Tankless Gas Water Heater

SERVICE

MANUAL

Troubleshooting Guide

and Instruction for Service

(To be performed ONLY by qualified service providers)

Document 11013

For the LAARS®Heating System

®

EverHot

Gas Water Heater Models:

IGI-180R-10(N,X) IGI-180C-5(N,X)

Save this manual for future reference

Interior Tankless

Key to Warning Symbols

Failure to comply with the following instructions may results in serious personal injury or

damage to the appliance.

Be careful of possible electric shock. Wiring inside this appliance may potentially be at

120 volts.

Disconnect power supply to unit when carrying out the following service repairs.

Read Fault Diagnosis and Wiring Diagram carefully to avoid incorrect wiring.

Do not disassemble. Parts within can not be exchanged or diagnosed faulty.

Please follow the instructions in the following chapters

to ensure safe and appropriate service.

After completing the service and confirming that there are no water or

gas leak

s or incorr

ect wiring, t

est operation of the appliance.

2

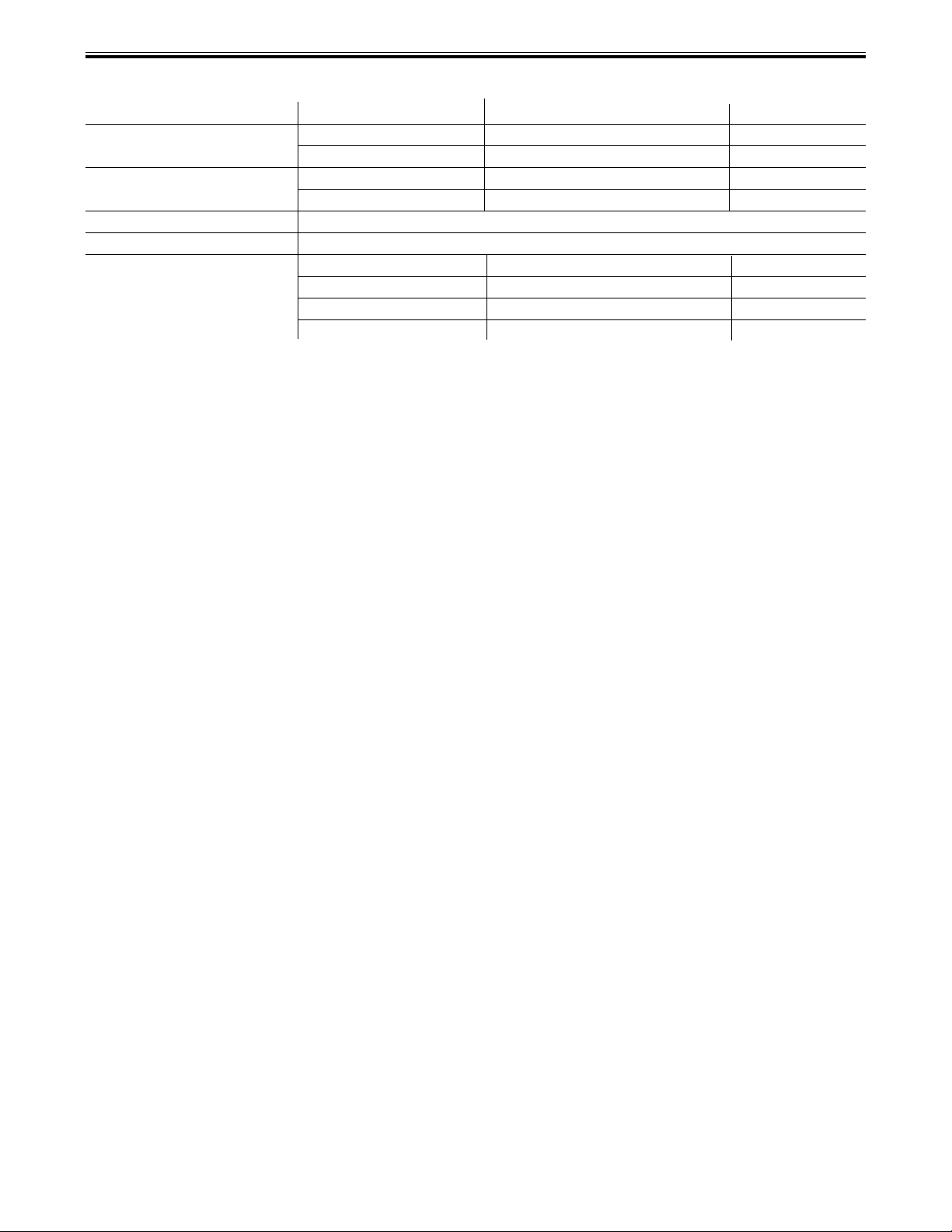

TABLE OF CONTENTS

Section Description Page

- - - Glossary of Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

I. . . . . . . . . . . .General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

II. . . . . . . . . . . Specifications (General). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

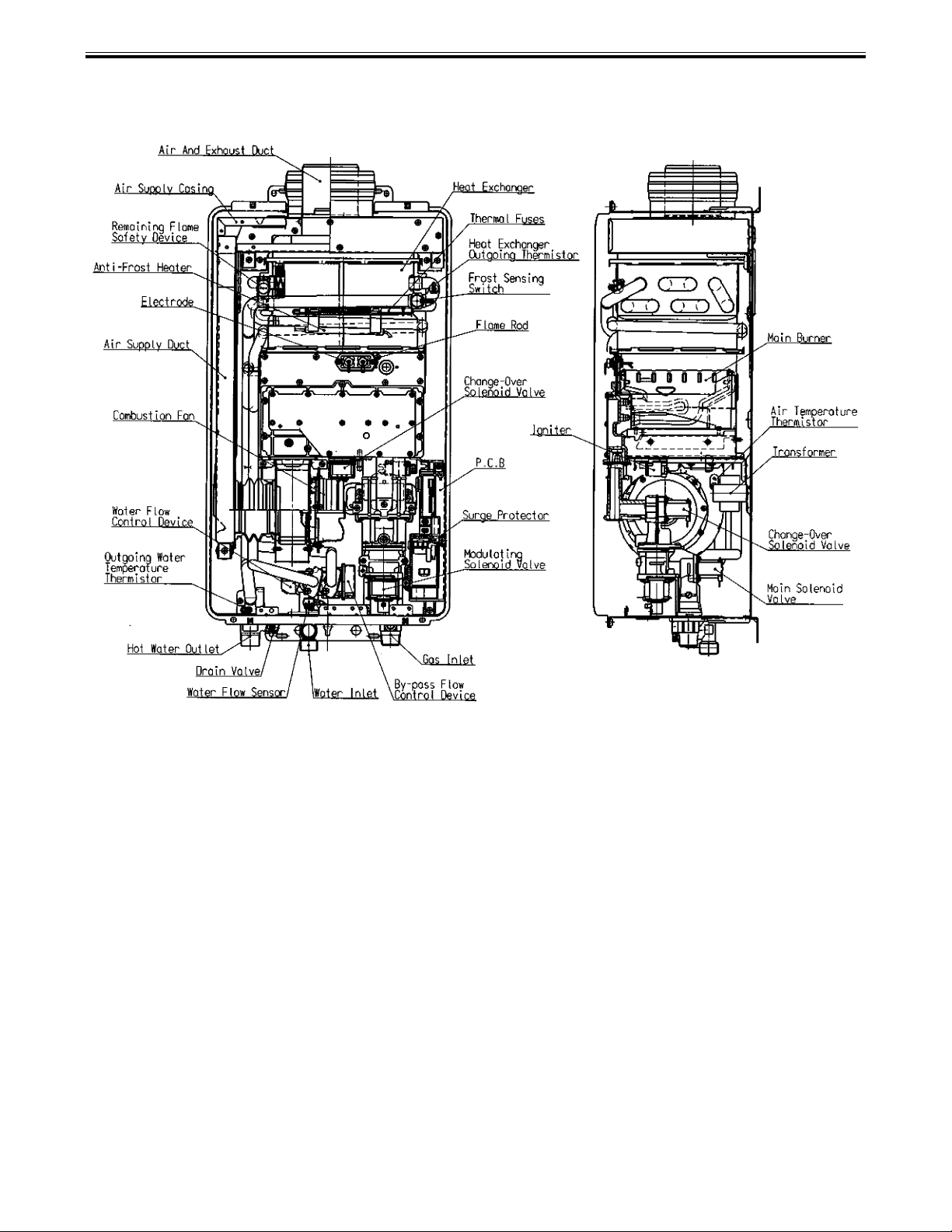

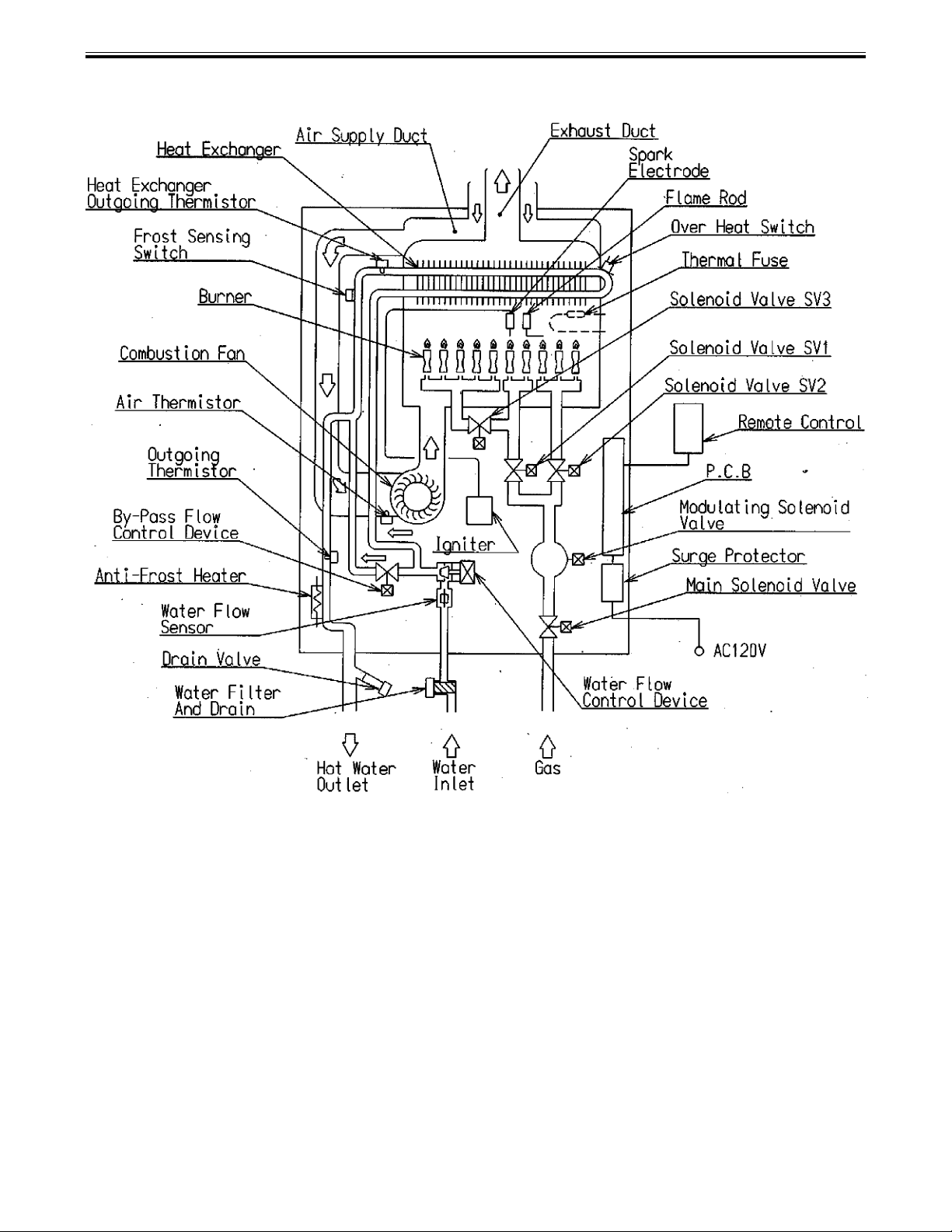

III. . . . . . . . . . .Main Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

IV. . . . . . . . . . .Safety Device Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

V. . . . . . . . . . . Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

VI. . . . . . . . . . .Troubleshooting (error messages). . . . . . . . . . . . . . . . . . . . . . . . . . .25

VII. . . . . . . . . . Gas Pressure Setting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

VIII. . . . . . . . . .Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

IX. . . . . . . . . . .Flushing Procedure for Lime Scale Removal . . . . . . . . . . . . . . . . . . .54

X. . . . . . . . . . . Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

a. How to Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . .6

b. Cut Away illustration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

c. Schematic illustration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

a. Combustion Specifications. . . . . . . . . . . . . . . . . . . . . . . . .11

b. Default Dip Switch Settings. . . . . . . . . . . . . . . . . . . . . . . .12

c. Venting Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

a. Operation Sequence Flow Chart. . . . . . . . . . . . . . . . . . . .21

b. Sequence Timing Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . .23

a. Quick Reference Diagnostic Points. . . . . . . . . . . . . . . . . .27

b. Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

c. Troubleshooting Flow Chart. . . . . . . . . . . . . . . . . . . . . . . .31

d. Trouble Shooting Procedure. . . . . . . . . . . . . . . . . . . . . . . .36

efer t

R

allation and oper

o inst

ation manual for t

• General Dimensions

• Piping Recommendations

• Remote Control Features

• Water Flo

w Rates vs Temperature

he following reference information:

3

GLOSSARY OF TERMS AND SYMBOLS

This glossary of terms and symbols is provided to assist you in understanding some of the

language used throughout this manual.

dB(A) - sound pressure level in decibels, “A” range

DC - direct current

AC - alternating current

WFCD - water flow control device

FB - feedback information

Hz - hertz

IC - integrated circuit

BTU/H - British thermal units per hour

PSI - Pounds per square inch

LED - light emitting diode

GPM - gallons per minute

mA - milliamps

W.C. - inches of water column

mm - millimeters

NOx - oxides of nitrogen NO & NO

OHS - overheat switch

PCB - printed circuit board

CPU - central processing unit

POT - potentiometer

rpm - revolutions per minute

SV - solenoid valve

Ø - diameter

∆°F - delta T or temperature rise above ambient

POV - modulating valve

TE - thermal efficiency

TH - thermistor

T

IN

T

out

- temperature of incoming water

- temperature of outgoing water

2

4

I - GENERAL INFORMATION

This tankless water heater is a high output, high efficiency appliance, which heats the water

continuously as hot water is being drawn for use. Unlike tank type storage water heaters, this water

heater does not store hot water. The burner operates whenever there is a demand for hot water and

is off when the hot water flow stops. Hot water is continuously supplied for any length of time

required as long as the specified flow rates are not exceeded. There is no need to set the

temperature higher than required for sufficient capacity. This water heater has sufficient capacity to

supply several hot water faucets simultaneously. The hot water flow capability will be dependent

upon the temperature of the outlet water selected. Operational feature of this water heater include:

• The burners ignite by direct spark ignition within 3 seconds of detecting minimum

operational water flow. There is no standing pilot.

• A variable speed combustion air blower forces the combustion air supply into the burner

compartment.

• Direct vent design uses only outside air for combustion. The venting system is a coaxial

design requiring a single 5 1/4" (13.3 cm) hole through the outside wall or roof. Vent pipe

fittings have internal gaskets for a tight seal to prevent leakage of flue products and

combustion air.

• The burner flame is continuously monitored and modulated to match the heating

requirements of the water flow. Temperature and flow sensors continually monitor the

water flow and outlet water temperature and adjust the burner and combustion air blower

to maintain temperature.

• The Indoor Direct Vent model series have a digital temperature control integrally mounted

to the front panel of the water heater. The outlet water temperature is adjustable from

96-160°F for residential models or 96-180˚F for commercial models. The front panel

temperature control also displays fault codes if the water heater malfunctions to assist with

servicing the water heater. No installation is required for the main temperature control.

• In addition to the main temperature controller, up to two optional bathroom temperature

controls are available on the residential models for setting the water temperature in the

bathroom fixtures up to 120°F.

• The heat exchanger coil is provided with anti-freeze heaters for protection in cold climate

conditions to ambient tem

peratures as low as -30°F (-34°C). Drain solenoids should be

installed to drain the water heater in the event of a power failure.

(See installation ins

tructions)

Tools Required for Troubleshooting

Multifunction Digital Test meter with needle point test leads.

Long reach (12") Magnetic Phillips screw driver (#2 Tip)

3/16 Allen wrench

Small (pocket size) blade screw driver

Monometer or Magnehelic inches water column gage

5

I - GENERAL INFORMATION (cont.)

HOW TO USE THIS MANUAL

It is intended for this manual to be used by qualified service personnel for the primary purpose of

troubleshooting analysis and repair of this tankless gas fired water heater. Understanding the basic

operation of the "Main Components" and the "Sequence of Operation" sections of this manual will

contribute greatly to your success in the troubleshooting analysis of this product.

Sections of this manual reference general information and specifications. The primary focus is trouble

shooting analysis and repair. The trouble shooting section consists of the following:

• Error Message Table.

Table showing Error Message as displayed on remote control indicating likely fault and

remedy.

• Quick Reference Diagnostics Points Table.

This guide will identify the specific diagnostic point for each component as well as the

correct electrical value for each component.

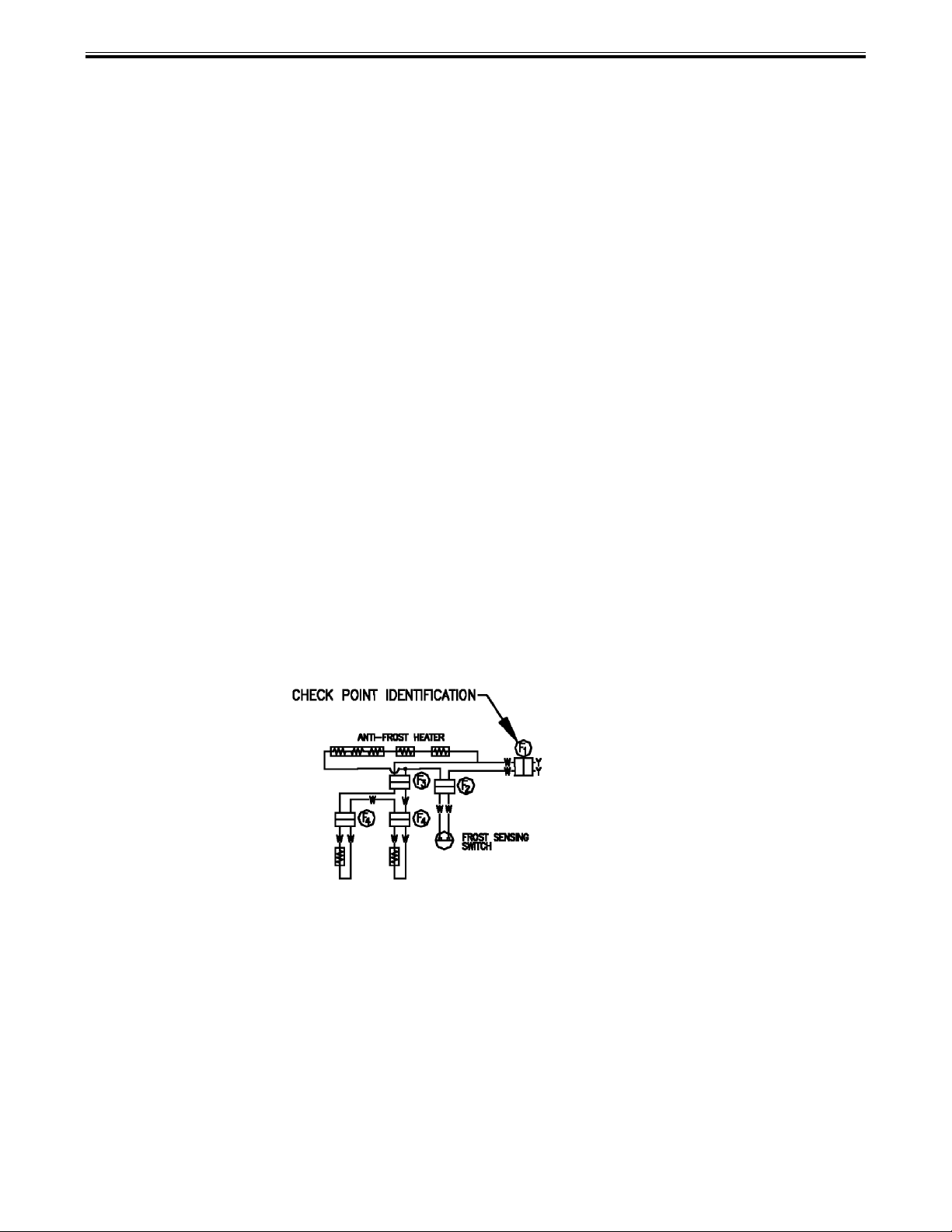

• Troubleshooting Flow Chart.

The "Trouble Shooting Flow Chart" identifies fault potentials and directs service to

the appropriate diagnostic check points. The check points are identified in the

troubleshooting procedure and are shown on the wiring diagram by means of an

encircled letter with a subscript number.

Example:

This chart will also r

efer to a page number to reference a pictorial version of the

component analysis as outlined in the "Trouble Shooting Procedure" section of this

manual.

• Trouble Shooting Procedure.

Pictorial procedure including diagnostic points, electrical values and referral to

"Service Procedure" for replacement of faulty components.

• Service Procedure.

Pictorial procedure for removal and replacement of components.

6

I - GENERAL INFORMATION (cont.)

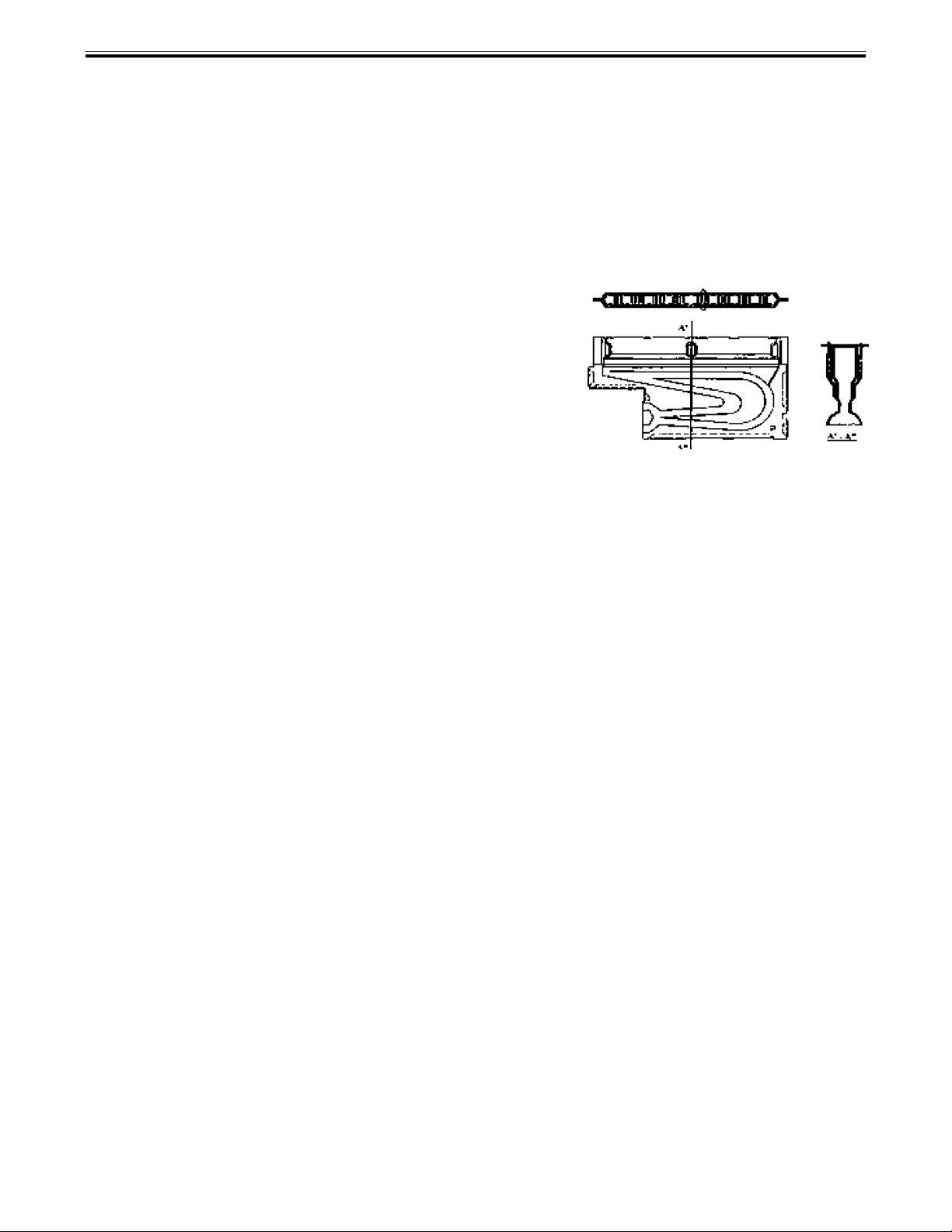

CUT-AWAY ILLUSTRATION

7

I - GENERAL INFORMATION (cont.)

SCHEMATIC ILLUSTRATION

8

II - SPECIFICATIONS - GENERAL

Model type RESIDENTIAL COMMERCIAL

Type of appliance Temperature controlled continuous

flow gas hot water system

Operation With / without remote controls, mounted

in kitchen, bathroom, etc.

Exhaust system Direct Vent - Forced combustion

Maximum/Minimum gas rate 180,000 BTU's - 15,000 BTU's Natural Gas

(Input BTU's) 180,000 BTU's - 15,000 BTU's Propane Gas

Hot water capacity, 0.5 to 6.5 GPM

(50°F rise)

Setpoint Temperature Factory setting - 120°F Factory setting - 140°F

(without remote)

Temperature range MC controller : 96 - 160°F

(with remote) BC controller : 96 - 120°F MCC controller : 96-180°F

BSC controller : 96 - 120°F

Approved gas type Natural or Propane - Ensure unit matches

gas supply type.

Installation Indoor Only

Dimensions Height 23 5/8"

Width 13 25/32"

Depth 8 13/16"

Weight 49 Lbs.

mal Efficiency rating 0.87 (Propane) 0.82 (Natural)

Ther

Noise level 49 dB (A)

Connections Gas supply 3/4" NPT (Male)

Cold water inlet 3/4" NPT (Male)

Hot water outlet 3/4" NPT (Male)

Ignition system Direct electronic ignition

Electrical consumption Operating - 75 watts

Standby - 5.5 watts

Anti-frost protection 100 watts

Water temperature control Simulation feedforward and feedback.

Water flow control Water flow sensor, electronic water control

device, and electronic by-pass control device

Recommended Minimum water

supply pressure 20 PSI (recommend 50-80 PSI for maximum performance)

Maximum water supply pressure 150 PSI

9

II - SPECIFICATIONS - GENERAL

Safety devices Appliance - AC 120 Volts - 60Hz. 15A - Dedicated

R

emote control DC 12 Volts (Digital)

Flame failure - Flame rod

Boiling protection - 203°F

Remaining flame (OHS) 194°F bi-metal switch

Thermal fuse 264°F

Automatic frost protection - Bimetal sensor & anti-frost heaters

Combustion fan rpm check - Integrated circuit

Over current - Glass fuse (3 amp)

If remote fails or becomes disconnected unit defaults to

100°F with water flowing, this is an anti-scald feature.

Remote control cable Non-polarized two core cable or low voltage thermostat wire

Clearances from combustibles Top of heater 6" (12" min. recommended for service)

Front of heater 6" (24" min. recommended for service)

Sides of heater 2"

Back of heater 0"

Floor 1

Vent/Air Intake 0"

2"

10

II - SPECIFICATIONS - COMBUSTION

Item Gas type Natural Propane

Gas consumption Minimum Btu’s 15,000 15,000

Maximum Btu’s 180,000 180,000

Injector Diameter Upper Ø.037 (.95mm) Ø.029 (.75mm)

Inches (mm) Lower Ø.062 (1.6mm) Ø.045 (1.15mm)

Main Burner B3A7-1(Lean and Rich Bunsen Burner)

Main Damper H73-115, Upper: Ø6, Lower: (Not used)

Gas Pressure Minimum supply 6" W.C. 10" W.C.

Supply/Manifold Maximum supply 10.5" W.C. 13.5" W.C.

Low Fire manifold 0.77” W.C 0.93” W.C

High Fire manifold 3.7” W.C 4.2” W.C

11

II - SPECIFICATIONS (cont.)

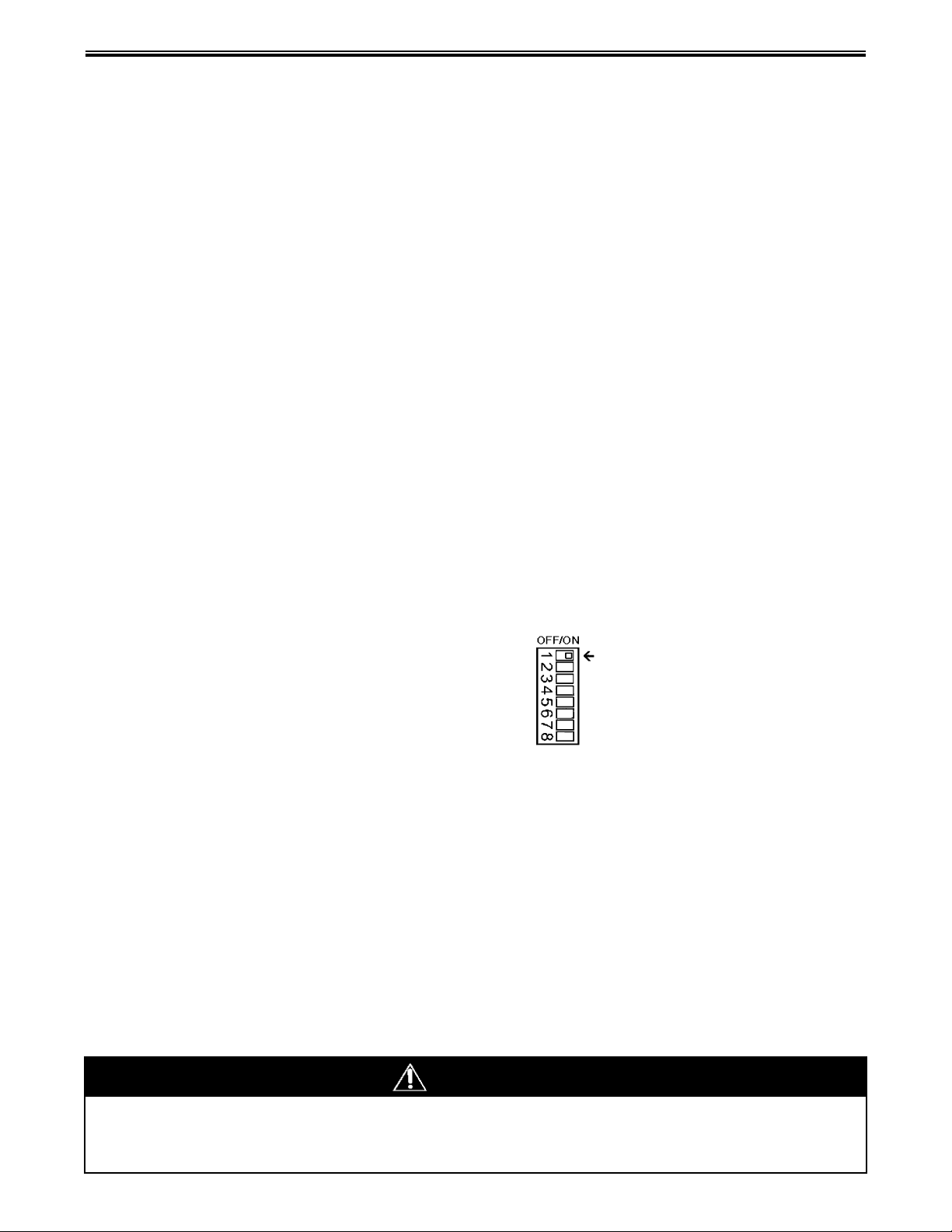

DIP SWITCH SETTINGS

Do not attempt to adjust dip switch settings from there factory default settings.

Doing so will result in damage to unit, property damage, personal injury or death.

Contact Technical Support for information pertaining to dip switch function.

FACTORY DEFAULT SETTING, RESIDENTIAL UNITS

Natural Gas Propane Gas

Dip Switch Settings: Dip Switch Settings:

(SW1) (SW2) (SW1) (SW2)

#1 = Off #1 = On #1 = Off #1 = Off

#2 = On #2 = Off #2 = On #2 = Off

#3 = Off #3 = Off #3 = Off #3 = Off

#4 = Off #4 = Off #4 = Off #4 = Off

#5 = Off #5 = Off

#6 = Off #6 = Off

#7 = Off #7 = Off

#8 = Off #8 = Off

DANGER

FACTORY DEFAULT SETTING, COMMERCIAL UNITS

Natural Gas Propane Gas

Dip Switch Settings: Dip Switch Settings:

(SW1) (SW2) (SW1) (SW2)

#1 = Off #1 = On #1 = Off #1 = Off

#2 = On #2 = Of

#3 = Off #3 = Off #3 = Off #3 = Off

#4 = Off #4 = On #4 = Off #4 = On

#5 = Off #5 = Off

#6 = Off #6 = Off

#7 = Off #7 = Off

#8 = Off #8 = Off

See page 13 for special dip switch settings base on vent length.

f #2 = On #2 = Off

12

II - SPECIFICATIONS (cont.)

DIP SWITCH SETTINGS

Combustion Blower Dip Switch Settings for Vent Length Compensation Under 22 Feet (6.7 m):

To assure optimum efficiency and reduced noise levels, the combustion blower switch has two dip switch

settings. Dip switch number 1 (top dip switch) is shipped from the factory set to the OFF position to

compensate for the maximum vent/air intake length.

Depending upon the vent/air intake length of the installation, Dip Switch Number 1 may need to be adjusted

to compensate for the venting system distance.

When the Total Equivalent Length of vent pipe is more than 22 feet (6.7 m), leave the Dip Switch Number 1 in

the OFF position. This is the factory Dip Switch setting.

When the Total Equivalent Length of vent pipe is 22 feet (6.7 m) or less, Dip Switch Number 1

must be moved to the ON position.

Dip Switch #1 is located in the top row of dip switches, 1 through 8 on the PC board. See the following

diagram to identify the correct switch. If you do not understand the information concerning the Dip Switch

settings or the location of the Dip Switch, contact LAARS® Heating System for assistance. Use the following

amples and the previous discussion on calculating the equivalent vent length to determine the correct

ex

setting for Dip Switch #1.

Example #1: Dip Switch Settings (Fig. 8)

You have 6 feet (1.82 m) of vent pipe and two 90˚ elbows.

D = 6 + (2 x 6) + (0 x 1.5)

alent v

eet (5.49 m) of eq

8 f

D = 1

Dip Swit

Example #2:

You have 15 feet (4.57 m) of vent pipe, one 90˚ elbow, and two 45˚ elbows.

D = 15 + (1 x 6) + (2 x 1.5)

D = 24 f

Leave Dip Switch #1 in the OFF position (factory setting).

ch #1 should be moved to ON position.

.3 m) of eq

eet (7

uiv

alent vent pipe

uiv

ent pipe

WARNING

Do not alter Dip Switch #1 before using the formula and venting charts to determine the equivalent vent

he exception of Dip Switch #1 shown in the illustration MUST NOT be

lengt

alt

h. All ot

ed. U

er

her dip swit

horized adjus

naut

hes wit

c

h t

tments can cause pr

operty damage, personal injury, scalding, or death.

13

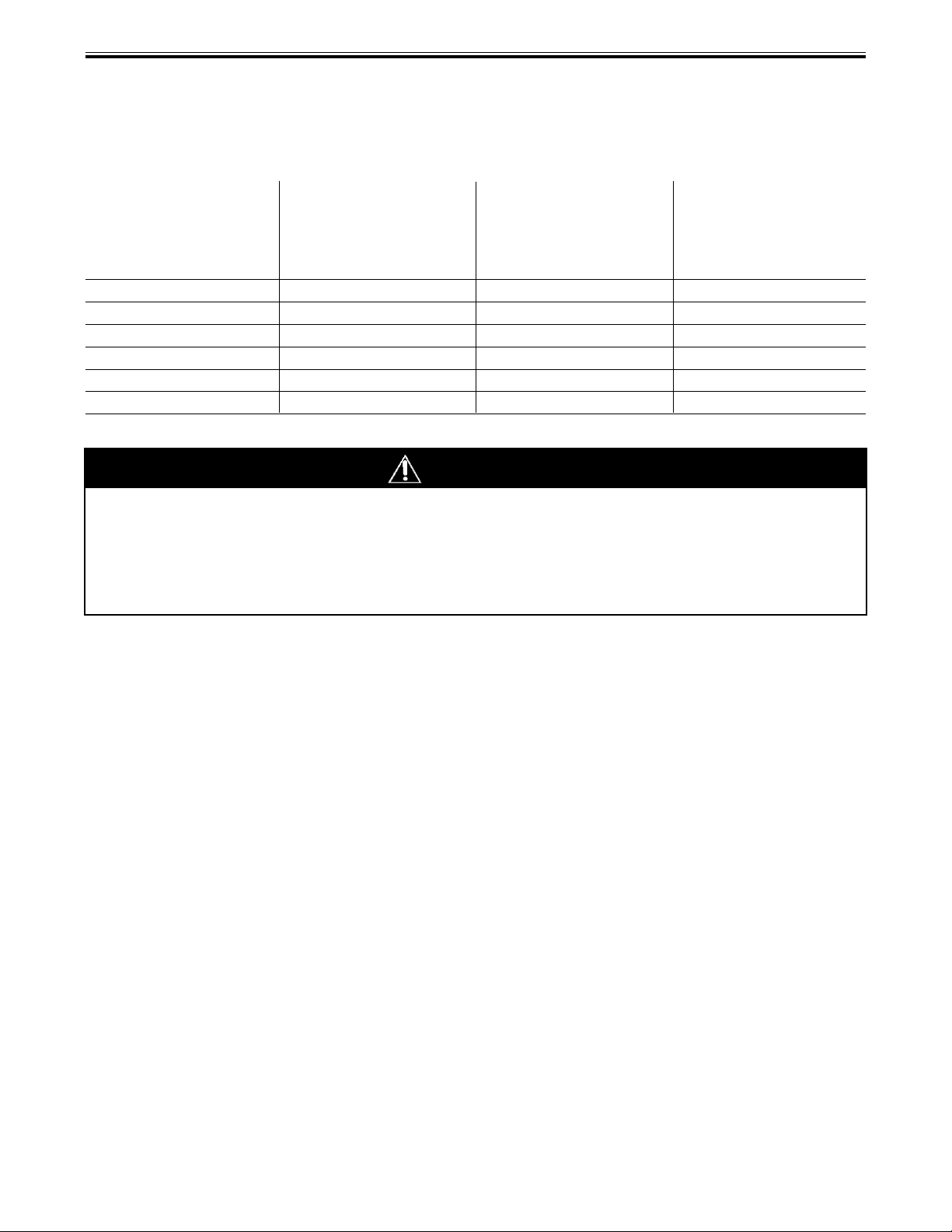

II - SPECIFICATIONS (cont.)

VENTING TABLE

Venting Table – Examples of Maximum Venting Distances with Various Elbow Combinations

Maximum Straight

Pipe Distance

35 Ft. (10.7 m) 1 41 (12.5 m)

29 Ft. (8.8 m) 2 41 (12.5 m)

23 Ft. (7.0 m) 3 41 (12.5 m)

17 Ft. (5.2 m) 4 41 (12.5 m)

33.5 Ft. (10.2 m) 1 1 41 (12.5 m)

32 Ft. (9.8 m) 1 2 41 (12.5 m)

27.5 Ft. (8.4 m) 2 1 41 (12.5 m)

Number of

90 degree elbows

Number of

45 degree elbows

Maximum Total

Equivalent Feet

(meters) of Vent Pipe

NOTICE

Each 90 degree elbow is equivalent to 6 feet in straight vent pipe length. Each 45 degree elbow is

equivalent to 1.5 feet (0.46 m) in straight pipe length. The total maximum equivalent vent pipe

distance cannot exceed 41 feet (12.5 m) for horizontal venting distance. The maximum vertical height

for through the roof venting cannot exceed 21 feet (6.4 m). A condensate collector must be used if

the venting system height is more than 5 feet (1.52 m) above the water heater.

14

III - MAIN COMPONENTS

1. Mechanical Water Regulator

The unique water regulator mechanism ensures the hot water is maintained with no noticeable

change to the desired temperature during use, even if water pressure drops due to another tap being

turned on and increasing the demand.

2. Preset Bypass

A preset volume of cold water is mixed with water heated in the heat exchanger.

3. Burner

The burner assembly is made up of 16 identical stainless steel

Bunsen burners, secured by an aluminized steel framework.

An aluminum manifold with 32 integral injectors supplies gas

to the burners, and is attached to the front lower cover of the

burner box and gas control assembly.

4. Gas Control Valve

The gas control valve uses four solenoids to fully modulate within four different input ranges to

respond quickly and accurately to changes in water flow rate. The four ranges are as follows: up to

18% of total btu’s (using three burners), up to 33% (using f

burners, and up to 100% (using sixteen burners) This increases the flexibility of the regulator/

modulating valve by supplying gas equally to each burners.

ive burners), up to 50% (using eight

15

III - MAIN COMPONENTS (cont.)

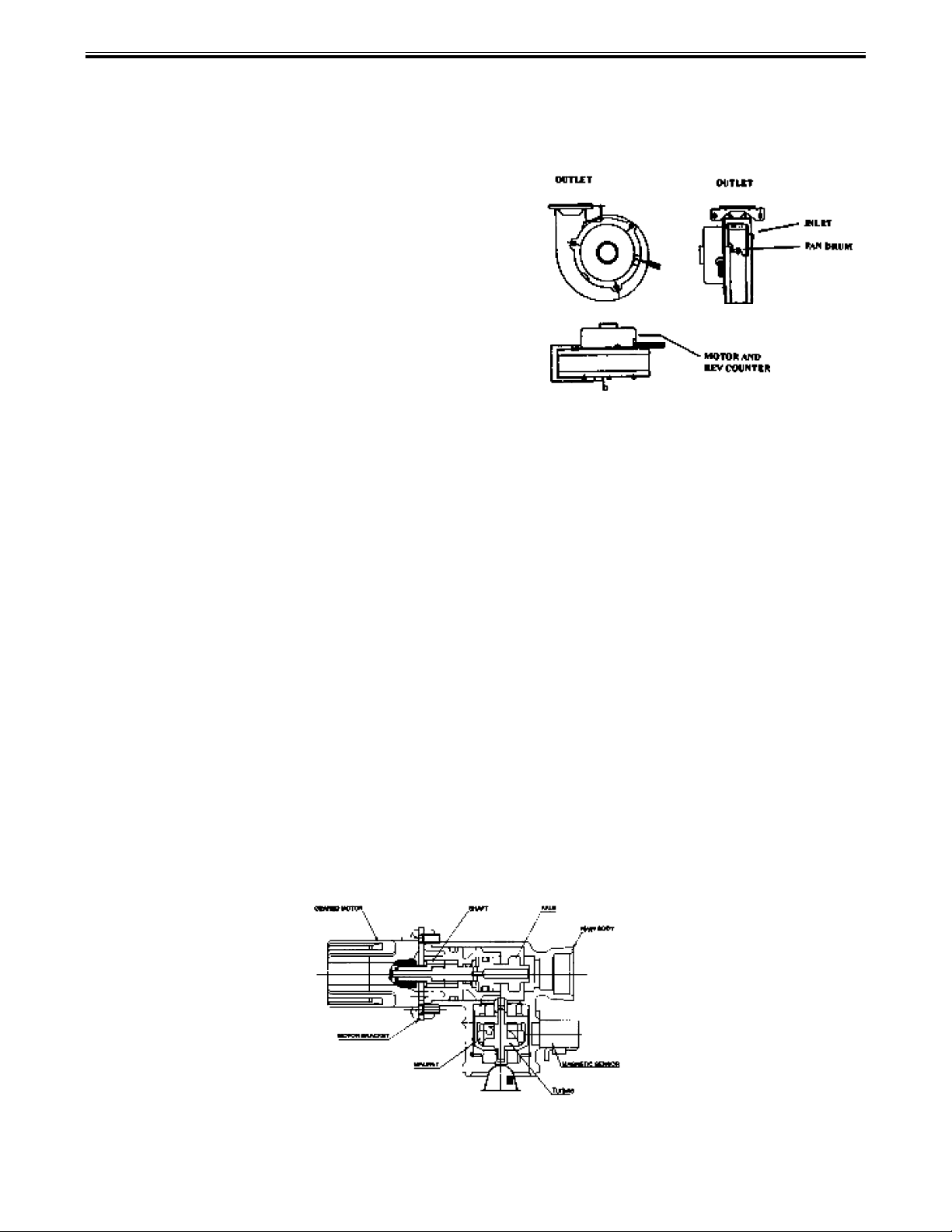

5. Combustion Fan

Air for the combustion is supplied by a centrifugal fan

driven by a DC motor. After a pre-purge period of 0.2

seconds, the fan speed is controlled by the PCB to

provide the correct volume of air for combustion. The

calculation for the fan speed is based upon incoming

water temperature, water flow and the temperature

selected on the remote controls.

The actual speed of the motor is continuously monitored

by a magnetic pulse sensor.

This sensor emits (4) pulses per rotation of the fan. This is

the fan feedback or confirmation data processed by the PCB.

The fan speed is constantly correcting to provide optimum combustion conditions. In addition, the

fan speed will determine the opening degree of the modulating gas valve. This enables the gas rate to

always match the volume of air for combustion, as well as the input required to heat the water.

6. Water Flow Sensor and Water Flow Control device

Water flow is detected by a turbine/magnetic pulse generating device. Water flows through the

turbine/magnetic sensor providing information to the PCB by generating a pre-determined number of

pulses in proportion to the water flow. These pulses are counted by the PCB – no pulse indicates no

water flow. The frequency of the magnetic pulses increases as the water flow increases, this enables

the PCB to calculate the exact water flow, and determine the water flow in gallons per minute. As

soon as the required water flow is detected, the PCB activates the combustion fan. The combustion

fan speed is monitored by a magnetic pulse sensor. The output from this sensor is processed by the

PCB which opens the gas modulating valve to a degree proportional to the fan speed. See above for

further details on the combustion fan.

The water flow control consists of a plug and barrel valve which is rotated by a motor to increase or

decrease the volume of water passing through the heat exchanger.

Automatic water flow control device.

16

IV - SAFETY DEVICE FUNCTION

Flame Failure

Situated to the right of the burner in the front of the combustion chamber, the flame rod monitors the

combustion process. This sensor monitors the flame intensity, while the PCB compares this signal to

the feed back signal from the combustion fan motor, water flow control, and gas flow through the POV

valve. If any one of the feedback signals are incorrect, the unit will shut off, preventing discharge of

gas to the burner.

Over Heat Protection Device

Also referred to as an Over Heat Switch. This device is fitted to a bend section at the inlet to the heat

exchanger. If the flame remains on to the burner after the tap is closed and the water temperature

inside the heat exchanger reaches 194 ° F, a 12 volt DC bi-metal cut-off switch will shut off the gas

supply to the solenoids.

No Water

Should the incoming water flow become restricted or stop, the water flow sensor will cease to send a

magnetic pulse signal to the PCB, in tur

n preventing gas to flow into the combustion chamber. If you

have restricted flow, first check to ensure the inline water filter is not clogged.

Thermal Fuse (Non-Resettable)

Wrapped around the entire surface of the heat exchanger you will find a thermal fuse. This device

activates in the event of excessive heat exchanger temperatures, or the temperature outside the heat

exchanger reaches 264 °F. If the thermal fuse melts, it breaks an electronic circuit which in turn shuts

off the power supply to the gas solenoids, deactivating the unit.

Combustion Fan Revolution Check

The combustion fan rpm’s are continually monitored by a magnetic pulse generator connected to the

PCB. If the fan revolutions deviate from the speed required for complete combustion, a signal is sent

to the PCB and the revolutions adjust accordingly. (If not the unit deactivates)

Automatic Frost Protection

When the temperature inside the appliance drops below 37°F , the frost sensing device inside the

appliance activates the anti-frost heaters to prevent the water inside the unit from freezing. The antifrost heaters remain ON until the temperature inside the appliance rises to 57°F. There are four (16)

watt anti-frost heaters located at various points throughout the main water flow area of the appliance.

The unit also incorporates the ability to fire for (3) seconds in the event the anti-frost heaters can not

keep the water temperature from dropping below 37°F. This unique feature will heat the water in the

lines inside the appliance back up to 57°F.

has power and gas.

There is an optional freeze protection system that can be added to the unit’s

Both of the above features function as long as the unit

piping. Refer to the auto drain down diagram in the product installation instructions for instructions

on how to install the optional freeze protection in the event of a power failure.

17

IV - SAFETY DEVICE FUNCTION (cont.)

Over temperature Cut-Off

The temperature of the outgoing hot water is constantly monitored by the water temperature

thermistor located near the outlet of the appliance. If the outgoing water temperature reaches 5 °F

above the preset temperature, the burner will automatically deactivate. The burner will ignite again

when the outgoing hot water temperature falls below the preset temperature.

18

V - SEQUENCE OF OPERATION

The preset temperature is selected at one of the remotes controls (where fitted). Where no remote

control is fitted , the default temperature can be set at 108, 120, 130, 140, 150, 160, 170, or 180°F.

To select one of the above temperatures as your default setting, you

and training (Contact your technical service group).

When the unit is first plugged into 120 volts, the PCB assumes an incoming water temperature of

77°F. This prevents the appliance from starting in “High fire” and producing very hot water the first

time it is used.

The data used to determine the outgoing water temperature, initially, is incoming water flow and the

remote control pre-set temperature.

From the incoming water flow and remote control pre-set temperature data, the CPU is able to

determine a suitable gas rate to initiate appliance operation once a hot water tap opens.

MUST obtain written permission

The calculation of temperature rise and water flow is called simulation feed-forward.

The water heater calculates incoming water temperature by subtracting the theoretical temperature

rise from the outgoing hot w

ater temperature to establish the correct gas flow.

When a hot water tap is opened, water begins to flow through the water heater. The turbine in the

water flow sensor begins to revolve. The revolution speed is proportional to the water flow. A sensor

located inside the device relays information in the form of magnetic pulses to the main PCB to

determine whether or not water is flowing, and also, the volume of water flowing. When a

predetermined water flow is sensed, the ignition sequence begins.

The combustion fan pre-purges the combustion chamber. A rev counter on the combustion fan

indicates the fan rpm to the main PCB. When the pre-purge cycle is completed, the PCB controls the

fan rpm by varying the DC voltage to the fan motor. This maintains the correct air/gas ratio

throughout the time the water heater is in use and ensures proper combustion.

The gas is ignited by direct spark and the flame is sensed by the flame rod. The opening degree of

the modulating valve is determined by the combustion fan speed.

The changeover valve directs gas to one side or both sides of the burner. At the point where the

changeover valve opens or closes the modulating valve is instantly re-adjusted by the PCB to

compensate for the change in the number of burners in use. From the information provided by the

water flow sensor and the water temperature thermistor, the PCB determines how much gas is

required to heat the water to the temperature selected on the remote control.

The PCB is programmed to provide the maximum volume of water possible at a given temperature

rise. As the water flow from the tap is increased, the PCB increases the gas and air flow to the burner.

19

V - SEQUENCE OF OPERATION (cont.)

When the hot water tap is turned off, the water flow sensor stops revolving, and the magnetic pulse

ceases, indicating to the PCB that there is no water flowing, in turn the PCB closes the gas valves. The

combustion fan continues to operate for 65 seconds. This will provide quicker ignition when the tap is

turned on and off in rapid succession, and removes the need for a pre-purge cycle allowing the burner

to re-light immediately when a hot water tap is opened again.

20

Loading...

Loading...