . . . . . . . . 16

Set Point . . . . . . . . . . . . . . . . . . . 16

Reset Ratio. . . . . . . . . . . . . . . . . . 16

Outdoor Cutoff Temperature . . . . . . . . . 17

Offset . . . . . . . . . . . . . . . . . . . . . 17

Minimum Water Temp . . . . . . . . . . . . 17

Maximum Water Temp . . . . . . . . . . . . 18

System Settings . . . . . . . . . . . . . . 18

Gain . . . . . . . . . . . . . . . . . . . . . 18

Lead Boiler Rotation . . . . . . . . . . . . . 18

Purge Delay . . . . . . . . . . . . . . . . . 19

Lag Delay . . . . . . . . . . . . . . . . . . 19

Standby Time. . . . . . . . . . . . . . . . . 19

System Run-On . . . . . . . . . . . . . . . 19

Setback. . . . . . . . . . . . . . . . . . . . 20

Last Stage Hold . . . . . . . . . . . . . . . 20

Day/Night Schedules . . . . . . . . . . . . . 21

Set Time . . . . . . . . . . . . . . . . . . . 21

History . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . 22

System & Outdoor Sensor Trim . . . . . . . 22

Soft-Off Delay . . . . . . . . . . . . . . . . 22

Output Trim. . . . . . . . . . . . . . . . . . 22

Configuration . . . . . . . . . . . . . . . . . 23

Display . . . . . . . . . . . . . . . . . . . 23

Display Boiler Modulation Status. . . . . . . 23

Display Messages . . . . . . . . . . . . . . 23

Boiler Stage Settings . . . . . . . . . . . . 24

Mode . . . . . . . . . . . . . . . . . . . . . 24

Ignition %. . . . . . . . . . . . . . . . . . . 25

Modulation Start % . . . . . . . . . . . . . . 25

Copy Settings - Boiler A Only . . . . . . . . 25

TROUBLESHOOTING. . . . . . . . . . . . 26

SPECIFICATIONS . . . . . . . . . . . . . . 28

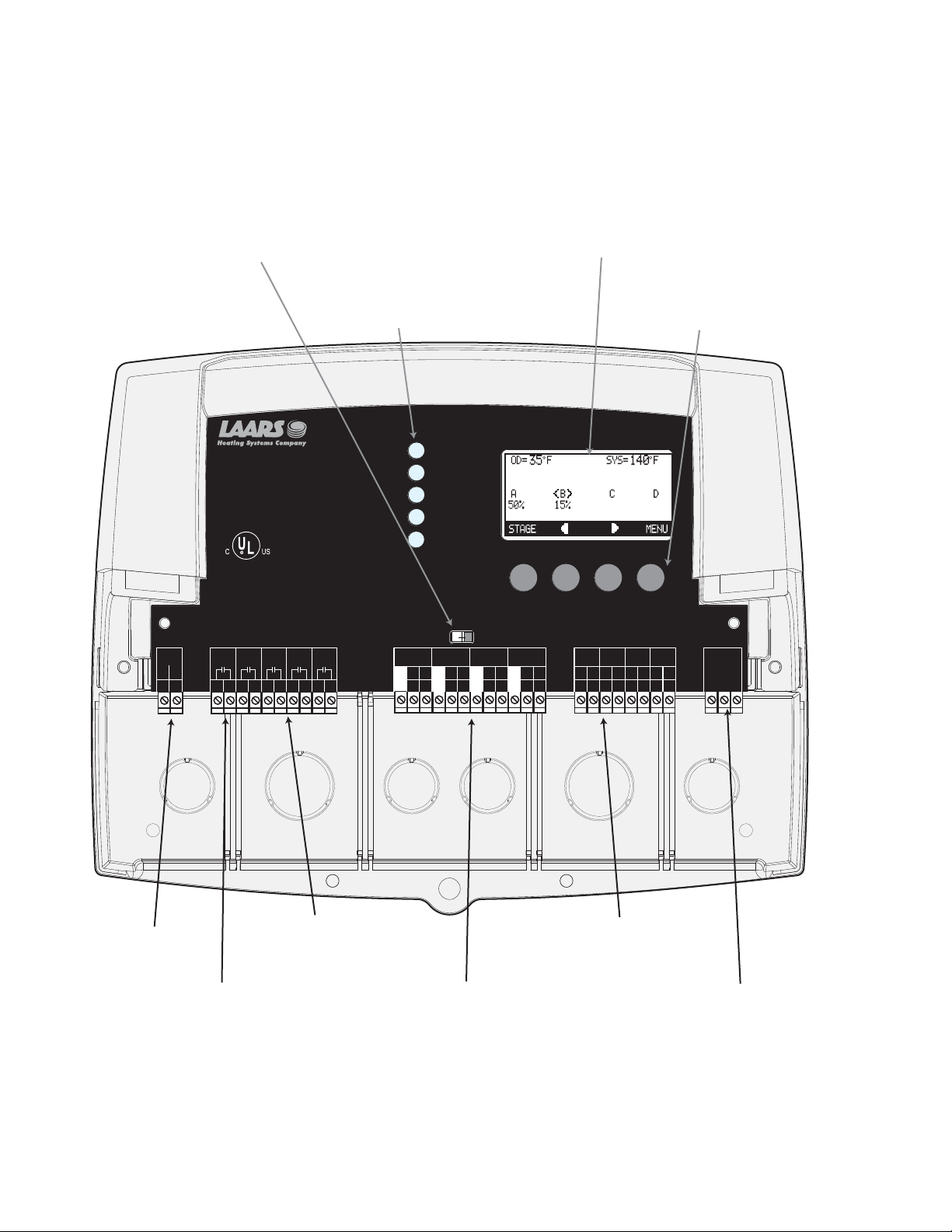

M4 LAYOUT

Page 3LAARS Modulating Controls M4 & M4-EXT

Program Switch to restrict access to

function changes. This switch is

covered with Wiring Enclosure.

LED indicates the

associated relay status.

OUTPUT RATINGS:

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

FOR ALL CIRCUITS

INPUT RATINGS:

INPUT RATINGS:

115VAC 60Hz , 30VA MAX

115VAC 60Hz , 30VA MAX

USE COPPER WIRE,

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CLASS 1 WIRE ONLY.

ENCLOSED

ENCLOSED

ENERGY

ENERGY

MANAGEMENT

MANAGEMENT

EQUIPMENT

PWR

PWR

L

L

1

1

EQUIPMENT

LISTED

LISTED

99RA

99RA

A

SYS

A

SYS

N

N

2

2

5

3

4

5

3

4

CAUTION: RISK OF ELECTRIC SHOCK

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

More than one disconnect switch may be required

to de-energize the equipment before servicing.

to de-energize the equipment before servicing.

D

C

B

C

D

9

10

11

8

9

10

11

678

6

7

B

12

12

M4

SYSTEM

SYSTEM

A

A

B

B

C

C

D

D

A

A

CUR / VLT

CUR / VLT

GND

GND

-

-

13

13

B

CUR / VLTBCUR / VLTCCUR / VLT

CUR / VLT

mA

mA

VLT

GND

mA

mA

VLT

GND

-

-

+

+

+

+

+

+

15

16

14

17

15

16

14

17

The digital display shows the system status, set point,

lead stage <in brackets>, and status of each stage.

To view and adjust settings, press the appropriate buttons.

Buttons function is presented on

Bottom Row of display.

FULL MODULATION SEQUENCING

Full Modulation Sequencing Control

---

---

DO NOT APPLY ANY VOLTAGE

DO NOT APPLY ANY VOLTAGE

OUTDOOR

OUTDOOR

TEMP

TEMP

VLT

VLT

T

T

+

+

25

24

25

24

TO INPUT TERMINALS

TO INPUT TERMINALS

PROVE

SYSTEM

SYSTEM

PROVE

/DHW

TEMP

/DHW

TEMP

T

O

O

26

26

O

O

O

T

O

30

29

28

27

30

29

28

27

SHUTDOWN

SHUTDOWN

/SETBACK

/SETBACK

O

O

32

31

32

31

EXTENSION

EXTENSION

MODULE

MODULE

RS-485

RS-485

VLT

VLT

+

+

18

18

RUNPROGRAM

RUNPROGRAM

C

CUR / VLT

mA

GND

mA

GND

-

-

+

+

20

19

19

20

VLT

VLT

+

+

21

21

D

D

CUR / VLT

mA

mA

GND

mA

mA

GND

-

-

+

+

+

+

23

22

23

22

120VAC Power

System Output controls

pumps, valves, or other

system components.

Four N.O. Boiler startup relay

outputs. Each is wired in series

with each boiler's limit circuit.

Four modulation outputs can be 0-10V,

0-5V, 2-10V, 1-5V, or 4-20ma. Go to

Startup Menu to determine the type of

output for each stage.

When connecting Outdoor and System

Sensors, no Polarity is observed.

Prove terminals must be connected

for M4 to operate boilers.

Connect Extension panels to

add additional stages using

a 6 pin phone line only (cable

provided with M4-Extension).

Page 4 LAARS Heating Systems

M4 OVERVIEW

SEQUENCES UP TO 4 FULLY MODULATING STAGES.

The M4 is the perfect control whenever multiple fully modulating stages are required for hydronic heating applications. The M4 controls

the on/off and the modulation of each stage to maintain precise system set point control.

PID TYPE LOGIC

The M4’s control algorithms allow it to look at the rate of change in the system. If the system temperature is changing quickly, the M4

will react quickly to adjust the modulating stages’ output. If the system temperature changes slowly, the M4 will make slow and gradual

output adjustments. Therefore, the M4 adapts to specific system requirements and minimizes fluctuations around the set point.

CONTROLS 0-10 V, 0-5 V, 2-10V, 1-5V, OR 4-20 MA MODULATING MOTORS

The M4 is designed to accurately control the output from 0 to 100% of modulation for each of these different types of motors. One M4

can even control a variety of the above different motors.

ONLY ONE SENSOR

When Set Point sensor type is selected, the M4 requires only one sensor located in the common output header of all stages. However,

when Reset is selected, an additional Outdoor Sensor is required for Outdoor Reset Ratio input.

DIGITAL DISPLAY OF ALL SYSTEM SETTINGS

The M4’s alphanumeric digital display names each system parameter in simple English and shows its precise value. The easy to follow

menu system allows users to quickly make changes to any system setting without having to learn any specialized codes or keyboard

commands.

AUTOMATIC ROTATION AMONG STAGES

Rotating the first stage to be activated on a call for output promotes even wear on each stage. The M4 has three modes of rotation: Manual,

Last On, or Time. The Time rotates the lead stage every selected time period from every hour to every 60 days.

OUTDOOR RESET

The M4 has a hydronic outdoor temperature reset function. This allows the M4 to change the set point based on outdoor temperature.

Furthermore, additional settings have been added to fine tune this operation, like Offset, Minimum, and Maximum Water Temperature

and night setback schedule.

STANDBY BOILERS

Each of the M4 stages can be configured as a Standby boiler with an adjustable Standby delay. A boiler can be used as a backup during

extended large demand periods.

SYSTEM OUTPUT

In Set Point mode, this output can be used to activate a system pump, combustion air damper, or perform any other function that is required

when any stage is active. In Outdoor Reset mode, the System Output will activate whenever the outdoor temperature is below the Outdoor

Cutoff setting. A System Prove input checks the status of components activated by the System output before stages can be activated.

STAGING (NORMAL) OR PARALLEL MODULATION

The M4 can stage boilers as needed. That will allow it to increase the modulation on the lead boiler. When the lead boiler reaches its

modulation start point adjustment and does not satisfy the load, the M4 will start the next boiler and so on... Moreover, the M4 allows

for a parallel mode that can modulate several boilers together as a one large boiler. This mode is useful for boilers with lower water

content, which are usually more efficient at lower firing points.

ADD UP TO 16 BOILER STAGE (OPTIONAL)

As a stand-alone, the M4 is designed to control four modulating boilers. However, it has the capability of expanding its control to two

extension panels each with six boiler stages. Thus, the M4 can control a total of up to 16 boiler stages.

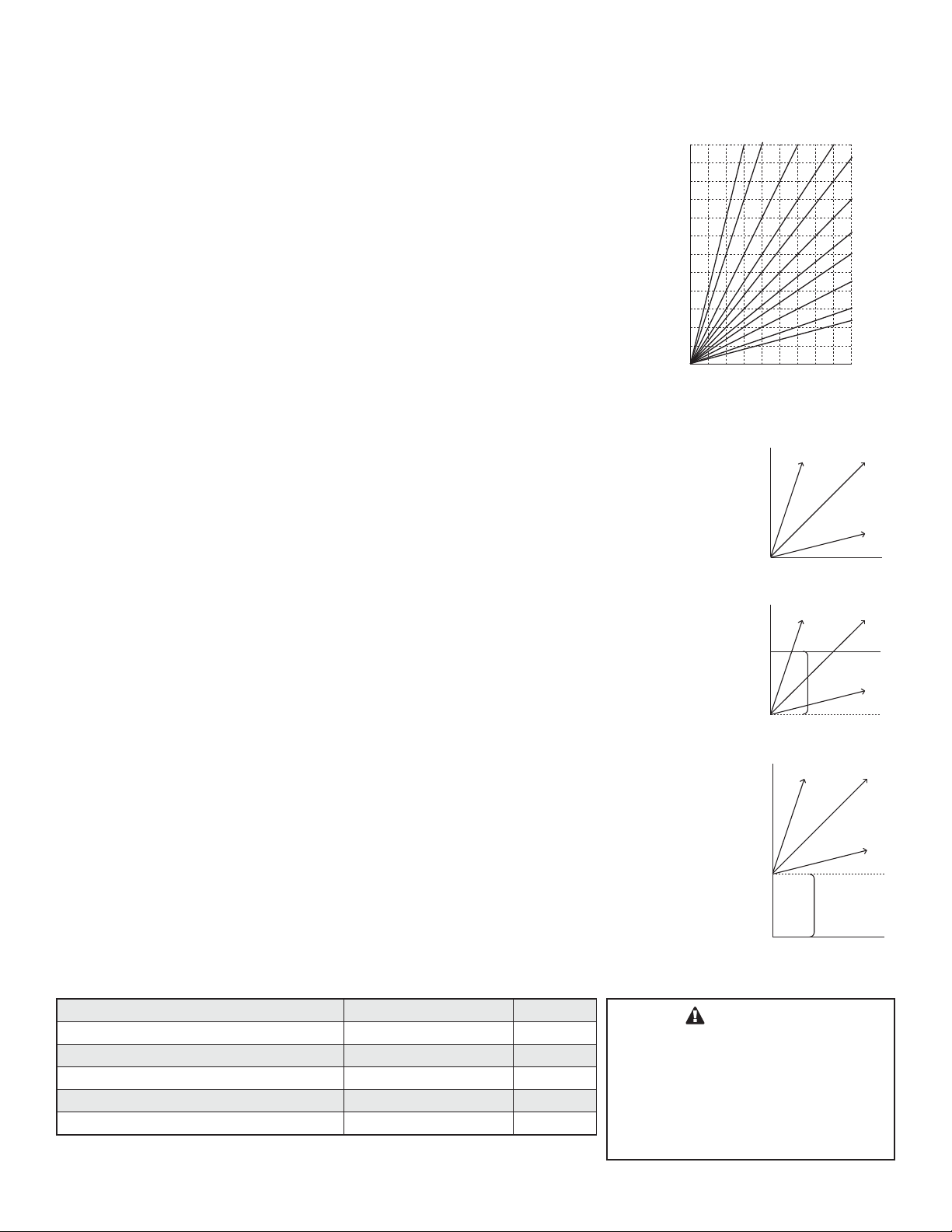

UNDERSTANDING OPERATION CONCEPT

Outdoor Temperature (in °F)

70 605040 20

30 0 -10

10 -20

100

120

110

130

140

150

160

180

170

190

200

210

220

1:3 1:2 1:1.5

1:1.25

1:1

1.25:1

1.5:1

2:1

3:1

4:1

Water Temperature (in °F)

Reset Ratio Curves

1:4

The M4 has multiple operating modes that satisfy most hydronic systems. It can change the

System Set Point based on outdoor temperature (Outdoor Reset) or it can modulate its stages

to achieve an adjustable fixed Set Point.

In Outdoor Reset, the M4 controls a hot water heating system to provide a building with

comfortable and even heat levels. The M4 varies the temperature of the circulating heating

water in response to changes in the outdoor temperature. The heating water temperature is

controlled through the modulation of stages.

The M4 also controls the system circulating pump with an adjustable Outdoor Cutoff. When

the outdoor temperature is above Outdoor Cutoff, the pump is off and no heating water is

circulated through the system. When the outdoor temperature drops below the Outdoor Cutoff,

the system pump relay is activated and the heating water circulates through the system. The

temperature of the heating water is controlled by the Reset Ratio, Water Offset, and changes

with Outdoor temperature.

Page 5LAARS Modulating Controls M4 & M4-EXT

RESET RATIO/OUTDOOR RESET

When a building is being heated, heat escapes through the walls, doors, and windows to

the colder outside air. The colder the outside temperature, the more heat escapes. If you

can input heat into the building at the same rate that it is lost out of the building, then

the building temperatures will remain constant. The Reset Ratio is an adjustment that

lets you achieve this equilibrium between heat input and heat loss.

The starting point for most systems is the 1.00 (OD):1.00 (SYS) (Outdoor Air

Temperature : Heating Water Temperature) ratio. This means that for every degree

the outdoor temperature drops, the temperature of the heating water will increase one

degree. The starting point of the curves is adjustable, but comes factory selected at

70

°F Outdoor Temp. and 100°F Water Temp. For example with a 1.00 (OD):1.00 (SYS)

ratio, if the outdoor temperature is 50

the starting point of 70°F. Therefore, the heating water temperature will increase 20° to

120°F.

Each building has different heat loss characteristics. A very well insulated building will

not lose much heat to the outside air, and may need a Reset Ratio of 2.00 (OD):1.00

(SYS) (Outdoor:Water). This means the outdoor temperature would have to drop

2 degrees to increase the water temperature 1 degree. On the other hand, a poorly

insulated building with insufficient radiation may need a Reset Ratio of 1.00 (OD):2.00

(SYS). This means that for each degree the outdoor temperature dropped the water

temperature will increase 2 degrees. The M4 has a full range of Reset Ratios to match

any buildings heat loss characteristics.

°F, this means the temperature has fallen 20° from

130

120

110

Water Temperature

100

70 405060

Outdoor Temperature

110

100

90

Water Temperature

80

70 405060

Outdoor Temperature

150

140

130

Water Temperature

120

1:4

1:4

1:4

-20 Offset

1:1

4:1

1:1

4:1

1:1

4:1

A heating curve that relies not only on Outdoor temperature but also on type of radiation

types of radiation based on average building insulation and heat loss. The contractor

can fine tune these adjustments based on the specific building need.

Type of Radiation in Building Reset Ratio Offset

Radiators (Steel & Cast Iron) 1.00 (OD) : 1.00 (SYS) 0˚F

Baseboard (Finned copper tube& Cast Iron) 1.00 (OD) : 1.00 (SYS) 0˚F

Radiant (High Mass/Concrete) 4.00 (OD) : 1.00 (SYS) -10˚F

Radiant (Low Mass/Joists) 2.00 (OD) : 1.00 (SYS) -10˚F

Fan Coils & Air Handlers 1.00 (OD) : 1.00 (SYS) 20˚F

will improve heat comfort. The following are suggested initial settings for different

90

100

70 405060

+20 Offset

Outdoor Temperature

WARNING

When controlling a non condensing

boiler directly without the use of a

mixing valve, minimum boiler water

temperature must be set to boiler

manufacturer specifications. In that

case, system temperature must not go

below such temperature.

Page 6 LAARS Heating Systems

MAKE SURE YOU HAVE THE RIGHT CONTROL

If you need the M4 to do additional tasks that either are not listed or do not know how to configure them, contact LAARS.

INITIAL SETUP

Setting an Initial Program will ease the configuration of the M4 and will give the opportunity to utilize many of the energy saving features

and give more comfortable heat when needed.

The program should consist of the following:

• Selecting the features that your system can utilize,

• Installation: Install the Control, switches and sensors,

• Setting the System Startup,

• Setting the System Settings,

• Setting the Stages

• Adjusting Reset Ratio and Water Offset (In Reset Mode Only)

SELECTING THE SYSTEM FEATURES

The M4 has been designed with Hydronic building heating as the primary purpose. With this in mind, many of the M4 features can be

utilized to ease, enhance and improve your system performance. Some of these features are listed in this section.

OUTDOOR RESET OR SET POINT

• The M4 can control the System Temperature either by adjusting the calculated temperature according to the Outdoor Temperature

(Outdoor Reset) or by maintaining an adjustable Set Point. The earlier relies on an Outdoor Sensor (supplied with the control) and

achieves better fuel savings in addition to better comfort.

NUMBER OF STAGES

• The M4 can be configured to control up to 4 modulating boilers. It can control up to 16 boiler stages using a maximum of two M4

Extension Panels

MODULATION MODE

•

The M4 can stage boilers using one of two methods. Normal Modulation Mode, allows it to increase the modulation of the lead

boiler. When the lead boiler reaches its modulation start point adjustment and does not satisfy the load, the M4 will start the next

boiler and so on. This mode targets boilers that can run more efficient at higher modulation rates.

• The Parallel Modulation Mode can modulate several boilers together as a one large boiler. This mode is useful for boilers that are

more efficient at lower firing points.

MODULATING SIGNAL

•

The M4 is designed to accurately control the output from 0 to 100% of modulation for each of these different types of motors. One

M4 can even control a variety of the above different modulation motors.

AUTOMATIC ROTATION AMONG BOILERS

• Rotating the first burner to be activated on a call for output promotes even wear on all burners. The M4 has three modes of rotation:

Manual, Last-ON, or Time automatically rotating every selected time period from every hour to every 60 days.

STANDBY BOILER

•

Any boiler can be configured as a Standby boiler. It withholds a specific boiler from being included in the Lead Rotation. However,

the Standby boiler will be fired only as a backup when all other stages combined cannot satisfy the demand and after an adjustable

delay period.

SETBACK OR DAY/NIGHT SCHEDULING

Two Setback modes are available for the M4:

• The Day/Night Scheduling provides an adjustable time-based schedule for the Setback.

• The Setback mode uses an external signal to switch the operation of the M4 in and out of setback mode.

Page 7LAARS Modulating Controls M4 & M4-EXT

System Run-On

• This feature lets the M4 run the SYS relay for a longer period after the boilers have been turned off. When this relay is used to

control a pump, it helps in dissipating the excess heat from the boilers combustion chamber.

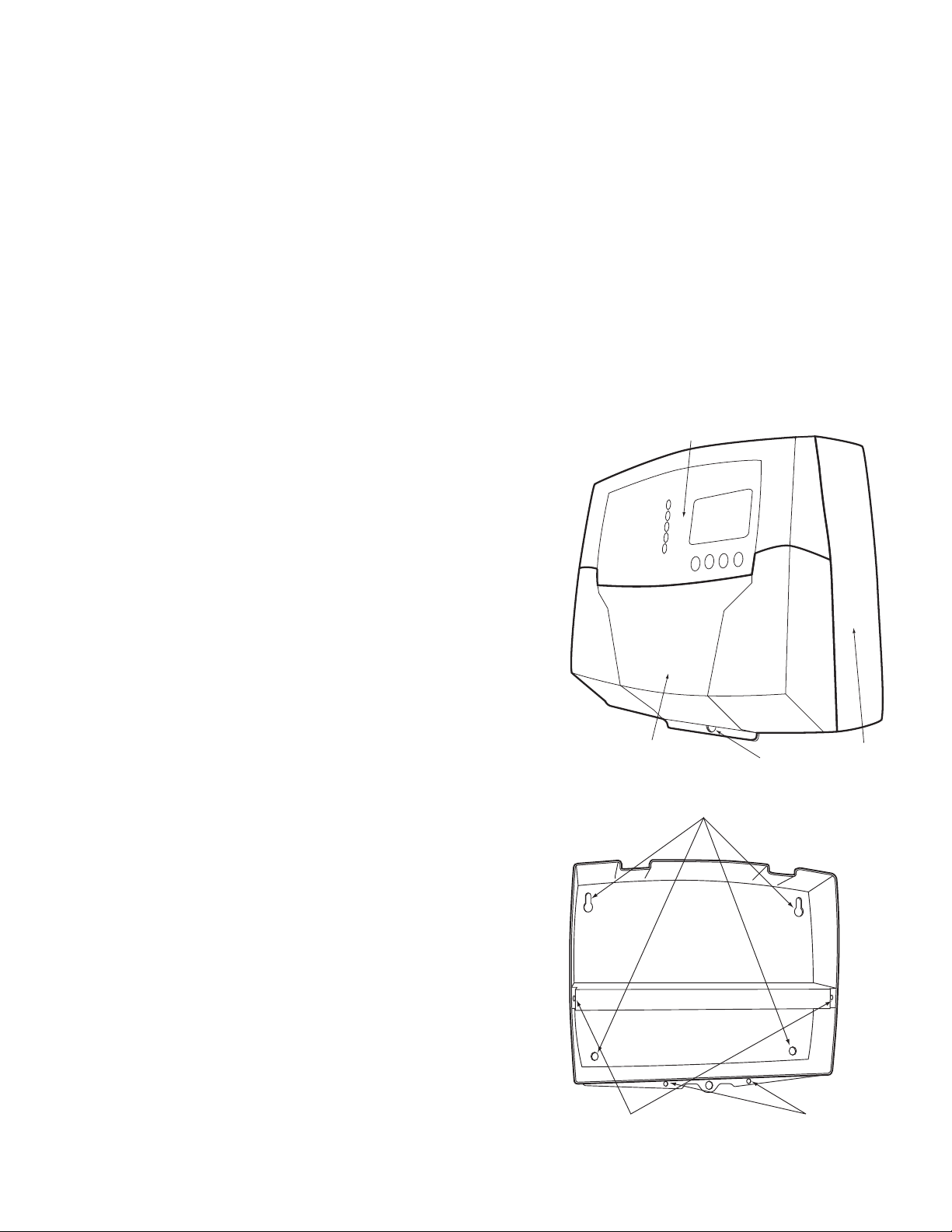

INSTALLATION

Each of the M4 or M4-Extension consists of three primary enclosure components.

• The Enclosure Display Module: contains the display, buttons, LEDs and electric wiring terminals. It has two screws to hold it to

the base. A program configuration switch, used to adjust M4 settings, is placed above the terminals. This switch is enclosed with

the enclosure wiring cover for security. Wiring terminals are of the plug-in type to ease installation and removal.

• The Enclosure Base: contains the holes to mount and hold the control against the wall or any flat surface. All other enclosure

components mount on the base. The bottom section of the Enclosure Base contains the wiring chamber with knockouts on the

bottom to easy installation.

• The Enclosure Wiring Cover: seals the wires from the external environment. It has two screws to hold it the base and a hole to

secure a lock on the wiring enclosure. A plastic web that separates the wiring chamber into high and low volt sections has been

provided.

MOUNTING THE ENCLOSURE

• Select a location near the equipment to be controlled.

• The surface should be flat, and be sufficiently wide and strong to hold the

M4 or M4-Extension.

• Keep the control away from extreme heat, cold, or humidity. Ambient

operating temperature is from 20 to 120°F.

• Remove the Enclosure Wiring Cover from the control enclosure by

removing the two bottom screws.

• Remove the Enclosure Display Module by removing the middle screws.

• Screw the Enclosure Base to the surface through the upper and lower

mounting holes on the back of the enclosure.

• Replace the Enclosure Display Module and replace the middle screws.

• Do not replace the enclosure wiring cover until all wiring is done.

Page 8 LAARS Heating Systems

INSTALL THE SENSORS

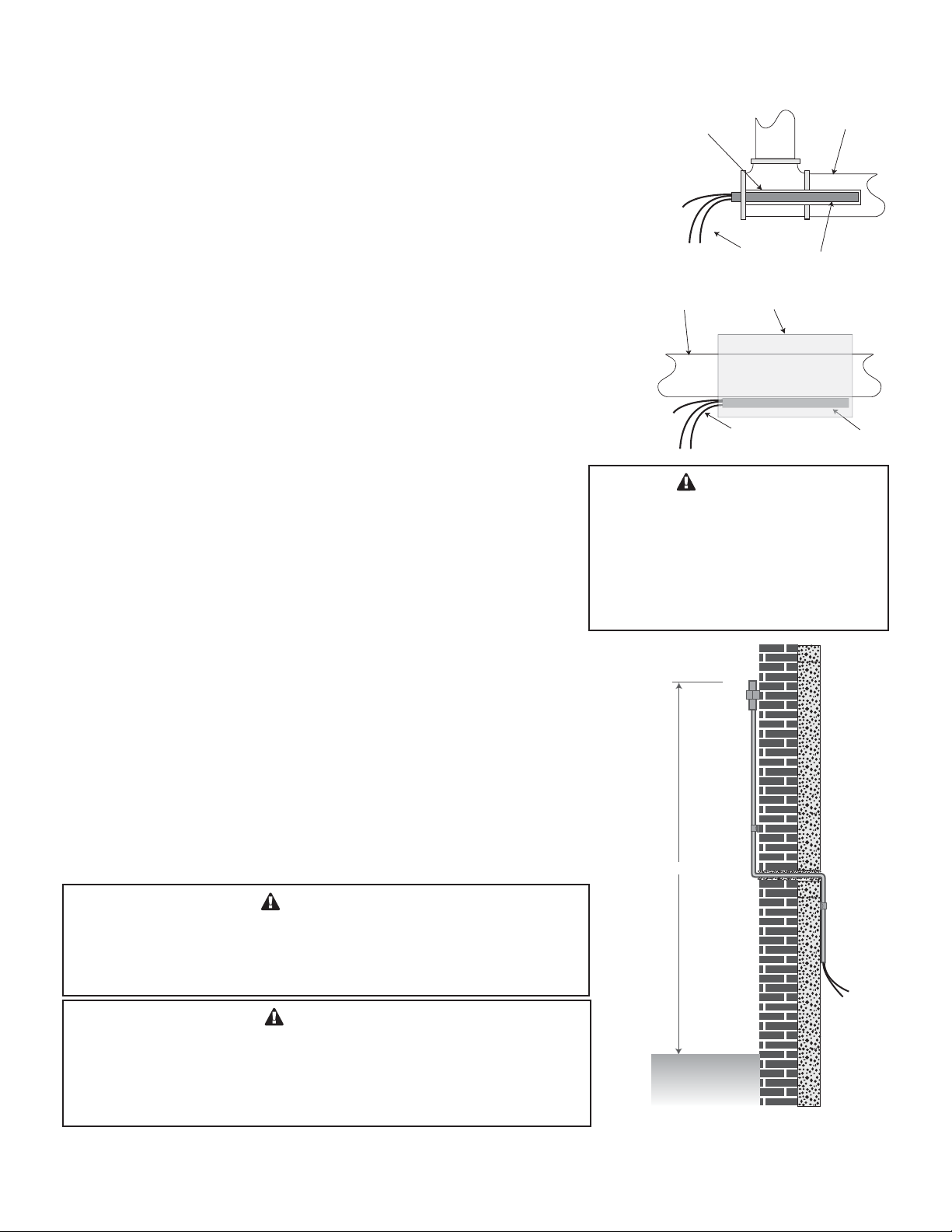

HEATING SYSTEM SENSOR (HSS) INSTALLATION

LOCATING HSS

• Put the Heating System sensor approximately 10' feet past the last boiler on

the common supply header but before any major takeoffs.

• The sensor must be located where it sees the output of all the boiler stages.

If a boiler is piped so that the sensor does not see its output, the M4 will not

sequence the boilers correctly.

• Only use a Standard Brass Tube sensor (HT #904015-00 or equivalent).

• The sensor wires can be extended up to 500' using a shielded 2-conductor

cable (Belden #8760 or equivalent). Do not ground the shield at the sensor

but at the panel using one of the terminals marked with an “O”.

• Do not run sensor wires in conduit with line voltage wiring.

IMMERSION HEATING SYSTEM SENSOR (HSS) INSTALLATION

• Install a 3/8"ID 1/2"NPT immersion well (HT #350147-00 or equivalent).

• Insert the sensor probe of the supplied sensor into the well.

STRAP-ON HEATING SYSTEM SENSOR (HSS) INSTALLATION

• Strap the sensor to the pipe using metal clamps. Do not over tighten the

clamp.

• Strap pipe insulation around the sensor and pipe.

Immersion Heating System Sensor

Immersion Well

3/8" ID 1/2" NPT

Shield

Heating System

Sensor

Strap-On Heating System Sensor

Common Supply Pipe

Pipe Insulation

Shield

Common Supply Pipe

Sensor Probe

Sensor Probe

CAUTION

If the HSS can not sense the correct

heating system water temperature being

supplied to the building, the M4 will not

provide comfortable heat levels. Be sure

the HSS is located on a main supply pipe

which can not easily be isolated from the

system.

OUTDOOR SENSOR INSTALLATION

• Only use the LAARS sensor included with the unit.

• Locate the sensor in the shade on the north side of the building. The sensor

should never be in direct sunlight.

• Be sure the location is away from doors, windows, exhaust fans, vents, or

other possible heat sources.

• The sensor should be mounted approximately 10' feet above ground level.

• Mount the sensor clip base to the outside of the building. Insert the sensor in

the middle and snap close the clip on the sensor.

• The sensor wires can be extended up to 500' using shielded 2-conductor

cable. Do not ground the shield at the sensor but at the panel using one of the

terminals marked with an “O”.

• Do not run sensor wires in conduit with line voltage wiring.

WARNING

The M4 is an operating control only. All boilers must have all safety

and limit controls required by code. It is the responsibility of the

installer to verify that all the safety and limits are working properly

before the M4 is installed.

CAUTION

Determining the proper location for the Outdoor Sensor is very

important. The M4 will base the heat on the outdoor temperature

information it receives from this location. If the sensor is in the

sun, or covered with ice, its reading will be different from the actual

Outdoor temperature (OD).

Page 9LAARS Modulating Controls M4 & M4-EXT

O

3

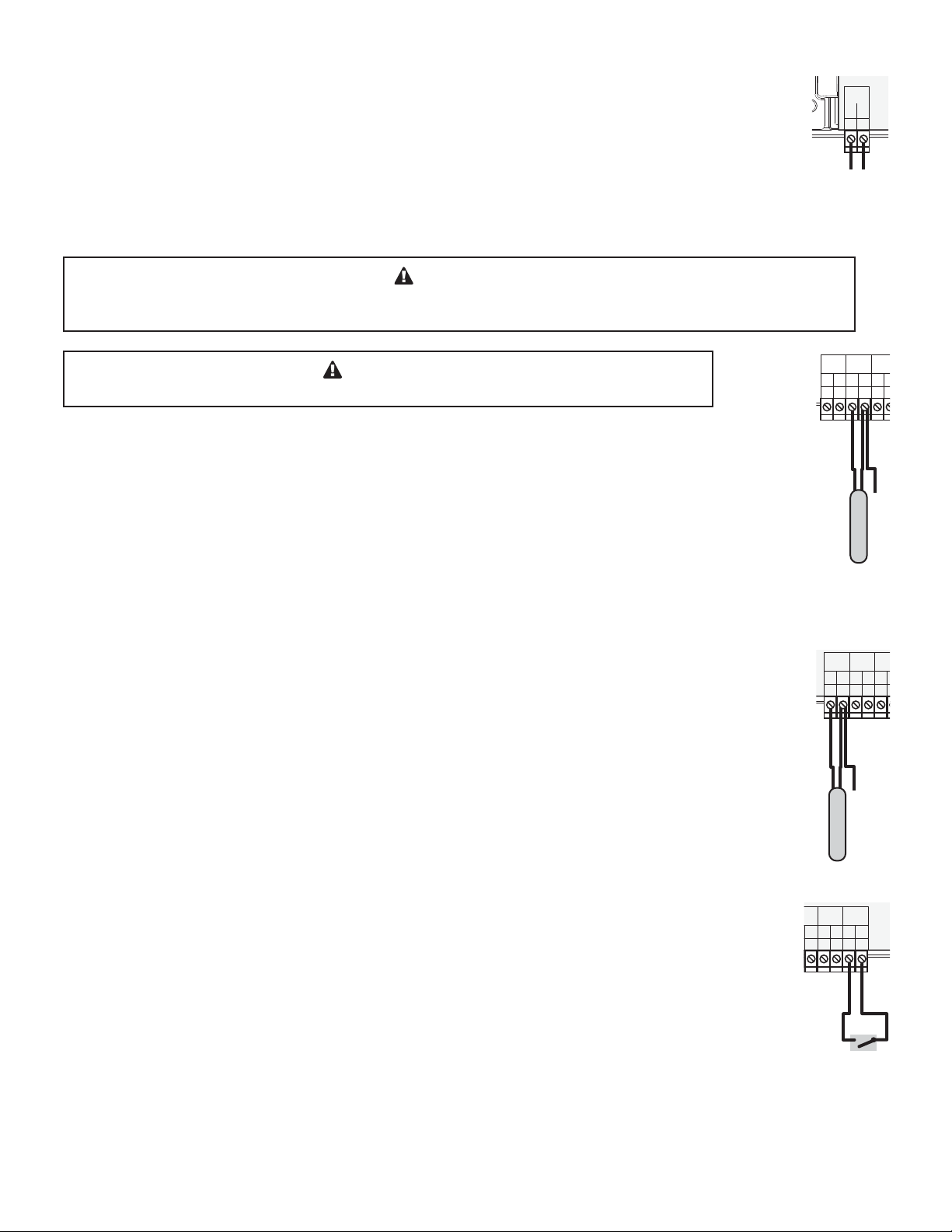

WIRING

WIRING THE POWER (TERMINALS 1, 2)

• Bring the 120VAC 60Hz power wires through the bottom Knockout of the enclosure.

• Class 1 voltages must enter the enclosure through a different opening from any Class 2 voltage wiring.

• Connect the hot line to terminal marked L.

• Connect the neutral line to the terminal marked N.

• LAARS recommends installing a surge suppressor on the power source to the M4.

WARNING

Class 1 voltages must enter the enclosure through a different opening from any Class 2 voltage wiring.

LAARS recommends installing a surge suppressor on the power source to the M4.

WARNING

Connect the shield at the control terminal end and cut the shield wire at the sensor

WIRING THE SENSORS

SYSTEM SENSOR WIRING (TERMINALS 27, 28)

• A M4 must be connected to a temperature sensor located in the common header.

• The M4 is designed to be connected to a HT #904015-00 temperature sensor for immersion in a 3/8ID well (HT

#350147-00 or equivalent). Contact the factory for additional temperature sensor options.

• Temperature sensor wires can be extended up to 500’ by splicing shielded 2-conductor cable (Belden #8760 or

equivalent).

• Temperature sensors have no polarity. Connect the two wires from the sensor to the M4 terminals marked

SYSTEM TEMP 27, 28.

• Connect the sensor shield to the circled terminal 28 with one of the sensor wires.

OUTD

2

Powe

EM

T

T

5

OR

O

P

O

2

PWR

L

1

20VAC

1

6

27

r

SYS

T

T

Line

S

EM

N

2

ource

TEM

P

O

8

2

ensor

stem S

Sy

Neutral

O

PR

W

/DH

9

2

led

nsor Shi

Se

E

V

3

OUTDOOR SENSOR WIRING (TERMINALS 25, 26)

• When Outdoor Reset is selected, the M4 will vary the system Set Point based on outdoor temperature.

• Whether in Set Point or Outdoor Reset modes, the outdoor sensor can be used as an Outdoor Cutoff.

The M4 will disable all Boilers when the outdoor temperature is above the adjustable Outdoor Cutoff

temperature. This feature will automatically be activated when an outdoor sensor is connected.

• For an outdoor sensor use a LAARS outdoor sensor (HT #904015).

• The sensor wires can be extended up to 500’ using shielded 2-conductor cable (Belden #8760 or equivalent).

• Temperature sensors have no polarity. Connect the wires from the outdoor

sensor to the M4 terminals marked OUTDOOR TEMP - 25, 26.

• Connect the shield to the circled terminal 26 with one of the sensor wires.

WIRING THE SHUTDOWN (TERMINALS 31, 32)

• This feature can be used whenever it is desirable to turn off the M4 stage outputs from a remote location or

another controller (i.e. EMS input).

• When the Shutdown feature is enabled by closing a dry contact, all active boilers will immediately modulate

down to low then off. The lead boiler will remain in low for a Soft-Off period; default setting is 45 seconds,

and then turn off.

• The System Output relay will remain active until the System Delay is over and then it will turn off.

• The Shutdown signal must be a dry contact only. No voltage can be placed across the SHUTDOWN terminals.

• Bring the two wires from the dry contact to the terminals marked SHUTDOWN- 31,32.

R

O

STEM

SY

MP

E

T

T

O

27

led

Shi

or

s

en

S

W

O

TD

U

SH

ETBACK

/S

O

31

32

Shutdown

ign

S

V

O

PR

W

/DH

O

29

28

N

al

O

OUTD

MP

E

T

T

26

25

nsor

doorSe

t

Ou

VE

TEM

O

PR

W

MP

H

D

/

O

O

30

29

28

Loading...

Loading...