Page 1

OmniView

HMI-OV215/-OV185/-OV156

User’s Guide (Version 1)

0-0096-22514

If it’s embedded, it’s Kontron

Page 2

OmniView–User’s Guide (V1)

Table of Contents

1. Introduction ................................................................3

1.1. Symbols used in this Guide ................................................4

2. Important Instructions ......................................................5

2.1. Note on the Warranty ......................................................5

2.2. Exclusion of Accident Liability Obligation ................................5

2.3. Liability Limitation / Exemption from the Warranty Obligation .............5

3. General Safety Instructions for IT Equipment ................................6

3.1. Electrostatic Discharge (ESD) .............................................7

3.1.1. Grounding Methods .....................................................7

4. Electromagnetic Compatibility (Class A Device) ..............................8

4.1. Electromagnetic Compatibility (EU) ........................................8

4.2. FCC Statement (USA) .......................................................8

4.3. EMC Compliance (Canada) ...................................................8

5. Scope of Delivery ...........................................................9

5.1. Optional Parts ............................................................9

5.2. Type Label and Product Identification ....................................10

6. Product Description ........................................................11

6.1. OmniView Touch Monitor Base ..............................................12

6.2. Product Images OmniView 21.5” AC PSU (other units similar) ...............13

6.3. Front View ...............................................................14

6.3.1. Display with Touch Screen ............................................15

6.3.2. Front Plate ..........................................................15

6.3.3. Calibrating the Touch Screen .........................................15

6.3.4. Power and Grounding ..................................................16

6.3.5. Interfaces ...........................................................17

6.4. I/O Panel View ...........................................................18

6.5. Rear Side ................................................................19

7. Installation Instructions ..................................................20

8. Maintenance and Prevention .................................................21

8.1. Touch Screen Care and Cleaning ...........................................21

9. Technical Data .............................................................22

9.1. Electrical Specifications ................................................22

9.2. Mechanical Specifications ................................................23

9.3. Environmental Specifications .............................................23

10. Regulatory and Certification Information ...................................24

10.1. Product Regulatory Compliance ...........................................24

10.1.1. Product Safety Compliance ...........................................24

10.1.2. Product EMC Compliance – Class A Compliance .........................24

10.1.3. Certifications/Registrations/Declarations ...........................24

11. Technical Appendix - Interfaces ............................................25

11.1. Power Connector – DC Power Supply .......................................25

11.2. DVI Input Connector .....................................................26

11.3. DVI Connector (DVI-I) ...................................................27

11.4. DisplayPort Input Connector .............................................29

11.5. DP Connectors (DP0/DP1) .................................................30

11.6. Power Connectors ........................................................31

11.7. VGA Input Connector .....................................................32

www.kontron.com 1

Page 3

OmniView – User’s Guide (V1.)

12. Technical Support ......................................................... 33

12.1. Returning Defective Merchandise ........................................ 33

2 www.kontron.com

Page 4

OmniView–User’s Guide (V1)

1. Introduction

The information contained in this manual may be subject to technical alteration, particularly as a

result of the constant upgrading of Kontron products. The attached documentation does not

entail any guarantee on the part of Kontron with respect to technical processes described in the

manual or any product characteristics set out in the manual. Kontron does not accept liability for

printing errors or other inaccuracies in the manual unless it can be proven that Kontron is aware

of such errors or inaccuracies or that Kontron is unaware of these as a result of gross negligence

and Kontron has failed to eliminate these errors or inaccuracies for this reason. Kontron expressly

informs the user that this manual only contains a general description of technical processes and

instructions which may not be applicable in every individual case. In cases of doubt, please

contact Kontron.

This manual is protected by copyright. All rights are reserved by Kontron. Copies of all or part of

this manual or translations into a different language may only be made with the prior written

consent of Kontron. Kontron points out that the information contained in this manual is

constantly being updated in line with the technical alterations and improvements made by

Kontron to the products and thus this manual only reflects the technical status of the products by

Kontron at the time of printing.

© 2014 by Kontron

Printing and duplication, even of sections, is only permissible with the express approval of

Kontron.

Kontron

14118 Stowe Drive

Poway, CA 92064-7147

www.kontron.com 3

Page 5

OmniView – User’s Guide (V1.)

Symbol

Meaning

This symbol indicates the danger of injury to the user or the risk of damage to the

product if the corresponding warning notices are not observed.

This symbol indicates that the product or parts thereof may be damaged if the

corresponding warning notices are not observed.

This symbol indicates general information about the product and the user manual.

This symbol indicates detailed information about the specific product configuration.

This symbol precedes helpful hints and tips for daily use.

1.1. Symbols used in this Guide

® Microsoft, MS-DOS, Windows 7, Windows 8 and Windows NT are registered trademarks of the Microsoft Corporation.

® IBM, PC-AT, OS/2 and PS/2 are registered trademarks of the International Business Machines Corporation.

® Intel and Pentium are registered trademarks of Intel Corporation.

® AMI is a registered trademark of American Megatrends, Inc.

Other product names cited in this manual may also be trademarks and are used here solely for identification purposes.

4 www.kontron.com

Page 6

OmniView–User’s Guide (V1)

2. Important Instructions

This chapter contains safety instructions which must be observed when using the OmniView.

The manufacturer’s instructions provide useful information on your OmniView.

2.1. Note on the Warranty

Due to their limited service life, parts which by their nature are subject to a particularly high

degree of wear (wearing parts) are excluded from the warranty beyond that provided by law. This

applies to batteries and to the display backlighting, for example.

2.2. Exclusion of Accident Liability Obligation

Kontron shall be exempted from the statutory accident liability obligation if the user fails to

observe the safety instructions.

2.3. Liability Limitation / Exemption from the Warranty Obligation

In the event of damage to the device caused by failure to observe the hints in this manual and

eventually on the device Kontron shall not be required to honor the warranty even during the

warranty period and shall be exempted from the statutory accident liability obligation.

www.kontron.com 5

Page 7

OmniView – User’s Guide (V1.)

3. General Safety Instructions for IT Equipment

Please read this chapter carefully and observe the instructions for your own safety and to ensure

correct use of the device.

The chapter also contains information on approval and interference suppression of your device.

The device has been built and tested by Kontron in accordance with UL/IEC 60950-1 and left the

premises in a perfectly safe condition.

In order to maintain the safe condition and ensure safe operation, the user must observe the

instructions and warnings on the device and in the manual.

The device must be used in accordance with the instructions for use.

The electrical installations in the room must correspond to the requirements of the local

(country-specific) regulations.

Take care that there are no cables, particularly power cables, in areas where persons can trip

over them.

Do not use a power cable in sockets shared by a number of other power consumers. Do not use

an extension cable.

For DC power connection: The unit is only completely disconnected from the DC main power

source, when the DC power cord is disconnected either from the power source or the unit.

Therefore, the DC power cord and its connectors must always remain easily accessible.

Do not place the device in direct sunlight, near heat sources, or in a damp place. Make sure the

device has adequate ventilation.

Only devices and components which fulfill the requirements of an SELV circuit (safety extra low

voltage) in accordance with UL/IEC 60950-1 may be connected to the interfaces of the system.

All plugs on the connection cables must be screwed or locked to the housing wherever

possible.

The device is designed to be mounted and operated only in the position described in this

document. The proper mounting is a vertical (or close to) position with the interfaces

downwards.

This device generates heat during operation. Make sure it is adequately ventilated. Do not

cover the ventilation holes in the display housing.

Maintenance or repair on the open device may only be done by qualified personnel authorized

by Kontron, who is aware of the associated dangers.

The device has no components internally that requires access or any set up by Kontron

personnel. If the unit malfunctions or a situation is encountered that requires that the unit be

opened, then return to Kontron for maintenance.

Only approved original accessories (optional parts) approved by Kontron may be used.

6 www.kontron.com

Page 8

OmniView–User’s Guide (V1)

The DC-input must fulfill SELV requirements of UL/IEC 60950-1 standard.

Safe operation is no longer possible when:

o the device has visible damage

o the device no longer functions

In these cases the device must be shut down and secured against unintentional operation.

3.1. Electrostatic Discharge (ESD)

A sudden discharge of electrostatic electricity can destroy static-sensitive devices or

micro-circuitry. Therefore proper packaging and grounding techniques are necessary precautions

to prevent damage. Always take the following precautions:

1. Transport boards in ESD-safe containers such as boxes or bags.

2. Keep electrostatic sensitive parts in their containers until they arrive at the ESD-safe

workplace.

3. Always be properly grounded when touching a sensitive board, component, or assembly.

4. Store electrostatic-sensitive boards in protective packaging or on antistatic mats.

3.1.1. Grounding Methods

By adhering to the guidelines below, electrostatic damage to the device can be avoided:

1. Cover workstations with approved antistatic material. Always wear a wrist strap connected

to workplace. Always use properly grounded tools and equipment.

2. Use antistatic mats, heel straps, or air ionizers for more protection.

3. Always handle electrostatically sensitive components by their edge or by their casing.

4. Avoid contact with pins, leads, or circuitry.

5. Turn off power and input signals before inserting and removing connectors or connecting

test equipment.

6. Keep work area free of non-conductive materials such as ordinary plastic assembly aids

and Styrofoam.

7. Use only field service tools which are conductive, such as cutters, screwdrivers, and

vacuum cleaners.

8. Always place drives and boards PCB-assembly-side down on the foam.

www.kontron.com 7

Page 9

OmniView – User’s Guide (V1.)

4. Electromagnetic Compatibility (Class A Device)

4.1. Electromagnetic Compatibility (EU)

This product is in conformity with the protection requirements of EU Council Directive

2004/108/EC on the approximation of the laws of the Member States relating to electromagnetic

compatibility. If the user modifies and/or adds to the equipment the prerequisites for the CE

conformity declaration (safety requirements) may no longer apply.

Generic standards - Emission standard for residential, commercial and light-industrial

environments (Emission): EN 61000-6-3

Emission of Information technology equipment – Radio disturbance characteristics – Limits and

methods of measurement: EN 55022/A

ITE - Immunity characteristics - Limits and methods of measurement: EN 55024.

4.2. FCC Statement (USA)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his own

expense.

4.3. EMC Compliance (Canada)

The method of compliance is self-declaration to Canadian standard ICES-003.

(English): This Class A digital apparatus complies with the Canadian ICES-003.

(French): Cet appareil numérique de la class A est conforme à la norme NMB-003 du Canada.

8 www.kontron.com

Page 10

OmniView–User’s Guide (V1)

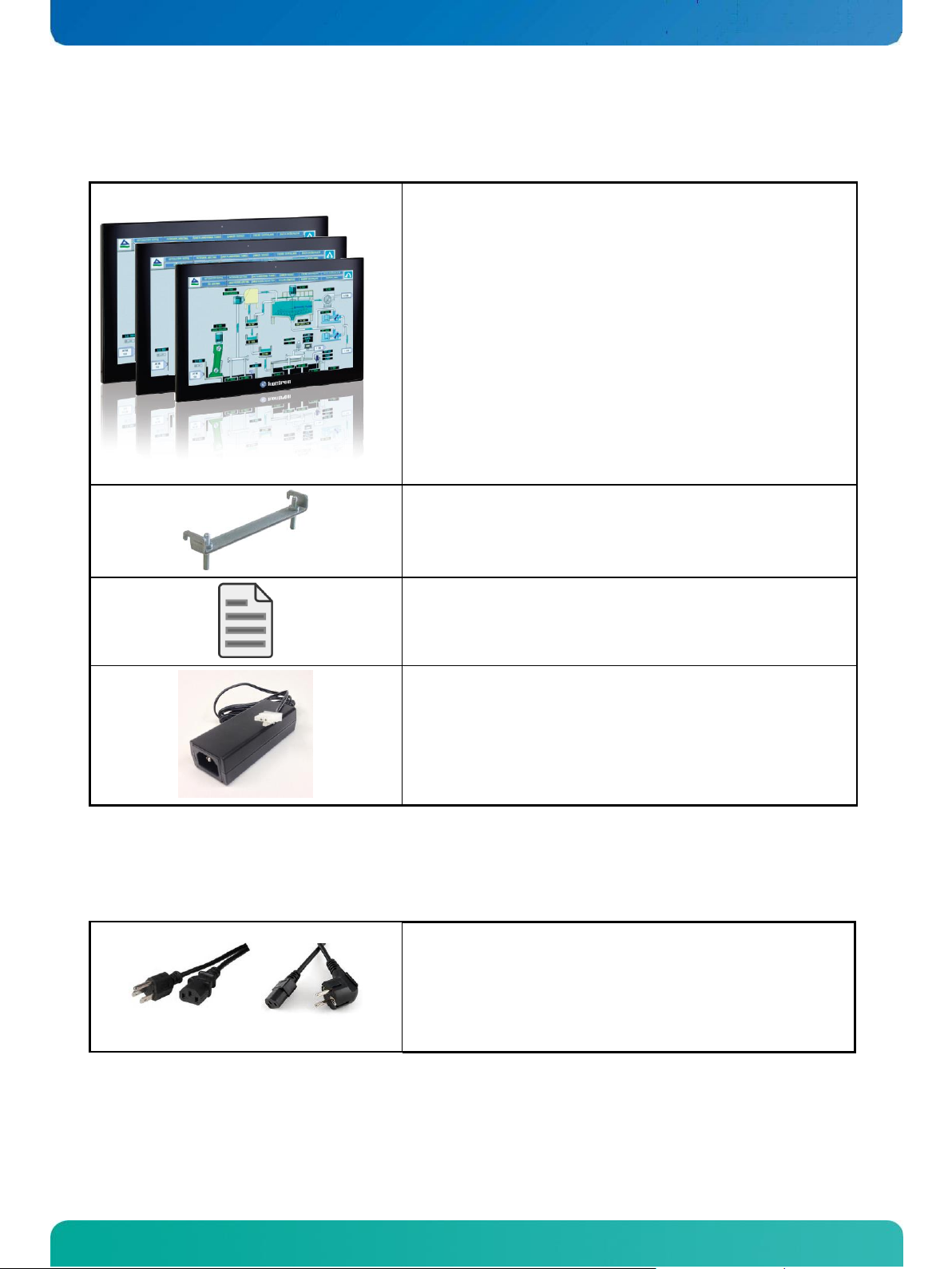

OmniView in the configuration ordered:

OmniView 156 (15.6”)

OmniView 185 (18.5”)

OmniView 215 (21.5”)

6x Mounting Clamp with Screws

General Safety Instruction for IT Equipment

Power Supply

AC(US) AC(EU)

AC Power cable to be used in conjunction with the

supplied Power Supply unit.

5. Scope of Delivery

Please check that your package is complete, and contains the items below (according to the

ordered unit configuration). If you discover damaged or missing items, please contact your dealer.

5.1. Optional Parts

Included with your OmniView is the following optional accessory.

www.kontron.com 9

Page 11

OmniView – User’s Guide (V1.)

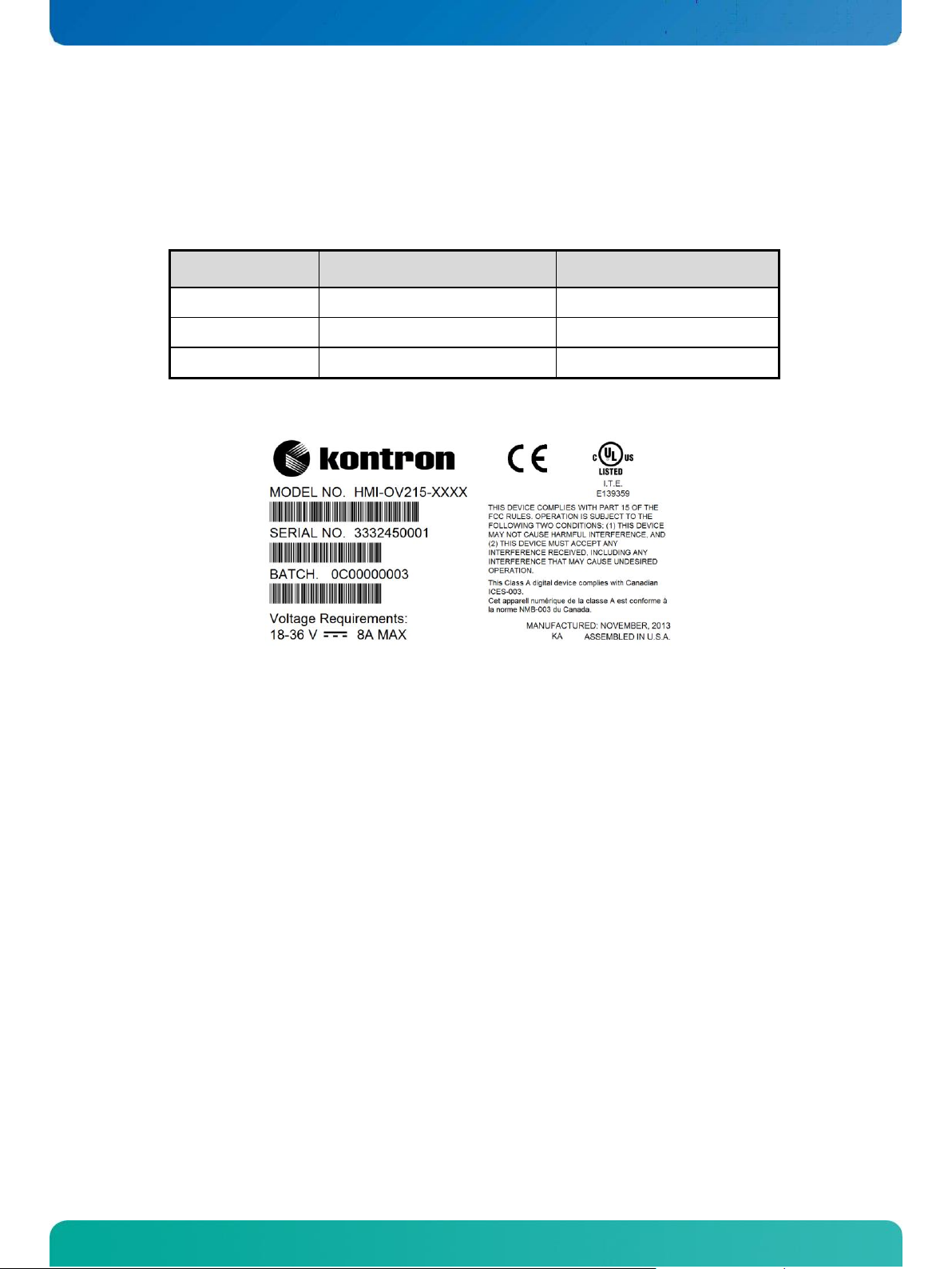

System Type

Model No.

Product Identification

OmniView 156

HMI-OV156-xxxx

15.6” display OmniView

OmniView 185

HMI-OV185-xxxx

18.5” display OmniView

OmniView 215

HMI-OV215-xxxx

21.5” display OmniView

5.2. Type Label and Product Identification

The type label with the corresponding Kontron product part and serial number is located on the

rear side of the display bezel. Figure 1 depicts the type of label for a DC supply OmniView. There

are three primary model numbers of the OmniView based on the screen size. The “-xxxx” suffix in

the model number identifies the ordered configuration.

Figure 1. OmniView Label

10 www.kontron.com

Page 12

OmniView–User’s Guide (V1)

All versions are suitable for installation in an instrument panel or other cabinet.

OmniView monitor must be mounted in an instrument panel or other cabinets using

the corresponding supplied mounting clamps.

Installation using the VESA® 100 mounting system must be properly designed to

support the complete load of the OmniView.

6. Product Description

Before you begin using your OmniView, you should take a few minutes to learn about the various

connectors that are part of your OmniView.

The OmniView is a touch-screen monitor designed for demanding industrial applications. The

OmniView is an integrated touch screen display. The system is designed to be mounted in the

user’s application by either of the following methods:

Installation in an instrument panel or other cabinets (preferred mounting method)

Installation by a heavy duty VESA® 100 compliant mounting system

The OmniView is very flexible and can be customized to meet the requirements of many

demanding applications. The rugged design offers excellent mechanical stability suitable for

operation in harsh industrial environments.

The OmniView is a touch monitor. The touch monitor base includes a display and touch screen.

The following sections detail each of these components and their function in the OmniView.

www.kontron.com 11

Page 13

OmniView – User’s Guide (V1.)

When operating the OmniView, make sure the air openings on the rear of the

display bezel are unobstructed.

The OmniView Touch Monitor is designed to comply with IP65 protection class

at the front side.

Specification / Model

HMI-OV156-xxxx

HMI-OV185-xxxx

HMI-OV215-xxxx

Viewable image size (diagonal)

39.6cm (15.6”)

47.01cm (18.51”)

54.6cm (21.5”)

Active Area

344.232mm (H) x 193.536mm (V)

409.8mm (H) x 230.4mm (V)

476.64mm (H) x 268.11mm (V)

Maximum Resolution

1366 x 768

1366 x 768

1920 x 1080

Pixel Pitch

252 x 252

300 x 300

0.248 x 0.248mm

Brightness

300 cd/m2 (typical)

300 cd/m2 (typical)

300 cd/m2 (typical)

Color Depth

16.7 million colors

16.7 million colors

16.7 million colors

Contrast Ratio

500 (typical)

1000 (typical)

5,000:1 (typical)

Response Time

8 ms (typical)

5 ms (typical)

16ms (typical)

Panel Backlight

LED

LED

LED

Specification / Model

HMI-OV156-xxxx

HMI-OV185-xxxx

HMI-OV215-xxxx

Touch Technology

Projected capacitive system

Projected capacitive system

Projected capacitive system

Sensor stack thickness

1.1mm

1.1mm

1.1mm

Cover glass thickness

1.1 +/-0.2mm

1.1 +/-0.2mm

1.1 +/-0.2mm

Touch Method

Fingers and thin gloves

Fingers and thin gloves

Fingers and thin gloves

Touch Point

6 touches

6 touches

6 touches

Response Time

25ms

25ms

25ms

Interface

USB 2.0

USB 2.0

USB 2.0

6.1. OmniView Touch Monitor Base

The touch-monitor base is configurable during ordering as a 15.6”, 18.5” or 21.5” display size.

Each touch-monitor base is equipped with a color TFT-LCD screen and multi-point projected

capacitive touch screen (PCAP). The OmniView is fanless; cooling of the display is through the

surface of the display bezel and air openings located on the top and bottom on the rear of the

display bezel. The tables below detail the technical specifications of the touch-monitor available

options.

Table 1. Display Specifications

Table 2. Touch Specifications

12 www.kontron.com

Page 14

OmniView–User’s Guide (V1)

Fig. 1: Bottom view

Fig. 2: Right view

Fig. 3: Front view

Fig. 4: Left view

Fig. 5: Top view

Fig. 6: Rear view

6.2. Product Images OmniView 21.5” AC PSU (other units similar)

www.kontron.com 13

Page 15

OmniView – User’s Guide (V1.)

1 TFT display with touch screen

2 Front border

1

2

6.3. Front View

Fig. 7: Front view of the OmniView

14 www.kontron.com

Page 16

OmniView–User’s Guide (V1)

Do not use a hard or a pointed object (like screw drivers) to operate the touch

screen; doing so may damage the touch screen surface.

The touch screen is covered with a glass panel and care should be taken when

cleaning it (see the section 8.1 “Touch Screen Care and Cleaning”).

The capacitive touch screen is factory-calibrated and needs no recalibration.

When using a stylus, make sure to use a special conductive stylus that works with

capacitive touch screens.

6.3.1. Display with Touch Screen

Depending on the OmniView ordered, the built-in display is a 15.6”/18.5”/21.5” size TFT display

with corresponding Projected Capacitive touch screen. The touch screen is USB connected.

For technical specification of the built-in display refer to chapter 9 “Technical Data”.

The display is equipped with a Projected Capacitive touch screen. The touch screen offers the

same degree of user comfort as the mouse buttons.

The surface of the display is also mechanically protected through the touch screen. The touch

screen (USB connected) registers contacts of a finger and allows moving the mouse pointer. This

functions only under integration of the necessary software. The corresponding touch screen

driver for your operating system is installed on your OmniView monitor.

6.3.2. Front Plate

The OmniView is suitable for installation in an instrument panel or other cabinet. At the front

side of the system, an aluminum front plate (bezel) with integrated anti-glare glass plate and

capacitive touch is located.

For the outline dimensions of the touch monitor base refer to section 10.2 “Mechanical

Specifications.”

6.3.3. Calibrating the Touch Screen

Unlike resistive touch displays, the capacitive touch screen needs no further calibration after

factory calibration. Only special, conductive styluses (not included) work with capacitive touch

screens.

www.kontron.com 15

Page 17

OmniView – User’s Guide (V1.)

WARNING: Do not attempt to modify the supplied power supply or use an

unapproved power cord set that is not the exact type required. You must use a

power cord set that meets the following criteria:

Rating: In the U.S. and Canada, cords must be UL (Underwriters Laboratories,

Inc.) Listed/CSA (Canadian Standards Organization) Certified type SJT, 18-3

AWG (American Wire Gauge). Outside of the U.S. and Canada, cords must be

flexible harmonized (<HAR>) or VDE (Verbena Deutscher Electrotechniker,

German Institute of Electrical Engineers) certified cord with 3x 0.75 mm

conductors rated 250 VAC.

Connector, wall outlet end: Cords must be terminated in grounding-type

male plug designed for use in your region. The connector must have

certification marks showing certification by an agency acceptable in your

region and for U.S. must be listed and rated for 125% of the overall current

rating of the server.

Connector, OmniView end: The connector that plugs into the DC power

receptacle on the I/O panel of the OmniView must be an approved power

connector approved by Kontron, America, Molex, power series 5539.

Cord length and flexibility: Cords must be less than 4.5 meters (14.8 feet)

long.

The system is only completely disconnected from the main power supply by

disconnecting the power from the unit or from the wall supply.

6.3.4. Power and Grounding

6.3.4.1. DC power Input

The OmniView is supplied by a 24VDC external power supply. This can be connected to the mains

power by either option of the US power cord or the EU power cord.

Electrical power disconnect: The unit can be disconnected from the electrical supply by either

unplugging the 4 pin power connector on the OmniView I/O panel, or by disconnecting the power

supply from the wall supply. The power cord(s) is considered the mains disconnect for the server

and must be readily accessible (either at the wall or on the unit) when installed.

Grounding the system: To avoid an electrical shock hazard, you must ensure the system has

proper grounding. The OmniView power cord includes the safety ground conductor and provides

proper grounding only for the OmniView. You must ensure proper grounding is provided for the

entire system into which the OmniView is embedded. You must provide additional, proper

grounding for the OmniView and the host equipment.

Overcurrent protection: There is no Over Current protection built into the OmniView. The

external power supply is designed to handle input 100-240 VAC 1.3A, 50-60Hz, and output 24VDC

1.67A max. If overcurrent protection is required beyond the limits of the supplied power supply,

you must provide supplemental protection for the OmniView.

16 www.kontron.com

Page 18

OmniView–User’s Guide (V1)

6.3.5. Interfaces

6.3.5.1. USB 2.0 Connector

The system is equipped at the bottom side with 1x USB 2.0 type B interface connector. This

connector provides connection from the touch screen to the required CPU/Computer. This cord is

available as an option, and only required if the touch screen function is required.

6.3.5.2. DVI-D Video Connector

The DVI-D supports both digital and analog connections. Digital devices can be connected directly

to this interface of the OmniView. Analog devices should be connected to this interface via a DVI

to VGA adapter (not included).

6.3.5.3. DisplayPort Video Connector

One Display Port (DP) connector comply with Display Port 1.1a specification.

6.3.5.4. VGA input

VGA input is obtained by connecting to a standard 15-pin D-sub female connector via a standard

VGA style cable (not supplied).

www.kontron.com 17

Page 19

OmniView – User’s Guide (V1.)

1 USB-B style connector for

touch panel functionality.

2 DC power in connector

3 Display Port input

4 DVI-D female connector

5 VGA input, 15-pin HD-Sub,

female

When powering on the OmniView, make sure that the air intake and exhaust

openings are not obstructed.

3 1 52 4

6.4. I/O Panel View

Fig. 8: I/O panel of OmniView

18 www.kontron.com

Page 20

OmniView–User’s Guide (V1)

1 Slots to attaché mounting clamps for

securing the system to an Instrument

panel (2 slots per clamp)

2 Mounting clamps (6x)

3 Touch Monitor Base air vents

4 Product Identification label area

Note for mounting clamps:

The OmniView 15.6”/18.5”/21.5” will be secured into an instrument panel or

cabinet with two mounting clamps on the top and bottom surfaces and one on

each the left and right surfaces as shown in fig15, position 2.

Please observe the safety instruction for handling assemblies with static sensitive

device.

Failure to take heed of this warning instruction can result in damage to the device.

2

2 1 1 2 1 2 1

3 3 4 1 1

6.5. Rear Side

Fig. 9: Rear side of OmniView

www.kontron.com 19

Page 21

OmniView – User’s Guide (V1.)

The OmniView should be installed and operated only by trained and qualified

personnel.

The unit must be placed such that there is sufficient space for connecting the cables

to the I/O interface connectors.

The voltage feeds must not be overloaded. Adjust the cabling and the external

overload protection to correspond with the rated voltage range indicated on the

type label.

The type label is located on the right side of the system.

The rear access panel must be secured by the supplied screws during operation.

Dimension for: OmniClient

156

185

215

Cut-Out for Mounting into a Panel

[mm] (W x H)

394 x 245

462 x 283

527 x 325

Requirements for Mounting

Metal mounting panel thickness

for proper mounting

1.5 – 6

1.5 – 6

1.5 – 9

Used clamps with screws for

mounting the OmniClient to

a panel

6x

Required Tool

#2 Phillips Screw Driver

Proper Torque

Tighten the screws with a torque of 0.5 Nm

Mounting Position

Ensure the vertical and horizontal alignment of the

system/display box.

In order to ensure IP65 front sealing against dust and water, mount the system on a

non-textured surface. Before you install the OmniView system into a panel or a

subframe for industrial cabinet, verify the perfect condition of the seal at the rear of

the front plate. The seal has to be in place without surface imperfections/defects

and dirt.

7. Installation Instructions

The mount clamps with screws (supplied), allow the easy and fast mounting of the OmniView156/185/215. Refer to the appropriate unit outline and mounting drawing for the correct

dimensions of cut-outs and air gap clearances required for mounting the unit into a wall or panel.

The OmniView outline and mounting drawing can be found on our web site www.kontron.com

20 www.kontron.com

Table 2: Requirements for OmniView mounting into a subframe/panel

Page 22

OmniView–User’s Guide (V1)

The front panel and the touch screen are covered by a plastic overlay and care

should be taken when cleaning it.

8. Maintenance and Prevention

Kontron systems require minimal maintenance and care to keep them operating correctly.

Occasionally wipe the system with a soft dry cloth.

You should only remove persistent dirt by use of a soft, slightly damp cloth (use only a

mild detergent).

8.1. Touch Screen Care and Cleaning

Mild detergent and water is recommended for cleaning. Use of strong solvents, which could

attack paint or plastic, should be avoided.

The plastic overlay or the touch screen surface is subject to burning and scaring from direct heat

sources such as cigarettes. The display front is sealed against dust, liquids, etc.

The front surface of the touch screen is a flexible plastic foil, so care should be used to avoid using

sharp objects such as knife, pen or pencil tips. Sharp objects can permanently damage the

functionality of the touch screen.

www.kontron.com 21

Page 23

OmniView – User’s Guide (V1.)

OmniView

OmniView 156

OmniView 185

OmniView 215

TFT LCD

Display

Screen size

15.6"

18.5"

21.5"

Active area

344.2 x 193.5

409.8 x 230

476.6 x 268.1

(H x V) [mm]

Resolution

1366 x 768

1366 x 768

1920 x 1080

(H x V) [pixel]

(SVGA)

(XGA)

(SXGA)

Pixel Pitch

252 x 252

300 x 300

248 x 248

(H x V) [mm]

Colour depth

16.7M

16.7M

16.7 M

Backlight

LED

LED

LED

Brightness cd/m2

400

350

300

Control signal

1x 6bit LVDS

1x 6bit LVDS

2x 8bit LVDS

Viewing angle (°)

70/70/50/60

70/70/65/60

89/89/89/89

(r / l / u / d)

Contrast ratio

500:1

1000:1

5000:1

Touch Screen

Projected Capacitive

Projected Capacitive

Projected Capacitive

DC IN Power Plug

On the bottom side

Power

DC: external 24 V power source (limited power source)

AC: via the optional external AC/DC adapter (limited power

source)

VESA 75/100 compliant

Rear side

Protection Class

IP65 Front (IP20 rear)

System Type

Input voltage

Input current

OmniView DC

24 VDC +/- 20%

A: max. 1.25 A

OmniViewAC

115-220 VAC +/-20%

A: max. 1A

Hint for DC power connection:

The OmniView must be connected only to a LPS (Limited Power Supply) DC mains

power supply complying with the requirements of UL/IEC 60950-1.

Hint for Using the Supplied AC power connection:

Use only a LPS (Limited Power Supply) power supply complying with the

requirements of UL/IEC 60950-1 to connect the OmniView to an AC power source.

9. Technical Data

9.1. Electrical Specifications

22 www.kontron.com

Page 24

OmniView–User’s Guide (V1)

OmniView

156

185

215

Height

261 mm (10.29")

313 mm (12.34")

341 mm (13.46")

Width

410 mm (16.14")

481 mm (18.94")

544 mm (21.43")

Depth (total)

66.5 mm (2.62")

66.5 mm (2.62")

66.5 mm (2.62")

Depth (from rear surface of

display)

56.9 mm (2.24")

56.9 mm (2.24")

56.9 mm (2.24")

Weight

4.2 kg

4.5 kg

4.7 kg

Front Panel

Aluminum front plate with glass touch panel

Housing

Chemical coated Aluminum casting

Thermal Management

passive cooling

Operating Temperature

0 … +50 °C

Storage / Transit Temp.

-20 … +60 °C

Relative Humidity

Operating: 20 % to 90 % non condensing

Storage / transit: 5 % to 90 % non-condensing

Max. Operating Altitude

up to 3,048 m (10,000 ft)

Max. Storage / Transit Altitude

up to 4,622 m (15,000 ft)

Operating Shock

15 g, 11 ms duration, half sine

Storage / Transit Shock

50 g, 11 ms duration, half sine

Operating Vibration

10 – 500 Hz, 1.0 g/ 3 axis

Storage / Transit Vibration

10 – 500 Hz, 2.0 g / 3 axis

Protection class

IP20

Front IP65

9.2. Mechanical Specifications

9.3. Environmental Specifications

www.kontron.com 23

Page 25

OmniView – User’s Guide (V1.)

10. Regulatory and Certification Information

10.1. Product Regulatory Compliance

10.1.1. Product Safety Compliance

The OmniView monitor complies with the following safety requirements:

UL60950-1 / CSA 60950-1 (USA/Canada)

IEC60950-1 (International), CB Certificate & Report including all international deviations

CE – Low Voltage Directive 2006/95/EC (Europe)

10.1.2. Product EMC Compliance – Class A Compliance

The OmniView monitor has been tested and verified to copmply with following electromagnetic

compatibility (EMC) regulations.

FCC/ICES-003 – Emissions (USA/Canada)

CISPR 22 – Emissions (International)

EN55022 – Emissions (Europe)

EN55024 – Immunity (Europe)

EN6100-3-2 – Harmonics (Europe)

EN6100-3-3 – Voltage Flicker (Europe)

CE-EMC Directive 2004/108/EEC (Europe)

10.1.3. Certifications/Registrations/Declarations

UL Listing (US/Canada)

CE Declaration of Conformity (Europe)

FCC/ICES-003 Class A Verification Report (USA/Canada)

24 www.kontron.com

Page 26

OmniView–User’s Guide (V1)

WARNING:

Do not attempt to modify or use an AC power cord set that is not the exact type

required. You must use a power cord set that meets the following criteria:

11. Technical Appendix - Interfaces

The following tables contain the plug assignments for the external connections of the OmniView.

Low-active signals are indicated by a minus sign.

11.1. Power Connector – DC Power Supply

The external power supply is connected to the wall power out let by either the optional USA or

EU AC power cable, and uses a standard IEC-60320-C13 power cord (See section 5.1 for details).

Rating: In the U.S. and Canada, cords must be UL (Underwriters Laboratories, Inc.) Listed/CSA

(Canadian Standards Organization) Certified type SJT, 18-3 AWG (American Wire Gauge). Outside

of the U.S. and Canada, cords must be flexible harmonized (<HAR>) or VDE (Verbena Deutscher

Electrotechniker, German Institute of Electrical Engineers) certified cord with 3x 0.75 mm

conductors rated 250 VAC.

Connector, wall outlet end: Cords must be terminated in grounding-type male plug designed for

use in your region. The connector must have certification marks showing certification by an agency

acceptable in your region and for U.S. must be listed and rated for 125% of the overall current

rating of the server.

Connector, OmniView end: The connector that plugs into the DC power receptacle on the

I/O panel of the OmniView must be an approved power connector approved by Kontron,

America, Molex, power series 5539.

Cord length and flexibility: Cords must be less than 4.5 meters (14.8 feet) long.

See section 5.1 for details of cords approved by Kontron.

www.kontron.com 25

Page 27

OmniView – User’s Guide (V1.)

Pin No.

SIGNAL

DESCRIPTION

1

TMDS DATA2-

TMDS DATA2 Differential negative signal

2

TMDS DATA2+

TMDS DATA2 Differential positive signal

3

TMDS DATA2 Shield

Shield for TMDS channel 2

4

NC

Not connected

5

NC

Not connected

6

DDC Clock

Clock DDC Interface

7

DDC Data

Data DDC Interface

8

NC

Not connected

9

TMDS DATA1TMDS DATA1 Differential negative signal

10

TMDS DATA1+

TMDS DATA1 Differential positive signal

11

TMDS DATA1 Shield

Shield for TMDS channel 1

12

NC

Not connected

13

NC

Not connected

14

+5V Power

+5V for EDID (un-powered monitor)

15

GND (for +5V)

Ground

16

HPD

Hot Plug Detect

17

TMDS DATA0TMDS DATA0 Differential negative signal

18

TMDS DATA0+

TMDS DATA0 Differential positive signal

19

TMDS DATA0 Shield

Shield for TMDS channel 0

20

NC

Not connected

21

NC

Not connected

22

TMDS Clock Shield

Shield for TMDS clock

23

TMDS CLOCK+

TMDS Clock Differential positive signal

24

TMDS CLOCK-

TMDS Clock Differential negative signal

11.2. DVI Input Connector

Connector: CN100 - DVI-D24P

26 www.kontron.com

Page 28

OmniView–User’s Guide (V1)

Pin No.

Signal

Description

Type

Pull U/D

1

TMDS Data 2-

Digital Red – (Link 1)

LVDS OUT

2

TMDS Data 2+

Digital Red + (Link 1)

LVDS OUT

3

TMDS Data 2/4 Shield

PWR

4

NC NC 5

NC NC 6

DDC Clock

DDC Clock

IO

2K2

7

DDC Data

DDC Data

IO

2K2

8

NC NC

9

TMDS Data 1-

Digital Green – (Link 1)

LVDS OUT

10

TMDS Data 1+

Digital Green + (Link 1)

LVDS OUT

11

TMDS Data 1/3 Shield

PWR

12

NC NC 13

NC NC 14

+5V

Power for monitor when in standby

PWR

15

GND

PWR

16

Hot Plug Detect

Hot Plug Detect

I

17

TMDS Data 0-

Digital Blue – (Link 1) / Digital sync

LVDS OUT

18

TMDS Data 0+

Digital Blue + (Link 1) / Digital sync

LVDS OUT

19

TMDS Data 0/5 Shield

PWR

20

NC NC 21

NC NC 22

TMDS Clock Shield

PWR

23

TMDS Clock+

Digital clock + (Link 1)

LVDS OUT

24

TMDS Clock-

Digital clock - (Link 1)

LVDS OUT

C1

ANALOG RED

Analog output carrying the red color signal

O

/75R

11.3. DVI Connector (DVI-I)

The DVI-I connector support DVI Digital output and DVI analog output.

Figure 2. DVI-I Female socket, front view

Signal Description – DVI-I connector:

www.kontron.com 27

Page 29

OmniView – User’s Guide (V1.)

C2

ANALOG GREEN

Analog output carrying the green color signal

O

/75R

C3

ANALOG BLUE

Analog output carrying the blue color signal

O

/75R

C4

ANALOG HSYNC

CRT horizontal synchronization output.

O C5

ANALOG GND

Ground reference for RED, GREEN, and BLUE

PWR

C6

ANALOG GND

Ground reference for RED, GREEN, and BLUE

PWR

28 www.kontron.com

Page 30

OmniView–User’s Guide (V1)

Pin No.

Signal

Description

1

ML_L3N

Main Link Ch. 3 Differential Input negative

2

GND

Ground

3

ML_L3P

Main Link Ch. 3 Differential Input positive

4

ML_L2N

Main Link Ch. 2 Differential Input negative

5

GND

Ground

6

ML_L2P

Main Link Ch. 2 Differential Input positive

7

ML_L1N

Main Link Ch. 1 Differential Input negative

8

GND

Ground

9

ML_LN1P

Main Link Ch. 1 Differential Input positive

10

ML_LN0N

Main Link Ch. 0 Differential Input negative

11

GND

Ground

12

ML_LNOP

Main Link Ch. 0 Differential Input positive

13

Config1

Config Pin1, connect to GND with 1M

14

Config2

Config Pin2, connect to GND with 1M

15

AUXP

Auxiliary Ch. Differential Input positive

16

GND

Ground

17

AUXN

Auxiliary Ch. Differential Input negative

18

HPD

Hot Plug Detect

19

POR

Connected to Ground

20

PO

Not Connected to internal circuits

11.4. DisplayPort Input Connector

Conn: CB102 – W+P: 8470-2-2-1-80-TR

www.kontron.com 29

Page 31

OmniView – User’s Guide (V1.)

Pin No.

Signal

Description

Type

Note

1

Lane 0 (p)

LVDS

2

GND PWR

3

Lane 0 (n)

LVDS

4

Lane 1 (p)

LVDS

5

GND PWR

6

Lane 1 (n)

LVDS

7

Lane 2 (p)

LVDS

8

GND PWR

9

Lane 2 (n)

LVDS

10

Lane 3 (p)

LVDS

11

GND PWR

12

Lane 3 (n)

LVDS

13

Config1

Aux or DDC

selection

I

14

Config2

(Not used)

O

15

Aux Ch (p)

Aux Channel (+) or

DDC Clk

AUX (+) channel used by DP

DDC Clk used by HDMI

16

GND PWR

17

Aux Ch (n)

Aux Channel (-) or

DDC Data

AUX (-) channel used by DP

DDC Data used by HDMI

18

Hot Plug

I Internally pull down (100Kohm).

19

Return

PWR

Same as GND

20

3.3V PWR

Fused by 1.5A resetable PTC fuse, common

for DP0 and DP1

11.5. DP Connectors (DP0/DP1)

The DP (Display Port) is based on standard DP type Foxconn 3VD51203-H7JJ-7H or Similar.

Figure 3. DP Connector, front view

30 www.kontron.com

Page 32

OmniView–User’s Guide (V1)

Pin No

Signal

Description

1

GND

Ground

2

GND

Ground

3

+12V / +24V DC

VDD / max 4A per pin

4

+12V / +24V DC

VDD / max 4A per pin

Pin No

Signal

Description

1

+12V / +24V

VDD / max 5A

2

GND

Ground

Pin No

Signal

Description

1

GND

Ground

2

GND

Ground

3

GND

Ground

4

GND

Ground

5

+12V / +24V DC

VDD / max 3A per pin

6

+12V / +24V DC

VDD / max 3A per pin

7

+12V / +24V DC

VDD / max 3A per pin

8

+12V / +24V DC

VDD / max 3A per pin

11.6. Power Connectors

The OmniView supports three power connector types.

Connector: CN104 – MOLEX 0039303045

Connector: J101 – 2.5mm DC Jack

Connector: CN116 – JST S8B-EH

www.kontron.com 31

Page 33

OmniView – User’s Guide (V1.)

Pin No

Signal

Description

1

Red

Red analog input

2

Green

Green analog input

3

Blue

Blue analog input

4

NC

Not connected (GND)

5

GND (red)

Ground

6

GND (green)

Ground

7

GND (blue)

Ground

8

GND

Ground

9

VGA 5V

+5V DC

10

GND

Ground

11

NC

Not connected

12

SD

Serial Data Line for DDC

13

HSYNC

Horizontal Sync

14

VSYNC

Vertical Sync

15

SCL

Serial clock input for DDC

11.7. VGA Input Connector

Connector: CN101 – 15pin HD-Sub, female

32 www.kontron.com

Page 34

OmniView–User’s Guide (V1)

12. Technical Support

For technical support, please contact our Technical Support department:

Tel: +49 (8341) 803-333

e-mail: support@kontron.com

Web: http://www.kontron.com/support

Make sure you have the following information on hand when you call:

the unit part id number (PN),

the serial number (SN) of the unit; the serial number can be found on the type label, placed on

the right side of the unit.

Be ready to explain the nature of your problem to the service technician.

If you have questions about Kontron or our products and services, you can reach us by the abovementioned telephone number and on e-mail address or at: www.kontron.com.

12.1. Returning Defective Merchandise

Please follow these steps before you return any merchandise to Kontron:

1. Download the corresponding form for returning a device with an RMA No. (Return of Material

Authorization)] from our website www.kontron.com / Support / RMA Information.

You also can contact our Customer Service department to obtain an RMA No.:

e-Mail: service@kontron.com

2. Ensure that you have received an RMA number from Kontron Customer Services before

returning any device. Write this number clearly on the outside of the package.

3. Describe the fault that has occurred.

4. Please provide the name and telephone number of a person we can contact to obtain more

information, where necessary. Where possible, please enclose all the necessary customs

documents and invoices.

5. When returning a device:

Pack it securely in its original box.

Enclose a copy of the RMA form with the consignment.

www.kontron.com 33

Page 35

OmniView – User’s Guide (V1.)

Europe, Middle East &

Africa

Oskar-von-Miller-Str. 1

85386 Eching/Munich

Germany

Tel.: +49 (0)8165/ 77 777

Fax: +49 (0)8165/ 77 219

info@kontron.com

North America

14118 Stowe Drive

Poway, CA 92064-7147

USA

Tel.: +1 888 294 4558

Fax: +1 858 677 0898

info@us.kontron.com

Asia Pacific

17 Building,Block #1,ABP.

188 Southern West 4th

Ring

Beijing 100070, P.R.China

Tel.: + 86 10 63751188

Fax: + 86 10 83682438

info@kontron.cn

Corporate Offices

34 www.kontron.com

Loading...

Loading...