LAARS 9600 CB-HWG Service Manual

Service Manual Document 2109

Service Manual for

9600 CB & HWG

HWG-M2 Series CB-M2 Series

HWG-M2-250 CB-M2-250

HWG-M2-200 CB-M2-200

HWG-M2-175 CB-M2-175

HWG-M2-150 CB-M2-150

Hot Water Generator Condensing Boiler

For Natural or For Natural or

Propane Gas Propane Gas

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in flue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction...................................................3

1B. Start Up Procedures ..................................... 9

1C. Checkout Procedures...................................9

1D. Cleaning the Combustion Chamber Coil.... 10

1E. Diverting Valve........................................... 10

1F. Safety Limit Switch ..................................... 10

1G. Boiler Control .............................................. 10

1H. Stack Switch............................................... 11

1I. Igniter .......................................................... 11

1J. Transformer ................................................. 11

1K. Unit Pump ................................................... 11

1L. Blower ......................................................... 11

1M. Gas Valve ................................................... 11

1N. Time Delay Relay (TDR) .............................. 11

1O. Operating Control ........................................ 11

1P. Vent TCO .................................................... 12

1Q. Intake TCO .................................................. 12

1R. Thermal Cut-Out (TCO)................................ 12

1S. Delayed Ignition........................................... 12

1T . High Gas Consumption ............................... 12

1U. Noisy Operation .......................................... 12

1V. Short Cycling .............................................. 13

1W. Lock Outs (& Trip Outs) .............................. 1 3

1X. Routine De-Liming Procedure ...................... 14

1Y. Sequence of Operation ................................ 14

SECTION 2.

Troubleshooting

2A. Code ........................................................... 15

9600 CB & HWG Service Manual

Page 3

SECTION 1.

General Information

1A. Introduction

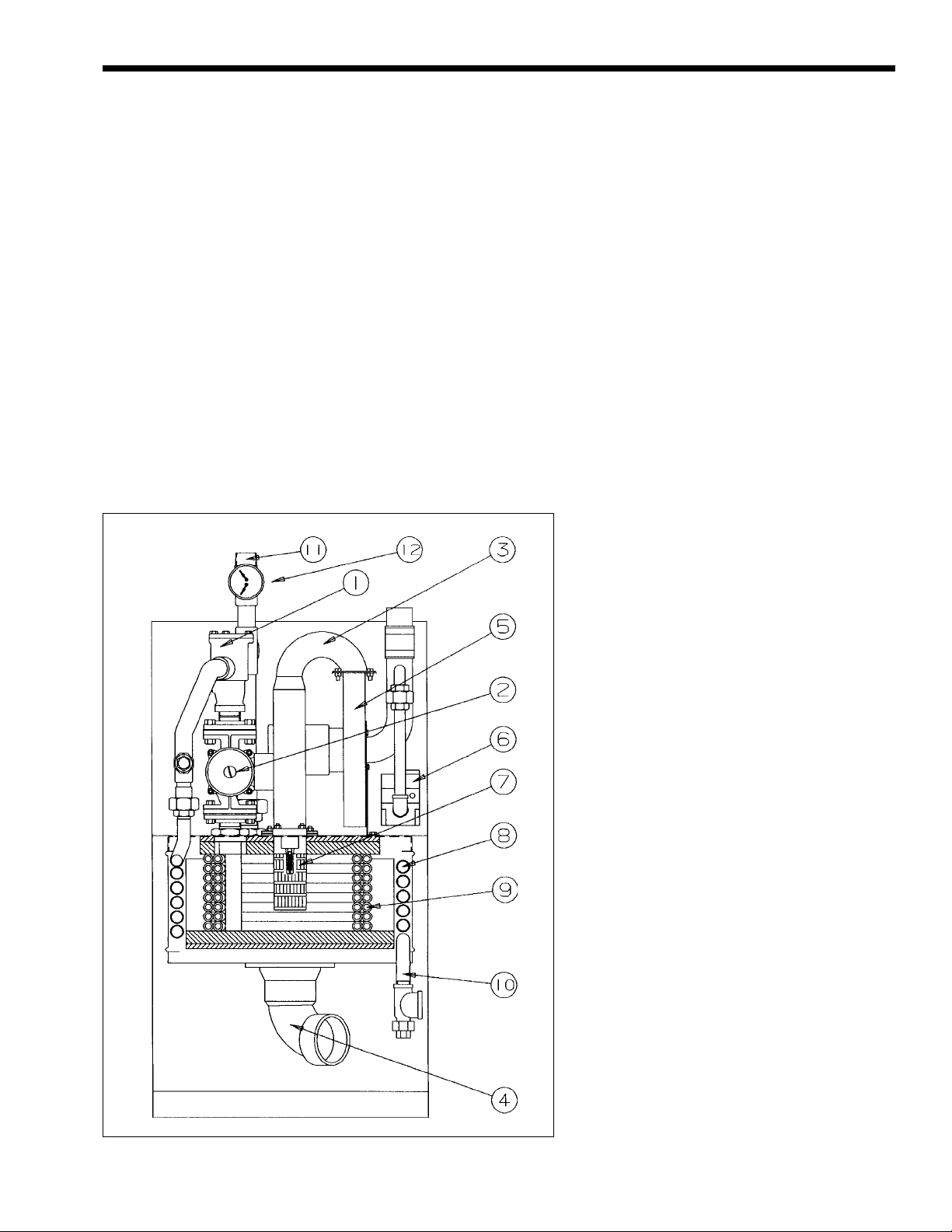

The Heatmaker 9600 CB condensing boilers and

the Heatmaker 9600 HWG non-automatic circulating

tank water heaters have a dual heat exchanger (H-X)

design. The primary H-X is a copper coil type which

operates in a non-condensing mode. A secondary

stainless steel H-X (economizer) surrounds the primary

H-X to condense water vapor from the flue gases and

extract the maximum amount of heat from the

combustion process. Condensate from the economizer

drains into the bottom of the outer shroud of the boiler

section and into the exhaust duct which provides for

condensate drainage.

Flow rates through the primary H-X are

controlled by a thermostatic diverting valve which

diverts water, as required, from the outlet of the

primary H-X back to its inlet so that the primary H-X

temperature is always maintained above the

condensation temperature of the water vapor in the flue

gases. A circulator is built into the unit to provide

enough head to circulate water through the H-X’s and

to a secondary heating loop or separate hot water

storage tank.

The forced draft premixed combustion system

contains a blower to provide air flow through the unit,

the air inlet and exhaust piping. The cylindrical burner

is provided with an air/gas mixture which is metered

through fixed orifices. A hot surface igniter (glow coil)

is controlled by the Integrated Boiler Control which

also controls the blower, circulator, and gas valve and

provides for burner flame safety.

The Heatmaker 9600 is designed to use 3" PVC*

or ABS DWV pipe or PVC, ABS or CPVC schedule

40 pipe for both air intake and flue material. Vent

terminations are provided with the unit.

* CB / HWG - M2- 250 flue material can only be ABS or CPVC.

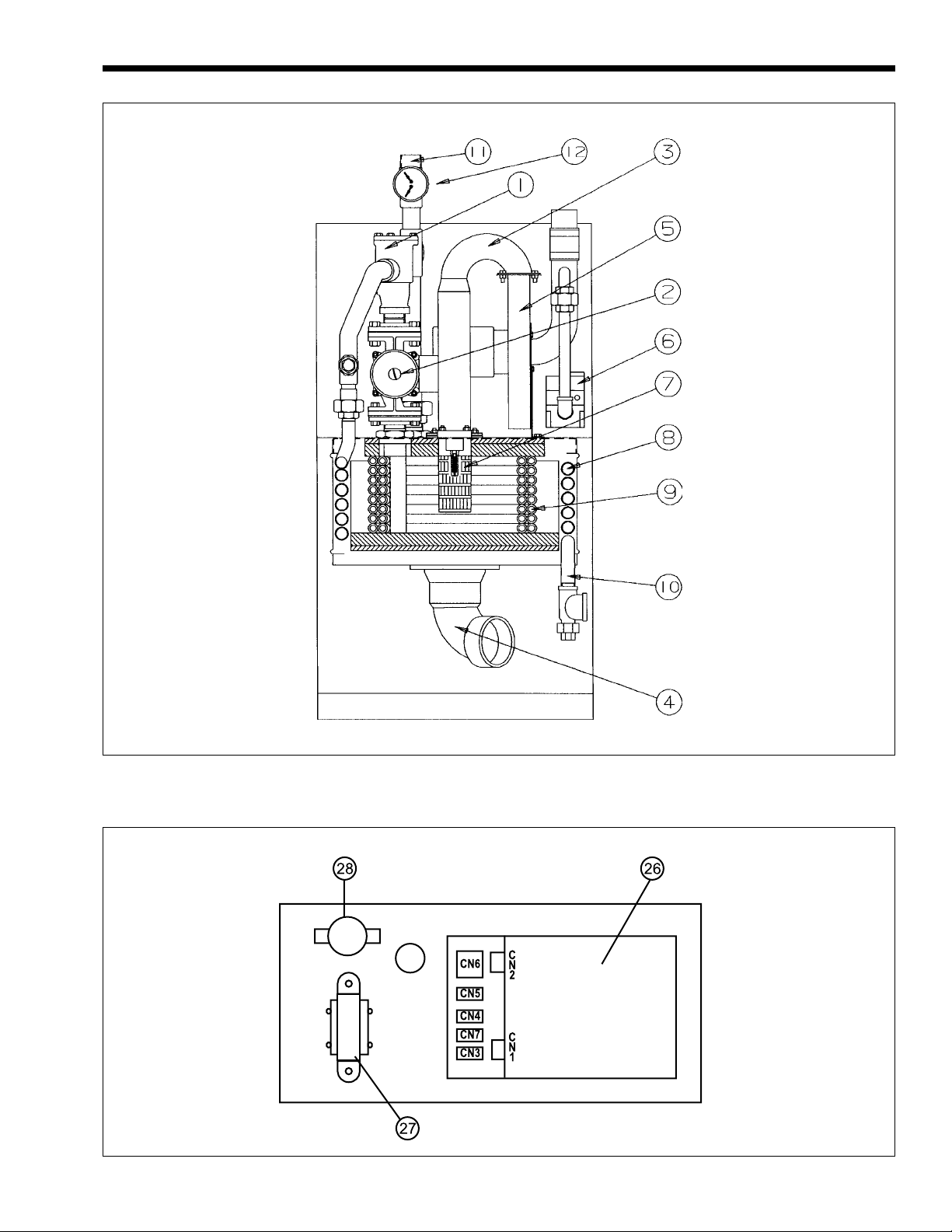

(1) Diverting valve

(2) Circulator

(3) Mixer tube

(4) Exhaust

(5) Blower

(6) Gas valve

(7) Burner

(8) Economizer

(9) Combustion coil

(10) Cold water inlet

(11) Hot water outlet

(12) Heat exchanger drain

(13) Air vent

Figure 1. Heatmaker 9600 Assembly View.

Page 4

LAARS Heating Systems

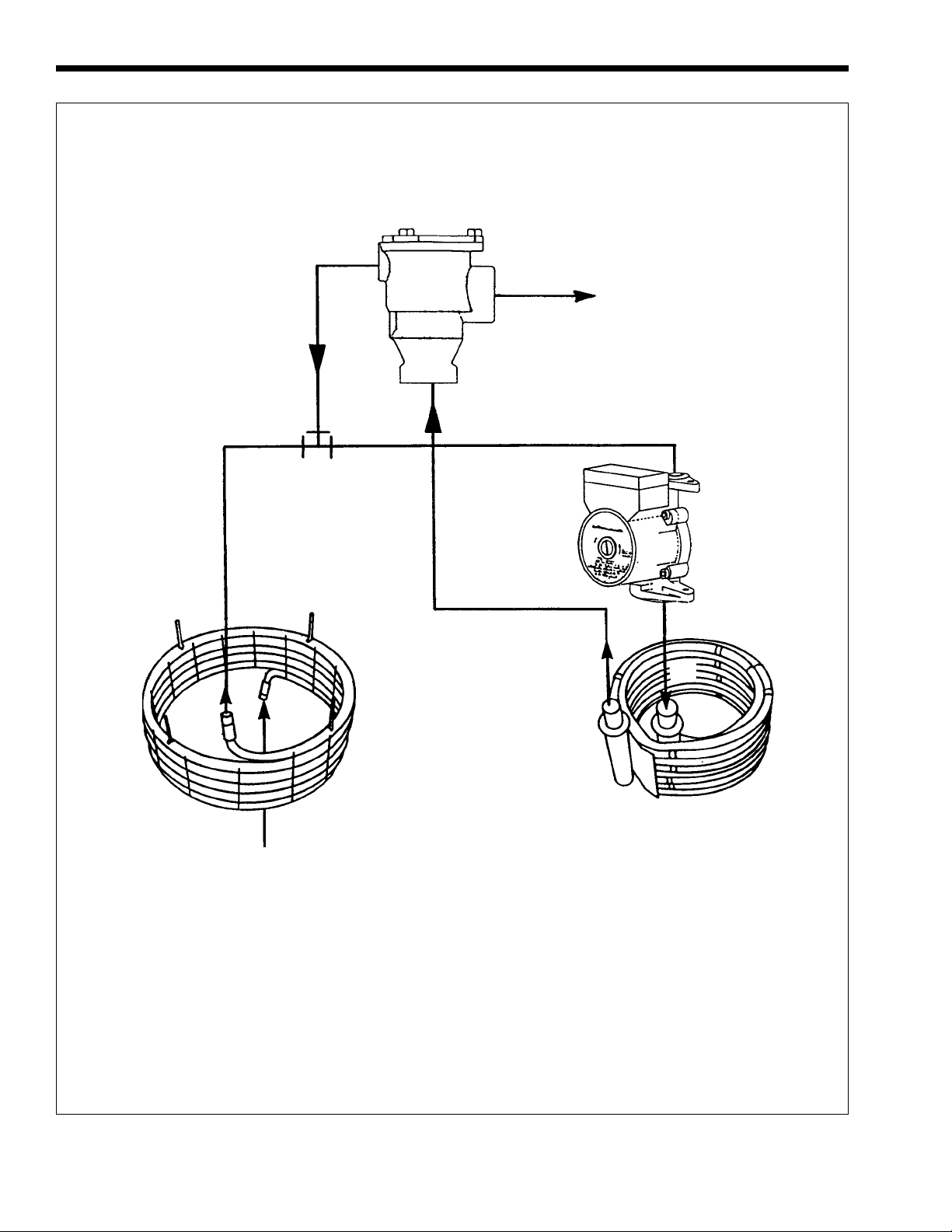

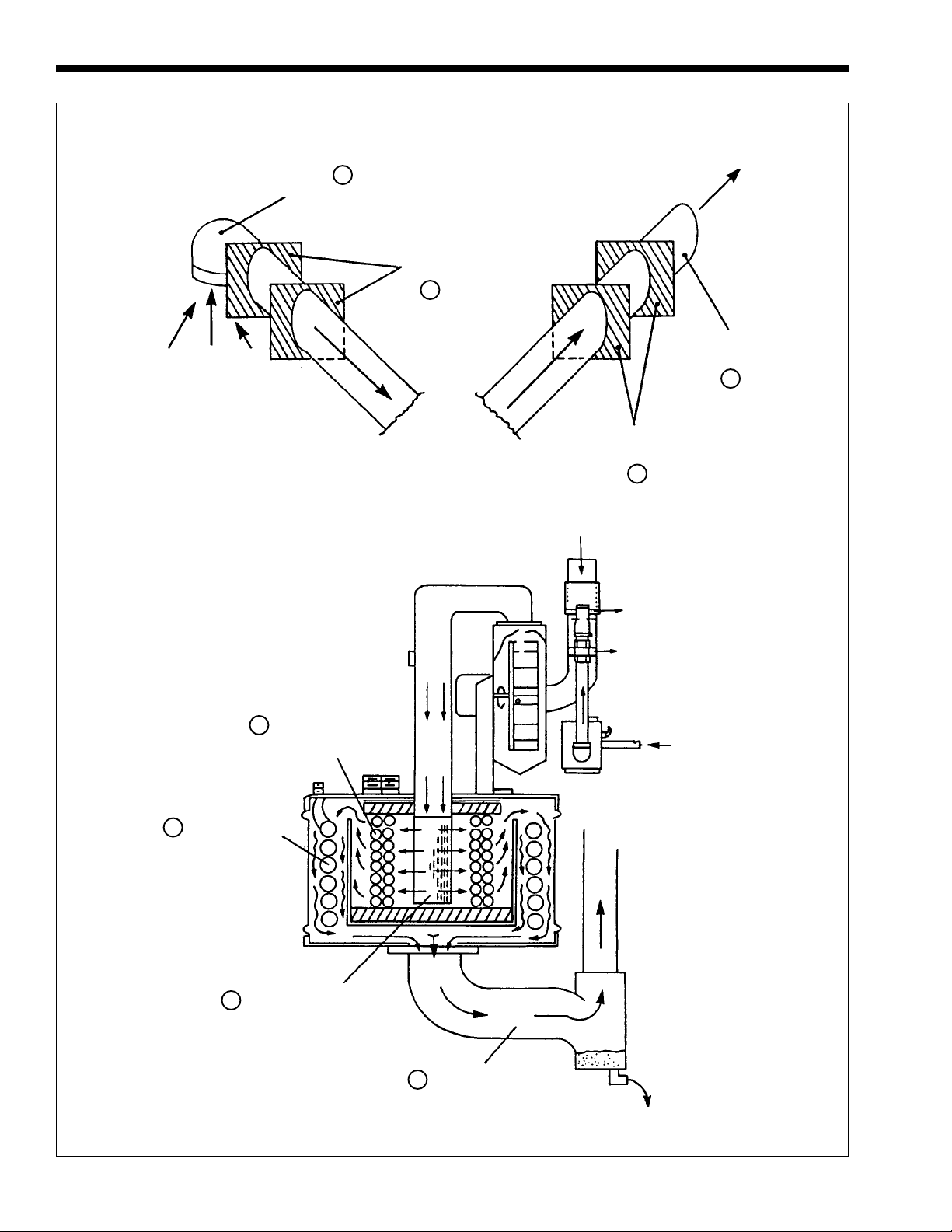

A PORTION OF

HOT WATER

IS RECYCLED

TO MAINTAIN

COMBUSTION

COIL INLET

TEMPERATURE

AT 140°F

THERMOSTATIC

DIVERTING

VALVE

(160° F THERMOSTAT)

(E)

(D)

(B)

(A)

ECONOMIZER

(A) Cold Water Inlet From Tank or System

(B) Economizer Outlet (10°F Rise above inlet)

(C) Combustion Coil Inlet 130-140°F Typical

(D) Combustion Coil Outlet

(E) Hot Water Outlet To Tank or System 160 - 170°F Typical

Figure 2a. Water Flow through a Heatmaker 9600.

HWG - Before S/N 394 - 068

CB - Before S/N 795 - 0014

COMBUSTION

COIL

9600 CB & HWG Service Manual

Page 5

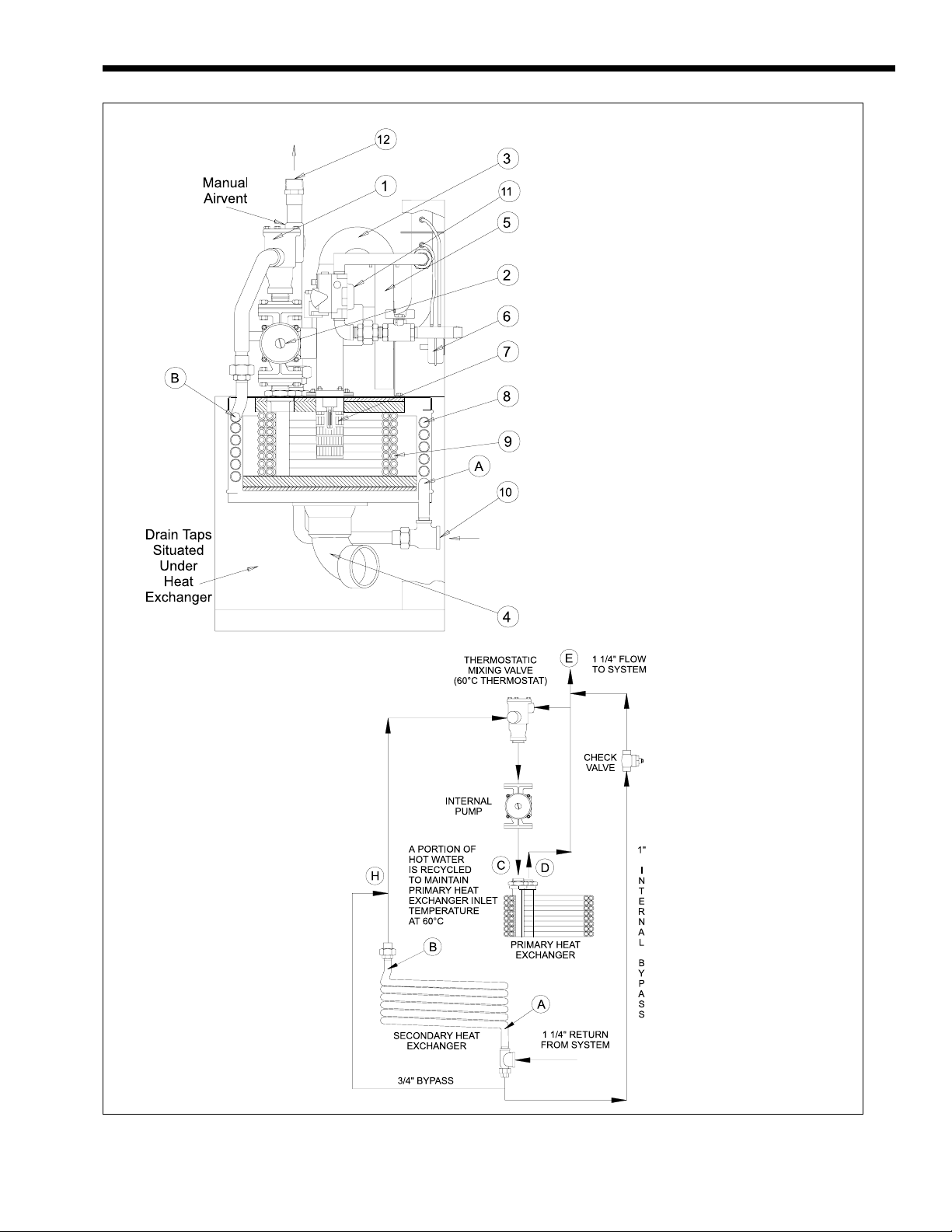

Legend

1 Mixing V alve

2 Internal Pump

3 Mixer Tube

4 Flue Outlet

5 Combustion Fan

6 Air Pressure Switch

7 Burner

8 Secondary Heat Exchanger

9 Primary Heat Exchanger

10 Return (From Primary Loop)

11 Gas V alve

12 Flow (T o Primary Loop)

A Secondary Heat Exchanger Inlet

B Secondary Heat Exchanger Outlet

C Primary Heat Exchanger Inlet

D Primary Heat Exchanger Outlet

Figure 2b. Water Flow through a Heatmaker 9600.

HWG - After S/N 394 - 067

CB - After S/N 795 - 0013

Page 6

LAARS Heating Systems

AIR

INTAKE

INTAKE

TERMINAL

EXHAUST

43

WALL

PLATE

50

EXHAUST

TERMINAL

44

WALL

PLATE

45

AIR

ORIFICE

GAS

ORIFICE

1

COMBUSTION

COIL

2

ECONOMIZER

7

FLAMEHOLDER

REFERENCE PAGE 8 FOR PART NUMBERS

Figure 3. Air/Fuel Flow Through Heatmaker 9600.

EXHAUST

46

ASSEMBLY

GAS

CONDENSATE

9600 CB & HWG Service Manual

Page 7

Figure 4. Cut Away View of Heatmaker 9600.

Figure 5. Control Box.

Page 8

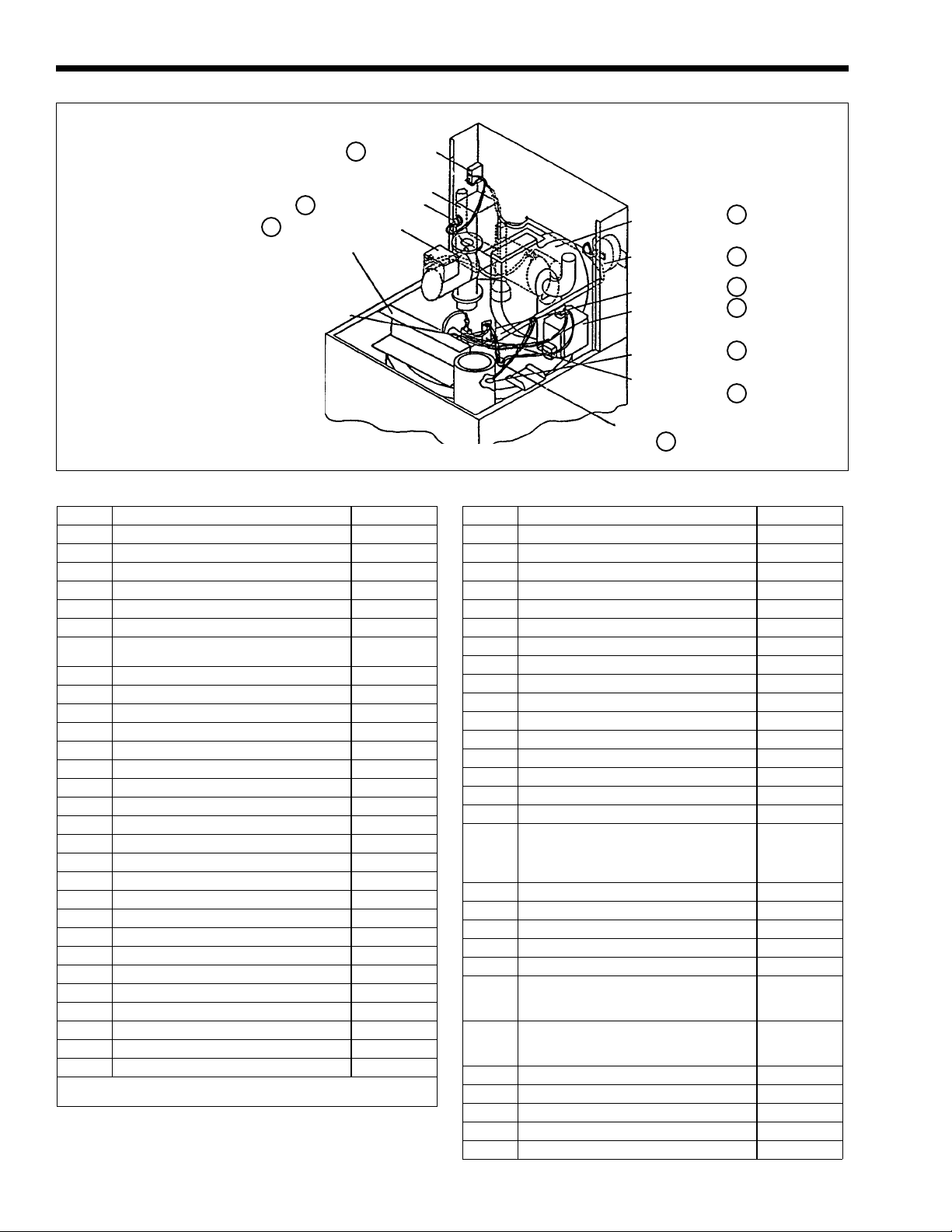

31

OPERATING LIMIT

38

CIRCULATOR PUMP

CONTROL BOX

SUB-ASSY

HEATMAKER

9600

HIGH LIMIT

32

SAFETY

SWITCH BOX

LAARS Heating Systems

BLOWER

ASSEMBLY

BLOCKED

FLUE

DETECTOR

IGNITER ASSY

GAS VALVE

VENT

THERMAL

CUT OUT

INTAKE

THERMAL

CUT OUT

16

30

6

36

34

33

Figure 6. Control Components

# Part Description Part #

1 Combustion Coil (Primary H-X) HWG 2400-086

Combustion Coil (Primary H-X) CB 2400-284

2 Economizer Coil (Secondary H-X) 10-078

3 Upper Head 10-034

4 Inner Shroud 10-112

5 Outer Shroud 10-124

Ignitor (w/Gasket) after s/n 391-126

6

791-044

6 Ignitor, before s/n 391-127 791-045 2400-248

7 Burner (Flameholder) (w/Gaskets) 2400-082

Burner (w/Gaskets) (250 Series) 2400-308

8 Upper Insulation (Blanket) 10-048

9 Upper Insulation (Board) 10-050

10 Lower Insulation (Board) 10-106

11 Lower Insualtion (Blanket) 10-108

12 Gasket, Igniter (1 req'd) 10-332

13 Gasket, Burner (2 req'd) 10-338

14 Gasket, Blower Inlet (1 req'd) 1-254

15 Gasket, Blower Discharge (1 req'd) 10-324

Gasket, Blower Discharge (250 series) 11-066

16 Blower Assembly (w/Gaskets) 2400-079

Blower Assembly (w/Gaskets) (250) 2400-310

17 Orifice, Air *

18 Orifice, Gas *

19 Orifice Union 1-252

20 Mixer Tube 10-252

Mixer Tube (250 Series) 11-016

21 Air Duct Hose 1-458

Air Duct Hose (250 Series) 11-038

22 Gas Valve Balance Line 2400-026

*Not available separately - purchase orifice kit for type of gas

and input desired.

2400-286

THERMAL

CUT OUT

35

# Part Description Part #

23 Jacket, Front Removeable 10-402

24 Jacket, Top 10-406*

25 Jacket, Bottom 10-010

26 Control, Boiler Integrated 2400-224

27 Transformer, 40 VA 2400-006

28 Time Delay Relay 2400-062

29 Wiring Harness 10-354

30 Stack Switch 2400-110

31 Operating Control 2400-056

32 Safety Limit 2400-055

33 Intake T.C.O. 2400-058

34 Exhaust T.C.O. 2400-058

35 T.C.O. 2400-020

36 Gas Valve 2400-014

Gas Valve (250 Series) 2400-015

37 Capacitor (Blower Start/Run) 2400-088

Pump, Grundfos UP 26-99-BF CB

CB-250

38

HWG

HWG-250

39 Valve, Pressure Relief (150 PSI) 2400-094

Valve, Pressure Relief (250 Series) 2400-095

40 Valve, Pressure Relief (125 PSI) 2400-096

Valve, Pressure Relief (250 Series) 2400-097

41 Diverting Valve (Complete) 2400-001

Thermostat (O-Rings

included)(160°F)

42

before S/N 394-068 or 795-0014

Thermostat (O-Rings

included)(140°F)

before S/N 394-067 or 795-0013

43 Terminal, Intake 2400-102

44 Terminal, Exhaust 2400-104

45 Flange, Wall, Vent Pipe 2400-100

46 Exhaust Assembly 2400-390

Exhaust Assembly (250 Series) 2400-402

* Specify Serial Number

2400-386

2400-387

2400-388

2400-389

2400-129

2400-130

Loading...

Loading...