Laars DP2000, DP3000 Installation, Operation And Service Manual

Installation, Operation and Service Instructions

Installation, Operation

and Service Manual

for the

XL-3 Oil-Fired

Pool Heater

Models DP2000

and DP3000

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in pool heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0223500-

Page 2

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Warranty....................................................... 3

SECTION 2.

Assembly & Installation

2A. Shipping Damage.........................................3

2B. Assembly and Location ................................3

2C. Outdoor Installation .......................................5

2D. Indoor Installation .......................................... 5

2D-1. Venting ......................................................... 5

2D-2. Clearances.................................................... 6

2D- 3. Combustion Air Supply.................................. 6

2E. Oil Piping ...................................................... 6

2F. Water Piping ................................................. 8

2F-1. Water Connections........................................ 8

2G. Pressure Relief Valve .................................... 9

2H. Automatic Chlorinators .................................. 9

2I . Electrical Wiring............................................9

2J. Time Clock Installation ................................ 10

2K. Special Pressure Switch ............................. 10

SECTION 3.

Operating Instructions

3A. Start Up Procedure..................................... 10

3B. Setting the Time Clock...............................11

3C. Winter Shutdown ........................................ 12

3D. Periodic Maintenance ................................. 12

SECTION 4.

Maintenance

4A. Trouble-Shooting........................................12

4B. Cleaning the Heat Exchanger .................... 13

4C. Trouble-Shooting Guide ............................. 13

4D. Operating Sequence................................... 14

4E. Trouble-Shooting........................................14

4E-1. Burner will not start (motor and

transformer do not come on) ...................... 14

4E-2. Burner Tries to Start, but the Primary

Control 10 Shuts Off (either motor or

transformer or both come on)..................... 15

4E-3. Oil Burner Will Not Shut Off....................... 15

4E-4. Setting the Correct Fuel-Air Mixture........... 15

4E-5. Regular Maintenance .................................16

SECTION 5.

Service Information

5A. Control and Cad Cell Tests ........................ 17

5B. Control & Cad Cell

Trouble-Shooting Guide .............................17

SECTION 6.

Parts List for Model DP

Oil-Fired Heater

6A. Parts List .................................................... 18

Model DP Oil-Fired Heater

Page 3

SECTION 1.

General Information

NOTICE TO INSTALLER: Deliver all

documents that come with the heater to the pool owner.

These include the Owner’s Information and Operating

Manual and this Installation Manual.

For your safety, do not store gasoline or other

flammable liquids or vapors in the vicinity of this or

any other appliance.

Use only #2 fuel oil or #2 diesel fuel. Heavier

fuels will not operate satisfactorily, and their use

will void the warranty.

NOTE: Read the Owner’s Information Manual

before starting this installation, and before starting up

the heater the first time.

1A. Warranty

The XL-3 pool heater is sold with a limited

warranty. Details are specified on the back page of this

manual. Make warranty claims to an authorized Laars

representative or to the factory. Claims must include

the serial number and model of the heater, installation

date and name of the installer.

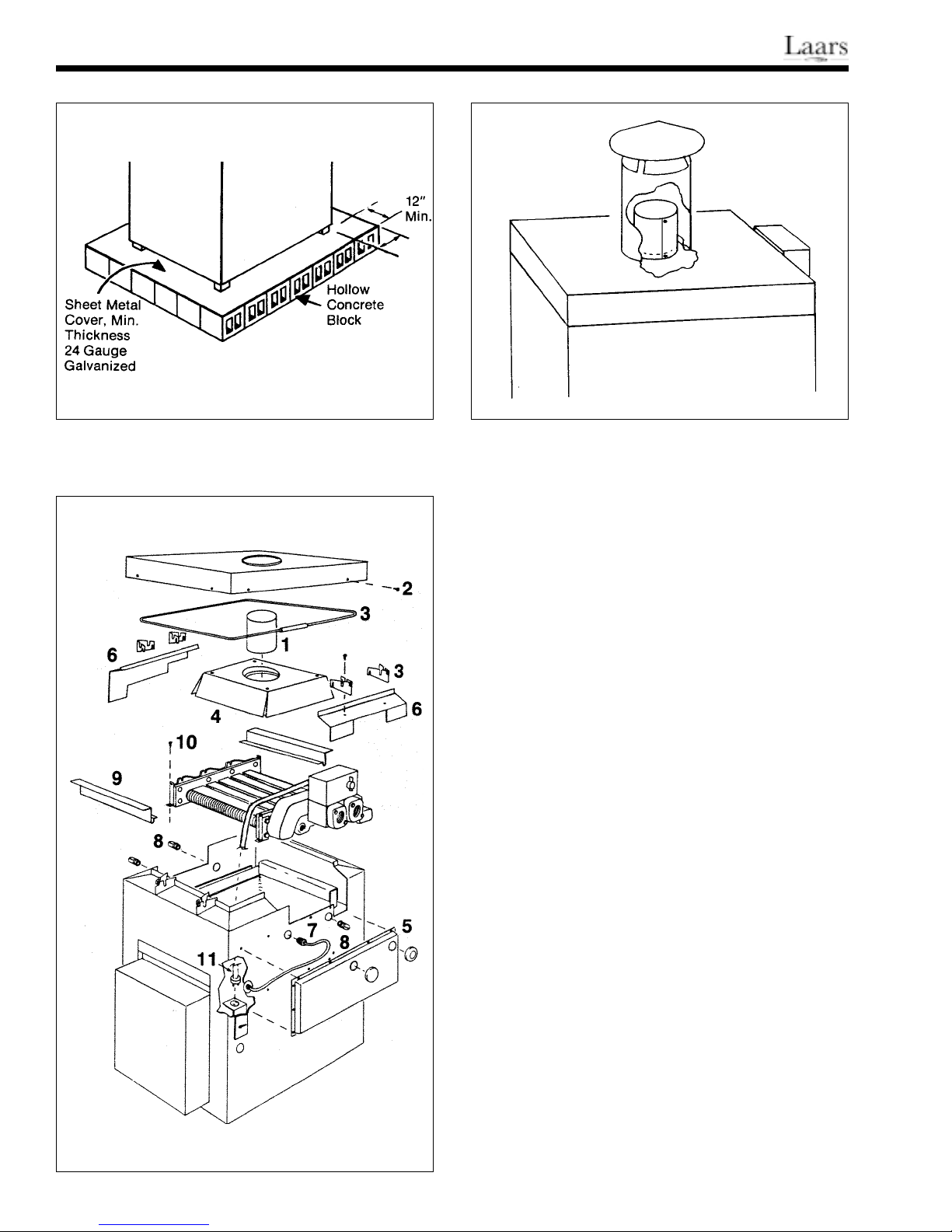

masonry must be laid with ends unsealed and joints

matched to provide a free circulation of air through the

masonry. Maintain the minimum clearances to

combustible surfaces as specified in Sections 2C and

2D of this manual. The heater must be level.

The XL-3 is shipped with the inner stack

packaged on top of the control panel door in the box

with the heater. The inner stack must be assembled

and installed before mounting the vent cap or vent

SECTION 2.

Assembly & Installation

2A. Shipping Damage

After unpacking the heater, check for visible

damage from shipment mishandling. Water Pik

Technologies carefully manufactures, inspects and

packages the heater before delivering it to the freight

carrier. Immediately file any claim for damage against

the freight carrier.

2B. Assembly and Location

Only use the XL-3 heater with pools filled with

potable water. Using the heater with mineral water,

salt water, sea water or other non-potable water will

void the warranty. The installation must comply with

all local building and safety codes.

Typically, install the heater on a noncombustible

surface. Under Standard NFPA No. 31, it is

permissible to install the heater on a combustible

surface when the installation complies with the

requirements of the American Insurance Association.

These requirements specify that the surface under the

heater must be hollow masonry not less than 4" thick,

covered with at least 24 gauge sheet metal. The

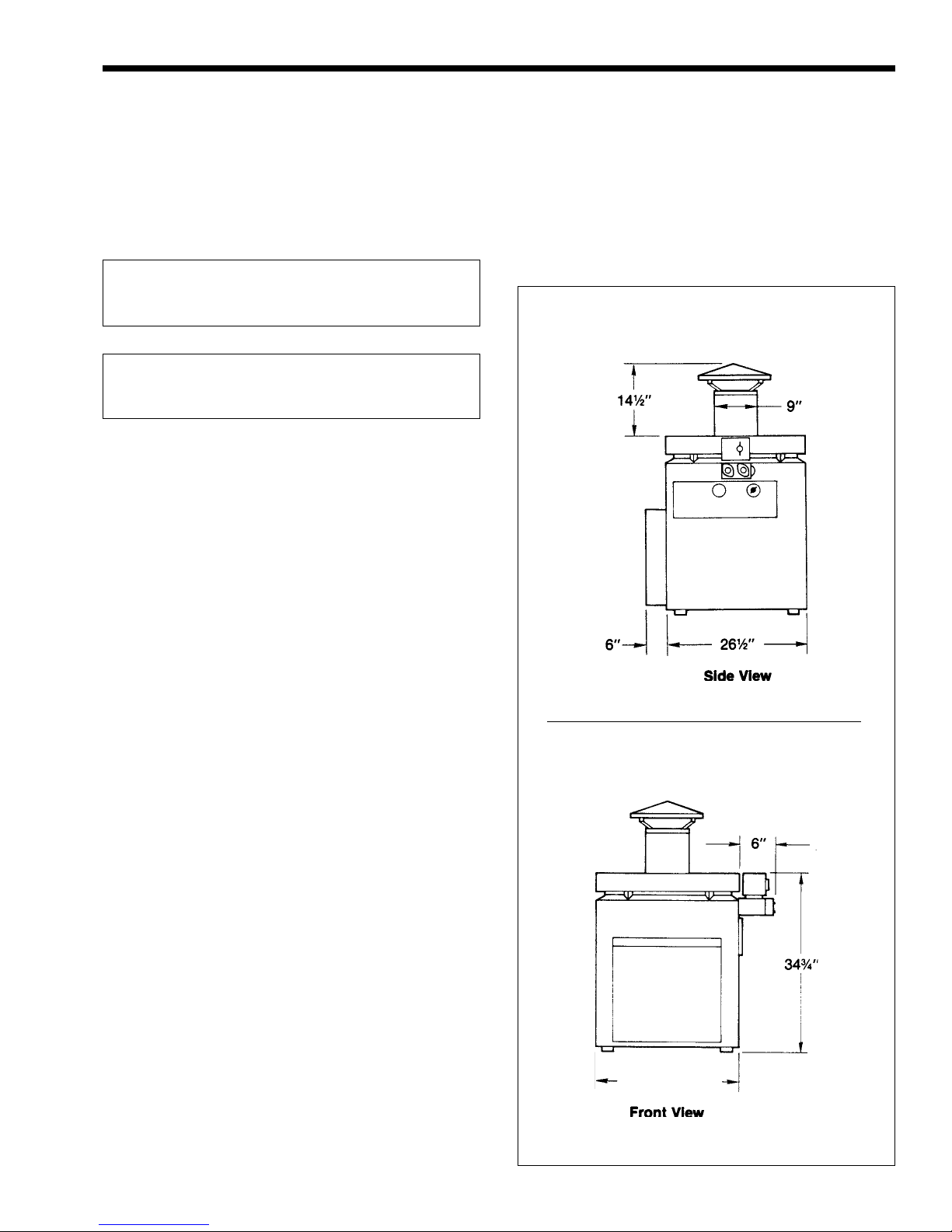

DP-2000: 22½"

DP-3000: 26¾"

Figure 1. XL-2 Oil-Fired Heater.

Page 4

Figure 2. Non-Combustible Platform. Figure 4. Inner Stack.

pipe. To assemble the inner stack, remove the tape

and small envelope from the sheet metal coil. Expand

the coil until the holes on each end are aligned. Use

the two screws supplied in the small envelope to

secure the ends together. Install the inner stack, 7"

(18cm) diameter, on the collar of the flue collector

before attaching the vent cap (outdoor installation) or

vent pipe (indoor installation) as shown in Fig. 4. The

XL-3 can be installed with the water connections on

either side. Water Pik Technologies ships the heater

with the water connections on the right side, but

changing the connections to the left side could simplify

the installation or improve access for service and

maintenance. Make the change before locating and

connecting the heater.

Follow these step-by-step instructions and

Figure 3 to reverse the heat exchanger:

Figure 3. Heat Exchanger Reversal.

1. Remove the control compartment door.

2. Remove the chimney cap assembly, or

barometric draft control if one is installed, and the

inner stack (1).

3. Remove the eight screws securing the top

assembly (2) and lift off.

4. Bend back retaining tabs and lift out the

wire guard (3). Take off the four V-baffles

(2 each side).

5. Lift out the flue collector assembly (4).

6. Remove the siphon loop cover (5) located on the

right side of the heater under the In-Out header.

7. Remove both gap spacers (6).

8. Disconnect the siphon loop on the header (7).

Remove both drain cocks (8) (one at each end of

the heat exchanger).

Model DP Oil-Fired Heater

9. Lift off both heat exchanger baffles.

10. Carefully remove the insulation at each corner of

the heat exchanger; it will be re-used. Remove the

four hold-down screws (10).

11. Unplug the electrical connector at the switch box

inside the control compartment. At the other end

of the conduit, loosen the brass compression

fitting one or two turns. Rotate the conduit

assembly and lay it on top of the heat exchanger.

FOR YOUR SAFETY: It is recommended that

two people perform the next step.

Page 5

12. Lift out and rotate the heat exchanger. Make sure

the insulation strips stay in position under the

header bars.

13. Put the screws through the hold-down clips at

each corner of the heat exchanger. Put the

insulation back in the corners.

14. Rotate the conduit assembly and attach it to the

switch box. Tighten the compression nut on the

other end.

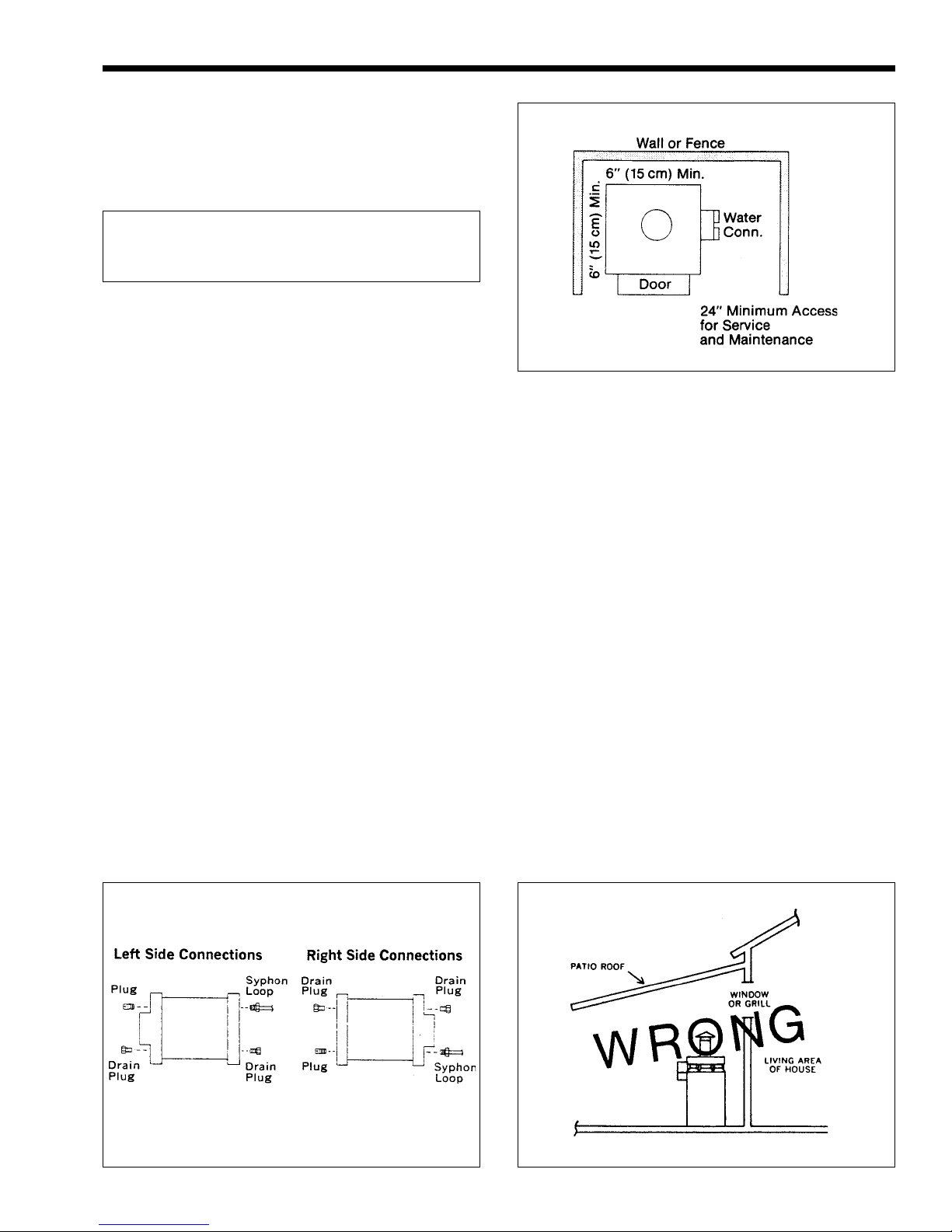

15. Replace the heat exchanger baffles and the flue

collector assembly.

16. Install the drain cocks and pipe plug according to

the illustration (see Fig. 5).

17. Straighten the siphon loop tubing and connect it to

the header where the drain plug was removed.

18. Replace the gap spacers, siphon loop cover and

rubber plugs and grommets.

19. Install the T-baffles on the gap spacers to match

the screw holes in the top assembly.

20. Replace the wire guard. Bend the tabs to secure it

in place.

21. Attach the top assembly. Install the inner stack

Figure 6. Minimum Clearances, Outdoor Installation.

22. Install the chimney cap assembly, or barometric

draft control if one was removed.

2C. Outdoor Installation

Install the Laars XL-3 heater in the open, or in an

enclosure without a roof. The chimney cap supplied

with the heater must be installed. The danger of fire

requires a minimum clearance from combustible

surfaces or shrubbery of 6 inches (15cm) (see Fig. 6).

The flue products must be dispersed in the outside air,

and fresh air available for proper combustion. Do not

install the heater under eaves where roof drainage

could fall directly on the heater.

It is possible that prevailing winds could cause a

downdraft. Therefore, keep the side of the heater at

least 3 feet (91 cm) from the face of any wall or fence.

2D. Indoor Installation

2D-1. Venting

If the heater is installed in an occupied building,

Figure 5. Connection Locations.

Figure 7. Incorrect Installation.

Page 6

Figure 8. Venting, Indoor Installation.

the room containing the heater must have its own

combustion and ventilation openings as described

below (see Fig. 8).

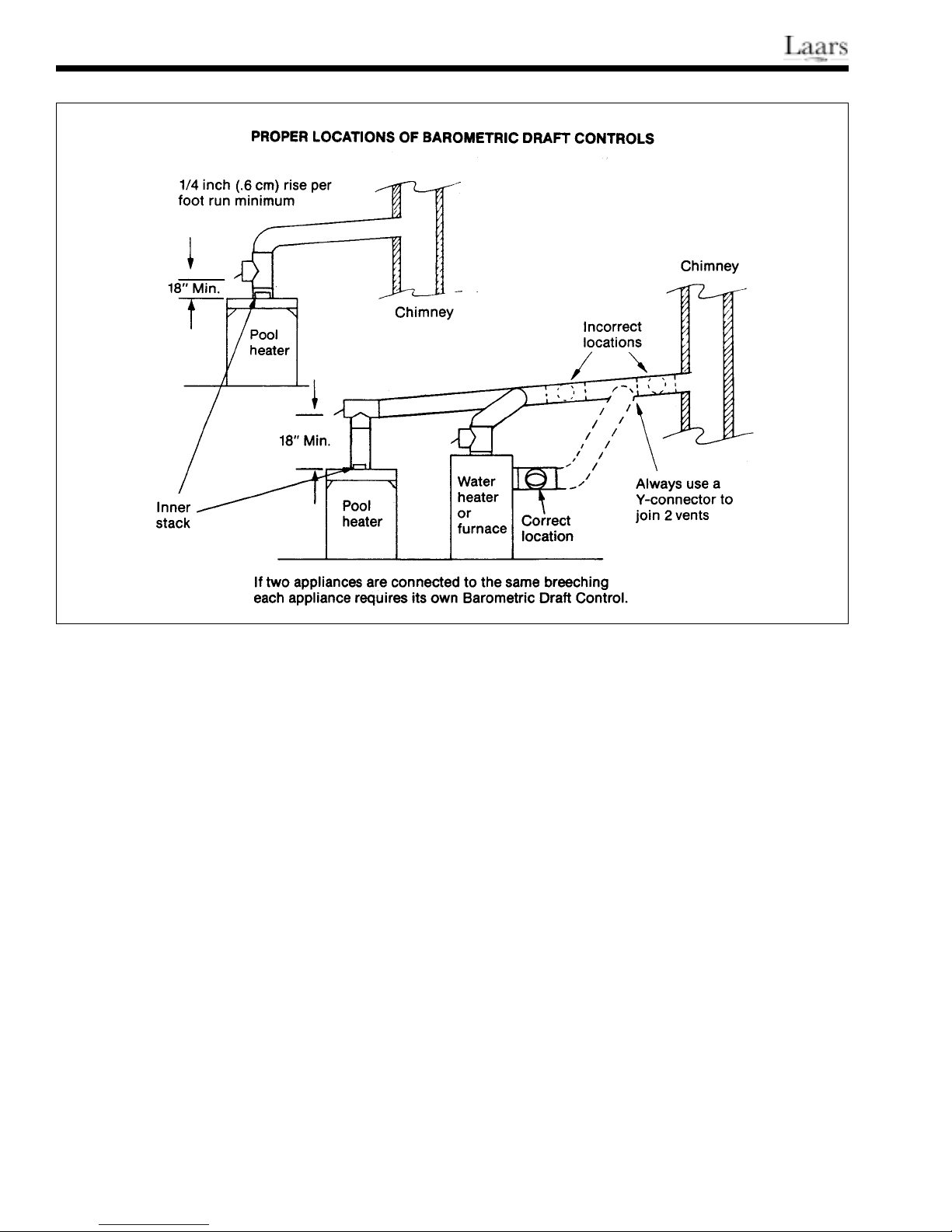

Vent the XL-3 to a permanent chimney or

through the roof with an approved stack when it is

installed indoors. You must install a barometric draft

control between the heater and the stack with a

minimum 13" clearance between the chimney

connector and any combustible surface. Observe

NFPA Standard No. 31 and all national and local

ordinances.

Run the vent pipe as directly as possible with

minimum turns. Never use a vent smaller than 9"

(23cm). On lateral runs, maintain a minimum pitch of

1/4" (.6cm) per linear foot. If a chimney is used, the

total equivalent straight length of flue piping between

the heater and the chimney should not exceed 75% of

the vertical height of the chimney above the flue pipe

connection. The chimney should be at least 9" (23cm)

diameter. Maintain adequate clearances between the

vent pipe and combustible materials. Check local codes

and the vent manufacturer’s instructions for proper

clearances. The 7" (18cm) dia. inner stack must be in

place.

Any change in the amount of draft in the

combustion chamber can affect the flame

characteristics. An approved barometric draft control

must be used on all indoor installations to maintain a

clean and consistent flame. When the system is

properly adjusted, the pressure in the stack below the

draft control will be approximately minus .03" W.C. If

this draft pressure cannot be achieved, the chimney is

too short or too small. Take corrective action.

Avoid locating the chimney termination in a

location susceptible to down draft conditions, or near

ventilation inlets to the building.

2D-2. Clearances

Provide the following minimum clearances from

combustible surfaces:

Water Inlet/Outlet side 24" (61cm)

Other side and rear 6" (15cm)

Front Control compartment 24" (61cm)

Chimney connector 13" (33cm)

2D-3. Combustion Air Supply

Do not install the heater in a room that does not

have enough air supply to support combustion. There

must be two openings to outside air provided; each

opening must have a free area equal to 80 sq. in.

(516.1 sq. cm). It is good practice to put one opening

near the floor and the other near the ceiling.

When installing the heater in an interior room, all

doors communicating with outside air must have

specified openings (see Fig. 9). There must be no

Loading...

Loading...