Page 1

AT8901 USER GUIDE

AdvancedTCA

M5301_TECH_2 Manual ID

1.0 Revision Index

1 June, 2006 Date of Issue

Page 2

AT8901 Preface

Revision History

Publication Title: AT8901 User Guide

ID Number: M5301_TECH_2

Rev.

Index

1.0 Initial issue, based on AT8902 User Guide 1 June 2006

Brief Description of Changes Date of Issue

Imprint

Kontron may be contacted via the following:

Kontron Canada, Inc. Kontron Modular Computers GmbH

616 Curé-Boivin Sudetenstrasse 7

Boisbriand, Québec 87600 Kaufbeuren

Canada J7G 2A7 Germany

Tel: (450) 437-5682 Tel: +49 (0) 8341 803 0

(800) 354-4223

Fax: (450) 437-8053 Fax: +49 (0) 8341803 330

E-mail: support@ca.kontron.com E-mail: support-kom@kontron.com

For further information about Kontron, our products or services, please visit our Internet web

site: www.kontron.com

Disclaimer

Copyright © 2006 Kontron AG. All rights reserved. All data is for information purposes only and

not guaranteed for legal purposes. Information has been carefully checked and is believed to

be accurate; however, no responsibility is assumed for inaccuracies. Kontron and the Kontron

logo and all other trademarks or registered trademarks are the property of their respective owners and are recognized. Specifications are subject to change without notice.

Page ii AT8901 User Guide

Page 3

AT8901 Preface

Table of Content

Revision History .........................................................................................................ii

Imprint ........................................................................................................................ii

Disclaimer ..................................................................................................................ii

Proprietary Note ........................................................................................................ix

Trademarks ...............................................................................................................ix

Environmental Protection Statement .........................................................................ix

Explanation of Symbols .............................................................................................x

For Your Safety ..........................................................................................................x

High Voltage Safety Instructions ...........................................................................xi

Special Handling and Unpacking Instructions ......................................................xi

General Instructions on Usage ............................................................................ xii

Two Year Warranty .................................................................................................. xiii

Chapter

1

1. Introduction .................................................................................................. 1 - 2

1.1 Product Overview .................................................................................... 1 - 2

1.1.1 AT8901 Features ............................................................................ 1 - 3

1.1.2 General compliances ...................................................................... 1 - 4

1.1.3 Board Layout .................................................................................. 1 - 5

1.1.4 Optional Accessories ...................................................................... 1 - 6

1.1.5 Hot Swap Capability ....................................................................... 1 - 6

1.1.6 Board Options ................................................................................. 1 - 6

1.2 Technical Specification ........................................................................... 1 - 7

1.3 Software Support ................................................................................... 1 - 11

Chapter

2

2. Installation ................................................................................................... 2 - 2

2.1 Safety Requirements ............................................................................... 2 - 2

2.2 AT8901 Initial Installation Procedures ..................................................... 2 - 3

2.3 Standard Removal Procedures ............................................................... 2 - 4

2.4 AMC Installation ...................................................................................... 2 - 4

Page iii AT8901 User Guide

Page 4

AT8901 Preface

2.5 Software Installation ................................................................................ 2 - 4

2.6 CLI Quick Start ........................................................................................ 2 - 4

Chapter

3

3. Hardware Description .................................................................................. 3 - 2

3.1 CPU and Memory .................................................................................... 3 - 3

3.2 Base Switch ............................................................................................ 3 - 6

3.3 AMC Bays ............................................................................................... 3 - 9

3.4 IPMI ....................................................................................................... 3 - 11

3.5 Synchronization Clock ........................................................................... 3 - 12

3.6 RTM Interface ........................................................................................ 3 - 13

3.7 Power Supply ........................................................................................ 3 - 14

3.7.1 Power Connector .......................................................................... 3 - 14

3.7.2 Power Distribution ......................................................................... 3 - 15

3.7.3 Power Supply AMCs ..................................................................... 3 - 16

3.7.4 Power Supply RTM ....................................................................... 3 - 16

3.7.5 Power Transients .......................................................................... 3 - 16

3.7.6 Optional Chassis to Logic Ground Connection ............................. 3 - 17

3.8 Reset ..................................................................................................... 3 - 17

3.9 Jumpers ................................................................................................ 3 - 17

3.10 Display Elements ................................................................................... 3 - 18

Chapter

4

4. Software Description ................................................................................... 4 - 2

4.1 Supported RFCs ..................................................................................... 4 - 2

4.1.1 Management ................................................................................... 4 - 2

4.1.2 Switching ........................................................................................ 4 - 4

4.1.3 Routing ........................................................................................... 4 - 5

4.1.4 QoS ................................................................................................. 4 - 6

4.2 Supported MIBs ...................................................................................... 4 - 6

4.2.1 Enterprise MIB ................................................................................ 4 - 6

Page iv AT8901 User Guide

Page 5

AT8901 Preface

4.2.2 Switching Package MIBs ................................................................ 4 - 7

4.2.3 Routing Package MIBs ................................................................... 4 - 7

4.2.4 QoS Package MIB .......................................................................... 4 - 7

4.3 Bootloader ............................................................................................... 4 - 7

4.3.1 Power On Self Test ......................................................................... 4 - 8

4.4 IPMI Firmware ....................................................................................... 4 - 10

4.4.1 Sensor Data Record (SDR) .......................................................... 4 - 11

4.4.2 Field Replaceable Unit (FRU) Information .................................... 4 - 14

4.4.3 E-Keying ....................................................................................... 4 - 14

4.4.4 IPMC Firmware Code ................................................................... 4 - 14

4.4.5 LEDs ............................................................................................. 4 - 15

4.4.6 Hot Swap Process ........................................................................ 4 - 16

4.5 Firmware Administration ....................................................................... 4 - 17

4.5.1 Startup Configurations .................................................................. 4 - 18

4.5.2 Updating Firmware ....................................................................... 4 - 19

4.5.3 Updating IPMI ............................................................................... 4 - 22

Appendix

A. Getting Help ................................................................................................ A - 2

A

Page v AT8901 User Guide

Page 6

AT8901 Preface

List of Tables

1-1 Fabric Interface Options ............................................................................. 1 - 6

1-2 Base Interface Options .............................................................................. 1 - 6

1-3 AT8901 Main Specifications ....................................................................... 1 - 7

1-4 AT8901 Software Specification .................................................................1 - 11

3-1 PCI Slots .................................................................................................... 3 - 3

3-2 Fast Ethernet Management (RJ45) Pin Assignment .................................. 3 - 4

3-3 Fast Ethernet Management (RJ45) LEDs Signification ............................. 3 - 4

3-4 Serial Port (RJ45) Pin Assignment ............................................................ 3 - 5

3-5 Serial console terminal cable interface: RJ45 Female to DB9 Female ..... 3 - 5

3-6 Base Interface Port Mapping ..................................................................... 3 - 6

3-7 Base Uplink (J27) Pin Assignment ............................................................. 3 - 7

3-8 Base Uplink (J27) LEDs Signification ........................................................ 3 - 7

3-9 AMC Bay Address ...................................................................................... 3 - 9

3-10 AMC B1 Channel Assignment ................................................................... 3 - 9

3-11 AMC B2 Channel Assignment ................................................................. 3 - 10

3-12 J30 Pin Assignment ................................................................................. 3 - 13

3-13 J31 Pin Assignment ................................................................................. 3 - 14

3-14 Power Connector (P10) ........................................................................... 3 - 15

3-15 Power Transients ..................................................................................... 3 - 16

3-16 Jumper Settings ( • Default Setting) ......................................................... 3 - 17

3-17 ATCA LEDs Signification ......................................................................... 3 - 19

3-18 Backplane Link LEDs Signification .......................................................... 3 - 20

3-19 Switch LED Assignment ........................................................................... 3 - 21

4-1 POST routines and error codes ................................................................. 4 - 8

4-2 POST Boot Steps ....................................................................................... 4 - 9

4-3 AT8901 sensors ........................................................................................4 - 11

4-4 LED state ................................................................................................. 4 - 15

4-5 OOS LED state ........................................................................................ 4 - 15

4-6 Health LED state ...................................................................................... 4 - 16

4-7 FLASH Partition Scheme (64MB) ............................................................ 4 - 17

Page vi AT8901 User Guide

Page 7

AT8901 Preface

List of Figures

1-1 AT8901 Board ......................................................................................... 1 - 5

3-1 Functional Block Diagram Base Board ...................................................... 3 - 2

3-2 Block Diagram AMC GbE Cross-connect via update channels ................. 3 - 8

3-3 Front Panel of AT8901 ............................................................................. 3 - 18

3-4 Symbols Chart ......................................................................................... 3 - 19

3-5 Backplane Switch LEDs Signification ...................................................... 3 - 20

Page viii AT8901 User Guide

Page 8

AT8901 Preface

Proprietary Note

This document contains information proprietary to Kontron AG. It may not be copied or transmitted by any means, disclosed to others, or stored in any retrieval system or media without

the prior written consent of Kontron AG or one of its authorized agents.

The information contained in this document is, to the best of our knowledge, entirely correct.

However, Kontron AG cannot accept liability for any inaccuracies or the consequences thereof,

or for any liability arising from the use or application of any circuit, product, or example shown

in this document.

Kontron AG reserves the right to change, modify, or improve this document or the product described herein, as seen fit by Kontron AG without further notice.

Trademarks

Kontron AG and the Kontron logo are trade marks owned by Kontron AG, Germany. In addition,

this document may include names, company logos and trademarks, which are registered trademarks and, therefore, proprietary to their respective owners.

Environmental Protection Statement

This product has been manufactured to satisfy environmental protection requirements where

possible. Many of the components used (structural parts, printed circuit boards, connectors,

batteries, etc.) are capable of being recycled.

Final disposition of this product after its service life must be accomplished in accordance with

applicable country, state, or local laws or regulations.

Page ix AT8901 User Guide

Page 9

AT8901 Preface

Explanation of Symbols

CE Conformity

This symbol indicates that the product described in this manual is in compliance with all applied CE standards. Please refer also to the section “Applied

Standards” in this manual.

Caution, Electric Shock!

This symbol and title warn of hazards due to electrical shocks (> 60V) when

touching products or parts of them. Failure to observe the precautions indicated and/or prescribed by the law may endanger your life/health and/or

result in damage to your material.

Please refer also to the section “High Voltage Safety Instructions” on the following page.

Warning, ESD Sensitive Device!

This symbol and title inform that electronic boards and their components are

sensitive to static electricity. Therefore, care must be taken during all handling operations and inspections of this product, in order to ensure product

integrity at all times.

Please read also the section “Special Handling and Unpacking Instructions”

on the following page.

Warning!

This symbol and title emphasize points which, if not fully understood and

taken into consideration by the reader, may endanger your health and/or

result in damage to your material.

Note...

This symbol and title emphasize aspects the reader should read through

carefully for his or her own advantage.

For Your Safety

Your new Kontron product was developed and tested carefully to provide all features necessary to ensure its compliance with electrical safety requirements. It was also designed for a

long fault-free life. However, the life expectancy of your product can be drastically reduced by

improper treatment during unpacking and installation. Therefore, in the interest of your own

safety and of the correct operation of your new Kontron product, you are requested to conform

with the following guidelines.

Page x AT8901 User Guide

Page 10

AT8901 Preface

High Voltage Safety Instructions

Warning!

All operations on this device must be carried out by sufficiently skilled personnel only.

Caution, Electric Shock!

High voltages are present inside the chassis when the unit’s power cord is

plugged into an electrical outlet. Turn off system power, turn off the power

supply, and then disconnect the power cord from its source before removing

the chassis cover. Turning off the system power switch does not remove

power to components.

Special Handling and Unpacking Instructions

ESD Sensitive Device!

Electronic boards and their components are sensitive to static electricity.

Therefore, care must be taken during all handling operations and inspections

of this product, in order to ensure product integrity at all times.

Do not handle this product out of its protective enclosure while it is not used for operational purposes unless it is otherwise protected.

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations. Where

a safe work station is not guaranteed, it is important for the user to be electrically discharged

before touching the product with his/her hands or tools. This is most easily done by touching a

metal part of your system housing.

It is particularly important to observe standard anti-static precautions when changing mezzanines, ROM devices, jumper settings etc. If the product contains batteries for RTC or memory

back-up, ensure that the board is not placed on conductive surfaces, including anti-static plastics or sponges. They can cause short circuits and damage the batteries or conductive circuits

on the board.

Page xi AT8901 User Guide

Page 11

AT8901 Preface

General Instructions on Usage

In order to maintain Kontron’s product warranty, this product must not be altered or modified in

any way. Changes or modifications to the device, which are not explicitly approved by Kontron

AG and described in this manual or received from Kontron’s Technical Support as a special

handling instruction, will void your warranty.

This device should only be installed in or connected to systems that fulfill all necessary technical and specific environmental requirements. This applies also to the operational temperature

range of the specific board version, which must not be exceeded. If batteries are present their

temperature restrictions must be taken into account.

In performing all necessary installation and application operations, please follow only the instructions supplied by the present manual.

Keep all the original packaging material for future storage or warranty shipments. If it is necessary to store or ship the board please re-pack it as nearly as possible in the manner in which it

was delivered.

Special care is necessary when handling or unpacking the product. Please, consult the special

handling and unpacking instruction on the previous page of this manual.

Page xii AT8901 User Guide

Page 12

AT8901 Preface

Two Year Warranty

Kontron AG grants the original purchaser of Kontron’s products a TWO YEAR LIMITED HARDWARE

WARRANTY

implied by anyone on behalf of Kontron are valid unless the consumer has the express written

consent of Kontron AG.

Kontron AG warrants their own products, excluding software, to be free from manufacturing

and material defects for a period of 24 consecutive months from the date of purchase. This warranty is not transferable nor extendible to cover any other users or long-term storage of the

product. It does not cover products which have been modified, altered or repaired by any other

party than Kontron AG or their authorized agents. Furthermore, any product which has been,

or is suspected of being damaged as a result of negligence, improper use, incorrect handling,

servicing or maintenance, or which has been damaged as a result of excessive current/voltage

or temperature, or which has had its serial number(s), any other markings or parts thereof altered, defaced or removed will also be excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in the event of any claim, he may

return the product at the earliest possible convenience to the original place of purchase, together with a copy of the original document of purchase, a full description of the application the

product is used on and a description of the defect. Pack the product in such a way as to ensure

safe transportation (see our safety instructions).

as described in the following. However, no other warranties that may be granted or

Kontron provides for repair or replacement of any part, assembly or sub-assembly at their own

discretion, or to refund the original cost of purchase, if appropriate. In the event of repair, refunding or replacement of any part, the ownership of the removed or replaced parts reverts to

Kontron AG, and the remaining part of the original guarantee, or any new guarantee to cover

the repaired or replaced items, will be transferred to cover the new or repaired items. Any extensions to the original guarantee are considered gestures of goodwill, and will be defined in

the “Repair Report” issued by Kontron with the repaired or replaced item.

Kontron AG will not accept liability for any further claims resulting directly or indirectly from any

warranty claim, other than the above specified repair, replacement or refunding. In particular,

all claims for damage to any system or process in which the product was employed, or any loss

incurred as a result of the product not functioning at any given time, are excluded. The extent

of Kontron AG liability to the customer shall not exceed the original purchase price of the item

for which the claim exists.

Kontron AG issues no warranty or representation, either explicit or implicit, with respect to its

products’ reliability, fitness, quality, marketability or ability to fulfil any particular application or

purpose. As a result, the products are sold “as is,” and the responsibility to ensure their suitability for any given task remains that of the purchaser. In no event will Kontron be liable for

direct, indirect or consequential damages resulting from the use of our hardware or software

products, or documentation, even if Kontron were advised of the possibility of such claims prior

to the purchase of the product or during any period since the date of its purchase.

Please remember that no Kontron AG employee, dealer or agent is authorized to make any

modification or addition to the above specified terms, either verbally or in any other form, written

or electronically transmitted, without the company’s consent.

Page xiii AT8901 User Guide

Page 13

AT8901 Introduction

Chapter

1

Introduction

Page 1 - 1 AT8901 User Guide

Page 14

AT8901 Introduction

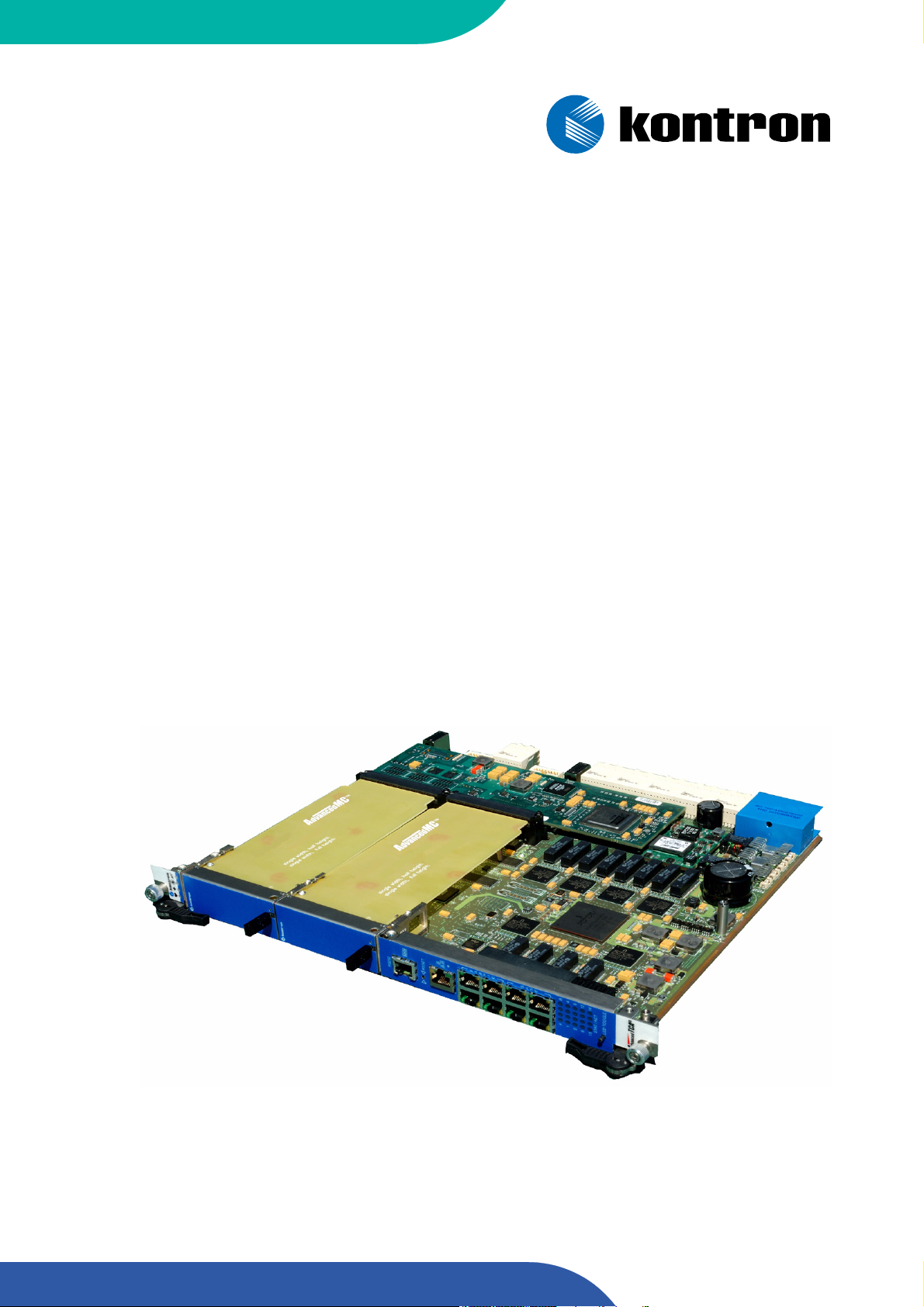

1. Introduction

The Board described in this manual is designed for the Advanced Telecom Computing Architecture (AdvancedTCA® or ATCA) defined by the PCI Industrial Computer Manufacturers

Group (PICMG). The main advantages of AdvancedTCA include high throughput, multi-protocol support, high-power capability, hot swappability, high scalability and integrated system

management. For further information regarding the AdvancedTCA standards and their use,

please consult the complete AdvancedTCA specification or visit the PICMG web site.

1.1 Product Overview

The Kontron AT8901 is a PICMG 3.0 compliant Hub Board for AdvancedTCA shelves, designed according to the RoHS directive. Suitable for 14 and 16 slot systems, it also provides 2

AMC slots for customization. This unique versatile design allows cost-optimised tailoring to the

requirements of the application.

The Base Interface switch provides Gigabit Ethernet services on Base Channels 2-16 and Fast

Ethernet to the Shelf Managers. AMC slots can be equipped with

• Processor-AMC, e.g. acting as the system controller (saving one ATCA slot)

• Storage-AMC as mass storage device for the Processor-AMC

• SETS-AMC providing network synchronisation for telecom applications

Performance

The AT8901 employs leading-edge switching technology providing full wire-speed throughput

at all load conditions. A powerful control processor runs higher layer protocols based on the

market leading LVL7 software suite.

Management

The AT8901 is managed either in-band or out of band via 10/100 Ethernet or RS232 management ports. The comprehensive set of supported protocols rounds out the feature set of Kontrons' second generation AdvancedTCA Hub Board.

Page 1 - 2 AT8901 User Guide

Page 15

AT8901 Introduction

1.1.1 AT8901 Features

PICMG 3.0 compliant Hub Board

• Supports Base Interface (GbE)

• For 14 and 16 slot shelves

• 2 AMC slots for customization

• Uplinks for Base Interface

• Comprehensive protocol support

• Full Hot-Swap capabilities

• Full Redundancy support

Base Interface (PICMG 3.0)

• Non-blocking layer 2/3 switching/routing

• 4x10/100/1000BASE-T uplinks on front panel

• 2xGbE connection to AMC slot B1

• 1xGbE connection to AMC slot B2

Management and Protocols

• Management via SNMP, TELNET, CLI

• In-band

• Out of band via Ethernet or RS232

• IPMI version 1.5

• Ethernet/Bridging protocols include

• Link aggregation (802.3ad)

• VLANs (802.1Q)

• Spanning tree (802.1D, 802.1w)

• QoS (802.1p)

• Flow control (802.3x)

•GVRP, GMRP

Page 1 - 3 AT8901 User Guide

Page 16

AT8901 Introduction

• Routing protocols include

• OSPFv2

•RIPv2

•VRRP

•DiffServ

•ARP

1.1.2 General compliances

The AT8901 conforms to the following specifications:

• PICMG 3.0 AdvancedTCA Base Specification, Revision 2.0

• AMC.0 AMC Base Specification

• AMC.2 AMC Gigabit Ethernet / 10 Gigabit XAUI Ethernet

• AMC.3 AMC Storage

• IPMI v1.5 Intelligent Platform Management Interface Specification

Page 1 - 4 AT8901 User Guide

Page 17

AT8901 Introduction

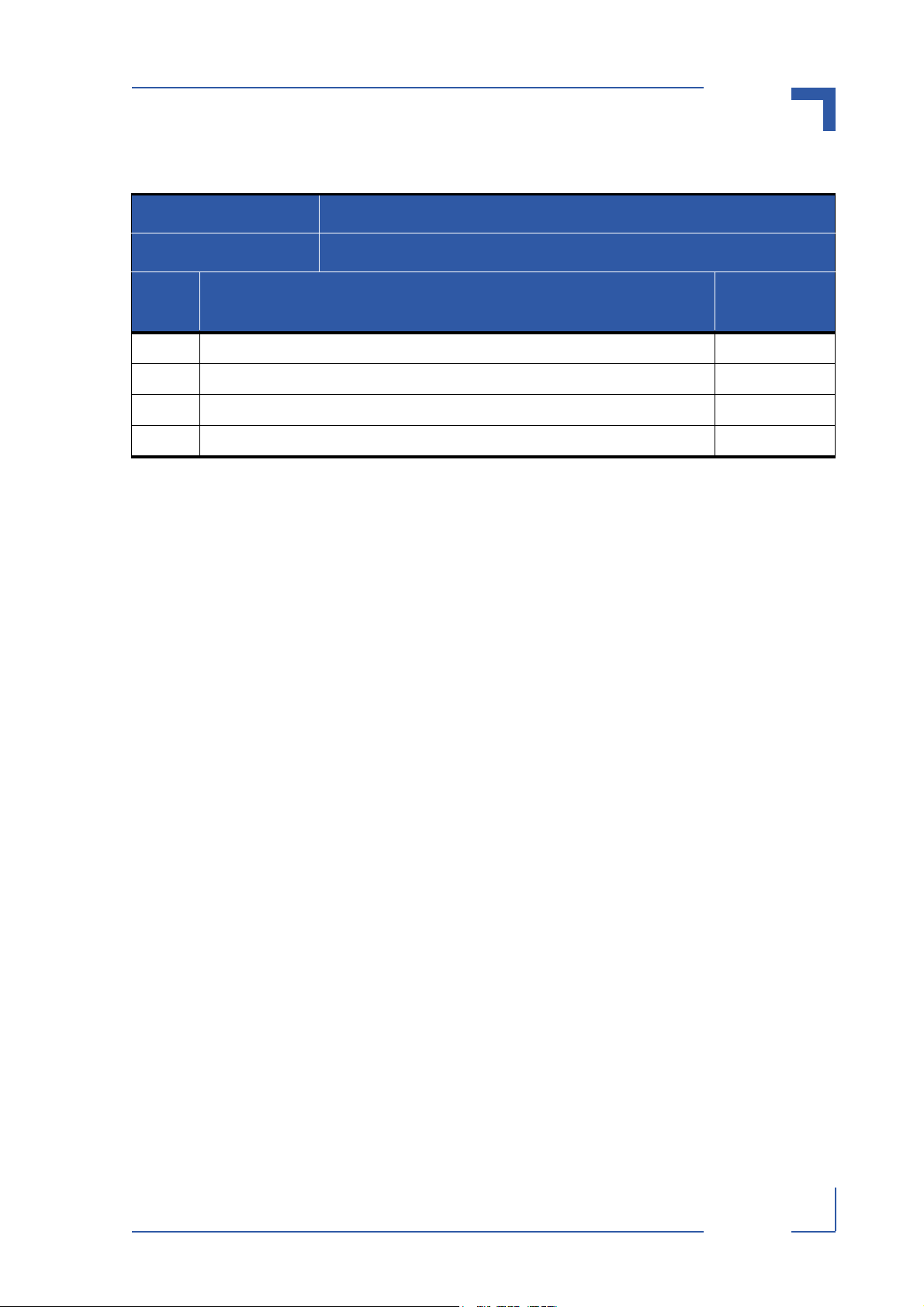

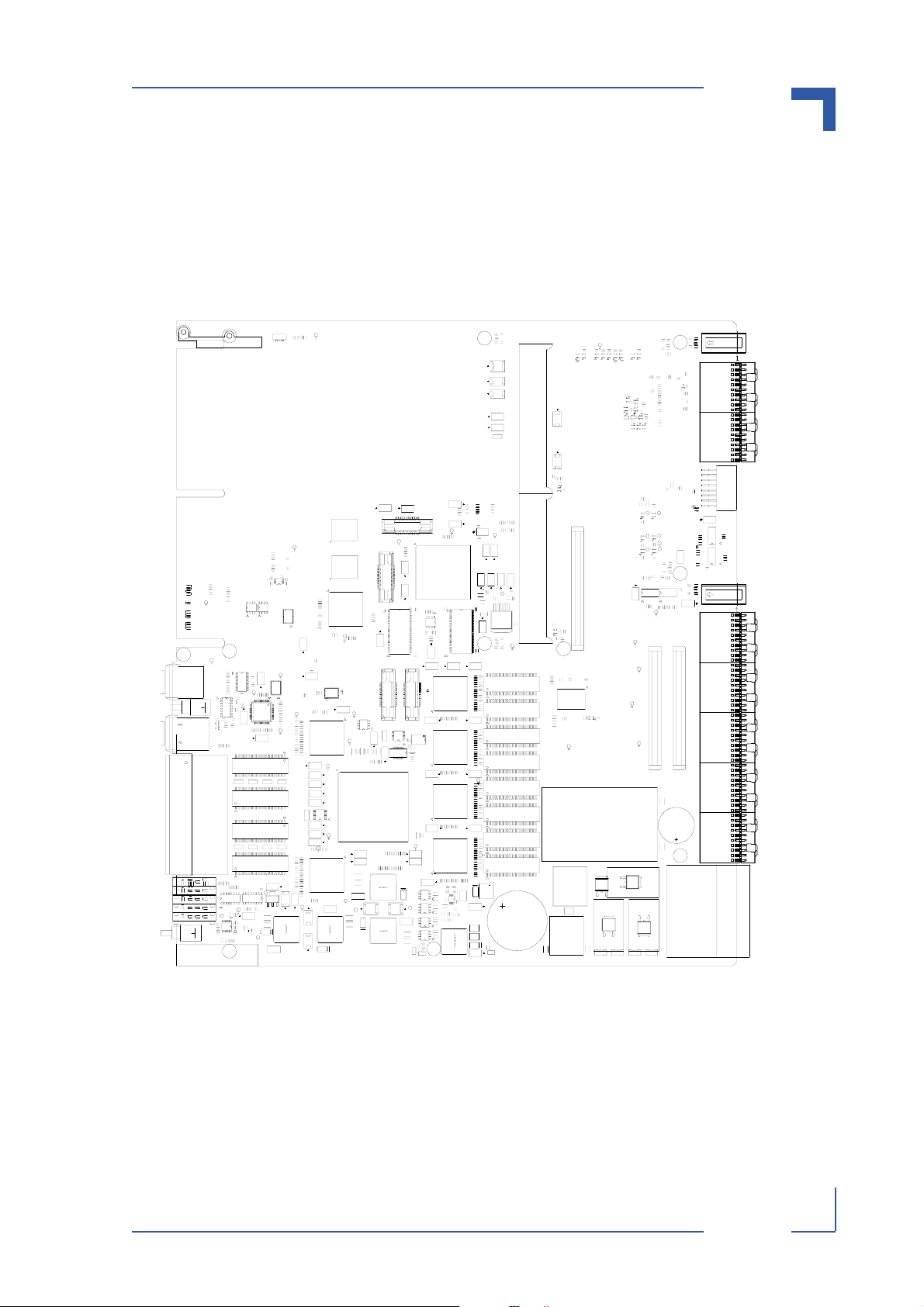

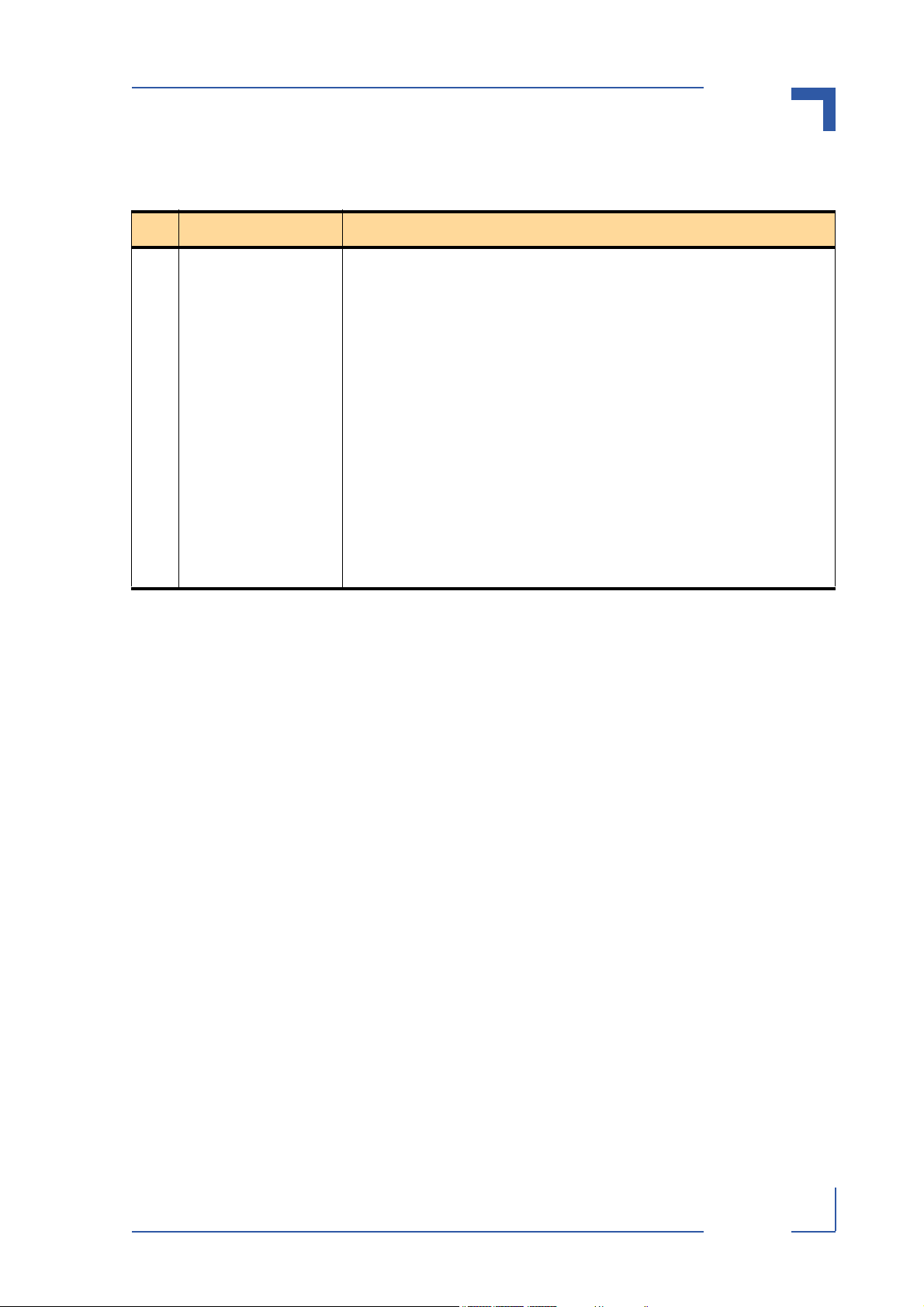

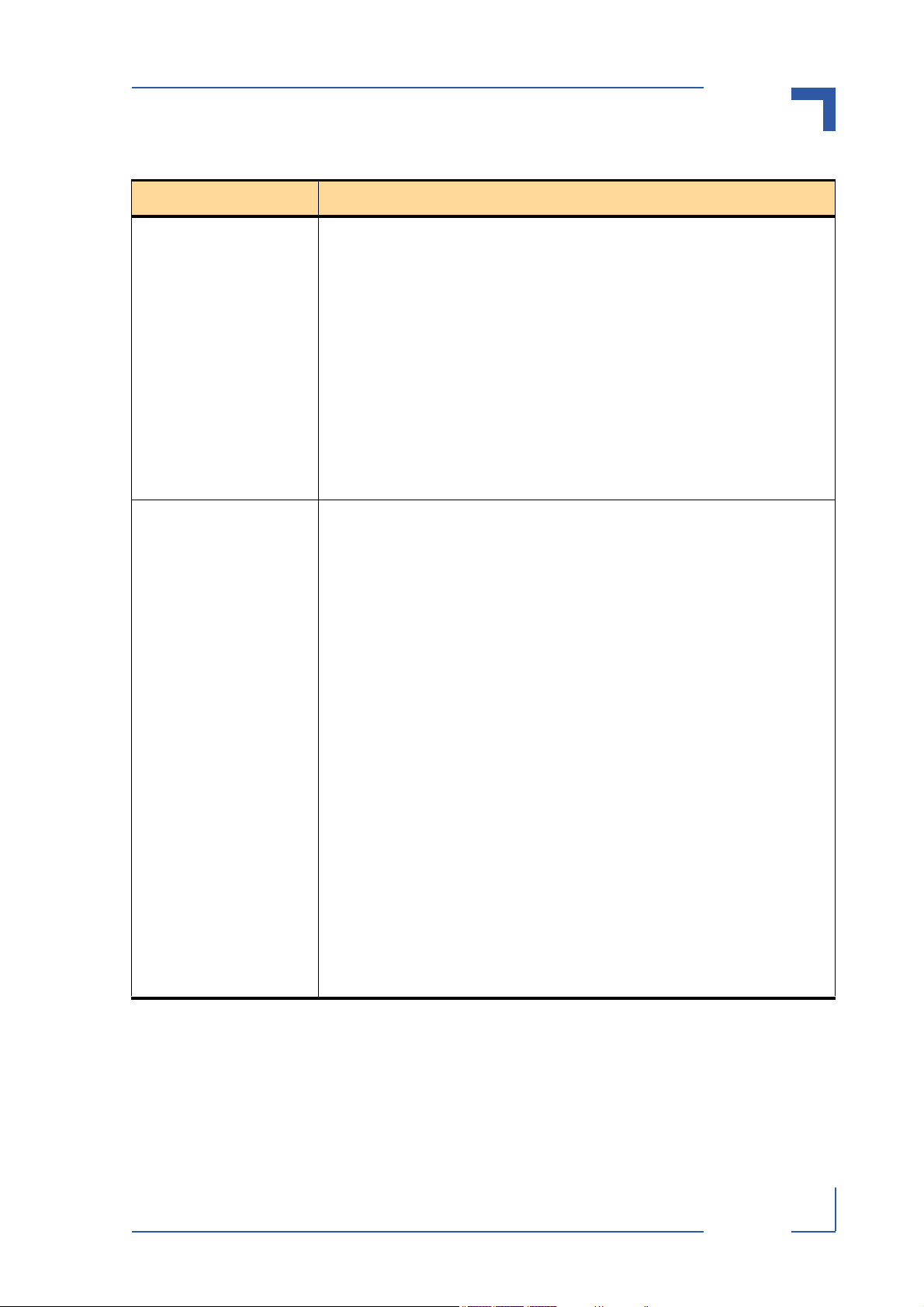

1.1.3 Board Layout

The following figure shows a top view of the AT8901 board.

Figure 1-1: AT8901 Board

MTG1

MTG2

R68

D1

R71

R70

D2

R74

R72

D3

R75

D4

R73

R78

C47

D5

D6

D7

D8

D9

D10

D11

MTG8

MATING

J37

SW1

J36

MATING

U4

MTG7

R1347

R1335

U120

R1336

R1342

R1337

R1343

R1334

R1333

C860

C81

R148

U12

R149

L3

R157

C90

C89

C88

R162

D12

L5

C102

D13

C104

L6

R194

R195

R196

R197

C139

J27

C172

D16

D14

R273

R274

R275

R276

D20

D19

D18

D21

D15

LP9

D23

LP8

D30

LP7

D33 D38D17 D22 D29

D34

LP6

D39

LP5

SW2

X1

C209

R279

R280

R281

D24

D25

U26

D32

D31

D35

D40

C220

R304

D36

R312 C236

Q2

C225

D41

R317

R316

C235

C230

U32

U31

C234

R319

R320

R322

R321

C237

C244

C241

R329

C246

MTG11

C248

C249

C250

C251

C247

J1

C19

U14

C117

L9

L8

C180

C183

D44

J13

C818

R93

R94

R97

R98

C819

C65

JP8

C108

C119

C118

L10

C120

R213

R212

R214

R211

U20

R241

R1044

R1045

R1042

R1043

L15

C221 C222

L19

J10

R51

R52

R53

R55

R56

C35

C44

U96

J32

U16

L7

U18

R248

R249

R242

R244

R245

R243

R246

R247

R1035

R1040

R1038

R1039

R1036

R1037

R1041

D27

R313

C238

C240

U1

R54

R57

R58

C31

R59

C34

R62

R63

R64

R67

C36

R65

R66

U53

U5

Y1

C73

C879

R1351

Y2

R1352

R140

R137

R138

R136

R139

R145

R150

R151

R154

R158

U13

R161

R163

R164

C91

R166

C103

R175

R174

R172

R177

R176

R171

R169

R170

C105

C107

C110

C111

C113

C115

C122

T4

C141

C140

C142

T7

T9

C174

C175

C173

C182

C187

T11

C189

C191

C194

C206

C210

C211

4

C215

C214

U27

U28

R306

R305

3

12

C227

C231

D45

L17

R326

U2

R80

R82

R83

R84

U6

R92

R101

R103

R1362

R110

R111

R113

R112

C56

R1387

C59

R1360

C69

C70

C78

C76

C77

R142

R141

Y3

C82

R160

R159

L4

C87

C85

R165

R167

R168

R173

R178

R179

R182

R183

U15

R186

R187

R191

R192

R198

R199

R203

R206

JP10

R253

R254

R257

R258

R261

R262

R264

R267

R268

R269

R270

R277

R278

R282

R288

R289

C212

C116

C127

C136

C143

C146

C150

U21

C155

C167

C169

R238

C176

R237

L12 R294

U24

C192

C207

R290

C216

R293

R307

C226

C228

C232

C239

L18

D47

C824

C20

C22

R48

R49

R50

R47

R46

++

U3

C50

C49

C48

C815

R99

R100

U66

R1292

R105

R106

C822

C823

L69

C825

C63

C62

C67

C66

++

J33

U11

C96

C94

C93

C95

C97

C98

C92

R188

Y4

R200

U17

C857

L70

C853

C840

C129

C128

C130

C132

C133

C131

C137

U19

C159

C158

C160

C163

C162

C161

C157

C170

L11

C181

U23

C185

C200

C198

C197

C195

C196

C199

C208

R1244

R1242

R1243

U25 U29

R291

R297

U85

R295

D37

R308

C213

R1165

C753

R1185

R311

R1142

R1143

R309

R314

R318

R323

U33U30

L20

R324

C245

C242

R330

R327

MTG10

R331

C2

R1

C1

MTG3

C3

C7

R4

B85

C936

B86

R1400

R1414

R1377

U138

U129

R1388

R1350

R1368

R1413

R1415

U141

U126

U112

U128

U123

U125

U110

R1301

R1303

C954

C955

B1

C939

C940

C953

C15

C872

U114

U119

R20

R22

C917

C867

U117

U137

R1393

C864

C865

R1300

U118

U106

U116

R379

U145

U147

U144

C16

R1397

R29

C17

B1

R1419

B170

C919

U136

R32

R33

C18

R34

R35

C821

R37

C820

R36

C816

L68

C26

C27

L2

C37

U99

R1358

C51

+

U95

C64

C68

C71

R120

R123

R124

C74

R128

C75

R129

R131

R134

C79

R135

R143

C80

R144

R146

R147

C83

R152

C84

R153

R155

R156

C86

C100

C99

C101

R180

C106

R181

R184

C109

R185

R189

C112

R190

R193

C114

R201

R202

R204

C121

R205

R207

C124

R208

R209

C125

R210

R215

C126

C135

C134

C138

R216

C144

R217

R218

C145

R219

R220

C147

R221

R222

C148

R223

R224

R225

C151

R227

R228

C152

R229

R230

C153

R231

R232

C154

C165

C164

C166

R233

C168

R234

R235

C171

R236

R239

C177

R240

R250

C179

R251

R252

R255

C186

R256

C188

R259

R260

R263

C190

R265

R266

C193

R272

C203

C202

R271

C201

R315

D26

C810

C787

C217

R292

C752

C809

C808

D28

C243

B85

L85

R1406

C28

C53

+

+

C38

+

C877

R79

R96

R95

C52

R114

C57

MTG6

C60

R117

B86

C25

R40

R41

R38

R39

C24

R45

R44

R43

R42

B2

C40

C39

R76

R81

Q1

U7

R102

B1

C58

C61

T1

T2

T3

J14

R1396

R107

C55

U142

C916

B170

R115

R116

R1437

C984

C970

C968

C975

C969

U148

R1433

R1436

R1425

R1422

U146

C966

R1432

C967

C985

C986

T5

T6

T8

T10

T12

L16

+

C229

D135

+

R333

21

43

L14

C204

43

21

L13

C727

C746

R1320

Q28

R1356

U102

R1297

U101

R1298

U104

R1295

R518

C906

C912

U131

R519

U22

D43

Q16

HS2

HS1

D129

D42

F4

F1

F2

R3

C5

C4

R2

C6

MTG4

C8

C11

R5

C10

R9

R8

R13

R12

R10

R11

R1412

R344

R1434

R15

R16

R17

R18

R19

R21

R23

R24

R1311

C256

C258

ANC1

C9

R6

C12

R1319

R1411

R1402

D137

R1304

R1309

R1307

R1306

R1308

PCB EDGE

J30

J31

Q29

R1410

R1416

R1417

R1299

U113

U103

R1296

MTG12

U105

R1294

C30

R61

C33

C32

C29

R60

MTG5

R1380

R1381

R511

C909

C316

U133

R1369

R517

C905

R1374

C904

C329

C339

J11

R1355

R1325

D146

C41

U151

R1458

C989

R1457

C988

C910

C993

R1385

R1409

U134

R1384

R1372

R1376

C907

C994

R69

C42

C902

C43

C46

R77

C45

ANC2

C913

PCB EDGE

J20

J21

J34

J35

J22

J23

C149

C156

J24

C178

MTG9

HS3

P10

F3

Page 1 - 5 AT8901 User Guide

Page 18

AT8901 Introduction

1.1.4 Optional Accessories

1.1.4.1 AMC

Two standard full height single width AMC bays for standard or custom AMCs are implemented.

AMC slots can be equipped with a

• Processor-AMC, e.g. acting as the system controller (saving one ATCA slot)

• HDD-AMC as mass storage device for the Processor-AMC

• SETS-AMC providing network synchronisation for telecom applications

1.1.4.2 RTM

RTM is optional. For further information on RTM, please refer to Chapter 3, section 3.6. and

visit our web site at www.kontron.com.

1.1.5 Hot Swap Capability

The board supports Full Hot Swap capability as required by PICMG 3.0 R1.0. It can be removed from or installed in the system while it is on (without powering-down the system). Please

refer to the PICMG 3.0 R1.0 specification for additional details.

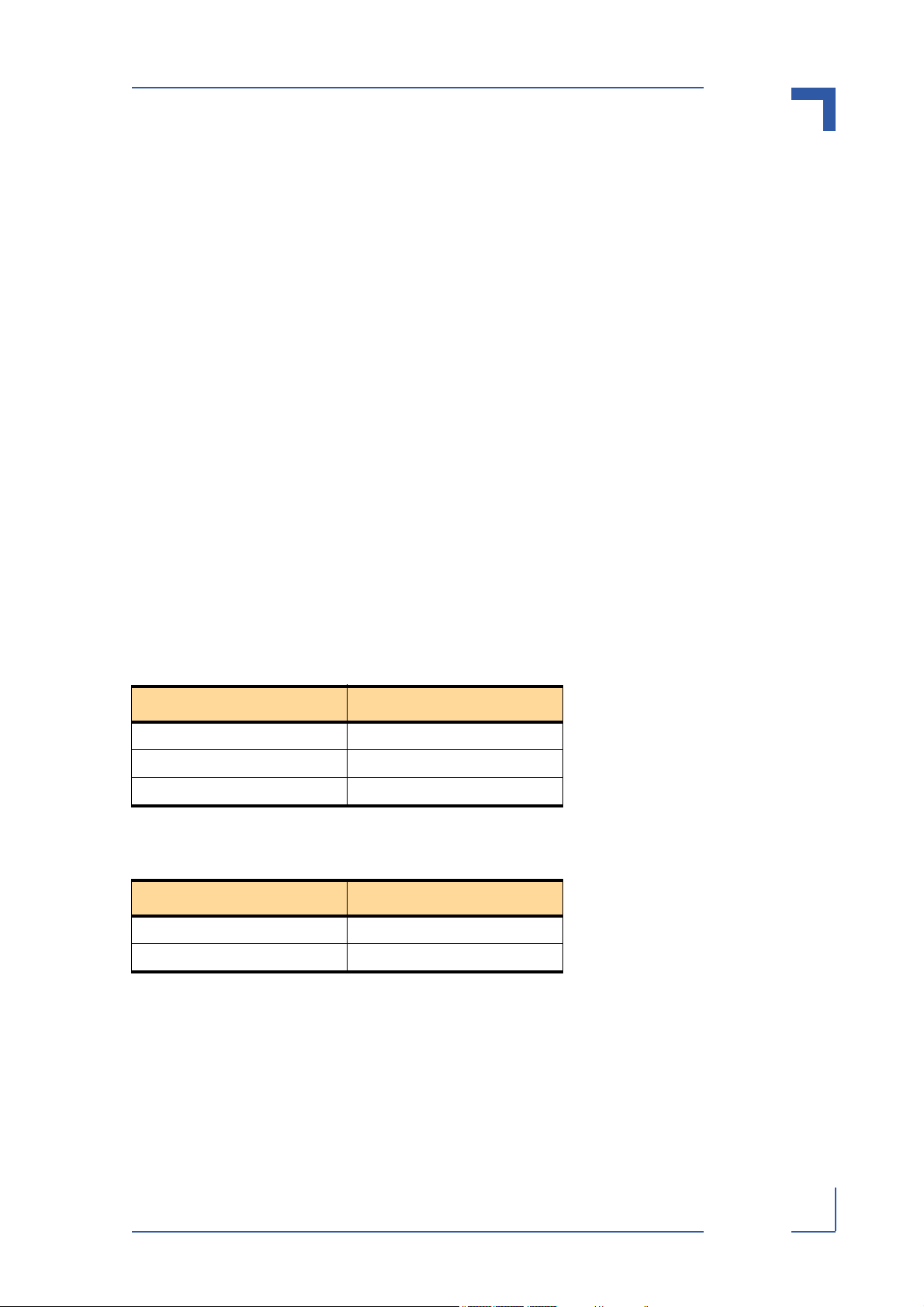

1.1.6 Board Options

The Kontron ATCA Hub family is available with different Fabric Mezzanine options:

Table 1-1: Fabric Interface Options

Product Fabric Interface

AT8901 none

AT8902 Gigabit Ethernet

AT8903 Advanced Switching

The Base Interface switch can be one of the following:

Table 1-2: Base Interface Options

Base Switch AT8901 Flavour

BCM56500 Full featured (enhanced QoS)

BCM56300 Lite featured

Page 1 - 6 AT8901 User Guide

Page 19

AT8901 Introduction

1.2 Technical Specification

Table 1-3: AT8901 Main Specifications

AT8901 SPECIFICATIONS

PowerPC IBM PPC 405

GPr 400MHz

Processor and Memory

• IBM PowerPC® 405 32-bit RISC processor core operating up to 400MHz with

16KB I- and D-caches

• PC-133 synchronus DRAM (SDRAM) interface

• 40-bit interface serves 32 bits of data plus 8 check bits for ECC applications

• 4KB on-chip memory (OCM)

• DMA support for external peripherals, internal UART and memory

• Scatter-gather chaining supported

• Four channels

• PCI Revision 2.2 compliant interface (32-bit, up to 66MHz)

• Ethernet 10/100Mbps (full-duplex) support with media independent interface

(MII)

• Two serial ports (16550 compatible UART)

• Internal processor local Bus (PLB) runs at SDRAM interface frequency

• IEEE 1149.1 (JTAG) boundary scan

Page 1 - 7 AT8901 User Guide

Page 20

AT8901 Introduction

Table 1-3: AT8901 Main Specifications (Continued)

AT8901 SPECIFICATIONS

Broadcom 5650x/5630x

GbE Switch

Ethernet

Broadcom 5466R

PHY

• 24 10/100/1000 Mbps Ethernet ports

• Fifth generation of StrataSwitch and StrataXGS product line

• Line-rate switching for all packet sizes and conditions

• On-chip data packet memory and table memory

• IPv6 routing and tunneling

• Advanced Fast Filter Processor (FFP) Content Aware classification

• Advanced security features in hardware

• Port-trunking and mirroring supported across stack

• Advanced packet flow control:

• Head-of-line-blocking prevention

• Back pressure support

• Eight QoS queues per port with hierarchical minimum/maximum shaping per

Class of Service (CoS) per queue per port

• Standard compliant 802.1ad provider bridging

• IEEE 1149.1 (JTAG) boundary scan

• Advanced power management Line-side and MAC-side loopback

• Ethernet@WireSpeed

• Cable plant diagnostics that detects cable plant impairments

• Automatic detection and correction of wiring pair swaps, pair skew, and pair po-

larity

• Robust CESD tolerance and low EMI emissions

• Support for jumbo packets up to 10 KB in size

• IEEE 1149.1 (JTAG) boundary scan

Backplane (Zone 2) • Base channel 1: 2 x Ethernet to ShMCs (10/100BASE-T)

• Base channels 2-16: 1 x GbE (1000BASE-T)

• CLK 1/2/3 (A/B)

• Update channels: 2 x GbE (1000BASE-BX)

RTM (Zone 3)

• 8 generic RTM channels from AMC Slot B1, 4 from B2

• SAS/SATA/FC interface for mass storage from each AMC Slot

Interfaces

• I2C IPMI connection

Front panel

• Serial port for management of PPC

• Fast Ethernet for management of PPC

• 4 RJ45 10/100/1000BASE-T Base Interface Uplinks

Page 1 - 8 AT8901 User Guide

Page 21

AT8901 Introduction

Table 1-3: AT8901 Main Specifications (Continued)

AT8901 SPECIFICATIONS

Mechanical • 8U form factor mechanically compliant to PICMG 3.0

• Single Slot (6HP)

• 2 standard full height/single width AMC Slots

• 280 mm x 322 mm (11.024“ x 12.677“)

• Weight: 1.9 kg (4.2 Ibs)

Power Requirements

• Typical: 45W

• Maximum (with 2 AMCs and RTM): 150W

• AMCs may consume up to 75W

• Operating Voltage: -38 to -72VDC

Temperature Designed to meet or exceed the following (Characteristics with AMC):

• Air Flow: 30 CFM min

• Operating: 0°C to +55°C (32°F to 131°F)

• Non-operating: -40°C to +70°C (-40°F to 158°F)

Humidity Designed to meet or exceed the following:

General

• Bellcore GR63, Section 4.1

• Operating: 15%-90% (non-condensing) at 55°C (131°F)

• Non-Operating: 5%-95% (non-condensing) at 40°C (104°F)

Altitude Designed to meet or exceed the following:

• Operating: 4000 m (13123 ft))

• Non-Operating: 15000m (49212 ft)

Vibration Designed to meet or exceed the following:

• Bellcore GR-63, Section 4.4

• Operating: 1.0G, 5-500Hz each axis

• Non-operating: 0.5G, 5-50Hz; 3.0G, 50-500Hz each axis

Shock Designed to meet or exceed the following:

• DIN/IEC 60068-2-27

• Bellcore GR-63, Section 4.3

• 30G, half-sine 11ms, each axis

Page 1 - 9 AT8901 User Guide

Page 22

AT8901 Introduction

Table 1-3: AT8901 Main Specifications (Continued)

AT8901 SPECIFICATIONS

Safety Designed to meet or exceed the following:

• UL 60950, 3rd edition

• EN 60950

• LVD 73/23/EEC

• Denan Law

EMC Designed to meet or exceed the following:

General

• FCC 47 CFR Part 15, Subpart B

• EN55022, EN55024

• EN 300 386

Reliability

LEDs • ATCA LEDs:

• MTBF: >200,000 hours @ 40°C / 104°F (Telcordia SR-332, Issue 1)

• 4 LEDs ("Ready for Hot Swap", "Out of Service", "Healthy", "Heart Beat")

• Ethernet:

• Shielded RJ-45 connectors with integrated LED's

• Base Ports :

• 4x Shielded RJ-45 connectors with integrated LED's

• User LEDs:

• 4 LEDs ("Base Status", "Base Selected", 2x not used)

• Switch LEDs:

• 16 LEDs (activity and link status for base channels)

HW Monitoring

Board Management

• Based on IPMI 1.5

• FRU Management

• Sensors (Voltage, Current, Temperature, Fuse)

• Status and Alerting

• Hot Swap

• Electronic Keying of Base Interfaces

Page 1 - 10 AT8901 User Guide

Page 23

AT8901 Introduction

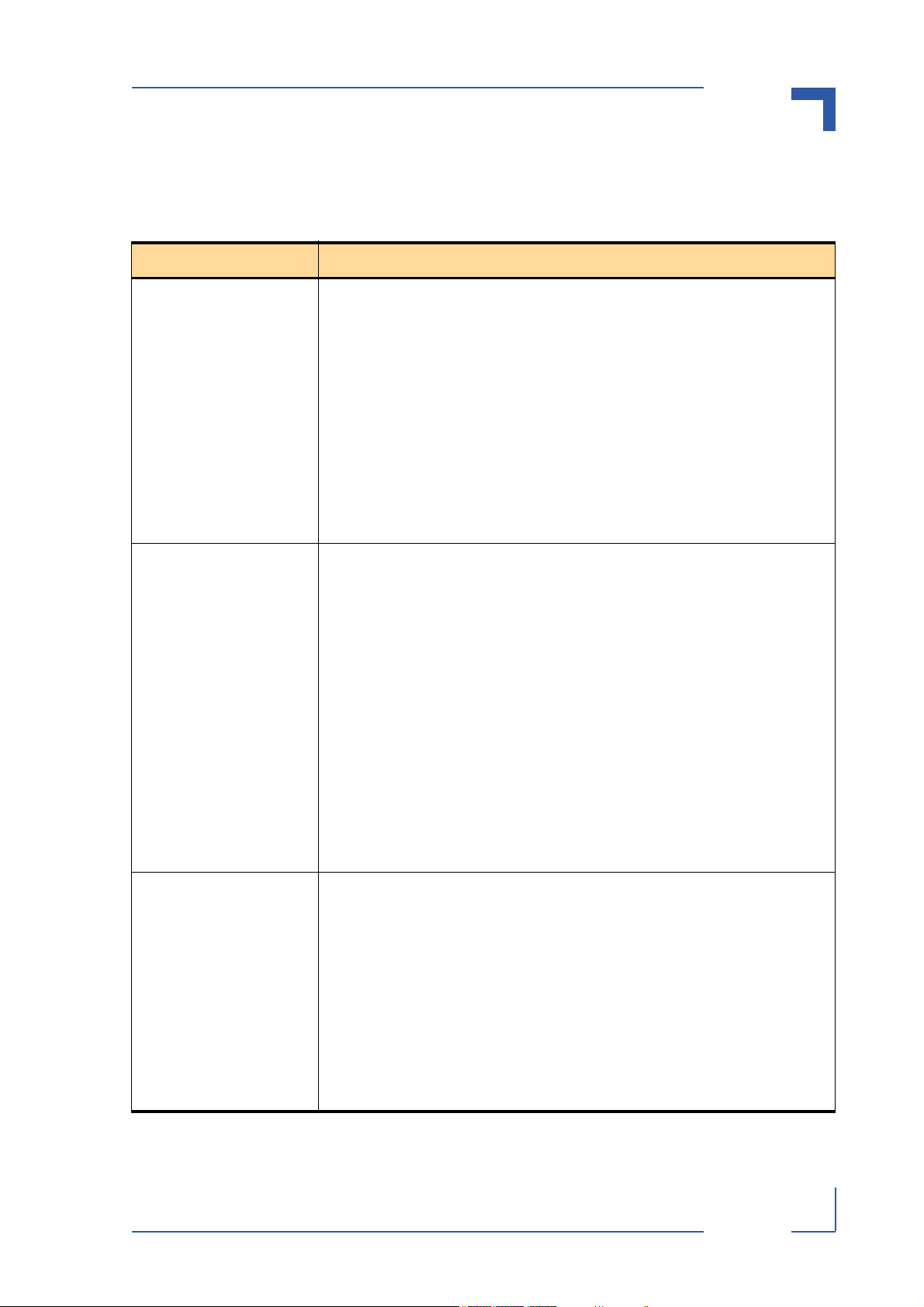

1.3 Software Support

The following table contains information related to software supported by the AT8901.

Table 1-4: AT8901 Software Specification

SPECIFICATIONS

General • Reliable field upgrades for all software components

• Dual boot images with roll-back capability

• Management via SNMP and Command Line Interface

• System access via TELNET, SSH and serial line

• Hot-Swap support

• Hot-Plug support for AMC modules

• Redundancy support for base fabric switch

• IP router on the base fabric

• Support for managing the optional SETS AMC module

• Modular software architecture to enable project specific customization

Ethernet/Bridging (Base

fabric switch)

Routing

• Static link aggregation (IEEE 802.3ad) on uplink ports

• Classic and rapid spanning tree algorithms supported (IEEE 802.1D, IEEE 802.1w)

• Quality Of Service on all ports (IEEE 802.1p)

• Full Duplex operation and flow control on all ports (IEEE 802.3x)

• Static MAC filtering

• Port Authentication (IEEE 802.1X)

• Auto negotiation of speeds and operational mode on all external GbE interfaces as

well as on all base fabric interfaces

• Layer 2 multicast services using GARP/GMRP (IEEE 802.1p)

• VLAN support including VLAN tagging (IEEE 802.3ac), dynamic VLAN registration

with GARP/GVRP (IEEE 802.1Q) and Protocol based VLANs (IEEE 802.1v)

• Double VLAN tagging

• Port Mirroring

• Redundancy of routing functionality using a second switch hub board

• IPv4 Forwarding on all base channels and connected uplink ports

• Quality of service according to the DiffServ standards

• ARP for all routable interfaces

• ICMP for all routable interfaces

• OSPF routing protocol version 2

• RIP routing protocol version 2

• VRRP (virtual router redundancy protocol) for transparent fail over of default routers

• IGMP snooping

Page 1 - 11 AT8901 User Guide

Page 24

AT8901 Introduction

Table 1-4: AT8901 Software Specification (Continued)

SPECIFICATIONS

Applications

Supported MIBS

• NTP client for retrieving accurate time and date information

• DHCP server

• Onboard event management

• Test and trace facilities

• POST (power on self tests) diagnostics

• Standards based SNMP implementation supporting SNMP v1, v2 and v3 for

monitoring and management purposes

• IPMI based management of the onboard AMC slots (AMC.*)

• Persistent storage of configuration across restarts

• Support for retrieving and installing multiple configurations

• Support for hot-plugging of the hub board as well as AMCs

• Switching Package MIBs

• RFC 1213 - MIB-II

• RFC 1493 - Bridge MIB

• RFC 1643 - Ethernet-like -MIB

• RFC 2233 - The Interfaces Group MIB using SMI v2

• RFC 2618 - RADIUS Authentication Client MIB

• RFC 2620 - RADIUS Accounting MIB

• RFC 2674 - VLAN & Ethernet Priority MIB

• RFC 2819 - RMON Groups 1,2,3 & 9

• RFC 3291 - Textual Conventions for Internet Network Addresses

• IANA-ifType-MIB

• IEEE 802.1X MIB (IEEE8021-PAE-MIB)

• IEEE 802.3AD MIB (IEEE8021-AD-MIB)

• Routing Package MIBs

• IANA-Address-Family-Numbers-MIB

• RFC 1724 - RIP v2 MIB Extension

• RFC 1850 - OSPF MIB

• RFC 2787 - VRRP MIB

• QoS Package MIB

• RFC 3289 - DIFFSERV-MIB & DIFFSERV-DCSP-TC MIBs

• FASTPATH Enterprise MIB

• Support for all managed objects not contained in standards based MIBs.

Page 1 - 12 AT8901 User Guide

Page 25

AT8901 Introduction

Table 1-4: AT8901 Software Specification (Continued)

SPECIFICATIONS

Bootloader u-boot Version 1.1.2

• POST

• multi image support

• loadable bootimage via network (bootp/tftp)

• reliable field upgradable

• H/W protected

• KCS interface to IPMC

• serial console support

Operating System

• MontaVista Linux Professional Edition 3.1

Page 1 - 13 AT8901 User Guide

Page 26

AT8901 Installation

Chapter

2

Installation

Page 2 - 1 AT8901 User Guide

Page 27

AT8901 Installation

2. Installation

The AT8901 has been designed for easy installation. However, the following standard precautions, installation procedures, and general information must be observed to ensure proper installation and to preclude damage to the board, other system components, or injury to

personnel.

2.1 Safety Requirements

The following safety precautions must be observed when installing or operating the AT8901.

Kontron assumes no responsibility for any damage resulting from failure to comply with these

requirements.

Warning!

Due care should be exercised when handling the board due to the fact that the

heat sink can get very hot. Do not touch the heat sink when installing or

removing the board.

In addition, the board should not be placed on any surface or in any form of storage container until such time as the board and heat sink have cooled down to

room temperature.

Note ...

Certain ATCA boards require bus master and/or rear I/O capability. If you are

in doubt whether such features are required for the board you intend to install,

please check your specific board and/or system documentation to make sure

that your system is provided with an appropriate free slot in which to insert the

board.

ESD Equipment!

This ATCA board contains electrostatically sensitive devices. Please observe

the necessary precautions to avoid damage to your board:

• Discharge your clothing before touching the assembly. Tools must be discharged before use.

• When unpacking a static-sensitive component from its shipping carton,

do not remove the component's antistatic packing material until you are

ready to install the component in a computer. Just before unwrapping the

antistatic packaging, be sure you are at an ESD workstation or grounded.

This will discharge any static electricity that may have built up in your

body.

• When transporting a sensitive component, first place it in an antistatic

container or packaging.

• Handle all sensitive components at an ESD workstation. If possible, use

antistatic floor pads and workbench pads.

• Handle components and boards with care. Don't touch the components

or contacts on a board. Hold a board by its edges or by its metal mounting

bracket.

• Do not handle or store system boards near strong electrostatic, electro-

magnetic, magnetic, or radioactive fields.

Page 2 - 2 AT8901 User Guide

Page 28

AT8901 Installation

2.2 AT8901 Initial Installation Procedures

The following procedures are applicable only for the initial installation of the AT8901 in a system. Procedures for standard removal and hot swap operations are found in their respective

chapters.

To perform an initial installation of the AT8901 in a system proceed as follows:

1. Ensure that the safety requirements indicated in section 2.1. are observed.

Warning!

Failure to comply with the instruction below may cause damage to the

board or result in improper system operation.

2. Ensure that the board is properly configured for operation in accordance with application

requirements before installing. For information regarding the configuration of the AT8901

refer to Chapter 4. For the installation of AT8901 specific peripheral devices and rear I/O

devices refer to the appropriate chapters.

Warning!

Care must be taken when applying the procedures below to ensure that

neither the AT8901 nor other system boards are physically damaged by

the application of these procedures.

3. To install the AT8901 perform the following:

1. Carefully insert the board into the slot designated by the application requirements for

the board until it makes contact with the backplane connectors.

Warning!

DO NOT push the board into the backplane connectors. Use the ejector

handles to seat the board into the backplane connectors.

2. Using the ejector handle, engage the board with the backplane. When the ejector handle is locked, the board is engaged.

3. Fasten the front panel retaining screws.

4. Connect all external interfacing cables to the board as required.

5. Ensure that the board and all required interfacing cables are properly secured.

4. The AT8901 is now ready for operation.

Page 2 - 3 AT8901 User Guide

Page 29

AT8901 Installation

2.3 Standard Removal Procedures

To remove the board proceed as follows:

1. Ensure that the safety requirements indicated in section 2.1. are observed.

Warning!

Care must be taken when applying the procedures below to ensure that

neither the AT8901 nor system boards are physically damaged by the

application of these procedures.

2. Disconnect any interfacing cables that may be connected to the board.

3. Unscrew the front panel retaining screws.

4. Wait until the blue LED is fully ON, this mean that the hot swap sequence is ready for board removal.

5. Disengage the board from the backplane by using both board ejection handles

6. After disengaging the board from the backplane, pull the board out of the slot.

2.4 AMC Installation

To install an AMC proceed as follows:

1. Remove the AMC filler panel.

2. Carefully engage the AMC into the card guide. Push the AMC until it fully mate with its con-

nector. Secure the AMC handle to the locking position.

3. In normal condition, the blue LED shall turn ON as soon as the AMC is fully inserted. It will

turn OFF at the end of the hot swap sequence.

2.5 Software Installation

The AT8901 comes as a pre-installed system with all necessary OS, Filesystem, drivers and

applications factory-installed with default configurations.

Updating the Software with new Operating System or applications or new versions is provided

by a dedicated update mechanism, which is described in Chapter 4.

2.6 CLI Quick Start

This section gives instructions for (initially) accessing the CLI (Command Line Interface) of the

AT8901 Base Fabric using either the Serial Console or the Fast Ethernet management interface (serviceport) on the front plate.

Serial Console CLI can be accessed directly with the appropriate cabling. A console menu allows to enter the Base Fabric console or to perform a system reset. Fast Ethernet access is

done by establishing a telnet connection (see below).

Page 2 - 4 AT8901 User Guide

Page 30

AT8901 Installation

In order to use the Fast Ethernet management port for CLI telnet access, an IP address must

be assigned. This implies that at least the first CLI access has to be done by Serial Console in

order to configure the serviceport IP settings. The corresponding procedure is described in the

following. User input is printed in bold letters.

1. Connect to serial port on AT8901 front plate using the adapter described in Chapter 3, sec-

tion 3.1.

Port settings are:

• 9600 bps

• 8 bit, no parity, 1 stop bit (8N1)

• no flow control

2. Ensure that the board is powered up.

3. Wait for boot process to complete, i.e. until the console selection menu appears.

b - connect Base Fabric console

r - reset system

4. Type “ b“ to connect to the Base Fabric console.

Connected to Base Fabric console

Press ^X or ^V to get to menu again

Base fabric switching application Release BETA 6.09 starting

(Unit 1)>

User:

5. Log in as admin and enter privileged mode (no passwords required by default).

User:admin

Password:

(Base Fabric) >enable

Password:

(Base Fabric) #

6. Set IP address and netmask (see below for an example IP address setting).

(Base Fabric) #serviceport ip 192.168.168.42 255.255.255.0

(Base Fabric) #

The FE management interface is available as from now.

Page 2 - 5 AT8901 User Guide

Page 31

AT8901 Installation

7. Save configuration by copying it to the flash, confirm by typing “y“.

(Base Fabric) #copy system:running-config nvram:startup-config

This operation may take a few minutes.

Management interfaces will not be available during this time.

Are you sure you want to save? (y/n) y

Configuration Saved!

(Base Fabric) #

To access the CLI via Fast Ethernet management port, open a telnet connection to the configured IP address, port 23.

For additional information on the system configuration, refer to documentation “AT8901/2/3 CLI

Reference Manual“.

Page 2 - 6 AT8901 User Guide

Page 32

AT8901 Hardware Description

Chapter

3

Hardware Description

Page 3 - 1 AT8901 User Guide

Page 33

AT8901 Hardware Description

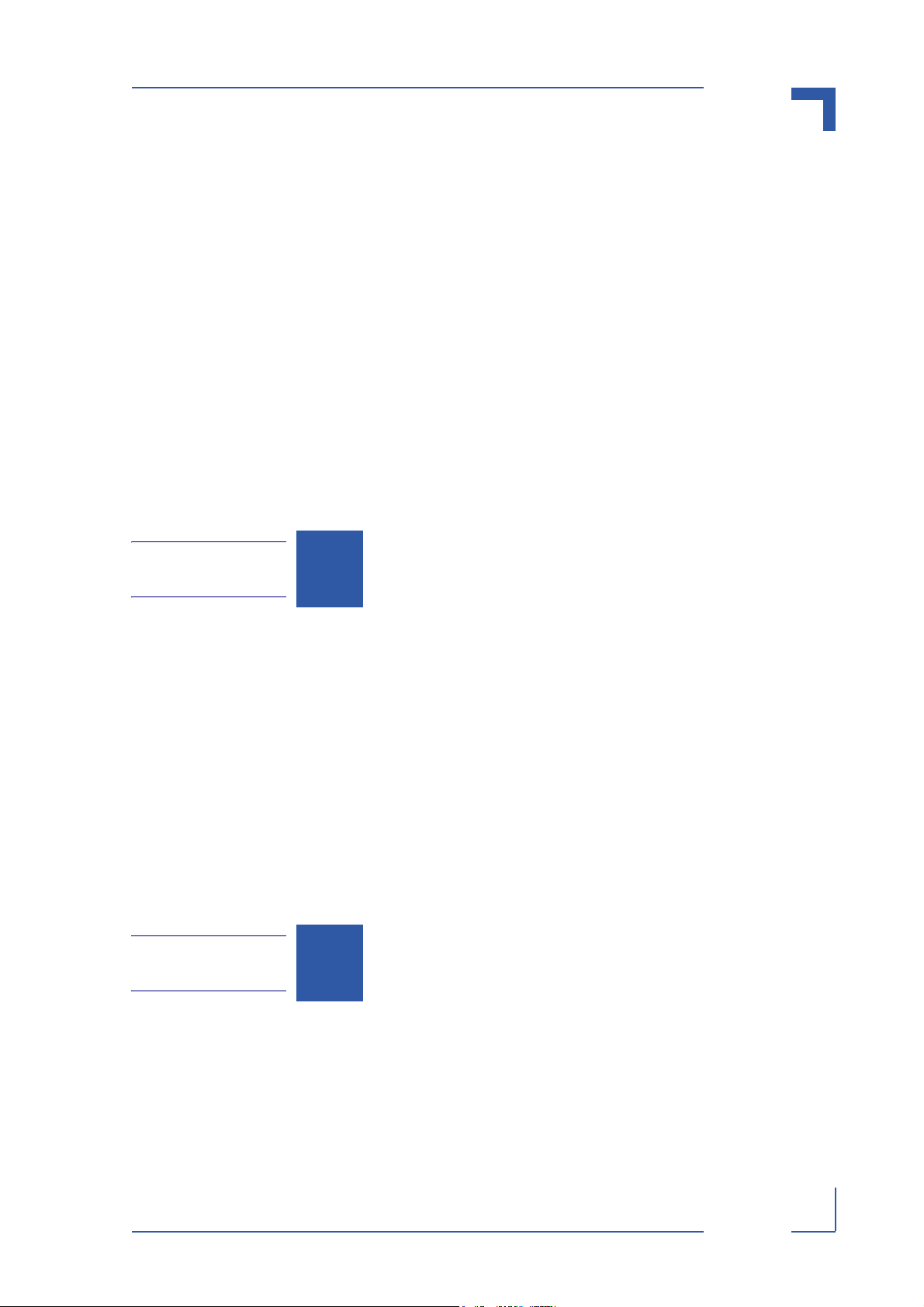

3. Hardware Description

The AT8901 is a PICMG 3.0 compliant Hub Board for AdvancedTCA shelves. It provides a

base interface suitable for 14 and 16 slot systems. It also provides two AMC slots for customization.

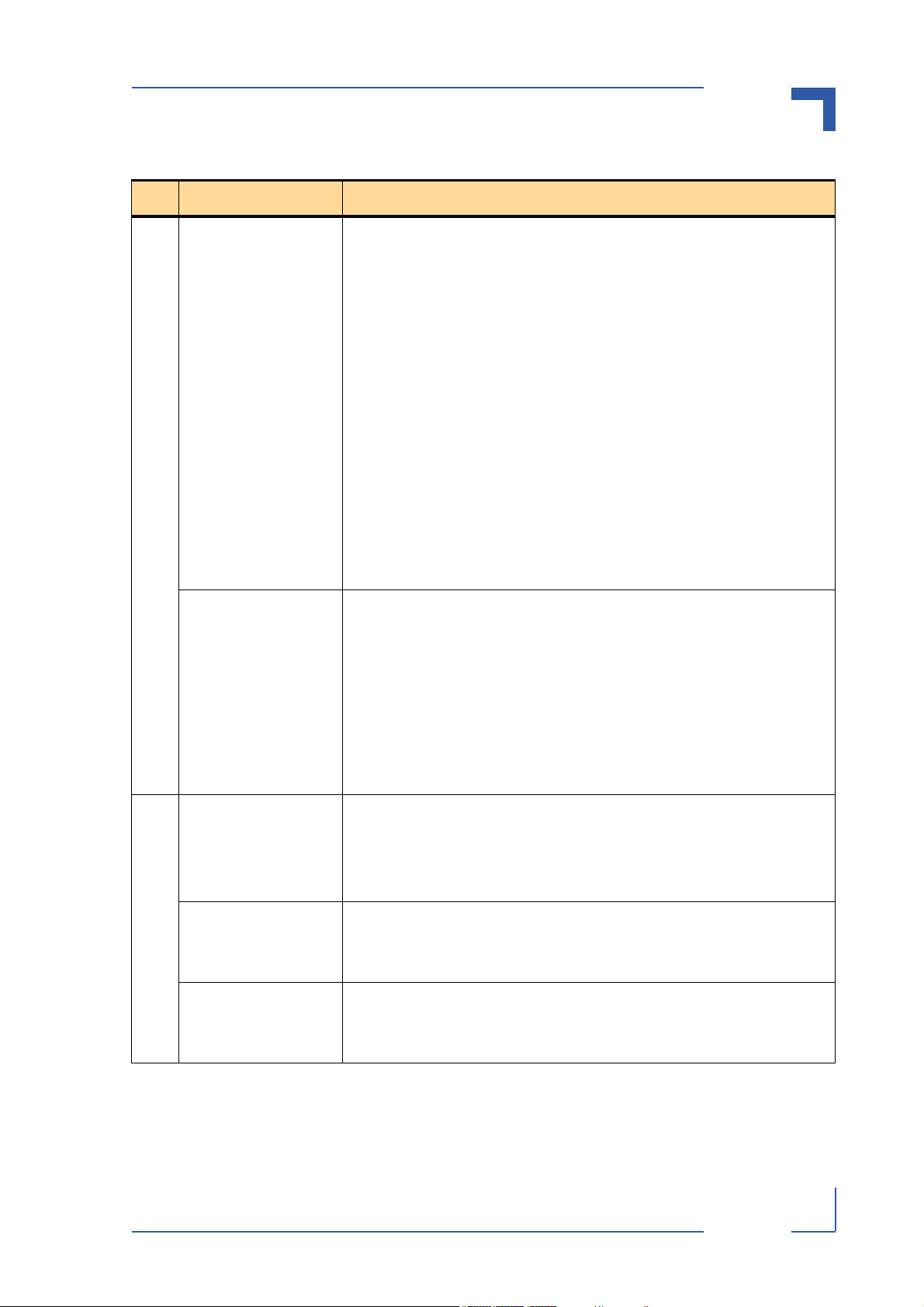

Figure 3-1: Functional Block Diagram Base Board

AMC B1 SATA/FC

AMC B2 SATA/FC

IPMB RTM

8 RTM Channels

4 RTM Channels

RTM-CPLD-LINK

AMC B1 GE Support Channel

AMC B1 GE Support Channel

ZONE 3

AMC B1

AMC.2 Type 8E2S2 or AMC.2 Type 8E2F2

AMC B2

AMC.2 Type 8E2S2 or AMC.2 Type 8E2F2

IPMB AMC B1

GE AMC B1

SATA/FC

IPMB AMC B2

GE AMC B2

RJ45

FE

2x4

RJ45

Array

RJ45

RS232

LEDs

256MB

SDRAM

PPC405GPr

400MHz

64MB

FLASH

BASE Interface 4 x 10/100/1000BaseT

PCI 32b/66MHz

CPLD

FWUM

R8C/13

IPMC

H8S2166

Control,

Sensor

Temp.

Sensor

Broadcom

BCM56500

24Port

Layer 3

Switch

Power Supply Unit

S

C

M

_

h

A

/

1

0

0

1

s

B

a

0

T

e

h

S

M

B

_

C

0

/

1

0

1

0

s

a

T

e

B

h

C

2

-

n

nel

a

6

1

IPMB A/B

-48V A/B

Version: V1.027

ZONE 2

ZONE 1

Page 3 - 2 AT8901 User Guide

Page 34

AT8901 Hardware Description

The main building blocks of the AT8901 are:

• CPU and Memory

• Base Switch

•AMC Bays

•IPMI

• Synchronization clock

• RTM Interface

• Power Supply

3.1 CPU and Memory

The CPU is an IBM PowerPC 405 GPr 400MHz 32-bit RISC processor with 16KB D-cache.

PCI Interface

The PCI interface is a 32bit/66MHz system to control the on-board Broadcom BCM56500 base

interface switch and the optional fabric mezzanine module. The internal PCI arbiter of the PowerPC 405 GPr is used.

The virtual PCI slots are ordered in the following way:

Table 3-1: PCI Slots

PCI-Slot IDSEL Device

1 0 Base Interface Switch: Broadcom BCM56500 / BCM56300

Fast Ethernet Management Interface

The internal Fast Ethernet MAC of the PowerPC 405 GPr is used as a management interface.

Additionally, a Fast Ethernet PHY transceiver and a RJ45 Connector with integrated magnetics

and two LED's, located on the front panel, are used to complete the network interface.

The PHY is controlled via the MDIO interface of the PowerPC 405 GPr. The MDIO address is

set to 0. The default setting of the PHY is to operate in auto-negotiation enabled mode, 10/100,

Full or Half duplex.

The PHY drives the two LEDs of the RJ 45 Connector, buffered by the CPLD.

The connection is established with a straight through Ethernet cable.

Page 3 - 3 AT8901 User Guide

Page 35

AT8901 Hardware Description

The standard RJ45 connector has the following pin assignment:

Table 3-2: Fast Ethernet Management (RJ45) Pin Assignment

Signal Pin

TX+ 1

TX- 2

RX+ 3

N.C. 4

N.C. 5

RX- 6

N.C. 7

N.C. 8

8

1

Green

Yel lo w

Table 3-3: Fast Ethernet Management (RJ45) LEDs Signification

Speed LED (yellow)

OFF 10BASE-T

ON 100BASE-TX

Status LED (green)

OFF Link Down

ON Link Up and no activity

BLINK Link up and activity

SDRAM

Five 512Mbit devices, soldered directly onto the PCB, provide 256 Mbyte of SDRAM plus 64

Mbyte for ECC.

The SDRAM interface of the PPC is 32 bit wide and operated at 133 MHz.

Flash

The CPU has two 32 Mbyte Flash Memory devices, which result in 64 Mbyte total Flash memory space. The sector width is 64 Kbyte.

The Flashes are connected to the 32 bit peripheral data bus. The PowerPC 405 GPr accesses

the Flashes with CS0#. The sector containing the bootloader code is write protected. The protection can be disabled by setting jumper FWPD.

Page 3 - 4 AT8901 User Guide

Page 36

AT8901 Hardware Description

RS232 Management Interface

One RS232 interface (UART0) of the PowerPC 405 GPr is connected to the front panel RJ45

connector, the other one (UART1) is used as programming interface for IPMI.

Table 3-4: Serial Port (RJ45) Pin Assignment

Signal Pin

RTS 1

DTR 2

TXD 3

GND 4

GND 5

1

RXD 6

DSR 7

CTS 8

8

External connection is established with a straight through Ethernet cable and a RJ45 (female)

to SubD (female) adapter if required. The adapter is described in the following table.

Table 3-5: Serial console terminal cable interface: RJ45 Female to DB9 Female

RJ45 Female RJ45 Pin

Number

Front View

1 RTS Y Request To Send 8

2 DTR Y Data Terminal Ready 6

3 TXD Y Transmit 2

4 GND N Ground 5 GND Y Ground 5

6 RXD Y Receive 3

7 DSR Y Data Set Ready 4

8 CTS N Clear To Send 7

- RI N Ring Indicator

- CD N Carrier Detect

Signal Connected Description DB9 Pin

Number

9

(Not used)

1

(Not used)

DB9 Female

Front View

Page 3 - 5 AT8901 User Guide

Page 37

AT8901 Hardware Description

3.2 Base Switch

The base switch is a Broadcom BCM56500 (full featured version) or BCM56300 (lite featured

version) 24 port GbE multilayer switch that can operate in 10/100/1000 Mbps. It integrates advanced Layer 3 switching features for IPv4 and IPv6 routing. The BCM56500 also includes enhanced QoS support and jumbo packet line rate switching.

The PPC controls the switch over a 32bit/66MHz PCI Interface.

Base Interface (Zone 2)

The board supports 15+2 ATCA backplane channels. The board can operate in a dual star and

full mesh configuration. The switch is connected to the backplane via four 10/100/1000BASET quad PHYs and eight 10/100/1000BASE-T dual magnetics. The pin assignment for the Zone

2 connectors is compliant to the PICMG 3.0 standard. GbE channels 0/20 and 0/24 of the

switch are the 100BASE-TX ShMC base channels (ShMC cross-connects).

Table 3-6: Base Interface Port Mapping

CLI ID Channel LED

0/1 Uplink 1 -

0/2 Uplink 2 -

0/3 Uplink 3 -

0/4 Uplink 4 -

0/5 16 16

0/6 15 15

0/7 14 14

0/8 13 13

0/9 12 12

0/10 11 11

0/11 10 10

0/12 9 9

0/13 8 8

0/14 7 7

0/15 6 6

0/16 5 5

0/17 4 4

0/18 3 3

0/19 2 2

0/20 SMCA 1

0/21 Local AMC B1, channel 0 -

0/22 Remote AMC B1, channel 1 -

0/23 Local AMC B2, channel 0 -

0/24 SMCB 1

Page 3 - 6 AT8901 User Guide

Page 38

AT8901 Hardware Description

1

Base Interface Uplink

The Hub Board supports four base interface uplinks to the front panel. The switch is connected

to the RJ45 connectors with integrated status LEDs on the front panel via a 10/100/1000BASET quad PHY and two 10/100/1000BASE-T dual magnetics. GbE channels 0/1 to 0/4 of the

switch map to uplink channels 1 to 4.

The upper four RJ45 connectors on the front panel are not used for the AT8901.

Table 3-7: Base Uplink (J27) Pin Assignment

Signal Pin

DB+ 1

DB- 2

DA+ 3

DD+ 4

DD- 5

DA- 6

DC+ 7

DC- 8

Green

Yel lo w

1

8

Table 3-8: Base Uplink (J27) LEDs Signification

Speed LED (yellow)

OFF 10BASE-T

BLINK 100BASE-TX

ON 1000BASE-T

Status LED (green)

8

Green

Yellow

1

OFF Link Down

ON Link Up and no activity

BLINK Link Up and activity

Page 3 - 7 AT8901 User Guide

Page 39

AT8901 Hardware Description

ShMC Cross-connection

The Hub Board provides two dedicated 10/100BASE-T connections to the shelf managers according to PICMG 3.0 rev. 2 (redundancy shelf manager cross-connection). Port 0/20 is connected to SMCA, 0/24 to SMCB.

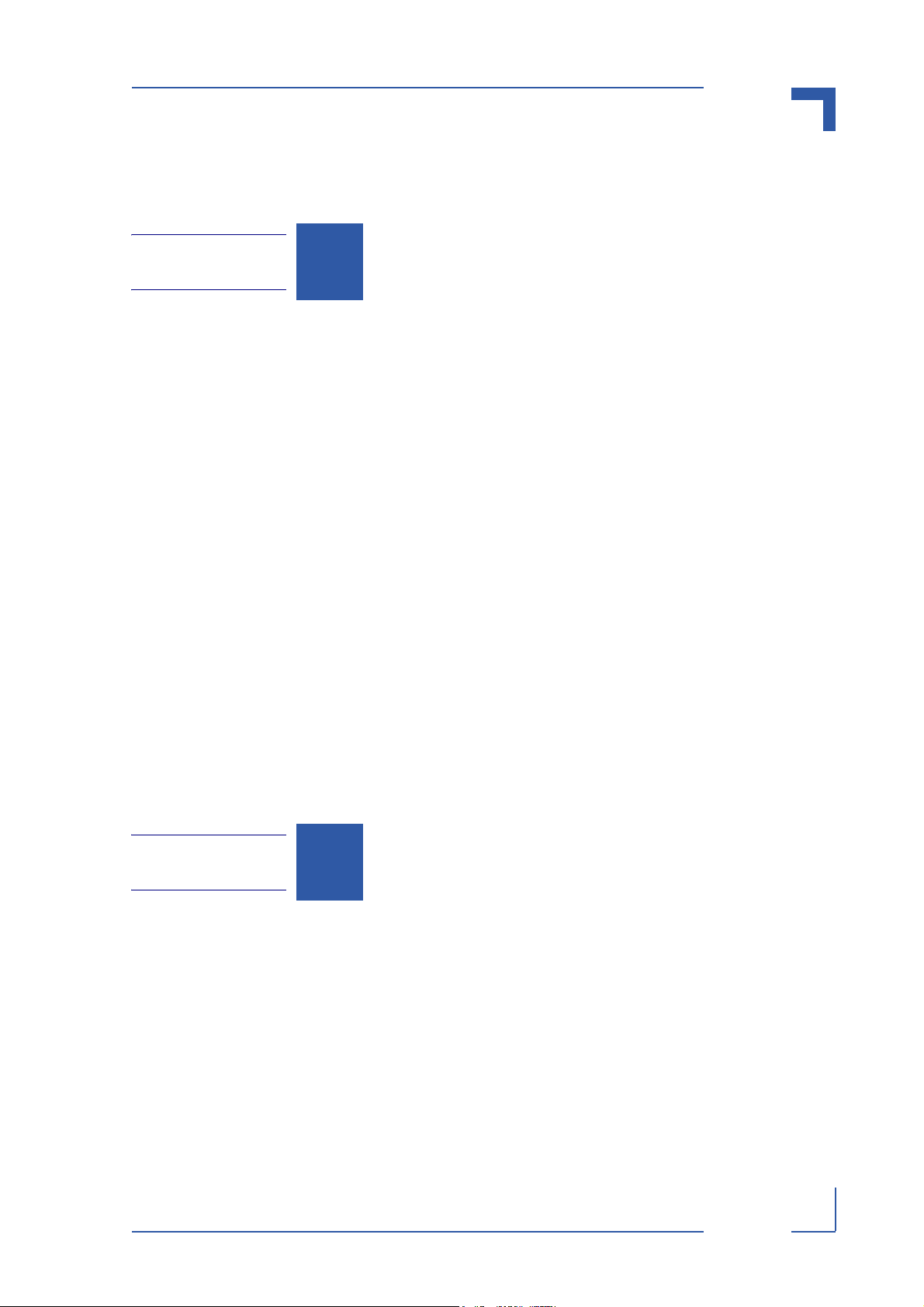

AMC GbE Support Channels

Each AMC bay has one GbE connection to the base interface switch (AMC Channel 0). On

Channel 1, AMC bay B1 has an additional link to the backplane update channel buffered by a

cross-point switch. The update channel connects to the base switch of the redundant Hub

Board.

In applications with a PrAMC used as a system controller in the ATCA Hub Board, the system

controller redundancy ensures that a fault in a base switch of one Hub Board does not cut the

connection to the redundant Hub Board (see block diagram below). The connections between

AMC B1 and the backplane are buffered by a cross-point switch that is controlled by the IPMC.

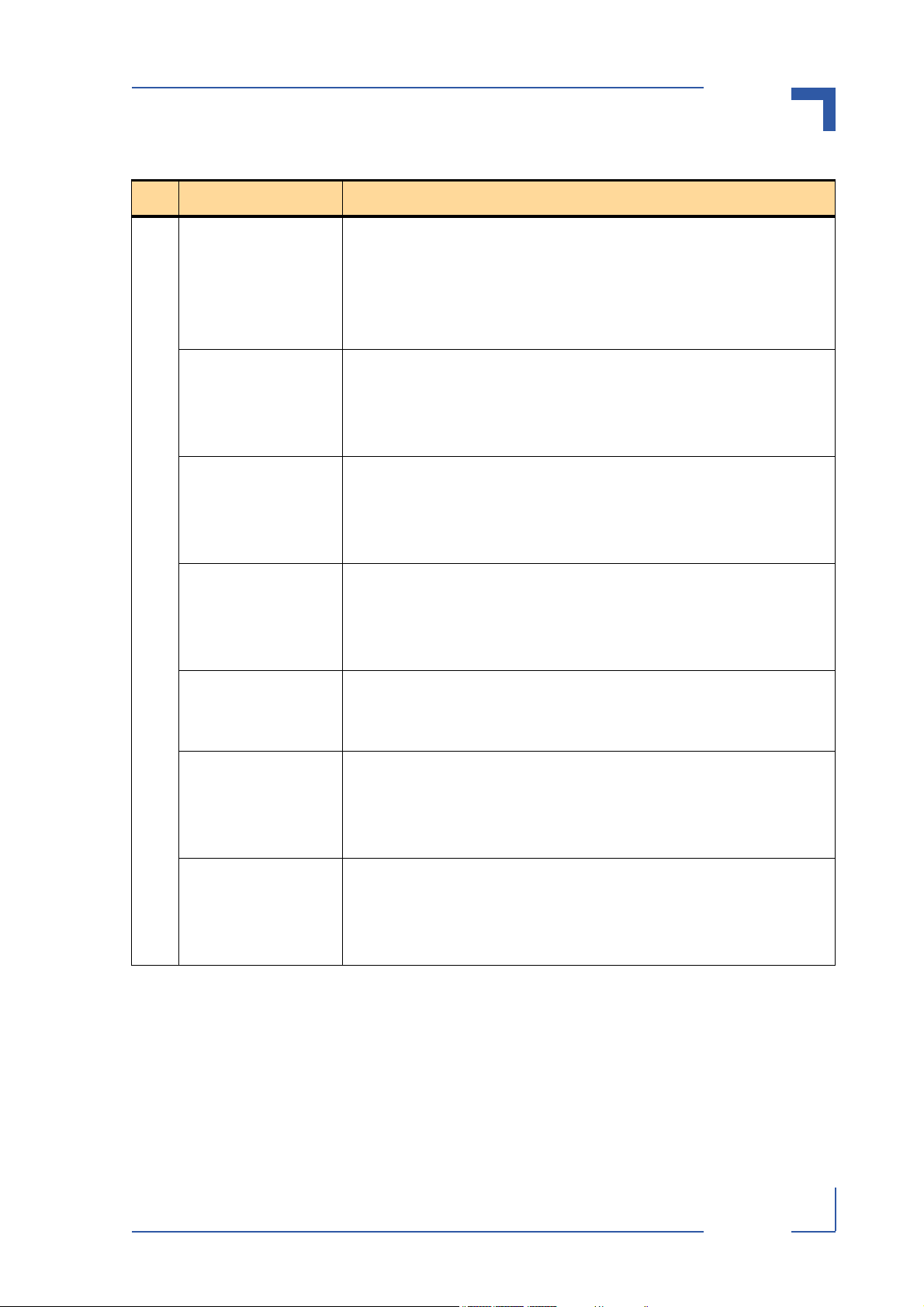

Figure 3-2: Block Diagram AMC GbE Cross-connect via update channels

The block diagram shows one solution for the AMC GbE support channels with a PrAMC as

System Controller.

Page 3 - 8 AT8901 User Guide

Page 40

AT8901 Hardware Description

3.3 AMC Bays

Two AMC bays for standard or custom AMCs with full height and single width are implemented

with B+ connectors.

Following AMC Geographic Addresses are implemented:

Table 3-9: AMC Bay Address

AMC AMC Bay ID GA [2..0] IPMB-L Address

1B1 UGU 7Ah

2 B2 UUG 7Ch

The state of each GA signal is represented by G (grounded), U (unconnected) or P (pulled up

to management power).

Table 3-10: AMC B1 Channel Assignment

Channel Region Connection

0 GbE Local Base Switch 0/21

1 GbE Remote Base Switch 0/22

2 SATA/FC AMC B2, channel 2

3 SATA/FC RTM, STOR0

4Fabric -

5Fabric -

6Fabric -

7Fabric -

8Fabric -

9Fabric -

10 Fabric -

11 Fabric -

12 - -

13 Extended RTM, AMC_B1_P13

14 Extended RTM, AMC_B1_P14

15 Extended RTM, AMC_B1_P15

16 Extended RTM, AMC_B1_P16

17 Extended RTM, AMC_B1_P17

18 Extended RTM, AMC_B1_P18

19 Extended RTM, AMC_B1_P19

20 Extended RTM, AMC_B1_P20

Page 3 - 9 AT8901 User Guide

Page 41

AT8901 Hardware Description

Table 3-11: AMC B2 Channel Assignment

Channel Region Connection

0 GbE Local Base Switch 0/23

1GbE -

2 SATA/FC AMC B1, channel 2

3 SATA/FC RTM, STOR1

4Fabric -

5Fabric -

6Fabric -

7Fabric -

8Fabric -

9Fabric -

10 Fabric -

11 Fabr i c -

12 - -

13 Extended -

14 Extended -

15 Extended -

16 Extended -

17 Extended RTM, AMC_B2_P17

18 Extended RTM, AMC_B2_P18

19 Extended RTM, AMC_B2_P19

20 Extended RTM, AMC_B2_P20

Page 3 - 10 AT8901 User Guide

Page 42

AT8901 Hardware Description

Interconnects to RTM

AMC Bay B1 has eight generic interconnects to the RTM Zone 3 (channels 13 to 20), B2 has

four interconnects (channels 17 to 20). The second SATA/FC port of each AMC Bay (channel

3) is also connected to the RTM.

For further details, please refer to section 3.6., RTM Interface.

AMC GbE Support Channels

The first GbE port of each AMC Bay (channel 0) is connected to the base switch, the second

one (channel 1) of AMC Bay 1 is also connected to the neighbouring Hub Board via Zone 2

Update Channel.

See also section 3.2.

AMC SATA/FC Channels

The first SATA port (channel 2) connects both AMC Bays together. A possible application is a

PrAMC in one Bay and a storage AMC in the other. The second SATA port (channel 3) of each

AMC Bay is connected to the RTM.

3.4 IPMI

The Hub Board supports an intelligent hardware management system, based on the Intelligent

Platform Management Interface (IPMI) Specification 1.5. The hardware management system

provides the ability to manage the power, cooling and interconnect needs of intelligent devices,

to monitor events and to log events to a central repository.

The main building blocks of the IPMI architecture of the AT8901 are:

• IPMC Intelligent Platform Management Controller

• FUM Firmware Update Manager

• CPLD Complex Programmable Logical Device

For further details please refer PICMG 3.0 standard Rev. 2.0.

IPMC

The IPM controller is a 16-bit microcontroller for IPMI applications and it is compliant to IPMI

version 1.5 specification. The microcontroller has large on chip memory of 512 Kbyte Flash and

40 Kbyte SRAM. The microcontroller provides six I2C interfaces to have access to the dedicated ShMCs, the AMCs, the fabric mezzanine module, the RTM and the on board peripheral devices such as SEEPROM and temperature sensor. The microcontroller also provides three

serial interfaces that are connected to the CPLD.

An LPC interface using the KCS protocol for communication between IPMC and PPC is implemented. IPMC operation is supervised by the FUM.

Page 3 - 11 AT8901 User Guide

Page 43

AT8901 Hardware Description

FUM

The Firmware Update Manager (FUM) is a microcontroller with embedded 16 Kbyte data flash

ROM and 1 Kbyte RAM.

The FUM is responsible for field upgrades, rollbacks and watchdog functions of the IPM controller. Four SPI compatible memory devices are connected to the FUM which build up two IPMI

firmware banks with 512 Kbyte each. One bank contains a copy of the current IPMC code. The

other bank can be written without affecting IPMC operation. Once the bank is updated, the FUM

writes its content into the IPMC. IPMC control signals are all buffered in the CPLD so that board

operation is not affected during update. In the case of a fault during the update process, the

FUM can configure the IPMC with the old firmware that is kept in the other bank. The FUM is

also the watchdog timer for the IPMC. There are several control signals to supervise the IPM

controller.

CPLD

The CPLD is responsible for connecting the PPC to the IPMC and FUM and for handling the

serial interfaces of PPC, IPMC and FUM to the RS232 connector on the front panel. The host

interface between PowerPC and CPLD, realized by PPC’s External Bus Interface (EBC), is

used as CPLD-Register-Interface and as communication interface to IPM controller. The EBC

is configured as a demultiplexed 8 Bit Address/Data interface. For accesses to the IPMC Controller, an EBC to LPC (Low Pin Count)-Bridge is included as protocol interface. The LPC interface is for communication between IPMC and PPC over KCS protocol. An additional LPC-IF is

connected to the Fabric mezzanine.

The CPLD controls the LEDs for the whole board via shift registers. It handles the signals to

monitor the AMCs, fabric mezzanine module and the RTM and handles the signals for the line

drivers for the synchronization clocks and the AMC GbE support channels.

An internal multiplexer controls the serial interfaces from the PPC, the FUM and the IPMC. It

is possible to connect each device to the other or to the RS232 connector on the front panel.

3.5 Synchronization Clock

The Synchronization Clock Interface provides three differential pairs per AMC for clock distribution from the AMCs to the Hub Board and vice versa to enable applications that require the

exchange of synchronous timing information among modules and consequently multiple

boards in a shelf. This allows modules to source clock(s) to the system in the case where it

provides a network interface function, or conversely to receive timing information from another

carrier board or module within the system. The three synchronization clock signals are CLK1,

CLK2, and CLK3, each supported by a differential pair. CLK1 and CLK2 are driven by the

AMCs to the backplane and CLK3 will be received from the backplane. AMC1 and 2 cannot

transmit or receive simultaneously signals to or from the backplane. Either the CLK signals of

AMC1 are valid or the CLK signals of AMC2. The Hub Board cannot receive any synchronization clocks from other carrier boards, it is only used for distribution. The three differential clock

signals are buffered by three differential line drivers that are controlled by the IPMC and CPLD

respectively.

For further details please refer AMC specification AMC0.RC1.1.

Page 3 - 12 AT8901 User Guide

Page 44

AT8901 Hardware Description

3.6 RTM Interface

The use of an RTM is optional. I/O signals from the Base Board are routed to Zone 3 where a

connector mates with the RTM. The RTM connection is compliant to the PICMG 3.0 standard.

For the connection between the Hub Board and the RTM two daughter card connectors with

40 differential pairs are used.

Each AMC Bay has eight (B1) or four (B2) pairs of generic interconnects to the RTM Zone 3

(AMC_B1_P13 to AMC_B1_P20 and AMC_B2_P17 to AMC_B2_P20). One SATA/FC interface for mass storage from each AMC Slot is implemented (STOR0 and STOR1). Also an I2C

IPMI connection is implemeted for an intelligent RTM.

The Zone 3 connector has the following pin assignment:

Table 3-12: J30 Pin Assignment

PIN ROW A ROW B ROW C ROW D ROW E ROW F ROW G ROW H

1 N.C. N.C. N.C. N.C. N.C. N.C. STOR0_

RX-

2 PROD_IO0 PROD_IO1 N.C. N.C. N.C. N.C. STOR0_

TX-

3 12V 3.3V_SUS SMB_SCL SMB_

SDA

4 PROD_IO2 PLD_DOUT PLD_CLK PLD_DIN N.C. N.C. STOR1_

5 JTAG_TDO TEST_JIG# N.C. PROD_IO3N.C. N.C. N.C. N.C.

N.C. N.C. STOR1_

RX-

TX-

STOR0_

RX+

STOR0_

TX+

STOR1_

RX+

STOR1_

TX+

6 JTAG_TDI 12V N.C. N.C. N.C. 12V N.C. N.C.

7 JTAG_TCK PROD_IO4 N.C. N.C. N.C. N.C. N.C. N.C.

8 JTA G _ T M S JTAG_

TRST#

9 N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C.

10 N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C.

# Active Low Signal

N.C. N.C. N.C. SMB_

ALERT#

N.C. N.C.

Page 3 - 13 AT8901 User Guide

Page 45

AT8901 Hardware Description

Table 3-13: J31 Pin Assignment

PIN ROW A ROW B ROW C ROW D ROW E ROW F ROW G ROW H

1 N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C.

2 N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C.

3 N.C. N.C. N.C. N.C. N.C. N.C. N.C. N.C.

4 N.C. N.C. N.C. N.C.N.C. N.C. N.C. N.C. N.C.

5 AMC_B1_

P13_TX+

6 AMC_B1_

P15_TX+

7 AMC_B1_

P17_TX+

8 AMC_B1_

P19_TX+

9 AMC_B2_

P 17_TX+

10 AMC_B2_

P19_TX+

AMC_B1_

P13_TX-

AMC_B1_

P15_TX-

AMC_B1_

P17_TX-

AMC_B1_

P19_TX-

AMC_B2_

P17_TX-

AMC_B2_

P19_TX-

AMC_B1_

P13_RX+

AMC_B1_

P15_RX+

AMC_B1_

P17_RX+

AMC_B1_

P19_RX+

AMC_B2_

P17_RX+

AMC_B2_

P19_RX+

AMC_B1_

P13_RX-

AMC_B1_

P15_RX-

AMC_B1_

P17_RX-

AMC_B1_

P 19_RX-

AMC_B2_

P17_RX-

AMC_B2_

P19_RX-

AMC_B1_

P14_TX+

AMC_B1_

P16_TX+

AMC_B1_

P18_TX+

AMC_B1_

P20_TX+

AMC_B2_

P18_TX+

AMC_B2_

P20_TX+

AMC_B1_

P14_TX-