Page 1

User Manual

XPS-E

100205 • 02/03/2017

Page 2

KUNBUS GmbH

ii XPS-E

1 Working with XPS ...........................................................................................................................3

1.1 Validity.......................................................................................................................................3

1.2 User...........................................................................................................................................3

1.3 Symbols.....................................................................................................................................3

1.4 Safe Work..................................................................................................................................4

1.5 Limitation of Liability ..................................................................................................................5

1.6 Customer Service......................................................................................................................5

2 Introduction .....................................................................................................................................6

3 Put into operation ...........................................................................................................................7

3.1 Connect the Gateway................................................................................................................7

3.2 Test the PROFIBUS connection................................................................................................8

3.3 Parametrization .........................................................................................................................9

3.4 set_prm Parametrization .........................................................................................................10

4 Data exchange...............................................................................................................................15

4.1 Send Data................................................................................................................................15

4.2 Receive Data...........................................................................................................................15

4.3 Send and Receive Data...........................................................................................................24

5 Status and Error Messages..........................................................................................................25

5.1 External Device Diagnostics....................................................................................................25

5.2 Communication Status ............................................................................................................26

6 Connector Assignment and Cabling ...........................................................................................27

6.1 PROFIBUS ..............................................................................................................................27

6.2 Serial Interface ........................................................................................................................29

7 FAQ.................................................................................................................................................32

8 Technical Data...............................................................................................................................33

Page 3

XPS-E 3 / 36

1 Working with XPS

1.1 Validity

This Document is valid for the following products:

– 100205

1.2 User

The Art may only be assembled, installed and put into operation by

trained, qualified personnel. Before assembly, it is absolutely

essential that this documentation has been read carefully and

understood. Expertise in the following fields is assumed:

– Electronic circuits,

– Basic knowledge of PROFIBUS,

– work in electrostatic protected areas,

– Locally applicable rules and regulations for occupational safety.

1.3 Symbols

The symbols used have the following meaning:

DANGER

Hazard

Observe this information without fail!

There is a safety hazard that can lead to serious injuries and death.

WARNING

Caution

There is a safety hazard that can result in minor injuries and material

damage.

NOTICE

Note

There is a safety hazard that can result in material damage.

Working with XPS-E

Page 4

XPS-E

4 / 36

1.4 Safe Work

WARNING

Damage and serious personal injury due wrong power supply

XPS-E is designed exclusively for PELV operation according to EN 60950 /

EN 60204 / VDE 0805-1

èOnly protective extra-low voltages according to the defined standards

may be used to supply and connect the alarm contact.

NOTICE

Electrostatic discharge

The device contains components that can be damaged or destroyed by

electrostatic discharge

èWhen handling the device, observe the necessary safety precautions

against electrostatic discharge (ESD), in accordance with EN 61340-5-1

and EN 61340-5-2, as well as IEC 61340-5-1 and IEC 61340-5-2.

NOTICE

Shielding

The shielding ground of the connected twisted pair cables is electrically

connected to the female connector.

èWhen connecting network segments, avoid ground loops, potential

transfers, and voltage equalization currents via the braided shield.

NOTICE

Damage due to subsequent processing

Avoid subsequent processing of the FNL.

Ø Soldering can cause components to become detached and thus

damage or destroy the module.

Ø Please note that the warranty shall become invalid if the products are

changed technically.

èSpeak to your contact person at the KUNBUS GmbH about customised

solutions.

Working with XPS-E

Page 5

XPS-E 5 / 36

1.5 Limitation of Liability

Warranty and liability claims will lapse if:

– the product has been used incorrectly,

– damage is due to non-observance of the operating manual,

– damage is caused by inadequately qualified personnel,

– damage is caused by technical modification to the product (e.g.

soldering).

1.6 Customer Service

If you have any questions or suggestions concerning this product,

please do not hesitate to contact us:

KUNBUS GmbH

Heerweg 15 C

73770 Denkendorf

Germany

+49 (0)711 3409 7077

support@kunbus.com

www.kunbus.com

Working with XPS-E

Page 6

XPS-E

6 / 36

2 Introduction

The intelligent PROFIBUS-DP gateways of the KUNBUS XPS-E

series allow the coupling of any serial devices with RS232 or

RS422/485 interface to PROFIBUS-DP according to the European

Standard EN50170. The protocol conversions required for the

coupling are executed either by means of a transparent universal

driver or by loadable device-specific converters. The following figure

shows a typical connection:

Illustration1: Typical Connection

Introduction

Page 7

XPS-E 7 / 36

3 Put into operation

3.1 Connect the Gateway

1 2 3 4

5

678

9

10

Illustration2: Connectors and Interfaces of the XPS-E

1 Bus Fail LED 2 Run LED

3 Address Switch x10 4 Address Switch x1

5 Connector for power supply 6 Mode-LED

7 TxD LED 8 RxD LED

9 Serial Interface 10 PROFIBUS Interface

Put into operation

Page 8

XPS-E

8 / 36

By executing the following steps, the XPS-E Gateway can be set into

operation:

◦ Connect XPS-E to PROFIBUS by using a standard PROFIBUS cable

with corresponding D-SUB PROFIBUS connector. For the connector

assignment please refer to chapter „Connector Assignment and Cabling

[}27]“ and follow the Installation Guidelines for PROFIBUS (No. 2.112,

PNO).

◦ Connect the serial end device with XPS-E

◦ Check your PROFIBUS network with regard to an unused Slave

address and adjust this free address at the coding switch of XPS-E.

◦ Plug in the power supply. The power supply of the XPS-E is connected

by spring clips at the front side.

ð As soon as the device is powered, the Status/Busfail LED is flashing

red.

NOTICE

The Status/Busfail LED is flashing red until the device is

parameterized and configured

In this status, no data exchange can take place (neither send nor receive).

Only after successful parameterization and configuration the Status/Run

LED is flashing green. Now, the device is ready for data exchange.

3.2 Test the PROFIBUS connection

If you have a PROFIBUS-DP configuration tool, you can test the

PROFIBUS connection to the XPS-E Gateway. For this purpose,

load the deliverable GSD file into your configuration tool.

The DP Master shall now configure XPS-E. If this configuration is

successful, the Status/Run LED is flashing green.

If you do not have a PROFIBUS-DP configuration tool or if you wish

to change the pre-defined parameters (User_Prm_Data) in the GSD

file, please refer to the following chapters for the parameterization.

Put into operation

Page 9

XPS-E 9 / 36

3.3 Parametrization

The parameterization data of XPS-E consists of 7 DP-Slave standard

bytes and 16 device-specific parameters bytes (User_Prm_data, ->

user_prm_len = 16). As user diagnostic data, 8 additional diagnostics

bytes are available. (diag_len = 8).

◦ For initialisation of XPS-E send a set_prm telegram. For this purpose,

use the parameters for PROFIBUS-DP and the serial interface

described in chapter 2.5.

◦ Check the parameterization with slave_diag.

◦ Then use the command chk_cfg to configure the XPS-E. Prior to that,

the configuration can be read with the command get_cfg from XPS-E. If

chk_cfg is executed directly after the initialization, the maximum

data_exchange telegram length is loaded from XPE-E. For shorter

data_exchange telegram length select one of the possible

configurations which are defined in the GSD file or select those

arbitrarily according to the PROFIBUS-DP standard.

ð After successful parameterization XPS-E is prepared for data exchange.

The Status/Run LED is now flashing green.

NOTICE

You can verify the parametrization and configuration telegram by

means of slave_diag.

In the following, only those parameters are described that are required for

operating the XPS-E. For the significance of the remaining PROFIBUS- DP

standard parameters please refer to the standard EN50170 and the GSD

file.

Also see about this

2 set_prm Parametrization [}10]

Put into operation

Page 10

XPS-E

10 / 36

3.4 set_prm Parametrization

The Bytes 1-7 are PROFIBUS-DP standard parameters, Byte 8-23

are device- specific parameters (usr_prm).

Oktet Parameter Name Value

1 Station_status 0x80*

2 WD_fact_1 0x00

3 WD_fact_2 0x00

4 Min TSDR 55

5 Ident_Number [0] 0x95

6 Ident_Number [1] 0x10

7 Group_Ident 0x00

8..11 Reserved 12 Baud Rate setting of serial interface See Table „Baud Rate of

Serial Interface“ [}10]

13 Character Transmission Mode of serial

interface

See Table „Character

Transmission Mode

“ [}10]

14 Handshake setting of serial interface See Table „Handshake-

Mode“ [}10]

15 XOFF-Timeout of serial interface See Section „Timeout Soft-

ware Handshake/Modbus“ [}10]

16 Receive Mode of PROFIBUS interface See Table „Data Transmis-

sion Mode“ [}10]

17 Receive Mode of PROFIBUS interface See Table „Extended

Gateway configuration

data“ [}10]

18 Trigger character for serial triggered

mode

(usually LF (0x0A)

-

19..23 Reserved -

Table1: set_prm

*Sync_Req and Freeze_Req are not supported.

Put into operation

Page 11

XPS-E 11 / 36

Next to standard parameters the parameters for the serial interface

are included in the GSD file. They are listed under the

User_Prm_Data. The values correspond to those described under

chapter „set_prm Parameterization”. A modification of these

parameters can be made by any kind of ASCII editor. Please note

that the number of parameters must not be changed and that the first

four and last six parameter bytes are to be set to 0.

In the following, the default settings of the GSD for serial interfaces of

XPS-E are listed.

9600 Baud / 8Bit / No Parity / 1 Stopbit / no Handshake / no

Timeout / Poll- Mode / RS232-Mode

This corresponds to the following entry in the GSD file:

User_Prm_Data = 0 0 0 0 96 56 78 0 80 0 0 0 0 0 0 0

Octet 1-7 are PROFIBUS-DP Standard, Octet 8-14 are the devicespecific diagnostics parameters (external diagnostics).

Oktet Parameter Value

1 Station_status_1 Bit7 Diag.Master_Lock

Bit6 Diag.Prm_Fault

Bit5 Diag.Invalid_Slave_Response

Bit4 Diag.Not_Supported

Bit3 Diag.Ext_Diag

Bit2 Diag.Cfg_Fault

Bit1 Diag.Station_Not_Ready

Bit0 Diag.Station_Non_Existent

2 Station_status_2 Bit7 Diag.Deactivated

Bit6 reserved

Bit5 Diag.Sync_Mode

Bit4 Diag.Freeze_Mode

Bit3 Diag.WD_On

Bit2 must be set to 1

Bit1 Diag.Stat_Diag

Bit0 Diag.Prm_Req

3 Station_status_3 Bit7 Diag.Ext_Diag_Overflow

Bit6..0 reserved

4 Master_Address Master address or 0xFF, if Slave is not yet

parameterised.

5 Ident_Number[0] 0x95

6 Ident_Number[1] 0x10

7 Number of ext.

diagnostic bytes

8

Put into operation

Page 12

XPS-E

12 / 36

8 XPS-E Status

See Chapter „External Device

Diagnostics” [}25]

9 Baud Rate of the serial

interface

See Chapter „Parameterization“, Section

„Baud Rate“ [}10]

10 Character Transmis-

sion Mode of serial

interface

See Chapter „Parameterization“, Section

„Character Transmission Mode“ [}10]

11 Handshake setting

serial interface

See Chapter „Parameterization“,

Section „Handshake“ [}10]

12 XOFF-Timeout of

serial interface

See Chapter „Parameterization“,

Section „XOFF“ [}10]

13 Receive Mode of DP-

interface

See Chapter „Parameterization“, Section

„Data Transmission Mode“ [}10]

14 Setting of driver phys-

ics of serial interface

(RS232/485)

See Chapter„Parameterization“,

Section „Data Transmission Mode“ [}10]

15 Trigger character for

Serial triggerd Mode

0x0A

Table2: slave_diag

Parameter Description

The parameters marked with (*) are the default values. These are

used if inadmissible parameters are entered during parameterization.

Baud Rate

Baud Rate (bit/s) Value (dec) Value (hex)

150 1 0x01

300 3 0x03

600 6 0x06

1.200 12 0x0C

2.400 24 0x18

4.800 48 0x30

9.600 * 96 0x60

19.200 192 0xC0

Table3: Baud Rate of Serial Interface Oktet 12

Put into operation

Page 13

XPS-E 13 / 36

Character Transmission

Mode

Transmission-Mode Value

(dec)

Value

(hex)

Value

(ASCII)

8 Datenbits, No Parity, 1 Stopbit (8N1) * 56 0x38 ‘8’

7 Datenbits, No Parity, 2 Stopbits (7N2) 78 0x4E ‘N’

7 Datenbits, Even Parity, 1 Stopbit (7E1) 69 0x45 ‘E’

7 Datenbits, Odd Parity, 1 Stopbit (7O1) 79 0x4F ‘O’

Table4: Character Transmisson Mode Oktet 13

NOTICE

The operating mode: 7 data bits, No Parity, 1 StopBit is not supported.

Handshake Flow Control

If data is exchanged via the serial interface, XPS-E supports the

following modes for the handshake:

– No Handshake

– Hardware Handshake. The receive data flow can be controlled at the

respective device by setting or re-setting the RTS-/CONTROL signal

(CTS/INDICATION=0 -> no sending). A corresponding example for

cabling can be found under chapter „S [}29]erial Interface“.

– Software Handshake. The receive data flow can be stopped by the

respective device by sending the control character XOFF (0x13). The

sending procedure will only be re-started if a XON character (0x11) is

received or a Timeout (XOFF-Timeout) for the receipt of the XON

character.

The interruption of the sending procedure or the XOFF timeout is

shown in the status byte of XPS-E (See Chapter„Communication

Status [}26]“ ) by means of the bit XOFF_CTS_FLAG.

Handshake-Mode Value

(dec)

Value

(hex)

Value

(ASCII)

Hardware Handshake (CTS, RTS for RS232

and CONTROL/INDICATION for RS422)

72 0x48 ‘H’

Software Handshake 83 0x53 ‘S’

NoHandshake * 78 0x4E ‘N’

Table5: Handshake-Modi Oktet 14

XOFF/ Modbus_timeout –

Timeout Software

Handshake/Modbus

The XOFF/Modbus timeout is calculated by means of VALUE *

100ms. This value is entered into Octet15 of the parametrization

data. If no software handshake or no Modbus Mode is selected, this

value is insignificant.

NOTICE

If the value 0 is given, the timeout is set to 10 seconds.

Put into operation

Page 14

XPS-E

14 / 36

DP-Data Transmission Mode

To offer the user several possibilities to adapt his application

optimally to the gateway functionality of XPS-E, 3 data transmission

modes can be used. The corresponding description is found under

chapter „Data Exchange“ ff. [}15]

Data Transmission Mode Value

(dec)

Value

(hex)

Value

(ASCII)

Poll-Mode * 80 0x50 ‘P’

Request-Mode 82 0x52 ‘R’

Serial triggered-Mode 83 0x53 ‘S’

Modbus RTU 83 0x4D ‘M’

Modbus ASCII 83 0x41 ‘A’

Table6: Data Transmission Mode Oktet 16

Extended Gateway

configuration data

Extended configuration byte

Bit Function

Bit7 ..Bit2 reserved

Bit1 Double baud rate

Bit0 RS232<->RS422

Table7: Extended configuration byte Oktet 17

– BIT0: RS232<->RS422 – Serial interface physics

With this parameter the interface physics can be set to RS232(0) or

RS485(1).

– BIT1: double Baudrate

Setting this bit doubles the baudrate for the serial interface

Exp: A selected baudrate of 19200 Baud can be increased to 38400

Baud by setting this bit.

– BIT7 – Bit2: reserved.

Trigger character for Serial

triggert mode

Here the trigger character for the serial triggerd mode is set. If the

seriell receive data stream contains the same sign, all received data

up to this character are sent to the DP-Master inclusive the trigger

character.Triggerzeichen eingetragen werden.

Trigger character Value

(dec)

Value

(hex)

Value

(ASCII)

LF * 10 0x0A LF

Table8: Trigger character Oktet 18

Also see about this

2 set_prm Parametrization [}10]

Put into operation

Page 15

XPS-E 15 / 36

4 Data exchange

4.1 Send Data

To send data via XPS-E onto a serial end device, the send flag of

XPS-E must be reset (ref. Communication Status, Bit 0 = 0), as

otherwise the send data to XPS-E will be discarded. For a send job,

the following data must be included into the telegram.

– Send job number. This job number must be different for each send

procedure. Reasonably, the value should be incremented by 1 at every

send procedure.

– Send data length. If the data length is set to 0, no data is sent via the

serial interface. Otherwise this byte includes the number of the following

user data.

– Send data (user data)

4.2 Receive Data

XPS-E has a 2Kbyte receive data buffer to temporarily store data

received from the connected serial end device. For data transfer to

the PROFIBUS-DP Master the operating modes Poll mode and

Request-Mode are available. The mode will be selected during

parameterization of XPS-E by the Master (See Chapter„s

[}10]et_prm Parameterization“, Section „DP-Data Transmission

Mode“). In the Poll mode available receive data will be sent at every

data_exchange.req with the corresponding data_exchange.res from

XPS-E to the PROFIBUS-DP Master. In the Request mode the XPSE sends this data only if in data_exchange.req a defined byte has

been changed (the receive request number). Thus, the polling of

existing receive data can be controlled by the Master.

The request mode is recommended for Masters that are polling the

slaves cyclically to generate a process image. (application may be

too slow to process the current data of the process image).

Data exchange

Page 16

XPS-E

16 / 36

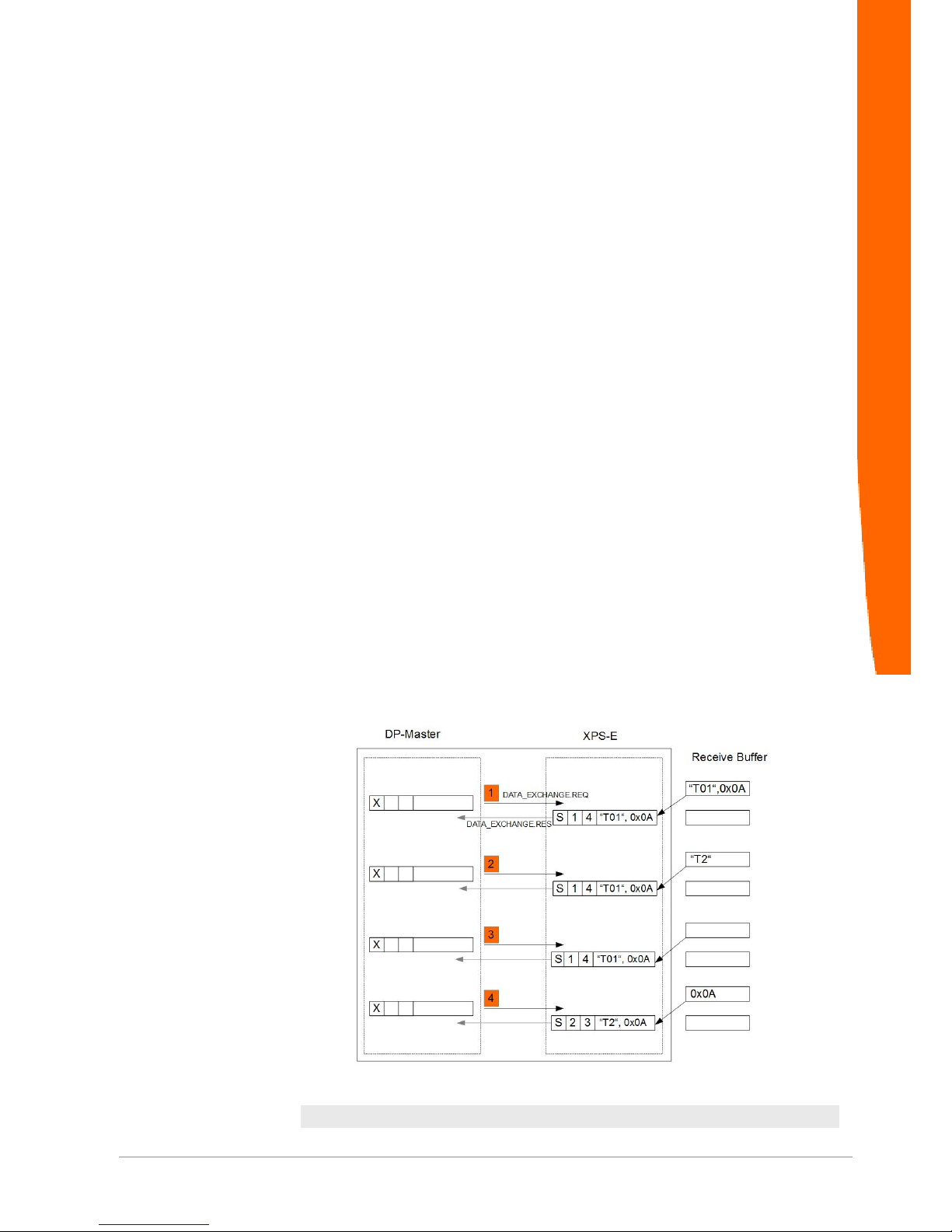

Poll Mode

In this mode XPS-E returns with every data_exchange the data

received up to the present time. Apart from the receive data and their

lengths a receive data number is entered into the telegram. This

confirmation number is automatically incremented if new receive data

is available in the telegram. If the receive telegram does not contain

new data (data length = 0), the confirmation number remains

unchanged.

NOTICE

If this mode is used when the Master is generating a Process Image

according to a Poll List it must be paid attention that this Poll List can

be read quickly enough as with every data_exchange the process

image will be overwritten. This may cause loss of data on part of the

application. Loss of data can be noticed when the confirmation

number is not subsequent.

Illustration3: Data Reception in Poll Mode

x= Receive Request Number S= Status

The telegrams mentioned above can either be started automatically

by the Master (cyclically during automatic polling) or by the

application.

NOTICE

The receive request number (X) in Poll Mode may not be set.

Data exchange

Page 17

XPS-E 17 / 36

1. The data_exchange.req telegram is sent to XPS-E. XPS-E has already

received the first characters at the interface. It returns them in the

response telegram data_exchange.res to the Master. The confirmation

is incremented by 1 and the length of the reception data is entered.

Moreover, the status (S) of XPS-E is returned.

¬

2. New data_exchange.req telegram.XPS-E returns the new data by

incrementing the confirmation number by 1.

¬

3. As response telegram to the data_exchange.req telegram, XPS/XPS-E

enters the old confirmation number as no new data has been received

at the serial interface. The receive data length is set to 0.

¬

4. XPS-E has again received new data. The confirmation number is

incremented by one and the data returned correspondingly by the

data_exchange.res telegram to the Master.

¬

If no time guarantee can be given and if data loss has to be excluded

under all circumstances, XPS-E must be run in the request mode.

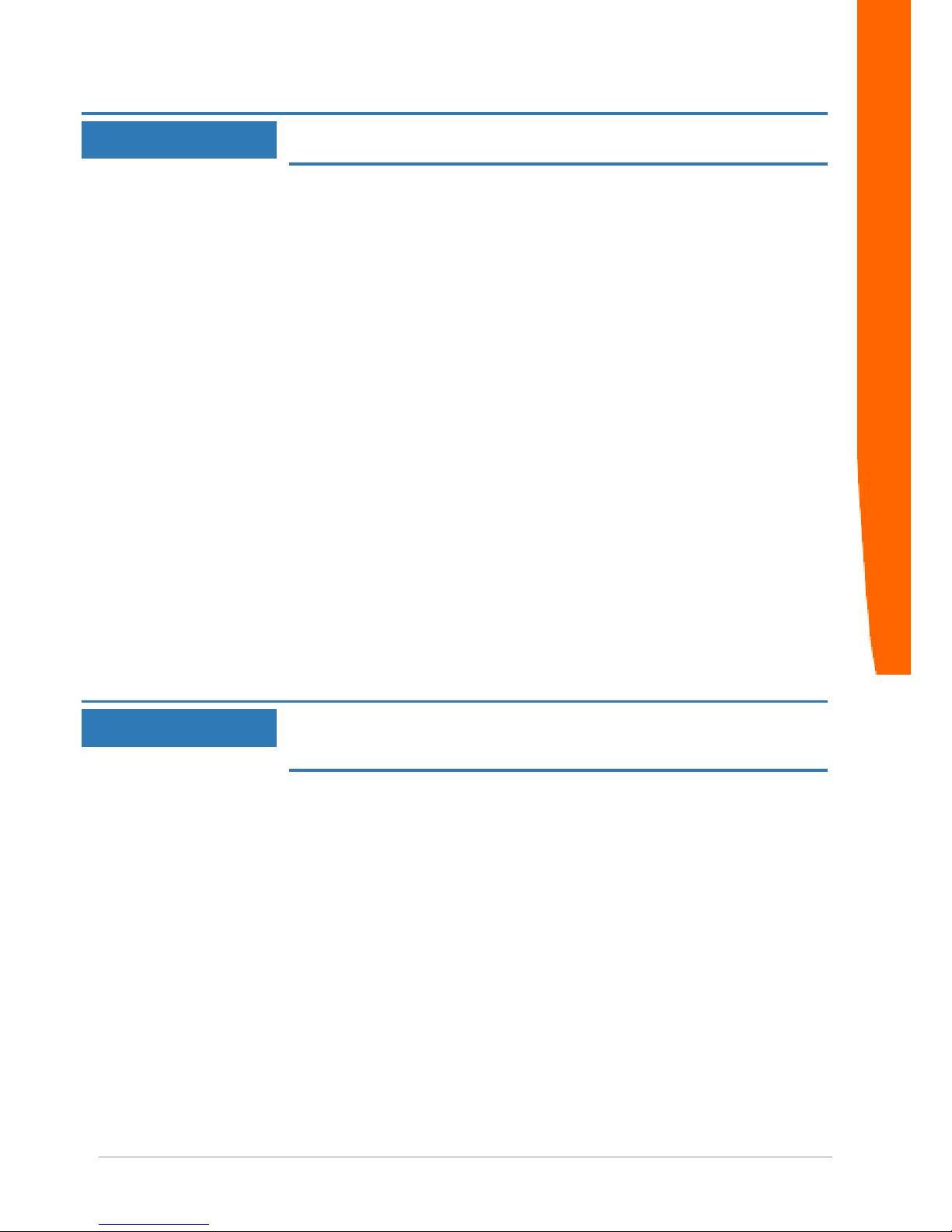

Serial triggered Mode

In serial triggered mode XPS/XPS-E waits for the termination of the

receive data by the trigger character defined within the external user

parameters of XPS-E (usually LF in ASCII-strings). The receive

confirmation number is not increased as long as no trigger character

is received. After the trigger character is received the Data Exchange

Resp.-buffer is updated with the received data inclusive the trigger

character. The data Exchange Resp.-buffer does not change as long

as the next trigger character is received.

Illustration4: Empfang im Seriell getriggerten–Modus(Endezeichen:0x0A)

x= Receive request number S= Status

Data exchange

Page 18

XPS-E

18 / 36

NOTICE

Please note, that it is not necessary to set the receive request number (X)

in polling/serial Mode

1. The data_exchange.req is transmitted to the XPS-E. XPS-E has already

received data via the serial interface. This data are transmitted with

data_exchange.res back to the DP-Master. The receive confirmation

number is incremented and data length and status are updated.

¬

2. Next data_exchange.req service. XPS-E responds with the old data.

New data are in fact received, but they do not contain the trigger

character.

¬

3. Next data_exchange.req service. XPS-E responds with the old data,

because no further serial data were received.

¬

4. Next data_exchange.req service. XPS-E has received in the meantime

the serial trigger character. The receive confirmation number is

incremented, data length, status and data_exchange.res buffer are

updated with the actual data.

¬

Request-Mode

In the request mode the XPS-E only sends receive data if a modified

receive-request number is contained in the request telegram. The

data are not returned in the first response telegram but in the

response telegram of the subsequent data_exchange service. This

means that the data are returned always only in the subsequent

cycle of the request. If the response telegram contains received data,

the XPS-E confirmation number is incremented by one and returned

in the response telegram (as in the poll mode).

NOTICE

If this mode is used while the master is automatically polling the slaves

according to the poll list, the data that have been received last remain in the

process image

Data exchange

Page 19

XPS-E 19 / 36

Illustration5: Data Reception in Request Mode

S= Status

Data exchange

Page 20

XPS-E

20 / 36

1. The data_exchange.req telegram is sent to the XPS-E which already

has received the first characters. It returns them, however, only in the

subsequent response telegram data_exchange.res.

¬

2. New data_exchange.req telegram with increased receive-request

number (further reception command). XPS-E returns the data received

at point in time. The confirmation number is increased by one.

¬

3. Another reception command to XPS-E (receive-request number has

been increased). The data that are returned are the data received at

point in time.

¬

4. No further reception command to XPS-E. XPS-E returns again the last

sent data. XPS-E has already received new data.

¬

5. No further reception command to XPS-E. XPS-E returns again the last

sent data.

¬

6. This data_exchange.req contains another reception command. The

data are returned, however, only at the next cycle.

¬

7. No further reception command because the request number has not

been increased. The data that are returned are the data received until

the point in time of the last read command.

¬

Data exchange

Page 21

XPS-E 21 / 36

Modbus RTU Master

XPS-E works in Modbus RTU Mode as Modbus Master. Modbus

Slave is not supported. In Modbus RTU Mode the parameters Baud

Rate, Data Mode, XOFF/Modbus timeout, Async. hardware mode

and Baud Rate Multiplier apply. The parameter XOFF/Modbus

timeout is adjusted in multiples of 100 ms and determines the timeout

period for a non-responding Modbus Slave.

The configured PROFIBUS DP IO data sizes (see XPS-E GSD file)

limit the max. size of the Modbus request and response telegrams

exchanged with the PROFIBUS DP Master. The max. possible size

of a Modbus RTU telegram is 237 Bytes (240 Bytes – 3 Byte header

information).

Transmit of a Modbus RTU

request telegram

Byte Telegram Element Value Range (dec)

1 Reserved

2 Send request number

0 – 255 (See Chapter

„S

end Data" [}15] )

3 Data length N of the following user

data

0 – 237 (See

Chapter„Send Data“,

Section „Modbus RTU-

Master“)

4 Adress Modbus RTU Slave 0 – 255

5 Modbus RTU Command 0 – 255

6+n Modbus RTU Data 0 – 255

Table9: Structure of a Modbus RTU Request-Telegram

The telegram buffer consists of 3 byte header and successive

Modbus specific application data (from byte 4).

By the header bytes the transmitting of the request telegram is

controlled. The header bytes are not transmitted to the Modbus

Slave.

– Byte 1

Reserved

–

Byte 2

The transmitting of the Modbus request telegram is triggered by

changing the Send request number in Byte 2. The Modbus RTU request

telegram is automatically generated incl. CRC and transmitted to the

Modbus slave.

– Byte 3

Byte 3 must be set to the size of the Modbus specific application data

from byte 4

For the detailed structure of the specific Modbus request telegrams

please refer to the Modbus slave user documentation.

Data exchange

Page 22

XPS-E

22 / 36

Reception of a Modbus RTU

response telegram

After transmitting a Modbus RTU request telegram, XPS-E waits for

a response of the addressed Modbus slave. After the correct

reception of the response telegram it is forwarded without CRC to the

PROFIBUS DP Master. If no response is received within the

configured timeout (See Chapter„Send Data“ [}15], Section „Modbus

RTU-Master) XPS-E reports via the receive status byte a timeout

error to the PROFIBUS DP Master.

Byte Telegram Element Value Range (dec)

1 Receive status 0 – 255

2 Receive confirmation number of

XPS-E

0 – 255 (See Chapter„

Receive Data“ [}15])

3

Data size N of the following user data 0 – 237 (See Chapter

Receive Data“,[}15]

Section „Modbus RTU

Master“).

4..4+N Modbus Data 0 – 255

Table10: Structure of a Modbus RTU Response-Telegramm

The telegram buffer consists of 3 byte header and successive

Modbus specific application data (from byte 4).

– Byte 1:Receive status of the Modbus RTU response telegram (Bit set =

status active):

Bit Meaning

0 Reserved

1 Reserved

2 Paritiy error

3 Receive data available

4 Reserved

5 Modbus request too large (max. PROFIBUS Output size-3)

6 Modbus response too large (max. PROFIBUS Input size - 3)

7 Modbus Timeout

Table11: Receive status of a Response-Telegram

Data exchange

Page 23

XPS-E 23 / 36

Status Meaning

0x02: Timeout expired. The Modbus slave did not respond within the

configured timeout period

0x08: Modbus response telegram correctly received

0x20: Modbus request too large (> configured PROFIBUS Output

size-3)

0x40: Modbus response too large (> configured PROFIBUS Input

size-3)

Table12: Status Codes

– Byte 2:If a correct Modbus response telegram is received, the receive

confirmation number is incremented (+1).

– Byte 3:Stores the data size of the Modbus response telegram

Modbus ASCII Master

The transmit and reception of Modbus ASCII telegrams complies with

the mechanism for the Modbus RTU Master described in detail in

chapter „R [}15]eceive Data“, Section „Modbus RTU Master.

Every request telegram received from the PROFIBUS DP Master is

automatically extended by a colon (:) as well as the calculated LRC

and a CR LF string.

Received response telegrams are checked and forwarded without

colon (:), LRC and CR LF string to the PROFIBUS DP Master.

Data exchange

Page 24

XPS-E

24 / 36

4.3 Send and Receive Data

It is generally possible in both modes to send and receive data

simultaneously. The request telegrams described in the previous

chapters then have to be completed only by the entries of the

transmission command (transmission command number, length of

transmission data, data).

Please note that the data are only accepted and transmitted by the

XPS-E if the transmission command number in the

data_exchange.req telegram to the XPS-E has changed.

Illustration6: Combined Send- and Receive Request

Data exchange

Page 25

XPS-E 25 / 36

5 Status and Error Messages

5.1 External Device Diagnostics

External device diagnostics can be realised by means of the service

slave_diag Octet 8 of the response telegram contains the device

status and is encoded as follows:

Illustration7: Byte Definition of external Device Diagnostics

1 RS_PORT_CFG_ERROR

Invalid parameter at parametrization of serial interface.

2 Not significant

Status and Error Messages

Page 26

XPS-E

26 / 36

5.2 Communication Status

In the status of the confirmation telegram of the service

data_exchange the status of the serial interface is encoded as

follows:

Illustration8: Byte Definition of Communication Status

0 RS_PORT_TX_DATA

Data are being transmitted.

1 Modbus_TIMEOUT

2 RS_PORT_PARITY_ERROR

Parity error of receive data of serial interface.

3 RS_PORT_RX_DATA_AVAIL

XPS-E has data in receive buffer.

4 XOFF_CTS_

XOFF was received or CTS is inactive.

5 OUTPUT_DATA_LEN_FAILURE

user data length exceeds maximal data_exchange length minus 3 (on

part of PROFIBUS)

6 RS_PORT_RX_OVERFLOW

Receive buffer overflow

7 XOFF_TOMEOUT

No XON received after XOFF- Timeout. Sending process was restar-

ted.

Status and Error Messages

Page 27

XPS-E 27 / 36

6 Connector Assignment and Cabling

6.1 PROFIBUS

Connector Assignment

The PROFIBUS connection is executed according to EN50170 as 9pin female D-SUB with the following assignment:

Pin RS422

Ref.

Signal Function Direction

1 - - Shielding 2 - - NC 3 B/B´ RxD/TxD-P Data (+) I/O

4 - CNTR-P Control character (+) O

5 C/C´ DGND Data Ground 6 - VP Supply for Terminator (+5V) 7 - - NC 8 A/A´ RxD/TxD-N Data (-) I/O

9 - CNTR-N Control character l (-) O

Table13: Connector Assignment PROFIBUS

O = Output I= Input

PROFIBUS Terminating Resistor

For correct operation of XPS-E both bus terminations of the line

segment must be provided with a terminator. This terminator must

match with the impedance level of the line. Typically, in case of new

PROFIBUS installations, Type A will be used. The assignment of the

individual terminating resistors of the terminator is depicted in the

following figure.

Illustration9: Assignment of PROFIBUS Terminator Type A

Connector Assignment and Cabling

Page 28

XPS-E

28 / 36

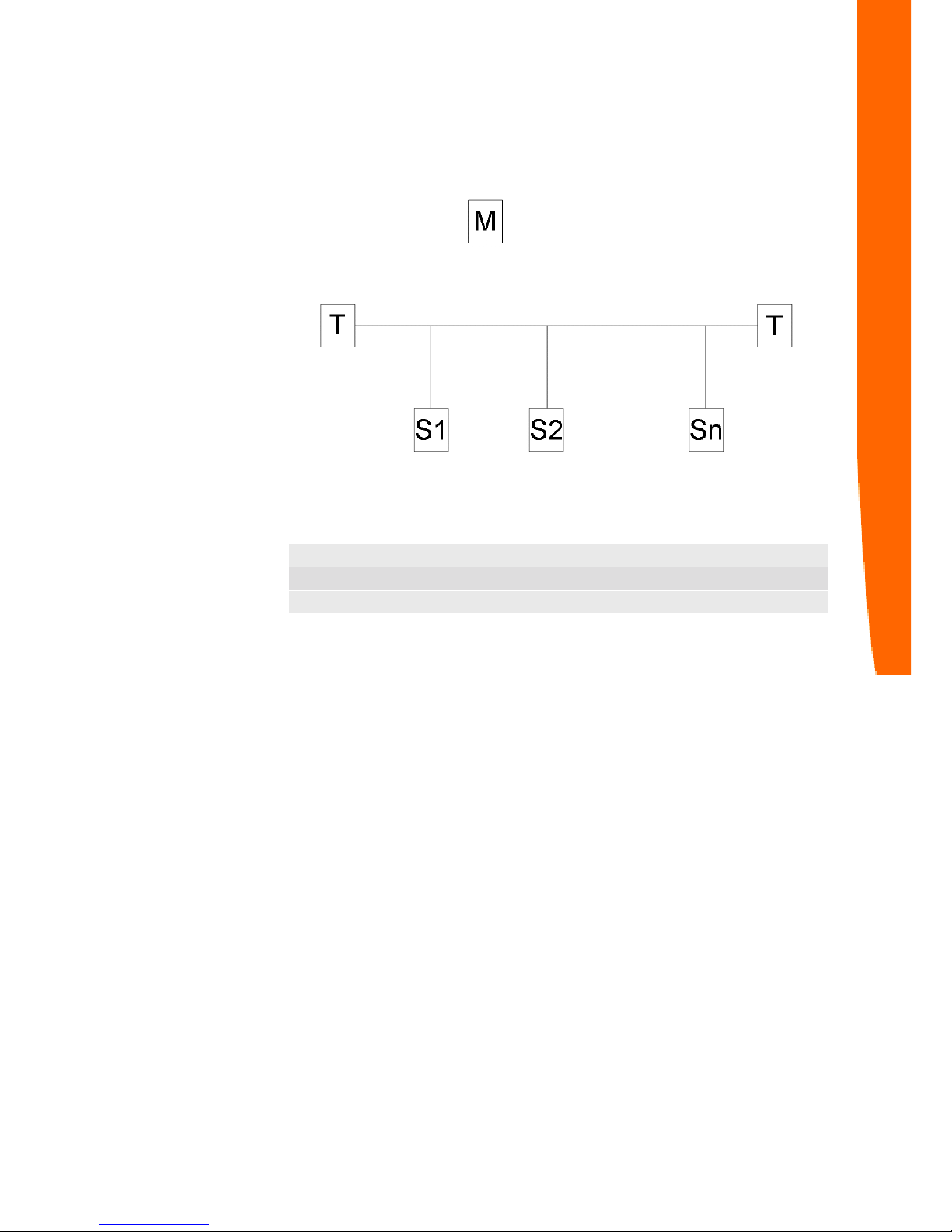

Cabling

Illustration10: Connection of a PROFIBUS-DP Slave within a Segment

T= Terminator

M= Master

S= Slave n<31

If no terminator with independent power supply shall be used (active

terminator), the termination must be realised directly at the last

stations of the bus. This station must then supply the terminator with

power. For details regarding the PROFIBUS installation please refer

to the PROFIBUS Installation Guidelines of the PROFIBUS User

Organisation (PNO, Order No.: 2.112).

Connector Assignment and Cabling

Page 29

XPS-E 29 / 36

6.2 Serial Interface

Connector Assignment RS232

The connection is realised via a 9-pin D-SUB plug.

Pin Signal FNI CCITT Function Direction

1 DCD M5 109 Data Carrier Detect I

2 RxD D2 104 Receive Data I

3 TxD D1 103 Transmit Data O

4 DTR S1 108.2 Data Terminal Ready O

5 GND E2 102 Ground 6 DSR M1 107 Data Set Ready I

7 RTS S2 105 Request to Send O

8 CTS M2 106 Clear To Send I

9 - - - Not connected -

Table14: Pin Assignment RS232 Interface

O= Output I= Input

Cabling RS232

RS232-Cabling without

Hardware Handshake

Illustration11: RS232 Cabling without Hardware Handshake

Connector Assignment and Cabling

Page 30

XPS-E

30 / 36

RS232-Cabling with

Hardware Handshake

Illustration12: RS232 Cabling with Hardware Handshake

RS422 Interface

The connection is realised via a 9-pin D-SUB plug.

Pin Signal Function Direction

1 I(B) Indicate (-) I

2 R(A) Receive Data (+) I

3 T(A) Transmit Data (+) O

4 T(B) Transmit Data (-) O

5 G Ground 6 R(B) Receive data (-) I

7 C(A) Control (+) O

8 I(A) Indicate (+) I

9 C(B) Control (-) O

Table15: Pin Assignment RS422 Interface

O = Output I= Input

Connector Assignment and Cabling

Page 31

XPS-E 31 / 36

RS422 Cabling without

Hardware Handshake

Illustration13: RS422 Cabling without Hardware Handshake

RS422 Cabling with

Hardware Handshake

Illustration14: RS422 Cabling with Hardware Handshake

Connector Assignment and Cabling

Page 32

XPS-E

32 / 36

7 FAQ

This section is treating the most frequent application problems and

their solutions.The most current questions and answers can be found

under

http://www.kunbus.de

DP-Master Status Message: Status 0xC2 (SAP/Service not

activated)

Make sure that the parametrization sequence of the parametrization

described in chapter „Parametrization“ [}9] has correctly been

executed. If necessary, repeat parametrization.

DP-Master Status Message: Status 0xC3 (no acknowledge)

Check the following points:

– Does the station address of the XPS-E correspond to the setting of the

PROFIBUS Master device?

– Are the bus parameters set correctly?

– Is the bus terminated correctly (switch position of the terminator

integrated in XPS-E)?

– Has XPS-E been connected correctly?

DP-Master Status Message: Status 0xC4 (bad telegram)

Check the terminating resistors at the bus. Pay attention to the switch

position of the terminating resistor at the XPS-E.

FAQ

Page 33

XPS-E 33 / 36

8 Technical Data

PROFIBUS-DP-Interface

Transmission protocol PROFIBUS-DP acc. to EN50170-3

Slave coupler

Transmission rates 9.6Kbit/s, 19.2Kbit/s, 93.75Kbit/s, 187.5Kbit/s,

500Kbit/s, 1.5Mbit/s, 3Mbit/s, 6Mbit/s, 12Mbit/s,

automatic adjustment

Potential segregation: Opto-coupler interface and DC/DC transducer

Isolation voltage U>500V

Terminator TYP A

Operating modes Sync_Req and Freeze_Req are not supported.

Addressing 1 - 99 Sync_Req and Freeze_Req are not sup-

ported.

Ident-Number 0x9510

Parametrization data: 23 Byte ( 16 Byte User Parameter)

Diagnostic information 6 Byte system diagnostics acc. to standard

8 Byte device-specific diagnostics

Data_Exchange Buffer 4 - 240 Byte I/O selectable (3 Bytes with

header functionality).

RS232-Interface

Interface RS232 interface with Handshake signals (RTS,

CTS).

RS422/485 interface with Handshake signals

(CONTROL, INDICATION).

Interface physics can be adjusted via

PROFIBUS by means of User_Parameter.

Transmission rates 150bit/s, 300bit/s, 600bit/s, 1.200bit/s, 2.400bit/

s,4.800bit/s, 9.600bit/s, 19.200bit/s

Character Transmission 8N1, 7N2, 7E1, 7O1

Handshake HW (RTS/CTS, CONTROL/INDICATION),

SW(XON/XOFF), no

XOFF Timeout adjustable to max. 25,5 seconds

Data transmission modes Poll mode, Request mode, serial triggered

mode

Receive buffer 2 KByte

Potential segregation optional

Connection

Power Supply 2-pin spring clip 2,5mm

2 without ferrule 1,5mm

2 with ferrule

PROFIBUS-DP 9-pin female D-SUB (DIN 41652)

RS-Port 9-pin male D-SUB (DIN 41652)

Technical Data

Page 34

XPS-E

34 / 36

Operating Indicators and Controls

PROFIBUS Status LED “green” means RUN

“red” means BUSFAIL

RS-PORT Status LED RxD “red” corresponds to: data will be re-

ceived

TxD “red“ corresponds to: data will be sent

Hardware physics “red” corresponds to:

RS232 mode

PROFIBUS address window at coding switch

Technical Data

Case synthetic profile with aluminium front panel,

lacquered

Dimensions 126mm x 90mm x 38mm (LxWxH)

Weight 190g

Voltage range 18 – 30VDC

Power assumption 100mA (24VDC)

Storage temperature -25C .. +70C

Operation temperature 0C .. +55C non condensing

Protection class 1

Protection kind IP52

Standards CE, EN60950, EN50081-2, EN50082-2

Technical Data

Page 35

XPS-E 35 / 36

List of Figures

Illustration 1 Typical Connection................................................................................................... 6

Illustration 2 Connectors and Interfaces of the XPS-E ................................................................. 7

Illustration 3 Data Reception in Poll Mode.................................................................................... 16

Illustration 4 Empfang im Seriell getriggerten–Modus(Endezeichen:0x0A).................................. 17

Illustration 5 Data Reception in Request Mode ............................................................................ 19

Illustration 6 Combined Send- and Receive Request................................................................... 24

Illustration 7 Byte Definition of external Device Diagnostics......................................................... 25

Illustration 8 Byte Definition of Communication Status................................................................. 26

Illustration 9 Assignment of PROFIBUS Terminator Type A ........................................................ 27

Illustration 10 Connection of a PROFIBUS-DP Slave within a Segment ........................................ 28

Illustration 11 RS232 Cabling without Hardware Handshake ......................................................... 29

Illustration 12 RS232 Cabling with Hardware Handshake .............................................................. 30

Illustration 13 RS422 Cabling without Hardware Handshake ......................................................... 31

Illustration 14 RS422 Cabling with Hardware Handshake .............................................................. 31

List of Figures

Page 36

XPS-E

36 / 36

List of Tables

Table 1 set_prm .......................................................................................................................... 10

Table 2 slave_diag ...................................................................................................................... 11

Table 3 Baud Rate of Serial Interface Oktet 12 .......................................................................... 12

Table 4 Character Transmisson Mode Oktet 13 ......................................................................... 13

Table 5 Handshake-Modi Oktet 14 ............................................................................................. 13

Table 6 Data Transmission Mode Oktet 16 ................................................................................ 14

Table 7 Extended configuration byte Oktet 17............................................................................ 14

Table 8 Trigger character Oktet 18 ............................................................................................. 14

Table 9 Structure of a Modbus RTU Request-Telegram ............................................................ 21

Table 10 Structure of a Modbus RTU Response-Telegramm....................................................... 22

Table 11 Receive status of a Response-Telegram....................................................................... 22

Table 12 Status Codes ................................................................................................................. 23

Table 13 Connector Assignment PROFIBUS ............................................................................... 27

Table 14 Pin Assignment RS232 Interface ................................................................................... 29

Table 15 Pin Assignment RS422 Interface ................................................................................... 30

List of Tables

Loading...

Loading...