Page 1

Installation and Operation Instructions Document 1342H

Installation and Operation

Instructions for

THE

FT

Wall-Mounted, Modulating

Gas, Condensing, Heating Only, Boiler

Model FTHW

SERIES

80,000 BTU/hr

100,000 BTU/hr

120,000 BTU/hr

140,000 BTU/hr

199,000 BTU/hr

• Natural Gas (NG) - Factory Conguration

• Propane Gas (LP) - Field-Convertible

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in ue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ou ni

d’autres vapeurs ou liquides inammables dans

le à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dans le bâtiment où vous vous

trovez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié

ou par le fournisseur de gaz.

H2375000H

Page 2

TABLE OF CONTENTS

SECTION 1 Product Accessories

1.1 Introduction ...................................................... 3

1.2 Included with the Unit ....................................... 3

SECTION 2 Product Characteristics

2.1 Model Nomenclature (model number) ..............4

2.2 Specications, 80 MBH and 100 MBH ............. 5

2.3 Dimensions ...................................................... 8

2.4 Names of Components .................................. 10

2.5 Product Flow Paths and Characteristics ........ 13

4.14.7 Multiple units using zones pumps

and an indirect for DHW

4.15 Pressure Relief Valve ..................................... 47

4.16 Disposal of Condensate ................................. 48

4.17 Electrical Wiring Connections ........................ 49

4.18 DIP Switches .................................................. 50

4.19 Control Board, Electrical Diagram ................. 51

4.20 Ladder Diagram ............................................. 52

4.21 Electrical Connections .................................... 53

................................ 46

SECTION 3 Safety Regulations

3.1 Safety Symbols .............................................. 14

3.2 Safety Precautions and Proper Use ............... 16

SECTION 4 Installation

NOTE: For Cascading Installations, please refer to

document 1349 ‘Cascading the FT Series Boiler’,

available online.

4.1

4.1 Location and Clearances ............................... 17

4.2 Wall Mount Bracket ........................................ 18

4.3 Combustion Air ...............................................19

4.4 Venting (Exhaust) ...........................................21

4.5 General Location Guideline ............................22

4.6 Locations for Vent Pipe Terminator ................ 23

4.6.1 Direct Venting Clearances ............................. 23

4.6.2 Venting Requirements in

the Commonwealth of Massachusetts ........... 24

4.7 Air Supply and Vent Connections ................... 26

4.7.1 Vent / Air Pipe Lengths ................................... 26

4.7.2 Direct Venting ................................................. 26

4.7.3 Indoor Combustion Air ................................... 27

4.8 Vent / Air Pipe Termination ............................. 27

4.9 Gas Supply and Piping ................................... 30

4.10 Gas Supply Pressure ..................................... 35

4.11 Gas Setup and Adjustment ............................ 36

4.12 High Altitude Installations. ........................... 37

4.13 Natural Gas to Propane Conversion ........... 38

4.14 Plumbing Guidelines ..................................42

4.14.1 External Plumbing and

Water Connection Guidelines ......................... 42

4.14.2 Applicable Backow Preventer ....................... 42

4.14.3 Diaphragm type Expansion tank .................... 42

4.14.4 Zoning with zone valve ................................... 43

4.14.5 Zoning with circulation pumps ........................ 44

4.14.6 Indirect Water Heating .................................... 45

SECTION 5 Control Display and Operation

5.1 Control Dial and Buttons ................................ 55

5.2 LCD Overview ............................................... 56

5.3 Operating Mode ............................................. 57

5.4 Setting the Clock ............................................ 58

5.5 CH Set Point Change Mode ........................... 59

5.6 Status Display Mode ...................................... 60

5.7 Installer Mode ................................................. 61

5.8 Storage Mode ................................................ 64

5.9 Outdoor Reset Adjustment ............................. 65

5.10 External Set Point Temperature Control ......... 65

5.11 Error Mode ..................................................... 66

SECTION 6 Error Codes

6.1 Error Code Table ............................................ 67

6.2 Fault Tree Analysis ........................................ 70

SECTION 7 Trouble Shooting

7.1 Diagnostics ..................................................... 72

7.2 Suggested Corrective Actions ........................ 73

SECTION 8 Maintenance

8.1 Annual startup & general maintenance .......... 75

8.2 Flushing the Boiler ......................................... 77

8.3 Freeze Protection ........................................... 77

SECTION 9 Installation Check

9.1 Quick View ..................................................... 78

9.2 Final Check Lists ............................................ 79

SECTION 10 Parts

10.1 Parts Lists & Illustrations (models 080-140) ... 80

10.2 Parts Lists & Illustrations (model 199) ............ 86

Page 3

The FT Series Heating Only, Boiler

SECTION 1 Product Accessories

1.1 Introduction

This manual provides information necessary for the

installation, operation, and maintenance of the FT Series

Heating Only , Boiler. All application and installation

procedures must be read and reviewed completely before

proceeding with the installation. Consult the manufacturer

(see the back cover), or your local manufacturer’s

representative, with any problems or questions regarding

this equipment. Experience has shown that most operating

problems are caused by improper installation.

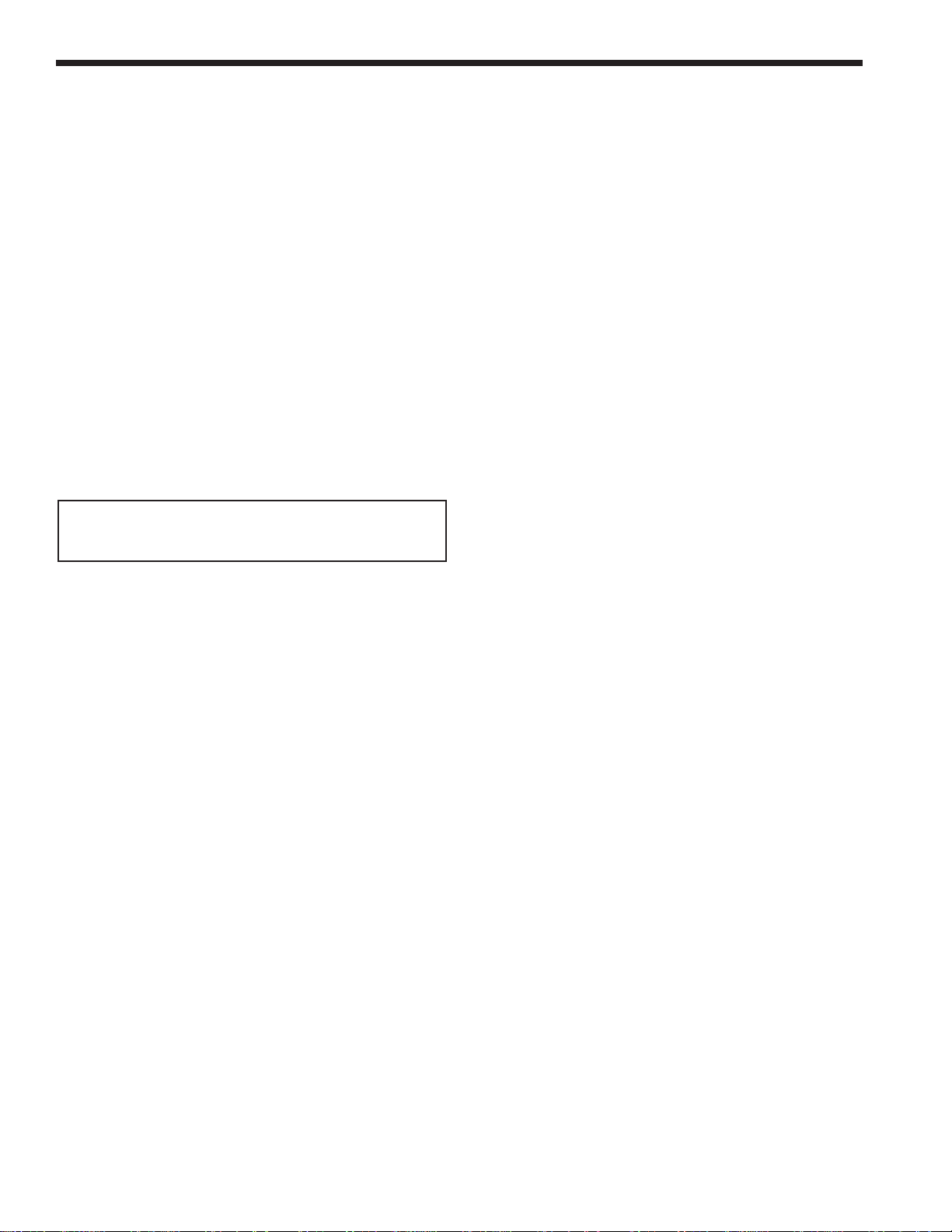

1.2 Included with the Unit

Item Description Qty

Page 3

All installations must be made in accordance with

1) American National Standard Z223.1/NFPA54-Latest Edition

“National Fuel Gas Code” or

2) CSA B149.1 “Natural Gas and Propane Installation Code” and

with the requirement of the local utility or other authorities having

jurisdiction. Such applicable requirements take precedence over

the general instructions contained herein.

All electrical wiring is to be done in accordance with the local

codes, or in the absence of local codes, with: 1) The National

Electrical Code ANSI/NFPA No. 70-latest Edition, or 2) CSA

STD. C22.1 “Canadian Electrical Code - Part 1”. This appliance

must be electrically grounded in accordance with these codes.

Wall Mounted Boiler

FTHW (all sizes)

Installation Instructions and

User’s Manual

Condensate Hose

Wall Mount Bracket

2 types of Wall Anchors

1

1

1

FT1894

4

4

1

Pressure Relief Valve

(CH LINE 3/4

˝

30psi)

Model: CASH ACME F-82

Mesh Screens

3”

1

2

Page 4

Page 4

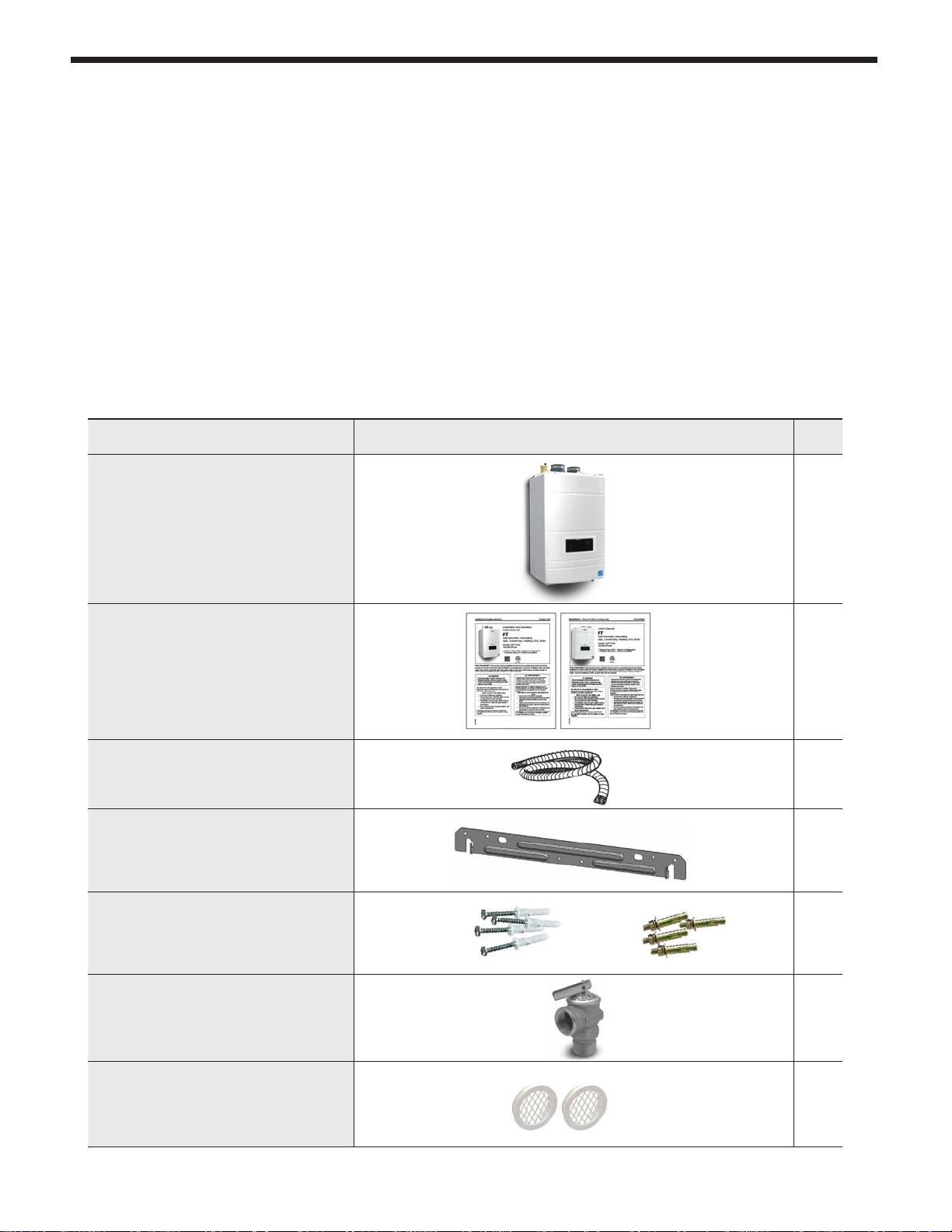

1.2 Included with the Appliance (continued)

Items Descriptions Qty

Propane Conversion Orice

80 / 100 / 120 / 140 MBH

O-Ring and Gasket Kit 1

Outdoor Temperature Sensor

with anchors and screws

Auto Fill Valve and Backow Preventer Valves are NOT

included (Field Supplied).

199 MBH

1

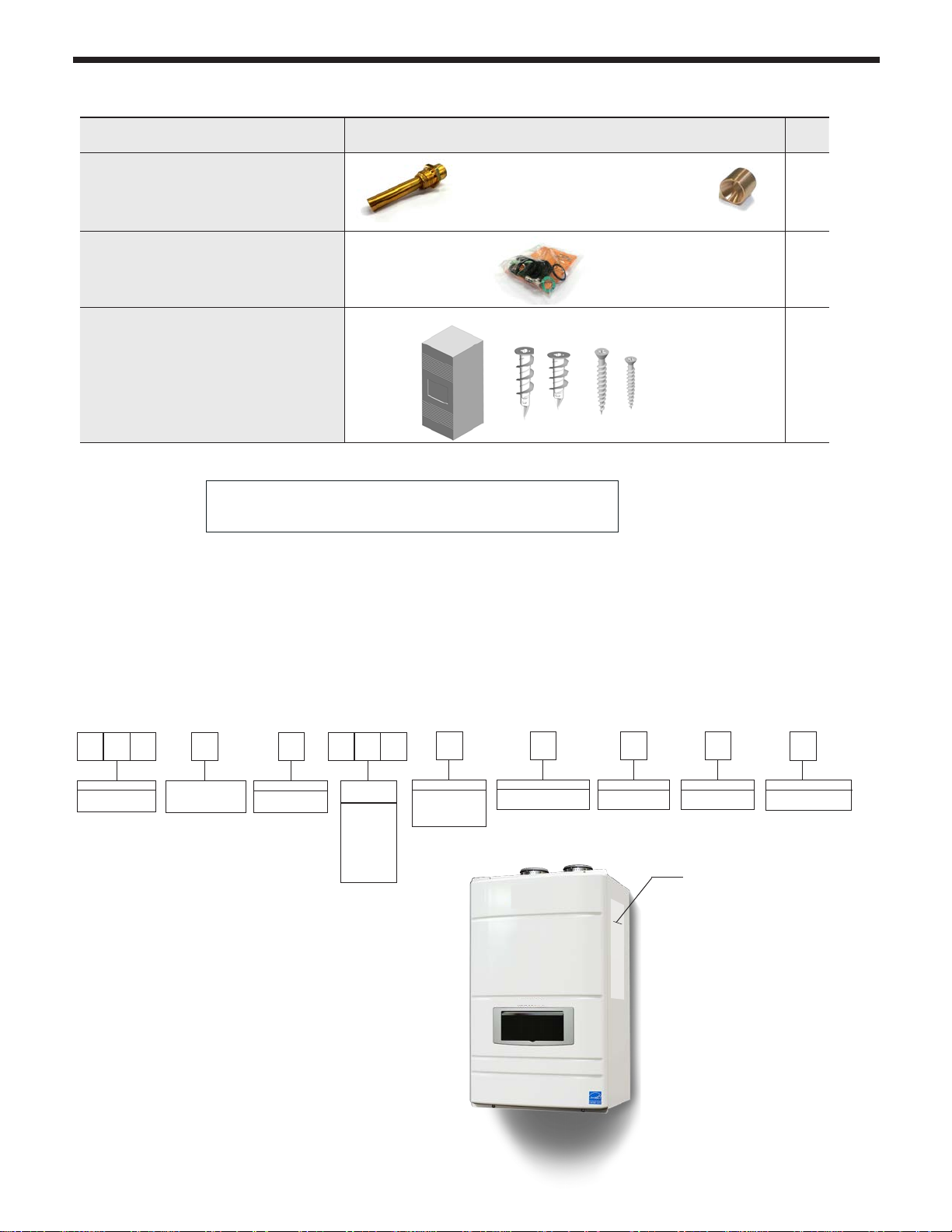

SECTION 2 Product Characteristics

2.1 Model Nomenclature (model number)

The Model Nomenclature is shown on your Rating Plate and consists of a series of letters and numbers

( Nomenclature ) that further identies the characteristics of your FT.

2 3 4 5 6 7 8 9 10 11 12 13

1

F T H W A 1 X N

M

SERIES

FT

H - Heating Only

CONFIG

W - Wall Hung

SIZE

MBTU/h

80

100

120

140

199

FUEL

N - Natural

P - Propane

ALTITUDE

A -

0 -10,000 Feet

REVISION

1 -

First

OPTIONS

X - Standard

MODEL NUMBER

N - with Pump

PUMP

Page 5

The FT Series Heating Only, Boiler

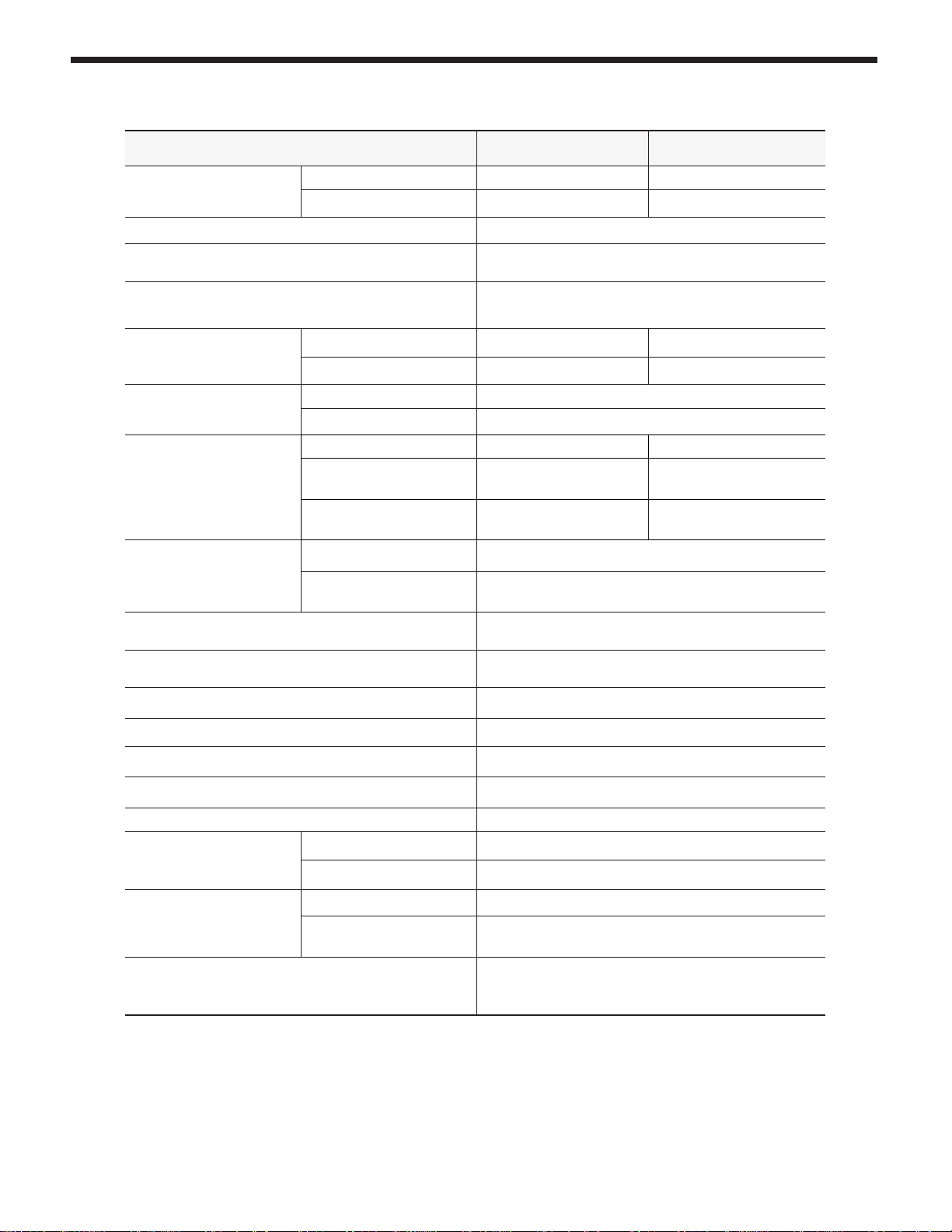

2.2 Specications, 80 MBH and 100 MBH

Model Name FTHW80 FTHW100

Page 5

Gas Input Rate

Installation Indoor / Wall hung type

Flue System

Vent Run 2˝(50ft*) , 3˝(100ft) Schedule 40 CPVC, PP

Orice Size

Gas Supply Pressure

Manifold Pressure

Power Supply

Ignition System

Burner System

MAX 80,000 Btu/h 100,000 Btu/h

MIN 16,000 Btu/h 20,000 Btu/h

Sealed Combustion Direct / Single Vent /Sidewall

NG 0.2”(5.05mm) 0.215˝ (5.45mm)

LP 0.157”(4.0mm) 0.169˝ (4.3mm)

NG 3.5˝ WC to 10.5˝ WC

LP 8.0˝ WC to 13.0˝ WC

Gas type LP NG

Max re

Min re

Main Supply 120V 60Hz / 4A

Maximum Power

Consumption

-0.102

˝

WC -0.102˝ WC

0.00

˝

WC 0.00˝ WC

Direct Electronic Ignition / Automatic Flame

Single Orice Premixed Fuel Modulation Metal

Vent

160W

Sensing

Ceramic Infrared

Gas Valve System Combination modulating (Current proportional)

Dimensions W17.3˝ - H29.0˝ – D14.9˝

Shipping Weight

Main Controller / Control Display NGTB-900CP / P-950EH

Water Pressure CH Min 15 ~ Max 30 PSI

CH Supply/Return 1 ¼˝ NPT

Connection Sizes

Gas Inlet 3/4˝ NPT

Casing Cold Rolled Carbon Steel

Materials

Heat Exchanger

Safety Devices

*Allowable 2” vent length for propane is 25’

98 lbs (44 kg)

Primary Heat Exchanger : Stainless Steel

Sub Heat Exchanger : Stainless Steel

Flame Rod, Overheat Cut Off Device, Gas Valve

Operation Detector, Water Temperature Sensor,

Over-heat Limit Switch,

Page 6

Page 6

2.2 Specications, 125 MBH and 140 MBH

Model Name FTHW120 FTHW140

Gas Input Rate

Installation Indoor / Wall hung type

Flue System

Vent Run 2˝(50ft*) , 3˝(100ft) Schedule 40 CPVC, PP

Orice Size

Gas Supply Pressure

Manifold Pressure

Power Supply

Ignition System Direct Electronic Ignition / Automatic Flame Sensing

MAX 120,000 Btu/h 140,000 Btu/h

MIN 24,000 Btu/h 28,000 Btu/h

Sealed Combustion Direct / Single Vent /Sidewall

NG 0.213˝ (5.4mm) 0.255˝ (6.5mm)

LP 0.173˝ (4.4mm) 0.191˝ (4.85mm)

NG 3.5˝ WC to 10.5˝ WC

LP 8.0˝ WC to 13.0˝ WC

Gas type LP NG

Max re

Min re

Main Supply 120V 60Hz / 4A

Maximum Power

Consumption

-0.216

˝

WC -0.216˝ WC

0.00

˝

WC 0.00˝ WC

Vent

160W

Burner System

Gas Valve System Combination modulating (Current proportional)

Dimensions W17.3˝ - H29.0˝ – D14.9˝

Shipping Weight 102 lbs (46 kg)

Main Controller / Control Display NGTB-900CP / P-950EH

Water Pressure CH Min 15 ~ Max 30 PSI

CH Supply/Return 1 ¼˝ NPT

Connection Sizes

Gas Inlet 3/4˝ NPT

Casing Cold Rolled Carbon Steel

Materials

Heat Exchanger

Safety Devices

*Allowable 2” vent length for propane is 25’

Single Orice Premixed Fuel Modulation Metal

Ceramic Infrared

Primary Heat Exchanger : Stainless Steel

Sub Heat Exchanger : Stainless Steel

Flame Rod, Overheat Cut Off Device, Gas Valve

Operation Detector, Water Temperature Sensor,

Over-heat Limit Switch,

Page 7

The FT Series Heating Only, Boiler

2.2 Specications, 199 MBH

Model Name FTHW199

Page 7

Gas Input Rate

Installation Indoor / Wall hung type

Flue System Sealed Combustion Direct / Single Vent / Concentric Vent

Vent Run 2˝(50ft*) , 3˝(100ft) Schedule 40 CPVC, PP

Orice Size

Gas Supply Pressure

Manifold Pressure

Power Supply

Ignition System Direct Electronic Ignition / Automatic Flame Sensing

MAX 199,000 Btu/h

MIN 19,900 Btu/h

NG 0.326˝ (8.3mm)

LP 0.244˝ (6.2mm)

NG 3.5˝ WC to 10.5˝ WC

LP 8.0˝ WC to 13.0˝ WC

Gas type

Max re

Min re

Main Supply 120V 60Hz / 4A

Maximum Power

Consumption

LP NG LP NG

-0.169

˝

WC -0.129”W.C -0.173˝ WC -0.134˝ WC

-0.015”W.C -0.015”W.C -0.015

160W

˝

WC -0.015˝ WC

Burner System

Gas Valve System Combination modulating (Current proportional)

Dimensions W19.6˝ - H32.0˝ – D16.2˝

Shipping Weight 118 lbs (54 kg)

Main Controller / Control Display NGTB-900CP / P-950EH

Water Pressure Min 15 ~ Max 30 PSI

Connection Sizes

Materials

Safety Devices

CH Supply/Return 1 ¼˝ NPT

Gas Inlet 3/4˝ NPT

Casing Cold Rolled Carbon Steel

Heat Exchanger

Detector, Water Temperature Sensor, Over-heat Limit Switch,

*Allowable 2” vent length for propane is 25’

Single Orice Premixed Fuel Modulation Metal Ceramic

Infrared

Primary Heat Exchanger : Stainless Steel

Sub Heat Exchanger : Stainless Steel

Flame Rod, Overheat Cut Off Device, Gas Valve Operation

Page 8

Page 8

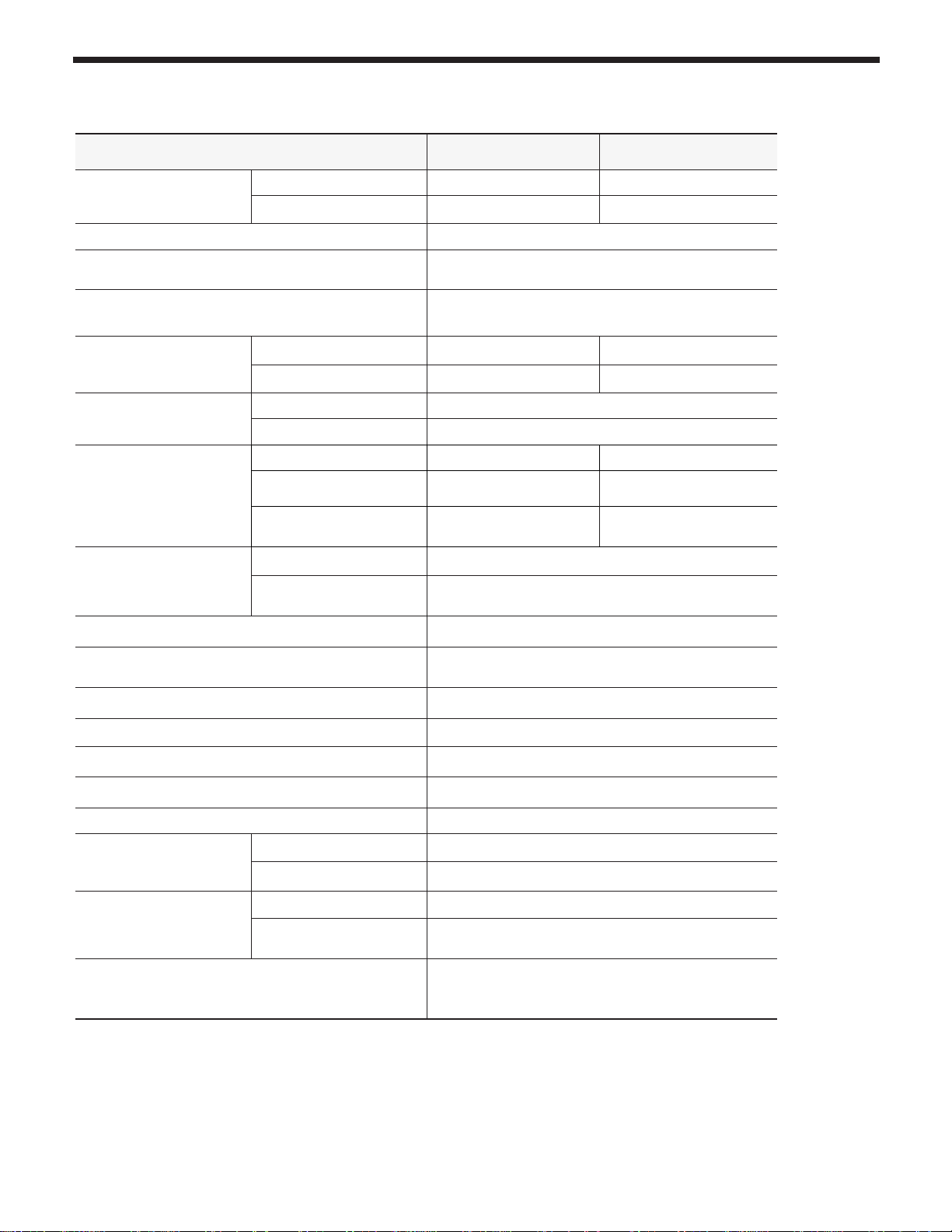

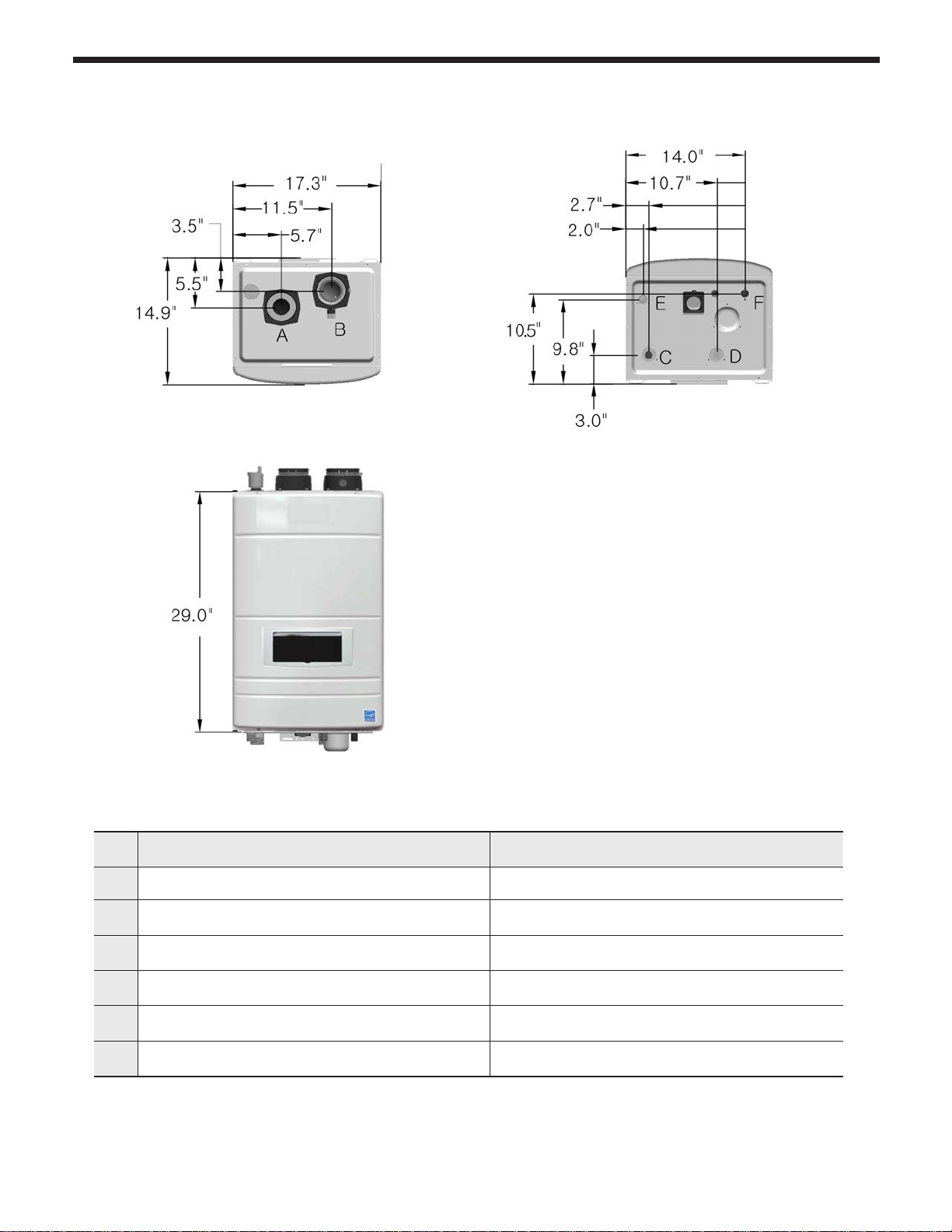

2.3 Dimensions

FTHW

80/100/120/140

Heating only boiler

Description Diameter

A Air Intake Collar 3˝

B Vent Pipe Collar 3˝

C 'CH' Supply

D 'CH' Return

E Gas Inlet 3/4˝

F Condensate Line 1/2˝

1

1

¼˝

¼˝

Page 9

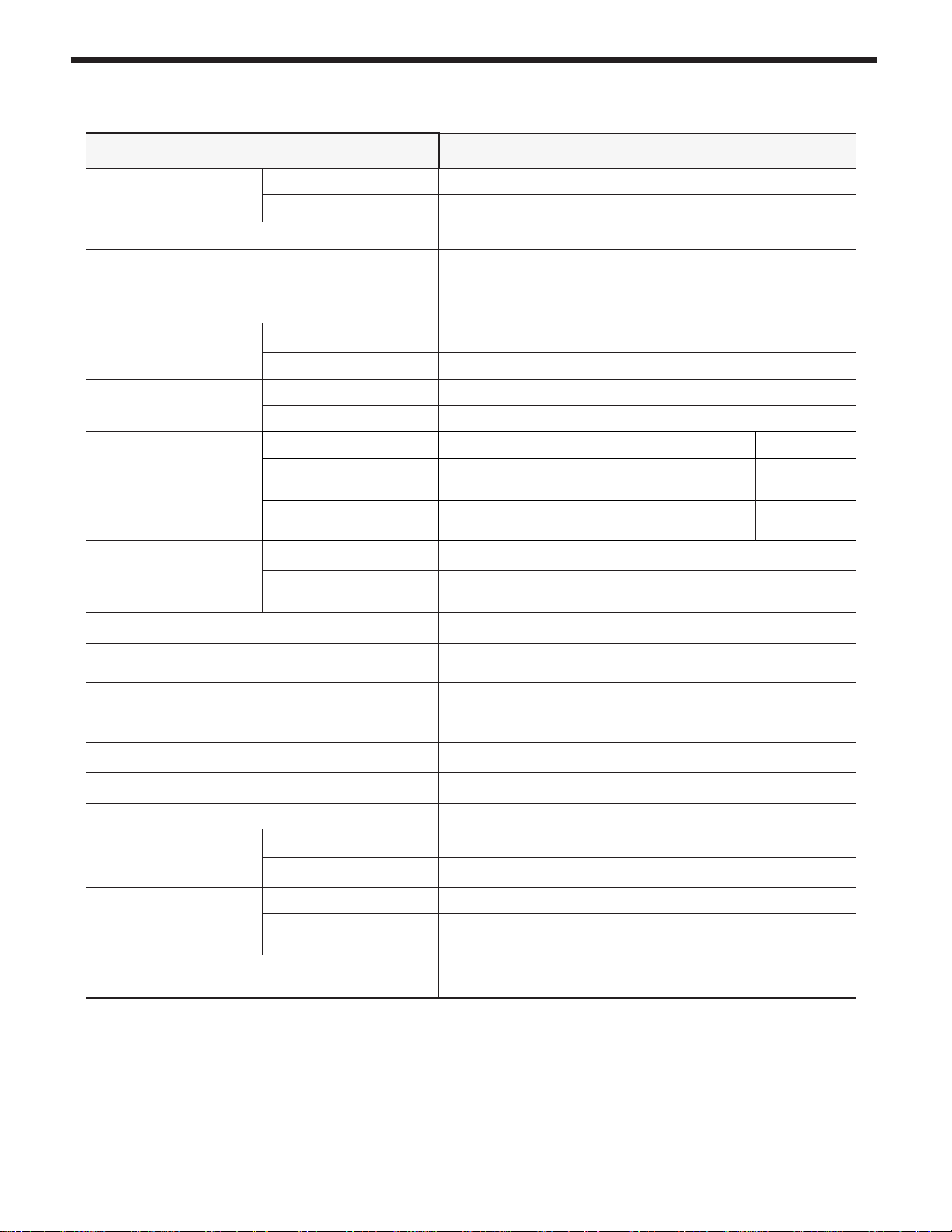

The FT Series Heating Only, Boiler

2.3 Dimensions

Page 9

FTHW

Heating only boiler

199

Description Diameter

A Air Intake Collar 3˝

B Vent Pipe Collar 3˝

C 'CH' Supply

D 'CH' Return

E Gas Inlet 3/4˝

F Condensate Line 1/2˝

1

1

¼˝

¼˝

Page 10

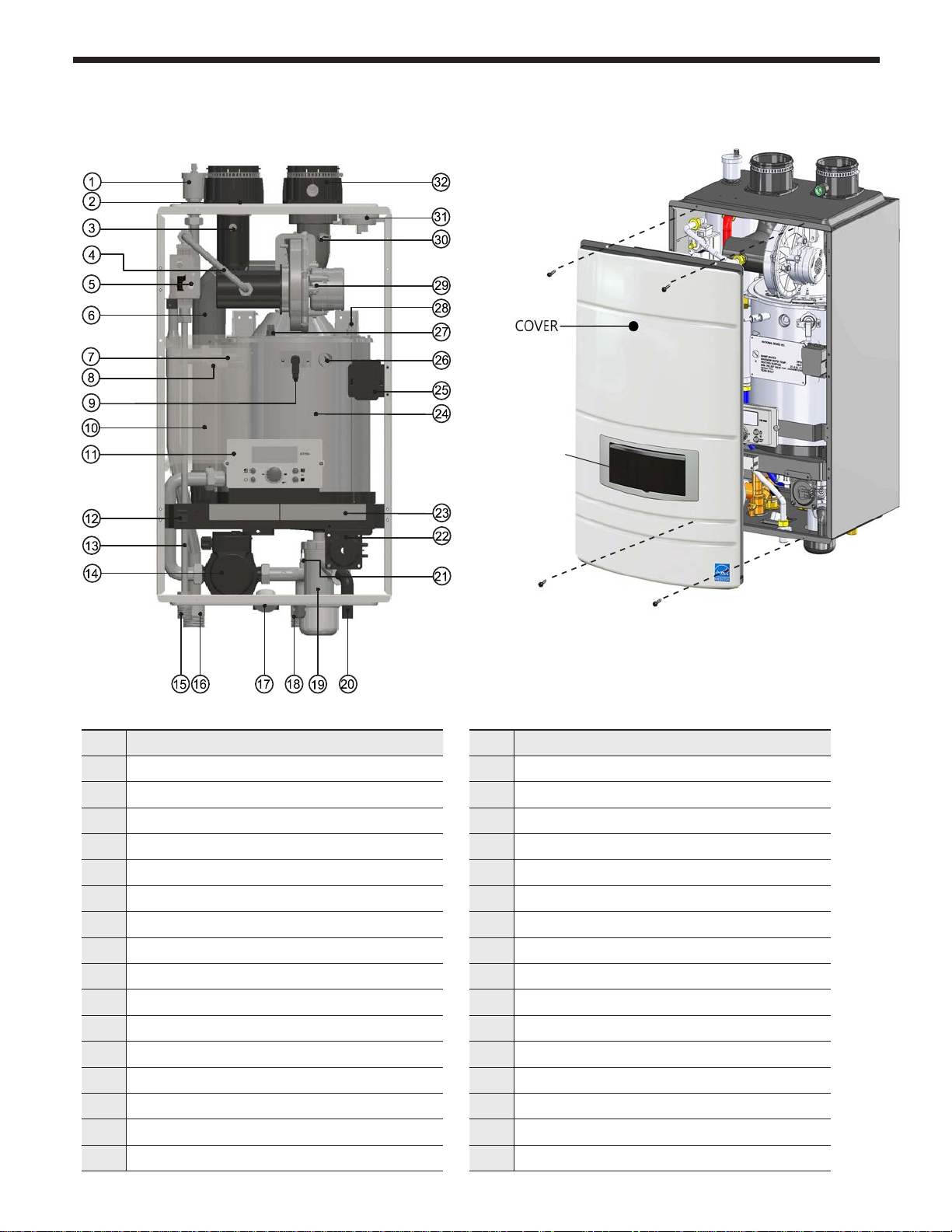

Page 10

2.4 Names of Components

FTHW

80/100

Heating only boiler

4 SCREWS

CONTROL

DISPLAY COVER

(HINGES UPWARD)

NO Name of Component

1

Air Vent (air eliminator)

2

Air Intake Collar

3

Air / Gas Mixing Pipe

4

Gas Inlet Pipe 2

5

Gas Valve

6

Exhaust Duct

7

Low Water Temperature Sensor

8

OP Sensor

9

Flame Detecting Sensor

10

Main PCB

11

Control Display

12

Manual ON/OFF Power Switch

13

Gas Inlet Pipe 1

14

‘CH’ Internal Pump

15

Gas Inlet Adapter

16

‘CH’ Supply Adapter

To remove the cover, unthread the 4 phillips head screws.

Keep the screws in a safe place for re-application of cover.

This is typical for all models of the FT.

NO Name of Component

17

CH Pressure Gauge

18

‘CH’ Return Adapter

19

Condensate Trap

20

Condensate Adapter

21

CH Return Temperature Sensor

22

Condensate Air Pressure Switch

23

Terminal Block

24

Heat Exchanger

25

Ignition Transformer

26

Sight Glass

27

Burner Overheat Switch

28

Igniter

29

BLDC Fan (blower)

30

Exhaust Temperature Sensor

31

Air Pressure Sensor

32

Vent Pipe Collar

Page 11

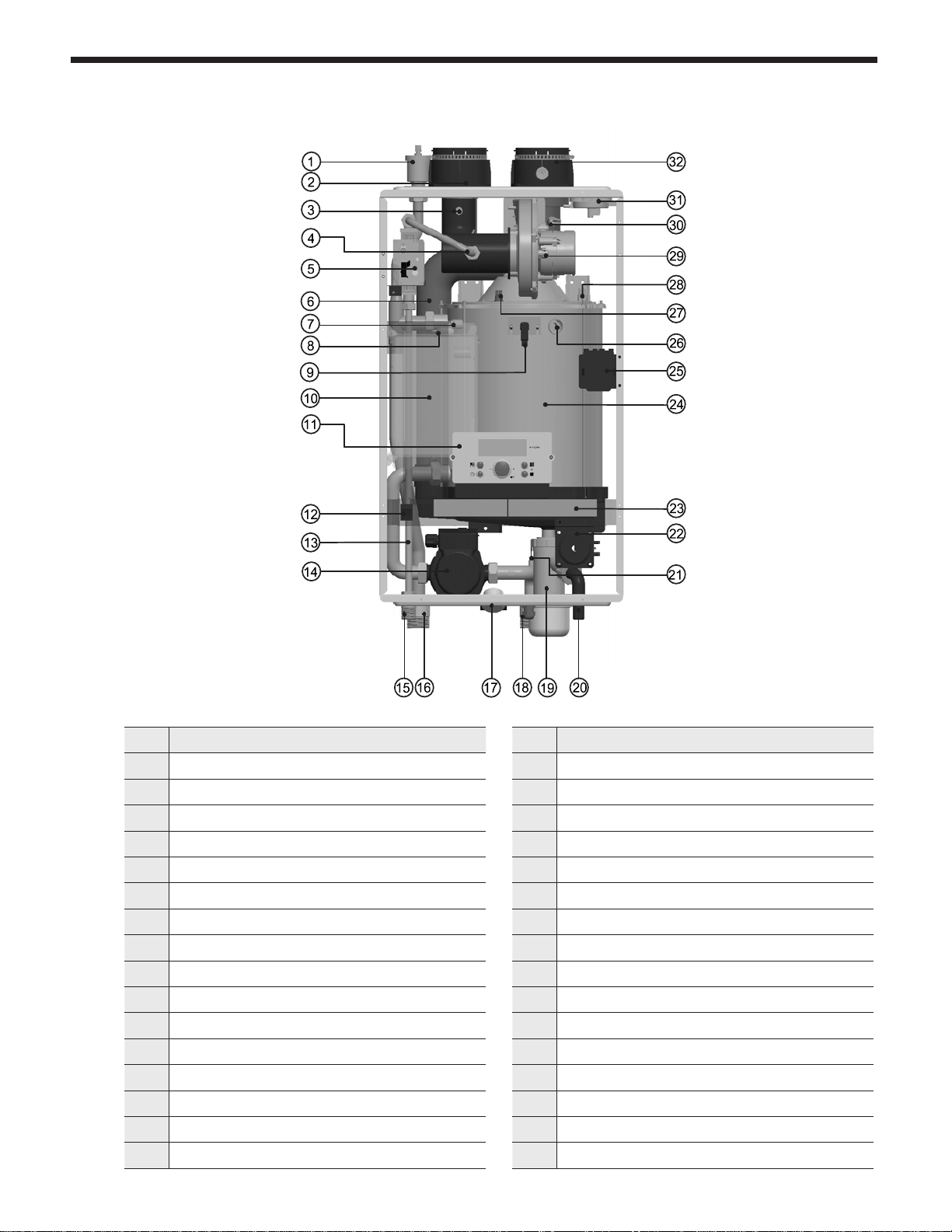

The FT Series Heating Only, Boiler

2.4 Names of Components (continued)

Page 11

FTHW

120/140

Heating only boiler

NO Name of Component

1

Air Vent (air eliminator)

2

Air Intake Collar

3

Air / Gas Mixing Pipe

4

Gas Inlet Pipe 2

5

Gas Valve

6

Exhaust Duct

7

Low Water Temperature Sensor

8

OP Sensor

9

Flame Detecting Sensor

10

Main PCB

11

Control Display

12

Manual ON/OFF Power Switch

13

Gas Inlet Pipe 1

14

‘CH’ Internal Pump

15

Gas Inlet Adapter

16

‘CH’ Supply Adapter

NO Name of Component

17

CH Pressure Gauge

18

‘CH’ Return Adapter

19

Condensate Trap

20

Condensate Adapter

21

CH Return Temperature Sensor

22

Condensate Air Pressure Switch

23

Terminal Block

24

Heat Exchanger

25

Ignition Transformer

26

Sight Glass

27

Burner Overheat Switch

28

Igniter

29

BLDC Fan (blower)

30

Exhaust Temperature Sensor

31

Air Pressure Sensor

32

Vent Pipe Collar

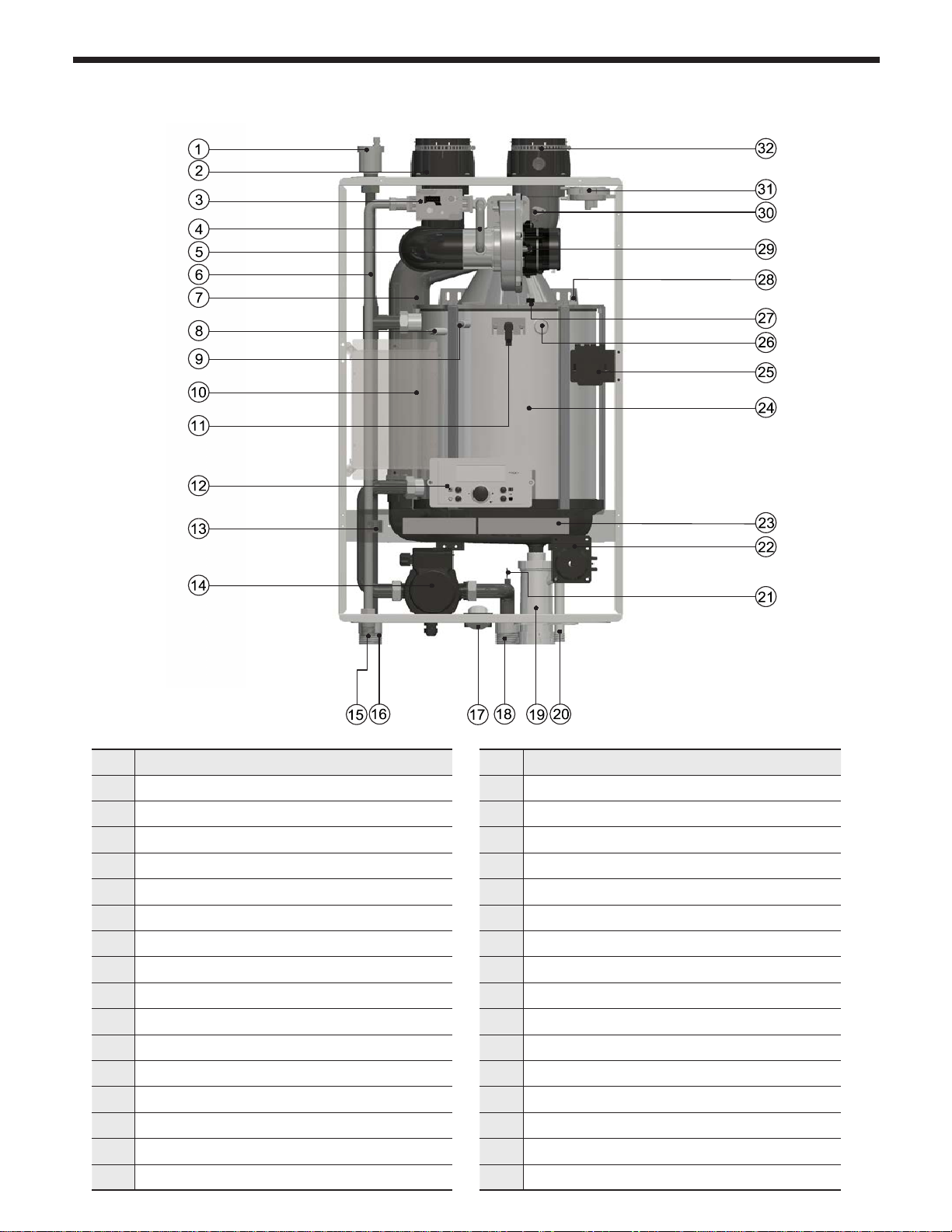

Page 12

Page 12

2.4 Names of Components (continued)

FTHW

Heating only boiler

199

NO Name of Component

1

Air Vent (air eliminator)

2

Air Intake Collar

3

Gas Valve

4

Gas Inlet Pipe 2

5

Air / Gas Mixing Pipe

6

Gas Inlet Pipe 1

7

Exhaust Duct

8

OP Sensor

9

Low Water Level Sensor

10

Main PCB

11

Flame Detecting Sensor

12

Control Display

13

Manual ON/OFF Power Switch

14

‘CH’ Internal Pump

15

Gas Inlet Adapter

16

‘CH’ Supply Adapter

NO Name of Component

17

CH Pressure Gauge

18

‘CH’ Return Adapter

19

Condensate Trap

20

Condensate Adapter

21

CH Return Temperature Sensor

22

Condensate Air Pressure Switch

23

Terminal Block

24

Heat Exchanger

25

Ignition Transformer

26

Sight Glass

27

Burner Overheat Switch

28

Igniter

29

BLDC Fan (blower)

30

Exhaust Temperature Sensor

31

Air Pressure Sensor

32

Vent Pipe Collar

Page 13

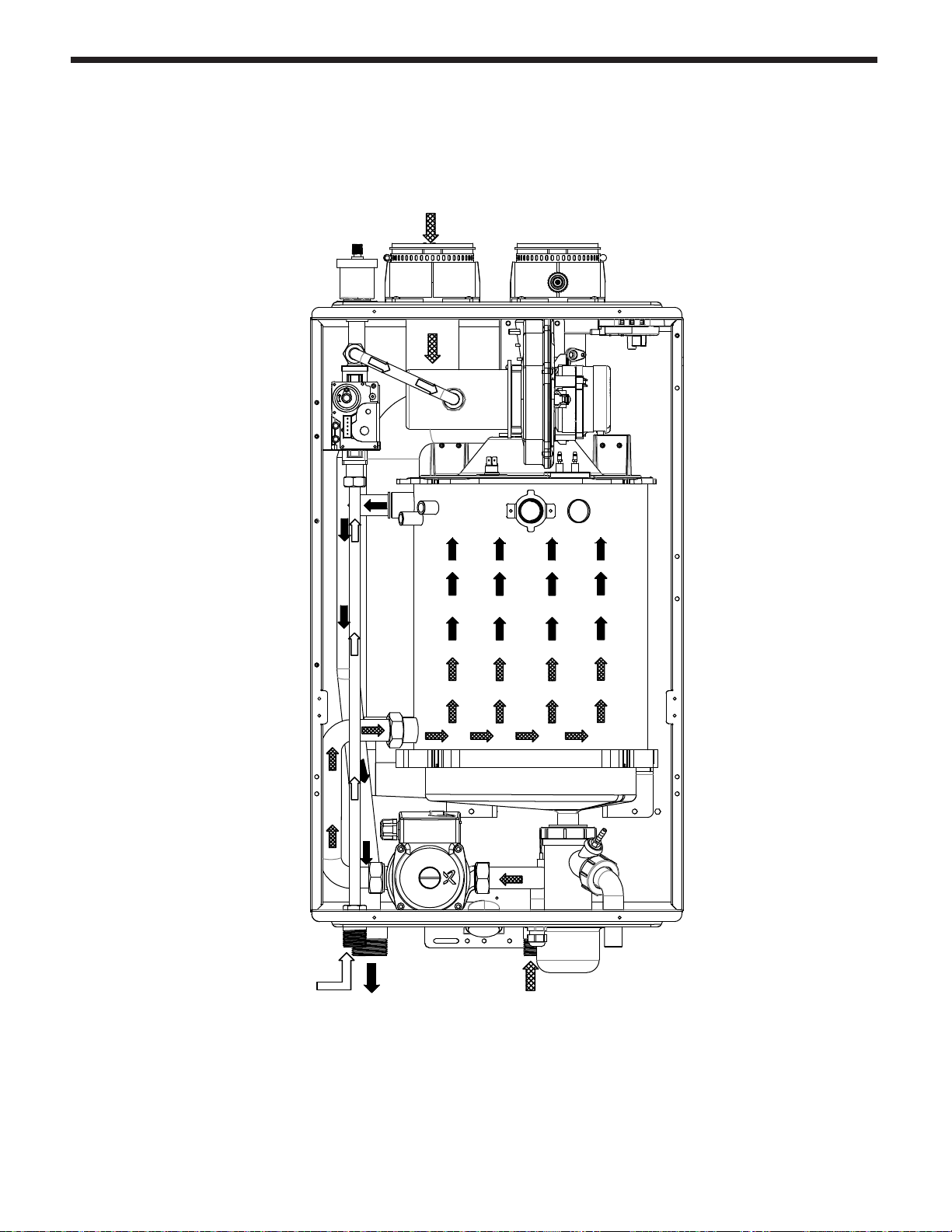

The FT Series Heating Only, Boiler

Gas

Input

Air Intake

2.5 Product Flow Paths and Characteristics

Water in the heating pipe is used for space heating.

Combustion

Air

Page 13

Vent

CH Supply CH Return

CH = Central Heat

Page 14

Page 14

SECTION 3 Safety Regulations

3.1 Safety Symbols

WARNING

To avoid product damage, personal injury, or even

possible death, carefully read, understand, and

follow all the instructions in the Installation and

Operation manual before installation, operation

and service the Boiler.

Manufacturer cannot anticipate every

circumstance that might involve a potential

hazard. Therefore, all possible incidents are not

included in our warnings. Proper installation,

operation, and service are your responsibility.

You must make sure that the operation and

settings of the Boiler are safe for you and for

others.

This manual provides Safety Symbols. When the

user fails to adhere to the following requirement,

it may cause death, serious injury, and substantial

property damage.

For safety symbols, ‘DANGER’, ‘WARNING’,

CAUTION’ are indicated and the denitions for these

terms are as follow:

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION

WARNING

FOR YOUR SAFETY READ BEFORE

OPERATING

If you do not follow these instructions exactly, a

re or explosion could result causing property

damage, personal injury or loss of life.

A. This appliance does not have a pilot. It

is equipped with an ignition device which

automatically lights the burner. Do not try to

light the burner by hand.

B. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next

to the oor because some gas is heavier than

air and will settle on the oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

re department.

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will

not push in or turn by hand, don’t try to repair

it, call a qualied service technician. Force

or attempted repair may result in a re or

explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a qualied

service technician to inspect the appliance and

to replace any part of the control system and

any gas control which has been under water.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury. It is also used to alert against

unsafe practices and hazards involving only

property damage.

WARNING

Cancer and Reproductive Harm.

www.P65WARNINGS.CA.GOV.

as required by the state of California Proposition 65.

This appliance must be installed in accordance with

local codes if any; if not, follow ANSI Z224.1/NFPA

54 or CAN/CSA B149.1, Natural Gas and Propane

Installation Code, as applicable.

This appliance is certied for use at altitudes up

to 4,500ft(1,370m) in accordance to the latest CSA/

CGA 2.17-M91 Gas-Fired Appliances for Use at

High Altitudes.

Page 15

The FT Series Heating Only, Boiler

DANGER

Vapors from ammable liquids will explode and

catch on re. These will cause death or severe

burns.

Do not use or store ammable products such as

gasoline, solvents or adhesives in the same room

or area near the appliance.

Keep ammable products

Far away from boiler

In approved containers

Tightly closed

Out of children’s reach

Vapors

Cannot be seen

are heavier than air

spread on the oor

Can spread from other rooms to the main burner

by air currents

Do not install the appliance where ammable

products will be stored.

Read and follow boiler warnings and instructions

thoroughly. If owner’s manual is missing, contact

the retailer or manufacturer.

This boiler must be installed by a qualied plumber,

a licensed gas tter, and/or a professional service

technician.

Improper installation and/or operation will cause a

potentially hazardous situation, such as serious injury

or death. Also, it will void the warranty.

• The National Fuel Gas Code NFPA 54 / ANSI Z224.1

• National Electric Code ANSI/NEPA 70

• All applicable local, state, national and provincial

codes, regulations and laws.

Proper care is your responsibility. Carefully read and

understand the Operating Information in this manual

before operating the Manufacturer Boiler.

Be aware of the location of the gas shut-off valve

and operation method. Close the gas shut-off valve

immediately if the appliance is subjected to re,

overheating, ood, physical damage, or any other

Page 15

damaging condition that might affect the operation

of the unit. Boiler must be checked by a qualied

technician before resuming operation.

DO NOT use this Boiler if any part has been under

water. Immediately call a qualied technician for

inspecting the Boiler and replacing any part of the

control system and gas control which have been

under water.

Do not power up the unit until the gas and water

supply valves are fully opened. Make sure that the

fresh air intake port and exhaust gas port are opened

and functional.

DO NOT attempt to install, repair, or service this

Boiler by yourself.

Do not change any part of the Boiler.

Contact a qualied technician if the Boiler needs

repair or maintenance.

Ask your gas supplier for a list of qualied service

providers.

DO NOT use spray paint, hair spray, or any other

ammable spray near Boiler or near the exterior fresh

air inlet port. DO NOT place any items in or around

the exterior exhaust gas outlet port and/or fresh air

inlet port. These could restrict or block the ow in or

out of the vent system.

“Caution: While repairing control, all wires are

labeled. You must connect the wires in accordance

with the instruction.

Wiring errors can cause improper and dangerous

operation.

“Verify proper operation after servicing operation”

This consists of the gas ignition system components

which are protected from water (dripping, spraying, rain,

etc.) during operation and service (circulator replacement,

condensate trap, control replacement, etc.).

After installing the heater, safety devices must be

tested.

This boiler is equipped with a blocked vent shutoff

system.

If the error code ‘41’ occurs, follow the instructions

below.

- First, turn off the manual gas valve.

- Make sure that there is no foreign object in the vent

passage or rodent screen.

- If you do not nd any problem, do the following.

- Turn off the error state by pressing the power button

of Control Display.

- If the error occurs repeatedly, call your service

technician or gas supplier.

Page 16

Page 16

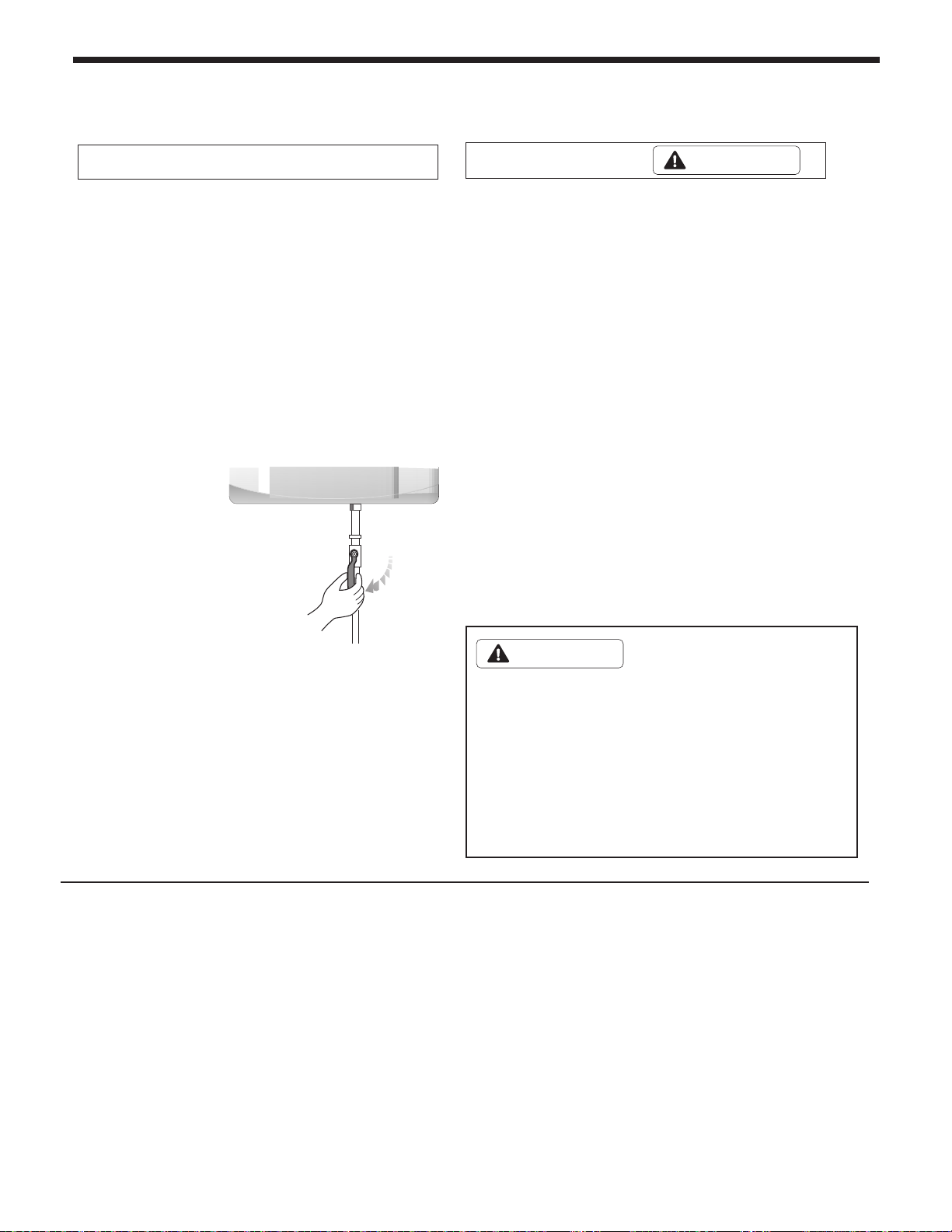

3.2 Safety Precautions and Proper Use

Before Operation

1. Check the Gas Type (NG/LP)

When using or moving the unit for the rst time, check

if gas type matches with the gas type of the Boiler.

Check whether the gas type which is supplied is NG

(Natural Gas) or LP (Propane) and also check the

Boiler gas type.

The gas type is indicated on the rating plate on side of

the Boiler.

2. Check the Power (120V 60Hz)

Check that the appliance is connected properly.

3. Check the Cold Water

Inlet valve

Please keep the

appliance water

inlet valve open

at all times. The

appliance will not ignite

when insufcient water

or no water is in the

heating pipes. (valve:

always open position)

open

When in Operation

1. Caution for Gas leak

Frequently check for a gas leak at the gas connection

portion with soapy water.

Steps to take if you have a Gas leak.

1. Shut down the boiler as soon as gas fumes are

detected.

2. Close the intermediate gas valve.

3. Open windows for ventilation.

4. Call a qualied service technician for immediate

repair.

2. Caution for Ventilation

Make sure that there is sufcient inow and outow of air

ventilation while using the unit.

If the ventilation is improper, combustion quality may

deteriorate inside the appliance and cause shortened life

of the appliance.

3. Burn Warning

Be careful not to burn yourself on the ue or pipes. They

become extremely hot during operation.

CAUTION

4. Check the Gas Valve

Check that the manual gas shut-off valve

that supplies the FT is opened.

5. Check the area around the appliance and remove

any combustible or ammable materials. Remove

laundry or any other items that are on or near the

boiler or vent pipe.

Carbon monoxide poisoning

If vent pipe fumes enter the room, it could cause

poisoning by carbon monoxide gas. Check that the

vent pipes are properly connected. Open windows

for ventilation. Call a qualied service technician for

immediate repair.

Gas leakage test.

Gas supply line must be inspected regularly.

WARNING

Do not use the appliance for any other purpose other

than for residential hydronic heating.

Do not store combustibles or ammable material such as

gasoline near the appliance.

Do not store other items on or near this boiler.

Do not store combustible (ammable) materials such as

papers.

Do not hang clothes on the vent pipe. This may start a

re.

Do not shut off the Boiler.

When you leave home for a long time, do not shut off

Boiler. The Boiler has a freeze protection function. The

ceramic heater is installed inside of the heater’s internal

pipe to protect the heater from freezing.

Do not wipe the appliance or Control Display

with wet cloth. Electric shock may occur, or internal

parts may fail due to the exposure to moisture.

Do not disassemble the Boiler.

If repair is required, call your local qualied technician.

Page 17

The FT Series Heating Only, Boiler

18

46

3

8

3

8

24

60

12

30

SECTION 4 Installation

Page 17

NOTE: For Cascading Installations, please refer

to document 1349 ‘Cascading the FT Series

Boiler’, available online.

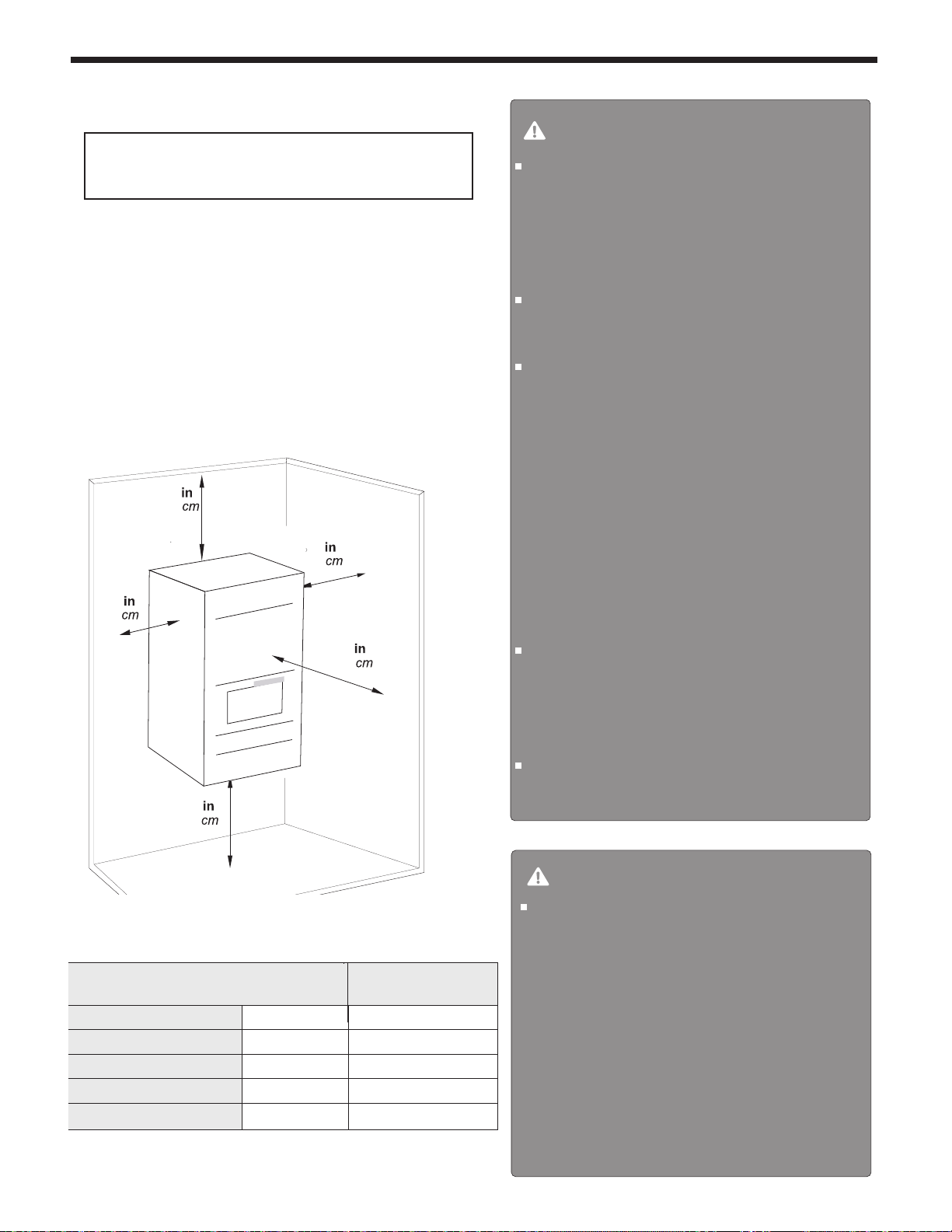

4.1 Location and Clearances

The FT must be mounted to a suitable wall by a

qualied heating contractor under the guidelines of a

boiler. The wall may be of concrete or wood. Suitable

fasteners for concrete or wood must be used. Failure to

wall mount this boiler using correct fasteners will affect

the performance and life expectancy of the boiler and

will void the warranty.

WARNING

Installations must comply with

• All the local, state, provincial, and national codes,

laws, regulations and ordinances.

• National Fuel Gas Code, ANSI Z223.1 – The latest

version.

• National Electrical Code.

• A National Standard of Canada CAN/CSA-B149.1

Check before placing the Boiler

• Always check the connected components which are

near to the heater. The components are below.

Water piping position / Venting adapter / Gas supply

piping / Electrical power / Condensate drain hose.

• Inspect area around Boiler. Remove any combustible

materials, gasoline and other ammable liquids.

Failure to keep Boiler area clear and free of

combustible materials, gasoline and other ammable

liquids and vapors can result in severe personal

injury, death or substantial property damage.

• The Boiler which has gas control system

components must be protected from any possible

danger during operation and service.

• If new Boiler replaces an existing appliance, check

and correct system problems, for example:

- Do not install if: System leaks causing oxygen

corrosion or heat exchanger cracks from hard water

deposits.

Provide clearances

• If the heater was installed in a narrow space

or corner, please ensure that there is sufcient

space for service and maintenance access. For

regular maintenance, gas and water lines must be

accessible.

The boiler must be installed on a wall that can bear its weight.

Minimum clearances to Combustibles.

For installation from

Non-Combustibles and Combustibles

Suggested Service

Clearance

TOP of appliance 18 in (46 cm) 18 in (46 cm)

BACK of appliance 0 in (0 cm) 0 in (0 cm)

FRONT of appliance 24 in (60 cm) 40 in (101 cm)

SIDE of appliance 3 in (7 cm) 8 in (20 cm)

BOTTOM of appliance 12 in (30 cm) 24 in (61 cm)

Table 1. Minimum Clearances

WARNING

CLEARANCES FOR SERVICE ACCESS

• If you do not provide the minimum clearances

shown, it might not be possible to service the

boiler without removing it from the space.

• Space must be provided with combustion /

ventilation air openings correctly sized for

all other appliances located in the same

space as the boiler. The boiler cover must be

securely fastened to prevent it from drawing

air from the boiler room. This is particularly

important if the boiler is in a room with other

appliances. Failure to comply with the above

warnings could result in substantial property

damage, severe personal injury, or death.

to Combustibles and for Service.

Page 18

Page 18

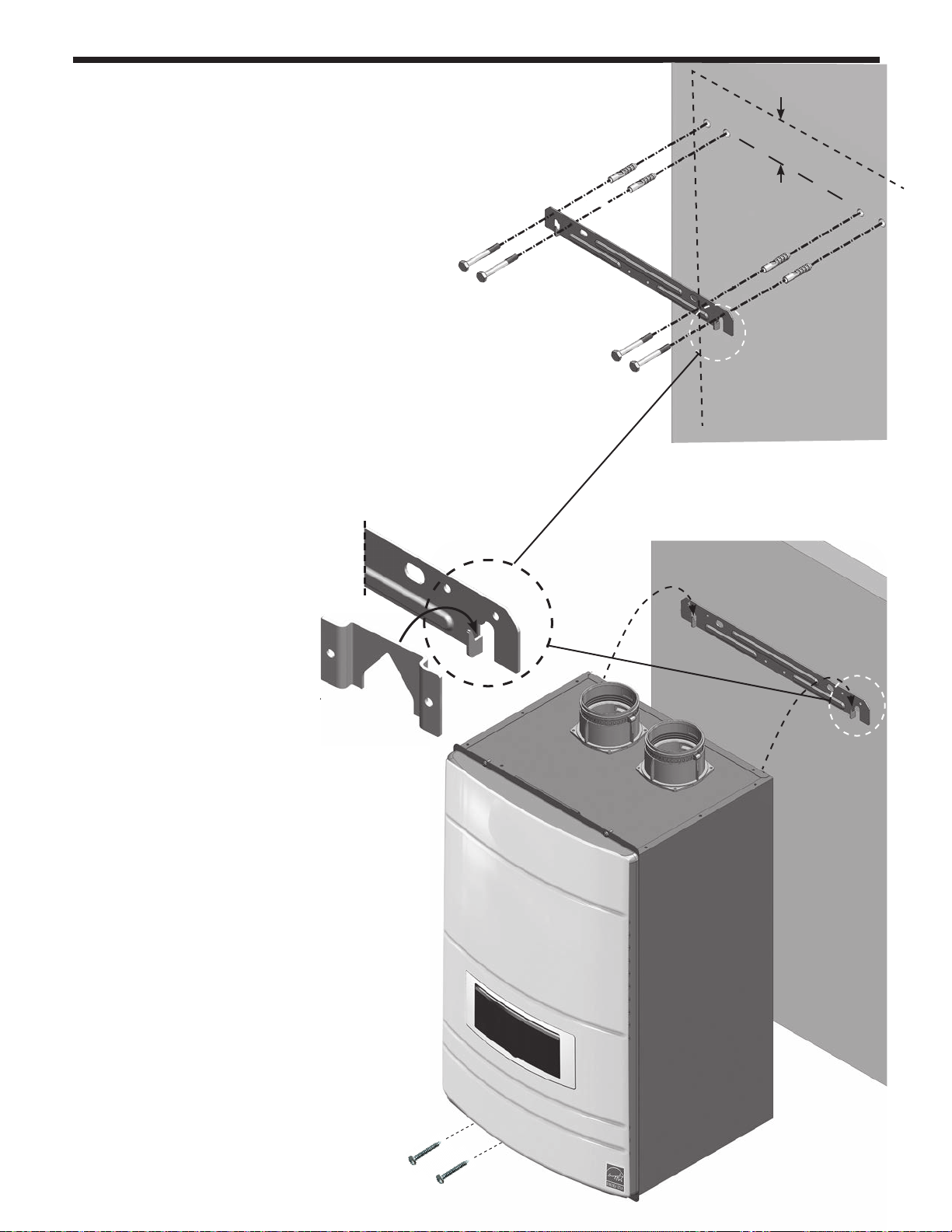

4.2 Wall Mount Bracket

4.2.2 The installation height and location

for your FT depends on your installation scenario. With all

clearances considered, and given adequate positioning for

air supply and venting, you will need to determine the best

position to mount the Wall Mount Bracket. The wall must

be concrete, wood, or plywood over studs, and must be

strong enough to hold the boiler!

• Start by familiarizing yourself to how the

included Wall Mount Bracket hooks underneath

the two Hangers that are attached to the back of

the boiler. The ‘hooks’ of the Wall Mount Bracket will

be 3” from the Top of the boiler once the boiler is hung.

• Position the Wall Mount Bracket at the location that it will go,

being sure that it is level, and then drill 4 holes (0.47”dia)

with a 1/2” drill bit, into the wall through the Bracket.

• If mounting to a concrete wall, then use the concrete

anchors. If onto wood or 5/8” (16 mm) plywood, then use

the wood screws. Do not hang the FT onto sheetrock unless

it is possible to fasten directly

into the structural studs. If the

included anchors do not suit

your installation, you must use

‘Field Supplied’ anchors that

are appropriate for the wall’s

construction.

Bolts (4)

Anchors

(4)

Wall Mount

Bracket

3" to Top

of Unit

*

Concrete,

Wood,

or 5/8" Plywood

Wall Mount

Bracket

Hangers (2)

(fastened to the back of unit)

4.2.1 Hang the Boiler

• Lift the boiler up, align the Hangers on the back

of the boiler with the hooks on the Wall Mount

Bracket, and hang the boiler onto the Wall Mount

Bracket. Do a visual inspection to make sure that

the boiler is hanging properly onto the hooks of

the Wall Mount Bracket.

• Fasten the bottom of the boiler to the wall using

2 suitable wall anchors (eld supplied).

Page 19

The FT Series Heating Only, Boiler

4.3 Combustion Air

Page 19

FT boilers must have provisions for combustion

and ventilation air in accordance with the applicable

requirements for Combustion Air Supply and Ventilation

in the National Fuel Gas Code, ANSI Z223 1; or in

Canada, the Natural Gas and Propane Installation Code,

CSA B149.1. All applicable provisions of local building

codes must also be adhered to.

A FT unit can take combustion air from the space

in which it is installed, or the combustion air can be

ducted directly to the unit. Ventilation air must be

provided in either case.

4.3.1 Combustion Air from Room

In the United States, the most common requirements

specify that the space shall communicate with the

outdoors in accordance with method 1 or 2, which follow.

Where ducts are used, they shall be of the same cross-

sectional area as the free area of the openings to which

they connect.

Method 1: Two permanent openings, one commencing

within 12” (300mm) of the top and one commencing

within 12” (300mm) of the bottom, of the enclosure

shall be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces

that freely communicate with the outdoors. When

directly communicating with the outdoors, or when

communicating to the outdoors through vertical ducts,

each opening shall have a minimum free area of 1

square inch per 4000 Btu/hr (550 square mm/kW) of

total input rating of all equipment in the enclosure. When

communicating to the outdoors through horizontal ducts,

each opening shall have a minimum free area of not

less than 1 square inch per 2000 Btu/hr (1100 square

mm/kW) of total input rating of all equipment in the

enclosure.

Method 2: One permanent opening, commencing

within 12” (300mm) of the top of the enclosure, shall

be permitted. The opening shall directly communicate

with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces

that directly communicate with the outdoors and shall

have a minimum free area of 1 square inch per 3000

Btu/hr (734 square mm/kW) of the total input rating of

all equipment located in the enclosure. This opening

must not be less than the sum of the areas of all vent

connectors in the conned space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform to

the requirements in the applicable codes listed above.

In Canada, consult local building and safety codes or, in

absence of such requirements, follow CAN/CGA B149.1

4.3.2 Ducted Combustion Air

The combustion air can be taken through the wall, or

through the roof. When taken from the wall, it must be

taken from out-of-doors by means of the Manufacturer

horizontal wall terminal. When taken from the roof, a

eld-supplied rain cap or an elbow arrangement must

be used to prevent entry of rain water.

Use ABS, PVC, CPVC, polypropylene, or galvanized

pipe for the combustion air intake. Route the intake

to the boiler as directly as possible. Seal all joints.

Provide adequate hangers. The unit must not support

the weight of the combustion air intake pipe. Maximum

linear pipe length allowed is shown in Table 5. Subtract

5 allowable linear ft. (1.5m) for every elbow used.

The connection for the intake air pipe is at the top of

the unit.

In addition to air needed for combustion, air shall also

be supplied for ventilation, including air required for

comfort and proper working conditions for personnel.

COMBUSTION AIR INSTALLATION STANDARDS

MATERIAL UNITED STATES CANADA

ABS ANSI/ASTM D1527

PVC, sch 40 ANSI/ASTM D1785 or D2665 Air pipe material must be chosen

CPVC, sch 40 ANSI/ASTM F441 CPVC, sch 40, ANSI/ASTM, Polypropylene

Polypropylene UL1738, ULC S636. based upon the intended application of the boiler.

Single wall galv. steel 26 gauge

Table 2. Required Combustion Air Pipe Material.

Page 20

Page 20

The instructions for the installation of the venting

system shall specify that the horizontal portions of

the venting system shall be supported to prevent

sagging; the methods of and intervals for support

shall be specied. These instructions shall also

specify that the venting system:

Category I, II and IV boilers must be installed so

that horizontal sections have a slope of at least ¼

inch per foot (21 mm/m) to prevent accumulation of

condensate; and

For Category II and IV boilers, where necessary,

have means provided for drainage of condensate.

NOTICE

CAUTION

The FT is standard as a Natural Gas Boiler and

must be converted if propane is the desired gas, unless

specically manufactured for propane.

Adequate drainage

• The appliance should be installed not to damage

the adjacent area. If such locations cannot be

avoided, it is recommended that a suitable drain

pan, adequately drained, be installed under the

appliance. The pan must not block combustion air

ow.

Les instructions d'installation du système

d'évacuation doivent préciser que les sections

horizontales doivent être supportées pour prévenir

le échissement. Les méthodes et les intervalles

de support doivent être spéciés. Les instructions

doivent aussi indiquer les renseignements suivants:

les chaudières de catégories I, II et IV doivent

présenter des tronçons horizontaux dont la pente

montante est d'au moins ¼ po par pied (21 mm/m)

entre la chaudière et l'évent; les chaudières de

catégories II et IV doivent être installées de façon à

empêcher l'accumulation de condensat;

et si nécessaire, les chaudières de catégories II et IV

doivent être pourvues de dispositifs d'évacuation du

condensat.

AVIS

Connecting the Water Supply

• To conserve water and energy, insulate all water

piping—especially the hot and recirculation water

lines. Never cover the drain or pressure relief valve.

Having a backow preventer in the cold water

supply line will prevent thermal expansion

backow. Contact the water supplier or local

plumbing inspector for information about how to

control this situation.

If overheating occurs or the gas supply fails to shut

off, turn off the manual gas valve.

This installation must conform with below section

• “Air for Combustion and Ventilation” of the

National Fuel Gas Code, ANSI Z224.1/NFPA 54,

or Sections 8.2, 8.3 or 8.4 of Natural Gas and

Propane Installation Code, CAN/CSA B149.1, or

applicable provisions of the local building codes.

Page 21

The FT Series Heating Only, Boiler

4.4 Venting, Exhaust

Page 21

DO NOT COMMON VENT FT UNITS.

never permitted to share a vent with

Category I appliances.

For Cascading Installations, please refer to

document 1349 ‘Cascading the FT Series Boiler’,

The ue temperature of the FT changes dramatically

with changes in operating water temperature.

Therefore, it is necessary to assess the application

of the boiler to determine the required certied vent

class. If the FT is installed in an application where

the ambient temperature is elevated, and/or installed

in a closet/alcove, CPVC, polypropylene, or stainless

steel material is required. If the system temperatures

are unknown at the time of installation, stainless,

polypropylene or CPVC material is recommended.

The FT is a Category IV appliance and may be installed

with PVC, CPVC or polypropylene that complies with

ULC-S636, ANSI/ASTM D1785 F441 (see Table 3) or

a stainless steel venting system that complies with UL

1738 Standard and ULC S636.

Failure to use the appropriate vent material, installation

techniques, glues/sealants could lead to vent failure

causing property damage, personal injury or death.

All venting must be installed according to this manual

and any other applicable local codes, including but not

limited to, ANSI Z224.1/NFPA 54, CAN/CSA B149.1

and ULC-S636. Failure to follow this manual and

applicable codes may lead to property damage, severe

injury, or death.

NOTICE

NOTICE

available online.

WARNING

WARNING

FT units are

NE PAS ÉVENT COMMUNE FT UNITÉS.

unités ne sont jamais autorisés à partager un

évent Catégorie I avec les appareils.

AVIS

FT

___________________________________________

Use of cellular core PVC (ASTM F891), cellular core

CPVC, or Radel® (polyphenolsulfone) in non-metallic

venting systems is prohibited and covering non-

metallic vent pipe and ttings with thermal insulation is

prohibited.

_________________________________________

INSTALLATIONS IN CANADA require the use of

venting material certied to ULCS636. All Gas

vents connected to the FT, plastic, stainless

steel or otherwise must be certied to this ULC

standard. Appropriate selection of vent material is

very important for proper performance and safe

operation of the FT.

The ue temperature of the FT changes

dramatically with changes in operating water

temperature. Therefore, it is necessary to assess

the application of the boiler to determine the

required certied vent class. If the FT is installed in

an application where the outlet water temperature

exceeds 145°F, and/or installed in a closet, class

IIB or higher vent material is required. If the

system temperatures are unknown at the time of

installation, class IIB or higher venting material is

recommended.

IN CANADA all venting used must meet the

following requirements:

1. ULC-S636 certied and marked

2. The rst 3 feet of venting must be accessible

for visual inspection.

3. All components used in the vent system must

WARNING

VENTING INSTALLATION STANDARDS

MATERIAL UNITED STATES CANADA

Stainless Steel UL 1738 Venting must be ULC-S636 certied for use as

PVC, sch 40 ANSI/ASTM D1785 venting material. The venting material must be chosen

CPVC, sch 40 ANSI/ASTM F441 based upon the intended application of the boiler.

Polypropylene UL1738 or ULC-S636

Table 3. Required Exhaust Vent Material.

Page 22

Page 22

4.4 Venting, Exhaust (continued)

be from a certied manufacturer.

4 . Vent system components must not be mixed

with alternate manufacturers certied

components and/or unlisted components.

5 . The venting must be installed according

to the vent manufacturers installation

instructions.

The unit’s vent can terminate through the roof, or

through an outside wall.

Vent pipe must pitch upward, toward the vent

terminal, not less than 1/4” per foot, so that

condensate will run back to the FT to drain. Route

vent pipe to the heater as directly as possible. Seal

all joints and provide adequate hangers as required

in the venting system manufacturer’s Installation

Instructions. Horizontal portions of the venting

system must be supported to prevent sagging and

may not have any low sections that could trap

condensate. The unit must not support the weight of

the vent pipe.

WARNING

Failure to vent this Boiler in accordance with

these instructions could cause a re, resulting

in severe property damage, personal injury or

death.

Do not interchange vent systems or materials

unless it is specied.

The use of thermal insulation covering pipe and

ttings is prohibited.

Do not apply an electric damper, draft hood or

vent damper with this Boiler.

Do not locate vent termination where exposed

to prevailing winds. Moisture and ice may fall

on surface around vent termination. To prevent

deterioration, surface must be in good repair

(sealed, painted, etc.).

4.5 General Location Guideline

1. Vent system installation must be in accordance

with Local codes or, in the absence of local codes,

the National Fuel Gas Code, ANSI Z224.1 /NFPA

54 and/or CSA B149.1, Natural Gas and Propane

Installation Code.

2. The Boiler is designed to be installed as a Direct

Vent (sealed combustion) type. The air for

combustion must be supplied directly from the

outside to the burner. Also, the ue gases must be

vented directly to the outdoors (through wall or roof).

3. Do not install venting system components on the

exterior of building except as specically required by

these instructions

- Vent terminals must be at least 1 foot from any door,

window, or gravity inlet into the building.

- Maintain the correct clearance and orientation

between the vent and air intake terminals.

The vent and air intake terminals must be at the

same height and their center lines must be spaced

apart 12˝ minimum.

- The bottom of the vent and air intake terminal must

be at least 12˝ above the normal snow line. In no

case should they be less than 12˝ above grade

level.

- Do not install the vent terminal directly over

windows or doors.

- Air intake terminal must not terminate in areas that

might contain combustion air contaminates, such

as near swimming pools.

- For sidewall venting, the minimum horizontal

distance between any adjacent individual Module

(Boiler) vent terminations is twelve (12) inches. It

is better to be far more than 12 inches for avoiding

frost damage to building surfaces where vent

terminations are placed.

- The minimum horizontal distance between any

adjacent individual module (boiler) roof vent

endpiece is one (1) foot.

Page 23

The FT Series Heating Only, Boiler

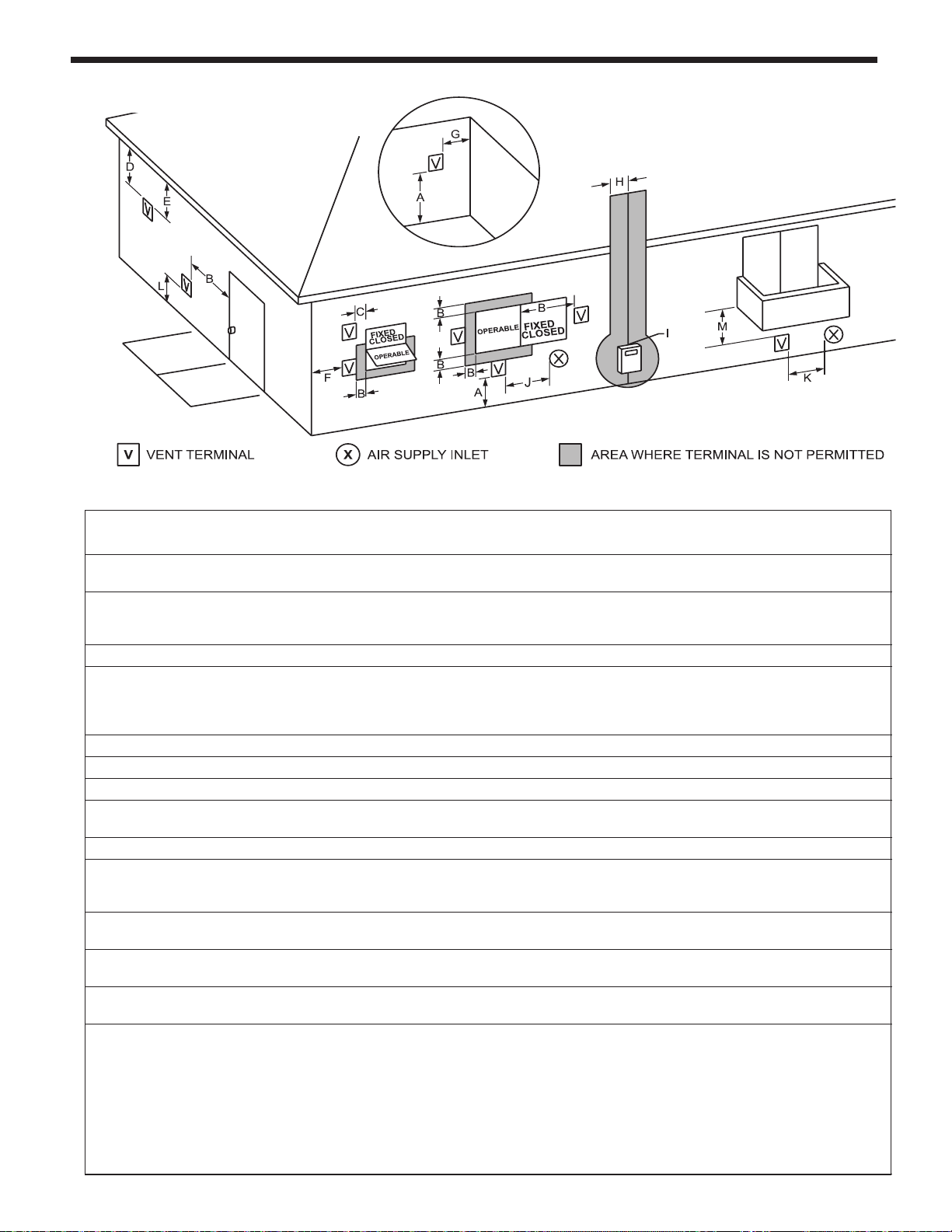

4.6 Locations for Vent Pipe Terminator

4.6.1 Direct Venting Clearances

Page 23

U.S. Installations (see note 1) Canadian Installations (see note 2)

A= Clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm)

deck, or balcony See note 6 See note 6

B= Clearance to window or door that may be Direct vent only: 12 inches (30cm); 36 inches (91 cm)

opened Other than Direct vent: 4 ft (1.2m) below or to NT 80 only - 12 inches (30 cm)

side of opening; 1 ft (30cm) above opening

C= Clearance to permanently closed window See note 4 See note 5

D= Vertical clearance to ventilated soft located

above the terminal within a horizontal See note 4 See note 5

distance of 2 feet (61cm) from the center

line of the terminal

E= Clearance to unventilated soft See note 4 See note 5

F= Clearance to outside corner See note 4 See note 5

G= Clearance to inside corner See note 4 See note 5

H= Clearance to each side of center line 3 feet (91 cm) within a height 15 feet

extended above meter/regulator assembly See note 4 above the meter/regulator assembly

I= Clearance to service regulator vent outlet See note 4 3 feet (91 cm)

J= Clearance to nonmechanical air supply Direct vent only: 12” (30cm) 80-285; 36” (91cm)

inlet to building or the combustion air inlet 399-850. Other than Direct vent: 4 ft (1.2m) below 36 inches (91 cm)

to any other appliance or to side of opening; 1 ft (30cm) above opening NT 80 only - 12 inches (30 cm)

K= Clearance to a mechanical air supply inlet 3 feet (91 cm) above if within 10 feet (3 m) 6 feet (1.83 m)

horizontally

L= Clearance above paved sidewalk or paved Vent termination not allowed in this location 7 ft (2.1 m)

driveway located on public property for category IV appliances. See note 5

M= Clearance under veranda, porch, deck, See note 4 12 inches (30 cm) (see note 3)

or balcony

Notes:

1. In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code.

2. In accordance with the current CAN/CSA-B149.1 Installation Codes.

3. Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

4. For clearances not specied in ANSI Z223.1 / NFPA 54, clearance is in accordance with local installation codes and the requirements of the gas supplier.

5. For clearances not specied in CAN/CSA-B149, clearance is in accordance with local installation codes and the requirements of the gas supplier.

6. IMPORTANT: Terminal must be placed such that it remains a minimum 12” above expected snow line. Local codes may have more

specic requirements, and must be consulted.

Table 4. Direct Vent Clearances

Page 24

Page 24

4.6.2 Venting Requirements in the

Commonwealth of Massachusetts

In Massachusetts the following items are required if

the side-wall exhaust vent termination is less than

seven (7) feet above nished grade in the area

of the venting, including but not limited to decks

and porches. From Massachusetts Rules and

regulations 248 CMR 5.08

1. Installation of Carbon Monoxide Detectors

At the time of installation of the side wall

vented gas fueled appliance, the installing plumber

or gastter shall observe that a hard-wired carbon

monoxide detector with an alarm battery back-up is

installed on the oor level where the gas appliance

is to be installed. In addition, the installing plumber

or gastter shall observe that a battery operated or

hard-wired carbon monoxide detector with an alarm

is installed on each additional level of the dwelling,

building or structure served by the side-wall

horizontally vented gas fueled equipment. It shall

be the responsibility of the property owner to secure

the services of qualied licensed professionals

for installation of hard-wired carbon monoxide

detectors.

a. In the event that the side-wall horizontally

vented gas fueled equipment is installed in a crawl

space or an attic, the hard-wired carbon monoxide

with alarm and battery back-up may be installed on

the next adjacent oor level.

b. In the event that the requirements of the

subdivision cannot be met at the time of completion

of installation, the owner shall have a period of thirty

(30) days to comply with the above requirements,

provided, however, that during said thirty (30) day

period, a battery operated carbon monoxide detector

with an alarm be installed.

2. Approved Carbon Monoxide Detectors

Each carbon monoxide detector shall comply

with NFPA 720 and be ANSI/UL 2034 listed and IAS

certied.

3. Signage. A metal or plastic identication plate

shall be permanently mounted to the exterior of

the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent

terminal for horizontally vented gas fueled heating

appliance or equipment. The sign shall read, in

print no less than one-half (1/2) inch in size: “GAS

VENT DIRECTLY BELOW, KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. Inspection The state or local gas inspector of

the side-wall horizontally vented gas fueled appliance

shall not approve the installation unless, upon

inspection, the inspector observes carbon monoxide

detectors and signage installed in accordance with the

provisions of 248 CMR 5.08(2)(a) 1-4.

Page 25

The FT Series Heating Only, Boiler

Page 25

DO NOT COMMON VENT FT UNITS.

NOTICE

FT units

are never permitted to share a vent with

Category I appliances.

Common Vent Test

NOTE: This section does not describe a method for

common venting FT units. It describes what must

be done when an existing unit is removed from a

common vent system.

At the time of removal of an existing boiler, the following steps

shall be followed with each appliance remaining connected to

the common venting system placed in operation, while the other

appliances remaining connected to the common venting system

are not in operation.

1. Seal any Not Used openings in the common venting system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deciencies which

could cause an unsafe condition.

3. Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes

dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at

maximum speed.

4. Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so the appliance will

operate continuously.

5. Operate the main burner for 5 minutes then, determine if the

cut-draw overows to the discharge opening. Use the ame

of a match or a candle or the smoke of a cigarette, a cigar or

a pipe

6. Once it has been determined, according to the method

indicated above, that each device connected to the drainage

system is placed in the open air in an adequate manner.

Install the doors and windows, fans, the registers of chimneys

and gas appliances to their original position

7. Any malfunction of the venting system should be corrected so

that the installation conforms to the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 and (or) the installation codes CAN/

CSA-B149.1. If the size of a section of the evacuation system

must be changed, the system should be modied to comply

with the minimum values of the relevant tables of appendix F

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and

(or) the installation codes CAN/CSA-B149.1

NOTICE

NE PAS ÉVENT COMMUNE FT UNITÉS.

AVIS

FT unités

ne sont jamais autorisés à partager un évent

Catégorie I avec les appareils.

Au moment du retrait d'une chaudière existante, les mesures

suivantes doivent être prises pour chaque appareil toujours raccordé

au système d'évacuation commun et qui fonctionne alors que

d'autres appareils toujours raccordés au système d'évacuation ne

fonctionnent pas:

1. Sceller toutes les ouvertures non utilisées du système

d'évacuation.

2. Inspecter de façon visuelle le système d'évacuation pour

déterminer la grosseur et l'inclinaison horizontale qui conviennent

et s'assurer que le système est exempt d'obstruction,

d'étranglement, de fuite, de corrosion et autres défaillances qui

pourraient présenter des risques.

3. Dans la mesure du possible, fermer toutes les portes et les

fenêtres du bâtiment et toutes les portes entre l'espace où les

appareils toujours raccordés au système d'évacuation sont

installés et les autres espaces du bâtiment. Mettre en marche

les sécheuses, tous les appareils non raccordés au système

d'évacuation commun et tous les ventilateurs d'extraction comme

les hottes de cuisinière et les ventilateurs des salles de bain.

S'assurer que ces ventilateurs fonctionnent à la vitesse maximale.

Ne pas faire fonctionner les ventilateurs d'été. Fermer les registres

des cheminées.

4. Mettre l'appareil inspecté en marche. Suivre les instructions

d'allumage. Régler le thermostat de façon que l'appareil fonctionne

de façon continue.

5. Faire fonctionner le brûleur principal pendant 5 min ensuite,

déterminer si le coupe-tirage déborde à l'ouverture de décharge.

Utiliser la amme d'une allumette ou d'une chandelle ou la fumée

d'une cigarette, d'un cigare ou d'une pipe.

6. Une fois qu'il a été déterminé, selon la méthode indiquée ci-

dessus, que chaque appareil raccordé au système d'évacuation

est mis à l'air libre de façon adéquate. Remettre les portes et

les fenêtres, les ventilateurs, les registres de cheminées et les

appareils au gaz à leur position originale.

7. Tout mauvais fonctionnement du système d'évacuation commun

devrait être corrigé de façon que l'installation soit conforme au

National Fuel Gas Code, ANSI Z223.1/NFPA 54 et (ou) aux codes

d'installation CAN/CSA-B149.1. Si la grosseur d'une section

du système d'évacuation doit être modiée, le système devrait

être modié pour respecter les valeurs minimales des tableaux

pertinents de l'appendice F du National Fuel Gas Code, ANSI

Z223.1/NFPA 54 et (ou) les codes d'installation CAN/CSA-B149.1

AVIS

Page 26

Page 26

4.7 Air Supply and Vent Connections

4.7.1 Vent / Air Pipe Lengths

Boiler model

FTHW (all sizes)

Table 5. Maximum Vent / Air Pipe Lengths for either 3” or 2 “ Pipes

NOTE: For each elbow, reduce the maximum allowable length

• 5 feet (1.5M) for each 3-inch 90-degree elbow

• 2.5 feet (0.75M) for each 3-inch 45-degree elbow

• 8 feet (2.4M) for each 2-inch 90-degree elbow

• 4 feet (1.2M) for each 2-inch 45-degree elbow

• Max 6 elbows for 3” vent, Max 4 elbows for 2” vent

NOTE: The FT is factory set to operate

using 3” piping for Intake and Vent. For

3” Pipe vent, the default setting for DIP

4 is ON. If your installation is using a 2”

vent pipe, DIP Switch 4 must be in the

OFF position.

Refer to Section 4:18

3˝ Combustion Air / Vent Pipe 2˝ Combustion Air / Vent Pipe

Max

100´ (30M)

50´

Propane models are limited to 25

*

equivalent feet of 2” vent

WARNING

• Use of cellular core CPVC, or Radel (polyphenolsulfone)

in venting systems is prohibited.

• Covering non-metallic vent pipe and ttings with thermal

insulation is prohibited.

• Do not obstruct the ow of combustion and ventilated air.

Max

(15M*)

*

4.7.2 Direct Venting

The FT boiler can use 3˝ or 2˝ diameter exhaust

and 3˝ or 2˝ diameter intake air ducts. To ensure the

draw of air directly from and exhaust of air directly

to the outside of the building, create an airtight seal

from the boiler collar to the vent termination.

(For installations in Canada) eld-supplied plastic

vent piping must comply with CAN/CSA B149.1

(latest edition) and be certied by the Standard

For Type BH Gas Venting Systems, ULC-S636.

Components of this listed system must not be

interchanged with other vent systems or unlisted

pipes or ttings. All plastic components and

specied primers and glues of the certied vent

system must be from a single system manufacturer

and must not be intermixed with another system

manufacturer’s parts.

Tightening — Boiler Collar (Socket) to Vent

Pipe & Inlet Pipe

- Clean and dry your selected PVC, CPVC vent

pipe and Manufacturer Boiler collar (socket).

- You can select to the size of vent pipe(2˝ & 3˝),

according to the installation conditions.

- Push the pipe into the collar (socket) until it

touches the bottom of the socket tting.

- For 2” installations, install a eld supplied 3” to

2” adaptor. Adaptor must be installed in vertical

section of piping only.

3” pipe

2” pipe connected, using an adapter

3” to 2”

adapter

is NOT

included.

Page 27

The FT Series Heating Only, Boiler

4.7.3 Indoor Combustion Air

Read and Follow Sections 4.3 Guidelines First.

1. Insert the termination end cap into the intake air duct.

2. Provide two openings to allow for circulation of

combustion air as specied by ANSI Z224.1/NFPA 54.

In Canada refer to CAN/CSA B-149.1

NOTE: The FT needs fresh air for safe operation and must

be installed so there are provisions for adequate

combustion and ventilation air.

Model FTHW80 FTHW100 FTHW120 FTHW140 FTHW199

Maximum Input (BTU/H) 80,000 100,000 120,000 140,000 199,000

Page 27

Indoor make up air is provided,

a minimum free area of 1 in2

per 1,000 BTU/H

2

80 in

13 1/4˝

(W) x 13 1/4˝ (H)

2

100 in

13 1/4˝

(W) x 13 1/4˝ (H)

2

120 in

13 1/4˝

(W) x 13 1/4˝ (H)

2

140 in

13 1/4˝

(W) x 13 1/4˝ (H)

2

199 in

13 1/4˝

(W) x 13 1/4˝ (H)

Table 6. Adequate Free Area

4.8 Vent / Air Pipe Termination

All Terminations:

• After connecting terminals, install vent screens on both the vent and air inlet.

Two 3” vent screens are included with each unit. Additional replacement screens are available for purchase.

2” Vent Screen P/N - FT1508

3” Vent Screen P/N - FT1730

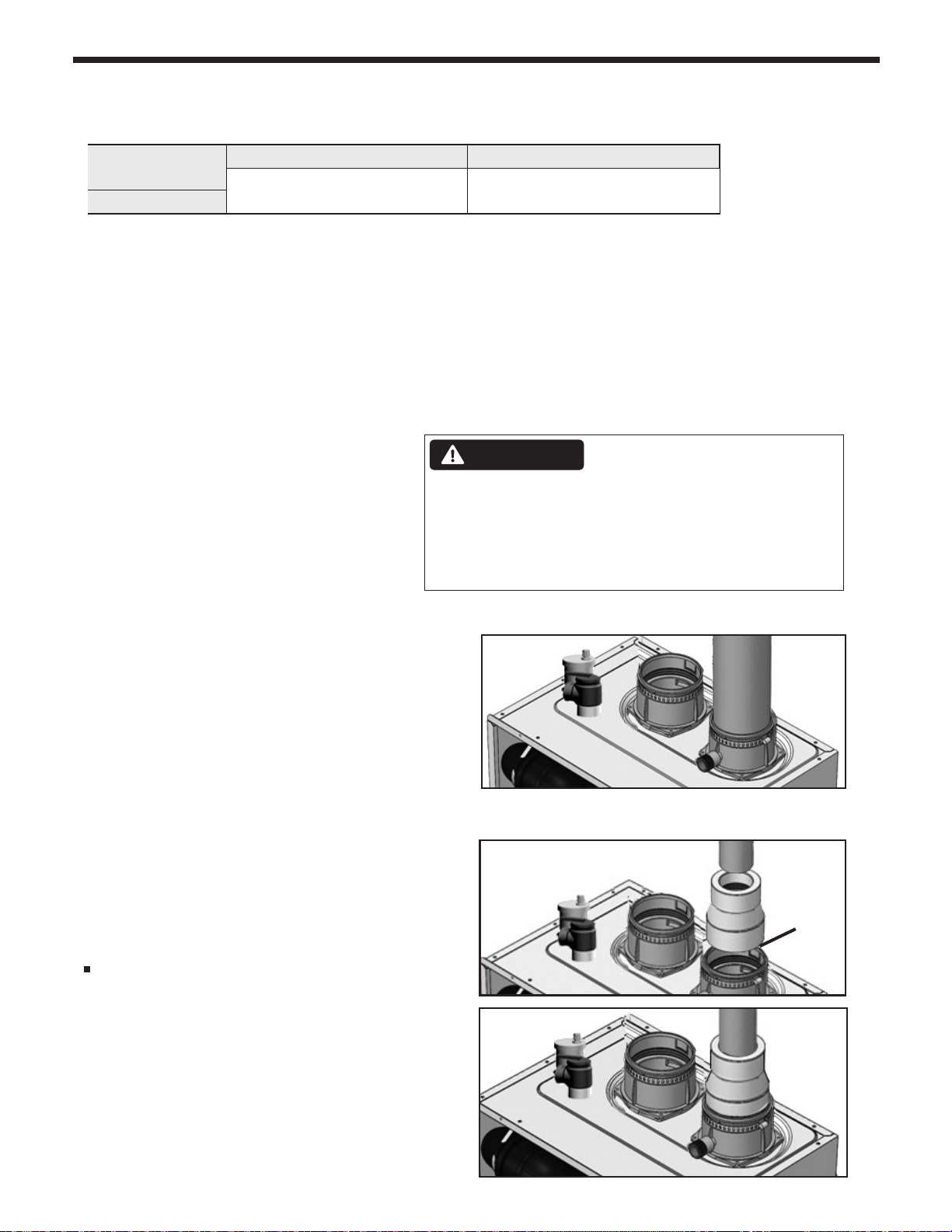

Vertical Vent Termination

• Direct Vent - Vertical Terminations

with Sloped Roof

Vent Screens

are required

Page 28

Page 28

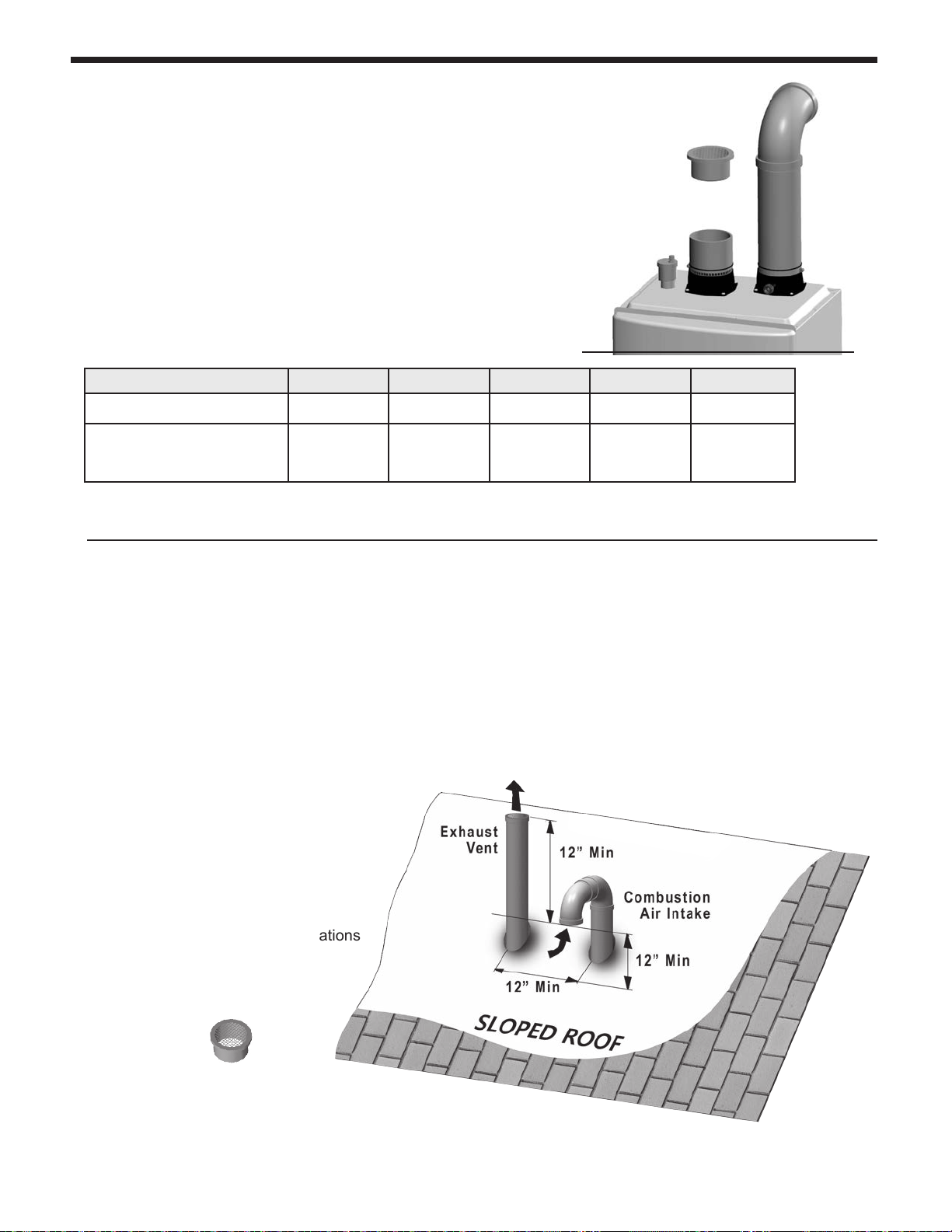

SIDE VIEW

FRONT VIEW

Exhaust Screen

12” MIN

1” MIN

Exhaust

Combustion

Intake

Air Intake Screen

Exterior Wall

NOTE: Must be 12”

Minimum distance

above highest

anticipated snow level

or grade, whichever is

greater (TYP).

NOTE: The Exhaust must

be equal to or above the

Combustion Intake while at

a Minimum of 12” apart.

12” MIN

Apart

Exhaust

90o Elbow

Exhaust

Screen

Exhaust

Exhaust

12” MIN

1” MIN

Sill

Combustion

Intake

Combustion

Intake

SIDE VIEWFRONT VIEW

Exterior Wall

NOTE: Must be 12”

Minimum distance

above highest

anticipated snow level

or grade, whichever is

greater (TYP).

12” MIN

12”

MIN

Exhaust Screen

Exhaust

12” MIN

12” MIN

1” MIN

Sill

Combustion

Intake

Combustion

Intake

SIDE VIEWFRONT VIEW

Air Intake Screen

90o Elbow

Exterior Wall

12”

NOTE: Must be 12”

Minimum distance

above highest

anticipated snow level

or grade, whichever is

greater (TYP).

Exhaust

MIN

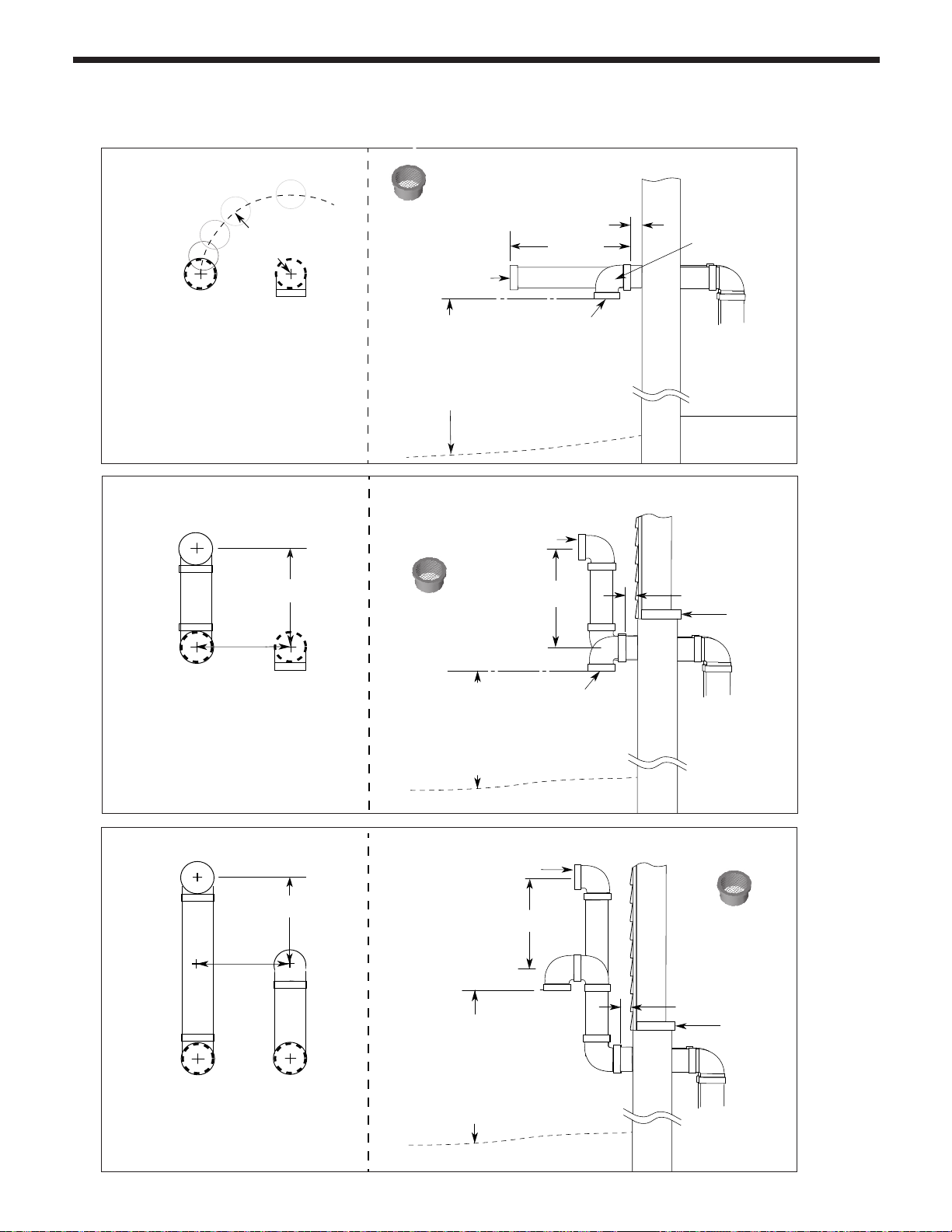

Horizontal Vent Termination

• Direct Vent - Sidewall Termination

A

4.8 Vent / Air Pipe Termination (continued)

Vent Screens are required

B

C

Vent Screens

are required

Vent

Screens are

required

Page 29

The FT Series Heating Only, Boiler

• Direct Vent - Optional Side wall Terminations

4. Concentric Vent Termination

• Direct Vent - Optional Horizontal and Vertical Concentric Vent

12” (30cm) Minimum

clearance above

highest anticipate

snow level.

Vent

12” Minimum clearance

above highest anticipated

snow level or grade,

whichever is greater.

Side Wall Kit

(2” or 3”)

Exterior Wall

Exhaust

Combustion Air

12” Minimum clearance

above highest anticipated

snow level or grade,

whichever is greater.

Side Wall Kit

(2” or 3”)

Exterior Wall

Exhaust

Concentric Vent Termination

• Direct Vent - Optional Horizontal

and Vertical Concentric Vent

Page 29

Exterior Wall

1" (25mm) to

12” Minimum clearance

above highest anticipated

snow level or grade, whichever

4" (100mm)

is greater.

Strap

Side Wall Kit

(2” or 3”)

12” Minimum clearance

above highest anticipated

snow level or grade,

whichever is greater.

Combustion Air

Vent

Exhaust

12” (30cm) Minimum

clearance above

highest anticipate

snow level.

Vent

Combustion Air

Page 30

Page 30

4.9 Gas Supply and Piping

Gas piping should be supported by suitable hangers or

oor stands, not the appliance.

Review the following instructions before proceeding with

the installation.

1. Verify that the appliance is tted for the proper type

of gas by checking the rating plate. FT will function

properly at elevations up to 10,000 feet

(3050 m). Refer to Section 4.12 for High Altitude

Settings.

2. For minimum and maximum gas supply pressures.

See Section 2.2 on page 5

3. Refer to Table 7, Table 8 and Table 9 to size piping.

4. Run gas supply line in accordance with all

applicable codes.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of the

gas controls.

7. All threaded joints should be coated with piping

compound resistant to action of liqueed petroleum

gas.

8. The appliance and its individual shutoff valve

must be disconnected from the gas supply piping

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.45kPa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or greater than

1/2 PSIG (3.45kPa).

10. The appliance and its gas connection must be leak

tested before placing it in operation.

11. Purge all air from gas lines.

CAUTION

PRV (included) must be installed immediately at the

top of boiler outlet to PRV, with no valves between.

Refer to Section 4.15

__________________________________________

WARNING:

Open ame can cause gas to ignite and result in

property damage, severe injury, or loss of life.

NOTE: The FT appliance and all other gas appliances

sharing the gas supply line must be ring at maximum

capacity to properly measure the inlet supply pressure.

The pressure can be measured at the supply pressure

port on the gas valve. Low gas pressure could be an

indication of an undersized gas meter, undersized gas

supply lines and/or an obstructed gas supply line.

SCHED 40 METAL PIPE CAPACITY FOR 1.50 SPECIFIC GRAVITY

NOMINAL PIPE SIZE @ 11" W.C. INLET AND 0.5" W.C. PRESSURE DROP

SIZE 1/2" 3/4" 1"

LENGTH MAXIMUM CAPACITY IN THOUSANDS OF BTU PER

HOUR

20 200 418 787

40 137 287 541

60 - 231 434

80 - 197 372

100 - 175 330

NOTES: 1. Follow all local and national propane gas codes for line sizing and

equipment requirements. 2. Verify that inlet gas pressure remains between

4 and 13 inches of water column before and during operation.

Source: ANSI Z223.1-80 National Fuel Gas Code.

UNDILUTED PROPANE

Table 7. Nominal Pipe Size, Propane

SCH 40 METAL PIPE CAPACITY FOR 0.60 SPECIFIC GRAVITY NATURAL GAS

NOMINAL PIPE SIZE @ 0.30" W.C. PRESSURE DROP

LENGTH 3/4" 1"

FT CUBIC FEET OF GAS PER HOUR

20 190 350

40 130 245

60 105 195

80 90 170

100

Table 8. Nominal Pipe Size, Natural Gas

ATTENTION

PRV (inclus) doit être installé immédiatement en haut

de la chaudière sortie de PRV, sans les vannes entre.

Se reporter à la Section 4.15

__________________________________________

EQUIVALENT LENGTHS OF STRAIGHT PIPE FOR TYPICAL SCH 40 FITTINGS

NOMINAL PIPE SIZE

FITTING 1/2" 3/4" 1"

LINEAR FEET

90° ELBOW 3.6 4.4 5.2

TEE 4.2 5.3 6.6

Table 9. Equivalent Pipe Lengths

Page 31

The FT Series Heating Only, Boiler

Natural Gas Pipe Sizing (Maximum)

Maximum capacity of pipe in cubic feet of gas per hour for gas pressures of 0.5psi or less

and a pressure drop of 0.5 Inch water column. (Based of a 0.60 Specic gravity gas)

For reference only. Referenced from gas pipe manufacturer specications for actual delivery capacity. The

DOE standard for Natural Gas is 1100 BTU/ ft3. Contact the local gas supplier for actual BTU/ ft3 rating.

Page 31

Pipe

Length (ft)

size

10 20 30 40 50 60 80 100 150 200

1/2˝ 82 58 47 41 37 37 29 26 20 18

3/4˝ 192 137 112 97 87 80 69 62 48 44

1˝ 383 269 218 188 168 153 132 118 91 82

1-1/4˝ 639 456 374 325 292 267 232 208 171 148

1-1/2˝ 1260 888 723 625 559 509 440 393 320 277

2˝ 2930 2080 1700 1470 1320 1200 1040 933 762 661

Table 10. Length of Corrugated Stainless Steel Pipe.

(Refer to the ANSI Z223.1 NATIONAL

FUEL GAS CODE 2012 EDITION)

Pipe

Length (ft)

size

10 20 30 40 50 60 80 100 150 200

1/2˝ 172 118 95 81 72 65 56 50 40 34

3/4˝ 360 247 199 170 151 137 117 104 83 71

1˝ 678 466 374 320 284 257 220 195 157 134

1-1/4˝ 1390 957 768 657 583 528 452 400 322 275

1-1/2˝ 2090 1430 1150 985 873 791 677 600 482 412

2˝ 4020 2760 2220 1900 1680 1520 1300 1160 928 794

Table 11. Length of Black Iron Pipe (Schedule 40 Metallic)

(Refer to the ANSI Z223.1 NATIONAL

FUEL GAS CODE 2012 EDITION)

Page 32

Page 32

4.9 Gas Supply and Piping (continued)

Propane Gas Pipe Sizing (Maximum)

Intended use : Pipe Sizing Between Single-or Second-Stage (Low Pressure) Regulator and Appliance.

For reference only. Referenced from gas pipe manufacturer specications for actual delivery capacity. The

DOE standard for Natural Gas is 1100 BTU/ft3. Contact the local gas supplier for actual BTU/ft3 rating.

Inlet Pressure : 11 in. w.c / Pressure Drop : 0.5in. w.c / Specic Gravity : 1.5

Pipe

Length (ft)

size

10 20 30 40 50 60 80 100 150 200

1/2˝ 129 91 74 64 58 53 45 41 31 28

3/4˝ 303 216 177 153 137 126 109 98 75 69

1˝ 605 425 344 297 265 241 208 186 143 129

1-1/4˝ 971 661 528 449 397 359 307 270 217 183

1-1/2˝ 1990 1400 1140 988 884 805 696 621 506 438

2˝ 4640 3290 2680 2330 2080 1900 1650 1480 1210 1050

Table 12. Length of Corrugated Stainless Steel Pipe.

(Refer to the ANSI Z223.1 NATIONAL

FUEL GAS CODE 2012 EDITION)

Length (ft)

Pipe

size

10 20 30 40 50 60 80 100 150 200

1/2˝ 291 200 160 137 122 110 101 94 84 67

3/4˝ 608 418 336 287 255 231 212 197 175 140

1˝ 1150 787 632 541 480 434 400 372 330 265

1-1/4˝ 2350 1620 1300 1110 985 892 821 763 677 543

1-1/2˝ 3520 2420 1940 1660 1480 1340 1230 1140 1010 814

2˝ 6790 4660 3750 3210 2840 2570 2370 2200 1950 1570

Table 13. Length of Black Iron Pipe (Schedule 40 Metallic)

(Refer to the ANSI Z223.1 NATIONAL

FUEL GAS CODE 2012 EDITION)

Page 33

The FT Series Heating Only, Boiler

Page 33

The gas connection tting on the unit is 3/4˝ male

NPT.

The supply line must be sized for the maximum

output of the boiler model being installed. If there

are additional gas appliances from the main

supply line, you must measure sizes of the supply

line according to the COMBINED total maximum

BTUH draw for the appliances as if they were all

operating at the same time.

Measure the length of the gas supply line from

the gas meter to the Boiler.

Use the tables in this manual or refer to the gas

line manufacturers sizing information to determine

the correct supply pipe size.

The gas shut-off valve in the gas supply line

should be installed close to the unit.

To facilitate any future maintenance, it is also

recommended that an approved gas union tting

be installed in the supply line between the shut-off

valve and the

Boiler.

1) Install an approved gas line pipe to gas line

connection under the Boiler.

Include manual shut off valve and gas union

connection, as shown.

2) Test gas pressure to make sure it meets the

minimum standards and does not exceed the

maximum standards for the boiler.

3) Leak test the gas line pipe before placing the

unit in operation. Use approved leak detector

liquid solutions only to check for leaks.