Page 1

PB-DOUT8

Eight-Channel Digital I/O

ModPack Piggyback

Manual ID 17984, Index 0110

Oct 98

Page 2

This page was intentionally left blank.

ID 17984, Index 0110

Page 3

PB-DOUT8

Preface

Preface

Revision History............................................................. 0-6

For Your Safety.............................................................. 0-5

Special Handling and Unpacking Instructions............ 0-5

HV Safety Instructions................................................ 0-6

Two Years Warranty ...................................................... 0-7

Table of Contents........................................................... 0-8

Oct 98

Page 0 - 3ID 17984, Index 0110

Page 4

Preface

Revision History

Manual/Product Title: PB-DOUT8

Manual ID Number: 17984

PB-DOUT8

REVISION HISTORY

Rev.

Index

0100 Initial Issue 01 01 Mar 98

0110 Chapters 1, 1.1, 1.5, 4.2, 4.3 et al. 01 01 Oct. 98

This document contains proprietary information of PEP Modular Computers. It may not be

copied or transmitted by any means, passed to others, or stored in any retrieval system or

media, without the prior consent of PEP Modular Computers or its authorized agents.

The information in this document is, to the best of our knowledge, entirely correct. However,

PEP Modular Computers cannot accept liability for any inaccuracies, or the consequences

thereof, nor for any liability arising from the use or application of any circuit, product, or example shown in this document.

Brief Description of Changes PCB Index Date of

Issue

PEP Modular Computers reserve the right to change, modify, or improve this document or the

product described herein, as seen fit by PEP Modular Computers without further notice.

Page 0 - 4

Oct 98ID 17984, Index 0110

Page 5

PB-DOUT8

Preface

For your safety

This PEP product is carefully designed for a long, fault-free life. However, its life expectancy

can be drastically reduced by improper treatment during unpacking and installation. Therefore, in the interest of your own safety and of correct operation of your new PEP product,

please take care of the following guidelines:

$ Before installing your new PEP product into a system, please, always switch off your

power mains. This applies also to installing piggybacks.

$ In order to maintain PEP’s product warranty, please, do not alter or modify this product

in any way. Changes or modifications to the device, which are not explicitly approved by

PEP Modular Computers and described in this manual or received from PEP Technical

Support as a special handling instruction, will void your warranty.

$ This device should only be installed in or connected to systems that fulfil all necessary

technical and specific environmental requirements. This applies also to the operational

temperature range of the specific board version, which must not be exceeded. If batteries are present, their temperature restrictions must be taken into account.

$ In performing all necessary installation and application operations, please, follow only

the instructions supplied by the present manual.

$ Keep all the original packaging material for future storage or warranty shipments. If it is

necessary to store or ship the board, please, re-pack it in the original way.

Special Handling and Unpacking Instructions

Electronic boards are sensitive to static electricity. Therefore, care must be taken during all

handling operations and inspections with this product, in order to ensure product integrity at all

times.

$ Do not handle this product out of its protective enclosure while it is not being worked

with, or unless it is otherwise protected.

$ Whenever possible, unpack or pack this product only at EOS/ESD safe work stations.

$ Where safe work stations are not guaranteed, it is important for the user to be electri-

cally discharged before touching the product with his/her hands or tools. This is most

easily done by touching a metal part of your system housing.

$ Particularly, observe standard anti-static precautions when changing piggybacks, ROM

devices, jumper settings etc. If the product contains batteries for RTC or memory backup, ensure that the board is not placed on conductive surfaces, including anti-static

plastics or sponges. They can cause short circuits and damage the batteries or tracks

on the board.

Oct 98

Page 0 - 5ID 17984, Index 0110

Page 6

Preface

PB-DOUT8

Safety Instructions for High Voltages

This chapter of the safety instructions applies to HV appliances (> 60 V) only.

Your new PEP product was developed and tested carefully to provide all features necessary

to ensure the renown electrical safety requirements. However, serious electrical shock hazards exist during all installation, repair and maintenance operations with this product. Therefore, always unplug the power cable to avoid exposure to hazardous voltage.

All operations on this device have to be carried out by sufficiently skilled personnel only.

Page 0 - 6

Oct 98ID 17984, Index 0110

Page 7

PB-DOUT8

Preface

Two Years Warranty

PEP Modular Computers grants the original purchaser of PEP products a TWO YEARS LIMITED

HARDWARE WARRANTY as described in the following. However, no other warranties that may

be granted or implied by anyone on behalf of PEP are valid unless the consumer has the

expressed written consent of PEP Modular Computers.

PEP Modular Computers warrants their own products, excluding software, to be exempt of

manufacturing and material defects for a period of 24 consecutive months from the date of

purchase. This warranty is not transferable nor extendible to cover any other users or longterm storage of the product. It does not cover products which have been modified, altered or

repaired by any other party than PEP Modular Computers or their authorized agents. Furthermore, any product which has been, or is suspected of being damaged as a result of negligence, improper use, incorrect handling, servicing or maintenance, or which has been

damaged as a result of excessive current/voltage or temperature, or which has had its serial

number(s), any other markings or parts thereof altered, defaced or removed will also be

excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in case of any claim, he may

return the product at the earliest possible convenience to the original place of purchase,

together with a copy of the original document of purchase, a full description of the application

the product is used on and a description of the defect. Pack the product in such a way as to

ensure safe transportation (see our safety instructions).

PEP provides for repair or replacement of any part, assembly or sub-assembly at their own

discretion, or to refund the original cost of purchase, if appropriate. In the event of repair,

refunding or replacement of any part, the ownership of the removed or replaced parts reverts

to PEP Modular Computers, and the remaining part of the original guarantee, or any new

guarantee to cover the repaired or replaced items, will be transferred to cover the new or

repaired items. Any extensions to the original guarantee are considered gestures of goodwill,

and will be defined in the “Repair Report” issued by PEP with the repaired or replaced item.

PEP Modular Computers will not accept liability for any further claims resulting directly or indirectly from any warranty claim, other than the above specified repair, replacement or refunding. Particularly, all claims for damage to any system or process in which the product was

employed, or any loss incurred as a result of the product not functioning at any given time, are

excluded. The extent of PEP Modular Computers liability to the customer shall not exceed the

original purchase price of the item for which the claim exist.

PEP Modular Computers issues no warranty or representation, either explicit or implicit, with

respect to its products, reliability, fitness, quality, marketability or ability to fulfil any particular

application or purpose. As a result, the products are sold “as is,” and the responsibility to

ensure their suitability for any given task remains of the purchaser. In no event will PEP be liable for direct, indirect or consequential damages resulting from the use of our hardware or

software products, or documentation, even if PEP were advised of the possibility of such

claims prior to the purchase of the product or during any period since the date of its purchase.

Please remember that no PEP Modular Computers employee, dealer or agent is authorized to

make any modification or addition to the above specified terms, either verbally or in any other

form written or electronically transmitted, without the company’s consent.

Oct 98 Page 0 - 7ID 17984, Index 0110

Page 8

Preface

Table of Contents

PB-DOUT8

Chapt

Chapter

1. Introduction.............................................................1 - 3

1.1 EMC Compliance..............................................1 - 3

1.2 Board Overview................................................1 - 3

1.3 Main Features...................................................1 - 4

1.4 Board Layout ....................................................1 - 5

1.5 Technical Specification.....................................1 - 6

Chapter

2. Configuration..........................................................2 - 3

2.1 Pinout................................................................2 - 3

1

1

2

2.2 Jumper Configuration .......................................2 - 5

Chapter

3. Installation ..............................................................3 - 3

3.1 Carrier Board Interfacing ..................................3 - 3

3.2 Carrier Board Installation..................................3 - 6

3

Page 0 - 8

Oct 98ID 17984, Index 0110

Page 9

PB-DOUT8

Preface

Chapter

4. Software References..............................................4 - 3

4.1 Technical Features...........................................4 - 3

4.2 Memory Map.....................................................4 - 3

4.3 PB-DOUT8 Registers.......................................4 - 4

4.4 Error Analysis...................................................4 - 6

4

Oct 98

Page 0 - 9ID 17984, Index 0110

Page 10

This page was intentionally left blank.

ID 17984, Index 0110

Page 11

PB-DOUT8

Introduction

Introduction

1.1EMC Compliance ................................................................. 1 - 3

1.2Board Overview....................................................................1 - 3

1.3Main Features ...................................................................... 1 - 4

1.3.1High-Side Power Switches............................................1 - 4

1.3.2Low-Side Power Switches............................................. 1 - 5

1.3.3Board Interfaces............................................................1 - 5

1.4Board Layout........................................................................ 1 - 5

Chapter

1

1.5Technical Specification......................................................... 1 - 6

22 Oct 98

Page 1 - 1Man. ID 17984, Rev. Index 0110

Page 12

This page was intentionally left blank.

Man. ID 17984, Rev. Index 0110

Page 13

PB-DOUT8

Introduction

1. Introduction

The PB-DOUT8 is a single-size ModPack piggyback (100 mm x 48 mm) designed to fit

any of the following carrier boards of the PEP Modular Computers ModPack range:

• VMOD

• VMOD-2/VMOD-2D,VMOD-4D

• VM642/662

• CXM-IMOD

It will also, where possible and appropriate, be compatible with future Modpack boards

The PB-DOUT8 is an 8-channel digital output module utilising “intelligent” power transis-

tors which prevent damage to the circuitry resulting from exposure to the following factors:

• overload;

• undervoltage and overvoltage;

• short circuit;

• overtemperature;

• electrostatic discharges.

In addition, the PB-DOUT8 module is provided with open-load detection.

1.1 EMC Compliance

The PB-DOUT8 piggyback module complies with the requirements of the following CErelevant standards:

• Emission: EN50081-1;

• Immission: EN50082-2;

• Electrical Safety: EN60950.

1.2 Board Overview

PB-DOUT8 is a piggyback output module consisting of eight channels with high-side

and eight channels with low-side switches. Each channel has its own status bit. The

switches are divided into four separate groups, each group having individual power supply (up to 40 V) and grounding. The channel groups are galvanically isolated from one

another and towards the VMEbus.

The output channels switch direct current, namely 1.3 A on the low side and 1.8 A on

the high side, although the minimum output current may vary with different temperatures

(see table 2-1 for exact figures). The maximum (peak) output current is instead typically

4.0 A on the low side and 5.0 A on the high side. The output voltage is typically 24 V DC.

22 Oct 98

Page 1 - 3Man. ID 17984, Rev. Index 0110

Page 14

PB-DOUT8

!

Introduction

The board interrupts, which are hard-coded, are generated and handled according to

various smart transistor conditions.

Attention!

Please check the specification of your carrier board to make sure

that it supports the output current of the PB-DOUT8.

PB-DOUT8 does not have a reverse voltage protection for the external 24 V power supply lines.

Figure 1-1: PB-DOUT8 Functional Block Diagram

CARRIER BOARDCARRIER BOARD

High-side

STAT

OUT

Power

Switches

LOGIC

IN

GND

External IF

Legend:

STAT = status

GND = ground

Process IF

PBDOUT-8PBDOUT-8

Low-side

Power

Switches

Opto-Coupling

ModPack IF

VME Bus IF

1.3 Main Features

In the following the main features of the principal functional blocks of the PB-DOUT8

digital output module are described.

1.3.1 High-Side Power Switches

The PB-DOUT8 module is provided with eight Siemens BTS412B2 smart power transistors for high-side switching having the following features:

• overload protection

• current limitation

• short-circuit protection

• thermal shutdown

• undervoltage and overvoltage shutdown

• open-load detection

• loss-of-ground protection

• ESD protection

Page 1 - 4

22 Oct 98Man. ID 17984, Rev. Index 0110

Page 15

PB-DOUT8

!

Introduction

1.3.2 Low-Side Power Switches

The PB-DOUT8 module is provided with four two-channel Siemens TLE 5224 G2 smart

power transistors for low-side switching having the following features:

• overload protection

• power limitation

• short-circuit protection

• overtemperature monitoring

• overvoltage protection

• ESD protection

1.3.3 Board Interfaces

The PB-DOUT8 piggyback module is provided with two digital I/O connectors. The one

on the input side is a 15-pin double-row connector, the one on the process side a 12-pin

double-row connector. The input connector is wired via the carrier board to a 50-pin

DSUB or to a 50-pin FB connector, while the process interface is wired to the carrier

board’s VMEbus socket.

Attention!

In fitting your PB-DOUT8 piggyback module onto its carrier board,

please make sure the PB-DOUT8 pin rows match the corresponding rows of pinholes of the carrier board socket (see chapter 3).

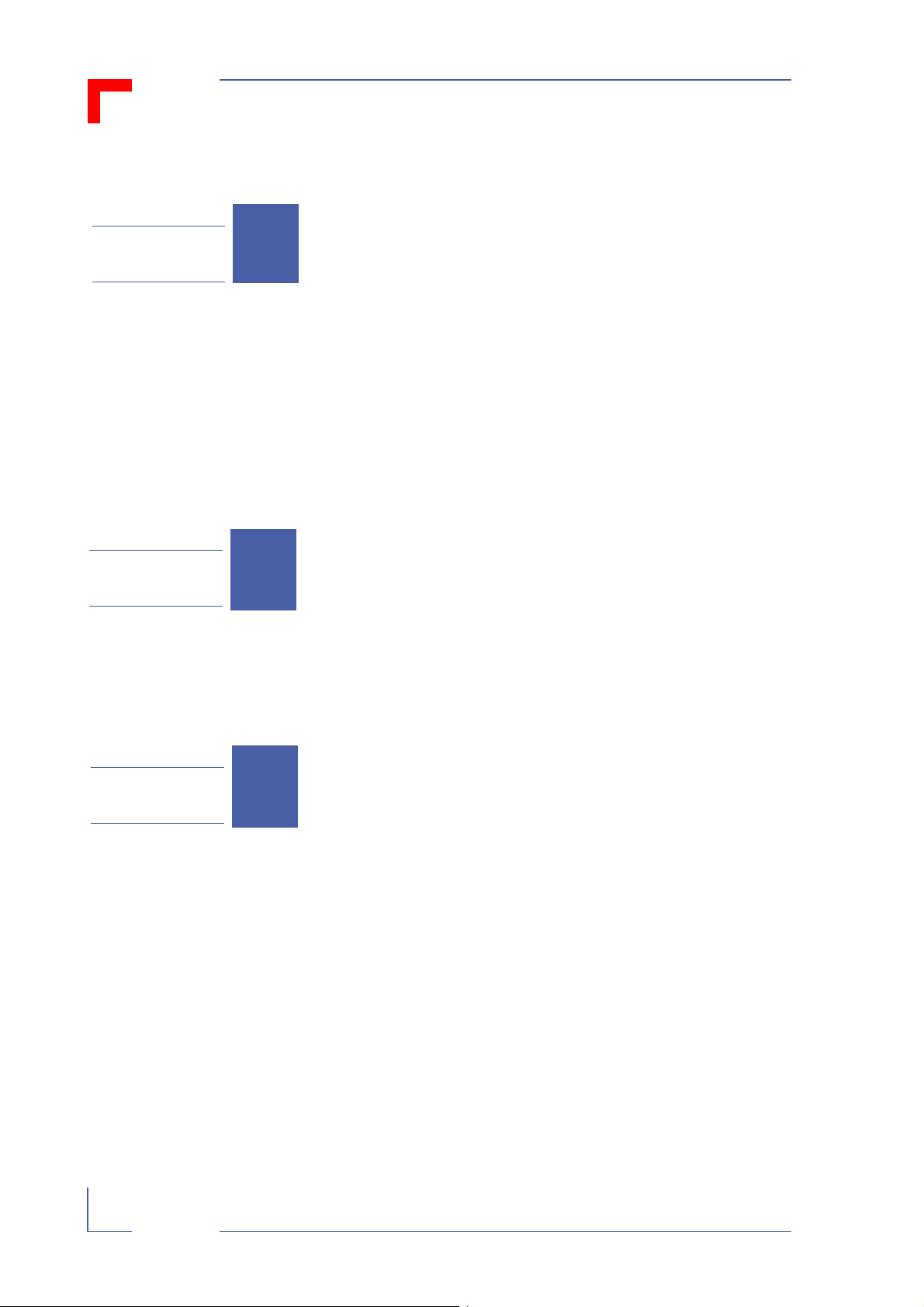

1.4 Board Layout

Figure 1-2: PB-DOUT8 Board Layout — Component Side (Left) and Solder Side (Right)

30

High-side

ST2

1

LOGIC

OPTO-COUPLERS

Power

Switches

24

ST1

1

22 Oct 98

Legend:

NSR = Not system-relevant

Low-side

Power

Switches

(NSR)

Page 1 - 5Man. ID 17984, Rev. Index 0110

Page 16

PB-DOUT8

1.5 Technical Specification

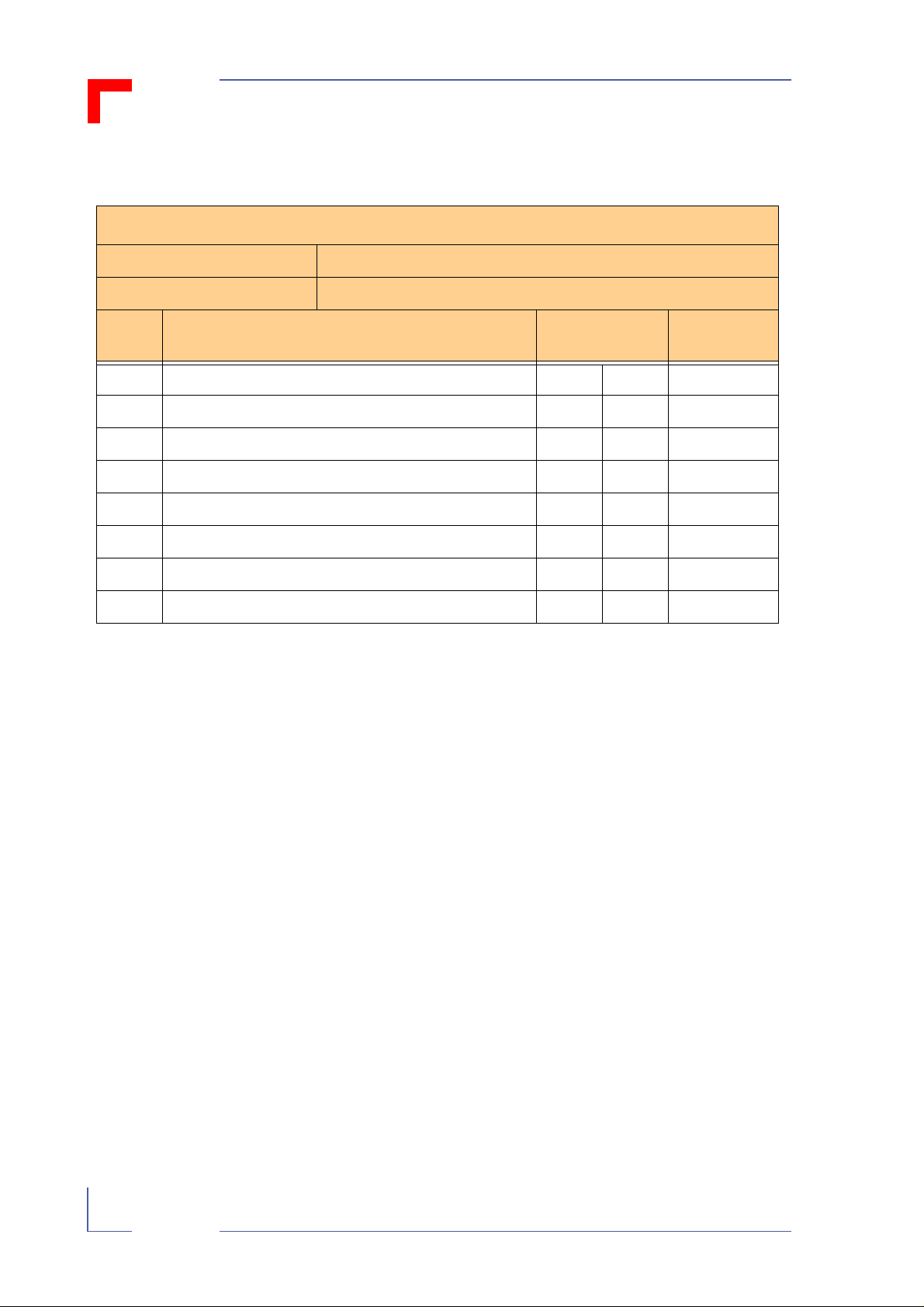

Table 1-1: PB-DOUT8 Technical Specification

PB-DOUT8 Specification

Introduction

Channels and Channel

Grouping

Isolation Voltages Group-to-group: 0.7 mm (0.7 kV)

Input Voltage Range: 10...40 V DC

Power Consumption 24V side:typ. 2mA per group

Temperature Range:

- Standard Operation

- Extended Operation

- Storage

Driving Current Typically: 1.3 A DC (low side),

Open Circuit Detection Typ. 30 µA

4 groups of channels, each consisting of

- 2 channels with high-side switches

- 2 channels with low-side switches

Group-to-VMEbus:4.0 mm (4.0 kV)

Nominal: 24 V DC

VMEbus side:typ. 95 mA

0° to + 70°C

- 40° to + 85°C

- 55° to + 125°C

1.8 A DC (high side)

Minimum (LS/HS): 1.0 A DC (0...+70°C)

0.6 A DC (-40...0°C)

Maximum (typ.) 4.0 A (low side),

5.0 A (high side)

Operating Frequency 0...250 Hz, incl. inductive load

Inductive Load 24 V/0.5 A/1,0 Henry

On-State Resistance Typically: 250 mOhm (low side),

220 mOhm (high side)

Switching Speed Typ. 1 ms, incl. status feedback

Page 1 - 6

22 Oct 98Man. ID 17984, Rev. Index 0110

Page 17

PB-DOUT8

Configuration

Configuration

2.1Pinout................................................................................... 2 - 3

2.2Jumper Configuration........................................................... 2 - 5

Chapter

2

22 Oct 98

Page 2 - 1Man. ID 17984, Rev. Index 0110

Page 18

This page was intentionally left blank.

Man. ID 17984, Rev. Index 0110

Page 19

PB-DOUT8

Configuration

2. Configuration

2.1 Pinout

The PBDOUT-8 is connected via its carrier board to a 50-way flat-band cable or DSUB

connector. Depending on the carrier board location where the piggyback is installed (“A”

of “B”), either the upper half or the lower half of the connector pins are used

The following tables show the output registers and the corresponding output lines for the

upper (“A”) and lower (“B”) location, with reference to the relative DSUB/FB connectors

of the carrier board:

Table 2-1: PB-DOUT8 Pinout (Lower Position)

Pin DSUB 50 FB 50 Pin DSUB 50 FB 50

OUT07L Pin 1 Pin 1 OUT03L Pin 5 Pin 13

OUT07H Pin 34 Pin 2 OUT03H Pin 38 Pin 14

OUT06L Pin 18 Pin 2 OUT02L Pin 22 Pin 15

OUT06H Pin 2 Pin 4 OUT02H Pin 6 Pin 16

GND0607 Pin 35 Pin 5 GND0203 Pin 39 Pin 17

VSS0607 Pin 19 Pin 6 VSS0203 Pin 23 Pin 18

OUT05L Pin 3 Pin 7 OUT01L Pin 7 Pin 19

OUT05H Pin 36 Pin 8 OUT01H Pin 40 Pin 20

OUT04L Pin 20 Pin 9 OUT00L Pin 24 Pin 21

OUT04H Pin 4 Pin 10 OUT00H Pin 8 Pin 22

GND0405 Pin 37 Pin 11 GND0001 Pin 41 Pin 23

VSS0405 Pin 21 Pin 12 VSS0001 Pin 25 Pin 24

22 Oct 98

Page 2 - 3Man. ID 17984, Rev. Index 0110

Page 20

PB-DOUT8

Table 2-2: PB-DOUT8 Pinout (Upper Position)

Pin DSUB 50 FB 50 Pin DSUB 50 FB 50

OUT07L Pin 26 Pin 27 OUT03L Pin 30 Pin 39

OUT07H Pin 10 Pin 28 OUT03H Pin 14 Pin 40

OUT06L Pin 43 Pin 29 OUT02L Pin 47 Pin 41

OUT06H Pin 27 Pin 30 OUT02H Pin 31 Pin 42

GND0607 Pin 11 Pin 31 GND0203 Pin 15 Pin 43

VSS0607 Pin 44 Pin 32 VSS0203 Pin 48 Pin 44

OUT05L Pin 28 Pin 33 OUT01L Pin 32 Pin 45

OUT05H Pin 12 Pin 34 OUT01H Pin 16 Pin 46

OUT04L Pin 45 Pin 35 OUT00L Pin 49 Pin 47

Configuration

OUT04H Pin 29 Pin 36 OUT00H Pin 33 Pin 48

GND0405 Pin 13 Pin 37 GND0001 Pin 17 Pin 49

VSS0405 Pin 46 Pin 38 VSS0001 Pin 50 Pin 50

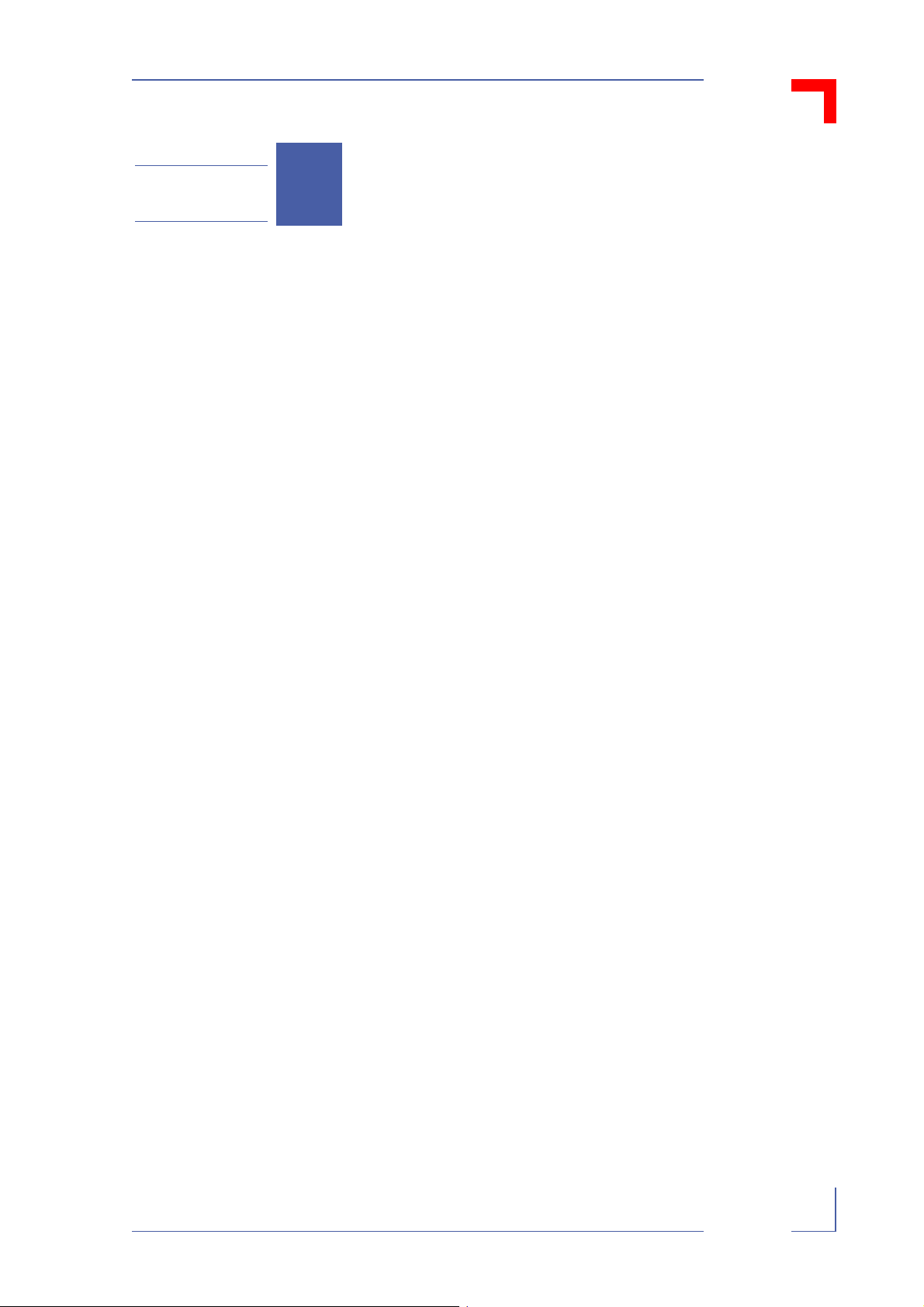

Figure 2-1: Pin Numbering of DSUB 50 and Front Panel Connector (FB 50)

Pin 33

Pin 50

Pin 34 Pin 1

Pin 18

Pin 17

Even pins

Pin 50

Pin 2

VMOD

2

Odd pins

Pin 49

Pin 1

Page 2 - 4

DSUB 50

FB 50

22 Oct 98Man. ID 17984, Rev. Index 0110

Page 21

PB-DOUT8

2.2 Jumper Configuration

The PB-DOUT8 module does not have any jumpers to be configured.

Configuration

22 Oct 98

Page 2 - 5Man. ID 17984, Rev. Index 0110

Page 22

This page was intentionally left blank.

Man. ID 17984, Rev. Index 0110

Page 23

PB-DOUT8

Installation

Installation

3.1Carrier Board Interfacing...................................................... 3 - 3

3.1.1Carrier Board VMEbus Connector BU1A/B................... 3 - 4

3.1.2Carrier Board External Interface Connector BU2A/B.... 3 - 4

3.2Carrier Board Installation...................................................... 3 - 6

Chapter

3

22 Oct 98

Page 3 - 1Man. ID 17984, Rev. Index 0110

Page 24

This page was intentionally left blank.

Man. ID 17984, Rev. Index 0110

Page 25

PB-DOUT8

$$

Installation

3. Installation

3.1 Carrier Board Interfacing

This section shows how to proceed with the installation of the PB-DOUT8 piggyback

module on a carrier board. Figure 2-2 shows an example configuration where two piggybacks standing in this case for two PB-DOUT8 modules are fit to a VMOD-2. The first

PB-DOUT8 on a carrier board would fit in the upper position (“A”), the second in the

lower position (“B”).

At first the two header-type connectors (BU1a/BU1b and BU0a/BU0b) of the carrier

board are illustrated, which directly interface to the PB-DOUT8 ST1 pin rows. The lower

case letters in the socket numbers refer to which piggyback location the connector is

used for, e.g. BU1a is socket 1 for PB-DOUT8 location “A”. An illustration showing in

detail all carrier board connectors concerning piggyback installation is given below.

Important!

Please take care to note that the denominations “ST1” and “ST2”

used for the PB-DOUT8 refer only to the piggyback pin row connectors themselves and fit to headers BU1a and BU2a or, respectively,

BU1b and BU2b on the carrier board.

Also the carrier boards have plugs called “ST1” (VMEbusVMEbus

connector) and “ST2” (50-way header), which have no direct relationship to those of the PB-DOUT8 connectors described in this

manual.

Figure 3-1: Carrier Board Connector Denominations

BU2a 26-way, 2-row

piggyback socket for

upper piggyback

ST3 front panel

connector (50-way)

— or —

ST2 on-board

50-way header

BU1a/BU0a 30/45-way

2/3-row upper

piggyback socket

ST1 VMOD-2's

VMEbus 96-way

connector (P1, J1)

22 Oct 98

BU2b 26-way, 2-row

piggyback socket for

lower piggyback

BU1b/BU0b 30/45-way

2/3-row lower

piggyback socket

Page 3 - 3Man. ID 17984, Rev. Index 0110

Page 26

PB-DOUT8

!

3.1.1Carrier Board VME Bus Connector BU1A/B

The Modpack carrier boards are provided with a three-row 45-pin socket. Some piggyback modules, like for instance PB-DOUT8, use only the first two rows (30 pins) of the

header, while other piggybacks, having three-row headers, use also the third row. For

this reason, the first two rows of the connector are named as if they were a separate

socket — “BU1”; the remaining third row instead is called “BU0”.

Attention!

When installing your PB-DOUT8 on its carrier board, please make

sure the piggyback’s pin rows match with the carrier board’s headers as is shown in the following figure.

Figure 3-2: Correct Installation of PB-DOUT8 on the Carrier Board

ST2 ST1

Installation

PB-DOUT8PB-DOUT8

XX

Carrier BoardCarrier Board

BU2 BU1 - 0

3.1.2 Carrier Board External Interface Connector BU2A/B

The 26-pin double-row sockets are totally isolated from the remaining circuits of the carrier board and only connect the output side of the PB-DOUT8 26-pin output header

directly to the upper or lower half of the carrier board’s 50-way front panel connector.

For a better understanding, an overview of piggyback connection in general to VMOD/

VMOD-2 is given in figure 3-3.

Page 3 - 4

22 Oct 98Man. ID 17984, Rev. Index 0110

Page 27

PB-DOUT8

Figure 3-3: PB-DOUT8 Carrierboard Connection

Installation

VMOD-2's ST2 (on-board)

50-way Header

Pin 50

Even

pins

Pin 2

VMOD

2

Pin 49

VMOD-2's ST3

Front Panel

Connector

(50-Way )

Odd

pins

Pin 1

VMOD-2's two 26-way

Headers BU2a (upper)

BU2b (lower)

PB-DOUT8

Position A

(ready for fitting)

Fitted PB-REL

Position B

VMOD-2's two 30/45-way

Header BU1/0a (upper PB)

BU1/0b (lower PB location)

VMOD's ST1

VMEbus

Connector

(96-Way )

PB's ST2

Short

Connector

(26-Way)

26

Even

Pins

2

25

Odd

Pins

1

PB-REL

PB-DOUT8

(ready for fitting)

(ready for fitting)

PB's ST2 and ST1

pin distribution as

seen from the PB's

component side.

!

Remember the PB's

ST2 pin numbers

have nothing to do

with the VMOD-2

ST2's (user I/O) pins.

30

Even

Pins

2

PB's ST1

Long

Connector

(30-Way)

29

Odd

Pins

1

22 Oct 98

Page 3 - 5Man. ID 17984, Rev. Index 0110

Page 28

PB-DOUT8

Installation

3.2 Carrier Board Installation

After the installation of the PB-DOUT8 piggyback on its carrier board, the latter has to

be configured and installed. Please refer to your carrier board’s user manual for configuration and installation of the latter.

Attention!

Please refer to your carrier board’s user manual also for

all security advice on high voltage and ESD.

Page 3 - 6

22 Oct 98Man. ID 17984, Rev. Index 0110

Page 29

PB-DOUT8

Software References

Software References

4.1 Technical Features............................................................... 4 - 3

4.2 Memory Map......................................................................... 4 - 3

4.3 PB-DOUT8 Registers........................................................... 4 - 4

4.3.1Interrupt Handling.......................................................... 4 - 4

4.3.2Assembly, Revision and ID Codes................................4 - 4

4.3.3I/O Registers................................................................. 4 - 5

4.4Error Analysis....................................................................... 4 - 6

Chapter

4

22 Oct 98

Page 4 - 1Man. ID 17984, Rev. Index 0110

Page 30

This page was intentionally left blank.

Man. ID 17984, Rev. Index 0110

Page 31

PB-DOUT8

!

Software References

4. Software References

4.1 Technical Features

PB-DOUT8 is wired via the carrier board it is fit into to a 50-pin DSUB or to a 50-pin FB

connector. There are no jumpers on the PB-DOUT8 piggyback.

During VMEbus reset, all low-side and high-side channels are switched off. Channels

are kept in sitched-off condition also during power-up/down (undervoltage) of the

VMEbus. External reset from VMOD2/CXM-IMOD is supported. Interrupts are supported, including a software-programmable IRQ vector.

The PB-DOUT8 read-back for output registers, including status bits, contribute to simplify software. All output registers are “0” after a hardware reset. Each group of channels

has its own register.

Attention!

Depending on the number of channels being switched on/off and

the actual load, PB-DOUT8 may require forced cooling if run above

standard/extended temperatures.

4.2 Memory Map

The PB-DOUT8 software interface supports eight I/O lines with eight byte-wide read/

write registers. If your VMOD-2 is jumpered to the base address $87FE2400, the memory map is the following:

Base +$01 Byte 1 DOUT00read/write

Base +$03 Byte 1 DOUT01read/write

Base +$05 Byte 1 DOUT02read/write

Base +$07 Byte 1 DOUT03read/write

Base +$09 Byte 1 DOUT04read/write

Base +$0B Byte 1 DOUT05read/write

Base +$0D Byte 1 DOUT06read/write

Base +$0F Byte 1 DOUT07read/write

..... reserved do not access

Base +$79 Interrupt control registerread/write

Base +$7B Assembly revision coderead/write*

Base +$7D Software revision coderead/write*

Base +$7F ID Byte ($E3)read/write*

Legend

read/write read/write operation

* writing is possible, but data are not used

22 Oct 98

Page 4 - 3Man. ID 17984, Rev. Index 0110

Page 32

PB-DOUT8

Software References

4.3 PB-DOUT8 Registers

4.3.1 Interrupt Handling

The piggyback interrupt register (IRQ register) is located on offset $79. Each HS/LS

channel is controlled by its own “interrupt enable” flag, which can be turned on/off at any

time, whether an interrupt is pending or not. After reset, all interrupts are disabled automatically.

The summarised “IRQ enabled” status of all single-channel interrupts is sent to a flag

(SI, “sum of interrupts”) in the interrupt status register, which permits a quick overview

on whether an interrupt is pending or not through the single channels. If an interrupt

request bit (SI bit) should be sent to the VMEbus, the “Master Interrupt Enable” bit (MIE

bit) is set. If the factor causing the interrupt request disappears by itself, for instance if a

low-side switch having undercurrent at switch on of an inductive load, the SI bit will clear

itself immediately. However, the interrupt request that was generated will stay active

independently of such error self-clearing. The interrupt to the VMEbus is cleared in the

IRQ service routine by clearing the MIE flag. After all errors have been handled in the

interrupt service routine, the MIE bit must be switched on again by the irg service routine

to re-enable the interrupts.

4.3.2 Assembly, Revision and ID Codes

Hardware Assembly and Revision Code

The hardware assembly code, which is made available after having completed the

installation of the piggyback, is stored on offset $7B. There is a difference between

TLE5224G and TLE5224G2 due to slightly different error behaviour.

The following hardware revision codes exist:

• $00: PB-DOUT8 Ind. 00 with TLE5224G assembled;

• $01: PB-DOUT8 Ind. 01 with TLE5224G assembled;

• $02: PB-DOUT8 Ind. 01 with TLE5224G2 assembled.

Writing to this register is possible. However, the written data are not used.

Software Revision Code

The software revision code is stored on offset $7D.The following software revision

codes exist:

• $00: Initial version;

• $01: Interrupts supported.

Writing to this register is possible. However, the written data are not used.

ID Code

The piggyback ID code §E3 is stored on offset $7F. Writing to this register is possible.

However, the written data are not used.

Page 4 - 4

22 Oct 98Man. ID 17984, Rev. Index 0110

Page 33

PB-DOUT8

Software References

4.3.3 I/O Registers

The input/output registers controlling the lines DOUT00 to DOUT07 are accessed on

offsets $01, $03, $05 ... $0F. In order to simplify multitasking applications, these registers can be read back. The read-back values stand for the status lines of the high-side/

low-side drivers. The write access will set the output lines.

Both the VMEbus and the VMOD-2 external reset signals reset the control logic, thus,

switching off all input lines. During VMEbus reset or VMEbusVMEbus undervoltage all

high-side/low-side drivers are switched off, and a local reset for the PBDOUT8 is created. After the reset is terminated, all output registers are set back to “0” and can be

read back as $00.

Each output uses a single high-side driver (BTS412B2) and half a double low-side driver

(TLE5224G2). The “enable” line of the TLE5224G2 (pin 11) is set permanently to “1”.

The data register offsets $01 to $0F control the data lines of the high-side and low-side

drivers as follows:

Table 4-1: Registers DOUT00 to DOUT07

MSB Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 LSB

Read IE 0 0 0 STH STL DOH DOL

Write IE — — — — — DOH DOL

Reset 0 0 0 0 0 0 0 0

Legend:

“0” Read bit as “0”. This data bit is not used, write “0”:

DOL Data output line controlling low-side driver:

“0” = driver disabled,

“1” = driver enabled.

DOH Data output line controlling high-side driver:

“0” = driver disabled,

“1” = driver enabled.

STL Status input line from the low-side driver. The status line from the low-side switch

is shown inverted in this register.

STH Status input line from the high-side driver. The status line from the high-side

switch is shown inverted in this register.

IE “IRQ enable” bit:

“0” = interrupt disabled,

“1” = interrupt enabled.

22 Oct 98

Page 4 - 5Man. ID 17984, Rev. Index 0110

Page 34

PB-DOUT8

Table 4-2: IRQ Control Register ($77)

MSB Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 LSB

Read IV7 IV6 IV5 IV4 IV3 BUSI SI MIE

Write IV7 IV6 IV5 IV4 IV3 BUSI SI MIE

Reset 0 0 0 0 0 0 0 0

Legend:

“0” Read bit as “0”. This data bit is not used, write “0”:

MIE “Master interrrupt enable” bit:

“0” = board is not generating interrupt,

“1” = board is generating interrupt.

SI Sum of interrupts:

“0” = non of the 8 channels is generating an interrupt,

“1” = one or more of the 8 channels is generating an interrupt.

Software References

BUSI VMEbus interrupt:

If both SI and MIE are equal to “1” BUSI is set by the Hardware Logic and an interrupt request is sent to the carrier board on which your PB-DOUT8 is installed.

Thus, BUSI directly represents the status of the PB-DOUT8 IRQ line.

Inside the interrupt service routine, the MIE bit must be written with “0”. The BUSI

bit will be cleared by the Hardware and the PB-DOUT8 interrupt request will be

cleared.

After handling all error flags of all high side switches, the SI flag will be reset to “0”

by the PB-DOUT8 logic.

To enable further interrupt in case of any errors, the application interrupt service

routine needs to write a “1” to the MIE bit.

IV7..3Programmable interrupt vector:

IV7...3 can be programmed, IV2...IV0 cannot be programmed and are preset to

“1”. IV7...IV0 are equal to $0F after reset.

4.4 Error Analysis

The PB-DOUT8 output module supports the following diagnostics modes:

• External power supply ON/OFF

• Overtemperature

• Short circuit to GND

• Short circuit to VCC

• Open load

• Undervoltage detection

• Overvoltage detection

Page 4 - 6

22 Oct 98Man. ID 17984, Rev. Index 0110

Loading...

Loading...