Page 1

BEDIENUNGSANWEISUNG

mit Montageanweisungen

Instructions for use and installation instructions

Instructions d’utilisation et avis de montage

Gebruiksaanwijzing en montagehandleiding

GEH 6300.0

072400 I41

Page 2

20 GEH 6300.0

For your information...

Please read this manual carefully before using your cooker. It contains

important safety advice; it explains how to use and look after your appliance

so that it will provide you with many years of reliable service.

If a fault develops with your appliance, please consult chapter “What to do if

trouble occurs”. You can often fix minor problems yourself, without having to

call in an engineer.

Please keep this manual in a safe place and pass it on to new owners for their

information and safety.

The following symbols are used in this operating manual:

[

The warning triangle warns of possible health hazards. It also warns of a

risk of damage to the appliance.

F

Stands for useful hints and tips.

Contents

Your appliance at a glance . . . . . . . . . . . . . . . . . . . . . . . 21

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connection and operation

Cooking zones

Oven

Before using the appliance for the first time . . . . . . . . . . . 23

Disposing of the packaging and your old appliance

Initial cleaning

Assembly of the infrared grill (acc. No. 545)

Using the cooking zones . . . . . . . . . . . . . . . . . . . . . . . . . 23

Using the burners

Switching the cooking zones on and off

Cross support for small pots (only with glass ceramic hobs)

Which are the best pots and pans?

The oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Symbols and operating modes

Temperature settings

Igniting the oven burner

Selecting the temperature

Selecting the operation mode

Pilot lights

Rack levels

Oven trays

backmobil

®

(acc. No. 600A)

Roasting

Guidelines for roasting

Baking

Tips on the table “Guidelines for baking“

Guidelines for baking

Grilling (only with accessory 545)

Cleaning and maintenance . . . . . . . . . . . . . . . . . . . . . . . . 27

For all surfaces

Removing fat and grease deposits

Information about the cleaning scraper

Suggestions on the use of oven sprays

Enamel

Stainless steel

Glass

Glass ceramic hob

Burners

Knobs

Removing and refitting the oven door

Removing and refitting the side racks

What to do if trouble occurs... . . . . . . . . . . . . . . . . . . . . . 29

Replacing the oven lamp

Rating label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation instructions for fitter. . . . . . . . . . . . . . . . . . . . 30

Safety instructions

Conditions for building in the appliance

Planning the supply lines

Installing in a fitted kitchen unit

Installing the glass ceramic surface

Installing the hob

Assembling the burners

Checking the supply lines

Checking the ring burners

Checking the oven burner

Factory setting / conversion possibilities . . . . . . . . . . . . . . 34

Conversion injector sets

Injector table

Converting ring burners

Resetting the oven burner

Final assembly

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table of permitted gas types and gas pressures

Table of heat input

Electrical connection

Gross calorific values according to EN 437

Page 3

GEH 6300.0 21

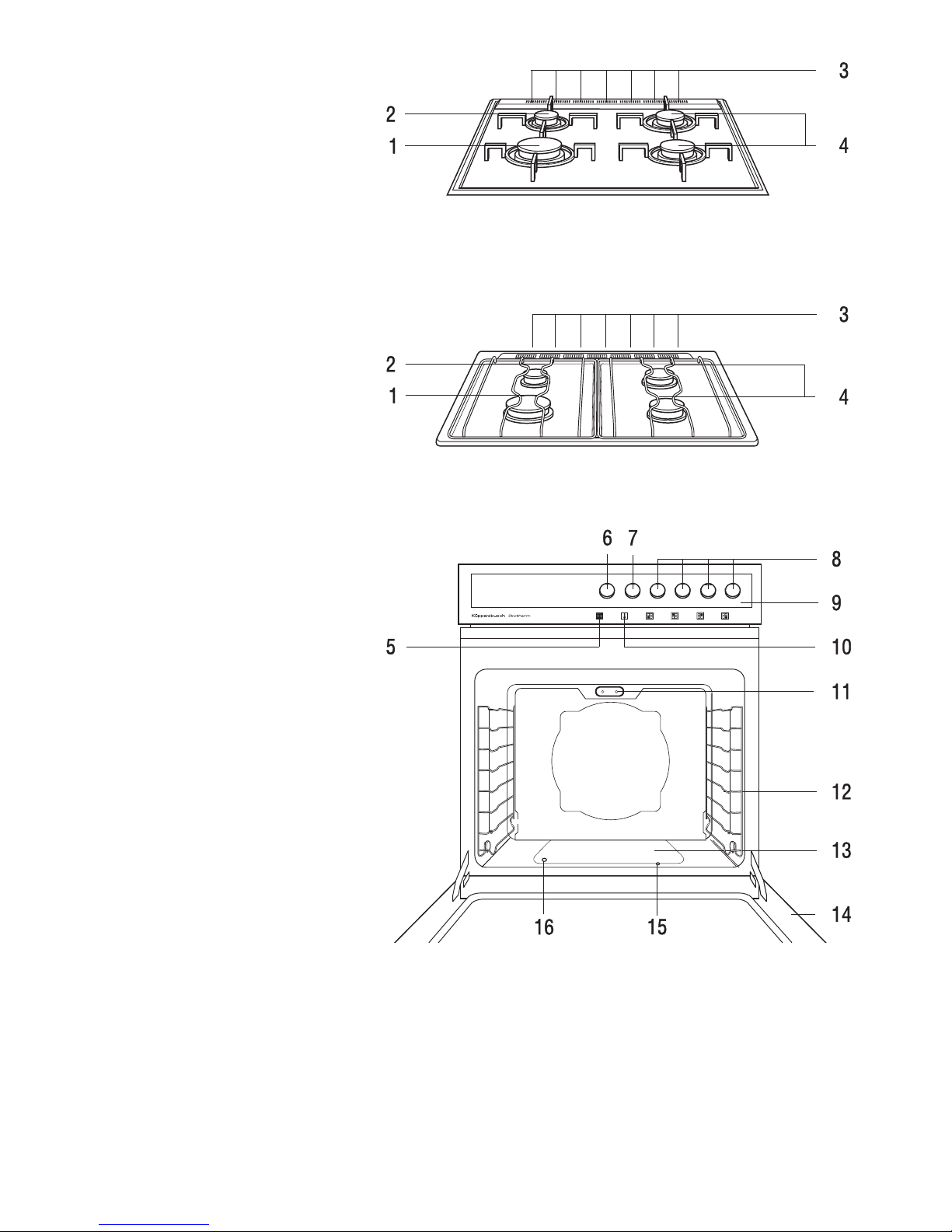

Your appliance at a glance

1 High speed ring

2 Simmering ring

3 Ventilation slits

4 Standard ring

5 Oven function indicator - eletric

6 Mode selector

7 Temperature control (oven)

8 Cooking zone controls

9 Control panel

10 Oven function indicator - gas

11 Plug contact with dummy plug for infrared grill

(acc. No. 545)

12 Side racks

13 Cover plate for oven burner

14 Oven door

15 Auxiliary ignition hole

16 Viewing hole

Accessories supplied:

Baking tray (aluminium)

Drip pan

Gridiron

Cross support for small pots

(only with glass ceramic hobs)

Optional accessories:

Cross support for small pots (acc. No. 160)

Grilling rack with lifter (acc. No. 125)

Pizza stone (acc. No. 145)

Gridiron (acc. No. 124)

Splash guard roasting tray (acc. No. 441)

Baking tray (aluminium) (acc. No. 542)

Drip pan (acc. No. 543)

backmobil

®

(acc. No. 600A)

Infrared plug-in grill (acc. No. 545)

Page 4

22 GEH 6300.0

Safety instructions

Connection and operation

■ Only one of the gas ring hobs supplied may be connected to this

Küppersbusch oven.

■ The gas cooker must be installed and connected in accordance with the

applicable conditions of installation.

■ The device may only be operated in well-ventilated spaces as gas flames

consume oxygen and cause a build-up of humidity and heat:

Keep at least one aperture such as e.g. a window or door open, or have a

ventilation system such as a cooking ventilation hood running in extraction

/ circulatory fan operating mode.

■ All work, such as connection to the gas mains or adjusting and converting

the appliance, should only be carried out by a qualified fitter. The legally

recognised regulations and the conditions for connection laid down by the

local gas board should be observed in all details.

■ Never use the appliance to heat a room.

■ In the event of any trouble during operation, immediately turn off the supply

of gas.

■ The appliance should only be serviced and repaired by a qualified technician

in accordance with the applicable safety regulations. Always ensure to

disconnect the appliance from the energy supply when repairs are being

carried out on facilities for directing the flow of gas. For your own safety,

do not allow anyone other than a qualified service technician to install,

service or repair this appliance.

■ If the cooker is run on liquefied petroleum gas (propane/butane) it is vital

to ensure that all joints between the gas bottle and the cooker are secure

and tight.

■ External flexible supply hoses should not be wedged into tight positions or

laid cross hot surfaces.

■ The surfaces of the cooker, the oven door and the appliance become very

hot in use. Always keep children away!

■ Make sure that trailing leads for kitchen appliances cannot become trapped

in the oven door.

■ Never use steam and/or pressure cleaners to clean the oven! Damage

caused to your appliance by cleaning it this way can make it lethally

dangerous.

■ Attention! The electronic one-hand spark ignition will not work if there is a

power failure. In such cases please use matches.

■ Do not lift the appliance by the handle of the oven door.

Cooking zones

■ The rings should not be ignited unless you are cooking something.

■ Always ensure that the plug-on rings and the burner tops are in the correct

position.

■ Overheated fats and oils may spontaneously ignite. Food involving the use

of fats and oils, e.g. chips, may only be cooked under supervision. Never

extinguish ignited fats and oils with water! Put the lid on, turn off the

cooking zone and remove the pan.

■ Always keep pressure cookers under observation until the right pressure has

been reached. First turn the burners of the rings up to maximum flame and

then (following the instructions of the manufacturer of the pressure cooker)

turn the heat down in good time.

■ The ventilation slits in the hob should not be covered over!

■ If the glass ceramic surface shows any signs of cracks, fissures or

breakage, switch off the appliance immediately and call Customer service.

Oven

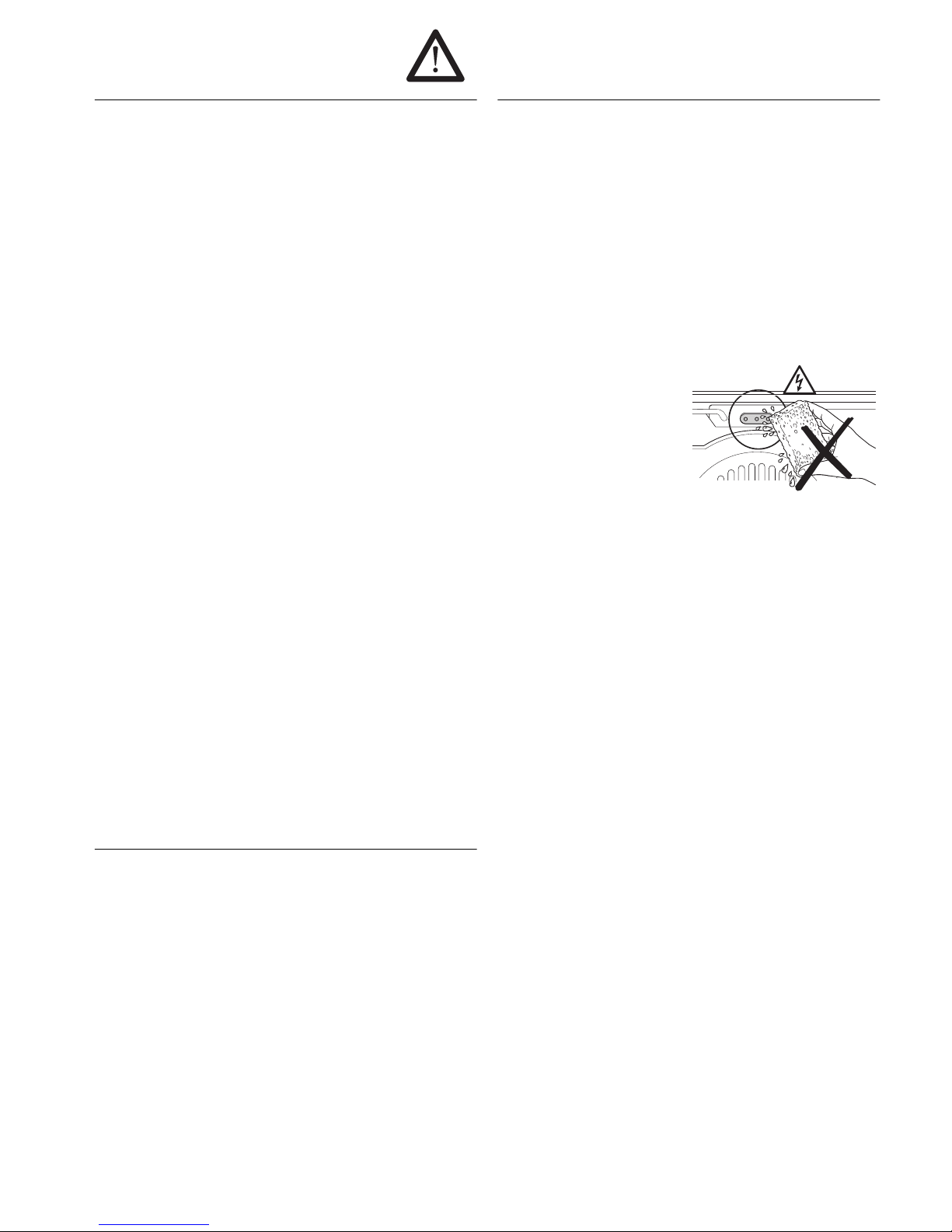

■ When carrying out repairs and replacing oven light bulbs, the cooker must

be disconnected from the mains (switch off the fuse).

■ Do not spend more than 15 seconds attempting to ignite the oven flame

when the door is closed. If the attempt is unsuccessful after this time

period, open the oven door and ventilate for at least one minute before

trying again.

■ Never store any objects in your oven which could cause a hazard if the oven

is unintentionally switched on.

■ Take special care when working in the hot oven and always use an oven

cloth, oven gloves or similar protection.

■ When grilling (acc. No. 545), keep at least 5 cm distance from the grill.

■ The grill (acc. No. 545) is removable. Only remove it when the oven is OFF

and the grill has cooled down.

■ The oven must not be used or

cleaned with the grill socket open.

The dummy plug or the infrared

grill (acc. No. 545) must always be

inserted!

Treat it like any other socket:

Never wipe the socket and ensure

that no water or oven spray enters

it.

■ The oven door must form a good seal when closed. In the event of damage

to the door sealing, hinges, sealing surfaces or to the glass pane, do not

use your cooker until it has been repaired and checked by a qualified and

authorised trained installer.

■ During use, open and shut the oven door with care to prevent the burner

flames being extinguished.

■ Attention! When opening and closing the oven door, do not reach into the

hinge. Risk of injury!

■ Always close the oven door completely when preparing food in the oven.

Page 5

GEH 6300.0 23

Before using the appliance for

the first time

Disposing of the packaging and your old appliance

Please dispose of the packaging that came with your appliance in an

environmentally friendly way.

If you bought your appliance in Germany, the dealer who sold it to you will

take the packaging back for recycling. Recycling in this way saves on

resources and cuts down on waste. Your old appliance still contains useful

raw materials. Take your old appliance to a recycling collection point. Please

make your old appliances unserviceable before disposing of it, to prevent it

from misuse.

Initial cleaning

– Remove packaging and non-essential components.

– We recommend that you clean your oven before using it for the first time.

Clean the glass ceramic cooking area or hob, the oven interior, baking trays,

drip pan, gridiron etc. using a damp cloth and a little detergent.

– Heat the oven.

Close the oven door.

Pre-heat the oven using top and bottom heating elements at maximum

temperature for 60 minutes. The “brand new smell” that results can be

safely ignored provided the kitchen or other space in which the device is

installed is well ventilated.

Assembly of the infrared grill (acc. No. 545)

[

Switch the fuse off!

–Pull the dummy plug out of the rear oven wall.

–

- Plug in the infrared grill

into the plug contact.

Using the cooking zones

Please note the safety instructions on page 22!

Using the burners

The rated capacities of the various burners are given in the Table of Heat Input

“Table of heat input” on page 36.

Using the different types of burner:

The high-speed ring is used

-to sear meat,

- to bring large quantities of liquid to the boil.

The standard ring is used

- to prepare medium-sized portions of foods,

- to roast meat.

The simmering ring is used

- to keep food warm and to braise or stew it,

- to prepare smaller portions of food,

- to cook food that easily burns.

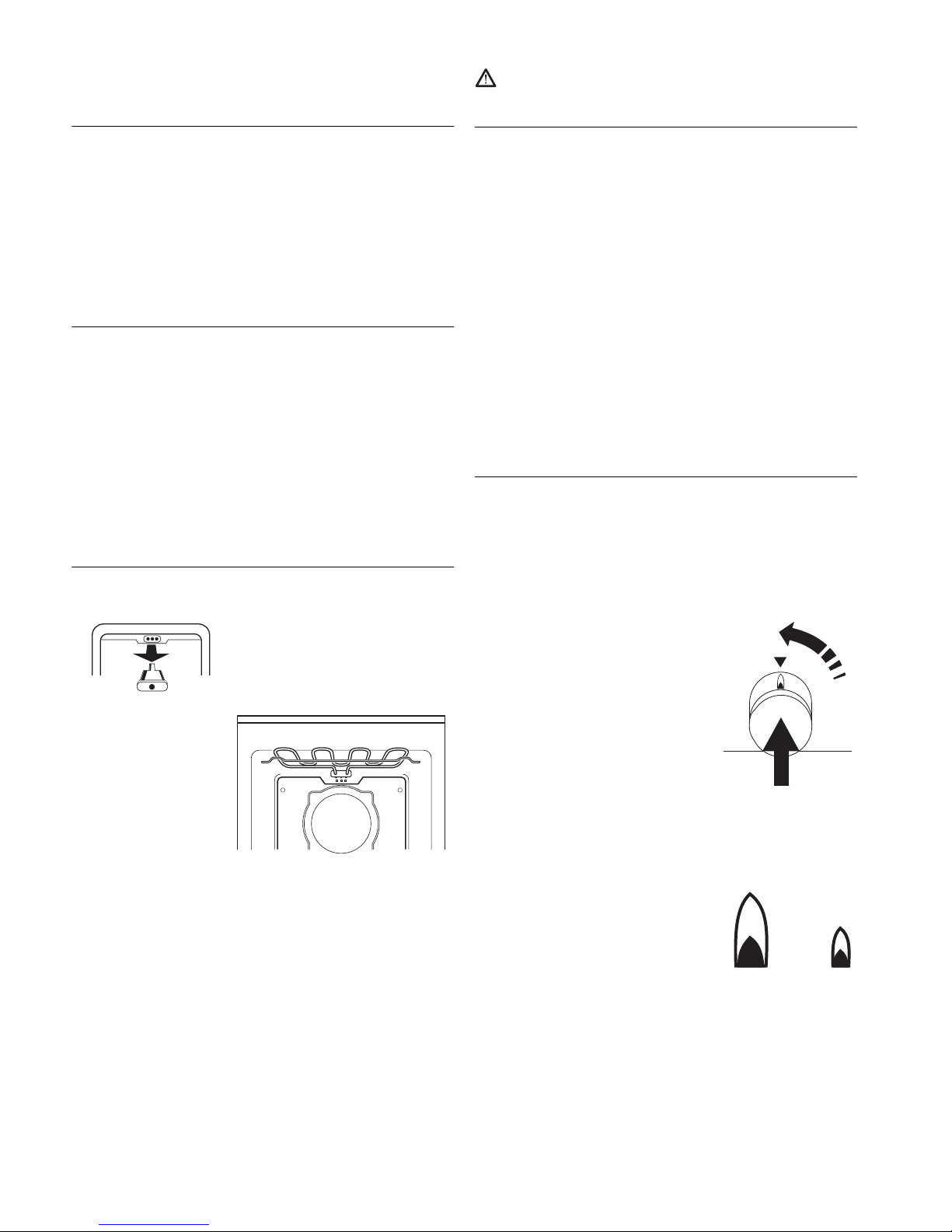

Switching the cooking zones on and off

Each cooking zone has its own control. All controls can be countersunk.

The symbols on the control panel indicate which regulator operates which

cooking zone.

The cooking zone burners are ignited by an electric spark. They can also be

lit with matches or something similar (e. g. in the event of power failure).

Igniting the cooking zone burners:

– Release the depressed cooking zone

regulator by pressing down.

– Turn the regulator anti-clockwise to the high

position and press in halfway, until a

resistance can be felt. The flame has been

ignited.

– Keep the cooking zone regulator depressed

for approximately a further 5 to 10 seconds

and then press it in again hard before

releasing it.

The flame is now burning.

If at any time the flame does not light successfully, allow about two seconds

and repeat the procedure. Press in the regulator a little bit longer and harder.

Adjusting the setting:

The maximum and minimum settings are marked

on the cooking zone controls. The burners can be

adjusted to any desired setting between maximum

and minimum.

– As far as possible, start cooking at the highest setting and continue at a

smaller setting.

Switching off the cooking zone burners:

– Turn the cooking zone control clockwise to zero setting.

F

All cooking zone burners are protected thermoelectrically. If at any time

the flame is extinguished unintentionally (e. g. due to pans boiling over

or due to a strong draught), the gas supply switches off automatically.

Page 6

24 GEH 6300.0

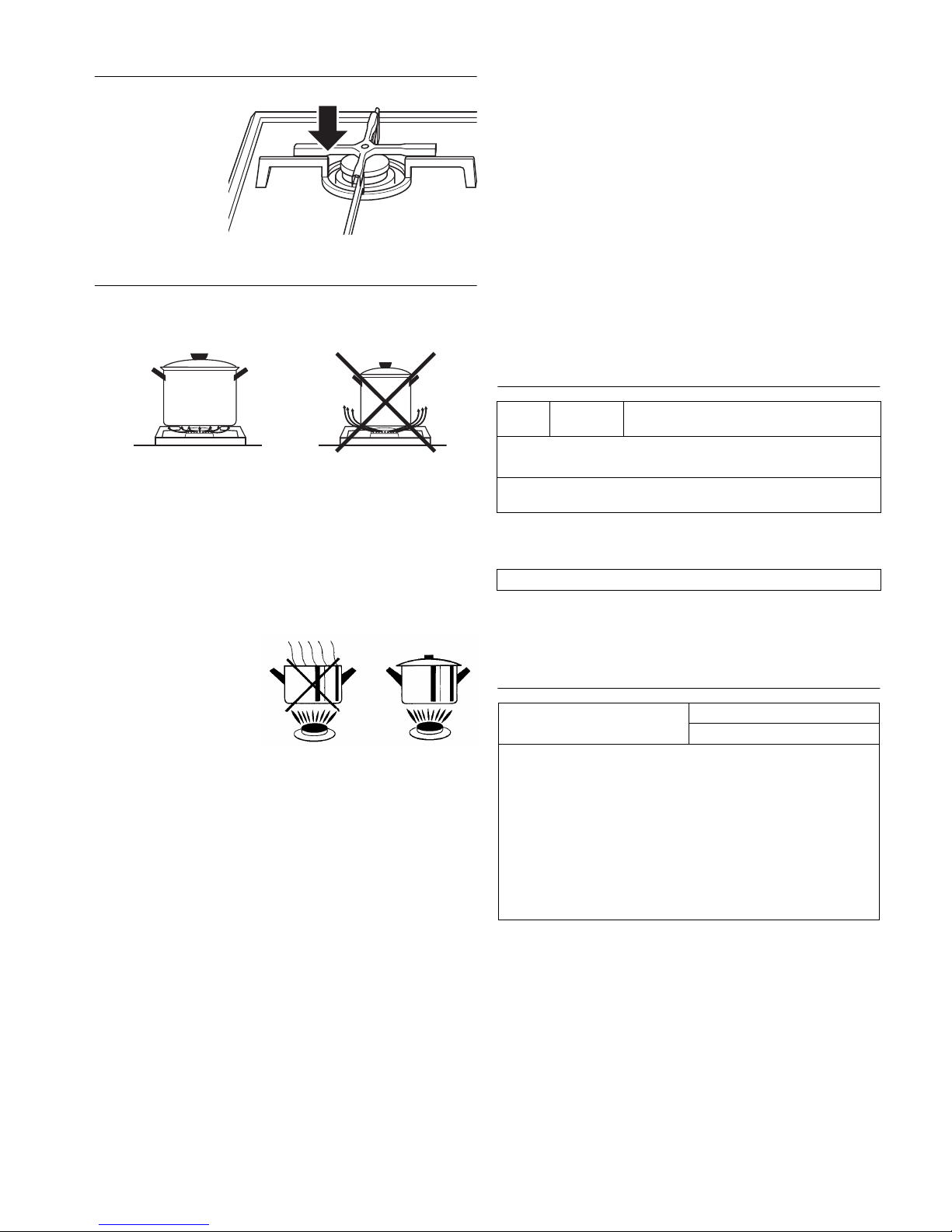

Cross support for small pots (only with glass

ceramic hobs)

The small pot cross

support can be installed

atop the simmering ring

on the pot support so that

small pots can be used

safely.

Which are the best pots and pans?

You can save time and power by choosing the best pans.

Choose a pot or pan whose diameter fits the burner size.

Make sure pots and pans are suited to the ring used. The flame should

completely cover the base. It ought not to exceed it.

Pot diameter recommendations:

High speed ring: 22 - 24 cm

Standard ring: 18 - 20 cm

Simmering ring*: 12 - 16 cm

* Small pots can be used on the simmering ring of the glass ceramic hob only

with the aid of the cross support.

Always make sure that the lid is on the saucepan.

The food will only boil over if the

flame is set too high. With a

little practice you will learn to

set the flame to just the right

heat so that the food will not

boil over, even when the lid is

on the saucepan.

Do not cook empty.

[

The use of spacers on the rings is not permitted for gas engineering

reasons.

The oven

[

Please note the safety instructions on page 22!

[

Attention. Risk of overheating! Do not cover the bottom of the oven

with aluminium foil and do not place pots or pans directly on the bottom

of the oven! This will trap heat and damage the enamel surface.

F

The controls are of the pop-out type and can be countersunk in every

setting. They pop out at a slight press of the finger. Adjustments cannot

be made whilst they are recessed.

F

The oven burner is protected thermoelectrically. If at any time the flame

is extinguished unintentionally the gas supply switches off automatically

and the oven function indicator - gas goes out.

However, when in use close the oven door with care to prevent the flame

being extinguished.

F

The cooling fan can continue to run after the oven has been switched

off, that is to say it switches itself back on because of the residual heat!

Symbols and operating modes

Following additional operating mode is possible with the accessory infrared

grill:

[

* If you turn the mode selector to “0”, the oven doesn't switch off. The

oven is in use as long as one of the two pilot lights is on.

Temperature settings

Dial

symbol

Operating

mode

Intended for

0*

OFF

!

Lighting

$

Top / Bottom

heat

Always set for the conventional operating mode using

Top and Bottom heat.

*

Grilling Surface grill for flat meat and slices and for gratinating

Temperature in °C Top/Bottom heat

Suitable for

260-280 Browning toppings

250 Baking pizza, baking

230 Baking

200 Baking, roasting, browning toppings

180 Baking, frying

160 Preserving

150 Baking

140 Meringues, honey cake

Page 7

GEH 6300.0 25

Igniting the oven burner

F

Only ignite the oven burner when the oven door is open.

F

The oven burner is ignited by an electric spark. It can of course also be

lit using a match or something similar at the auxiliary lighting port (B)

(e. g. in the event of power failure).

F

If at any time the flame does not light successfully, ventilate the oven,

then ignite once more.

– Release the depressed temperature control

by pressing down.

– Turn the regulator to the left to 280 °C and

press it in halfway until resistance is felt.

The flame will then be ignited.

– Hold the temperature control down for

another 5-10 seconds until the oven

function indicator - gas is illuminated.

– Press in the temperature regulator firmly

once more, before releasing.

The flame is now burning.

Selecting the temperature

– Reset the temperature control to the desired temperature.

The oven burner continues at maximum setting until the selected

temperature has been reached.

The size of flame only controls oven temperature when the oven is closed. If

the oven is left open, the flames automatically increase.

Selecting the operation mode

Selecting the operation mode:

with the mode selector (the switch

on the left)

Pilot lights

The oven function indicator - electric on the control panel is illuminated when

a function has been selected.

The oven function indicator - gas on the control panel is illuminated when the

oven burner has ignited and goes off about 20 seconds after the burner has

been switched off.

Rack levels

There are 8 rack levels in the side racks. These are numbered from 0 to 7,

from bottom to top. The drip pan, for example, can be positioned at position 0.

Side racks:

Rack level 0 is the lowest

possible level.

Oven trays

Baking trays:

■ Lift them slightly before taking them out of the oven.

When you put them back in the oven, make sure that the sloping edge of

the tray is pointing towards the oven door.

■ Slide the drip pan and baking tray with the two slots right to the back of

the oven.

Gridiron:

■ The crossbars on the racks

should point towards the back of

the oven (away from you).

Grilling rack with lifter to

insert in the drip pan (accessory)

■ The grilling rack is inserted in the drip

pan. Its lifter allows you to remove both

the tray and the drip pan together from

the oven. The drip pan remains in place

to catch any drips and you can easily

serve the food.

Splash guard roasting tray (accessory) for roasting and

grilling

■ The roasting tray is inserted in the drip pan and prevents the fat from

splashing out of the drip pan.

backmobil® (acc. No. 600A)

The backmobil® replaces the shelf

racks in your oven. You can slide it

out of the oven in one piece like a

trolley, and easily separate its

components for cleaning.

If your oven is fitted with a

backmobil

®

, please read the

instructions that came with it.

Roasting

F

Use the drip pan and the gridiron.

F

Turn the meat over after 2/3rds of the cooking time.

■ Only cook meat or fish in the oven if the item weighs over 1 kg.

■ Cooking time depends on the type of meat, its quality and its thickness.

To measure the joint, lift it slightly, as a joint tends to compress under its

own weight.

■ A layer of fat around the joint can double the cooking time.

■ If you are cooking a number small pieces of meat or poultry in the oven,

increase the cooking time by about 10 minutes for each additional piece.

For example, the time needed to roast a chicken is normally about

60 minutes. To cook 2 chickens, cook for 65 to 75 minutes.

F

Be sure to follow the guidelines for shelf positions.

For meat, insert the tray at level 3 and the drip pan in level 2.

Roasting in a pan (oven)

■ We recommend that you roast leaner types of meat in a covered roasting

pan (e.g. roast veal, braised beef or frozen meat) to retain the meat’s juices.

■ You can use any type of heat-resistant pan (stainless steel, enamel, cast

iron or glass) as long as it does not have a plastic or wooden handle.

■ If you use a cooking brick, follow the manufacturer’s instructions.

We recommend the following procedure:

– Rinse the pan with water or grease it lightly.

Page 8

26 GEH 6300.0

– Season the meat as required and place in the pan. Put the lid on the pan

and place the pan in the cold oven.

– Select Top/Bottom heat $ and set the temperature to between 180 and

200 °C.

Make your gravy in the usual way.

Guidelines for roasting

*whole chicken 45 - 60 min.

Baking

Baking tins

Always place in the middle of the grill. Tins should not overlap the edges of

the grill. Place square tins crosswise.

Use light-coloured tins for baking if possible.

F

Bake only on one level.

Tips on the table “Guidelines for baking”

The table in the next column contains a selection of cakes etc., the necessary

temperatures, cooking times and rack levels.

■ A temperature range is given, since the optimum temperature depends on

the recipe you are using for the dough and the size and shape of the item

you are baking.

■ We recommend that you use the lower temperature to start with, increasing

it only if you want a deeper brown or if baking is taking too long.

■ If you are not sure how to bake your own recipes, select a similar one from

the table and use the temperatures and baking times as a guide.

■ Food that is dissimilar in height will brown differently at the beginning.

Please do not change the temperature setting, because this will even itself

out as baking continues.

■ Baking moist cakes can produce steam, which forms condensation in the

oven. Most escapes through the vapour channel and can collect on kitchen

tiles and fronts of units as condensation. This is physically necessary.

Guidelines for baking

The recommended temperatures for the preferred operating modes are

highlighted.

Please observe the notes concerning this table in the last column!

Type of meat Top heat/bottom heat $Roasting time

Temperature in °C per cm of the thickness

of the joint in mins.

Joint of beef

170-190 18

Roast beef

200 – 220 10 – 12

Fillet

200 – 220 8

Veal

170 – 180 12

Roast pork

170 – 190 12 – 15

Smoked loin of pork

170 – 190 8

Game

170 –190 15

Wild boar

170 – 190 15

Fillet of game

200 – 220 8 – 10

Mutton

170 –190 15

Duck

170 –190 12

Goose

170 –190 12

Chicken

180 – 200 8

Turkey

170 –190 12

Fish

200 – 220 8

Type of cake or biscuit

Top heat/bottom heat $ Baking time

rack level Temperature in °C in minutes

Cake mixture

Ring cake 2 170-180 50-65

Tin cake 2 170-180 50-70

Madeira cake 2 160-170 60-70

Gateaux and flans 2 170-180 40-65

Flan bases 2 170-180 25-35

Fine fruit flans 2 170-180 45-60

Small biscuits 2 170-180 15-30

Large flat cakes:

with a dry topping 2 170-180 25-35

with a moist topping 2 170-180 35-60

Kneaded dough

Flan bases 2 180-200 25-35

Cheese cake 2 160-170 70-100

Small bisquits 2 170-180 15-35

Large flat cakes:

with a dry topping 2 170-180 25-35

with a moist topping 2 170-180 35-60

Leavened dough

Ring cake 2 170-180 40-65

Yeast cake 2 170-180 40-50

Rich sweet bread (preheated) 2 175-180 50-70

Small biscuits 2 170-180 15-30

Large flat cakes:

with a dry topping 2 170-180 25-35

with a moist topping 2 170-180 33-60

Sponge cake

Gateaux and flans 2 175-180 30-40

Rolls 2 190-200 12-20

Biscuits made with white of egg

Meringue 3 140 60-70

Cinnamon stars 3 150-160 15-20

Macaroons 3 150-160 20-40

Other doughs

Puff pastry 3 200-220 15-30

Puff pastry made with leavened

dough

3 200-225 30-40

Puff pastry made with curd

cheese

3 200-225 30-40

Choux pastry 2 200-220 30-40

Dough made with curd cheese

and oil

2 170-180 25-35

Honey cake 2 140-150 20-35

Bread and pizza

Leaven and bread made with

yeast (preheat: 230 °C,

prebake: 10 min., 230 °C)

2 180 50-60

Bread made with yeast/white

bread.

2 200 30-50

Pretzels (preheat: 230 °C) 2 220 15-20

Pizza (preheat: 250 °C) 1 250 8-12

2 baking trays with Pizza (pre-

heat: 250 °C)

1 und 3 250 10-14

Page 9

GEH 6300.0 27

Grilling (only with accessory 545)

[

Always close the oven door when grilling.

– Set the mode selector to Grill*.

The oven function indicator - electric

on the control panel illuminates.

F

Temperature regulator stays at 0.

– Always close the oven door when

grilling.

– Preheat the oven for 5 to 10 minutes.

– Put the drip pan with roasting tray into the 1st rack level from the bottom

and the gridiron into the rack level as per the table.

Cleaning and maintenance

You should carefully read this chapter before you use your appliance the first

time. If cleaned correctly and looked after regularly the appliance will remain

beautiful and clean for many years. The following tips will help you to clean

and care for your oven's various surfaces gently but thoroughly.

For all surfaces

[

Do not, under any circumstances, use steam or pressure cleaning

machines to clean the appliance! Damage caused to your appliance by

cleaning it this way can make it lethally dangerous.

[

Risk of burning! Make sure the appliance has cooled down before

cleaning.

[

Please follow the instructions provided with the cleaning agents you plan

to use.

Clean the oven each time you use it. Dirt left will burn into the surface next

time you use it. These burned on residues can sometimes be impossible to

remove completely.

To clean an oven that is not very dirty, use a damp cloth, a soft brush or a

soft sponge and a weak solution of detergent and warm water. Always rinse

the surfaces with cold water to remove all traces of detergent. Detergent

residues can cause discoloration and blotches. Wipe dry afterwards.

F

The following pointers will help you to carry out a more thorough cleaning

of the various parts of your oven.

F

VSR O-FIX-C is perfect for the cleaning of glass ceramic, enamel and the

coated inside of the door. This cleaning powder is available from

KÜPPERSBUSCH Customer Service.

Do not use any

- aggressive or bleaching cleaning agents containing for example active

oxygen, chlorine or corrosive components.

- abrasive cleaning or scouring agents, such as steel wool, soap-impregnated

steel wool, stiff brushes, metal or plastic sponges or any similar cleaners

with an abrasive surface.

Removing fat and grease deposits

First, soak any heavy deposits to loosen them. A wet cloth is ideal. This will

make them easier to remove later.

Information about the cleaning scraper

[

Caution! Risk of cutting! The blade of the cleaning scraper is very sharp!

Always hold the cleaning scraper flat to the surface

and push the grease away from you

[

Do not scratch the surface with the edge of

the scraper and take care not to damage the

sealing with the edge.

Suggestions on the use of oven sprays

[

Please follow the manufacturer's instructions carefully.

Oven sprays attack aluminium, paint and plastic!

For environmental reasons you should not use oven spray at all. If you

nevertheless want to use it, only spray it in the oven interior and on enamel

baking trays.

Dish Rack

level

Grill

F

1st side 2d side

in minutes

Pork chops/Escalope 6 6-8 4-6

Fillet of pork 5 10-12 8-10

Sausages 6 6-8 4-6

Shashlik 4 7-8 5-6

Rissoles 4 8-10 6-8

Beef steak 6 4-6 3-5

Slices of liver 6 3-4 2-3

Escalope of veal 5 5-7 4-5

Veal steak 5 6-8 4-6

Mutton chops 5 8-10 6-8

Lamb chops 5 8-10 6-8

Half a chicken 3 10-12 8-10

Fillet of fish 6 6-7 4-5

Trout 4 4-7 3-6

Toast 5 2-3 2-3

Toasted sandwiches 4 6-8

Page 10

28 GEH 6300.0

Enamel

Oven interior, front, baking trays, drip pan, enamel hobs

Some plastic sponges with abrasive side can be used. Some products do

however contain grains in the abrasive side of the sponge which can cause

scratches.

Carefully test a small area that is out of sight.

F

The type of scraper normally used for glass-ceramic surfaces is suitable

for removing heavy dirt.

F

We recommend VSR O-FIX C for thorough cleaning. Oven spray may be

used - however not on an enamel hob!

Stainless steel

Stainless steel door front, control panel, backmobil (acc. No. 600A)

[

Stainless steel is very easy to scratch!

Do not use a scraper!

[

Remove any calcium, grease or starch deposits right away. They will stain

the surface!

We recommend that you use a proprietary stainless steel cleaner.

We recommend cleaning the stainless steel surfaces weekly with a proprietary

stainless steel cleaner. This will create a protective film that protects the

surfaces from discoloration.

Glass

Door interior – coated glass

[

Avoid using oven spray if you can. If used regularly, an oven spray will

attack the coated surface of the glass.

The type of scraper normally used for glass-ceramic surfaces is suitable for

removing heavy dirt.

F

We recommend VSR O-FIX C or glass cleaner for thorough cleaning.

Door front, control panel

F

Clean the oven front with a weak solution of detergent and warm water,

using a damp cloth or a soft sponge. Do not use a glass cleaner.

Glass ceramic hob

First remove heavy dirt and food residues with the cleaning scraper when the

cooking surface is still warm.

Clean the cooled down cooking surface with water and a small amount of

detergent, with a cleaning agent for glass ceramic surfaces or with

VSR O-FIX-C. Wipe off the surface with clear water then dry it thoroughly.

F

Residues of cleaning agents can cause discolouring the next time you

switch it on. Cloths and sponges which are used for the cleaning of other

surfaces can cause discolouring.

F

Weekly cleaning with cleaning agent for glass ceramic surfaces protects

against discolouration and can often remove stains and resistant dirt.

Burners

F

Burner covers and attachments can be put in the dishwasher.

Clean the burner covers and the attachments with hot soapy water. Allow both

parts to dry before you replace them.

Take care that attachments and burner covers are replaced correctly after

cleaning. Engage burner covers by turning.

Knobs

Clean the knobs with a weak solution of detergent and warm water, using a

damp cloth or a soft sponge.

Removing and refitting the oven door

Removing the oven door

– Open the oven door as far as it will

go.

– Fold up the clamps on the door

hinges.

– Take hold of the oven door on both

sides and close it slowly.

– When the oven door is about half-

closed, the hinges will fall out of the

catches.

– The oven door can now be removed.

Reassembling the oven

door

– Grasp the oven door at both sides

and slide the hinges into the

openings on the oven.

– Slowly open the oven door until it

is fully open.

– Fold down the clamps on the

door hinges.

– Close the oven door.

Removing and refitting the side racks

Removing the side racks.

– Undo the screws.

– Take out the racks.

Refitting the side racks

– Insert the side racks and screw

into place in front.

Page 11

GEH 6300.0 29

What to do if trouble occurs...

[

Repairs must be carried out by a qualified service engineer!

But there are some problems that you can fix yourself. You should first check

that you are using the oven correctly. Repairs during the guarantee period are

chargeable, if they are caused by user error or non-observance of the following

instructions:

Replacing the oven lamp

[

Caution! Danger of electric shock! Disconnect the oven from the mains

before you open the oven lamp cover. Switch off or pull out the fuse!

[

Allow the appliance and the lamp to cool before changing the lamp. If

the oven has been used recently, the lamp will be hot!

Type: 25 W, 230/240 V, fitting: E14

Important: bulbs must be heat-resistant up to 300 °C!

These lamps are available from KÜPPERSBUSCH Customer Service or from

your dealer.

[

If the fitting has become solid due e.g. to dirt or long use then glass may

splinter during removal. Hold a towel or cloth over the fitting to catch any

splinters.

Changing the light bulb

– Unscrew the shelf rack.

– Carefully lever out the glass

cover with a screwdriver.

– Remove the faulty light bulb

and screw in the new one.

– Replace the glass cover.

Rating label

Should you need to contact Customer service or order spare parts, always

quote the information printed on the model identification plate.

The oven's identification plate is located just

inside the oven on the right hand side and is

visible when the door is open.

– Make a note of this information before you

consult Customer Service.

Fault Cause Remedy

Oven and cooking zones will

not ignite.

Power and/or gas

supply interrupted.

Check fuses. Is the mains

plug in the wall socket?

Check gas supply.

Cooking zones will not

ignite.

Food remains or

cleaning agent

between the spark

ignition and the

burner.

Release carefully and clean.

Spark ignition

defective.

Call Customer Service.

Light with matches in the

meantime.

Plug-on rings, burner

cover, spark plug and/

or thermal probe wet.

Dry thoroughly, or allow to

dry.

The cooking zone or the

oven does not ignite - no

igniting sound can be heard.

The knob is loose - it is

pushed down and positioned slightly in front

of the panel.

Press in the knob firmly, it

will then turn back into the

right position.

[

Do not let the knobs

snap out, they could

loosen from their fastening device and no longer ignite.

The flame of the burners

suddenly changes.

Plug-on rings or burner

tops are skew.

Shift plug-on rings or burner

tops until they click into

place.

Plug-on rings, burner

cover, spark plug and/

or thermal probe wet.

Dry thoroughly, or allow to

dry.

Flames go out when set low

if a drawer or cupboard door

is closed.

Poor ventilation system

due to improper

installation siting.

Please request

Küppersbusch Customer

Service to supply a solution.

The cooking zone control

suddenly needs to be held

down longer until the flame

ignites.

Temperature sensor

bent.

Carefully bend the

temperature sensor back into

the correct position.

Plug-on rings or burner

tops are skew.

Insert plug-on rings / burner

cover properly so they click

in place.

Plug-on rings, burner

cover, spark plug and/

or thermal probe wet.

Dry thoroughly, or allow to

dry.

Oven does not heat up. Temperature control

and/or mode selector

have not been

switched on.

Set temperature control and

mode selector as required.

The flame has gone

out.

Reignite.

Oven light no longer works. Blown lamp. Replace the oven lamp.

Oven door glass cracked. Switch off the appliance; call

Customer Service.

Oven door will not shut. Door or door sealing

dirty.

Clean door and sealing using

only warm soapy water and a

damp cloth.

Fruit juice or egg white

stains on enamel parts.

Moist cake or meat

juices.

Harmless changes in the

enamel, cannot be remedied.

Oven production number

Oven model type

Model designation hob

Page 12

30 GEH 6300.0

Installation instructions for fitter

Safety instructions

Please heed the safety instructions on page 22!

■ Important! The gas category permitted for the connection of the appliances

can differ from region to region. In case of doubt enquire at your local gas

board to find out which categories of gas come into question. Check whether

the data on the rating label are in accordance with the local connection

conditions (type of gas and gas pressure) and with the appliance setting. If

there are any discrepancies the appliance must be converted accordingly! All

settings for the appliance are stated in this user guide. This appliance

should not be connected to a pipe for extracting combustion products.

■ When connecting the appliance to the gas mains you should particularly

observe the relevant regulations and guidelines of the institutions of the

country where the appliance is operated. In Germany and Austria these are:

DVGW-TRGI 1986 Technical guidelines for gas installations (Germany)

TRF 1988/1996 Technical guidelines for liquefied petroleum gas (Germany)

ÖVGW-TRGI and TRG 2, part 1 Technical guidelines (Austria)

You should also observe the regulations of the local gas supply companies

and those stipulated by the authorities (e.g. fire protection regulations).

■ The appliance should only be connected and put into operation by a

qualified gas fitter who should also be the only person to carry out any work

such as maintenance and repair or adjustment and conversion. The legally

recognised regulations and the conditions for connection laid down by the

local gas board should be observed in all details.

Work which has been improperly carried out endangers the safety of the

user!

■ This appliance should not be connected to a pipe for extracting combustion

products. It must be installed and connected in accordance with the

applicable conditions of installation. Particular attention should be paid to

sufficient ventilation measures.

■ If the connection plug should not be accessible, protect the appliance by

line-protecting switches, fuses or contactors whose contact opening has a

width of at least 3 mm.

■ When making any repair, ensure the appliance is electrically dead using the

devices above and cut off the gas supply.

■ The appliance is supplied ready to plug in. It should be connected only to

a properly protected wall socket. Installing and wiring a socket or replacing

the connection cable should only be performed by an electrician and in

observance of the relevant regulations.

■ The socket for plugging in the unit must be outside the installation space.

■ The ventilation openings must not be covered over.

■ When converting from natural gas to liquefied petroleum gas, it is always

necessary to change the main injectors and the low flame injectors. Only

special injectors supplied by Küppersbusch Customer Service may be used.

This also applies if the reverse is the case. This conversion should only be

carried out by a qualified gas fitter.

■ Any conversions to different types of gas must be permanently marked on

the nameplate of the appliance. Always use only the labels supplied with

the special injectors.

■ No changes may be made to the appliance unless with the express approval

of the manufacturer.

■ Ensure that all live connections are safely insulated when installing the oven.

Conditions for building in the appliance

■ The installation space must have a volume of at least 20 m

3

and it must

be possible to ventilate the area by a window or a door opening out into

the fresh air.

■ Additional space in an adjacent cupboard is needed for the gas connection.

■ The wall connection strip should be made of heat-resistant material and must

not be provided with sockets in the area around the hob. We recommend

using a support strip made of plastic and a covering strip made of aluminium.

The lateral part on the worktop must not be longer than 30 mm.

■ The wall above the wall connection strip in the area around the appliance

must be made of non-inflammable material. Wood, plastic, PVC foil etc. do

not meet this requirement.

■ In normal use adjacent furniture may be subjected to increased

temperatures. Such furniture must comply with the relevant legal and

technical requirements. The plastic finish or the veneer of built-in kitchen

furniture must have been produced using a heat-resistant adhesive

(100 °C).

■ Lateral distance to high cupboards on both sides must be a minimum of

300 mm.

■ Minimum distance to adjacent wall cupboards hung high and exhaust hoods

above the oven is 650 mm.

■ Before installation and after every removal of the hob, make sure sealing is

undamaged and sits tight. If not, replace it/them. Do not use silicone or the

like for additional sealing as this presents a risk of the coated cooking

surfaces being damaged when the hob is removed.

Exception: Uneven surfaces (e.g. ceramic tiling), where sealing with

temperature-resistant permanently elastic material is necessary (e.g.

silicone suitable for ceramics). This sealant may only be applied around thee

hob edges and never underneath it.

Planning the supply lines

Threaded appliance joint: R ½" ISO/R 7-1

The required gas connection R ½" must be connected in accordance with the

current statutory installation conditions and guidelines of the country in question. In Germany, a gas connection may be carried out either as a fixed connection with a gas shutoff valve or using an officially-approved gas safety pipe

with a socket.

Take the following into account when planning the supply lines:

Gas connection with flexible gas safety hose

The joint must be provided with a stop cock and must be accessible. It is

recommended to have a safety gas outlet in the right-hand cabinet. A flexible

gas safety hose, 800 mm in length (as per DIN 3383) is screwed directly onto

the connection points of the hob and screwed on tightly so that no gas

escapes.

If connecting from the left-hand cabinet it is necessary to have a flexible gas

safety hose. Length: max. 1.50 m!

Gas connection to immobile fitting

The joint must be provided with a stop cock and must be accessible.

Electrical connection

Electrical connection must be carried out in accordance with national and local

regulations. For the power supply to the oven and the electric automatic spark

ignition a 230-240 shockproof socket is required well away from the

installation site. The appliance is supplied ready to plug in.

Page 13

GEH 6300.0 31

Installing in a fitted kitchen unit

The cooker must be installed absolutely

horizontally.

F

We recommend sealing the rear areas of the installation facing the wall

and adjacent high cupboards. This prevents cooking flames going out

under unusual ventilation conditions should drawers and/or cupboard

doors in adjacent furniture not be closed carefully.

Preparing the built-in cupboard

– In the upper area of the side wall of the cupboard cut out an opening

measuring 100 x 100 mm for the supply lines.

[

Note the niche dimensions! A gap of at least 5 mm must exist between

the inbuilt oven and the cooking hob to ensure adequate ventilation.

F

Important: Remove the back wall of the cupboard and the crossbar

between the side walls, if applicable!

Cutting out the openings in the worktop

■ Important: Do not mark out the opening in the worktop unless the worktop

is already properly fitted.

■ The working surface must be installed horizontally and the opening must be

cleanly cut.

■ No cross-bars may be in the area of the cut-out underneath. They have to

be reduced at least to the opening size of the worktop. Completely remove

the front cross bar!

The appliance comes supplied with a template for marking out the opening in

the worktop.

Place the template against the

front edge of the cabinet.

Mark out the opening for the

cooker in the worktop and cut

out.

Seal the cut sections

– The cut sections should be sealed with a water-repellent protection paint.

Checking or replacing the sealing

– Make sure that the sealing of the hob is properly seated.

Use temperature-resistant permanently elastic sealant around the hob edges

on uneven surfaces (tiling, etc.).

– Do not apply this sealant under the hob on the work surface/s, as this/these

would then be damaged during any later removal.

Remove transport securing devices.

– The plastic clips used to secure the burner covers and burner tubes are to

be removed.

– The burner covers and intermediate rings are to be removed from all four

burners.

– The two front burners are screwed onto housing sheets to secure them in-

transit. Undo the screws.

Preparing the gas connection

Check that the details on the nameplate (see page 29) are the same as the

type of gas used in your area. If there are any discrepancies, the hob will have

to be converted for the corresponding type or quality of gas (see page 34).

Screw the gas safety hosing tight

to the oven connection using two

open-jawed spanners by

counter-tensioning.

[

Make sure nothing near the

piping is bent. If this

happens the knobs won’t fit

properly!

Sliding the appliance into

place

Insert the appliance a short way into a

cupboard alcove.

Pull the supply lines through the

opening in the side wall.

Now slide the oven all the way into its

space.

[

Do not bend, jam, tension or fold

the gas connection piping / hosing

when doing so!

Fastening in the appliance

– Open the oven door.

– Using the screws provided and

slanting them outwards, fasten

the appliance to the cabinet.

Readjusting the retractable knobs!

After the appliance has been connected and fitted the knobs must be checked

to see whether they work in different positions.

If, on account of connecting to the gas supply or fitting into the kitchen units,

the knobs no longer work perfectly, the following steps should be taken:

– remove both middle knobs;

– loosen the screws next to the valve shaft, which are visible through the knob

opening;

– using a screwdriver to raise or lower the valve shafts through the knob

opening, align the handle shaft with the centre of the hole and then

retighten the screws using a second screwdriver;

– replace the knobs and check again.

Page 14

32 GEH 6300.0

Installing the glass ceramic surface

F

When installing stone worktops the glass ceramic surface cannot be

fastened with clips. See page “Special case: Installing glass ceramics

surface in a stone work surface” page 32.

F

The parts are not assembled when delivered.

Drive in the clips

– Align the clips carefully and drive them in with a hammer.

Worktops with more than 30 mm

thickness:

With worktops with 30 mm

thickness the clips have to be

screwed down with two screws

(not supplied)!

– Attach the separate fume duct on the rear of the worktop recess with the

enclosed screws 4.2 x 16 mm.

Clipping the glass ceramic surface in place

– Now lay the surface down, align it and clip it in place.

[

The glass ceramic surface must rest evenly in the opening. If the strain

of the glass ceramic surface is too great the appliance can crack when

heating up.

F

If the glass ceramic surface is not fixed tightly

in the opening it is slightly too big. In such

cases, screw the clips tight using two screws

each (not supplied) and bend the retaining

devices outward a little to increase spring

tension.

Installing the burners

– Raise the burner with the tool

provided and move it into

position.

– Screw on the holding sheet for

the burner.

Special case: Installing glass ceramics surface in a stone

work surface

In these cases, the clips are not screwed to the cutout but to the hob.

for 30 mm work surfaces

for 40 mm work surfaces

– Insert the cooking area

surface edge at the back

and carefully lower it. Use

manual pressure on the

clips here.

– Press the cooking area

surface down until it is

entirely in contact atop the

working surface.

F

If the cutout in the work surface is a little too big it is possible to bend

the clip retainers outward to increase spring tension.

Page 15

GEH 6300.0 33

Installing the hob

– Attach the separate fume duct on the rear of the worktop recess.

– Insert the support frame and fasten with six screws 4.2 x 16 mm.

– Position the hob loosely.

– Raise the burner with the tool provided, position and screw on with three

screws 4.2 x 16 mm and washers in the holes with the thread collar visible.

– Then align the hob and fasten to the appliance with screws 4.2 x 32 mm

and washers through the remaining free hole at each burner location.

Assembling the burners

– Assemble the burner:

Place the burner cover and

attachment carefully in the

correct position.

– Turn the cover to bring into

position.

Checking the supply lines

Power supply

■ Check the installation of the connection cable. It must not be tightly wedged

in, pass across the cooker or be located at a ventilation channel.

Gas supply:

■ Check that all joints are tight and secure. The hoses must be installed in

such a way that they are at a safe distance from hot surfaces.

The hoses must not be tightly wedged in!

Checking the ring burners

– Ignite the burner and check that it is burning steadily.

– The flame should be steady.

[

Check whether the flames keep burning at low setting if doors / drawers

in adjacent furniture are opened / closed. If they go out, the rear of the

installation must be sealed due to poor ventilation. A solution to this

problem can be requested of Küppersbusch Customer Service.

Checking the oven burner

– Ignite the burner and check

that it is burning steadily.

– Heat the oven at the highest

temperature level for at least

10 minutes and then turn it

down to the lowest

temperature level. The burner

should burn with a small, but

steady flame.

Check air adjustment using the

table below if necessary and

then re-set.

The flames should burn

steadily, but not as strongly as those of the ring burners.

Guidelines for the air setting

Natural gas H, E, E+ 3.0 mm

Natural gas L, LL 1.0 mm

Liquefied petroleum gas 50 mbar 2.5 mm

Liquefied petroleum gas 30/37 mbar 3.0 mm

Cover

Attachment

Page 16

34 GEH 6300.0

Factory setting / conversion possibilities

This appliance can be converted to run on other types of gas.

[

Adjustment and conversion work should only be carried out by a qualified

gas fitter! The applicable rules and regulations should be observed.

Disconnect the appliance from the power supply so that it is completely

free of voltage.

[

The type of gas and the gas supply pressure must correspond to the gas

setting specified on the appliance. The factory setting is indicated on an

information plate or on the identification plate.

[

Any subsequent conversions to different types of gas must be

permanently marked on the nameplate of the appliance.

[

Only use special injectors obtained from the Customer Service.

Conversion injector sets

Injector table

Converting ring burners

Main injectors

If the ring burners are set to run on a different type or quality of gas the main

injector must be replaced.

– Remove the burner cover and plug-on accessories.

– Use a socket wrench to unscrew the injector.

– Place the new injector into the socket wrench and screw it in as far as it

will go.

Low flame injectors

After you have removed the control knobs (for the rings and the oven) and

removed the control panel (see below) the low flame injectors can be adjusted

or reset. If you are using natural gas and liquefied petroleum gas the low flame

injectors must be changed. Screw in the injectors as far as they will go (see

Injector Sets table).

– Disconnect the appliance from the

power supply (unplug from the mains

or switch off the fuse).

– Remove the control knobs (for rings

and oven).

– Open the oven door.

■ Important: The control panel remains

connected to the appliance due to the electrical wiring. It must therefore be

handled with care!

– Unscrew the two screws on left and

right under the control panel and the

two behind it.

– Lift the control panel towards the front

and, holding it by the lower edge,

draw it slightly towards the front and

carefully remove it by lowering it

downwards.

– Unscrew the low flame

injectors

replace them and screw

the new ones in as far as

they will go.

Gas type, pressure Injector sets

Natural gas H, E, E+, G 20 (20/25 mbar) on demand

Natural gas L, LL, G 25 (20 mbar) acc. No. 219

Natural gas L, G 25 (25 mbar) on demand

Liquefied petroleum gas butane/propane,

G 30 (50 mbar)

acc. No. 211

Liquefied petroleum gas butane/propane,

G 30 (28-30/37 mbar)

acc. No. 218

Liquefied petroleum gas propane, G 31 (50 mbar) on demand

Gas type, pressure High speed ring Standard ring Simmering ring Oven ring

Main

injector

Low setting

injector

Main

injector

Low setting

injector

Main

injector

Low setting

injector

Main

injector

Low setting

injector

Natural gas H, E, E+

G 20 (20/25 mbar)

125569347724115077

Natural gas LL G 25 (20 mbar) 145 62 117 52 79 47 165 82

Natural gas L G 25 (25 mbar) 118 61 104 49 78 44 155 80

Liquefied petroleum gas butane/

propane G 30 (50 mbar)

73 34 62 26 49 23 82 44

Liquefied petroleum gas butane/

propane G 30 (28-30/37 mbar)

81 39 70 28 53 24 92 52

Liquefied petroleum gas propane

G 31 (50 mbar)

79 36 67 30 51 26 89 48

Page 17

GEH 6300.0 35

Resetting the oven burner

Main injector

When resetting the oven burner the burner injectors must be replaced.

– Loosen the cover plate.

– Then detach the air slide and the oven burner.

– Set the parts aside and unscrew the burner injector using a socket wrench

of type SW 14.

– Screw in the new injector as shown in the Injector table.

– Reinsert the burner and screw it down tightly.

– Adjust the air using the table below.

– Heat the oven at the highest temperature level for at least 10 minutes and

then turn it down to the lowest temperature level. The burner should burn

with a small, but steady flame.

Readjust the air if necessary.

The flames should burn steadily, but not as strongly as those of the ring

burners.

Guidelines for the air setting

Low setting injector

The readjustment is carried out at the oven thermostats (oven temperature

control). The control panel must first be removed. (See “Low flame injectors”).

For natural gas and liquefied petroleum gas

Unscrew the injector and replace it by the new injector. Screw in the new

injector as far as it will go.

Finally, check burning behaviour.

Final assembly

On completion of the conversion and setting work, final assembly can be

performed.

■ Once correctly installed the device is to be protected on all sides by covers

so that contacting any operationally insulated part is impossible.

■ The cover may only be removed by tools.

– Mount the control panel.

– Install the knobs for regulating the

cooking rings and the thermostat that

controls the oven.

Natural gas H, E, E+ 3.0 mm

Natural gas L, LL 1.0 mm

Liquefied petroleum gas 50 mbar 2.5 mm

Liquefied petroleum gas 30/37 mbar 3.0 mm

Page 18

36 GEH 6300.0

Technical data

Table of permitted gas types and gas pressures

Table of heat input

Total nominal heat input = 11.7 kW

Connected load of the appliance = 843 g/h

Electrical connection

Connection standard mains plug into a wall socket.

Power consumption at 230 V: 2.5 kW,

at 235 V: 2.6 kW

Power supply 230-240 V, 50 Hz

Fuse rating 16 A

Gross calorific values according to EN 437

The HSB calorific value can be obtained from the relevant gas supply company

upon installation.

The flow rate is calculated as follows:

heat input kW x 1000

Flow rate l/min = --------------------------------------

gross calorific value kWh/m

3

x 60

Country

(ISO abbreviation)

Natural gas

H, E

(G 20)

Natural

gas LL

(G 25)

Natural gas

L

(G 25)

Pressure couple

natural gas E+

(G 20/25)

Propane

(G 31)

Pressure couple

(butane/propane)

(G 30/31)

Butane

(butane/propane)

(G 30)

Category

mbar mbar mbar mbar mbar mbar mbar mbar

Germany (DE)

20 20 50 II

2ELL3B/P

Denmark (DK)

Finland (FI)

Sweden (SE)

Iceland (IS)

Norway (NO)

20 28-30 II

2H3B/P

Netherlands (NL)

25

25

50

28-30

II

2L3P

II

2L3B/P

France (FR)

Belgium (BE)

20/25 28-30/37 II

2E+3+

United Kingdom (GB)

Spain (ES)

Italy (IT)

Portugal (PT)

Ireland (IE)

Greece (GR)

20 28-30/37 II

2H3+

Austria (AT)

20 50 II

2H3B/P

Luxembourg (LU)

20 28-30/37 I

2E, I3+

Burners Natural gas

20 mbar

25 mbar

Butane/propane gas

Input

kW

Input

kW

Gas rate

g/h

Simmering ring high 1.1 1.1 79

low 0.3 0.3 22

Standard ring high 1.9 1.9 137

low 0.38 0.38 27

High speed ring high 2.8 2.8 202

low 0.56 0.56 40

Oven ring high 4.0 4.0 288

low 1.0 1.0 72

Gas type Calorific value Hs 15 °C

MJ/m

3

kWh/m

3

MJ/kg kWh/kg

Natural gas H

(G 20)

37.78 10.5

Natural gas L (G 25) 32.49 9.03

Butane (G 30) 49.47 13.75

Propane (G 31) 50.37 14.00

Loading...

Loading...