Kubota LA555, LA1055, LA805 Operator's Manual

1AIABCMAP0180

OPERATOR'S MANUAL

FRONT LOADER

KUBOTACorporation

U.S.A. :KUBOTATRACTORCORPORATION

3401

DelAmoBlvd.,Torrance,CA

90503

,U.S.A.

Telephone:(

310)370-3370

Canada :KUBOTACANADALTD.

590014

thAvenue,Markham,Ontario,L3S4K4,Canada

Telephone:(

905)294-7477

France :KUBOTAEUROPES.A.S

19-25

,RueJulesVercruysse,Z.I.BP88,

95101

Ar㷅enteuilCedex,France

Telephone:(

33)1-3426-3434

Italy :KUBOTAEUROPES.A.SItalyBranch

ViaGrandi,

2920068

PeschieraBorrome(MI)Italy

Telephone:(

39)02-51650377

Germany :KUBOTA(DEUTSCHLAND)GmbH

SenefelderStr.

3-563110

Rod㷅au/Nieder-Roden,Germany

Telephone:(

49)6106-873-0

U.K. :KUBOTA(U.K.)LTD.

DormerRoad,Thame,Oxfordshire,OX

93

UN,U.K.

Telephone:(

44)1844-214500

Spain :KUBOTAESPAÑAS.A.

AvenidaRecombaNo.

5

,Poli㷅noIndustriallaLa㷅una,Le㷅anes,

28914

(Madrid)Spain

Telephone:(

34)91-508-6442

Australia :KUBOTATRACTORAUSTRALIAPTYLTD.

25-29

PermasWay,Tru㷅anina,VIC

3029

,Australia

Telephone:(

61)-3-9394-4400

Malaysia :SIMEKUBOTASDN.BHD.

No.

3

JalanSepadu25/

123

TamanPerindustrianAxis,

Seksyen

25,40400

ShahAlam,Selan㷅orDarulEhsanMalaysia

Telephone:(

60)3-736-1388

Philippines:KUBOTAPHILIPPINES,INC.

155

PanayAvenue,SouthTrian㷅leHomes,

1103

QuezonCity,Philippines

Telephone:(

63)2-9201071

Taiwan :SHINTAIWANAGRICULTURALMACHINERYCO.,LTD.

16

,Fen㷅pin㷅2ndRd,TaliaoShian㷅Kaohsiun㷅

83107

,TaiwanR.O.C.

Telephone:(

886)7-702-2333

Indonesia :P.T.KUBOTAINDONESIA

JalanSetyabudi

279

,Semaran㷅,Indonesia

Telephone:(

62)-24-7472849

Thailand :SIAMKUBOTACORPORATIONCO.,LTD.

101/19-24

Moo20,NavanakornIndustrialEstate,TambonKhlon㷅nuen㷅,AmphurKhlon㷅luan㷅,

Pathumthani

12120

,THAILAND

Telephone:(

66)2-909-0300

Korea :KUBOTAKOREACO.,LTD.

106-24

Mon㷅san-Ri,Mankyun㷅-Up,Kimje-City,Chonrapuk-Do,KOREA

Telephone:(

82)-63-544-5822

India :KUBOTAAGRICULTURALMACHINERYINDIAPVT.LTD.

Re㷅us,Level

2

Altius,OlympiaTechPark,No.1SIDCOIndustrialEstate,Guindy,Chennai

600032

,TN,India

Telephone:(

91)-44-4299-4237

Vietnam :KUBOTAVIETNAMCO.,LTD.

LotB-

3A2

-CN,MyPhuoc3IndustrialPark,BenCatDistrict,BinhDuon㷅Province,Vietnam

Telephone:(

84)-650-3577-507

WesternDivision :

1175

S.GuildAvc.,Lodi,CA

95240

Telephone :(

209)334-9910

CentralDivision :

14855

FAABlvd.,FortWorth,TX

76155

Telephone :(

817)571-0900

NorthernDivision :

6300

atOneKubotaWay,Groveport,OH

43125

Telephone :(

614)835-1100

SoutheastDivision :

1025

NorthbrookParkway,Suwanee,GA

30024

Telephone :(

770)995-8855

English (U.S.A.)

Code No. 7J292-6911-1AR. A. 1-1. -. K

©

KUBOTA Corporation 2013

READ AND SAVE THIS MANUAL

L

A

1

0

5

5

PRINTED IN U.S.A.

LA555MODELS

LA805

LA1055

L

A

8

0

5

•

L

A

5

5

5

•

FOREWORD

You are now the proud owner of a KUBOTA Loader. This loader is a product of

KUBOTA quality engineering and manufacturing. It is made of fine materials

and under a rigid quality control system. It will give you long, satisfactory

service. To obtain the best use of your loader, please read this manual carefully.

It will help you become familiar with the operation of the loader and contains

many helpful hints about loader maintenance. It is KUBOTA’s policy to utilize as

quickly as possible every advance in our research. The immediate use of new

techniques in the manufacture of products may cause some small parts of this

manual to be outdated. KUBOTA distributors and dealers will have the most upto-date information. Please do not hesitate to consult with them.

3

SAFETY FIRST

This symbol, the industry’s “Safety Alert Symbol”, is used throughout this

manual and on labels on the machine itself to warn of the possibility of personal

injury. Read these instructions carefully. It is essential that you read the

instructions and safety regulations before you attempt to assemble or use this

unit.

3

DANGER : Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

3

WARNING : Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

3

CAUTION : Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

IMPORTANT : Indicates that equipment or property damage could result

if instructions are not followed.

NOTE : Gives helpful information.

CONTENTS

SAFE OPERATION ............................................................................................ -1

SERVICING OF LOADER ........................................................................................... 1

SPECIFICATIONS....................................................................................................... 2

SUITABLE TRACTOR ............................................................................................. 2

LOADER SPECIFICATIONS ................................................................................... 2

BUCKET SPECIFICATIONS.................................................................................... 3

DIMENSIONAL SPECIFICATIONS ......................................................................... 3

OPERATIONAL SPECIFICATIONS......................................................................... 4

LOADER TERMINOLOGY....................................................................................... 6

PRE-OPERATION CHECK ......................................................................................... 7

LUBRICATION......................................................................................................... 7

TRANSMISSION FLUID .......................................................................................... 7

TREAD..................................................................................................................... 7

REAR BALLAST ...................................................................................................... 8

Liquid ballast in rear tires.................................................................................................. 8

TIRE INFLATION ..................................................................................................... 8

Inflation pressure ..............................................................................................................8

TEST OPERATION.................................................................................................. 9

4 Position bucket control valve type ................................................................................. 9

REMOVING AIR FROM THE HYDRAULIC SYSTEM ............................................. 9

DUAL REMOTE HYDRAULIC CONTROL SYSTEM............................................. 10

Control Lever and Hydraulic Hose Connections............................................................. 10

Loader / Remote Control Valve Lever ............................................................................10

OPERATING THE LOADER...................................................................................... 11

FILLING THE BUCKET.......................................................................................... 11

LIFTING THE LOAD .............................................................................................. 12

CARRYING THE LOAD ......................................................................................... 12

DUMPING THE BUCKET ...................................................................................... 13

LOWERING THE BUCKET.................................................................................... 13

OPERATING WITH FLOAT CONTROL................................................................. 13

LOADING FROM A BANK ..................................................................................... 14

PEELING AND SCRAPING ................................................................................... 14

LOADING LOW TRUCKS OR SPREADERS FROM A PILE................................. 15

BACKFILLING........................................................................................................ 15

HANDLING LARGE HEAVY OBJECTS................................................................. 16

VALVE LOCK......................................................................................................... 16

BUCKET LEVEL INDICATOR................................................................................ 17

FRONT REMOTE HYDRAULIC CONTROL SYSTEM (if equipped) ..................... 18

Install the Coupler...........................................................................................................18

Control Switch................................................................................................................. 18

Remote Control Coupler Connecting and Disconnecting ...............................................19

MULTI-COUPLER SYSTEM (if equipped) ............................................................. 19

ATTACHING ATTACHMENTS .............................................................................. 22

CONTENTS

DETACHING ATTACHMENTS .............................................................................. 24

Hydraulic Quick Attach Coupler Switch (if equipped) .....................................................24

DISMOUNTING THE LOADER.............................................................................. 25

MAINTENANCE..................................................................................................... 25

ATTACHMENTS .................................................................................................... 25

Quick attach bucket ........................................................................................................ 25

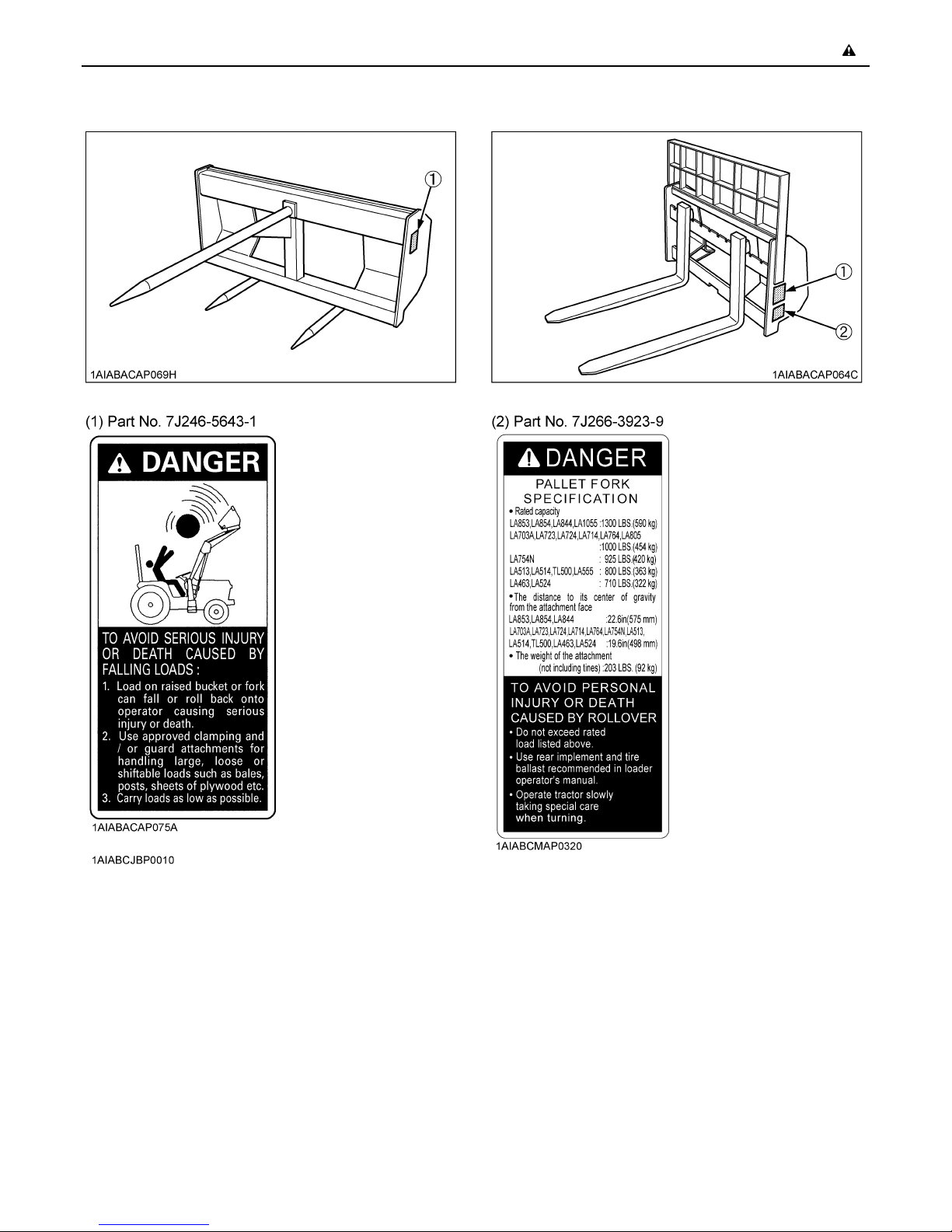

Bale spear.......................................................................................................................26

Pallet fork ........................................................................................................................ 26

ASSEMBLE PALLET FORK .................................................................................. 26

SPILL GUARD (if equipped) .................................................................................. 27

Adjustment of Spill Guard Link ....................................................................................... 28

MAINTENANCE......................................................................................................... 29

LUBRICATION....................................................................................................... 29

RE-TIGHTENING OF HARDWARE....................................................................... 29

DAILY CHECKS..................................................................................................... 30

EVERY 50 HOURS................................................................................................ 30

Checking main frame bolt torque .................................................................................... 30

General torque specification...........................................................................................31

REMOVING THE LOADER ....................................................................................... 32

STORING THE LOADER .......................................................................................... 34

REINSTALLING THE LOADER................................................................................. 35

SAFE OPERATION

Most loader equipment accidents can be avoided by following simple safety precautions.

These safety precautions, if followed at all times, will help you operate your loader safely.

-1SAFE OPERATION

1. BEFORE OPERATING THE LOADER

1. Read and understand all instructions and precautions

found in both the tractor and the loader operator's

manuals before using the loader.

Lack of knowledge can lead to accidents.

2. It is the owner's responsibility to ensure that anyone

who will operate the loader reads this manual first and

becomes familiar with the safe operation of the loader.

3. For your safety, a ROPS with a seat belt is strongly

recommended by KUBOTA in almost all applications.

If your tractor has a foldable ROPS, fold it down only

when absolutely necessary and raise it up and lock it

again as soon as possible. Do not wear the seat belt

when a foldable ROPS is down or a fixed ROPS is

removed. If you have any questions, consult your local

KUBOTA dealer.

Always use the seat belt when the tractor is equipped

with a ROPS. Never use the seat belt when the tractor

is not equipped with a ROPS.

4. Visually check for hydraulic leaks and broken, missing,

or malfunctioning parts.

Make necessary repairs before operating.

5. Replace damaged or illegible safety labels. See

following pages for required labels.

6. When the front loader is mounted on the tractor, enter

and exit the operator's seat only from left side of the

tractor.

7. Engage the loader control valve lock to prevent

accidental actuation when the implement is not in use

or during transport. Do not utilize the valve lock for

machine maintenance or repair.

8. Assemble, remove and reinstall the loader only as

directed in this manual. Failure to do this could result

in serious personal injury or death.

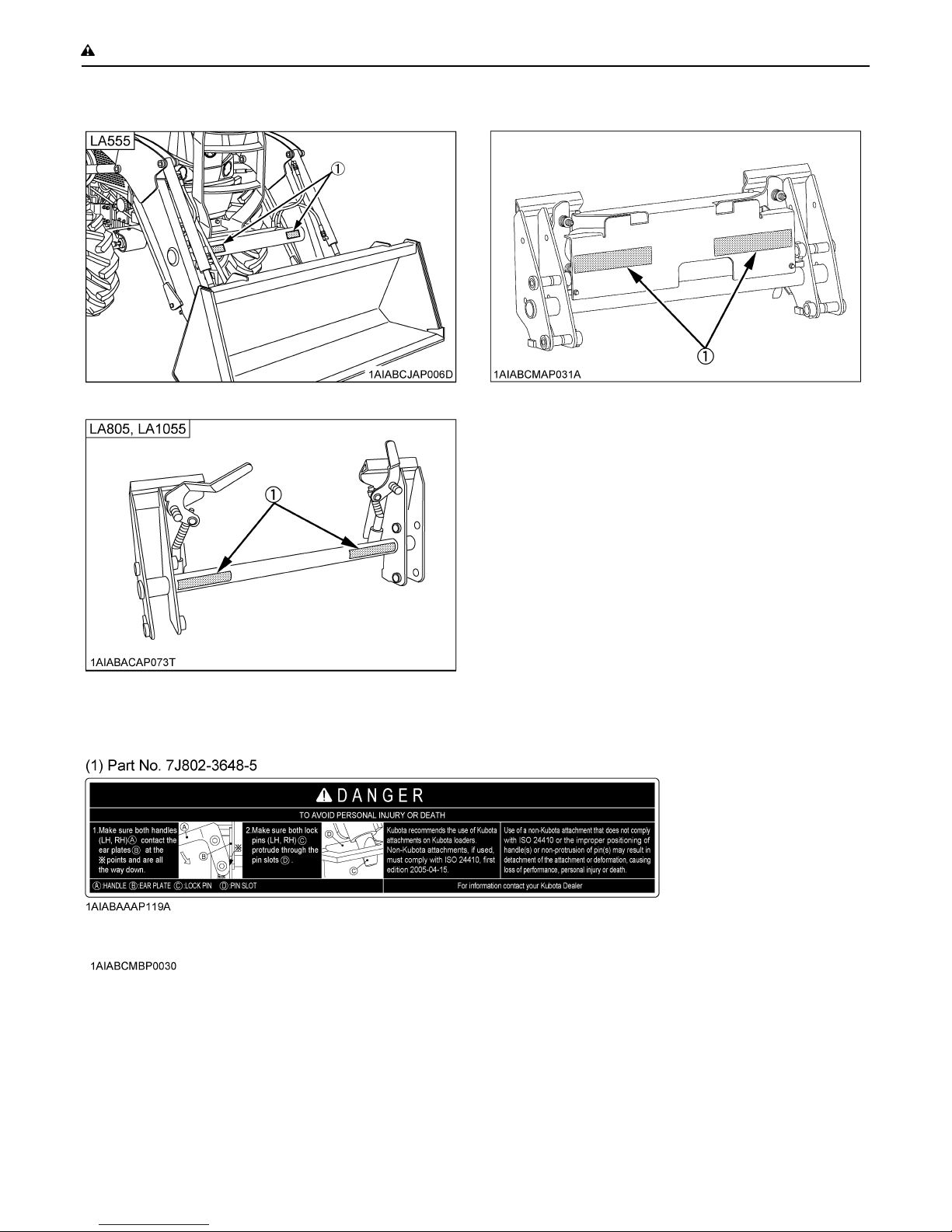

9. Follow the precautions below when attaching

attachments.

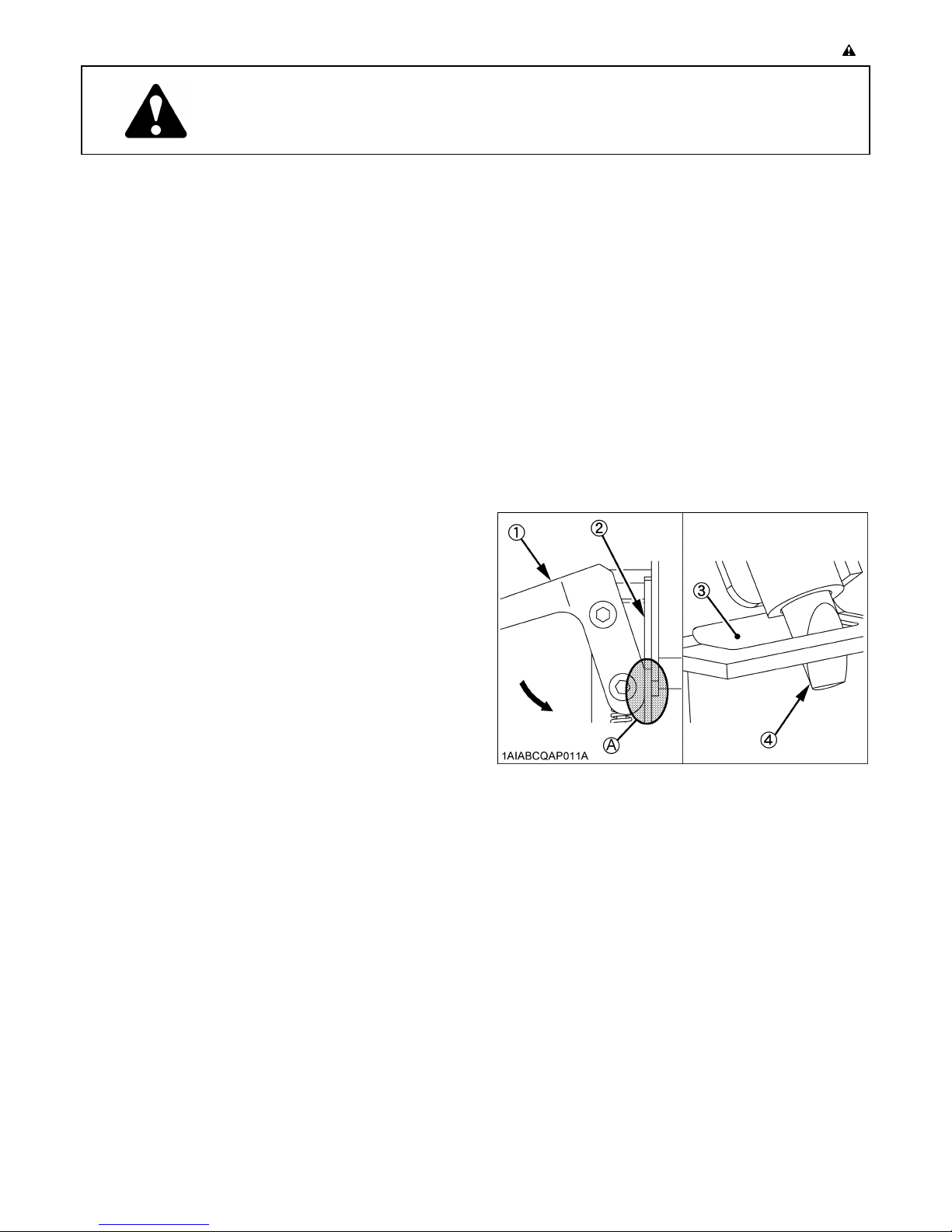

A Make sure both handles (LH, RH) contact the ear

plates at the points (A) and are all the way down.

A Make sure both lock pins (LH, RH) protrude through

the pin slots.

A Kubota recommends the use of Kubota attachments

on Kubota loaders. Non-Kubota attachments, if used,

must comply with ISO 24410, first edition 2005-04-15.

A Use of a non-Kubota attachment that does not comply

with ISO 24410 or the improper positioning of

handle(s) or non-protrusion of pin(s) may result in

detachment of the attachment or deformation, causing

loss of performance, personal injury or death.

(1) Handle

(2) Ear plate

(3) Pin slot

(4) Lock pin

(A) The handle contacts the ear

plate at the points.

SAFE OPERATION-2

2. OPERATING THE LOADER

1. Operate the loader only when properly seated at the

controls. Do not operate from the ground.

2. Move and turn the tractor at low speeds.

3. Never allow anyone to get under the loader bucket or

reach through the boom when the bucket is raised.

4. Keep children, others and livestock away when

operating loader and tractor.

5. Do not walk or work under a raised loader bucket or

attachment unless it is securely blocked and held in

position.

6. For tractor stability and operator safety, rear ballast

must be added to the 3-point hitch and to the rear

wheels when using loader.

7. To increase stability adjust the rear wheels to the

widest setting that is suitable for your application.

8. Exercise extra caution when operating the loader with

a raised bucket or attachment.

9. Do not lift or carry any person on the loader, in the

bucket, or other attachment.

10.Avoid loose fill, rocks and holes. They can be

dangerous for loader operation or movement.

11.Avoid overhead wires and obstacles when the loader

is raised. Contacting electric lines can cause

electrocution.

12.Gradually stop the loader boom when lowering or

lifting.

13.Use caution when handling loose or shiftable loads.

14.Using loaders for handling large, heavy, or shiftable

objects is not recommended without proper handling

attachments.

15.Handling large heavy objects can be extremely

dangerous due to :

A Danger of rolling the tractor over.

A Danger of upending the tractor.

A Danger of the object rolling or sliding down the

loader boom onto the operator.

16.If you must perform this sort of work (item 15), protect

yourself by :

A Never lift the load higher than necessary to clear

the ground.

A Add rear ballast to the tractor to compensate for the

load or use rear implement.

A Never lift large objects with equipment that may

permit them to roll back onto the operator.

A Move slowly and carefully, avoiding rough terrain.

17.Never lift or pull a load from any point on the loader

with a chain, rope, or cable. Doing so could cause a

rollover or serious damage to the loader.

18.Be extra careful when operating the tractor on a slope,

always operate up and down, never across the slope.

Do not operate on steep slopes or unstable surfaces.

19.When operating another implement on a hillside, be

sure to remove the loader to reduce the risk of rollover.

20.Carry loader boom at a low position during transport.

(You should be able to see over the bucket.)

21.Allow for the loader length when making turns.

3. AFTER OPERATING THE LOADER

1. When loader work is complete and parking or storing,

choose flat and hard ground. Lower the loader boom

to the ground, stop the engine, set the brakes and

remove the key before leaving the tractor seat.

2. Make sure the detached loader is on stands and on a

hard, level surface.

3. Before disconnecting hydraulic lines, relieve all

hydraulic pressure by moving the controls.

4. Do not remove the loader from the tractor without an

approved bucket attached.

4. SERVICING THE LOADER

1. Always wear safety goggles when servicing or

repairing the machine.

2. Do not modify the loader. Unauthorized modification

may affect the function of the loader, which may result

in personal injury.

3. Do not use the loader as a work platform or a jack to

support the tractor for servicing or maintenance.

Securely support the tractor or any machine elements

with stands or suitable blocking before working

underneath.

For your safety, do not work under any hydraulically

supported devices. They can settle or suddenly leak

down or be accidentally lowered.

4. Escaping hydraulic oil under pressure can have

sufficient force to penetrate the skin, causing serious

personal injury. Do not use hands to search for

suspected leaks. If injured by escaping fluid, obtain

medical treatment immediately.

5. Do not tamper with the relief valve setting. The relief

valve is pre-set at the factory. Changing the setting

can cause overloading of the loader and tractor which

may result in serious personal injury.

6. When servicing or replacing pins in cylinder ends,

bucket, etc., always use a brass drift and hammer.

Failure to do so could result in injury from flying metal

fragments.

DANGER,WARNING AND CAUTION LABELS

-3SAFE OPERATION

SAFE OPERATION-4

-5SAFE OPERATION

CARE OF DANGER,WARNING AND CAUTION LABELS

1. Keep danger, warning and caution labels clean and free from obstructing material.

2. Clean danger, warning and caution labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing danger, warning and caution labels with new labels from your local KUBOTA dealer.

4. If a component with danger, warning and caution label (s) affixed is replaced with new part, make sure new label (s) is

(are) attached in the same location (s) as the replaced component.

5. Mount new danger, warning and caution labels by applying on a clean dry surface and pressing any bubbles to outside

edge.

SERVICING OF LOADER

Your dealer is interested in your new loader and has the

desire to help you get the most value from it. After reading

this manual thoroughly, you will find that you can do some

of the regular maintenance yourself.

However, when in need of parts or major service, be sure

to see your KUBOTA dealer.

For service, contact the KUBOTA dealership from which

you purchased your loader or your local KUBOTA dealer.

When in need of parts, be prepared to give your dealer the

loader serial number.

Locate the serial numbers now and record them in the

space provided.

KUBOTA LOADER

Model

Serial Number

1SERVICING OF LOADER

Date of Purchase

Name of Dealer

(To be filled in by purchaser)

(1) Serial number

2 SPECIFICATIONS

SPECIFICATIONS

SUITABLE TRACTOR

LA555:L3560

LA805:L3560,L4060

LA1055:L4760,L5060,L5460,L6060

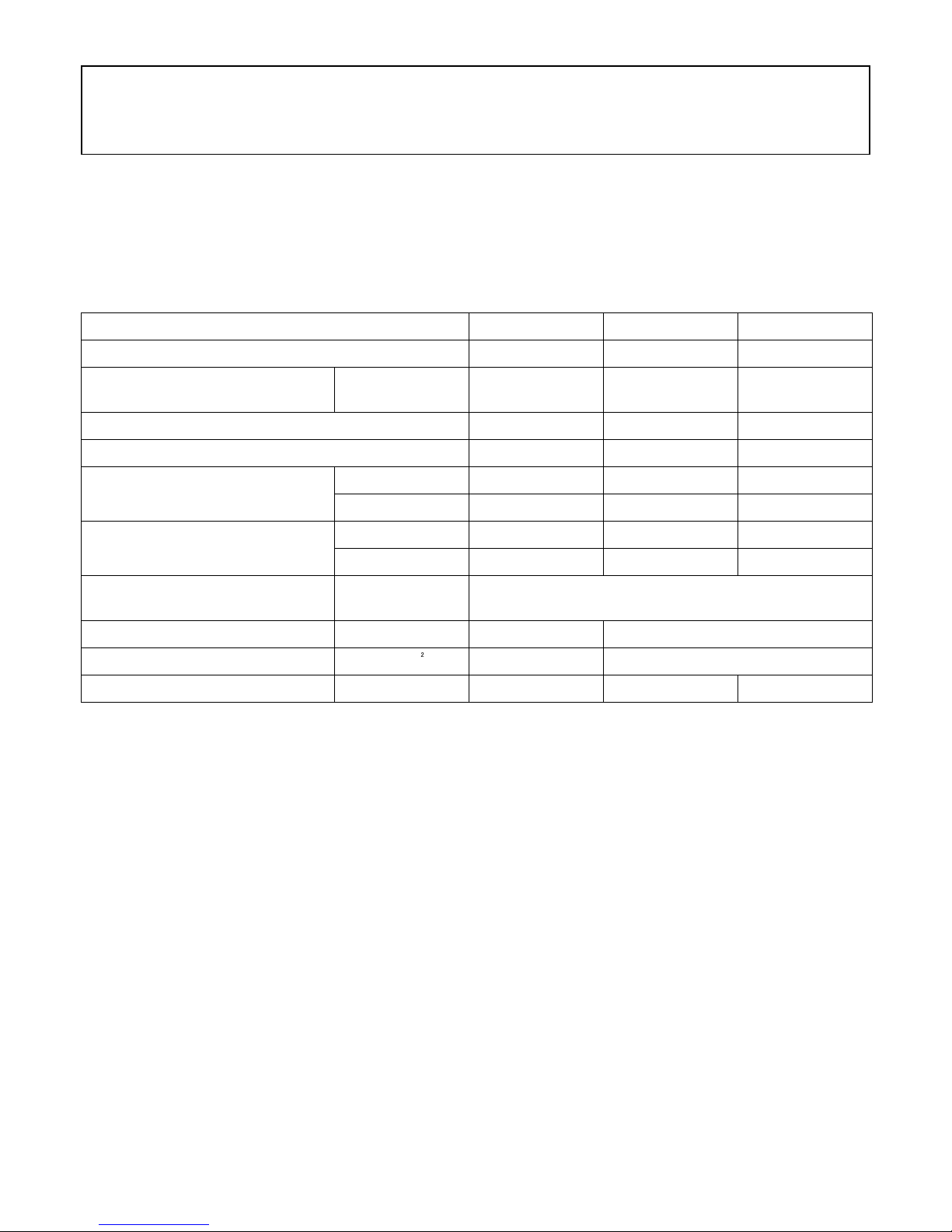

LOADER SPECIFICATIONS

LOADER MODEL LA555 LA805 LA1055

TRACTOR MODEL L3560 L4060 L6060

WHEEL BASE(WB) mm (in)

FRONT TIRES 7-16 8.3-16 9.5-16

REAR TIRES 12.4-24 14.9-24 14.9-26

BOOM CYLINDER

BUCKET CYLINDER

CONTROL VALVE

(STANDARD PART OF TRACTOR)

RATED FLOW L/m (GPM) 31.5 (8.3) 37 (9.8)

MAXIMUM PRESSURE MPa (kg/cm , psi) 17.7 (180,2560) 18.1 (185,2630)

NET WEIGHT(APPROXIMATE) kg (lbs.) 455 (1003) 580 (1279) 640 (1411)

BORE mm (in) 45 (1.77) 50 (1.97) 60 (2.36)

STROKE mm (in) 476 (18.7) 520 (20.5) 496 (19.5)

BORE mm (in) 45 (1.77) 50 (1.97) 55 (2.17)

STROKE mm (in) 476 (18.7) 466 (18.3) 469 (18.5)

4 Position bucket

control valve type

1805

(71.1)

One Detent Float Position, Two Stage Bucket Dump,

Power Beyond Circuit

1895

(74.6)

1915

(75.4)

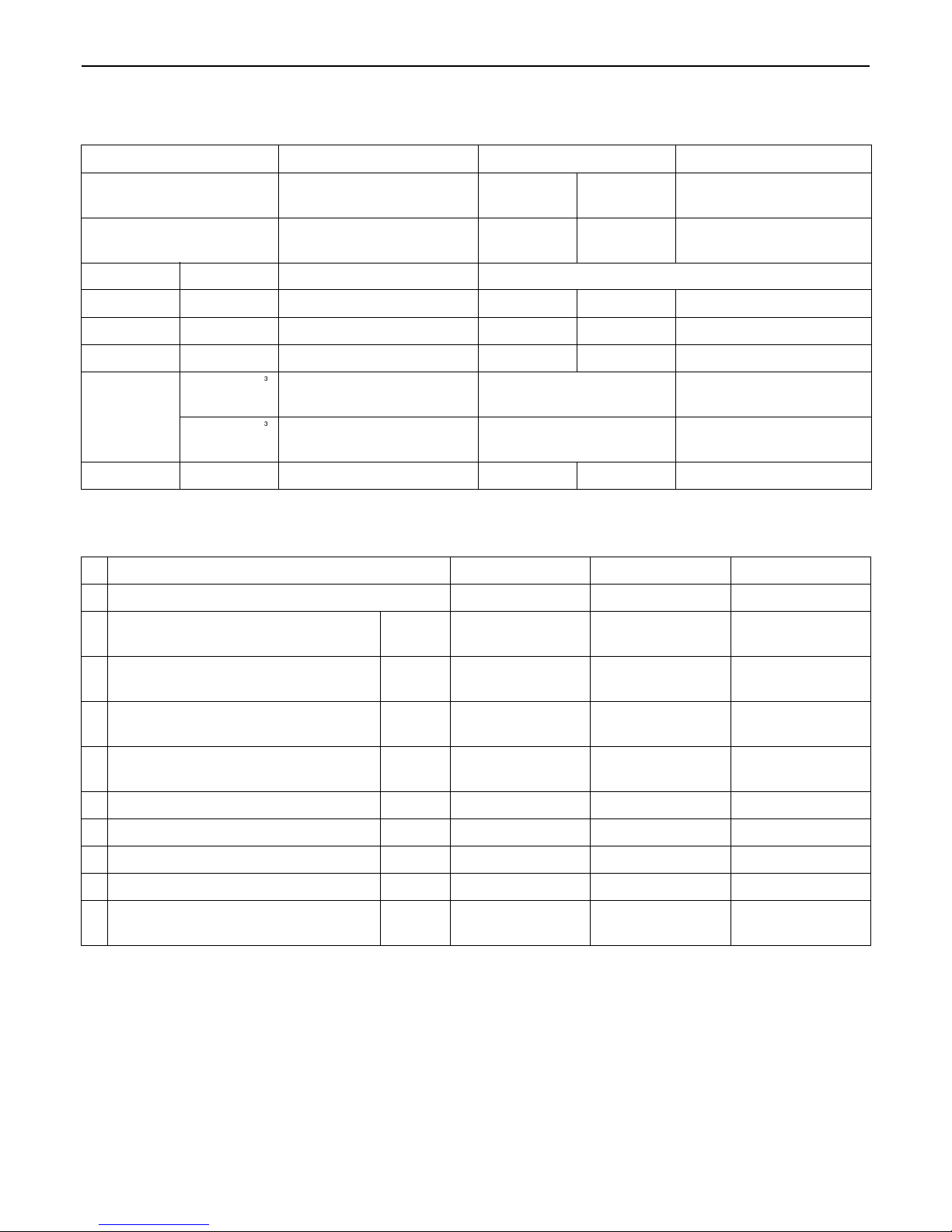

BUCKET SPECIFICATIONS

LOADER MODEL LA555 LA805 LA555,LA805,LA1055

3SPECIFICATIONS

MODEL SQUARE 66"

TYPE QUICK ATTACH

WIDTH mm (in.) 1675 (66) 1830 (72)

DEPTH (L) mm (in.) 458 (18) 547 (21.5) 477 (18.8) 607 (23.9)

HEIGHT (M) mm (in.) 562 (22.1) 570 (22.4) 608 (23.9) 570 (22.4)

LENGTH (N) mm (in.) 544 (21.4) 630 (24.8) 610 (24) 691 (27.2)

STRUCK m

(CU.FT.)

CAPACITY

HEAPED m

(CU.FT.)

WEIGHT kg (lbs.) 120 (265) 150 (331) 180 (397) 136 (300)

0.23 (8.1) 0.31 (10.9) 0.36 (12.7)

0.28 (9.9) 0.37 (13.1) 0.45 (16.0)

SQUARE

72"

QUICK

ATTACH

ROUND 72"

HD

QUICK

ATTACH

SQUARE 72" LIGHT

MATERIAL

QUICK ATTACH

DIMENSIONAL SPECIFICATIONS

LOADER MODEL LA555 LA805 LA1055

TRACTOR MODEL L3560 L4060 L6060

MAX. LIFT HEIGHT (TO BUCKET

A

PIVOT PIN)

mm (in.) 2448 (96.4) 2659 (104.7) 2862 (112.7)

MAX. LIFT HEIGHT UNDER LEVEL

B

BUCKET

CLEARANCE WITH BUCKET

C

DUMPED

REACH AT MAX. LIFT HEIGHT

D

(DUMPING REACH)

E MAX. DUMP ANGLE deg. 40 42 46

F REACH WITH BUCKET ON GROUND mm (in.) 1691 (66.6) 1840 (72.4) 1975 (77.8)

G BUCKET ROLL-BACK ANGLE deg. 30 41 42

H DIGGING DEPTH mm (in.) 124 (4.9) 130 (5.1) 174 (6.9)

OVERALL HEIGHT IN CARRYING

J

POSITION

mm (in.) 2277 (89.6) 2459 (96.8) 2662 (104.8)

mm (in.) 1928 (75.9) 2033 (80.0) 2216 (87.2)

mm (in.) 721 (28.4) 591 (23.3) 667 (26.3)

mm (in.) 1338 (52.7) 1383 (54.4) 1447 (57.0)

Loading...

Loading...