Page 1

REPAIR MANUAL

REPARATURANLEITUNG

MANUALE DI RIPARAZIONE

MANUEL DE RÉPARATION

MANUAL DE REPARACIÓN

ART.NR.: 3.206.009-E

KTM Group Partner

950ADVENTURE2003

Page 2

Page 3

950ADVENTURE

REPAIR

MANUAL

Page 4

Page 5

1 SERVICE-INFORMATIONS

2 GENERAL INFORMATION

3 REMOVING AND REFITTING ENGINE

4 DISASSEMBLING ENGINE

5 SERVICING INDIVIDUAL COMPONENTS

6 ASSEMBLING ENGINE

7 ELECTRICAL

8 FUEL SYSTEM

9 TROUBLE SHOOTING

10 CHASSIS

11 TECHNICAL SPECIFICATIONS

12 PERIODIC MAINTENANCE SCHEDULE

13 WIRING DIAGRAMS

14

15

16

Page 6

Page 7

IMPORTANT

INFORMATION

KTM REPAIR MANUAL IN LOOSE-LEAF FORM

STORING THE REPAIR MANUAL IN THE BINDER

– Put the index into the binder.

– Put the front page of the repair manual (210x297 mm) into the transparent pocket provided for

this purpose on the outside of the binder.

– Put the spine label (170x45 mm) into the transparent pocket provided for this purpose on the

spine of the binder.

– Put the summary list of contents (150x297 mm) into the transparent pocket provided for this

purpose on the inside of the binder or insert this page on the beginning of the manual.

– Then insert the individual chapters of the manual between the sheets of the index according to

the page number printed in the right bottom corner of each page.

Example: page no. 3-5 3 = chapter 3 5 = page 5

All pages with a page number that begins with the digit 3, for example, must be put under the

index heading „Chapter 3“.

– Index sheets that have not been marked with a certain chapter are for your personal convenience.

T

he respective headings can be entered in the list of contents.

Page 8

Page 9

INTRODUCTION

This repair manual offers extensiv repair-instructions and is an up-to-date version that describes the

latest models of the series. However, the right to modifications in the interest of technical

improvement is reserved without updating the current issue of this manual.

A description of general working modes common in work shops has not been included. Safety rules

common in the work shop have also not been listed. We take it for granted that the repairs are

made by qualified profesionally trained mechanics.

Read through the repair manual before beginning with the repair work.

WARNING

STRICT COMPLIANCE WITH THESE INSTRUCTIONS IS

ESSENTIAL TO AVOID DANGER TO LIFE AND LIMB.

!

CAUTION

!

NON-COMPLIANCE WITH THESE INSTRUCTIONS CAN LEAD

TO DAMAGE OF MOTORCYCLE COMPONENTS OR RENDER

MOTORCYCLES UNFIT FOR TRAFFIC !

„NOTE” POINTS OUT USEFUL TIPS.

Use only ORIGINAL KTM SPARE PARTS when replacing parts.

The KTM high performance engine is only able to meet user expectations if the maintenance work is

performed regularly and professionally.

KTM Austria’s certificate of achievement for its quality system ISO 9001 is the beginning of an

ongoing total reengineered quality plan for a brighter tomorrow.

KTM Sportmotorcycle AG

5230 Mattighofen, Austria

All design and assembly modification rights reserved.

Page 10

Page 11

REPLY FAX FOR REPAIR MANUALS

We have made every effort to make our repair manuals as accurate as possible but it is always possible for

a mistake or two to creep in.

To keep improving the quality of our repair manuals, we request mechanics and shop foremen to assist us

as follows:

If you find any errors or inaccuracies in one of our repair manual – whether these are technical errors,

incorrect or unclear repair procedures, tool problems, missing technical data or torques, inaccurate or

incorrect translations or wording, etc. – please enter the error(s) in the table below and fax the completed

form to us at 0043/7742/6000/5349.

NOTE to table:

– Enter the complete item no. for the repair manual in column 1 (e.g.: 3.206.009-E).

You will find the number on the cover page or in the left margin on each right page of the manual.

– Enter the corresponding page number in the repair manual (e.g.: 5-7c) in column 2.

– Enter the current text (inaccurate or incomplete) in column 3 by quoting or describing the respective

passage of the text. If your text deviates from the text contained in the repair manual, please write your

text in German or English if possible.

–

Enter the correct text in column 4.

Your corrections will be reviewed and incorporated in the next issue of our repair manual.

Item no. of repair manual Page Current text Correct text

Additional suggestions, requests or comments on our Repair Manuals (in German or English):

Name mechanic/shop foreman Company/work shop

Page 12

Page 13

GENERAL INFORMATION

Repair manual KTM LC8

Art.-Nr. 3.206.009-E

OIL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

AIR INTAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

SLS-SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

SPECIALTOOLS – CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

SPECIALTOOLS – ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

BLEEDING THE CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

INDEX

2-1

2

Page 14

Page 15

2-2

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Oil system

Pressure pump 1 draws engine oil from oil tank

2 through oil filter 3 and the oil return valve 4

and pumps it past the pressure relief valve 5

through the oil filter 6 into the annular groove

7.

The main bearing

8, the conrod bearings 9 and

the spraying nozzle

bk (front timing chain) are

supplied with oil through holes in the crankshaft.

An oil duct leads to spraying nozzle

bl (piston

cooling), the timing chain tensioner

bm, the

camshaft

bn and the oil pressure switch bo in the

front cylinder.

Another oil duct leads from the annular groove

to a distributor groove

bp in the clutch cover.

From there an oil duct leads to the spraying

nozzle

bq (piston cooling). Another oil duct

supplies the timing chain tensioner

br, the

spraying nozzle

bs (timing chain) and the

camshaft

bt on the rear cylinder with oil.

Another oil duct leads to the oil line

ck that

lubricates the transmission gears. The suction

pump

cl draws the oil from the oil sump cn

through the screen cm into the oil tank 2.

1

5

6

7

8

9

bk

bm

bn

bo

bp

bq

br

bs

bt

ck

cn

cm

cl

bl

8

2

3

4

Page 16

2-3

Intake system

Fresh air is drawn into the filter box through the intake snorkel 1, past the carburetors 2 and through the air filter 3.

The cleaned air is conducted to the combustion chamber through the carburetors and intake ports.

1

2

2

3

Page 17

2-4

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

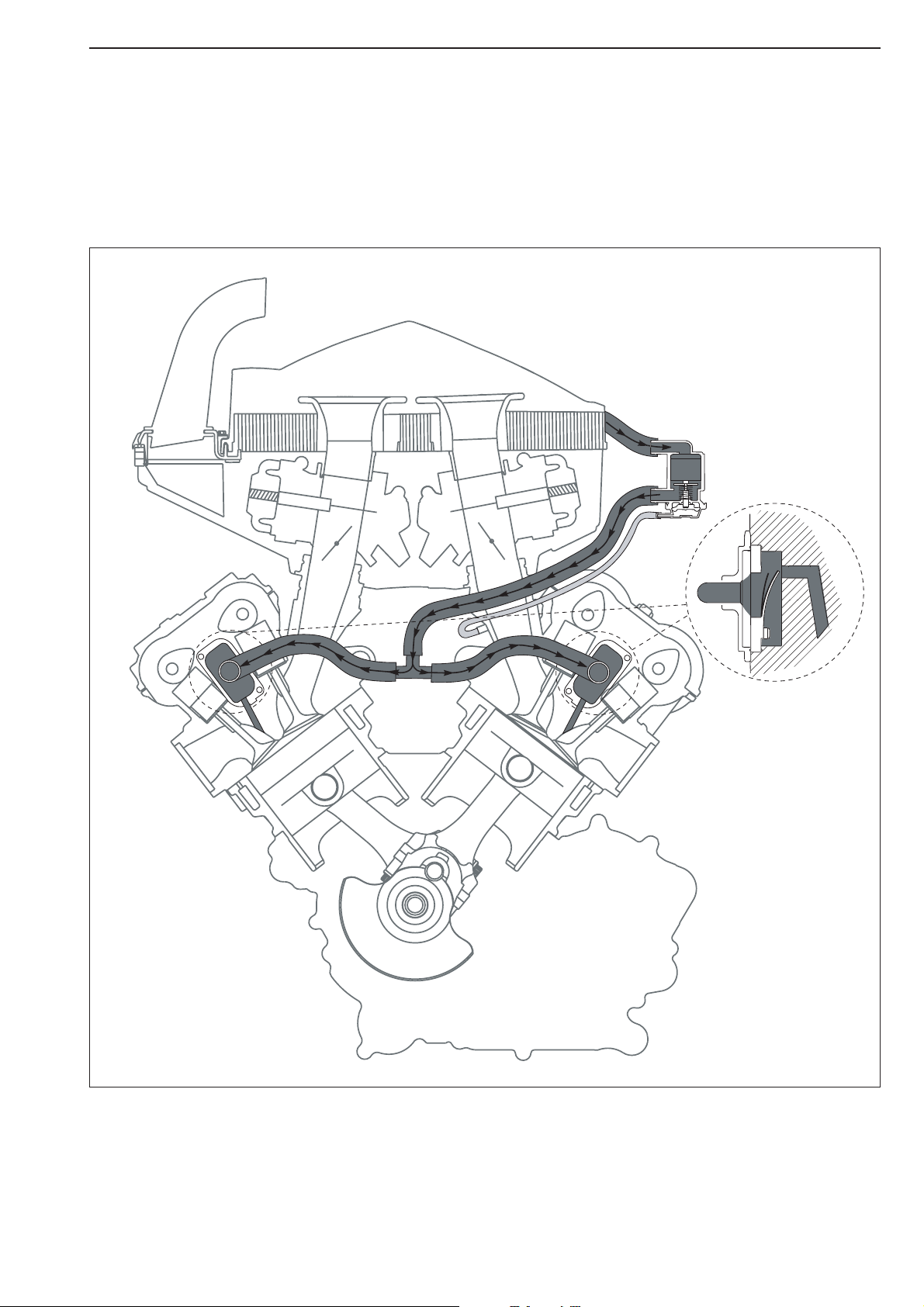

Secondary air system

The secondary air system supplies fresh air to the emissions in the exhaust port, resulting in the afterburning (oxidation) of the

emissions. A line leads from the filter box

1 to the control valve 2 which opens as soon as the throttle valves 3 are opened. The

line continues to the reed valves

4 in the cylinder heads which are actuated by the pressure pulsation in the exhaust system. As a

result, cleansed fresh air arrives in the exhaust port. The oxygen content in the air and the high exhaust gas temperature cause the

emissions to oxidize.

If the throttle valves are closed and the engine goes into an overrun condition, the underpressure in the intake port will rise and the

control valve will close. This prevents exhaust backfire (combustion of the unburned fuel/air mixture).

1

2

3

3

4

4

4

Page 18

2-5

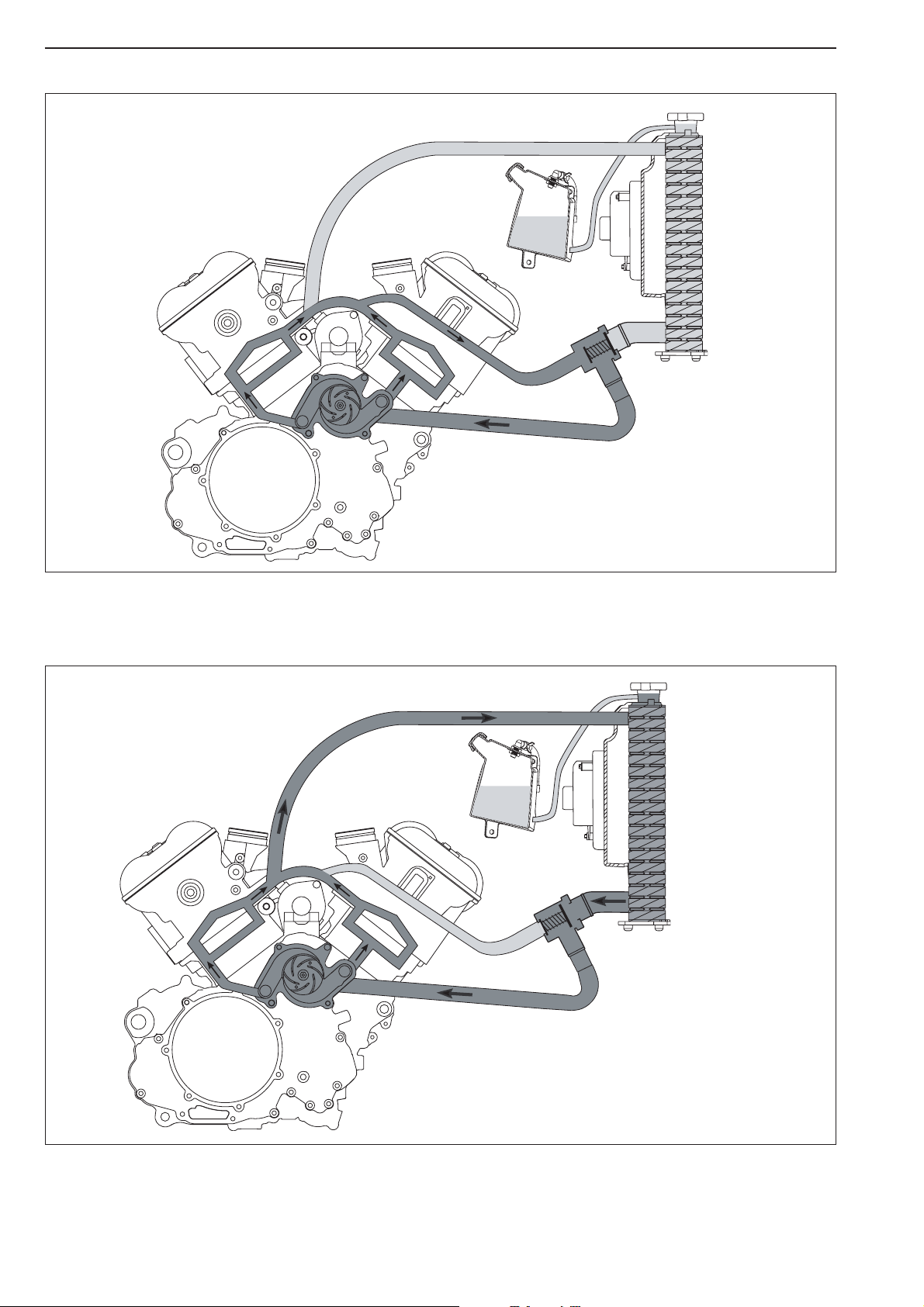

Closed thermostat

The thermostat is closed if the temperature of the cooling liquid drops below 75° C. The water pump 1 pumps the cooling liquid

through the cylinder and cylinder heads

2 and the thermostat 2.

Open thermostat

The thermostat 3 opens at 75° C. The water pump 1 pumps the cooling liquid through the cylinder and cylinder heads 2, the

aluminum cooler

4 and the thermostat. The pressure in the cooling system (max. 1.4 bar) is regulated by a valve in the radiator

cap

5. The cooling liquid level in the compensating tank 6 must be between the MIN and MAX marks when the engine is cold.

The fan

7 switches on at 102° C.

Cooling system

1

1

2

2

3

4

5

6

7

2

2

3

Page 19

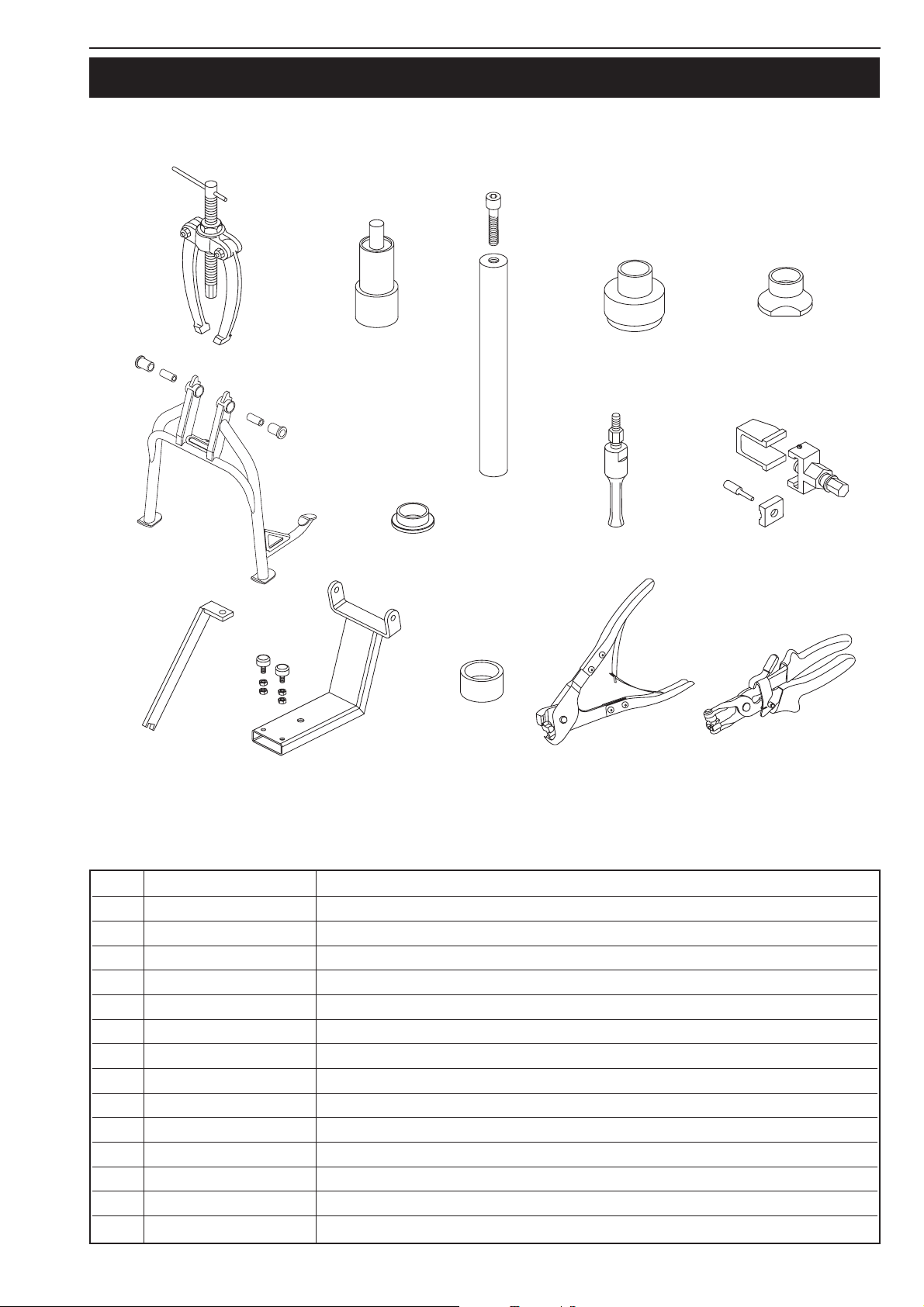

2-6

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

SPECIALTOOLS

– CHASSIS

FIG PART NO DESCRIPTION

1 151.12.017.000 Gear puller

2 584.29.086.000 Pressing tool for swing arm bearing

3 584.29.089.000 Chassis tool holder

4 584.29.091.000 Press-in tool for

bearing seat / rear wheel bearing

5 584.29.092.000

Knock-out tool for bearing seat

6 600.03.022.000 Center stand

7 600.10.013.000 Sleeve for pressing tool for swim arm bearing

8 600.29.018.000 Internal gear puller 28 mm

9 600.29.020.000 Chain rivet tool

10 600.29.055.000 Center stand lock

11 600.29.055.100 Floor jack attachment

12 600.29.056.000 Anvil dolly (for 584.29.086.000)

13 600.29.057.000 Pliers for Öttiker clamps

14 600.29.057.100 Pliers for spring-loaded band-type clamp

1

6

2

3

7

4

8

5

9

bl

bk

bn

bo

bm

Page 20

2-7

bm

5

1

8

6

648

2

bl

9

LOCTITE

3

4

7

243

bn

bo

bp

bq

bk

br

bt

ck

cm

dl

cn

co

dm

bs

cp

dn

cq

do

cr

dp

cs

ct

dq

cl

dk

dr

Page 21

2-8

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

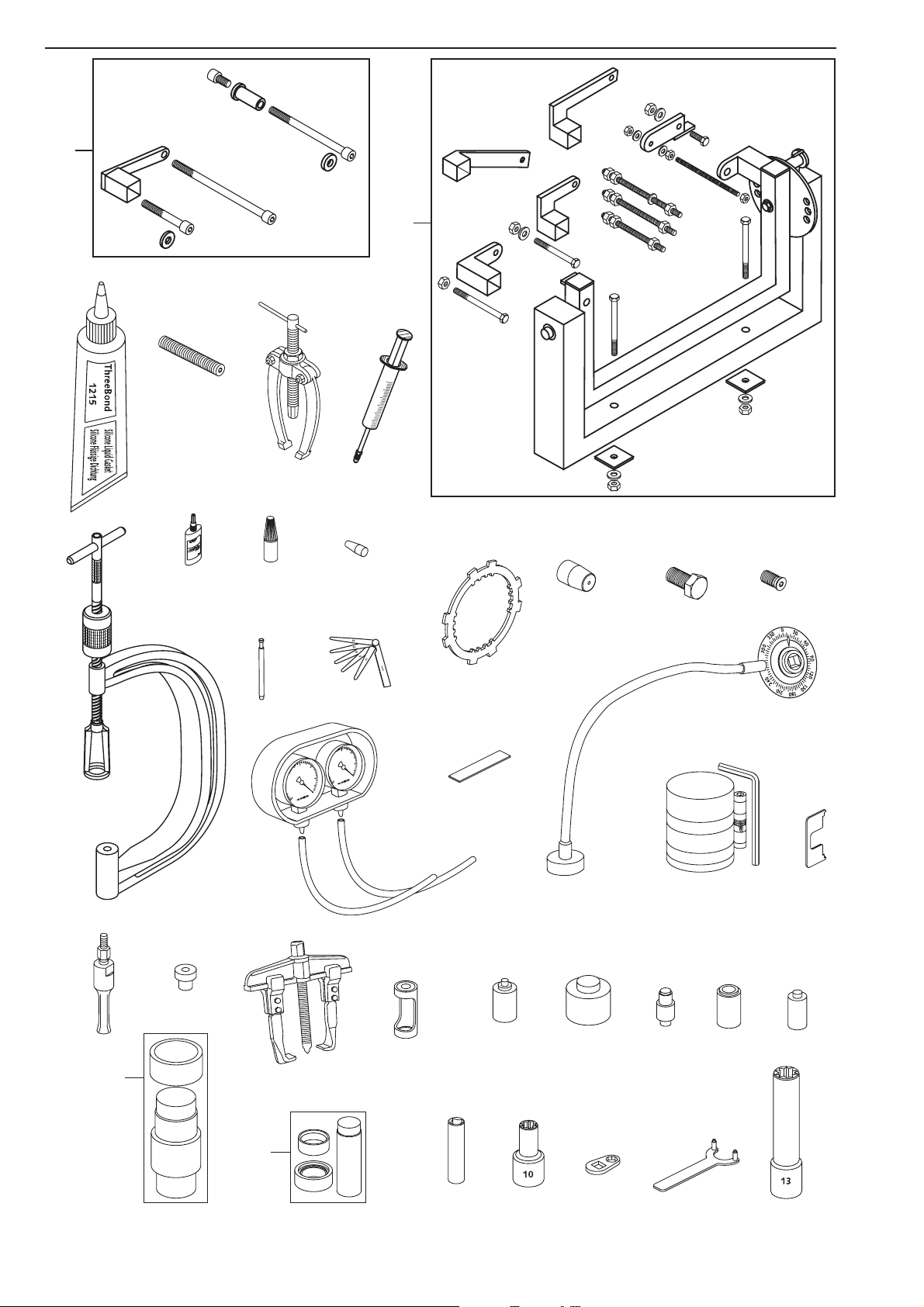

SPECIAL TOOLS

– ENGINE

FIG PART NO DESCRIPTION

1 309098 Seal Three-Bond

2 0113 080802 Crankshaft locking bolt

3 151.12.017.000 Gear puller

4 503.29.050.000 Bleeding syringe for hydraulic clutch

5 560.12.001.000 Universal-engine work stand

6 584.29.059.000 Loctite 648 green 20 ml

7 585.29.005.000 Protection sleeve for shaft seal ring of water pump

8 590.29.019.000 Valve spring mounter

9 590.29.026.006 Limit plug gauge 6,05 mm

10 590.29.041.000 Feeler gauge for valve clearance

11 6 899 785 Loctite 243 blu 6 cm3

12 600.29.002.000 Engine holder for engine work stand

13 600.29.003.000 Clutch holder

14 600.29.005.000 Protection sleeve for shaft seal ring of output shaft

15 600.29.009.000 Magneto extractor

16 600.29.009.010 Protection bolt for magneto extractor

17 600.29.010.000 Degree wheel

18 600.29.011.000 Carburator synchronisation tool

19 600.29.012.000 Plastigauge-measuring strips

20 600.29.015.000 Piston ring mounting tool

21 600.29.016.000 Setting gauge for float level

22 600.29.018.000 Internal gear puller 28 mm

23 600.29.031.000 Protection sleeve for crankshaft (for pulling of the primary gear)

24 600.29.033.000 Puller for primary gear

25 600.29.041.000 Valve spring mounter insert

26 600.29.043.010 Pressing tool for seal of clutch release shaft

27 600.29.043.020 Pressing tool for seal of output shaft

28 600.29.043.030 Pressing tool for seal and bearing of shifting shaft

29 600.29.043.040 Pressing tool for seal of water pump

30 600.29.043.050 Pressing tool for seal of balancer shaft

31 600.29.044.050 Pressing tool for main bearings (In/out)

32 600.29.046.028 Pressing tool for supporting bearing (In)

33 600.29.073.000 Spark plug wrench 16 mm

34 600.29.075.000 Special nut for conrod

35 600.29.081.000 Special tool for cylinder head nuts

36 600.29.082.000 Holder for water pump wheel

37 600.29.083.000 Special nut for cylinder head nuts

Page 22

2-9

Checking the oil level of the hydraulic clutch

To check the oil level in the master cylinder of the clutch remove the

cover. For this purpose, remove bolts and cover together with the rubber

boot

1. The oil level in the horizontal-standing master cylinder should

be 4 mm below the upper edge. If necessary add SAE 10 biodegradable

hydraulic oil (e.g. Motorex Kupplungs-Fluid 75).

!

CAUTION

!

O

NLY USE SAE 10 BIODEGRADABLE HYDRAULIC OIL TO REFILL THE MASTER

CYLINDER

.

NEVER USE BRAKE FLUID NOR MIX BIODEGRADABLE HYDRAULIC OILS WITH

MINERAL OILS

!

Bleeding of the hydraulic clutch

For bleeding, the cover of the master cylinder of the clutch needs to be

removed. For this purpose, remove bolts and take off cover together

with rubber bellows

1. At the slave cylinder of the clutch, remove the

bleeder nipple. At its place, mount the bleeder syringe

2 which is filled

with biodegradable hydraulic oil (e.g. Motorex Kupplungs-Fluid 75).

Refill oil, until oil is discharged from the bore

A of the master cylinder in

a bubble-free state. Make sure that the oil does not overflow.

!

CAUTION

!

HAVING COMPLETED THE BLEEDING PROCEDURE, YOU HAVE TO VERIFY THAT THE OIL

LEVEL IN THE MASTER CYLINDER IS CORRECT

. FOR FILLING OF THE MASTER CYLINDER,

USE

SAE 10 BIODEGRADABLE HYDRAULIC OIL ONLY

(

EX. MOTOREX KUPPLUNGS-

F

LUID 75); NEVER USE BRAKE FLUID NOR MIX BIODEGRADABLE HYDRAULIC OILS WITH

MINERAL OILS

.

A

1

2

Page 23

REMOVING AND REFITTING ENGINE

Repair manual KTM LC8

Art.-Nr. 3.206.009-E

REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

INDEX

3-1

3

Page 24

Page 25

3-2

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

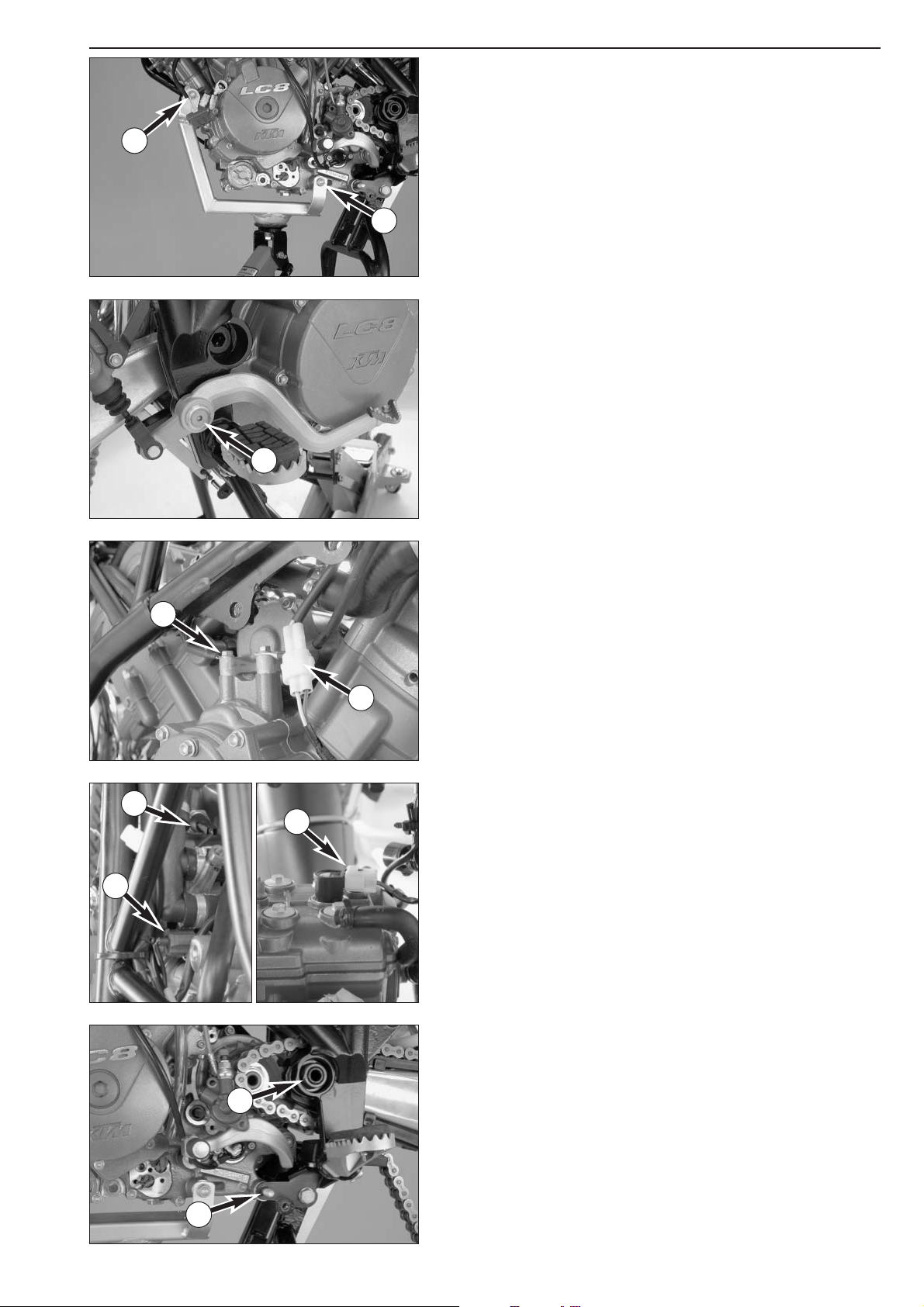

Removing the engine

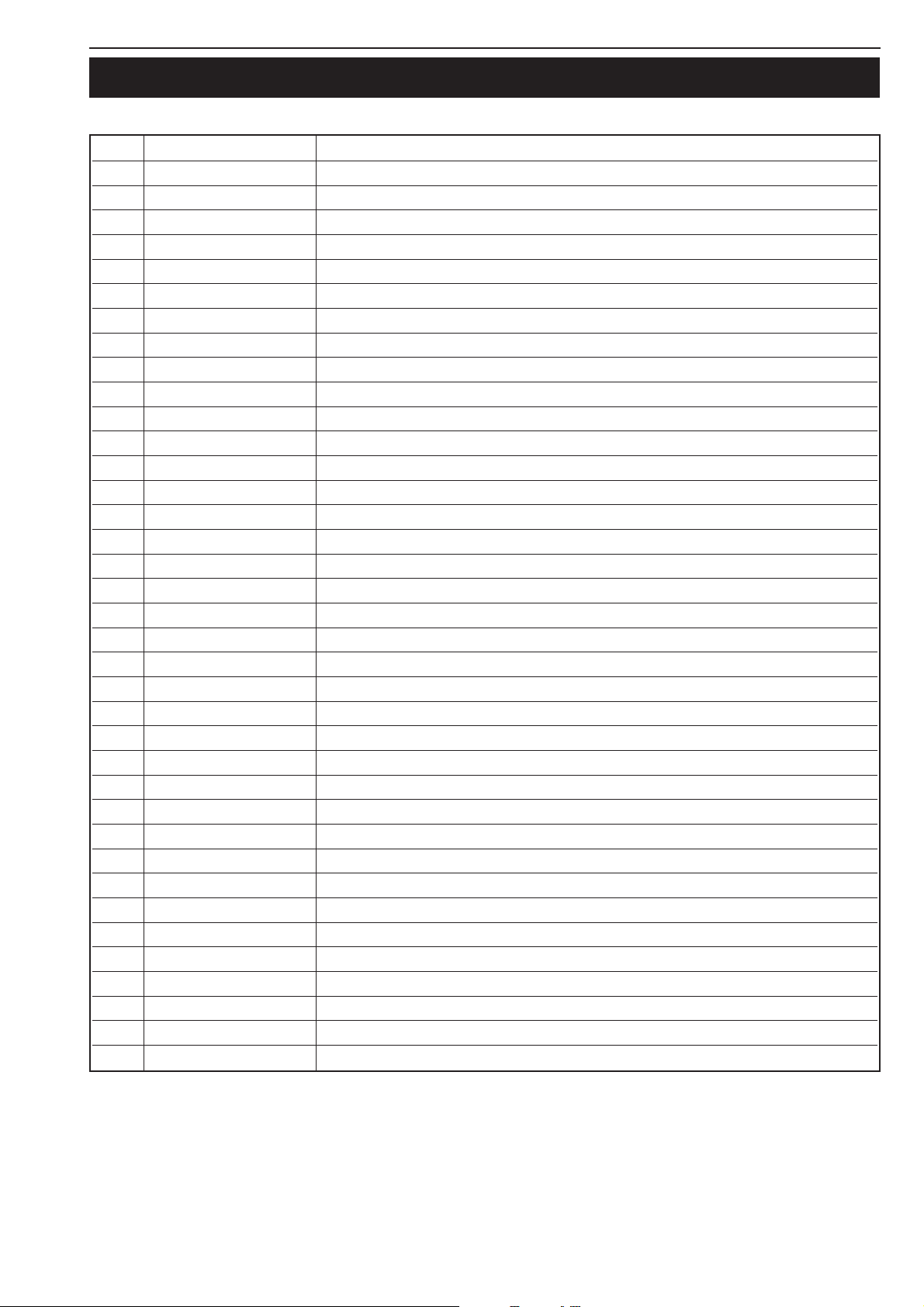

– Screw the center stand 600.03.022.000 onto the frame 1 and jack

up the motorcycle on a firm, even surface.

– Remove the left bump rubber and lock the center stand with the lock

600.29.055.000

2.

NOTE: if available, use the center stand already on the bike.

– Unlock the seat lock with the ignition key and remove.

– Remove the bolts

3 on the left and right of the front side covers,

disconnect the front turn signal, pull the tank vent hoses off of the

fuel tank and remove the side covers.

– Open the tank cover, unscrew the fixing bolts

4 and remove the

upper tank compartment.

– Remove the bolts

5 on the lower tank compartment and the fuse

box, take the cover off the fuse box and dismount the lower tank

compartment.

– Close the fuel cocks, disconnect the gasoline hoses, unscrew the

upper

6 and lower 7 fixing bolts on both fuel tanks and remove the

tanks together with the lower vent hoses.

NOTE: it is easier to disconnect the gasoline hoses if you remove the

front bolts on the underride protection and fold the engine guard down.

– Drain the engine oil from the oil tank and the engine: see page 12-4.

– Remove the 4 bolts

8 on the underride protection and take off the

underride protection.

– Remove both bolts

9 on the front cover and take off the cover.

– Open the lid on the battery compartment and disconnect the battery

terminals

bk (starting with the negative pole).

– Take out the battery and remove the upper battery cover.

1

1

2

3

3

3

4

4

5

5

5

5

6

6

7

8

8

9

10

10

Page 26

3-3

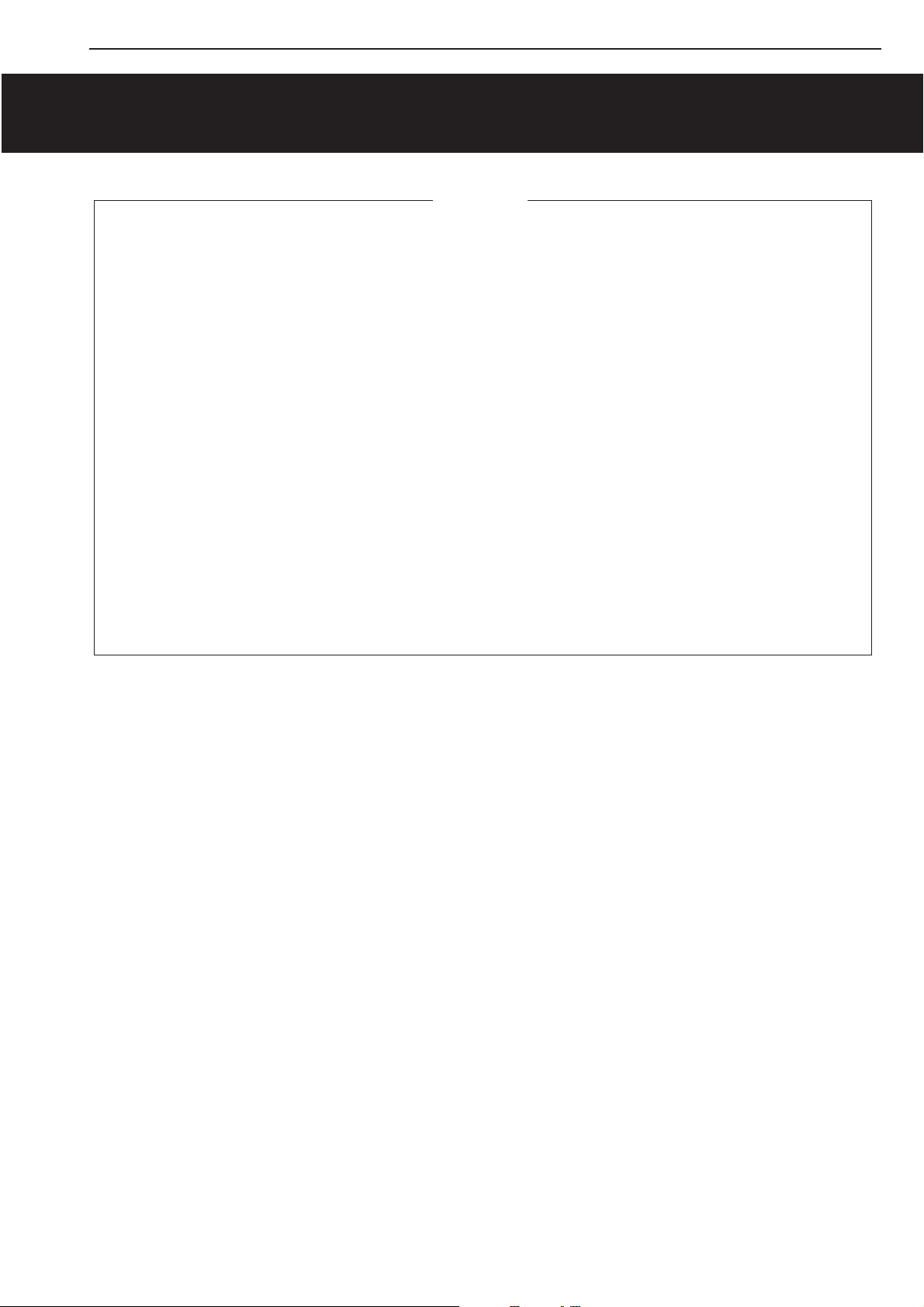

– Unscrew the bolts 1 and remove the intake snorkel 2 together with

the frame from the air filter box.

– Disconnect the vent hose and the EPC hose and remove the upper

half of the air filter box.

– Turn the intake trumpet

3 in a clockwise direction and remove.

Remove air filter.

– Unbolt both side covers on the lower air filter box and remove the

clamps on the carburetor connection boot.

– Detach the EPC hoses

4 from both carburetors and pull the hoses

out of the lower air filter box.

– Remove both vent hoses from the carburetors.

– Lift both carburetors, carefully draw the cable for the idle speed

adjustment and the gasoline hose through the openings in the lower

air filter box.

– Detach the fuel hoses from the carburetors.

– Pull the carburetor connection boots off of the intake manifolds.

– Detach the SLS valve

5 from the lower air filter box, pulling the thin

hose from the intake manifold and the thick hose from the valve.

Remove the valve.

– Remove the EPC valve

6 from the lower air filter box and

disconnect.

–Tilt up the carburetors and fasten to the handlebar with a wire or

rubber band. They do not need to be completely dismounted.

– Take the lower air filter box out of the frame.

NOTE: cover the intake ports with a cloth to prevent any parts from

falling inside.

– Unscrew both nuts

7 on the front exhaust manifold flange on the

cylinder head, loosen the exhaust clamp

8 on the front exhaust

manifold, pull the front exhaust manifold out of the rear exhaust pipe

and remove.

– Unscrew the rear exhaust manifold from the cylinder head.

6

4

4

5

7

2

1

3

8

Page 27

3-4

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

– Disconnect the electric connections from the fan motor and the

temperature switch

1.

– Drain the cooling liquid from the radiator and engine: see

page 12-16.

– Detach the water hoses from the radiator (special pliers

600.29.057.100) and unscrew the radiator

2 .

NOTE: fan and radiator shield do not need to be dismounted from the

radiator.

– Pull off the oil lines from the oil tank to the valve covers

3 and the

return line

4 (special pliers 600.29.57.100), unscrew the oil lines

from the oil terminal

5 and pull out. Remove the O-rings.

– Loosen the fixing bolts

6 on the oil tank, remove the oil tank and

carefully pull out the oil line.

– Disconnect the side stand switch

7 and take the cable out of the

cable clips.

– Loosen the two bolts and the nut

8 and remove the side stand.

– Unscrew the clutch slave cylinder

9 and the chainguard bk and pull

the locking pin out of the pushrod.

– Dismount the chain roller and chain securing guide.

1

2

2

2

3

4

5

6

6

7

8

9

10

Page 28

3-5

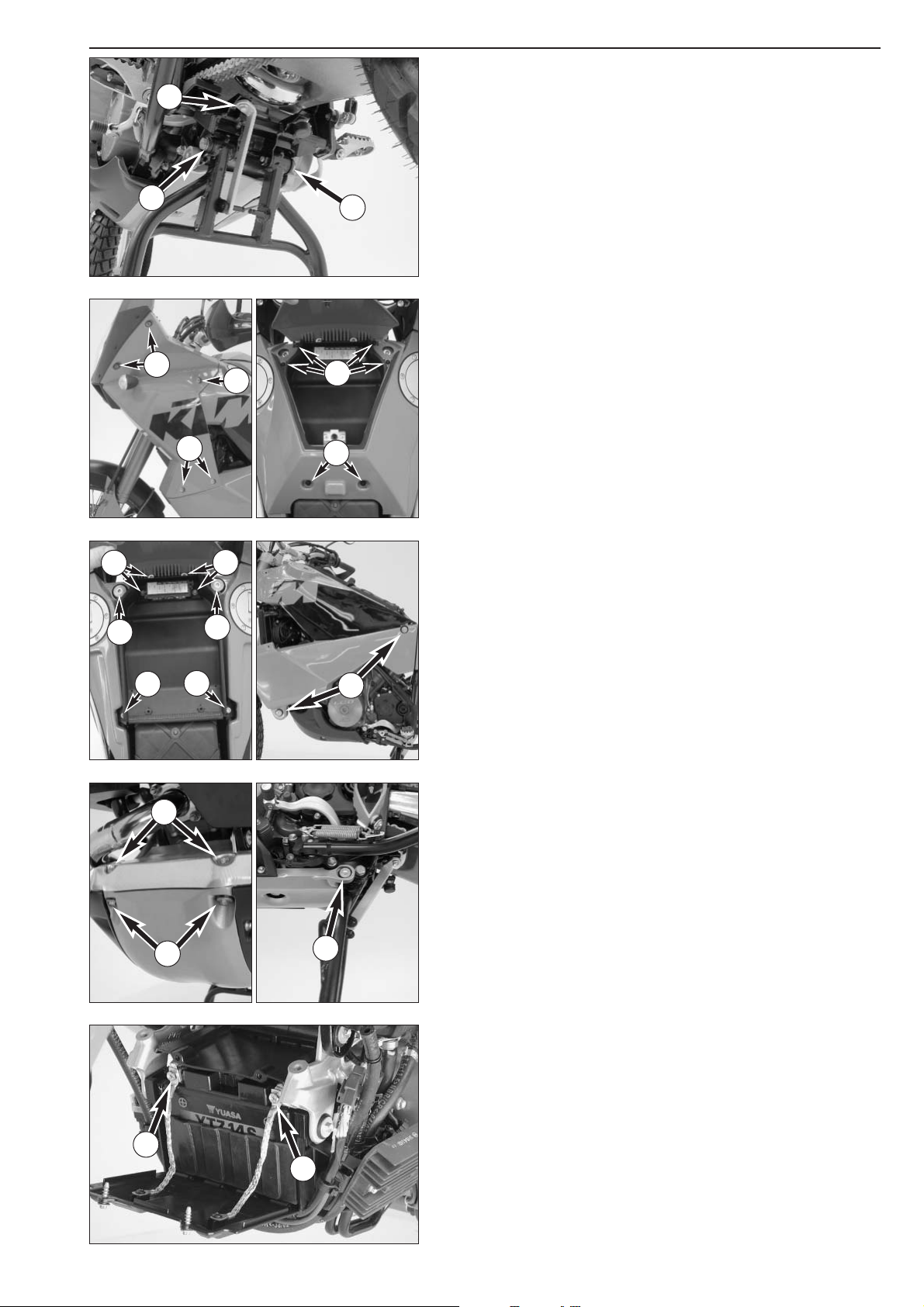

– Unscrew the nut on the wheel spindle, pull out the rear wheel

spindle, take the chain off of the rear sprocket and place over the side

of the bracket

1. Remove the chain from the engine sprocket.

– Detach the connector

2.

– Remove the engine vent hose

3, discarding the hose clamp.

– Unscrew the positive starter engine cable and draw out the wiring

harness.

– Detach connector

4 on the starter relay.

– Pull out the gasoline pump vent hose

5 towards the bottom.

– Unscrew the ground connection

6.

– Disconnect the fuel hose

7.

– Loosen the bolts on the side support

8 and the nut on the bolt 9,

pull out the bolt and remove support together with the battery case.

– Unscrew the front oil line

bk.

1

2

2

2

4

4

3

5

6

7

8

8

9

10

Page 29

3-6

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

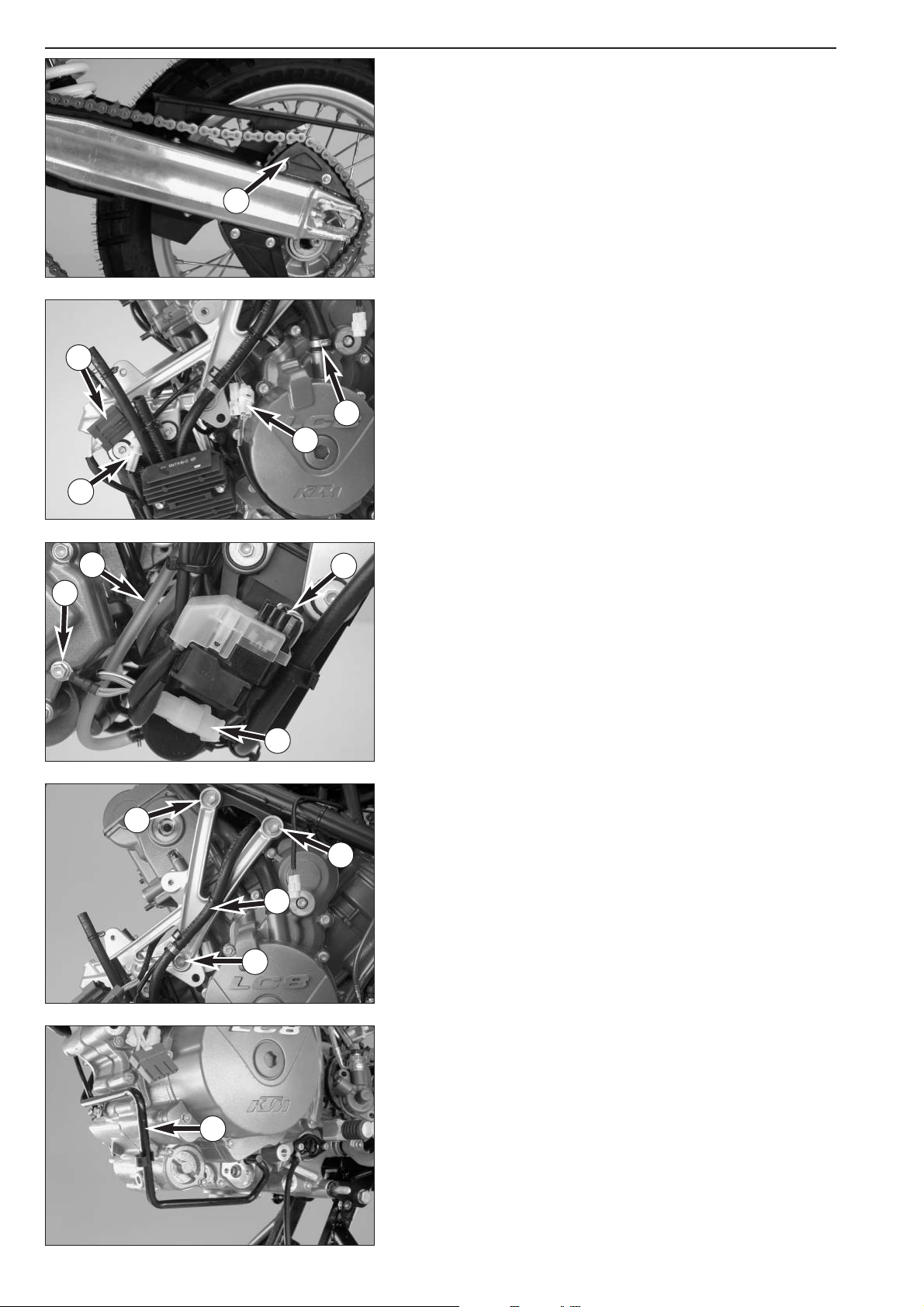

– Use the trolley jack to position the attachment 600.29.055.100 on

the engine, insert the bolt

1 through the front of the engine bracket

and fasten with the nut. Screw one of the bolts

2 on the rear of the

side stand fixture and slightly lift the engine.

– Remove the bolt 3 and tilt the foot brake pedal to the side.

– Unscrew the ground wire connection

4.

– Detach the connector from the pulse generator

5.

– Detach the connector from the oil pressure switch

6, the

temperature sensor

7 and from the front 8 and rear ignition coil.

Remove any cable clips necessary.

– Pull the bolt

9 out of the lower support (if necessary, raise or lower

the engine slightly).

– Loosen the nut on the swing arm pivot

bk and knock out the swing

arm pivot with a suitable pipe.

– Pull the engine towards the front with the trolley jack, lower and pull

away towards the side.

– Disconnect all hoses and lines from the engine.

1

2

3

4

5

6

7

8

9

10

Page 30

3-7

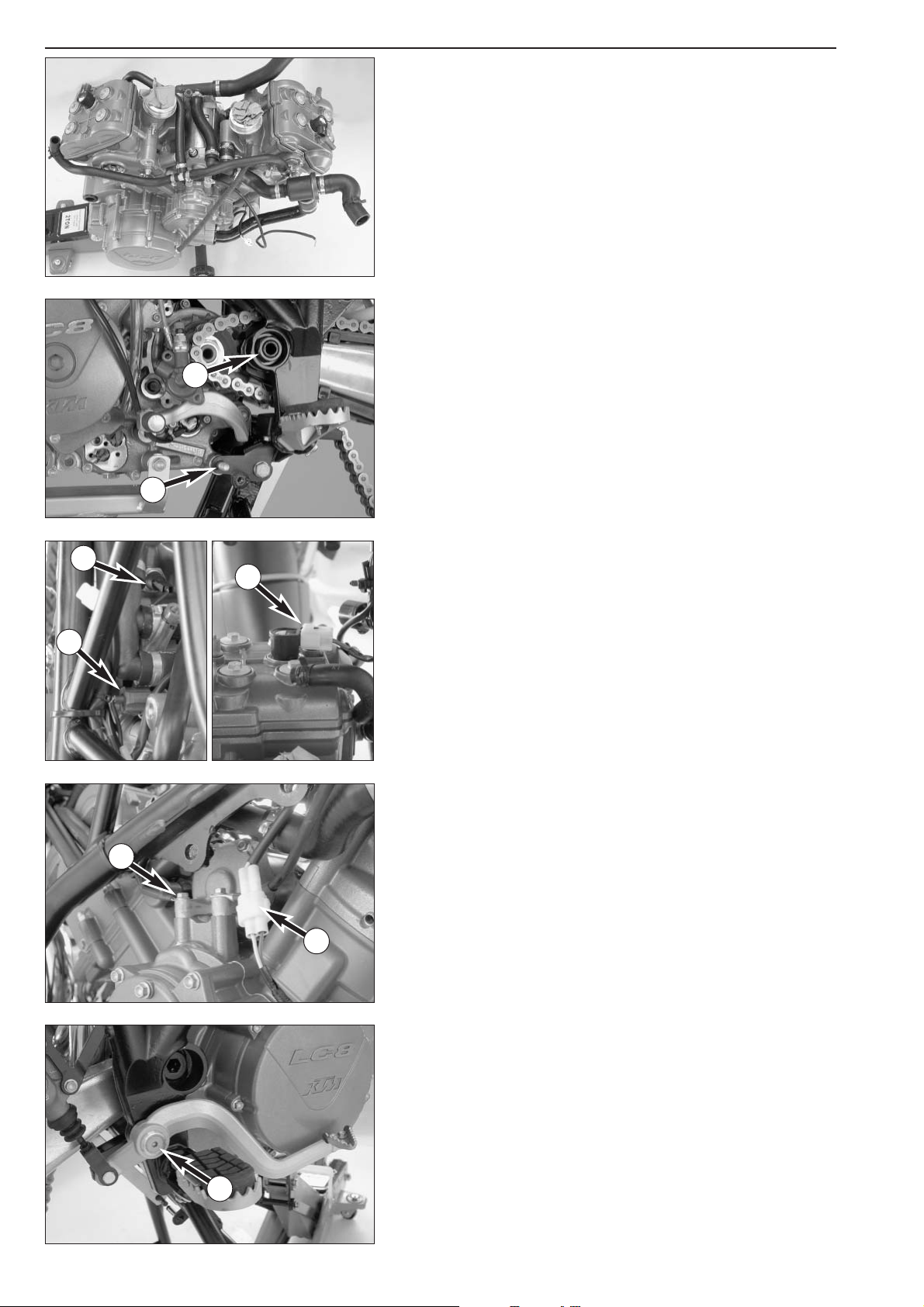

Refitting the engine

– Before mounting the engine, attach the water, SLS and vacuum hoses

(Öttiger clamps - special pliers 600.29.057.000 or spring-loaded

band-type clamps - special pliers 600.29.057.100)

– Position the swing arm and fix with the swing arm pivot on the right

and a suitable pipe on the left.

– Lift the engine into the frame with the trolley jack, insert the sealing

washer in the rear exhaust flange and secure with copper paste if

necessary.

– Guide the chain along the side of the pinion and insert the swing arm

pivot

1, screw on the nut but do not tighten yet.

– Insert the bolt

2 in the lower support (raise or lower the engine

slightly if necessary).

– Remove the trolley jack attachment 600.29.055.100 from the engine.

– Plug the connector on the oil pressure switch

3, the temperature

sensor

4 and the front and rear ignition coil 5. Use cable clips to

fasten the wiring harnesses.

– Screw on the ground wire connection

6.

– Attach the pulse generator connector

7.

– Position the foot brake pedal, apply Loctite 243 to the bolt

8 and

tighten to 25 Nm.

1

2

3

4

5

6

7

8

Page 31

3-8

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

– Mount the front oil line 1 inserting new O-rings. Tighten the bolts.

– Align the side supports and battery case against the engine, insert the

bolt

2 and mount the nut.

– Mount the bolts

3 ( M10x23), lifting the engine slightly if necessary.

Tighten the nut and bolts to 40 Nm.

– Tighten the nut on the swing arm pivot to 130 Nm.

– Connect the fuel hose

4 and fasten with a cable clip.

– Run the positive starter cable to the starter and screw on the starter

engine. Run the starter ground to the battery case.

– Attach both starter relay connectors

5.

– Run the gasoline pump vent hose

6 upwards along the wiring

harness to the engine bracket and back down, forming an arch.

!

CAUTION

!

I

F YOU RUN THE HOSE STRAIGHT UP WITHOUT AN ARCH, WATER WILL BE ABLE TO

PENETRATE

, CAUSING THE GASOLINE PUMP TO BE SOILED AND DAMAGED.

– Screw on the ground wire

7 from the regulator.

– Attach the connector

8.

– Slip on the hose from the engine ventilation

9 and mount the new

Öttiker clamp with the special pliers 600.29.057.000.

1

5

5

6

2

3

3

4

7

8

8

8

9

Page 32

3-9

– Place the chain over the pinion and rear sprocket, lift the rear wheel

and slide the wheel spindle through.

– Press the rear wheel towards the front to apply the chain tensioner

1

and tighten the nut on the wheel spindle to 110 Nm.

– Actuate the foot brake pedal to apply the brake shoes against the

brake disk.

– Check the chain tension, see owners manual, page 25.

– Mount the chain securing guide and the chain roller.

– Insert the locking pin in the pushrod and mount the clutch slave

cylinder

2. Screw on the chainguard 3.

– Position the side stand and tighten the two bolts and the nut

4

to 45 Nm.

– Mount the side stand switch

5 and fasten the cable with the cable

clips.

– Carefully install the oil line, mount the oil tank and tighten the fixing

bolts

6.

– Connect the return line

7 to the oil tank and mount the spring-

loaded band-type clamp with the special pliers 600.29.057.100.

– Attach the oil lines from the oil tank to the valve covers

8 (special

pliers 600.29.057.100).

– Mount both oil lines on the oil terminal

9 with new O-rings, insert

the bolts (M6x20) in the retaining brackets bk and tighten to 10 Nm.

6

2

3

4

7

8

9

6

5

10

10

1

1

Page 33

3-10

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

– Screw on the radiator together with the fan and the radiator shield

1, tighten the bolts to 10 Nm.

– Connect the water hoses on the radiator (special pliers

600.29.057.100)

– Attach the electric connections for the fan motor and the temperature

switch

2.

– Screw the rear exhaust manifold on to the cylinder head.

– Insert the front exhaust manifold in the rear exhaust pipe, mount to

the front cylinder head together with the sealing washer and tighten

the exhaust nuts

3.

NOTE: the exhaust nuts should be tightened evenly without bending the

metal sheet.

– Tighten the exhaust clamp

4 on the front manifold.

– Mount the lower air filter box on the intake ports, connect the drain

hose and push the fuel hose and the cable for the idle speed

adjustment down through the opening in the lower air filter box.

!

CAUTION

!

–

MAKE SURE THERE ARE NO KINKS IN THE CARBURETOR VENT HOSES AND RUN

THEM DOWN BEHIND THE STARTER ENGINE WITHOUT FORMING AN UPWARD

ARCH

.

–

REMOVE THE CLOTH USED TO COVER THE INTAKE PORTS.

– Mount the EPC valve

5 on the lower air filter box and connect.

– Mount the secondary air system valve

6 on the lower air filter box,

connecting the thin hose to the intake manifold and the thick hose

directly to the valve.

– Attach the carburetor connection boots to the intake manifold.

NOTE: the clamps on the carburetor connection boots must be aligned

so that they can be tightened through the openings in the side covers.

– Connect the fuel hoses to the carburetors.

NOTE: to make it easier to connect the fuel hoses, disconnect the fuel

hose from the connecting piece (on the side of the engine brace) and

pull the fuel hose up. Reconnect after mounting the carburetor.

–Insert the carburetor in the carburetor connection boots, tighten the

clamps on the carburetor connection boots and screw both side

covers on the lower air filter box.

– Connect both vent hoses to the carburetors and fasten the choke

cable

7 with a cable clip (see photo).

– Insert the EPC hoses

8 in the corresponding openings in the lower air

filter box and connect to the carburetors.

– Mount the air filter, position the intake trumpet

9 and turn in a

counter-clockwise direction.

– Mount the intake snorkel

bk with the frame to the filter housing.

– Screw on the upper air filter box half. Connect the vent hose and the

EPC hose.

1

2

1

1

3

4

6

5

7

8

8

9

10

Page 34

3-11

– Fit the upper battery cover and place a battery with battery cover into

the battery compartment.

– Fit the front battery compartment lid and connect both battery cables

1 together to the connections on the front lid (start with the positive

cable).

– Close the front battery compartment lid.

– Mount the underride protection, apply Loctite 243 to the 4 bolts 2

(M8x14 collar bolts) and tighten to 25 Nm.

– Mount the front cover, apply Loctite 243 to both bolts

3 (M8x16)

and tighten to 25 Nm.

– Mount the lower tank compartment and screw on the fuse box

4.

Mount the fuse box cover.

– Fill cooling liquid into the radiator, compensating tank and engine:

see page 12-16.

– Add engine oil: see page 12-5.

– Connect the fuel sender to the right tank. Connect the gasoline and

vent hoses and mount the tanks.

– Screw in the upper

5 (M8x40) and lower 6 (M8x55) or 7 (M8x50)

fixing bolts and open the fuel cocks.

– Connect the front turn signal and attach the vent hoses to the tanks.

Fasten both side covers with the bolts

8 and tighten.

– Mount the upper tank compartment and fasten with the bolts

9.

– Close the tank compartment lid and mount the seat.

– Remove the center stand lock

bk 600.29.055.000, remount the left

bump rubber and remove the center stand

bl.

– Check all hose connections for leakage before you take a trial run.

– Check all hoses, lines and cables for a proper fit.

2

2

3

5

5

4

4

4

4

6

1

1

7

8

8

8

9

9

10

11

Page 35

DISASSEMBLING THE ENGINE

Repair manual KTM LC8

Art.-Nr. 3.206.009-E

VALVE COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

SPARK PLUG SHAFT INSERTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

SETTING CYLINDER REAR TO TDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

CAMSHAFTS CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

CHAIN TENSIONER CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

TIMING CHAIN CYLINDER REAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

DOUBLE TIMING GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

CYLINDER HEAD REAR WITH CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

SETTING CYLINDER FRONT TO TDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

CAMSHAFTS CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

OIL PRESSURE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

CHAIN TENSIONER CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

TIMING CHAIN CYLINDER FRONT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

CYLINDER HEAD FRONT WITH CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . .4-7

WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

OIL SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

PRIMARY PINION AND CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

GENERATOR COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

ROTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

FREEWHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

BALANCER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

SHIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

ENGINE CASE HALF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

OIL PUMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

INDEX

4-1

4

Page 36

Page 37

Clean the engine thoroughly on the outside prior to disassembling.

– Clamp the engine in the work stand using the special tool

600.29.002.000.

Valve covers

– Pull out the spark plug connectors.

– Unscrew the spark plugs using the special tool 600.29.073.000.

– Remove the bolts

1 on the valve covers, remove both valve covers.

– Dismount the gaskets of the bolts, the valve covers and the spark

plug shafts

2.

Spark plug shaft inserts

– Pull the spark plug shaft inserts out of the spark plug shafts (pry out

carefully with 2 screwdrivers if necessary), remove the O-rings

3 (2

pieces for each spark plug shaft) and discard.

Starter motor

– Remove both bolts 4 and pull the starter motor out of the case. The

starter motor is sealed off with an O-ring on the case side.

4-2

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

1

1

1

2

3

4

4

Page 38

Setting cylinder rear to TDC

– Unscrew the plug 1 from the generator cover to be able to turn the

crankshaft.

–Turn the crankshaft in a counterclockwise direction until the rear

cylinder is in the TDC position. The marks

2 (crosses) must coincide

with the flat outer surface of the cylinder head at the camshaft gears.

NOTE: the camshaft gears are identical for both cylinders but have

marks for cylinders rear and front. Match the respective mark to the

respective cylinder, i.e. the crosses for cylinder rear and the circles for

cylinder front.

– Remove the case bolt and screw in the special tool 0113 080802

3

to block the crankshaft.

Camshafts cylinder rear

– Check and note down the valve clearance before you dismount the

camshafts.

Valve clearance: intake 0.125 - 0.175 mm

exhaust 0.225 - 0.275 mm

– Loosen the bolts on the camshaft bearing bridge from the rear

cylinder and carefully remove the camshaft bearing bridge.

!

CAUTION

!

W

HEN TIGHTENING THE BOLTS OF THE CAMSHAFT BEARING BRIDGE, MAKE SURE THAT

THE VALVES ARE NOT ACTUATED BY THE CAMSHAFT

(SEE ILLUSTRATION), OTHERWISE

THE BEARING BRIDGE WILL BREAK

.

– Remove the camshafts from the cylinder head without tilting.

4-3

1

2

2

3

Page 39

4-4

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Chain tensioner cylinder rear

– Remove the bolt from the chain tensioner 1.

NOTE: measure the preload on the chain tensioner element before

dismounting:

– Apply the chain tensioner bolt to the chain tensioner element without

compressing the spring.

–Measure the distance between the sealing washer and the cylinder

head.

The measured value should be between 6 mm and 11 mm. If the value

is lower, the tensioning rail could be worn or the timing chain excessively

elongated. If it is higher, the engine was turned to TDC against the

running direction.

– Remove the sealing washer.

– Pull out the chain tensioner element

2.

NOTE: the housing and the tensioning piston on the chain tensioner

element are compression molded. If they fall apart during disassembly,

the chain tensioner element must be replaced.

Timing chain cylinder rear

– Loosen the bearing bolt 3 on the double timing gear and pull out of

the cylinder head together with the needle bearing. The double

timing gear will slide down slightly, relieving the timing chain.

– Remove the O-ring on the bearing bolt.

– Use a wire hook

A which you can bend from a piece of welding wire

to lift the side of the chain

4 towards the inside from the chain teeth

5 over the gear teeth 6 of the double timing gear. Hold the double

timing gear towards the outside by inserting your finger through the

hole in the bearing bolt.

1

2

A

5

3

4

6

Page 40

4-5

Double timing gear

– Lift the double timing gear out of the cylinder head, letting the chain

fall into the slot.

Cylinder head rear with cylinder

– Remove the outer nut 1.

– Loosen the cylinder-head nuts crosswise. Special nut 600.29.083.000

is required for the inside nuts

2.

– Pull the cylinder head and cylinder up until the piston-pin retainer can

be lifted out of the groove on the generator side with a suitable

screwdriver.

NOTE: the piston-pin retainer can easily be removed if the piston is held

in place by the cylinder.

–Press the piston pins out of the piston by hand and remove the

cylinder together with the piston.

– Discard the cylinder-base gasket.

Setting cylinder front to TDC

Loosen the crankshaft locking bolt and continue to turn the engine

towards the front cylinder's TDC position, keeping the timing chain on

the rear cylinder slightly tensioned and holding the conrod in the center

of the opening in the case.

!

CAUTION

!

–IF YOU DO NOT HOLD THE CHAIN, IT MAY GET JAMMED BETWEEN THE TIMING

GEAR OF THE BALANCER SHAFT AND THE TENSIONING RAIL

.

–IF THE CONROD IS NOT POSITIONED IN THE CENTER OF THE OPENING IN THE

CASE

, THE CONROD BOTTOM WILL BLOCK ON THE BALANCER SHAFT AND

PREVENT THE CRANKSHAFT FROM TURNING

.

–Turn the crankshaft until the front cylinder is in the TDC position. The

marks

3 (circles) must coincide with the flat outer surface of the

cylinder head at the camshaft gears.

– The same camshaft gears are used in both cylinders but they have

marks for cylinder rear and front. Use the camshaft gear marked with

a cross for cylinder rear and the camshaft gear marked with a circle

for cylinder front cylinder.

– Block the crankshaft again.

1

2

3

3

Page 41

4-6

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Camshafts cylinder front

– Check and note down the valve clearance before you dismount the

camshafts.

Valve clearance: intake 0.125 - 0.175 mm

exhaust 0.225 - 0.275 mm

– Loosen the bolts on the camshaft bearing bridge from the front

cylinder and carefully remove the camshaft bearing bridge.

!

CAUTION

!

WHEN TIGHTENING THE BOLTS OF THE CAMSHAFT BEARING BRIDGE

, MAKE SURE THAT

THE VALVES ARE NOT ACTUATED BY THE CAMSHAFT

(SEE ILLUSTRATION), OTHERWISE

THE BEARING BRIDGE WILL BREAK

.

– Remove the camshafts from the cylinder head without tilting.

Oil pressure switch

– Loosen the oil pressure switch 1 and unscrew. Discard sealing

washer.

Chain tensioner cylinder front

– Remove the bolt on the chain tensioner 2.

NOTE: measure the preload on the chain tensioner element before

dismounting:

– Apply the chain tensioner bolt to the chain tensioner element without

compressing the spring.

–Measure the distance between the sealing washer and the cylinder

head.

The measured value should be between 6 mm and 11 mm. If the value

is lower, the tensioning rail could be worn or the timing chain excessively

elongated. If it is higher, the engine was turned to TDC against the

running direction.

– Remove the sealing washer.

– Pull out the chain tensioner element

3.

NOTE: the housing and the tensioning piston on the chain tensioner

element are compression molded. If they fall apart during disassembly,

the chain tensionerelement must be replaced.

1

2

3

Page 42

4-7

Timing chain cylinder front

– Loosen the bearing bolt 1 on the double timing gear and pull out of

the cylinder head together with the needle bearing. The double

timing gear will slide down slightly, relieving the timing chain.

– Remove the O-ring on the bearing bolt.

– Use a wire hook

A which you can bend from a piece of welding wire

to lift the side of the chain

2 towards the inside from the chain teeth

3 over the gear teeth 4 of the double timing gear. Hold the double

timing gear towards the outside by inserting your finger through the

hole in the bearing bolt.

– Lift the double timing gear out of the cylinder head, letting the chain

fall into the slot.

Cylinder head front with cylinder

– Remove the outer nut 5.

– Loosen the cylinder-head nuts crosswise. Special nut 600.29.083.000

is required for the inside nuts

6.

– Pull the cylinder head and cylinder up until the piston-pin retainer can

be lifted out of the groove on the clutch side with a suitable

screwdriver.

NOTE: the piston-pin retainer can easily be removed if the piston is held

in place by the cylinder.

–Press the piston pins out of the piston by hand and remove the

cylinder together with the piston.

– Discard the cylinder-base gasket.

A

1

2

3

4

5

6

Page 43

Water pump

– Remove the water pump cover 1, discard the O-ring gasket.

NOTE: also remove the 2 dowel pins used to keep the water pump cover

in a central position.

– Hold the water pump wheel with special tool 600.29.082.000,

remove the bolt 2 and pull the water pump wheel 3 off of the

shaft.

NOTE:

– The bolt and the water pump wheel only need to be removed if the

water pump will be serviced. They do not need to be removed if you

are only dismounting the clutch cover.

– If the water pump wheel cannot be removed because it is being held

by residual thread adhesive, the water pump shaft and the water

pump wheel can be pressed out from the inside later.

!

CAUTION

!

I

F YOU TRY TO LOOSEN THE BOLT ON THE WATER PUMP WITHOUT USING SPECIAL

TOOL

600.29.082.000, YOU MAY BREAK THE DRIVER ON THE BALANCER SHAFT OR

WATER PUMP SHAFT

.

Oil screen

– Remove the oil screen cover 4.

–Carefully pull the oil screen

5 out of the clutch cover with a pair of

pliers.

Clutch cover

– Remove the bolts and detach the inner clutch cover together with the

outer clutch cover. Be careful not to lose the dowel pins.

NOTE:

– The outer clutch over can remain on the inner clutch cover if you also

remove the bolt

6 on the outer clutch cover.

– If the case bolt for the blocking hole is still mounted, it must also be

removed.

4-8

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

1

2

3

4

5

6

Page 44

4-9

Clutch

– Remove the bolts on the clutch springs crosswise and lift off the

pressure cap.

– Pull out the clutch push rod.

– Insert a wire hook in the recess in the clutch disks and pull all of the

clutch disks out of the clutch hub.

NOTE: leave the spring washer and supporting ring in the clutch. They

will be detached together with the inner clutch hub, at which time they

can be easily removed.

– Slip on the holder for the inner clutch hub

A 600.29.003.000,

counteract the inner clutch hub and loosen the nut.

– Pull off the inner clutch hub together with the clutch pressure booster

and the underlying washer, which usually adheres to the inner clutch

hub.

NOTE: you do not need to dismount the primary pinion if you are only

replacing the outer clutch hub:

– Remove the engine locking bolt 0113 080802.

– Continue turning the crankshaft until the flat part of the pickup ring

1 coincides with the teeth on the outer clutch hub.

– Pull the needle bearing

2 out of the outer clutch hub with a suitable

screwdriver, carefully pushing the outer clutch hub back and forth.

–Press the outer clutch hub away from the primary pinion and remove.

NOTE: the gear for the oil pump drive is located on the back of the

outer clutch hub and can easily fall down.

1

2

A

Page 45

4-10

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Primary pinion and clutch

If you are completely dismounting the engine, the primary pinion must

be detached before you remove the clutch.

– Mount the special tool 0113 080802 (engine locking bolt) and hold

the crankshaft in the rear or front cylinder's TDC position.

– Unscrew the pickup

1.

– Loosen the nut

2 of the primary pinion (A/F 46 mm, LH thread) and

remove together with the washer.

– Loosen the nut

3 of the balancer shaft (A/F 30 mm) and remove

together with the washer.

– Pull the outer clutch hub away from the case until the pickup ring

4

can be removed. It is secured by a pin.

– Completely remove the outer clutch hub together with the needle

bearing.

NOTE:

– The gear for the oil pump drive is located on the back of the outer

clutch hub and can easily fall down.

– Remove the spacing washer inserted between the gear for the oil

pump drive and the bearing which may adhere to the bearing.

– Pull off the gear on the balancer shaft

5.

– Insert the pressure tool 600.29.031.000

6 in the hole in the

crankshaft and pull off the primary gear

7 from the crankshaft using

the puller 600.29.033.000.

– Remove the balance weight

8 from the balancer shaft; carefully pry

the woodruff key out of the shaft groove with a screwdriver.

– Slip off the timing chain and pull the engine sprocket off of the

balancer shaft.

– Unscrew the chain tensioning rail

9.

NOTE: if you intend to reuse the timing chain, engine sprocket and

chain tensioning rail, mark the running direction and the cylinder

allocation.

1

2

3

4

5

6

7

8

9

Page 46

4-11

Generator cover

– Loosen all of the bolts on the generator cover except the bolt on the

starter idler shaft

1 and remove the generator cover, being careful

not to lose the dowel pins. Discard the gasket.

NOTE: the rotor's magnetic retaining force will prevent the cover from

being removed easily.

– Unscrew the nut

2 and remove the engine sprocket together with

the lock washer.

Rotor

– Remove the upper starter idler gear 3.

– Remove the rotor bolt

4 and the washer.

– Screw the pressure bolt 600.29.009.010

5 in the crankshaft.

– Pull the rotor off of the crankshaft using the puller 600.29.009.000

6; remove the pressure bolt and the engine locking bolt.

Freewheel

– Remove the freewheel lock 7 and lift the freewheel 8 of the

crankshaft.

– Pull the lower starter idler gear

9 from the balancer shaft.

Balancer shaft

– Gently tap the balancer shaft off on the clutch side with a rubber

hammer.

!

CAUTION

!

–MAKE SURE THE TIMING CHAIN DOES NOT GET CAUGHT.

NOTE: a stop disk is located on the outside of the roller bearing on the

balancer shaft (on the clutch side) which should be removed before the

balancer shaft is dismounted.

– Remove the timing chain and unscrew the tensioning rail.

NOTE: if you intend to reuse the timing chain and chain tensioning rail,

mark the running direction and the cylinder allocation.

1

2

3

4

5

6

7

8

9

Page 47

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

4-12

Shift mechanism

– Push the shift rail 1 away from the shift locating drum and pull out

the shift shaft

2.

– Remove the bolt

3 from the shift locating drum.

–Press the locking lever

4 down to relieve the shift locating drum 5,

remove the shift locating drum.

– Loosen the bolt and remove the locking lever

4 (not required for

further engine removal).

Engine case half

– Remove the gear shift sensor 6 with the pin and spring. Unscrew the

oil filter cover

7, discarding the gasket on the oil filter cover and the

oil filter.

– Unscrew all HH bolts accessible from the generator side.

–Tilt the case horizontally with the generator side up.

– Lift the case half of the generator side while lightly tapping the drive

shaft with a rubber hammer. If necessary, tap the drive shaft

downwards.

!

CAUTION

!

–DO NOT USE A SCREWDRIVER OR SIMILAR TOOL TO PRY THE CASE HALVES APART

SINCE THIS MAY DAMAGE THE SEALING AREAS

.

– Discard the case gasket.

– Remove the crankshaft from the case.

1

2

3

4

5

6

7

Page 48

4-13

Transmission

– Remove the oil rail 1 for the transmission lubrication. It is secured at

the bottom to keep it from twisting.

– Pull out the shift rails

2 together with the upper shift rail springs.

–Tilt the shift forks

3 to the side; watch the shift rollers 4 while you

remove the shift drum

5.

– Remove the shift forks and the lower springs of the shift rails.

– Bring the engine into a vertical position (mounting position) and

remove the lock ring

6 and washer from the countershaft.

– Simultaneously pull both transmission shafts out of the bearing seats.

NOTE: also remove the spacing washer on the countershaft which often

adheres to the bearing.

1

2

2

4

4

4

3

3

3

5

6

Page 49

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

4-14

Oil pumps

– Remove the lock ring 1 from the oil pump shaft; remove the spacing

washer

2 and oil pump gear 3.

– Pull the needle roller

4 out of the pump gear and remove the washer

underneath.

– Loosen the bolts on the outer oil pump

5 (pressure pump) and

remove the oil pump housing.

NOTE: the centering pins are usually retained in the oil pump housing; if

they are retained, pull them out with pliers.

– Remove the inner oil pump

6 (suction pump).

– Remove the suction pump's inner and outer rotor (

7 and 8) from

the oil pump shaft.

– Pull the needle roller

9 out of the oil pump shaft.

– Pull the oil pump shaft and the two pressure pump rotors out of the

engine housing.

– Remove both rotors from the oil pump shaft and pull out the needle

roller.

1

2

3

4

5

6

7

8

9

Page 50

Page 51

SERVICING INDIVIDUAL COMPONENTS

Repair manual KTM LC8

Art.-Nr. 3.206.009-E

ROLLER BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

MAIN BEARINGS - GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . .5-3

REPLACING BEARING SHELLS, OUTPUT END . . . . . . . . . . . . . . . . . . . . . . .5-4

REPLACING BEARING SHELLS, GENERATOR END . . . . . . . . . . . . . . . . . . . .5-4

REPLACING THE CONROD BEARINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

SELECTING THE BEARING SHELLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

REPLACING THE SUPPORTING BEARINGS IN THE CLUTCH COVER . . . . . .5-6

OVERHAULING THE WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

CHECKING THE SUCTION PUMP FOR WEAR . . . . . . . . . . . . . . . . . . . . . . .5-8

CHECKING THE PRESSURE PUMP FOR WEAR . . . . . . . . . . . . . . . . . . . . . . .5-8

BYPASS VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

DISASSEMBLING THE CYLINDER HEAD AND CHECKING

PARTS FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

CHECKING THE PISTONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

ASSEMBLY INSTRUCTIONS FOR PISTON RINGS . . . . . . . . . . . . . . . . . . . .5-10

CHECKING THE PISTON RING END GAP . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

MEASURING PISTONS + CYLINDERS, ESTABLISHING THE PISTON

MOUNTING CLEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

PISTON AND CYLINDER IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . .5-11

ASSEMBLING THE CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

GENERATOR COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

VALVE GEAR – CHECKING PARTS FOR WEAR . . . . . . . . . . . . . . . . . . . . . .5-13

CLUTCH – CHECKING PARTS FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . .5-14

SHIFT MECHANISM – CHECKING PARTS FOR WEAR . . . . . . . . . . . . . . . .5-15

PREASSEMBLING THE SHIFT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

GENERAL INFORMATION ON SERVICING THE TRANSMISSION . . . . . . . .5-16

ASSEMBLING THE MAIN SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

ASSEMBLING THE COUNTERSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

CHECKING THE FREEWHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

REPLACING THE FREEWHEEL HUB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

INDEX

5-1

5

Page 52

Page 53

5-2

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Replacing the roller bearing

– Remove all bearing locking screws 1 from both case halves.

– Remove all shaft seal rings and the dowel pins from the case halves.

Heat both case halves evenly in an oven at 150° C; the roller bearings

will fall out of the case by themselves. If any roller bearings should be

left in the case, tap the case lightly on a flat wooden surface.

NOTE: the shift shaft bearing

2 must be pressed out with the pressing

tool 600.29.043.030, although this bearing is usually highly resistant to

wear.

– Replace all of the roller bearings. The new roller bearings can be

inserted by hand until flush as soon as the case temperature has

reached approx. 150° C. The roller bearings should fit tightly after

cooling down. Use a mandrel to carefully press in any bearings that

are not flush with the surface.

NOTE: the shift shaft bearing

2 must be pressed in flush with the

pressing tool 600.29.043.030.

–Press in the shaft sealing ring

3 for the push rod until flush using the

special tool 600.29.043.010.

–Press in the shaft sealing ring for the countershaft

4 until flush using

the special tool 600.29.043.020.

–Press in the shaft sealing ring for the shift shaft

5 until flush using

the special tool 600.29.043.030.

–

Apply Loctite 243 to all bearing locking screws 1 and tighten to 6 Nm.

1

1

1

1

2

3

4

5

Page 54

5-3

Replacing the main bearings-general information

NOTE:

– The bearing shells for the friction bearings are pressed in and out in a

cold state.

– Mark the position of the bearing end gap

1 on the engine case with

a felt-tip pin to facilitate reassembly.

–Press the main bearing shells out of both engine case halves from the

inside to the outside using the press mandrel 600.29.044.050

2

(smaller diameter).

Before you select the bearing shells you must measure the crankshaft.

– Measure the diameter of the two main bearing pins at 3 points that

are 120° apart using a micrometer gauge. This only applies to

crankshafts that you will continue to use.

Diameter of main bearing pin: 49.965 mm – 49.975 mm (yellow)

49.976 mm – 49.985 mm (blue)

49.986 mm – 49.995 mm (red)

NOTE:

– Use the bearing color indicated for the respective measurement.

– The crankshaft must be replaced if the measurement falls short of the

minimum diameter or if the crankshaft is worn.

– New crankshafts do not need to be measured. Use new bearings

according to the colored circles

3 marked on the crankshaft web of

the new crankshaft.

NOTE: there are 2 types of bearings for each bearing color – the

grooved bearing shell (with the lubricating groove and oil bore) is

pressed into the top of the case half of the generator end and the

smooth bearing shells (without lubricating groove) are pressed into the

bottom of the case half of the generator end and into the case half of

the output end

– Measure the bearing bores with a micrometer to ensure that the

bearing shells are seated firmly in the engine case after being pressed

in.

Nominal dimension: 54.000 mm – 54.015 mm

NOTE: if the bearing bores are too big, the engine case must be

replaced.

Measure the inner diameter of the bearings after they are pressed in to

ensure that the bearing clearance is correct.

NOTE: the inner diameter of the bearings must be measured at a 90°

angle to the bearing end gap.

The diameter of the main bearing pin must be deducted from the inner

diameters of the bearings, the difference is the radial clearance of the

main bearing.

Setpoint value for the radial clearance of the main bearing:

0.025 mm – 0.055 mm

Wear limit: 0.080 mm

Example:Inner bearing diameter measured 50.020 mm

Main bearing pin measured 49.980 mm

50.020 – 49.980 = 0.040 mm radial clearance

1

2

3

Page 55

5-4

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Replacing bearing shells, output end

– Center the new bearing shells (both smooth) with the assembling

sleeve 600.29.044.050

1. The assembling sleeve is beveled on one

side so the bearing shells can be pushed in easily. The bearing shells

should protrude 1-2 mm on the other side of the assembling sleeve to

make it easier to position them in the engine case.

– Position the bearing shells on the output end of the case such that

the end gap on the bearing shells points to the marks

2 made when

disassembling.

–Press in the bearings from the outside to the inside through the

assembling sleeve up to the stop using the press mandrel

600.29.044.050

3.

!

CAUTION

!

– ALWAYS PRESS IN BEARING SHELLS FROM THE OUTSIDE TO THE INSIDE OTHERWISE

THEY WILL NOT BE POSITIONED CORRECTLY AND THE BEARING RADII OF THE

CRANKSHAFT WEBS WILL PRESS AGAINST THE BEARING SHELLS

. THIS IS WHY THE

BEARING SHELLS ARE SEATED

2 MM BELOW THE EDGE OF THE BEARING BORE.

– THE ASSEMBLING SLEEVE SERVES AS A STOP

. IT IS NOT REMOVED UNTIL THE

BEARING SHELLS ARE SEATED IN THE CORRECT POSITION

.

Replacing bearing shells, generator end

– Center the new bearing shells (smooth – on the bottom, grooved –

on the top) with the assembling sleeve 600.29.044.050 – same

procedure as for the bearing shells, output end (see above).

– Position the bearing sleeves at the generator end of the case with the

bearing shell end gap pointing to the marks

4 made when

disassembling. Do not cover the oil bore.

–Press the bearings into the engine case half from the outside to the

inside through the assembling sleeve up to the stop using the special

tool 600.29.044.050.

!

CAUTION

!

– ALWAYS PRESS IN BEARING SHELLS FROM THE OUTSIDE TO THE INSIDE OTHERWISE

THEY WILL NOT BE POSITIONED CORRECTLY AND THE BEARING RADII OF THE

CRANKSHAFT WEBS WILL PRESS AGAINST THE BEARING SHELLS

. THIS IS WHY THE

BEARING SHELLS ARE SEATED

2 MM BELOW THE EDGE OF THE BEARING BORE.

– THE ASSEMBLING SLEEVE SERVES AS A STOP. IT IS NOT REMOVED UNTIL THE

BEARING SHELLS ARE SEATED IN THE CORRECT POSITION

.

–

IF THE BEARING SHELLS ARE INCORRECTLY ALIGNED OR IF SMOOTH BEARING

SHELLS ARE PRESSED IN ON TOP

, THE OIL SUPPLY TO THE SPRAYING NOZZLES TO

COOL THE PISTONS AND LUBRICATE THE TIMING CHAIN WILL BE INTERRUPTED

,

LEADING TO SERIOUS ENGINE DAMAGE.

NOTE:

– After replacing all friction and roller bearings, dismount the spraying

nozzles and oil nozzles and clean the oil ducts with compressed air to

make sure they are not clogged.

– Coat the friction bearings with Molycote grease.

Apply Loctite 243 to the spraying nozzles and oil nozzles and tighten to 10 Nm.

2

3

4

1

Page 56

5-5

Replacing the conrod bearings

– Clamp each conrod in a vise using protective jaws.

– Loosen the bolts

1 on the conrod bearing covers with the special

wrench socket 600.29.075.000 and remove the bearing covers.

NOTE: mark the conrod caps to ensure that each cap is mounted to the

same conrod when it is measured and assembled.

– Remove the conrod caps.

– Clean the crankshaft and blow compressed air through the lubrication

bores.

Selecting the bearing shells

Before you select the new bearing shells you must measure the conrod

journal.

– Measure the diameter of the conrod journal at 3 points that are 120°

apart using a micrometer gauge.

Diameter of the conrod journal: 41.990 mm – 42.000 mm (blue)

42.001 mm – 42.011 mm (red)

NOTE:

– Use the bearing color indicated for the respective measurement.

– The crankshaft must be replaced if the measurement falls short of the

minimum diameter or if the crankshaft is worn.

– Clamp each conrod in a vise, insert new bearing shells, position the

crankshaft with a plastigauge measuring strip

A (600.29.012.000) on

top and mount the conrod caps with the old bolts, as described

below.

!

CAUTION

!

–

INSERT THE PLASTIGAUGE MEASURING STRIPS AT A 90° ANGLE TO THE BEARING

END GAP

.

– DO NOT TURN THE CONRODS ON THE CONROD JOURNAL

.

– Unclamp the conrods and compare the width of the plastigauge

measuring strip with the information on the packing. The width of

the plastiguage measuring strip is equivalent to the bearing clearance.

Setpoint value of the conrod bearing clearance:

0.030 mm – 0.060 mm

Wear limit: 0.080 mm

– Clamp each conrod in a vise using protective jaws, apply a thin layer

of Molycote grease to the bearing shells, position the crankshaft and

mount the conrod caps with new bolts.

!

CAUTION

!

THE BEARING SHELLS SHOULD BE MOUNTED IN AN OFFSET POSITION IN THE CONROD

TO ALLOW ROOM FOR THE CRANKSHAFT RADIUS

2. IF THE CONRODS ARE

MOUNTED BACKWARDS

, THE BEARING SHELLS WILL EXERT PRESSURE ON THE RADIUS

AND BLOCK THE CONRODS

.

–Tighten the conrod bearing bolts with the special wrench socket

600.29.075.000 to 25 Nm (1st stage). The tighten to 30 Nm (2nd

stage) and finally by another 60° (3rd stage).

NOTE: use a degree wheel

3 (600.29.010.000) to make sure the

conrod bearing bolts are tightened correctly.

1

2

2

3

A

Page 57

5-6

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Replacing the supporting bearings in the clutch cover

– Pull the bearing shells out of the clutch cover using the puller

151.12.017.000 and the internal extractor 600.29.018.000

1.

– Measure the diameter of the bearing pin at 3 points that are 120°

apart using a micrometer gauge.

Diameter of the supporting bearing pin: 27.985 mm – 28.000 mm

NOTE: The crankshaft must be replaced if the measurement falls short of

the minimum diameter or if the crankshaft is worn.

– Center the new bearing shells with the assembling sleeve

600.29.046.028

2. The assembling sleeve is beveled on one side so

the bearing shells can be pushed in easily. The bearing shells should

protrude 1-2 mm on the other side of the assembling sleeve to make

it easier to position them in the clutch cover.

– Place the bearing shells on the clutch cover with the assembling

sleeve and press in the bearing shells to the stop using the press

mandrel 600.29.046.028

3.

1

2

3

Page 58

5-7

Overhauling the water pump

– Remove the washer 1 from the water pump shaft and pry the shaft

sealing ring

2 out of the case.

NOTE: if the water pump wheel cannot be removed because it is being

held by residual thread adhesive, the water pump shaft and the water

pump wheel can be pressed out from the inside after the lock ring

4 is

removed.

– Remove the outer lock ring

3 from the water pump shaft using

suitable pliers.

–Press the water pump shaft out of the bearing from the outside to the

inside. The inner lock ring

4 does not need to be removed.

– Heat the case evenly in an oven at 150° C; the old bearing will fall

out of the bearing seat by itself and the new bearing can easily be

pressed into the bearing seat by hand. The bearing should fit flush

and tightly after it cools down.

– Insert the water pump shaft in the new bearing from the inside to the

outside.

NOTE: the recess in the water pump shaft should point towards the

inside.

–Mount the lock ring

3.

– Place the protective sleeve

5 585.29.005.000 on the pump shaft and

press in a new shaft sealing ring

2 until flush using the pressing tool

600.29.043.040. Mount the washer

1.

1

2

3

4

5

2

Page 59

5-8

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Checking the suction pump for wear

– Insert both suction pump rotors in the housing.

–Use a feeler gauge

A to check the clearance between the inner and

outer rotor:

Setpoint value: 0.1 mm

Wear limit: 0.2 mm

– Use a feeler gauge

A to check the clearance between the outer rotor

and the housing:

Setpoint value: 0.2 mm

Wear limit: 0.4 mm

– Use a feeler gauge A and a straight edge B to check the axial

clearance:

Setpoint value: 0.04 mm – 0.09 mm

Wear limit: 0.25 mm

Checking the pressure pump for wear

– Insert both pressure pump rotors in the case.

–Use a feeler gauge

A to check the clearance between the inner and

outer rotor:

Setpoint value: 0.1 mm

Wear limit: 0.2 mm

– Use a feeler gauge A to check the clearance between the outer rotor

and the case:

Setpoint value: 0.2 mm

Wear limit: 0.4 mm

– Use a feeler gauge and a straight edge to check the axial clearance:

Setpoint value: 0.04 mm – 0.09 mm

Wear limit: 0.25 mm

Bypass valve

– Remove the lock ring 1 on the bypass valve using suitable pliers and

take the individual bypass valve parts out of the housing.

NOTE: the spring is pretensioned.

– Check parts for visible wear and damage.

– Measure the length of the pressure spring:

Minimum length of pressure spring: 42.0 mm

– Clean parts, oil the pistons and insert in the bore. Position the spring,

place a washer on the spring and mount the lock ring in the groove

using suitable pliers.

A

A

A

A

1

A

B

Page 60

5-9

Disassembling the cylinder head and checking parts for wear

NOTE: the illustration shows the font cylinder. The procedure for the

rear cylinder is identical.

– Pull all of the bucket tappets

1 out of the cylinder head.

NOTE:

– Note down the mounting position to ensure that the same bucket

tappet is inserted in the same bore during installation.

– The compensating washers

2 for the valve clearance (shims) usually

adhere to the bottom of the bucket tappets and should be set aside

together with the bucket tappets.

– Invert the cylinder and cylinder head and remove the three Allen bolts

3 and nuts.

–Remove the cylinder and pistons from the cylinder head and discard

the cylinder head gasket.

– Unscrew the chain guide.

–Press the valve springs together using the valve assembling tool

(590.29.019.000 with the attachment 600.29.041.000

4) and

remove the valve spring key from the valve shaft. Relieve the springs

and remove from the cylinder head.

NOTE: note down the mounting position of the valves to ensure that the

valves are mounted in the same position during installation.

– Pull the valve shaft seal off the valve shaft with pliers and remove the

valve spring washer.

NOTE: a washer (14x30x2) is located under the spring retainers for the

exhaust valve springs to increase the spring preload.

– Repeat the above procedure for the other valves.

– Clean all parts.

Sealing area

Check the spark plug thread and valve seats for damage or cracks. Use a

straight edge

A and a feeler gauge B to check the sealing area to the

cylinder for distortion. Max. distortion: 0.05 mm.

Valve seats

The valve seats may not be impacted. Width of sealing seat: intake max.

1.40 mm; outlet max. 1.40 mm. Reseat the valves if necessary.

Valves

Check the valve disk for wear and runout. The valve disk runout should

not exceed 0.03 mm. The valve seat may not be impacted. The sealing

area should be in the middle of the valve seat. The valve shaft is hardchrome-plated. Wear usually occurs at the valve guide.

Valve guides

The valve guides are checked with the limit plug gauge

C

590.29.026.006 (Ø 6.05 mm). If the limit plug gauge can easily be

pushed into the valve guide, the valve guide needs to be replaced at a

special workshop.

Valve springs

Check the valve springs for fractures or other wear. Measure the spring

length with a sliding caliper in an unloaded condition:

Minimum length of inner spring: 38.0 mm

Maximum length of outer spring: 41.3 mm

1

2

3

3

3

A

B

C

4

Page 61

5-10

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

Checking the pistons

– Mark the position of the piston arrow in the cylinder to facilitate

reassembly and to ensure that the same piston is mounted in the

same cylinder again.

–Press the piston up out of the cylinder.

– Replace the piston if oil consumption is high or the piston skirt is

excessively grooved.

– If the piston is to be reinstalled:

1. Check the piston bearing surface for damage.

2. Piston ring grooves: the piston rings must move freely in the groove.

Use old piston rings or sandpaper (400 grit) to clean the piston ring

grooves.

3. Check the piston rings for damage and end gap.

4. The piston pins must move freely in the bolt hole when mounted.

Replace piston pins that are badly discolored or have visible running

marks. Place the piston pin in the conrod and check for clearance.

Maximum clearance in the conrod eye: 0.08 mm.

NOTE: the piston pin may not have any clearance when mounted and

should be easy to move when applying slight counterpressure.

Checking the piston ring end gap

– Insert the piston ring in the cylinder and align with the piston

(approx. 10 mm under the upper edge of the cylinder).

– Measure the end gap with a feeler gauge

A.

Piston ring end gap: max. 0.50 mm

If the end gap is larger than indicated above, check the cylinder for

wear. If the cylinder wear is within the tolerance limits, replace the piston

ring.

Assembly instructions for piston rings

– Mount the oil scraper ring in the lower piston ring groove with the

mark facing the piston head.

–Mount the compression ring in the middle piston ring groove with the

mark facing the piston head.

–Mount the compression ring in the upper piston ring groove with the

mark facing the piston head.

Measuring pistons and cylinders, establishing the piston

mounting clearance

–To establish cylinder wear, use a micrometer to measure the cylinder

in the middle of the bearing surface.

– Measure the X and Y axis of the cylinder diameter to establish any

ovality.

NOTE: if the Nicasil coating on the cylinder is worn but not damaged, a

replacement cylinder can be ordered from our KTM dealer/importer

(new Nicasil coating, used cylinder).

– Measure the piston at the piston skirt across the piston pin, 9 mm

from the lower edge.

Piston size I: 99.960 mm – 99.972 mm

Piston size II: 99.973 mm – 99.984 mm

Wear limit: 99.930 mm

– The piston mounting clearance is the difference between the smallest

cylinder diameter and the piston diameter.

Piston mounting clearance: 0.04 mm – 0.06 mm

Wear limit: 0.10 mm

1

A

x

y

Page 62

Piston and cylinder identification

The cylinder size 1 is impressed in the bottom of the cylinder near the

chain tunnel; 1 is size I, 2 is size II.

The piston size

2 is impressed in the top of the piston; 1 is size I, 2 is

size II.

Assembling the cylinder head

– Slide the valve spring washers 3 over the valve guides and mount

new valve shaft seals

4.

– Lubricate the valve shafts and insert the valves in their original

position in the valve guides.

NOTE: a washer (14x30x2) is located under the spring retainers for the

exhaust valve springs to increase the spring preload.

– Mount the inner and outer valve springs

5 with the spring retainers

6 and compress the springs using the valve assembling tool

(590.29.019.000 with the attachment 600.29.041.000).

–Grease the valve spring keys

7 and position on the valve shafts.

Relieve the valve springs.

–Tap the valve spring retainers to set the keys.

5-11

3

4

5

1

2

6

7

Page 63

5-12

Repair manual KTM LC8 Art.-Nr. 3.206.009-E

– Place the lubricated piston on the cylinder and clamp the piston rings

together with the piston ring clamping band 600.29.015.000

1.

– Use a plastic hammer to tap lightly on the top of the piston ring

clamping band until it is flush with the cylinder.

– Use the hammer handle to carefully tap the piston into the cylinder,

making sure the piston rings do not get caught.

!

CAUTION

!

IFTHE PISTON RINGS ARE PROPERLY CLAMPED BY THE PISTON RING CLAMPING BAND

AND THE CLAMPING BAND IS FLUSH WITH THE CYLINDER

, IT SHOULD BE EASY TO

PUSH THE PISTON INTO THE CYLINDER BY TAPPING LIGHTLY WITH THE HAMMER

HANDLE

. APPLYING MORE FORCE WILL ONLY DAMAGE THE PISTON RINGS.

– Invert the cylinder head, mount a new cylinder head gasket and put

the cylinder into position.

NOTE: the cylinder and the cylinder head are marked at the exhaust

flange