Page 1

If it's embedded, it's Kontron.

» Kontron User's Guide «

RTM8242

Document Revision 1.0

April 2012

Page 2

www.kontron.com

Revision History

Rev. Index Brief Description of Changes Date of Issue

1.0 First Release April 2012

Customer Service

Contact Information: Kontron Canada, Inc.

4555 Ambroise-Lafortune

Boisbriand, Québec, Canada

J7H 0A4

Tel: (450) 437-5682

(800) 354-4223

Fax: (450) 437-8053

E-mail: support@ca.kontron.com

Visit our site at: www.kontron.com

© 2011 Kontron, an International Corporation. All rights reserved.

The information in this user's guide is provided for reference only. Kontron does not assume any liability

arising out of the application or use of the information or products described herein. This user's guide may

contain or reference information and products protected by copyrights or patents and does not convey any

license under the patent rights of Kontron, nor the rights of others.

Kontron is a registered trademark of Kontron. All trademarks, registered trademarks, and trade names used

in this user's guide are the property of their respective owners. All rights reserved. Printed in Canada. This

user's guide contains information proprietary to Kontron. Customers may reprint and use this user's guide in

other publications. Customers may alter this user's guide and publish it only after they remove the Kontron

name, cover, and logo.

Kontron Modular Computer GMBH

Sudetenstrasse 7

87600 Kaufbeuren

Germany

+49 (0) 8341 803 333

+49 (0) 8341 803 339

support@kontron-modular.com

Kontron reserves the right to make changes without notice in product or component design as warranted by

evolution in user needs or progress in engineering or manufacturing technology. Changes that affect the

operation of the unit will be documented in the next revision of this user's guide.

iRTM8242

Page 3

www.kontron.com

Table of Contents

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Preventing Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

How to Use This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Customer Comments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Advisory Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Powering Up the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Storing Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Regulatory Compliance Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Table of Contents

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

1. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 What’s Included. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Board Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Hot-Swap Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Interfacing with the Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.1 RTM (rear transition module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. Board Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 SFP+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 MMC Boot Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Hardware Management Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.1 Sensor Data Record (SDR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5.2 Hardware Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5.3 Field Replaceable Unit (FRU) Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.4 MMC Firmware Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.5 MMC Firmware Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.6 Hot-Swap Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

ii RTM8242

Page 4

Table of Contents

www.kontron.com

2.6 Face Plate Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6.1 Hot Swap LED (LED0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.6.2 Out Of Service (LED1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.6.3 Healthy LED (LED2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.6.4 SFP+ and SFP LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3. Hot Swap and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 RTM Hot Swap and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1.1 Installing the RTM in the chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1.2 Removing the RTM from the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

A. Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.1 Connectors and Headers Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.2 SFP+ Connectors (J1-J8). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.3 SFP Connectors (J9-J12). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

B. Getting Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.1 Returning Defective Merchandise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.2 When Returning a Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

C. Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

iii RTM8242

Page 5

List of Figures

www.kontron.com

List of Figures

Figure 2-1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

iv RTM8242

Page 6

List of Tables

www.kontron.com

List of Tables

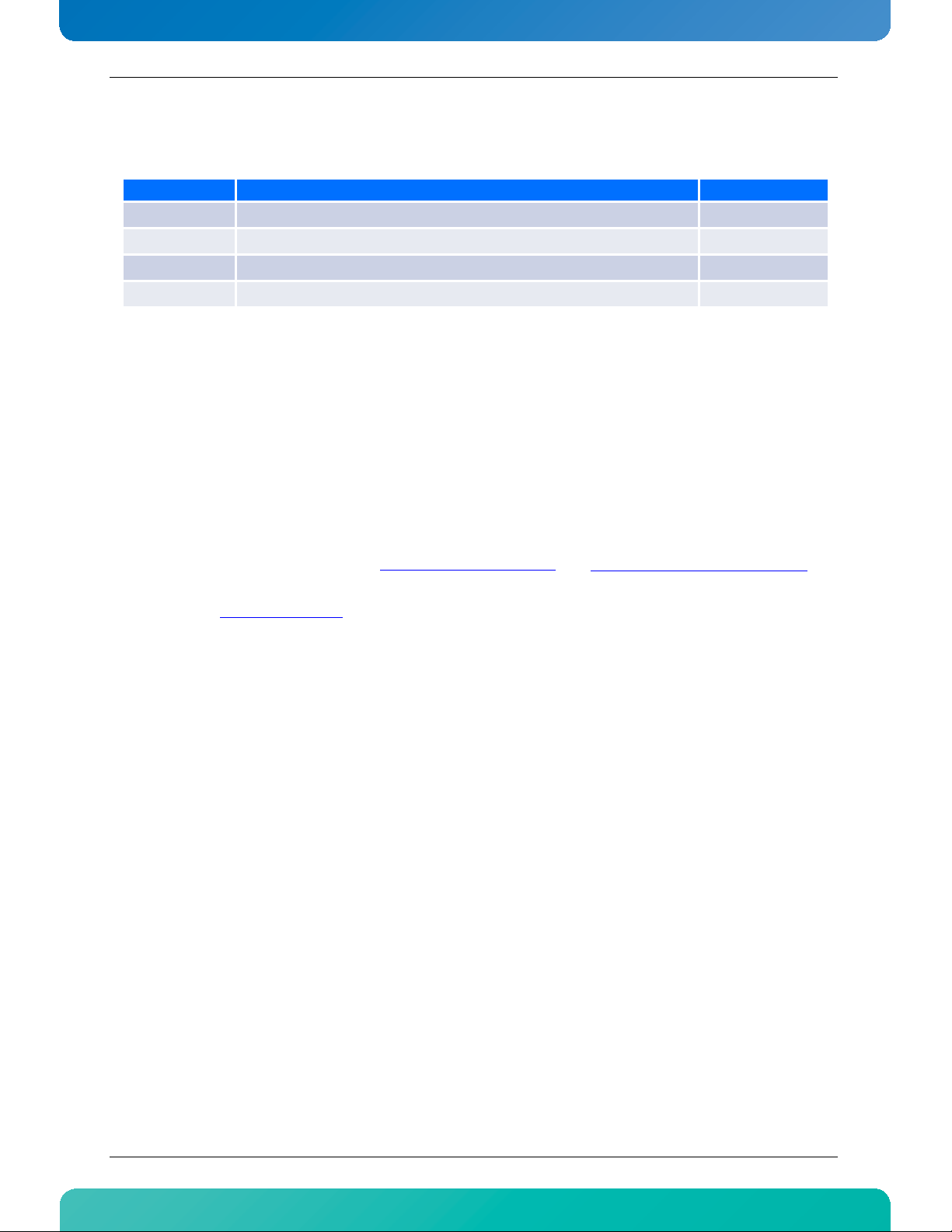

Table 1-1 Board Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2-1 Approved SFP Copper list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2-2 Approved SFP Optical list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2-3 Approved SFP+ list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2-4 IPMI Hardware Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2-5 Board Information Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2-6 Product Information Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2-7 Type 16 Module Current Requirements Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2-8 Hot-Swap LED Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

vRTM8242

Page 7

Safety Instructions

www.kontron.com

Safety Instructions

Before You Begin

Before handling the board, read the instructions and safety guidelines on the following pages to prevent

damage to the product and to ensure your own personal safety. Refer to the "Advisories" section in the

Preface for advisory conventions used in this user's guide, including the distinction between Warnings,

Cautions, Important Notes, and Notes.

• Always use caution when handling/operating the product. Only qualified, experienced, authorized

electronics service personnel should access the interior of the product. The power supplies produce

high voltages and energy hazards, which can cause bodily harm.

• Use extreme caution when installing or removing components. Refer to the installation

instructions in this user's guide for precautions and procedures. If you have any questions, please

contact Kontron Technical Support

WARNING

High voltages are present inside the chassis when the unit's power cord is plugged

into an electrical outlet. Turn off system power, turn off the power supply, and then

disconnect the power cord from its source before removing the chassis cover. Turning

off the system power switch does not remove power to components.

vi RTM8242

Page 8

Safety Instructions

www.kontron.com

Preventing Electrostatic Discharge

Static electricity can harm system boards. Perform service at an ESD workstation and follow proper ESD

procedure to reduce the risk of damage to components. Kontron strongly encourages you to follow proper

ESD procedure, which can include wrist straps and smocks, when servicing equipment.

Take the following steps to prevent damage from electrostatic discharge (ESD):

•When unpacking a static-sensitive component from its shipping carton, do not remove the

component's antistatic packing material until you are ready to install the component in a

computer. Just before unwrapping the antistatic packaging, be sure you are at an ESD workstation

or grounded. This will discharge any static electricity that may have built up in your body.

•When transporting a sensitive component, first place it in an antistatic container or packaging.

•Handle all sensitive components at an ESD workstation. If possible, use antistatic floor pads and

workbench pads.

•Handle components and boards with care. Don't touch the components or contacts on a board. Hold

a board by its edges or by its metal mounting bracket.

•Do not handle or store system boards near strong electrostatic, electromagnetic, magnetic, or

radioactive fields.

•When you want to remove the protective foil (if present), make sure you are properly grounded and

that you touch a metallic part of the board.

CAUTION

Removing the protective foil from the top and bottom cover might create static.

When you remove those protections, make sure you follow the proper ESD procedure.

vii RTM8242

Page 9

Preface

www.kontron.com

Preface

How to Use This Guide

This user's guide is designed to be used as step-by-step instructions for installation, and as a reference for

operation, troubleshooting, and upgrades.

For the circuits, descriptions and tables indicated, Kontron assumes no responsibility as far as patents or

other rights of third parties are concerned.

The following is a summary of chapter contents:

•Chapter 1, Product Description

•Chapter 2, Board Features

•Chapter 3, Hot Swap and Installation

•Appendix A, Connector Pinout

•Appendix B, Getting Help

•Appendix C, Glossary

viii RTM8242

Page 10

Preface

www.kontron.com

Customer Comments

If you have any difficulties using this user's guide, discover an error, or just want to provide some feedback,

please send a message to: support@ca.kontron.com

problems as soon as possible and post the revised user's guide on our Web site. Thank you.

. Detail any errors you find. We will correct the errors or

Advisory Conventions

Seven types of advisories are used throughout the user guides to provide helpful information or to alert you

to the potential for hardware damage or personal injury. They are Note, Signal Paths, Jumpers Settings, BIOS

Settings, Software Usage, Cautions, and Warnings. The following is an example of each type of advisory. Use

caution when servicing electrical components.

Note:

Indicate information that is important for you to know.

Signal Path:

Indicate the places where you can find the signal on the board.

Jumper Settings:

Indicate the jumpers that are related to this section.

Software Usage:

Indicates how you can access this feature through software.

CAUTION

Indicate potential damage to hardware and tells you how to avoid the problem.

WARNING

Indicates potential for bodily harm and tells you how to avoid the problem.

ESD Sensitive Device:

This symbol and title inform that electronic boards and their components are sensitive to static

electricity. Therefore, care must be taken during all handling operations and inspections of this

product, in order to ensure product integrity at all times.

Please read also the section "Special Handling and Unpacking Instructions".

CE Conformity:

This symbol indicates that the product described in this manual is in compliance with all applied CE

standards. Please refer also to the section "Regulatory Compliance Statements" in this manual.

Disclaimer: We have tried to identify all situations that may pose a warning or a caution condition in this

user's guide. However, Kontron does not claim to have covered all situations that might require the use of a

Caution or a Warning.

ix RTM8242

Page 11

www.kontron.com

Unpacking

Follow these recommendations while unpacking:

•Remove all items from the box. If any items listed on the purchase order are missing, notify Kontron

customer service immediately.

•Inspect the product for damage. If there is damage, notify Kontron customer service immediately.

•Save the box and packing material for possible future shipment.

Powering Up the System

Before any installation or setup, ensure that the board is unplugged from power sources or subsystems.

If you encounter a problem, verify the following items:

•Make sure that all connectors are properly connected.

Preface

•Verify your boot devices.

•If the system does not start properly, try booting without any other I/O peripherals attached,

including AMC adapters.

Make sure your system provides the minimum DC voltages required at the board's slot, especially if DC power

is carried by cables.

If you are still not able to get your board running, contact our Technical Support for assistance.

Storing Boards

Electronic boards are sensitive devices. Do not handle or store device near strong electrostatic,

electromagnetic, magnetic or radioactive fields.

xRTM8242

Page 12

www.kontron.com

Regulatory Compliance Statements

FCC Compliance Statement for Class A Devices

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generated, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Preface

•Consult the dealer or an experience radio/TV technician for help.

WARNING

This is a Class A product. If not installed in a properly shielded enclosure and used in

accordance with this User's Guide, this product may cause radio interference in

which case users may need to take additional measures at their own expense.

Safety Certification

All Kontron equipment meets or exceeds safety requirements based on the IEC/EN/UL/CSA 609501 family of standards entitled, "Safety of information technology equipment." All components are

chosen to reduce fire hazards and provide insulation and protection where necessary. Testing and

reports when required are performed under the international IECEE CB Scheme. Please consult the

"Kontron Safety Conformity Policy Guide" for more information. For Canada and USA input voltage

must not exceed -60Vdc for safety compliance.

CE Certification

The product(s) described in this user's guide complies with all applicable European Union (CE)

directives if it has a CE marking. For computer systems to remain CE compliant, only CE-compliant

parts may be used. Maintaining CE compliance also requires proper cable and cabling techniques.

Although Kontron offers accessories, the customer must ensure that these products are installed

with proper shielding to maintain CE compliance. Kontron does not offer engineering services for

designing cabling systems. In addition, Kontron will not retest or recertify systems or components

that have been reconfigured by customers.

xi RTM8242

Page 13

Preface

www.kontron.com

Limited Warranty

Kontron grants the original purchaser of Kontron's products a TWO YEAR LIMITED HARDWARE WARRANTY as

described in the following. However, no other warranties that may be granted or implied by anyone on behalf

of Kontron are valid unless the consumer has the express written consent of Kontron.

Kontron warrants their own products, excluding software, to be free from manufacturing and material

defects for a period of 24 consecutive months from the date of purchase. This warranty is not transferable nor

extendible to cover any other users or long- term storage of the product. It does not cover products which

have been modified, altered or repaired by any other party than Kontron or their authorized agents.

Furthermore, any product which has been, or is suspected of being damaged as a result of negligence,

improper use, incorrect handling, servicing or maintenance, or which has been damaged as a result of

excessive current/voltage or temperature, or which has had its serial number(s), any other markings or parts

thereof altered, defaced or removed will also be excluded from this warranty.

If the customer's eligibility for warranty has not been voided, in the event of any claim, he may return the

product at the earliest possible convenience to the original place of purchase, together with a copy of the

original document of purchase, a full description of the application the product is used on and a description

of the defect. Pack the product in such a way as to ensure safe transportation (see our safety instructions).

Kontron provides for repair or replacement of any part, assembly or sub-assembly at their own discretion, or

to refund the original cost of purchase, if appropriate. In the event of repair, refunding or replacement of

any part, the ownership of the removed or replaced parts reverts to Kontron, and the remaining part of the

original guarantee, or any new guarantee to cover the repaired or replaced items, will be transferred to cover

the new or repaired items. Any extensions to the original guarantee are considered gestures of goodwill, and

will be defined in the "Repair Report" issued by Kontron with the repaired or replaced item.

Kontron will not accept liability for any further claims resulting directly or indirectly from any warranty

claim, other than the above specified repair, replacement or refunding. In particular, all claims for damage

to any system or process in which the product was employed, or any loss incurred as a result of the product

not functioning at any given time, are excluded. The extent of Kontron liability to the customer shall not

exceed the original purchase price of the item for which the claim exists.

Kontron issues no warranty or representation, either explicit or implicit, with respect to its products

reliability, fitness, quality, marketability or ability to fulfil any particular application or purpose. As a result,

the products are sold "as is," and the responsibility to ensure their suitability for any given task remains that

of the purchaser. In no event will Kontron be liable for direct, indirect or consequential damages resulting

from the use of our hardware or software products, or documentation, even if Kontron were advised of the

possibility of such claims prior to the purchase of the product or during any period since the date of its

purchase.

Please remember that no Kontron employee, dealer or agent is authorized to make any modification or

addition to the above specified terms, either verbally or in any other form, written or electronically

transmitted, without the company's consent.

xii RTM8242

Page 14

Chapter 1

Product Description

www.kontron.com

1.1 Product Overview .............................................. 2

1.2 What’s Included ................................................ 2

1.3 Board Specifications.......................................... 3

1.4 Hot-Swap Capability .......................................... 4

1.5 Interfacing with the Environment ......................... 4

1RTM8242

Page 15

Product Description

www.kontron.com

1. Product Description

1.1 Product Overview

The RTM8242 is an ATCA Rear Transition Module offering 84Gbps total uplinks with 4x 1GbE SFP and 8x 10GbE

SFP+. It has been designed for the AT8242 ATCA Dual Octeon-II CN68XX Processor Blade.

RTM architecture includes:

• Support for 4x SFP 1GbE uplink;

- 1000Base-SX/LX Optical Modules

- 1000Base-T Copper Module

• Support for 8x SFP/SFP+ 10/1GbE uplink;

- 10GBase-SR/LR Optical Modules

- 1000Base-SX/LX Optical Modules

- 1000Base-T Copper Module

1.2 What’s Included

This board is shipped with the following items:

• One RTM8242 board

• One Quick Reference Sheet.

• One Documentation & Drivers disk

If any item is missing or damaged, contact the supplier.

2RTM8242

Page 16

www.kontron.com

1.3 Board Specifications

Table 1-1:Board Specifications

Features Description

Compatible Products •AT8242

• PICMG3.0 R3.0

Compliancy

IPMI Features

Supervisory

Mechanical • 322.25 x 93.74 x 29 mm

Power Requirements • 18W Typical; 25W Max.

Environmental

Temperature*

Environmental

Humidity*

Environmental Altitude*

Environmental Shock*

Environmental

Vibration*

Reliability • MTBF: 784373 hours @ 40°C/104°F (Telcordia SR-332, issue 2)

Safety / EMC

Warranty Two years limited warranty

• PICMG HPM.1

• PICMG3.1 R2.0

• Management Controller compliant to PICMG 3.0, AMC.0 R2.0 and IPMI v2.0.

• Management Controller is run time field reprogrammable without payload impact.

• Robust fail safe reprogramming implementation (which includes two firmware images) that

performs automatic or manual rollback if a problem occurs during critical reprogramming

phase.

• Remote upgrade capability (via IPMB).

• Management Controller self test which can detect a failure in its code integrity and trigger an

automatic rollback.

• Hardware system monitor through IPMI sensors (voltages and temperatures), alarms, events,

power failure.

• Operating: 0-55°C/32-131°F with 3.8CFM airflow

• Storage and Transit: -40 to +70°C/-40 to 158°F

• Operating: 15% to 90% @55°C/131°F non-condensing

• Storage and Transit: 5% to 95% @ 40°C/104°F non-condensing

• Operating: 4,000 m / 13,123 ft

• Storage and Transit: 15,000 m / 49,212 ft

• Operating: 3G, half-sine 11ms, each axis

• Storage and Transit: 18G, half-sine 6ms, each axis

• Swept sine: 5-200Hz. 0.2G, each axis

• Operating random: 5Hz to 10Hz @ +12dB/oct (slope up)

10Hz to 50Hz @ 0.02m2/s3 (0.0002g2 /Hz) (flat)

50Hz to 100Hz @ -12dB/oct (slope down)

• Storage & transit: 5Hz to 20Hz @ 1m2/s3 (0.01g2 /Hz) (flat)

20Hz to 200Hz @ -3dB/oct (slope down)

• Safety: CE Mark to EN 60950-1:2001. Meets or exceeds UL 60950-1/CSA C22.2 No 60950-1-07

• Designed to meet GR-1089-CORE

• EMI/EMC: FCC 47 CFR Part 15, Class A; CE Mark to EN55022/EN55024/EN300386

Product Description

* Designed to meet or exceed

3RTM8242

Page 17

Product Description

www.kontron.com

1.4 Hot-Swap Capability

The RTM8242 supports Full Hot Swap capability as per PICMG3.0 R3.0. It can be removed from or installed in

the system while it is on (without powering-down the system). Please refer to the PICMG3.0 R3.0

specification for additional details.

1.5 Interfacing with the Environment

1.5.1 RTM (rear transition module)

The RTM8242 is a single slot (6HP, 30.48mm) AdvancedTCA Rear Transition Module. This module provides

additional connectivity for AT8242 front boards.

1.5.1.1 FRU Data EEPROM

• FRU Data EEPROM size is 128Kbit and it includes board identification and serial number information.

1.5.1.2 Hot Swap

As a Hot Swappable Intelligent Managed FRU, the RTM8242 (FRU2) includes a Management Controller, the

AdvancedTCA Hot Swap indicator (Blue LED) and the standard AdvancedTCA handle switch.

1.5.1.2.1 Insertion and Removal of the Managed FRUs

After insertion, the front board detects and activates the management components of the FRU. When the

handle is closed, the power budget and the e-keying negotiations start. Then, the front board's IPMC

activates the payload components of the FRU.

Opening the bottom handle on the RTM will start the deactivation process of the RTM8242.

The operational state of the FRU is reported through the management subsystem’s FRU Hot Swap sensors.

The BLUE LED is 100% off when a FRU is operational and unsafe for extraction. An always on(100%) indicates

that a FRU can safely be extracted; transitional states are identified through blinking patterns. Additional

details on the standard FRU Hot Swap sensor and the BLUE LED usage can be found in the AdvancedTCA

specifications.

4RTM8242

Page 18

Chapter 2

Board Features

www.kontron.com

2.1 Block Diagram .................................................. 6

2.2 SFP................................................................. 6

2.3 SFP+ ............................................................... 7

2.4 MMC Boot Block ................................................ 7

2.5 Hardware Management Overview .......................... 7

2.6 Face Plate Indicators.......................................... 12

Page 19

www.kontron.com

2. Board Features

2.1 Block Diagram

Figure 2-1:Block Diagram

2.2 SFP

The RTM8242 has 4 SFP module connectors available on the RTM face plate. The SFP module signals come

from the front board at 1Gb through Zone 3 connectors.

6RTM8242

Page 20

www.kontron.com

Table 2-1:Approved SFP Copper list

Manufacturer Part Number Description Company

ABC U-5710RZ 1000BASE-T Copper SFP Transceiver Avago

FCLF-8521-3 1000BASE-T Copper SFP Transceiver Finisar

Table 2-2:Approved SFP Optical list

Manufacturer Part Number Description Company

FTLF8519P2BNL 1.25 Gb/s 1000Base-SX Ethernet Finisar

FTLX8571D3BCV 1G/10G Dual-Rate SFP+ transceivers Finisar

2.3 SFP+

The RTM8242 has 8 SFP/SFP+ module connectors available on the RTM face plate. The SFP+ module signals

come from the front board at 1/10Gb through Zone 3 connectors after passing through a signal conditioning

PHY.

Table 2-3:Approved SFP+ list

Manufacturer Part Number Description Company

AFBR-703SDDZ 10Gb/1Gb Ethernet, 850nm SFP+ Transceiver Avago

AFBR-703SDZ-IN2 10Gb Ethernet, 850nm SFP+ Transceiver Intel

FTLX8571D3BCL 10Gb/s 850nm Multimode Datacom SFP+ Transceiver Finisar

FTL X1471D3BCL

10Gb/s 1310nm Single Mode Datacom SFP+

Tr ans ce ive r

Finisar

2.4 MMC Boot Block

The MMC runs Boot Block and IPMI firmware from its internal 512KB flash memory.The Boot Block firmware

keeps the last two copies of the IPMI firmware in a dedicated external flash memory. The Boot Block

activates the selected IPMI image and can rollback a firmware update in case of problems.

2.5 Hardware Management Overview

The RTM MMC communicates with the front board using the IPMB-L channel. Kontron’s Intelligent RTM

address on the IPMB-L is fixed and has a value of 0xA6.

7RTM8242

Page 21

www.kontron.com

The memory subsystem of the MMC consists of an integrated flash memory to hold the MMC operation code

and integrated RAM for data. The field replacement unit (FRU) inventory information is stored in the

nonvolatile memory on an EEPROM connected via a local I2C interface to the MMC. It is possible to store up to

4 KBytes within the FRU inventory information.

The onboard voltages and temperatures are monitored by the MMC. The MMC will send an event to the front

board if any of the thresholds are exceeded. These and other events are sent over the IPMB-L bus to the front

board's IPMC which forwards them to the SHMC. This ensures that 'post-mortem' logging information is

available even if the power of the RTM is disabled.

To increase the reliability of the RTM8242 management subsystem, an external watchdog supervisor for the

MMC is implemented. If the MMC ceases to service the watchdog supervisor, the watchdog resets the MMC.

The external watchdog supervisor is not configurable and must not be confused with the IPMI watchdog timer

commands.

2.5.1 Sensor Data Record (SDR)

Every sensor on the RTM is associated with a Sensor Data Record (SDR). Sensor Data Records contain

information about the sensor’s identification such as sensor type, sensor name and sensor unit. The SDR also

contains the configuration of a specific sensor such as threshold/hysteresis and event generation

capabilities that specify sensor behaviour. Some fields of the SDR are configurable through IPMI command

and are set with built-in initial values. Finally, the sensor owner field must reflect the module addresses that

allows a system management software to identify the owner of the SDR when it is scanned from the front

board IPMC and merged within the IPMC Device SDR repository.

From an IPMI perspective, the RTM8242 management controller is set up as a satellite management

controller (SMC). It supports sensor devices, and uses the IPMI static sensor population feature of IPMI to

merge the hot swapped RTM sensor with the front board sensors population. The SHMC is informed about an

RTM insertion through the RTM Module Hot Swap sensor and a radial presence line on the RTM connector. All

SDRs can be queried using Device SDR commands. Module sensors that have been implemented are listed

below.

2.5.2 Hardware Sensors

Table 2-4:IPMI Hardware Sensors

IPMI

sensor

ID

0 IPMI Info-1 Internal Management Controller firmware diagnostic * N

1 IPMI Info-2 Internal Management Controller firmware diagnostic * N

2 FRU Agent FRU Information Agent - FRU0 Data Error Detection * N

3 Module HS Hot Swap state * N

4 IPMBL State IPMB-L branch from FRU0 fault detection sensor * N

5 MMC Stor Err Management sub-system health: non volatile memory error * N

6 MMC Reboot IPMC reboot detection * N

7 IPMC VChange IPMC Version Change Detection * N

Sensor Name Description (Sensor Type, Event trigger) Scanning En-

abled under

Power State

Health LED

(Green to Amber)

8RTM8242

Page 22

www.kontron.com

IPMI

sensor

ID

8 FPGA VChange FPGA Version Change Detection * N

9 Temp Air In Inlet Temperature (degrees) * X

10 Temp Air Out Outlet Temperature (degrees) * X

11 Temp Switch Switch Temperature (degrees) * X

12 Temp MMC Module Management Controller Temperature (Degrees) * X

13 Vcc +3.3VSUS Voltage on board 3.3V suspend (management) power supply * X

14 Vcc +12V In Voltage on board 12V payload power supply - X

15 Vcc +5V Voltage on board 5V backend power supply - X

16 Vcc +3.3V Voltage on board 3.3V backend power supply - X

17 Vcc +1.5V Voltage on board 1.5V backend power supply - X

18 Vcc +1.2V Voltage on board 1.2V backend power supply - X

19 Vcc +1V Voltage on board 1.0V backend power supply - X

20 VPUMP Voltage on board blue LED VPUMP suspend power supply * X

21 Power State Board Power State * N

22 Power Good Actual power good status * N

23 Health Error General health status * N

Sensor Name Description (Sensor Type, Event trigger) Scanning En-

abled under

Power State

X Exceed critical threshold / Error Assertion

Health LED

(Green to Amber)

*Power On/Off

-Power On

N No change

2.5.2.1 IPMB-L Link Sensor

The RTM8242 has an IPMB-L link to communicate with the processor board and other devices in the chassis

through IPMB-0 bus. MMC monitors the bus for any link failure and sends the bus failure event to the front

board upon the recovery occurs.

2.5.3 Field Replaceable Unit (FRU) Information

The FRU Information provides inventory data about the boards where the FRU Information Device is located.

The part number or version number can be read through software.

FRU information in the RTM8242 includes data describing the RTM8242 board according to AMC.0 R2.0

specification requirements. This information is retrieved from the RTM, enabling reporting of board-specific

information through a standardized mechanism.

9RTM8242

Page 23

www.kontron.com

Table 2-5:Board Information Area

Board Information Area

Field Description Value (hex)

Format Version 0x01

Board Area Length *Calculated

Language code 0x00

Manufacturing Date / Time *Based on mfg. date

Board Manufacturer type/length *Calculated

Board Manufacturer “Kontron”

Board Product Name type/length *Calculated

Board Product Name “RTM8242”

Board Serial Number type/length *Calculated

Board Serial Number Manufacturer S/N

Board Part Number type/length *Calculated

Board Customer Part Number "T5709###_R"

FRU File ID type/length *Calculated

FRU File ID "FRU5709-YY"

No more fields 0xC1

Padding 0x00

Board Area Checksum *Calculated

Table 2-6:Product Information Area

Product Information Area

Field Description Value (hex)

Format Version 0x01

Product Area Length *Calculated

Language Code 0x00

Manufacturer Name type/length *Calculated

Manufacturer Name “Kontron”

Product Name type/length *Calculated

Product Name “RTM8242”

Product Part/Model Number type/length *Calculated

Product Part/Model Number "T5709_XX"*

Product Version type/length *Calculated

Product Version “XX” *

Product Serial Number type/length *Calculated

Product Serial Number Manufacturer S/N

Asset Tag type/length 0xC0

Asset Tag

FRU File ID type/length *Calculated

10 RTM8242

Page 24

www.kontron.com

Product Information Area

FRU File ID bytes "FRU5709-YY"**

No more fields 0xC1

Padding 0x00

Product Info Area Checksum *Calculated

Table 2-7:Type 16 Module Current Requirements Records

Type 16 – Module Current Requirements Record

Record Type ID C0h

Record format version 02h

Manufacturer ID 00315Ah (PICMG Record ID)

PICMG Record ID 16h (Module Power Descriptor table)

Record Format Version 00h

Current Draw 15h (2.1 Amps at 12 V => 25.2 Watts)

2.5.4 MMC Firmware Code

MMC firmware code is organized into boot code and operational code, both of which are stored in internal

flash memory. Upon an MMC reset, the MMC executes the boot code and performs the following:

1 Self test to verify the status of its hardware and memory.

2 Performs a checksum of the operational code.

3 Set operational state that tells the Boot Block that the firmware operates correctly.

Upon successful verification of the operational code checksum, the firmware will jump to the operational

code.

2.5.5 MMC Firmware Upgrade Procedure

The upgrade procedure is compliant to PICMG HPM.1. MMC Firmware upgrades can be done by using IPMITOOL

from sourceforge

from the front board or remotely on the chassis. It has been designed to be upgradeable

through any IPMI interface without payload impact.

2.5.6 Hot-Swap Process

The RTM8242 has the ability to be hot-swapped in and out of the front board. The onboard MMC manages the

RTM's power-up and power-down transitions. The list below illustrates this process for power down request.

1 Ejector latch is opened. MMC firmware detects the event.

2 MMC sends "Module Handle Open" event message to the front board. The corresponding M state of

the RTM moves from M4-> M5.

11 R TM8 24 2

Page 25

www.kontron.com

3 If the SHMC grants the request, the front board IPMC forwards the grant to the RTM. The RTM moves

from M5->M6.

4 The firmware deasserts payload power and sends "Module Quiesced" event message to the front

board and transitions from M6 to M1 state.

2.5.6.1 Hot-Swap LED

The RTM8242 supports a blue Hot Swap LED mounted on the front panel. This LED indicates when it is safe to

remove the RTM from the front board. The on-board MMC drives this LED to indicate the hot-swap state. The

following states are possible:

Table 2-8:Hot-Swap LED Description

LED state Description

OFF M4 state; normal state when board is in operation.

ON M1 state; ready for hot swap.

Short blink M5 state; deactivation request

Long blink M2 state; activation request.

The SHMC or higher level software can reject the deactivation request. If this occurs, the RTM will return the

Hot Swap LED to a solid off condition, indicating that the RTM has returned to M4 state.

When request is granted and main RTM payload power is successfully removed from the RTM slot, the Hot

Swap LED is on continuously, indicating it is safe to remove the RTM from the chassis.

Refer to the AT8242 manual for information on "Managed FRU Deactivation Policies" affecting the FRU

deactivation process.

2.6 Face Plate Indicators

The state of LED1 and LED2 can be controlled with standard PICMG LED APIs.

2.6.1 Hot Swap LED (LED0)

The Blue / Hot Swap LED indicates the hot swap status of the RTM. The LED is ON when it is safe to remove the

RTM from the slot. During normal operation, this LED is OFF.

2.6.2 Out Of Service (LED1)

The AdvancedTCA LED1 is red or amber and indicates an Out-of-Service (OOS) condition. During normal

operation, the OOS LED is OFF. This LED is ON during firmware upgrade and is user configurable if needed by a

customer application.

12 RTM8242

Page 26

www.kontron.com

2.6.3 Healthy LED (LED2)

The AdvancedTCA LED2 is green or amber and indicates a Healthy condition. The healthy LED indicates if the

blade is powered up and all voltages and temperatures are within specifications. During normal operation,

this LED is ON (green). This LED is also ON (amber) when one of the RTM8242 voltage or temperature sensor

pass a threshold.

2.6.4 SFP+ and SFP LED

The Green LEDs indicate the link status of the connection. The LED is ON when there is a link, otherwise it’s

OFF.

13 RTM8242

Page 27

Chapter 3

Hot Swap and Installation

www.kontron.com

3.1 RTM Hot Swap and Installation............................. 15

Page 28

www.kontron.com

3. Hot Swap and Installation

3.1 RTM Hot Swap and Installation

Because of the high-density pinout of the hard-metric connectors in Zone 3, some precautions must be taken

when connecting or disconnecting a RTM to/from an AT8242:

1 Rail guides must be installed on the enclosure to slide the RTM to the AT8242.

2 Do not force the RTM if there is mechanical resistance while inserting it.

3 Screw the faceplate to the enclosure to firmly attach the RTM to its enclosure.

4 Use extractor handles to disconnect and extract the RTM from its enclosure.

WARNING

Always use a grounding wrist wrap before installing or removing the board from a

chassis.

3.1.1 Installing the RTM in the chassis

To install the RTM:

1 Remove the filler panel from the slot.

2 Ensure the RTM is configured properly.

3 Carefully align the PCB edges at the bottom and top card guide.

4 Insert the RTM in the system until it makes contact with the front board.

5 Using both ejector handles, engage the RTM in the front board connectors until both ejectors are

locked.

6 Fasten screws at the top and bottom of the faceplate.

3.1.2 Removing the RTM from the chassis

1 Unscrew the top and the bottom screw of the faceplate.

2 Unlock the lower handle latch.

3 Wait until the blue LED is fully ON, this means that the hot swap sequence is ready for RTM removal.

4 Use both ejectors to disengage the RTM from the front board.

5 Pull the RTM out of the chassis.

15 RTM8242

Page 29

www.kontron.com

A. Connector Pinouts

A.1 Connectors and Headers Summary

Connector Description

J1 - J8 SFP+ Connectors

J9 - J12 SFP Connectors

J31 RTM Connector

J32 RTM Connector

A.2 SFP+ Connectors (J1-J8)

Pin Signal Pin Signal

1 Ve eT 11 VeeR

2 TX_Fault 12 RD-

3 TX_Disable 13 RD+

4 SDA 14 VeeR

5 SCL 15 VccR

6 MOD-ABS 16 VccT

7 Rate_Select 0 17 VeeT

8 RX_LOS 18 TD+

9 Rate_Select 1 19 TD-

10 VeeR 20 VeeT

A-1 RTM8242

Page 30

www.kontron.com

A.3 SFP Connectors (J9-J12)

Pin Signal Pin Signal

1 Ve eT 11 VeeR

2 TX_Fault 12 RD-

3 TX_Disable 13 RD+

4 SDA 14 VeeR

5 SCL 15 VccR

6 MOD-ABS 16 VccT

7 Rate_Select 0 17 VeeT

8 RX_LOS 18 TD+

9 Rate_Select 1 19 TD-

10 VeeR 20 VeeT

A-2 RTM8242

Page 31

www.kontron.com

B. Getting Help

If, at any time, you encounter difficulties with your application or with any of our products, or if you simply

need guidance on system setups and capabilities, contact our Technical Support at:

North America EMEA

Tel.: (450) 437-5682 Tel.: +49 (0) 8341 803 333

Fax: (450) 437-8053 Fax: +49 (0) 8341 803 339

If you have any questions about Kontron, our products, or services, visit our Web site at: www.kontron.com

You also can contact us by E-mail at:

North America: support@ca.kontron.com

EMEA: support@kontron-modular.com

Or at the following address:

North America EMEA

Kontron Canada, Inc. Kontron Modular Computers GmbH

4555, Ambroise-Lafortune Sudetenstrasse 7

Boisbriand, Québec 87600 Kaufbeuren

J7H 0A4 Canada Germany

B.1 Returning Defective Merchandise

Before returning any merchandise please do one of the following:

•Call

1 Call our Technical Support department in North America at (450) 437-5682 and in EMEA at +49

(0) 8341 803 333. Make sure you have the following on hand: our Invoice #, your Purchase

Order #, and the Serial Number of the defective unit.

2 Provide the serial number found on the back of the unit and explain the nature of your problem

to a service technician.

B-1 RTM8242

Page 32

www.kontron.com

• E-mail

3 The technician will instruct you on the return procedure if the problem cannot be solved over

the telephone.

4 Make sure you receive an RMA # from our Technical Support before returning any merchandise.

1 Send us an e-mail at: RMA@ca.kontron.com

orderprocessing@kontron-modular.com

your company name, your address, your city, your postal/zip code, your phone number, and

your e-mail. You must also include the serial number of the defective product and a description

of the problem.

in North America and at:

in EMEA. In the e-mail, you must include your name,

B.2 When Returning a Unit

• In the box, you must include the name and telephone number of a contact person, in case

further explanations are required. Where applicable, always include all duty papers and

invoice(s) associated with the item(s) in question.

• Ensure that the unit is properly packed. Pack it in a rigid cardboard box.

• Clearly write or mark the RMA number on the outside of the package you are returning.

• Ship prepaid. We take care of insuring incoming units.

North America EMEA

Kontron Canada, Inc. Kontron Modular Computers GmbH

4555, Ambroise-Lafortune Sudetenstrasse 7

Boisbriand, Québec 87600 Kaufbeuren

J7H 0A4 Canada Germany

B-2 RTM8242

Page 33

www.kontron.com

C. Glossary

Acronyms Descriptions

ACPI Advanced Configuration & Power Interface

AdvancedMC (Same as AMC). Advanced Mezzanine Card.

AMC (Same as AdvancedMC). Advanced Mezzanine Card.

AMC.0 Advanced Mezzanine Card Base Specification.

AMC.1

AMC.2

AMC.3

ATC A Advanced Telecommunications Computing Architecture

BIOS Basic Input/Output System

CMOS

CPU Central Processing Unit. This sometimes refers to a whole blade, not just a processor component.

CTS Clear To Send

DTR Data Terminal Ready

EMI ElectroMagnetic Interference

FCC Federal Communications Commission

FRU

GND GrouND

HDD Hard disk Drive

HPM PICMG Hardware Platform Management specification family

HPM.1 Hardware Platform Management IPM Controller Firmware Upgrade Specification

I2C Inter Integrated Circuit bus

ID IDentification

IEEE Institute of Electrical and Electronics Engineers

IPM Intelligent Platform Management

IPMB Intelligent Platform Management Bus

IPMB-0 Intelligent Platform Management Bus Channel 0, the logical aggregation of IPMB-A and IPMB-B.

IPMB-A Intelligent Platform Management Bus A

IPMB-B Intelligent Platform Management Bus B

IPMB-L Intelligent Platform Management Bus Local

IPMC Intelligent Platform Management Controller

IPMI Intelligent Platform Management Interface

IPMIFWU Intelligent Platform Management Interface FirmWare Update

LED Light-Emitting Diode

MMC Module Management Controller. MMCs are linked to the IPMC.

NC Not Connected

OOS Out Of Service

PCI Express and Advanced Switching on AdvancedMC. A subsidiary specification to the Advanced

Mezzanine Card Base Specification (AMC.0).

Ethernet Advanced Mezzanine Card Specification. A subsidiary specification to the Advanced

Mezzanine Card Base Specification (AMC.0).

Advanced Mezzanine Card Specification for Storage. A subsidiary specification to the Advanced

Mezzanine Card Base Specification (AMC.0).

Complementary Metal Oxide Semiconductor. Also refers to the small amount of battery (or capacitor)

powered CMOS memory to hold the date, time, and system setup parameters.

Field Replaceable Unit. Any entity that can be replaced by a user in the field. Not all FRUs are hot

swappable.

C-1 RTM8242

Page 34

www.kontron.com

Acronyms Descriptions

OS Operating System

PICMG PCI Industrial Computer Manufacturers Group

PICMG® PCI Industrial Computer Manufacturers Group

POST Power-On Self-Test

RAM Random Access Memory

RS-232 (Same as RS232). Recommended Standard 232.

RS232 (Same as RS-232). Recommended Standard 232.

RTM Rear Transition Module

RTS Request To Send

SAS Serial Attached SCSI

SFP, SFP+ Small Form-factor Pluggable

SHMC Shelf Management Controller

TX Tr ans mit

TXD Tr ansmit

USB Universal Serial Bus

VCC Power supply

C-2 RTM8242

Loading...

Loading...