Page 1

BEDIENUNGSANLEITUNG2005

OWNER’S MANUAL

MANUALE D’USO

MANUEL D’UTILISATION

MANUAL DE INSTRUCCIONES

ART. NR. 3.211.51

950 ADVENTURE

950 ADVENTURE S

Page 2

ENGLISH

1

IMPORTANT »

Please insert the serial numbers of your motorcycle in the boxes below

Frame number

Engine number

Key number

Stamp of dealer

All information contained is without obligation. KTM-Sportmotorcycle AG particularly reserves the right

to modify any equipment, technical specifications, prices, colors, shapes, materials, services, service work,

constructions, equipment and the like so as to adapt them to local conditions or to cancel any of the above

items, all without previous announcement and without giving reasons. KTM may stop manufacturing certain models without previous notice. KTM shall not be held liable for any deviations of availability and/or

ability to deliver, illustrations, descriptions, printing and/or other errors. The illustrated models partly contain extra equipment, which is not applied to standard models.

© 2004 by KTM-SPORTMOTORCYCLE AG, Mattighofen AUSTRIA; All rights reserved; Reprint, also in

extracts, with written allowance of KTM-SPORTMOTORCYCLE AG, Mattighofen only.

COMSUMER INFORMATION FOR AUSTRALIA ONLY

Tampering with noise control system prohibited

Owners are warned that the law may prohibit:

(a) The removal or rendering inoperative by any person other than for purposes of maintenance, repair or

replacement, of any device or element of design incorporated into any new vehicle for the purpose of

noise control prior to its sale or delivery to the ultimate purchaser or while it is in use; and

(b) the use of the vehicle after such device or element of design has been removed or rendered inopera-

tive by any person.

We strongly suggest that you read this manual carefully and completely before going on your first ride.

It contains a great deal of information and advice which will help you use and handle your bike properly.

In your own interest, please pay particular attention to notices that are marked as follows:

– IGNORING THESE INSTRUCTIONS, CAN ENDANGER YOUR BODY AND YOUR LIFE.

– IGNORING THESE INSTRUCTIONS COULD CAUSE DAMAGE TO PARTS OF YOUR MOTORCYCLE OR THAT

THE MOTOR-CYCLE IS NOT ROAD-SAFE ANYMORE.

Page 3

ENGLISH

2

INTRODUCTION »

We would like to congratulate you on your purchase of a KTM motorcycle.

You are now the owner of a state-of-the-art sport motorcycle that guarantees to bring you lots of fun and

enjoyment, provided that you clean and maintain it appropriately. Before you go for your first ride, be sure

to read this manual carefully and thoroughly in order to familiarize yourself with how to operate your new

motorcycle and with its characteristics, even if this means that you will have to dedicate some of your

valuable time to this task. Only by doing so will you learn how to tune your motorcycle to your specific

needs and how to protect yourself against injury. Besides, this manual contains important information on

motorcycle maintenance. At the time this manual was typeset, it was up-to-date with the latest state of

this production series. It cannot be completely ruled out, however, that minor discrepancies may exist

resulting from further design upgrades of these motorcycles.This manual is an important part of your motorcycle and should be passed on to any subsequent owner in case you decide to sell it.

We expressly point out that work marked with an asterisk in the chapter "Maintenance work on the chassis and engine" must be performed by an authorized KTM workshop If maintenance work should become

necessary during a competition it should be performed by a trained mechanic. KTM strongly recommends

that all service work to your KTM should be performed by a qualified KTM dealer.

The designations "left, right, front, rear“ always refer to the direction of travel.

For your own safety, use KTM-approved parts and accessories only. KTM is not liable for damage that

arises in connection with the use of other products.

Take special care to follow the recommended run in, inspection, and maintenance intervals. Heeding

these guidelines will significantly increase the life of your motorcycle.

Off-road motorcycle driving is a wonderful sport and we hope that you will be able to enjoy it to the full.

It may, however, involve potential problems for the environment or lead to conflicts with others. These

problems or conflicts can be avoided if the motorcycle is used responsibly. To safeguard the future of

motorcycle sports, make sure that you use the motorcycle in accordance with the law, show that you are

environmentally conscious and respect the rights of others.

We wish you a lot of fun when driving !

KTM SPORTMOTORCYCLE AG

5230 MATTIGHOFEN, AUSTRIA

Page 4

ENGLISH

3

IMPORTANT LIMITED WARRANTY AND LIMITED GUARANTEE INFORMATION »

The KTM 950 Adventure models are designed to withstand normal use on roads and easy terrain

(unpaved roads).

The service, care and operating instructions for the engine and chassis specified in the owner's manual

must be observed to ensure that the bike runs smoothly and to avoid premature wear.

The service work described in the "Lubrication and maintenance schedule“ must be performed by an

authorized KTM workshop that can verify having attended the respective training programs. Only these

workshops will have trained personnel qualified to service the 950 Adventure. The service work must be

recorded in the service manual, otherwise the warranty will become null and void.

The fuels and lubricants specified in the owner's manual or those of an equal quality must be used in

accordance with the maintenance schedule.

The warranty or guarantee shall become void for damage and consequential damage caused by manipulations or conversions to the motorcycle.

The use of the motorcycle under extreme conditions, e.g. on extremely muddy and wet terrain, can lead

to higher than average wear on components such as the drive train or the brakes. In this case it may

become necessary to service or replace wear parts before the service limit specified in the maintenance

schedule has been reached.

In accordance with the international quality management ISO 9001 standard, KTM uses

quality assurance processes that lead to the highest possible product quality.

Page 5

ENGLISH

4

INDEX »

Page

SERIAL NUMBER LOCATIONS . . . . . . . . . . . . . . . . . . . .5

Chassis number . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Engine number, engine type . . . . . . . . . . . . . . . . . . .5

OPERATION INSTRUMENTS . . . . . . . . . . . . . . . . . . . . .5

Clutch lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Choke lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Hand brake lever . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Multi-functional digital speedometer . . . . . . . . . . . . . .6

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Setting options in the display . . . . . . . . . . . . . . . . . . .7

Cooling liquid temperature display . . . . . . . . . . . . . . .8

Indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Ignition lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Combination switch . . . . . . . . . . . . . . . . . . . . . . . . .9

Emergency OFF tip switch, light switch, starter tip switch

. .9

Storage compartment . . . . . . . . . . . . . . . . . . . . . . .10

Filler caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Seat lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Fuel taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Shift lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Side stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Center stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Foot brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Compression damping of fork . . . . . . . . . . . . . . . . . .11

Rebound damping of fork . . . . . . . . . . . . . . . . . . . .12

Spring preload of the fork . . . . . . . . . . . . . . . . . . . .12

Damping action during compression of shock absorber . .12

Rebound damping of shock absorber . . . . . . . . . . . .12

Shock absorber's preload adjuster . . . . . . . . . . . . . . .13

Baggage carrier plate . . . . . . . . . . . . . . . . . . . . . . . .13

Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Footrests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

GENERAL TIPS AND WARNINGS FOR STARTING

THE MOTORCYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Instructions for initial operation . . . . . . . . . . . . . . .14

Running in the LC8 engine . . . . . . . . . . . . . . . . . . .14

Accessories and payload . . . . . . . . . . . . . . . . . . . . .14

DRIVING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . .15

Check the following before each start . . . . . . . . . . .15

Starting when the engine is cold . . . . . . . . . . . . . . .16

Starting when the engine is warm or hot . . . . . . . . .16

Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Stopping and parking . . . . . . . . . . . . . . . . . . . . . . .17

Starting off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Shifting/Riding . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

PERIODIC MAINTENANCE SCHEDULE . . . . . . . . . . . . .20

MAINTENANCE WORK ON CHASSIS AND ENGINE . . . .22

Removing and remounting the seat . . . . . . . . . . . . .22

Tool set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Adjusting the fork and shock absorber . . . . . . . . . .23

Adjusting compression damping of fork . . . . . . . . . .23

Adjusting rebound damping of fork . . . . . . . . . . . . .23

Adjusting the spring preload on the fork . . . . . . . . . .23

Compression damping of shock absorber . . . . . . . . .24

Rebound damping of shock absorber . . . . . . . . . . . .24

Page

Adjusting the preload of the shock absorber . . . . . . .25

Breathing the fork legs . . . . . . . . . . . . . . . . . . . . .25

Cleaning the dust sleeves of the telescopic fork . . . .25

Checking the chain tension . . . . . . . . . . . . . . . . . . .25

Correct chain tension . . . . . . . . . . . . . . . . . . . . . . .26

Chain maintenance . . . . . . . . . . . . . . . . . . . . . . . .26

Checking the chain for wear . . . . . . . . . . . . . . . . . .26

General informations about KTM disc brakes . . . . . .27

Adjusting of free travel at the hand brake lever . . . . .28

Checking of brake fluid level - front brake . . . . . . . .28

Refilling the front brake fluid reservoir . . . . . . . . . . .28

Checking the front brake pads . . . . . . . . . . . . . . . . .28

Changing the basic position of the foot brake lever . .29

Checking rear brake fluid level . . . . . . . . . . . . . . . . .29

Refilling the rear brake fluid reservoir . . . . . . . . . . . .29

Checking the rear brake pads . . . . . . . . . . . . . . . . .29

Dismounting and mounting the front wheel . . . . . . . .30

Dismounting and mounting the rear wheel . . . . . . . . .31

Checking the shock absorption rubbers in the rear hub . . . . .31

Tires, air pressure . . . . . . . . . . . . . . . . . . . . . . . . . .32

Checking spoke tension . . . . . . . . . . . . . . . . . . . . . .32

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Demounting and mounting the battery . . . . . . . . . . .33

Charging the battery . . . . . . . . . . . . . . . . . . . . . . . .33

Connecting the battery jumper cable . . . . . . . . . . . .33

Main fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Fuses for individual current consumers . . . . . . . . . .34

Replacing the headlight lamps . . . . . . . . . . . . . . . . .35

Adjusting the headlight range . . . . . . . . . . . . . . . . . .36

Replacing the brake and tail light bulbs . . . . . . . . . .36

Replacing the flasher bulbs . . . . . . . . . . . . . . . . . .36

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Checking the cooling liquid level in the compensating tank . .37

Checking the cooling liquid level in the radiator . . . . .38

Bleeding the cooling system . . . . . . . . . . . . . . . . . .38

Changing the original position of the clutch lever . . . .39

Checking the oil level of the hydraulic clutch . . . . . .39

Checking and adjusting the throttle cable play . . . . . .39

Checking and adjusting the choke cable play . . . . . . .40

Adjusting the engine idle speed . . . . . . . . . . . . . . . .40

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Checking the engine oil level . . . . . . . . . . . . . . . . .40

Changing the engine oil and the oil filter, cleaning

the oil screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Activating the ignition curve for low-octane fuel . . . .44

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . .45

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

CONSERVATION FOR WINTER OPERATION . . . . . . . . .47

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

RE-INITIATION AFTER TIME OF STORAGE . . . . . . . . .47

TECHNICAL SPECIFICATIONS - CHASSIS . . . . . . . . . . .48

TECHNICAL SPECIFICATIONS - ENGINE . . . . . . . . . . .50

HEAD WORD INDEX . . . . . . . . . . . . . . . . . . . . . . . . . .52

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . .APPENDIX

CONSUMER INFORMATION USA ONLY . . . . . . .APPENDIX

Page 6

ENGLISH

5

SERIAL NUMBER LOCATIONS »

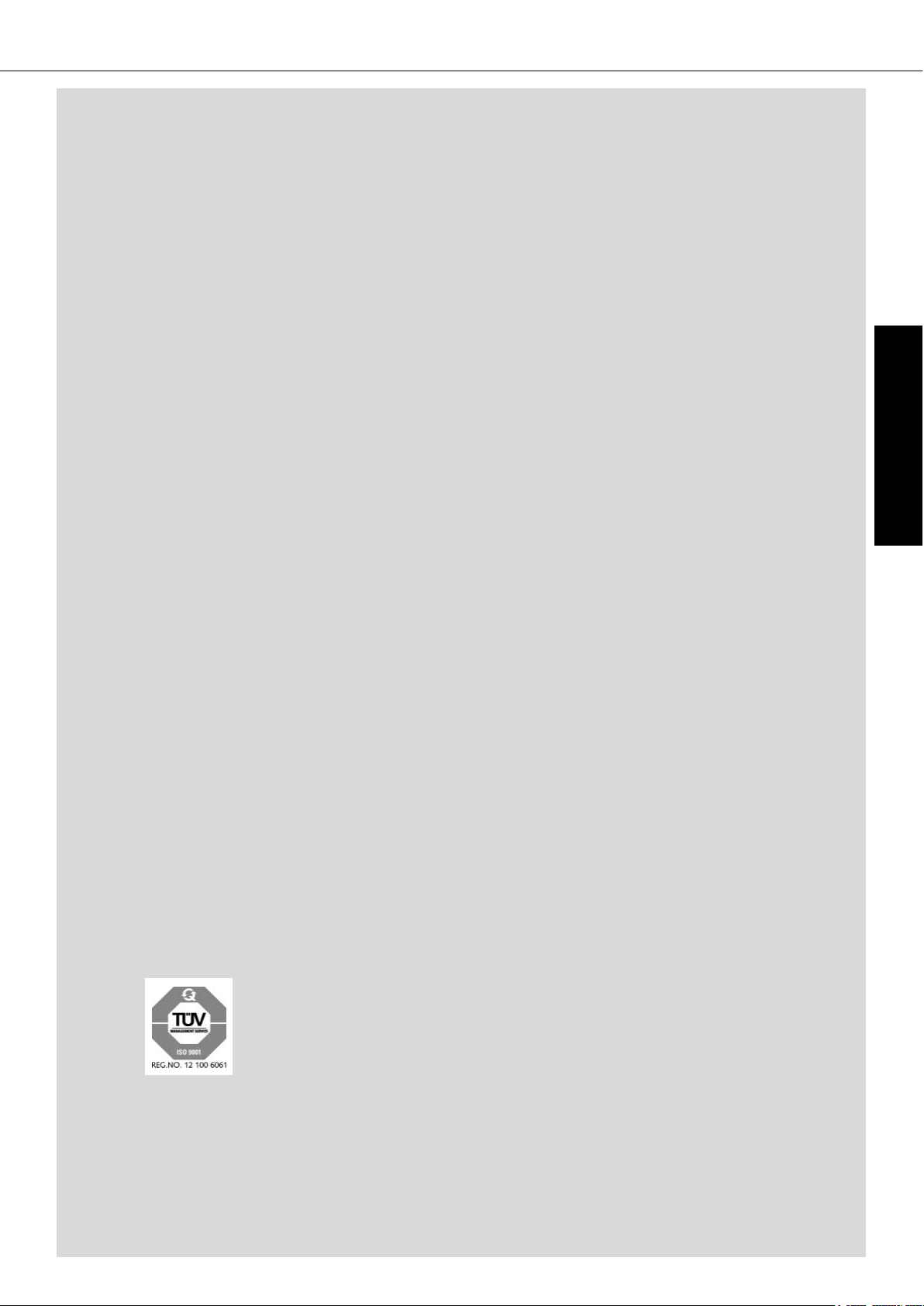

Chassis number

The chassis number is located on the right side of the steering head tube and

on the type label. Write this number into the relevant area on page 1.

Engine number, engine type

The engine number and engine type are embossed in the engine case near

the shift lever. Write this number into the relevant area on page 1.

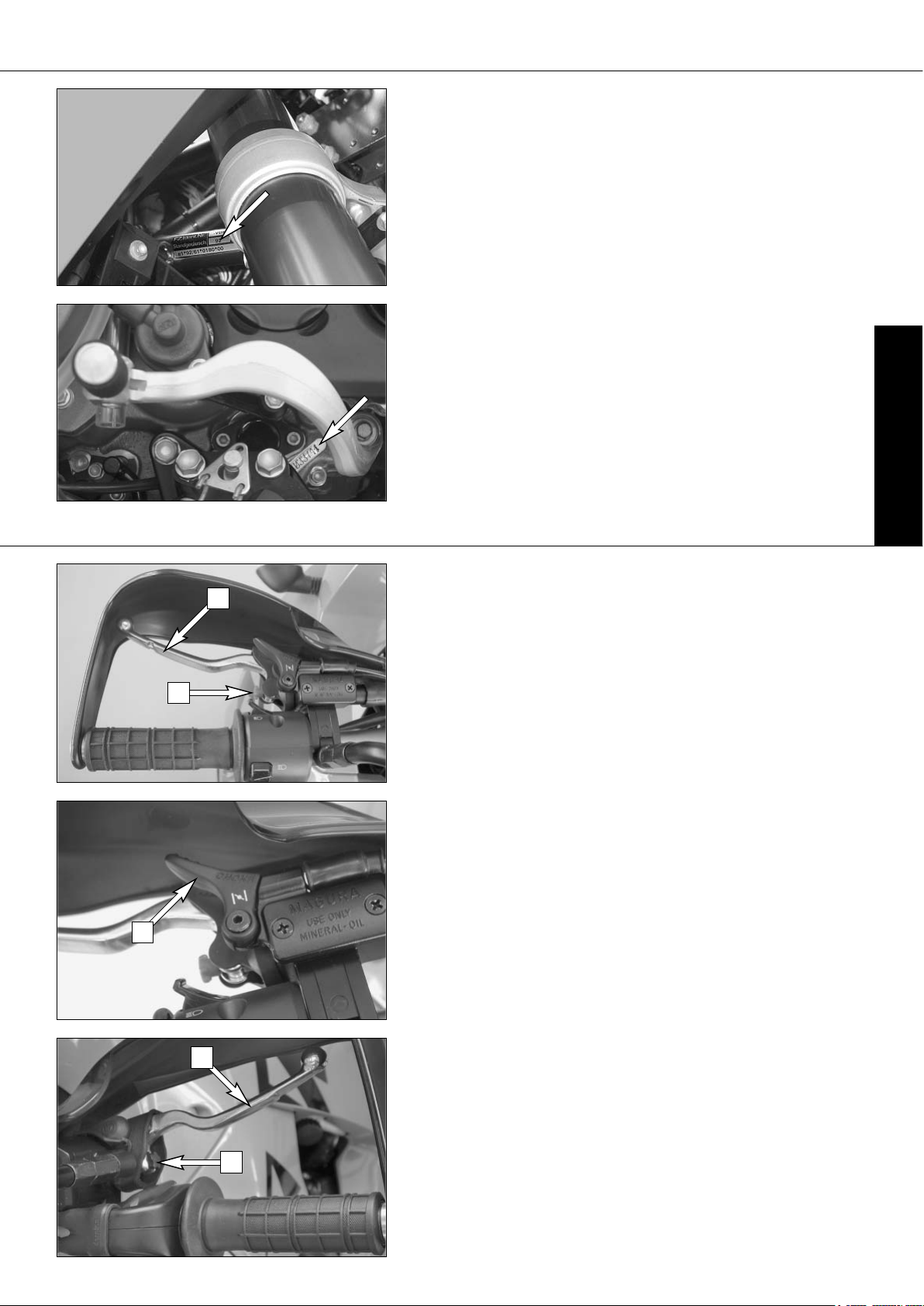

Clutch lever

The clutch lever [1] is located on the left side of the handlebar. The adjusting screw [A] is used to change the original position of the clutch lever (see

maintenance work on chassis and engine).

The clutch is hydraulically actuated and adjusts itself automatically.

Choke lever

If the choke lever [2] is pulled backwards, a bore in the carburetors will be

opened in the carburetor through which the engine may draw in additional

fuel. This produces a „rich“ fuel/air mixture necessary for cold start. The fuel

quantity and thus the engine speed are determined by the choke lever position.

At temperatures over 5°C (41°F) it will suffice to pull the choke lever half way

out. At temperatures below 5°C (41°F) the choke lever should be pulled all

the way out. The hole is closed again by pushing the choke lever all the way

back in.

Hand brake lever

The hand brake lever [3] is mounted on the handlebars on the right and actuates the front wheel brake. The adjusting screw [B] can be used to change

the basic position of the hand brake lever (see "Maintenance").

OPERATION INSTRUMENTS »

1

2

3

B

A

Page 7

ENGLISH

6

OPERATION INSTRUMENTS »

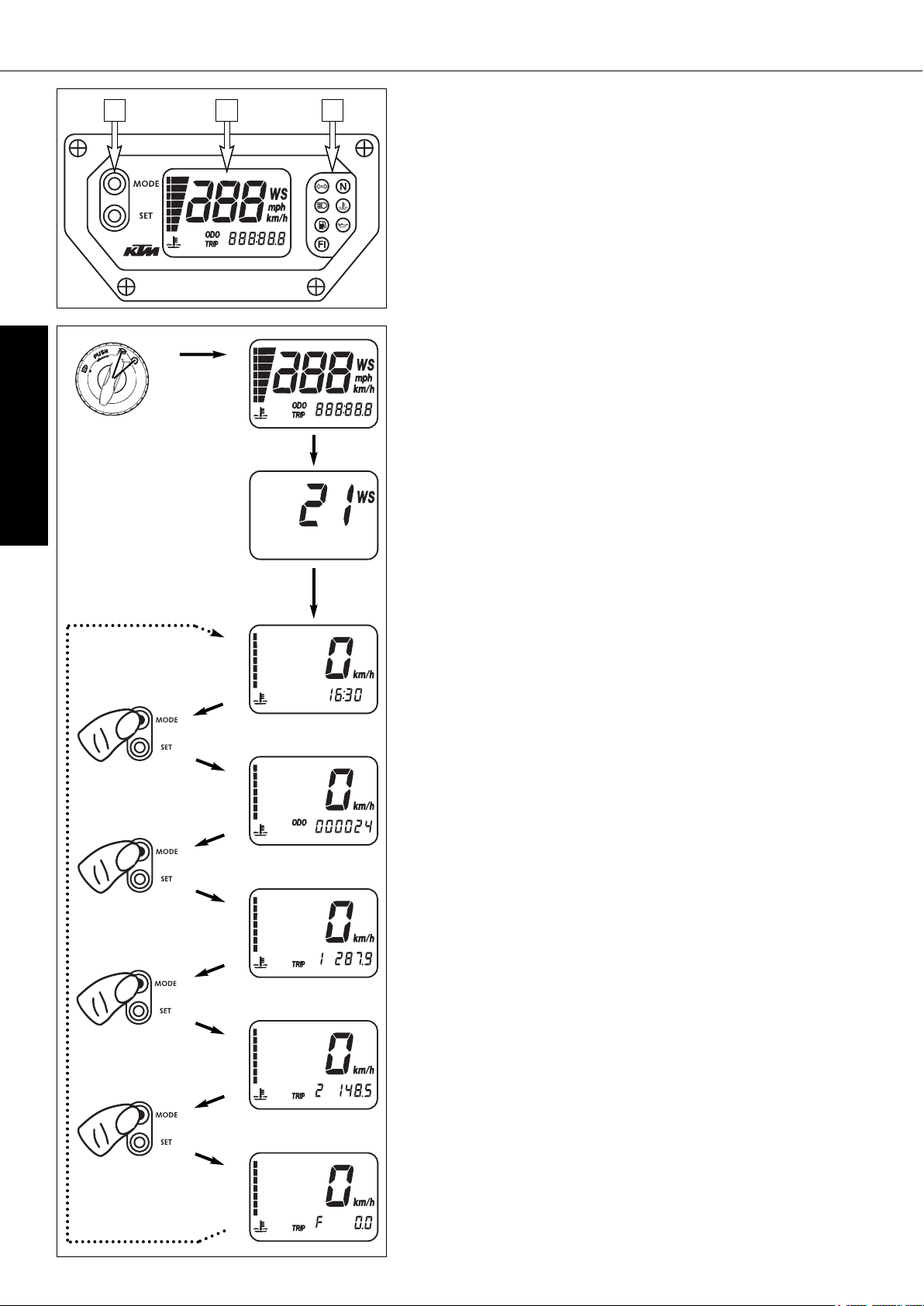

Multi-functional digital speedometer

The universal instrument is divided into 3 parts.

Use the MODE and SET [1] button to change the display and the basic settings in the display.

Display [2] shows all of the information that may be of interest to you.

5 display modes can be selected with the MODE button.

The indicator lamps [3] provide additional information on the motorcycle's

running condition.

Display

TEST

When you switch on the ignition, all of the display elements will light up for

1 second for the function test.

WS (wheel size)

The display will change and show the diameter of the front wheel in inches

for 1 second (WS = wheel size).

Then the CLOCK mode will be displayed, or the mode that was active when

the ignition was switched off.

CLOCK

You will recognize the CLOCK display by the blinking dots between the hours

and minutes. It displays the speed, temperature of the cooling liquid and the

clock.

To switch to the next display mode, press the MODE button.

ODO

The speed, temperature of the cooling liquid and the total kilometers or miles

traveled are shown in the ODO mode.

To switch to the next display mode, press the MODE button.

TRIP 1

The TRIP 1 mode shows the speed, the temperature of the cooling liquid and

the trip odometer 1.

To switch to the next display mode, press the MODE button.

TRIP 2

The TRIP 2 mode shows the speed, the temperature of the cooling liquid and

the trip odometer 2.

To switch to the next display mode, press the MODE button.

TRIP F

The TRIP F (fuel) mode shows the speed, the temperature of the cooling liquid and the distance traveled since reaching the low-fuel mark (the low-fuel

indicator lamp will blink).

To return to the CLOCK mode, press the MODE button.

TEST

WS

ODO

CLOCK

TRIP 1

TRIP 2

TRIP F

1 2 3

Page 8

ENGLISH

7

OPERATION INSTRUMENTS »

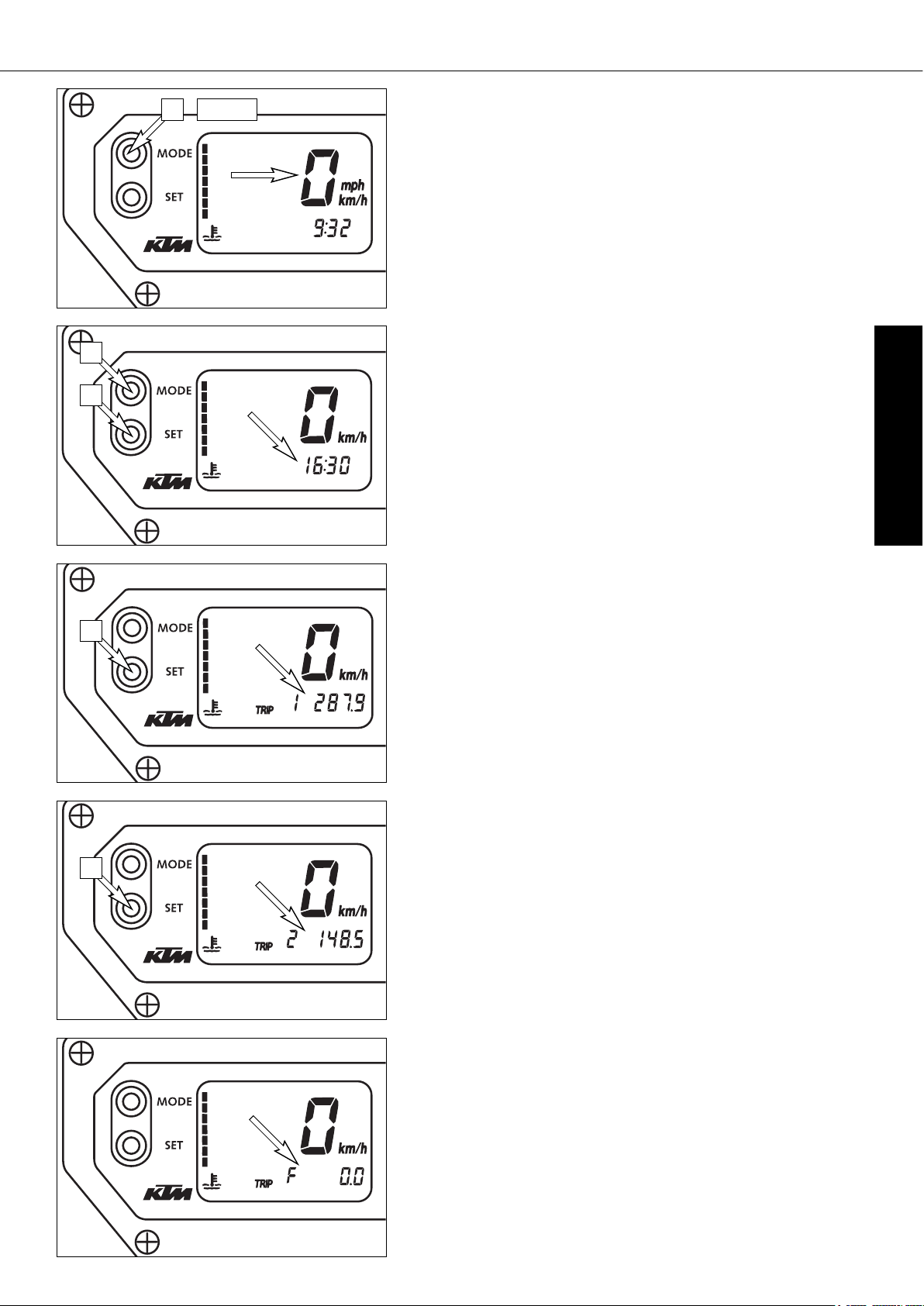

Setting options in the display

KILOMETERS OR MILES.

You can have the speed and distance shown in kilometers or miles in the display. The display can be adapted to the respective country on long-distance

trips.

To switch from kilometers to miles, switch on the ignition and press the MODE

[1] button for approx. 10 seconds. The km/h display will switch to mph. The

speed and the stored distances will be converted and displayed in miles.

To return to kilometers, proceed as described above.

CLOCK

Switch on the ignition and change to the CLOCK mode.

Simultaneously press MODE [1] and SET [2]. The numbers on the clock will

start to blink. Use the MODE button to set the hours and the SET button to

set the minutes.

The press the MODE and SET buttons simultaneously.

NOTE:

0:00 will be displayed if the clock is not supplied with electricity. This can

be caused by a defective fuse or a fault in the board electric system (see

Troubleshooting).

TRIP 1

The trip meter 1 runs continuously and counts up to 999.9. It can be used

to measure the length of a certain route on a trip or the distance between two

refueling stops.

To return the trip meter 1 to zero, switch on the ignition, change to the TRIP

1 mode and press the SET button.

RESETTING TRIP 2

The trip meter 2 runs continuously and counts up to 999.9. It can be used

similarly to TRIP 1 or together with a switch available as an accessory (see

below) for trips according to a roadbook.

To return the trip meter 2 to zero, switch on the ignition, change to the TRIP

2 mode and press the SET button.

NOTE

A Tripmaster switch (Part no. 582.14.069.044) is available as an accessory

and enhances the trip meter 2 functions. You can correct the displayed route

by increasing or decreasing in increments of 0.1. For example, if you have

taken the wrong road when driving according to a roadbook, you can easily

correct the display to correspond to the roadbook again. It can also be used

to change the display modes. The switch is mounted on the handlebars so

that you can keep your hands on the handlebars.

TRIP F

When the fuel level reaches the reserve mark, the display will automatically

switch to TRIP F and begin to count (no matter which display mode was active

before). At the same time, the fuel warning lamp will start to blink. You will

still have enough reserve fuel for aprox 50 kilometers (30 miles).

After refueling, it will take approx. 3 minutes for TRIP F to automatically reset

to 0 and return to the previous display mode.

1 10 sec

1

2

2

2

Page 9

ENGLISH

8

OPERATION INSTRUMENTS »

Cooling liquid temperature display

The temperature display [1] is shown in 7 bars. The more bars that light up,

the hotter the cooling liquid. When the lowest bar lights up, the cooling liquid has reached a temperature of approx. 40°C (104°F). When the upper bar

lights up 120°C (248°F), all of the bars will start to blink and the red warning lamp [2] will light up.

POSSIBLE CAUSES FOR AN INCREASE IN TEMPERATURE, CAUSING THE RED

WARNING LIGHT FOR THE COOLING LIQUID TEMPERATURE TO LIGHT UP:

–

DRIVING TOO SLOWLY AND DRIVING WITH A HEAVY LOAD AT HIGH AIR TEMPERATURES

– NOT ENOUGH COOLING LIQUID IN THE SYSTEM

– THE VENTILATOR ON THE RADIATOR IS NOT RUNNING

– IMPROPER USE OF THE CLUTCH WHEN DRIVING SLOWLY

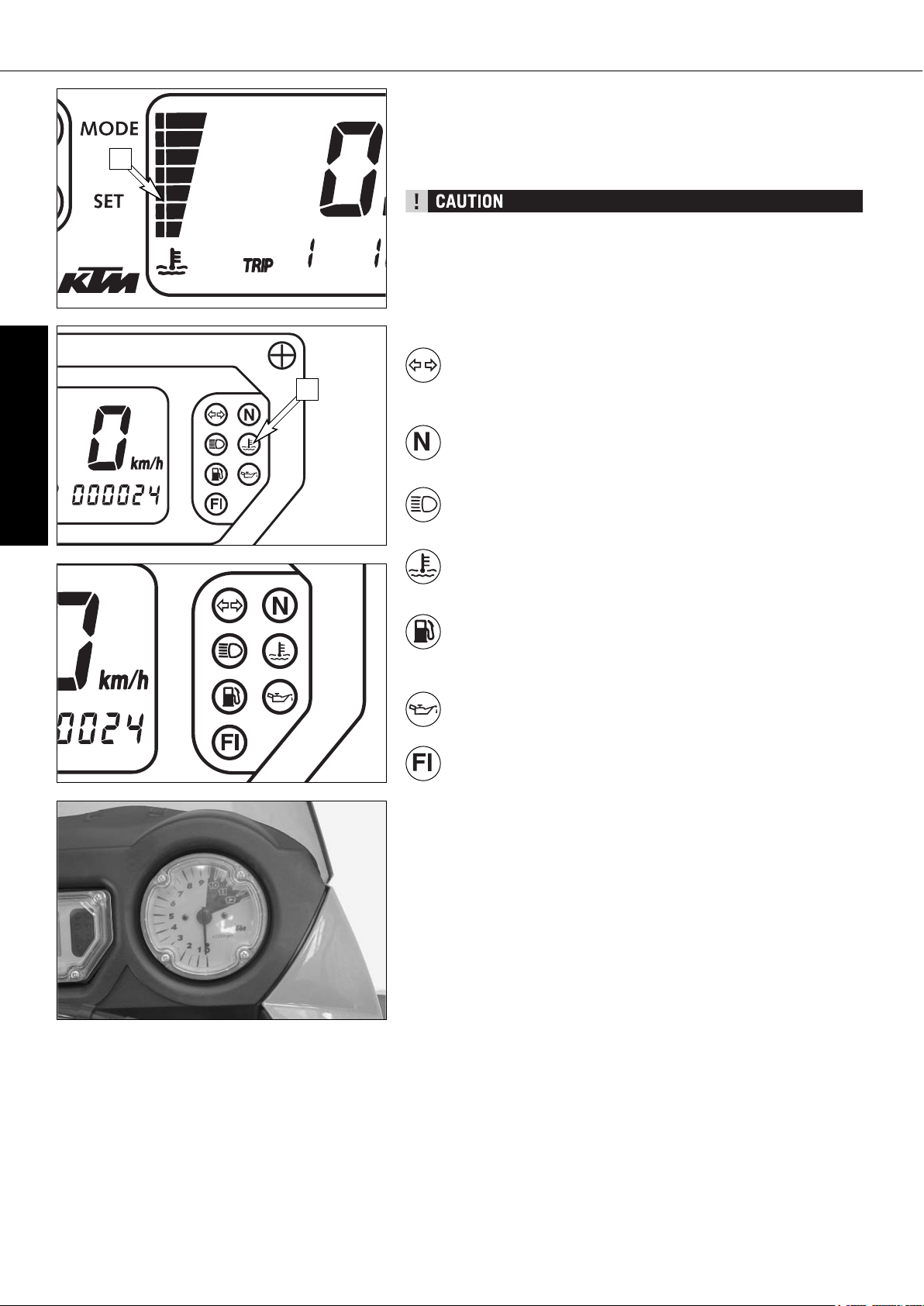

Indicator lamps

The green indicator lamp will blink in the blinker rhythm when the

blinker is switched on.

NOTE:

The indicator lamp will blink slower when a blinker is broken.

The green indicator lamp will light up when the gearbox is in an idling

position.

The blue indicator lamp will light up when the high beams are

switched on.

The red warning light will light up when the cooling liquid has reached

a temperature of approx. 120°C (248°F).

The orange warning light will start to blink when the fuel level has

reached the reserve mark. At the same time the display will automatically change to TRIP F (see TRIP F).

The red warning lamp lights up when the ignition is switched on but

the engine is not running. When the engine is started, the warning

lamp will go out as soon as the oil pressure is high enough.

This indicator lamp has no function.

Tachometer

The tachometer shows the engine speed in revolutions per minute. Do not run

the engine beyond the black mark at 9500 rpm.

The speed limiter will set in at 9600 rpm, drastically reducing the engine

power above this rotational speed.

120°C (248°F)

110°C (230°F)

100°C (212°F)

70°C (158°F)

60°C (140°F)

50°C (122°F)

40°C (104°F)

1

2

Page 10

ENGLISH

9

OPERATION INSTRUMENTS »

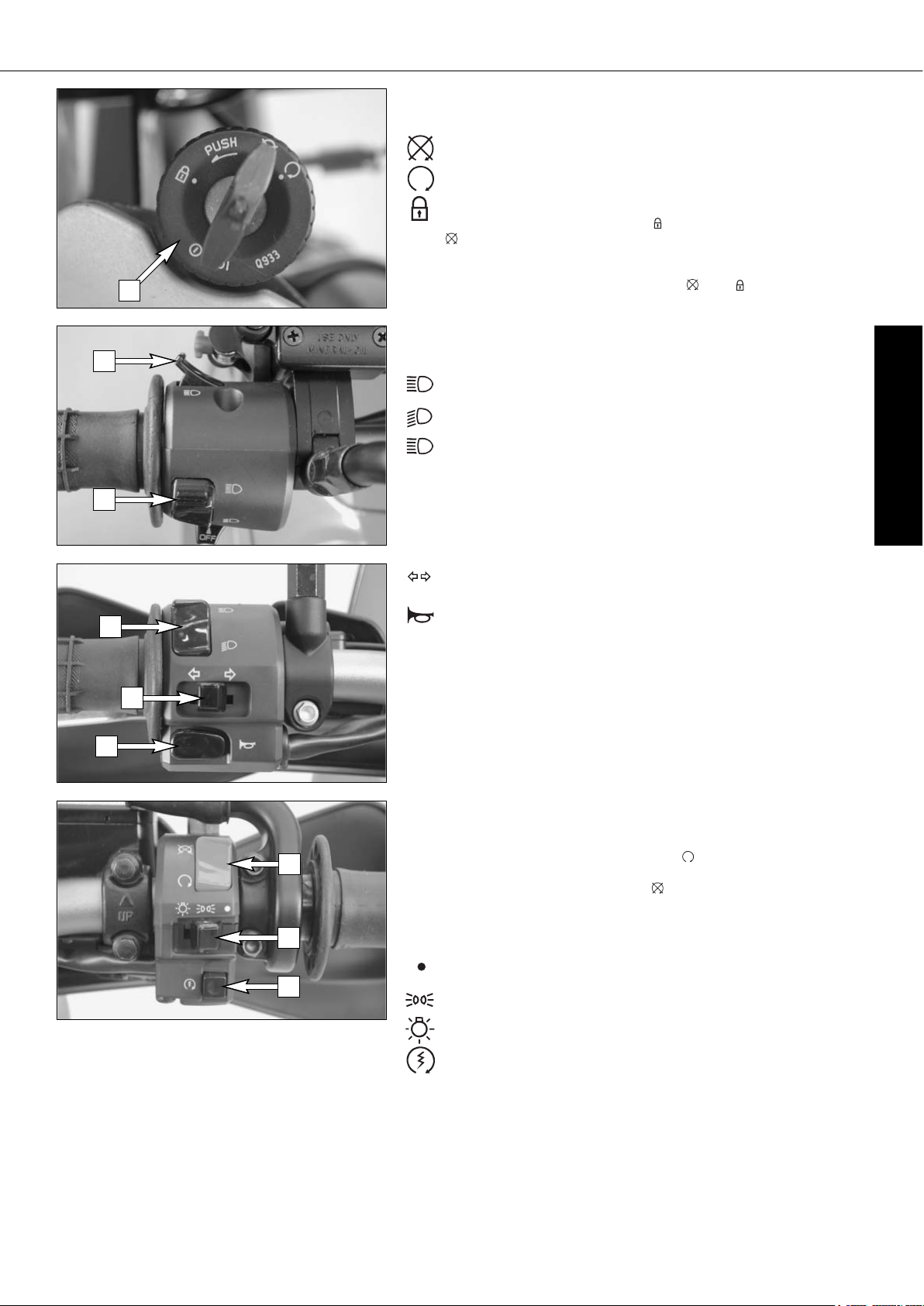

Ignition lock

The ignition lock [1] has 3 switching positions.

Ignition off, (engine can't be started)

Ignition on, (engine can be started)

Ignition off, handlebar blocked

To switch the ignition to position turn the ignition key to position

and firmly press it into the lock. Turn the handlebar all the way to

the left, then turn the ignition key to the left.

The ignition key can be withdrawn in position and .

Combination switch

The rocker switch LIGHTS [2] actuates the high beam or low beam.

= High-beam light

= Low-beam light

The light signal (high beam) is actuated with button [3].

The indicator switch [4] returns to central position after actuation. Press

flasher switch towards switch housing to switch off the flasher.

The horn is sounded with button [5].

Emergency OFF tip switch, light switch, starter tip switch

The emergency off switch [6] is provided for emergency situations and should

not be used to switch off the engine.

The engine is ready for operation in position (ignition circuit and starter

circuit are switched on).

The engine cannot be started in position (ignition circuit and starter circuit are interrupted).

The light switch [7] has 3 positions:

= Light off

= Parking light on

= Headlight on

Use the starter tip switch [8] to operate the electric starter.

1

2

3

2

4

5

6

7

8

Page 11

ENGLISH

10

OPERATION INSTRUMENTS »

Filler caps

The 950 Adventure has 2 separate fuel tanks.

Both filler caps [2] can be locked and are equipped with a tank vent system.

To open, insert the ignition key, turn 45° in a clockwise direction and fold up

the filler cap.

The ignition key can be pulled out to open the other filler cap. Simply press

on the filler cap to close.

Seat lock

The seat is unlocked by inserting the ignition key in the lock [3] on the side

and turning the key in a counterclockwise direction. See "Maintenance Work"

to remove and remount the seat.

Fuel taps

The 950 Adventure is equipped with 3 fuel taps which only need to be closed

to remove the fuel tank.

Fuel cannot flow to the carburetors if the fuel pump is not running, so the

fuel tap [4] does not need to be closed when the motorcycle is switched off.

Both fuel taps [5] must be open when the motorcycle is running. The level in

the fuel tanks is equalized by means of a connecting hose.

Storage compartment

A storage compartment is located under the seat to hold small, frequently

used items.

To open, turn the quick release [1] approx. 180° in a counterclockwise direction and lift the cover. To lock, close the cover, insert the quick release in the

dolly and turn 180° in a clockwise direction.

1

2

2

3

4

5

5

Page 12

ENGLISH

11

OPERATION INSTRUMENTS »

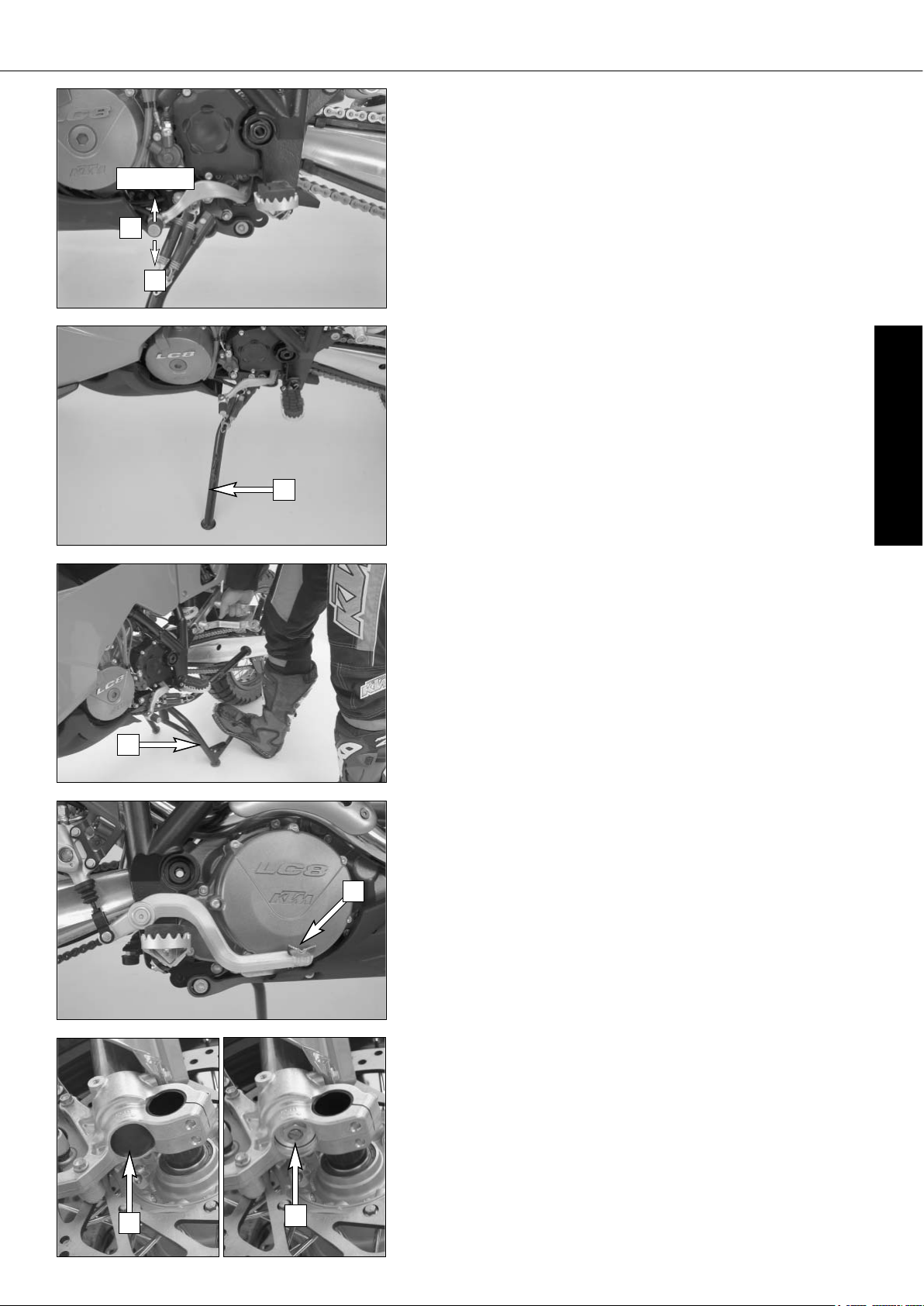

Shift lever

The shift lever is mounted on the left side of the engine. The position of the

gears is shown in the illustration. Neutral, or the idle speed, is located between

first and second gear.

Side stand

The side stand [1] is coupled with a safety starter system. Pay attention to

Driving Instructions.

Center stand

The bike is equipped with a side stand and a center stand [2].

Foot brake pedal

The foot brake pedal [3] is located in front of the right footrest. Its basic

position can be adjusted to your seat position (see maintenance work).

Compression damping of fork

The fork's damping action during compression travel (compression damping)

can be adjusted. This allows you adjust the damping behavior to match your

driving style and the payload.

The adjusting screws [5] are located under the cap [4] on the lower end of

the fork legs.

More information is provided in the chapter "Adjusting the fork and shock

absorber.“

4

5

3

2

1

1

2,3,4,5,6

N

Page 13

ENGLISH

12

OPERATION INSTRUMENTS »

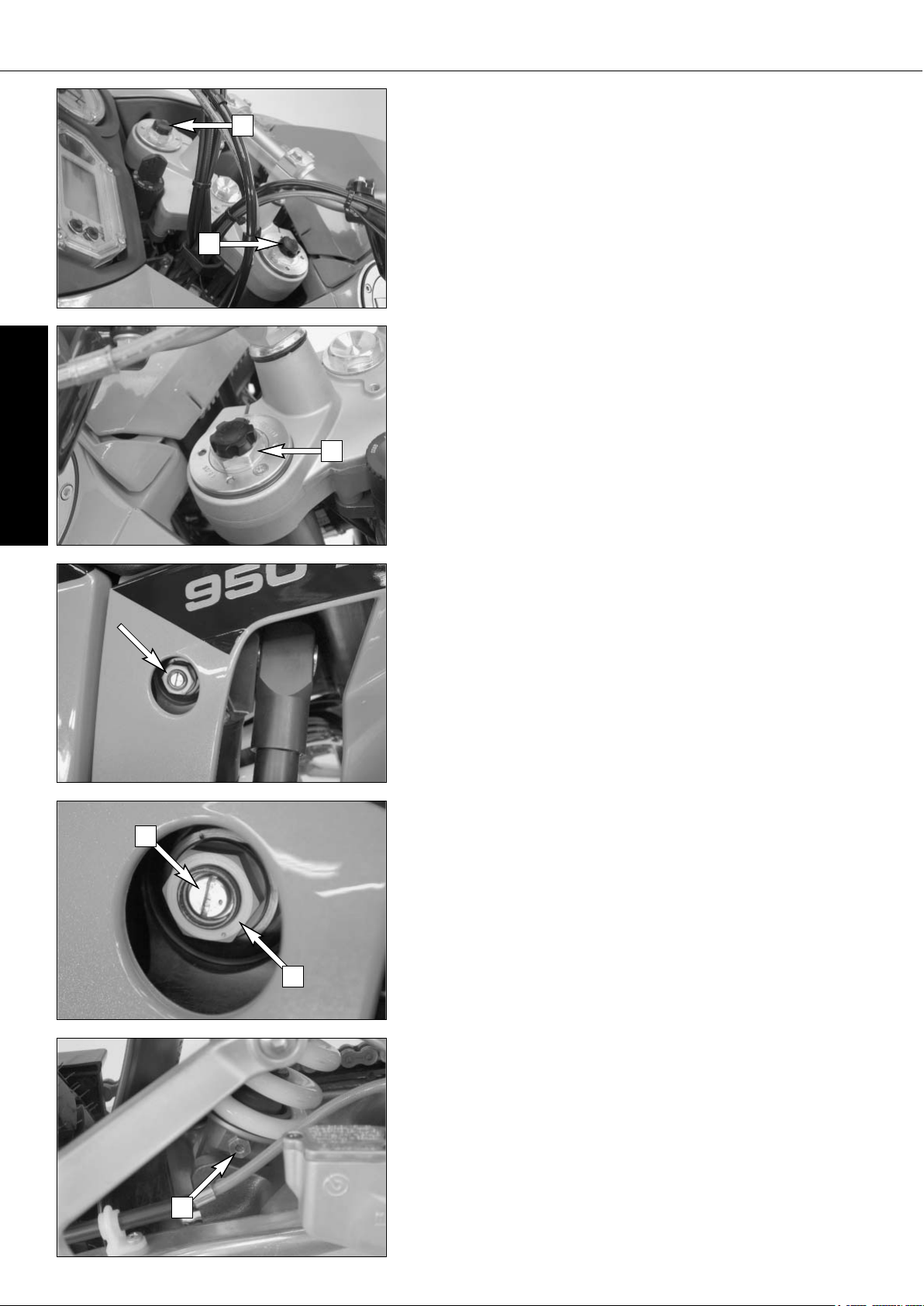

Rebound damping of fork

The fork's damping action during rebound travel (rebound damping) can also

be adjusted. This allows you adjust the damping behavior to match your driving style and the payload.

The adjusting screws [1] are located on the upper end of the fork legs.

More information is provided in the chapter "Adjusting the fork and shock

absorber.“

Spring preload of the fork

The fork's preload can be adjusted by means of the adjusting screws [2].

More information is provided in the chapter "Adjusting the fork and shock

absorber.“

Damping action during compression of shock absorber

The shock absorber's damping action during compression travel (compression

damping) can be adjusted. This allows you adjust the shock absorber's damping behavior to match your driving style and the payload.

The damping rate can be adjusted in the low and high-speed range (Dual

Compression Control). The designation low and high-speed refers to the movement of the shock absorber and not to the motorcycle's driving speed.

The adjusting screw [3] for the low-speed range can be adjusted with a

screwdriver.

The adjusting screw [4] for the high-speed range can be adjusted with a

17 mm socket wrench.

More information is provided in the chapter "Adjusting the fork and shock

absorber.“

Rebound damping of shock absorber

The shock absorber's damping action during rebound travel (rebound damping) can also be adjusted. This allows you adjust the damping behavior to

match your driving style and the payload.

The adjusting screw [5] is located on the bottom of the shock absorber.

More information is provided in the chapter "Adjusting the fork and shock

absorber.“

1

1

2

3

4

5

Page 14

ENGLISH

13

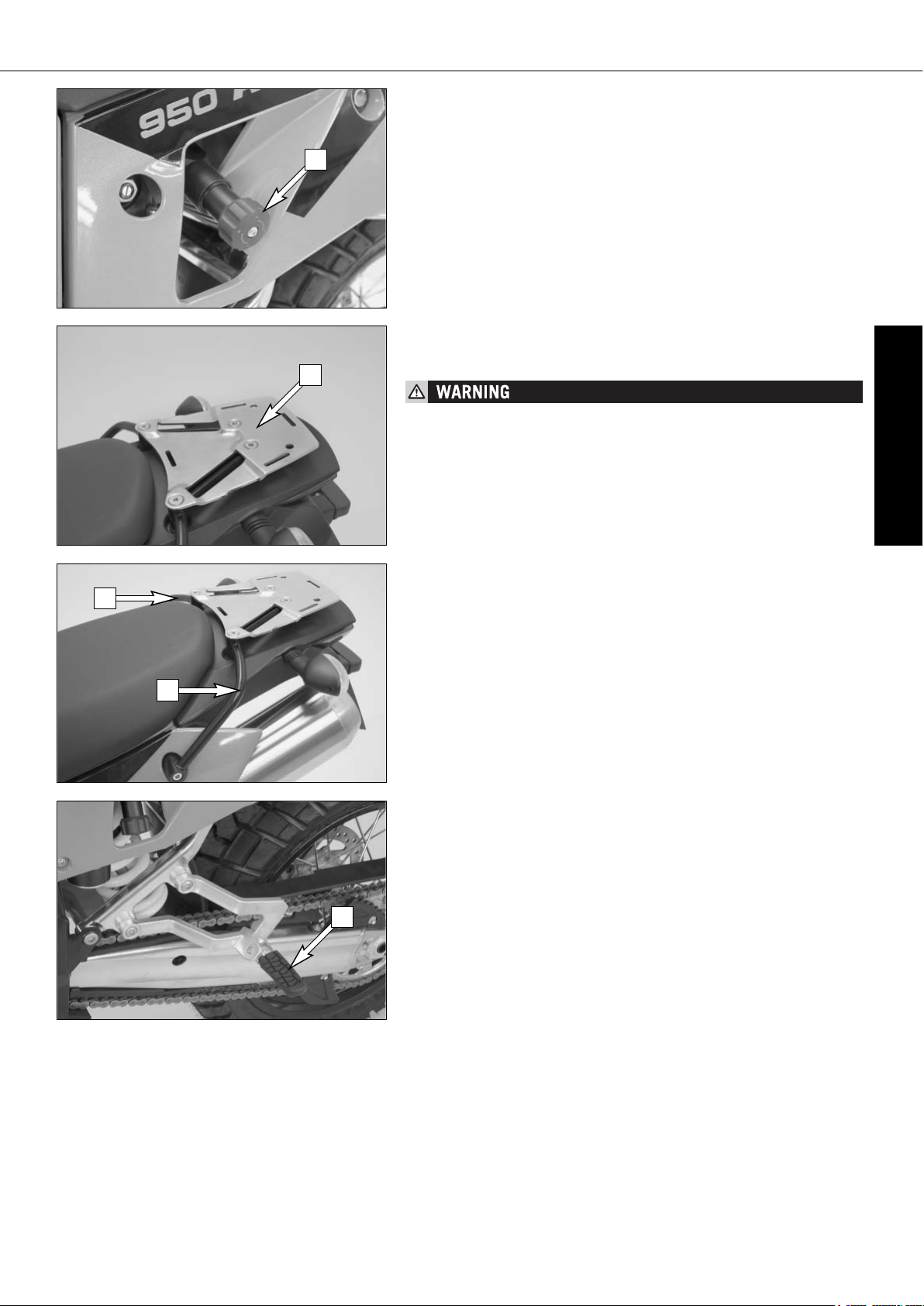

Shock absorber's preload adjuster

The shock absorber's preload adjuster is infinitely variable by means of the

hand wheel [1]. This allows the shock absorber to be adapted to match your

body weight and the payload.

The hand wheel can be swung out to make adjustments.

Baggage carrier plate

The base plate for your choice of case system can be attached to the baggage

carrier plate [2].

– DO NOT LOAD MORE THAN 8 KG ON THE TRUNK CARRIER RACK.

– OBSERVE THE BAGGAGE MANUFACTURER'S INSTRUCTIONS.

Grips

The passenger can hold on to both grab handles [3].

Footrests

The passenger footrests [4] fold up.

OPERATION INSTRUMENTS »

1

2

3

3

4

Page 15

ENGLISH

14

GENERAL TIPS AND WARNINGS FOR STARTING THE MOTORCYCLE »

Instructions for initial operation

– Make sure the work for the „pre-delivery inspection“ was per-

formed by your authorized KTM workshop. The DELIVERY CERTIFICATE and SERVICE MANUAL will be handed over when you

pick up your vehicle.

– Read these operating instructions carefully before your first ride.

– Enter the chassis, engine and key numbers on page 1.

– Familiarize yourself with the operating elements.

– Adjust the hand brake lever and foot brake lever to your most

comfortable position.

– This motorcycle is equipped with 2 catalytic converters.

Leaded fuel will destroy the catalytic converters. Please use

unleaded fuel only.

– Get used to handling the motorcycle on an empty parking lot,

before starting on a longer drive. Also try to drive as slowly as

possible and in standing position, to improve your feeling for

the vehicle.

– Do not drive along off-road tracks which go beyond your abitily

and experience.

– Hold the handlebars with both hands and leave your feet on

the foot rests while driving.

– Remove your foot from the foot brake lever when you are not

braking. If the foot brake lever is not released the brake pads

rub continuously and the braking system is overheated.

– Do not make any alterations to the motorcycle and always use

ORIGINAL KTM SPARE PARTS. Spare parts from other man-

ufacturers can impair the safety of the motorcycle.

– Motorcycles are sensitive to changes in the weight distribution.

Read the section on "Accessories and payload“ when carrying

luggage.

– Pay attention to running-in procedure.

Running in the LC8 engine

Even finely machined surfaces of engine parts have rougher surfaces than parts that slide on each other for a long time. Therefore,

every engine must be run in. For this reason, do not demand maximum performance from the engine for the first 1000 kilometers

(620 miles). The vehicle must be run in at low, changing performance level for the first 1000 km (620 miles). The maximum number of revolutions per minute must not go exceed 6500 rpm. Once

you have run your engine in for 1000 km, you may push it to its

9500 rpm limit , i.e. up to the black zone indicated in the tachometer. Exceeding the above listed rotations as well as pushing high

rpm when the engine is cold will have an adverse effect on the life

of your engine.

– WEAR SUITABLE CLOTHING WHEN DRIVING A MOTORCYCLE.

CLEVER KTM DRIVERS ALWAYS WEAR A HELMET, BOOTS, GLOVES

AND A JACKET, REGARDLESS OF WHETHER DRIVING ALL DAY OR

JUST FOR A SHORT TRIP. THE PROTECTIVE CLOTHING SHOULD BE

BRIGHTLY COLORED SO THAT OTHER VEHICLE CAN SEE YOU AS

EARLY AS POSSIBLE. YOUR PASSENGER WILL ALSO NEED SUIT-

ABLE PROTECTIVE CLOTHING.

– DO NOT DRIVE AFTER HAVING CONSUMED ALCOHOL.

– ALWAYS TURN ON THE LIGHT TO MAKE SURE THAT OTHER DRIV-

ERS BECOME AWARE OF YOU AS EARLY AS POSSIBLE.

– DRIVE AT A MODERATE SPEED FOR THE FIRST FEW KILOMETERS

OF EACH TRIP TO ALLOW THE TIRES TO REACH THE NECESSARY

OPERATING TEMPERATURE. MAXIMUM ROAD GRIP IS ASSURED

WHEN THE TIRES ARE WARM.

– THE FRONT AND REAR WHEEL ARE ALLOWED TO BE FITTED ONLY

WITH TIRES THAT HAVE THE SAME PROFILE TYPE.

– THE TIRES MUST BE DESIGNED FOR A MAXIMUM SPEED OF 240

KPH (SPEED SYMBOL V) AND MUST BE AUTHORIZED BY KTM.

– DO NOT EXCEED THE RESPECTIVE MAXIMUM SPEED FOR TIRES

DESIGNED WITH A SPEED INDEX OF LESS THAN "V“ (240 KPH).

A STICKER SHOWING THE MAXIMUM SPEED MUST BE AFFIXED TO

THE MOTORCYCLE WITHIN THE DRIVER'S FIELD OF VISION.

– NEW WHEELS HAVE A SMOOTH SURFACE, WHICH MEANS THAT THEY

MUST BE RUN IN TO ACHIEVE FULL GRIP. FOR THIS PURPOSE,

RIDE THE MOTORCYCLE CAREFULLY AT MODERATE SPEED DURING THE FIRST 200 KILOMETERS WITH NEW TIRES, TILTING THE

VEHICLE AT DIFFERENT ANGLES SO THAT ALL SECTIONS ARE

PROPERLY ROUGHENED. TIRES WILL NOT DISPLAY THEIR FULL

GRIP CHARACTERISTICS UNTIL THEY ARE PROPERLY RUN IN.

– WHEELS WITH A DIFFERENT RIM DIAMETER OR OTHER RIM WIDTH

MAY NOT BE MOUNTED OTHERWISE THE VEHICLE HANDLING WILL

NO LONGER BE SAFE.

– OBSERVE THE TRAFFIC REGULATIONS, DRIVE DEFENSIVELY AND

TRYING TO LOOK AHEAD AS FAR AS POSSIBLE SO THAT ANY HAZARDS CAN BE RECOGNIZED AS EARLY AS POSSIBLE.

– CHOOSE YOUR DRIVING SPEED ACCORDING TO THE CONDITIONS

AND YOUR DRIVING SKILLS.

– DRIVE CAREFULLY ON UNKNOWN ROADS OR ON UNFAMILIAR

TRIALS.

– RENEW THE VIZOR ON YOUR HELMET OR THE GLASS OF YOUR

GOGGLES ON TIME SO AS TO ENSURE OPTIMUM VISION IN ANY

SITUATION. WHEN LIGHT SHINES DIRECTLY ON SCRATCHED VISOR

OR GOGGLES, THE OPERATOR WILL BE BLINDED.

– NEVER LEAVE YOUR MOTORCYCLE WITHOUT SUPERVISION IF THE

ENGINE IS RUNNING.

Accessories and payload

Accessory parts and baggage can significantly decrease a motorcycle's driving stability. Please observe the following warnings.

– NEVER DRIVE FASTER THAN 130 KPH (80 MPH) IF YOU HAVE

MOUNTED ACCESSORY PARTS ON YOUR MOTORCYCLE. ACCESSORY

PARTS CAN SIGNIFICANTLY IMPAIR THE MOTORCYCLE'S HANDLING, ESPECIALLY IN THE MAXIMUM SPEED RANGE.

– NEVER DRIVE FASTER THAN 130 KPH (80 MPH) IF YOUR MOTOR-

CYCLE IS LOADED WITH CASES OR OTHER BAGGAGE. THEY WILL

IMPAIR THE MOTORCYCLE'S HANDLING AT HIGHER SPEEDS AND

CAN EASILY CAUSE IT TO GO OUT OF CONTROL

– IF YOU HAVE CASES MOUNTED, DO NOT EXCEED THE MANUFAC-

TURER'S RECOMMENDED MAXIMUM PAYLOAD.

– FASTEN THE BAGGAGE CLOSE TO THE CENTER OF THE MOTOR-

CYCLE AND DISTRIBUTE THE WEIGHT EVENLY ON THE FRONT AND

REAR WHEELS AND ON THE LEFT AND RIGHT.

– BAGGAGE MUST BE SECURELY AND ADEQUATELY FASTENEND;

LOOSE BAGGAGE WILL SIGNIFICANTLY IMPAIR DRIVING SAFETY.

– A HIGH PAYLOAD WILL CHANGE THE MOTORCYCLE'S HANDLING

AND CONSIDERABLY INCREASE THE BRAKING DISTANCE; ADAPT

YOUR DRIVING SPEED ACCORDINGLY.

– NEVER EXCEED THE MAXIMUM PERMISSIBLE LADEN WEIGHT AND

THE AXLE WEIGHTS. THE MAXIMUM PERMISSIBLE LADEN WEIGHT

IS MADE UP OF THE FOLLOWING COMPONENTS:

– MOTORCYCLE READY FOR OPERATION AND TANK FULL

– LUGGAGE

–

DRIVER AND PASSENGER WITH PROTECTIVE CLOTHING AND HELMET

Page 16

ENGLISH

15

DRIVING INSTRUCTIONS »

Check the following before each start

When you start, the motorcycle must be in perfect mechanical condition. For

safety reasons, you should make a habit of performing an overall check of

your motorcycle before each start.

The following checks should be performed:

1 FUEL

Check the fuel quantity in the tanks.

2 CHAIN

A loose chain can fall from the chain wheels; an extremely worn chain can

tear, and insufficient lubrication can result in unnecessary wear of chain

and chain wheels.

3 TIRES

Check for damaged tires. Tires showing cuts or dents must be replaced.

The tread depth must comply with the legal regulations. Also check the

air pressure. Insufficient tread and incorrect air pressure deteriorate the

driving performance.

4 BRAKES

Check correct functioning of the braking system. Check for sufficient

brake fluid in the reservoir. The reservoirs have been designed in such a

way that brake fluid does not need to be refilled even when the brake pads

are worn. If the level of brake fluid falls below the minimum value, this

indicates a leak in the braking system or completely worn out brake pads.

Arrange for the braking system to be checked by a KTM specialist, as complete failure of the braking system can be avoided.

Also check the state of the brake hose and the thickness of the brake

linings.

Check free travel at hand brake lever and foot brake lever.

5 CABLES

Check the adjustment and smooth operation of the throttle cables and the

choke cable.

6 COOLING FLUID

Check the level of cooling fluid when the engine is cold.

7 ELECTRICAL SYSTEM

Start the engine and check the headlight, taillight, brake light, turn

signal, indicator lamps and horn for proper functioning.

8 CHECK OIL LEVEL

Insufficient oil results in premature wear and consequently to engine

damage.

9 BAGGAGE, PAYLOAD

Never exceed the maximum total weight (400 kg, 883 lbs) and the motorcycle's wheel loads. The maximum total weight is comprised of:

– the motorcycle in a running condition and refueled (220 kg, 485 lbs)

– the baggage and accessories

– the driver and passenger with protective gear and helmet

Adjust the tire inflation pressure as well as the preload and damping properties of the fork and shock absorber to the total weight.

10 REAR MIRROR

Sit on the motorcycle and check the adjustment of the rear mirror.

NEVER DRIVE FASTER THAN 130 KPH (80 MPH) IF YOUR MOTORCYCLE IS LOADED

WITH CASES OR OTHER BAGGAGE. THEY WILL IMPAIR THE MOTORCYCLE'S HANDLING AT HIGHER SPEEDS AND CAN EASILY CAUSE IT TO GO OUT OF CONTROL.

Page 17

ENGLISH

16

DRIVING INSTRUCTIONS »

Starting when the engine is cold

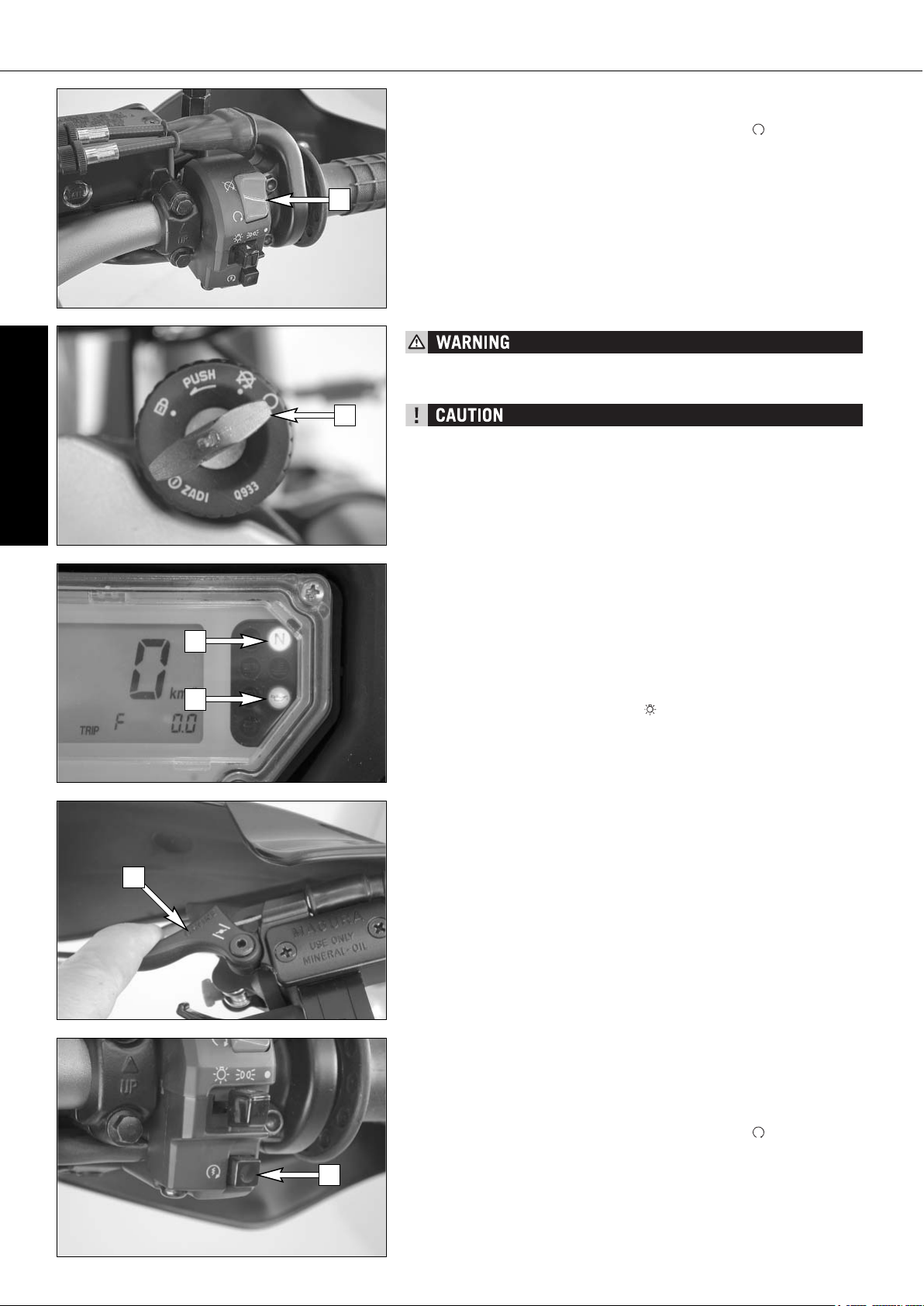

1 Switch on emergency OFF switch [1].

2 Switch on ignition (turn ignition key [2] into position ).

NOTE:

Usually the operating noise of the fuel pump can briefly be heard after

the ignition is switched on.

3 Switch transmission to idle (green indicator lamp N [3] lights up).

4 Operate cold starting device (choke) [5].

Only pull the choke lever half way out at outer temperatures over 5°C (41°F).

Pull the choke lever all the way out at outer temperatures below 5°C.

5 Do not accelerate; operate starter button [6].

6 The oil pressure warning lamp [4] should go out as soon as the engine is

running.

7 Push the choke lever back in after a short time (max. 1 km, 0,6 mile).

8 Take the motorcycle off of the main stand or side stand.

DO NOT START THE ENGINE AND ALLOW IT TO IDLE IN A CLOSED ROOM. EXHAUST

FUMES ARE POISONOUS AND CAN CAUSE LOSS OF CONSCIOUSNESS AND DEATH.

ALWAYS PROVIDE ADEQUATE VENTILATION WHILE THE ENGINE IS RUNNING.

– IF THE OIL PRESSURE WARNING LAMP DOES NOT GO OUT AS SOON AS THE

ENGINE IS RUNNING, IMMEDIATELY SWITCH OFF THE ENGINE. IF THE ENGINE

IS NOT SWITCHED OFF, ENGINE DAMAGE WILL OCCUR WITHIN A SHORT

PERIOD OF TIME. CHECK THE ENGINE OIL LEVEL OR CONTACT A KTM WORK-

SHOP.

– MAXIMUM PERIOD FOR CONTINUOUS STARTING: 5 SECONDS. WAIT AT LEAST

5 SECONDS BEFORE TRYING AGAIN.

– DON’T RIDE YOUR MOTORCYCLE WITH FULL LOAD AND DON’T REV ENGINE

WHEN COLD. BECAUSE THE PISTON IS WARMING UP FASTER THAN THE

WATER COOLED CYLINDER, IT CAN CAUSE ENGINE DAMAGE. ALWAYS LET THE

ENGINE WARM UP BEFORE AND REFRAIN FROM DRIVING WITH FULL LOAD

UNTIL THE ENGINE IS WARM.

IF THE ENGINE IS DOES NOT CRANK WHEN YOU ACTUATE THE STARTER

TIP SWITCH:

– the transmission is switched to idle

– Check if the emergency OFF switch is on

– Check if the ignition is on

– the headlight is on (Light switch in position).

– If this is not the case, the battery is discharged

– If the lights are on, proceed as described in the „Trouble-shooting“

section or contact a KTM dealer.

IF THE ENGINE CRANKS BUT DOES NOT START, WHEN YOU ACTUATE THE

STARTER TIP SWITCH:

– Check if the fuel tap is open

– Check if the choke lever has been operated

– Check if sufficient fuel is in the tank

– If this is not the case, refill the tank

– if sufficient fuel is in the tank, proceed as described in the „Trouble-

shooting“ section or contact a KTM dealer.

NOTE:

This motorcycle is equipped with a safety starting system. The engine can

only be started if the transmission is in neutral or the clutch lever is pulled.

If the side stand is folded down, the engine can only be started if the transmission is in neutral or the clutch lever is pulled. The engine will stall if a

gear is engaged and the clutch lever is released with the side stand folded

down.

Starting when the engine is warm or hot

1 Switch on emergency OFF switch [1].

2 Switch on ignition (turn ignition key [2] into position ).

3 Switch transmission to idle (green indicator lamp N [3] lights up).

4 Do not accelerate; operate starter button [6].

5 The oil pressure warning lamp [4] should go out as soon as the engine is

running.

6 Take the motorcycle off of the main stand or side stand.

1

2

3

4

5

6

Page 18

ENGLISH

17

DRIVING INSTRUCTIONS »

Starting off

Turn on the light, pull the clutch lever and engage 1st gear. Slowly

release the clutch lever while you open the throttle.

– BEFORE YOU START OFF, CHECK THAT THE MAIN STAND HAS BEEN

SWUNG UP FULLY. IF THE STAND DRAGS ON THE GROUND, THE

MOTORCYCLE CAN GO OUT OF CONTROL.

– ALWAYS TURN ON THE LIGHT WHEN YOU DRIVE. OTHER DRIVERS

WILL BE ABLE TO SEE YOU MUCH SOONER.

Shifting/Riding

You are now in first gear, refered to as the drive or uphill gear.

Depending on the conditions (traffic, road gradient, etc.), you can

shift to a higher gear. Close throttle, at the same time pull clutch

lever and shift to the next higher gear. Let clutch lever go again

and open throttle. If you turned on the choke, make sure you turn

it off again as soon as engine is warm.

Only accelerate to the extent that road and weather conditions allow.

Be especially careful when you accelerate in curves. Abrupt opening of the throttle can cause the motorcycle to go out of control

and also increases fuel consumption.

By shifting down, use the brakes if necessary and close throttle at

the same time. Pull clutch lever and shift down to the next gear.

Let clutch lever go slowely and open throttle or shift down again.

If the engine is killed f.ex. at a crossing, simply pull the clutch

lever and start. It is not necessary to switch the gear to NEUTRAL.

– AVOID ABRUPT LOAD CHANGES WHILE RIDING AROUND BENDS

AND ON WET OR SLIPPERY GROUND. OTHERWISE YOU MIGHT

EASILY LOSE CONTROL OVER YOUR MOTORCYCLE.

– WHILE RIDING YOUR MOTORCYCLE, NEVER SWITCH THE IGNI-

TION LOCK TO POSITIONS AND .

– DO NOT TRY TO CHANGE THE SETTINGS WHILE DRIVING. YOUR

ATTENTION WILL BE DISTRACTED FROM THE TRAFFIC AND MAY

CAUSE YOU TO LOSE CONTROL OF YOUR MOTORCYCLE.

– THE PASSENGER MUST HOLD ON TO THE DRIVER OR THE GRAB

HANDLE ON THE BAGGAGE CARRIER DURING THE RIDE AND KEEP

HIS FEET ON THE PASSENGER FOOTRESTS.

– REGULARLY MAKE SURE THAT THE BAGGAGE AND CASES ARE

TIGHTLY FASTENED.

– AFTER FALLING WITH THE MOTORCYCLE, CHECK ALL FUNCTIONS

THOROUGHLY BEFORE STARTING UP OPERATIONS AGAIN.

– A BENT HANDLEBAR MUST ALWAYS BE REPLACED. NEVER TRY TO

STRAIGHTEN THE HANDLEBAR BECAUSE THIS WILL CAUSE IT TO

LOSE ITS STABILITY.

– HIGH RPM RATES WHEN THE ENGINE IS COLD HAVE AN ADVERSE

EFFECT ON THE LIFE OF YOUR ENGINE. WE RECOMMEND YOU RUN

THE ENGINE IN A MODERATE RPM RANGE FOR A FEW MILES GIVING IT A CHANCE TO WARM UP. AFTER THAT NO FURTHER PRECAUTIONS IN THIS RESPECT NEED BE TAKEN. THE ENGINE HAS

REACHED OPERATING TEMPERATURE AS SOON AS THE SECOND

BAR ON THE TEMPERATURE INDICATOR LIGHTS UP.

– IF THE RED OIL PRESSURE WARNING LAMP LIGHTS UP WHILE DRIV-

ING, THE OIL PRESSURE IS TOO LOW TO ADEQUATELY LUBRICATE

THE ENGINE. STOP IMMEDIATELY AND SWITCH OFF THE ENGINE.

IF YOU CONTINUE TO DRIVE, ENGINE DAMAGE WILL OCCUR WITHIN

A SHORT PERIOD OF TIME. CHECK THE ENGINE OIL LEVEL OR CONTACT AN AUTHORIZED KTM WORKSHOP.

– NEVER HAVE THE THROTTLE WIDE OPEN WHEN CHANGING DOWN

TO A LOWER GEAR. THE ENGINE WILL OVERSPEED, DAMAGING THE

VALVES. IN ADDITION, THE REAR WHEEL BLOCKS SO THAT THE

MOTORCYCLE CAN EASILY GET OUT OF CONTROL.

– NEVER USE YOUR MOTORCYCLE WITHOUT AN AIR FILTER.

OTHERWISE DUST AND DIRT MAY ENTER THE ENGINE AND CAUSE

INCREASED WEAR.

– STOP IMMEDIATELY IF A PERCEPTIBLE POWER LOSS OCCURS

WHILE DRIVING DUE TO A DEFECTIVE IGNITION CAUSED BY A

CYLINDER MISFIRING OR BREAKING DOWN. IF THE UNBURNED

FUEL/AIR MIXTURE REACHES THE CATALYTIC CONVERTER, IT WILL

IGNITE AND THE RESULTING HEAT WILL DESTROY THE CATALYTIC

CONVERTER AND THE ADJOINING COMPONENTS.

– THE RED COOLANT WARNING LAMP LIGHTS UP WHEN THE COOLANT

TEMPERATURE HAS REACHED 120°C (248°F).

POSSIBLE CAUSES FOR THE INCREASE IN TEMPERATURE:

– LOW DRIVING VELOCITY AND HIGH LOAD SITUATION IN HIGH AIR

TEMPERATURES

– LEVEL OF COOLANT IN THE SYSTEM IS INSUFFICIENT

– FAN AT RADIATOR IS NOT RUNNING

–

IMPROPER USE OF THE CLUTCH WHILE DRIVING AT LOW VELOCITIES

LET THE ENGINE COOL DOWN. CHECK THE COOLING LIQUID LEVEL

IN THE RADIATOR - CAUTION SCALDING HAZARD! DO NOT DRIVE

ON, UNTIL THERE IS SUFFICIENT LIQUID IN THE COLING SYSTEM.

HOWEVER, CALL ON ONE OF KTM’S DEALERS AS SOON AS POSSIBLE IN ORDER TO HAVE THE DEFECT REMEDIED.

– IN THE EVENT THAT, WHILE RIDING ON YOUR MOTORCYCLE, YOU

NOTICE ANY UNUSUAL OPERATION-RELATED NOISE, STOP IMMEDIATELY, TURN THE ENGINE OFF, AND CONTACT AN AUTHORIZED

KTM DEALER.

Braking

Close throttle and apply the hand and foot brakes at the same time.

When driving on sandy, wet or slippery ground use mainly the rear

wheel brake. Always brake with feeling, blocking wheels can cause

you to skid or fall. Also change down to lower gears depending on

your speed.

When driving downhill, use the braking effect of the engine. Change

down one or two gears but do not overspeed the engine. In this

way, you will not need to brake so much and the brakes will not

overheat.

– IN THE RAIN, OR AFTER THE MOTORCYCLE HAS BEEN WASHED,

BRAKING ACTION MAY BE DELAYED DUE TO WET BRAKE DISCS.

FIRST, THE BRAKES MUST BE BRAKED DRY.

– ON SALT-SPRAYED OR DIRTY ROADS BRAKE ACTION MAY BE

DELAYED AS WELL. FIRST, THE BRAKES MUST BE BRAKED CLEAN.

– REMEMBER THAT THE STOPPING DISTANCE WILL BE LONGER IF

YOU ARE CARRYING A PASSENGER OR BAGGAGE.

– WHEN YOU BRAKE, THE BRAKE DISCS, BRAKE PADS, BRAKE

CALIPER AND BRAKE FLUID HEAT UP. THE HOTTER THESE PARTS

GET, THE WEAKER THE BRAKING EFFECT. IN EXTREME CASES,

THE ENTIRE BRAKING SYSTEM CAN FAIL.

Stopping and parking

Apply the brakes fully and put the engine into neutral. To stop the

engine, switch off the ignition. Park the motorcycle on a firm surface and lock.

– ALWAYS PARK YOUR MOTORBIKE ON A SOLID AND HORIZONTAL

SURFACE.

– NEVER LEAVE YOUR MOTORCYCLE WITHOUT SUPERVISION AS

LONG AS THE ENGINE IS RUNNING.

– MOTORCYCLE ENGINES PRODUCE A GREAT AMOUNT OF HEAT

WHILE RUNNING. THE ENGINE RADIATORS, EXHAUST, EXHAUST

SYSTEM, BRAKE DISCS, AND SHOCK ABSORBERS CAN BECOME

VERY HOT. DO NOT TOUCH ANY OF THESE PARTS AFTER OPERATING THE MOTORCYCLE, AND TAKE CARE TO PARK IT WHERE PEDESTRIANS ARE NOT LIKELY TO TOUCH IT AND GET BURNED

– NEVER PARK YOUR MOTORCYCLE IN PLACES WHERE THERE EXIST

FIRE HAZARDS DUE TO DRY GRASS OR OTHER EASILY FLAMMABLE MATERIALS.

ALWAYS TAKE OUT THE IGNITION KEY WHEN PARKING YOUR MOTORCYCLE SO THAT IT CANNOT BE USED BY UNAUTHORIZED PERSONS.

Page 19

ENGLISH

18

DRIVING INSTRUCTIONS »

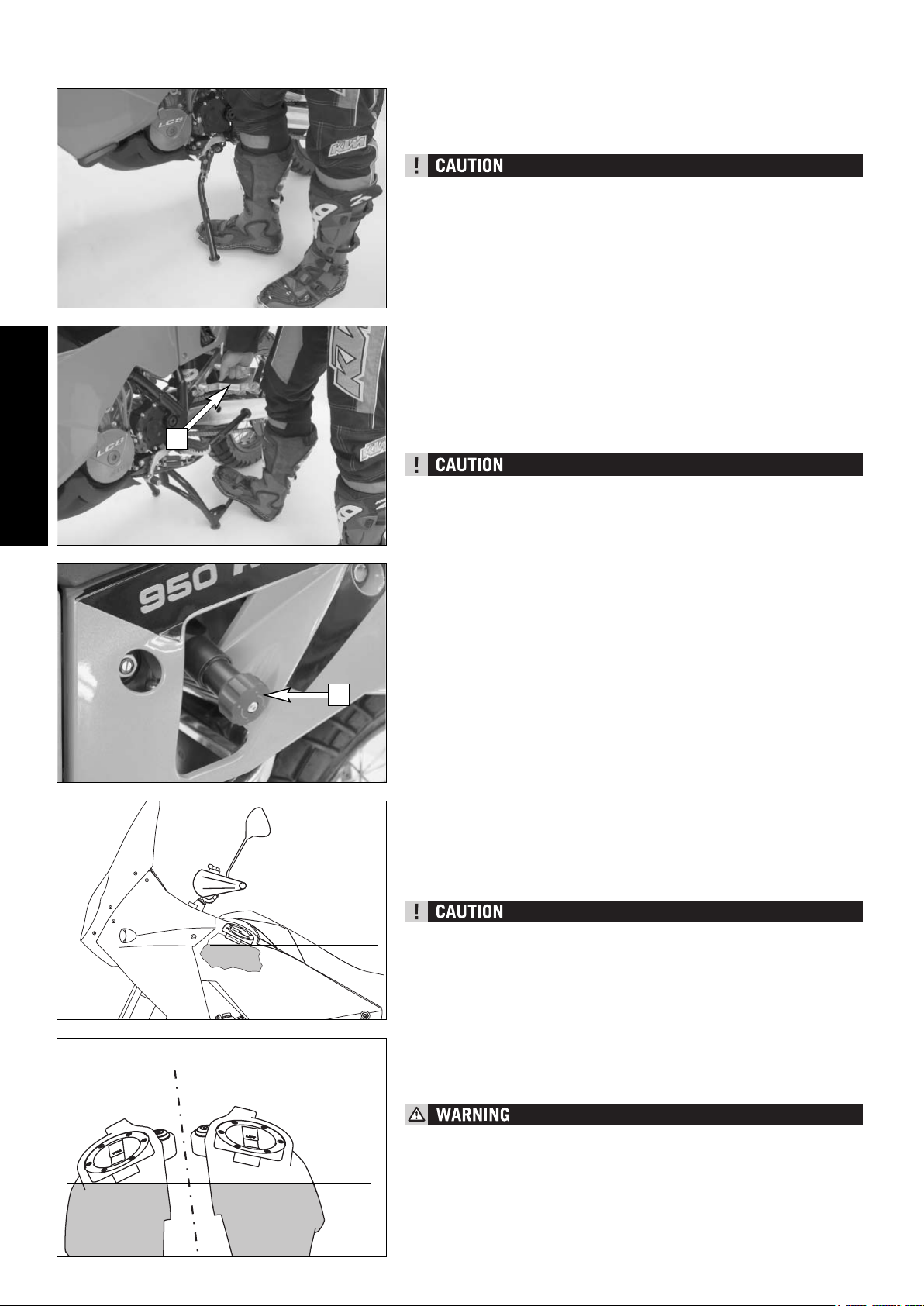

INFORMATION ABOUT THE SIDE STAND

Use your foot to push the side stand forward as far as possible, and lean your

motorcycle to the side. Make sure that your motorcycle is standing safely on

solid ground. Just in case, you can also put in a gear.

THE SIDE STAND IS DIMENSIONED FOR THE WEIGHT OF THE MOTORCYCLE ONLY.

IF YOU ARE SITTING ON THE MOTORBIKE AND THUS APPLY AN ADDITIONAL LOAD

ONTO THE SIDE STAND, YOU MAY CAUSE DAMAGE TO THE SIDE STAND OR THE

ENGINE CASE, AND YOUR MOTORBIKE MAY FALL OVER.

NOTE REGARDING THE CENTER STAND:

We advise the following procedure to place the motorcycle on the center stand

as effortlessly as possible:

a) press main stand to ground using foot

b) put your weight on the stand stabilizer and pull the motorcycle back by

the footrest support (see illustration).

Make sure that the ground is solid and that your motorcycle is standing

securely.

– THE CENTER STAND IS DESIGNED TO HOLD THE WEIGHT OF THE MOTORCY-

CLE ONLY. BY SITTING ON THE MOTORCYCLE, YOU WILL PUT ADDITIONAL WEIGHT

ON THE CENTER STAND, POSSIBLY CAUSING THE CENTER STAND OR FRAME

TO BE DAMAGED OR THE MOTORCYCLE TO FALL DOWN.

–

DO NOT PULL THE MOTORCYCLE BACK ON THE CENTER STAND BY HOLDING

THE HAND WHEEL [2] ON THE SHOCK ABSORBER ADJUSTMENT (IT COULD CAUSE

THE SHOCK ABSORBER TO LEAK) BUT USE THE FOOTREST BRACKET [1].

Fuel

In the condition at delivery, the LC8 engine requires unleaded fuel with at

least RON 95 (USA = Premium RON 91).

If using lower octane fuel, it is easy to change over to the pre-programmed

ignition curve for 80 - 94 octane (RON) (see activating the ignition curve for

low-octane fuel).

– USE UNLEADED FUEL WITH AT LEAST RON 95 (USA = PREMIUM RON 91). IF

USING LOWER OCTANE FUEL, THE IGNITION CURVE MUST BE CHANGED, OTH-

ERWISE ENGINE DAMAGE WILL OCCUR.

– THIS MOTORCYCLE IS EQUIPPED WITH 2 CATALYTIC CONVERTERS. LEADED

FUEL WILL DESTROY THE CATALYTIC CONVERTERS. PLEASE USE UNLEADED

FUEL ONLY.

The 950 Adventure has 2 tanks with 1 filler neck each. Fill the right tank

first, then the left tank (see drawing for the maximum filling level). If the right

tank is filled up to the filler neck, fuel may overflow when the motorcycle is

parked on the side stand after refueling when the fuel becomes warm.

GASOLINE IS HIGHLY FLAMMABLE AND POISONOUS. EXTREME CAUTION SHOULD

BE USED WHEN HANDLING GASOLINE. DO NOT REFUEL THE MOTORCYCLE NEAR

OPEN FLAMES OR BURNING CIGARETTES. ALWAYS SWITCH OFF THE ENGINE

BEFORE REFUELLING. BE CAREFUL NOT TO SPILL GASOLINE ON THE ENGINE OR

EXHAUST PIPE WHILE THE ENGINE IS HOT. WIPE UP SPILLS PROMPTLY. IF GASOLINE IS SWALLOWED OR SPLASHED IN THE EYES, SEEK A DOCTOR’S ADVICE

IMMEDIATELY.

MAX

MAX

2

1

Page 20

ENGLISH

19

Page 21

ENGLISH

20

PERIODIC MAINTENANCE SCHEDULE »

A CLEAN MOTORCYCLE CAN BE CHECKED MORE QUICKLY WHICH SAVES MONEY!

1st Service

after

1000 km

7500 km

or

once a year

15000 km

or

every 2 years

Engine

Change engine oil and oil filter

z z z

Clean oil screens of engine and oil tank

z z z

Clean magnetic drain plugs of engine and oil tank

z z z

Check oil lines for damage and kink-less arrangement

z z z

Renew spark plugs

z

Check and adjust valve clearance

z z

Check engine fastening bolts for tight fit

z z z

Check all engine bolts accessible from the outside for tight fit

z z z

Check clutch linings

z

Check clutch pressure booster system

z

Carburetor

Check carburetor connection boots for cracks and leaks

z z

Check synchronisation of carburators using special tool, if necessary adjust

z z

Check idle setting (1400 rpm)

z z

Check breeder hoses and fuel lines for damage and kink-free arrangement

z z

Add-on-parts

Check cooling system for leaks and antifreeze protection

z z z

Check radiator fan for proper operation

z z z

Check exhaust system for leaks and correct fitment

z z z

Check actuating cables for damage, smooth operation, and kink-less arrangement,adjust and lubricate

z z z

Check fluid level of the clutch master cylinder

z z

Check air filter, renew if necessary, clean air filter box

z

Check cables for damage and kink-less arrangement

z z z

Check headlamp adjustment

z z z

Check electrical system for function (low/high beams, stop light, turn indicators,headlamp,

z z z

flasher, tell-tale lamps, speedometer illumination, horn, side-stand switch, clutch switch,

emergency-off switch)

Make sure all bolts and nuts are tight

z z z

Brakes

Check brake fluid level, lining thickness, and brake discs

z z z

Change brake fluid

z

Check brake lines for damage and leaks

z z z

Check/adjust smooth operation, free travel of handbrake/footbrake levers

z z z

Check bolts of brake system for tight fit

z z z

Chassis

Check suspension strut and fork for leaks and proper operation

z z z

Clean fork dust sleeves

z z

Bleed fork legs

z z z

Check swinging-fork pivot

z z z

Check/adjust steering-head bearing

z z z

Check all chassis bolts for tight fit (fork plates, fork leg, axle nuts/bolts,

z z z

swinging-fork pivot, reversing lever, suspension strut)

Wheels

Check spoke tension and rim joint

z z z

Check tire condition and inflation pressure

z z z

Check chain, sprockets and chain guides for wear, force fit and tension

z z z

Check bolts on pinion and chain sprocket for locking devices and a tight fit

z z z

Lubricate chain

z z z

Check wheel bearings and jerk damper for play

z z

IF MOTORCYCLE IS USED FOR COMPETITION 7500 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE!

SERVICE INTERVALLS SHOULD NEVER BE EXCEEDED BY MORE THAN 500 KM.

MAINTENANCE WORK DONE BY KTM AUTORIZED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER!

950

ADVENTURE

2005 US

Page 22

ENGLISH

21

PERIODIC MAINTENANCE SCHEDULE »

IMPORTANT RECOMENDED MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENT ORDER

at least

once a year

every 2 years

or 15000 km

Perform complete fork maintenance

z

Perform complete suspension strut maintenance

z

Clean and lubricate steering-head bearing and sealing elements

z

Clean and adjust the carburetors

z

Treat the electrical contacts and switches with contact spray

z

Treat battery connections with contact grease

z

Change coolant fluid

z

VITAL CHECKS AND CARE PROCEDURES TO CONDUCTED BY THE OWNER OR THE MECHANIC

before

each start

after

every cleaning

every 1000 km or

after off road use

Check oil level

z

Check brake fluid level

z

Check brake pads for wear

z

Check lighting system for proper operation

z

Check horn for proper operation

z

Lubricate and adjust actuating cables and nipples

z

Bleed fork legs in regular intervals

z

Clean chain

z

Lubricate chain

z z

Check chain tension

z

Check tire pressure and wear

z

Check coolant level

z

Check fuel lines for leaks

z

Check all control elements for smooth running

z

Check brake performance

z z

Treat exposed metal components (except for the braking and exhaust

z

systems) with wax-based anti-corrosion agents

Treat ignition/steering lock and light switch with contact spray

z

Page 23

ENGLISH

22

MAINTENANCE WORK ON CHASSIS AND ENGINE »

ALL SERVICING AND ADJUSTMENT PROCEDURES DESIGNATED BY AN ASTERISK * REQUIRE THE KNOWLEDGE AND SKILLS

OF A PROFESSIONAL. IN THE INTEREST OF YOUR OWN SAFETY, HAVE THESE PROCEDURES CARRIED OUT AT A AUTHORIZED

KTM WORKSHOP! AT A KTM WORKSHOP YOUR MOTORCYCLE WILL RECEIVE OPTIMAL SERVICING BY SPECIALLY TRAINED

MECHANICS.

– WHEN CLEANING THE MOTORCYCLE, DO NOT USE A HIGH PRESSURE CLEANING UNIT IF POSSIBLE, OTHERWISE WATER

WILL PENETRATE THE BEARINGS, CARBURETOR, ELECTRIC CONNECTORS ETC.

– DO NOT USE TOOTHED WASHERS OR SPRING WASHERS WITH THE ENGINE FASTENING SCREWS, AS THESE WORK INTO

THE FRAME PARTS AND KEEP WORKING LOOSE. INSTEAD, USE SELF-LOCKING NUTS.

– IF YOU UNSCREW ANY SCREWED CONNECTIONS WITH SELF-LOCKING NUTS, THEY MUST BE REPLACED WHEN MOUNT-

ING. IF NO SELF-LOCKING NUTS ARE AVAILABLE, APPLY LOCTITE 243 TO THE THREAD. THE SCREWS AND NUTS MUST BE

REPLACED IF THE THREAD IS DAMAGED.

– ALL SCREWS AND NUTS MUST BE TIGHTENED TO THE SPECIFIED TORQUE FIGURES USING A TORQUE WRENCH. IF SCREWS

OR NUTS ARE NOT ADEQUATELY TIGHTENED, THEY CAN BECOME LOOSE AND CAUSE THE MOTORCYCLE TO GO OUT OF

CONTROL WHILE YOU DRIVE. TIGHTENING THE SCREWS AND NUTS TOO TIGHTLY CAN DAMAGE THE THREAD AND

COMPONENTS.

– LET YOUR MOTORCYCLE COOL DOWN BEFORE BEGINNING ANY MAINTENANCE WORK IN ORDER TO AVOID GETTING BURNED.

– DISPOSE OF OIL, GREASE, FILTERS, FUELS, CLEANING AGENTS ETC. ACCORDING TO YOUR LOCAL REGULATIONS.

– UNDER NO CIRCUMSTANCES MAY USED OIL BE DISPOSED OF IN THE SEWAGE SYSTEM OR IN THE OPEN COUNTRYSIDE. 1

LITER USED OIL CONTAMINATES 1,000.000 LITERS WATER.

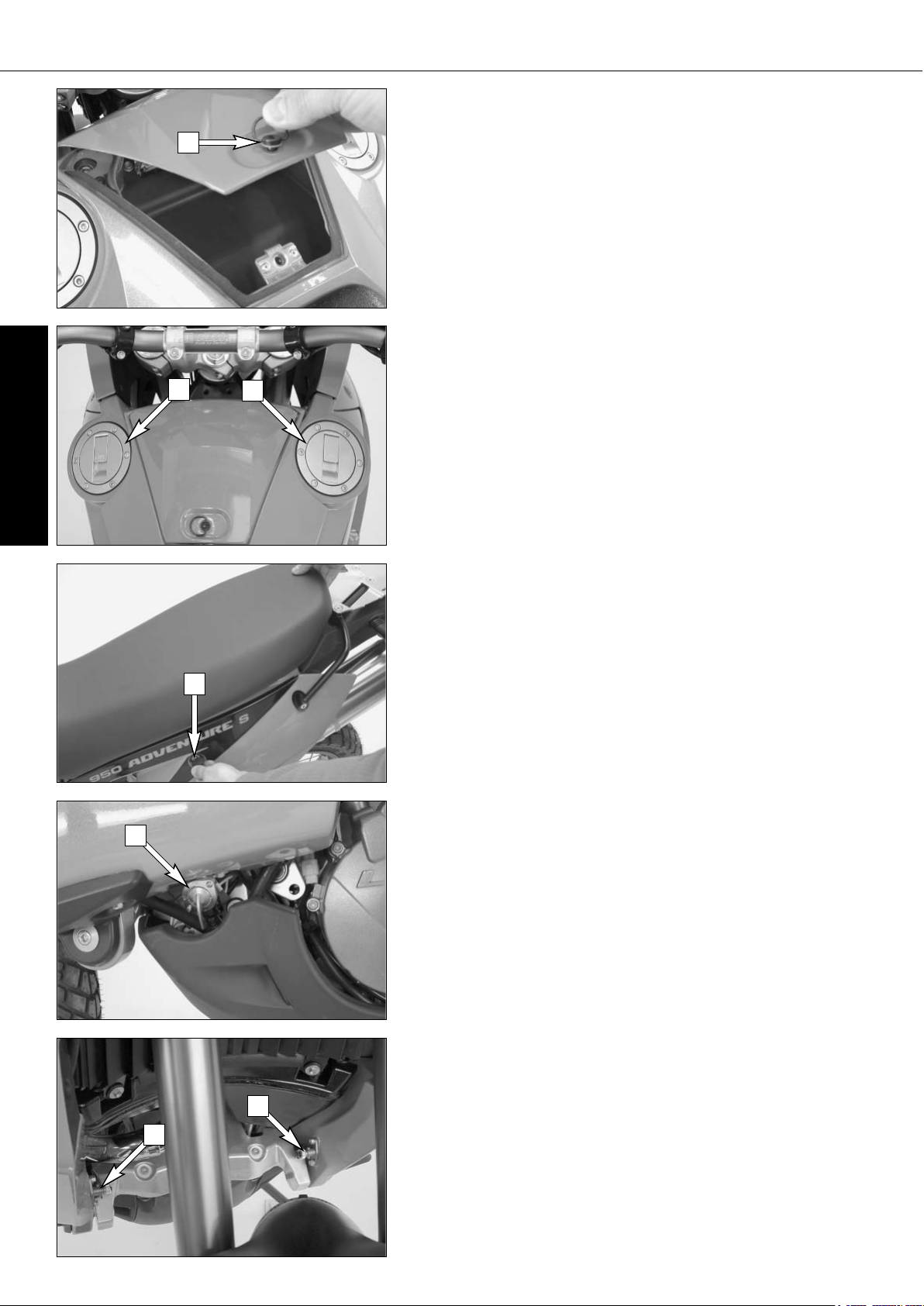

Removing and remounting the seat

Insert the ignition key in the seat lock and turn in a counterclockwise direction to unlock the seat. Lift the back of the seat and pull off towards the rear.

To remount, fit the nose [1] of the seat in the front, lower the back while pushing towards the front. Both noses [2] should fit into the frame. Insert the catch

bolts [3] in the lock housing and push the seat down in the back until you

hear the catch bolts snap into place.

Check whether the seat is correctly mounted.

IF NOT CORRECTLY MOUNTED, THE SEAT CAN SLIP WHILE YOU ARE DRIVING AND

CAUSE YOU TO LOSE CONTROL OF YOUR MOTORCYCLE.

Tool set

The tool set [4] and a recess [5] for several tool set wrenches are found under

the seat.

5

4

1

2

3

Page 24

ENGLISH

23

MAINTENANCE WORK ON CHASSIS AND ENGINE »

Adjusting the fork and shock absorber

There are a number of ways to adjust the fork and shock absorber to match

the chassis to your driving style and the payload.

We have provided a table with pragmatical values to help you tune up your

motorcycle. These tune-up specifications are reference values only and should

serve as a basis for your personal chassis and suspension tuning. Do not make

arbitrary changes to the settings (maximum ±40%) since this may impair the

handling characteristics (particularly in the high-speed range).

We recommend the "Driving Sport" damping adjustment for off-road rides on

soft subgrades (e.g. sand) and the "Driving Comfort" damping adjustment for

off-road rides on hard subgrades (e.g. rocks).

Adjusting compression damping of fork

Hydraulic compression damping determines the reaction when the fork is compressed. The degree of compression can be adjusted with adjusting

screws at the bottom of the fork legs.Remove the protecting cap [1].

Turn the adjusting screws [2] clockwise to increase damping, turn it counterclockwise to reduce damping during compression. Make the same damping

rate adjustments to both fork legs.

STANDARD ADJUSTMENT

– Turn adjusting screw clockwise as far as it will go.

– Turn 15 clicks in a counterclockwise direction.

Adjusting rebound damping of fork

Hydraulic rebound damping determines the reaction when the fork is

rebound. By turning the adjusting screw [3] (REB), the degree of damping of

the rebound can be adjusted. Turn the knob clockwise to increase damping,

turn it counterclockwise to reduce damping during rebounding. Make the same

damping rate adjustment to both fork legs.

STANDARD ADJUSTMENT

– Turn adjusting screw clockwise as far as it will go.

– Turn 18 clicks in a counterclockwise direction.

Adjusting the spring preload on the fork

The fork spring preload can be adjusted by turning the adjusting screws [4]

(wrench size 24 mm) ± 5 mm (0,2 in).

Turning in a clockwise direction will increase the preload, turning in a counterclockwise direction will decrease the preload. 1 turn will change the preload by 1 mm.

Changing the preload will not affect the rebound damping adjustment, although

adjusting screw [3] will turn at the same time.

Generally, if the preload is higher, the rebound damping should also be set

higher.

STANDARD ADJUSTMENT:

Turn the adjusting screw in a counterclockwise direction up to the stop and

then 5 turns in a clockwise direction.

BASIC SETTING

FORK

950 ADVENTURE

950 ADVENTURE S

Driving Comfort

Basic Setting

Driving Sport

Maximum Payload

Compression adjuster (clicks) 201510 10

Rebound adjuster (clicks) 231813 13

Spring preload (turns) 5

5

87

1

2

3

3

3

4

Page 25

ENGLISH

24

MAINTENANCE WORK ON CHASSIS AND ENGINE »

Compression damping of shock absorber

The shock absorber can synchronize the compression damping in the low and

high-speed range separately (Dual Compression Control).

Low and high speed refers to the movement of the shock absorber during compression and not to the speed of the motorcycle.

The low and high-speed technology overlaps.

The low-speed setting is primarily for slow to normal shock absorber compression rates.

The high-speed setting is effective at fast compression rates.

Turning in a clockwise direction will increase the damping, turning counterclockwise will decrease the damping.

STANDARD ADJUSTMENT LOW-SPEED:

– turn the adjusting screw [1] to the limit in a clockwise direction using a

screwdriver.

– unscrew the respective number of clicks for the specific type of shock absorber

in a counterclockwise direction.

950 Adventure . . . . . . . .20 clicks

950 Adventure S . . . . . . .20 clicks

STANDARD ADJUSTMENT HIGH-SPEED:

– Turn the adjusting screw in a clockwise direction up to the stop with a

socket wrench (wrench size 17 mm).

– Turn the adjusting screw in a counterclockwise direction the number of

turns specified for the respective type of shock absorber.

950 Adventure . . . . . . . .1.5 turns

950 Adventure S . . . . . .1.5 turns

THE DAMPING UNIT OF THE SHOCK ABSORBER IS FILLED WITH HIGH-COMPRESSION NITROGEN. NEVER TRY TO TAKE THE SHOCK ABSORBER APART OR TO DO

ANYMAINTENANCE WORK YOURSELF. SEVERE INJURIES COULD BE THE RESULT.

NEVER UNSCREW THE BLACK SCREW CONNECTION (24MM).

Rebound damping of shock absorber

By using the adjusting screw [4], the degree of damping of the rebound can

be adjusted. Turn the knob in a clockwise direction to increase damping, turn

it in a counterclockwise direction to reduce damping during rebounding.

STANDARD ADJUSTMENT:

– turn the adjusting screw clockwise to the stop.

– then turn the adjusting screw counterclockwise, counting the number of

clicks that corresponds to the respective type of shock absorber.

950 Adventure . . . . . . . .15 clicks

950 Adventure S . . . . . . .15 clicks

THE DAMPING UNIT OF THE SHOCK ABSORBER IS FILLED WITH HIGH-COMPRESSION NITROGEN. NEVER TRY TO TAKE THE SHOCK ABSORBER APART OR TO DO

ANY MAINTENANCE WORK YOURSELF. SEVERE INJURIES COULD BE THE RESULT.

NEVER UNSCREW THE BLACK SCREW CONNECTION [5] (15MM).

BASIC SETTING

SHOCK ABSORBER

950 ADVENTURE

Driving Comfort

Basic Setting

Driving Sport

Maximum Payload

Compression adjuster Low Speed (clicks) 252015 15

Compression adjuster High Speed (turns)

2

1.5

1 1

Rebound adjuster (clicks) 201510 10

Spring preload (turns) 6

6

10 18

BASIC SETTING

SHOCK ABSORBER

950 ADVENTURE S

Driving Comfort

Basic Setting

Driving Sport

Maximum Payload

Compression adjuster Low Speed (clicks) 252015 15

Compression adjuster High Speed (turns)

2

1.5

1 1

Rebound adjuster (clicks) 201510 10

Spring preload (turns) 6

6

10 12

1

4

5

Page 26

ENGLISH

25

MAINTENANCE WORK ON CHASSIS AND ENGINE »

Adjusting the preload of the shock absorber

The baggage and passenger put the main load on the shock absorber. To guarantee maximum handling performance, the preload of the shock absorber must

be adapted to the load.

The preload is hydraulically adjusted by turning the hand wheel [1]. Turning

in a clockwise direction will increase the preload, turning in a counterclockwise direction will reduce the preload.

Our pragmatical values are provided in the table "Basic settings for the shock

absorber" to help you to make the necessary adjustments.

STANDARD ADJUSTMENT:

– Turn the hand wheel in a counterclockwise direction up to the stop

– Turn the hand wheel 6 turns in a clockwise direction

Breathing the fork legs

Breath the fork legs regularly (see Maintenance Schedule).

To breath, place the motorcycle on the side stand and briefly remove the bleeder

screws [2] to allow any overpressure to escape from the fork.

EXCESSIVE PRESSURE IN THE INTERIOR OF THE FORK CAN CAUSE LEAKS IN THE

FORK. IF YOUR FORK IS LEAKING, IT IS RECOMMENDED TO OPEN THE BREATHER

PLUGS BEFORE HAVING THE SEALS REPLACED.

Cleaning the dust sleeves of the telescopic fork

The dust-protection bellows [3] are to remove dust and coarse dirt particles

from the fork tube. However, after some time, dirt may also get in behind the

dust-protection bellows. If this dirt is not removed, the oil sealing rings located

behind it may start to leak.

Use a screwdriver to lever the dust-protection bellows out of the outer tubes

and slide them downward.

Clean dust-protection bellows, outer tubes, and fork tubes thoroughly, and oil

them thoroughly with Universal oil spray (Motorex Joker 440) or engine oil.

Then, push dust-protection bellows into the outer tubes by hand.

NO OIL MAY REACH THE FRONT TIRE OR THE BRAKE DISKS SINCE THIS WOULD

CONSIDERABLY REDUCE THE TIRE'S ROAD GRIP AND THE BRAKING EFFECT OF

THE FRONT BRAKE.

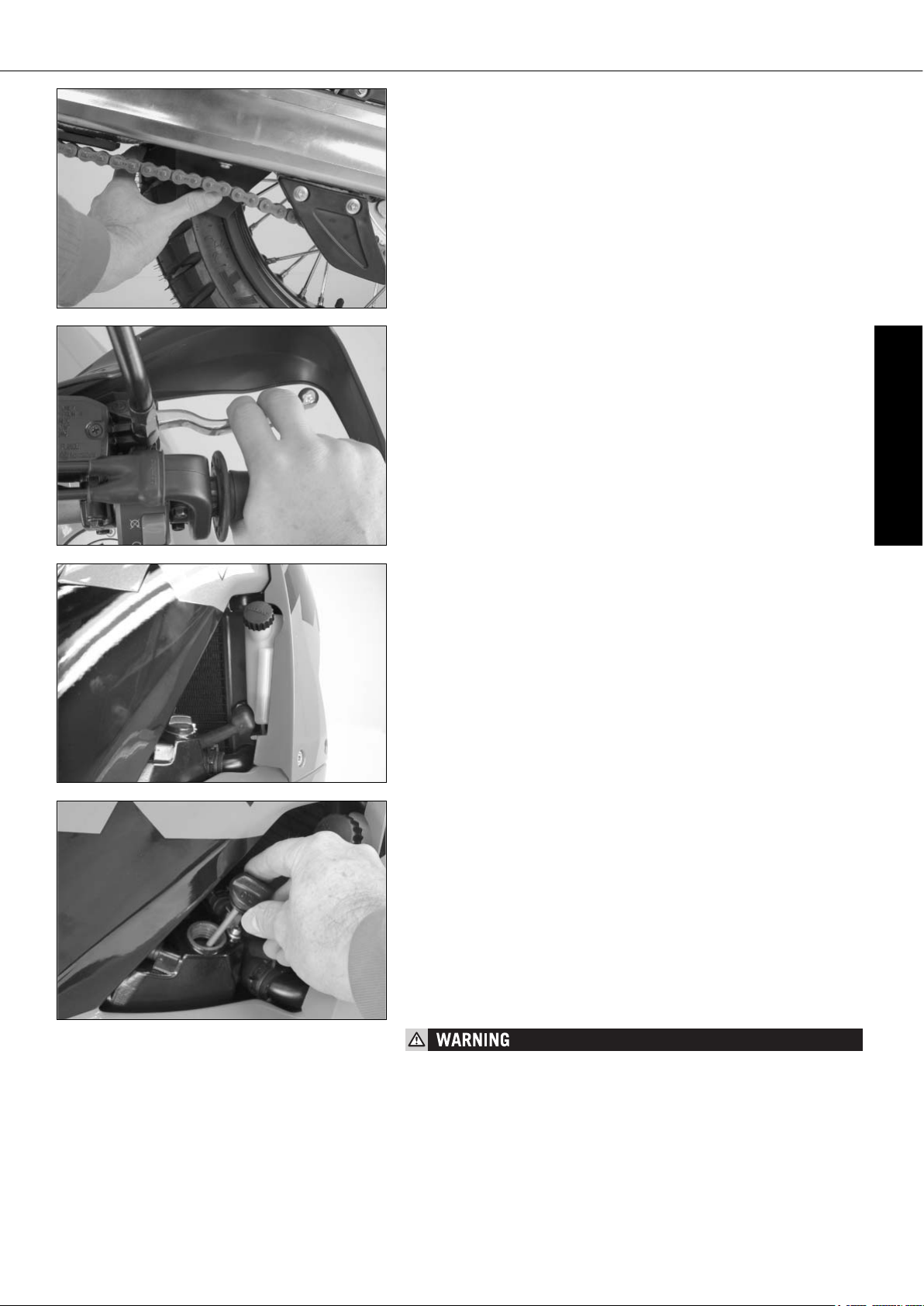

Checking the chain tension

Place the motorcycle on the side stand and switch the transmission to idle.

The chain should sag 35…40 mm (1.37 … 1.57 in) at the lower chainguard

screw [4].

– IF CHAIN TENSION IS TOO GREAT, PARTS WITHIN THE SECONDARY POWER

TRANSMISSION (CHAIN, CHAIN SPROCKETS, TRANSMISSION AND REAR WHEEL

BEARINGS) WILL BE SUBJECTED TO UNNECESSARY STRESS, RESULTING IN

PREMATURE WEAR AND EVEN CHAIN BREAKAGE.

– TOO MUCH SLACK IN THE CHAIN, ON THE OTHER HAND, CAN RESULT IN THE

CHAIN JUMPING OFF THE CHAIN WHEELS. IF THIS HAPPENS, THE CHAIN COULD

ALSO BLOCK THE REAR WHEEL OR DAMAGE THE ENGINE.

– IN EITHER CASE THE OPERATOR IS LIKELY TO LOSE CONTROL OF THE MOTOR-

CYCLE.

35 … 40 mm

1

2

3

4

Page 27

ENGLISH

26

MAINTENANCE WORK ON CHASSIS AND ENGINE »

Correct chain tension

Loosen collar nut [1], loosen counter nuts [2], and turn right and left

adjusting screws [3] equally far. Tighten counter nuts [2].

Before tightening the wheel spindle, verify that the chain adjusters [4] are

sitting close to the adjusting screws and that the rear wheel has been

aligned with the front wheel.

Tighten collar nut [1] with 90 Nm.

IF YOU DON’T HAPPEN TO HAVE A TORQUE WRENCH AT HAND, MAKE SURE YOU

HAVE THE TIGHTENING TORQUE CORRECTED BY A KTM DEALER AS SOON AS POSSIBLE. A LOOSE AXLE MAY LEAD TO AN UNSTABLE DRIVING BEHAVIOR OF YOUR

MOTORCYCLE.

Chain maintenance

The maintenance of the X-ring chain is reduced to a minimum. Clean with a

soft water jet. Never use a brush or solvent to clean the chain. When the chain

is dry use a chain spray specially made for X-ring chains (Motorex Chainlube

622).

– NO LUBRICATION IS ALLOWED TO REACH THE REAR TIRE OR THE BRAKE DISK,

EITHERWISE THE ROAD ADHERENCE AND THE REAR WHEEL BRAKING EFFECTS

WOULD BE STRONGLY REDUCED AND THE MOTORCYCLE COULD EASILY GET

OUT OF CONTROL.

– THE CHAIN DOES NOT HAVE A CHAIN JOINT FOR SAFETY REASONS. ALWAYS

HAVE THE CHAIN REPLACED IN AN AUTHORIZED KTM WORKSHOP WHERE THE

SERVICE TECHNICANS HAVE THE REQUIRED RIVETING TOOL.

– NEVER MOUNT A NORMAL CHAIN JOINT.

Also check sprockets and chain guides for wear, and replace if necessary.

Checking the chain for wear

To check the chain for wear proceed as follows:

Switch the transmission to idle and put a load of approx. 15 kilograms

(33 lbs) on the lower part of the chain (see illustration). Now measure the

distance between 18 chain rollers on the upper part of the chain. The chain

needs to be replaced when the distance is 272 mm (10.70 in). Since chains

do not always wear evenly, repeat the measurement at different parts of the

chain.

Replace the chain if any X-rings are missing.

NOTE:

If you mount a new chain, the sprockets should also be replaced. New chains

wear faster if used on old used sprockets.

15 KG

max. 272 mm

1 2 3

16 17 18

1

3

4

2

4

Page 28

ENGLISH

27

MAINTENANCE WORK ON CHASSIS AND ENGINE »

General informations about KTM disc brakes

BRAKE CALIPERS:

The brake calipers of this series “float“. This means that the brake calipers

are not solidly attached to the caliper support. Thus, the brake pads are always

in optimum contact with the brake disc. Secure the screws of the caliper support with Loctite 243 and tighten to 25 Nm.

FOR SAFETY REASONS, ALWAYS HAVE MAINTENANCE WORK AND REPAIRS TO THE

BRAKE SYSTEM PERFORMED BY AN AUTHORIZED KTM WORKSHOP.

BRAKE PADS:

Your motorcycle is equipped with sintered brake pads in the front and rear

and homologated accordingly. They guarantee maximum braking

performance.

Front brake pads: Toshiba TT 2172 HH

Rear brake pads: Toshiba TT 2701 HH

BRAKE PADS AVAILABLE IN THE ACCESSORY TRADE ARE OFTEN NOT AUTHORIZED FOR OPERATION OF YOUR KTM MOTORCYCLE IN ROAD TRAFFIC. THE BRAKE

PADS DESIGN AND FRICTION FACTOR AND THEREFORE THE BRAKING POWER CAN

DEVIATE SIGNIFICANTLY FROM ORIGINAL KTM BRAKE PADS. IF YOU USE DIFFERENT BRAKE PADS THAN THOSE PROVIDED WITH THE ORIGINAL EQUIPMENT, IT

CANNOT BE WARRANTED THAT THEY ARE AUTHORIZED FOR USE IN ROAD TRAFFIC. YOUR MOTORCYCLE WILL NOT LONGER COMPLY WITH THE REGULATIONS

AUTHORIZING THE USE OF VEHICLES FOR ROAD TRAFFIC AND THE WARRANTY

WILL BE VOID.

BRAKE FLUID RESERVOIRS:

The brake fluid reservoirs on the front and rear wheel brakes have been

designed in such a way that even if the brake pads are worn it is not necessary to top up the brake fluid. There is no reason to remove the reservoir cap

under normal conditions. If the brake fluid level drops below the minimum

either the brake system has a leak or the brake pads are completely worn down.

In this case, consult an authorized KTM dealer immediately.

BRAKE FLUID:

KTM fills the brake systems with Motorex Brake Fluid DOT 5.1 brake fluid,

one of the best brake fluids that is currently available. We recommend that

you continue to use it. DOT 5.1 brake fluid is based on glycol ether and of an

amber color. If you do not have any DOT 5.1 for refilling, you may use DOT

4 brake fluid. However, you should replace it as soon as possible

by DOT 5.1.

Never use DOT 5 braking fluid. It is based on silicone oil and has a purple

color. Gaskets and brake hoses are not compatible with it.

Brake fluid is exposed to a high thermal load and absorbs moisture from the

air, which lowers the boiling point. The brake fluid should therefore be changed

at the prescribed intervals.

HAVE THE BRAKE FLUID FOR THE FRONT AND REAR BRAKE CHANGED AT AN

AUTHORIZED KTM WORKSHOP EVERY 2 YEARS.

BRAKE DISCS:

Wear reduces the thickness of the brake disc in the area of contact [1] with

the brake pads. The brake disk should not be thinner than 4.5 mm (0.18 in)

at the weakest point [A]. Check the wear at several points.

BRAKE DISKS THAT ARE LESS THAN 4.5 MM (0.18 IN) THICK ARE A SAFETY HAZARD. HAVE WORN BRAKE DISKS REPLACED IMMEDIATELY.

1

A

Page 29

ENGLISH

28

MAINTENANCE WORK ON CHASSIS AND ENGINE »

Adjusting of free travel at the hand brake lever

Free travel at the hand brake lever may be readjusted by using adjusting

screw [1]. In this way, the position of the point of pressure (i.e., the resistance you feel on the hand brake lever when the brake pads are pressed against

the brake disc) can be adjusted for any hand size.

AT THE HAND BRAKE LEVER, FREE TRAVEL MUST AT LEAST BE 3 MM (0.12 IN).

ONLY THEN MAY THE PISTON IN THE HAND BRAKE CYLINDER BE MOVED (TO BE

RECOGNIZED BY THE GREATER RESISTANCE OF THE HAND BRAKE LEVER). IF

THIS FREE TRAVEL IS NOT PROVIDED, PRESSURE WILL BUILD UP IN THE BRAKING SYSTEM, AND THE FRONT WHEEL BRAKE MAY FAIL DUE TO OVERHEATING.

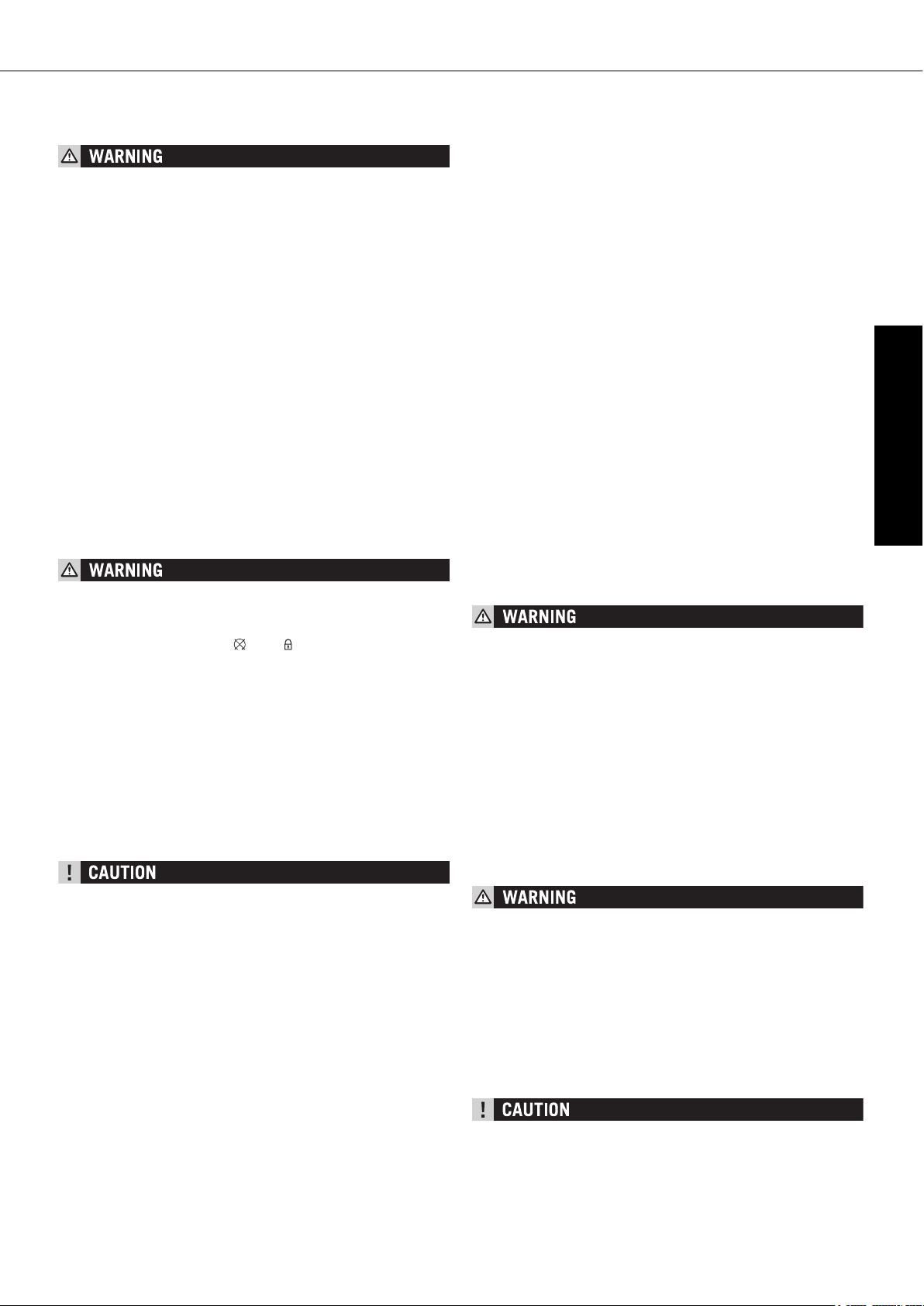

Checking of brake fluid level - front brake

The brake fluid reservoir is linked with the hand brake cylinder at the

handlebar and the reservoir is provided with an inspection glass. With the reservoir in a horizontal position, the brake fluid level should not go below middle

of the glass.

– IF THE BRAKE FLUID LEVEL DROPS BELOW THE MINIMUM EITHER THE BRAKE

SYSTEM HAS A LEAK OR THE BRAKE PADS ARE COMPLETELY WORN DOWN.

IN THIS CASE, CONSULT AN AUTHORIZED KTM DEALER IMMEDIATELY.

– HAVE THE BRAKE FLUID CHANGED AT AN AUTHORIZED KTM WORKSHOP

EVERY 2 YEARS.

Refilling the front brake fluid reservoir *

It is not necessary to refill brake fluid under normal conditions (see General

information on KTM disk brakes).

However, the brake fluid must be refilled as soon as the brake fluid level reaches

the MIN mark.

Remove the screws [2] and the cover [3] with the rubber boot [4]. Push the

front brake caliper pistons all the way back, demounting the front wheel if

necessary. Move the hand brake cylinder in a horizontal position and fill DOT

5.1 brake fluid (Motorex Brake Fluid DOT 5.1) up to 5 mm (0.2 in) under the

top edge of the reservoir. Remount the rubber boot, cover and screws. Wash

off any overflowing or spilled brake fluid with water. Actuate the front brake

until you feel the point of pressure.

– ACTUATE THE FRONT BRAKE UNTIL YOU FEEL THE POINT OF PRESSURE.

– NEVER USE DOT5 BRAKE FLUID! IT IS BASED ON SILICONE OIL AND OF A PUR-

PLE COLOR. SEALS AND BRAKE HOSES MUST BE ESPECIALLY ADAPTED

TO IT.

– STORE BRAKE FLUID OUT OF REACH OF CHILDREN.

– BRAKE FLUID CAN CAUSE SKIN IRRITATION. AVOID CONTACT WITH SKIN AND

EYES. IF YOU GET BRAKE FLUID IN YOUR EYES, RINSE WITH PLENTY OF WATER