LAARS HWG-M2-250 Installation Manual

Installation, Operation and Maintenance Instructions Document 2108C

Installation,

Operation and

Maintenance

Instructions for

9600 HWG

Condensing Water

Heater for Natural Gas

or Propane

Models HWG-M2-150

HWG-M2-175

HWG-M2-200

HWG-M2-250

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

If the information in this manual is not

WARNING

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by a

qualified installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

AVERTISSEMENT

10-427C

A subsidiary of BRADFORD WHITE Corporation

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

Introduction and Unpacking

1.1 Special Installation Considerations ............... 3

1.2 Materials Installer Must Provide ....................3

1.3 Unpacking .................................................... 4

SECTION 2.

Locating and Clearances

2.1 Locating the 9600 HWG ............................... 4

2.2 Locating the Unit for Proper Venting

Distance from the Outside Wall or

Roof Termination .......................................... 4

2.3 Locating Vent Openings on Outside Wall ..... 5

2.4 Locating Unit for Proper Vent Height ............ 5

2.5 Locating Unit with Respect to Ventilation ...... 5

2.6 Locating Unit with Respect to

Storage Tanks .............................................. 5

SECTION 3.

Installation

3.1 Installing Vent Piping Terminal ..................... 5

3.2 Connecting Gas to the 9600

HWG Water Heater ...................................... 6

3.3 Connecting Water System Piping,

Fittings & Accessories .................................. 6

3.4 Tank Temperature Control ........................... 7

3.5 Condensate Drain Connection ...................... 7

3.6 Electrical Connections .................................. 7

3.7 Main Power ................................................. 10

3.8 Temperature Control .................................. 10

SECTION 4.

Start Up

4.1 Filling the System ....................................... 10

4.2 Operation Checklist .................................... 10

4.3 Anti-Freeze ................................................. 11

SECTION 5.

Maintenance

5.1 Owner Care and Maintenance .................... 11

5.2 Routine De-Liming Procedure..................... 11

5.3 Therostat Replacement .............................. 12

5.4 Vent and Condensate Drain Inspection

(performed annually)................................... 12

5.5 Cleaning Combustion Chamber Coil

and/or Burner .............................................. 12

5.6 Combined Water (potable) Heating and

Space Heating ............................................ 13

SECTION 6.

Quick Reference Trouble Shooter

6.1 Short Cycling .............................................. 13

6.2 9600 Overheats Quickly or

Knocks During Operation............................ 17

6.3 Delayed Ignition .......................................... 17

6.4 Occasional Lockouts .................................. 17

S9301A Control Module .............................. 14

SECTION 7.

Replacement Parts List

................................................................... 18

To the Installer: After installation these instructions

must be given to the owner or left on or near the

Water Heater.

To the User: This booklet contains important

information that will help you in maintaining and

operating this Water Heater. Please retain it for

future reference.

Warning: Should overheating occur or the gas

supply fail to shut off, turn off the manual gas

control valve to the appliance.

Important: This unit must be installed in

accordance with state and local codes by a qualified

installer!

9600 HWG Water Heater

p

Page 3

SECTION 1.

Introduction & Unpacking

1.1 Special Installation Considerations

BEFORE YOU BEGIN:

It is important for you to take a few minutes to

review this Installation and Operating Instructions

manual before you begin installation. This will make

installing and operating the unit easier and faster.

Direct vent-sealed combustion.

The 9600 HWG Water Heater does not and

should not take combustion air from inside the

building. All of the air is drawn in from the outdoors

through a 3-inch diameter plastic pipe. 3" PVC, ABS

or CPVC pipe is used for air intake and exhaust

venting. (PVC not permitted on HWG-M2-250

exhaust)

No chimney......flue......or draft inducer required.

Because this is a sealed combustion, forced draft unit,

it does not require, and must not be connected to a

chimney, existing venting system, or draft inducer.

CAUTION

Connection of this vent to a chimney, existing

venting system, or draft inducer will result in

poor and possibly dangerous operation.

The supplied vent terminations are designed to

be installed through the nearest outside wall (see

Sections 2C and 2D).

The 9600 HWG Water Heater is protected

against over pressurization. A 150 PSI pressure relief

valve is fitted to the unit. It is installed in the

dedicated fitting on the top of the water heater.

IMPORTANT: The inlet gas pressure to the

appliance must not exceed 13" WC.

A high quality circulator is built into the 9600

HWG Water Heater and will provide sufficient head

pressure and volume to circulate water to the storage

tank(s) (see Table 3).

All installations must be made in accordance

with the: 1) American National Standard Z223.1Latest Edition “National Fuel Gas Code” and with the

requirement of the local utility or other authorities

having jurisdiction, or; 2) Can-CGA B149 installation

code and / or local installation codes.

Such applicable requirements take precedence

over the general instructions contained herein.

All electrical wiring is to be done in accordance

with local codes, or in the absence of local codes,

with: 1) the National Electrical Code ANSI/NFPA

No. 70-latest Edition, or; 2) CSA standard C22.1

“Canadian Electrical Code - Pt 1. This appliance

must be electrically grounded in accordance with

these codes.

1.2 Materials Installer Must Provide

1. Total combined feet allowed for intake and exhaust

vent pipe per instructions. The following are acceptable materials for intake and exhaust vents:

Acceptable Intake Pipe Material

Models 150-200 Model 250

3-inch or 4-inch PVC schedule

40 pipe per ASTM D-1785 std.

3-inch or 4-inch PVC DWV

pipe per ASTM D-2665 std.

3-inch or 4-inch ABS-DWV

pipe per ASTM D-2661 std. or

ASTM F-628 std.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch AL29-4C

stainless steel complying with

UL std. 1738.

Acce

table Intake Pipe Material

Models 150-200 Model 250

3-inch or 4-inch PVC schedule

40 pipe per ASTM D-1785 std.

3-inch or 4-inch PVC DWV

pipe per ASTM D-2665 std.

3-inch or 4-inch ABS-DWV

pipe per ASTM D-2661 std. or

ASTM F-628 std.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch AL29-4C

stainless steel complying with

UL std. 1738.

2. Electrical connection to a 120VAC/15Amp

service.

3. Gas connection that will provide 250 cubic feet/

hour at 4 to 13 inch water gauge pressure.

4. Condensate drainage: a floor drain is preferred a condensate pump may be used.

5. Miscellaneous copper fittings and bronze valves

will be required to complete the piping system.

3-inch or 4-inch PVC schedule

40 pipe per ASTM D-1785 std.

3-inch or 4-inch PVC DWV

pipe per ASTM D-2665 std.

3-inch or 4-inch ABS-DWV

pipe per ASTM D-2661 std. or

ASTM F-628 std.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch AL29-4C

stainless steel complying with

UL std. 1738.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch AL29-4C

stainless steel complying with

UL std. 1738.

Page 4

LAARS Heating Systems

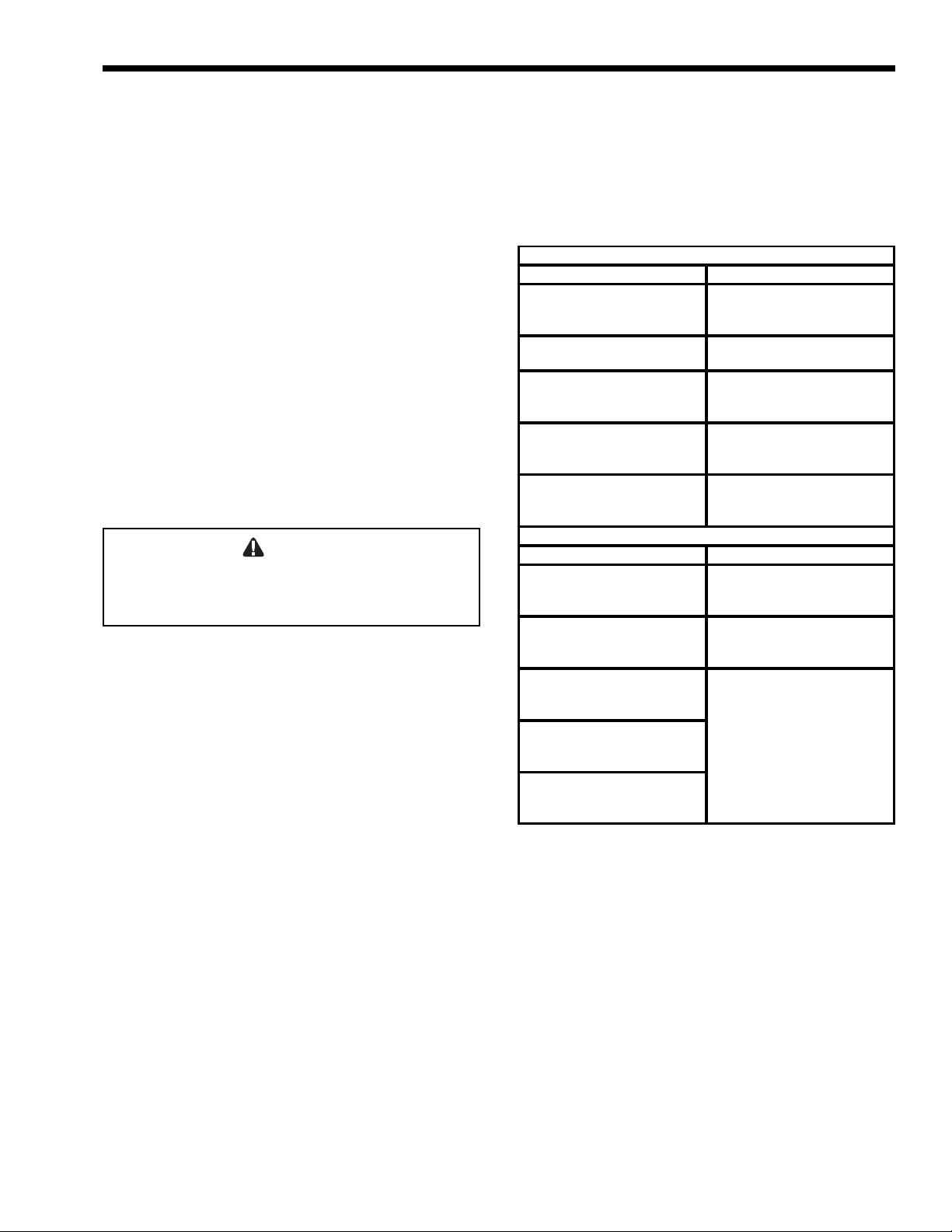

1.3 Unpacking

The 9600 HWG Water Heater is shipped in a

single carton with the following standard components

on top of the unit (see Figure 1).

1) Exhaust terminal

2) Intake terminal

3) Vent terminal backing plate (4)

4) Hubless coupling reducer

5) Hubless coupling (2)

Figure 1. Contents of shipping package.

1. Remove all packing and tie-down materials.

2. Check contents of the carton against items

shown above.

Minimum Recommended

Clearances Clearance for

From Accessibility

Combustible and Venting

Construction

BOTH AGA CGA

Left Side 1" 6" 48"

Right Side (Controls) 1" 12" 24"

Top 1" 14" 24"

Back 1" 9" 24"

Front 1" 24" 48"

Vent 0"

Table 1. Location clearances.

SECTION 2.

Locating and Clearances

2.1 Locating the 9600 HWG

The appliance should be located in an area

where leakage of any connections will not result in

damage to the area adjacent to the appliance or to

lower floors of the structure.

When such a location is not available, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance.

The unit is design certified by AGA / CGA for

installation on combustible flooring; in basements; in

closets, utility rooms or alcoves. It must not be

installed on carpeting.

The location for the unit should be chosen with

regard to the vent pipe lengths, external plumbing,

ventilation of operating components and accessibility

for service and cleaning.

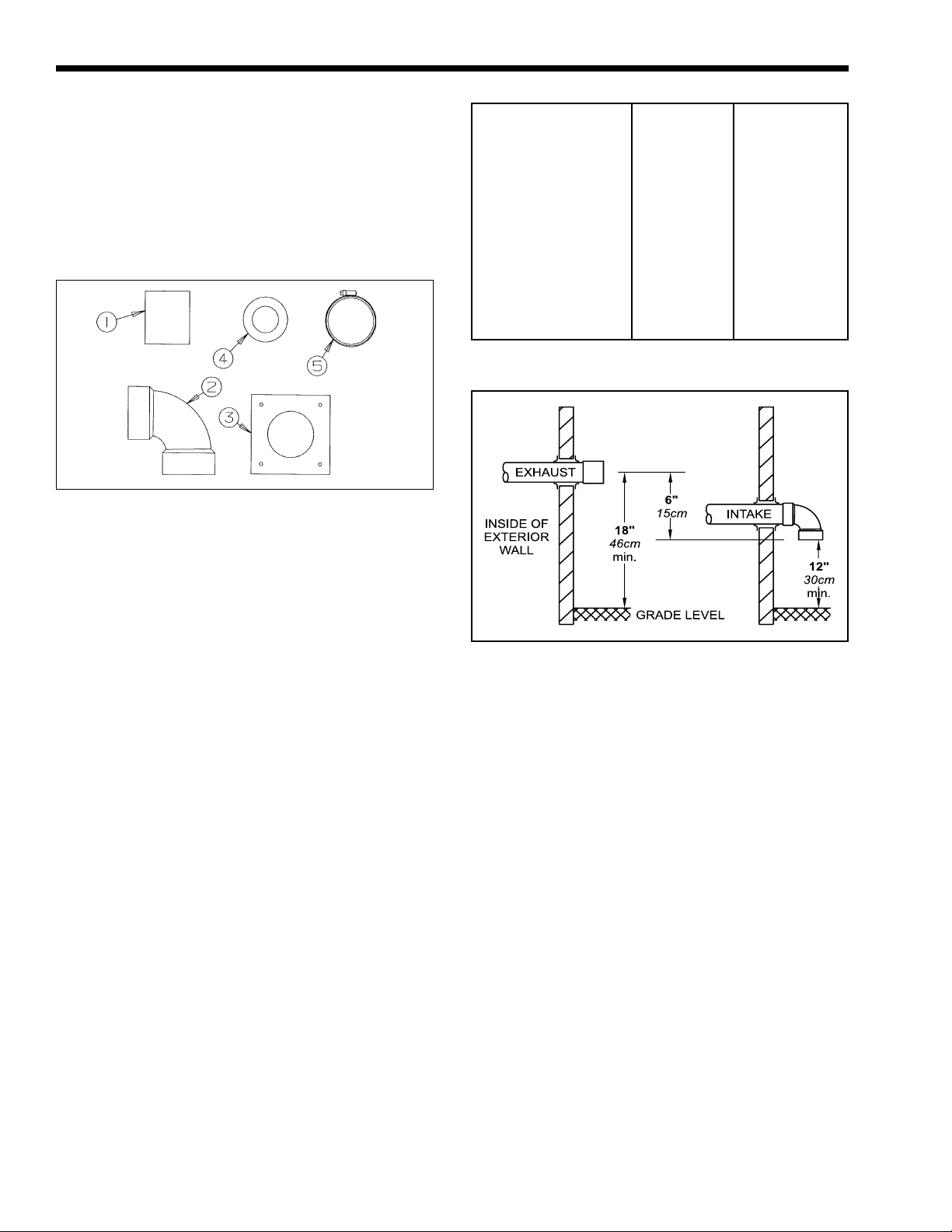

If there is potential for snow accumulation in your

area, both the vent terminals should be installed at an

appropriate level above grade (see Figures 2 and 3).

The following dimensions and requirements

should be met when choosing the location for the unit

(see Table 1):

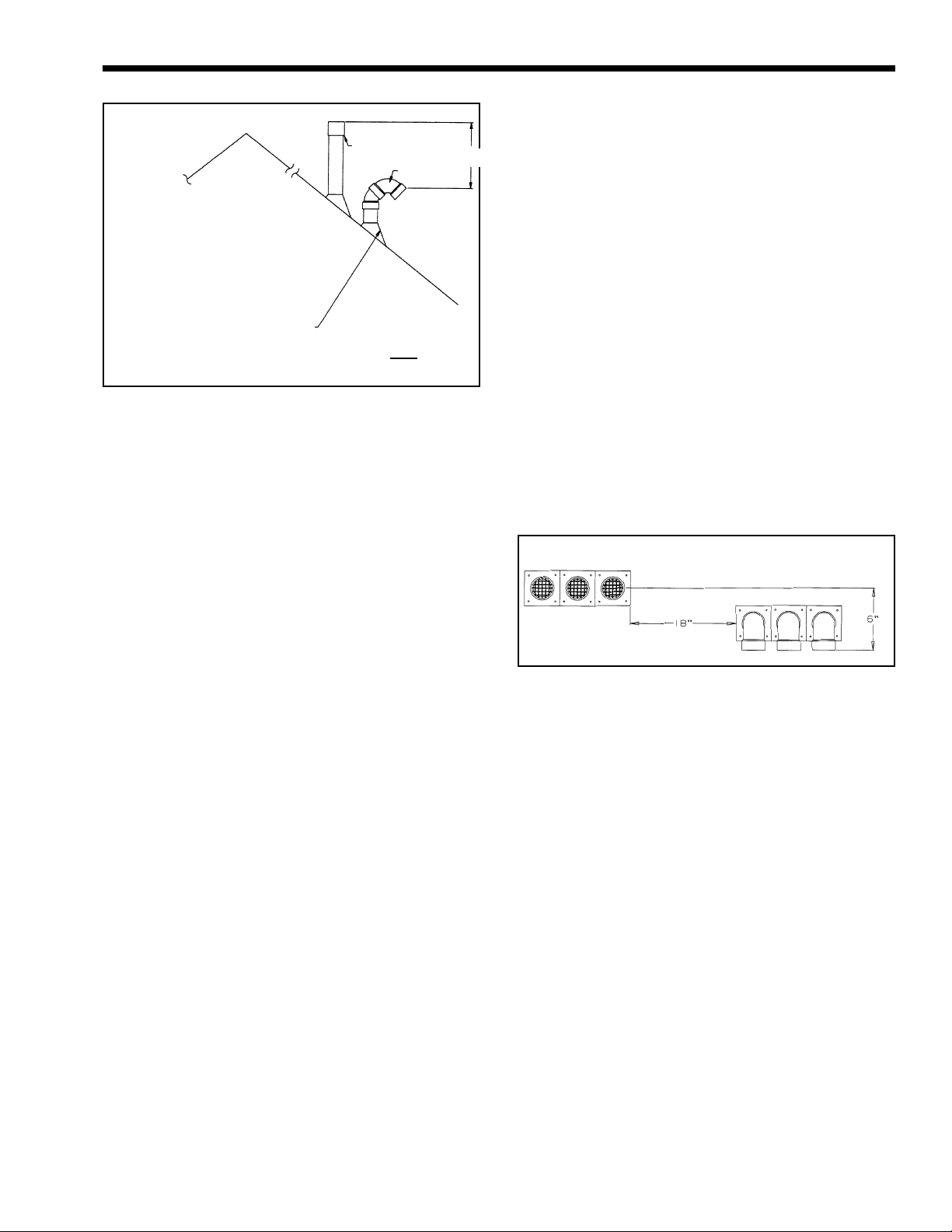

Figure 2. Suggested vent terminal installations.

2.2 Locating the Unit for Proper Venting

Distance from the Outside Wall or

Roof Termination

Intake Exhaust

Maximum run: Maximum run:

3" pipe size 3" pipe size

55 equivalent feet 55 equivalent feet

4" pipe size 4" pipe size

85 equivalent feet 85 equivalent feet

Minimum run: Minimum run:

11 equivalent feet 21½ equivalent feet

Intake Terminal is Exhaust Terminal is

P/N 2400-102. P/N 2400-104.

Equivalent feet is determined by adding 10

linear feet for each 90° elbow and 5 linear feet for

each 45° elbow to be installed to the actual linear feet

of pipe required.

Example: 8' of pipe, 2 x 45° elbows and a 90°

elbow.

Equivalent Feet: 8' + (2 x 5') + (1 x 10') = 28.

9600 HWG Water Heater

Exhaust

Terminal

NOTE: If flue passes through a flat

roof with parapet walls exhaust terminal

level must be above the level of the wall.

If flue passes through a sloped or

peaked roof it is not necessary to locate

it to conform with location requirements

for conventional chimneys.

Typical Soil Pipe

Flashing Acceptable

Figure 3. Alternate vent terminal installations.

Roof terminals for air

intake

entry of rain water.

Intake

Terminal

must prevent

18"

Min.

Page 5

units, refer to Figure 4 for intake and exhaust

terminal locations.

2.4 Locating Unit for Proper Vent Height

The vent locations you select must permit direct

pipe runs to the terminal from the boiler. Since the

9600 HWG Water Heater is designed to drain any

water that collects in the vent, it is important that you

do not build any traps or low points into the vent

where water could collect and restrict the vent. It is

recommended that 1/4" per foot of vent be built into

the vent system to direct any water in the vent back

toward the boiler. Note that standard DWV elbows

have a built in allowance for the required 1/4" per foot

pitch.

If a 4" pipe size is used to permit longer vent

runs the installer must supply 4" hubless couplings (2)

and 3 x 4 bushings (2) to adapt to the unit fittings. 4"

inlet and exhaust screens are provided for installation

in contractor provided 4" coupling and elbow

terminations.

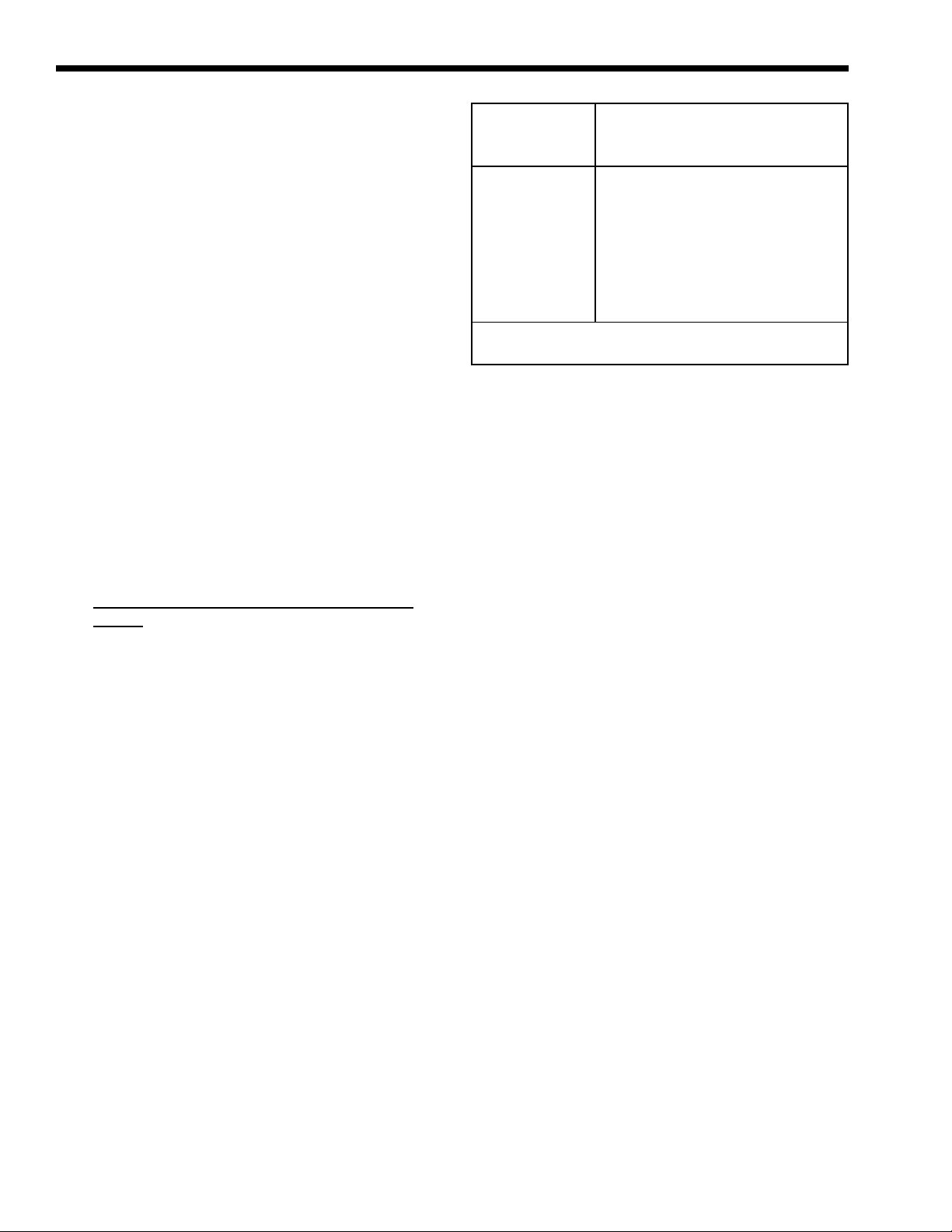

NOTE: It is required that a minimum separation

of 18" be maintained between the intake and exhaust

terminals and that both terminals be installed on the

same wall of the building. The intake terminal must

not be installed above the exhaust terminal since this

would tend to pull exhaust gases back into the intake

(see Figures 2 and 3).

2.3 Locating Vent Openings on Outside Wall

1. Exhaust terminal location.

The exhaust terminal fitting requires a 4" (10cm)

diameter hole through the outside wall. The

center line of this opening must be at least 18"

(46cm) above grade and at least 14" (35.6cm)

from any other building opening such as doors,

windows, etc.

Vent opening should be well away from

shrubbery or other obstructions that would block

or restrict the exhaust.

Whenever possible, locations under windows or

near doors should be avoided. Steaming at the

flue terminal is a normal occurrence. This should

be considered when deciding flue terminal

position.

2. Intake terminal location.

The intake terminal requires a separate 4"

(10cm) diameter hole to install the intake fitting.

The center line of the hole should be at least 16"

(41cm) above grade outdoors and 18" (46cm)

away from the exhaust outlet. The intake should

never be located above the exhaust terminal.

3. Intake and exhaust location for multiple unit

installation. For the installations of multiple

2.5 Locating Unit with Respect to Ventilation

While the 9600 HWG Water Heater requires no

indoor air for combustion, adequate airflow around

the unit must be provided for proper cooling of

electrical components.

EXHAUST

INTAKE

Figure 4. Multiple units minimum vent terminal

separation.

2.6 Locating Unit with Respect to

Storage Tanks

For the best results the 9600 HWG Water Heater

should be located within 10 feet of the storage tanks.

If the unit must be installed with longer piping

runs, then the larger diameter tubing must be used.

Calculate the necessary pipe size for your installation

(see Table 2).

SECTION 3.

Installation

3.1 Installing Vent Piping Terminal

The water heater is provided with intake and

exhaust terminals for use with 3" diameter plastic

pipe.

The installer is responsible for obtaining the vent

pipe and fittings. The maximum combined length of

the intake and exhaust pipe and maximum number of

elbows are determined by using the guidelines on Page

4.

Page 6

LAARS Heating Systems

The following steps are recommended for vent

installation:

1. Obtain the necessary 3" or 4" diameter plastic

piping and fittings as determined beforehand.

2. Position unit at previously selected location.

3. Unpack vent terminals and vent terminal backing

plates.

4. Cut holes in outside wall for vent terminals in

the previously selected locations.

5. Mount the vent terminals’ backing plates.

6. Fit all of the vent pipes together without

cementing. Make sure that there are no water

traps and that any pitch is inclined back towards

the boiler.

7. Make sure that the flexible vent connections at

the unit fit properly.

8. Begin cementing the intake and exhaust pipes,

start at the vent terminals and work back towards

the appliance. Note that the intake terminal is a

90 degree elbow fitting that is designed to face

down.

9. Support both intake and exhaust pipes with

hangers.

DO NOT RELY ON 9600 HWG TO SUPPORT

PIPES.

Horizontal runs must be supported adjacent to

each fitting and at 5ft. intervals between fittings.

ABS pipe must be supported at 3ft. intervals.

10. Tighten the flexible couplings to connect the

water heater to the vent pipes.

3.2 Connecting Gas to the 9600 HWG

Water Heater

1. The water heater requires gas at an inlet gas

pressure of at least 4" WC and no greater than

13" WC. Check with your local gas utility or

supplier for availability of these delivery

pressures.

2. Referring to TABLE 2, size supply piping to

keep flow capacity to the unit above 250 cubic

feet per hour (CFH) per unit installed.

3. Run gas supply line in accordance with all

applicable codes.

4. Locate and install manual shutoff valves in

accordance with state and local requirements.

5. Install drip leg and ground joint union

(see Figure 5).

6. All threaded joints should be coated with piping

compound resistant to action of liquefied

petroleum gas.

7. The 9600 HWG unit and its individual shutoff

valve must be disconnected from the gas supply

Length Capacity of Pipe in MBTU/h

of (.6 Specific Gravity)

Pipe 3/4" 1" 1-1/4"

10' 278 520 1,050

20' 190 350 730

30' 152 285 590

40' 130 245 500

50' 115 215 440

75' 93 175 360

100' 79 150 305

150' 64 120 250

Additional length to be added for each tee or bend:

1.7' 2.2' 2.7'

Table 2. Gas supply piping.

piping during any pressure testing of that system

at test pressures in excess of 1/2 psig (3.45kpa).

It must be isolated from the gas supply system

by closing its individual manual shutoff valve

during any pressure testing of the gas supply

piping system at test pressures equal to or less

than 1/2 PSIG (3.45kpa).

Failure to do so will possibly result in damage to

the gas control system.

8. The 9600 HWG Water Heater and its gas

connections must be leak tested before placing

the unit in operation.

9. Purge all air from gas lines.

3.3 Connecting Water System Piping,

Fittings & Accessories

Installing tank & piping

The 9600 HWG can be used with several

different types of readily available storage tanks. A

bronze circulating pump is built into the appliance.

The pump draws water from the storage tank and

pumps the water through the heater and back into

the tank.

Position the storage tank(s).

At the previously selected locations, position the

storage tank(s). Use Table 3 to determine the pipe size

necessary to provide adequate flow between the 9600

HWG and the tank(s).

Hot water outlet piping, fittings, and accessories.

1. Begin piping to the tank from the hot water

outlet at the top of the 9600 HWG cabinet.

2. Pipe the outlet from the relief valve (located on

top of the unit) such that any discharge from the

relief valve will be conducted to a suitable place

for disposal when relief occurs. Do not reduce

line size or install any valves in this line. The

line must be installed to allow complete drainage

of both the valve and the line.

3. Install a shut off valve in the piping between the

thermometer fitting and the tank.

Loading...

Loading...