Page 1

DOWNTOWN 200i

By KWANG YANG Motor Co., Ltd.

1st Edition, Dec 2009

All rights reserved. Any reproduction or

unauthorized use without the written

permission of KWANG YANG Motor Co., Ltd.

is expressly prohibited.

T300-SK40AA-A1

Page 2

DOWNTOWN 200i

PREFACE

This Service Manual describes the

technical features and servicing

procedures for the KYMCO

Downtown

200

i.

Section 1 contains the precautions for

all operations stated in this manual.

Read them carefully before any

operation is started.

Section 2 is the removal/installation

procedures for the frame covers which

are subject to removal/installation

frequency during maintenance and

servicing operations.

Section 3 describes the inspection/

adjustment procedures, safety rules

and service information for each part,

starting from periodic maintenance.

Sections 5 to 12 give instructions for

disassembly, assembly and

adjustment of engine parts. Section 13

is the AFI system. Section 14 to 15 is

the removal/ installation of chassis.

Section 16 to 19 states the testing and

measuring methods of electrical

equipment.

Most sections start with an assembly

or system illustration and

troubleshooting for the section. The

subsequent pages give detailed

procedures for the section.

KWANG YANG MOTOR CO., LTD.

QUALITY TECHNOLOGY DEPT.

EDUCATION SECTION

TABLE OF CONTENTS

GENERAL INFORMATION

1

EXHAUST MUFFLER/FRAME

COVERS

2

INSPECTION/ADJUSTMENT

3

LUBRICATION SYSTEM

4

ENGINE REMOVAL/INSTALLATION

5

CYLINDER HEAD/VALVES

6

CYLINDER/PISTON

7

DRIVE AND DRIVEN PULLEYS/VBELT

8

FINAL REDUCTION

9

A.C. GENERATOR/STARTER

CLUTCH

10

CRANKCASE/CRANKSHAFT

11

COOLING SYSTEM

12

FUEL INJECTION SYSTEM

13

STEERING HANDLEBAR/FRONT

WHEEL/FRONT BRAKE/FRONT

SHOCK ABSORBER/FRONT FORK

14

REAR BRAKE/REAR FORK/REAR

WHEEL/REAR SHOCK ABSORBER`

15

BATTERY/CHARGING SYSTEM

16

IGNITION SYSTEM

17

STARTING SYSTEM

18

LIGHTS SWITCHES / FUEL PUMP

19

The information and contents

included in this manual may be

different from the motorcycle in case

specifications are changed.

CHASSIS

ELE

C

TRI

C

AL

EQUIPMENT

ENGINE

Page 3

1. GENERAL INFORMATION

1-0

DOWNTOWN 200i

1

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

GENERAL INFORMATION

________________________________________________________________________________

SERIAL NUMBER------------------------------------------------------------------------------------1-1

SPECIFICATION -------------------------------------------------------------------------------------1-2

SERVICE PRECAUTIONS-------------------------------------------------------------------------1-3

TORQUE VALUES-----------------------------------------------------------------------------------1-4

SPECIAL TOOLS-------------------------------------------------------------------------------------1-6

LUBRICATION POINTS ----------------------------------------------------------------------------1-7

CABLE & HARNESS ROUTING---------------------------------------------------------------------1-8

1

Page 4

1. GENERAL INFORMATION

1-1

DOWNTOWN 200i

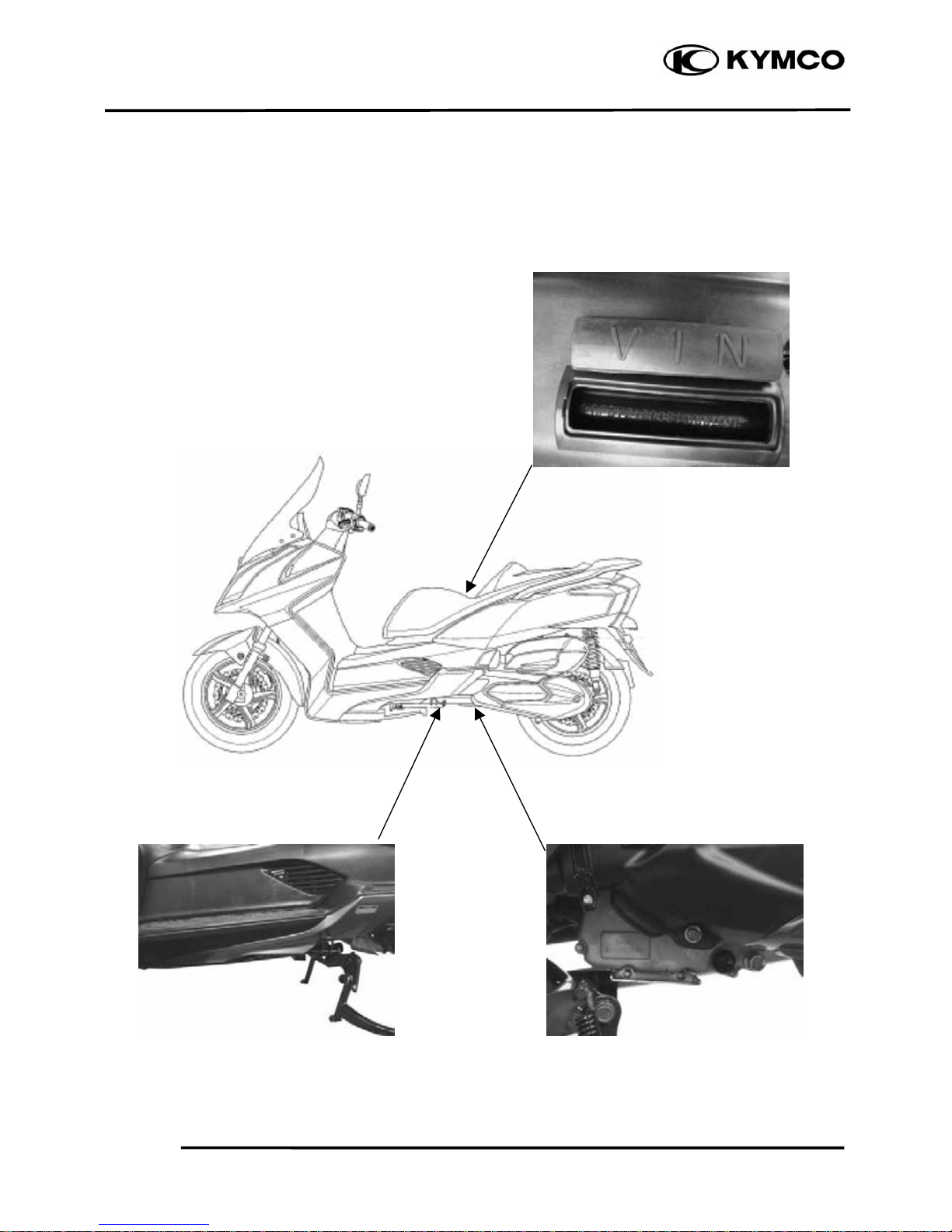

SERIAL NUMBER

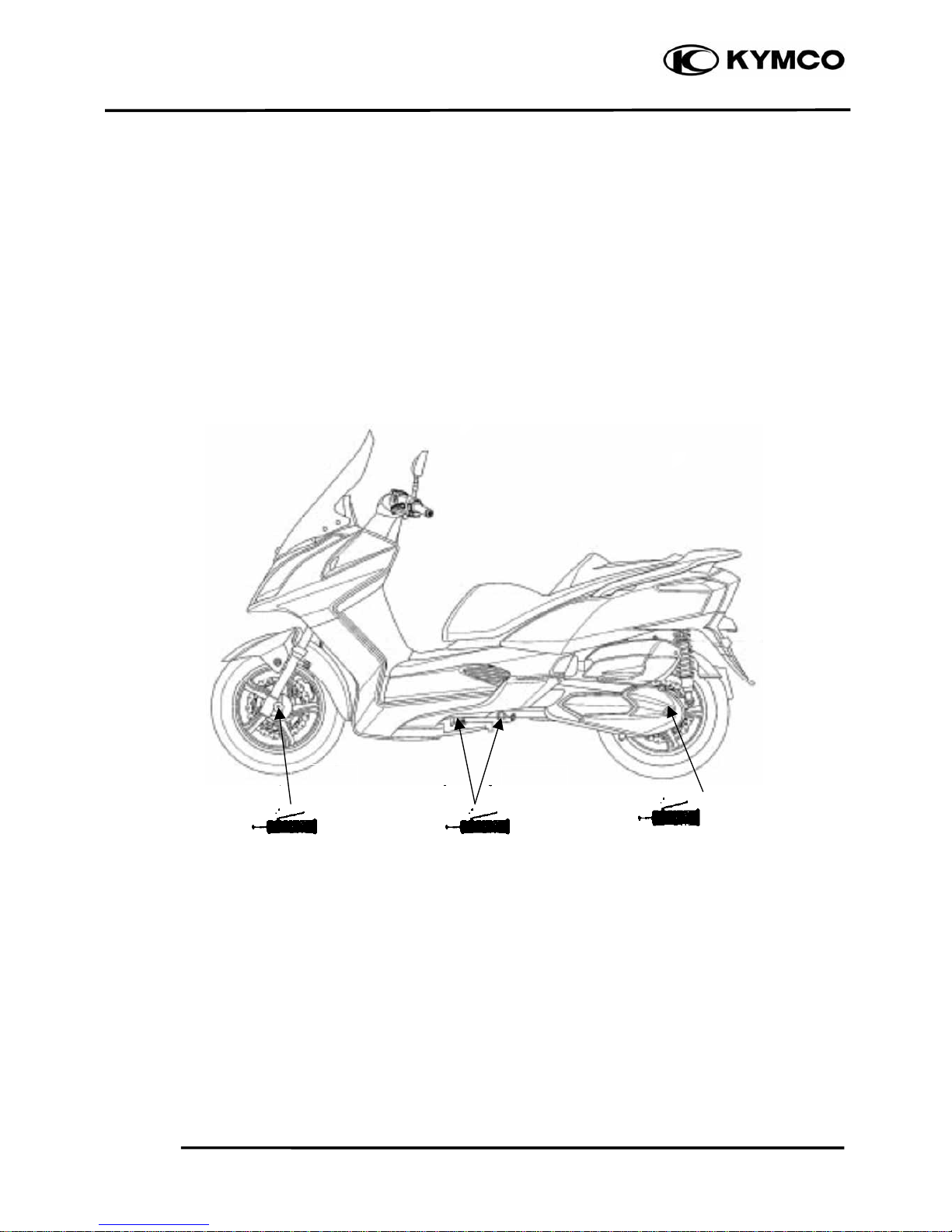

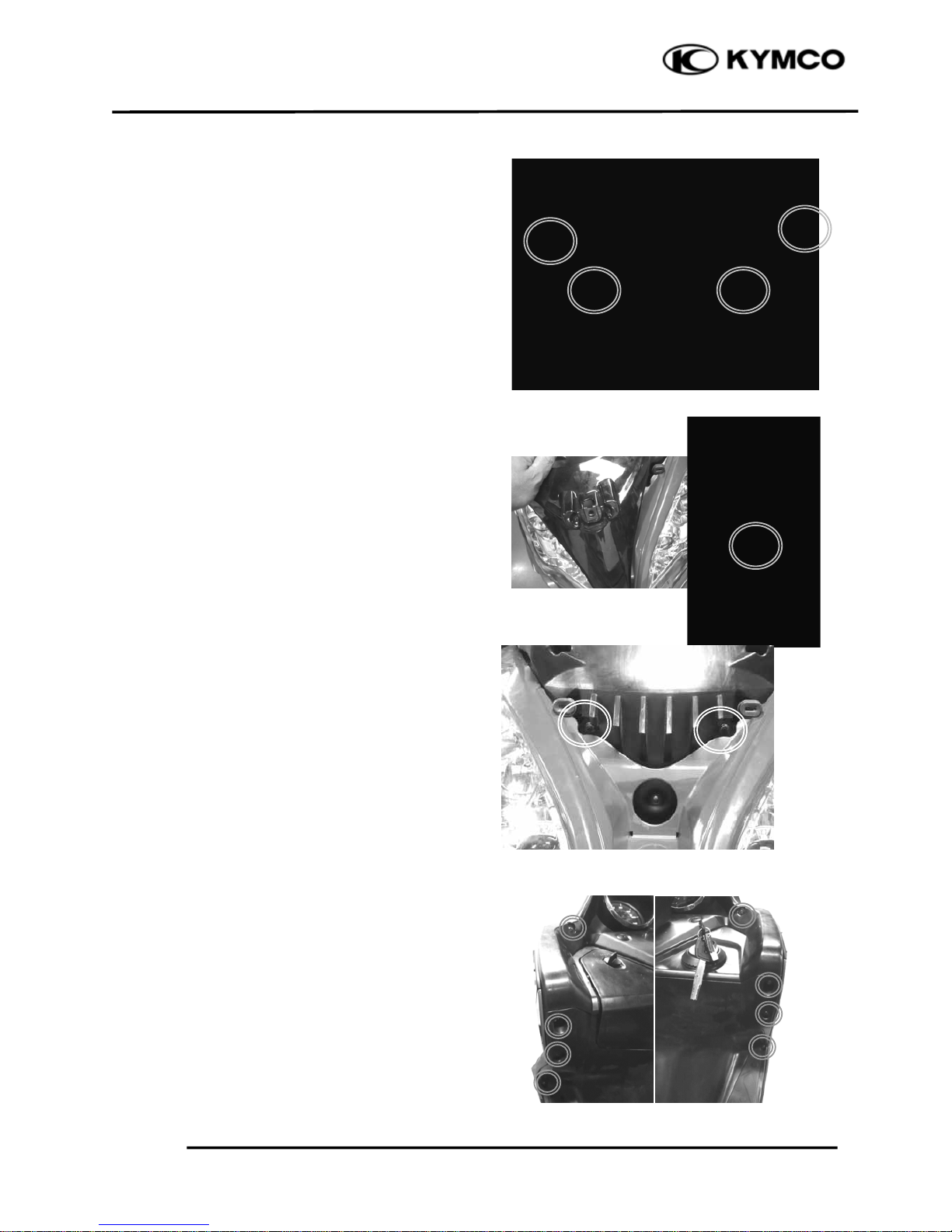

Location of Frame Serial Number

(inside luggage box)

Location of Vehicle Identification

Number (VIN)

Location of Engine Serial Number

Page 5

1. GENERAL INFORMATION

1-2

DOWNTOWN 200i

SPECIFICATIONS

Name Downtown 200i

Model No. SK40AA

Overall length 2200 mm

Overall width 800 mm

Overall height 1410 mm

Wheel base 1545 mm

Engine type 4 stroke O.H.C.

Displacement 205 cc

Fuel Used 92# nonleaded

gasoline

Front wheel

70

Rear wheel

104

Total

174

Front wheel

149

Rear wheel

205

Total

354

Ground clearance (mm)

140

Braking distance (m)

7.9m / 30 km/hr

Min. turning radius (m)

2.6

Engine part

Starting system

Starting motor

Type

Gasoline 4-cycle

Cylinder arrangement Single cylinde

r

Combustion chamber type Semi-sphere

Valve arrangement O.H.C.-4V

Bore x stroke (mm) φ66 * 60

Compression ratio 10.5:1

Compression pressure

(kg/cm²)

16

Max. output (ps/rpm)Engine 20.6 /8000

Max. torque (kg-m/rpm) 2.03 / 6500

Open 5° BTDC

Close 32° BTDC

Open 34° BTDC

Close 5° BTDC

Intake

0.10

Exhaust

0.10

Idle speed (rpm)

1600±100 rpm

Cooling Type

Liquid cooling

Lubrication type

Forced pressure &

wet sump

Oil pump type Inner/outer roto

r

Oil filter type Full-flow filtration

Oil capacity 1.5ℓ

Exchanging capacity 1.3 ℓ

Fi injection system

Air cleaner type & No Paper element, wet

Fuel capacity 12.5 ℓ

Brand Keihin(LGF9)

Throttle Body

Butterfly type

Venturi diameter (mm)

32

Fuel pump pressure

3 bar

Electrical system

Ignition type

ECU

Ignition timing

4°~32°

Spark plug CR7E (NGK)

Spark plug gap 0.6~0.7mm

Battery Capacity 12V10AH

Transmission system

Clutch type

Dry multi-disc

Transmission type

CVT

Operation type Auto centrifugal

Reduction gear type

Two-stage reduction

1

st

0.81 ~ 2.57

2nd 9.54

Moving device

Tire type

Tubeless

Front wheel

120/80-14 58S

Rear wheel

150/70-13 64S

Front wheel

2.0

Rear wheel

2.25

Wheel material

Aluminium

Left 40°

Right 40°

Front Disk brake

Rear Drum brake

Damping Device

Front

Telescope

Rear Swing arm

Front 110 mm

Shock absorber

stroke

Rear 100 mm

Page 6

1. GENERAL INFORMATION

1-3

DOWNTOWN 200i

Symbols:

The following symbols represent the

servicing methods and cautions included in

this service manual.

: Apply engine oil to the

specified points. (Use

designated engine oil for

lubrication.)

: Apply grease for lubrication.

: Transmission Gear Oil (90#)

: Use special tool.

: Caution

: Warning

Special

Engine Oil

Grease

Gear Oil

*

Page 7

1. GENERAL INFORMATION

1-4

DOWNTOWN 200i

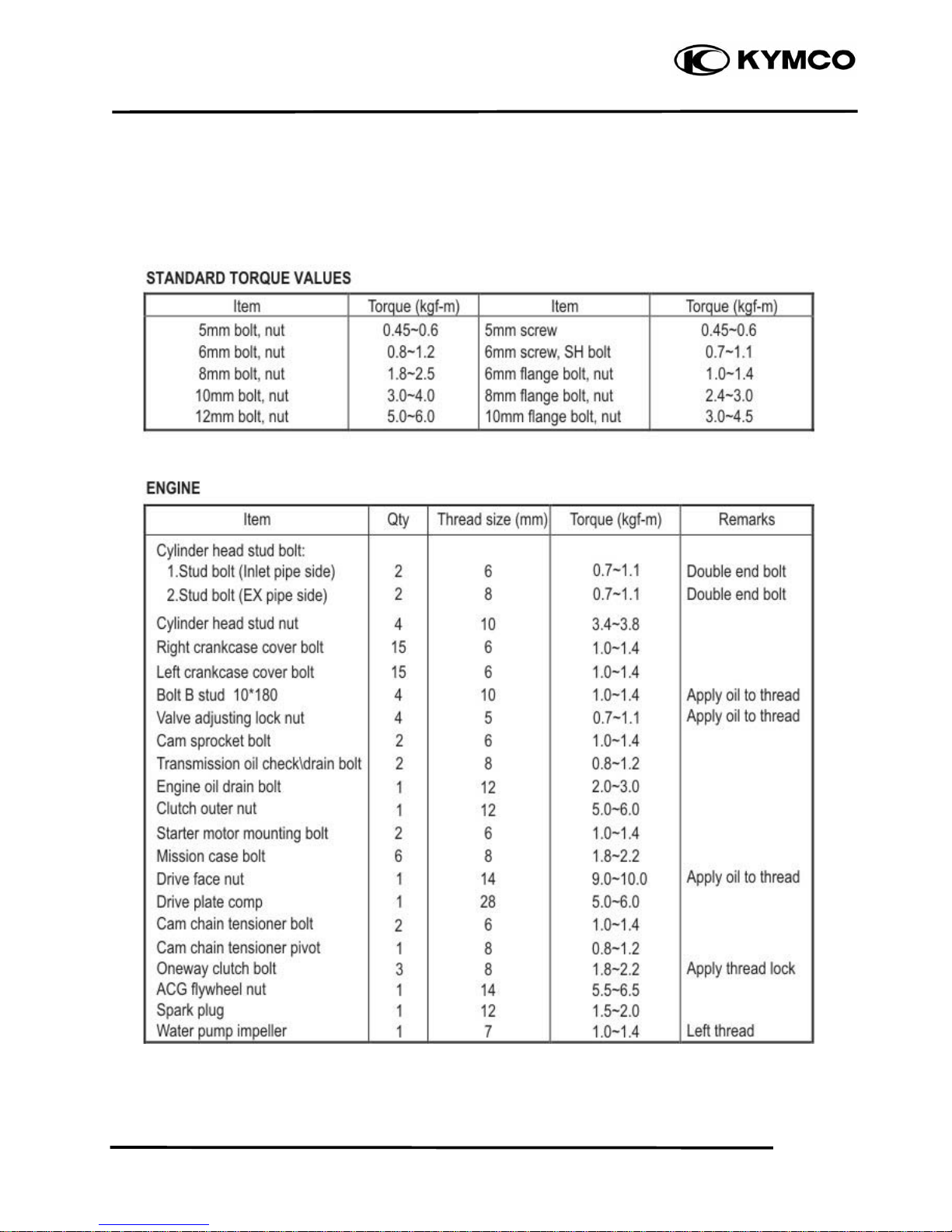

TORQUE VALUES

Page 8

1. GENERAL INFORMATION

1-5

DOWNTOWN 200i

TORQUE VALUES

FRAME

Page 9

1. GENERAL INFORMATION

Downtown 200i

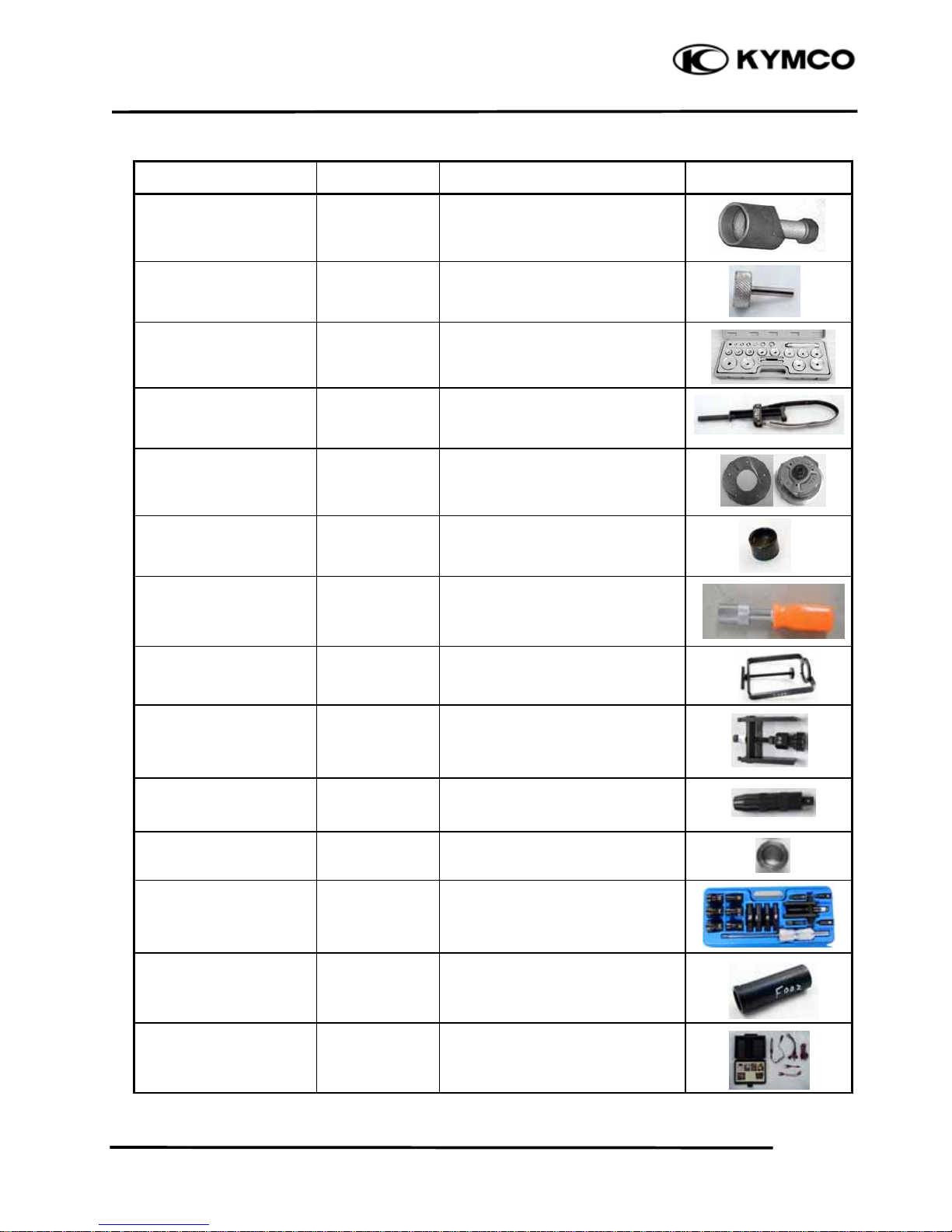

SPECIAL TOOLS

Tool Name Tool No. Performance Photo

Flywheel Puller A120E00003 A.C. generator flywheel removal

Tappet Adjuster A120E00012 Tappet adjustment

Oil Seal & Bearing

Installer

A120E00014 Oil seal & bearing installing

Flywheel Holder A120E00021 A.C. generator flywheel holding

#41 Nut & Fitting A120E00028 Clutch disassembly & assembly

Thread Protector A120E00029 Protecting the crankshaft’s

thread

Valve Cotter Installer A120E00051 Valve cotter installation

Clutch Spring

Compressor

A120E00053 Clutch disassembly & assembly

Shaft Collar Puller A120E00088 Bearing crankcase removal

Shaft Collar Driver A120E00091 Bearing crankcase removal

Shaft Collar Installer A120E00092 Bearing crankcase installation

Bearing Puller A120E00093 Bearing removal

Lock Nut Socket Wrench A120F00002 Steering stem removal or

installation

Electric Repair Kit A120F00032 Fuel injection system diagnosis

1-6

Page 10

1. GENERAL INFORMATION

1-7

DOWNTOWN 200i

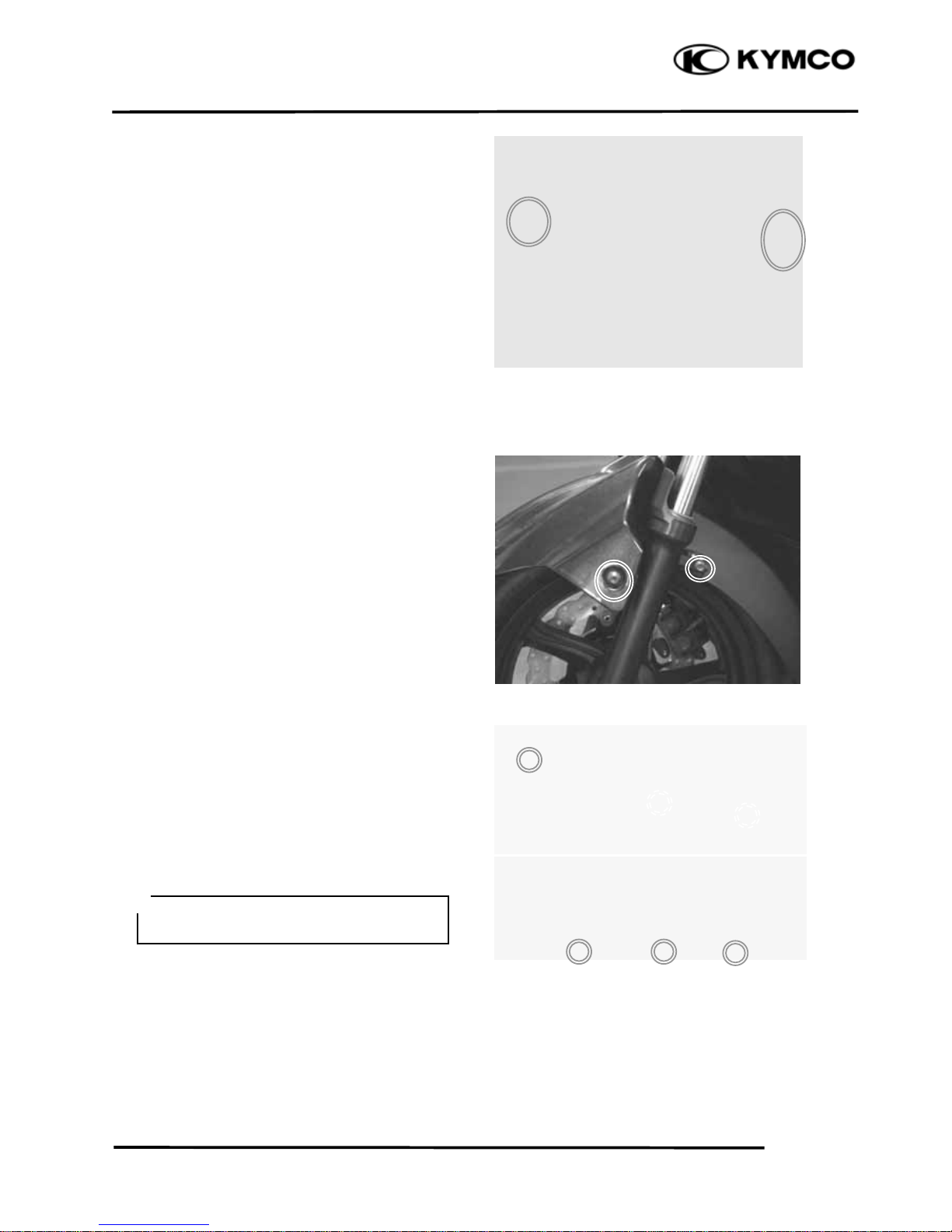

LUBRICATION POINTS

FRAME

The following is the lubrication points for the frame.

Use grease for parts not listed.

Apply engine oil or grease to cables and movable parts not specified. It will avoid abnormal noise

and damage the durability of the motorcycle.

Grease

Grease

Front wheel axle &nut

Rear wheel axle &nut

Grease

Side stand pivot

& Main stand pivot

Page 11

1. GENERAL INFORMATION

1-8

DOWNTOWN 200i

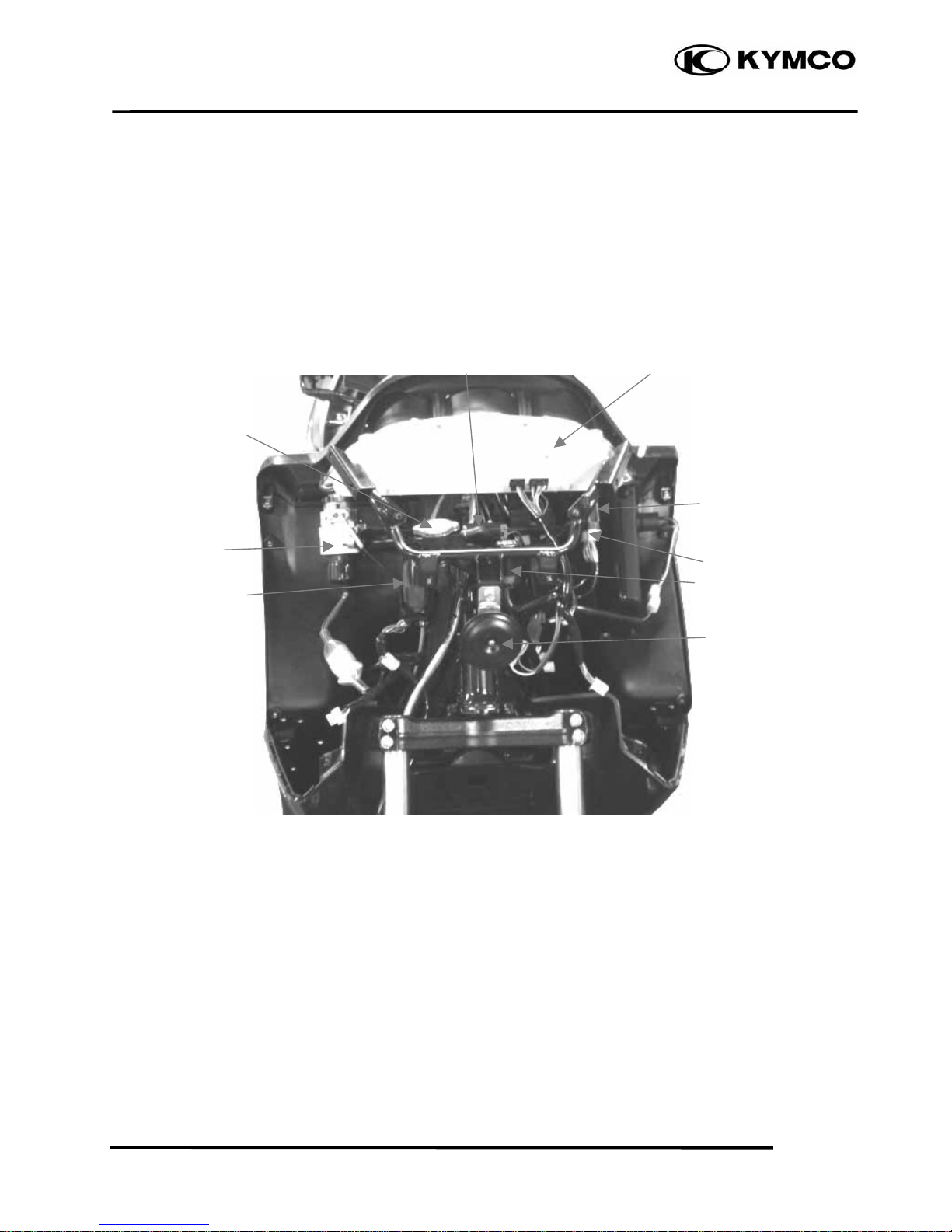

CABLE & HARNESS ROUTING

Tilt Switch Speedometer

Radiator Filler Cap

Ignition Switch

ECU

Horn

Winker Relay

Hi Beam Relay

Lo Beam Relay

Page 12

1. GENERAL INFORMATION

1-9

DOWNTOWN 200i

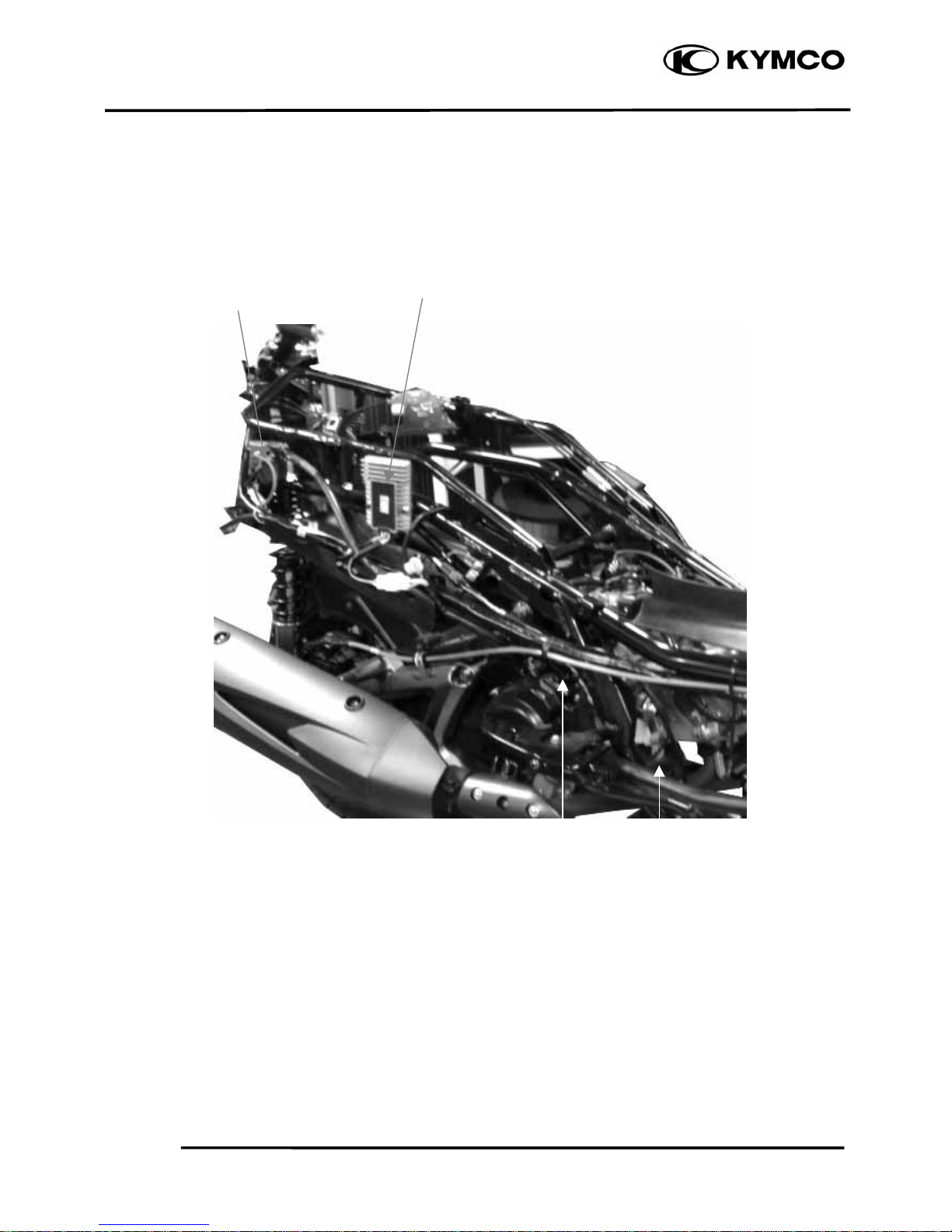

ISC Throttle Body TPS WTS

InjectorMAP Sensor

Page 13

1. GENERAL INFORMATION

1-10

DOWNTOWN 200i

Oil controller

Fuel Pump Relay

Ignition Coil

Output Voltage Connector

Coolant Reserve Tank

Page 14

1. GENERAL INFORMATION

1-11

DOWNTOWN 200i

Starter Relay Regulator/Rectifier

CPS O2 Sensor

Page 15

2

. EXHAUST MUFFLER/FRAME COVERS

2-0

DOWNTOWN 200i

2

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

EXHAUST MUFFLER/FRAME COVERS

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 2- 1

TROUBLESHOOTING----------------------------------------------------- 2- 1

FASTENER REMOVAL AND REINSTALLATION------------------ 2- 2

FRAME COVERS REMOVAL/INSTALLATION--------------------- 2- 3

EXHAUST MUFFLER ----------------------------------------------------- 2-14

2

Page 16

2

. EXHAUST MUFFLER/FRAME COVERS

2-1

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When removing frame covers, use care not to pull them by force because the cover joint claws

may be damaged.

• Make sure to route cables and harnesses according to the Cable & Harness Routing.

TORQUE VALUES

Exhaust muffler pipe nuts 1.8~2.2 kgf-m

Exhaust muffler brake /RR Frok 3.2~3.8 kgf-m

RR fork/Engine case 3.0~4.0 kgf-m

TROUBLESHOOTING

Noisy exhaust muffler

• Damaged exhaust muffler

• Exhaust muffler joint air leaks

Lack of power

• Caved exhaust muffler

• Clogged exhaust muffler

• Exhaust muffler air leaks

Page 17

2

. EXHAUST MUFFLER/FRAME COVERS

2-2

DOWNTOWN 200i

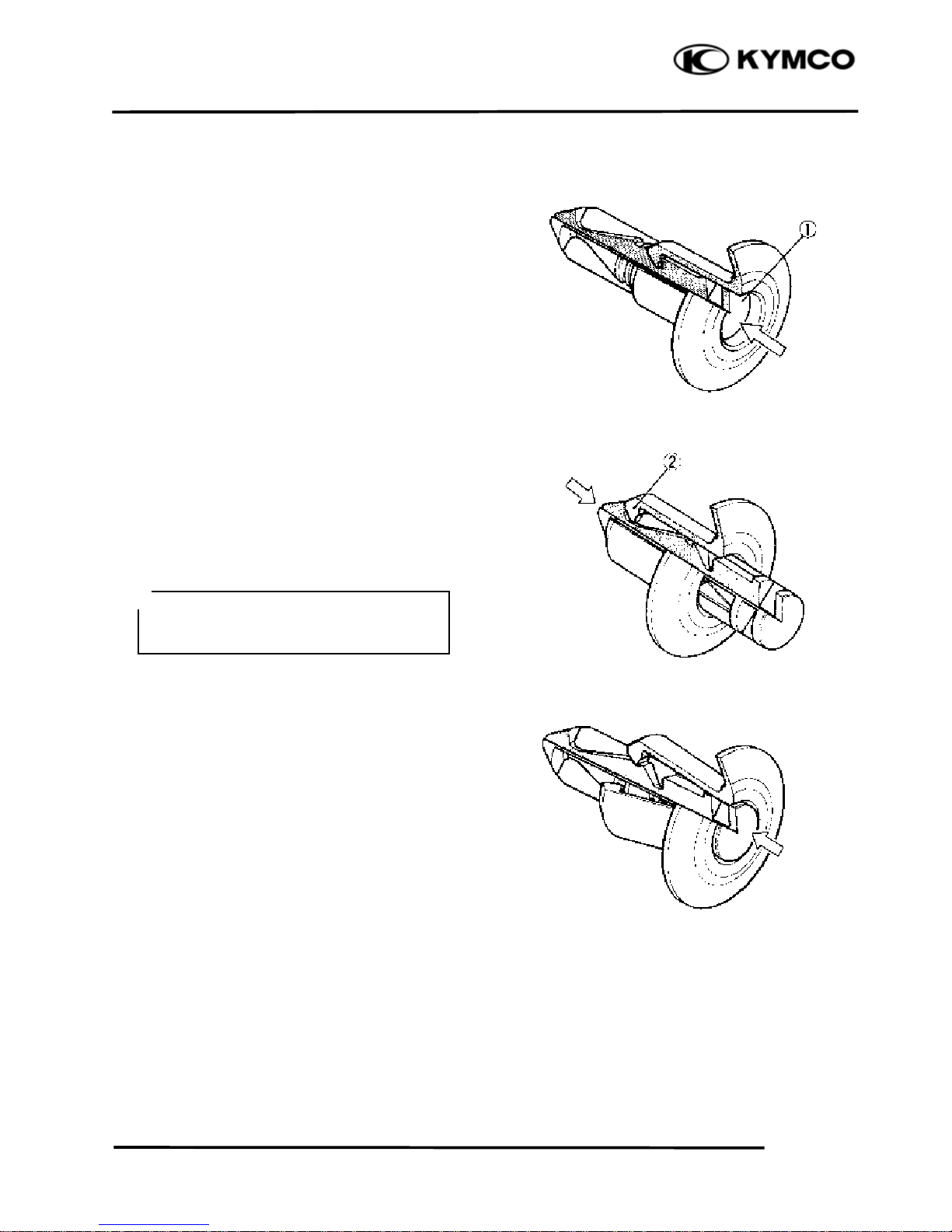

FASTENER REMOVAL AND

REINSTALLATION

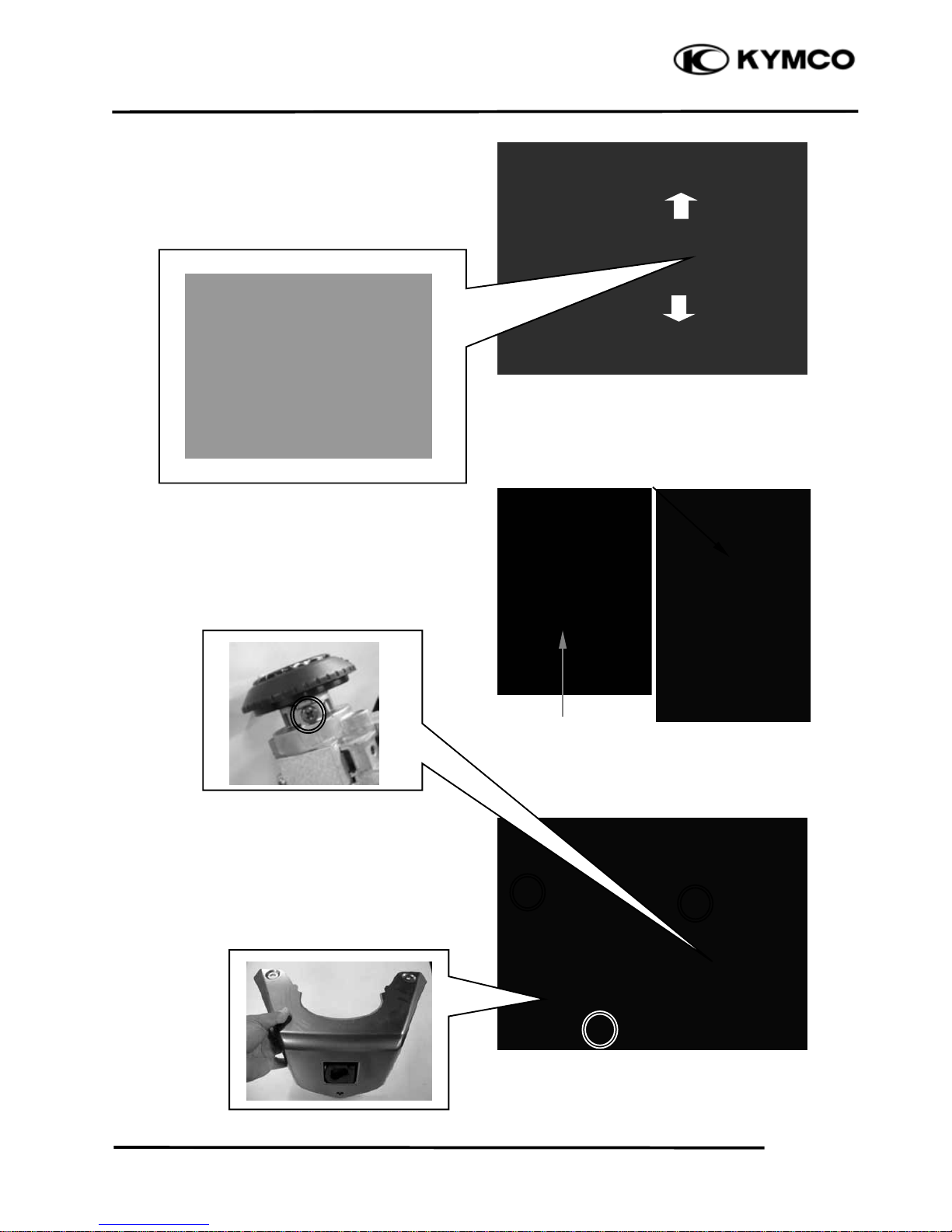

REMOVAL

Depress the head of fastener center piece {.

Pull out the fastener.

INSTALLATION

Let the center piece stick out toward the head

so that the pawls | close.

Insert the fastener into the installation hole.

Push in the head of center piece until it

becomes flush with the fastener outside face.

To prevent the pawl | from damage,

insert the fastener all the way into the

installation hole

*

Page 18

2

. EXHAUST MUFFLER/FRAME COVERS

2-3

DOWNTOWN 200i

FRAME COVERS REMOVAL/

INSTALLATION

SEAT

Unlock the seat with the ignition key.

Open the seat.

Remove the two nuts and the seat.

Installation is in the reverse order of removal.

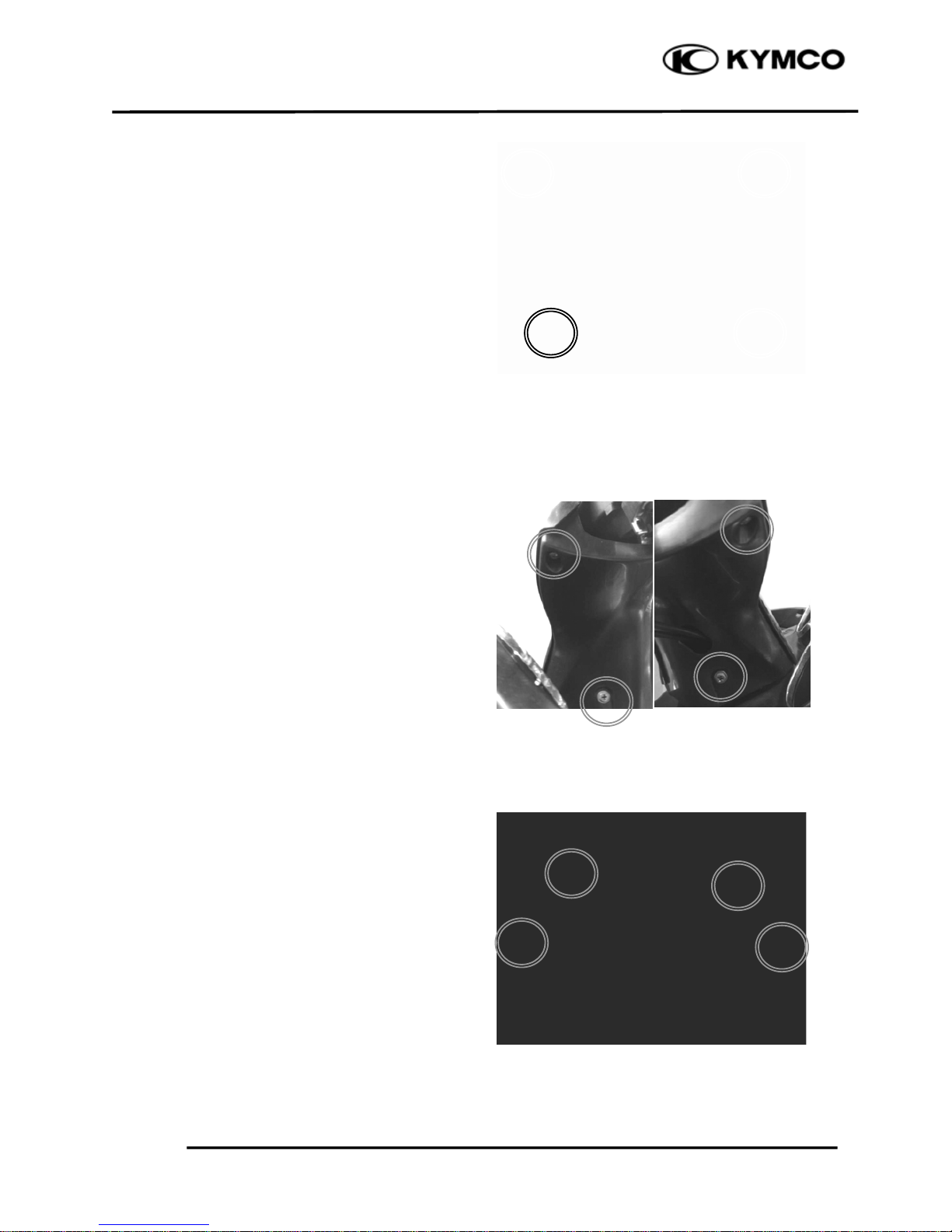

LUGGAGE BOX

Unlock the seat with the ignition key.

Open the seat.

Remove four bolts, and the fastener on the

right side of luggage box, then lift luggage

box.

Disconnect the luggage box light connector,

then remove the luggage box.

Installation is in the reverse order of removal.

Luggage Box Light Connecto

r

Page 19

2

. EXHAUST MUFFLER/FRAME COVERS

2-4

DOWNTOWN 200i

CENTER COVER

Remove the luggage box.

Remove the center cover.

Installation is in the reverse order of removal.

Remove four bolts and then remove the rear

carrier.

Center Cove

r

During removal, do not pull the joint

claws forcedly to avoid damage.

*

Page 20

2

. EXHAUST MUFFLER/FRAME COVERS

2-5

DOWNTOWN 200i

Installation is in the reverse order of removal.

UPPER/LOWER HANDLEBAR COVER

Remove the four screws and then remove

upper handlebar cover.

Remove the four screws, then remove the

bottom handlebar cover.

Disconnect the throttle cable refer to the

“THROTTLE BODY /TPS” section, then

pull the throttle cable out from the lower

cover. Remove the lower cover.

Installation is in the reverse order of removal.

Page 21

2

. EXHAUST MUFFLER/FRAME COVERS

2-6

DOWNTOWN 200i

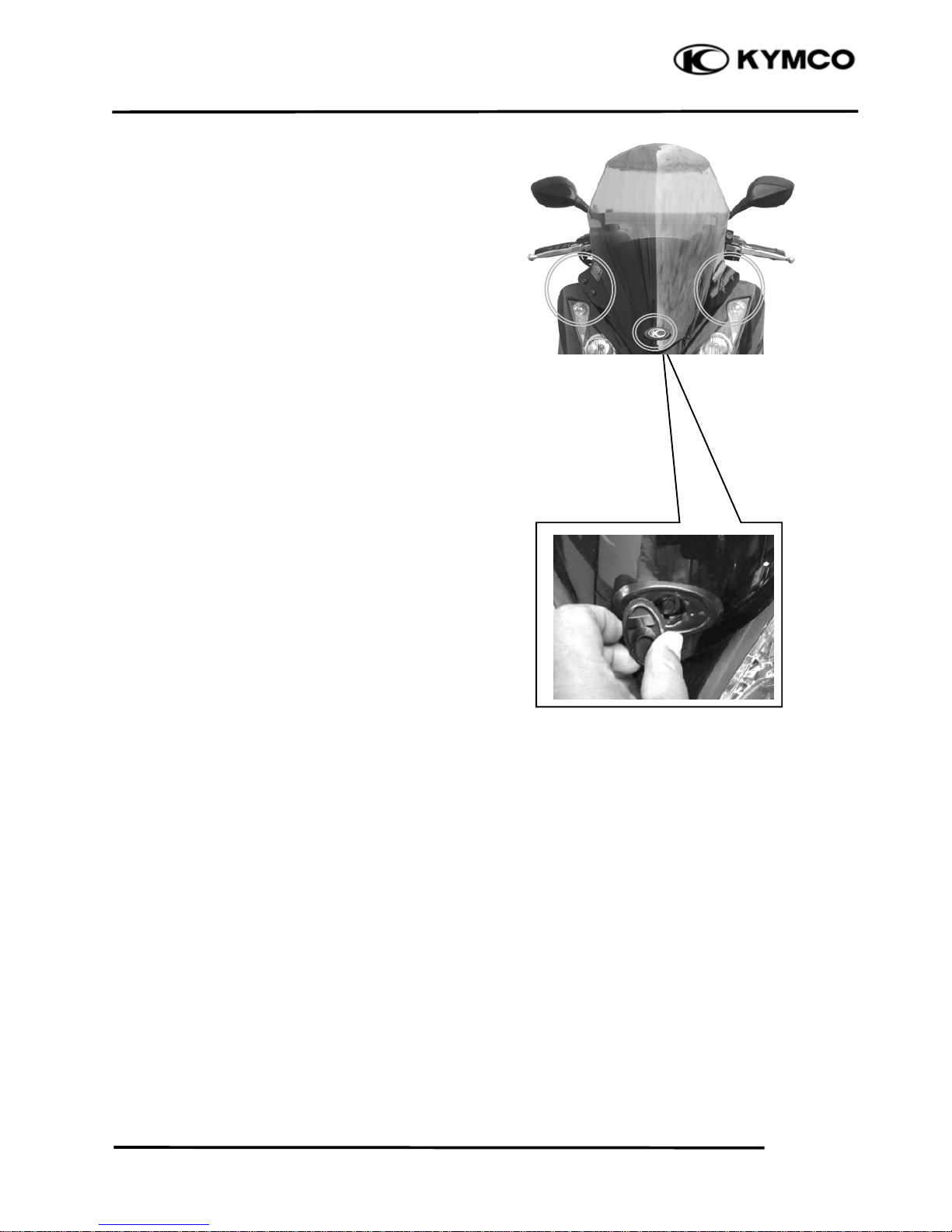

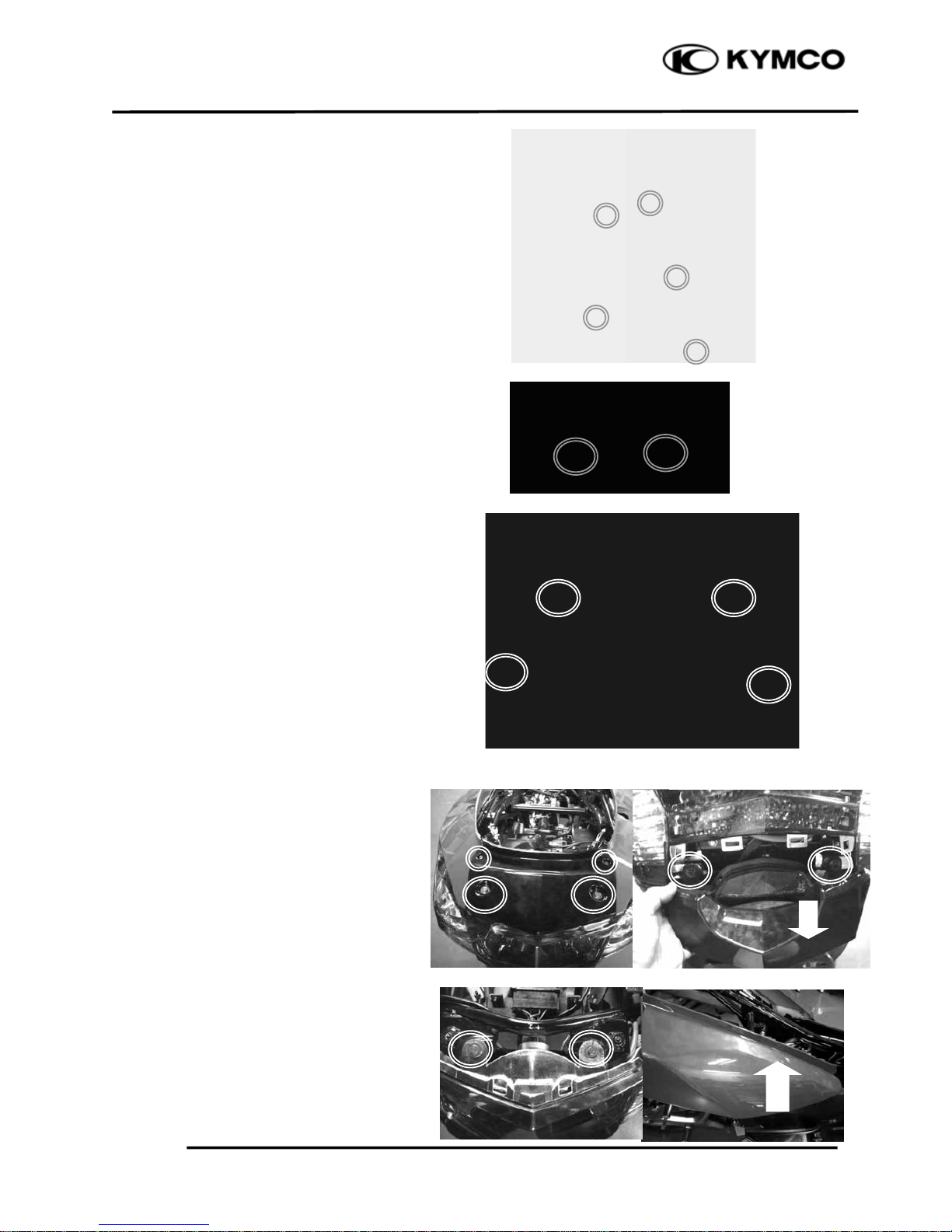

WINDSHIELD/WINDSHIELD GARNISH

Remove five bolts and windshield garnish.

Page 22

2

. EXHAUST MUFFLER/FRAME COVERS

2-7

DOWNTOWN 200i

FRONT CENTER COVER

Remove the windshield

Remove four screws, then remove the front

center cover.

Remove the front cover.

Installation is in the reverse order of removal.

FRONT COVER

Remove the small front cover(black) screw

Remove the small front cover(black)

Remove two nuts.

Remove eight screws from the inner cover.

Remove the front cover

Page 23

2

. EXHAUST MUFFLER/FRAME COVERS

2-8

DOWNTOWN 200i

Disconnect the headlight/position light

connector and right/left turn signal light

connectors.

Installation is in the reverse order of removal.

FRONT FENDER

Remove four screws attaching to the front

fender.

Installation is in the reverse order of removal.

RIGHT/LEFT FOOT SKIRT

Remove the six screws attaching to the right

or left skirt.

Installation is in the reverse order of removal.

During removal, do not pull the joint

claws forcedly to avoid damage.

*

Page 24

2

. EXHAUST MUFFLER/FRAME COVERS

2-9

DOWNTOWN 200i

FRONT LOWER COVER

Remove the front cover

Remove the foot skirt

Remove seven screws and front lower cover.

Installation is in the reverse order of removal.

REAR FENDER

Remove the body cover and then the rear

fender.

Installation is in the reverse order of removal.

BODY COVER

Remove the rear center cover.

Remove the right and left foot skirts

Remove the rear carrier.

Remove six screws and two nuts, then

remove the body cover.

Disconnect the taillight connector.

Page 25

2

. EXHAUST MUFFLER/FRAME COVERS

2-10

DOWNTOWN 200i

TIRE FENDER

Remove the body cover.

Remove four bolts attaching to the tire fender

Installation is in the reverse order of removal.

FLOORBOARD

Remove the body cover

Remove the right /left skirt

Remove two screws.

Taillight Connecto

r

Page 26

2

. EXHAUST MUFFLER/FRAME COVERS

2-11

DOWNTOWN 200i

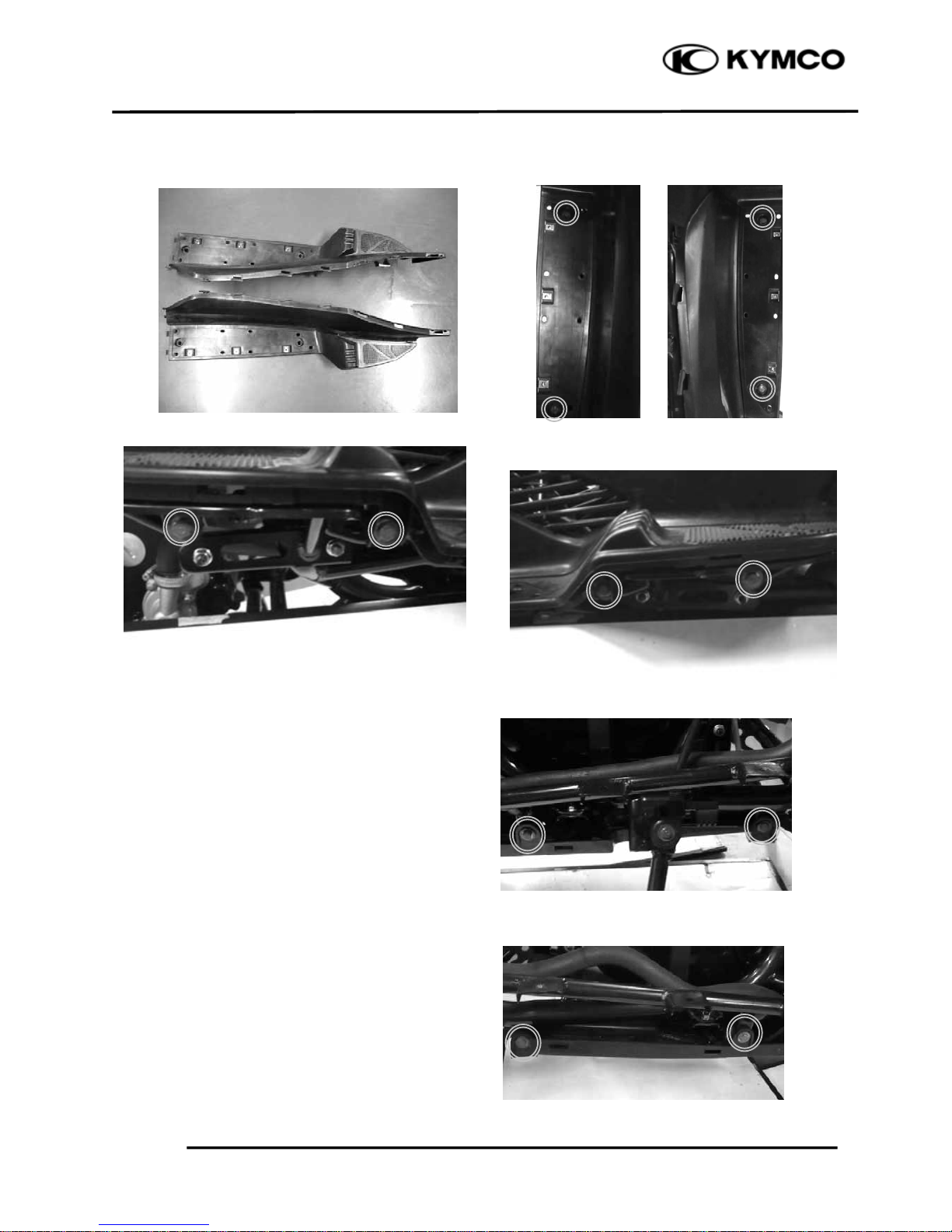

Remove eight bolts, then remove the

floorboard.

UNDER COVER

Remove four bolts

Remove the under cover.

Page 27

2

. EXHAUST MUFFLER/FRAME COVERS

2-12

DOWNTOWN 200i

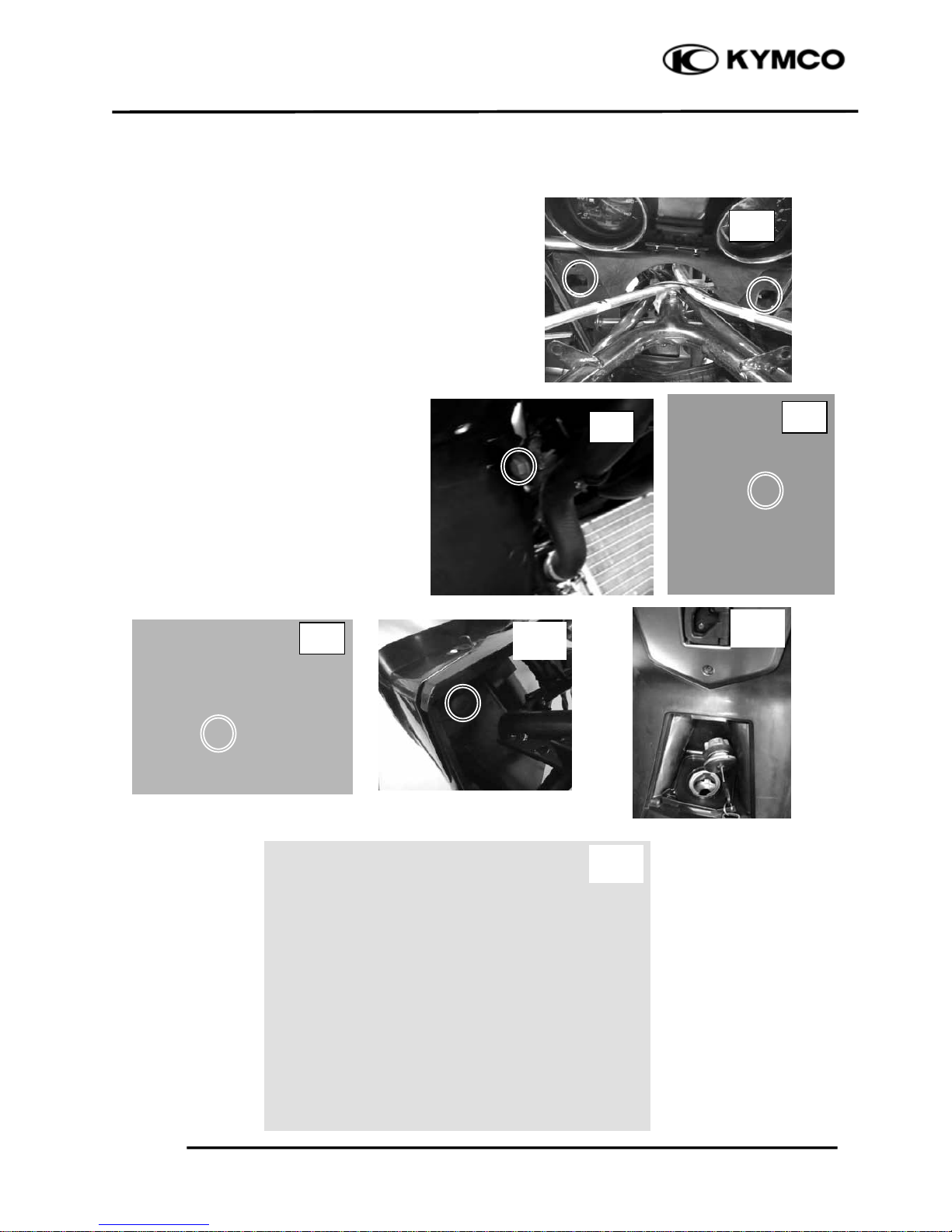

Remove the fuel tank cap cover.

Installation is in the reverse order of removal.

METER PANEL

Disconnect the speedometer wires.

Disconnect the DC power connectors.

Remove one screws

Remove the ignition key garnish

Remove three screws from the inner cover,

then remove the handler panel.

Installation is in the reverse order of removal.

Speedometer Wires

DC power Connectors

Page 28

2

. EXHAUST MUFFLER/FRAME COVERS

2-13

DOWNTOWN 200i

INNER COVER

Remove the front cover.

Remove the front lower cover.

Remove the floorboard

Remove four bolts and front glove box one

screw.

Remove two fastener bolts, then remove

the fuel tank fill cap.

Remove the inner cover

(3)

(1)

(2)

(2)

(4)

(5)

(6)

Page 29

2

. EXHAUST MUFFLER/FRAME COVERS

2-14

DOWNTOWN 200i

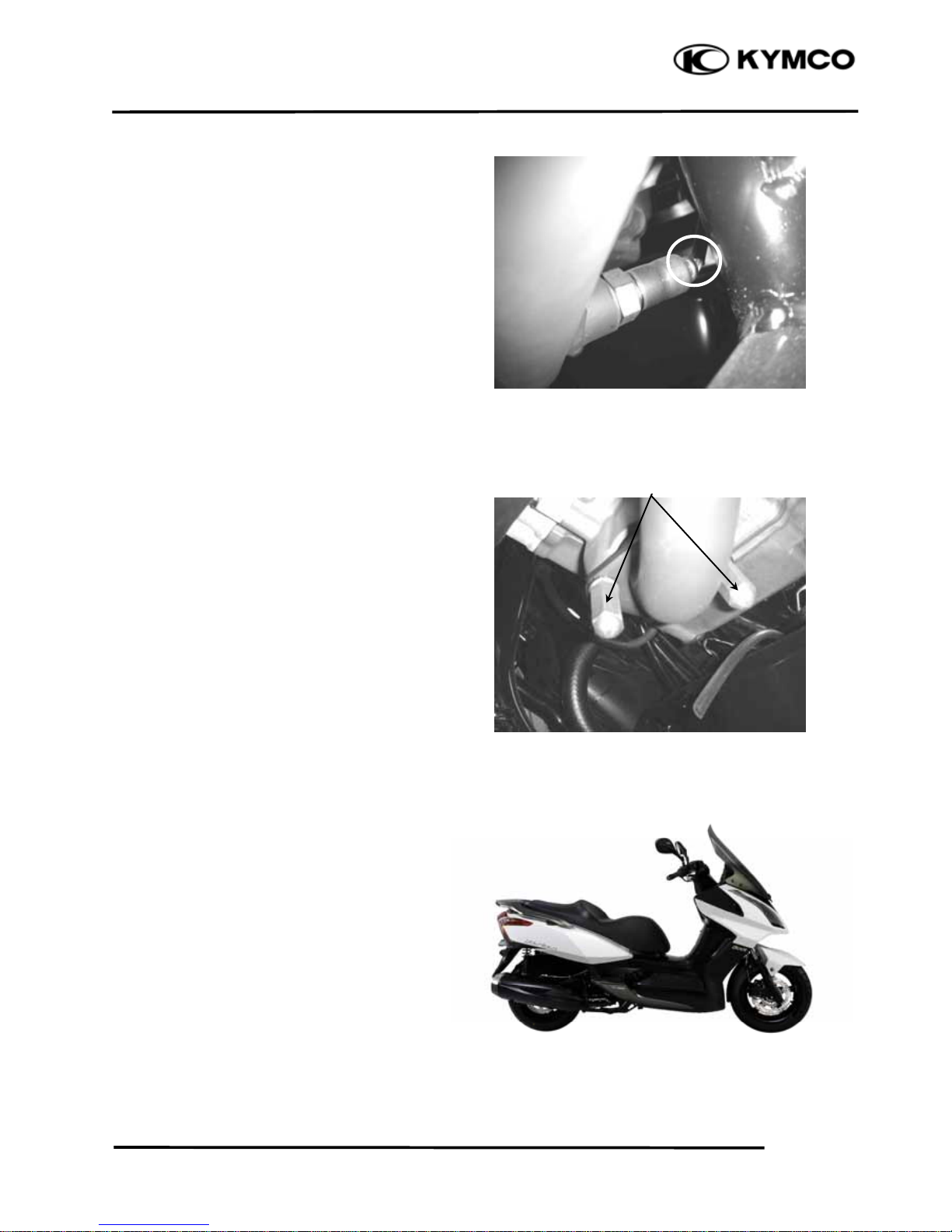

EXHAUST MUFFLER

REMOVAL

Disconnect the connector with O2 heater/O2

sensor.

Remove the two exhaust pipe joint nuts

Remove three muffler mount bolts and

muffler and gasket.

N

uts

Page 30

2

. EXHAUST MUFFLER/FRAME COVERS

2-15

DOWNTOWN 200i

INSTALLATION

Replace the gasket with a new one.

Install the exhaust muffler and three

mounting bolt.

Install and tighten the two exhaust pipe joint

nuts to the specified torque

Torque: 20 N•m (2 kgf•m,)

Tighten the three mounting bolts

Torque: 35 N•m (3.5 kgf•m,)

Remove the coolant tank cover.

Gaske

t

Page 31

3. INSPECTION/ADJUSTMENT

3-0

DOWNTOWN 200i

3

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

INSPECTION / ADJUSTMENT

_________________________________________________________________________________________

SERVICE INFORMATION ----------------------------------------------------------------------- 3- 1

MAINTENANCE SCHEDULE ------------------------------------------------------------------- 3- 2

THROTTLE OPERATION ------------------------------------------------------------------------ 3- 3

ENGINE OIL----------------------------------------------------------------------------------------- 3- 4

RESERVE TANK ----------------------------------------------------------------------------------- 3- 5

AIR CLEANER-------------------------------------------------------------------------------------- 3- 6

SPARK PLUG --------------------------------------------------------------------------------------- 3- 6

VALVE CLEARANCE----------------------------------------------------------------------------- 3- 7

CYLINDER COMPRESSION--------------------------------------------------------------------- 3- 7

FINAL REDUCTION GEAR OIL---------------------------------------------------------------- 3- 8

DRIVE BELT ---------------------------------------------------------------------------------------- 3- 8

BRAKE SYSTEM----------------------------------------------------------------------------------- 3- 9

CLUTCH SHOE WEAR --------------------------------------------------------------------------- 3- 10

SUSPENSION --------------------------------------------------------------------------------------- 3- 10

NUTS/BOLTS/FASTENERS---------------------------------------------------------------------- 3- 11

WHEELS/TIRES ------------------------------------------------------------------------------------ 3- 11

STEERING HANDLEBAR------------------------------------------------------------------------ 3- 11

SIDE STAND ---------------------------------------------------------------------------------------- 3- 12

3

Page 32

3. INSPECTION/ADJUSTMENT

3-1

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL

! WARNING

• Before running the engine, make sure that the working area is well ventilated. Never run the engine in a

closed area. The exhaust contains poisonous carbon monoxide gas, which may cause death to people.

• Gasoline is extrem

ely flammable and is explosive under some conditions. The working area must be

well ventilated and do not smoke or allow flames or sparks near the working area or fuel storage area.

SPECIFICATIONS

ENGINE

Throttle grip free play : 2~6 m

m

Spark plug : NGK: CR7E

Spark plug gap : 0.6 mm ~ 0.7 mm

Valve clearance : IN: 0.10 mm EX: 0.10 mm

Idle speed : 1600±100 rpm

Engine oil capacity:

Cylinder compression: 16±2 kg/cm²

At disassembly : 1.5 Liter Ignition timing : ECU

At change : 1.3 Liter Coolant type : Water Cooling

Gear oil capacity :

At disassembly : 0.23 Liter

At change : 0.21 Liter

TIRE

1 Rider 2 Riders

Front 2.00 kg/cm² 2.00 kg/cm²

Rear 2.25 kg/cm² 2.25 kg/cm²

TIRE SPECIFICATION

Front : 120/80-14 58S

Rear : 150/70-13 64S

TORQUE VALUES

Front axle nut : 2 kg-m

Rear axle nut : 12 kg-m

SPECIAL TOOL

Tappet Adjuster E012

Page 33

3. INSPECTION/ADJUSTMENT

3-2

Page 34

3. INSPECTION/ADJUSTMENT

3-3

DOWNTOWN 200i

THROTTLE OPERATION

Check the throttle grip for smooth movement.

Measure the throttle grip free play.

Free Play: 2~6 m

m

Major adjustment of the throttle grip free play is

m

ade with the adjusting nut at the throttle body

side. Adjust by loosening the lock nut and turning

the adjusting nut.

Minor adjustment is made with the adjusting nut

at the throttle grip side.

Slide the rubber cover(1) out and adjust by

loosening the lock nut(3) and turning

the

adjusting nut(2).

Lock Nu

t

Adjusting Nu

t

Page 35

3. INSPECTION/ADJUSTMENT

3-4

DOWNTOWN 200i

ENGINE OIL

OIL LEVEL INSPECTION

Stop the engine and support the scooter upright

on the level ground.

Wait for 2~3 m

inutes and check the oil level

with the dipstick. Do not screw in the dipstick

when checking the oil level.

OIL CHANGE

Remove the oil drain bolt to drain the engine oil.

Install the aluminum washer and tighten the oil

drain bolt.

Torque: 2.5 kg-m

Pour the recommended oil through the oil filler

hole.

OIL CAPACITY

Engine oil capacity: 1.5 L

Engine oil exchanging capacity: 1.3 L

Engine Oil Viscosity : SAE 5W50

OIL FILTER SCREEN INSPECTION

Drain the engine oil.

Remove the oil filter screen attaching the leftunder crankcase.

Clean the oil filter screen.

Install the oil filter screen and filter screen cap.

Fill the engine with recommended engine oil.

OIL FILTER REPLACEMENT

Remove the oil filler cap attaching the right-under

crankcase cover.

• Replace the aluminum washer with a new

one if it is deformed or damaged.

*

Dipstick

Oil Drain Bol

t

Oil Filter Screen

Oil Filter Cap

Page 36

3. INSPECTION/ADJUSTMENT

3-5

DOWNTOWN 200i

The spring will come out when the filter cap is

removed.

Let the engine oil drain out.

Check that the O-ring is in good condition.

Install a new oil filter.

RESERVE TANK

COOLANT LEVEL INSPECTION

The reserve tank is under left floorboard .Check the

coolant level through the inspection window(1) at the

left side skirt white the engine is at the normal

operating temperature , with the scooter In an upright

position.

If the coolant level is below the LOWER level

m

ark(3), remove the left floor mat ,remove the lid

screw(4), the reserve tank lid(5), and then the reserve

tank cap(6) to add coolant mixture until it reaches the

upper level mark .

Spring

Make sure the rubber seal on the oil filter

facing the left crankcase.

*

Add coolant to the reserve tank only. Do not

attempt to add coolant by removing the

radiator cap. Coolant in the radiator is under

pressure and is very hot and can cause

serious burns.

*

Page 37

3. INSPECTION/ADJUSTMENT

3-6

DOWNTOWN 200i

AIR CLEANER

AIR FILTER REPLACEMENT

Remove the body cover.

Remove seven screws attaching to the air cleaner

cover.

Remove six screws attaching to the filter.

Check the filter and replace it if it is excessively

dirty

or damaged.

CHANGE INTERVAL

More frequent replacement is required when

riding in unusually dusty or rainy areas.

SPARK PLUG

Remove the spark plug cap and spark plug.

Check the spark plug for wear and fouling

deposits.

Clean any fouling deposits with a spark plug

cleaner or a wire brush.

Specified Spark Plug: NGK-CR7E

Measure the spark plug gap.

Spark Plug Gap: 0.6 – 0.7 m

m

Torque:17.2 N-m

• The air cleaner element has a viscous type

paper element. Do not clean it with

compressed air.

• Be sure to install the air cleaner element

and cover securely.

*

• When installing, first screw in the spark

plug by hand and then tighten it with a

spark plug wrench.

*

Air Cleaner Cove

r

Deformation

0.6~0.7 mm

}

Gap

Wear

Fouling

Deposits

Cracks

Damage

Spark Plug

Page 38

3. INSPECTION/ADJUSTMENT

3-7

DOWNTOWN 200i

VALVE CLEARANCE

Remove the seat assy and luggage box.

Remove the four bolts and then cylinder head

cover.

Turn the A.C. generator flywheel to the top dead

center (TDC) on

the compression stroke so that

the “T” mark on the flywheel aligns with the

index mark on the left crankcase cover.

Inspect and adjust valve clearance.

Valve Clearance:

IN: 0.10 mm

EX: 0.10 mm

Loosen the lock nut and adjust by turning the

adjusting nut

Valve Adjuster E012

Feeler Gauge

CYLINDER COMPRESSION

Warm up the engine before compression test.

Remove the center cover and luggage box.

Remove the spark plug.

Insert a compression gauge.

Open the throttle fully and push the starter button

to test the com

pression.

Max. Compression: 16±2 kg/cm

2

If the compression is low, check for the following:

‧Leaky

valves

‧Valve clearance too sm

all

‧Leaking cy

linder head gasket

‧Worn piston rings

‧Worn piston/cy

linder

If the compression is high, it indicates that carbon

deposits have accum

ulated on the combustion

chamber and the piston head.

• Inspect and adjust valve clearance while

the engine is cold (below 35℃).

*

• Check the valve clearance again after the

lock nut is tightened.

*

Bolts

Top Dead Center Mark

Special

Cylinder Head Cove

r

Page 39

3. INSPECTION/ADJUSTMENT

3-8

DOWNTOWN 200i

FINAL REDUCTION GEAR OIL

Remove the transmission fluid drain bolt.

Remove the transmission fluid filler bolt, then

slowly

rotate the rear wheel to drain the fluid.

Fill the transmission with the recommend fluid to

the capacity

listed below.

Transmission fluid type: SAE 90

Transmission fluid capacity: 0.23 L

Transmission fluid exchanging

capacity: 0.21 L

Install the transmission filler bolt and tighten it to

the specified torque.

DRIVE BELT

Remove the left crankcase cover.

Inspect the drive belt for cracks or excessive wear.

Replace the drive belt with a new one if necessary

and in accordance with the Maintenance Schedule.

Oil FillerBol

t

• Place the scooter on its main stand on level

ground.

*

Oil Drain Bol

t

Drive Bel

t

Page 40

3. INSPECTION/ADJUSTMENT

3-9

DOWNTOWN 200i

BRAKE SYSTEM

There is adjuster on each brake lever.Each

adjuster has four positions so that the released

lever position can be adjusted to suit the rider’s

hands.

To adjust the distance of the lever from the

handlebar grip,push

the lever(1) forward and turn

the adjuster knob(2) to align the number with the

arrow mark(3) on the lever holder.

BRAKE DISK/BRAKE PAD

Check the brake disk surface for scratches,

unevenness or abnormal wear.

Check if the brake disk runout is within the

specified service lim

it.

Check if the brake pad wear exceeds the wear

indicator line.

BRAKE FLUID

Turn the steering handlebar upright and check if

both brake fluid levels is at the upper limit. If the

brake fluid is insufficient, fill to the upper limit.

Specified Brake Fluid: DOT-4

Keep grease or oil off the brake disk to

avoid brake failure.

*

The brake fluid level will decrease if the

brake pads are worn.

*

Page 41

3. INSPECTION/ADJUSTMENT

3-10

DOWNTOWN 200i

CLUTCH SHOE WEAR

Start engine and check the clutch operation by

increasing the engine speed gradually.

If the motorcycle tends to creep or the engine stop,

check the

clutch shoes for wear and replace if

necessary.

SUSPENSION

FRONT

Check the action of the front shock absorbers by

compressing them several times.

Check the entire shock absorber assembly for oil

leaks, looseness or dam

age.

REAR

Each shock absorber(4) on your scooter has 5

spring preload adjustment positions for different

load or riding conditions.

Use a pin spanner(5) to adjust the rear shock

spring

preload. Position 1 is for light loads and

smooth road conditions. Position 3 to 5 increase

spring preload for a stiffer rear suspension and

can be used when the scooter is heavily loaded.

Be certain to adjust both shock absorbers to the

sam

e spring preload positions.

Page 42

3. INSPECTION/ADJUSTMENT

3-11

DOWNTOWN 200i

NUTS/BOLTS/FASTENERS

Check all important chassis nuts and bolts for

looseness.

Tighten them to their specified torque values if

any

looseness is found.

WHEELS/TIRES

Check the tires for cuts, imbedded nails or other

damages.

Check the tire pressure.

Tire Pressure

1 Rider 1 Rider (with

passenger)

Front 2.00 kg/cm² 2.00 kg/cm²

Rear 2.25 kg/cm² 2.25 kg/cm²

Tire Size:

Front 120/80-14 58S

Rear 150/70-13 64S

Check the front axle nut for looseness.

Check the rear axle nut for looseness.

If the axle nuts are loose, tighten them to the

specified torques.

Torque:

Front axle nut 2 kg-m

Rear axle nut 12 kg-m

STEERING HANDLEBAR

Raise the front wheel off the ground and check

that the steering handlebar rotates freely.

If the handlebar moves unevenly, binds, or has

vertical m

ovement, adjust the steering head

bearing.

• Tire pressure should be checked when tires

are cold.

*

Front Axle Nut

Rear Axle Nut

Page 43

3. INSPECTION/ADJUSTMENT

3-12

DOWNTOWN 200i

SIDE STAND

Your scooter's side stand is not only necessary when

you park, but it contains an important safety feature.

This feature cuts-off the ignition if you try to ride the

scooter when the side stand is down. Perform the

following side stand inspection.

INTERLOCK FUNCTION CHECK

Check the side stand ignition cut-off system,

1. Place the scooter on its center stand.

2. Put the side stand up and start the engine.

3. Lower the side stand. The engine should stop as

you put the side stand down.

If the side stand system does not operate as

described, see your KYMCO dealer for

service.

*

Page 44

4. LUBRICATION SYSTEM

4-0

DOWNTOWN 200i

4

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

LUBRICATION SYSTEM

________________________________________________________________________________

LUBRICATION SYSTEM------------------------------------------------------------------------- 4-1

SERVICE INFORMATION ----------------------------------------------------------------------- 4-2

TROUBLESHOOTING ---------------------------------------------------------------------------- 4-2

ENGINE OIL/OIL FILTER------------------------------------------------------------------------ 4-3

OIL PUMP-------------------------------------------------------------------------------------------- 4-5

4

Page 45

4. LUBRICATION SYSTEM

4-1

DOWNTOWN 200i

LUBRICATION PART

Dipstick

Oil Filter

Oil Pump

Drive Chain

Page 46

4. LUBRICATION SYSTEM

4-2

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The m

aintenance of lubrication system can be performed with the engine installed on the frame.

• Drain the coolant before starting any

operations.

• Carefully

when removing and installing the oil pump not to allow dust and foreign matters to enter the

engine and oil line.

• Do not attem

pt to disassemble the oil pump. The oil pump must be replaced as a set when it reaches its

service limit.

• After the oil pum

p is installed, check each part for oil leaks.

SPECIFICATIONS

ENGINE OIL

Engine Oil Capacity At disassembly: 1.5 liter At change: 1.3 liter

Recommended Oil SAE5W50# API: SJ

TROUBLESHOOTING

Oil level too low Poor lubrication pressure

• Natural oil consum

ption • Oil level too low

• Oil leaks • Clogged oil filter or oil passage

• Worn piston rings • Faulty

oil pump

• Worn valve guide

• Worn valve guide seal

Oil contamination

• Oil not changed often enough

• Faulty

cylinder head gasket

• Loose cy

linder head bolts

Page 47

4. LUBRICATION SYSTEM

4-3

DOWNTOWN 200i

ENGINE OIL/OIL FILTER

Remove the oil dipstick and check the oil level

with the oil dipstick.

If the level is near the lower level, fill to the upper

level with the recom

mended engine oil.

OIL CHANGE

Remove the oil drain bolt located at the left side

of the engine to drain the engine oil.

After the oil has been completely drained, install

the

aluminum washer and tighten the oil drain

bolt.

Torque: 24.5

N-m

Pour the recommended oil through the oil filler

hole.

OIL FILTER SCREEN

Drain the engine oil.

Remove the oil filter screen cap.

Remove the oil filter screen and spring.

Check the oil filter screen for clogging or damage

and

replace if necessary. Check the filter screen

O-ring for damage and replace if necessary.

Install the oil filter screen, spring, O-ring and

filter screen cap.

Torque: 12.7N-m

Recommended Oil: SAE5W50# API: SJ

Oil Capacity:

At disassembly: 1.5 liter

At change: 1.3 liter

Start the engine and check for oil leaks. Start

the engine and let it idle for few m

inutes, then

recheck the oil level.

Oil Dipstick

• Place the scooter upright on level ground

for engine oil level check.

• Run the engine for 2~3 minutes and check

the oil level after the engine is stopped for

2~3 minutes.

*

• The engine oil will drain more easily while

the engine is warm.

*

Page 48

4. LUBRICATION SYSTEM

4-4

DOWNTOWN 200i

OIL FILTER REPLACEMENT

Remove the oil filler cap attaching the right-under

crankcase cover.

The spring will come out when the filter cap is

rem

oved.

Let the engine oil drain out.

Check that the O-ring is in good condition.

Install a new oil filter.

Oil Filter Cap

Spring

Make sure the rubber seal on the oil filter

facing the left crankcase

*

Page 49

4. LUBRICATION SYSTEM

4-5

DOWNTOWN 200i

OIL PUMP REMOVAL

Remove twelve bolts attaching the right crankcase

cover.

Remove the A.C. generator flywheel with special

tool.

Special tool:

Flywheel Puller E003

Universal Holder E021

Remove the gasket and dowel pins.

Remove the starter idle gear and starter clutch.

Remove the two bolts and oil separator cover.

Remove the oil pump driven gear clip to remove

the oil pum

p driven gear and drive chain.

Dowel Pin

Starter Idle Gea

r

Oil Separator Cove

r

Oil Pump Drive Chain

Page 50

4. LUBRICATION SYSTEM

4-6

DOWNTOWN 200i

Remove two oil pump mounting bolts and the oil

pump.

OIL PUMP INSTALLATION

Install the oil pump into the crankcase.

After the oil pump is installed, tighten the two

m

ounting bolts.

Install the pump driven gear and drive chain by

aligning

the pump driven gear with the cutout in

the pump shaft.

Install and tighten the pump driven gear bolts.

Install the oil separator cover and tighten the bolts.

Install the starter idle gear and starter clutch.

Install the gasket and dowel pins.

Install the right crankcase cover and tighten the

twelve bolts.

Torque: 1.2 kg-m

Arrow Mark

Pump Shaf

t

Diagonally tighten the bolts in 2~3 times.

*

Install the oil pump with the arrow on the

pump body facing up and fill the oil pump

with engine oil before installation.

*

Oil Separator Cove

r

Dowel Pin

Starter Idle Gea

r

Page 51

5

. ENGINE REMOVAL/INSTALLATION

5-0

DOWNTOWN 200i

5

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

ENGINE REMOVAL/INSTALLATION

__________________________________________________________________________________

SERVICE INFORMATION------------------------------------------------ 5-1

ENGINE REMOVAL/INSTALLATION

--------------------------------- 5-2

ENGINE HANGER

--------------------------------------------------------- 5-6

5

Page 52

5. ENGINE REMOVAL/INSTALLATION

5-1

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• A floor jack or other adjustable support is required to support and maneuver the engine. Be

careful not to damage the scooter body, cables and wires during engine removal.

• Use shop towels to protect the scooter body during engine removal.

• Drain the coolant before removing the engine.

• After the engine is installed, fill the cooling system with coolant and be sure to bleed air from the

water jacket. Start the engine to check for coolant leaks.

• Before removing the engine, the rear brake caliper must be removed first. Be careful not to bend

or twist the brake fluid tube.

SPECIFICATIONS

Engine oil capacity:

At disassembly: 1.5 L

At change: 1.3 L

Coolant capacity:

Radiator: 870 cc

Hose with cool coolant: 169 cc

Hose with hot coolant: 194 cc

Reserve tank: 490 cc

Total capacity: 1360 cc

TORQUE VALUES

90304-GHE8-0040 Engine hanger (Engine side) 5.0 kgf-m (50 N-m)

90305-LBD4-9000 Engine hanger (Frame side) 6.5 kgf-m (65 N-m)

95801-10060 Rear fork mount bolts 3.5 kgf-m (35 N-m)

90305-KFW6-9120-M1 Rear axle nut 12.0 kgf-m (120 N-m)

95801-10035-00 Rear cushion lower/upper mount bolts 4.0 kgf-m (40 N-m)

Page 53

5

. ENGINE REMOVAL/INSTALLATION

5-2

DOWNTOWN 200i

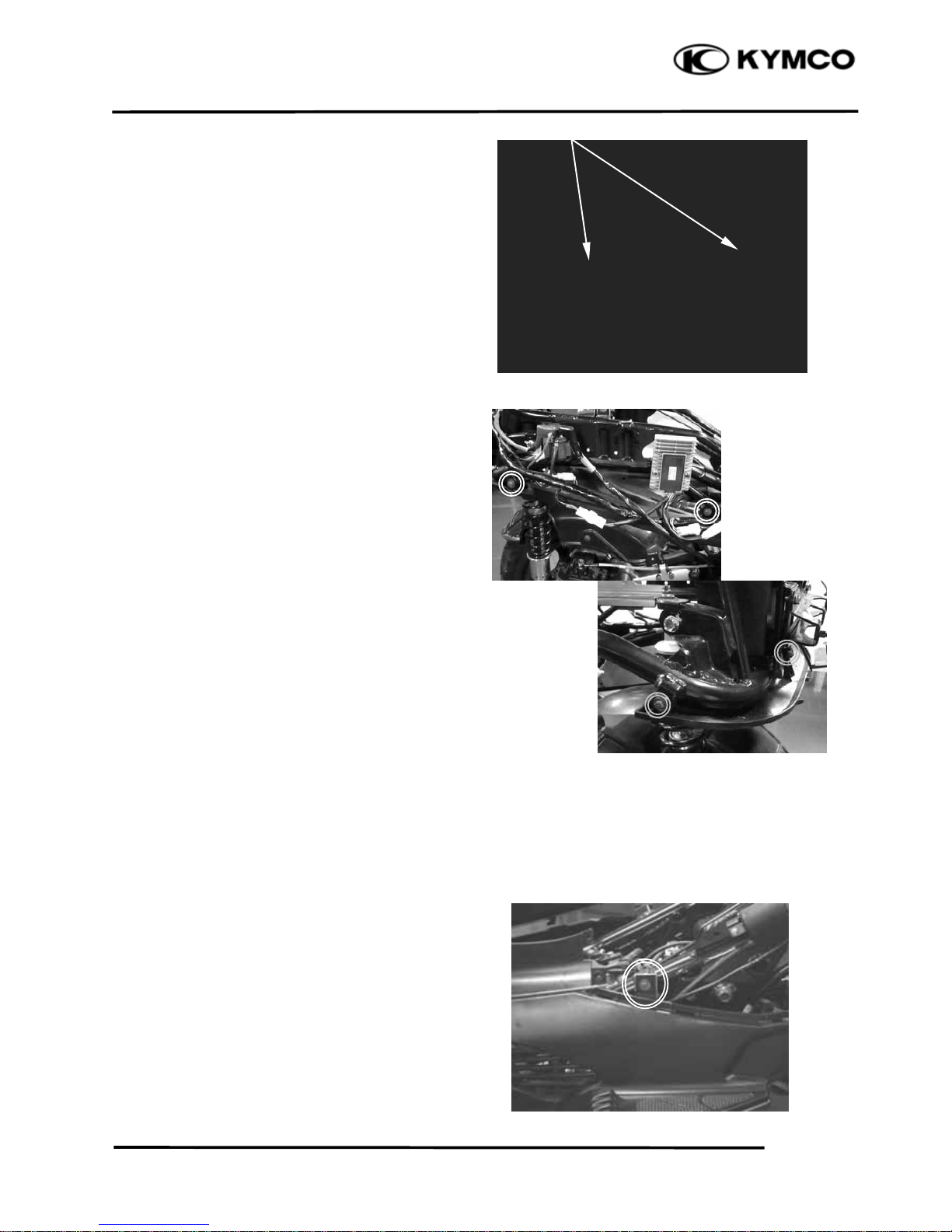

ENGINE

REMOVAL/INSTALLATION

REMOVAL

Remove the air cleaner

Disconnect the connector including of ISC,

Throttle body, TPS, WTS, MAP sensor and

injector.

Disconnect the O2 sensor connector.

Disconnect the throttle cables.

Disconnect the Regulator/Rectifier

connector.

Disconnect the starter relay wire from

starter motor.

Remove a bolt from fuel hose guide.

Disconnect the fuel hose from fuel injector.

Disconnect the input water hose.

Disconnect the air bleed hose.

Fuel hose guide

Water pumpOil filter

Water hose

Page 54

5. ENGINE REMOVAL/INSTALLATION

5-3

DOWNTOWN 200i

Remove the muffler.

Remove the rear fork mounting bolts (1)

attaching to the crankcase.

Torque: 3.5 kgf-m (35 N-m)

Remove the rear axle nut (2).

Torque: 12.0 kgf-m (120 N-m)

Remove two bolts (3) attaching to rear brake

hose clamps.

Remove two bolts (4) attaching to the rear

brake caliper.

Torque: 3.2 kgf-m (32 N-m)

Disconnect the alternator connector (5).

Disconnect the ignition pulse generator

connector (6).

Release the rubber cap and remove the

terminal screw (7) to disconnect the start

motor cable from the start motor.

Remove the bolt and engine ground cable.

(6) (5)

(7)

(3)

(2)

(1)

(4)

Page 55

5

. ENGINE REMOVAL/INSTALLATION

5-4

DOWNTOWN 200i

Remove the spark plug cap.

Disconnect the lower radiator hose from

lower radiator pipe.

Remove the right and left rear cushion lower

m

ount bolts.

Torque: 4.0 kgf-m

(40N-m)

Spark Plug Cap

Mount Bolt

Radiator Hose

Page 56

5. ENGINE REMOVAL/INSTALLATION

5-5

DOWNTOWN 200i

Remove the engine mount nut and pull it out.

Remove the engine from the frame.

Torque: 6.5 kgf-m (65 N-m)

INSTALLATION

Installation is in the reverse order of removal.

After installation, inspect and adjust the

following:

• Throttle grip free play

• Fill the cooling system with coolant and

start the engine to bleed air from the system.

API/ABV Reset (Refer to chapter14, page 17)

At removing the engine, be careful not

to catch your hand or finger between

the engine hanger and crankcase.

*

Mount Nut

Page 57

5

. ENGINE REMOVAL/INSTALLATION

5-6

DOWNTOWN 200i

ENGINE HANGER

REMOVAL

Remove the engine mount nut and pull it out.

Remove the left/right engine hanger mount

bolt.

Remove the engine from frame.

INSTALLATION

Installation is in the reverse order of removal.

Tighten the engine hanger mount bolts to the

specified torque.

Torque: 6.5 kgf-m (65 N-m)

Be careful to put the engine down.

*

Mount Nut

Page 58

6. CYLINDER HEAD/VALVES

6-0

DOWNTOWN 200i

6 .

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

CYLINDER HEAD/VALVES

_________________________________________________________________________________________

SCHEMATIC DRAWING------------------------------------------------------------------------- 6-1

SERVICE INFORMATION ----------------------------------------------------------------------- 6- 2

TROUBLESHOOTING ---------------------------------------------------------------------------- 6- 3

CYLINDER HEAD COVER REMOVAL------------------------------------------------------- 6- 4

CAMSHAFT REMOVAL-------------------------------------------------------------------------- 6- 4

CYLINDER HEAD REMOVAL------------------------------------------------------------------ 6- 6

CYLINDER HEAD DISASSEMBLY------------------------------------------------------------ 6- 7

CYLINDER HEAD ASSEMBLY ---------------------------------------------------------------- 6- 8

CYLINDER HEAD INSTALLATION----------------------------------------------------------- 6- 9

CAMSHAFT INSTALLATION------------------------------------------------------------------- 6- 9

CYLINDER HEAD COVER INSTALLATION------------------------------------------------ 6- 11

6

Page 59

6. CYLINDER HEAD/VALVES

6-1

DOWNTOWN 200i

SCHEMATIC DRAWING

Page 60

6. CYLINDER HEAD/VALVES

6-2

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder head can be serviced with the engine installed in the frame. Coolant in the radiator and

water hoses must be drained.

• When assembling, apply molybdenum disulfide grease or engine oil to the valve guide movable parts and

valve arm sliding surfaces for initial lubrication.

• The valve rocker arms are lubricated by engine oil through the engine oil passages. Clean and unclog the

oil passages before assembling the cylinder head.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

• After removal, mark and arrange the removed parts in order. When assembling, install them in the reverse

order of removal.

SPECIFICATIONS

Standard (mm)

Ite

m

IN 0.10

EX 0.10

Cylinder head compression pressure 16 kg/cm²

IN 35.8281

EX 35.8437

IN 12.00~12.018

EX 12.00~12.018

Valve rocker arm shaf

t

IN 11.966~11.984

O.D. EX 11.966~11.984

IN 1.2

EX 1.2

IN 4.990~4.975

EX 4.970~4.955

IN 5.00~5.012

EX 5.00~5.012

Valve stem-to-guide IN 0.010~0.037

clearance EX 0.030~0.057

TORQUE VALUES

SPECIAL TOOL

Valve spring compressor E063

Valve clearance (cold)

Camshaft cam height

Valve rocker arm I.D.

Valve guide I.D.

Valve stem O.D.

Valve seat width

Page 61

6. CYLINDER HEAD/VALVES

6-3

DOWNTOWN 200i

TROUBLESHOOTING

• The poor cylinder head operation can be diagnosed by a compression test or by tracing engine top-end

noises.

Poor performance at idle speed White smoke from exhaust muffler

• Compression too low • Worn valve stem or valve guide

• Damaged valve stem oil seal

Compression too low

• Incorrect valve clearance adjustment Abnormal noise

• Burned or bend valves • Incorrect valve clearance adjustment

• Incorrect valve timing • Sticking valve or broken valve spring

• Broken valve spring • Damaged or worn camshaft

• Poor valve and seat contact • Worn cam chain tensioner

• Leaking cylinder head gasket • Worn camshaft and rocker arm

• Warped or cracked cylinder head

• Poorly installed spark plug

Compression too high

• Excessive carbon build-up in combustion

chamber

Page 62

6. CYLINDER HEAD/VALVES

6-4

DOWNTOWN 200i

CYLINDER HEAD COVER REMOVAL

Remove the met-in box.

Remove the body cover and center cover.

Disconnect the breather hose to air cleaner.

Remove the cylinder head cover four bolts.

Remove the cylinder head cover.

CAMSHAFT REMOVAL

Remove the injector and inlet pipe.

Remove two screws attaching the thermostat.

Turn the cam chain tensioner screw clockwise to

tighten it.

Torque: 1.0 kgf-m (9.8 N-m)

Cylinder Head Cover

Bolts

Cam chain tensioner

Thermosta

t

Inlet pipe

Injector

Page 63

6. CYLINDER HEAD/VALVES

6-5

DOWNTOWN 200i

Remove four nuts attaching to the cylinder head.

.

Remove two bolts attaching to the camshaft gear.

Remove the camshaft gear from the cam chain

Remove the set plate located beside the rocker

arm shaft.

• Diagonally loosen the cylinder head cap

nuts in 2 or 3 times.

*

Set Plate

N

uts

Bolts

Page 64

6. CYLINDER HEAD/VALVES

6-6

DOWNTOWN 200i

Remove the rocker arm with bolt as shown.

CAMSHAFT INSPECTION

Check each cam lobe for wear or damage.

Check each camshaft bearing for play or damage.

Replace the camshaft assembly with a new one if

the bearings are noisy or have excessive play.

CYLINDER HEAD REMOVAL

Remove the muffler.

Remove the throttle body.

Drain the coolant from the radiator and water

hose, then remove the thermostat water hose.

Remove the camshaft.

Remove the Temp/Map Sensor and intake

manifold.

Remove the bolt attaching the thermostat housing

and the thermostat housing.

Remove the cylinder head.

If the surface of rocker arm is worn, check

each cam lobe for wear or damage.

*

Rocker Arm

Rocker Ar

m

Camshaft

Bol

t

Thermosta

t

Page 65

6. CYLINDER HEAD/VALVES

6-7

DOWNTOWN 200i

Remove two nuts attaching to the upper/lower

side of cylinder head.

Remove two bolts attaching to the cylinder head.

Remove the cylinder head.

Remove the dowel pins and cylinder head gasket.

Remove the cam chain guide.

Remove all gasket material from the cylinder

head mating surface.

CYLINDER HEAD DISASSEMBLY

Remove the valve spring cotters, retainers,

springs, spring seats and valve stem seals using a

valve spring compressor.

Valve spring compressor E040

Remove carbon deposits from the exhaust port

and combustion chamber.

• Be sure to compress the valve springs

with a valve spring compressor.

• Mark all disassembled parts to ensure

correct reassembly.

*

Be careful not to drop any gasket material

into the engine.

*

Special

Dowel pinsCylinder Head Gaske

t

Cam Chain Guide

Valve Spring Compresso

r

Nut

Bolts

Page 66

6. CYLINDER HEAD/VALVES

6-8

DOWNTOWN 200i

VALVE STEM INSPECTION

Inspect each valve for bending, burning, or

abnormal stem wear.

Remove carbon deposits from the combustion

chamber.

Clean off any gasket remnants from the cylinder

head contact surface.

CYLINDER HEAD ASSEMBLY

Install the valve spring seats and stem seals.

Lubricate each valve stem with engine oil and

insert the valves into the valve guides.

Be sure to install new valve stem seals.

Install the valve spring.

Valve spring compressor E040

Be careful not to damage the cylinder head

mating surface.

*

Special

• Tap the valve stems gently with a plastic

hammer for 2~3 times to firmly seat the

cotters.

• Be careful not to damage the valves.

*

Exhaust valveIntake valve

Valve spring compressor

Valves

Page 67

6. CYLINDER HEAD/VALVES

6-9

DOWNTOWN 200i

CYLINDER HEAD INSTALLATION

Install the dowel pins and a new cylinder head

gasket.

Install the cam chain guide.

Install the cylinder head.

Install the camshaft.

Install the intake valve rocker arm and the rocker

arm shafts.

CAMSHAFT INSTALLATION

Install the set plate to prevent the rocker arm shaft

from pull out.

Torque: 1.2 kgf-m (8.9 N-m)

• Clean the intake valve rocker arm shaf

t

off any grease before installation.

*

Dowel Pins

Gasket

Cam chain guide

Nut

Bolts

Cylinder Head

Fix plateBolt

Page 68

6. CYLINDER HEAD/VALVES

6-10

DOWNTOWN 200i

Tighten the four cylinder head nuts and the four

bolts between the cylinder head and cylinder.

Torque:

Cylinder head nuts: 3.6 kgf-m (35.3 N-m)

Turn the A.C. generator flywheel so that the “T”

mark on the flywheel aligns with the index mark

on the right crankcase cover.

Keep the round hole on the camshaft gear facing

up and align two bolts on the camshaft gear with

the cylinder head surface (Position the intake and

exhaust cam lobes down.) and install the cam

chain over the camshaft gear.

Install the thermostat bolt.

Torque: 1.2 kgf-m (11.8 N-m)

Turn the cam chain tension screw counterclockwise to release it.

• Apply engine oil to the threads of the

cylinder head cap nuts.

• Diagonally tighten the cylinder head cap

nuts in 2~3 times.

• First tighten the cylinder head cap nuts and

then tighten the bolts between the cylinder

and cylinder head to avoid cracks.

*

N

uts

Camshaft Gea

r

Round hole

Bolts

Page 69

6. CYLINDER HEAD/VALVES

6-11

DOWNTOWN 200i

CYLINDER HEAD COVER

INSTALLATION

Adjust the valve clearance.

Install a new cylinder head cover O-ring and

install the cylinder head cover.

Install the inlet pipe.

Install the injector.

Install and tighten the cylinder head cover bolts.

Be sure to install the O-ring into the groove

properly.

*

Thermostat

Inlet pipe

Injector

Page 70

7. CYLINDER/PISTON

7-0

DOWNTOWN 200i

7

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

CYLINDER/PISTON

_________________________________________________________________________________________

SCHEMATIC DRAWING------------------------------------------------------------------------- 7-1

SERVICE INFORMATION ----------------------------------------------------------------------- 7-2

TROUBLESHOOTING ---------------------------------------------------------------------------- 7-2

CYLINDER REMOVAL--------------------------------------------------------------------------- 7-3

PISTON REMOVAL ------------------------------------------------------------------------------- 7-3

PISTON INSTALLATION ------------------------------------------------------------------------ 7-7

CYLINDER INSTALLATION-------------------------------------------------------------------- 7-7

7

Page 71

7. CYLINDER/PISTON

7-1

DOWNTOWN 200i

SCHEMATIC DRAWING

Page 72

7. CYLINDER/PISTON

7-2

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder and piston can be serviced with the engine installed in the frame.

• When installing the cylinder, use a new cylinder gasket and make sure that the dowel pins are correctly

installed.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

SPECIFICATIONS

Item

Standard (mm) Service Limit (mm)

Cylinder

I.D. 66.0~66.02 66.10 over

Ring-to-groove top

0.015~0.055 0.09 over

clearance

Second

0.015~0.055 0.09 over

top

0.15~0.30 0.50 over

Piston, Ring end gap Second

0.30~0.45 0.50 over

piston ring Oil side rail

0.2~0.7

1.0 over

Piston O.D.(A)

65.98~65.99 65.9belw

Piston O.D.(B

)

66.99~66.00

65.9belw

Piston O.D. measuring position

9mm from bottom of skirt

. Piston-to-cylinder clearance

0.010~0.030 0.1 over

Piston pin hole I.D.

17.002~17.008 17.06 over

Piston pin O.D

16.994~17.000 16.80 belw

Piston-to-piston pin clearance

0.002~0.014 0.02 over

Connecting rod small end I.D. bore

17.016~17.034 17.06 over

TROUBLESHOOTING

• When hard starting or poor performance at low speed occurs, check the crankcase breather for white

smoke. If white smoke is found, it means that the piston rings are worn, stuck or broken.

Compression too low or uneven

compression Excessive smoke from exhaust muffler

• Worn or damaged cylinder and piston rings • Worn or damaged piston rings

• Worn, stuck or broken piston rings • Worn or damaged cylinder and piston

Compression too high Abnormal noisy piston

• Excessive carbon build-up in combustion • Worn cylinder, piston and piston rings

chamber or on piston head • Worn piston pin hole and piston pin

• Incorrectly installed piston

Page 73

7. CYLINDER/PISTON

7-3

DOWNTOWN 200i

CYLINDER REMOVAL

Remove the cylinder head.

Remove the cam chain guide.

Remove the cylinder.

Remove the cylinder gasket and dowel pins.

Clean any gasket material from the cylinder

surface.

PISTON REMOVAL

Remove the piston pin clip.

Press the piston pin out of the piston.

Water Hose

Dowel Pins

Cam Chain Guide

Gaske

t

Cylinde

r

Piston PinPiston Piston Rings

Place a clean towel in the crankcase to

keep the piston pin clip from falling into

the crankcase.

*

Dowel Pins

Page 74

7. CYLINDER/PISTON

7-4

DOWNTOWN 200i

Inspect the piston, piston pin and piston rings.

Remove the piston rings.

Clean carbon deposits from the piston ring

grooves.

Install the piston rings onto the piston and

measure the piston ring-to-groove clearance.

Service Limits:

Top: 0.09 mm replace if over

2nd: 0.09 mm replace if over

Remove the piston rings and insert each

piston ring into the cylinder bottom.

Measure the piston ring end gap.

Service Limit: 0.5mm replace if over

Measure the hole I.D. of piston pin

Service Limit: 17.06 mm replace if over

Take care not to damage or break the

piston rings during removal.

*

Use the piston head to push each piston

ring into the cylinder.

*

Page 75

7. CYLINDER/PISTON

7-5

DOWNTOWN 200i

Measure the piston pin O.D.

Service Limit: 16.8 mm replace if below

Measure the piston O.D.

Service Limit: 65.9mm replace if below

Measure the piston-to-piston pin clearance.

Service Limit: 0.02mm replace if over

CYLINDER INSPECTION

Inspect the cylinder bore for wear or damage.

Measure the cylinder I.D. at three levels of

top, middle and bottom at 90° to the piston

pin (in both X and Y directions).

Service Limit:

66.1 mm repair or replace if over

Measure the cylinder-to-piston clearance.

Service Limit:

0.1 mm repair or replace if over

The true roundness is the difference between

the values measured in X and Y directions.

The cylindricity (difference between the

values measured at the three levels) is subject

to the maximum value calculated.

Service Limits:

True Roundness:

0.05mm repair or replace if over

Cylindricity: 0.05 mm repair or replace if over

Middle

Bottom

Top

Take measurement at 9mm from the bottom

and 90° to the piston pin hole.

*

Page 76

7. CYLINDER/PISTON

7-6

DOWNTOWN 200i

Measure the connecting rod small end I.D.

Service Limit: 17.06 mm replace if over

PISTON RING INSTALLATION

Install the piston rings onto the piston.

Apply engine oil to each piston ring.

• Be careful not to damage the piston and

piston rings during assembly.

• All rings should be installed with the

markings facing up.

• After installing the rings, they should

rotate freely without sticking.

• Stagger the ring end gaps as the figure

shown.

*

Second

Side Rail

Top

Second

Top

Side Rail

Oil Ring

Page 77

7. CYLINDER/PISTON

7-7

DOWNTOWN 200i

PISTON INSTALLATION

Remove any gasket material from the

crankcase surface.

Install the piston, piston pin and a new piston

pin clip.

CYLINDER INSTALLATION

Install the dowel pins and a new cylinder

gasket on the crankcase.

• Be careful not to drop foreign matters into

the crankcase.

*

• Position the piston “IN” mark on the intake

valve side.

• Place a clean towel in the crankcase to

keep the piston pin clip from falling into

the crankcase.

*

The piston must be changed in pair with

cylinder.

*

Piston

Page 78

7. CYLINDER/PISTON

7-8

DOWNTOWN 200i

Install the cam chain guide.

Install the cylinder head gasket and dowel

pins.

Connect the water hose to the cylinder.

Install the cylinder head.

Tighten the cylinder base bolt.

• Insert the tab on the cam chain guide into

the cylinder groove.

*

Gaske

t

Dowel Pin

Cam Chain Guide

Page 79

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-0

DOWNTOWN 200i

8

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

DRIVE AND DRIVEN PULLEYS/V-BELT

_________________________________________________________________________________________

SCHEMATIC DRAWING------------------------------------------------------------------------- 8- 1

SERVICE INFORMATION ----------------------------------------------------------------------- 8- 2

TROUBLESHOOTING ---------------------------------------------------------------------------- 8- 2

LEFT CRANKCASE COVER -------------------------------------------------------------------- 8- 3

DRIVE PULLEY ------------------------------------------------------------------------------------ 8- 3

CLUTCH OUTER/DRIVEN PULLEY/V-BELT----------------------------------------------- 8- 3

8

Page 80

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-1

DOWNTOWN 200i

SCHEMATIC DRAWING

Page 81

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-2

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The drive pulley, clutch and driven pulley can be serviced with the engine installed.

• Avoid getting grease and oil on the drive belt and pulley faces. Remove any oil or grease from them to

minimize the slipping of drive belt and drive pulley.

SPECIFICATIONS

Item

Standard (mm) Service Limit (mm)

Clutch lining thickness

4.0 2.0

Clutch outer I.D.

152.1~152.2 152.2

Weight roller O.D

19.92~20.08 20

TORQUE VALUES

Drive face nut 9.5 kgf-m (93.1 N-m) Apply oil

Clutch outer nut 5.5 kgf-m (54 N-m)

Clutch drive plate nut 5.5 kgf-m (54 N-m)

SPECIAL TOOLS

Universal holder E017

Clutch spring compressor E053

Fittings & Nut Wrench, 41mm E033

TROUBLESHOOTING

Engine starts but motorcycle won‘t move Lack of power

• Worn drive belt • Worn drive belt

• Broken ramp plate • Weak driven face spring

• Worn or damaged clutch lining • Worn weight roller

• Broken driven face spring • Faulty driven face

Engine stalls or motorcycle creeps

• Broken clutch weight spring

Page 82

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-3

DOWNTOWN 200i

LEFT CRANKCASE COVER

REMOVAL

Remove the met-in box and carrier.

Remove the body cover, center cover and rear

fender A together.

Remove the protector cover of left crankcase

cover.

Remove the bolts attaching to the left crankcase

cover.

Remove the gasket and dowel pins.

INSPECTION

Check the bearing for wear or damage.

Replace the bearing with a new one if the bearing

is noisy or have excessive play.

DRIVE PULLEY

DRIVE PULLEY FACE REMOVAL

Remove the left crankcase cover.

Hold the drive pulley using a universal holder and

remove the drive face nut and washer.

Remove the drive pulley face.

Universal Holder E017

CLUTCH OUTER/DRIVEN PULLEY/VBELT

REMOVAL

Remove the drive pulley face.

Hold the clutch outer with the universal holder

and remove the clutch outer nut, bushing and

washer.

Universal Holder E017

Remove the clutch outer, driven pulley and belt

together.

Remove the drive belt from the movable drive

face.

Special

Special

Left Crankcase Cove

r

Drive Pulley Face

Universal Holde

r

Movable Drive Face

Bushing Nu

t

Bearing

Page 83

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-4

DOWNTOWN 200i

INSPECTION

Check the drive belt for cracks, separation or

abnormal or excessive wear.

Replace a new belt at every 20,000km.

MOVABLE DRIVE FACE ASSEMBLY

Remove the pulley face, clutch outer, driven

pulley and belt.

Remove the movable drive face assembly.

Remove the drive pulley collar.

DISASSEMBLY

Remove the ramp plate.

Remove the weight rollers.

• Use specified genuine parts for

replacement.

*

Ramp Plate

Weight Rolle

r

Movable Drive Face Assembly

Page 84

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-5

DOWNTOWN 200i

INSPECTION

Check each weight roller for wear or damage.

Check the movable drive face bushing for wear or

damage.

ASSEMBLY

Page 85

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-6

DOWNTOWN 200i

Install the weight rollers into the movable drive

face.

Install the ramp plate.

Insert the drive pulley collar into the movable

drive face.

INSPECTION

Inspect the clutch outer for wear or damage.

Measure the clutch outer I.D.

Service Limit: 153.5 mm replace if over

Check the clutch shoes for wear or damage.

Measure the clutch lining thickness.

Service Limit: 2.0 mm replace if below

• The direction of all weight rolls is same. The

color side is towards to clockwise.

*

Ramp Plate

Clutch Linin

g

Page 86

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-7

DOWNTOWN 200i

CLUTCH/DRIVEN PULLEY

DISASSEMBLY

Hold the clutch/driven pulley assembly with the

clutch spring compressor.

Set the tool in a vise and remove the clutch drive

plate nut.

Clutch Spring Compressor E053

Fittings & Nut Wrench, 41mm E033

Loosen the clutch spring compressor and

disassemble the clutch/driven pulley assembly.

Remove the seal collar.

Pull out the guide roller pins and guide rollers.

Remove the movable driven face from the driven

face.

Remove the oil seal from the movable driven

face.

ASSEMBLY

• Be sure to use a clutch spring compressor

to avoid spring damage.

*

Guide Roller Pin

Oil Seal

Special

Clutch/Driven Pulle

y

Clutch Spring Compresso

r

Lock Nut Wrench

Movable Driven Face

O-rin

g

Guide Rolle

r

Page 87

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-8

DOWNTOWN 200i

INSPECTION

Measure the driven face spring free length.

Service Limit: 136 mm replace if below

DRIVEN PULLEY FACE BEARING

REPLACEMENT

Check the bearings for play and replace them if

they have excessive play.

Drive the inner needle bearing out of the driven

pulley face.

Remove the snap ring and drive the outer bearing

out of the driven face.

Apply grease to the outer bearing.

Drive a new outer bearing into the driven face

with the sealed end facing up.

Seat the snap ring in its groove.

Apply grease to the driven face bore areas.

• Discard the removed bearing and replace

with a new one.

*

• Discard the removed bearing and replace

with a new one.

*

Outer Bearing

Guide Pins

Grooves

Page 88

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-9

DOWNTOWN 200i

Press a new needle bearing into the driven face.

CLUTCH DISASSEMBLY

Remove the clips and retainer plate to

disassemble the clutch.

• Keep grease off the clutch linings.

*

Clips

Retainer Plate

Clutch Linin

g

Page 89

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-10

DOWNTOWN 200i

CLUTCH ASSEMBLY

Install the damper rubbers on the drive plate pins.

Install the clutch weights/shoes and clutch springs

onto the drive plate.

Install the retainer plate and secure with the clips.

CLUTCH / DRIVEN PULLEY ASSEMBLY

Clean the pulley faces and remove any grease

from them.

Apply grease to the O-rings and install them onto

the moveable driven face.

Movable Driven Face

Clips

Drive Plate

Page 90

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-11

DOWNTOWN 200i

Install the movable driven face onto the driven

face.

Apply grease to the guide rollers and guide roller

pins and then install them into the holes of the

driven face.

Install the seal collar.

Remove any excessive grease.

Set the driven pulley assembly, driven face spring

and clutch assembly onto the clutch spring

compressor.

Compress the tool and install the drive plate nut.

Set the tool in a vise and tighten the drive plate

nut to the specified torque.

Torque: 75 N-m

Clutch Spring Compressor E053

Fittings & Nut Wrench, 41mm E033

• Be sure to clean the driven face off any

grease.

*

• Align the flat surface of the driven face

with the flat on the clutch drive plate.

*

• Be sure to use a clutch spring compressor

to avoid spring damage.

*

Special

Guide Pins

Grooves

Clutch/Driven Pulle

y

Clutch Spring Compresso

r

Lock Nut Wrench

Page 91

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-12

DOWNTOWN 200i

INSTALLATION

Install the movable drive face assembly and drive

pulley collar onto the crankshaft.

Put the drive belt on the driven pulley.

Put the drive belt on the drive pulley collar.

Install the clutch/driven pulley and clutch outer

onto the drive shaft.

Install washer and the clutch outer nut.

Hold the clutch outer with the universal holder to

tighten clutch outer nut.

Torque: 54 N-m

Universal Holder E017

Install the drive pulley face, washer and drive

face nut.

Hold the drive pulley with the universal holder

and tighten the drive face nut.

Torque: 93.1 N-m

Movable Drive Face Assembl

y

• Keep grease off the drive shaft.

*

Special

• Do not get oil or grease on the drive belt or

drive pulley faces.

*

Drive Pulley Colla

r

Movable Drive Face Assembly

Clutch Oute

r

Bushing Nu

t

Drive Pulley Face

Universal Holde

r

Page 92

8. DRIVE AND DRIVEN PULLEYS/

V-BELT

8-13

DOWNTOWN 200i

Install the left crankcase cover.

Left Crankcase Cove

r

Page 93

9. FINAL REDUCTION

9-0

DOWNTOWN 200i

9

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

FINAL REDUCTION

_________________________________________________________________________________________

SCHEMATIC DRAWING------------------------------------------------------------------------- 9-1

SERVICE INFORMATION ----------------------------------------------------------------------- 9-2

TROUBLESHOOTING ---------------------------------------------------------------------------- 9-2

FINAL REDUCTION DISASSEMBLY--------------------------------------------------------- 9-3

FINAL REDUCTION INSPECTION ------------------------------------------------------------ 9-3

FINAL REDUCTION ASSEMBLY-------------------------------------------------------------- 9-5

9

Page 94

9. FINAL REDUCTION

9-1

DOWNTOWN 200i

SCHEMATIC DRAWING

Page 95

9. FINAL REDUCTION

9-2

DOWNTOWN 200i

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The servicing operations of this section can be made with the engine installed.

• When replacing the drive shaft, use a special tool to hold the bearing inner race for this operation.

SPECIFICATIONS

Specified Oil: SAE 90#

Oil Capacity:

At disassembly : 0.23 liter

At change : 0.21 liter

TORQUE VALUES

Transmission case bolt 0.8-1.2 kgf-m (9.8 N-m)

Oil check/drain bolt 1.8-2.2 kgf-m (19.7 N-m)

SPECIAL TOOLS

Bearing puller E037

TROUBLESHOOTING

Engine starts but motorcycle won‘t move

• Damaged transmission

• Seized or burnt transmission

Abnormal noise

• Worn, seized or chipped gears

• Worn bearing

Oil leaks

• Oil level too high

• Worn or damaged oil seal

Page 96

9. FINAL REDUCTION

9-3

DOWNTOWN 200i

FINAL REDUCTION DISASSEMBLY

Remove the exhaust muffler.

Remove the rear brake caliper.

Remove the right rear shock absorber.

Remove the rear fork.

Remove the rear wheel.

Remove the left crankcase cover.

Remove the clutch outer/driven pulleys.

Drain the transmission gear oil into a clean

container.

Remove the transmission case cover attaching

bolts.

Remove the transmission case cover.

Remove the gasket and dowel pins.

Remove the final shaft.

Remove the final gear and countershaft.

FINAL REDUCTION INSPECTION

Inspect the countershaft and gear for wear or

damage.

Countershaf

t

Final Gea

r

Final Shaf

t

Transmission Case Cove

r

Dowel Pin

Page 97

9. FINAL REDUCTION

9-4

DOWNTOWN 200i

Inspect the final gear and final shaft for wear,

damage or seizure.

Check the left crankcase bearings for excessive

play and inspect the oil seal for wear or

damage.

Inspect the drive shaft and gear for wear or

damage.

Check the transmission case covers bearings for

excessive play and inspect the final shaft

bearing oil seal for wear or damage.

Drive Shaft Bearing

Countershaft Bearing