STATIONARY PARTS MANUAL

REEL AUGGIE MIXER

MODELS 3125/3130

Table of Contents

Abbreviations .................................................................................................. 2

Using This Service Parts Listing ..................................................................... 3

Front End and Subframe Parts ....................................................................... 4

Front Drive Parts ............................................................................................ 6

Chains and Tighteners .................................................................................... 8

Door Parts...................................................................................................... 9

Reel and Auger Part s - 3125 Only ................................................................ 10

Reel and Auger Part s - 3130 Only ................................................................ 12

T op Guard Parts ........................................................................................... 14

HA Y MAXX System ...................................................................................... 15

Scale Parts .................................................................................................. 16

Repair Liner Parts......................................................................................... 18

Decals.......................................................................................................... 19

Paint ............................................................................................................ 19

Hardware Part Number Listing ...................................................................... 20

Part Number Listing...................................................................................... 22

Catalog Part Number 006054 Unit Serial Number_____________

Operator Instruction Manual for this unit: 006046

© Copyright 2004 Kuhn Knight, Inc.

3125/3130ST 006054 R032504

Abbreviations

Assy . . . . . . . . . . . . . . . . . . . . . . . . . Assembly

A/R . . . . . . . . . . . . . . . . . . . . . . . . As Required

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bolt

Brg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bearing

BSN . . . . . . . . . . . . . . . . . Before Serial Number

Btm . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bottom

C-Bolt . . . . . . . . . . . . . . . . . . . . . . Carriage Bolt

Cttr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cotter

CV . . . . . . . . . . . . . . . . . . . . . Constant Velocity

Deg . . . . . . . . . . . . . . . . . . . . . . . . . . . . Degree

Dia . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diameter

ea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Each

eq or Equiv . . . . . . . . . . . . . . . . . . . . . Equivalent

Fln . . . . . . . . . . . . . . . . . . . . . Flanged Lock Nut

Fw . . . . . . . . . . . . . . . . . . . . . . . . . Flat Washer

Ga . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gauge

Gr or Grd . . . . . . . . . . . . . . . . . . . . . . . . . Grade

Hd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Head

Hfw . . . . . . . . . . . . . . . . . . . . Heavy Flat Washer

Hyd . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic

ID . . . . . . . . . . . . . . . . . . . . . . . . Inside Diameter

Ill or Illus . . . . . . . . . . . . . . . . . . . . . . Illustration

Ind . . . . . . . . . . . . . . . . . . . . . . . . . . . . Indicator

Jn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Jam Nut

Kw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Keyway

LH . . . . . . . . . . . . . . . . . . . . . . . . . . . .Left Hand

Ln . . . . . . . . . . . . . . . . . . . . . . . . . . . . Lock Nut

Lw . . . . . . . . . . . . . . . . . . . . . . . . .Lock Washer

Mtg Hrd . . . . . . . . . . . . . . . . Mounting Hardware

NC . . . . . . . . . . . . . . . . . . . . . . .National Coarse

NF . . . . . . . . . . . . . . . . . . . . . . . . .National Fine

NLA . . . . . . . . . . . . . . . . . . . No Longer Available

NPT . . . . . . . . . . . . . . . . . . National Pipe Thread

OD . . . . . . . . . . . . . . . . . . . . . Outside Diameter

Pc(s) . . . . . . . . . . . . . . . . . . . . . . . . . . Piece(s)

PD . . . . . . . . . . . . . . . . . . . . . . . Pitch Diameter

PTO . . . . . . . . . . . . . . . . . . Power Takeoff (shaft)

Qty . . . . . . . . . . . . . . . . . . . . . . . . . . . . Quantity

RH . . . . . . . . . . . . . . . . . . . . . . . . . . Right Hand

SN . . . . . . . . . . . . . . . . . . . . . . . . Serial Number

SHCS . . . . . . . . . . . . . Socket Head Cap Screw

Spk, or Spkt or Sprkt . . . . . . . . . . . . . . Sprocket

Sq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Square

SS . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel

SSB . . . . . . . . . . . . . . . . . . . Stainless Steel Bolt

St . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Straight

Std . . . . . . . . . . . . . . . . . . . . . . . . . . . . Standard

STS . . . . . . . . . . . . . . . . . . . Self Tapping Screw

UASN . . . . . . . . . . . . Used After Serial Number

UBSN . . . . . . . . . . . Used Before Serial Number

W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . With

W/O . . . . . . . . . . . . . . . . . . . . . . . . . . . With Out

2

© Copyright 2004 Kuhn Knight, Inc.

Using This Service Parts Listing

This listing uses a number indentation system to

specify the parts of an assembly . Any number which

is indented to the right, indicates that it is a component of the item to the upper left. Example:

Part no Qty Description

102-AAA # Assembly A

102-BBB # Sub-Assembly B

(Component of A)

140-xxx # Sub-Component of B

140-xxx # Sub-Component of B

102-CCC # Sub-Assembly C

(Component of A)

etc.

3125/3130ST 006054 R032504

The serial number may consist of a number, or a

number with a letter prefix. When referring to serial

number breaks in the text of this manual, a serial

number with a prefix will have been manufactured

after a serial number without a prefix (A001 made

after 0123). Likewise, a higher prefix letter would

indicate manufacture after a lower prefix letter (B001

made after A123). Therefore, if the text refers to units

manufactured after serial number B123, this would

include “B” series numbers greater than 123, and all

numbers with a higher letter prefix.

If you cannot find the part you need, be as descriptive

as possible when placing an order:

Using this system, the subassemblies and their

components are included if an Assembly is ordered.

Similarly , the components of a subassemblies are

included if a subassembly is ordered.

The quantity (Qty) associated with an assembly ,

represents the number of times an assembly

could be

shown in the drawing. The subassembly quantity

however, is the number of times a subassembly is

used to build one assembly . Similarly , the component

quantity refers to the number of times a given component is found in one subassembly .

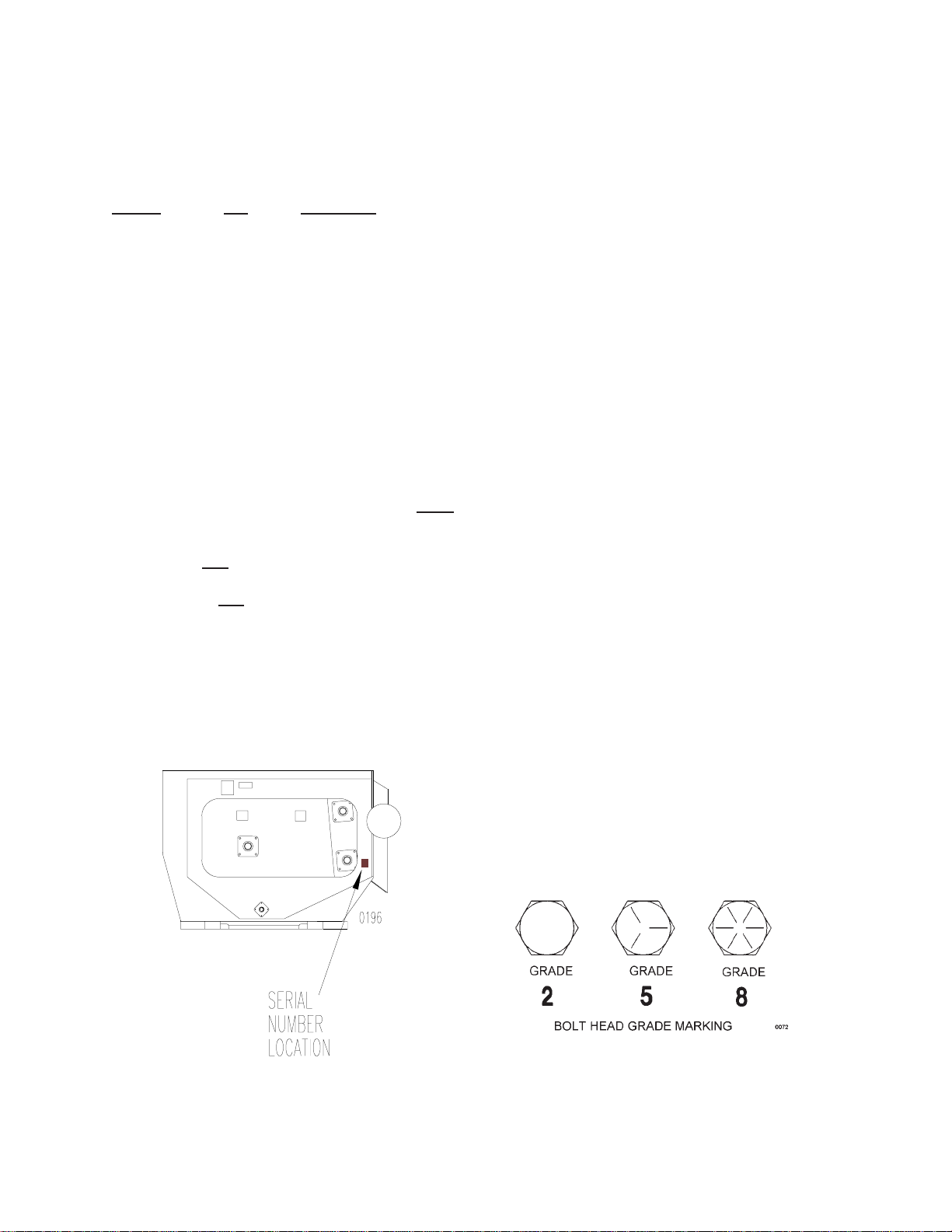

MODEL AND SERIAL NUMBER INFORMA TION i s

located near the front left hand corner (Fig. A). The

model number, serial number and p art number should

be known when asking service personnel for parts.

Sprockets: give the bore size, number of teeth,

and size of keyway.

Roller chain: give the size of chain (stamped on

the side of each link) and number

of links.

Shafting: give the diameter , length, and quantity

and size of keyways.

Hardware is generally not included with parts. If you

need any hardware, check the size, the length, and

the grade (Fig. B), then check the hardware list in this

manual for the part numbers.

All hex head bolts are grade 5, and nuts are

grade 5 unless otherwise stated.

The hardware listing also includes zerks, cotter pins,

set screws, and roller chain links.

The illustrations in this manual are meant to be

used only as a guide for identifying parts and

locating their relative positions.

Fig. A

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

Fig. B

3

3125/3130ST 006054 R032504

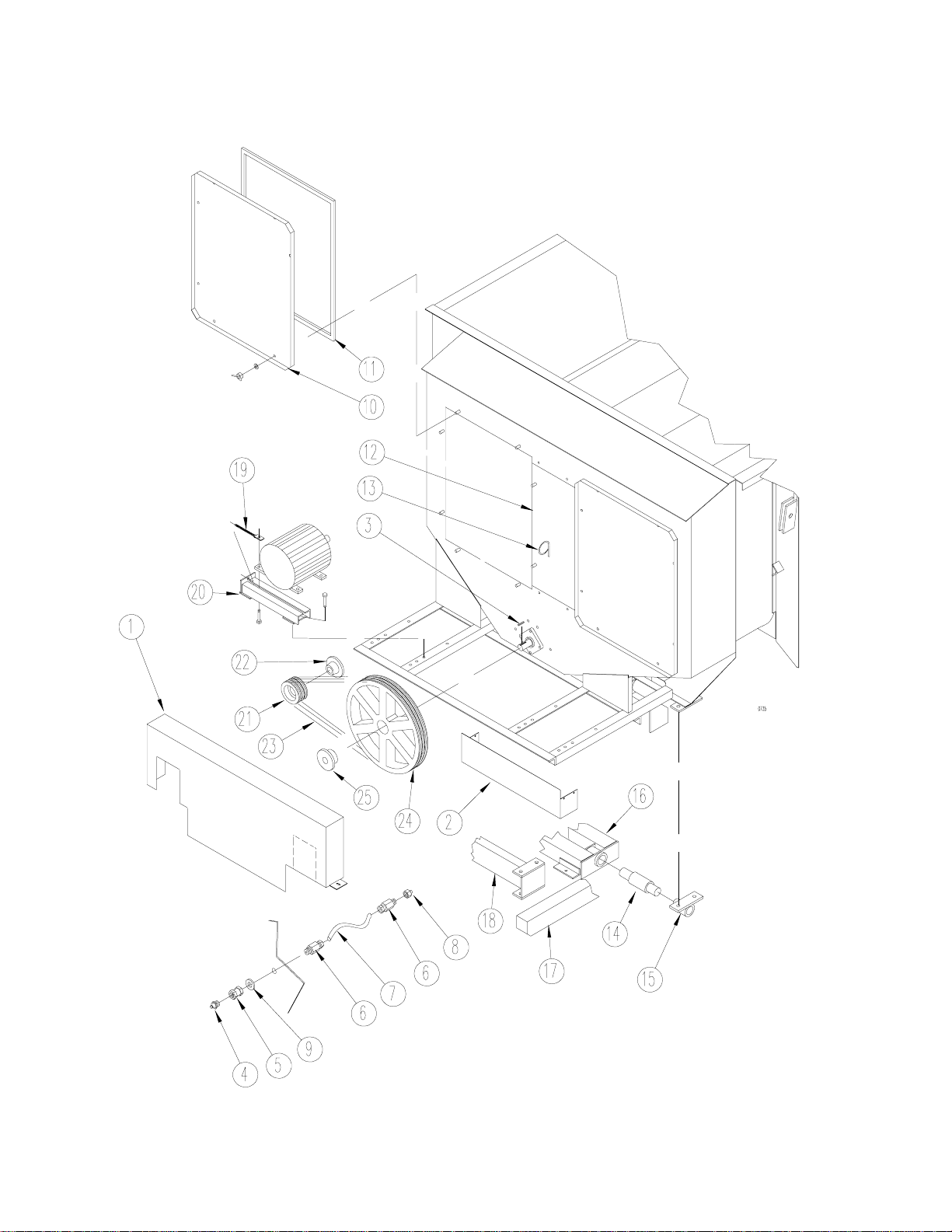

Front End and Subframe Parts

Customer

supplied

motor

4

© Copyright 2004 Kuhn Knight, Inc.

3125/3130ST 006054 R032504

Front End and Subframe Parts

REF P ART NO QT Y DESCRIPTION

1 102-550 1 Upper Shield; Mtg Hrd: 3/8" x 1 1/4" B, Fw, Lw & Nut (2 ea)

2 136-867 1 Lower Shield; Mtg Hrd: 1/4” x 3/4” B, Lw , N (4 ea) Fw (8 ea)

3 170-627 1 Key, SQ 5/16” x 1 3/4”

GREASE LINES

4 170-865 1* Grease Zerk 1/8” NPT

5 172-024 1* Coupling

6 172-822 2* Compression Fitting

7 180-630** Grease Line Tubing

18" Required for upper auger bearing

16" Required for lower auger bearing

23" Required for front reel bearing

21" Required for inner input shaft bearing

21" Required for outer input shaft bearing

8 172-823*** 1* Adapter Fitting; 1/4” SAE x 1/8” NPTF

9 170-244 1* Flat Washer 3/8"

10 136-835 2 Safety Shield; Front Drive; Mtg Hrd: 3/8" NC Wing Nut (171-929) & Fw (8ea)

1 1 171-935** 10’6” Front Shield Gasket; 3/8" x 3/4" Closed Cell Foam (QTY PER SHIELD)

12 136-837 1 Sheet, Center Panel; Mtg Hrd: 3/8” x 7/8” Bolt, Fw, Lw, N

13 134-900 1 Hose Hanger (weld on)

14 172-138* 4 Weigh Bar; 2 1/8" Dia (J-star-black finish)

173-230* 4 Weigh Bar; 2 1/8" Dia (Weigh-tronix-white finish)

15 101-742 4 Weigh Bar Mount Spool; Mtg Hrd To Unit: 5/8" x 1 3/4" Bolt, Fw & Ln (2 ea)

16 101-771 2 Weigh Bar Mount

17 171-819 2 Skid Rail; 3” x 4” x 168” (3125); Mtg Hrd: 3/8” x 4 1/2” C-Bolt, Fw, Nut

134-890 2 Skid Rail; 3” x 4” x 191 3/4” (3130); Mtg Hrd: 3/8” x 4 1/2” C-Bolt, Fw, Nut

18 101-909 2 6” Riser (for units without minus scale); Mtg Hrd; 5/8" x 1 3/4" Bolt, Fw & Ln (4 ea)

Single motor only

19 101-788 2 Jacking Bolt; Mtg Hrd: Nut, Fw (2 ea)

20 101-880 2 Motor Rail Assy; Mtg Hrd: Rail to frame: 1/2" x 1 1/2" B, Fw & Lw, Nut (2 ea)

Rail to motor: 3/8” x 1 1/2" B, Heavy Fw, Lw, (2 ea) Fw, Nut (4 ea)

21 175-308 1 Pulley 4 Groove 4.55 OD

22 172-178 1 Bushing, 1 3/8 ID (Standard on 3125 single motor only)

172-179 1 Bushing, 1 5/8 ID (Standard on 3130 single motor only)

23 172-161 4 Belt; Bx78-MBL

24 172-266 1 Pulley 4 Groove 20.35 OD

25 172-180 1 Bushing, 1 3/8 ID

Double motor only

19 101-788 4 Jacking Bolt; Mtg Hrd: Nut, Fw (2 ea)

20 101-880 4 Motor Rail Assy; Mtg Hrd: Rail to frame: 1/2" x 1 1/2" B, Fw & Lw, Nut (2 ea)

Rail to motor: 3/8” x 1 1/2" B, Heavy Fw, Lw, (2 ea) Fw, Nut (4 ea)

21 175-309 2 Pulley 3 Groove 4.55 OD

22 171-954 2 Bushing, 1 3/8 ID (Standard on all double motor)

23 172-161 4 Belt; Bx78-MBL

24 172-266 1 Pulley 4 Groove 20.35 OD

25 172-180 1 Bushing, 1 3/8 ID

Motor bushings available to fit 172-176 (motor) pulley

171-144 A/R Bushing, 1 7/8 ID

* Quantity required to complete 1 grease line assy

** Sold by the linear foot.

*** Not required on all installations

***** All (4) weigh bars must be the same type to properly function and will work with either the J-Star or Weigh-tronix indicator.

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

5

3125/3130ST 006054 R032504

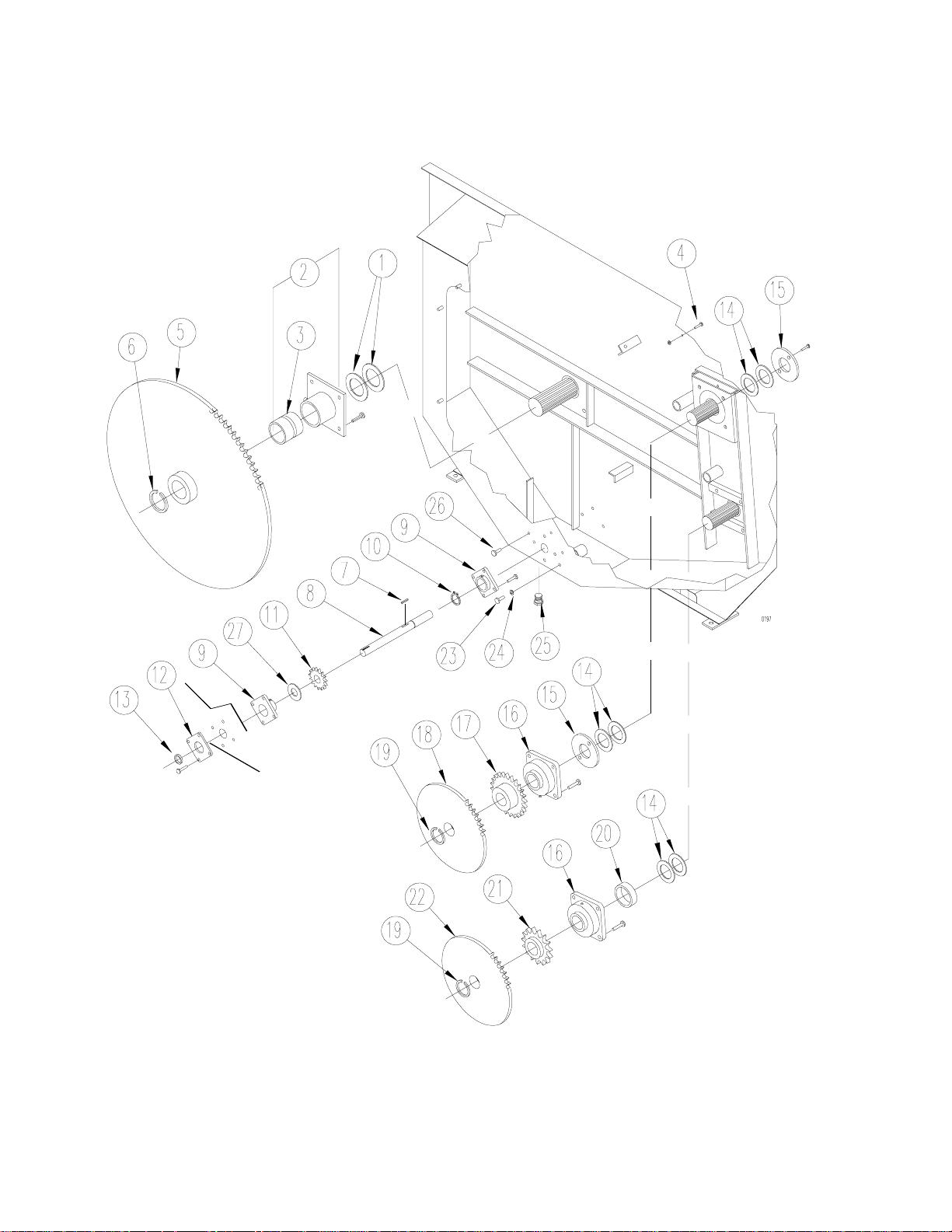

Front Drive Parts

6

© Copyright 2004 Kuhn Knight, Inc.

3125/3130ST 006054 R032504

Front Drive Parts

REF P ART NO QT Y DESCRIPTION

1 135-598 2 Seal W asher, 3 1/2” ID x 4 3/4” OD

2 102-249 1 Bearing Assembly; Mtg Hrd: 5/8" x 1 1/2" Bolt, Lw, Nut

3 135-662 1 Bushing, Straight, 3 1/2” ID

4 170-373 1 Plug, (No Hay MAXX) 1/2” x 1 1/4”, Ln

5 136-810 1 Sprocket; 100-B-100, 3 1/2" Splined Bore

6 171-607 1 Snap Ring, External; 3 1/2"

7 171-409 1 Key, SQ 3/8” x 1 1/4”

8 134-954 1 Input Shaft; 1 3/8" x 15 3/8"

9 171-585 2 Bearing; 1 3/8", Outer Bearing; Mtg Hrd: 1/2" x 1 3/4" Bolt, Lw & Nut (4 ea)

Inner Bearing Mtg Hrd: 1/2" x 1 1/2" Bolt, Lw, Fw, Nut (3 ea)

10 170-499 1 Snap Ring, External; 1 3/8"

11 133-394 1 Sprocket; 60-B-13, 1 3/8" Bore

12 136-260 1 Seal Retainer

13 173-164 1 Seal; 1.375" ID x 1.84" OD x .25" (C/R # 13536)

14 135-597 6 Seal; 3" ID x 4 1/4" OD

15 136-836 2 Seal Housing; 6” Dia; Mtg Hrd: 5/16" x 1 1/2" Bolt, Fln (2 ea)

16 170-053 2 Bearing; 2 1/2", Mtg Hrd: Upper auger: 5/8" x 2" Bolt, Lw, Nut (4 ea)

Lower auger; 5/8" x 3" Bolt, Lw, Fw , Nut (4 ea)

17 136-849 1 Sprocket; 80-B-30, 2 1/2" Splined Bore

18 136-844 1 Sprocket; 60-B-81, 2 1/2" Splined Bore

19 170-152 2 Snap Ring; External; 2 1/2"

20 136-858 1 Seal Sp acer; 3” Dia x 1” LG

21 136-850 1 Sprocket; 100-B-15, 2 1/2" Splined Bore

22 136-847 1 Sprocket; 80-B-54, 2 1/2" Splined Bore

23 170-149 1 Oil Plug, 1/2” x 1”

24 172-884 1 Washer, 1/2” Nylon

25 171-919 1 Drain Plug, 1 1/4” PVC

26 170-054 3 Plug, 3/8” x 1”, Fw, Lw, Nut

27 175-317 AR Washer, S pecial 1.38” x 2.12” x .048”

175-318 AR Washer, Special 1.38” x 2.12” x .075”

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

7

3125/3130ST 006054 R032504

Chains and Tighteners

REF PART NO QT Y DESCRIPTION

1 170-518 1 Machine Chain; #4 x 30 Links

2 172-005 1 Spring, Extension 6” LG x 1” OD

3 173-442 1 Roller Chain; 60H-1-192 Pitch, W/Connector Link

4 170-800 3 Clinch Pin, 3/16” x 1 1/2”

5 101-761 2 Chain Tightener Arm

6 134-155 2 Tightener Block; Mtg Hrd: 1/2" x 2 3/4" Bolt, Fw, Lw & Nut

7 101-818 1 Chain Tightener Arm

8 170-478 2 Machine Chain; #4 x 12 Link

9 172-751 2 Spring, Extension 8 1/4” LG x 1 1/2” OD

10 173-443 1 Roller Chain; 80H-1-88 Pitch, W/Connector Link

11 134-086 1 Tightener Block; Mtg Hrd: 1/2" x 4" Bolt, Fw, Lw & Nut

12 173-444 1 Roller Chain; 100H-1-130 Pitch, W/Connector Link

8

© Copyright 2004 Kuhn Knight, Inc.

Door Parts

3125/3130ST 006054 R032504

REF PART NO QT Y DESCRIPTION

1 102-436 1 Door Assembly; Mtg Hrd:1/4” x 1” Bolt, N, 3/8” Nut (2 ea)

2 102-086 1 Hand Wheel; Mtg Hrd:1/4” x 1 1/2” Bolt, Lw , N (2 ea)

3 102-095 1 Door Latch; Mtg Hrd: 3/8” x 2” Ln, Nut

4 136-864 1 Hand Wheel Shaft; 3/4” Dia x 21 1/2” Lg

5 135-826 1 Sprocket; 50B-10, 3/4” Bore; Mtg Hrd: 170-454;5/16” x 1 1/2” Roll Pin (1 ea)

6 170-192 1 Bushing, S traight 3/4” ID x 1” Lg

7 171-178 1 Roller Chain; 50-1-48 Pitch W/Connector Link

8 134-235 1 Sprocket; 50B-42, 1” Bore

9 170-243 2 Bushing, S traight 1” ID x 3/4” Lg

10 170-120 1 Key, Woodruff; 1/4” x 7/8”

11 171-012 2 Key, 1/4” SQ x 1 7/8”

12 130-785 2 Sprocket; 50B-12, 1” Bore

13 135-824 1 Door Shaft; 1” Dia x 39 1/4” Lg

14 171-937 2 Magnet; Mtg Hrd: 1/4” x 1” Truss Head Bolt, Fw , lw , N (6 ea)

15 136-326 2 Flow Control Plate; Mtg Hrd: 5/16" x 1" B, Lw, N (4 ea) (if adding optional, holes

must be drilled in shell if customer installed)

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

9

3125/3130ST 006054 R032504

Reel and Auger Part s - 3125 Only

10

© Copyright 2004 Kuhn Knight, Inc.

3125/3130ST 006054 R032504

Reel and Auger Part s - 3125 Only

REF PART NO QTY DESCRIPTION

1 102-535 1 Rear Panel (upper); Mtg Hrd: 5/16” x 1 B, Fw, Fln (21 ea) 1/2” x 1 1/4” B, Ln, Fw (2 ea)

2 171-919 2 Drain Plug; 1-1/4" PVC

3 102-543 1 Reel Weldment

4 102-247 1 Front Plug Assembly , 3 1/2”

5 102-251 1 Rear Plug Assembly , 2”

6 171-920 8 Spring; Reel Cross Pipe Compression, 16”LG x 2 3/8”OD

7 102-544 2 Reel Cross Pipe; Mtg Hrd: 3/8" x 5" Bolt, Lw, Nut

8 102-246 2 Cross Tube Wiper Assembly; Mtg Hrd: 3/8" x 5" Bolt, Lw, Nut

9 135-698 8 Retaining Sleeve

10 135-676 2 Plastic Wiper Blade; Long; Mtg Hrd: 1/4" x 7/8" Bolt, (171-083 Fw), Lw , Nut

1 1 135-675 4 Plastic Wiper Blade; Short; Mtg Hrd: 1/4" x 7/8" Bolt, (171-083 Fw), Lw, Nut

12 102-260 1 Bearing Assembly, 2"; Mtg Hrd: 5/8" x 1 1/4" Bolt, Lw, Nut

13 135-701 1 Plastic Sleeve

14 171-048 A/R Washer, S pecial; 2”ID x 3”OD x .081" Thick (4 max)

15 171-049 A/R Washer, S pecial; 2”ID x 3”OD x .127" Thick (4 max)

16 170-142 1 Snap Ring; 2", External

17 170-057 2 Bearing; 1 1/2", Mtg Hrd: 1/2" x 1 1/2" Bolt, Lw & Nut (4 ea)

18 102-541 1 Upper Auger Assembly

19 102-530 1 Front Plug Assembly , 2 1/2” S plined

20 102-537 1 Rear Plug Assembly, 1 1/2”

21 135-555 6 Flighting Brace, 3/8” x 1 1/2” x 5 1/2”

22 136-855 2 Flighting, RH; 14”P x 18”OD x 5 9/16ID x 3/8 THK x 53” LG

23 136-820 1 Flighting, LH; 14”P x 18”OD x 5 9/16ID x 1/4 THK x 7” LG

24 174-558 25 Knife, Sickle Section (Qty May Vary) Mtg Hrd: 5/16" x 3/4" Bolt, Lw & Nut (2 ea)

174-558 25 Optional additional Knife Sickle Section; Mtg Hrd: 5/16" x 3/4" Bolt, Lw & Nut (2 ea)

25 104-082 1 Lower Auger Assembly

26 102-531 1 Front Plug Assembly , 2 1/2” S plined

27 102-537 1 Rear Plug Assembly, 1 1/2”

28 142-185 1 Flighting, RH; 18”P x 18”OD x 5 9/16 ID x 3/8 THK x 18” LG

29 134-547 4 Auger Gusset, 1/2” x 2” x 5 3/8”

30 142-184 5 Flighting, LH; 18”P x 18”OD x 5 9/16 ID x 3/8 THK x 18” LG

31 136-817 2 Paddle

32 136-839 1 Spacer T ube; 3” x 1/4” x 1 1 1/16”

33 175-781 18 Lower Auger Knife; (Weld on)

34 174-064* 3 Scallop Knife, RH; (Used on Item 12) (Qty may vary)

174-065* 15 Scallop Knife, LH; (Used on Item 11) (Qty may vary)

35 174-093* 36 Screw, socket head, 1/2” x 1 1/2”; Mtg Hrd: 1/2” lock jam nut (Qty may vary)

*Used with Roughage Maxx option only .

1501 West 7th Ave., Brodhead, WI 53520

Kuhn Knight, Inc.

701 Cherry Ave., Greeley, CO 80632

11

3125/3130ST 006054 R032504

Reel and Auger Part s - 3130 Only

12

© Copyright 2004 Kuhn Knight, Inc.

3125/3130ST 006054 R032504

Reel and Auger Part s - 3130 Only

REF PART NO QTY DESCRIPTION

1 102-535 1 Rear Panel (upper); Mtg Hrd: 5/16” x 1” B, Fw, Fln (21 ea) 1/2” x 1 1/4” B, Ln, Fw (2 ea)

2 171-919 2 Drain Plug; 1 1/4" PVC

3 102-534 1 Reel Weldment

4 102-247 1 Front Plug Assembly, 3 1/2”

5 102-251 1 Rear Plug Assembly , 2”

6 171-920 8 Spring; Reel Cross Pipe Compression, 16” LG x 2 3/8” OD

7 102-538 2 Reel Cross Pipe; Mtg Hrd: 3/8" x 5" Bolt, Lw, Nut

8 102-253 2 Cross Tube Wiper Assembly; Mtg Hrd: 3/8" x 5" Bolt, Lw, Nut

9 135-698 8 Retaining Sleeve

10 135-677 2 Plastic Wiper Blade; Long; Mtg Hrd: 1/4" x 7/8" Bolt, (171-083 Fw), Lw , Nut

1 1 135-675 4 Plastic Wiper Blade; Short; Mtg Hrd: 1/4" x 7/8" Bolt, (171-083 Fw), Lw, Nut

12 102-260 1 Bearing Assembly, 2"; Mtg Hrd: 5/8" x 1 1/4" Bolt, Lw, Nut

13 135-701 1 Plastic Sleeve

14 171-048 A/R Washer, Special; 2”ID x 3”OD x .081" Thick (4 max)

15 171-049 A/R Washer, Special; 2”ID x 3”OD x .127" Thick (4 max)

16 170-142 1 Snap Ring; 2", External

17 170-057 2 Bearing; 1 1/2", Mtg Hrd: 1/2" x 1 1/2" Bolt, LW & Nut (4 ea)

18 102-532 1 Upper Auger Assembly

19 102-530 1 Front Plug Assembly , 2 1/2” S plined

20 102-537 1 Rear Plug Assembly , 1 1/2”

21 135-555 8 Flighting Brace, 3/8” x 1 1/2” x 5 1/2”

22 136-819 2 Flighting, RH; 14”P x 18”OD x 5 9/16ID x 3/8 THK x 65 1/2” LG

23 136-820 1 Flighting, LH; 14”P x 18”OD x 5 9/16ID x 1/4 THK x 7” LG

24 174-558 30 Knife, Sickle Section (Qty May Vary) Mtg Hrd: 5/16" x 3/4" Bolt, Lw & Nut (2 ea)

174-558 30 Knife, Sickle Section (optional) Mtg Hrd: 5/16" x 3/4" Bolt, Lw & Nut (2 ea)

25 104-083 1 Lower Auger Assembly

26 102-531 1 Front Plug Assembly , 2 1/2” S plined

27 102-537 1 Rear Plug Assembly , 1 1/2”

28 142-185 1 Flighting, RH; 18”P x 18”OD x 5 9/16ID x 3/8 THK x 18” LG

29 134-547 4 Auger Gusset, 1/2” x 2” x 5 3/8”

30 142-184 7 Flighting, LH; 18”P x 18”OD x 5 9/16ID x 3/8 THK x 18” LG (6 1/4 pitches required)

31 136-817 2 Paddle

32 136-839 1 Spacer Tube; 3” x 1/4” x 1 1 1/16”

33 175-781 22 Lower Auger Knife; (W eld on)

34 174-064* 3 Scallop Knife, RH; (Used on Item 12) (Qty may vary)

174-065* 19 Scallop Knife, LH; (Used on Item 1 1) (Qty may vary)

35 174-093* 44 Screw , socket head, 1/2” x 1 1/2”; Mtg Hrd: 1/2” lock jam nut (Qty may vary)

*Used with Roughage Maxx option only .

1501 West 7th Ave., Brodhead, WI 53520

Kuhn Knight, Inc.

701 Cherry Ave., Greeley, CO 80632

13

3125/3130ST 006054 R032504

Top Guard Parts

REF P ART NO QTY DESCRIPTION

1 136-917 1 Mounting Angle, 3125 only 2” x 2” x 123 3/4”; Mtg Hrd: 5/16" x 1" B, Fln (2 ea)

136-918 1 Mounting Angle, 3130 only 2” x 2” x 147 3/4”; Mtg Hrd: 5/16" x 1" B, Fln (2 ea)

2 134-951 11 Top Pipe, 3125 only 83” Lg; Mtg Hrd: 5/16" x 1" B, Fln (2 ea)

134-951 13 T op Pipe, 3130 only 83” Lg; Mtg Hrd: 5/16" x 1" B, Fln (2 ea)

3 134-777 6 Cross Bar , 3125 only 123 3/4” Lg; Mtg Hrd: 5/16" x 1" B, Fln (2 ea)

134-778 6 Cross Bar, 3130 only 147 3/4” Lg; Mtg Hrd: 5/16" x 1" B, Fln (2 ea)

14

© Copyright 2004 Kuhn Knight, Inc.

HAY MAXX System

3125/3130ST 006054 R032504

REF P ART NO QTY DESCRIPTION

1 102-553 1 Upper HAY MAXX Attachment; Mtg Hrd: 1/2" x 1 1/2" B, LN (5ea.), FW (8ea.)

2 102-552 1 Lower HAY MAXX Attachment; Mtg Hrd: 1/2" x 1 1/4" Bolt,FW, LN (3 ea.)

1/2" x 1 1/2" Bolt, LN (2 ea.), FW, (4 ea.)

3 134-771 5 Pivot Bushing

4 102-554 1 Haypan Backstop; Mtg Hrd: 3/4” FW, 3/16” x 2” Cotter Pin

5 102-555 1 Bucket Guard; Mtg Hrd: 1/2" x 1 1/2" B, FW, LN (1ea.)

6 102-556 1 Bucket Guard; Mtg Hrd: 1/2" x 1 1/2" B, FW, LN (1ea.)

7 134-012 2 Bucket Guard Mount; Mtg Hrd: 3/8" x 1 1/4" B, LW, Nut (2ea.)

8 174-558 50

A

Auger Knife (3125) (Quantity listed is tot al for HA Y MAXX option)

Mtg Hrd: (Knife only) 5/16" x 3/4" Bolt, L W & Nut (2 ea.)

Mtg Hrd: (Knife with back plate)5/16" x 1" Bolt, L W & Nut (2 ea. Knife)

A

60

Auger Knife (3130) (Quantity listed is total for HAY MAXX option)

Mtg Hrd: (Knife only) 5/16" x 3/4" Bolt, L W & Nut (2 ea.)

Mtg Hrd: (Knife with back plate)5/16" x 1" Bolt, L W & Nut (2 ea. Knife)

9 136-921 8 Backing Plate

10 141-533 6 Top Guard Pipe, 55-1/2”

11 141-534 1 Top Guard Pipe, 85-1/2”

A: Auger knife Quantities listed are the total number of knives needed for the HAY MAXX option. Knife quantity includes standard

factory installed knives on upper auger. Only order quantity needed to total the amount of knives listed above for a field

installation.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

Kuhn Knight, Inc.

15

3125/3130ST 006054 R032504

Scale Parts

REF PART NO QTY DESCRIPTION

1 172-128 1 Digi-Star Model EZ-2000 Basic Indicator, 1" high display

172-800 1 Digi-Star Model EZ-2000V Indicator, 1.7" high display

172-130 1 Digi-Star Model EZ-3200 Indicator, 1" high display

174-501 1 Digi-Star Model EZ-3200 Indicator (serial port), 1" high display

175-209 1 Digi-Star Model EZ-3200 Indicator (with rev counter and serial port ), 1" high display

172-500 1 Digi-Star Model EZ-3200V Indicator, 1.7" high display

174-502 1 Digi-Star Model EZ-3200V Indicator (with serial port), 1.7" high display

175-210 1 Digi-Star Model EZ-3200V Indicator (with rev counter and serial port), 1.7"high display

175-211 1 Digi-Star Model EZ-3500 Indicator (with rev counter and serial port), 1" high display

175-212 1 Digi-Star Model EZ-3500V Indicator (with rev counter and serial port), 1.7" high display

172-803 1 Digi-Star RD 2000 Remote, 1" high display w/ 25' Cord

172-801 1 Digi-Star RD 2000V Remote, 1.7" high display w/ 25’Cord

172-804 1 Digi-Star RD 2000 T/R Remote, 1" high display w/ Transmitter & 25' Cord

172-802 1 Digi-Star RD 2000V T/R Remote, 1.7" high display w/ Transmitter & 25' Cord

Mtg Hrd for Digi-Star indicators: 1/4" x 3/4" Bolt, Flat washer, Lock washer & N (2 ea)

173-225 1 Weigh-Tronix Model 615 Basic Indicator, 1" high display

173-226 1 Weigh-Tronix Model 615XL Basic Indicator, 2" high display

173-227 1 Weigh-Tronix Model 715 Indicator, 1" high display

174-503 1 Weigh-Tronix Model 715 Indicator (serial port), 1" high display

175-574 1 Weigh-Tronix Model 1040 Indicator, 1.1 high display (serial and remote ports)

175-575 1 Weigh-Tronix Model 1040 Indicator, 2" high display(speed sensor & dual serial ports)

175-576 1 Weigh-Tronix Model 1040 Indicator, (serial & remote ports) 2" high display

175-577 1 Weigh-Tronix Model 1040 Indicator (speed sensor & dual serial ports), 1.1 high display

175-045 1 Weigh-Tronix Model 2015 Indicator (with serial port), 1" high display

174-505 1 Weigh-Tronix 712 Remote, 1" high display w/ 30' Cord

174-506 1 Weigh-Tronix 712XL Remote, 2" high display w/ 30' Cord

174-507 1 Weigh-Tronix 1012 Remote, 1" high display w/ 30' Cord

175-074 1 Weigh-Tronix 1012XL Remote, 2" high display w/ 30' Cord

175-578 1 Weigh-Tronix RD64 Remote, 1.1" high display w/ 30' Cord

175-579 1 Weigh-Tronix RD64XL Remote, 2" high display w/ 30' Cord

175-595 1 Weigh-Tronix RD125RF Wireless Remote, 1" high display w/ power cord

16

© Copyright 2004 Kuhn Knight, Inc.

3125/3130ST 006054 R032504

Scale Parts

REF PART NO QTY DESCRIPTION

2 101-835 1 Indicator Mount Mtg Hrd: Spring (170-238) 3/8" x 2" Bolt, Flat washer & Lock nut

134-409 1 Remote indicator mount, Mtg Hrd: 5/16" x 3/4" Bolt,Lock washer,Nut (2 ea)

102-772 1 Angled remote indicator mount, Mtg Hrd: 5/16" x 3/4" Bolt,Lock washer,Nut (2 ea)

3 175-051 1 Digi-Star RD1000 remote mirror mount (not shown)

175-052 1 Mirror mount for Digi-Star above (not shown)

175-046 1 Weigh-Tronix 1012M remote mirror mount (not shown)

175-582 1 Weigh-Tronix RD64M remote mirror mount (not shown)

175-583 1 Mirror mount for Weigh-Tronix above (not shown)

175-569 1 Digi-Star RD1000 Wireless remote, 1" high display w/ power cord (not shown)

175-048 1 Digi-Star RF900 tranceiver for above

175-049 1 Replacement cable for RF900 tranceiver (not shown)

175-050 2 Magnet mount for above tranceiver (not shown)

4 172-183 1 Power cord assy, stationary application or unit with revolution counter

172-354 1 Power cord assy, trailer and truck application with out rev counter

172-136 1 Power supply 120 VAC input, 4-6 AMP 13.8 VDC

5 170-415 1 Plug, tractor mount

6 103-052 1 Junction Box W/15’ cable; #10 x 1" Sheet metal screw (2 ea)

173-156 1 15’ Replacement junction box cable

172-166 1 10’ Junction box extension cable (not shown)

172-165 1 30’ Junction box extension cable (not shown)

7 174-719 1 Digi-Star Remote indicator cord (not shown)

174-003 1 Digi-Star dual remote cable (not shown)

8 101-917 1 Digi-Star Alarm horn assembly Mtg Hrd: #6 x 3/4" Bolt, Lock washer, Nut (2 ea)

101-918 1 Weigh-Tronix Alarm horn assembly Mtg Hrd: #6 x 3/4" Bolt, Lock washer, Nut (2 ea)

9 172-143 1 Digi-Star D-22A hand held transmitter (Installed Receiver is Required)

174-926 1 Digi-Star DXT-21 hand held transmitter (Installed Receiver is Required)

172-350 1 Weigh-tronix hand held transmitter (Installed Receiver is Required)

10 175-626 1 Weigh-Tronix printer (not shown)

175-627 1 Weigh-Tronix printer data cord (not shown)

175-628 1 Weigh-Tronix printer paper 1 roll (not shown)

174-000 1 Digi-Star printer (not shown)

174-002 1 Digi-Star printer power cord (not shown)

174-001 1 Digi-Star printer data cord (not shown)

174-004 1 Digi-Star printer paper 1 roll (not shown)

11 173-211 4 Contact pin

12 173-212 4 Contact socket

173-216 1 Pin extraction tool (not shown)

13 173-213 1 Power cord connector

174-923 1 Nut, connector

14 173-214 1 Strain relief

15 173-215 1 Junction box cord connector

174-923 1 Nut, connector

16 173-217 1 Power connector chassis

17 173-218 1 Seal for power connector chassis

18 173-219 1 Load cell connector chassis

19 171-158 1 Battery box (not shown)

20 171-380 2 Battery terminals (not shown)

21 171-936 1 Battery hold-down strap (not shown)

22 132-988 1 16 Ga. Ground (not shown)

23 172-386 1 Precision calibrator for scale indicators (not shown)

24 171-960 1 Cord splice kit (not shown)

Refer to subframe or undercarriage mounting section for weigh bars or load cells for your specific application.

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

17

3125/3130ST 006054 R032504

Repair Liner Parts

REF PART NO QTY DESCRIPTION

Hot Roll Steel Stainless Steel

1 136-889 136-890 2 Reel Liner (3125 only)

136-873 136-874 2 Reel Liner (3130 only)

2 136-887 136-888 2 Auger Liner (3125 only)

136-881 136-882 2 Auger Liner (3130 only)

3 136-883 136-884 2 Reel End Liner

4 136-875 136-876 1 Auger End Liner (Front)

5 136-877 136-878 1 Auger End Liner (Lower Rear)

6 136-879 136-880 1 Auger End Liner (Upper Rear)

7 136-885 136-886 1 Rear Upper Liner

8 134-705 136-891 1 Front Upper Liner

9 134-716 134-980 1 Door Opening Liner

18

© Copyright 2004 Kuhn Knight, Inc.

Decals

The following decals are listed below for your convenience.

Use the operator’s manual for decal location, part number and ordering.

Unit Decals:

P ART NO QT Y DESCRIPTION

175-439 1 Complete Set Of Decals For 3125

175-442 1 Complete Set Of Decals For 3130

170-849 2 WARNING - Stay Clear Of . . .

171-712 1 NOTICE - Retighten Set Screws . . .

171-748 1 Door Gauge

171-820 4 DANGER - Rotating Auger Inside . . .

171-91 1 1 NOTICE - Operating Precautions

171-913 1 WARNING - Do Not Operate . . .

171-915 2 DANGER - Shield Missing . . .

171-947 4 DANGER - Do Not Hand Load . . .

171-948 1 BEWARE - If Mixer . . .

171-949 1 “U.S. Patent No. . . .”

172-292 1 Mixer Full Line

172-786 1 DANGER - Rotating Parts . . .

172-820 1 WARNING - Lifting Instructions . . .

172-883 1 Oil Level Plug

173-040 1 CAUTION PTO Operation. . .

173-044 1 Made in Wisconsin. . .

173-078 1 DANGER Shield Missing. . .

175-414 2 “3125”

175-415 2 “3130”

173-447 2 “REEL AUGGIE”

173-448 9ft Stripe For 3125 Only

13ft Stripe For 3130 Only

174-514 3 “KUHN KNIGHT”

175-519 1 WARNING , Rotating Driveline

175-782 2 Roughage Maxx (Optional)

174-556 1 HAY MAXX System (Optional)

3125/3130ST 006054 R032504

Paint

170-366 Kuhn Knight Yellow Aerosol Can

170-812 Kuhn Knight Yellow Quart Can

170-813 Kuhn Knight Yellow Gallon Can

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

Kuhn Knight, Inc.

19

3125/3130ST 006054 R032504

Hardware Part Number Listing

All fasteners are NC thread, Grade 5 unless otherwise specified.

HEX HEAD BOLTS

Size .............................................. Part No

1/4 x 1/2 .....................................173-279

1/4 x 3/4 .....................................170-803

1/4 x 7/8 .....................................171-094

1/4 x 1 ........................................170-310

1/4 x 1-1/2 ..................................170-068

1/4 x 2 ........................................172-986

1/4 x 2 (Grade 8) .......................175-073

1/4 x 2-3/4 ..................................171-203

1/4 x 3 ........................................171-403

1/4 x 3 1/2 ..................................173-640

1/4 x 4 ........................................173-505

5/16 x 5/8 ...................................170-532

5/16 x 3/4 ...................................170-262

5/16 x 3/4 (Stainless steel) .......174-787

5/16 x 7/8 ...................................170-256

5/16 x 1 ......................................170-027

5/16 x 1-1/4 (Full thread) ..........170-188

5/16 x 1-1/2 ................................170-372

5/16 x 1-3/4 ................................170-263

5/16 x 2 ......................................172-987

5/16 x 2-1/2 ................................170-369

5/16 x 3 ......................................170-295

5/16 x 3-1/4 ................................171-639

5/16 x 3-1/2 ................................173-748

5/16 x 4 ......................................170-293

5/16 x 4-1/2 ................................170-294

5/16 x 5 (Grade 8) .....................172-983

5/16 x 5-1/2 (Grade 8) ...............172-952

3/8 x 3/4 .....................................170-439

3/8 x 3/4 (Stainless steel) .........174-788

3/8 x 7/8 .....................................170-268

3/8 x 7/8 (soc. hd.capscrew)...172-044

3/8 x 1 ........................................170-054

3/8 x 1-1/4 ..................................170-005

3/8 x 1-1/4 (Stainless steel)......174-917

3/8 x 1-1/2 ..................................170-368

3/8 x 1-3/4 ..................................172-383

3/8 x 2 ........................................170-245

3/8 x 2-1/4 ..................................170-320

3/8 x 2-1/2 ..................................170-257

3/8 x 2-1/2 (Full thread) ............170-128

3/8 x 2-1/2 (Lag) ........................171-775

3/8 x 3 ........................................170-380

3/8 x 3-1/2 ..................................170-292

3/8 x 4 ........................................170-877

3/8 x 4-1/4 (Black oxide)...........171-813

3/8 x 4-1/2 ..................................170-519

3/8 x 5 ........................................170-493

3/8 x 5-1/2 ..................................174-196

3/8 x 5-1/2 (Full thread) ............170-593

3/8 x 6 ........................................174-304

3/8 x 6-1/2 ..................................171-291

3/8 x 7 ........................................172-587

7/16 x 3/4 ...................................170-265

7/16 x 1 ......................................170-032

7/16 x 1-1/4 ................................170-354

7/16 x 1-1/4 (Grade 8) ...............174-216

7/16 x 1-1/2 ................................170-059

7/16 x 2 ......................................170-356

7/16 x 2-1/2 ................................170-379

7/16 x 3 ......................................170-270

7/16 x 5-1/2 ................................170-377

7/16 x 6 ......................................170-378

1/2 x 3/4 .....................................171-252

1/2 x 1 ........................................170-149

1/2 x 1-1/4 ..................................170-373

20

1/2 x 1-1/2 ..................................170-002

1/2 x 1-1/2 (Grade 8) .................172-951

1/2 x 1 3/4 ..................................171-774

1/2 x 2 ........................................171-802

1/2 x 2-1/4 ..................................172-387

1/2 x 2-1/2 ..................................170-885

1/2 x 2-1/2 (Full thread) ............171-099

1/2 x 2-3/4 ..................................172-007

1/2 x 3 ........................................170-168

1/2 x 3 1/2 ..................................170-167

1/2 x 3-1/2 (Grade 8) .................172-950

1/2 x 4 ........................................ 173-111

1/2 x 4 (Full thread) ...................171-509

1/2 x 5 ........................................171-412

1/2 x 6 ........................................173-506

1/2 x 6 (Grade 8) .......................174-944

1/2 x 6-1/2 .................................. 173-711

1/2 x 7 ........................................174-328

1/2 x 7-1/2 ..................................175-107

1/2 x 8-1/2 ..................................170-504

1/2 x 11 .......................................170-506

9/16 x 1 ......................................173-699

9/16 x 1-1/4 ................................173-700

9/16 x 1-1/2 ................................173-701

9/16 x 2 ......................................172-219

5/8 x 1 ........................................171-087

5/8 x 1-1/4 ..................................171-366

5/8 x 1-1/2 ..................................170-153

5/8 x 1-3/4 (Full thread) ............170-030

5/8 x 2 ........................................170-009

5/8 x 2 (Full thread) ...................171-772

5/8 x 2-1/4 ..................................173-009

5/8 x 2-1/2 ..................................172-381

5/8 x 2-1/2 (Full thread) ............170-129

5/8 x 2-3/4 ..................................172-356

5/8 x 3 ........................................170-258

5/8 x 3-1/2 ..................................170-038

5/8 x 4 ........................................170-371

5/8 x 4-1/2 ..................................170-067

5/8 x 5 ........................................170-065

5/8 x 5-1/2 ..................................172-421

5/8 x 6 ........................................170-381

5/8 x 6-1/2 ..................................173-777

5/8 x 7-1/2 ..................................173-019

5/8 x 9-1/2 ..................................171-039

3/4 x 1-1/2 ..................................173-507

3/4 x 2 ........................................171-768

3/4 x 2 (Full thread) ...................170-058

3/4 x 2 (Grade 8) .......................171-877

3/4 x 2-1/4 ..................................171-275

3/4 x 2-1/2 ..................................170-374

3/4 x 2-1/2 (Grade 8) .................175-055

3/4 x 3 ........................................170-014

3/4 x 3 UNF.................................173-776

3/4 x 3-1/2 ..................................170-195

3/4 x 3-1/2 (Grade 8) .................171-899

3/4 x 4 ........................................170-419

3/4 x 4 (Grade 8) UNF ............... 173-579

3/4 x 4-1/2 ..................................170-846

3/4 x 4-1/2 (Grade 8) .................173-039

3/4 x 4-1/2 (Grade 8) UNF ........173-588

3/4 x 5 ........................................173-508

3/4 x 5 UNF.................................173-510

3/4 x 5-1/2 (Grade 8) UNF ........173-514

3/4 x 6 ........................................ 171-116

3/4 x 6 UNF................................. 173-511

3/4 x 6 (Grade 8) .......................173-231

3/4 x 7 ........................................173-745

© Copyright 2004 Kuhn Knight, Inc.

3/4 x 7 UNF.................................173-747

3/4 x 7-1/2 ..................................175-004

3/4 x 8 ........................................173-509

7/8 x 2-1/4 ..................................172-892

7/8 x 3 ........................................172-002

7/8 x 3-1/2 ..................................173-020

7/8 x 4 ........................................173-299

7/8 x 4 UNF.................................171-092

7/8 x 6-1/2 ..................................173-774

7/8 x 7 ........................................173-749

7/8 x 7 UNF.................................174-097

7/8 x 8 ........................................173-750

7/8 x 8 UNF.................................173-515

1 x 3-1/2 .....................................173-021

1 x 4 ............................................ 175-119

1 x 4 (Grade 8) ..........................175-248

1 x 7 UNF .................................... 173-516

1 x 8 ............................................174-723

1 x 8 (grade 8) UNF ...................173-713

1-1/4 x 4-1/2 (grade 8) ..............175-003

M8 x 16MM (Grade 8.8).............174-610

M8 x 20MM (Grade 8.8).............175-193

M8 x 25MM (Grade 8.8).............174-900

M10 x 22MM (Grade 8.8)...........175-016

M10 x 25MM (Grade 8.8)...........173-344

M12 x 25MM (Grade 8.8)...........171-566

M12 x 35MM (Grade 8.8)...........175-020

M12 x 40MM (Grade 12.9).........175-190

M12 x 45MM (Grade 10.9)......... 174-911

M14 x 30MM (Grade 8.8)...........173-518

SELF TAPPING SCREW

1/4 x 3/4 .....................................174-874

CARRIAGE BOLTS

1/4 x 1-1/4 (Grade 2) ................. 170-311

1/4 x 1-1/2 (Grade 2) .................170-355

1/4 x 2 (Grade 2) .......................170-299

1/4 x 2-1/2 (Grade 2) .................171-394

1/4 x 2-3/4 (Grade 2) .................170-508

1/4 x 3 ........................................170-509

5/16 x 1 (Grade 2) .....................170-370

5/16 x 1-1/2 (Grade 2) ...............170-296

5/16 x 2-1/2 (Grade 2) ...............171-395

5/16 x 5-1/2 (Grade 2) ...............170-494

3/8 x 3-1/2 (Grade 2) .................171-283

3/8 x 4-1/2 (Grade 2) .................170-191

3/8 x 5 (Grade 2) .......................170-495

3/8 x 6-1/2 (Grade 2) .................171-174

3/8 x 8 (Grade 2) .......................170-297

3/8 x 13 (Grade 2) .....................170-298

3/8 x 13-1/2 (Grade 2) ...............170-300

1/2 x 1-1/2 (Grade 5) .................174-918

1/2 x 6-1/2 (Grade 2) .................171-098

1/2 x 9 (Grade 2) .......................171-255

5/8 x 2 ........................................ 175-110

5/8 x 2-1/2 (Grade 5) .................174-790

PLOW BOLTS

5/8 x 2 ........................................174-767

3/4 x 2-1/2 ..................................174-948

TRUSS HEAD BOLTS

#6-32 x 3/4 ................................. 172-416

#6-32 x 1 ....................................173-079

#8-32 x 1-1/2 ..............................171-210

#10-32 x 3/4 ............................... 171-604

#10-32 x 1 ..................................172-882

1/4 x 3/4 .....................................170-193

1/4 x 1 ........................................170-194

5/16 x 1 ...................................... 170-117

Hardware Part Number Listing

3125/3130ST 006054 R032504

SET SCREWS (Socket Head)(Cup

Point)

1/4 x 1/4 ...................................170-247

1/4 x 5/8 ...................................172-985

5/16 x 1/4 .................................170-993

5/16 x 5/16 ...............................170-248

5/16 x 5/16 UNF .......................170-825

5/16 x 3/8 UNF .........................173-367

5/16 x 1/2 .................................170-254

5/16 x 5/8 UNF .........................170-456

5/16 x 1 (Sq hd).......................173-610

5/16 x 1-1/2 ..............................172-917

3/8 x 1/4 ...................................170-856

3/8 x 3/8 ...................................170-151

3/8 x 1/2 ...................................170-857

3/8 x 1/2 UNF............................171-469

3/8 x 3/4 ...................................174-190

3/8 x 3/4 (Sq hd)......................170-290

3/8 x 1 ......................................170-021

3/8 x 1 (Sq hd) .........................173-609

3/8 x 1 (Sq hd) (Dog pt) 171-551

7/16 x 7/16 ...............................170-288

7/16 x 1 (Sq hd).......................170-147

1/2 x 5/8 ...................................170-249

1/2 x 1 ......................................170-438

1/2 x 1-1/4 (half dog point) .....171-085

5/8 x 5/8 ...................................170-250

3/4 x 3/4 (Sq hd) (Dog pt) .......170-251

HEX NUTS

#6-32 ..........................................172-418

#10-32 ........................................171-606

1/4 ...............................................170-125

5/16 ............................................. 170-119

3/8 ...............................................170-007

7/16 .............................................170-062

7/16 (Grade 8) UNF ...................174-217

1/2 ...............................................170-004

9/16 .............................................173-702

5/8 ............................................... 170-011

3/4 ...............................................170-017

3/4 UNF.......................................170-159

3/4 (Grade 8) UNF .....................173-520

7/8 ...............................................171-776

1 ..................................................173-022

1 UNF ..........................................173-714

1 (Grade 8) .................................175-247

1 (Grade 8) UNF ........................173-519

1-1/8 UNF ...................................174-095

1-1/4 UNF ...................................170-130

1-1/4 (Grade 8) ..........................175-006

M8 x 1.25MM ..............................172-949

M30 x 1.5MM ..............................174-902

M50 x 1.5MM ..............................175-200

LOCK NUTS

#6-32 ..........................................174-188

#10-32 ........................................174-073

1/4 ...............................................170-069

5/16 .............................................170-137

3/8 ...............................................170-047

7/16 .............................................170-239

1/2 ...............................................170-042

1/2 UNF.......................................170-566

1/2 (Grade 8) ..............................171-671

9/16 .............................................172-220

5/8 ...............................................170-031

3/4 ...............................................170-185

3/4 (Grade 8) ..............................171-900

3/4 (Grade 8) UNF .....................173-578

7/8 ...............................................173-069

7/8 UNF.......................................171-093

1 ..................................................174-928

1 UNF ..........................................170-527

M45 x 1.5MM ..............................175-199

M50 x 1.5MM ..............................175-197

JAM NUTS

1/4UNF........................................171-386

5/16 .............................................173-521

3/8 ...............................................170-022

7/16 .............................................170-046

1/2 ...............................................170-036

5/8 ...............................................170-037

3/4 ...............................................170-035

1 ..................................................174-927

FLAT WASHERS

#10 ..............................................171-525

1/4 ...............................................170-301

1/4 Heavy ...................................171-083

1/4 Fender ..................................173-672

5/16 .............................................170-127

5/16 Fender ................................ 173-811

3/8 ...............................................170-244

3/8 Heavy ...................................170-302

3/8 Aluminum ..............................173-900

7/16 .............................................170-138

1/2 ...............................................170-040

1/2 (Grade 8) ..............................172-984

9/16 .............................................173-693

5/8 ...............................................170-066

5/8 (Grade 8) ..............................173-581

3/4 ...............................................170-015

7/8 ...............................................173-298

7/8 Heavy ...................................170-131

1 ..................................................170-122

1-1/4............................................170-928

LOCK WASHERS

#6 ................................................172-417

#10 ..............................................171-605

1/4 ...............................................170-124

5/16 ............................................. 170-118

3/8 ...............................................170-006

7/16 .............................................170-061

1/2 ...............................................170-003

9/16 .............................................173-692

5/8 ...............................................170-010

3/4 ...............................................170-016

3/4 External Tooth ......................174-793

7/8 ...............................................172-003

1 ..................................................171-021

1-1/4............................................175-005

ZERKS

1/8 NPT .......................................170-865

1/8 NPT-45 Deg ..........................170-864

1/8 NPT-65 Deg ..........................170-215

1/8 NPT-90 Deg ..........................170-866

3/16 drive in................................174-124

1/4-28 .........................................170-023

1/4-28 - 45 Deg..........................170-148

1/4-28 - 90 Deg..........................170-049

1/4 NPT .......................................170-277

1/4 NPT - 45 Deg........................174-130

COTTER PINS

1/16 x 1/2 .................................170-992

3/32 x 3/4 .................................170-364

1/8 x 1 ......................................170-045

1/8 x 1-1/4 ................................170-033

1/8 x 1-1/2 ................................170-382

5/32 x 1 ....................................170-421

5/32 x 1-1/2 ..............................170-236

5/32 x 3 ....................................170-135

3/16 x 1-1/4 ..............................170-991

3/16 x 2 .................................... 170-115

1/4 x 1-1/2 ................................170-521

1/4 x 2 ......................................170-056

1/4 x 2-1/2 ................................173-961

ROLLER CHAIN

CONNECTOR LINKS

#50 ............................................170-088

#50-2R......................................170-094

#60 ............................................170-089

#60-2R......................................170-095

#60H..........................................171-102

#80 ............................................170-090

#80H..........................................170-821

#100 ..........................................170-091

#100H .......................................171-969

#120 ..........................................170-092

#140 ..........................................170-093

#140H .......................................173-552

#160 ..........................................170-888

OFFSET LINKS

#50 ............................................170-096

#50-2R......................................170-102

#60 ............................................170-097

#60-2R......................................170-103

#60H..........................................171-103

#80 ............................................170-098

#80H..........................................170-820

#100 ..........................................170-099

#100H .......................................172-145

#120 ..........................................170-100

#140 ..........................................170-101

#140H .......................................173-553

#160 ..........................................170-887

ROLLER LINKS

#50 ............................................171-415

#60 ............................................171-416

#80 ............................................171-417

#80H..........................................170-795

#100 ..........................................171-418

#100H .......................................172-146

#120 ..........................................171-419

#140 ..........................................171-420

#160 ..........................................171-421

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

21

3125/3130ST 006054 R032504

Part Number Listing

101-742 ...5

101-761 ...8

101-771 ...5

101-788 ...5

101-818 ...8

101-835 ...17

101-880 ...5

101-909 ...5

101-917 ...17

101-918 ...17

102-086 ...9

102-095 ...9

102-246 ...11

102-247 ...11, 13

102-249 ...7

102-251 ...11, 13

102-253 ...13

102-260 ...11, 13

102-436 ...9

102-530 ...11, 13

102-531 ...11, 13

102-532 ...13

102-534 ...13

102-535 ...11, 13

102-537 ...11, 13

102-538 ...13

102-541 ...11

102-543 ...11

102-544 ...11

102-550 ...5

102-552 ...15

102-553 ...15

102-554 ...15

102-555 ...15

102-556 ...15

102-772 ...17

103-052 ...17

104-082 ...11

104-083 ...13

130-785 ...9

132-988 ...17

133-394 ...7

134-012 ...15

134-086 ...8

134-155 ...8

134-235 ...9

134-409 ...17

134-547 ...11, 13

134-705 ...18

134-716 ...18

134-771 ...15

134-777 ...14

134-778 ...14

134-890 ...5

134-900 ...5

134-951 ...14

134-954 ...7

134-980 ...18

135-555 ...11, 13

135-597 ...7

135-598 ...7

135-662 ...7

135-675 ...11, 13

135-676 ...11

135-677 ...13

135-698 ...11, 13

135-701 ...11, 13

135-824 ...9

135-826 ...9

136-260 ...7

136-326 ...9

136-810 ...7

136-817 ...11, 13

136-819 ...13

136-820 ...11, 13

136-835 ...5

136-836 ...7

136-837 ...5

136-839 ...11, 13

136-844 ...7

136-847 ...7

136-849 ...7

136-850 ...7

136-855 ...11

136-858 ...7

136-864 ...9

136-867 ...5

136-873 ...18

136-874 ...18

136-875 ...18

136-876 ...18

136-877 ...18

136-878 ...18

136-879 ...18

136-880 ...18

136-881 ...18

136-882 ...18

136-883 ...18

136-884 ...18

136-885 ...18

136-886 ...18

136-887 ...18

136-888 ...18

136-889 ...18

136-890 ...18

136-891 ...18

136-917 ...14

136-918 ...14

136-921 ...15

141-533 ...15

141-534 ...15

142-184 ...11, 13

142-185 ...11, 13

170-053 ...7

170-054 ...7

170-057 ...11, 13

170-120 ...9

170-142 ...11, 13

170-149 ...7

170-152 ...7

170-192 ...9

170-238 ...17

170-243 ...9

170-244 ...5

170-366 ...19

170-373 ...7

170-415 ...17

170-478 ...8

170-499 ...7

170-518 ...8

170-627 ...5

170-800 ...8

170-812 ...19

170-813 ...19

170-849 ...19

170-865 ...5

171-012 ...9

171-048 ...11, 13

171-049 ...11, 13

171-144 ...5

171-158 ...17

171-178 ...9

171-380 ...17

171-409 ...7

171-585 ...7

171-607 ...7

171-712 ...19

171-748 ...19

171-819 ...5

171-820 ...19

171-911 ...19

171-913 ...19

171-915 ...19

171-919 ...7, 11, 13

171-920 ...11, 13

171-935 ...5

171-936 ...17

171-937 ...9

171-947 ...19

171-948 ...19

171-949 ...19

171-954 ...5

171-960 ...17

172-005 ...8

172-024 ...5

172-128 ...16

172-130 ...16

172-136 ...17

172-138 ...5

172-143 ...17

172-161 ...5

172-165 ...17

172-166 ...17

172-178 ...5

172-179 ...5

172-180 ...5

172-183 ...17

172-266 ...5

172-292 ...19

172-350 ...17

172-354 ...17

172-386 ...17

172-500 ...16

172-751 ...8

172-786 ...19

172-800 ...16

172-801 ...16

172-802 ...16

172-803 ...16

172-804 ...16

172-820 ...19

172-822 ...5

172-823 ...5

172-883 ...19

172-884 ...7

173-040 ...19

173-044 ...19

173-078 ...19

173-156 ...17

173-164 ...7

173-211 ...17

173-212 ...17

173-213 ...17

173-214 ...17

173-215 ...17

173-216 ...17

173-217 ...17

173-218 ...17

173-219 ...17

173-225 ...16

173-226 ...16

173-227 ...16

173-442 ...8

173-443 ...8

173-444 ...8

173-445 ...19

173-446 ...19

173-447 ...19

173-448 ...19

174-000 ...17

174-001 ...17

174-002 ...17

174-003 ...17

174-004 ...17

174-064 ...11, 13

174-065 ...11, 13

174-093 ...11, 13

174-501 ...16

174-502 ...16

174-503 ...16

174-505 ...16

174-506 ...16

174-507 ...16

174-514 ...19

174-558 ...11, 13, 15

174-647 ...19

174-719 ...17

174-923 ...17

174-926 ...17

175-045 ...16

175-046 ...17

175-048 ...17

175-049 ...17

175-050 ...17

175-051 ...17

175-052 ...17

175-074 ...16

175-209 ...16

175-210 ...16

175-211 ...16

175-212 ...16

175-308 ...5

175-309 ...5

175-317 ...7

175-318 ...7

175-569 ...17

175-574 ...16

175-575 ...16

175-576 ...16

175-577 ...16

175-578 ...16

175-579 ...16

175-582 ...17

175-583 ...17

175-595 ...16

175-626 ...17

175-627 ...17

175-628 ...17

175-781 ...11, 13

180-630 ...5

22

© Copyright 2004 Kuhn Knight, Inc.

Loading...

Loading...