Laars EBP0110, EBP0175, EDP0110, EDP0175, EDN0110 Installation, Operation And Maintanance Manual

...Page 1

Installation, Operation and Maintenance Instructions Document 1187B

Installation,

Operation and

Maintenance

Instructions for

Endurance

EBP Series Modulating Combination Boiler

(natural or propane gas)

EDP Series Modulating Hydronic Boiler

(natural or propane gas)

EDN Series Modulating Boiler, non ferrous

(natural or propane gas)

WARNING

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty. As an additional measure of safety,

Laars strongly recommends installation of suitable carbon monoxide detectors in the vicinity of this

appliance and in any adjacent occupied spaces.

If the information in this manual is not

WARNING

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by

a qualified installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion ou

pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualifié ou

par le fournisseur de gaz.

AVERTISSEMENT

H2313500B

A subsidiary of BRADFORD WHITE Corporation

Page 2

Page 2

TABLE OF CONTENTS

SECTION 1.

General Information

1.1 Introduction................................................... 3

1.2 Codes and Standards................................... 3

1.3 Unpacking the Appliance.............................. 4

1.4 Locating the Appliance ................................. 4

1.5 Clearances ................................................... 4

SECTION 2.

Venting Options

2.1 Concentric Direct Vent ................................. 5

2.1.1 Concentric Vent Description ......................... 5

2.1.2 Laars Concentric Vent Kits ........................... 5

2.1.3 Horizontal Concentric Vent Location ............ 5

2.2 Stainless Steel Single Pipe Horizontal

and Vertical Vents — Category IV ................ 9

2.3 Air Source For Combustion (when not

ducted to the Endurance) ........................... 11

2.3.1 Air From Inside the Building ....................... 11

2.3.2 All Air From Outdoors .................................11

2.3.3 Connecting Special Gas Vent to the

Appliance.................................................... 12

2.4 Non-Concentric Combustion Air ................. 12

SECTION 3.

Gas Piping

3.1 Gas Piping .................................................. 12

3.2 Domestic Water Piping (EBP only) ............. 13

3.3 Anti-Freeze — Domestic Water .................. 14

SECTION 4.

Hydronic Heat Piping

4.1 Hydronic Piping .......................................... 14

4.2 Using in a Combined Hot Water Heating

and Chilled Water Cooling System ............. 17

4.3 Water Quality and Treatment ..................... 17

4.4 Anti-Freeze ................................................. 17

4.4.1 Endurance Boiler Low

Temperature Feature ................................. 17

4.4.2 Anti-Freeze Boiler Additives ....................... 17

SECTION 5.

Electrical Connections

5.1 Electrical Connections ................................ 20

SECTION 6.

Using the Boiler Control

6.1 Front Panel Display .................................... 22

6.2 Control Logic .............................................. 22

6.3 View Menu.................................................. 22

6.4 Setpoint Menu ............................................ 24

6.4.1 “SP” Supply Temperature ........................... 24

6.4.2 “PO” Pump Operation ................................. 24

6.4.3 “Pd” Pump Delay ........................................ 24

6.4.4 “Oar” Outdoor Reset................................... 24

6.4.5 “Oal” Minimum Outdoor Reset Point .......... 25

6.4.6 “rc” Outdoor Reset Ratio ............................ 25

6.4.7 “oTo” Warm Outdoor Shutdown ................. 25

6.4.8 “unl” Temperature Units ............................. 25

LAARS Heating Systems

6.4.9 “Add” Control Address ................................ 25

6.4.10 “Dif” Burner On Differential ......................... 25

6.5 Calculated Control Values .......................... 25

6.5.1 ACV Release (EBP only) ............................ 25

6.5.2 Tank Charge Setting (EBP only) ................ 25

6.5.3 Burner On Point.......................................... 25

6.5.4 Modulation Point......................................... 25

6.6 Other Control Functions ............................. 25

6.6.1 Using Buttons on Control ........................... 25

6.6.2 Alarm Acknowledge.................................... 26

6.6.3 Power On/Off .............................................. 26

6.6.4 Low Fire Hold ............................................. 26

6.6.5 High Fire Hold ............................................ 26

6.6.6 Pump Operation ......................................... 26

6.6.7 Anti-Condense Valve Operation ................. 26

6.6.8 Field-Supplied Outdoor Reset Controls ...... 27

SECTION 7.

Boiler Start Up

7.1 Removal of Boiler From Common Vent ...... 27

7.2 Filling the System ....................................... 28

7.3 Firing Burner............................................... 28

SECTION 8.

Maintenance and Component Description

8.1 Unit Pump................................................... 29

8.2 Gas Valve ................................................... 29

8.3 Safety Limit Switch ..................................... 29

8.4 Boiler Control.............................................. 29

8.5 Ignition Control ........................................... 30

8.6 Ignitor / Flame Sensor Assembly................ 30

8.7 Transformer ................................................ 30

8.8 PMW Board ................................................ 30

8.9 Blower ........................................................ 30

8.10 Transfer Tank (EBP) .................................. 30

8.11 Thermostatic Union (EDP/EDN) ................. 31

8.12 Cleaning the Boiler Coil .............................. 31

SECTION 9.

Servicing

9.1 Sequence of Operation .............................. 31

9.2.1 Fault Code Identification ............................. 33

9.2.2 Fault Correction .......................................... 33

9.2.3 Resolving Lockouts (LO) ............................ 33

SECTION 10.

Air Orifice and Gas Valve Adjustment

................................................................... 35

SECTION 11.

Symptom Evaluations

11.1 Delayed Ignition.......................................... 35

11.2 Short Cycling .............................................. 36

11.3 Noisy Operation.......................................... 36

11.4 Insufficient Hot Water (EBP only) ............... 36

11.5 High Gas Consumption .............................. 37

SECTION 12.

Parts Identification

................................................................... 38

Page 3

Endurance

Page 3

SECTION 1.

General Information

1.1 Introduction

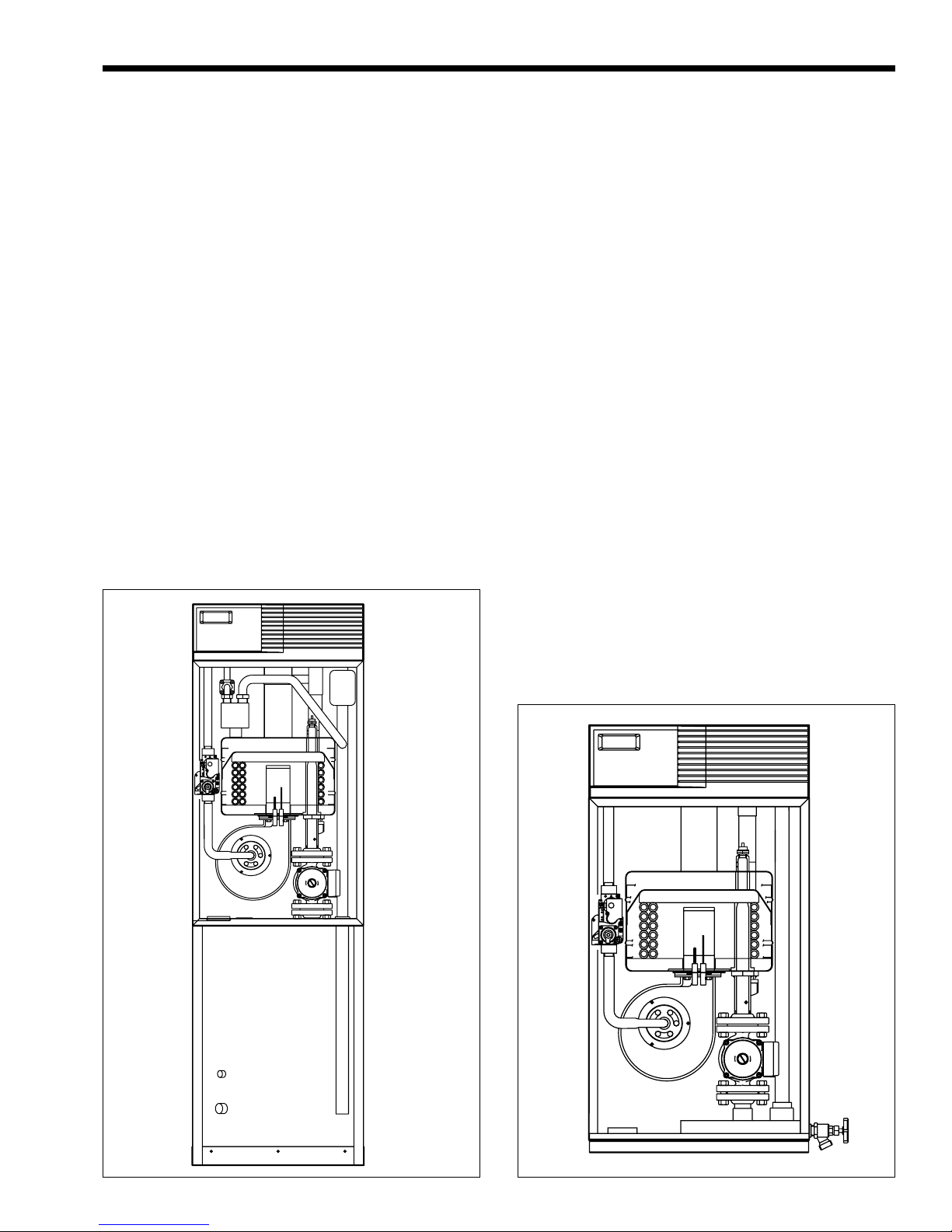

EBP - This appliance is a low pressure, direct

vent, hot water boiler that provides priority domestic

hot water on demand as well as hydronic space

heating. The unit has a twenty gallon tank which holds

boiler water (as opposed to domestic water storage).

The boiler water is kept hot at all times to

provide immediate response to call for heat or

domestic water. Domestic water is heated by the boiler

water through a stainless steel plate heat exchanger.

EDP/EDN - This appliance is a low pressure,

direct vent, cold start hot water boiler that provides

heat for hydronic space heating. The model number

structure is shown in Figure 3.

Both appliances incorporate a circulating pump

and a bypass loop, and provide circulation for the

heating system and adequate flow for its own needs.

It may be necessary to install a system circulator to

achieve the required flow rate through the system.

Both appliances feature a forced draft, premixed

combustion system. All air for combustion is supplied

with the gas to the burner (flame holder). Both the

intake air and the gas are metered through separate

orifices before entering the combustion air blower. The

blower forces the air/fuel mixture through the flame

holder and into the combustion chamber. The mixture

is ignited from the hot surface ignitor and burns. Hot

gases are forced out between the passes of the heat

exchanger into the flue collector. Flue gases are

discharged into the outside atmosphere through the

vent terminal.

The appliance can operate with a concentric vent

system that will provide outside air for combustion.

Other venting arrangements can be provided for the

appliance to include an alternative 50 equivalent feet

maximum horizontal or condensate trapped vertical

vent.

1.2 Codes and Standards

The Endurance may be a direct vent or Category

IV Boiler. All installations must be made in

accordance with:

a. The National Fuel Gas Code, ANSI Z223.1/

NFPA 54 latest edition, or

b. CSA B149.1 Natural Gas and Propane

Installation Code.

c. The requirements of the local utility or other

authorities having jurisdiction take precedence

over the general instructions contained herein.

All electrical wiring is to be done in accordance with:.

a. The National Electrical Code (NFPA 70), latest

edition or

Figure 1. Combo Heating/Domestic Water (Model EBP).

Figure 2. Heating Unit (Model EDP/EDN).

Page 4

Page 4

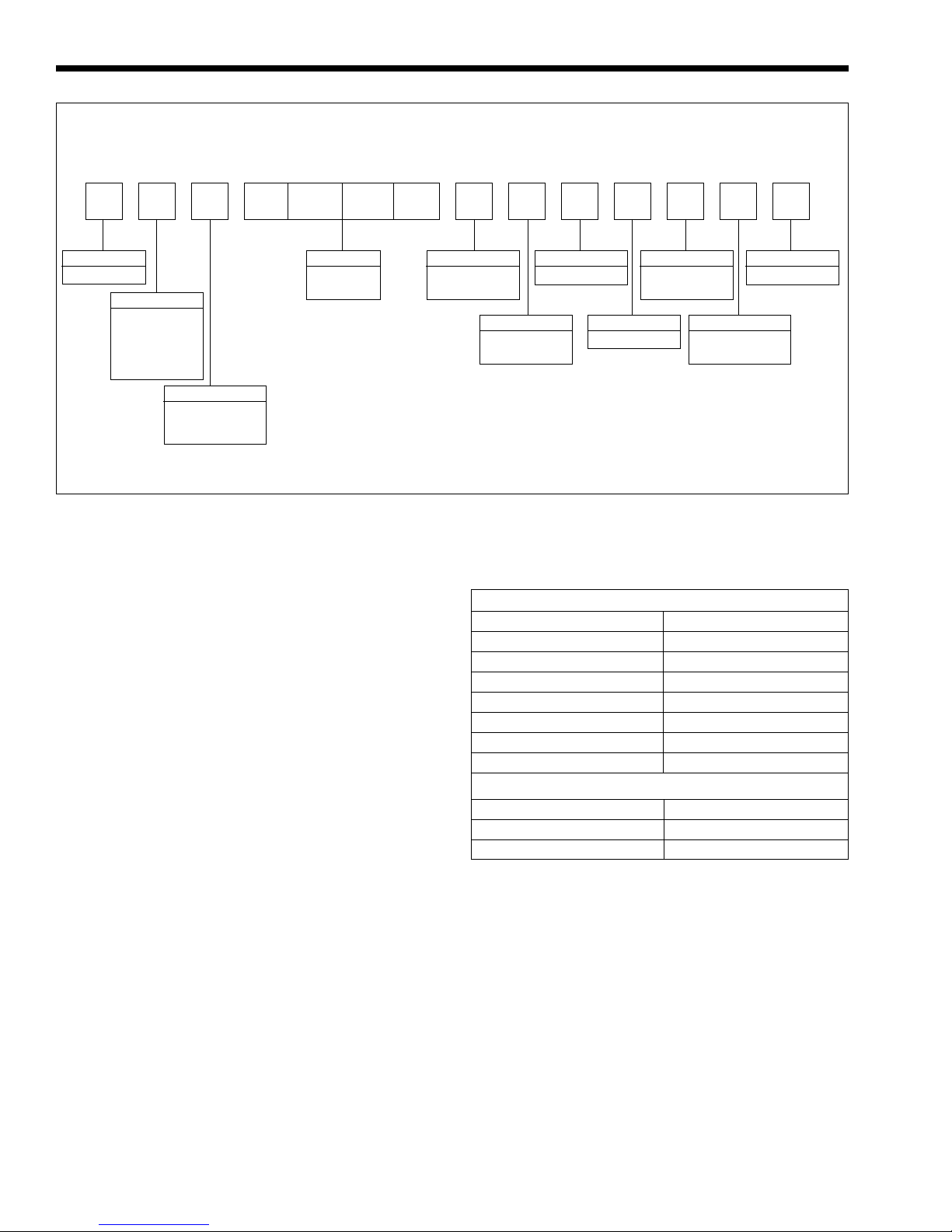

1234567891011121314

E IF2 X

LAARS Heating Systems

Prod. Line

E = Endurance

Usage

B = Combination,

Heating &

Domestic

Water

D =Heating Only

Type

P =Standard

N =Non Ferrous

(ED Units Only)

Figure 3. Model Structure.

BTU Input

0 1 1 0

0 1 7 5

b. The Canadian Electrical Code (CSA C22.1),

latest edition.

c. All applicable local installation codes must also

be adhered to.

All vent installations must be made in accordance with:

a. The applicable venting requirements of the

National Fuel Gas Code (ANSI Z223.1/NFPA

54), latest edition; or

b. in Canada, The Natural Gas and Propane

Installation Code (CSA B149.1), latest edition.

All applicable provisions of local building codes

should also be adhered to.

Fuel

N =Natural Gas

P =Propane

A = 0' - 5,000'

H =Over 5,000'

Altitude

Location

I = Indoor

Firing Mode

F = Modulating

Revision

2 = Second

Revision

Country of Sale

A = USA & Canada

R =Russia

1.5 Clearances

The dimension and criteria in Table 1 should be

followed when choosing the location for the unit.

Minimum Clearances From Combustible Materials

Back 1 inch 25mm

Left Side 1 inch 25mm

Right Side 1 inch 25mm

Front 1 inch 25mm

Top (Alcove Install) 1 inch 25mm

Top (Closet Install)* 22 inches 559mm

Vent: Concentric, Direct 0 inch 0mm

Vent: Category 3 inches 76mm

Options Code

X =None

1.3 Unpacking the Appliance

Remove all packing and tie down materials.

Make immediate claims (to the carrier) if the appliance

and its packaging are damaged.

1.4 Locating the Appliance

The appliance is designed for installation on

combustible flooring, in alcoves, basements, closets, or

utility rooms. It must NOT be installed on carpeting.

IF INSTALLED IN A FINISHED AREA,

PROVISION SHOULD BE MADE FOR DRAINAGE

OF ANY ACCIDENTAL SPILLAGE OR LEAKAGE.

The location for the unit should be chosen with

regard to venting dimensions, convenient access to

piping, and accessibility for service and cleaning.

The boiler shall be installed so that the gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation or service (circulator replacement, control

replacement, etc.).

Suggested Serviceability Clearances

Front 18 inches 457mm

Left Side 6 inches 152mm

Right Side 6 inches 152mm

*Minimum closet height 6'9" 206 cm

Table 1. Clearances.

SECTION 2.

Venting Options

The Endurance boilers are certified as direct

vent, sealed combustion boilers, when vented using

one of the following two methods:

1) Concentric direct vent, which has a flue gas pipe

inside a combustion air pipe.

2) Non-concentric direct vent, using separate pipes

for the flue gases and the combustion air.

The Endurance boilers can also take air from the

space (when properly sized), and be vented as a

Category IV appliance.

Page 5

Endurance

Page 5

The following sections describe the requirements

for each of these methods.

IMPORTANT NOTE REGARDING ENDURANCE

VENTING: Regardless of the venting arrangement

being used, the flue gas vent material used with

the Endurance MUST be stainless steel special

gas vent listed to U.L. Standard 1738 and U.L.C.

Standard 636. Endurance flue gases must never

be vented into a masonry chimney or vented with

B-vent or other galvanized vent material.

Endurance units are not permitted to be common

vented with any other appliance(s), including

other Endurance appliances.

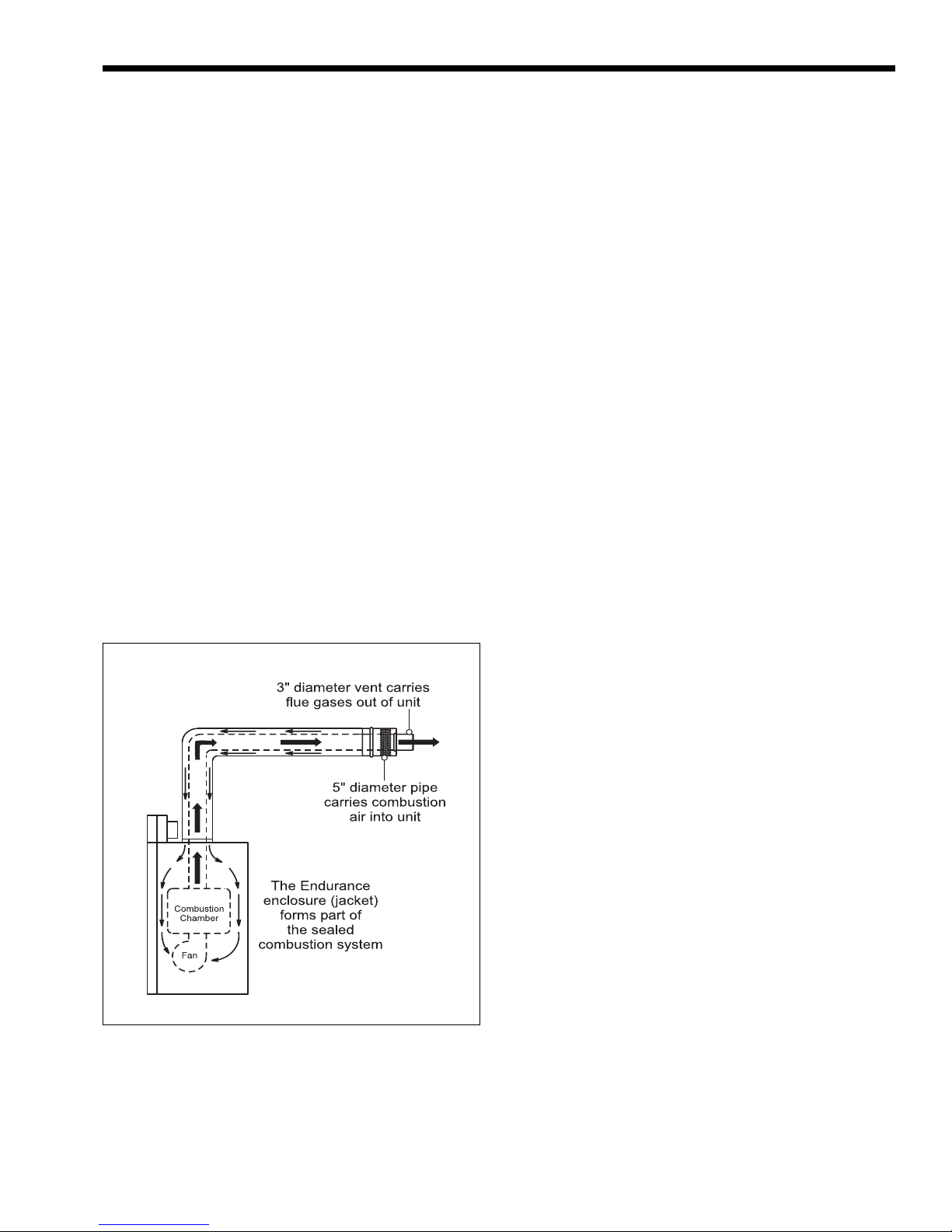

2.1 Concentric Direct Vent

2.1.1 Concentric Vent Description

Endurance concentric direct vent is a sealedcombustion system. It can be used for vent systems

with a maximum of 15 linear feet (4.6m) and three

elbows. All of the air is drawn in from the outside

through a 5" stainless steel outer pipe. Flue gases are

vented through a 3" stainless steel pipe that is

positioned inside the 5" intake pipe. Hot flue gases are

surrounded by the intake flow of cooler outdoor air

(see Figure 4). Laars offers two concentric vent kits,

described in section 2.1.2. Laars concentric vents may

be installed through, and be in contact with,

combustible materials.

Figure 4. Combustion Air and Flue Gas Paths.

2.1.2 Laars Concentric Vent Kits

The Endurance is certified with a maximum of

15 linear feet (4.6m) of concentric piping and three

sets of elbows. There are two concentric vent kits

offered by Laars. Both kits, and all Laars Endurance

vent material meet the requirements of U.L. Standard

1738 and U.L.C. Standard 636. The horizontal vent kit

is part number 2400-009. The vertical vent kit is part

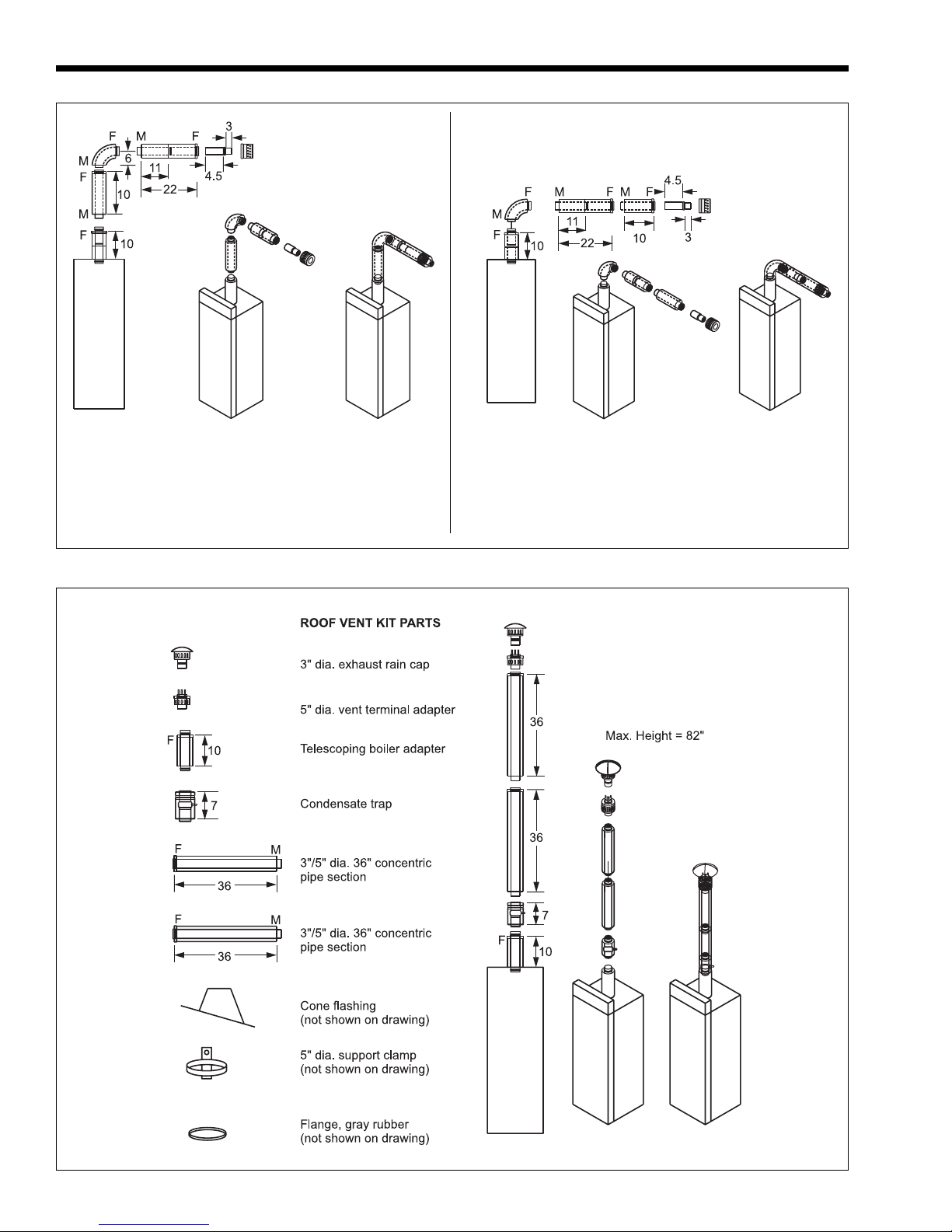

number 2400-011. See Figures 5 and 6, which show

the components included with the kits and venting

configurations. Installation instructions are included

with the kits. Rules for concentric venting, vent

material and vent terminal placement are discussed in

the rest of section 2 of this manual.

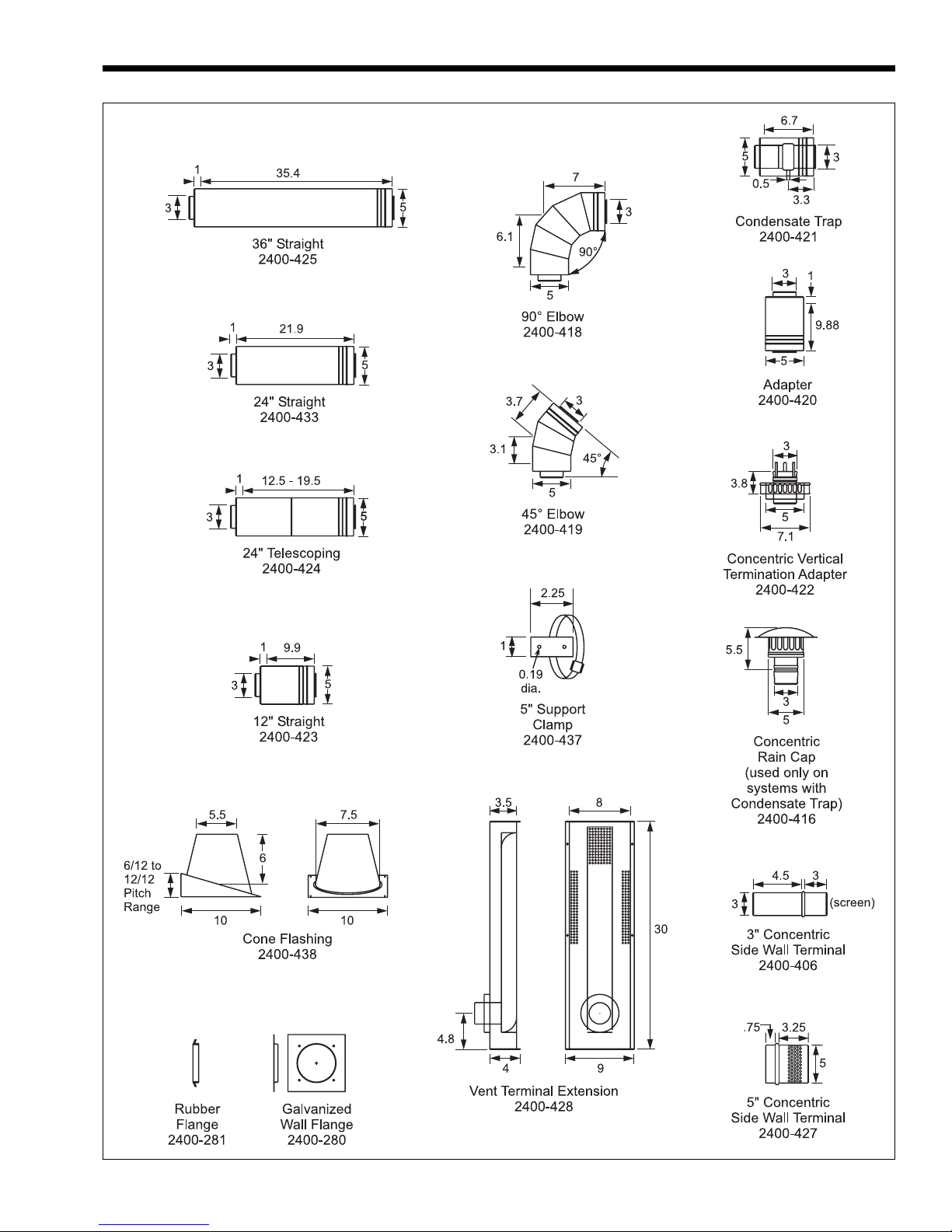

For additional length, and/or fittings, to extend

the kits to maximum 15 linear feet (4.6m) and three

elbows, individual components are available. These

components are shown in Figure 7.

2.1.3 Horizontal Concentric Vent

Location

The centerline of the vent opening must be at

least 16-1/2" (42cm) above grade, outside. Should it

be impossible to locate the opening centerline 16-1/2"

(42cm) above grade, use optional concentric vent

terminal extension (part number 2400-428), shown in

Figure 7.

In the U.S., vent terminals must be at least 3 feet

(0.9m) above any forced air inlet located within 10

feet (3.0m). In Canada, vent terminals must be at least

6 feet (1.8m) from any forced air inlet.

In the U.S., a direct vent terminal must be at least

12" (30cm) from any window or door that may be

opened, or any other nonmechanical opening. For an

Endurance that is not direct vented (vented as

Category IV), the vent terminal must be at least 4 feet

(1.2m) below or to the side of, and 12" (30cm) above

any such opening.

In Canada, a direct vent or non-direct vent

terminal must be at least 36" (91cm) from any window

or door that may be opened, or any other nonmechanical opening.

The vent opening should be well away from

shrubbery or other obstructions that would prevent

free air flow to and from the vent terminal.

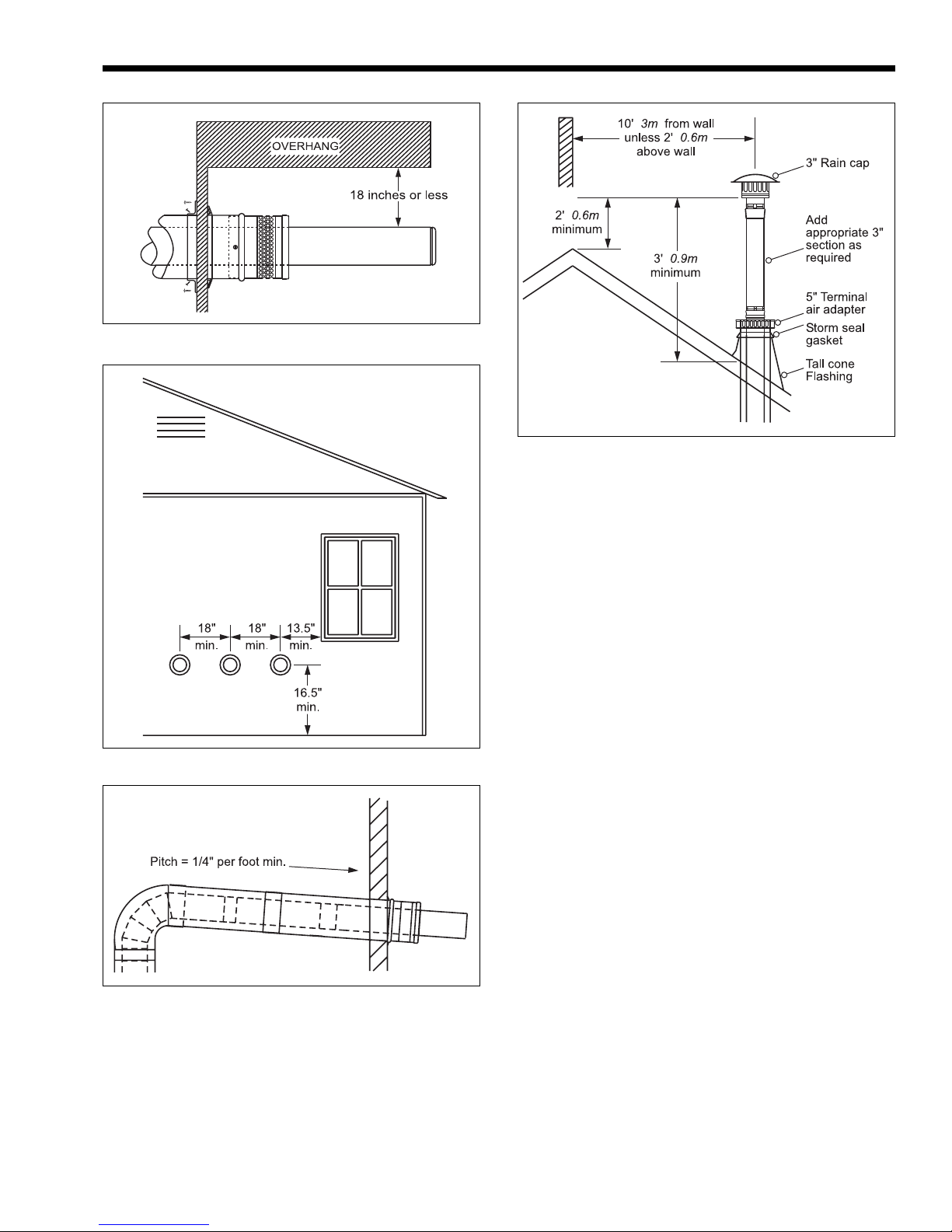

If the vent terminal location chosen is less than

18" (46cm) below an overhang, the 3" vent pipe must

extend to the outside edge of the overhang, to prevent

the accumulation of flue gas (see Figure 9).

Accumulating flue gas can contaminate the

combustion air, causing nuisance lockouts of the

ignition system. In addition, accumulation of flue

gases can settle on, and damage the structure’s

surfaces.

Vent terminals must not terminate in a location

where condensate or vapor may be a nuisance, hazard,

or could be a detriment to other equipment. See Figure

8 for more detail concerning vent terminal placement

in the U.S. and Canada.

Do not locate the vent terminal where blockage

by snow is a possibility, or where flue products could

strike against building materials and cause

degradation.

When multiple Endurance units are used, the

concentric vent terminals may be side-by-side,

Page 6

Page 6

LAARS Heating Systems

Configuration 1:

Maximum horizontal = 28"

Maximum vertical = 26"

(Measurements are from the centerlineof the venting to

the boiler top or face of outside wall.)

Dimensions shown in inches.

Figure 5. Horizontal Vent Kit 2400-009.

Configuration 2:

Maximum horizontal = 38"

Maximum vertical = 16"

(Measurements are from the centerline of the venting to

the boiler top or face of outside wall.)

Dimensions shown in inches.

Figure 6. Vertical Vent Kit 2400-011.

Page 7

Endurance

Page 7

Figure 7. Concentric Vent Parts.

Dimensions shown in inches.

Page 8

Page 8

LAARS Heating Systems

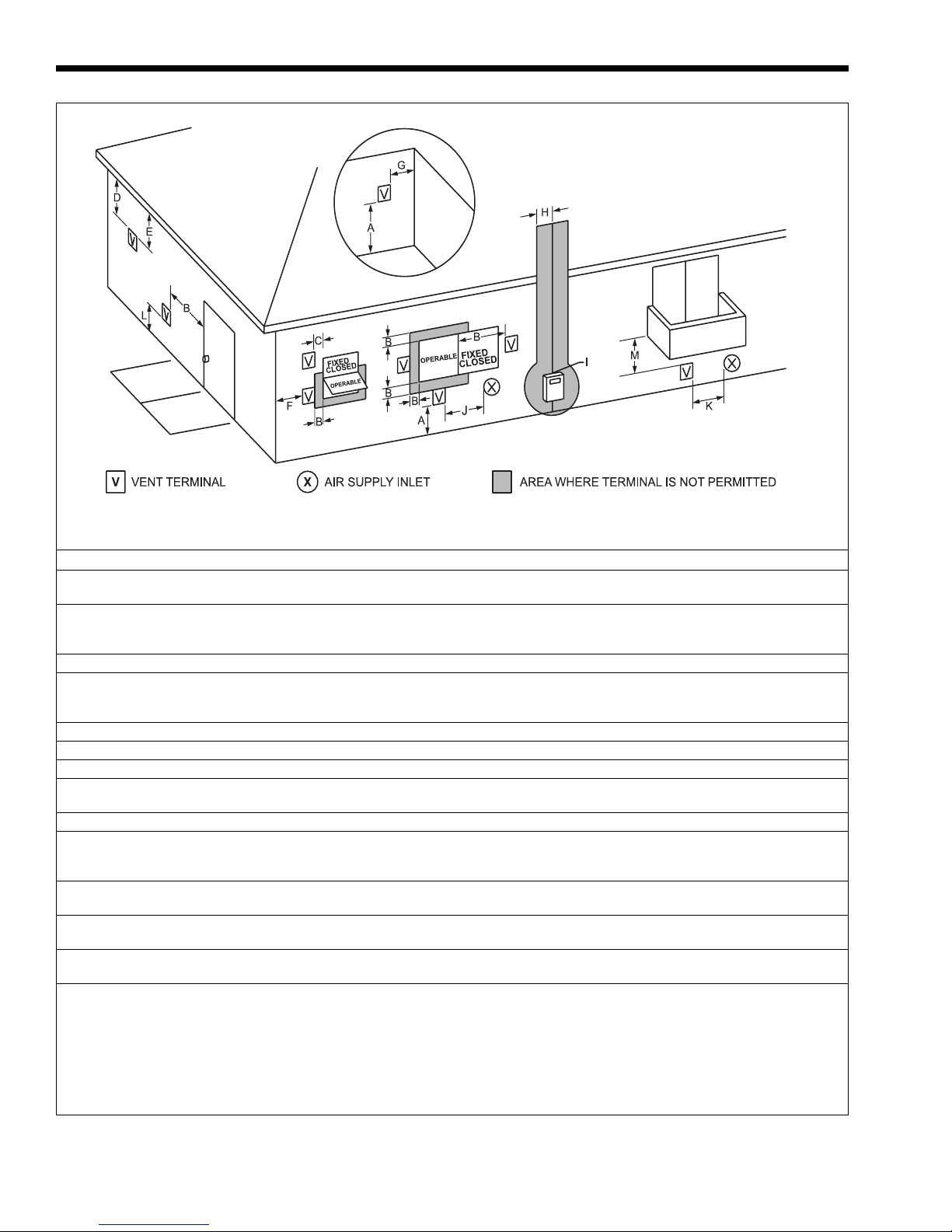

U.S. Installations (see note 1) Canadian Installations (see note 2)

A= Clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm)

deck, or balcony

B= Clearance to window or door that may Direct Vent Only: 12 inches (30 cm)

be opened Other Than Direct Vent: 4 feet (1.2 m) below or 36 inches (91 cm)

C= Clearance to permanently closed window See note 4 See note 5

D= Vertical clearance to ventilated soffit located

above the terminal within a horizontal See note 4 See note 5

distance of 2 feet (61cm) from the center line of the terminal

E= Clearance to unventilated soffit See note 4 See note 5

F= Clearance to outside corner See note 4 See note 5

G= Clearance to inside corner See note 4 See note 5

H= Clearance to each side of center line See note 4 3 feet (91 cm) within a height 15 feet

extended above meter/regulator assembly above the meter/regulator assembly

I= Clearance to service regulator vent outlet See note 4 3 feet (91 cm)

J= Clearance to nonmechanical air supply Direct Vent Only: 12 inches (30 cm)

inlet to building or the combustion air inlet Other Than Direct Vent: 4 feet (1.2 m) below or 36 inches (91 cm)

to any other appliance to side of opening; 1 foot (30 cm) above opening

K= Clearance to a mechanical air supply inlet 3 feet (91 cm) above if within 10 feet (3 m) 6 feet (1.83 m)

L= Clearance above paved sidewalk or paved Vent termination not allowed in this location Vent termination not allowed in this

driveway located on public property location

M= Clearance under veranda, porch, deck, See note 4 12 inches (30 cm) (see note 3)

or balcony

Notes:

1. In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code.

2. In accordance with the current CAN/CGA-B149 Installation Codes.

3. Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

4. For clearances not specified in ANSI Z223.1 / NFPA 54, clearance is in accordance with local installation codes and the requirements of

the gas supplier.

5. For clearances not specified in CAN/CGA-B149, clearance is in accordance with local installation codes and the requirements of the gas

supplier.

to side of opening; 1 foot (30 cm) above opening

horizontally

Figure 8. Vent Terminal Clearance.

Page 9

Endurance

Figure 9. Clearance from Overhang.

Figure 10. Multiple Concentric Vent Clearances.

Page 9

Figure 12. Vertical Vent Terminal Placement.

The vertical vent terminal must be placed such

that the bottom of the vent cap is at least 2-feet (0.6m)

above any structure (such as the peak of a roof or

adjacent wall) within 10 feet (3.0m), and must be at

least 3 feet (0.9m) above where the vent pipe exits the

roof (see Figure 12).

When vertical vent systems have horizontal

components, they must have a condensate drip tee in

the offset. All horizontal portions of the vent system

must slope a minimum 1/4" per foot toward the

condensate drip tee. Laars vertical vent kit and

individual venting components have condensate tees

that work in a vertical vent system, and therefore it is

not necessary to have an offset in a vertical vent

system that uses these parts.

Figure 11. Vent System Pitch.

provided that they are at least 18" (46cm) apart,

centerline to centerline (see Figure 10).

A horizontal vent system must pitch downward,

toward the terminal and away from the Endurance, as

shown in Figure 11. It must pitch at least 1/4" per foot

(21mm per meter). Be sure to take this into

consideration when choosing the vent terminal

location.

2.2 Stainless Steel Single Pipe Horizontal

and Vertical Vents – Category IV

Stainless steel special gas vent listed to U.L.

Standard 1738 and U.L.C. Standard 636 must be used

to vent all models. Three-inch or 4-inch material can

be used. Vent pipe and fittings are manufactured to

these standards by HeatFab, Inc. under the trade name

of Saf-T Vent

®

Vent

, and by ProTech Systems, Inc. under the trade

name FasNSeal

manufacturer’s instructions regarding design, location

and assembly of the vent system.

The appliance may be vented with any number

of elbows or fittings, providing that the maximum

equivalent feet of venting is not exceeded. Equivalent

feet of vent material is shown in table 2, along with

information about vent temperature and pressure.

Elbows (90°) in the vent system shall be considered to

be 5 equivalent feet (1.5m).

A horizontal vent system must pitch downward,

toward the terminal and away from the Endurance, as

shown in Figure 11. It must pitch at least 1/4" per foot

®

, by Z-Flex™ under the trade name of Z-

®

. Follow the special gas vent

Page 10

Page 10

LAARS Heating Systems

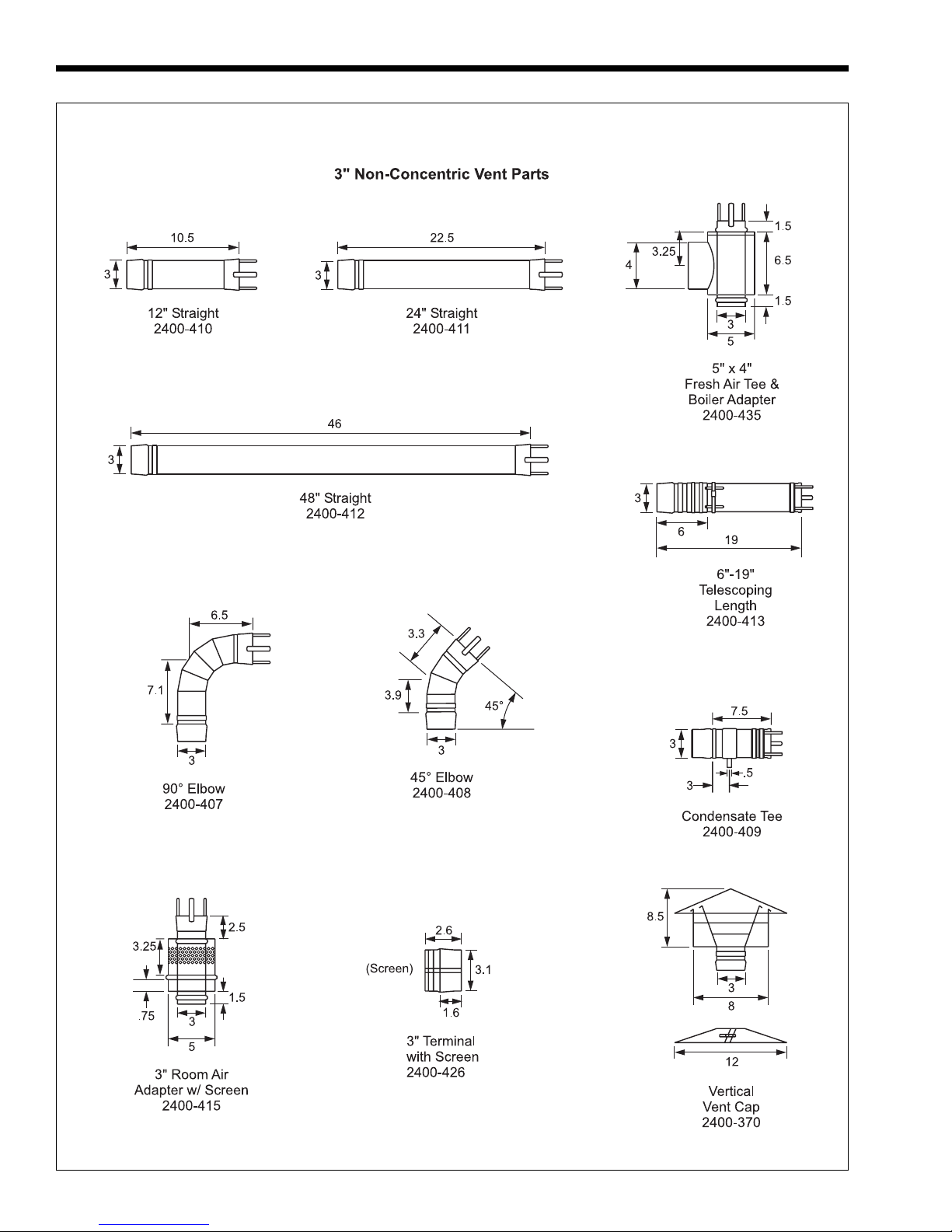

Figure 13. 3" Vent Parts.

Dimensions shown in inches.

Page 11

Endurance

Page 11

Minimum clearance from

combustibles (vent) U.S.* 3" 8cm

Minimum clearance from

combustibles (vent) Canada 6" 15cm

Max. flue gas temp. 325°F 163°C

Max vent pressure 1.5" w.c. 0.4kPa

Max. equivalent ft. of 3" venting (any 50 15

combination of horizontal or vertical) equiv. feet equiv. meters

Max. equivalent ft. of 4" venting (any 100 30

combination of horizontal or vertical) equiv. feet equiv. meters

*Note: To use 3" (8cm) clearance, the vent must be open on at

least one side. If fully enclosed, clearance is 6" (15cm)

Table 2. Category IV Vent Parameters.

(21mm per meter). Be sure to take this into

consideration when choosing the vent terminal

location.

For applications requiring vertical venting

through a roof, the same limitations for length and

fittings apply (see Table 2). Vertical vents greater than

7 feet (2.1m) in length must use a condensate trap.

When vertical vent systems have horizontal

components, they must have a condensate drip tee in

the offset. All horizontal portions of the vent system

must slope a minimum 1/4" per foot toward the

condensate drip tee. Laars vertical vent kit and

individual venting components have condensate tees

that work in a vertical vent system, and therefore it is

not necessary to have an offset in a vertical vent

systems that use these parts.

The vertical vent terminal must be placed such

that the bottom of the vent cap is at least 2-feet (0.6m)

above any structure (such as the peak of a roof or

adjacent wall) within 10 feet (3.0m), and must be at

least 3 feet (0.9m) above where the vent pipe exits the

roof (see Figure 12).

Laars offers 3" vent parts for non-concentric

venting, including an in-line condensate tee and vent

caps for vertical venting. See Figure 13 for 3" vent

parts, and Figure 15 for an example of the inline

condensate in a vertical vent system.

IMPORTANT NOTE REGARDING ENDURANCE

VENTING: Regardless of the venting arrangement

being used, the flue gas vent material used with the

Endurance MUST be stainless steel special gas

vent listed to U.L. Standard 1738 and U.L.C.

Standard 636. Endurance flue gases must never be

vented into a masonry chimney or vented with B-vent

or other galvanized vent material. Endurance units

are not permitted to be common vented with any

other appliance(s), including other Endurance

appliances.

2.3 Air Source For Combustion

(when not ducted to the Endurance)

When using Category IV venting methods the

appliance draws all combustion air through its top and

from the adjacent space. When locating the appliance

in unconfined spaces in buildings, infiltration may be

adequate to provide air for combustion and

ventilation. However, in buildings of unusually tight

construction, or when locating the appliance in a

confined space, additional air should be provided and

the guidelines below must be followed:

2.3.1 Air From Inside the Building

The following method shall be used to size the

air openings for boilers that are getting all of their

combustion air from inside the building.

The confined space shall be provided with two

permanent openings communicating directly with

other spaces of sufficient volume so that the combined

volume of all such spaces meets the criteria for an

unconfined space. The total input of all gas utilization

equipment installed in the combined spaces shall be

used to determine the required minimum volume.

Each opening shall have a minimum free area of not

less than 1 in.

2

/1000 Btu/hr (220 mm2/kW) of the total

input rating of all gas utilization equipment in the

confined space, but not less than 100 in.

2

(645 cm2).

One opening shall commence within 12 in. (30 cm) of

the top, and one opening shall commence within 12 in.

(30cm) of the bottom, of the enclosure. The minimum

dimension of air openings shall be not less than 3 in.

(8 cm).

2.3.2 All Air From Outdoors

When all air is provided from outdoors, but not

ducted directly to the Endurance, the following

methods shall be used to size the air opening(s).

a. Two permanent openings, one commencing

within 12 in. (30 cm) of the top and one

commencing within 12 in. (30 cm) of the bottom,

of the enclosure shall be provided. The openings

shall communicate directly, or by ducts, with the

outdoors or spaces (crawl or attic) that freely

communicate with the outdoors.

a1. Where directly communicating with the

outdoors or where communicating to the

outdoors through vertical ducts, each

opening shall have a minimum free area of

2

1 in.

/4000 Btu/hr (550 mm2/kW) of total

input rating of all equipment in the

enclosure.

a2. Where communicating with the outdoors

through horizontal ducts, each opening

shall have a minimum free area of not less

than 1 in.

2

/2000 Btu/hr (1100 mm2/kW) of

total input rating of all equipment in the

enclosure.

b. One permanent opening, commencing within 12

in. (30 cm) of the top of the enclosure, shall be

permitted where the equipment has clearances of

at least 1 in. (2.5 cm) from the sides and back

and 6 in. (16 cm) from the front of the appliance.

Page 12

Page 12

LAARS Heating Systems

The opening shall directly communicate with the

outdoors or shall communicate through a vertical

or horizontal duct to the outdoors or spaces that

freely communicate with the outdoors and shall

have a minimum free area of:

b1. 1 in.

2

/3000 Btu/hr (700 mm2/kW) of total

input rating of all equipment in the

enclosure, and

b2. Not less than the sum of the areas of all

vent connectors in the confined space.

2.3.3 Connecting Special Gas Vent to

the Appliance

When drawing combustion air from the adjacent

space, part number 2400-415 (room adapter with

screen) can be used. One portion of this assembly

connects to the 5" air collar (with a screen for the

combustion air) and the other part connects to the 3"

flue opening (see Figure 14). The rest of the 3" vent

system can be connected to the adapter within the

2400-415.

2400-435 tee

(to separate

venting from

combustion

air)

Combustion

Chamber

Fan

2400-416

concentric rain cap

(use only on systems

with condensate trap)

2400-435 tee

(to separate

venting from

combustion air)

3" diameter vent

(50 equivalent feet, maximum)

4" combustion air pipe

(15 equivalent feet, maximum)

Non-Concentric Direct Vent with

Horizontal Vent.

2400-370

vertical vent cap

(can be used on system with

or without condensate trap)

2400-409 condensate trap

(used if vent height is

greater than 7 feet)

4" combustion air pipe

2400-426

3" vent termination

with screen

vent

gases

combustion

air

4" air terminal

(field-supplied)

combustion

air

Figure 14. Combustion Air from Room.

2.4 Non-Concentric Combustion Air

An alternate, non-concentric combustion air

source may be installed (as shown in Figure 15),

provided that the minimum 4" diameter combustion

air duct does not exceed 15' (4.6m). Termination

should include an air screen and be located in a

qualified air space (see Section 2.3) or outside.

Separated combustion air / flue gas may be

considered either “mechanical draft” or “direct vent”.

To be considered “direct vent”, all of the combustion

air and flue gas piping must be sealed stainless steel

special gas vent, listed to U.L. 1738 and U.L.C. 636.

4" air terminal

(field-supplied)

Combustion

Chamber

Fan

Figure 15. Non-Concentric Combustion Air.

Non-Concentric Direct Vent with

Vertical Vent.

When the system meets this requirement, vent

terminal clearances may be less than that of a nondirect vent system. See Figure 8 for direct vent

terminal clearances.

The combustion air pipe may be galvanized

material, but if used, the system is a “mechanical

vent” system, and the vent terminal clearances must be

per the rules for “mechanical vent” systems. See

Figure 8.

SECTION 3.

3.1 Gas Piping

The appliance requires an inlet gas pressure of at

least 4" w.c. (1.0kPa) and no greater than 13" WC

Page 13

Endurance

Length Capacity of Pipe

of Pipe 1/2" 3/4" 1" 1-1/4"

ft. m MBTU/h kW MBTU/h kW MBTU/h kW MBTU/h kW

10 3 132 38.7 278 81.5 520 152.4 1050 307.7

20 6.1 92 27 190 55.7 350 102.6 730 213.9

30 9.1 73 21.4 152 44.5 285 83.5 590 172.9

40 12.2 63 18.5 130 38.1 245 71.8 500 146.5

50 15.2 115 33.7 215 63 440 128.9

75 22.9 93 27.2 175 51.3 360 105.5

100 30.5 79 23.1 150 44 305 89.4

150 45.7 64 18.8 120 35.2 250 73.3

Additional length to be added for each tee or elbow

ft m ft m ft m ft m

1.3 0.4 1.7 0.5 2.2 0.7 2.7 0.8

Table 3. Gas Pipe Sizing.

Page 13

(3.2kPa). Check with your local gas utility or supplier

for availability of this pressure range.

Refer to Table 3 to size the supply piping to

minimize pressure drop between meter or regulator

and unit.

1. Run gas supply line in accordance with all

applicable codes.

2. Locate and install manual shutoff valves in

accordance with state and local requirements.

3. Install drip leg, ground joint union and drip cap

to trap sediment and for test gauge access.

4. Support all piping with proper hangers.

5. All threaded joints should be coated with piping

compound resistant to the action of liquefied

petroleum gas.

6. The boiler and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of ½ psig (3.5kPa).

7. The boiler must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than ½ psig (3.5kPa)

8. The boiler and its gas connection must be leak

tested before placing the boiler in operation.

9. Purge all air from gas lines.

3.2 Domestic Water Piping (EBP only)

1. Connect tempering (mixing) valve 12 “Hot” port

to hot water outlet from unit. This valve should

be rated no higher than 120°F mixed delivery

temperature or as local codes dictate.

RECOMMENDS ANTI-SCALD TEMPERING

(MIXING) VALVES (see Figure 16).

2. Connect gate or shutoff valve 13 to tempering

(mixing) valve 12 “MIX” port, and cold

water inlet.

3. Install supplied flow restrictor 14 ahead of

tempering (mixing) valve tee.

4. Connect pressure relief valve 1 (if required by

codes), rated at maximum 150 PSI as close to the

unit as possible. No other valves or restrictions

may be installed between the Endurance and the

relief valve.

DO NOT USE A TEMPERATURE/PRESSURE

RELIEF VALVE AS THIS IS NOT A STORAGE

HOT WATER HEATER.

NOTE: Installations with water containing 10 or

more grains of hardness, must be installed with

appropriate water treatment.

LAARS

Figure 16. Domestic Water Piping. Figure 17. Domestic Water Piping With Storage Tank.

Page 14

Page 14

Figure 18. EBP Domestic Water Piping with Recirculating Loop.

LAARS Heating Systems

WARNING

Failure to install a hot water tempering (mixing)

valve (12) creates a scalding hazard with potential for

serious bodily injury.

(mixing) valves are not designed as anti-scald valves.

Some brands of tempering

Where domestic water is supplying multiple

apartments or large whirlpool tubs, an additional

storage tank may be connected as shown in Figure 17.

The bronze circulator shown must be connected to the

tank aquastat and must not run continuously. If the

circulator is wired to run continuously, the unit’s

domestic water flow switch will keep the unit in

domestic water priority, and no water will be allowed

to be sent to the heating system.

Where domestic water is supplying a

recirculating loop, pipe per Figure 18. If the circulator

is wired to run continuously, the unit’s domestic water

flow switch will keep the unit in domestic water

priority, and no water will be sent to the heating

system. Wire the loop’s circulator through an aquastat

to maintain domestic water priority, while still

allowing the heating systems to function properly.

3.3 Anti-Freeze — Domestic Water

Endurance EBP units use a flat plate heat

exchanger to heat domestic (potable) water indirectly.

Endurance units are equipped with a Low

Temperature control feature that recognizes when the

boiler water temperature (not the domestic/potable

water temperature) has fallen below 39° (4°C). If this

condition is recognized, the Endurance pump will run

for 5 minutes, or until the boiler water temperature

reaches 45°F (7°C). If the boiler water temperature

remains below 45°F (7°C) for 5 minutes, the appliance

will start its ignition sequence, in hopes of firing, and

heating the boiler water. The display will show [ICE]

during this time.

This feature is intended to assist in protecting the

boiler from freezing conditions, and does not help to

protect any other part of the boiler or water heater

system. This feature will not help to protect the

domestic (potable) water in the system from freezing

conditions.

Caution

Power outage, interruption of gas supply, failure of

system components, activation of safety devices,

etc., may prevent a heater from firing. Any time a

heater is subjected to freezing conditions, and

the heater is not able to fire, and/or the water is

not able to circulate, there is a risk of freezing in

the heater or in the pipes in the system. When

water freezes, it expands. This can result in

bursting of pipes in the system, or damage to the

heater, which could result in leaking or flooding

conditions.

SECTION 4.

Hydronic Heat Piping

4.1 Hydronic Piping

The appliance incorporates its own circulating

pump and bypass loop and is capable of providing

flow through heating zones, in addition to what it

needs for itself. Model size 110 is capable of providing

flow for two heating zones (up to 67 feet of ¾"

baseboard each), and model 175 is capable of

providing flow for four heating zones (up to 67 feet of

¾" baseboard, each).

Page 15

Endurance

Figure 19. Hydronic Piping EDP/EBP with Zone Valves.

Page 15

Figure 20. Piping, Single EDP/EBP Boiler for Multiple Temperature Systems.

Figure 21. Piping, Model “EDP/EDN” for Radiant Floor.

Page 16

Page 16

Figure 22. Hydronic Piping EBP/EDP for Systems Zoned with Circulators.

LAARS Heating Systems

Figure 23. Hydronic Piping EDP for Low-Temp and/or Multi-Temp Systems.

EDP/EDN boilers installed in radiant (in floor)

systems and other low mass boilers should be provided

with a buffer/blender tank to assure a controlled supply

temperature, and to prevent short cycling. In radiant

systems utilizing 3-way tempering valves, a bypass

pipe must be installed between supply and return piping.

1. EBP ONLY: Connect system supply to 1¼"

supply connection marked “SUPPLY”.

2. EDP/EDN ONLY: Connect 1¼" thermostatic

union to system supply connection in direction

designated with union.

3. Pipe the discharge of the relief valve, full size, to

a drain or in a manner to prevent injury in the

event of pressure relief.

4. Install an air purger in flow supply line as shown

in piping diagrams.

5. Install automatic float type air vent on air scoops.

6. Install a diaphragm expansion tank in boiler

outlet piping. To ensure sufficient expansion

volume for the hydronic system water, due to

heat-up and cool-down during normal operation,

a #30 or larger expansion tank must be used on

EBP combo units.

NOTE: Never install expansion tank and auto fill

valve on return.

7. If necessary, install a properly sized circulator

with optional isolation valves in supply beyond

expansion tank.

Caution

To avoid the risk of fire which can result in property

damage, all hot water pipes must be installed with a

minimum 1" (25mm) clearance from combustible

materials.

Page 17

Endurance

Page 17

8. Connect boiler feed water supply with shut off

valve to inlet connection of automatic fill valve.

Locate in boiler outlet piping.

9. If codes require, install suitable back flow

preventer between automatic fill valve and city

main.

10. The appliance may be installed in single and

multiple zone systems (using either zone valves

or zone circulators) in the same manner as any

other residential boiler.

Caution

The EBP/EDP appliance must not be direct

connected to a heating system utilizing oxygen

permeable tubing (see warranty). Provide a water to

water heat exchanger between systems to prevent

corrosion of tank or other components. Non-toxic

heating system antifreeze may be added to the

hydronic system provided that the concentration

does not exceed 35% and the antifreeze contains

an anti foamant.

4.2 Use in a Combined Hot Water Heating

and Chilled Water Cooling System

When the appliance is used in connection with a

refrigeration system, it must be installed so that the

chilled medium is piped in parallel with the boiler with

appropriate valves to prevent the chilled medium from

entering it.

The boiler piping system of an appliance

connected to heating coils located in air handling units

where they may be exposed to refrigerated air

circulation must be equipped with flow control valves

or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle.

4.3 Water Quality and Treatment

Water quality control is steadily increasing in

importance in view of the use of modern regulation

technology and the modern boiler designs used in

central heating systems.

The life of a central heating boiler can be

severely diminished as a result of the formation of

scale deposits and/or corrosion products. The

formation of such deposits should be prevented

wherever possible.

Continual water make-up is not permitted.

A suitable water treatment may be used to

prevent excessive scale deposits in the boiler and

corrosion in the system.

4.4 Anti-Freeze

Proper precautions for freeze protection are

recommended for boiler installations in areas where

the danger of freezing exists.

4.4.1 Endurance Boiler Low

Temperature Feature

Endurance boilers are equipped with a Low

Temperature control feature that recognizes when the

water temperature at the outlet of the boiler has fallen

below 39°F (4°C). If this condition is recognized, the

Endurance pump will run for 5 minutes, or until the

boiler outlet temperature reaches 45°F (7°C). If the

boiler outlet temperature remains below 45°F (7°C) for

5 minutes, the appliance will start its ignition

sequence, in hopes of firing the boiler and heating the

water. The display will show [ICE] during this time.

This feature is intended to assist in protecting the

boiler from freezing conditions, and does not help to

protect any other part of the heating system. This

feature will only help when there is power to the boiler

and when the internal water flow components in the

Endurance are working properly. This feature will not

be able to prevent freezing if the low temperature

water condition persists. See Section 4.4.2 for

information concerning further freeze protection for

the Endurance.

4.4.2 Anti-Freeze Boiler Additives

Caution

Power outage, interruption of gas supply, failure of

system components, activation of safety devices,

etc., may prevent a boiler from firing. Any time a

boiler is subjected to freezing conditions, and

the boiler is not able to fire, and/or the water is

not able to circulate, there is a risk of freezing in

the boiler or in the pipes in the system. When

water freezes, it expands. This can result in

bursting of pipes in the system, or damage to the

boiler, which could result in leaking or flooding

conditions.

Do not use automotive anti-freeze. When the

Endurance is the combination space heating domestic

water model (EBP), a non-toxic anti-freeze, such as

propylene glycol, must be used. Maintaining a mixture

of minimum 65% water and maximum 35% properly

inhibited HVAC glycol, which contains an antifoamant, is the preferred method of freeze protection

for Endurance boilers. Percentage of glycol used in

the Endurance boiler must not exceed 35%.

Typically, this mixture will serve as burst protection

for temperatures down to approximately -35°F (-30°C).

IMPORTANT NOTES: Different glycol products may

provide varying degrees of protection. Glycol

products must be maintained properly in a heating

system, or they may become ineffective. Consult the

glycol specifications, or the glycol manufacturer, for

information about specific products, maintenance of

solutions, and set up according to your particular

conditions.

Page 18

Page 18

LAARS Heating Systems

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING

If you do not follow these instructions exactly, a fire or explosion

may result, causing property damage, personal injury or loss of life.

A. This appliance is equipped with an ignition

device which automatically lights the pilot. Do

not try to light the pilot by hand.

B. BEFORE OPERATING smell all around the

appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air

and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on

this label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

Gas Shutoff

Valve

Combination

Gas Control

• If you cannot reach your gas supplier, call

the fire department.

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will

notpush in or turn by hand, don’t try to repair it,

call a qualified service technician. Force or

attempted repair may result in a fire or

explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualified

service technician to inspect the appliance and

to replace any part of the control system and

any gas control which has been under water.

4. This appliance is equipped with an ignition

device which automatically lights the burner.

Do not try to light the burner by hand.

5. Remove front door.

6. Turn gas shutoff valve clockwise to “off”.

Handle will be horizontal, do not force.

7. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B” in the safety

information above (to the left) on this label. If

you don’t smell gas, go to the next step.

8. Turn gas shutoff valve counterclockwise to

“on”. Handle will be vertical.

9. Replace front door.

10. Turn on all electric power to appliance, depress

on/off button on control panel, depress black

button on top of control panel.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the

instructions “To Turn Off Gas To Appliance”

and call your service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if

service is to be performed.

3. Remove front door.

4. Turn gas shutoff valve clockwise to “off”. Do

not force.

5. Replace front door.

Page 19

Endurance

PAR MESURE DE PRUDENCE, LISEZ CE QUI SUIT AVANT DE

FAIRE FONCTIONNER L’APPAREIL

MISE EN GARDE

Si vous ne suivez pas ces instructions à la lettre, un incendie ou une

explosion pourrait se produire et causer des dommages matériels,

des blessures personnelles ou même la mort.

A. Cet appareil est muni d'un dispostif d'allumage qui

allume automatiquement la veilleuse. Ne tentez pas

d'allumer la veilleuse manuellement.

B. AVANT D’UTILISER, vérifiez s’il n’y a pas d’odeur de

gaz près de l’appareil. Vérifiez s’il n’y a pas d’odeur

de gaz près du plancher, car le gaz est plus lourd

que l’air et peut se déposer sur le plancher.

QUE FAIRE EN CAS D’ODEUR DE GAZ

• N’essayez pas d’allumer n’importe quelque

appareil que ce soit.

• Ne touchez pas à un commutateur électrique.

N’utilisez pas le téléphone de votre résidence.

• Appelez immédiatement votre fournisseur de gaz

en utilisant le téléphone de votre voisin. Suivez

les instructions de votre fournisseur de gaz.

• Si vous ne pouvez joindre votre fournisseur de

gaz, appelez le service des incendies.

C. Ne ppoussez ou tournez la manette d'admission

du gaz qu'à la main ; ne jamais utiliser d'outil. Si

la manette reste coincée, ne tentez pas de la

réparer ; appelez un technicien qualifié. Le fait de

forcer la manette ou de la réparer peut

déclencher une explosion ou un incendie.

D. N’utilisez pas cet appareil si l’une des pièces a

été plongée sous l’eau. Communiquez

immédiatement avec un technicien de service

qualifié afin qu’il inspecte l’appareil et remplace

toute pièce du système de commande et toute

commande de gaz qui aurait été plongée sous

l’eau.

Page 19

NOTICE D’UTILISATION

1. ARRÊTEZ ! Lisez l’information de sécurité cidessus, sur cette étiquette.

2. Réglez le thermostat au réglage le plus bas.

3. Coupez l’alimentation électrique à l’appareil.

4. Cet appareil est doté d’un dispositif d’allumage

qui allumera automatiquement le brûleur.

Ne tentez

5. Enlever la porte avant.

Valve de fermeture

pas d’allumer le brûleur manuellement.

Commande de gaz

multifonctions

du gaz

6. Faites tourner la valve de fermeture du gaz dans

le sens des aiguilles d’une montre et mettez-la

à «off». La poignée sera horizontale. N’employez

pas de force.

7. Attendre cinq (5) minutes pour laisser échapper

tout le gaz. Reniflez tout autour de l'appareil, y

compris près du plancher, pour déceler une

odeur de gaz. Si vous sentez une odeur de gaz,

ARRÊTEZ ! Passez à l'étape B des instructions

de sécurité sur la pportion, supérieure (à gauche)

de cette étiquette. S'il n'y a pas d'odeur de gaz,

passez à l'étape suivante.

8. Faites tourner la valve de fermeture du gaz dans

le sens contraire des aiguilles d’une montre et

mettez-la à «on». La poignée sera verticale.

9. Replacer la pporte avant.

10. Rétablissez l’alimentation électrique à l’appareil,

appuyez sur le bouton «on/off» qui se trouve sur le

panneau de commande, appuyez sur le bouton noir

qui se trouve sur le panneau de commande.

11. Réglez le thermostat à la température désirée.

12. Si l’appareil ne se met pas en marche, suivez les

instructions intitulées “Comment couper l'admission

de gaz de l'appareil” et appelez un technicien

qualifié ou le fournisseur de gaz.

FERMETURE DE L’ALIMENTATION EN GAZ

1. Réglez le thermostat au réglage le plus bas.

2. Coupez toute alimentation électrique à l’appareil

si celui-ci doit faire l’objet d’un entretien.

3. Retirez le panneau d’accès aux commandes et le

couvercle avant qui se trouve sur le dessus.

4. Faites tourner la valve de fermeture du gaz dans

le sens des aiguilles d’une montre et mettez-la

à «off». N’utilisez pas de force.

5. Replacez le couvercle avant.

30-414A

Page 20

Page 20

SECTION 5.

Electrical Connections

5.1 Electrical Connections

All electrical wiring must conform to local codes

and/or the latest edition of the National Electric Code

(NEC; NFPA 70) or the Canadian Electric Code, Part

1 (CEC; CSA C22.1). Any applicable local codes must

also be adhered to.

The unit must be electrically grounded in

accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirement, with the latest edition of the National

Electric Code (NEC; NFPA 70) or the Canadian

Electric Code, Part 1 (CEC; CSA C22.1). Any

applicable local codes must also be adhered to.

Single pole switches, including those of safety

control and protective devices must not be wired in a

grounded line.

All electrical connections are made through the

electrical knockouts on the control panel. The

knockout on the right side of the control panel can be

used to mount a wiring box, if desired.

NOTE: All internal electric components have been

pre-wired. No attempt should be made to connect

electric wires to any other location except the wiring

box as described below.

1. Main power: Connect a fused 120 volt supply

(15 amp) to the main power switch (see

Figure 24) (hot leg is connected directly to

switch). Neutral leg to white wire. Ground wire

can be connected to the grounding screw in the

box or on the switch.

2. For single zone installations: (If external pump is

required, e.g., because of large system pressure

drop) connect room thermostat wires to the red

and white/red wires. Connect circulator (120 volt,

5 amps maximum) between the blue wire and the

white wire (neutral) (see Figure 25). Note that the

blue/white pump wire connects to a dry contact.

LAARS Heating Systems

ENDURANCE

FIELD WIRING BOX

BLU/WHT

WHT

BLU/WHT

BLK

GRN/YEL

WHT/RED

RED

Figure 24. Single Zone With Room Thermostat (internal

pump provides system flow).

ENDURANCE

FIELD WIRING BOX

BLU/WHT

WHT

BLU/WHT

BLK

GRN/YEL

WHT/RED

RED

Figure 25. Single Zone with Added Circulator(s) and

Room Thermostat(s).

120 VAC NEUT.

CIRCULATOR

120 VAC LINE

GROUND

T'STAT (T)

T'STAT (T)

120 VAC NEUT.

120 VAC LINE

GROUND

T'STAT (T)

T'STAT (T)

CIRCULATOR

C1

120 VAC

ROOM T'STAT

The line voltage and pump wire must be

connected per the wiring figures, or the pump

may not be energized.

3. Zone Valves and Thermostats: Install external 24

volt transformer of sufficient V.A. to power

combined load of zone valves. Consult zone

valve manufacturer’s instructions. Connect

BLU/WHT

WHT

BLU/WHT

BLK

GRN/YEL

WHT/RED

RED

ENDURANCE FIELD

WIRING BOX

Figure 26. Multiple Zones Utilizing Four Wire Zone Valves with (Dry) End Switches.

120 VAC NEUT.

CIRCULATOR

120 VAC LINE

GROUND

T'STAT (T)

T'STAT (T)

CIRCULATOR

C1

ZONE THERMOSTATS

120 VAC

TRANSFORMER

120 VAC

Page 21

Endurance

Page 21

ZONE THERMOSTATS

C1

BLU/WHT

WHT

BLU/WHT

BLK

GRN/YEL

WHT/RED

RED

ENDURANCE FIELD

CIRCULATOR

120 VAC NEUT.

CIRCULATOR

120 VAC LINE

GROUND

T'STAT (T)

T'STAT (T)

120 VAC

R

1

2

3

TACO ZONE VALVES

RELAY

24VAC COIL

N.O.CONTACTS

WIRING BOX

Figure 27. Multiple Zones with Three Wire Zone Valves (Requires Isolation Relay).

REMOVE CONNECT CONNECT

JUMPER BLUE/WHITE RED-RED/WHITE

FROM

ZC-ZR

ZC-ZR

ZC-LI

24VAC

POWER

PR,JN

ZC-P

PR,JN

THERMOSTATS

ZONE1

ZONE2

RED

RED/WHT

MFG&MODEL

ARGO AR8---

B&G ZT-

HONEYWELL R8---

TACO 005

TACO SR502

SINGLE RELAY 1-3

TRANSFORMER

24 VAC

11

22

33

120 VAC

NOTE: This wiring is NOT the same

as shown by valve manufacturer.

TO

ZC

ZC

ZC

ZC

3

ZONE3

TO

X-X

X-X

H1-H2

3-4

XI-X2

5-6

BLUE/WHT

WHT

BLK

FIELD

WIRING BOX

CIRULATOR/ZONE VALVE (HOT)

120 VAC (NEUTRAL)

120 VAC (HOT)

BOILER T-T

BOILER T-T

Figure 28. Multiple Zones with Circulators and Room Thermostats.

W

R

RELAY

24 VOLT

NO CONTACT

LAARS

P/N 2400-060

TYPICAL ZONE PUMPS RELAY

ZONE1

120 VOLT CIRCULATORS

Y

N

P ZC H X1 X2

G

Rc

(HOT)

L1

L2

ZONE3

ZONE2

NOTE: This wiring required only for

single zone applications utilizing clock

thermostats requiring 24 volt power

supply.

120

VAC

TO T-T BOILER

CONNECTIONS

Figure 29. Wiring for Single Zone Power Stealing Type Clock Thermostats That Require 24 VAC.

120V/24-20VA

TRANSFORMER

Page 22

Page 22

LAARS Heating Systems

circulator (120 volt, 5 amp maximum) between

the blue wire and the white wire (neutral) (see

Figure 26).

4. Multi zone/Multi-relay-circulator Installations:

Multiple circulators must not exceed 5 amps total

when connected to blue wire (see Figure 28).

NOTE: On zone valve systems such as Taco,

Automag and others which do not have isolated (dry)

contact end switches, a single pole isolating relay

must be utilized (see Figure 27).

SECTION 6.

Using the Boiler Control

6.1 Front Panel Display

Figure 30 shows the front panel display of the

boiler control. The Endurance boiler control has four

buttons, which are used to access viewing and

programming menus. The LED’s at the top of the

control show the sequence of events, from left to right:

Pump Status, TH Status (boiler attempting to run) and

Gas Valve Status.

There are three LEDs that illuminate at the top of

the controller, shown as L1, L2 and L3 in Figure 30.

These light from left to right, in order of the events

that happen when the Endurance receives a call for

heat.

L1 (LED on top left of display) lights when the

pump is energized.

L2 (LED in the middle top of display) lights

when the boiler is attempting to light burner.

L3 (LED on the top right of display) lights when

the gas valve is energized.

Figure 30. Boiler Control.

6.2 Control Logic

The user sets the Burner Control Point by

programming the Burner Off Point. The boiler control

modulates the burner to keep the boiler outlet

temperature at the boiler control point.

The Burner Off Point minus the Off Point

Differential is the Burner Control Point. The Off Point

Differential is fixed at 10°F (6°C).

For instance, if the Burner Off Point is chosen as

190°F (88°C), with a fixed 10°F (6°C) differential, the

control will strive to keep the supply temperature at

180°F (82°C).

In this example, when the Endurance gets the

initial call for heat, it will start at low fire, and begin

its heat-up. The control monitors how quickly the

supply temperature is increasing, and bases its

modulating rate (output Btu/hr) on that rate of change.

The output of the unit will reduce as the water

temperature approaches 180°F (80°C). It will attempt

to remain at 180°F (80°C) for the entire call for heat.

If the system requires less heat than the lowest

modulating rate, the outlet water temperature will rise

past the Burner Control Point of 180°F (82°C), and

will eventually reach the Burner Off Point of 190°F

(88°C) and shut off.

The control also has a Burner On Point that is

calculated by subtracting the Burner On Differential

from the Burner Control Point. The Burner On

Differential is adjustable from 4 to 30°F (2 to 17°C) in

the EDP/EDN models, and is fixed at 13°F (7°C) on

the EBP models (to ensure that the tank will always be

charged properly for domestic water calls for heat). In

the example here, with a 13°F (7°C) Burner On

Differential, that would mean a Burner On Point of

167°F (75°C). During a call for heat, if the Endurance

reaches its Burner Off Point, the control will allow the

supply temperature to drop to the Burner On Point of

167°F (75°C) before it fires again. Figure 31 shows a

graph of this example.

6.3 View Menu

The boiler control allows the user to view the

temperatures that are being read by the sensors.

The default display for the boiler control is the

supply temperature (defined below). To scroll through

and view the other readings, press the up or down

button. Figures 32 and 33 show the locations of the

temperature sensors in the EBP and EDP/EDN units.

Temperatures available in the view menu are:

a. Supply Temperature (shown as the default

display) — The temperature of the water leaving

the boiler heat exchanger.

b. Return Temperature (shown as “rtn”) – The

temperature of the water entering the boiler heat

exchanger. (Note that this is not system return

temperature. It is the inlet to the heat exchanger,

which is system return mixed with boiler outlet

water.)

c. Tank Temperature (shown as “tnt”, EBP only) –

The temperature of the water in the transfer tank.

d. Heat Exchanger Delta T (shown as “dt”) – The

temperature difference between the inlet and

outlet of the boiler heat exchanger.

5. Outdoor Air Temperature (shown as “Oat” when

used) – The temperature at the outdoor air

sensor.

Page 23

Endurance

Page 23

Figure 31. Control Logic Example.

6. Calculated Setpoint for Outdoor Reset (shown as

“CSP” – when used) – The temperature that the

controller has calculated for a setpoint, based on

the outdoor temperature, when outdoor reset is

being used.

Figure 32. EDP/EDN Flow Schematic.

Page 24

Page 24

LAARS Heating Systems

Figure 33. EBP Flow Schematic.

6.4 Setpoint Menu

The setpoint menu is accessed by pressing the

enter button, and holding it for 3 seconds. Move

through the setpoint parameters by pressing the up and

down arrows. When the desired parameter is

displayed, press the enter button. Use the up and down

arrows to change the value of that parameter, and

press enter to save the change. Parameters that can be

set on the Endurance boilers are shown in the next

sections.

The boiler control will automatically return to

the view mode if the control buttons are not pressed

for 30 seconds.

6.4.1 “SP” Supply Temperature

Shown as “SP” in the control, the supply

temperature is the Burner Off Point. When the

temperature of the water that is leaving the boiler heat

exchanger reaches this setting, the Endurance shuts

off. If there is still a call for heat, it will energize again

when it reaches the Burner On Point. Default value is

190°F (88°C). It is adjustable from 170-220°F (77104°C) on EBP units, and from 155-220°F (68-104°C)

on the EDP/EDN units. SP has a fixed 10°F (6°C)

differential to the Burner Control Point. SP minus the

10°F (6°C) differential gives you the Burner Control

Point, which is the temperature the Endurance will

attempt to maintain, using its modulation features. The

differential between SP and the Burner On Point is

adjustable, using the Burner On Differential.

6.4.2 “PO” Pump Operation

This parameter, shown as “PO” in the selection

screen, allows the user to choose between the

Endurance pump running continuously (“Con”), or

running in the automatic mode (“Aut”) such that the

pump is energized only when there is a call for heat,

and has the option of a pump time delay when the call

for heat ends.

6.4.3 “Pd” Pump Delay

Pump delay is shows as “Pd” on the screen.

When pump operation “PO” parameter is set for

automatic (“Aut”), the user can choose the pump delay

time. This is the length of time that the Endurance

pump will run after the call for heat has ended. It can

be used to purge heat from the boiler, putting it into

the system or transfer tank. It is adjustable from 0 to

10 minutes, and the default value is 3 minutes.

NOTE: Some systems are designed such that the

Endurance pump will be left with only the internal

recirculation path when a call for heat has ended.

Make sure the system design is known before setting

a pump time delay, so that the water has a path

during the purge time.

6.4.4 “Oar” Outdoor Reset

Outdoor reset can be turned on and off using the

“Oar” parameter. You must have an outdoor sensor,

properly located, to use this function.

IMPORTANT NOTE: The Endurance outdoor reset is

limited, to ensure that internal water temperature is

high enough to prevent heat exchanger

condensation. EBP units are limited further, to keep

the temperature of the water in the 20 gallon transfer

tank high enough to serve the domestic water plate

heat exchanger at all times. This feature is not meant

to replace or mimic a system outdoor reset controller.

Page 25

Endurance

Page 25

6.4.5 “Oal” Minimum Outdoor

Reset Point

The “Oal” parameter tells the controller what the

minimum allowable supply temperature can be,

regardless of the outdoor reset calculation.

For EDP/EDN units, the default setting is 170°F

(77°C) and it is adjustable 155-200°F (68-93°C).

For EBP units, the default setting is 170°F

(77°C) and it is adjustable 170-200°F (77-93°C). Note

that the difference between EBP and EDP/EDN

adjustment ranges is because the EBP units must be

able to keep the transfer tank at a high enough

temperature to generate the domestic water through

the DHW heat exchanger.

6.4.6 “rc” Outdoor Reset Ratio

The outdoor reset ratio is shown as “rc” in the

display. The ratio determines part of the relationship

between the outdoor temperature and the Endurance

supply temperature. It is adjustable between 0.1 and 5.

The reset number represents the increase in the

Calculated Setpoint (CSP)for every degree below the

warm outdoor shutdown temperature.

The boiler control calculates CSP = Oal + (oTo –

air temp) x rc.

6.4.7 “oTo” Warm Outdoor Shutdown

When in the outdoor reset function is on, the

control has the ability to shut down the boiler system

when the outdoor temperature sensor reads the “oTo”

temperature that is set. This parameter is adjustable

from 55°-70°F (13°-21°C) and has a default setting of

65°F (18°C). The warm outdoor shutdown feature

will, of course, not affect the generation of domestic

water in the EBP models.

6.4.8 “unI” Temperature Units

The control has the ability to display and be

programmed in both °F (Fahrenheit) or °C (Celsius).

The “unl” lets the user choose between °F and °C.

6.4.9 “Dif” Burner On Differential

The differential between the Burner Control

Point and the Burner On Point is shown as “Dif” in the

display. If the Endurance reaches the Burner Off Point

during a call for heat, and the call for heat continues,

this differential will determine at what point below the

Burner Control Point the Endurance will energize

again. In the EBP models, this differential is fixed at

13°F (7°C) to ensure that the transfer tank will be

properly charged. In the EDP/EDN models, this

differential is adjustable 4°-30°F (2°-17°C).

6.5 Calculated Control Values

There are several control values that are not

directly set by the user, but are calculated by the boiler

control, once the user has set the parameters in Section

6.4. These do not show on the control display, but it is

helpful to know how they affect the control logic of

the Endurance units.

6.5.1 ACV Release (EBP only)

When the EBP is in tank charge mode, and there

is a call for space heating, the EBP needs to know at

what temperature it can release the ACV (anticondensing valve) back to the space heating position,

allowing the hot water to go into the system. The ACV

release point is the “burner off” point minus 5°F

(3°C). For example, if the “burner off” point is 190°F

(88°C), the ACV release point is 185°F (85°C). This

means that when the supply temperature reads 185°F

(85°C) in the tank, it will release the ACV for heating

mode.

6.5.2 Tank Charge Setting (EBP only)

When the temperature at the tank sensor goes

below the tank charge setting, the EBP will be in “tank

charge” mode. The tank charge setting equals the

programmed “burner off” point minus a fixed 40°F

(22°C) differential. For example, if the “burner off”

point is 190°F (88°C), the EBP will go into “tank

charge” mode when the tank sensor reads below 150°F

(66°C). The ACV will close, and the EBP will run to

bring the supply temperature up to 185°F (85°C), and

the ACV will be released back to the space heating

mode (as long as there is no call for domestic hot

water).

6.5.3 Burner On Point

The “Burner On” point is calculated by

subtracting the “Burner On Differential (Dif)” from

the “Burner Control Point.” For EBP units the

differential is fixed at 13°F (7°C) and for EDP/EDN

units, it is adjustable (shown as “Dif” in the setup

menu) from 4°-30°F (2°-17°C). This value tells the

Endurance when to re-energize during a call for heat

in which the Endurance reached its “Burner Off

Point.”

6.5.4 Modulation Point

During a call for heat, the Endurance will ignite

at low fire and will begin to modulate to match the

load as it approaches the “Burner Control Point.”

There is no fixed temperature when this will occur,

and this value is not displayed on the Endurance.

6.6 Other Control Functions

6.6.1 Using Buttons on Control

Figure 30 shows a drawing of the control,

including the placement of the four buttons. Table 4

shows the actions associated with each of the buttons.

Page 26

Page 26

Button Action Result

Up Arrow Press for 1/2 second 1. Scrolls up through view menu

(Upper Right Button) 2. In setup menu, scrolls up through setup menu

3. In setup menu, after parameter is chosen, increases

the value of that parameter

Down Arrow Press for 1/2 second 1. Scrolls down through view menu

(Lower Right Button) 2. In setup menu, scrolls down through setup menu

3. In setup menu, after parameter is chosen, decreases

the value of that parameter

Enter Press and hold for 3 seconds Puts the control is setup mode

(Lower Left Button)

Enter Press for 1/2 second 1. When in setup view, chooses the parameter that the

(Lower Left Button) user wants to adjust

2. When in setup menu, saves an adjusted parameter

Enter & Up Arrow Together Press both together for 2 seconds High fire hold for 5 minutes

(Lower Left and Upper

Right Buttons Together)

Enter & Down Arrow Together Press both together for 2 seconds Low fire hold for 5 minutes

(Lower Left and Lower Right

Buttons Together)

Power Press for 1/2 second When in alarm mode, allows the user to scroll through

(Upper Left Button) menu for 30 seconds

Power Press and hold for 3 seconds Turns control off or on to allow programming without a

(Upper Left Button) call for heat interruption.

LAARS Heating Systems

Table 4. Boiler Control Button Functions.

6.6.2 Alarm Acknowledge

When an alarm is activated (LO or one of the F

codes), the control will flash between the alarm

display and the supply temperature. Pressing the

power button (upper left button) for half a second will

allow the user to scroll through the menus for 30

seconds, before reverting back to the alarm display.

6.6.3 Power On/Off

Pressing the power button on the control (upper

left button) for 3 seconds will turn the controller off.

This will not de-energize the boiler’s power, but will

de-energize the controller. The display will still work,

but the boiler will not acknowledge a call for heat, and

will not be able to fire. This allows the user to check

and set parameters when the boiler is unable to fire.

The display will show “OFF”. When the power button

is pressed again for 3 seconds, the display will show

“ON” briefly, and the boiler will then resume normal

operation.

6.6.4 Low Fire Hold

By pressing and holding the enter button and the

down arrow button for 2 seconds, the user will fix the

Endurance in low fire for 5 minutes. There is no

change in the boiler control display when the unit is in

this mode.

6.6.5 High Fire Hold

By pressing and holding the enter button and the

up arrow button for 2 seconds, the user will fix the

Endurance in high fire for 5 minutes. This can be used

to check and/or set combustion on the appliance.

There is no change in the boiler control display when

the unit is in this mode.

6.6.6 Pump Operation

The Endurance’s internal pump will operate

when any of the following conditions occur:

• Low temperature mode.

• Tank charge mode.

• Heating system (T-T) call for heat.

• Domestic hot water (DHW) call for heat.