Page 1

Installation, Operation and Maintenance Instructions Document 1105

Installation, Operation and

Maintenance Instructions for

HW-M2 Series H-M2 Series HP-M2 Series

H Series

OUT OF

PRODUCTION

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

Page 2

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1A. HW Series, H Series, HP Series .................. 4

1B. to the Installer: Before You Begin ................. 4

1C. Codes and Standards................................... 5

1D. Unpacking the H Series................................ 5

1E. Locating the H Series ................................... 5

1F. Clearances ................................................... 5

SECTION 2.

Venting Options

2A. Locating Unit With Respect to Ventilation .... 5

2B. Chimney Venting (USA Only) ....................... 6

2C. Installation .................................................... 6

2D. Alternate Venting Method (Canada Only)..... 6

2E. Installing Stainless Steel

Horizontal / Vertical Venting ......................... 8

2F. Connecting special Gas Vent to H Series .... 8

2G. Appliance Joint Procedure

Part #2400-350 ............................................. 8

2H. Appliance Joint Procedure

Part #2400-352 or Z-Vent

#02SVEPXX030 ........................................... 8

2I. Securing Special Gas Vent .......................... 8

SECTION 3.

Venting and Air Source

3A. The Direct Vent Kits

(part numbers 2400-326 or 2400-328) ....... 10

3B. Installing Direct Vent Kits ............................ 10

3C. Locating the Vent on an Outside Wall ........ 10

3D. Air Source For Combustion

(when not direct vented) ............................. 10

SECTION 4.

Gas Connection to H Series

4A. Gas Connection to H Series ....................... 11

4B. Domestic Water Piping ............................... 12

PRODUCTION

OUT OF

SECTION 5.

Hydronic Heat Piping

5A. Hydronic Heat Piping .................................. 12

5B. Feed Water Make-Up ................................. 12

5C. Hydronic Piping - HW Series ...................... 13

5D. Using In a Combined Hot Water

Heating and Chilled Water Cooling

System ....................................................... 13

SECTION 6.

Electrical Connections

6A. Electrical Connections ................................ 16

SECTION 7.

HP Mounting Piping

7A. Wall Mounting Instructions

Paloma/Hytech Replacement ..................... 17

7B. New Wall Mount Installation ....................... 17

7C. Hydronic Systems Connections ................. 17

7D. Plumbing Accessories Installation .............. 17

7E. Gas Supply Connection .............................. 17

SECTION 8.

HP Venting and Electrical

8A. Venting the HP-M2-Series .......................... 17

8A-1. AGA ............................................................ 17

8A-2. CGA............................................................ 18

8B. Electrical Connections ................................ 18

8C. Manufactured Home (Mobile Home)

Appliance Installation Instructions .............. 18

8C-1. Appliance Mounting .................................... 18

SECTION 9.

Check, Test and Start Up

9A. Filling System ............................................. 19

9B. Firing Burner ............................................... 19

9C. Check Limit Control Operation ................... 19

9C-1. Operating and Low Limit Control HW-M2 ... 19

9C-2. Operating Control H-M2 ............................. 20

9C-3. Safety Limit Operation H(W)-M2 ................ 20

9C-4. Stack Switch Operation H(W)-M2............... 20

9D. Common Vent Test .................................... 20

9E. Lighting and Shutdown Instructions ........... 20

Page 3

H Series

Page 3

SECTION 10.

Maintenance

10A. Owner Care and Maintenance ................... 20

10B. Service Maintenance .................................. 21

SECTION 11.

Burner Input and Boiler

Component Descriptions

11A. Adjusting Burner/Input ................................ 21

11A-1. Measuring CO2* .......................................... 21

11A-2. Measuring O2.............................................. 21

11B. Cleaning Combustion Chamber Coil .......... 21

11C. Unit Pump................................................... 22

11D. Gas Valve................................................... 22

11E. Safety Limit Switch ..................................... 22

11F. Operating Control ....................................... 22

11G. Igniter ......................................................... 22

11H. Pressure Differential Switch ....................... 22

11I. Transformer................................................ 23

11J. Low Limit (HW-M2 Series Only) ................. 23

11K. Blower ........................................................ 23

11L. Priority Relay - R1 (HW-M2 series only)..... 23

11M. Boiler Control.............................................. 23

11N. Stack Switch ............................................... 23

11O. Transfer Tank and Domestic Hot

Water Coil (HW-M2 series only) ................. 23

11P. Thermostatic Union

(H(P)-M2-Series Only) ................................ 23

11Q. Time Delay Relay (TDR)

11R. DHW Coil Replacement ............................. 24

11S. Tank Replacement ..................................... 24

PRODUCTION

(H(P)-M2-series only) ................................. 24

OUT OF

SECTION 12.

Symptom Evaluations

12A. Delayed Ignition .......................................... 24

12B. Noisy Operation .......................................... 25

12C. Insufficient Hot Water

(HW - M2 - series only) .............................. 25

12D. High Gas Consumption

(see also Cross Contamination) ................. 26

12E. Shortcycling

(H-M2, HP-M2 Series only) ........................ 26

12F. Cross Contamination and

Combustion Related Short Cycling

(units installed with Quick Vent) ................. 26

12G. Lock Outs

Integrated Boiler Control Lock Outs ........... 27

SECTION 13.

Sequence of Operation

................................................................... 27

SECTION 14.

Replacement Parts

................................................................... 37

SECTION 15.

Trouble Shooting

15A. S9301A Control Module ............................. 41

15B. Quick Reference Trouble Shooter .............. 42

HW-M2 Series H-M2 Series HP-M2 Series

HW-M2-130 H-M2-130* HP-M2-130*

HW-M2-100 H-M2-100 HP-M2-100

HW-M2-60 H-M2-60 HP-M2-60

Integrated Hydronic Heating Hydronic Heating Only Hydronic Heating Only

and Domestic Hot Water Appliance for Natural or Propane Gas. for Natural or Propane Gas

for Natural or Propane Gas. (Wall Hung).

* Field conversion only.

Page 4

Page 4

LAARS Heating Systems

SECTION 1

General Information

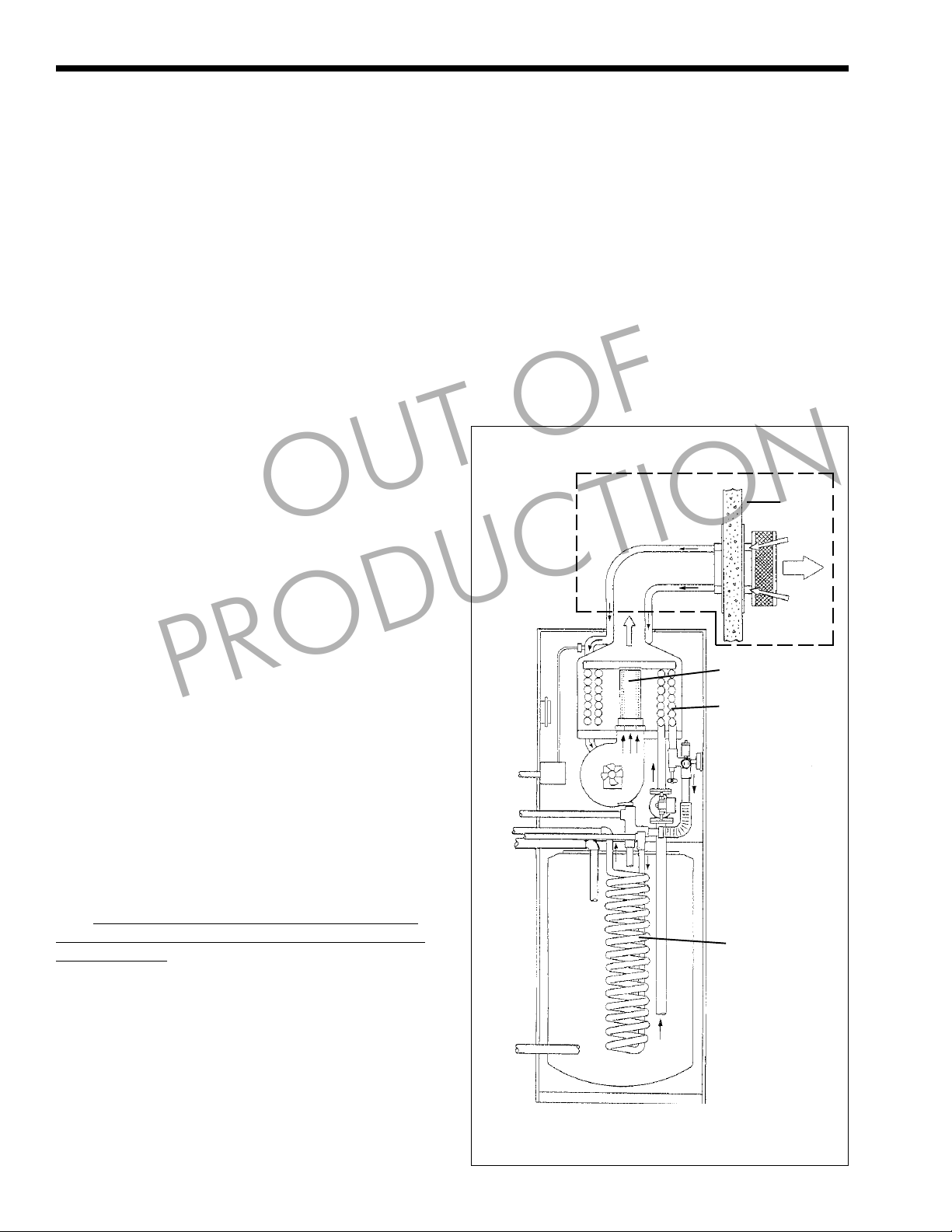

1A. HW Series, H Series, HP Series

The H Series boiler is a low pressure, hot water

boiler that is available in two (2) design

configurations. The HW series provides domestic hot

water as well as hydronic space heating. It includes an

insulated storage tank through which boiler water is

circulated. A heat exchanger within the tank transfers

heat from the boiler to the domestic hot water. The H

and HP series boilers are designed to provide hot

water for space heating, and can be plumbed to an

indirect water heater to supply domestic hot water.

By replacing the air and the gas orifices, the

basic H Series boiler has the flexibility to operate on

either natural or LP gas and may be fired at 60,000,

100,000 or 130,000 BTU/HR input. The H Series can

be direct vented by utilizing an optional concentric

vent system that will provide outside air for

combustion. H(W)(P)-60,100 & 130 appliances may

also be vented with 3" or 4" diameter stainless steel

horizontal / vertical venting as described on page 6.

The maximum length shall not exceed 50 equivalent

feet of 3" diameter or 100 equivalent feet of 4"

diameter. H(W)(P)-M2-130 appliances may also be

connected to a lined internal chimney.

The H Series features a forced draft, pre-mixed

combustion system. All air for combustion is supplied

with the gas to the burner (flameholder). Both the

intake air and the gas are metered through separate

orifices before entering the combustion air blower.

The blower forces the air/fuel mixture through the

flameholder and into the combustion chamber. The

mixture is ignited from the hot surface igniter and

burns. Hot gases are forced out between the passes of

the heat exchanger into the flue collector. Flue gases

are discharged into the outside atmosphere through the

vent terminal, a chimney, horizontal or vertical

alternate vent.

Model H(W)-M2-60 & H(W)-M2-100 UNITS

MUST NOT BE CHIMNEY CONNECTED.

Installations with water containing 10 grains of

hardness or higher, must be installed with appropriate

water treatment.

PRODUCTION

OUT OF

1. Gas Burner*

2. Sealed Combustion* w/ P/N 2400-236 or

2400-238

3. Outside Vent Wall*

4. Outside Air For Combustion*

5. Copper Coil Heat Exchanger*

6. Thermostatic Union (H-M2)

7. Domestic Hot Water Coil (HW(D)-M2)*

8. Heating System Water Outlet

9. Heating System Water Return

10. Gas Supply

(*see Figure 1)

d

c

g

Î

l

Í

j

i

e

f

1B. To the Installer: Before You Begin

The H Series is uniquely different from any

heating boiler you have installed in the past. It is

important for you to take a few minutes to review the

contents of the Installation and Operating section of

this manual before you begin installation. This will

avoid making mistakes and causing confusion when

installing and operating the unit.

Î

k

Figure 1. HW-M2.

Page 5

H Series

Page 5

1C. Codes and Standards

All installations must be made in accordance

with: 1). The National Fuel Gas Code, ANSI Z223.1 latest edition or 2). CAN/CGA - B149 “Installation

Codes for Gas Burning Appliances and Equipment” or

with the requirements of the local utility or other

authorities having jurisdiction. Such applicable

requirements take precedence over the general

instructions contained herein. All electrical wiring is

to be done in accordance with 1). The National

Electrical Code ANSI/NFPA70-latest edition or 2).

The CSA standard C22.1 “Canadian Electrical Code Part 1” and local codes.

All vent installations must be made in

accordance with: 1). Part 7, Venting of Equipment of

the National Fuel Gas Code, ANSI 223.1- latest

edition, or applicable provisions of the local building

codes or 2). CAN/CGA - B149

When required by the jurisdiction authority, the

installations must conform to the American Society of

Mechanical Engineers’ Safety Code for Controls and

Safety Devices for Automatically fired Boilers, No.

CSD-l.

1D. Unpacking the H Series

a. Remove all packing and tie down materials.

b. On HW models, remove three (3) shipping bolts

from underside of base.

c. Make immediate claims ( to carrier ) if unit is

damaged.

PRODUCTION

OUT OF

1E. Locating the H Series

The H Series design is certified by the AGA and

CGA for installation on combustible flooring, in

alcoves, basements, closets, or utility rooms. It must

not be installed on carpeting. IF INSTALLED IN A

FINISHED AREA, PROVISION SHOULD BE

MADE FOR DRAINAGE OF ANY ACCIDENTAL

SPILLAGE OR LEAKAGE.

The location for the unit should be chosen with

regard to venting dimensions, convenient access to

piping, ventilation of operating components and

accessibility for service and cleaning.

The boiler shall be installed so that the gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation or service (circulator replacement, control

replacement, etc.).

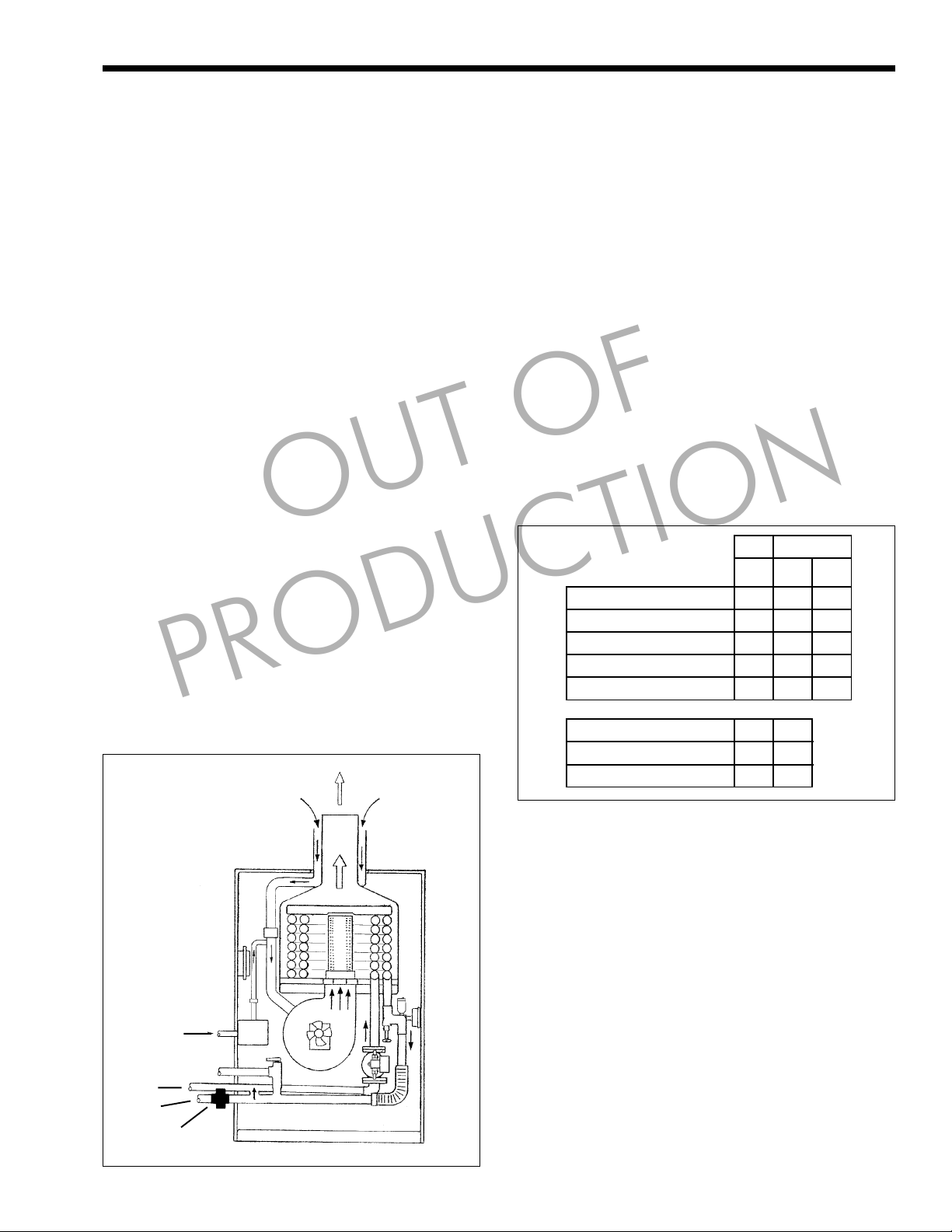

1F. Clearances

The following dimensions and criteria should be

followed when choosing the location for the unit:

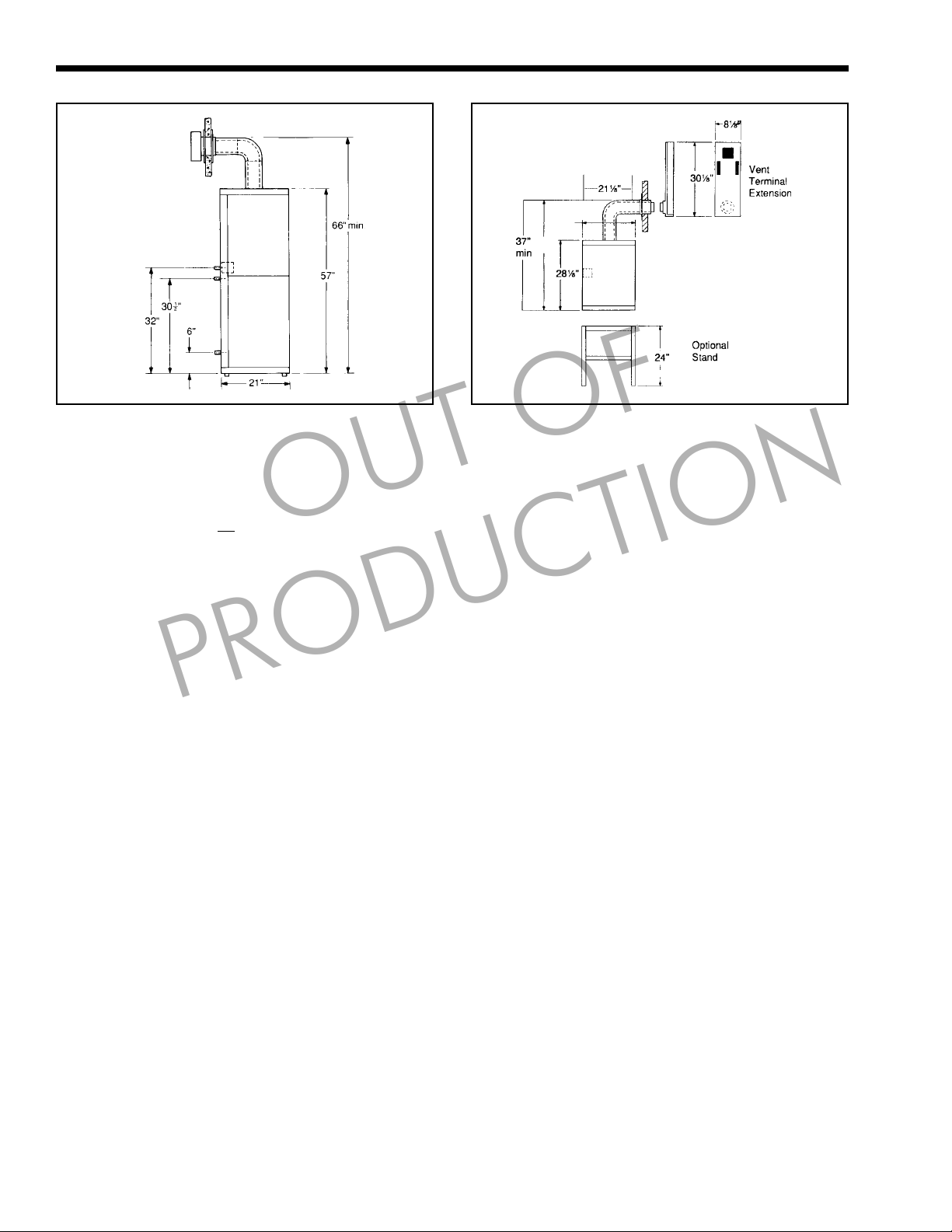

A. B.

AGA/

AGA CGA

CGA

Left Side 1" 6" 24"

Right Side (controls) 1" 12" 24"

Top 1" 14" 16"

Back 1" 9" 12"

Front 1" 24" 24"

l

k

j

h

Figure 2. H-M2.

Õ

Ö

Vent: Direct Vent 0" 0"

Chimney Connect 6" 6"

Alternate 3" 3"

Clearances

A. Minimum clearance from combustible

construction to meet AGA/CGA requirements.

B. Recommended clearance for accessibility and

venting.

SECTION 2.

Venting Options

2A. Locating Unit With Respect

to Ventilation

While the H Series, when direct vented, requires

no interior air for combustion, adequate airflow

around the unit and to the enclosed room must be

provided for proper cooling of electrical components.

Page 6

Page 6

SUPPLY

DOMESTIC

RETURN

LAARS Heating Systems

↑

3.5" deep

Figure 3. HW-M2.

2B. Chimney Venting (USA Only)

Model H(W)-M2-60 and H(W)-M2-100 MUST

NOT BE CHIMNEY OR B-VENT CONNECTED.

Model H(W)-M2-130 is a category l boiler and

may be vented in chimneys subject to the following

requirements:

Chimney must be internally lined or “B” vent

type. EXTERNAL OR UNLINED CHIMNEYS MAY

ONLY SERVE AS A CHASE for utilization of

stainless steel alternative venting providing no other

equipment is vented into it, or the chimney may have

an approved liner installed into the flue.

Two (2) or more vent connectors, from either

power or natural draft units, may enter a common gas

vent providing they conform to the requirements and

tables of the National Fuel Gas Code, ANSI Z223.1/

NFPA 54- latest edition, or applicable provision of the

local building code. None may be connected to

equipment with a positive vent pressure.

Locate unit as close to chimney as possible for

shortest vent connector.

2C. Installation

Determine height of chimney or B-Vent and

length of lateral run. Select vent connector diameter

from:

1). Table 1 or 2 of the National Fuel Gas Code,

ANSI Z223.1 / NFPA 54- latest edition (see

excerpts), or

2). Table G-3 of the Can /CGA - B149 Installation

Code.

Install an adaptor at the flue outlet of the unit to

step up to the diameter of the vent connector. Install

elbow for vent connector, if required. This elbow

should be full size of the vent connector. DO NOT

install a three (3) inch elbow between the flue outlet

PRODUCTION

OUT OF

Figure 4. H-M2.

on the unit and the adaptor. DO NOT use plastic vent

pipe in any part of the chimney vent connection.

Install vent connector between elbow, if used,

and chimney. Pitch vent connector up toward chimney

¼" per foot of lateral run. Secure all joints with

sheetmetal screws.

2D. Alternate Venting Method

(Canada Only)

The H Series may be vented vertically up

through a masonry chimney using a 4" diameter ULC

Certification Flexible Stainless Steel Vent.

Observe the following requirements:

1). The flexible vent must be run from the boiler up

through the entire chimney.

2). The chimney must terminate with a suitable vent

cap.

3). If chimney is exposed, the vent pipe should be

insulated.

4). The vent pipe must be installed with a ¼" per

foot upward slope from the boiler to the

chimney.

5). The vent pipe must be supported every 3' to

prevent sagging.

6). All joints in the vent must be secured with at

least two corrosion resistant screws and sealed

with an approved silicone sealant and checked

for gas tightness.

7). The vent system should be checked once a year

by a qualified serviceman.

Note: Boiler may not be vented in common with

another gas appliance or be vented using B-vent.

Page 7

H Series

Page 7

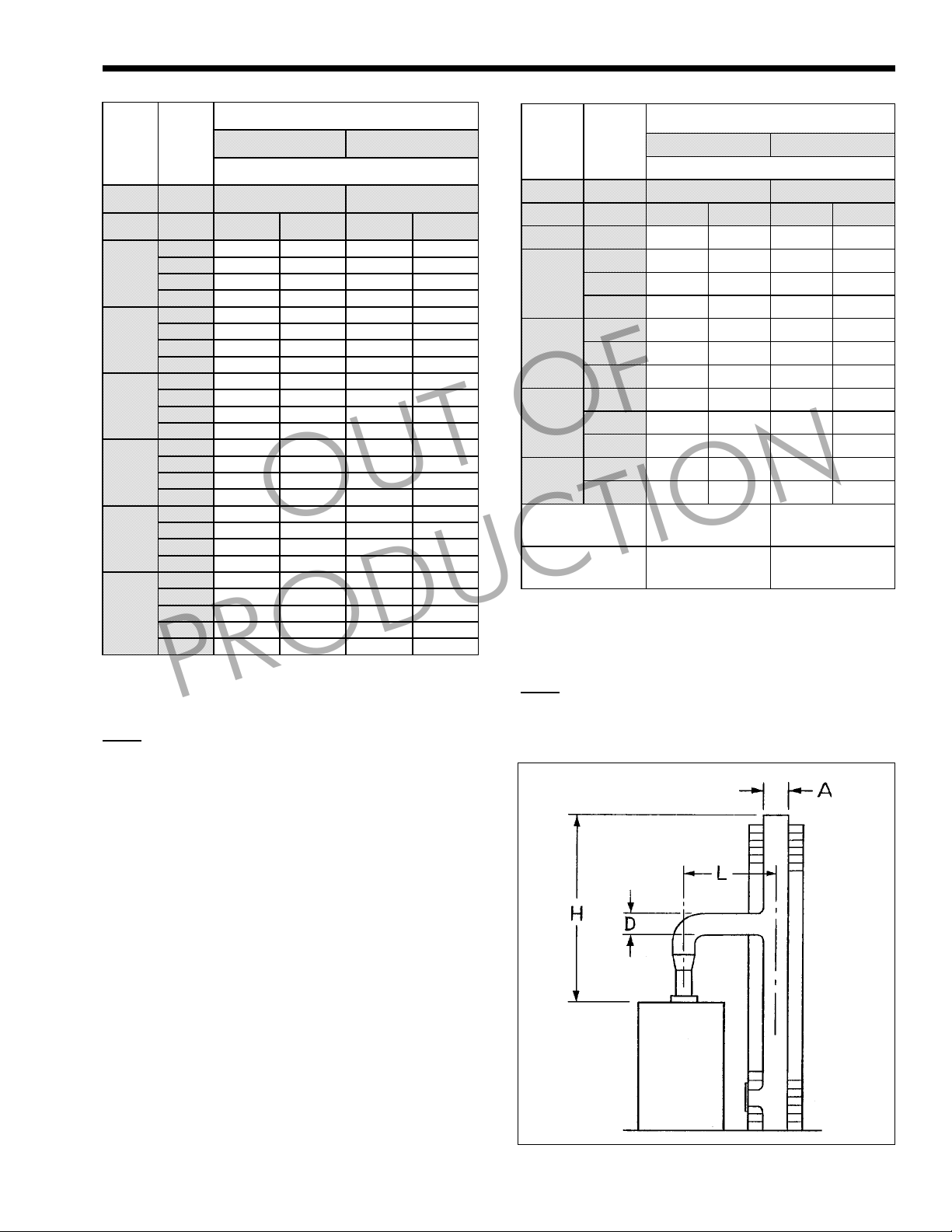

Vent Connector Diameter (A & D)

Height Lateral

H L Fan Assist Fan Assist

(ft) (ft) Min Max Min Max

0 85 249 126 373

6

8

10

15

20

30

Capacity of Tybe B Double-Wall with Single Wall

Metal Connectors Serving a Single Category I Appliance.

NOTE: TABLES APPLY TO MODEL H(W)-M2 130

(CATAGORY 1) APPLIANCES ONLY.

2 85 156 123 231

4 102 152

6 114 147

0 83 273 123 412

2 83 176 121 261

5 107 168

8 122 161

0 82 293 120 444

2 82 193 119 287

5 105 185

10

0 80 325 116 499

2 80 225 115 337

5 102 216

10 128 201

0 78 346 114 537

2 78 248 113 375

5 100 239

10 125 223

0 76 372 110 584

2 76 281 109 429

5 98 271

10 122 255

15

PRODUCTION

5" 6"

Appliance Rating in MBH

OUT OF

Table 1.

Type B Double Connector Diameter to be used with

chimney areas within the size limits at bottom

Height Lateral

H L Fan Assist Fan Assist

(ft) (ft) Min Max Min Max

10 2 68 519

2 53 475 64 613

15

20

30

50

Minimum Internal

Area of Chimney

Square Inches

Maximum Internal

Area of Chimney

Square Inches

Type-B Double Wall Flue Connector Serving a

NOTE: DERATE "FAN MAX" CAPACITY IN TABLE 2 BY

20% WHEN SIZING FLEXIBLE METAL FLUELINERS.

5 99 594

10 126 565

2 51 522 61 678

5 80 503 95 658

10 122 627

2 47 581 57 762

5 75 561 90 741

10 115 709

2 51 840

5 83 819

Capacity of Masonary Chimney Flue with

Single Category Appliance.

7" 8"

Appliance Rating in MBH

50 63

269 352

Table 2.

Figure 5. Tiled Lined Chimney. Masonry Chimney

Serving a Single Category I Appliance (see Table 2).

Page 8

Page 8

LAARS Heating Systems

2E. Installing Stainless Steel

Horizontal / Vertical Venting

(non concentric)

Stainless Steel Special Gas Vent listed to U.L.

Standard 1738 and U.L.C. Standard 636 may be used

to vent all H Series H(W)(P) and DH(P) models. Vent

pipe and fittings are manufactured to these Standards

by Heat-Fab, Inc. under the trade name of Saf-T

Vent® and by Z-Flex™ under the trade name of

Z-Vent. Follow the Special Gas Vent manufacturers’

instructions regarding design, location and assembly

of the vent system.

The H Series appliance may be vented with any

number of elbows or fittings provided that the

maximum equivalent feet of venting is not exceeded.

90° elbows in the vent system shall be considered to

be 10 equivalent feet. When vented with Special Gas

Vent, the H Series must not be common vented with

any other appliance.

2F. Connecting Special Gas Vent

to H Series

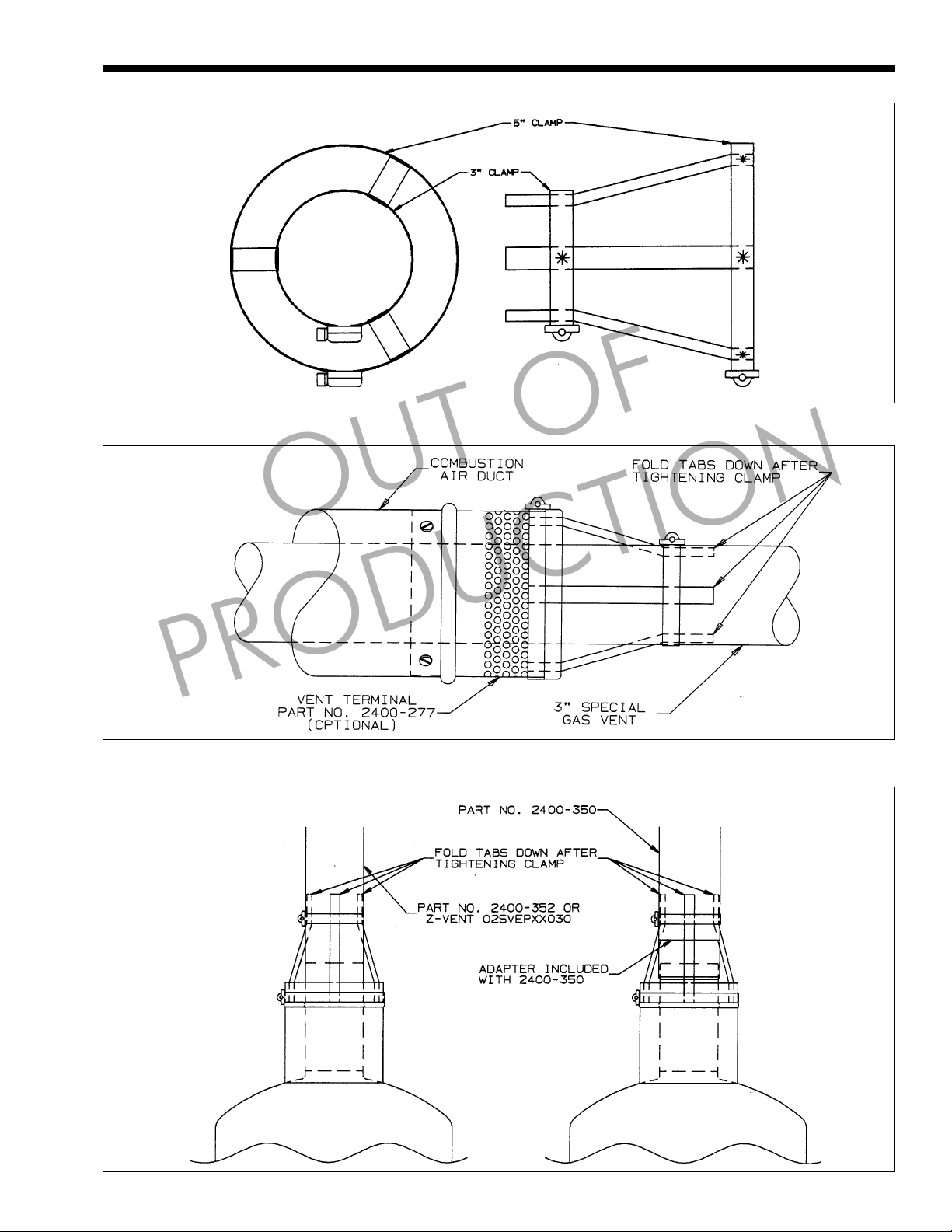

Teledyne part number 2400-372 (Figure 6) is

used to secure the Special Gas Vent to the flue outlet

of the H Series*. Heat-Fab pipe or fittings (part

numbers 2400-350 or 2400-352) or the male end of

Z-Vent pipe (Z-Vent # 02 SVEPXX030) may be

installed over the flue outlet of the H Series.

*If a duct is used around the Special Gas Vent to

bring in combustion air from another location, the

connection of that duct to the appliance must be

secured with sheetmetal screws.

Each joint between the appliance and the last

joint before the location where the Special Gas vent

exits the duct must also be secured with sheetmetal

screws.

In this application, part number 2400-372 is not

used at the boiler flue collar. It is used, and must be

used, to secure the Special Gas Vent at the point

where the Special Gas Vent exits the duct.

The combustion air supply should be protected

from debris entering the duct. This may be done with a

H Series Vent Terminal, part number 2400-277, as

shown in Figure 7 or with a large mesh screen.

Follow the Special Gas Vent manufacturer’s

instructions for cleaning and sealing all parts before

assembling.

PRODUCTION

OUT OF

2G. Appliance Joint Procedure

Part #2400-350 (See Figure 8)

Apply 1/4" bead of silicone sealer (GE108 or

Novagard 400) to the 3 inch (3") flue outlet of the H

Series approximately one inch (1") from the end.

Slide flue adapter over the H Series flue outlet

(flared up end) and push down to stop (do not force

adapter beyond stop).

Apply another bead of silicone around this joint

and smooth out.

Apply 1/4" bead of silicone to the straight end of

the 2400-350 pipe approximately 1/4" from the end.

Slide the pipe into the adapter until it bottoms in

the adapter.

Apply another bead of silicone around this joint

and smooth out.

2H. Appliance Joint Procedure

Part #2400-352 or Z-Vent

#02SVEPXX030 (see Figure 8)

Apply 1/4" bead of Silicone sealer (GE 108 or

Novagard 400) to the 3 inch (3") flue outlet of the H

Series approximately one inch (1") from the end.

Slide pipe over the H Series flue outlet and push

down to stop (do not force pipe beyond stop).

Apply another bead of silicone around this joint

and smooth out.

2I. Securing Special Gas Vent

Attach part number 2400-372 to 5" collar on

appliance or end of five inch (5") combustion air duct

and tighten large clamp.

Form tabs on part number 2400-372 onto Special

Gas Vent pipe and secure tabs with the 3" clamp.

After the clamp has been tightened, fold the end

of the tabs down over the clamp.

DO NOT use screws in any portion of the 3"

Special Gas Vent.

For vertical venting see instructions in the

Vertical Vent Kit pertaining to use of raincaps and

condensate drip tee's.

Page 9

H Series

Figure 6. Part Number 2400-372.

Page 9

OUT OF

PRODUCTION

Figure 7. Vent Terminal Used As An Air Screen.

Figures 8 and 9. Vent Pipe Attachment.

Page 10

Page 10

LAARS Heating Systems

SECTION 3.

Venting and Air Source

3A. The Direct Vent Kits

(part numbers 2400-326 or 2400-328)

When using the Direct Vent Kit, the H Series is a

sealed combustion unit. All of its air is drawn in from

the outside through the 5" outer pipe. Flue gases are

vented through the 3" vent pipe positioned inside the

5" intake pipe. The hot flue gases are surrounded by

the intake flow of cooler outdoor air. This vent system

may be installed through, and be in contact with,

combustible materials.

3B. Installing Direct Vent Kits

The Direct Vent H Series is certified with a

maximum of 15 linear feet of vent pipe and one set of

elbows. Systems may be vented with a maximum of

three sets of concentric elbows providing the

maximum length is reduced by three linear feet for

each additional elbow set. Provide a minimum of 16"

above the top of the boiler for vent installation and

servicing. There are two vent kits available. Part

numbers 2400-326 and 2400-328 provides all of the

required materials. Part number 2400-326 for vent

installations which require adjustable height and

horizontal run. This kit will permit vertical and

horizontal lengths of pipe from 2' or 4'. One foot

extensions and 2' to 4' extensions are available to

increase vent lengths to the maximum allowed.

Additional sets of elbows are also available.

Part number 2400-328 provides all of the

required materials for vent installations which may

have a fixed height of 11 inches and an adjustable

horizontal run of 2' - 4'. Accessories for P/N 2400-326

also fit P/N 2400-328.

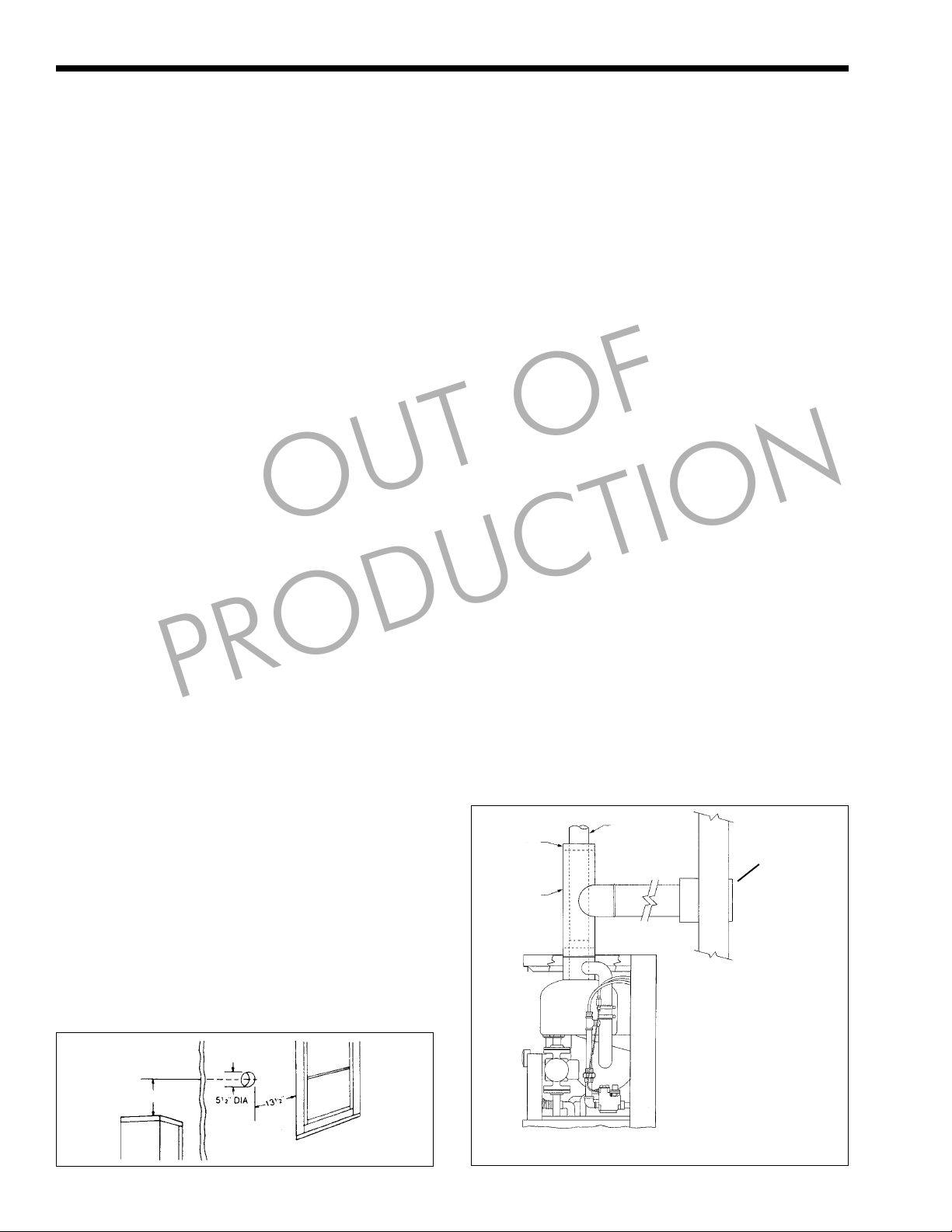

3C. Locating the Vent on an Outside Wall

Exterior vent should terminate 16½" above

grade, and at least 13 ½" from any other building

opening such as doors, windows, etc. Units

terminating below the top of the boiler must reduce

allowable vent length by 1" for every foot of vertical

drop below the top.

Vent opening should be well away from

shrubbery or other obstructions that would prevent

free air flow to and from vent terminal. Do not

PRODUCTION

OUT OF

terminate vent under decks, stairways, or car ports.

When ever possible, locations under windows should

be avoided.

NOTE: Should it be impossible to locate

opening center line 16 ½" above grade, use optional

Vent Terminal Extension (Part Number 2400-278).

(see Figure 4).

Vent terminals must also be at least 3' above any

forced air inlet located within 10', and at least 7' above

grade when located adjacent to a public walkway, and

cannot terminate in a location where condensate or

vapor may be a nuisance, hazard, or could be a

detriment to other equipment. Vent terminals must

have a minimum clearance of 4 feet horizontally from,

and in no case above or below electrical meters, gas

meters, regulators, and relief equipment unless a 4 foot

horizontal distance is maintained .

Do not locate the vent terminal where blockage

by snow is a possibility, or where flue products could

strike against building materials and cause degradation.

3D. Air Source For Combustion

(when not direct vented)

When using these venting methods the H Series

draws all combustion air through the top of the unit

and from the space around the boiler. When locating

the unit in unconfined spaces in buildings, infiltration

may be adequate to provide air for combustion and

ventilation; however, in buildings of unusually tight

construction, or when locating the unit in a confined

space, additional air should be provided and the

following guidelines must be followed.

1. If the space is in a building of unusually tight

construction, air should be obtained from

outdoors, or from spaces which freely connect

with outdoors.

PLUG

5" TEE

3" VENT

4" MIN. DIA

INTAKE AIR

SCREEN

8" MIN.

Figure 10. Direct Vent Terminal Clearance.

H, HP or HW with

Separate Air

Source.

ALTERNATE TO 1. - 3. ABOVE

Figure 11. H, HP or HW with Separate Air Source.

Page 11

H Series

2. For boilers in confined rooms, two permanent

openings shall be provided - one within 12" of

the ceiling, and one within 12" of the floor of

each room. Each opening shall be at least one

square inch per 1,000 BTU/HR boiler input, but

not be less than 100 square inches. These

openings shall freely connect with areas having

adequate infiltration from outside.

3. When all air is provided from outdoors, the

confined space shall be provided with two

openings as outlined above. These openings shall

connect directly, or by ducts, with outdoors or

spaces (crawl or attic) that freely connect with

the outdoors, and shall be of the size listed below

for that particular arrangement.

a. One square inch of free area per 4,000

BTU/HR of boiler input for direct outdoor

air supply through an outside wall, or

through vertical ducting directly to outside.

b. One square inch of free area per 2,000

BTU/HR of boiler input for direct outdoor

air through horizontal ducting.

c. All ducting shall be of the same size as the

opening to which it is connected.

OUT OF

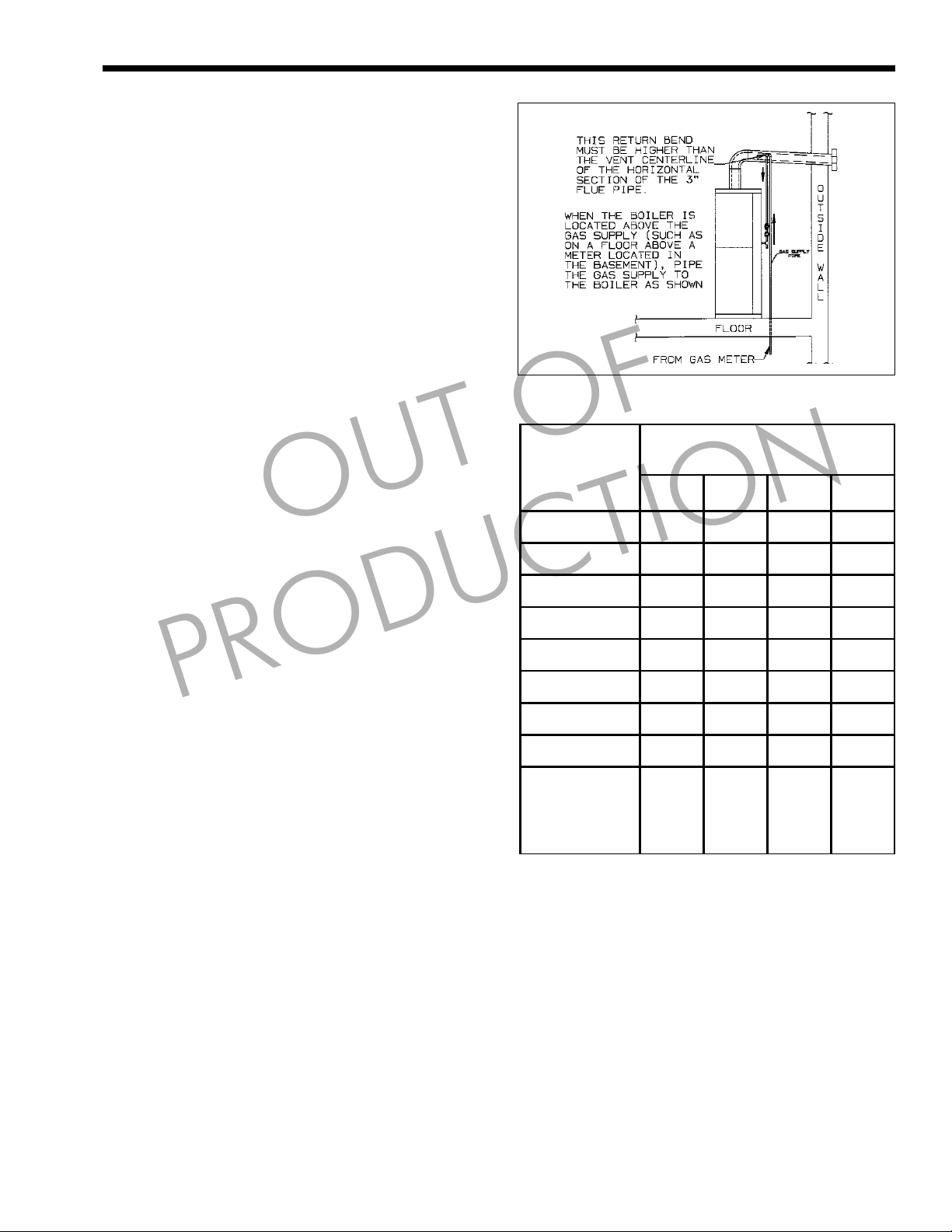

Figure 12. Gas Piping.

Length

of

Pipe

10' 132 278 520 1,050

20' 92 190 350 730

Capacity of Pipe in MBTU / HR

Page 11

(.6 Specific Gravity)

½" ¾" 1" 1¼"

SECTION 4.

Gas and Domestic Water Piping

4A. Gas Connection to H Series

least 4" W.C and no greater than 13" W.C. Check with

your local gas utility or supplier for availability of this

pressure range.

minimize pressure drop between meter or regulator

and unit.

applicable codes. IF UNIT IS INSTALLED ABOVE

GAS SUPPLY, RUN PIPPING UP TO A POINT

ABOVE VENT CENTER LINE AND BACK DOWN

TO UNIT. THIS WILL PREVENT WATER FROM

ENTERING GAS SUPPLY SHOULD A LEAK

DEVELOP IN THE BOILER SECTION (see

Figure 12).

accordance with state and local requirements.

to trap sediment and for test gauge access (see

Figure 12).

compound resistant to action of liquefied petroleum

gas whether LPG is used or not.

be disconnected from the gas supply piping system

PRODUCTION

The H Series requires an inlet gas pressure of at

Referring to Table 4, size supply piping to

Run gas supply line in accordance with all

Locate and install manual shutoff valves in

Install drip leg, ground joint union and drip cap

Support all piping with proper hangers.

All threaded joints should be coated with piping

The boiler and its individual shutoff valve must

30' 73 152 285 590

40' 63 130 245 500

50' 115 215 440

75' 93 175 360

100' 79 150 305

150' 64 120 250

Additional

length to be

added for each

tee or bend

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5kPa).

The boiler must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5kPa).

The boiler and its gas connection must be leak

tested before placing the boiler in operation.

Purge all air from gas lines.

Note: H Series’ are certified for 4" to 13" W.C.

We find on L/P the unit performs better when the low

pressure regulator is not set over 9" W.C. Use an

appliance regulator (maxitrol RV48 or equivalent) if

more than 3" lock up occurs in gas supply.

1.3' 1.7' 2.2' 2.7'

Table 4. Gas Pipe Capacity.

Page 12

Page 12

WATER

H

E

A

T

M

A

K

E

R

Figure 13. Domestic Water Piping.

1

6"*

15

AQUASTAT

OPTIONAL RETURN LINE PIPING

* or per valve manufacturers instructions.

CIRCULATOR

4B. Domestic Water Piping

Connect hot water tempering valve (12) “HOT”

port to hot water outlet from unit. This valve should be

mounted 3" to 6" below the outlet and set for 120° F

mixed delivery temperature or as local codes dictate.

H SERIES RECOMMENDS ANTI SCALD VALVE

SUCH AS SPARCO OR DANFOSS. (see Figure 13).

Connect gate or shutoff valve (13) to tempering

valve (12) “MIX” port, and cold water inlet.

Install supplied flow restrictor (14) ahead of mix

valve tee.

Connect pressure relief valve (1) (if required by

codes), maximum 150 PSI as close to the unit as

possible. No other valves or restrictions may be

installed between the H Series and the relief valve.

(DO NOT USE A TEMPERATURE/

PRESSURE RELIEF VALVE AS THIS IS NOT A

STORAGE HOT WATER HEATER).

*Model 60 is not recommended for larger hot

water demands.

Failure to install a hot water tempering valve (12)

creates a scalding hazard with potential for serious

bodily injury.

not designed as anti scold valves.

Installations with water containing 10 grains of

hardness or higher, must be installed with appropriate

water treatment.

PRODUCTION

WARNING

Some brands of tempering valves are

SOFTENER

12

OUT OF

SUPPLIED

13

14

13

LAARS Heating Systems

SECTION 5.

Hydronic Heat Piping

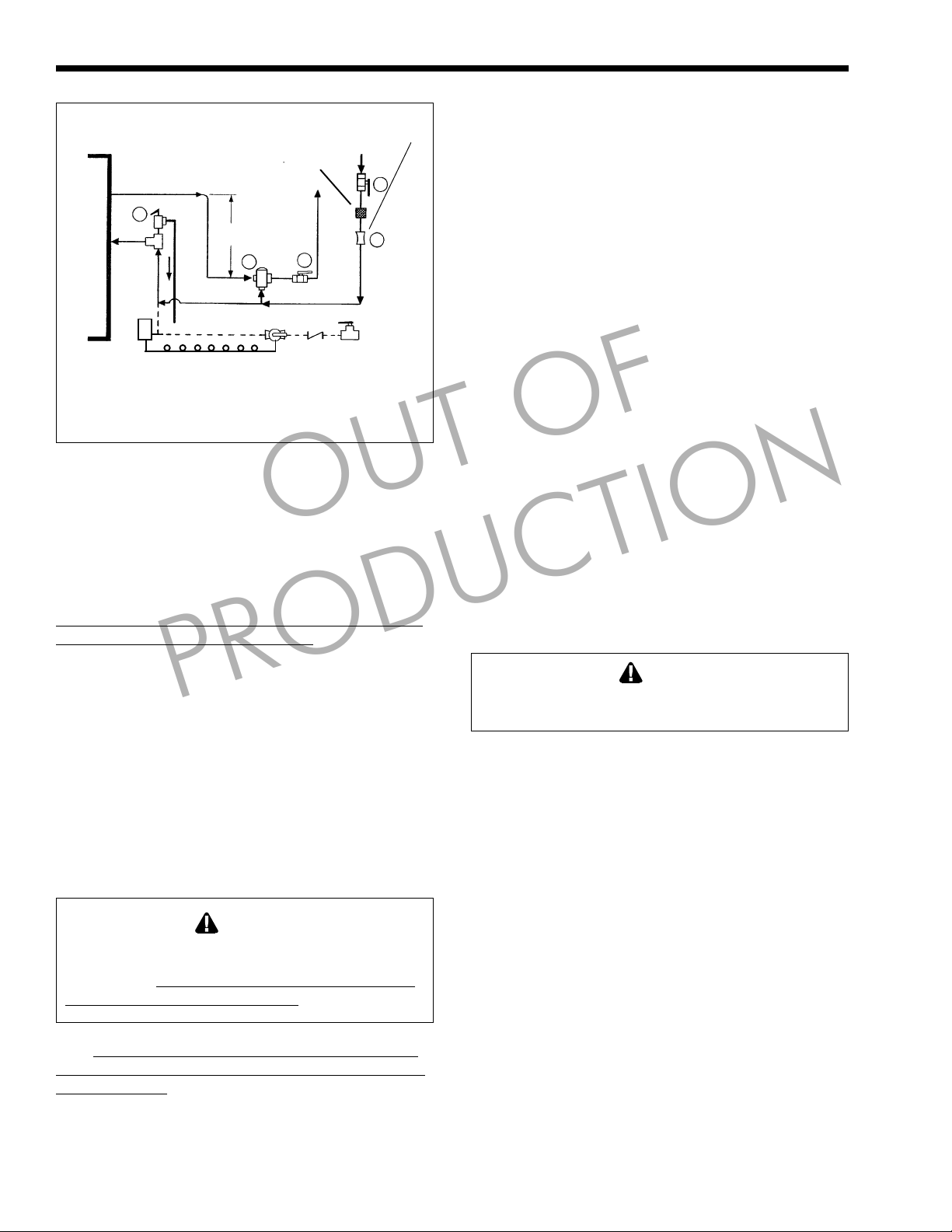

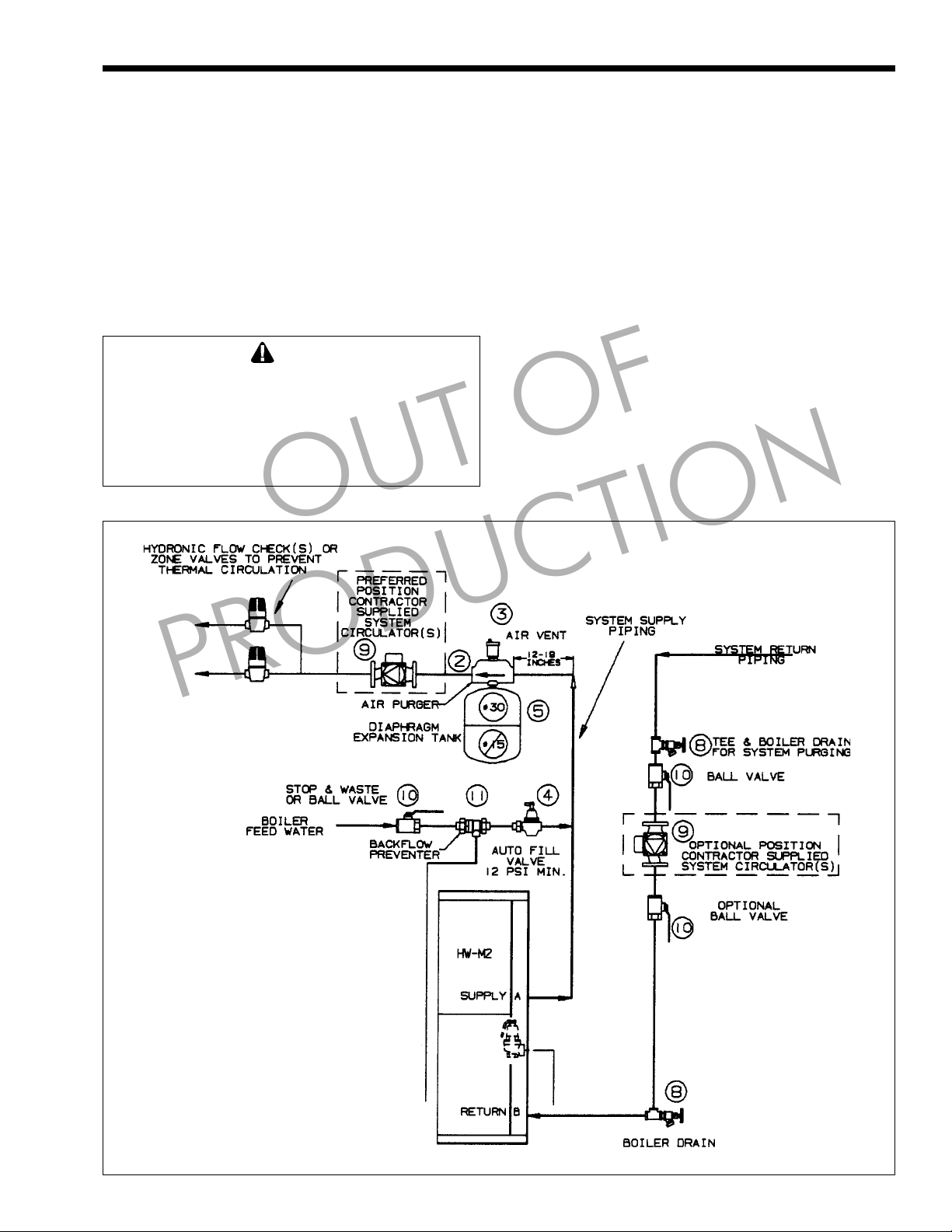

5A. Hydronic Heat Piping

Hydronic Connections, Fittings and Accessories

(see Figure 16).

NOTE: A SEPARATE HEATING

CIRCULATOR MUST BE PROVIDED IN

SYSTEM PIPING, FOR ALL MODELS.

Connect system supply to 1" supply connection (A).

1. Install thermostatic union (supplied) on H, HP

boilers.

2. Pipe the discharge of the relief valve, full size, to

a drain or in a manner to prevent injury or

property damage in the event of pressure relief.

3. Install an air purger (2) in supply line.

4. Install automatic float type air vent (3) on air

purger.

5. Connect diaphragm type expansion tank (5) to

air purger.

6. Install a boiler drain valve (8) adjacent to unit in

return line.

7. Connect system return to 1" return connection (B).

8. Install a properly sized circulator (9) with

optional isolation valves (10).

Caution

All hot water pipes must be installed with a

minimum 1" clearance from combustible materials.

NOTE: H, HP boilers installed in radiant (in

floor) systems and other low mass systems should be

provided with a buffer tank to assure constant supply

temperature without excessive boiler short cycling

(see Figure 17).

5B. Feed Water Make-Up

Connect boiler feed water supply with shut off

valve to inlet connection of automatic fill valve (4).

If codes require, install suitable back-flow

preventor (11) between automatic fill valve and city

main.

To ensure sufficient expansion volume of the

hydronic system water due to heat-up and cool-down

during normal operation, a #30 or larger expansion

tank must be used on all HW series applications.

Page 13

H Series

Page 13

5C. Hydronic Piping - HW Series

HW-M2 boilers are installed in single and

multiple zone systems ( using either zone valves or

zone circulators) in the same manner as any other

residential boiler. Systems with zone circulators or

single zone systems require the installation of a

hydronic flow check (6) to prevent gravity circulation

of heating supply water when no heat is desired.

To minimize heat loss from the storage tank

(HW) during standby periods, it is recommended that

the piping between the H Series up to and including

the vertical leg be insulated with ½" - ¾" of insulation.

Caution

Unless equipped with optional stainless steel tank,

the HW model must not be direct connected to a

heating system utilizing oxygen permeable tubing,

(see warranty). Provide a water to water heat

exchanger between systems to prevent corrosion of

tank or other components.

OUT OF

Nontoxic heating system antifreeze may be

added to the hydronic system provided that the

concentration does not exceed 35% and the antifreeze

contains an anti-foamant.

5D. Using In a Combined Hot Water

Heating and Chilled Water Cooling

System

When the H Series is used in connection with a

refrigeration system, it must be installed so that the

chilled medium is piped in parallel with the boiler

with appropriate valves to prevent the chilled medium

from entering it.

The boiler piping system of a H Series boiler

connected to heating coils located in air handling units

where they may be exposed to refrigerated air

circulation must be equipped with flow control valves

or other automatic means to prevent gravity

circulation of the boiler water during the cooling

cycle.

PRODUCTION

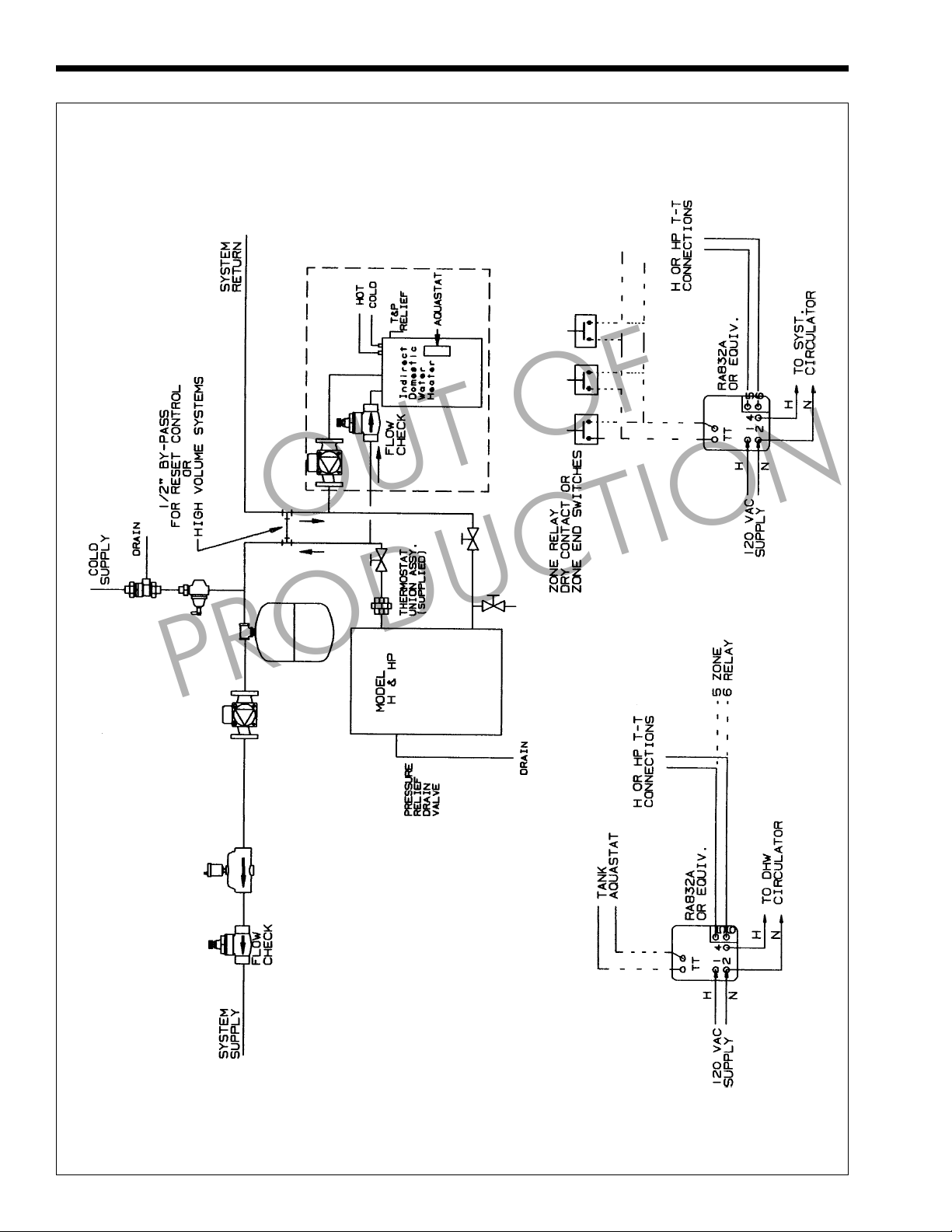

Figure 14. Hydronic Piping (HW).

Page 14

Page 14

LAARS Heating Systems

OUT OF

PRODUCTION

Figure 15. Hydronic Piping with Indirect H(P).

Page 15

H Series

Page 15

OUT OF

Figure 16. Hydronic Piping H(P) Models.

PRODUCTION

Figure 17. Hydronic Piping H(P) in Radiant “in floor” or Low Mass Heating System.

Page 16

Page 16

LAARS Heating Systems

SECTION 6.

Electrical Connections

6A. Electrical Connections

All electrical wiring must conform to local codes

and/or the 1). National Electric Code or 2). Canadian

Electrical Code - Part 1.

The unit must be electrically grounded in

accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirement, with the 1). National Electrical Code.

ANSI/NFPA NO.70- latest edition, or the CSA

Standard C22.1 “Canadian Electrical Code - Part 1”.

Single pole switches, including those of safety

controls and protective devices must not be wired in a

grounded line.

All electrical connections are made in the field

wiring box which is located on the right side of the

unit.

OUT OF

PRODUCTION

Figure 18. Single Zone.

NOTE: All internal electric components have

been pre-wired. No attempt should be made to connect

electric wires to any other location except the wiring

box as described below.

1. Main power

Connect a 15 amp fused 120 volt supply to the

main power switch illustrated (hot leg is

connected directly to switch). Neutral leg to

white wire. Ground wire can be connected to the

grounding screw in the box or on the switch.

2. For single zone installations, connect room

thermostat (T-T) wires to the red and white/red

wires. Connect circulator (120 volt, 5 amps

maximum) between the blue wire and the white

wire (neutral) (see Figure 18). Set thermostat

anticipator to 0.9 amps.

3. Zone Valves and Thermostats: Fig 19 (Fig 20 for

3 wire zone valve such as TACO) or DC

magnatrol valves.

Install external 24 volt transformer of sufficient

V.A. to power combined load of zone valves.

Consult zone valve manufacturer’s instructions.

Connect circulator (120 volt, 5 amp maximum)

between the blue wire and the white wire (neutral).

4. Multi-Zone/ Multi-Relay-Circulator

Installations: Multiple circulators must not

exceed 5 amps when connected to blue wire.

Blue wire must be used on all HW series (see

Figure 21).

NOTE: On zone valve systems such as Taco,

Automag and others which do not have isolated (dry)

contact end switches, a single pole isolating relay must

be utilized. (see Figure 20).

LEGEND

S1 Disconnect Switch

TH1

24-Volt Thermostats

TH2 R2

TH3 R3

C1

Zone Circulators Max 5 AMP

C2 ZV2

120 VAC.

C3 ZV3

Figure 19. Zoning with Zone Valves.

Figure 20. Zoning with 3 Wire Zone Valves. Figure 21. Zoning with Circulators

R1

ZV1

Zone Relays.

Honeywell R845A or

equivalent.

Zone Valves.

Honeywell V8043 or

equivalent.

Page 17

H Series

Page 17

SECTION 7.

HP Mounting Piping

The Model HP-M2-Series may be used as either

a Paloma Pak/Hytech boiler replacement or as a new

wall-mount installation. Carefully unpack HP unit.

Read all installation instructions before starting the

installation. Remove the Front removable jacket and

find the plumbing accessories package inside the unit.

7A. Wall Mounting Instructions

Paloma/Hytech Replacement

Hang the HP-M2 as assembled from the

manufacturer onto the existing wall bracket. Do not

remove the brackets which are attached to the new

unit. If the existing wall bracket does not align with

the slotted mounting holes on the rear of the HP-M2,

remove the old bracket from the wall and follow

instructions for new wall mount below.

7B. New Wall Mount Installation

Remove the bolts, nuts and washers that secure

the two mounting brackets to the bottom and rear of

the HP-M2 cabinet. Remove the U-channel spacer

bracket from each wall bracket and discard. (Spacer

brackets are used only with original bracket in Paloma

Pak/Hytech retrofit installations)

Attach the included mounting template to the

selected wall location. Mark and drill holes for

appropriate mounting hardware at the template

specified locations. Remove template from the wall

and securely affix the two wall brackets to the wall

surface with appropriate mounting hardware (provided

by installer).

assemble the bolts, nuts and washers to affix the unit

onto the wall brackets.

U-CHANNEL SPACER BRACKETS WHEN

MOUNTING THE WALL BRACKETS DIRECTLY

TO A WALL.

7C. Hydronic Systems Connections

the necessary fittings to match the Paloma Pak supply

and return piping. If the original wall bracket is

compatible with the slotted mounting holes on the rear

of the HP-M2, the supply and return pipe unions

attach directly to the existing piping. If the installation

is new or if the old bracket is incompatible or

unusable, the return and supply connections will

require re-piping to match the HP-M2 connections.

7D. Plumbing Accessories Installation

1) Attach boiler drain plumbing accessory to the

PRODUCTION

Lift the HP-M2 onto the wall brackets and re-

NOTE: DO NOT REINSTALL THE

The H SERIES HP-M2 Series is supplied with

labeled “return” on the bottom of the HP-M2.

OUT OF

2) Separate Thermostatic Union Assembly halves

and thread the 1" nipple side to the labeled

“supply” on the bottom of the HP-M2. Attach the

remainder of the union assembly onto the top

half of the union. Be sure to use appropriate

thread sealers to assure leak-tight joints.

3) a. Where the HP-M2 is a direct replacement

for a PalomaPak/Hytech the installation is

completed by connecting union halves

together.

b. If the installation is new, refer to the piping

schematics and instructions on page 10 -12.

7E. Gas Supply Connection

If the installation is a direct retrofit, the gas

supply will require re-piping to connect to the HP-M2

gas inlet. If the gas is supplied from below the unit, be

sure to run supply pipe to a point higher than the vent

center line before connection to the unit gas valve.

On new installations refer to the gas piping

section for gas pipe sizing and related information.

SECTION 8.

HP Venting and Electrical

8A. Venting the HP-M2-Series

The HP-M2 may be vented using any of the

venting options available to the H(W)-M2-Series.

These options include Direct Vent, Outside Air

vented, Alternate horizontal/vertical venting (using

“Special Gas Vent”) or internal lined or “B” Vent type

chimneys.

MODEL HP-M2-60 & HP-M2-100 MUST

NOT BE CHIMNEY CONNECTED OR “B”

VENT CONNECTED.

8A-1. AGA

When used as a retrofit boiler vented into a

chimney or a “B” Vent, be sure to check current vent

and vent connector sizing tables. Only units fired at

130MBTU/hr may be vented with this option. Under

no circumstances shall the HP-M2-60 be chimney

connected or “B” vented using 3" vent or vent

connectors. The unit 3" vent collar must be increased

to a size which will accommodate the chimney system

for the appropriate BTU/hr input of the boiler.

In the event the unit firing rate and masonry

chimney parameters do not fall within the

recommendations in the latest N.F.G.C.* chimney

sizing tables, a flexible chimney liner may be utilized

in the chimney. Sizing capacity for metal chimney

liners may be obtained by 20% de-rating (or 80%) of

the “fan max” capacity from B vent tables. See page 5

for vent table excerpts.

*National Fuel Gas Code ANSI Z223.1 / NFPA 54.

Page 18

Page 18

LAARS Heating Systems

8A-2. CGA

Refer to page 4 for Alternate Venting Method.

8B. Electrical Connections

If the installation is new, wire the unit per the

applicable wiring diagram for line voltage (120VAC)

and control (24VAC) wiring connections.

Do not connect an external voltage source to the

HP 24 volt (T-T) wires. Install an isolation relay if

required per diagram Figure 20.

Where a HP-M2-Series in a Paloma Pak/Hytech

retrofit is connected to a single zone system, the

original transformer relay control-pak should be

removed and all field wiring connected to the unit

electrical connection junction box on the right side of

the unit. The 120VAC power input, 120VAC system

circulator output and thermostat should be wired as

outlined in figure 18.

Be sure to set the thermostat heat anticipator to

0.9 amp for single zone connection.

If a retrofit installation includes multiple zones,

any one of the options provided in this manual may be

OUT OF

used, or the existing transformer relay control-pak

may be utilized and re-wired according to the diagram

below. Where two wire or three wire zone valves are

used, this is the preferred wiring method on retrofits.

8C. Manufactured Home (Mobile Home)

Appliance Installation Instructions

These appliances are design certified to conform

to the requirements of ANS Z21.10.3 for installation

in manufactured homes (mobile homes) when installed

in conformance with this manual supplement and the

manual.

8C-1. APPLIANCE MOUNTING

Model HP Series appliances are provided with a

wall mounting bracket.

Model H Series appliances are provided with

mounting holes in the base. Either lag bolts or through

bolts must be used for secure attachment of the

appliance to the structure.

Model HW Series appliances are attached to the

structure by attaching angle brackets from the structure to the secured clearance brackets. See Figure 23.

PRODUCTION

Figure 22. Paloma Pak/Hytech Transformer Relay Control Pak Rewiring.

Figure 23. Mounting in Mobile Homes.

Page 19

H Series

Page 19

SECTION 9.

Check, Test and Start Up

9A. Filling System

1. Open all supply and return valves.

2. Fill heating system to minimum operating

pressure of 12 psig.

3. Open bleed pet cock and bleed air from boiler

coil until a good stream of water comes out.

(H(P)-M2 series), Item 8 on page 33.

4. Purge all lines by opening vents, or with flushing

valves.

5. Close gas valve.

6. Turn on 120 volt power, and listen for unit

circulator to start. Unit will cycle off on lockout.

7. Open all vents again to discharge any additional

air and close off after air is eliminated.

8. System is now ready for operation.

OUT OF

9B. Firing Burner

1. Be sure that system has been filled properly (see

above) and is leak tight.

2. Open gas cock (s). Open manual gas shutoff

valve by turning to “on” position.

3. Turn on main switch, and set thermostat to call

for heat. In approximately 2 seconds, blower will

come on.

PRODUCTION

NOTE: Burner may not ignite on first attempt

because of air in gas lines. In this case, blower will

stop after 5 minutes. Should this happen, turn off main

switch. Wait 5 minutes and turn on main switch again.

4. If burner fails to ignite after three attempts, refer

to Trouble Shooting Section 2, Service Manual

or call service for troubleshooting.

Caution

Should any pronounced odor of gas be detected, or

if the gas burner does not appear to be functioning

in a normal manner, close main shutoff valve, do

not shut off switch, and contact your heating

contractor, gas company, or factory representative.

5. You MUST check flame monitoring control

(ignition system safety shutoff device).

a. Close gas cock with burner operating.

b. In 3 seconds, FLAME indicator light will

go out and blower will continue to run on

post purge cycle. Two additional attempts

to light will follow including pre-purge,

igniter on, valve/flame on and post purge.

(Ignition will not occur-gas off.)

c. Open gas cock. Switch unit “OFF” and then

“ON” again. Burner should start after about

45 seconds. It is recommended that the unit

be checked with a standard CO² or O²

tester. Insert tester probe at least 6" into

exhaust pipe through outside vent terminal.

Readings should be:

CO2 - 8% to 8.5% (nat. gas)

CO2 - 9% to 9.8% (LP gas)

O2 - 7% to 4½%

6. Check Burner Input (other equipment off)

a. Measure the time, in seconds, it takes to use

one cubic foot of gas.

b. Divide the number of seconds into 3,600.

c. Multiply the result by the heating value of

the gas to obtain BTU/HR input.

Example: If it takes 36 seconds to use one cubic

foot of gas and the heating value of the gas is

1,000 BTU/CU FT, (approx. natural gas value).

INPUT = 3,600/36 x 1,000 = 100,000 BTU/HR

Input Ranges

H(W)-M2-130 - 127,400 TO 132,600 BTU/HR

H(W)-M2-100 - 98,000 TO 102,000 BTU/HR

H(W)-M2-60 - 58,800 TO 61,200 BTU/HR

Because of the altitude and other minor

variations, it is possible the input will not fall within

this range and the gas orifice must be replaced. See

chart in an orifice kit.

9C. Check Limit Control Operation

9C-1. Operating and Low Limit

Control HW-M2

When water temperature reaches low limit set

point (180°F) with no call for heat, H Series will shut

down.

Turn up the room thermostat. Boiler pump

(inside jacket) will now run.

If water temperature is below operating control

cut out temperature (210°F) burner will fire.

When operating control cut-out temperature is

reached (210°F) burner will go off, blower will post

purge for 30 seconds and the boiler pump and system

circulator will continue to operate until room

thermostat is satisfied.

When water temperature drops below low limit

cut-in temperature (150°F) and there is a continued

call for heat, the system circulator will go off. The

boiler pump will continue to operate and the burner

will remain on. When low limit cut-out temperature is

reached (180°F) the system circulator will come on.

Page 20

Page 20

LAARS Heating Systems

9C-2. Operating Control H-M2

Burner will run until operating control cut-out

temperature (185°F) is reached.

When Operating Control cut-out temperature is

reached, burner will go off and boiler pump will

continue to run and blower will post purge for 30

seconds.

When temperature reaches Operating Control

cut-in temperature (160°F), burner will start and

continue to run until a call for heat is satisfied or

Operating Control cut-out temperature is reached

again.

9C-3. Safety Limit Operation H(W)-M2

If boiler water temperature exceeds operating

control cut-out temperature for any reason, the safety

limit will interrupt power to the gas valve at

approximately 215°F, the blower will post purge for

30 seconds and the unit will shut down. The safety

limit will reset at 195°F.

Note: temperature of limit operations are all

approximate; allow for gauge and tolerance variations.

OUT OF

9C-4. Stack Switch Operation H(W)-M2

If, for any reason, the combustion air blower

fails to provide adequate air flow, or if the flue is

blocked so as to prevent sufficient air flow for proper

combustion, the contacts of the stack switch will open

and the unit will shut down. After 5 minutes, purge

light will flash.

Close all covers. Reset room thermostats and

place these instructions in a place convenient to the

unit.

Please be sure that the warranty card is mailed to

by either you or the property owner.

9D. Common Vent Test

Required only if H Series is not being chimney

connected. At the time of removal of an existing

boiler, the following steps shall be followed with each

appliance remaining connected to the common venting

system placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

Seal any unused opening in the common venting

system.

Visually inspect the venting system for proper

size and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition.

Insofar as is practical, close all building doors

and windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance not

connected to the common venting system. Turn on any

exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do

PRODUCTION

not operate a summer exhaust fan. Close fireplace

dampers.

Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a cigarette,

cigar or pipe.

After it has been determined that each appliance

remaining connected to the common venting system

properly vents, when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas burning appliance to their previous

conditions of use.

Any improper operation of the common venting

system should be corrected so the installation

conforms with the 1). National Fuel Gas Code,

ANSI Z223.1 latest edition, or 2). Can / CGA - B149

When re-sizing any portion of the common

venting system, the common venting system should be

re-sized to approach the minimum size as determined

using the appropriate tables in Part 11 in the National

Fuel Gas Code, ANSI Z223.1-latest edition.

9E. Lighting and Shutdown Instructions

9E-1. Lighting

1. Ensure that boiler is filled with water, air is bled

from boiler coil and that boiler water pressure is

at a minimum of 12 psi.

2. Open main gas cock.

3. Open gas cock on gas valve.

4. Turn “ON” disconnect switch (on right side of

unit).

5. After 45 seconds, ignition will occur (if there is a

call for heat).

9E-2. Shutdown

1. Turn “OFF” disconnect switch.

2. Close gas cock on gas valve.

3. Close main gas cock.

SECTION 10.

Maintenance

10A. Owner Care and Maintenance

Inspect venting system - Annually remove

screws on vent terminal and remove terminal. Inspect

interior with flashlight.

General Housekeeping - Keep boiler area clear

and free from combustible materials, gasoline and

other flammable vapors and liquids.

Page 21

H Series

Page 21

Keep boiler jacket louvers clear for proper

cooling of internal components.

Do not obstruct boiler room ventilation screens

or grills.

10B. Service Maintenance

Cleaning Heat Exchanger to be done by qualified

service person.

1. Turn off electric and gas supplies and remove the

jacket.

2. Remove the vent assembly and top cover.

3. Remove the top half of the combustion chamber

by removing the three screws and nuts that clamp

the top half to the bottom half, the clamp on the

induction tube and the 1/8" diameter balance

lines.

4. Remove the top insulator cap by spreading the

retainer.

5. Remove the igniter - to avoid damage during

cleaning.

6. Clean the finned tubing with a wire brush and

vacuum all loose material from the combustion

chamber. Wipe flameholder (burner) with a clean

dry rag.

7. Replace all parts in the reverse order in which

they were removed.

8. Restart the unit as indicated by the operating

instructions plate.

OUT OF

PRODUCTION

SECTION 11.

Burner Input and Boiler

Component Descriptions

2. The pressure on the outlet side (manifold) of the

gas valve and "T" above air orifice is between

negative .05" and negative .35" water column

with the unit operating.

To increase the input, install larger diameter gas

orifice. Each size will change the input approximately

5 C. F. H. Once the correct input has been achieved,

the burner should be checked with an oxygen (O2) or

carbon dioxide (CO2) gas analyzer.

The unit should be in operation 5 minutes before

adjusting input or taking CO2 or O2 readings. This

time will allow for pre-heating of the intake air.

Insert the probe of the O2 or CO2 tester at least

6" into the vent through the vent terminal. If CO2 is

being measured, the readings should be between 8.0

and 8.5 for natural gas and 9.0 and 9.8% for propane.

If O2 is being measured, the readings should be

between 7 and 6.

11A-1. Measuring CO

When operating on natural gas, readings below

8.0 generally indicate a lean mixture (not enough gas).

Readings above 9.25 generally indicate a rich mixture

(too much gas). Inputs should be increased or

decreased to correct lean or rich mixtures.

NOTE: If the mixture is very rich (not enough

air for complete combustion), it is possible to get low

readings on a CO2 analyzer. This situation does not

occur often but it can be detected if reading continues

to go lower as the input is increased. If this condition

is suspected, a CO test should be taken at the vent

outlet. Inputs must be reduced to correct high CO

reading and to bring CO2 readings to proper levels.

* The following numbers apply to natural gas

only. The range of operation for LP is 9.0 to 9.8.

*

2

11A. Adjusting Burner/Input

The H Series burner system is a pre-mixed,

forced combustion system. Outside air is drawn

through the air orifice (located in the air induction

system) and mixed with the gas drawn in downstream

of the air orifice. The gas is metered through an orifice

located in the gas orifice union. All the air required for

complete combustion comes into the system in this

manner.

Adjusting the input is limited to changing the gas

orifice to achieve the proper input. The air orifice

cannot be altered and the gas valve pressure setting

cannot be changed.

Before changing the gas orifice to correct input,

service representatives should make the following

checks:

1. The pressure on the inlet side of the gas valve is

between 4" and 13" water column.

11A-2. Measuring 0

Readings above 7% indicate a lean mixture (not

enough gas). Readings below 4½% indicate a rich

mixture. Input should be increased to correct lean

mixtures or decreased to correct rich mixtures.

11B. Cleaning Combustion Chamber Coil

1. Turn off electric and gas supplies and remove the

jacket.

2. Remove the vent assembly and top cover.

3. Remove the top half of the combustion chamber

by removing the 3 screws and nuts that clamp the

top half to the bottom half, the clamp on the air

orifice hose and the two clear plastic lines

connected to the "T" on the air induction elbow.

4. Remove the top insulator cap by spreading the

retainer.

5. Remove the igniter.

2

Page 22

Page 22

LAARS Heating Systems

6. Clean the finned tubing with a wire brush and

vacuum all loose material from the combustion

chamber.

7. Replace all parts in the reverse order in which

they were removed.

8. Restart the unit as indicated by the lighting

instruction label.

11C. Unit Pump

The unit pump operates whenever there is a call

for heat or hot water.

It is a wetted-rotor type pump and should always

be filled with water when it is operating so that it will

cool properly.

If a pump change is required for any reason,

valve off the boiler and drain approximately 1 or 2

gallons of water from the unit. Turn off the main

disconnect switch and unplug the pump wires, remove

the pump motor. The pump housing need not be

removed. The replacement pump motor should be

installed in the reverse order from which the old pump

motor was removed. After filling the system be sure to

bleed the coil.

NOTE: If the pump motor is not defective the

pump cartridge alone may be changed (Taco Pumps

Only).

11D. Gas Valve

The gas valve is a solenoid operated, negative

pressure regulated valve. The outlet pressure is

regulated at minus 0.2 inches w.c. It is designed to

operate with supply pressures of 4-13 inches w.c.

Within that range of supply pressures, the regulated

discharge pressure may vary from minus .05 to minus

.35 inches w.c. The regulator is not adjustable and the

effect of this variation in discharge pressure is not

significant. Because of the fixed regulator setting, gas

flow must be adjusted by changing the gas orifice.

To remove the gas valve, shut off 120 volt power

and the master gas cock in gas line, loosen the nut on

the gas orifice union and remove the orifice union plus

piping to the gas valve. Disconnect the wires from the

gas valve. The valve may now be unscrewed from the

inlet piping. It may be necessary to deflect the inlet

piping somewhat in order to clear the boiler jacket.

After the valve has been removed, replace with a new

valve in the reverse order in which the old valve was

removed. Do not over tighten the fittings into the

valve body as this may cause damage to the valve.

NOTE: When fueled by LP gas, H Series

perform best with 9-10 in. W.C. supply pressure. If no

other appliances are being supplied by the LP supply

set the low pressure regulator to 9-10 in. W.C.

11E. Safety Limit Switch

The Safety Limit Switch has a fixed set point at

215°F. It will reset automatically.

PRODUCTION

OUT OF

To replace the switch , shut off the 120 volt

power and valve off the boiler, drain 1 or 2 gallons of

water from the boiler and remove the nut which holds

the safety limit bulb in the boiler discharge fitting.

Remove the bulb from the fitting and remove the 2

screws which hold the switch assembly to the

electrical control box. Disconnect the 2 wires from the

quick connects at switch and remove the safety limit

assembly. To replace, perform the same operations in

reverse. Push the sensing bulb as far into the fitting as

possible before tightening sealing nut. No more than

1/2" of sensing bulb should be visible after

installation. Fill the boiler and be sure to bleed the coil

at the coil bleed petcock. Turn on disconnect switch

and check boiler operation.

11F. Operating Control

The Operating Control maintains boiler

discharge temperature between 170-210°F during the

space heating cycle. It has a fixed set point of 210°F

(HW-M2 Series only) and a differential of 40°F,

therefore, its contacts open at 210°F and they reclose

at 170°F. If replacement is necessary, shut off the 120

volt power and disconnect the wires to the sensor.

Valve off and drain 1 or 2 gallons of water from the

boiler and remove sensor. Install new sensor, refill

boiler and bleed coil at coil bleed petcock. Check

boiler operation after installation of new Operating

Control. The Operating Control on the H(P)-M2 series

has a fixed set point of 185°F. Its contacts open at

185°F and they reclose at 160°F.

11G. Igniter

The igniter is a “glow bar” type silicon carbide

unit. It is energized whenever there is a call for heat

and the red "IGNITER" light on the boiler control is

lit. After the igniter is switched off and the boiler

continues to run, the igniter functions as a flame

sensor for the boiler control.

If the ignitor fails and must be replaced, always

install a new igniter gasket with the replacement

igniter.

Caution

Ignitor gets hot.

11H. Pressure Differential Switch

The Pressure Differential Switch is a normally

open single pole switch which is designed to detect

pump operation and water flow. To replace, turn off

electrical power & boiler feed water. Valve off and

drain 1 or 2 gallons of water from the boiler, unplug

wires from the switch and remove switch. Install new

switch in reverse order. Refill boiler and bleed air

from the coil bleed petcock. Turn on electrical power

and recycle system.

Page 23

H Series

Page 23

11I. Transformer

The control transformer accepts 120 VAC power

and provides 40 VA of 24 VAC power for the boiler

control only. It is not capable of supplying control

power for external devices such as zone valves. They

must have their own separate power supply.

11J. Low Limit

(HW-M2 Series Only)

The H Series Mark 2 may be equipped with a

strap-on Low Limit. The Low Limit control performs

two functions. It controls the temperature of the water

in the transfer tank and it prevents the house circulator

from operating when insufficient tank water

temperature causes the domestic hot water delivery

temperature to drop below 140°F. The Low Limit

Control has a fixed differential of 15°F and is set to

turn the burner on at 140°F tank water temperature

and to turn it off when the sensor reaches 155°F.

Because of the thermal lag in the sensor, the tank

water temperature will reach about 180°F before the

burner actually is turned off. The boiler temperature

may reach operating temperature due to this thermal

lag.

If replacement is necessary, shut off the 120 volt

power. Simply remove and attach wire for wire.

Clamp the new Low Limit to the hot outlet pipe as

close to the domestic exchanger plate as possible and

cover area with tank insulation blanket. Return boiler

to service.

11K. Blower

centrifugal blower. It is designed to provide about 2"

w.c. of suction at 30 CFM. This performance is

necessary to operate the gas valve reliably, to

overcome induction system friction losses and to

eliminate any sensitivity to wind striking the vent

terminal. It is powered by a 120 volt motor which

draws about 1.3 amps at rated load. It is powered by

the integrated boiler control whenever there is a call

for heat and 30 seconds thereafter. If a blower change

is required, turn off the 120 volt power and unplug the

power wires from the blower motor. Remove the three

nuts from the blower discharge flange and the four

nuts from the blower inlet flange. The blower may

now be deflected enough to permit its removal. Install

the new blower using new gaskets, in the reverse order

from which the old blower was removed. The four

inlet flange nuts, however, should only be finger tight

initially and then tightened with a wrench after all

other operations have been completed. The

combustion should be checked for correct air-fuel

ratio whenever the blower is replaced (see Burner

Adjustment).

PRODUCTION

The Combustion Air Blower is a high head

OUT OF

11L. Priority Relay - R1

(HW-M2 series only)

The Priority Relay is a normally open single pole

relay which accepts a 24 VAC signal from the low

limit aquastat and the T-T wires to provide 120 VAC

power to the system circulator when the tank

temperature remains above 150°F.

11M. Boiler Control

The Integrated Boiler Control Module controls

the combustion process, the gas valve, the igniter, the

blower, the unit pump and the system circulator. It

provides blower prepurge as well as burner flame

sensing. When replacing the boiler control turn off

disconnect switch and press in tabs on each end of

plugs to remove from control. All plugs are color

coded and it is not possible to miswire the control.

11N. Stack Switch

The Stack Switch is a normally open single pole

switch which is operated by the pressure difference

across the air orifice. It is set to close when a static

pressure difference of 1 in. w.c. is generated by the

combustion air blower. Its function is to prove airflow

and to inhibit burner operation in the event of flue or

chimney stoppage. The switch is wired directly to the

boiler control. It is located on the inside of the jacket

back panel adjacent to the boiler bracket.

11O. Transfer Tank and Domestic Hot

Water Coil (HW-M2 series only)

The transfer tank contains approximately 20

gallons of boiler water. It functions as an energy

storage vessel to reduce boiler cycling on small output

heating zones and to provide heat for domestic hot

water through the domestic hot water (DHW) coil

immersed in it. The DHW coil may be removed from

the tank if either tank or the DHW coil must be

replaced. The coil is secured to the tank with (6) -3/8"

- 16 bolts which are replaceable if they are broken or

stripped.

11P. Thermostatic Union

(H(P)-M2-Series only)

The thermostatic union is a 1¼" NPTF union

which has a thermostatic element on the inside. The

element has two small bypass holes to allow some

water to flow into the system when the element is

closed. When the boiler first starts and cold system

water is returning, the element is closed and boiler

water is recirculated back to the return until the supply

water reaches 160°F and the element opens. To

replace the element shut off and drain the section of

the system that the thermostatic union is installed in.

Open the union and replace the element with a new

one. The element should be installed so that its spring

Page 24

Page 24

LAARS Heating Systems

and actuator are on the system side. Close union, open

valves, refill and bleed system, bleed coil at coil bleed

petcock and restart boiler.

11Q. Time Delay Relay (TDR)

(H(P)-M2-series only)

The Time Delay Relay controls the unit pump

and keeps it operating for approximately one minute

after the blower post purge stops. Control voltage on

the TDR is 24 volts from the limit circuit. The

contacts to supply pump power are 120 VAC. They

delay on open one minute after the 24 volt control

voltage is interrupted. Turn off disconnect switch

before changing TDR.

11R. DHW Coil Replacement

Shut off boiler feed water, domestic water supply

to coil and electrical power to boiler. Valve off system

and drain the water from the tank. Disconnect boiler

discharge union from coil fitting, remove relief valve

discharge piping and cut the horizontal hot and cold

water pipes about 6 inches away from plate.

Disconnect and remove low limit sensor. Remove the

six coil retaining nuts and take out coil. Remove the

old coil gasket and clean gasket sealing surface on

tank. Remove the pressure relief valve from old coil

and install in new coil assembly with thread sealing

tape or pipe joint compound. Install new gasket in

recess on tank (if it doesn’t fit snugly in tank recess

remove it and stretch it). Place new coil in tank and

screw on coil retaining nuts. Tighten nuts evenly to

seat gasket properly. Do not over tighten. Make up

boiler discharge union, fill boiler and check around

gasket for leaks. If the coil plate is leak tight make up

hot and cold water pipes with slip couplings and

reassemble relief valve discharge piping. Connect and

reinstall low limit sensor. Turn on domestic water

supply and electrical power. Bleed air from coil bleed

petcock and recycle boiler. Boiler fill pressure is 12

PSI minimum.

11S. Tank Replacement

The tank can be replaced by disconnecting the

DHW coil as explained above and unbolting the lower

pump flange bolts. Access to the tank is possible by

removing the jacket lower front panel. This is done by

removing the screws that hold the panel at the base

and by cutting an aluminum pop rivet on each side at

the top approximately 2 inches down. These rivets

hold the lower front panel to the jacket back. A flat

bladed tool like a putty knife is ideal for this purpose.

Drive the blade down from the top in the crease

between the jacket back and the lower front panel.

This will cut the rivets. Remove the four screws that

hold the electrical box and move it aside. The lower

front panel may now be lifted up above the base and

removed. When the boiler is shipped from the factory

PRODUCTION

OUT OF

there are shipping bolts which hold the tank and the

base together. The installer was instructed to remove

these bolts before installing the boiler. If this was done

nothing will be holding the tank in place at this time

except the hydronic piping at the rear of the appliance.

Remove the supply and return connections and

remove the tank. Installation of the new tank is done

in the reverse order. If the tank alone is being replaced

it is easier to remove tank and coil together and

change the coil from the old tank to the new one when

both are free of the jacket.

SECTION 12.

Symptom Evaluations

12A. Delayed Ignition

Possible Causes - Time of occurrence

a. High lockups on LP - occurs on start-up.

b. Gas valve regulation problem - occurs on start-up.

c. Defective burner (flameholder) - occurs

primarily on burner shutdown

d. Natural gas orifice in LP unit - occurs on start-up

High lock up pressures on LP fuel systems are

the most common cause of delayed ignitions on H

Series boilers. The high LP supply pressure results

from improper second stage regulator selection or a

faulty regulator.

It can be detected by measuring the gas supply

pressure to the unit at the inlet pressure tap on the gas

valve. Use a water manometer or pressure gage with a

scale reading of at least 25 in. W.C. or 15 oz/in².

Install the pressure tap in the 1/8' NPTF plugged port

located above the gas inlet port on the gas valve. The

gas supply to the boiler must be shut off before

making this connection. The H Series boiler is