User Manual

Gateway component for EtherNet/IP

PR100066 • 1/7/2016

Table of Contents KUNBUS GmbH

Table of Contents

1 General Information ........................................................................................................................3

1.1 Disclaimer..................................................................................................................................3

1.2 Notes Regarding this User Manual............................................................................................4

1.3 Validity .......................................................................................................................................4

1.4 Limitation of Liability ..................................................................................................................4

1.5 Customer Service ......................................................................................................................4

2 Safe Use ...........................................................................................................................................5

2.1 User ...........................................................................................................................................5

2.2 Symbols.....................................................................................................................................5

3 Overview ..........................................................................................................................................6

3.1 Functionality ..............................................................................................................................6

3.2 Control Elements .......................................................................................................................8

3.3 Status LEDs.............................................................................................................................11

4 Installation .....................................................................................................................................12

4.1 Preparations for Trouble-free Operation..................................................................................12

4.2 Requirements .........................................................................................................................14

4.3 Connecting Gateway Components..........................................................................................15

4.4 Installing a Gateway in the Control Cabinet ............................................................................16

4.5 Connecting a Power Supply ....................................................................................................17

4.6 Connecting a Gateway to the Fieldbus....................................................................................18

5 Configuration.................................................................................................................................19

5.1 Supported Size of the Process Data ......................................................................................19

5.2 Address Assignment................................................................................................................20

5.3 Ethernet/IP Configuration ........................................................................................................21

5.4 Configuration of Modbus TCP .................................................................................................22

6 Technical Data...............................................................................................................................24

6.1 Technical Data.........................................................................................................................24

ii Gateway component for EtherNet_IP

1 General Information

1.1 Disclaimer

© 2015 KUNBUS GmbH, Denkendorf (Germany)

The contents of this user manual have been prepared by KUNBUS

GmbH with the utmost care. Due to technical development, KUNBUS

GmbH reserves the right to change or replace the contents of this

user manual without prior notice. You can always obtain the latest

version of the user manual at our homepage: www.kunbus.de

KUNBUS GmbH shall be liable exclusively to the extent specified in

General Terms and Conditions (www.kunbus.de/agb.html).

The contents published in this user manual are protected by

copyright. Any reproduction or use for the in-house requirements of

the user is permitted. Reproduction or use for other purposes is not

permitted without the express, written consent of KUNBUS GmbH.

Contraventions shall result in compensation for damages.

General Information

Trademark protection

– KUNBUS is a registered trademark of KUNBUS GmbH

– Windows® and Microsoft® are registered trademarks of Microsoft Corp.

KUNBUS GmbH

Heerweg 15 c

73770 Denkendorf

Germany

www.kunbus.de

Gateway component for EtherNet_IP 3 / 25

1.2 Notes Regarding this User Manual

This user manual provides important technical information that can

enable you as a user to integrate the Gateways into your applications

and systems efficiently, safely and conveniently. It is intended for

trained, qualified personnel, whose sound knowledge in the field of

electronic circuits and expertise in EtherNet/IPTM is assumed.

As an integral part of the module, the information provided here

should be kept and made available to the user.

1.3 Validity

This document describes the application of the KUNBUS Gateway

with the product number:

– PR100066, release 00

1.4 Limitation of Liability

Warranty and liability claims will lapse if:

General Information

– the product has been used incorrectly,

– damage is due to non-observance of the operating manual,

– damage is caused by inadequately qualified personnel,

– damage is caused by technical modification to the product (e.g.

soldering).

1.5 Customer Service

If you have any questions or suggestions concerning this product,

please do not hesitate to contact us:

KUNBUS GmbH

Heerweg 15 C

73770 Denkendorf

+49 (0)711 3409 7077

support@kunbus.de

www.kunbus.de

Gateway component for EtherNet_IP

4 / 25

2 Safe Use

2.1 User

The Gateway may only be assembled, installed and put into

operation by trained, qualified personnel. Before assembly, it is

absolutely essential that this documentation has been read carefully

and understood. Expertise in the following fields is assumed:

– electronic circuits,

– basic knowledge of EtherNet/IP,

– work in electrostatic protected areas,

– locally applicable rules and regulations for occupational safety.

2.2 Symbols

The symbols used have the following meaning:

Safe Use

DANGER

CAUTION

NOTICE

Danger

Always observe this information!

There is a safety hazard that can lead to serious injuries and death.

Caution

There is a safety hazard that can result in minor injuries and material

damage.

Note

There is a safety hazard that can result in material damage.

Gateway component for EtherNet_IP 5 / 25

3 Overview

3.1 Functionality

The KUNBUS Gateway is a protocol converter. It allows

communication between networks with different protocols.

Overview

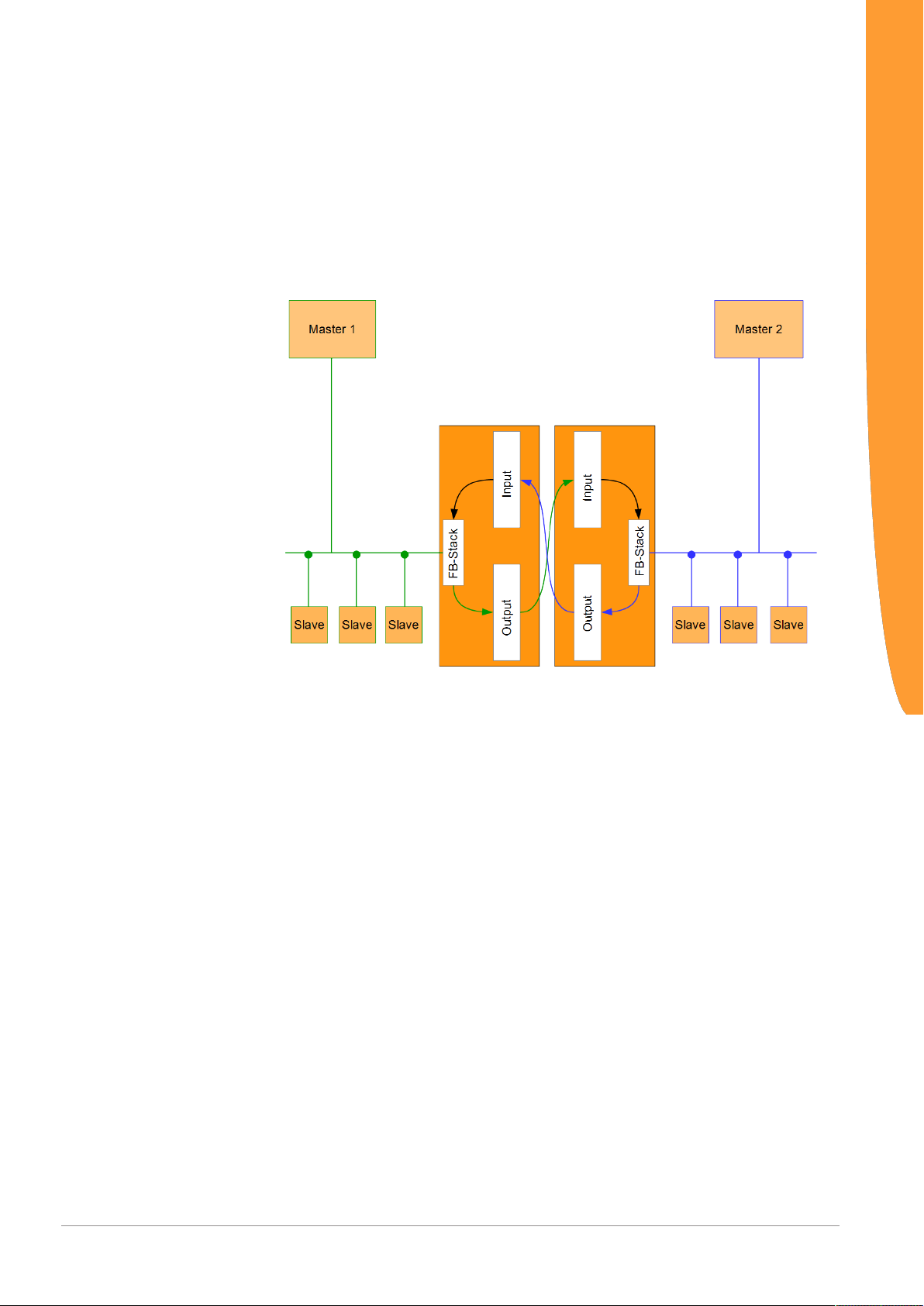

Illustration1: Functionality

A Gateway consists of 2 gateway components that master one

specific protocol each. You can combine these gateway components

as you wish. This design offers you a high degree of flexibility, since

you can exchange the individual gateway components at any time.

The following gateway components are currently available as slaves:

– CANopen

– CC-Link

– DeviceNet

– EtherCAT

– EtherNet/IP

– Modbus RTU

– Modbus TCP

– POWERLINK

– PROFIBUS

– PROFINET

– Sercos III

Gateway component for EtherNet_IP

6 / 25

Features

This gateway component enables communication with Ethernet/IP

and Modbus TCP. It supports the following functions:

– RPI

Minimal Requested Packet Interval: 1ms

– ACD (Address Conflict Detection)

– DLR

You can use the gateway component in a Device Level Ring.

Overview

Gateway component for EtherNet_IP 7 / 25

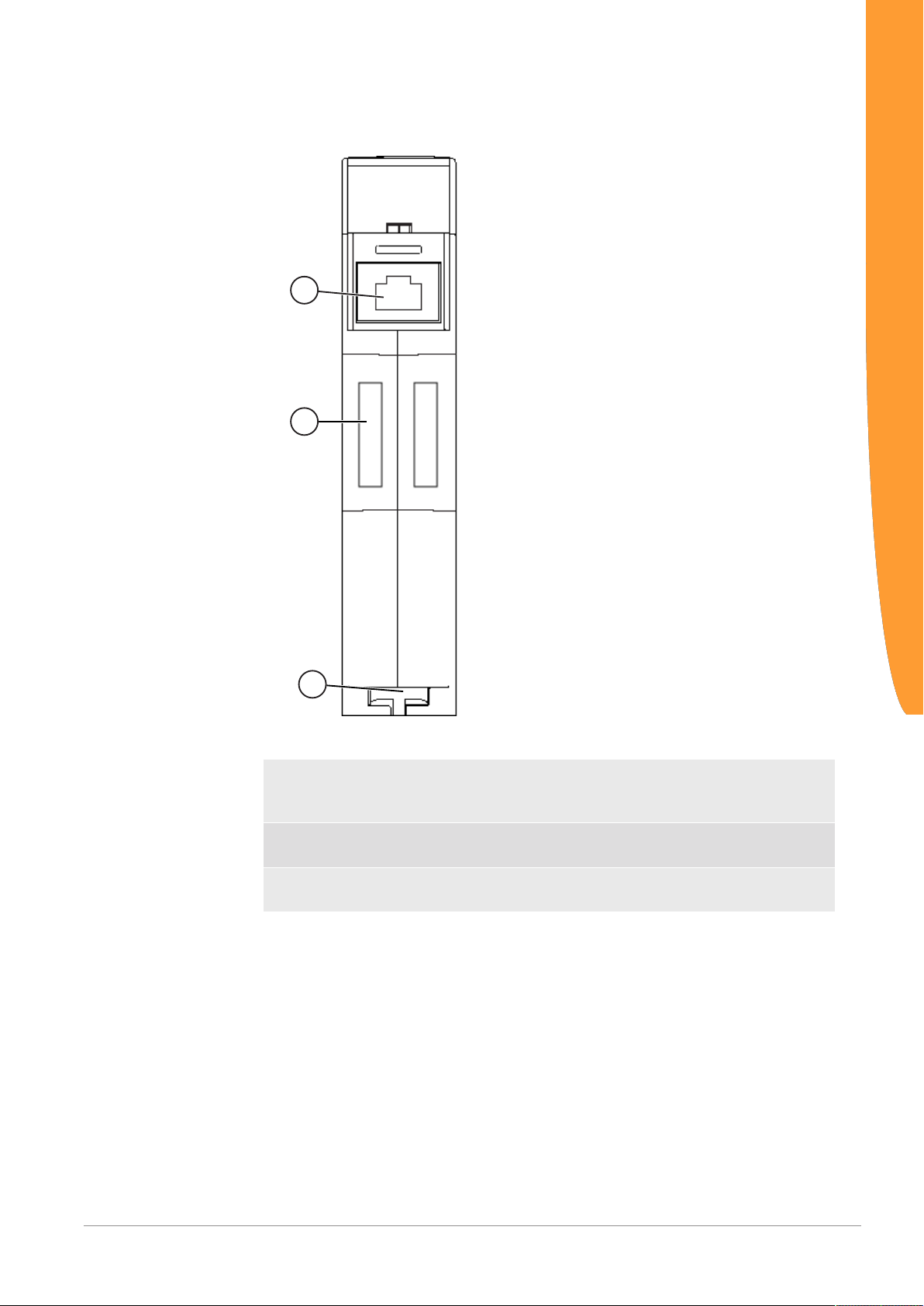

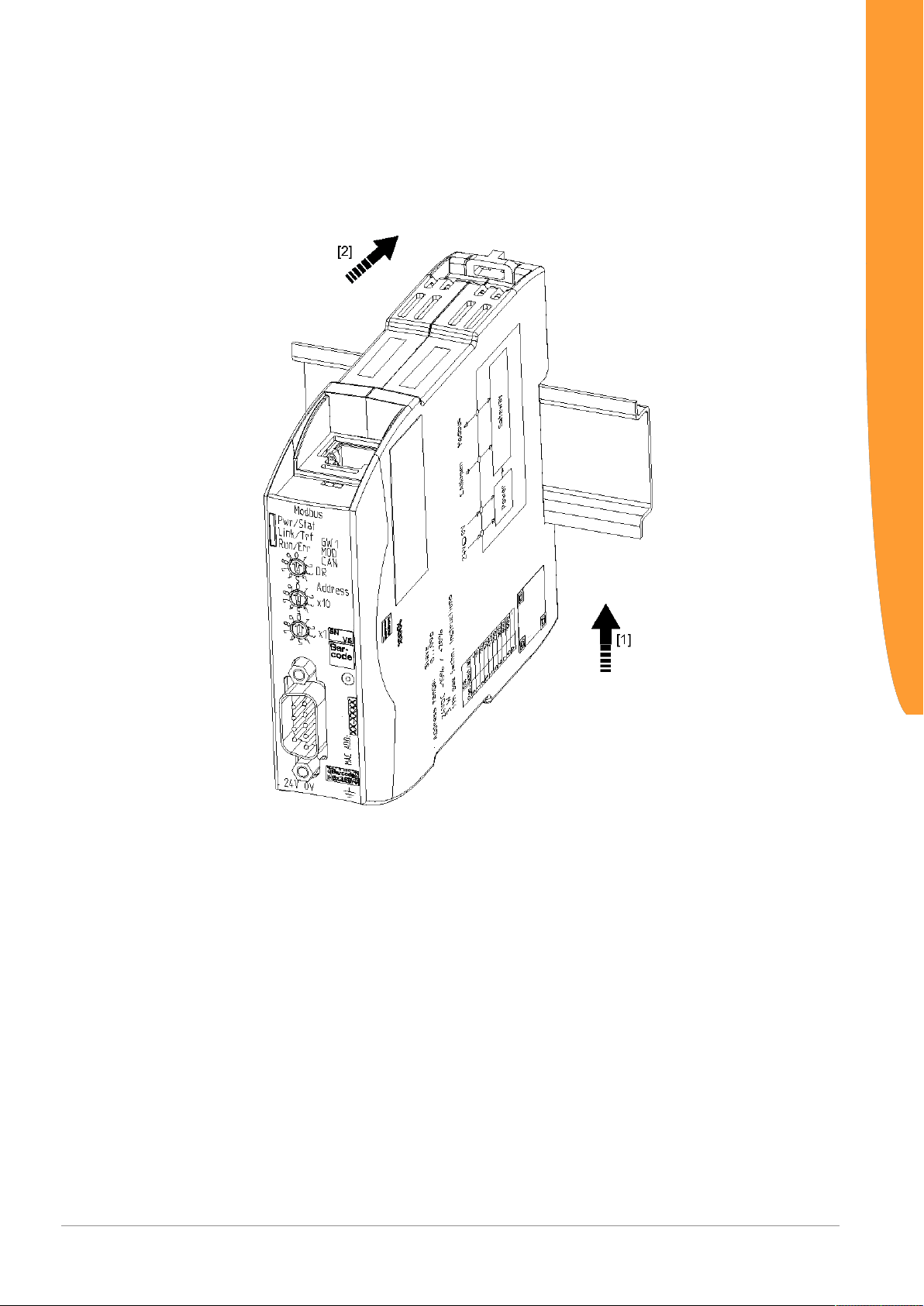

3.2 Control Elements

1

2

3

Front view

Overview

Illustration2: Front view

1 Status LEDs

2 Coding switch

8-pin DIP switch for setting the IP address.

3 Fieldbus connection

RJ45 socket for the connection to the fieldbus (2 sockets in all,

s. figure top view)

Gateway component for EtherNet_IP

8 / 25

Top

1

2

3

Overview

Illustration3: Top

1 Fieldbus connection

RJ45 socket for connection to the fieldbus (2 pcs, see figure

front view).

2 Interconnect ports

for interconnecting the gateway components.

3 Locking clamps

for securely attaching the gateway component to the DIN rail.

Gateway component for EtherNet_IP 9 / 25

Bottom

1

2

Overview

Illustration4: Bottom

1 Mains connection

with 24 V power supply

2 Locking clamps

for securely attaching the gateway component to the DIN rail.

Gateway component for EtherNet_IP

10 / 25

3.3 Status LEDs

The signals of the status LEDs for EtherNet/IP have the following

meaning:

LED designation Signal Meaning

Power off Gateway component not running

MS off No power supply

NS off Gateway component is switched off or has

L/A 1 + 2 off No connection

blinks,

green

on, green Operational

flashes, red Correctable error (e.g. second gateway

on, red Serious error/defect in the gateway

on, green Gateway component operational

blinks,

green

on, red Unrecoverable error

flashes, red Configuration error

flashes red

and green

blinks,

green

on, green Connection is established

flashes, red Connection interrupted (e.g. due to time-

on, red Set IP address is already being used by

green Connection to another device. No data ex-

blinks,

green

Initialization phase not yet completed

component missing)

Configuration not completed

Self-test

no IP address

IP address set but no CIP connection has

been established yet

out)

another network subscriber

change takes place.

Connection established. Data exchange

takes place.

Overview

Gateway component for EtherNet_IP 11 / 25

4 Installation

4.1 Preparations for Trouble-free Operation

In the following section we have compiled some general information

for you that is important for trouble-free operation. If you are already

acquainted with this topic, you can skip to the next section. There,

you will learn about which conditions are necessary for installing the

gateway.

Cable routing

Route your cables separately in cable groups. This will protect your

gateway from any unintended electromagnetic interferences.

The following groups should be routed separately from each other:

Group Line

A Data and power supply lines for:

DC voltage below 60V

AC voltage below 25V

B Data and power supply lines for:

DC voltage between 60V and 400V

AC voltage between 25 and 400V

C Power supply lines above 400V

Installation

– You can route cables of the same group together in cable ducts or

bundles.

– Cables of group A and B:

– Route the groups in separate bundles or

– in cable ducts at a minimum distance of 10 cm from each other.

– Cables of group C

– Route the groups in separate bundles or

– in cable ducts at a minimum distance of 50 cm from the other

groups.

Gateway component for EtherNet_IP

12 / 25

Shielding

Shield your cables. This will reduce any unintended electromagnetic

interferences.

Potential equalization

Potential differences occur when devices are connected to different

earths. These potential differences cause malfunctions.

To prevent malfunctions, you have to route an equipotential

equalization conductor.

When doing so, bear in mind the following points:

– Select an equipotential equalization conductor with low impedance.

– Select the following as a reference value for the cross-section of the

potential equalization cable:

– 16 mm2 for potential equalization cables of up to 200 m in length

– 25 mm2 for potential equalization cables of more than 200 m in

length

– Use potential equalization cables made of copper or galvanized steel.

– Connect potential equalization cables extensively with the earth rail.

– The smallest surfaces possible should be sandwiched between

potential equalization cables and signal cables.

Installation

If the devices of the control system are connected by shielded signal

cables that are earthed on both sides, the impedance must be 10%

of the shielding impedance.

Gateway component for EtherNet_IP 13 / 25

4.2 Requirements

The Gateway was designed for use in a control cabinet.

NOTICE

ü The protection class of the control cabinet must be equivalent to at least

IP54.

ü For installation in the control cabinet you need a DIN rail 35 x 7.5mm

(EN50022).

◦ Install the DIN rail horizontally in the control cabinet according to the

manufacturers' specifications. When doing so, make sure that the

Gateway is at a sufficient distance from other devices.

Your gateway could be damaged if temperatures are too high.

èMake sure that the ambient temperature in the control cabinet is less

than 60°C.

èKeep the ventilation slots unobstructed. These must not be covered by

cables etc.

èMaintain sufficient distance from other devices.

Installation

Illustration5: Distances for installation

◦ Connect each gateway component individually to functional earth.

ð Your control cabinet now meets all requirements for installing the

Gateway component for EtherNet_IP

When doing so, make sure that the power supplies of both gateway

components have the same ground.

gateway.

14 / 25

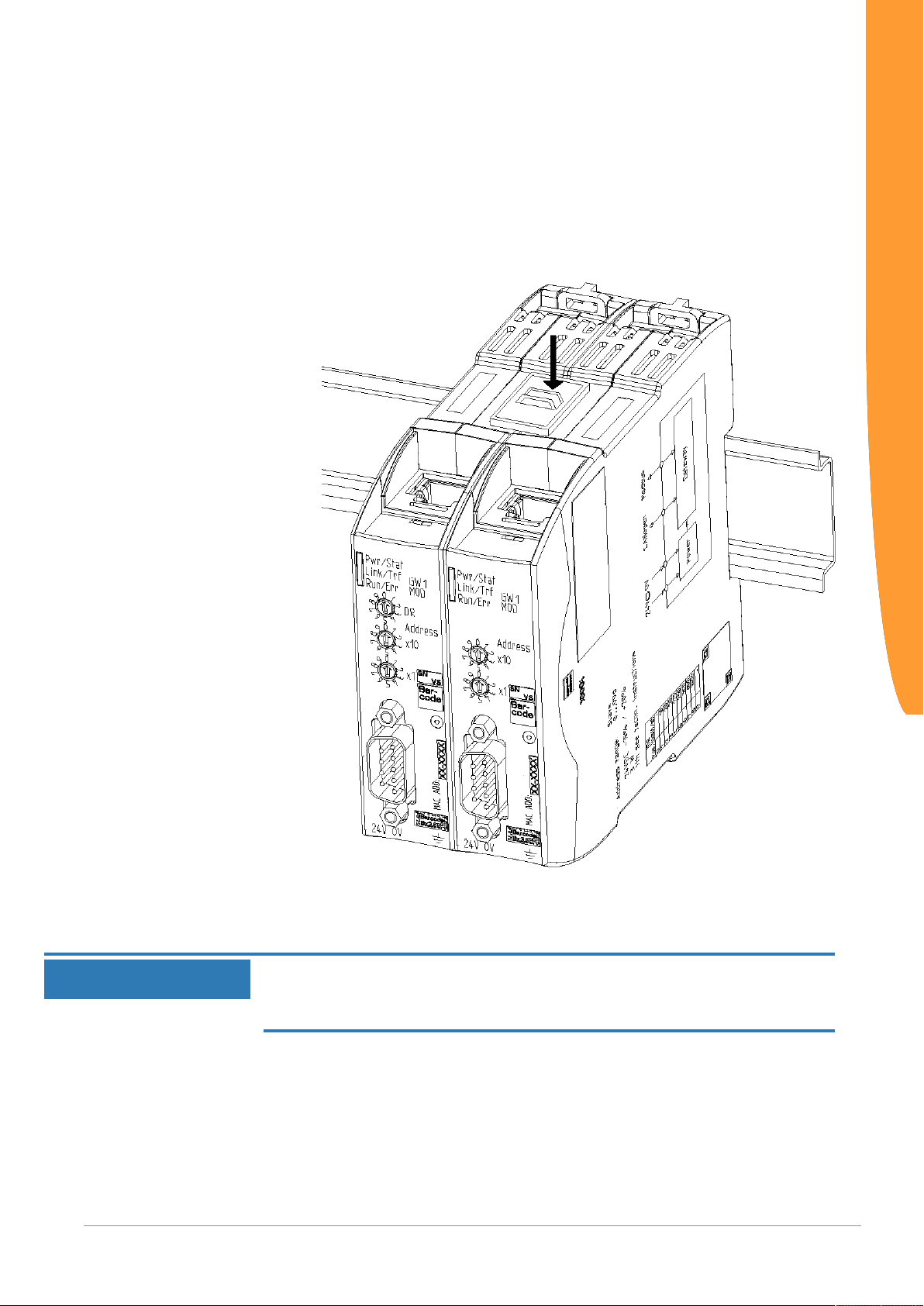

4.3 Connecting Gateway Components

In order to attain a fully functional gateway, you have to interconnect

both gateway components.

◦ Connect an interconnect port to each gateway component using the

plug-in jumper (product number PR100204).

◦

Installation

Illustration6: Connecting gateway components

ð You can now install the gateway in the control cabinet.

Only ever interconnect 2 gateway components.

NOTICE

If you connect additional components, severe defects could result on all

devices.

Gateway component for EtherNet_IP 15 / 25

4.4 Installing a Gateway in the Control Cabinet

◦ Hold the raster element of the gateway on the DIN rail.

◦ Press down the locking elements towards the gateway.

◦ Make sure that the gateway is firmly attached to the DIN rail.

Installation

Gateway component for EtherNet_IP

16 / 25

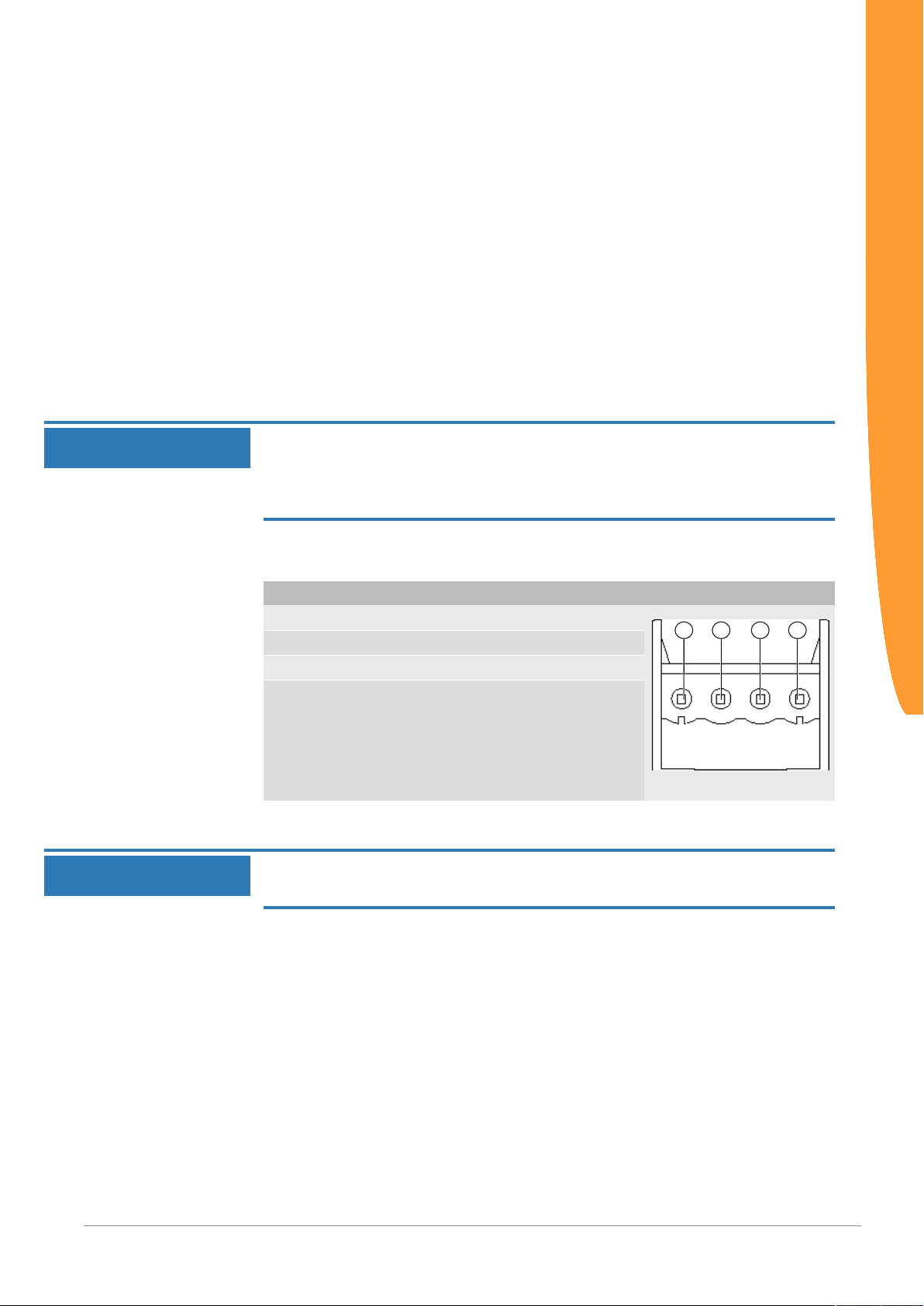

4.5 Connecting a Power Supply

3

1

2

4

To connect the gateway component to the power supply, you need a

spring-loaded terminal (e.g. Metz-Connect SP995xxVBNC).

You have to connect each gateway component separately to a power

supply. Never interconnect functional earth and GND, otherwise the

galvanic isolation between gateway GND and fieldbus ground will be

removed. Instead, connect the functional earth with low impedance to

the potential equalization. You can then dispense with this

connection if the shield of the fieldbus cable is connected to the

potential equalization with lower impedance when entering the

control cabinet.

Installation

NOTICE

NOTICE

Connect each of the two gateway components to its own power

supply

èEnsure in particular that no potential differences occur between the

GND pins (2).

Pin assignment:

Pin Assignment

1 24V for module supply

2 GND

3 Do not connect!

4 Functional earth

Do not connect GND to PE

This connection could cause unintended malfunctions.

Gateway component for EtherNet_IP 17 / 25

4.6 Connecting a Gateway to the Fieldbus

To connect the gateway component to EtherNet/IP, you need Two

RJ45 connectors.

The pin assignment complies with the Ethernet standard.

Installation

Gateway component for EtherNet_IP

18 / 25

5 Configuration

5.1 Supported Size of the Process Data

NOTICE

The gateway component for EtherNet/IP supports process data of a

length up to 480 bytes.

Type Direction Assembly

Instance

Exclusive Owner Output (master -> slave) 100 up to 480 bytes

Input (slave -> master) 150 up to 480 bytes

Input Only Output (master -> slave) 254 0 bytes

Input (slave -> master) 150 up to 480 bytes

Listen Only Output (master -> slave) 255 0 bytes

Input (slave -> master) 150 up to 480 bytes

Bear in mind that the maximum length of the process data is always

determined by the fieldbus with the shorter data length.

Example:

Ethernet/IP supports 480 bytes per direction.

PROFIBUS supports 244 bytes per direction.

In conjunction with Ethernet/IP / PROFIBUS this means that 244

bytes are transmitted and updated cyclically.

Size

Configuration

Gateway component for EtherNet_IP 19 / 25

5.2 Address Assignment

Setting IP Address

With the 8-pin address switch you can set the IP address of the

Gateways.

You can set values in binary format between 0-255.

Configuration

Assigning IP Address

manually:

Receiving IP Address from

the DHCP Server

Setting IP Address using the

Master Software

◦ Set any address between 1-254

ð The gateway component uses the address 192.168.1.X with the net

mask 255.255.255.0 and gateway 192.168.1.1

◦ Open the website http://192.168.1.X

◦ Log on:

Logon data for the initial logon :

User: Admin

Password: 1701

◦ Click on the "Change Configuration" button

◦ Set the IP address required

◦ Confirm your entry by pressing the "Apply" button

◦ Set all address switches to "0"

◦ Restart the gateway component by switching this off and then on again.

ð The set IP address is now used.

◦ Set the value "255" (all switches in the direction of the numbers) to

activate the DHCP mode.

ð Assign the IP address automatically from the DHCP server.

◦ Set the value "0" (all switches to "Off")

ð The gateway component uses the IP address that was last set using

the software.

◦ You can change this IP address at any time via the EtherNet/IP-

protocol or website.

◦ Restart the gateway component by switching this off and then on again.

ð The set IP address is now used.

Gateway component for EtherNet_IP

20 / 25

5.3 Ethernet/IP Configuration

Standard Objects

The following objects are available to you for addressing the process

data:

– Identity Object, Class Code: 01 Hex

– Message Router, Class Code: 02 Hex

– Assembly Object, Class Code: 04 Hex

– Connection Manager Object, Class Code: 06 Hex

– TCP/IP Interface Object, Class Code: F5 Hex

– Ethernet Link Object, Class Code: F6 hex

– Device Level Ring, Class Code: 47 Hex

– Quality of Service, Class Code: 48 Hex

These objects comply with the ODVA standard. You can find further

information in the specifications for EtherNet/IP. You can find details

about the implemented attributes from the EDS file provided.

Device Specific Objects

Configuration

Fieldbus Input Data, Class

Code: A0 hex

Fieldbus Output Data, Class

Code: A1 hex

The following objects are device specific. You can use these to

access the input and output data acyclically.

– Fieldbus Input Data, Class Code: A0 Hex

– Fieldbus Output Data, Class Code: A1 Hex

You can use this object to read data that was sent from the gateway

component to the EtherNet/IP-Master. This data originates from the

Master of the other gateway components.

You can use this object to write data that was sent from the EtherNet/

IP-Master to the gateway component. This data is copied to the input

data area of the other gateway component. The Master of the other

gateway component can read this data there.

Gateway component for EtherNet_IP 21 / 25

5.4 Configuration of Modbus TCP

You can also use these gateway components as a protocol converter

for Modbus TCP.

Functions

The following Modbus functions are implemented:

Function code Description

0x01 read coils

0x02 read discrete inputs

0x05 write single coil

0x0f write multiple coils

0x03 read holding registers

0x04 read input registers

0x06 write single register

0x10 write multiple registers

0x16 mask write register

0x17 read/write multiple registers

Register

The following registers are implemented in the gateway component:

Configuration

Address area Function Access

1-240 Input register, receives values of the partner

gateway component.

1025-1264 Input register, sends values to the partner

gateway component.

40001-40240 Input register, compatible with Siemens con-

trollers

30001-30240 Output register, compatible with Siemens con-

trollers

4097 Status of the partner gateway component Read only

0x01 Hardware is initialized and checked

0x02 Connection to the partner gateway

component is checked

0x03 The opposite side is detected

0x04 Interface to the partner gateway com-

ponent functions.

Read only

Read/write

Read only

Read/write

Gateway component for EtherNet_IP

22 / 25

Address area Function Access

4098 Status of the other fieldbus Read only

0x00 Fieldbus not connected. Check all

connections

0x01 Fieldbus connected, no data commu-

nication. Check whether an IP ad-

dress is set

0x02 Gateway component configured, no

data communication

0x03 Cyclical data exchange

Configuration

Input Register

Siemens controllers use 2 predefined address areas. Therefore, the

input and output registers can each be accessed via 2 addresses,

one KUNBUS address and one Siemens address. Both addresses

address the same memory cell, however. No separate address areas

is defined for the input register. Read the holding register with

function code 0x04.

Register area for bit by bit access (coils)

You can also access the input and output data area bit by bit via

coils. The same memory is addressed with the coils as with the

registers.

Example: Coils 1-16 correspond to the bits in register 1,

Coils 17-32 correspond to the bits in register 2.

Address area Use Access Meaning

1 - 3840 Input Bits Read only Values that the other gateway component

supplies.

16385 - 20224 Output Bits Read/write Values that are supplied to the other gateway

component

Discrete Inputs

No separate address area is defined for discrete inputs. Read the

coils with function code 0x02.

Gateway component for EtherNet_IP 23 / 25

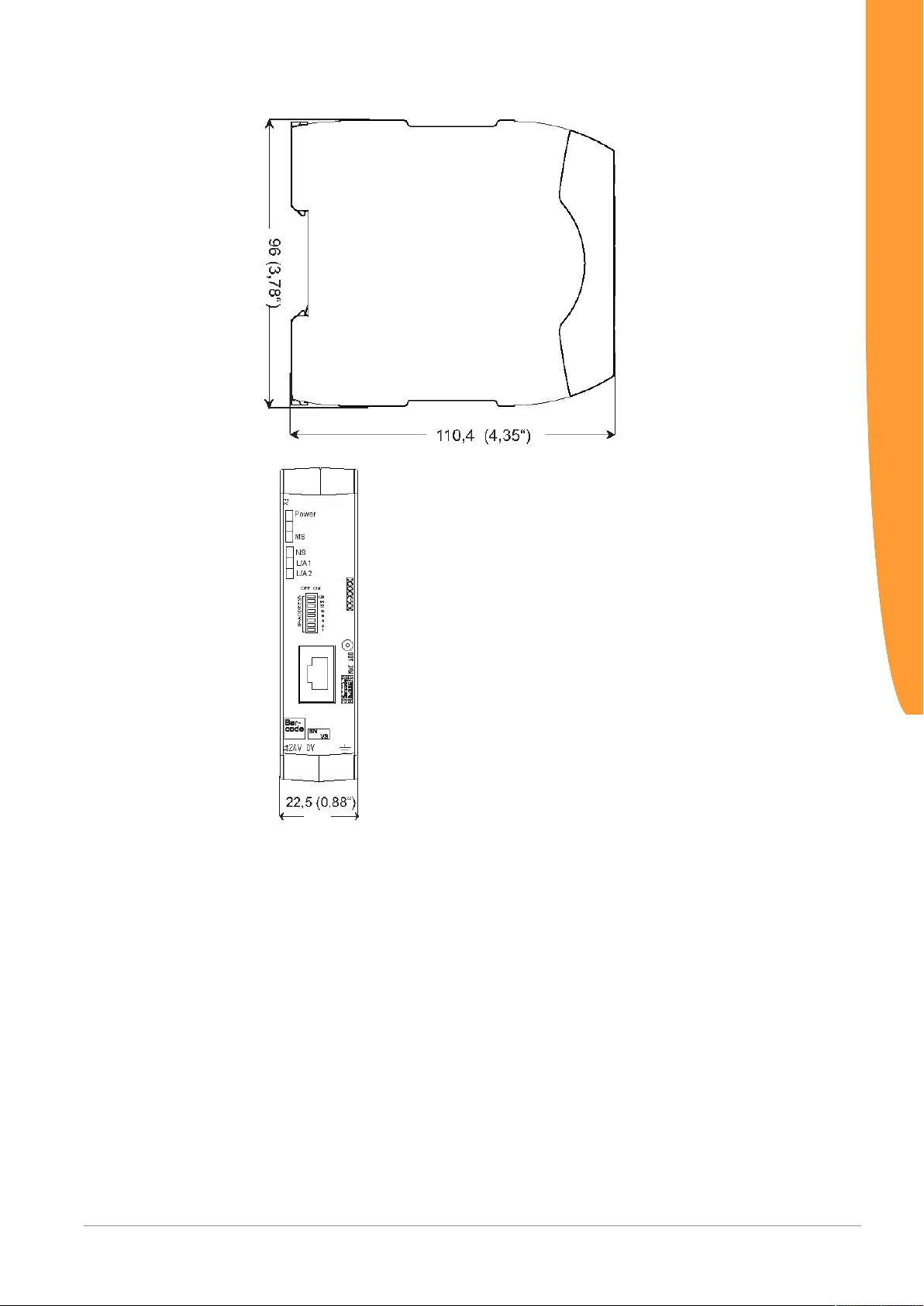

6 Technical Data

6.1 Technical Data

Dimensions

Width 22.5 mm

Height 96 mm

Depth 110.4 mm

Weight 90 g

Electrical data

Power supply 24 V DC

Power consumption during operation

(cyclical data exchange)

Status display LED

Environmental conditions

Ambient temperature 0 – 60 °C

Storage temperature - 25 – 60 °C

Humidity 93 % (at 40 °C)

Condensing Not allowed

Protection class

Control cabinet

Housing

Terminal area

Technical Data

100mA

IP54

IP20

IP20

Assembly data

DIN rail 35 x 7.5 mm

Height 96 mm

Depth 110.4 mm

Gateway component for EtherNet_IP

24 / 25

Illustration7: Side dimensions

Technical Data

Illustration8: Front dimensions

Gateway component for EtherNet_IP 25 / 25

Loading...

Loading...