Kuhn Rikon 3115 User Manual

TT

rr

ailer Pailer P

T

r

ailer P

TT

rr

ailer Pailer P

arar

ts Mants Man

ar

ts Man

arar

ts Mants Man

andand

and

andand

ualual

ual

ualual

StaSta

Sta

StaSta

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using This Service Parts Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front End Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sprockets, Chains and Tighteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Stationary Motor Mount Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

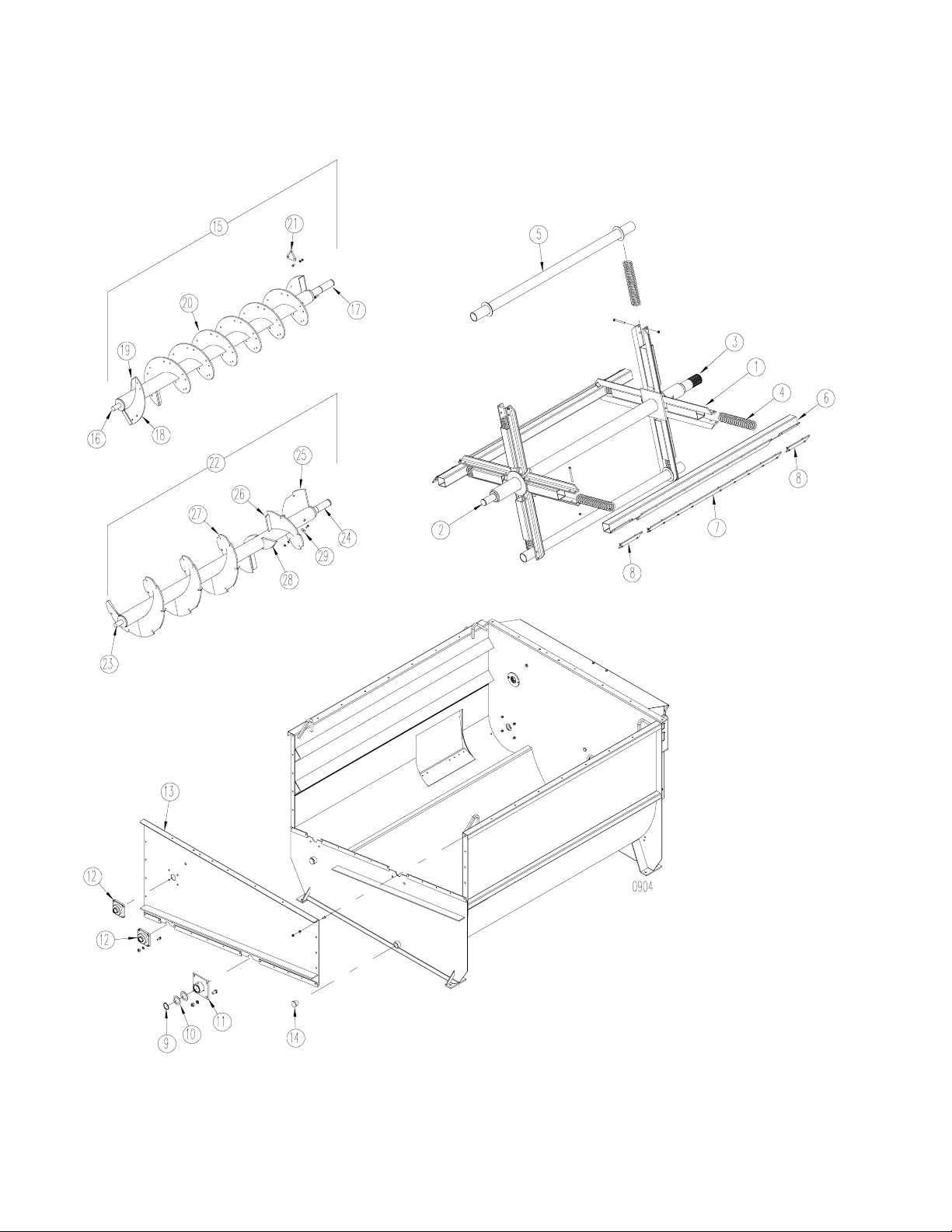

Reel and Auger Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bucket Guard Parts - Trailer Type Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Top Grid Parts - Stationary Type Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hydraulic Door Parts - Trailer Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Door Parts - Stationary Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Electric Door Parts - Stationary Type (Optional) . . . . . . . . . . . . . . . . . . . . . 16

Slide Tray Parts - Trailer Type (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjustable Slide Tray Parts - Optional Trailer Type . . . . . . . . . . . . . . . . . . . 18

Selector Valve Parts - Trailer Type (Optiopnal) . . . . . . . . . . . . . . . . . . . . . . 19

Undercarriage Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Scale Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PTO Driveline - 540 RPM - 6 Spline - 1-3/8” Yoke . . . . . . . . . . . . . . . . . . . 24

Jackstand Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

HAY MAXX System (Stationary Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Repair Liner Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Optinal Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hardware Part Number Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Part Number Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

tionartionar

tionar

tionartionar

REEL REEL

REEL

REEL REEL

Models 3Models 3

Models 3

Models 3Models 3

*Serial Number A0029 and After

y* Py* P

y* P

y* Py* P

AA

UGGIE MIXERSUGGIE MIXERS

A

UGGIE MIXERS

AA

UGGIE MIXERSUGGIE MIXERS

Table of Contents

arar

ts Mants Man

ar

ts Man

arar

ts Mants Man

11

1

11

1515

15

1515

ualual

ual

ualual

Catalog Part Number 06050 Unit Serial Number_____________

Operator’s Instruction Manual for this unit: 006047

© Copyright Kuhn Farm Machinery, Inc. Vernon, NY 13476 – USA

3115TS 006050 R051205

Abbreviations

Assy .................................................... Assembly

A/R .................................................. As Required

B ................................................................... Bolt

Brg........................................................... Bearing

BSN ................................... Before Serial Number

Btm .......................................................... Bottom

C-Bolt ............................................. Carriage Bolt

Cttr ............................................................. Cotter

CV ........................................... Constant Velocity

Deg .......................................................... Degree

Dia ........................................................ Diameter

ea ............................................................... Each

eq or Equiv .......................................... Equivalent

Fln ........................................... Flanged Lock Nut

Fw.................................................... Flat Washer

Ga............................................................. Gauge

Gr or Grd .................................................... Grade

Hd ............................................................... Head

Hfw ......................................... Heavy Flat Washer

Hyd ....................................................... Hydraulic

ID ................................................ Inside Diameter

Ill or Illus ............................................. Illustration

Ind .......................................................... Indicator

Jn ........................................................... Jam Nut

Kw .......................................................... Keyway

LH ......................................................... Left Hand

Ln ......................................................... Lock Nut

Lw ................................................... Lock Washer

Mtg Hrd ..................................Mounting Hardware

NC .............................................. National Coarse

NF................................................... National Fine

NLA ...................................... No Longer Available

NPT .................................... National Pipe Thread

OD ........................................... Outside Diameter

Pc(s) ...................................................... Piece(s)

PD ............................................... Pitch Diameter

PTO .................................... Power Takeoff (shaft)

Qty ......................................................... Quantity

RH ..................................................... Right Hand

SN ................................................ Serial Number

SHCS ........................... Socket Head Cap Screw

Spk, or Spkt or Sprkt ............................ Sprocket

Sq ............................................................ Square

SS ............................................... Stainless Steel

SSB ..................................... Stainless Steel Bolt

St ............................................................ Straight

Std ........................................................ Standard

STS ....................................... Self Tapping Screw

UASN .......................... Used After Serial Number

UBSN ....................... Used Before Serial Number

W ................................................................. With

W/O ...................................................... With Out

2

© Copyright 2005 Kuhn Knight, Inc.

Back to Table of Contents

Using This Service Parts Listing

This listing uses a number indentation system to

specify the parts of an assembly.Any number which

is indented to the right, indicates that it is a component of the item to the upper left. Example:

Part no Qty Description

102-AAA # Assembly A

102-BBB # Sub-Assembly B

(Component of A)

140-xxx # Sub-Component of B

140-xxx # Sub-Component of B

102-CCC # Sub-Assembly C

(Component of A)

etc.

3115TS 006050 R051205

The serial number may consist of a number, or a

number with a letter prefix. When referring to serial

number breaks in the text of this manual, a serial

number with a prefix will have been manufactured

after a serial number without a prefix (A001 made

after 0123). Likewise, a higher prefix letter would

indicate manufacture after a lower prefix letter (B001

made after A123). Therefore, if the text refers to

units manufactured after serial number B123, this

would include “B” series numbers greater than 123,

and all numbers with a higher letter prefix.

If you cannot find the part you need, be as descriptive

as possible when placing an order:

Using this system, the subassemblies and their

components are included if an Assembly is ordered.

Similarly, the components of a subassemblies are

included if a subassembly is ordered.

The quantity (Qty) associated with an assembly,

represents the number of times an assembly

could be

shown in the drawing. The subassembly quantity

however, is the number of times a subassembly is

used to build one assembly. Similarly, the component

quantity refers to the number of times a given component is found in one subassembly.

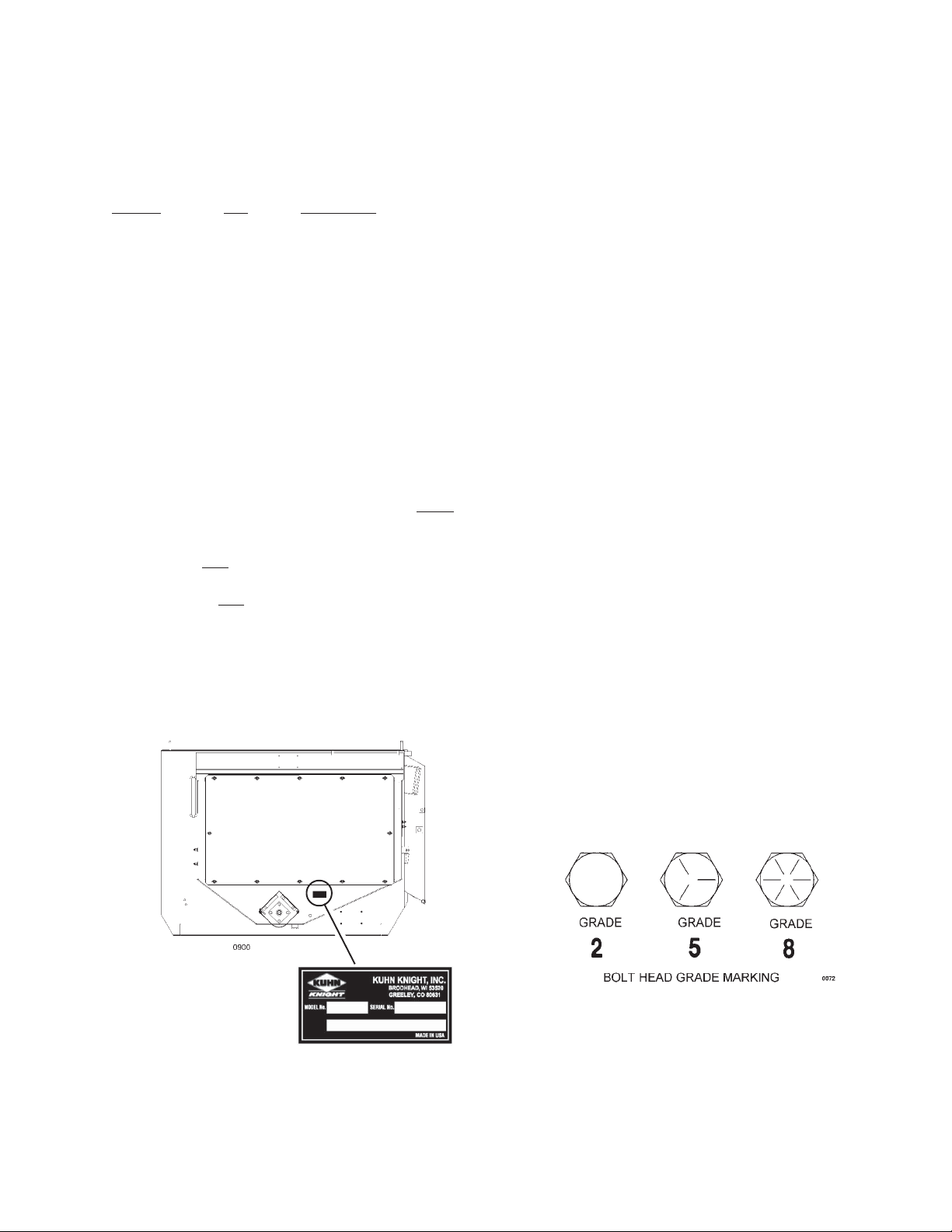

MODEL AND SERIAL NUMBER INFORMATION is

located near the front left hand corner (Fig. A). The

model number, serial number and part number should

be known when asking service personnel for parts.

Sprockets: give the bore size, number of teeth,

and size of keyway.

Roller chain: give the size of chain (stamped on

the side of each link) and number

of links.

Shafting: give the diameter, length, and quantity

and size of keyways.

Hardware is generally not included with parts.If you

need any hardware, check the size, the length, and

the grade (Fig. B), then check the hardware list in this

manual for the part numbers.

All hex head bolts are grade 5, and nuts are

grade 5 unless otherwise stated.

The hardware listing also includes zerks, cotter pins,

set screws, and roller chain links.

The illustrations in this manual are meant to be

used only as a guide for identifying parts and

locating their relative positions.

Back to Table of Contents

Figure A

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

Fig. B

3

3115TS 006050 R051205

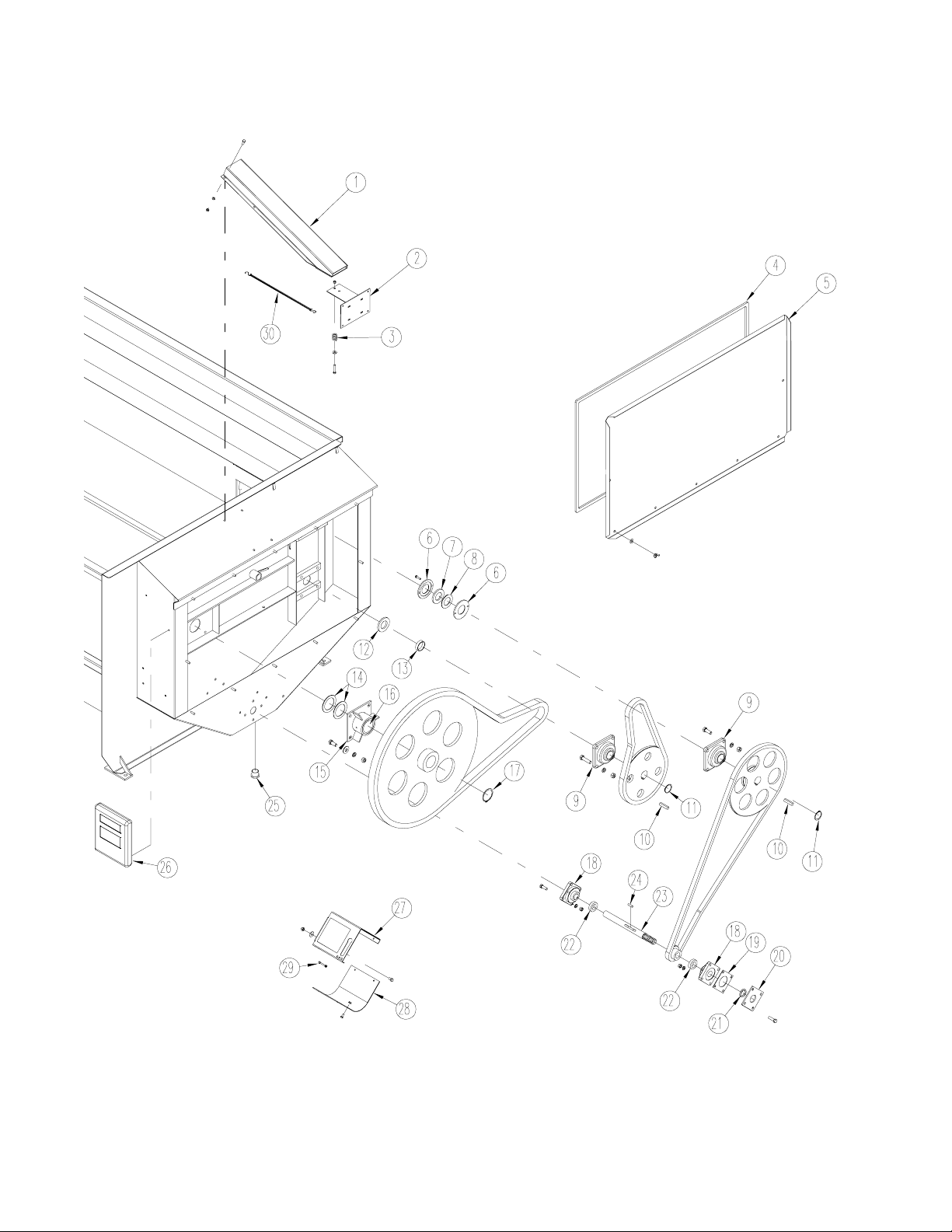

Front End Parts

4

© Copyright 2005 Kuhn Knight, Inc.

Back to Table of Contents

3115TS 006050 R051205

Front End Parts

REF PART NO QTY DESCRIPTION

1 133-921* 1 Scale Indicator Mount Arm; Mtg Hrd: 3/8"x1" B, Lw, Nut (4ea)

2 101-835 1 Indicator Mount

3 170-238* 1 Spring, Compression 7/8" x 1-1/2"

4 171-935 15' Front Shield Gasket; 3/8"x3/4" Closed Cell Foam

5 133-849 1 Front Shield; Mtg Hrd: 3/8" Fw and 171-929 Wing Nut (12ea)

6 133-852 2 Seal Retainer

7 133-376 1 Seal; 2" ID x 3-1/2" OD x 5/16 Thick

8 134-756 1 Seal: 2" ID x 3-3/8" OD x 1/8" Thick

9 170-008 2 Roller Bearing; Flange, 2", Mtg Hrd: 5/8" x -3/4" B, Lw, Nut (4ea)

10 170-898 2 Key; 1/2" x 1/2" x 2-1/2"

11 170-142 2 Snap Ring; 2" External

12 133-376 1 Seal; 2" ID x 3-1/2" OD x 5/16 Thick

13 133-853 1 Spacer

14 135-597 2 Reel Bearing Seal

15 102-511 1 Bearing Assembly, 3"; Mtg Hrd: 5/8" x 1-1/2" B, Fw, Lw, Nut (4ea)

16 136-309 1 Plastic Sleeve, 3"

17 171-934 1 Snap Ring; 3": External

18 171-585 2 Bearing; Flange, 1-3/8"; Mtg Hrd: 1/2" x 1-3/4" B, Lw, Nut (4ea) (Rear Bearing)

1/2" x 1-3/4" B, Lw, Nut (4ea) (Outer Bearing)

19 134-366 1 Bearing Spacer

20 136-260 1 Seal Retainer; 1/4" x 4-7/8" x 4-7/8"

21 173-164 1 Seal; 1-3/8" ID x 1 27/32" OD, 1/4" Thick C/R # 13536

22 172-193* 2 Lock Collar; 1-3/8" ID

23 136-042* 1 Input Shaft; 1- 3/8" Dia x 15-3/4"

24 171-409 1 Key; 3/8" x 3/8" x 1-1/4"

25 171-919 1 Drain Plug; 1-1/4" NPT

26 175-387 1 Operator's Manual Holder; Mtg Hrd: 5/16" x 1" B, Fw, Lw, Nut (4ea)

27 143-147* 1 PTO Shield; Mtg Hrd: 7/16" x 3/4" Bolt, Fw, Ln (3ea)

28 133-920* 1 Lower PTO Shield; Mtg Hrd: 5/16" x 3/4" Bolt, Fln

29 172-986* 1 PTO Shear Bolt, 1/4 x 2 Grade 5

30 171-936* 1 Hydraulic Hose Retaining Strap

* Parts are for Trailer model units only. See "Stationary Motor Mount" pages for stationary model front end parts

Kuhn Knight, Inc.

Back to Table of Contents

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

5

3115TS 006050 R051205

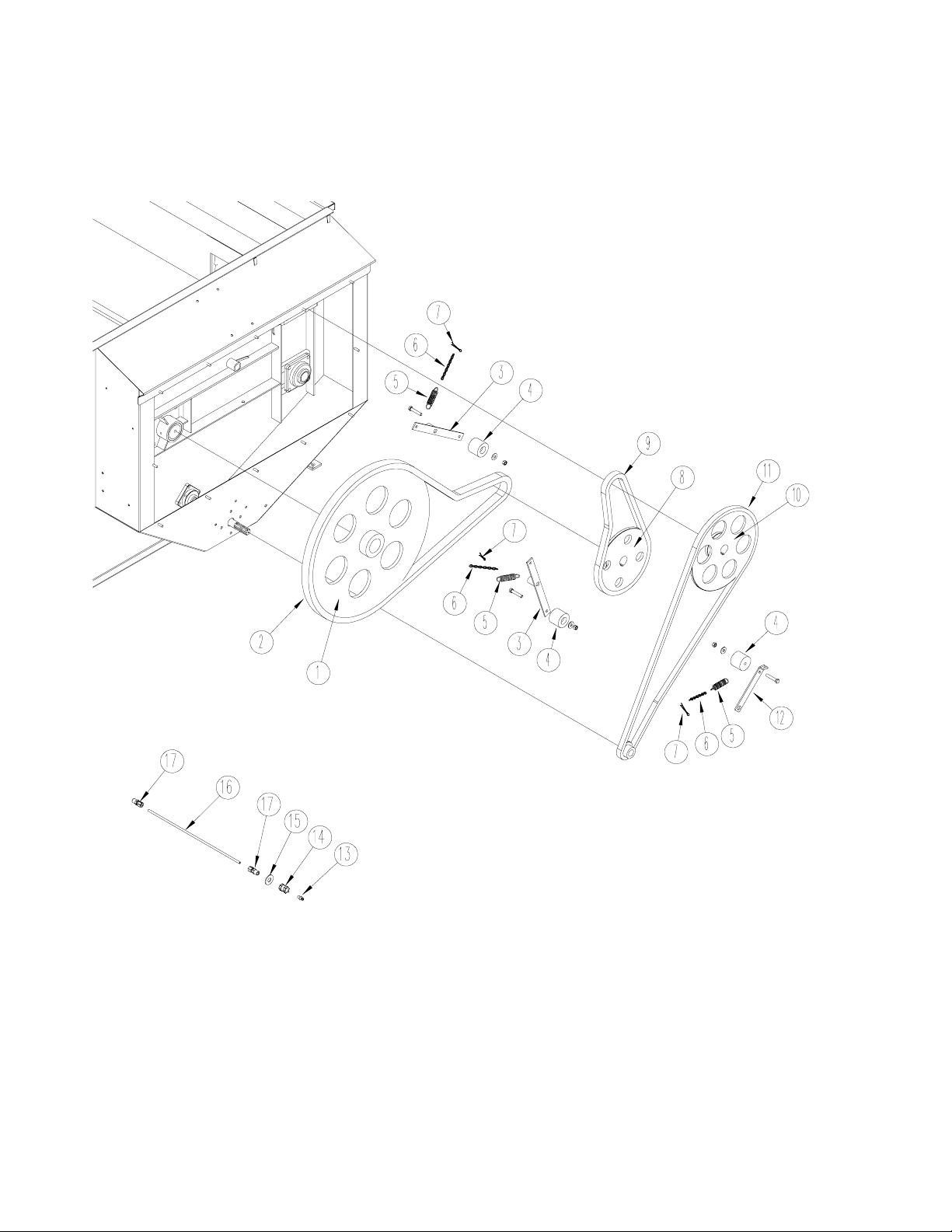

Sprockets, Chains and Tighteners

6

© Copyright 2005 Kuhn Knight, Inc.

Back to Table of Contents

Sprockets, Chains and Tighteners

REF PART NO QTY DESCRIPTION

1 133-913 1 Sprocket; 100-B-82, 3" Splined Bore

2 171-931 1 Roller Chain; 100H-1-110 Pitch, W/Connector Link

3 101-818 2 Chain Tightener Arm (#80)

4 134-155 3 Tightener Block, Mtg Hrd: 1/2" x 2 3/4" B, Fw, Lw, Nut (1ea)

5 172-006 3 Spring, Extension

6 170-478 3 Machine Chain; #4 x 12 Link (7")

7 170-800 3 Clinch Pin

8 136-908 1 Sprocket; 100-B-12, 80-42, 2" Bore

9 174-654 1 Roller Chain; 80-1-68 Pitch, W/Connector Link

10 136-907 1 Sprocket; 80-B-15/ 60-72, 2" Bore

11 174-653 1 Roller Chain; 60-1-160 Pitch, W/Connector Link

12 101-817 1 Chain Tightener Arm (#60)

GREASE LINE PARTS

13 170-865 1 Zerk, 1/8" NPT

14 172-024 1 Pipe Coupling, 1/8" NPT

15 170-244 1 Flat Washer, 3/8"

16 180-630 Grease Line Tubing (5’ total length required for all grease fittings)

18"* Required for Reel Bearing (inside oil bath)

20"* Required for Upper Auger Bearing (inside oil bath)

12"* Required for Lower Bearing (inside oil bath)

20"* Required for Input Shaft Bearings (inside oil bath)

17 172-822 2 Adapter, 1/8" NPTF x 1/4" Taper

3115TS 006050 R051205

* Quantity required to complete 1 grease line assy

Back to Table of Contents

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

7

3115TS 006050 R051205

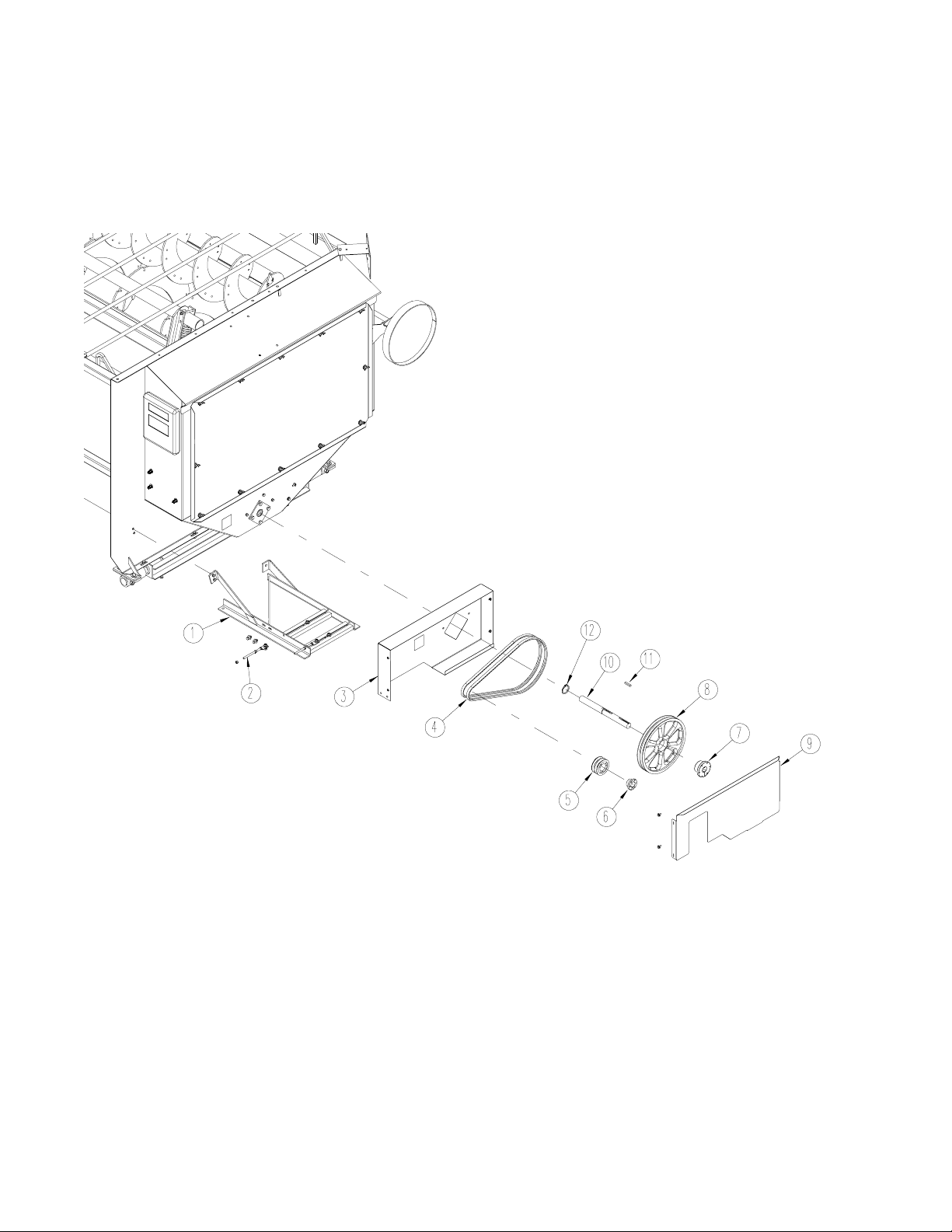

Stationary Motor Mount Parts

8

© Copyright 2005 Kuhn Knight, Inc.

Back to Table of Contents

3115TS 006050 R051205

Stationary Motor Mount Parts

REF PART NO QTY DESCRIPTION

1 104-081 1 Motor Mount; Mtg Hrd: 1/2" x 1" Bolt, FW, LN (5ea)

2 101-788 2 Jacking Bolt

3 104-581 1 Drive Shroud Assembly; Mtg Hrd: 7/16" x 3/4" Bolt, FW, LN (3ea) and 3/8" x 7/8"

Bolt, FW, LN (2ea)

4 171-924 2 V-Belt; BX-60 Raw Edge Cog

5 171-955 1 Motor Pulley; 2 Groove, 3.95 OD SH

6 171-954 1 Bushing; 1-3/8 QD - SHX 1-3/8"

7 171-923 1 Bushing; Split Taper, 1-3/8 QD SK

8 171-921 1 Pulley; 2 Groove, 13.95 OD SK

9 140-849 1 Drive Shield; Mtg Hrd: 1/4" x 3/4" Bolt, FW, LW (4ea)

10 134-953 1 Input Shaft, 1-3/8" x 15-3/8"

11 170-627 1 Key; 5/16 x 5/16 x 1-3/4"

12 170-499 1 Snap Ring; 1-3/8" External

Back to Table of Contents

Kuhn Knight, Inc.

1501 West 7th Ave., Brodhead, WI 53520

701 Cherry Ave., Greeley, CO 80632

9

3115TS 006050 R051205

Reel and Auger Parts

10

© Copyright 2005 Kuhn Knight, Inc.

Back to Table of Contents

Loading...

Loading...