Page 1

BEFORE BEGINNING TO

BUILD...................................2

SAMPLE STEP................................................................3

REQUIRED TOOLS

.........................................................4

WARRANTY INFORMATION

..........................................5

PREPARING THE RADIO SYSTEM

...............................5

ASSEMBLY................................................................6-26

REPLACEMENT PARTS...............................................26

OPERATION.................................................................27

KYOZ7125 No. 40602

Entire Contents © Copyright 1996

Page 2

IMPORTANT: PLEASE READ THROUGH THE ENTIRE

INSTRUCTION MANUAL BEFORE BUILDING THE

SEABREEZE 600.

We want your experience of building this model to be a

success. So before you remove any parts from their

packages and begin assembly:

• Read through the entire manual carefully to make sure

that you are thoroughly acquainted with the model.

• If for any reason you think this model may not be for you,

return it immediately. Please Note: Your hobby dealer

cannot accept a model kit for return after assembly

has begun.

• The Kyosho Seabreeze 600 is a sophisticated radio

controlled sailboat. Sailboats are no harder to operate

than any other boat. With time and practice, you will

come to enjoy the serenity of operating sailboats. If you

follow the directions closely, the Kyosho Seabreeze 600

will provide many years of enjoyable R/C sailing.

This Kyosho instruction manual uses a cross-reference

system to help you locate all of the bagged parts. DO NOT

open each bag and dump out the parts. Carefully remove

the header card from the bag and discard the staple. Slip

the header card into the bag or tape it to the outside of the

bag so that the bag number shows. This will help you find

parts when you need them.

REMOVE THE

HEADER CARD

SLIP CARD

INTO BAG

OR

TAPE TO

OUTSIDE

On pages 26 of this instruction manual, you will find a

complete list of replacement and optional parts. If you need

to replace a part, consult this guide for the manufacturer's

stock number for the items needed. In the left margin of

each page of instructions you will find a directory of small

parts that will be used in each step. For ease of

identification, these parts are shown actual size, enabling

you to place the part directly on the picture to ensure you

have selected the appropriate part.

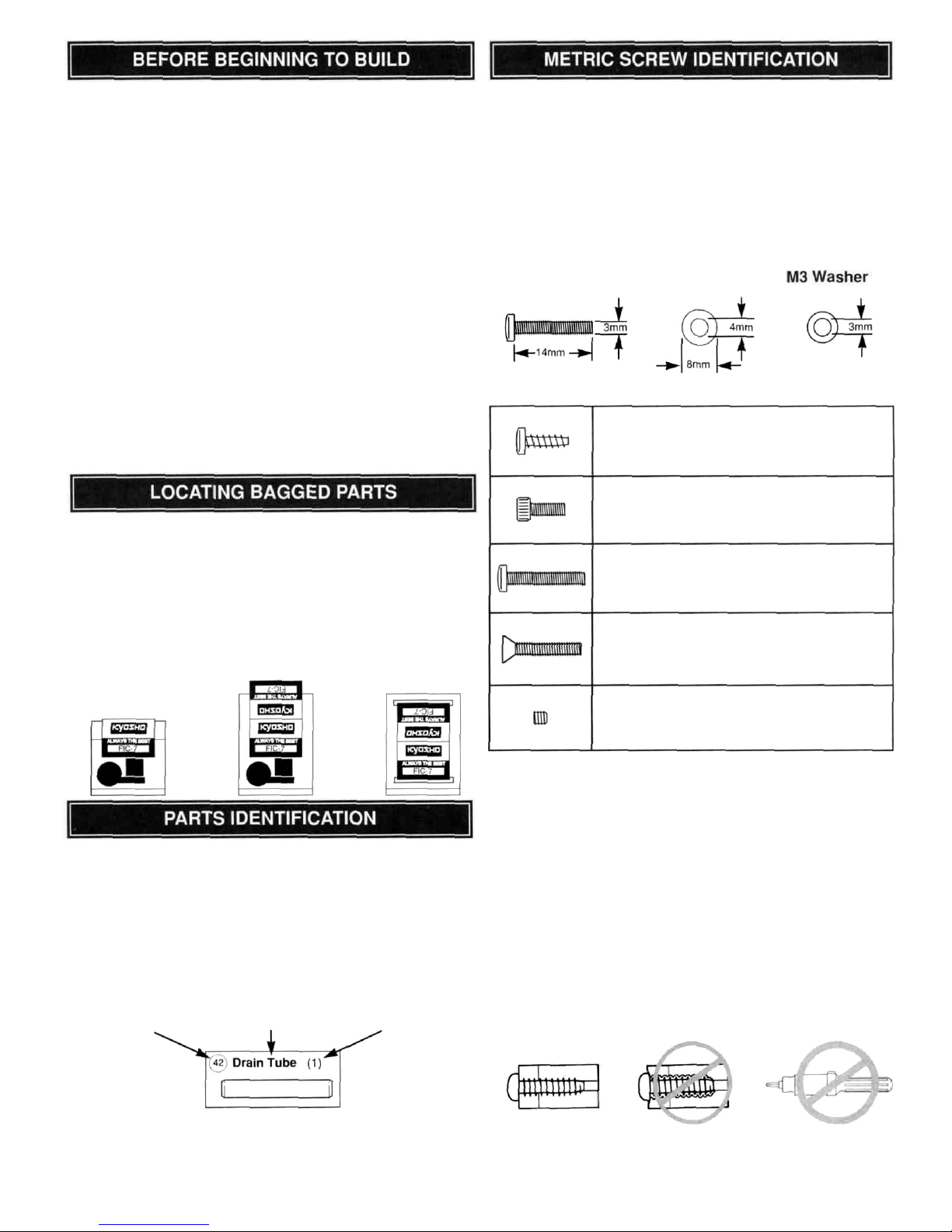

Key Number Part Name Quantity Used

All nuts and bolts used throughout this kit are metric size.

Therefore, some of the notations may not be familiar to

you. An M3 nut is a 3 millimeter (3mm) nut. An M3 x 14

screw is 3mm in diameter and 14mm long. Some round

parts may be labeled as an "M3 Washer" (a washer with a

3mm inside diameter) or an "M4 x 8 Bushing" (a bushing

with a 4mm inside diameter and an 8mm outside

diameter). A few different types of screws are used in the

construction of your model. Here are some examples and

how they will be indicated in the instructions.

M3x14Screw Bushing

Set Screws have a hex head that requires a hex

wrench. These are for joining parts where the

head of a screw may interfere with other parts.

Flat head (F/H) screws have a fine thread and a

tapered head. This allows the head of the screw to

be flush with the part it is holding so that the screw

head does not catch on anything.

Screws have a fine thread and are used with nuts

most of the time. They are for high stress joints

where strength is required.

A cap screw is used where two pieces of metal

are to be joined. The hex head allows a hex

wrench to be used, providing more torque

for tightening.

A self-tapping (S/T) screw has a coarse thread

and is used to thread into plastic. Be careful not to

tighten the screw too much. This may strip

the plastic.

IMPORTANT SCREW INFORMATION:

Do not use excessive force when tightening self-tapping

screws into plastic. Over-tightening will cause the threaded

portion of the plastic to strip. It is recommended to stop

tightening when some resistance is felt as the head of the

screw contacts the part. Avoid using power screwdrivers

when assembling your kit. They tend to overtighten screws.

Do not use thread locking compound on self-tapping

screws. The thread locking compound may damage the

plastic. Use thread locking compound only on screws that

are fastened with a nut or threaded into a metal surface.

Correct

Incorrect

Power Screwdriver

2

Page 3

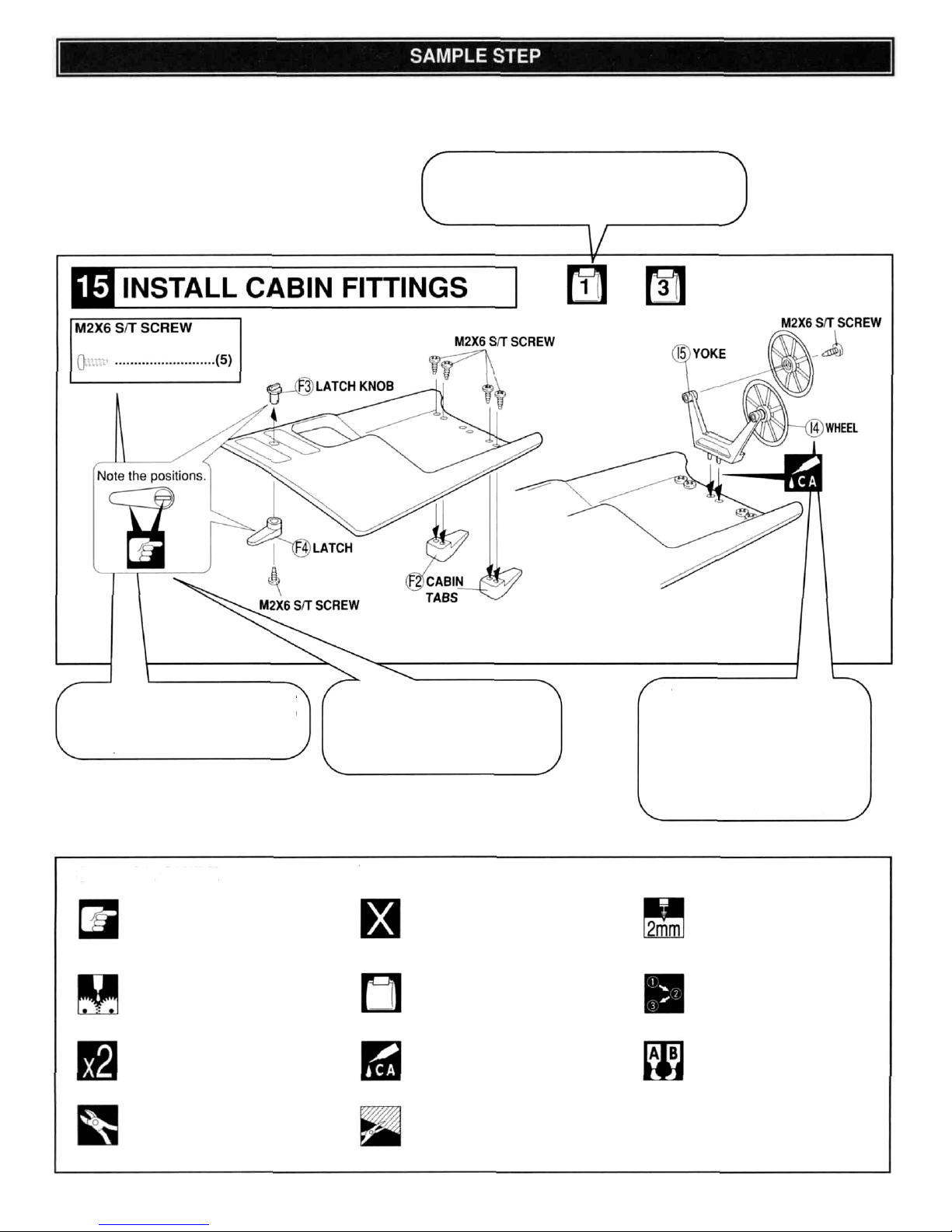

To help you get acquainted with how to use this manual, a sample step is shown below. Take a few minutes to study this

step so that you understand what some of the symbols mean. Below the sample step you will find a symbol guide.

A similar symbol guide will be shown at the bottom of each page of assembly steps.

The parts located in this box are

shown full size. Also shown is the

part name and quantity required for

this step.

Many symbols may be used in

each step. Check the symbol

guide for an explanation of the

symbols used.

All parts except screws, washers

and nuts are identified with a key

number. If a replacement part is

required in the future, find the key

number of the part needed in the

replacement part list on page 26.

Refer to the stock # and Mfg#

when ordering replacement parts.

The bag symbol with the number inside it

shows what bag contains the parts required

for this step. This symbol shows that the parts

are in bag

1.

(Do not actually perform this step)

SYMBOL GUIDE

This symbol means to pay special

attention to the instructions given.

This symbol requires that grease be

applied to the part.

This symbol requires that the procedure

be performed as many times as shown.

This sample shows to perform the

procedure twice.

This symbol requires you to cut off the

excess material.

This symbol means that the parts are

not included and must be purchased

separately.

The number inside this symbol shows

what bag contains the parts for that

step.

This symbol requires that thick

cyanoacrylate glue (CA) be used to

attach the parts. Be very careful with

CA—it will bond almost anything

including your fingers.

This symbol requires that the shaded

area shown be removed from

the part.

This symbol requires that a hole be

drilled to a specific size. This sample

would require a 2mm (1/16" or

5/64") hole.

This symbol requires that the parts

be assembled in a specific order.

This symbol requires that 6-minute

epoxy be used to assemble the

parts. Warning: Read and follow all

instructions included with the epoxy.

Some people have allergic reactions

to epoxy and its fumes.

3

Page 4

Some precautions need to be observed when building your

Kyosho kit to avoid problems:

1) Take time to read the instruction manual thoroughly.

2) Try to avoid working over a deep pile carpet. In the

event that a small part or screw should fall onto the

carpet, it would be difficult to find.

3) Place a mat or towel on the work surface where you will

be building the kit. This will prevent parts from rolling off

and will protect the work surface at the same time.

4)

Avoid running the boat in very cold temperatures. Both

plastic and metal parts become brittle at low

temperatures. In addition, grease and oil become

thick, causing premature wear and poor performance.

5) Trial fit all parts to ensure proper fit before attaching

them permanently.

Remove all flashing from parts before assembly,

as

shown in the example below.

6)

INCORRECT

Too much

removed.

Not enough

removed.

Do not

Use a sharp

hobby knife

to trim the

flash off.

remove the

flashing with

the cutter.

7) Important: Throughout the instruction manual

symbols are used to alert you to perform certain

procedures. A symbol guide is provided at the bottom

of each page to assist you.

THESE ARE NOT INCLUDED IN THE KIT

Phillips Screwdriver

Hobby Knife (XACR4320)

Needle Nose Pliers

(XACR2680)

Wire Cutters

Tapered Reamer (KYOR1050)

(Used for drilling holes. A drill and

bits will also work fine.)

220 Grit Sandpaper

6-Minute Epoxy (Such as Great

Planes' Pro'" Epoxy GPMR6045)

Thick Cyanoacrylate Glue (Such

as Great Planes Pro'" CA+

GPMR6008)

Rubbing Alcohol

THESE ITEMS ARE REQUIRED TO RUN THE SEABREEZE 600

2-Channel Radio

(preferably with

watertight servos.

Batteries for the

radio system

(12 AA Batteries)

If you use Nickel Cadmium Batteries in the radio

system, the batteries are recyclable. At the end of

their useful life, under various state and local laws, it

may be illegal to dispose of these batteries into the

municipal waste system. Check with your local solidwaste officials for details concerning recycling options

or proper disposal in your area.

IMPORTANT INFORMATION BEFORE BUILDING YOUR

SEABREEZE 600

Use the following diagram to

tie all the rigging knots.

4

Page 5

• For 90 days after you purchase your Seabreeze 600, Kyosho will either

repair or replace, at no charge, any incorrectly made part.

• Make sure you SAVE THE RECEIPT OR INVOICE you were given when

you bought your model! It's your proof of purchase - and we must see it

before we can honor the warranty.

• To send your Seabreeze 600 in for repairs covered under warranty, you

should send your boat to Kyosho's authorized U.S. repair facility:

Hobby Services

1610 Interstate Drive

Champaign, Illinois 61821

Attn. Service Department

Phone: (217) 398-0007 9:00 A.M. - 5:00 P.M. Central Time M-F

• For details on your return, be sure to follow steps 1-4 under the "Repair

Services Available Anytime" section.

Limit of our Liability:

Our liability under this warranty is limited to the repair or replacement by Hobby

Services of defective parts and does not include cost of shipping to us. Hobby

Services does pay the shipping expense to return warranty items to you.

Exclusion and/or Voidance of Warranty:

This warranty does not apply to damage or defects resulting from misuse,

abnormal service, damage in shipment, damage resulting from a crash or

damage caused by the batteries. The warranty is voided if the model is

modified, altered or repaired by anyone other than Hobby Services. This

warranty gives you specific legal rights, and you may have other rights that

vary from state to state within the U.S. We are sorry, but we cannot be

responsible for crash damage and/or resulting loss of the boat, radio,

accessories, etc.

Repair Services Available Anytime:

• After the 90-day warranty has expired, you can still have your Seabreeze

600 repaired for a small charge by the experts at Kyosho's authorized U.S.

repair facility, Hobby Services, at the address listed under Warranty

Information.

• To speed up the repair process, please follow the instructions listed below:

1. Under all circumstances, return the ENTIRE system: boat and radio.

2. Make sure the transmitter is turned off and all batteries are disconnected.

3. Send written instructions which include: a list of all items returned, a

THOROUGH explanation of the problem and the service needed, and your

phone number where you can be reached during the day. If you expect your

repair to be covered under warranty, be sure to include proof of date of

purchase (your store receipt or purchase invoice).

4. Also include your full return address.

Repair charges and postage may be prepaid or billed C.O.D. All repairs

shipped outside the United States must be prepaid in U.S. funds only.

Specification and Description Changes

All pictures, descriptions and specifications found in this instruction manual are

subject to change without notice. Kyosho maintains no responsibility for

inadvertent errors in this manual.

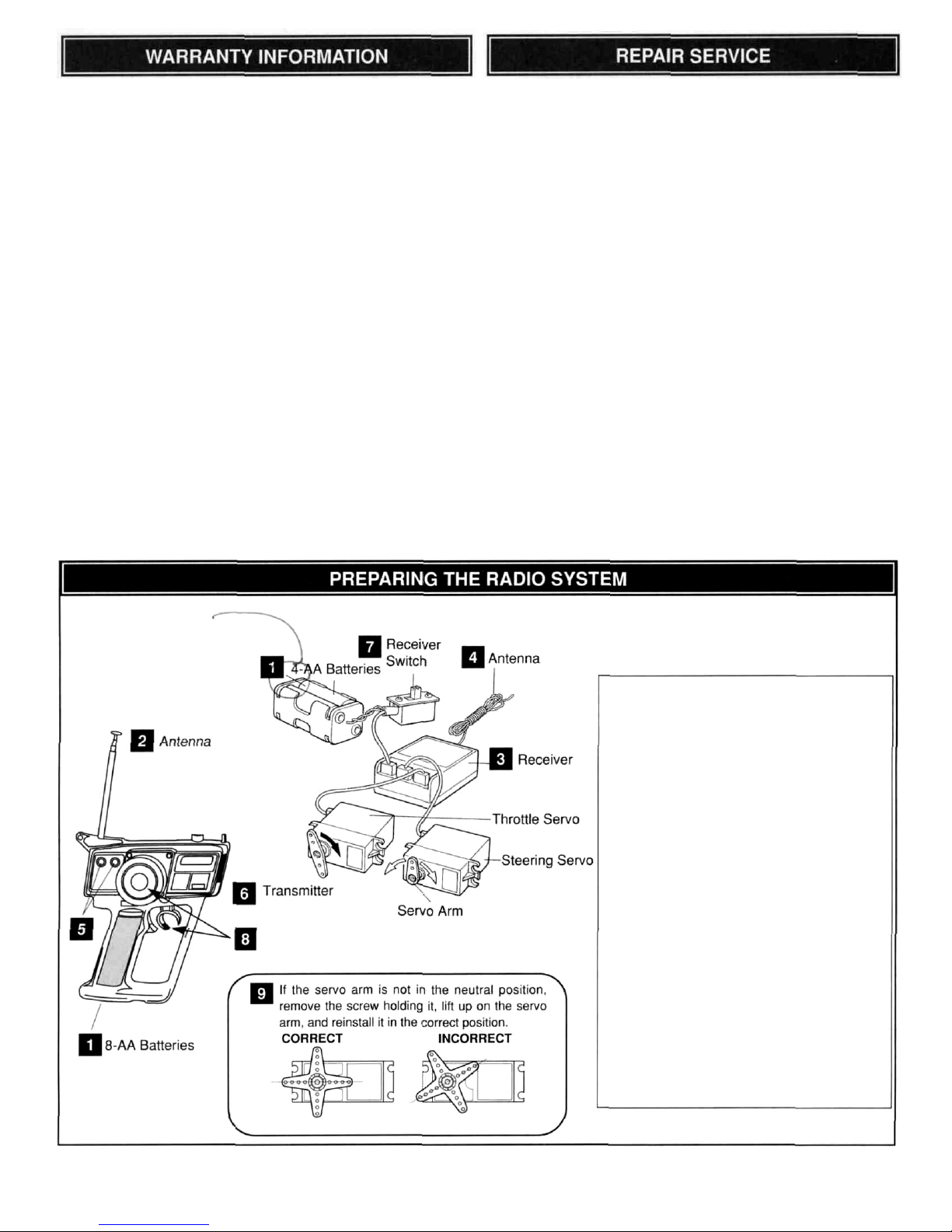

Set up the radio system following the

manufacturer's instructions and as

explained below.

1. Install the batteries in the transmitter and

the receiver battery holders.

2. Extend the transmitter antenna.

3. Connect the steering servo, throttle servo

and receiver battery to the receiver.

4. Extend the receiver antenna.

5. Adjust the servo trims to neutral position.

6. Turn the transmitter on.

7. Turn the receiver on.

8. Operate the rudder and sail control.

Make sure the servo arms move in

proportion to the movement of the

steering wheel and throttle trigger.

9. Check that the rudder and sail

servos are in the neutral position. See

diagram at left.

10. Turn the receiver off, then the transmitter.

Page 6

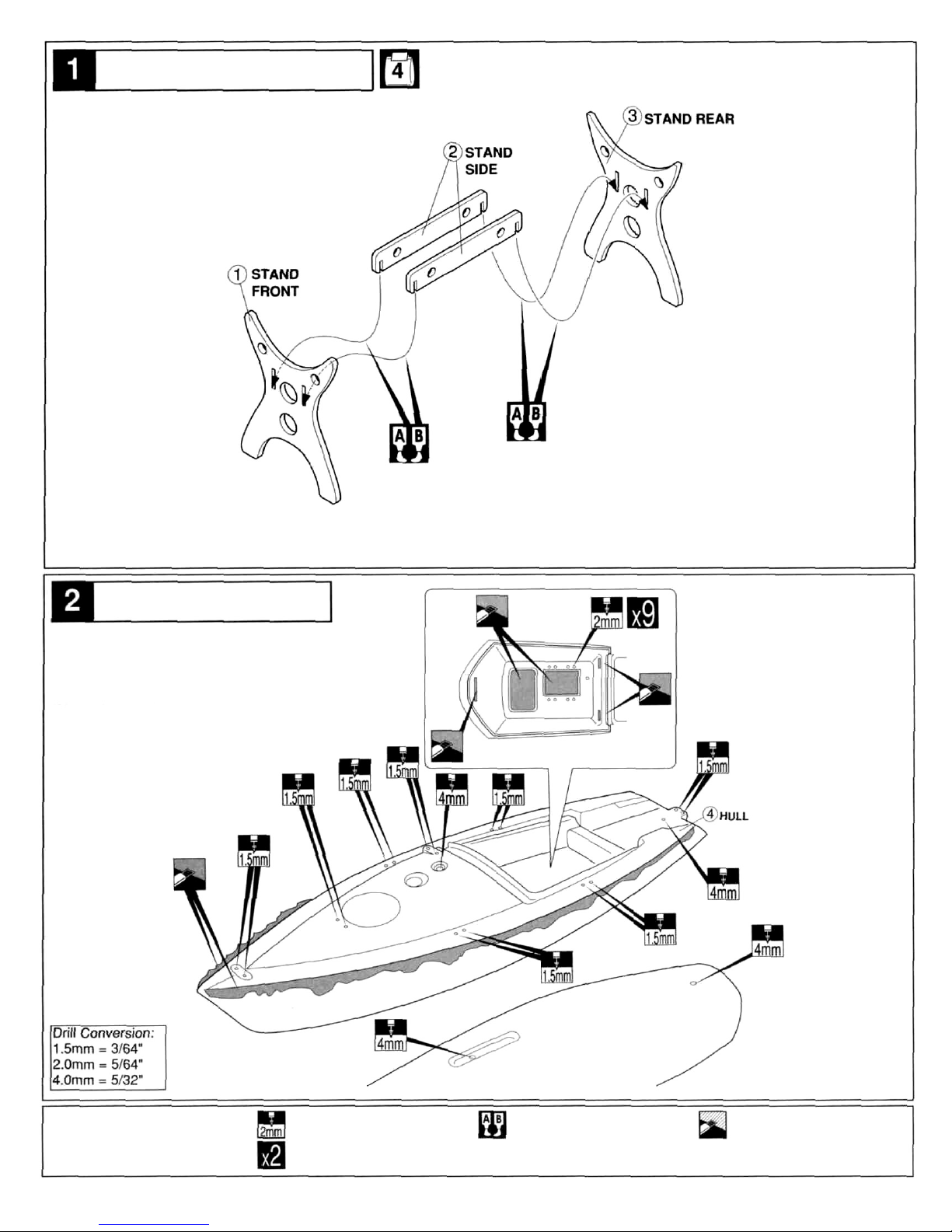

Remove the die-cut parts from the plywood

sheet and assemble as shown using epoxy.

ASSEMBLE STAND

Carefully remove any flashing from the

hull using a sharp hobby knife.

Drill the holes using the sizes and

locations shown.

6

SYMBOL GUIDE

Drill hole to the specified

diameter.

Repeat this process as

many times as specified.

Apply 6-min. epoxy.

Remove the shaded

area using a hobby knife.

PREPARE HULL

Page 7

SYMBOL GUIDE

Important information.

Apply 6-min. epoxy. Apply thick CA.

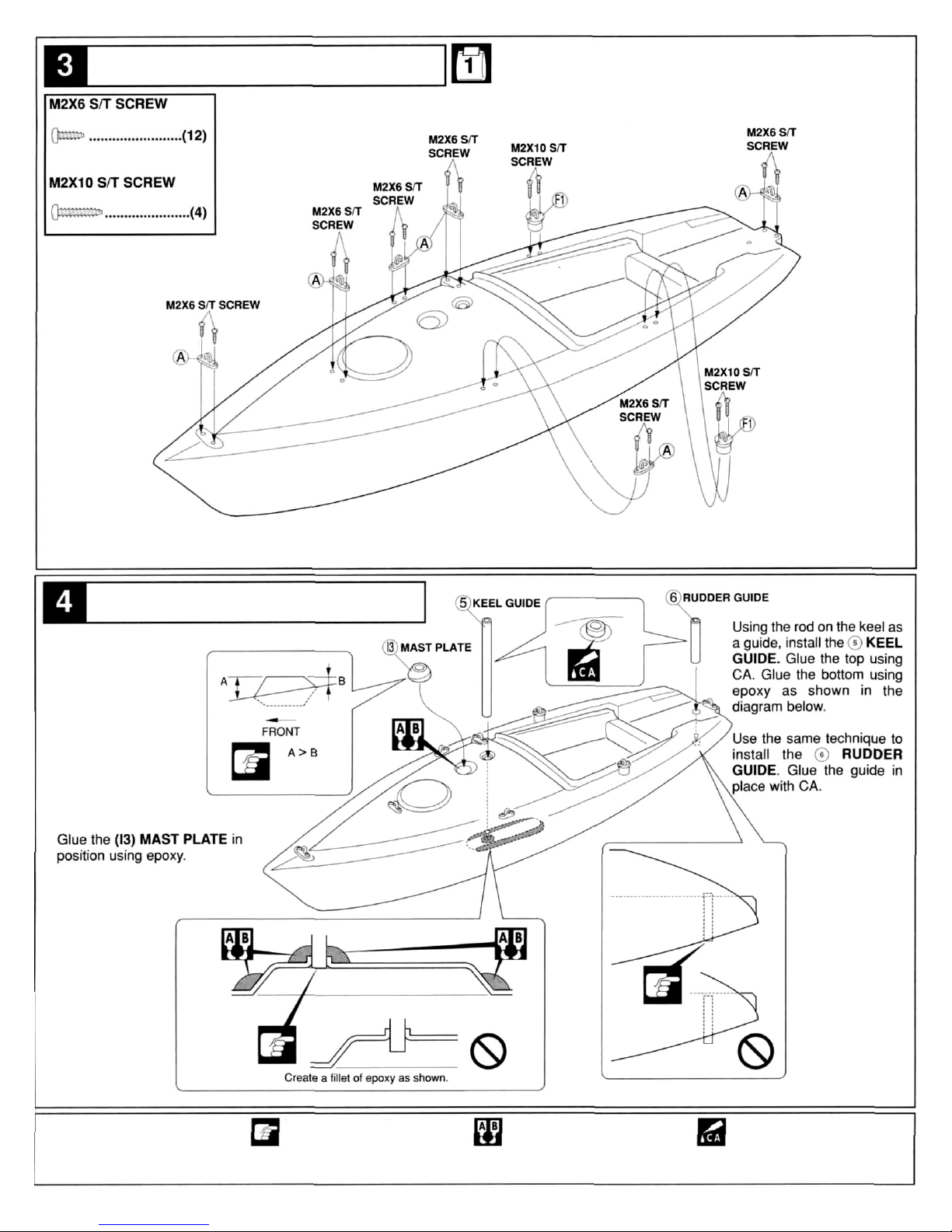

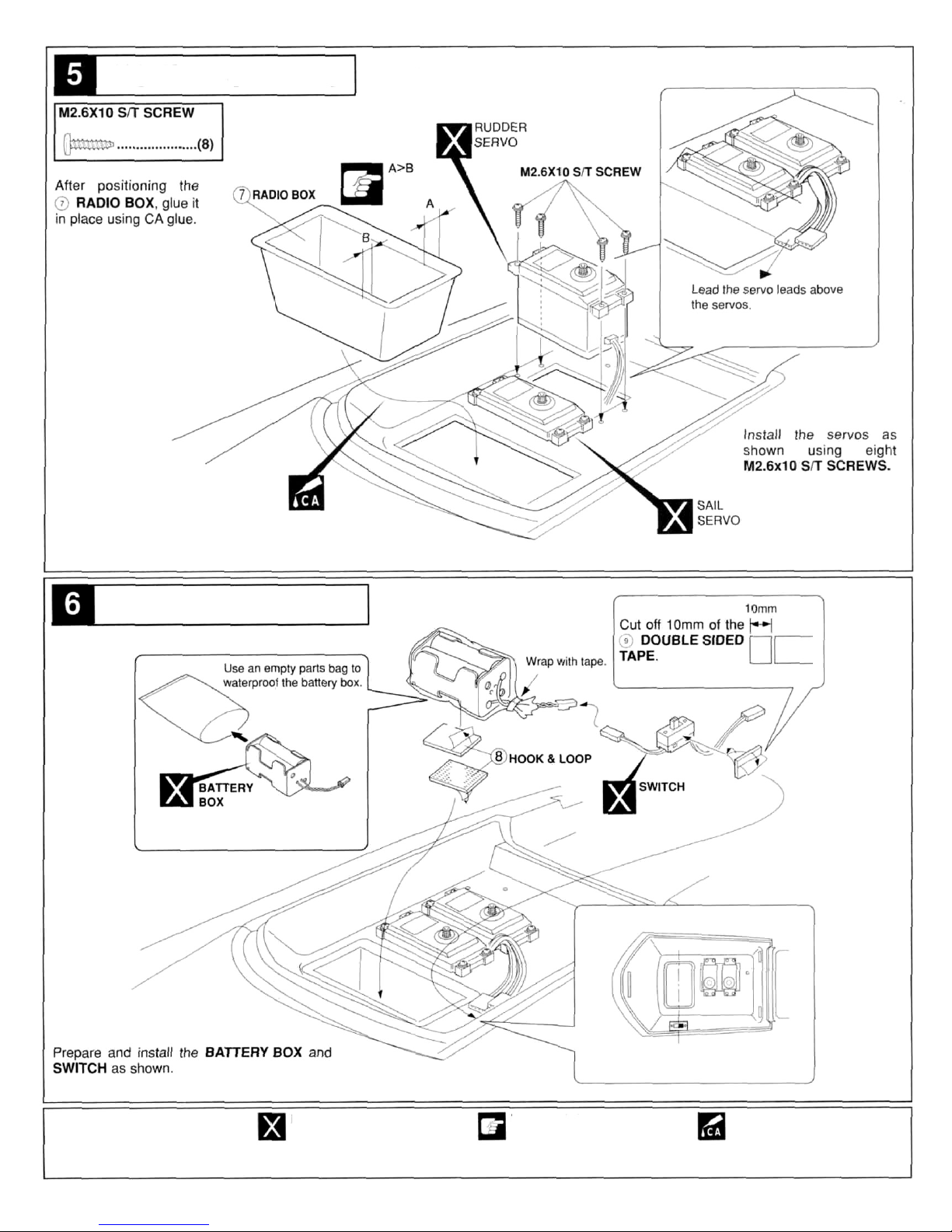

INSTALL DECK FITTINGS

Attach the fittings as shown below.

INSTALL HULL GUIDES

7

Page 8

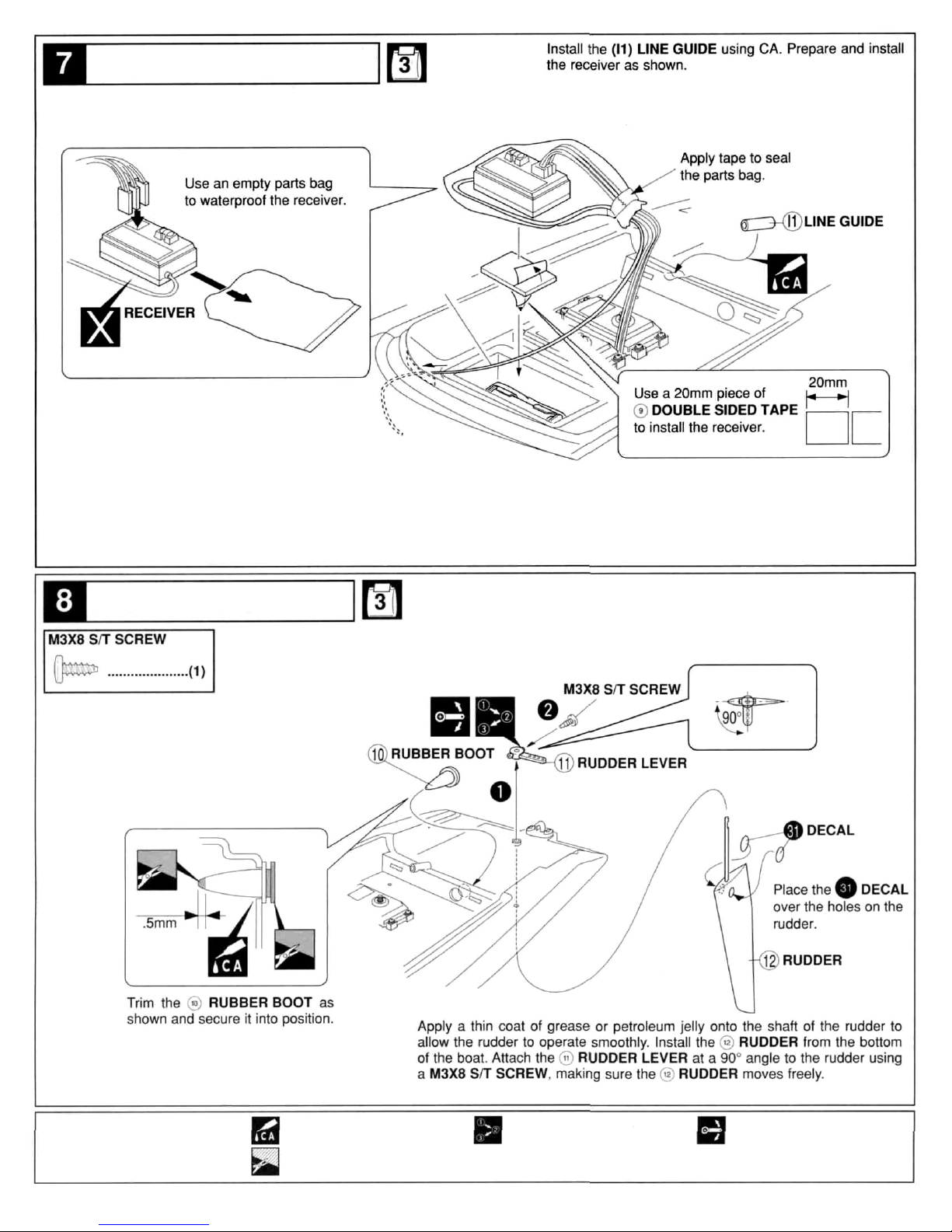

INSTALL SERVOS

8

SYMBOL GUIDE

Not included.

Important information.

Apply thick CA.

INSTALL BATTERY

Page 9

INSTALL RECEIVER

9

SYMBOL GUIDE

Apply thick CA.

Remove shaded portion.

Assemble in this order.

Part must move freely

without binding.

INSTALL RUDDER

Page 10

INSTALL RUDDER LINKAGE

Prepare the rudder control linkage and install as shown.

INSTALL SAIL CONTROL

SYMBOL GUIDE

Make a knot.

Remove shaded portion.

Not included.

10

Page 11

INSTALL SAIL CONTROL HORN

PREPARE JIB SAIL LINES

11

Not included.

Make a knot.

Apply thick CA.

SYMBOL GUIDE

Page 12

PREPARE CABIN

12

SYMBOL GUIDE

Drill hole to the specified

diameter.

Remove shaded portion.

Repeat this process as

many times as specified.

Make a knot.

INSTALL GUIDE RING LINES

Page 13

INSTALL CABIN FITTINGS

INSTALL KEEL

13

SYMBOL GUIDE

Apply thick CA.

Apply 6-min. epoxy.

Important information.

Page 14

14

SYMBOL GUIDE

Remove shaded portion.

Make a knot.

Drill hole to the specified

diameter.

PREPARE SAILS

INSTALL SAIL LINES

Page 15

PREPARE MAIN BOOM

PREPARE UPPER MAIN MAST

Prepare the main boom as shown in the diagram.

SYMBOL GUIDE

Important information.

Apply thick CA.

15

Page 16

16

Wrap the rigging line

around the cleat at

least 8 times before

securing. Attach the

main sail as shown.

SYMBOL GUIDE

Important information.

Part must move freely

without binding.

Apply CA.

PREPARE LOWER MAIN MAST

ATTACH MAIN SAIL

Page 17

ADJUST MAIN SAIL

SECURE MAIN SAIL

Attach MAIN SAIL to the MAST

as shown in the diagrams.

SYMBOL GUIDE

Important information.

Make a knot.

Apply CA.

17

Page 18

ATTACH JIB SAIL AND BOOM

18

SYMBOL GUIDE

Important information.

Apply CA.

PREPARE JIB BOOM

Page 19

INSTALL SUPPORT LINES

SYMBOL GUIDE

Make a knot. Repeat this process as

many times as specified.

Prepare the mast rigging according to the diagram.

19

Page 20

INSTALL MAST SUPPORT LINES

Attach the rigging cord prepared in the previous step as shown.

Note the lengths and attachment points of each line.

20

SYMBOL GUIDE

Make a knot.

Page 21

INSTALL UPPER JIB LINE

Install the upper jib rigging by

passing the rigging cord through the

JIB ANCHOR and tying it to the

MAST STOPPER.

MAST STOPPER

21

SYMBOL GUIDE

Make a knot.

JIB ANCHOR

Page 22

INSTALL AND ADJUST MAIN RIGGING

Attach the SNAP RINGS to the

DECK FITTINGS. Adjust the sails

as shown.

22

SYMBOL GUIDE

Important information.

Page 23

ADJUST SAILS

FRONT OF

BOAT

Use the following

diagram to adjust

the sails.

SAILS CLOSED

SAIL

CONTROL

Both the main and jib sails

should remain open 5°

when fully closed.

SAIL

CONTROL

Both the main and jib sails

should open to around

50° when fully opened.

SAILS OPENED

INSTALL CABIN

Install the cabin in the order

shown. Adjust the rigging

after installing the cabin.

Adjust so that the

distances are equal.

Assemble in this order.

Important information.

SYMBOL GUIDE

OPEN

CLOSED

23

Page 24

PLACE DECALS

• Apply numbered decals in

the positions shown.

• Decal numbers in

parentheses are placed on

the opposite side.

• Decals without numbers

can be placed anywhere.

24

Page 25

MAST ADJUSTMENT

A sailboat can be set up so that it has a tendency to either turn into

the wind (weather helm) or out of the wind (lee helm). Both properties

can be changed by adjusting the rigging. It is suggested to adjust for

a "weather helm" condition.

LEE HELM

WEATHER HELM

WIND DIRECTION

WEATHER HELM

LEE HELM

SAILING FUNDAMENTALS

When heading for point B have the rudder in

neutral position and set the sails

perpendicular to the wind.

Slowly move the rudder to the left and

maintain sail position.

When heading towards point C, adjust sails

and rudder similar to 1.

Steer hard left and close the sails at the

same time.

Return rudder to neutral and adjust sails

slowly to avoid "sail shiver."

Proceed into the wind towards point A by

tacking (zigzagging). Continue operating

sails slowly to avoid shivering.

Continue the same procedure as step 6, then

steer around point A and return to step 1.

25

SYMBOL GUIDE

WIND

DIRECTION

The closest possible heading into the

wind is a little over 45° to either side of the wind.

Any closer and the sails will "shiver" or flap.

Page 26

CLOSED

HAUL

ABEAM

QUARTER

26

CLOSED

HAUL

ABEAM

QUARTER

RUNNING

Starboard Track: Sails

are on the left of the hull.

Port Track: Sails are on

the right of the hull.

DIRECTIONAL SAILING

WIND DIRECTION

Page 27

If you have followed all of the previous instructions and find

everything to be operating properly, your Seabreeze 600 should

now be ready to run! Here are the procedures that should be

followed (some of these things may already be completed):

1. If your radio system has rechargeable batteries, charge the

transmitter and receiver batteries according to the

manufacturer's instructions.

2. Tear a paper towel in half and place the two halves in the

bottom of the mechanical compartment to absorb any

moisture that may enter the hull.

Warning: Before proceeding, make sure that no one in the

area is operating a transmitter on the same

frequency (channel) as yours.

3. Turn on the transmitter and receiver in that order.

4. Attach the hatch.

5. Check to make sure the sail and rudder are operating

properly. Note: Looking at the boat from the rear, the trailing

edge of the rudder must move to the right when the

transmitter steering wheel/stick is turned right (clockwise).

6. Ask yourself, "If the boat becomes stranded in the water, will

I be able to retrieve it either by waiting for the wind to blow it

in to shore or by using a retrieval boat?" There is always a

chance of something going wrong and the boat going

"dead"; therefore, you should always have a plan for

retrieval in that event.

9. Your Seabreeze 600 will often take on a little water,

especially when running in rough water or when making

very tight turns. Keep a roll of paper towels handy and dry

out the hull after every run. If you notice excessive amounts

of water in the hull, check for leaks especially around the

hull/deck joint. Always store your Seabreeze 600 with the

hatch and radio box cover removed to allow the interior

to dry out completely. If you neglect to do this, it may

result in corrosion of the electronic components.

10. Check the keel and rudder for weeds or other debris.

Remove any foreign material which may have become

entangled.

11. When you have finished for the day, dry the boat inside

and

out.

Important Note: If, for whatever reason, your boat takes on a

large amount of water, swamps or sinks, causing the radio

equipment to get wet, you must do the following: Immediately

remove all batteries and radio equipment from the boat. Open

the receiver (if water entered the plastic bag) and servo cases (if

not watertight servos), and dry all components completely before

reassembling. To dry electrical components, use a paper towel to

absorb the water droplets, then use a hair dryer to make sure

they are completely dry. Use compressed air to dry out all wire

connectors. (Use eye protection when working with compressed

air.) Dry the inside of the boat. Reinstall the components and

check for proper operation before running. -

Caution: If you go out in a boat to retrieve a model boat, be

sure to wear an approved flotation device. Never

swim or wade in the water to retrieve a model

boat.

7. Place the boat in water that will allow the keel to clear the

bottom. Make sure that the bottom is free of debris that may

tangle with the keel.

8. Immediately after removing the boat from the water, place it

on its stand and remove the hatch. This will allow air to enter

and help carry away moisture that may have entered the

radio comparment.

27

Loading...

Loading...