Page 1

Paper feeder

PF-60PF-60

Page 2

Conventions

Throughout this manual, the following conventions are used:

Italic letters refer related chapters or sections or documentations.

This symbol followed by WARNING denotes that the following paragraph(s) includes

precautions which, if ignored, could result in personal injury, and/or irrevocable

damage to the paper feeder.

When followed by CAUTION this symbol denotes that the following paragraph(s)

include the precautions which, if ignored, could result in damage to the paper feeder.

PF-60

Page 3

About the chapters

The manual is comprised of the following chapters:

Chapter 1: Product Information

Chapter 2: Installation

Chapter 3: Maintenance

Chapter 4: Operation Overview

Chapter 5: Disassembly

Chapter 6: Troubleshooting

Chapter 7: Paper Specifications

Appendix A: Diagrams

Contents

Contents

Contents

PF-60

Page 4

REVISION HISTORY

Version Date Replaced Pages Remarks

1.00 2-Apr-2001 -

TO OBTAIN THE LATEST PRINTER DRIVERS AND UTILITIES, VISIT US AT OUR INTERNET HOME

PAGE: http://www.kyocera.com/w2k

PF-60

Page 5

Chapter 1

Product Information

Page 6

Chapter 1 Contents

1-1 Specifications................................................................................................................................... 1-3

1-2 Names of parts ................................................................................................................................. 1-4

Page 7

1-1 Specifications

Table 1-1-1 Specifications

Item Description

Compatible printer Kyocera Mita Page Printers

FS-1800/1800N and FS-3800/3800N

Number of paper cassettes 1

Paper sizes Legal size and A5 to A4/letter universal cassette

14.8 to 21.0 cm × 21.6 to 29.7 cm

(5-13/16 to 8-1/2 × 8-1/4 to 11-11/16 inches)

Paper capacity 500 sheets maximaum, 80 g/m2 (16 to 28 lb/ream)

Environmental requirements Temperature: 10 to 32.5°C (50 to 90.5°F)

Humidity: 20 to 80 % RH

Ideal conditions are 20°C/65 % RH, altitude under 2000 m.

Dimensions Width: 34.5 cm (13-9/16 inches)

Height: 10.5 cm (4-1/8 inches)

Depth: 45.2 cm (17-13/16 inches)

Weight 3.6 kg (7-15/16 lb.)

Power supply Supplied from printer

1-3

PF-60

Page 8

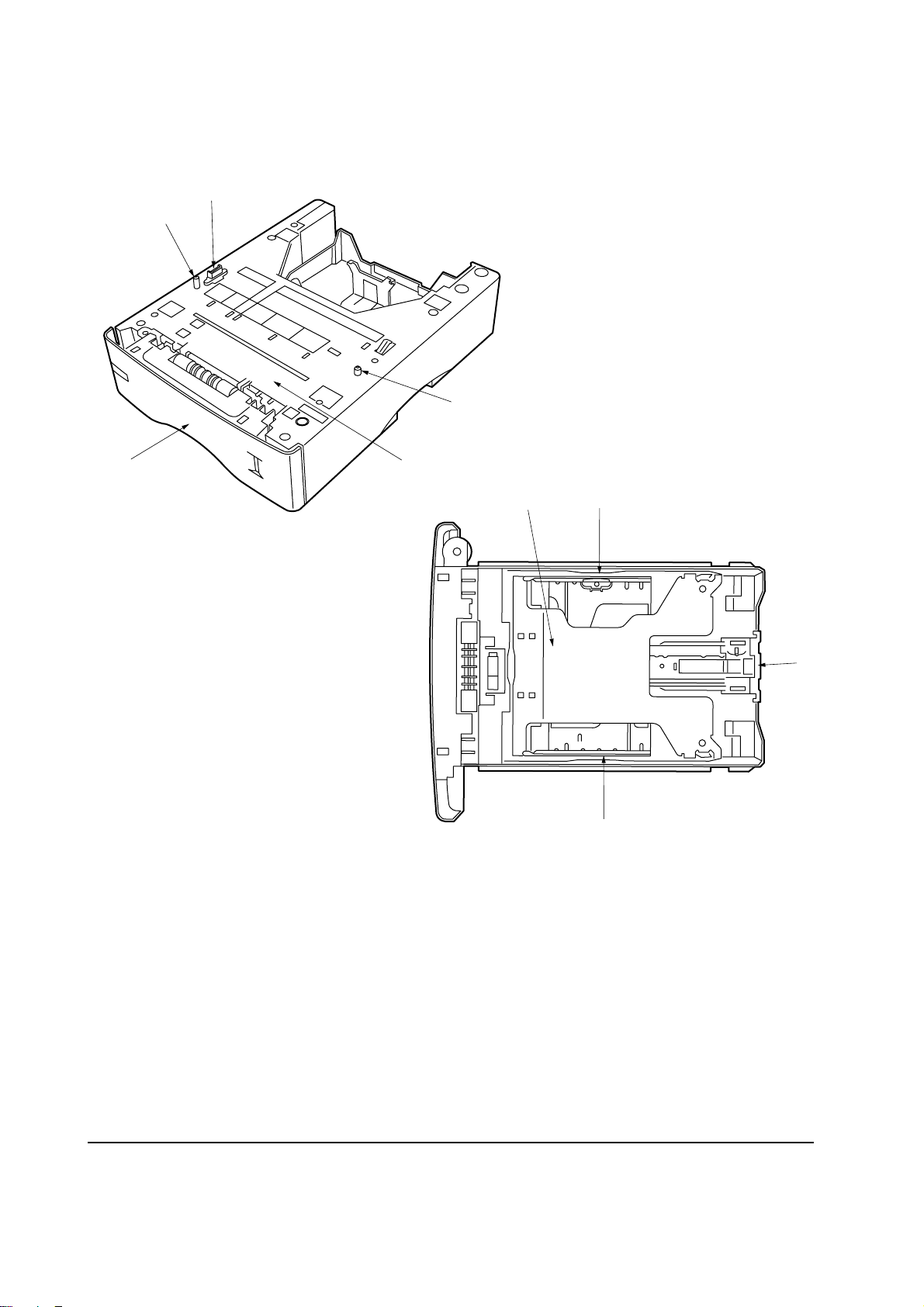

1-2 Names of parts

1

2

2

3

1 Interface connector

2 Positioning pins

3 Paper cassette

4 Top cover assembly

5 Bottom plate

4

5

6

7

6

PF-60

6 Paper guides

7 Paper stopper

Figure 1-2-1 Names of parts

1-4

Page 9

Chapter 2

Installation

Page 10

Chapter 2 Contents

2-1 Installing the paper feeder .............................................................................................................. 2-3

Page 11

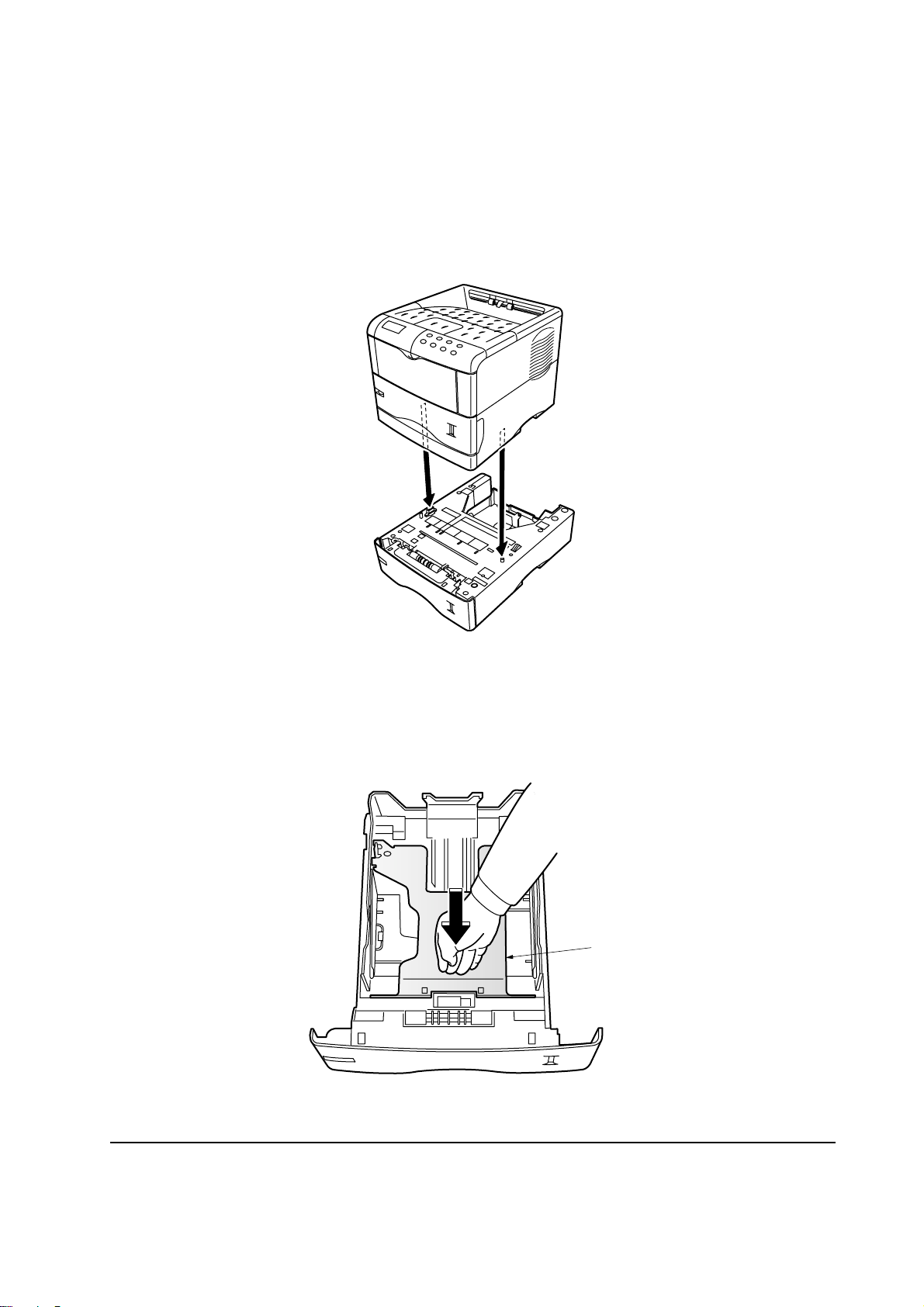

2-1 Installing the paper feeder

Note: When installing more than one paper feeder, first stack the paper feeders together.

1. Turn off the printer and disconnect the power cord and printer cable. Gently place the printer on

top of the paper feeder(s).

Figure 2-1-1 Place the printer

2. Pull the paper cassette all the way out of the paper feeder. Push down the bottom plate 1 until it

locks.

1

Figure 2-1-2 Push down the bottom plate

2-3

PF-60

Page 12

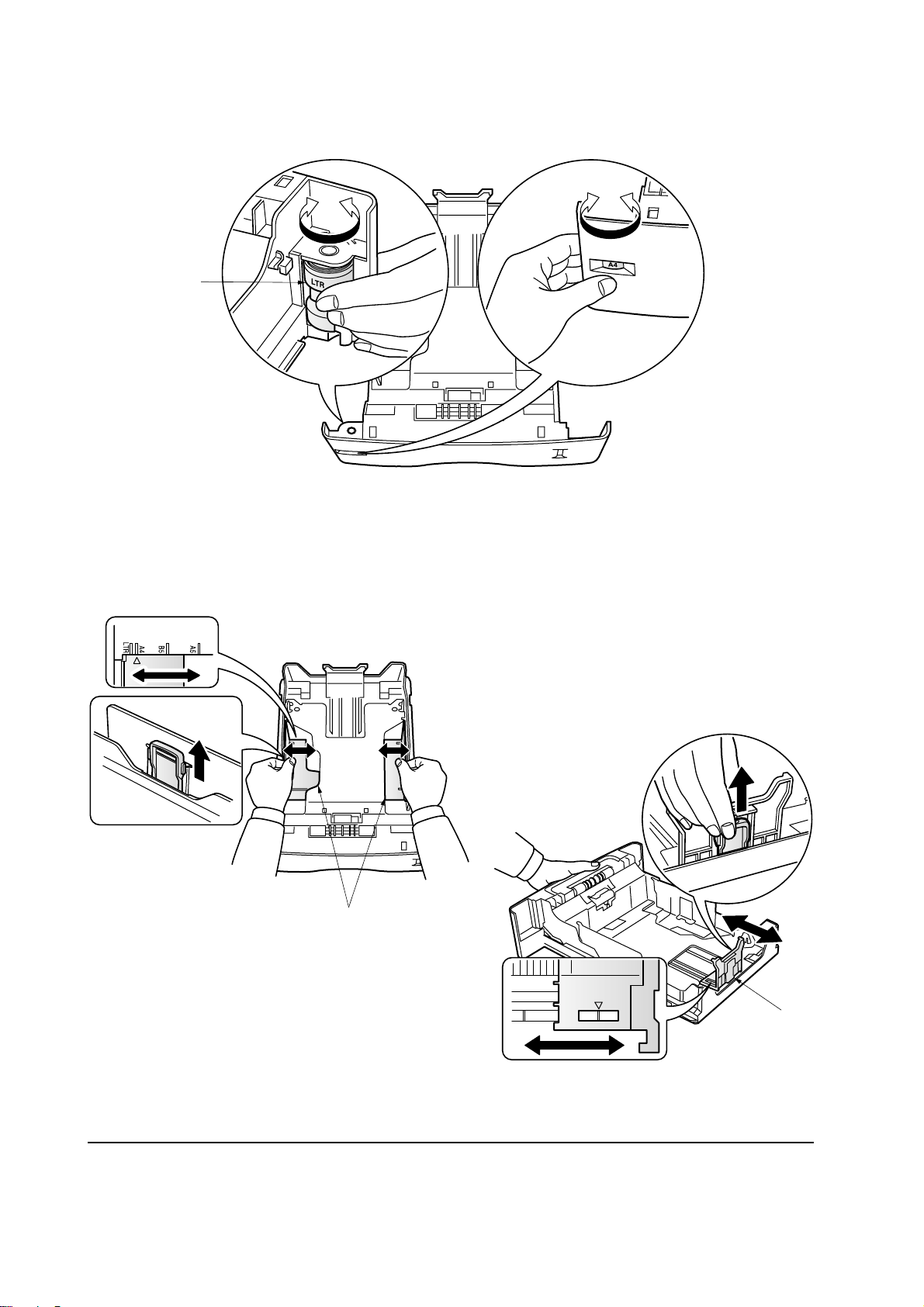

3. Set the paper size dial 2 to the size of paper to be used.

2

Figure 2-1-3 Set the paper size dial

4. Adjust the paper guides 3 and paper stopper 4 to the size of paper to be used.

3

B5A4

4

PF-60

Figure 2-1-4 Adjust the paper guides and paper stopper

2-4

Page 13

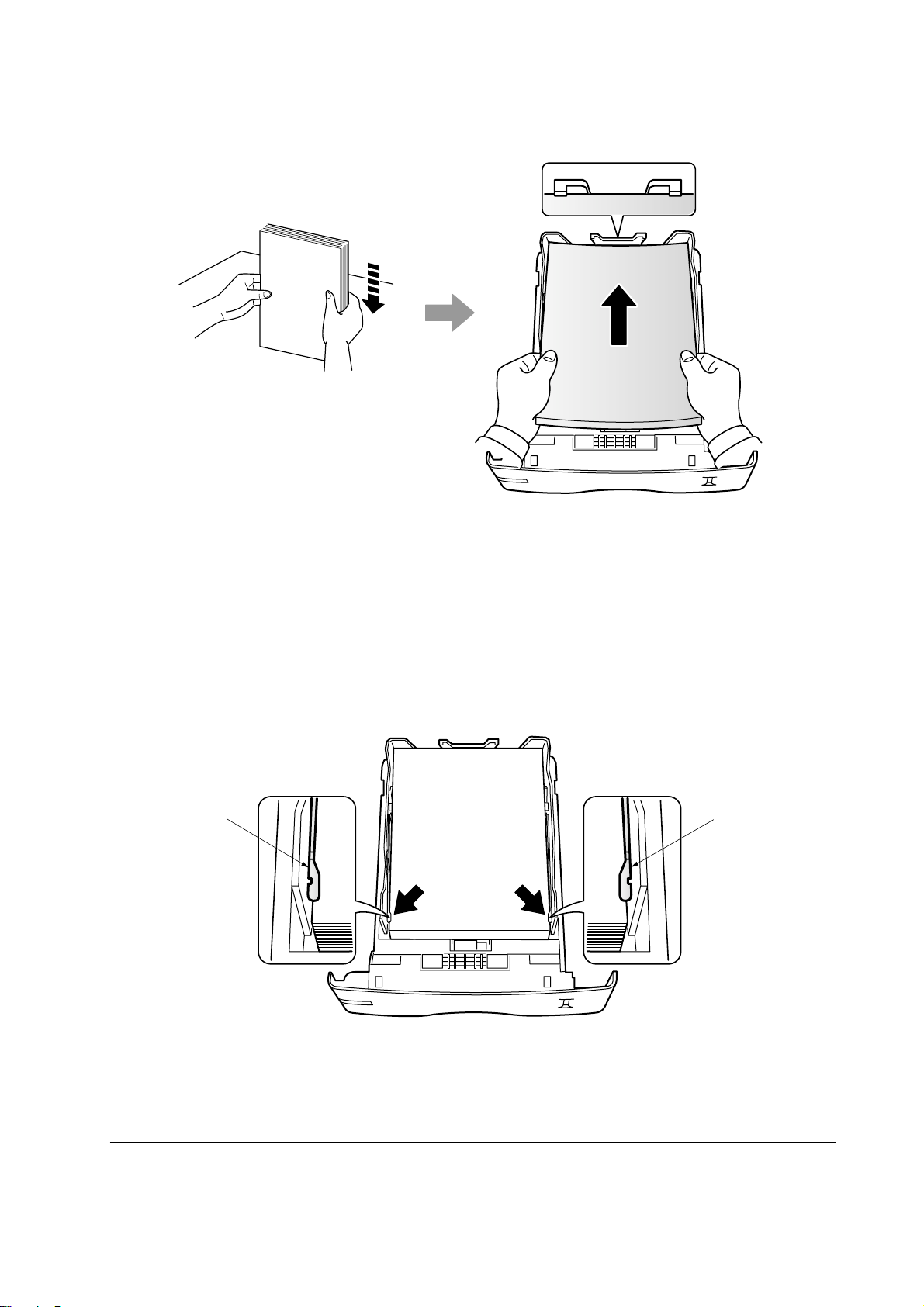

5. Load paper.

Figure 2-1-5 Load paper

6. Set the stack of paper so that it is under the clips 5 as shown in the figure. Insert the paper

cassette back in.

5

5

Figure 2-1-6 Set the stack of paper

2-5

PF-60

Page 14

Chapter 3

Maintenance

Page 15

Chapter 3 Contents

3-1 Maintenance ..................................................................................................................................... 3-3

3-1-1 Cleaning the pickup roller, feed roller and conveying roller....................................................... 3-3

Page 16

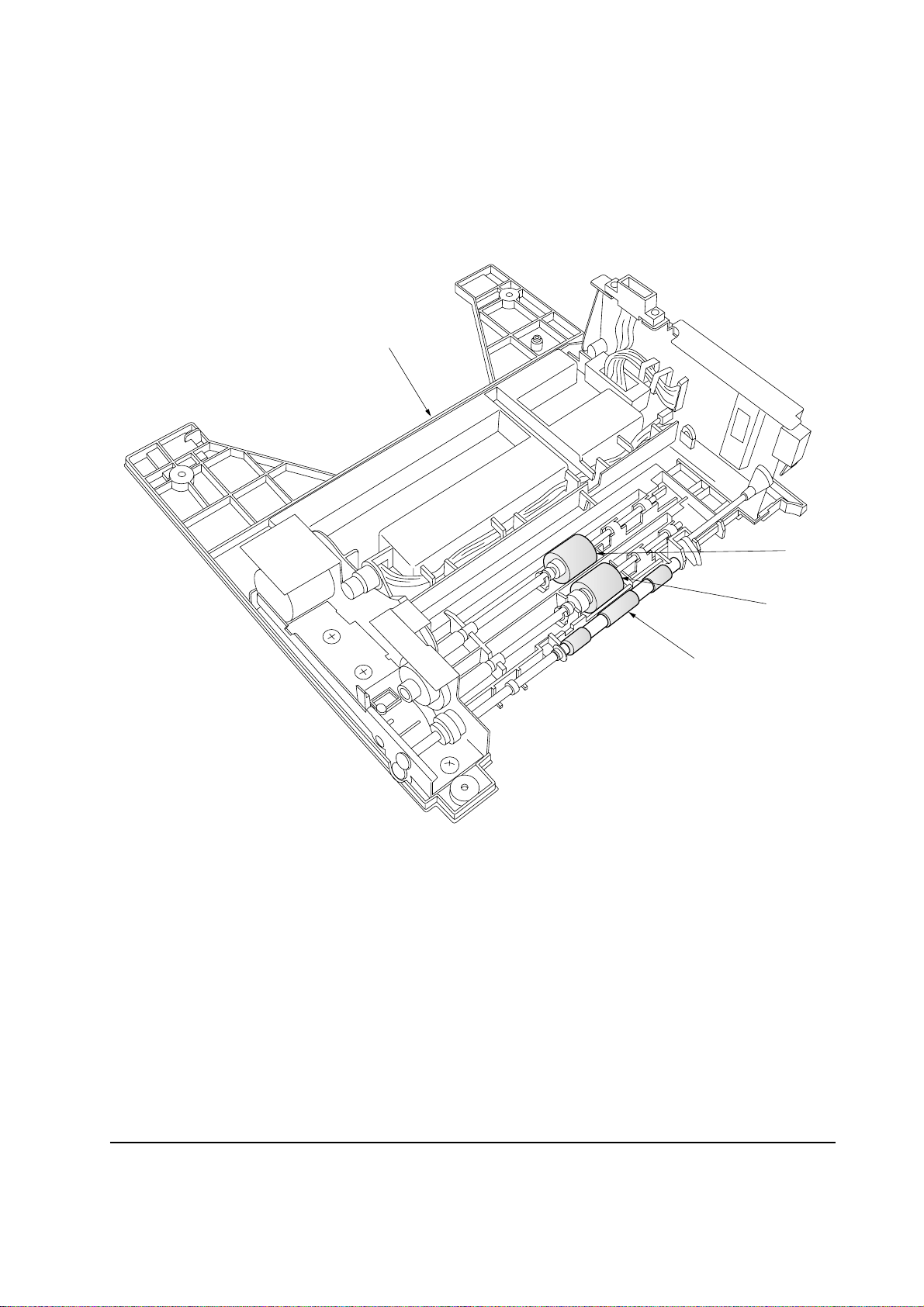

3-1 Maintenance

3-1-1 Cleaning the pickup roller, feed roller and conveying roller

Remove the top cover assembly 1. See page 5-4. Using the cleaning cloth, wipe the pickup roller

2, feed roller 3 and conveying roller 4.

1

2

3

4

Figure 3-1-1 Cleaning the pickup roller, feed roller and conveying roller

3-3

PF-60

Page 17

Chapter 4

Operation Overview

Page 18

Chapter 4 Contents

4-1 Paper feeding system...................................................................................................................... 4-3

4-1-1 Paper feed control ..................................................................................................................... 4-4

4-1-2 Paper feeding mechanism......................................................................................................... 4-5

4-2 Electrical control system ................................................................................................................ 4-6

4-2-1 Electrical parts layout ................................................................................................................ 4-6

4-2-2 Operation of circuit board .......................................................................................................... 4-7

(1) Paper feeder board.................................................................................................................... 4-7

Page 19

4-1 Paper feeding system

The figure below shows the components in the paper feeder and the paths through which the paper

travels. The sensors, motor etc., are described in the following pages.

4

2

1

3

1 Pickup roller

2 Feed roller

3 Retard pulley

4 Conveying roller

5 Feed pulley

Figure 4-1-1 Paper feeding path

5

4-3

PF-60

Page 20

4-1-1 Paper feed control

The following diagram shows interconnectivity of the paper feeding system components

including the sensor and rollers.

The paper feeder board controls the paper feed operation. Upon reception of the paper feed

start signal from the engine board of the printer, it drives the motor and clutch.

Engine board (printer)

YC205-1

YC205-11

YC205-9

YC205-5

YC205-7

YC205-6

YC205-8

YC205-10

YC205-12

YC205-4

YC205-3

YC205-2CN2-12

OP24 V

OPRDY

OPSDO

OPSCLK

OPSDI

OPSEL0

OPSEL1

OPSEL2

GND

PFSEL

OP5 V

GND

Paper feeder board

CN2-1

CN2-2

CN2-3

CN2-4

CN2-5

CN2-6

CN2-7

CN2-8

CN2-9

CN2-10

CN2-11

CN6-2

CN7-1

CN1-2

PFM

MCS

6

4

1 Paper feed clutch

2 Pickup roller

3 Feed roller

PFCL

1

2

3

5

: Power train

4 Paper feed motor

5 Conveying roller

6 Motor clock sensor

PF-60

Figure 4-1-2 Paper feed control

4-4

Page 21

4-1-2 Paper feeding mechanism

When a paper feed start signal is received from the engine board of the printer, the paper

feed clutch 1 turns on to rotate the pickup roller 2 and feed roller 3, to start the paper

feed operation. At this point, multiple paper feeding is prevented by the retard pulley 4. The

paper feed motor 5 then conveys the paper through the conveying roller 6 and feed pulley

7 into the printer by rotating the conveying roller 6. The paper feed sensor 8 detects

paper jams.

5

1

2

3

8

2

Figure 4-1-3 Paper feeding mechanism

7

6

3

4

4-5

PF-60

Page 22

4-2 Electrical control system

4-2-1 Electrical parts layout

1

8

2

3

4

5

1 Paper feeder board

2 Paper feed motor

3 Paper feed clutch

4 Paper gauge sensor 1

Figure 4-2-1 Electrical parts layout

6

7

5 Paper gauge sensor 2

6 Paper feed sensor

7 Paper size switch

8 Motor clock sensor

PF-60

4-6

Page 23

4-2-2 Operation of circuit board (1) Paper feeder board

The paper feeder board serially communicates with the engine board of the printer and the

paper feeder board of the lower paper feeder to exchange control signals.

Upon reception of a paper feed start signal from the engine board of the printer, CPU IC3

controls the paper feed operation by operating the paper feed motor and paper feed clutch.

The motor drive circuit consists mainly of motor driver IC5. It drives the paper feed motor

based on the control signals (PFM, PWM) from CPU IC3.

The reset circuit consists mainly of reset IC1. It monitors the 5 V DC supply voltage. When

the power is turned on or when the power supply becomes low, it outputs a RESET signal to

CPU IC3, to prevent system malfunction or runaway.

Paper feeder board

+24 V

Engine board

(printer)

Paper feeder

board

(middle or

bottom)

SEL [2-0],

PFSEL

OPSCLK,

OPSDO

OPREADY,

OPSDI

Serial

communication

SEL [2-0],

PFSEL

OPSCLK,

OPSDO

OPREADY,

OPSDI

EEPROM

(IC2)

PFM

PWM

PFCL

CPU

(IC3)

PSSW[0-2]

MCS

DI, DO

PFS

RESET

+5 V

+5 V

Motor

drive

circuit

(IC5)

+24 V

+5 V

+5 V

Paper feed

sensor

Paper

feed

motor

Paper

feed

clutch

Paper

size

switch

Motor

clock

sensor

Reset

circuit

(IC1)

PGS1, 2

Paper gauge

sensor 1, 2

Figure 4-2-2 Paper feeder board circuit block diagram

4-7

PF-60

Page 24

Chapter 5

Disassembly

Page 25

Chapter 5 Contents

5-1 General instructions ........................................................................................................................ 5-3

5-1-1 Screw/hardware......................................................................................................................... 5-3

5-1-2 Before starting disassembly ...................................................................................................... 5-3

5-2 Disassembly ..................................................................................................................................... 5-4

5-2-1 Removing the top cover assembly ............................................................................................ 5-4

5-2-2 Removing the paper feeder board............................................................................................. 5-5

5-2-3 Removing the pickup roller and feed roller ................................................................................ 5-7

5-2-4 Removing the retard pulley........................................................................................................ 5-8

Page 26

5-1 General instructions

This chapter provides the procedure for removal and replacement of field replacement components.

For other components not explained in this chapter, the diagrams in the Parts Catalog. It is

recommended that your refer to diagrams in the Parts Catalog as a supplemental reference to this

chapter. It features all the part drawings and help you disassemble or refit the parts in the paper

feeder.

When replacing of a component, reverse the procedure for the removal procedure explained in this

chapter.

WARNING To avoid injury electric shock, make sure that AC power is removed and the

power cord is unplugged from both the power line and the printer.

5-1-1 Screw/hardware

Screws and hardware used in the printer are listed in the Ecosys Screw catalog. These screw symbol

numbers are universal to most Ecosys printers.

CAUTION When securing a self-tapping screws, align it with the thread carefully. First turn

it counterclockwise, then slowly clockwise. Do not overtighten. In case the selftapped thread is damaged, the whole part may have to be replaced with a new

part.

5-1-2 Before starting disassembly

Before proceeding, unplug the power cord from the printer and the power supply.

WARNING Never attempt to operate the printer with components removed.

CAUTION The paper feeder use electrostatic sensitive parts inside (circuit boards, etc.).

Provide an antistatic (discharging) device, such as a wrist strap, that can effectively

discharge your body before touching those components.

5-3

PF-60

Page 27

5-2 Disassembly

5-2-1 Removing the top cover assembly

1. Pull out the paper cassette 1.

2. Remove four screws 2.

3. Remove the top cover assembly 3.

2

2

2

2

3

1

PF-60

Figure 5-2-1 Removing the top cover assembly

5-4

Page 28

5-2-2 Removing the paper feeder board

1. Remove the top cover assembly. See page 5-4.

2. Remove two screws 1.

3. Remove four connectors 2.

4. Remove the paper feeder board assembly 3.

2

1

1

2

3

Figure 5-2-2 Removing the paper feeder board assembly

5-5

PF-60

Page 29

5. Release the harness from the wire saddles 4.

6. Remove two connectors 5.

7. Remove one screw 6.

8. Remove the paper feeder board 7.

4

5

5

6

7

Figure 5-2-3 Removing the paper feeder board

PF-60

5-6

Page 30

5-2-3 Removing the pickup roller and feed roller

1. Remove the top cover assembly. See page 5-4.

2. Push the shaft lock levers 1 and slide the shafts 2 as indicated by the arrows in the below

diagram.

3. Remove the pickup roller 3 and feed roller 4.

1

3

2

1

2

4

Figure 5-2-4 Removing the pickup roller and feed roller

5-7

PF-60

Page 31

5-2-4 Removing the retard pulley

1. Remove the top cover assembly. See page 5-4.

2. Disengage the two hooks 1 of the retard guide 2 using a flat-head screwdriver or other

tool and then remove the guide.

3. Lift the retard pulley 3 in the direction of arrow a and then remove it in the direction of

arrow b.

2

1

1

b

3

a

Figure 5-2-5 Removing the retard pulley

PF-60

5-8

Page 32

Chapter 6

Troubleshooting

Page 33

Chapter 6 Contents

6-1 Troubleshooting............................................................................................................................... 6-3

6-1-1 General error handling............................................................................................................... 6-3

(1) Maintenance messages............................................................................................................. 6-3

6-1-2 Diagnostic (Service error messages) ........................................................................................ 6-4

(1) B2 Paper feeder (Top) paper feed motor error ...................................................................... 6-4

(2) B3 Paper feeder (Middle) paper feed motor error.................................................................. 6-4

(3) B4 Paper feeder (Bottom) paper feed motor error ................................................................. 6-4

(4) C0 Paper feeder communication error................................................................................... 6-5

6-1-3 Circuit board terminal voltages .................................................................................................. 6-6

(1) Pepar feeder board.................................................................................................................... 6-6

6-1-4 Correcting a paper jam .............................................................................................................. 6-8

Page 34

6-1 Troubleshooting

6-1-1 General error handling

(1) Maintenance messages

Message Corrective action

Add paper

(option paper feeder)

Paper feed unit

Open

The paper has run out. Supply paper according to the paper source

displayed.

Open the paper feeder, then close tightly.

6-3

PF-60

Page 35

6-1-2 Diagnostic (Service error messages)

The printer does not operate when a message is displayed. The message is categorized as follows:

(1) B2 Paper feeder (Top) paper feed motor error

Meaning Suggested causes Corrective action

Paper feed motor error

in the top paper feeder.

• Defective paper feeder board.

• Defective gate array U204 on the printer’s

engine board (KP-864).

Replace paper feeder

board. See page 5-5.

Refer to printer’s

Service Manual.

• Blown-out fuse (F201) on the printer’s

engine board.

• Defective harness between paper feeder

Replace harness.

interface connector and printer’s engine

board.

(2) B3 Paper feeder (Middle) paper feed motor error

Meaning Suggested causes Corrective action

Paper feed motor error

in the middle paper

feeder.

• Defective paper feeder board.

• Defective gate array U204 on the printer’s

engine board (KP-864).

Replace paper feeder

board. See page 5-5.

Refer to printer’s

Service Manual.

• Blown-out fuse (F201) on the printer’s

engine board.

• Defective harness between paper feeder

Replace harness.

interface connector and printer’s engine

board.

(3) B4 Paper feeder (Bottom) paper feed motor error

Meaning Suggested causes Corrective action

Paper feed motor error

in the bottom paper

feeder.

• Defective paper feeder board.

• Defective gate array U204 on the printer’s

engine board (KP-864).

Replace paper feeder

board. See page 5-5.

Refer to printer’s

Service Manual.

• Blown-out fuse (F201) on the printer’s

engine board.

• Defective harness between paper feeder

Replace harness.

interface connector and printer’s engine

board.

PF-60

6-4

Page 36

(4) C0 Paper feeder communication error

Meaning Suggested causes Corrective action

Communication error

between paper feeder

and printer’s engine

board.

• Defective paper feeder board.

• Improper installation between paper feeder

and printer.

• Improper connector insertion.

• Defective gate array U204 on the printer’s

engine board (KP-864).

• Blown-out fuse (F202) on the printer’s

engine board.

• Defective harness between paper feeder

interface connector and printer’s engine

board.

Replace paper feeder

board. See page 5-5.

Follow installation

instruction carefully

again.

Remedy.

Refer to printer’s Service

Manual.

Replace harness.

6-5

PF-60

Page 37

6-1-3 Circuit board terminal voltages (1) Pepar feeder board

Connector Pin# Signal I/O Voltage Function

(CN1) 1 PFCL O 0 V/24 V DC Paper feed clutch, On/Off

2 24 V O 24 V DC Power supply

(CN2) 1 24 V I 24 V DC Power supply from printer

2 OPRDY O 0 V/5 V DC Paper feeder, Ready/Not ready

3 OPSDO I 5 V/0 V DC Serial communication data signal

with printer

4 OPSCLK I 5 V/0 V DC (Pulse) Serical communication clock signal

5 OPSDI O 5 V/0 V DC Serial communication data signal

with printer

6 OPSEL0 I 0 V/5 V DC Paper feeder identifying signal 0

7 OPSEL1 I 0 V/5 V DC Paper feeder identifying signal 1

8 OPSEL2 I 0 V/5 V DC Paper feeder identifying signal 2

9 GND – – Power ground

10 PFSEL I 0 V/5 V DC Paper feeder identifying signal

11 5 V I 5 V DC Power supply from printer

12 GND – – Signal ground

13 – – – Reserved

(CN3) 1 24 V O 24 V DC Power supply

2 OPRDY I 0 V/5 V DC Paper feeder, Ready/Not ready

3 OPSDO O 5 V/0 V DC Serial communication data signal

with printer

4 OPSCLK O 5 V/0 V DC (Pulse) Serical communication clock signal

5 OPSDI I 5 V/0 V DC Serial communication data signal

with printer

6 OPSEL0 O 0 V/5 V DC Paper feeder identifying signal 0

7 OPSEL1 O 0 V/5 V DC Paper feeder identifying signal 1

8 OPSEL2 O 0 V/5 V DC Paper feeder identifying signal 2

9 GND – – Power ground

10 PFSEL O 0 V/5 V DC Paper feeder identifying signal

11 5 V O 5 V DC Power supply

PF-60

12 GND – – Signal ground

6-6

Page 38

Connector Pin# Signal I/O Voltage Function

(CN4) 1 PSSW0 I 0 V/5 V DC Paper size switch detecting signal

2 GND – – Signal ground

3 PSSW1 I 0 V/5 V DC Paper size switch detecting signal

4 PSSW2 I 0 V/5 V DC Paper size switch detecting signal

(CN6) 1 GND – – Signal ground

2 MCS I 0 V/5 V DC (Pulse) Paper feed motor clock signal

3 5 V O 5 V DC Power supply

(CN7) 1 24 V O 24 V DC Power supply

2 PFM O 0 V/24 V DC (PWM) Paper feed motor, On/Off

6-7

PF-60

Page 39

6-1-4 Correcting a paper jam

If a paper jam occurs in the paper feeder, remove the jammed paper as described below.

After you have removed the jammed paper, open and close the printer’s top cover to clear the

error message from the message display.

1. Pull out the paper cassette 1.

2. Remove the jammed paper

Figure 6-1-1 Jam in the paper feeder

1

PF-60

6-8

Page 40

Chapter 7

Paper Specifications

Page 41

Chapter 7 Contents

7-1 General guidelines........................................................................................................................... 7-3

7-1-1 Paper availability............................................................................................................................. 7-3

7-1-2 Selecting the right paper................................................................................................................. 7-4

7-2 Paper specifications ........................................................................................................................ 7-5

7-2-1 Points of consideration ................................................................................................................... 7-5

(1) Condition of the paper ........................................................................................................................ 7-5

(2) Composition........................................................................................................................................ 7-5

(3) Paper size........................................................................................................................................... 7-6

(4) Smoothness........................................................................................................................................ 7-6

(5) Basis weight........................................................................................................................................ 7-6

(6) Thickness (Caliper) ............................................................................................................................. 7-6

(7) Moisture content ................................................................................................................................. 7-6

(8) Paper grain ......................................................................................................................................... 7-7

7-2-2 Other paper properties.................................................................................................................... 7-7

(1) Porosity ............................................................................................................................................... 7-7

(2) Stiffness .............................................................................................................................................. 7-7

(3) Curl ..................................................................................................................................................... 7-7

(4) Electrostatic properties ....................................................................................................................... 7-8

(5) Whiteness ........................................................................................................................................... 7-8

(6) Quality control..................................................................................................................................... 7-8

(7)Packaging ............................................................................................................................................ 7-8

7-2-3 Special paper.................................................................................................................................. 7-8

(1) Colored paper ..................................................................................................................................... 7-9

(2) Preprinted paper ................................................................................................................................. 7-9

Page 42

7-1 General guidelines

The paper feeder may not be used to print on paper not satisfying the requirements below. Also,

special types of print media such as overhead projection (OHP) film, envelopes, adhesive backed

labels, and paper containing watermarks must not be used with printing with the paper feeder.

These types can result in jams, misfeeds, and paper waste, and in extreme cases can damage the

paper feeder.

NOTE Kyocera mita assumes no liability for problems that occur when paper not satisfying

these requirements is used with the paper feeder.

Selection of the right paper is important. The wrong paper can result in jams, misfeeds, curl, poor

print quality, and paper waste, and in extreme cases can damage the paper feeder and the printer.

The guidelines given below will increase the productivity of your office by ensuring efficient,

trouble-free printing and reducing wear and tear on the paper feeder and the printer.

7-1-1 Paper availability

Most types of paper are compatible with a variety of machines. Paper intended for xerographic

copiers can also be used with the paper feeder and the printer.

There are three general grades of paper: economy, standard, and premium. The most significant

difference between grades is the ease with which they pass through the printer.

This is affected by the smoothness, size, and moisture content of the paper, and the way in which

the paper is cut. The higher the grade of paper you use, the less risk there will be of paper jam and

other problems, and the higher the level of quality your printed output will reflect.

Differences between paper from different suppliers can also affect the paper feeder's performance.

A high-quality printer cannot produce high-quality results when the wrong paper is used. Lowpriced paper is not economical in the long run if causes printing problems.

Paper in each grade is available in a range of basic weights (defined later). The traditional standard

weights are 16, 20, and 28 pounds (60 g/m2 to 105 g/m2).

7-3

PF-60

Page 43

7-1-2 Selecting the right paper

Printer printing is a process involving laser light, electrostatic discharge, toner , and heat. In addition,

as the paper passes through the printer it undergoes considerable sliding, bending, and twisting

motions. A high-quality printing paper matching the requirements withstands all these stresses,

enabling the paper feeder and the printer to turn out clean, crisp printed copy consistently.

Remember that all paper is not the same. Some of the factors to consider when selecting paper is as

following in the next section.

PF-60

7-4

Page 44

7-2 Paper specifications

The following table summarizes the basic paper specifications that should be applied to the paper

used with the paper feeder. Details are given following the table.

Table 7-2-1 Specifications

Item Specification

Weight 60 to 105 g/m2 (16 to 28 lbs./ream)

Thickness 0.086 to 0.110 mm (3.4 to 4.3 mils)

Dimensional accuracy ±0.7 mm (±0.0276 inches)

Squareness 90° ±0.2°

Moisture content 4 to 6 %

Direction of grain Long grain

Pulp content 80 % or more

7-2-1 Points of consideration

The following section provides general information which should be considered when selecting

paper for using with the paper feeder.

(1) Condition of the paper

Avoid using paper that is bent at edges, curled, dirty, torn, or contaminated with lint, clay, or paper

shreds.

Used of paper in these conditions can lead to illegible printing, misfeeding, and paper jams, and can

shorten the life of the paper feeder and the printer. In particular, avoid using paper with a surface

coating or other surface treatment. The paper should have as smooth and even a surface as possible.

(2) Composition

Do not use paper that has been coated or surface-treated and contains plastic or carbon. The heat of

fusing can cause such paper to give off harmful fumes.

Bond paper should contain at least 80% pulp. Not more than 20% of the total paper content should

consist of cotton or other fibers.

7-5

PF-60

Page 45

(3) Paper size

The paper feeder is usable with the paper sizes as tabled below.

Table 7-2-2 Paper size

Paper size Dimension

ISO A4 210 × 297 mm

JIS B5 182 × 257 mm

ISO A5 148 × 210 mm

Letter 8-1/2 × 11 inches

Legal 8-1/2 × 14 inches

(4) Smoothness

The paper should have a smooth, uncoated surface. Paper with a rough or sandy surface can cause

voids in the printed output. Paper that is too smooth, however, can cause multiple feeding and

fogging problems. (Fogging is a gray background effect.)

(5) Basis weight

Paper that is too light or too heavy can cause misfeeding, jams, and premature wear of the paper

feeder and the printer. Uneven paper weight can cause multiple feeds, print defects, poor toner

fusing, blurring, and other print quality problems. The proper weight is 60 to 105 g/m2 (16 to 28 Ibs/

ream).

(6) Thickness (Caliper)

Thick paper is referred to as high-caliper paper and thin paper as low-caliper paper . The paper used

with the paper feeder should be neither extremely thick nor extremely thin. If you are having problems

with paper jams, multiple feeds, and faint printing, the paper may be too thin. If you are having

problems with paper jams, and blurred printing the paper may be too thick. The proper thickness is

0.086 to 0.110 mm (3.4 to 4.3 mils).

(7) Moisture content

Moisture content is defined as the percent ratio of moisture to the dry mass of the paper. Moisture

can affect the paper's appearance, feedability, curl, electrostatic properties, and toner fusing

characteristics.

The moisture content of the paper varies with the relative humidity in the room. When the relative

humidity is high and the paper absorbs moisture, the paper edges expand, becoming wavy is

appearance. When the relative humidity is low and paper loses moisture, the edges shrink and

tighten, and print contrast may suffer.

PF-60

7-6

Page 46

Wavy or tight edges can cause misfeeding and alignment anomalies.

The moisture content of the paper should be 4 % to 6 %.

T o ensure the proper moisture content it is important to store the paper in a controlled environment.

Some tips on moisture control are:

Store paper in a cool, dry location.

Keep the paper in its wrapping as long as possible. Rewrap paper that is not in use.

Store paper in its original carton. Place a pallet etc. under the carton to separate it from the floor .

After removing paper from storage, let it stand in the same room as the printer for 48 hours

before use.

Avoid leaving paper where it is exposed to head, sunlight, or damp.

(8) Paper grain

When paper is manufactured, it is cut into sheets with the gain running parallel to the length

(long grain) of parallel to width (short grain).

Short grain paper can cause feeding problems in the paper feeder and the printer . All paper used

in the paper feeder and the printer should be long grain.

7-2-2 Other paper properties

(1) Porosity

Refers to the density of the paper structure; that is, to how openly or compactly the fibers are

bonded.

(2) Stiffness

Limp paper can buckle inside the paper feeder and the printer, while paper that is too stiff may

bind. Either way the result is a paper jam.

(3) Curl

Most paper has a natural tendency to curl in one direction. The paper should be loaded so that the

natural curl is downward, to counteract the upward curl imparted by the printer . Printed sheets will

then come out flat. Most paper also has a top and bottom surface. Loading instructions are usually

given on the paper package.

7-7

PF-60

Page 47

(4) Electrostatic properties

During the printing process the paper is electrostatically charged to attract the toner. The paper

must be able to release this charge so that printed sheets do not cling together in the output tray.

(5) Whiteness

The contrast of the printed page depends on the whiteness of the paper. Whiter paper provides a

sharper, brighter appearance.

(6) Quality control

Uneven sheet size, corners that are not square, ragged edges, welded (uncut) sheets, and crushed

edged and corners can cause the paper feeder and the printer and the printer to malfunction in

various ways. A quality paper supplier should take considerable care to ensure that these problems

do not occur.

(7) Packaging

Paper should be packed in a sturdy carton to protect it from damage during transport. Quality paper

obtained from a reputable supplier is usually properly packaged.

7-2-3 Special paper

The following types of special paper can be used:

Colored paper

Preprinted paper

Use paper that is sold specifically for use with copiers (heat-fusing type).

Since the composition and quality of special paper very considerably, special paper is more likely

than white bond paper to give trouble during printing. No liability will be assumed if moisture etc.

given off in printing on special paper causes harm to the machine or operator.

NOTE Before purchasing any type of special paper, test a sample on the paper feeder

and the printer and check that printing quality is satisfactory.

Specifications for each type of special paper are given on next page.

PF-60

7-8

Page 48

(1) Colored paper

Colored paper should satisfy the same conditions as white bond paper, listed in used in the paper

must be able to withstand the heat of fusing during the printing process (up to 200 °C or 392 °F).

(2) Preprinted paper

Preprinted paper should have a bond paper base. The preprinted ink must be able to withstand the

heat of fusing during the printing process, and must not be affected by silicone oil.

Do not use paper with any kind of surface treatment, such as the type of paper commonly used for

calendars.

7-9

PF-60

Page 49

Appendix A

Diagrams

Page 50

Appendix A Contents

Wiring diagram .......................................................................................................................................A-3

Page 51

BE

BE

BE

BE

BE

BE

BE

BE

BE

BE

BE

BE

+24 V

+5 V

SCLK

SDO

SDI

READY

GND

PFSEL

SEL0

SEL1

SEL2

GND

CN8-1

CN8-2

CN8-3

CN8-4

CN8-5

CN8-6

CN8-7

CN8-8

CN8-9

CN8-10

CN8-11

CN8-12

CN2-1

CN2-2

CN2-3

CN2-4

CN2-5

CN2-6

CN2-7

CN2-8

CN2-9

CN2-10

CN2-11

CN2-12

CN2-13

+24 V

READY

SDO

SCLK

SDI

SEL0

SEL1

SEL2

GND

PFSEL

+5 V

GND

N.C

1

!

4

3

5

2

@

0

6

7

8

9

BE

BE

BE

BE

BE

BE

RD

BE

BE

BE

BE

BE

PSSW0

SGND

PSSW1

PSSW2

CN4-1

CN4-2

CN4-3

CN4-4

CN10-1

CN10-2

CN10-3

CN10-4

PSSW0

SGND

PSSW1

PSSW2

+24 V

PFCL

CN1-1

CN1-2

1

2

3

4

1

2

3

4

BE

BE

BE

BE

BE

BE

BE

BE

BE

BE

BE

BE

1

2

3

4

5

6

7

8

9

0

!

@

INTERFACE IN

BN

BN

BN

BN

BN

BN

BN

BN

BN

BN

BN

BN

+24 V

+5 V

SCKD

SDO

SDI

READY

GND

PFSEL

SEL0

SEL1

SEL2

GND

CN9-1

CN9-2

CN9-3

CN9-4

CN9-5

CN9-6

CN9-7

CN9-8

CN9-9

CN9-10

CN9-11

CN9-12

CN3-1

CN3-2

CN3-3

CN3-4

CN3-5

CN3-6

CN3-7

CN3-8

CN3-9

CN3-10

CN3-11

CN3-12

+24 V

READY

SDO

SCKD

SDI

SEL0

SEL1

SEL2

GND

PFSEL

+5 V

GND

1

!

4

3

5

2

@

0

6

7

8

9

BN

BN

BN

BN

BN

BN

BN

BN

BN

BN

BN

BN

1

2

3

4

5

6

7

8

9

0

!

@

INTERFACE OUT

Paper feeder board

Paper size switch

Paper feed

sensor

Paper gauge sensor 1, 2

Motor clock sensor

Paper feed

clutch

Paper feed

motor

PFCL

PFM2

PFM1

CN7-1

CN7-2

PFM

BE

BE

BE

BE

BE

BE

SGND

MCS

+5 V

CN6-1

CN6-2

CN6-3

CN12-1

CN12-2

CN12-3

+5 V

MCS

SGND

1

2

3

3

2

1

Wire color

Brown

Blue

Red

Mark

BN

BE

RD

Wiring diagram

A-3

PF-60

Loading...

Loading...