Kuppersbusch GKS 11742.0-35 F-UL Instructions And Recommendations For The Use, Installation And Maintenance

Page 1

Dear customer,

thank you for buying one of our products.

We are sure that this new, modern, functional and practical appliance, made using the finest quality

materials, will fully satisfy your requirements. This new appliance is very easy to use, but in order to

obtain the best results, we strongly recommend that you read this booklet carefully before use.

These instructions are valid exclusively for countries the identification symbols of which appear

on the cover of the instruction booklet and the label on the appliance.

The manufacturer cannot be considered responsible for any damages to people or to things in the

event of incorrect installation or improper use of the appliance.

INSTRUCTIONS AND

RECOMMENDATIONS FOR THE USE,

INSTALLATION AND MAINTENANCE OF

BUILT-IN GAS CERAMIC HOBS

MODEL: GKS 11742.0-35 F-UL

COD. 04059ULKUP - 04.06.2009

The Manufacturer cannot be held responsible for any imprecision due to printing or copying errors

contained in this booklet. The figures shown are purely indicative. We reserve the right to make any

changes to our products which we consider to be necessary or useful, also in the interest of the user,

without affecting their essential characteristics in terms of functionality and safety.

Kuppersbusch USA

1883 Massaro Blvd. Tampa, FL 33619

Toll: (800) 459-0844 P: 813-288-8890 F: 813-288-8604

All manuals and user guides at all-guides.com

all-guides.com

Page 2

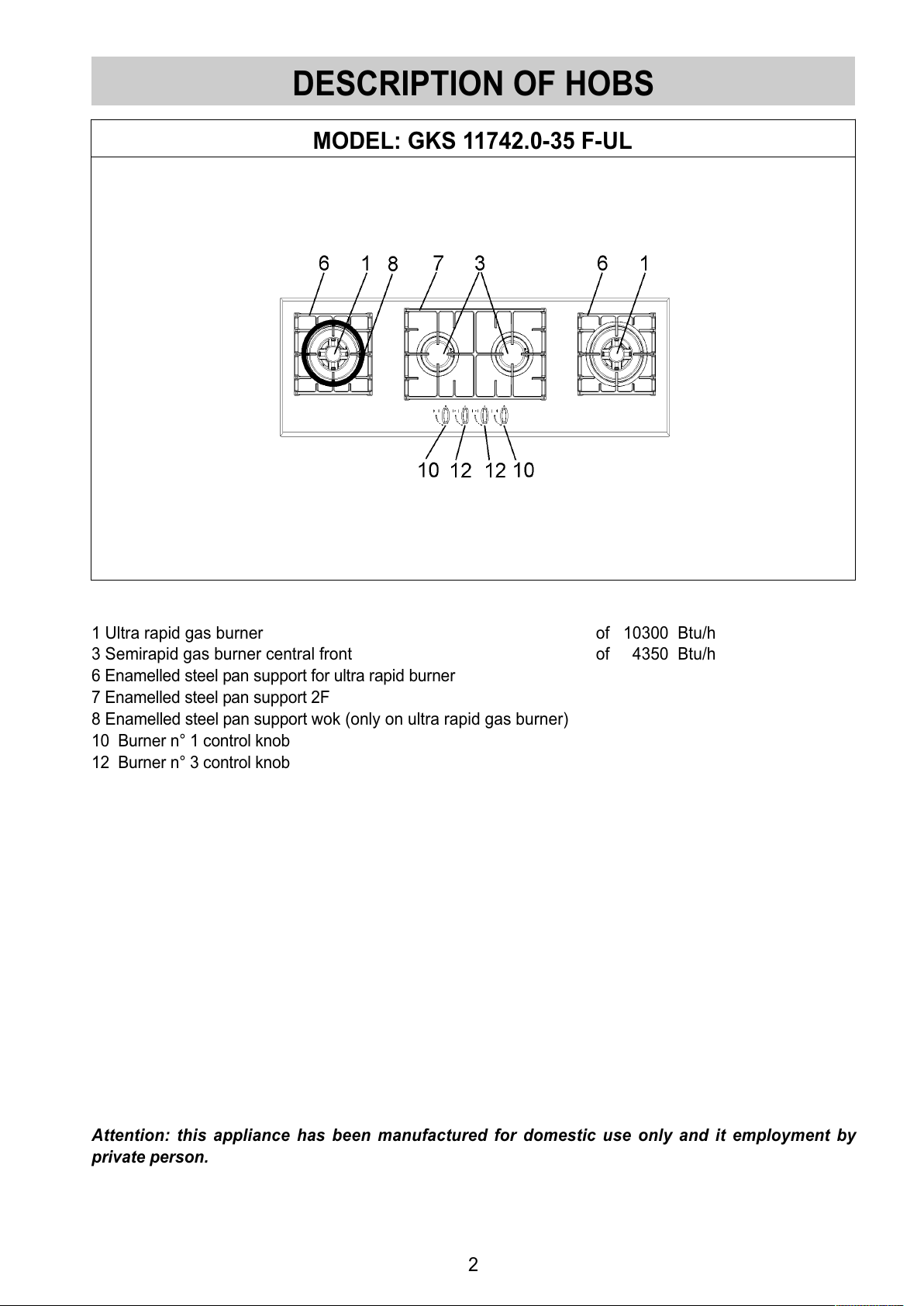

DESCRIPTION OF HOBS

MODEL: GKS 11742.0-35 F-UL

2

1 Ultra rapid gas burner of 10300 Btu/h

3 Semirapid gas burner central front of 4350 Btu/h

6 Enamelled steel pan support for ultra rapid burner

7 Enamelled steel pan support 2F

8 Enamelled steel pan support wok (only on ultra rapid gas burner)

10 Burner n° 1 control knob

12 Burner n° 3 control knob

Attention: this appliance has been manufactured for domestic use only and it employment by

private person.

All manuals and user guides at all-guides.com

Page 3

3

SAFE GUARD INSTRUCTIONS

1) SAFE GUARD INSTRUCTIONS

For all appliances:

- the product shall be installed according with the a statement that the installation must conform with local

codes or, in absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

- The product must be electrically grounded in accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70.

- The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressure in excess of ½ psi (3.5 kPa). The maximun

gas supply pressure is 4 inch WC and 11 inch WC and the gas pressure regulator provided is regulated to

1 inch water column above the manufacturer’s specified manihold pressure.

- Always disconnect all cord connect appliances shall include instructions relative to location ot the wall

receptacle and the warning to the user to disconnect the electrical supply before servicing the appliance.

- Save the orifices removed from the appliance for future use.

- When a flexible service cord of the grounding type is provided to connect the appliance to a line-voltage

electrical supply, the instructions shall also include the intent of the warning statement specified in 1.29.12.

- The maximum depth cabinets installed above cooking tops be 13 in. (330 mm).

- Keeping appliance area clear and free from combustible materials, gasoline, and other flammable vapors

and liquids.

- Not obstructing the flow combustion and ventilation air.

WARNING: If the information on this manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer; service agency or the

gas supplier.

All manuals and user guides at all-guides.com

Page 4

4

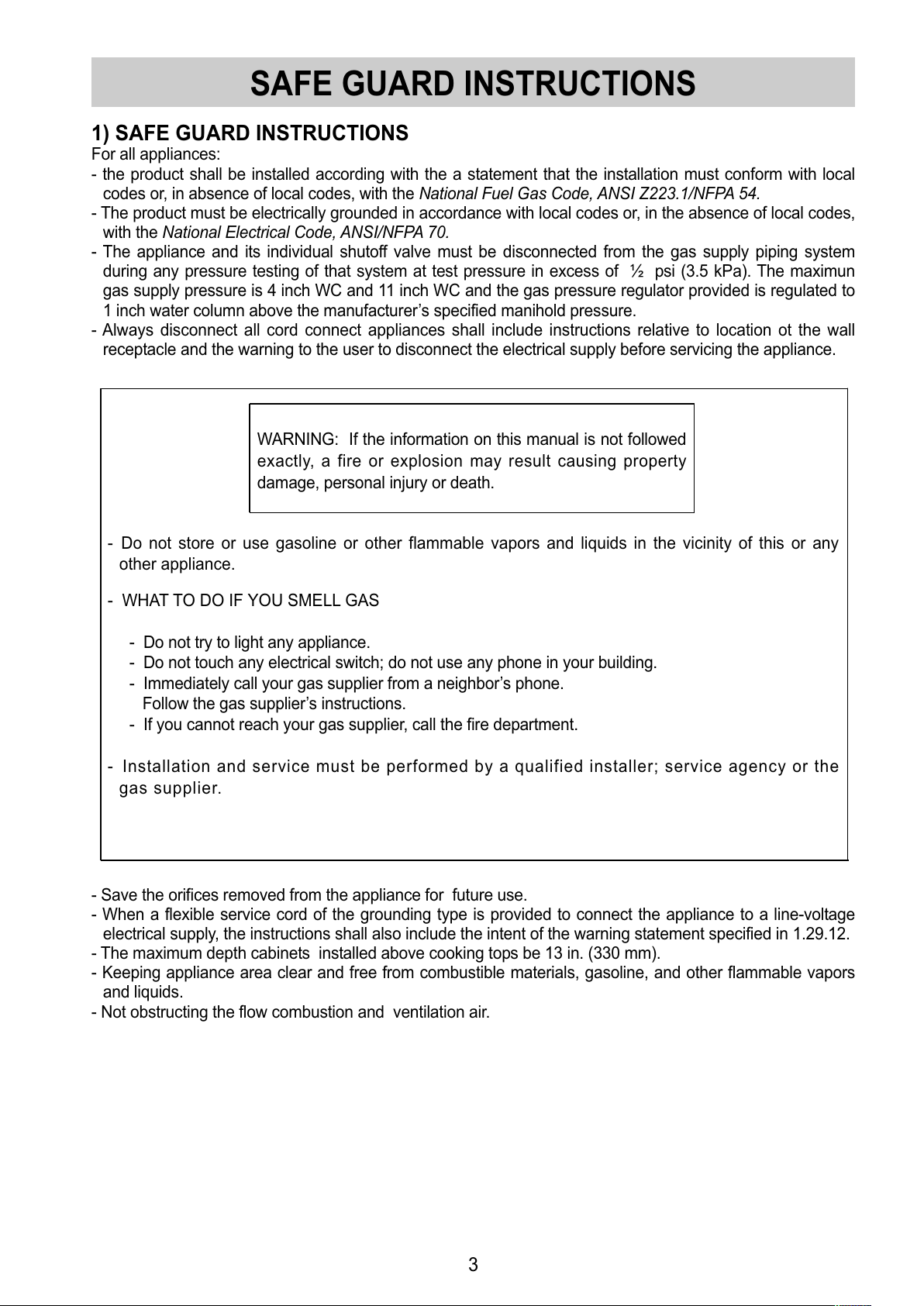

2) BURNERS

A diagram is screen-printed above each knob on

the front panel. This diagram indicates to which

burner the knob in question corresponds. After

having opened the gas mains or gas bottle tap, light

the burners as described below:

- manual ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

place a lighted match near the burner.

- Electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

depress and release the ignition button “E”.

- Automatic electrical ignition

Push and turn the knob corresponding to the

required burner in an anticlockwise direction until it

reaches the full on position (large flame fig. 1), then

depress the knob.

- Lighting burners equipped with flame failure

device

The knobs of burners equipped with flame failure

device must be turned in an anticlockwise direction

until they reach the full on position (large flame fig. 1)

and come to a stop. Now depress the knob in

qu estion and repeat the previously indicated

operations.

Keep the knob depressed for about 10 seconds

once the burner has ignited.

HOW TO USE THE BURNERS

Bear in mind the following indications in order to

achieve maximum efficiency with the least possible

gas consumption:

- use adequate pans for each burner (consult the

following table and fig. 2).

- When the pan comes to the boil, set the knob to

the reduced rate position (small flame fig. 1).

- Always place a lid on the pans.

- Use only pan with a flat bottom.

WARNINGS:

- burners with flame failure device may only be

ignited when the relative knob has been set to

the Full on position (large flame fig. 1).

- Matches can be used to ignite the burners in a

blackout.

- Never leave the appliance unattended when

the burners are being used. Make sure there

are no children in the near vicinity. Particularly

make sure that the pan handles are correctly

positioned and keep a chek on foods requiring

oil and grease to cook since these products

can easily catch fire.

- The machine must not be used by people

(including children) with impaired mental or

physical capacities, or without experience of

using electrical devices, unless supervised or

instructed by an expert adult responsible for

their care and safety. Children should not be

allowed to play with the equipment.

- Never use aerosols near the appliance when it

is operating.

- If the built-in hot plate has a lid, any spilt food

should be immediately removed from this

before it is opened. If the appliance has a glass

lid, this could shatter when the hot plate

becomes hot. Always switch off all the burners

before closing the lid.

- Containers wider th a n the unit are

recommended.

USE

FIG. 1 FIG. 2

Burners Power ratings Pan Ø in cm

Ultra rapid 10300 Btu/h 24 ÷ 26

Semirapid 4350 Btu/h 16 ÷ 18

All manuals and user guides at all-guides.com

Page 5

5

USE

Notes:

use of a gas cooking appliance produces heat and moisture in the room in which it is installed.

The room must therefore be well ventilated.

Intensive and lengthy use of the appliance may require additional ventilation. This can be

achieved by opening a window or by increasing the power of the mechanical exhausting system if

installed.

WARNING!

NEVER use this appliance as a space heater

to heat or warm the room. Doing so may result

in carb o n mono x i de po i so n in g and

overheating ot the oven.

All manuals and user guides at all-guides.com

Page 6

6

CLEANING

CAUTION:

before cleaning the appliance, disconnect it

from the gas and electricity supplies.

3) WORKTOP

If you wish to maintain the shine of the ceramic

surface, treat the glass with a silicon-based film

product before use to protect the surface against

water and dirt. This protective film is not durable,

so it is advisable to repeat the application of the

product frequently.

It is very important to clean the hob every time you

use it, while the glass is still warm.

Do not clean using abrasive metal scourers, powder

abrasives or corrosive sprays.

Depending on the degree of dirt, we recommend:

- for light stains, a damp sponge is sufficient.

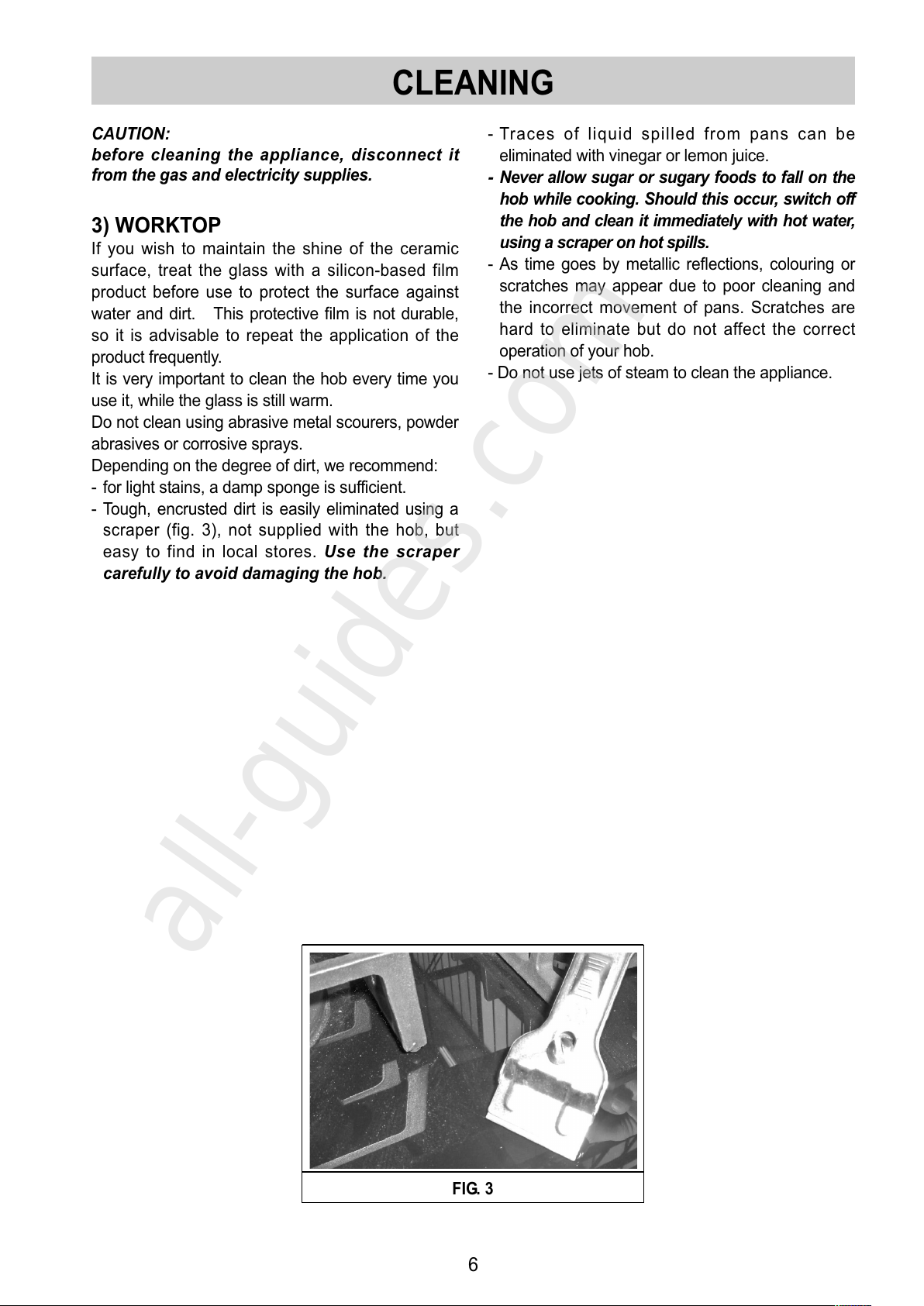

- Tough, encrusted dirt is easily eliminated using a

scraper (fig. 3), not supplied with the hob, but

easy to find in local stores. Use the scraper

carefully to avoid damaging the hob.

- Traces of liquid spilled from pans ca n be

eliminated with vinegar or lemon juice.

- Never allow sugar or sugary foods to fall on the

hob while cooking. Should this occur, switch off

the hob and clean it immediately with hot water,

using a scraper on hot spills.

- As time goes by metallic reflections, colouring or

scratches may appear due to poor cleaning and

the incorrect movement of pans. Scratches are

hard to eliminate but do not affect the correct

operation of your hob.

- Do not use jets of steam to clean the appliance.

FIG. 3

All manuals and user guides at all-guides.com

all-guides.com

Page 7

7

FIG. 5

CLEANING

The enamelled grids, enamelled covers “A”, “B” and

“C”, and burner heads “M” (see fig. 4 and 4/A) must

also be washed and the ignition elements “AC” and

safety cut-off sensors “TC” (see fig. 5) must be

cleaned. Do not wash them in the dishwasher.

Cleaning operations must be carried out when the

hob and components are not hot and the use of

meta l scouring pads, powder abrasives and

corrosive sprays must be avoided.

Do not allow vinegar, coffee, milk, salt water, lemon

juice or tomato juice to remain in prolonged contact

with the surfaces.

WARNINGS:

when reassembling the components, observe

the following recommendations:

- check that the holes in the burner heads “M”

(fig. 4) are not blocked by foreign bodies.

- Ensure that the enamelled covers “A”, “B”

and “C” (fig. 4 and 4/A) are corre c t l y

positioned on the burner head. The covers are

correctly positioned on the head when they

are perfectly stable.

- If the opening and closing of any valve is

awkward, do not force it but request urgent

intervention b y the technical assistanc e

service.

- Do not use jets of steam to cle a n the

appliance.

- To prevent difficulties with lighting, regularly

clean the ignition elements (ceramic and

electrode) and safety cut-off devices.

FIG. 4 FIG. 4/A

FIGURE 1

All manuals and user guides at all-guides.com

Page 8

8

INSTALLATION

FIG. 6 FIG. 7

COMPLY WITH THE

DIMENSIONS (mm)

A B C D E

4F (110) 1060 345 80 min 127.5 75

min

TECHNICAL INFORMATION

FOR THE INSTALLER

Installation, adjustments of controls and

maintenance must only be carried out by a

qualified engineer.

Incorrect installation may c a u s e damage to

persons, animals or property for which the

Manufacturer shall not be considered responsible.

During the life of the system, the automatic

safety or regulating devices on the appliance

may only be modified by the manufacturer or by

his duly authorized dealer.

4) INSTALLING THE WORKTOP

Check that the appliance is in a good condition after

having removed the outer packaging and internal

wrappings from around the various loose parts. In

case of doubt, do not use the appliance and contact

qualified personnel.

Never leave the packaging materials (cardboard,

bags, polystyrene foam, nails, etc.) within

children’s reach since they could become

potential sources of danger.

The measurements of the opening made in the top of

the modular cabinet and into which the hot plate will be

installed are indicated in either fig. 6. Always comply

with the measurements given for the hole into which

the appliance will be recessed (see fig. 6 and 7)

.

5) FIXING THE HOT PLATE

The hot plate has a special seal which prevents

liquid from getting into the cabinet. Strictly comply

with the following instructions in order to correctly

apply this seal:

- detach the seals from their backing, checking

that the transparent protection still adheres to the

seal itself.

- Evenly and securely fix the seal to the hot plate,

pressing into place with the fingers and remove

the strip of protective paper from the seal and set

the plate into the hole made in the cabinet.

- The prospective walls (left or right) that exceed the

working table in height must be at a minimum

distance from the cutting as mentionned both in

the columns and the scheme.

- In o r d er to a v oid acc i dental touch with th e

overheat i n g bottom of the hob, during the

working, is necessary to put a wooden insert,

fixed b y screws, at a minimum distance of

150 mm from th e l o we r su r fa c e of the top

(see fig. 6).

All manuals and user guides at all-guides.com

Page 9

9

INSTALLATION

6) ROOM VENTILATION

To ensure correct operation of the appliance, it is

important to ensure that the room where the hot

plate is installed has sufficient ventilation.

7) GAS CONNECTION

Natural Gas and Propane Gas

Natural Gas installations require the connection of

a gas regulator at the appliance. This regulator is

supplied with the appliance on purchase.

Asse m ble the regula t or (not i ng the gas flow

direction) and transition pieces (supplied with the

appliance), in accordance with below figure.

The transition piece on the supply side of the

regulator must be provided by the installer.

Unions compatible with the hose fittings must be

used and connections tested for gas leaks.

Ensure the supply connection point is accessible

with the appliance installed.

Warning: ensure that the hose assembly is

restrained from accidental contact with the flue or

flue outlet of an underbench oven.

All manuals and user guides at all-guides.com

Page 10

10

INSTALLATION

FIG. 8

8) ELECTRICAL CONNECTION

The electrical connections of the appliance

must be carried out in compliance with the

provisions and standards in force.

Before connecting the appliance, check that:

- the electrical capacity of the mains supply and

current sockets suit the maximum power rating of

the appliance (consult the data label applied to the

underside of the hot plate).

- The socket or system has an efficient earth

connection in compliance with the provisions and

standards in force. The manufacturer declines all

responsibility for failing to comply with these

provisions.

When the appliance is connected to the

electricity main by a socket:

- fit a standard plug suited to the load indicated on

the data label to the cable.

- Fit the wires following figure 8, taking care of

respecting the following correspondences:

Letter L (live) = wire;

Letter N (neutral) = wire;

earth symbol = green or yellow-green wire.

- Never use reductions, adapters of shunts for

connection since these could create false contacts

and lead to dangerous overheating.

- The outlet must be accessible after the built-in.

When the appliance is connected straight to the

electricity main:

- install an omnipolar circuit-breaker between the

appliance and the electricity main. This circuit-

breaker should be sized, in compliance with

current installation regulations.

- Reme m b er th at th e ea r t h wi r e mu s t no t be

interrupted by the circuit-breaker.

- For optimum safety, the electrical connection may

also be protected by a high sensitivity differential

circuit- breaker.

You are strongly advised to fix the relative yellow-

green earth wire to an efficient earthing system.

All manuals and user guides at all-guides.com

Page 11

11

INSTALLATION

FIG. 9 FIG. 10

9) FIXING THE HOT PLATE

The hot plate has a special seal which prevents

liquid from infiltrating into the cabinet. Strictly

comply with the following instructions in order to

correctly apply this seal:

- detach the seals from their backing, checking that

the transparent protection still adheres to the seal

itself.

- Overturn the hot plate and correctly position seal

“E” (fig. 9) under the edge of the hot plate itself, so

that the outer side of the seal perfectly matches

the outer perimetral edge of the hot plate. The

ends of the strips must fit together w i thout

overlapping.

- Evenly and securely fix the seal to the hot plate,

pressing into place with the fingers and remove

the strip of protective paper from the seal and set

the plate into the hole made in the cabinet.

- Fix the hob with the proper brackets “S” and turn

the screw “F” until the bracket “S” stick on the top

(fig. 10).

- The prospective walls (left or right) that exceed the

working table in height must be at a minimum

distance from the cutting as mentionned both in

the columns and the scheme.

- In o r der to avoid accidental touch with the

overheating bottom of the hob, during the working,

is necessary to put a wooden insert, fixed by

screws, at a minimum distance of 150 mm from

the lower surface of the top (see fig. 6).

All manuals and user guides at all-guides.com

all-guides.com

Page 12

12

ADJUSTMENTS

FIG. 11

Always disconnect the appliance from the

electricity main before making any adjustments.

All seals must be replaced by the technician at

the end of any adjustments or regulations.

Our b u rners do not require primary a i r

adjustment.

10) TAPS

“Reduced rate” adjustment

- Switch on the burner and turn the relative knob to

the “Reduced rate” position (small flame fig. 1).

- Remove knob “M” (fig. 11) of the tap, which is

simply pressed on to its rod.

- Insert a small screwdriver “D” into hole “C” (fig. 11)

and turn the throttle screw to the right or left until

the burner flame has been adequately regulated to

the “Reduced rate” position.

Check that the flame does not go out when the

knob is sharply switched from the “Full on” to the

“Reduced rate” position.

It is understood that only burners operating

with Natural Gas or To w n gas should be

subjected to the above mentioned adjustments.

The s c rew must be ful l y locked w hen the

burners operate with Propane HD-5 (turn

clockwise).

All manuals and user guides at all-guides.com

Page 13

13

CONVERSIONS

ARRANGEMENT OF THE BURNERS

FIG. 12

BURNERS

GAS

NORMAL

PRESSURE

inches water

column

INJECTOR

DIAMETER

1/100 mm

NOMINAL HEAT

INPUT (B

tu/h

)

N° DESCRIPTION

Min. Max.

1

ULTRA RAPID

PROPANE HD - 5

NATURAL GAS

11

7

91 zE

160 zE

5100

5100

10300

10300

3

SEMIRAPID

PROPANE HD - 5

NATURAL GAS

11

7

58

100 zE

2050

1700

4350

4350

TABLE

11) REPLACING THE INJECTORS

The burners can be adapted to different types of

gas by mounting injectors suited to the type of gas

in question. To do this, first remove the burner tops

using a wrench “B”. Now unscrew injector “A” (see

fig. 12) and fit a injector corresponding to the

utilized type of gas in its place.

It is advisable to strongly tighten the injector in

place.

After the injectors have been replaced, the

burners must be regulated as explained in

paragraphs 10. The technician must reset any

seals on the regulating or pre-regulating devices.

The envelope with the injectors and the labels can

be included in the kit, or at disposal to the

authorized customer Service Centre.

For the sake of convenience, the nominal rate table

als o li s ts the heat inputs of the burn ers, the

diameter of the injectors and the working pressures

of the various types of gas.

All manuals and user guides at all-guides.com

Page 14

14

SERVICING

FIG. 16

FIG. 17

FIG. 13 FIG. 14

FIG. 15

Always disconnect the appliance from the

electricity and gas mains before proceeding

with any servicing operation.

12) REPLACING COMPONENTS

Replacement of the components housed inside

the appliance: remove the trivets and the burners

from the upper part of the working table; remove

the fixing screws of the burner (fig. 13) and the

knobs fixed by pressure with the hans, in order to

take off the appliance.

After having carried out the above listed operations,

the burners (fig. 14), taps (fig. 15) and electrical

components can all be replaced (fig. 16).

NB: the ignition bar must be removed before

replacing the taps in appliances with automatic

ignition systems.

It is advisable to change seal “D” whenever a tap is

replaced to ensure a perfect tightness.

Greasing the taps (see fig. 17)

If a tap be c omes st iff to operate, it must be

imme d i ately greased in compliance w ith th e

following instructions:

- remove the tap.

- Clean the cone and its housing using a cloth

soaked in diluent.

- Lightly spread the cone with the relative grease.

- Fit the cone back in place, operate it several times

and then remove it again. Eliminate any excess

grease and check that the gas ducts have not

become clogged.

- Fit all parts back in place, complying with the

demounting order in reverse.

- The tight closure test must be done using a foamy

liquid. The use of the flame is prohibited.

To facilitate the servicing technician’s task, here is a

chart with the types and sections of the powering

cables and the ratings of the electrical components.

All manuals and user guides at all-guides.com

Page 15

15

TECHNICAL DATA ON THE DATA LABEL

4 BURNERS (110)

PROPANE HD - 5 = 11 inches water column

NATURAL GAS = 7 inches water column

Σ Qn Natural Gas = 29300 Btu/h

Σ Qn Propane HD - 5 = 29300 Btu/h

Voltage = 120 V AC

Frequency = 60 Hz

All manuals and user guides at all-guides.com

Page 16

16

TECHNICAL ASSISTANCE AND SPARES

Before leaving the factory, this appliance was tested and regulated by specially qualified experts in order to

guarantee the best operating results.

The original spare parts can be found only in our Technical Assistance Centres and authorised shops.

Every repair or regulation operation which should become subsequently necessary must be carried out with

the utmost care and attention by qualified personnel.

This is why we recommend that you always contact the Dealer who sold the appliance or our nearest

Assistance Centre, specifying the brand, the model, the serial number and the type of problem affecting your

appliance. The pertinent data is stamped on the label applied to the underside of the appliance and on the

label applied to the packing box.

This information enables the technical assistance department to acquire the appropriate spare parts and

consequently guarantee prompt and targeted intervention. We recommend that you write this data in the

spaces below and keep it to hand at all times:

BRAND: .........................................................

MODEL: .........................................................

SERIES: .........................................................

All manuals and user guides at all-guides.com

all-guides.com

Page 17

Kuppersbusch USA

1883 Massaro Blvd. Tampa, FL 33619

Toll: (800) 459-0844 P: 813-288-8890 F: 813-288-8604

All manuals and user guides at all-guides.com

Loading...

Loading...