Page 1

PB-TIM2 User’s Manual Preface

PB-TIM2

General Purpose 16+8 bit

Timer Piggyback

Order No. 14257

User’s Manual

Issue 1 Preliminary

Unpacking and Special Handling Instructions

This PepCard product is carefully designed for a long and fault-free life; nonetheless, its life expectancy can be drastically

reduced by improper treatment during unpacking and installation.

Observe standard anti-static precautions when changing piggybacks, ROM devices, jumper settings, etc. If the product

contains batteries for RTC or memory back-up, ensure that the board is not placed on conductive surfaces, including

anti-static plastics or sponges. These can cause shorts and damage to the batteries or tracks on the board.

When installing the board, switch off the power mains to the chassis. Do not disconnect the mains as the ground

connection prevents the chassis from static voltages, which can damage the board as it is inserted.

Furthermore, do not exceed the specified operational temperature ranges of the board version ordered. If batteries are

present, their temperature restrictions must be taken into account.

Keep all the original packaging material for future storage or warranty shipments. If it is necessary to store or ship the

board, re-pack it as it was originally packed.

July 30, 1997 © 1996 PEP Modular Computer Page 0-1

Page 2

Preface PB-TIM2 User’s Manual

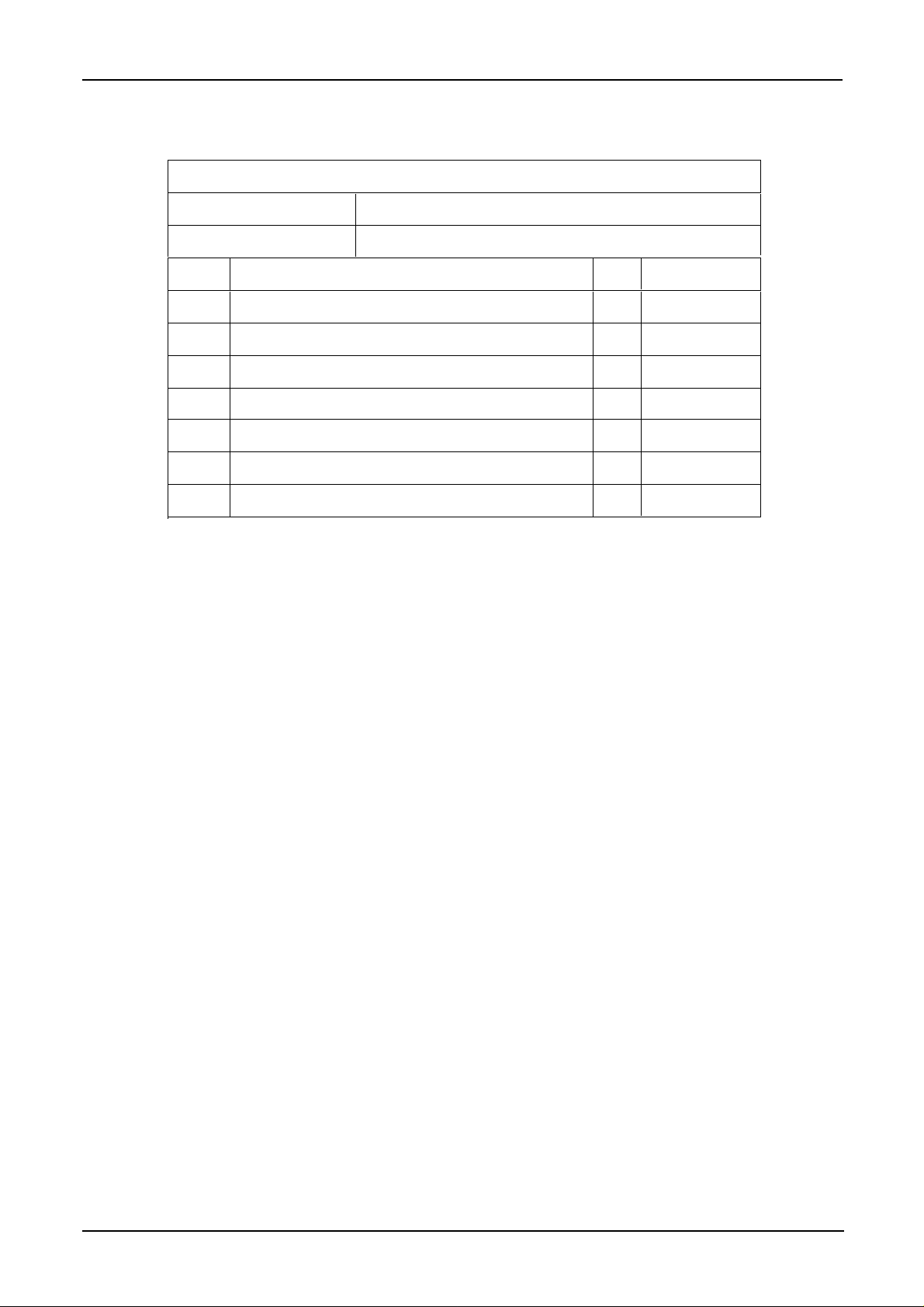

R EVISION HISTORY

Revision History

Manual/Product Title PB-TIM2

Publication Number 14257

Issue Brief Description of Changes Rev. Date of issue

1 First release of Issue 1 manual 1 19th Mar. 1996

Date of issue = the release date of the issue. This date does not necessarily reflect the date the improvements were first

made.

This document contains proprietary information of PEP Modular Computers. It may not be copied or transmitted by any

means, passed to others, or stored in any retrieval system or media, without the prior consent of PEP Modular

Computers or its authorized agents.

The information in this document is, to the best of our knowledge, entirely correct. However, PEP Modular

Computers cannot accept liability for any inaccuracies, or the consequences thereof, nor for any liability arising from

the use or application of any circuit, product, or example shown in this document.

PEP Modular Computers reserve the right to change, modify, or improve this document or the product described

herein, as seen fit by PEP Modular Computers without further notice.

Page 0-2 © 1996 PEP Modular Computers July 30, 1997

Page 3

PB-TIM2 User’s Manual Preface

r

f

PEP Modular Computers® Two Year Limited Warranty

We grant the original purchaser of PEP products the following hardware warranty. No other warranties that may be granted o

implied by anyone on behalf of PEP are valid unless the consumer has the express written consent of PEP Modular

Computers.

PEP Modular Computers warrants their own products (excluding software) to be free from defects in workmanship and

materials for a period of 24 consecutive months from the date of purchase. This warranty is not transferable nor extendible to

cover any other consumers or long term storage of the product.

This warranty does not cover products which have been modified, altered, or repaired by any other party than PEP

Modular Computers or their authorized agents. Furthermore, any product which has been, or is suspected of being damaged

as a result of negligence, misuse, incorrect handling, servicing or maintenance; or has been damaged as a result of excessive

current/voltage or temperature; or has had its serial number(s), any other markings, or parts thereof altered, defaced, or removed

will also be excluded from this warranty.

A customer who has not excluded his eligibility for this warranty may, in the event of any claim, return the product at the

earliest possible convenience, together with a copy of the original proof of purchase, a full description of the application it is

used on, and a description of the defect; to the original place of purchase. Pack the product in such a way as to ensure safe

transportation (we recommend the original packing materials), whereby PEP undertakes to repair or replace any part, assembly

or sub-assembly at our discretion; or, to refund the original cost of purchase, if appropriate.

In the event of repair, refund, or replacement of any part, the ownership of the removed or replaced parts reverts to PEP

Modular Computers, and the remaining part of the original guarantee, or any new guarantee to cover the repaired or replaced

items, will be transferred to cover the new or repaired items. Any extensions to the original guarantee are considered gestures o

goodwill, and will be defined in the "Repair Report" returned from PEP with the repaired or replaced item.

Other than the repair, replacement, or refund specified above, PEP Modular Computers will not accept any liability for any

further claims which result directly or indirectly from any warranty claim. We specifically exclude any claim for damage to any

system or process in which the product was employed, or any loss incurred as a result of the product not functioning at any

given time. The extent of PEP Modular Computers liability to the customer shall not be greater than the original purchase

price of the item for which any claim exists.

PEP Modular Computers makes no warranty or representation, either express or implied, with respect to its products,

reliability, fitness, quality, marketability or ability to fulfill any particular application or purpose. As a result, the products are

sold "as is," and the responsibility to ensure their suitability for any given task remains the purchaser's.

In no event will PEP be liable for direct, indirect, or consequential damages resulting from the use of our hardware or software

products, or documentation; even if we were advised of the possibility of such claims prior to the purchase of, or during any

period since the purchase of the product.

Please remember that no PEP Modular Computers employee, dealer, or agent are authorized to make any modification or

addition to the above terms, either verbally or in any other form written or electronically transmitted, without consent.

July 30, 1997 © 1996 PEP Modular Computer Page 0-3

Page 4

Preface PB-TIM2 User’s Manual

TABLE OF CONTENTS

Chapter/Section/Sub-section Page

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Board Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2. Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Normal Timer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Board Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Timer Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.1 Hardware Single Shot (Retrigerable) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.2 Hardware Single Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.3 TIC Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.4 Period Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.5 Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.6 Square Wave Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.7 PWM Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.8 Input Signal Edge Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.9 Event Signal Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3. Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Board Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Input Electrical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1.1 Input Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1.2 Input Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.1.3 Input EMI Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.1.2 Output Electrical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -4

3.1.3 MODPACK Timing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 VMEbus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 PB-TIM2 Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Register Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.1 Channel Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.2 Channel Mode Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.3 Channel Interrupt Pending Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.4 Channel Interrupt Clear Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 4

4.2.5 Channel Interrupt Authorization Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.6 Prescaler Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.7 Counter Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.8 Comparator Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.9 Common Control Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.10 Common Interrupt Pending Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.11 Common Interrupt Authorization Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.12 Interrupt Vector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.2.13 Write EEPROM Access Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.14 Read EEPROM Access Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.15 Software ID Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.16 Hardware ID Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Page 0-4 © 1996 PEP Modular Computers July 30, 1997

Page 5

PB-TIM2 User’s Manual Preface

5. Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 ST100 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.2 ST101 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.1.3 ST102 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.4 ST102 VMOD-2(D)/IMOD Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

July 30, 1997 © 1996 PEP Modular Computer Page 0-5

Page 6

Preface PB-TIM2 User’s Manual

This page has been left blank intentionally.

Page 0-6 © 1996 PEP Modular Computers July 30, 1997

Page 7

PB-TIM2 User’s Manual Chapter 1 Introduction

1

1. INTRODUCTION

1.1 Product Overview

The PB-TIN2 is an optoisolated, general purpose timer piggyback for the VMOD-2 and CXM-IMOD range of PEP

boards. Three independent timers with 16+8 bit resolution and possessing 9 modes of operation are galvanically isolated

from the process. Three inputs and an output per counter may be software configured.

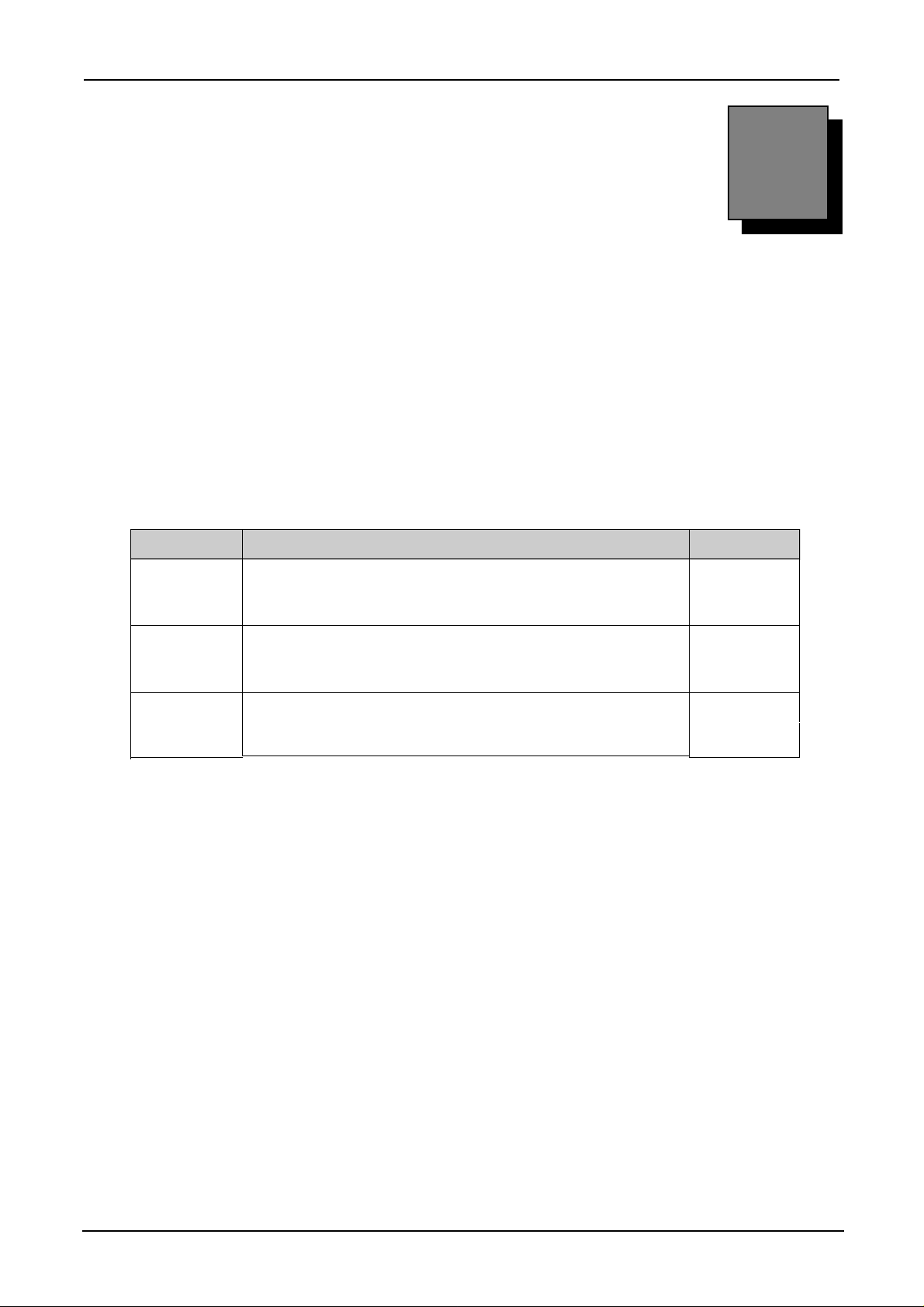

1.2 Ordering Information

Product Description Order Nr.

PB-TIM2 Modpack with 3 independently configurable timers possessing 3

optoisolated 24V DC filtered inputs and 1 optoisolated 24V DC,

200mA output per counter.

PB-TIM2 Modpack with 3 independently configurable timers possessing 3

optoisolated 12V DC filtered inputs and 1 optoisolated 24V DC,

200mA output per counter.

PB-TIM2 Modpack with 3 independently configurable timers possessing 3

optoisolated 5V DC filtered inputs and 1 optoisolated 24V DC,

200mA output per counter.

13745

13746

13747

July 30, 1997 © 1996 PEP Modular Computers Page 1-1

Page 8

Chapter 1 Introduction PB-TIM2 User’s Manual

1.3 Specifications

Timer 16-bit up/down synchronous counter

16-bit preset register

16-bit comparator

16-bit zero detection

16-bit last value latch

8-bit prescaler

1-bit toggle register

Input Channels Trigger, gate and clear together with a common

clear. All optoisolated and protected against reverse

polarity

Output Channels 1 digital output per counter, 24V DC @ 200mA with

inductive load protection, high-side switch

Input Voltage 5V, 12V(15V) or 24V

Input Current 15mA typically

Switching Level 2V, 7.4V or 18.6V respectively

Input Frequency Up to 300 kHz, embedded filter

Output Frequency Up to 10 kHz

Isolation Voltages 1500V DC I/O to system, 100V DC between inputs

Timer Clock 4 MHz (250 ns) derived from 16 MHz System Clk.

DTACK-Generation On-board generation

Environment

Operating Temperature 0ºC to 70ºC

Extended Temperature -40ºC to +85ºC

Storage Temperature -55ºC to +85ºC

Humidity 0 to 95% non-condensing

Piggyback Size Width : 48 mm

Length : 102 mm

Depth : 10 mm

Modpack Interface 16-Bit data bus

Page 1-2 © 1996 PEP Modular Computers July 30, 1997

Page 9

PB-TIM2 User’s Manual Chapter 1 Introduction

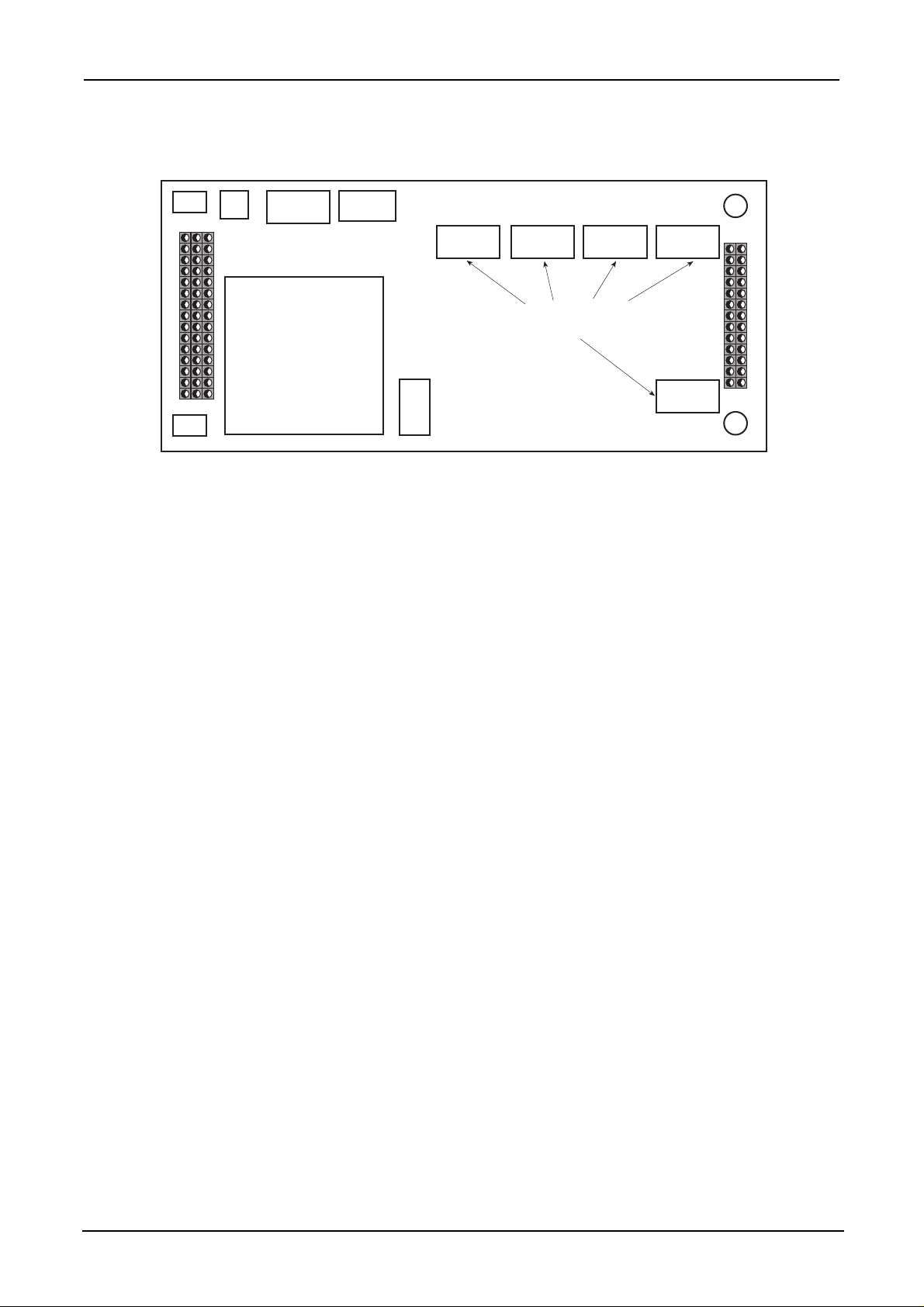

1.4 Board Overview

ROM

Optoisolation

Stage

FPGA

1.5 Features

• 3 independent timers

• 16 bit resolution

• 8-bit prescaler

• 9 different modes

• 3 inputs per timer, software defined

• 1 output per timer, software defined

• common clear, software defined

• 1 EEPROM (2 kbit) for software driver / parameter backup (for future use)

• inputs with optoisolation, RC filters and configurable thresholds

• input frequency up to 300 kHz

• outputs with optoisolation and open collector source circuitry (high-side switch)

• output frequency up to 10 kHz

• board ID: $E1

• software ID: $01

• full interrupt handling

July 30, 1997 © 1996 PEP Modular Computers Page 1-3

Page 10

Chapter 1 Introduction PB-TIM2 User’s Manual

This page has been left blank intentionally.

Page 1-4 © 1996 PEP Modular Computers July 30, 1997

Page 11

PB-TIM2 User’s Manual Chapter 2 Functional Description

2

2. FUNCTIONAL DESCRIPTION

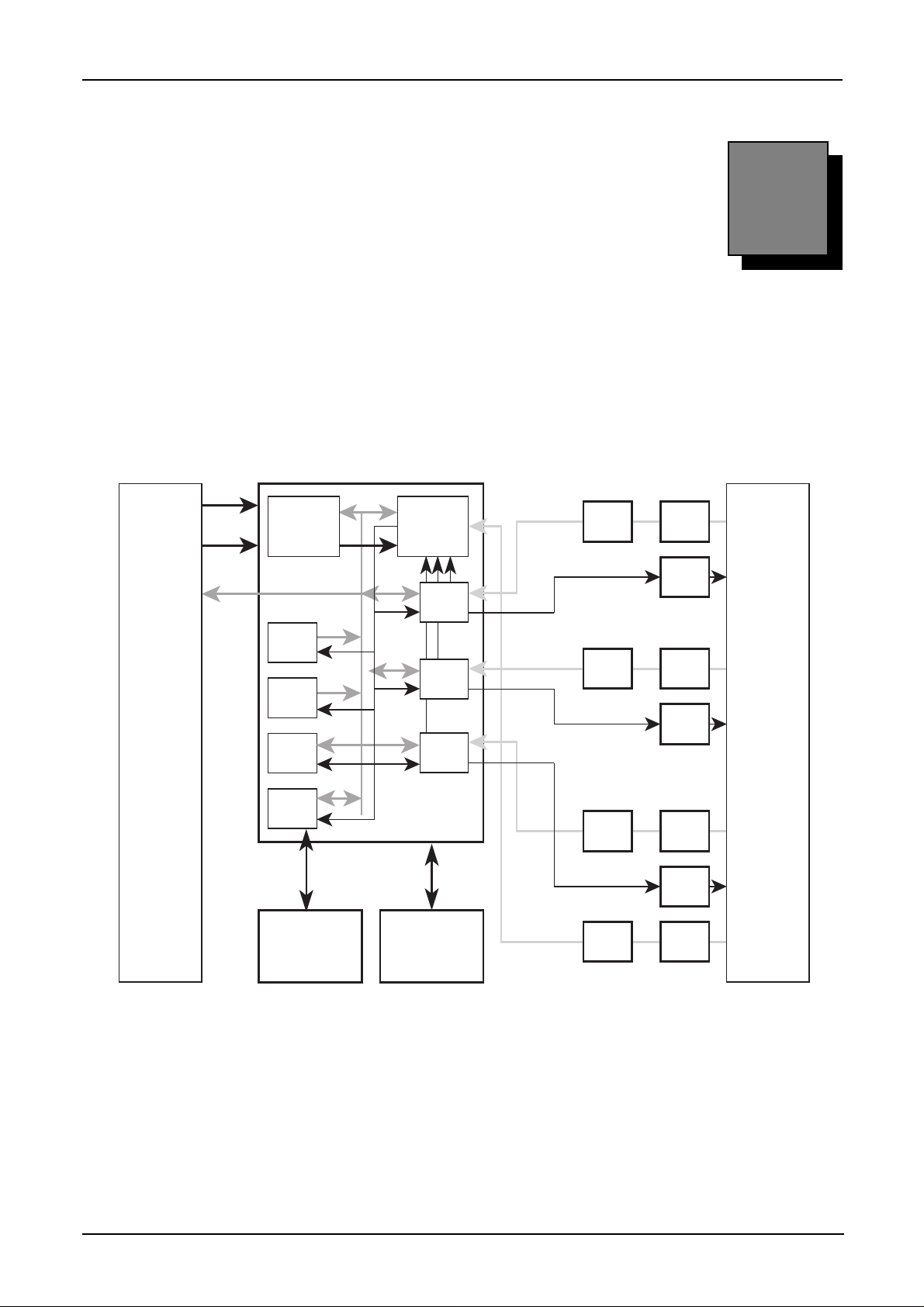

In timer mode, the PB-TIM2 requires that input (A) be used as a trigger, input (B) as a gate and input (C) as a clear. The

block diagram of the piggyback is provided in figure 2.0.1.

Figure 2.0.1 Block diagram of the PB-TIM2 piggyback

VMOD-ST VMOD-STFPGA

Control

ISYSCLK

ISYSRES

IIR/W

IDS0

IDS1

CS

INTA

IA1..IA7

UDTACK

INT

ID0..ID15

Address

Data

Decoding

and

Timing

Logic

ID

SW

Board

ID

IRQ

Vector

Control

Logic

and

Status

Channel

1

Channel

2

Channel

3

RC +

Schmitt

RC +

Schmitt

OPTO

OPTO

OPTO

OPTO

A, B, C Inputs

Output

A, B, C Inputs

Output

Serial

Decoder

Configuration

PROMEEPROM

RC +

Schmitt

RC +

Schmitt

OPTO

OPTO

OPTO

A, B, C Inputs

Output

Common

Clear

July 30, 1997 © 1996 PEP Modular Computers Page 2-1

Page 12

Chapter 2 Functional Description PB-TIM2 User’s Manual

2.1 Normal Timer Mode

With reference to the single channel block diagram of figure 2.1.0 below, the input line (A) is used as a trigger, input

line (B) functions as a gate that disables the timer when active and the third input (C) may be used as a clear input. An

additional clear input is common to all three timers. The output line acts as either non-zero detection or as a toggle

function on zero detection.

Figure 2.1.0 Block diagram of a single channel

Divide by

16 MHz

Sys Clk

Match IRQ

4 Logic

Last V alue

4 MHz

Timer Clk

Clock

Zero

Detector

16-bit

Comparator

8-bit

Prescaler

16-bit Last

Value Register

Q0 - Q15

Reset

16-bit

Timer Register

D0 - D15

Load

Count Enable

Zero

Logic

Toggle

Logic

Logic

Logic

Logic

Logic

Logic

Logic

Common

Clear

C

A

B

OUTPUT

Compare V alue

16-bit Compare /

Preset Register

Page 2-2 © 1996 PEP Modular Computers July 30, 1997

Page 13

PB-TIM2 User’s Manual Chapter 2 Functional Description

2.2 Board Operation

After power-up, all outputs are passive and all registers are cleared including the interrupt registers. Prescalers are set to

divide by one and the counters are disabled. Input (A) operates as a trigger responding to a rising edge signal, input (B)

operates as a gate that enables the counters when a voltage is applied, input (C) is initialized as a timer clear and the

common clear signal is disabled on all three timers.

Under normal operation, the timers are able to be read transparently with continuous comparisons being made between the

current timer value and zero or a preset value. The timer outputs may be activated if the comparison shows a non-zero

value or may be toggled when the timer passes through zero. The timers may be reloaded with a preset value through the

use of the (A) input; timer operation may be blocked by using the (B) or gate input while the counter(s) may be reset

using the local (C) clear input or common clear.

The software allows the prescaler value(s) to be set; enables or clears the timer(s); defines the edge selection on the trigger

input (A) and whether the (B) gate input is edge or level sensitive. In addition, it gives interrupt authorization on

comparison; zero detect; input (A) or (B) and identifies/clears pending interrupts and configures the timer as a ring

counter; sets the counter direction (up or down) and defines when or from which source the timer should be reloaded.

When accessing the board registers, the piggyback will generate a DTACK on each memory location; reading a location

that is not registered in the address map will produce irrelevant data ($FF). Timer and comparator values are 16-bit and

may be accessed as either 3 consecutive bytes or as 2 consecutive words.

Upon initialization, the process should verify the board’s hardware and software IDs.

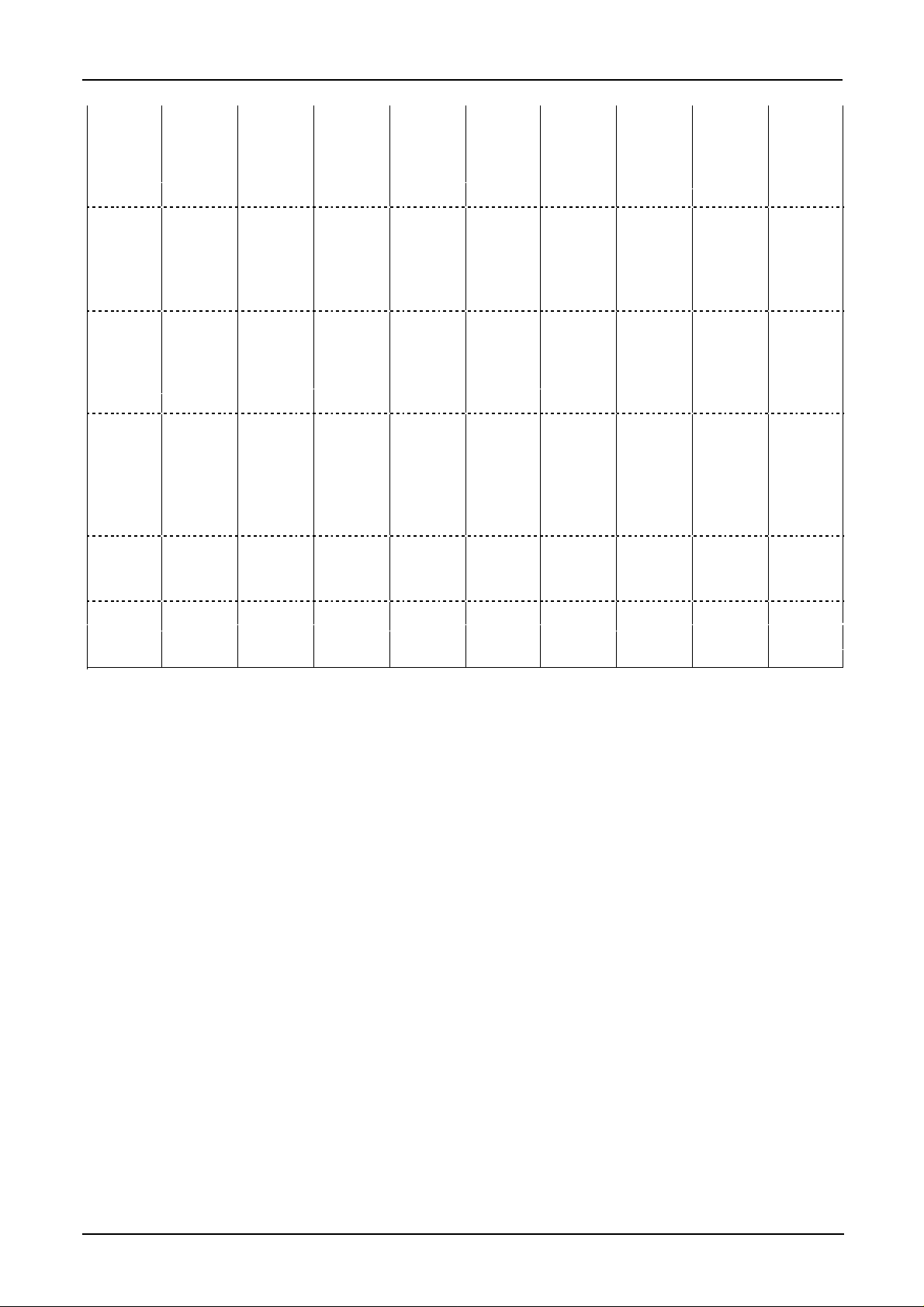

2.3 Timer Operating Modes

Table 2.3.1 summarizes the timer possibilities indicating the input and output functions, the interrupt possibilities, the

measurement results and the timer modes.

Table 2.3.1 Timer Characteristics

Mode Timer Compare

Register

Hard

single

shot

Soft

single

shot

Countdown

stop at 0/

load on

A

Countdown

stop at 0

Period Load on

Software

Control

Software

load

A B C Output IRQ Result

edge

Clear

counter/

output

Clear

counter/

output

Passive

if 0

Passive

if 0

On 0

On 0

Tick Count-

down

load at 0

Mode Timter Compare

July 30, 1997 © 1996 PEP Modular Computers Page 2-3

Period Enable

counting

Ring

counting

Software

Register

Control

Clear

counter/

output/

Ring

mode

A B C Output IRQ Result

Passive

if 0

On 0

Page 14

Chapter 2 Functional Description PB-TIM2 User’s Manual

Measure

period

Measure

freq.

Generate

freq.

1/2

PWM

Edge

sampling

Count up

Stop on

B

Count up

Stop on

B

Count-

down

Load at 0

Count-

down

Stop at

0/ load

on A

Count up Enable

Half

period

Half

cycle

Enable

counting

Enable

counting

Enable

counting

Ring

counting

Enable

counting

counting

Load on

edge

Up =

count

enable

v = stop

counting

1v =

count

enable

2v = stop

counting

Clear

counter/

output

Clear

counter/

output

Clear

counter/

output/

Ring

mode

Clear

counter/

output

Clear

counter/

output

Toggle at

0

Passive

if 0

On A

On Bv

On 2nd

Bv

edge

Counter

register

Counter

register

Counter

register

Pulse

duration

With reference to table 2.3.1, a ‘v’ on its own represents an edge; 1v indicates the first edge and 2v represents the second

edge.

2.3.1 Hardware Single Shot (Retrigerable)

In this mode, the timer always counts down, the pulse duration is stored in the comparator register and the output acts as

zero detection with input (A) used to load/reload the timer with the preset/comparator register.

2.3.2 Hardware Single Shot

This mode is the same as the one described in 2.3.1 above except that the software starts the period directly by writing the

bits ENABLE and LOAD in the Channel Control Register.

2.3.3 TIC Generation

The period is stored in the preload/comparator register and upon zero detection, the timer is reloaded and an event IRQ is

generated (IRQ plus flag).

Count up Thresh-

old

Enable

counting

Up =

count

enable

Clear

counter/

output

On

match

Counter

register

Page 2-4 © 1996 PEP Modular Computers July 30, 1997

Page 15

PB-TIM2 User’s Manual Chapter 2 Functional Description

2.3.4 Period Measurement

The timer is cleared by the software which also authorizes counting. When input (B) is valid (level sensitive gate) i.e.

goes high, the timer starts counting until input (B) goes low again at which point an event interrupt is generated (IRQ

plus flag).

2.3.5 Frequency Measurement

The mode is the same as the one described in 2.3.4 above except that input (B) toggles on the rising and falling edges.

2.3.6 Square Wave Generation

The value of half the square wave period is stored in the comparator/preload register with the timer being reloaded and the

output toggling on each zero detection.

2.3.7 PWM Generation

For this mode, two of the three timers are required with each providing one part of the signal. The timer modes need to be

set to single shot with an internal link between the two timers. This procedure is explained in more detail in the section

on programming.

2.3.8 Input Signal Edge Sampling

After a reset, the timer operates in free run mode. At each edge detection on the (A) input, the current timer value is stored

in the counter register and an event interrupt is generated (IRQ and flag).

2.3.9 Event Signal Duration

After a reset, the timer operates in free run mode when the (B) gate input is active. A preset value can be placed in the

preset/comparator register that will react when the gate has been active for a given number of cycles. The counter value

returns the cumulated time of the active input (B) and in the event of an overrun, an external event interrupt can be

generated (IRQ and flag).

July 30, 1997 © 1996 PEP Modular Computers Page 2-5

Page 16

Chapter 2 Functional Description PB-TIM2 User’s Manual

This page has been left blank intentionally.

Page 2-6 © 1996 PEP Modular Computers July 30, 1997

Page 17

PB-TIM2 User’s Manual Chapter 3 Configuration

3

3. CONFIGURATION

3.1 Board Overview

Solder Side

Component Side

July 30, 1997 © 1996 PEP Modular Computers Page 3-1

Page 18

Chapter 3 Configuration PB-TIM2 User’s Manual

3.1.1 Input Electrical Specification

The 10 inputs (3 per counter and one common) are all optoisolated from the supply with a rating of 1500V. Isolation

between the inputs is rated at 100V. The inputs (A), (B) and (C) all have separated differential inputs while the common

clear is referenced to V-. The inputs are protected against reverse voltage and sink typically 15mA.

Note

For those customers possessing the PB-TIM2 without optoisolation for improved speed performance,

the TTL inputs need to be inverted to maintain the characteristics laid down in this manual.

The inputs may be configured to cater for different operational voltages and frequency limits.

3.1.1.1 Input Voltage Selection

The following table shows the association between component values and operational voltages.

Input Component

A0 D1

B0 D3

C0 D5

A1 D8

B1 D10 0 Ohm Resistor 6.8V Zener Diode 18V Zener Diode

C1 D12

A2 D15

B2 D17

C2 D19

Clear D22

5V Operation 12V Operation 24V Operation

Page 3-2 © 1996 PEP Modular Computers July 30, 1997

Page 19

PB-TIM2 User’s Manual Chapter 3 Configuration

3.1.1.2 Input Frequency Response

The following table shows the association between component values and maximum input frequency response.

Input Component

A0 C1

B0 C2

C0 C3

A1 C4

B1 C5 10nF Capacitor 1nF Capacitor 330pF Capacitor

C1 C6

A2 C7

B2 C8

C2 C9

To reduce the cut-off frequency, larger capacitor values should be used. The values provided in the table are provided as an

example and have been simulated over the full operating temperature range.

3.1.1.3 Input EMI Protection

30 kHz 300 kHz * 1 MHz

* Default

The design allows for additional enhanced EMI protection by replacing the following components with a suitable SMD

coil.

Input Component

A0 R34

B0 R35

C0 R36

A1 R37

B1 R38 0 Ohm Resistor

C1 R39

A2 R40

B2 R41

C2 R42

Clear R43

Default

July 30, 1997 © 1996 PEP Modular Computers Page 3-3

Page 20

Chapter 3 Configuration PB-TIM2 User’s Manual

3.1.2 Output Electrical Specification

The three outputs are all optoisolated from the supply with a rating of 1500V. These channels use the common V+ and

V- supply rails and are equipped with an open collector circuitry that is capable of sourcing up to 200mA at a voltage

difference of 24V between the V+ and V- inputs. The outputs are inductive load protected and function correctly within a

voltage range between 5V and 30V.

3.1.3 MODPACK Timing Specifications

DTACK is generated on board and assuming a 16 MHz system clock and 4 MHz timer clock, is generated 5 cycles after

Chip Select and Data Strobes. This condition is valid for both read and write cycles.

Page 3-4 © 1996 PEP Modular Computers July 30, 1997

Page 21

PB-TIM2 User’s Manual Chapter 4 Programming

4

4. PROGRAMMING

4.1 VMEbus Interface

4.1.1 PB-TIM2 Address Map

Address Read Write

Counter 0

$01 $FF Channel Control Register

$05 $FF Channel Mode Register

$09 Channel Interrupt Pending Register Channel Interrupt Clear Register

$11 $FF Channel Interrupt Authorization Register

$15 $FF Prescaler Value

$18, $19 $0

$1A Counter Value Byte 1 Comparator Value Byte 1

$1B Counter Value Byte 0 Comparator Value Byte 0

Counter 1

$20

... Same as Channel 0 Same as Channel 0

$3F

Counter 2

$40

... Same as Channel 0 Same as Channel 0

$5F

Common Registers

$61 $FF Common Control Register

$65 Common Interrupt Pending Register

$69 $FF Common Interrupt Authorization Register

$6D $FF Interrupt Vector

$79 Software ID Byte

$7E Read EEPROM Access Register Write EEPROM Access Register

$7F Hardware Byte

July 30, 1997 © 1996 PEP Modular Computers Page 4-1

Page 22

Chapter 4 Programming PB-TIM2 User’s Manual

4.2 Register Allocation

4.2.1 Channel Control Register

Write Only Register

Channel 0 1 2

Address $01 $21 $41

Bit 7 6 5

Function Load Enable Clear

After Reset 0 0 0 0 0 0 0 0

Where • Clear : Clears the timer (all 0’s) and the output (Toggle flip-flop) when this bit is set to

1

• Enable : Enable timer operation (i.e. starts the timer or single measurement when this bit

is set to 1

• Load : Loads the timer with the Comparator/Preset register value when set to 1

4.2.2 Channel Mode Register

Write Only Register

Channel 0 1 2

Address $05 $25 $45

Bit 7 6 5

4 3 2 1 0

4 3 2 1 0

Function Output Reload Mode 1 Mode 0 B IN 1 B IN 0 A IN 1 A IN 0

After Reset 0 0 0 0 0 0 0 0

Where • A I N 0 and 1 : Defines the input mode

A IN 1 A IN 0 Mode

0 0 Rising Edge

0 1 Falling Edge

1 x Both Edges

• B IN 0 : Defines input (B) level or edge 0 active high - rising edge

1 active low - falling edge

• B IN 1 : Defines input (B) level or edge 0 level

1 edge operation

Page 4-2 © 1996 PEP Modular Computers July 30, 1997

Page 23

PB-TIM2 User’s Manual Chapter 4 Programming

• Mode 0 & Mode 1 : Defines the timer mode

Mode Value Function

0 0 Stops on 0 or (B) event

0 1 Ring Counter

1 0 Counts down, input (A) loads

counter

1 1 Counts up, input (A) used as a

strobe

• Reload : Defines timer mode 0 does not reload

1 reloads on 0

• Output : Defines output operation 0 passive if 0 in timer

1 toggles on timerr 0 detection

4.2.3 Channel Interrupt Pending Register

Read Only Register

Channel 0 1 2

Address $09 $29 $49

Bit 7 6 5

Function Trig Zero Gate Match

After Reset 0 0 0 0

Where • Match : A 1 in this location means an interrupt pending on MATCH

• Gate : A 1 in this location means an interrupt pending on GATE input (B)

• Zero : A 1 in this location means an interrupt pending on zero crossing

• Trig : A 1 in this location means an interrupt pending on TRIG input (A)

4 3 2 1 0

July 30, 1997 © 1996 PEP Modular Computers Page 4-3

Page 24

Chapter 4 Programming PB-TIM2 User’s Manual

4.2.4 Channel Interrupt Clear Register

Write Only Register

Channel 0 1 2

Address $09 $29 $49

Bit 7 6 5

Function Trig Zero Gate Match

After Reset 0 0 0 0

Where • Match : A 1 in this location will clear an interrupt pending on MATCH

• Gate : A 1 in this location will clear an interrupt pending on GATE input (B)

• Zero : A 1 in this location will clear an interrupt pending on zero crossing

• Trig : A 1 in this location will clear an interrupt pending on TRIG input (A)

4.2.5 Channel Interrupt Authorization Register

Write Only Register

Channel 0 1 2

Address $11 $31 $51

Bit 7 6 5

4 3 2 1 0

4 3 2 1 0

Function Trig Zero Gate Match

After Reset 0 0 0 0

Where • Match : A 1 in this location authorizes an interrupt on MATCH

• Gate : A 1 in this location authorizes an interrupt on GATE input (B)

• Zero : A 1 in this location authorizes an interrupt on zero crossing

• Trig : A 1 in this location authorizes an interrupt on TRIG input (A)

4.2.6 Prescaler Value

Write Only Register

Channel 0 1 2

Address $15 $35 $55

Bit b7 b6 b5

After Reset 0 0 0 0 0 0 0 1

b4 b3 b2 b1 b0

After reset, the default value for b0 is 1; if all the bits are cleared (0) then the prescaling factor is 256.

Page 4-4 © 1996 PEP Modular Computers July 30, 1997

Page 25

PB-TIM2 User’s Manual Chapter 4 Programming

4.2.7 Counter Value

Read Only Register

Channel 0 1 2

Address $1A $3A $5A

Bit b15 b14 b13

After Reset 0 0 0 0 0 0 0 0

Channel 0 1 2

Address $1B $3B $5B

Bit b7 b6 b5

After Reset 0 0 0 0 0 0 0 0

4.2.8 Comparator Value

Write Only Register

Channel 0 1 2

Address $1A $3A $5A

Bit b15 b14 b13

b12 b11 b10 b9 b8

b4 b3 b2 b1 b0

b12 b11 b10 b9 b8

After Reset 0 0 0 0 0 0 0 0

Channel 0 1 2

Address $1B $3B $5B

Bit b7 b6 b5

After Reset 0 0 0 0 0 0 0 0

b4 b3 b2 b1 b0

July 30, 1997 © 1996 PEP Modular Computers Page 4-5

Page 26

Chapter 4 Programming PB-TIM2 User’s Manual

4.2.9 Common Control Register

Write Only Register

Address $61

Bit 7

Function PWM 1 T IN 2 ST2 ST1 ST0

After Reset 0 0 0 0 0

Where • STx : Authorizes common clear function on corresponding channel

• T IN 2 : Defines the operation of timer channel 2. A 1 in this location will link the

• PWM 1 : Defines the operation of channel 1. A 1 in this location will internally link the

(A) input of channel 0. With this configuration, both channels generate half a Pulse

Width Modulation signal

4.2.10 Common Interrupt Pending Register

Read Only Register

Address $65

6 5 4 3 2 1 0

output of channel 0 to the counter clock of channel 2 (channel 0 and 2 will

also be cascaded)

output of channel 0 to the (A) input of channel 1 and the output of channel 1 to the

Bit 7

Function CH 2 CH 1 CH 0

After Reset 0 0 0

Where • CH x : A 1 in this position means an interrupt pending from the corresponding channel

Note : If an interrupt is pending from a given channel then the only way to clear it is to use the channel interrupt clear

register.

6 5 4 3 2 1 0

Page 4-6 © 1996 PEP Modular Computers July 30, 1997

Page 27

PB-TIM2 User’s Manual Chapter 4 Programming

4.2.11 Common Interrupt Authorization Register

Write Only Register

Address $69

Bit 7

Function CH 2 CH 1 CH 0

After Reset 0 0 0

Where • CH x : A 1 in this position authorizes interrupts from the corresponding timer

4.2.12 Interrupt Vector

Write Only Register

Address $6D

Bit 7

Function V7 V6 V5 V4 V3 V2 IS1 IS0

After Reset 0 0 0 0 0 0 x x

6 5 4 3 2 1 0

6 5 4 3 2 1 0

Where • V2-V7 : Programmable interrupt vector bits

Upon receipt of an INTACK signal, the interrupt vector register is placed on the data bus

• IS0 & IS1 : Shows the interrupt source as in the following table

IS1 IS0 Interrupt Source

0 1 Channel 0

1 0 Channel 1

1 1 Channel 2

If an interrupt is generated, a vector is placed on the data bus during the INTACK signal. The upper 6 bits of this vector

are user definable while the two lower bits define the interrupt source. Pending interrupts are latched in a corresponding

register and an interrupt may be cleared by writing a bit in the Interrupt Clear Register. In the event that several

interrupts have been generated, the signals will remain active until all have been serviced.

Note : All interrupt sources are edge triggered.

July 30, 1997 © 1996 PEP Modular Computers Page 4-7

Page 28

Chapter 4 Programming PB-TIM2 User’s Manual

4.2.13 Write EEPROM Access Register

Write Only Register

Address $7E

Bit b7

After Reset 0 0 0

Where • WDATA : This contains the bit that has to be written to the EEPROM

• CS : The status of the EEPROM chip select (0 = disabled, 1 = enabled)

• CLK : Value of the SPI clock pin to access the EEPROM

Data is written to the EEPROM at one bit at a time and only then when the EEPROM is chip selected. This serial bit

transfer is clocked with the SPI clock.

4.2.14 Read EEPROM Access Register

Read Only Register

Address $7E

Bit b7

After Reset x x x x x x x 0

b6 b5 b4 b3 CLK CS WDATA

b6 b5 b4 b3 CLK CS RDATA

Where • RDATA : This shows the current value of the SPIDI (SPI data input)

4.2.15 Software ID Byte

Read Only Register

Address $79

Bit b7

After Reset 0 0 0 0 0 0 0 1

The value is $01 and allows identification of the FPGA program version. Changes in the FPGA program will be

reflected in this ID byte such that the software can automatically adjust.

b6 b5 b4 b3 b2 b1 b0

Page 4-8 © 1996 PEP Modular Computers July 30, 1997

Page 29

PB-TIM2 User’s Manual Chapter 4 Programming

4.2.16 Hardware ID Byte

Read Only Register

Address $7F

Bit b7

After Reset 1 1 1 0 0 0 0 1

The value is always $E1

b6 b5 b4 b3 b2 b1 b0

July 30, 1997 © 1996 PEP Modular Computers Page 4-9

Page 30

Chapter 4 Programming PB-TIM2 User’s Manual

This page has been left blank intentionally.

Page 4-10 © 1996 PEP Modular Computers July 30, 1997

Page 31

PB-TIM2 User’s Manual Chapter 5 Pinouts

5

5. PINOUTS

The PB-TIM2 has three sets of connectors. ST100 with 15 pins is the left-most with reference to the diagram below,

ST101 sits to the right with 30 pins and ST102 with 26 pins is on the far right.

5.1 Main Board

Figure 5.1.0 : Board Connectors

Pin1

Pin1

ST100 ST101 ST102

Pin15

Pin29

Pin2

Pin30

Pin1 Pin2

Pin26Pin25

July 30, 1997 © 1996 PEP Modular Computers Page 5-1

Page 32

Chapter 5 Pinouts PB-TIM2 User’s Manual

5.1.1 ST100 Connector

The ST100 connector fits the BU0A or BU0B sockets on the IMOD or VMOD-2 range of PEP MODPACK carrier

boards. The table shown below shows the signals related to this connector.

Pin Number Signal Pin Number Signal

1 GND 9 ID13

2 N/C 10 ID12

3 N/C 11 ID11

4 N/C 12 ID10

5 N/C 13 ID9

6 IDS1* 14 ID8

7 ID15 15 GND

8 ID14

5.1.2 ST101 Connector

The ST101 connector fits the BU1A or BU1B sockets on the IMOD or VMOD-2 range of PEP MODPACK carrier

boards. The table shown below shows the signals related to this connector.

Signal Pin No. Pin No. Signal

GND 1 2 Vcc

N/C 3 4 N/C

R/W* 5 6 CLK

RESET* 7 8 UDTACK*

N/C 9 10 CS*

N/C 11 12 N/C

ID7 13 14 IDS0

ID6 15 16 N/C

ID5 17 18 IA6

ID4 19 20 IA5

ID3 21 22 N/C

ID2 23 24 N/C

ID1 25 26 N/C

ID0 27 28 IA1

GND 29 30 Vcc

Page 5-2 © 1996 PEP Modular Computers July 30, 1997

Page 33

PB-TIM2 User’s Manual Chapter 5 Pinouts

5.1.3 ST102 Connector

The ST102 connector fits the BU2A or BU2B sockets on the IMOD or VMOD-2 range of PEP MODPACK carrier

boards. The table shown below shows the signals related to this connector.

Signal Pin No. Pin No. Signal

V+ 1 2 V+

Channel 0 A+ 3 4 Channel 0 A-

Channel 0 B+ 5 6 Channel 0 BChannel 0 C+ 7 8 Channel 0 CChannel 0 MATCH+ 9 10 Channel 1 A+

Channel 1 A- 11 12 Channel 1 B+

Channel 1 B- 13 14 Channel 1 C+

Channel 1 C- 15 16 Channel 1 MATCH +

Channel 2 A+ 17 18 Channel 2 AChannel 2 B+ 19 20 Channel 2 BChannel 2 C+ 21 22 Channel 2 C-

Channel 2 MATCH+ 23 24 Clear+

V- 25 26 V-

Note

Channelx MATCH+ is a source signal generated from V+

Clear+ is an input signal related to V-.

July 30, 1997 © 1996 PEP Modular Computers Page 5-3

Page 34

Chapter 5 Pinouts PB-TIM2 User’s Manual

5.1.4 ST102 VMOD-2(D)/IMOD Connection

Figure 5.1.4.1 VMOD-2(D)/IMOD Front-Panel

Pin 49Pin 50

Pin 2

VMOD-2

Pin 1

Table 5.1.4.1 Front-Panel Connector Pinout

Front

Panel

VMOD-2

Pin Nr.

Front

Panel

VMOD-2D

Pin-Nr.

Piggyback

ST102 Pin

Number

Pin 34

Front

Panel

VMOD-2

Pin Nr.

Pin 17

Pin 18

VMOD

2D

Front

Panel

VMOD-2D

Pin-Nr.

Pin 23Pin 50

Pin 1

Piggyback

ST102 Pin

Number

50 50 1 & 2 49 17 25 & 26

48 33 3 47 49 4

46 16 5 45 32 6

44 48 7 43 15 8

42 31 9 41 47 10

40 14 11 39 30 12 Piggyback

A

38 46 13 37 13 14

36 29 15 35 45 16

34 12 17 33 28 18

32 44 19 31 11 20

30 27 21 29 43 22

Page 5-4 © 1996 PEP Modular Computers July 30, 1997

Page 35

PB-TIM2 User’s Manual Chapter 5 Pinouts

28 10 23 27 26 24

Front

Panel

VMOD-2

Pin Nr.

24 25 1 & 2 23 41 25 & 26

22 8 3 21 24 4

20 40 5 19 7 6

18 23 7 17 39 8

16 6 9 15 22 10

14 38 11 13 5 12 Piggyback

12 21 13 11 37 14

10 4 15 9 20 16

8 36 17 7 3 18

6 19 19 5 35 20

4 2 21 3 18 22

2 34 23 1 1 24

Front

Panel

VMOD-2D

Pin-Nr.

Piggyback

ST102 Pin

Number

Front

Panel

VMOD-2

Pin Nr.

Front

Panel

VMOD-2D

Pin-Nr.

Piggyback

ST102 Pin

Number

B

An optional 50-way header behind the front-panel connector has an identical pin-out to the front-panel connector. It is

provided for applications where the flat-band cable is to be routed internally or where an alternative front panel is to be

fitted and used. In some cases, cables can be routed through the systems interior i.e. To the back panel (from this

optional connector) and some from the external connector on the front-panel. In doing so, take care not to exceed the fanout ability of the piggyback’s driver circuits.

Note

With systems that have more than one of this type of connector or which use several VMOD-2 or

IMODs with various piggybacks, it is advisable to put a drop of paint on the back of the mating

connector and on the front panel of the VMOD-2 or IMOD to indicate connections. The connector

splits virtually in half (pins 1 to 24 and 27 to 50) for connection to the piggybacks B and A

respectively. For more information on the VMOD-2/IMOD series of PEP MODPACK carrier boards,

refer to the relevant manual.

July 30, 1997 © 1996 PEP Modular Computers Page 5-5

Page 36

Chapter 5 Pinouts PB-TIM2 User’s Manual

This page has been left blank intentionally

Page 5-6 © 1996 PEP Modular Computers July 30, 1997

Loading...

Loading...