Page 1

If it's embedded, it's Kontron.

» Kontron User's Guide «

AT8060

Document Revision 1.2

October 2013

Page 2

www.kontron.com

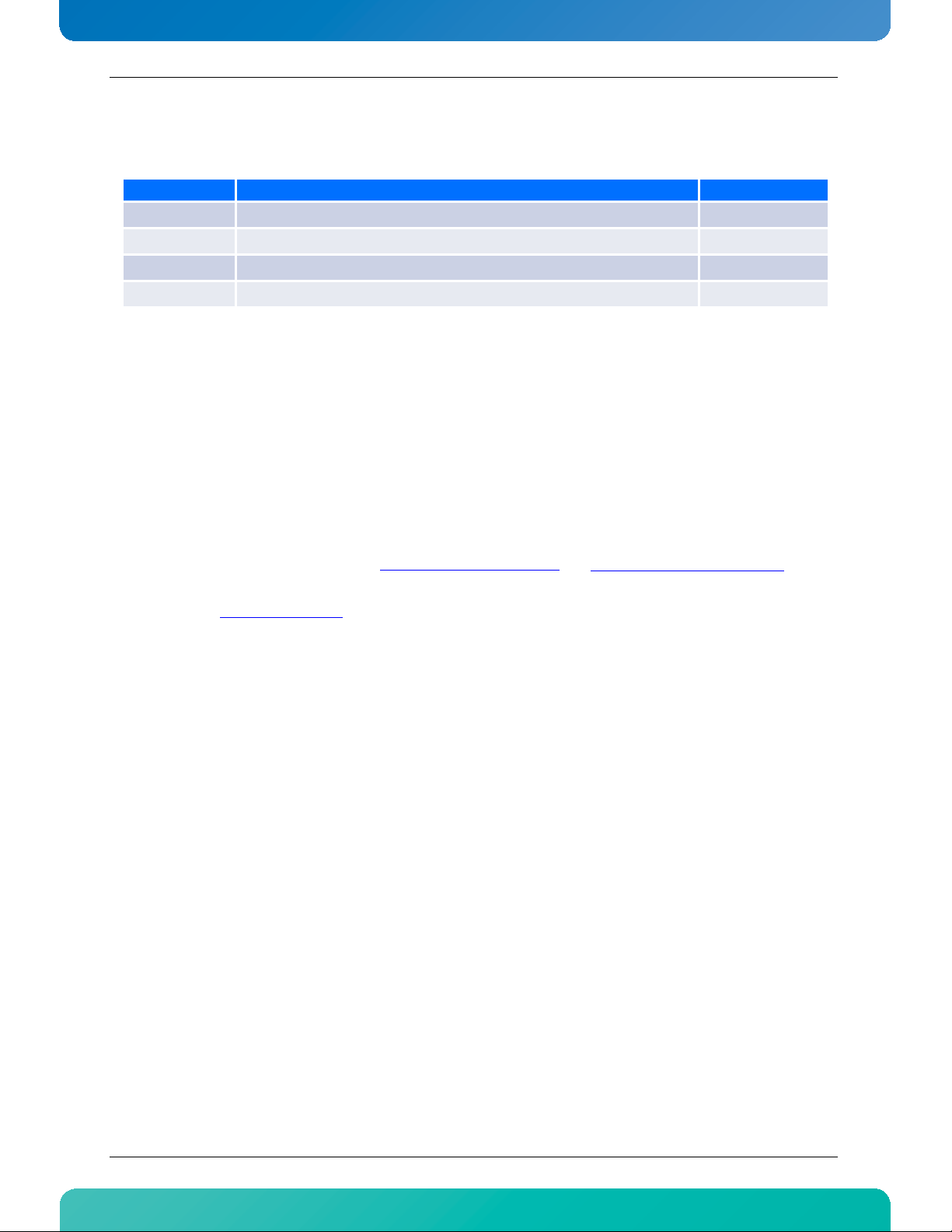

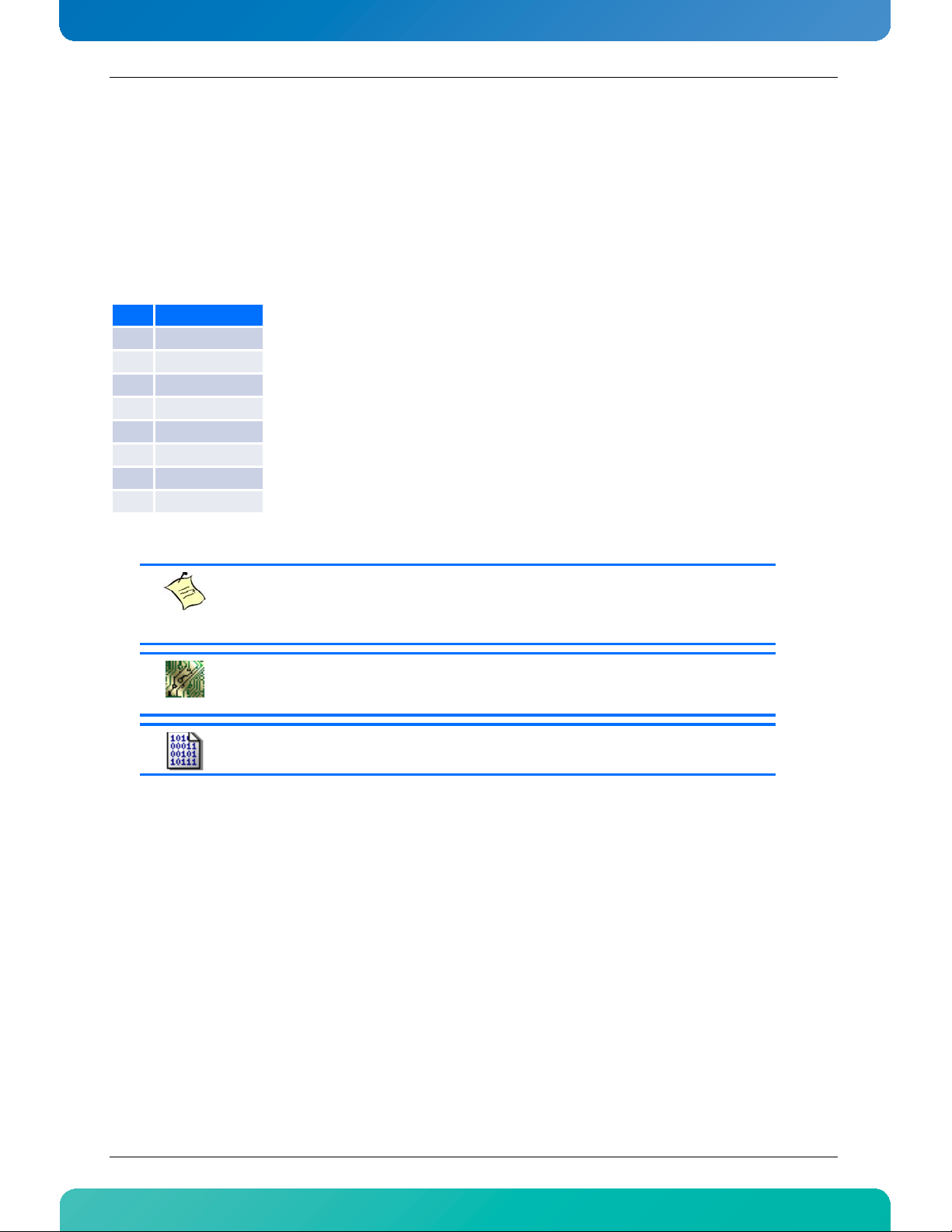

Revision History

Rev. Index Brief Description of Changes Date of Issue

1.0 First Release April 2012

1.1 Add Web interface section in charter 4.3 June 2012

1.2 Add new memory installation instructions section 3.3.2 October 2013

Customer Service

Contact Information: Kontron Canada, Inc.

4555 Ambroise-Lafortune

Boisbriand, Québec, Canada

J7H 0A4

Tel: (450) 437-5682

(800) 354-4223

Fax: (450) 437-8053

E-mail: support@ca.kontron.com

Visit our site at: www.kontron.com

© 2011 Kontron, an International Corporation. All rights reserved.

The information in this user's guide is provided for reference only. Kontron does not assume any liability

arising out of the application or use of the information or products described herein. This user's guide may

contain or reference information and products protected by copyrights or patents and does not convey any

license under the patent rights of Kontron, nor the rights of others.

Kontron is a registered trademark of Kontron. All trademarks, registered trademarks, and trade names used

in this user's guide are the property of their respective owners. All rights reserved. Printed in Canada. This

user's guide contains information proprietary to Kontron. Customers may reprint and use this user's guide in

other publications. Customers may alter this user's guide and publish it only after they remove the Kontron

name, cover, and logo.

Kontron Modular Computer GMBH

Sudetenstrasse 7

87600 Kaufbeuren

Germany

+49 (0) 8341 803 333

+49 (0) 8341 803 339

support-kom@kontron.com

Kontron reserves the right to make changes without notice in product or component design as warranted by

evolution in user needs or progress in engineering or manufacturing technology. Changes that affect the

operation of the unit will be documented in the next revision of this user's guide.

i AT8060

Page 3

www.kontron.com

Table of Contents

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Preventing Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

How to Use This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Customer Comments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Advisory Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Powering Up the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Adapter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Storing Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Table of Contents

Regulatory Compliance Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

1. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 What’s Included. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Board Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Hot-Plug Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Interfacing with the Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6.1 RTM (rear transition module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.6.2 Advanced Mezzanine Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. Board Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 System Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.1 Processors (SandyBridge-EP Series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.2.2 Intel Patsburg PCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3 USB 2.0 Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 USB Flash Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Serial ATA/Serial Attached SCSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.1 Serial Attached SCSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.5.2 Serial ATA (PCH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

ii AT8060

Page 4

Table of Contents

www.kontron.com

2.6 Redundant BIOS Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Ethernet Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7.1 Fabric Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.7.2 Base Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.7.3 SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.8 Serial Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9 AMC Mezzanine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.10 FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.11 Redundant IPMC Firmware & BootBlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.12 LEDs Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.12.1 Hot Swap LED (LED0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.12.2 Out Of Service (LED1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.12.3 Healthy LED (LED2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3. Installing the Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1 Setting Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.1 Jumper Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.1.2 Jumper Setting & Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.2 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3.1 Memory List and Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.3.2 Installing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.4 Onboard Connectors and Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.5 Board Hot Swap and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5.1 Installing the Board in the Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.5.2 Removing the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.5.3 Installing an AMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.5.4 Removing an AMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.5.5 Installing the (RTM806X or RTM8050) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.5.6 Removing the (RTM806X or RTM8050) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4. Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 Hardware Management Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Configuring LAN interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

iii AT8060

Page 5

Table of Contents

www.kontron.com

4.3 Web Management Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3.1 Connecting to the Web Management Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4.3.2 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.3.3 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.3.4 Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.3.5 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.3.6 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.3.7 Logout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.4 Hardware Management Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5 IPMC Specific Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5.1 Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.6 IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.6.1 Supported Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.6.2 Sensor Data Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.6.3 FRU Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.6.4 Clock E-Keying Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

5. Software Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1 AMI UEFI Setup Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.1.1 Accessing the UEFI Setup Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

5.1.2 Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

5.1.3 Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

5.1.4 Advanced Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

5.1.5 Chipset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

5.1.6 Server Mgmt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

5.1.7 Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

5.1.8 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

5.1.9 Save & Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

5.2 Boot Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.2.1 Entering BIOS Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

5.2.2 SAS Option ROM (RTM8050) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

5.2.3 SAS Option ROM (RTM806X). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

5.3 Console Redirection (VT100 Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.3.1 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

5.3.2 ANSI and VT100 Keystroke Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

5.3.3 VT-UTF8 Keystroke Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

iv AT8060

Page 6

Table of Contents

www.kontron.com

6. Thermal Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6.1 Thermal Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6.1.1 Heat Sinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

6.1.2 Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

6.1.3 Airflow blockers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

6.1.4 System Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

6.1.5 Thermal Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

A. Memory & I/O Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.1 Memory Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.2 Kontron I/O Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

A.3 PCI IDSEL and Device Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

B. Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.1 Connectors and Headers Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.2 Post Codes (J2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.3 AMC B1(J19) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.4 USB Dual Port (J12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

B.5 Serial Port, COM1(J13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

B.6 USB Flash Drive(J10, J11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

B.7 Base Interface & Fabric Interface (J23) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

B.8 RTM Connector (J30) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

B.9 RTM Connector (J31) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-5

B.10 Power (P10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-6

C. BIOS Setup Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.1 Memory Reference Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.2 SEC Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.3 PEI Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

C.4 DXE Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

C.5 ACPI/ASL Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

D. Software Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

E. Getting Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

E.1 Returning Defective Merchandise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1

E.2 When Returning a Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-2

F. Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

v AT8060

Page 7

List of Figures

www.kontron.com

List of Figures

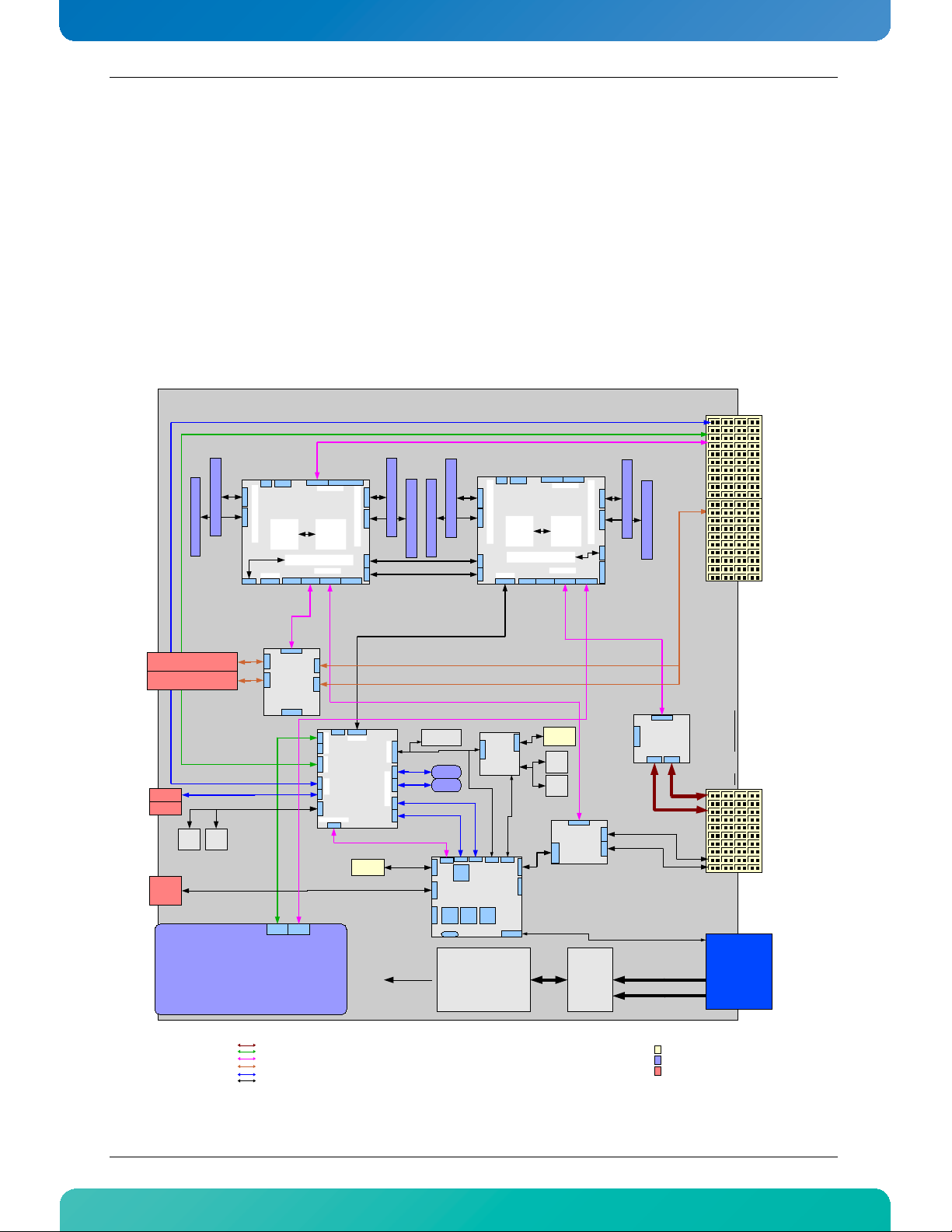

Figure 2-1: Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 2-2: Faceplate LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 3-1: Jumper Settings and Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 3-2: Onboard Connectors and Headers Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 4-1: E-Keying possibilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Figure 6-1: Pressure Curve in Imperial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Figure 6-2: Pressure Curve in Metric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Figure 6-3: CPU Thermal Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

vi AT8060

Page 8

List of Tables

www.kontron.com

List of Tables

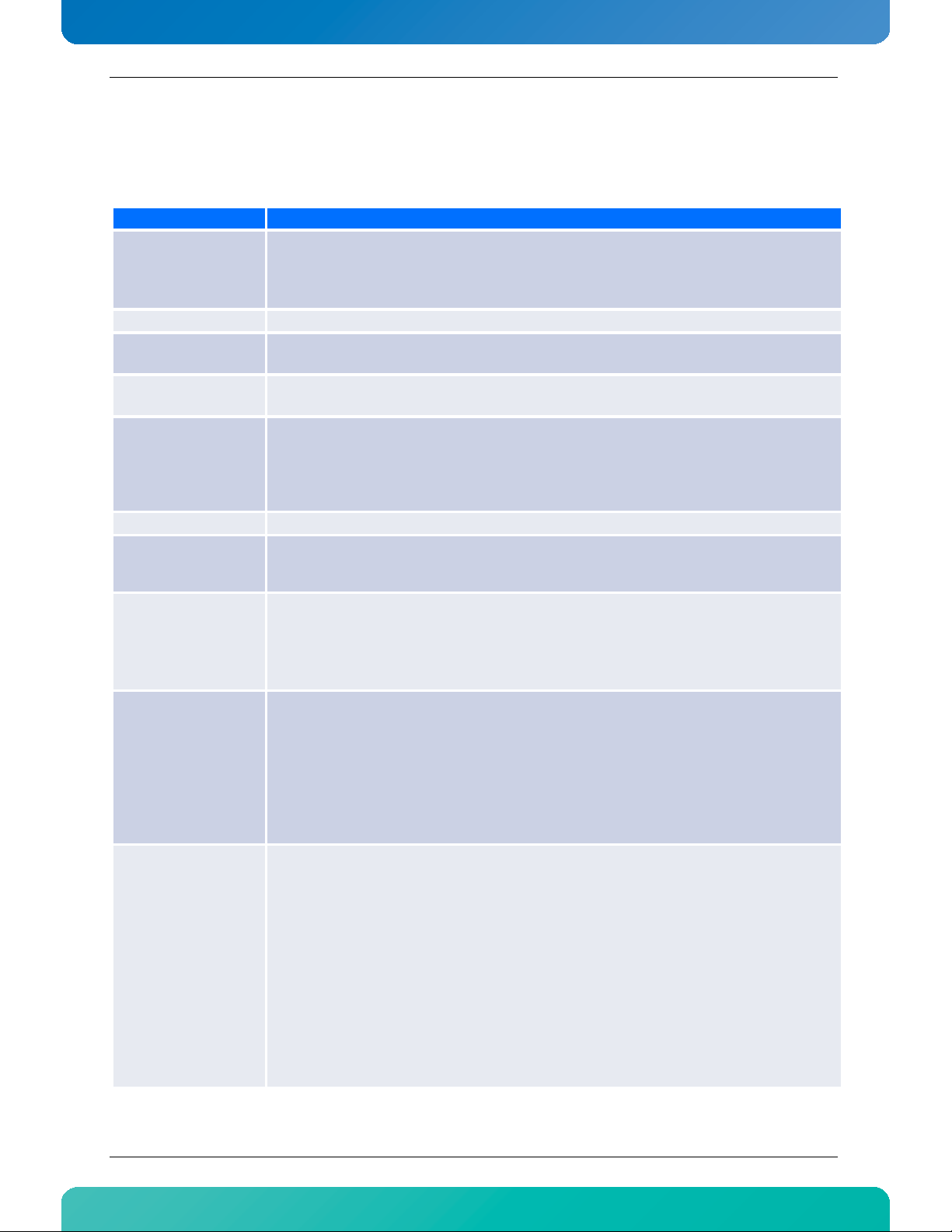

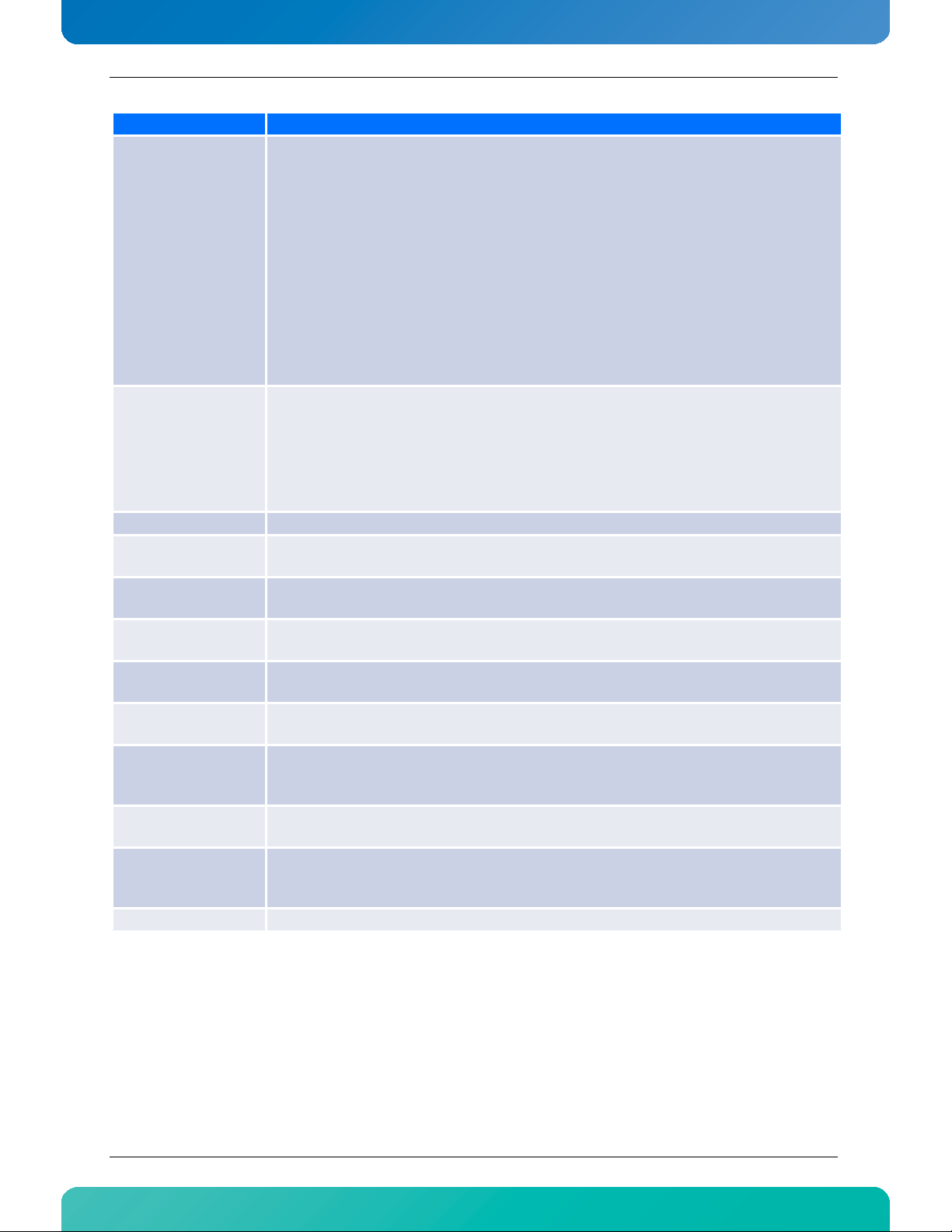

Table 1-1 Board Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2-1 SFP LED Significations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2-2 Serial Interface connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 2-3 Faceplate LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 3-1 Jumper Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 3-2 Approved Memory List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 3-3 Onboard Connectors and Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 4-1 Privilege Level Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 4-2 IPM Device Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 4-3 Watchdog Timer Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 4-4 Device Messaging Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 4-5 Chassis Device Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 4-6 Event Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 4-7 PEF and Alerting Supported Commands for IPMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 4-8 Sensor Device Supported Commands for IPMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 4-9 FRU Device Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 4-10 SDR Device Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 4-11 SEL Device Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 4-12 LAN Device Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 4-13 Serial/Modem Device Supported Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 4-14 SOL Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 4-15 PICMG 3.0 Commands for IPMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 4-16 AMC.0 Carrier Commands for IPMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 4-17 HPM Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 4-18 IPMC Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 4-19 IPMC Health Indicator Sensor Aggregation Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 4-20 Board Information Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 4-21 Product Information Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 4-22 E-Keying capabilities of the board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 4-23 AMC Carrier Activation and Carrier Information Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 4-24 Carrier AMC.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 6-1 Temperature Sensors Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 6-2 Pressure curve AT8060 with AM4320 in bay AMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

vii AT8060

Page 9

Safety Instructions

www.kontron.com

Safety Instructions

Before You Begin

Before handling the board, read the instructions and safety guidelines on the following pages to prevent

damage to the product and to ensure your own personal safety. Refer to the "Advisories" section in the

Preface for advisory conventions used in this user's guide, including the distinction between Warnings,

Cautions, Important Notes, and Notes.

• Always use caution when handling/operating the computer. Only qualified, experienced,

authorized electronics service personnel should access the interior of the computer. The power

supplies produce high voltages and energy hazards, which can cause bodily harm.

• Use extreme caution when installing or removing components. Refer to the installation

instructions in this user's guide for precautions and procedures. If you have any questions, please

contact Kontron Technical Support

WARNING

High voltages are present inside the chassis when the unit's power cord is plugged

into an electrical outlet. Turn off system power, turn off the power supply, and then

disconnect the power cord from its source before removing the chassis cover. Turning

off the system power switch does not remove power to components.

viii AT8060

Page 10

Safety Instructions

www.kontron.com

Preventing Electrostatic Discharge

Static electricity can harm system boards. Perform service at an ESD workstation and follow proper ESD

procedure to reduce the risk of damage to components. Kontron strongly encourages you to follow proper

ESD procedure, which can include wrist straps and smocks, when servicing equipment.

Take the following steps to prevent damage from electrostatic discharge (ESD):

•When unpacking a static-sensitive component from its shipping carton, do not remove the

component's antistatic packing material until you are ready to install the component in a

computer. Just before unwrapping the antistatic packaging, be sure you are at an ESD workstation

or grounded. This will discharge any static electricity that may have built up in your body.

•When transporting a sensitive component, first place it in an antistatic container or packaging.

•Handle all sensitive components at an ESD workstation. If possible, use antistatic floor pads and

workbench pads.

•Handle components and boards with care. Don't touch the components or contacts on a board. Hold

a board by its edges or by its metal mounting bracket.

•Do not handle or store system boards near strong electrostatic, electromagnetic, magnetic, or

radioactive fields.

•When you want to remove the protective foil (if present), make sure you are properly grounded and

that you touch a metalic part of the board.

CAUTION

Removing the protective foil from the top and bottom cover might create static.

When you remove those protections, make sure you follow the proper ESD procedure.

ix AT8060

Page 11

Preface

www.kontron.com

Preface

How to Use This Guide

This user's guide is designed to be used as step-by-step instructions for installation, and as a reference for

operation, troubleshooting, and upgrades.

For the circuits, descriptions and tables indicated, Kontron assumes no responsibility as far as patents or

other rights of third parties are concerned.

The following is a summary of chapter contents:

•Chapter 1, Product Description

•Chapter 2, Board Features

•Chapter 3, Installing the board

•Chapter 4, Hardware Management

•Chapter 5, Software Setup

•Chapter 6, Thermal Considerations

•Appendix A, Memory & I/O Maps

•Appendix B, Connector Pinout

•Appendix C, BIOS Setup Error Codes

•Appendix D, Software Update

•Appendix E, Getting Help

•Appendix F, Glossary

x AT8060

Page 12

Preface

www.kontron.com

Customer Comments

If you have any difficulties using this user's guide, discover an error, or just want to provide some feedback,

please send a message to: Tech.Writer@ca.kontron.com

or problems as soon as possible and post the revised user's guide on our Web site. Thank you.

. Detail any errors you find. We will correct the errors

Advisory Conventions

Seven types of advisories are used throughout the user guides to provide helpful information or to alert you

to the potential for hardware damage or personal injury. They are Note, Signal Paths, Jumpers Settings, BIOS

Settings, Software Usage, Cautions, and Warnings. The following is an example of each type of advisory. Use

caution when servicing electrical components.

Note:

Indicate information that is important for you to know.

Signal Path:

Indicate the places where you can find the signal on the board.

Jumper Settings:

Indicate the jumpers that are related to this section.

BIOS Settings:

Indicate where you can set this option in the BIOS.

Software Usage:

Indicates how you can access this feature through software.

CAUTION

Indicate potential damage to hardware and tells you how to avoid the problem.

WARNING

Indicates potential for bodily harm and tells you how to avoid the problem.

ESD Sensitive Device:

This symbol and title inform that electronic boards and their components are sensitive to static

electricity. Therefore, care must be taken during all handling operations and inspections of this

product, in order to ensure product integrity at all times.

Please read also the section "Special Handling and Unpacking Instructions".

CE Conformity:

This symbol indicates that the product described in this manual is in compliance with all applied CE

standards. Please refer also to the section "Regulatory Compliance Statements" in this manual.

Disclaimer: We have tried to identify all situations that may pose a warning or a caution condition in this

user's guide. However, Kontron does not claim to have covered all situations that might require the use of a

Caution or a Warning.

xi AT8060

Page 13

www.kontron.com

Unpacking

Follow these recommendations while unpacking:

•Remove all items from the box. If any items listed on the purchase order are missing, notify Kontron

customer service immediately.

•Inspect the product for damage. If there is damage, notify Kontron customer service immediately.

•Save the box and packing material for possible future shipment.

Powering Up the System

Before any installation or setup, ensure that the board is unplugged from power sources or subsystems.

If you encounter a problem, verify the following items:

•Make sure that all connectors are properly connected.

Preface

•Verify your boot devices.

•If the system does not start properly, try booting without any other I/O peripherals attached,

including AMC adapters.

Make sure your system provides the minimum DC voltages required at the board's slot, especially if DC power

is carried by cables.

If you are still not able to get your board running, contact our Technical Support for assistance.

Adapter Cables

Because adapter cables come from various manufacturers, pinouts can differ. All cables are available from

Kontron Sales Department.

Storing Boards

Electronic boards are sensitive devices. Do not handle or store device near strong electrostatic,

electromagnetic, magnetic or radioactive fields.

xii AT8060

Page 14

www.kontron.com

Regulatory Compliance Statements

FCC Compliance Statement for Class B Devices

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generated, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Preface

•Consult the dealer or an experience radio/TV technician for help.

WARNING

This is a Class B product. If not installed in a properly shielded enclosure and used in

accordance with this User's Guide, this product may cause radio interference in

which case users may need to take additional measures at their own expense.

Safety Certification

All Kontron equipment meets or exceeds safety requirements based on the IEC/EN/UL/CSA 609501 family of standards entitled, "Safety of information technology equipment." All components are

chosen to reduce fire hazards and provide insulation and protection where necessary. Testing and

reports when required are performed under the international IECEE CB Scheme. Please consult the

"Kontron Safety Conformity Policy Guide" for more information. For Canada and USA input voltage

must not exceed -60Vdc for safety compliance.

CE Certification

The product(s) described in this user's guide complies with all applicable European Union (CE)

directives if it has a CE marking. For computer systems to remain CE compliant, only CE-compliant

parts may be used. Maintaining CE compliance also requires proper cable and cabling techniques.

Although Kontron offers accessories, the customer must ensure that these products are installed

with proper shielding to maintain CE compliance. Kontron does not offer engineering services for

designing cabling systems. In addition, Kontron will not retest or recertify systems or components

that have been reconfigured by customers.

xiii AT8060

Page 15

Preface

www.kontron.com

Limited Warranty

Kontron grants the original purchaser of Kontron's products a TWO YEAR LIMITED HARDWARE WARRANTY as

described in the following. However, no other warranties that may be granted or implied by anyone on behalf

of Kontron are valid unless the consumer has the express written consent of Kontron.

Kontron warrants their own products, excluding software, to be free from manufacturing and material

defects for a period of 24 consecutive months from the date of purchase. This warranty is not transferable nor

extendible to cover any other users or long- term storage of the product. It does not cover products which

have been modified, altered or repaired by any other party than Kontron or their authorized agents.

Furthermore, any product which has been, or is suspected of being damaged as a result of negligence,

improper use, incorrect handling, servicing or maintenance, or which has been damaged as a result of

excessive current/voltage or temperature, or which has had its serial number(s), any other markings or parts

thereof altered, defaced or removed will also be excluded from this warranty.

If the customer's eligibility for warranty has not been voided, in the event of any claim, he may return the

product at the earliest possible convenience to the original place of purchase, together with a copy of the

original document of purchase, a full description of the application the product is used on and a description

of the defect. Pack the product in such a way as to ensure safe transportation (see our safety instructions).

Kontron provides for repair or replacement of any part, assembly or sub-assembly at their own discretion, or

to refund the original cost of purchase, if appropriate. In the event of repair, refunding or replacement of

any part, the ownership of the removed or replaced parts reverts to Kontron, and the remaining part of the

original guarantee, or any new guarantee to cover the repaired or replaced items, will be transferred to cover

the new or repaired items. Any extensions to the original guarantee are considered gestures of goodwill, and

will be defined in the "Repair Report" issued by Kontron with the repaired or replaced item.

Kontron will not accept liability for any further claims resulting directly or indirectly from any warranty

claim, other than the above specified repair, replacement or refunding. In particular, all claims for damage

to any system or process in which the product was employed, or any loss incurred as a result of the product

not functioning at any given time, are excluded. The extent of Kontron liability to the customer shall not

exceed the original purchase price of the item for which the claim exists.

Kontron issues no warranty or representation, either explicit or implicit, with respect to its products

reliability, fitness, quality, marketability or ability to fulfil any particular application or purpose. As a result,

the products are sold "as is," and the responsibility to ensure their suitability for any given task remains that

of the purchaser. In no event will Kontron be liable for direct, indirect or consequential damages resulting

from the use of our hardware or software products, or documentation, even if Kontron were advised of the

possibility of such claims prior to the purchase of the product or during any period since the date of its

purchase.

Please remember that no Kontron employee, dealer or agent is authorized to make any modification or

addition to the above specified terms, either verbally or in any other form, written or electronically

transmitted, without the company's consent.

xiv AT8060

Page 16

Chapter 1

Product Description

www.kontron.com

1.1 Product Overview .............................................. 2

1.2 What’s Included................................................ 2

1.3 Board Specifications.......................................... 3

1.4 Compliance ...................................................... 5

1.5 Hot-Plug Capability............................................ 5

1.6 Interfacing with the Environment......................... 5

1 AT8060

Page 17

Product Description

www.kontron.com

1. Product Description

1.1 Product Overview

The AT8060 is a single width ATCA compliant processor blade. It implements Intel’s next generation Xeon

dual processors codename Sandybridge on Romley platform. The AT8060 uses the full bandwidth of the four

DDR3 memory channels with 4 VLP DDR3 Sockets per CPU. High speed interfaces such as dual 10GBase-KX4 in

the fabric interface can deliver maximum performance using the PCIe ports from the processors. Dual 8GT/s

QPI interfaces between both CPUs provide 40GByte/s/direction for a minimum latency on memory access and

CPU process.

The chipset, the Patsburg-B, is connected to the processors via a DMI2 interface and to various I/O

components.

Three Ethernet controllers from Intel are implemented to provide high speed interfaces in the fabric

interface (82599), the base interface (82576) and on both Board and RTM faceplates (Powerville).

Additional I/O interfaces can be added with RTM and AMC cards using the x8 PCIe Gen2 provided for each. 4

SAS2 interfaces are connected to RTM interace from the PCH for storage. The AT8060 operates in two power

level modes, a regular power mode up to 225W for NEBS-like operation and a High Power mode up to 350W

for higher-class chassis applications.

1.2 What’s Included

This board is shipped with the following items:

• One AT8060 board

• One RJ45-DB9 serial adaptor (1015-9404)

• One AMC filler panel

If any item is missing or damaged, contact the supplier.

2 AT8060

Page 18

www.kontron.com

1.3 Board Specifications

Table 1-1: Board Specifications

Features Description

• Dual socket Intel Xeon Processors from the SandyBridge-EP series E5-2600 processor family.

Processors

Chipset • Patsburg-B C600 Series

Bus Interface

Expansion Slot

System Memory

Flash Memory • Two connectors for two optional eUSB (embedded USB) flash drive modules

Storage

I/O

Board Specifications

BIOS Features

• 8cores 1.8GHz 70W

• 8cores 2.0GHz 95W

• 6cores 2.3GHz 95W

• Dual QPI 8GT/s between both CPUs

• DMI Gen2 5GT/s from CPU to Chipset

• 1 Mid-size AdvancedMC bay with PCIe x8 Gen 2 connection

• PCIe x8 Gen2 connection to RTM

• Support of DDR3 1066 to 1600MHz with ECC

• Standard voltage(1.5V) and low-voltage(1.35V) modules are supported

• 4 memory channnels per CPU with a single DIMM location per channel

• Up to 8GB memory modules per socket for a total of 64GB (note: 16GB modules could be

supported in a near future for a total of 128G)

• Single SATA GEN1 (1.5Gb/s), GEN2 (3Gb/s) and GEN3 (6Gb/s) on the AMC storage interface.

• Four SATA GEN1 (1.5Gb/s), GEN2 (3Gb/s), GEN3 (6Gb/s) and SAS 3Gb/s storage interfaces on

the RTM.

•Dual SFP

•Dual USB

• RJ45 Serial Port

• TPM mezzanine

• Video debug port available on the RTM

• PICMG3.0 R3.0(AdvancedTCA Base Specification)

• PICMG3.1 R1.0 (Ethernet/Fiber Channel over AdvancedTCA)

• AMC.0 R2.0 (Advanced Mezzanine Card Base Specification)

• AMC.1 R2.0 types 1, 2, 4, 8 (Advanced Mezzanine Card PCI-Express)

• AMC.3 R1.0 (Advanced Mezzanine Card Storage)

• ACPI rev 2.0

•HPM.1

•IPMI 2.0

• AMI UEFI with Compatibility Support Module for legacy option ROMs and Operating System

support

• Save BIOS Configuration to SPI.

• Boot from Ethernet PXE (Base and Fabric interfaces and management Lan)

• Boot from Ethernet iSCSI (Fabric interfaces)

• Boot from SAS/SATA; and boot from USB 2.0 (Floppy, CD-ROM, Hard Disk)

• Diskless, Keyboard less, and battery less operation extensions

• System, video and LAN BIOS shadowing

• Robust BIOS flash Update with rollover capability (HPM.1)

• Field updateable BIOS

• Advanced Configuration and Power Interface (ACPI 2.0, 3.0 & 4.0)

• Console redirection to serial port (VT100)with CMOS setup access, and SOL (Serial over LAN)

• Event (correctable/uncorrectable ECC,PCIe, POST errors); log support to IPMC

Product Description

3 AT8060

Page 19

www.kontron.com

Features Description

• Management Controller compliant IPMI v2.0.

• Remote control capability (power on-off /clean shutdown/cold reset) via any IPMI channels

including LAN.

• Full speed 115200 bps Serial Over LAN (+LAN access to BIOS menu setup) and IPMI Over LAN

(IPMI v2.0) always available.

• Serial data caching and replay to ease software application troubleshooting and post mortem

IPMI Features

Supervisory

OS Compatibility • Validated with: Red Hat Enterprise Linux 5.5 and 6.1.

Power Requirements

Environmental

Temperature*

Environmental

Humidity*

Environmental Altitude*

Environmental Shock*

Environmental

Vibration*

Reliability

Safety / EMC

Warranty Two years limited warranty

analysis.

• Bios Post Code errors are sent to the chassis manager's for System Event Logging.

• Configurable automatic “clean ACPI shutdown” policy on disk storage deactivation (AMC or

RTM).

• Standard PCIe Hot Plug operation embedded with PICMG AMC/RTM activation.

• Robust IPMI firmware Update with rollover capability, without any payload impact (HPM.1).

• Override configuration for activation of the board/AMC/RTM without Shelf Manager

Intervention.

• Supports a system management interface (KCS interrupt driven) via an IPMI V2.0 compliant

controller.

• Standard IPMI Watchdog for all CPU running phases (BIOS execution / OS loading and running).

• IPMI Hardware system monitor (power/voltages), memory and all critical component's is

monitored.

• Extensive sensor monitoring (around 100 IPMI sensors) and event generation based on

thresholds and discrete readings.

1- NEBS power mode: =<235W (210W front board and AMC + 25W RTM)

2- High power mode: =< 350W

Operating: 0-55°C/32-131°F with 30CFM airflow

Storage and Transit: -40 to +70°C/-40 to 158°F

Operating: 15% to 90% @55°C/131°F non-condensing

Storage and Transit: 5% to 95% @ 40°C/104°F non-condensing

Operating: 4,000 m / 13,123 ft

Storage and Transit: 15,000 m / 49,212 ft

Operating: 3G each axis

Storage and Transit: 18G each axis

Operating: 5-200Hz. 0.2G, each axis

Storage and Transit: 5Hz to 20Hz @ 1 m2/s3 (0.01g2 /Hz) (flat)

20Hz to 200Hz @ -3dB/oct (slope down)

• Whole board protected by active breaker

• USB voltage protected by active breaker

Meet or exceed:

• Safety: UL 60950-1; CSA C22.2 No 60950-1-03; EN 60950-1:2001; IEC60950-1

• EMI/EMC: FCC 47 CFR Part 15, Class B; CE Mark to EN55022/EN55024/EN300386

Product Description

* Designed to meet or exceed

4 AT8060

Page 20

www.kontron.com

1.4 Compliance

This product conforms to the following specifications:

• PICMG3.0 R3.0(AdvancedTCA Base Specification)

• PICMG3.1 R1.0 Option 1 and 9(Ethernet/Fiber Channel over AdvancedTCA)

• AMC.0 R2.0 (Advanced Mezzanine Card Base Specification)

• AMC.1 R2.0 type 1, 2, 4 and 8 (Advanced Mezzanine Card PCI-Express)

• AMC.3 R1.0 (Advanced Mezzanine Card Storage)

• ACPI rev 2.0

•HPM.1

•IPMI 2.0

Product Description

1.5 Hot-Plug Capability

The AT8060 supports Full Hot Swap capability as per PICMG3.0 R3.0 for the board itself, the RTM module and

AMC bay. It can be removed from or installed in the system while it is on (without powering-down the

system). Please refer to the PICMG3.0 R3.0 specification for additional details about Hot Swap.

The AT8060 supports PCI-Express Hotplug on AMC B1 and RTM. The IPMC uses the standard PCI Express

Hotplug Controller on the CPU board allowing hot insertion and removal of an AMC or RTM module within the

OS.

1.6 Interfacing with the Environment

1.6.1 RTM (rear transition module)

The AT8060 supports different single slot (6HP) AdvancedTCA Rear Transition Modules: RTM8050 and

RTM806X. These modules provide additional connectivity for AT8060 CPU front blade.

1.6.1.1 Standard Compliance

• PICMG3.0 R3.0 - Advanced Telecommunication Computing Architecture

1.6.1.2 Serial Port Feature

• One serial port available on the RTM face plate through a RJ-45 connector.

5 AT8060

Page 21

Product Description

www.kontron.com

• RS-232 signal levels at RTM face plate connector.

• Serial port speed capability is: 9.6kbits/s to 115.2kbits/s.

1.6.1.3 Debug Video Feature

A header is present on the RTM to connect a debug video cable. This interface is suitable for low rate video,

not for HD or intensive use. Video signals are VGA standard signals. Custom video cable available on demand,

please contact Technical Support.

1.6.1.4 Hot Swap

The RTM supports hot swapping by using the switch connected to the face plate lower ejector. This switch

indicates the coming hot swap action. The insertion of the RTM to a slot is always done over a non powered

connector. During the extraction procedure, the management power is disabled only when the RTM806X is

removed. This procedure meets the AdvancedTCA AMC behavior.

1.6.1.4.1 Inserting the RTM into the slot

The presence of the RTM is indicated by one signal. The front blade IPMC recognizes the RTM insertion when

the signal is low. After recognizing the RTM, the IPMC turns the blue LED ON and enables the management

power to the RTM. Once the IPMB-L link is working, the IPMC accesses the MMC to retrieve FRU data. After

knowing the type of RTM inserted, the IPMC negotiates with the shelf manager in order to activate the +12V

payload power.

After RTM local voltages ramp up, the front board IPMC informs the shelf manager there is a functional RTM

blade present.

1.6.1.4.2 Removing the RTM from the slot

The RTM_EJECT signal goes HIGH by opening the RTM lower ejector handle. This indicates to the front blade

IPMC that a hot swap action is going to take place. The IPMC then negotiates the removal with the System

manager and if it is granted, it proceeds with the removal process.

The IPMC proceeds to the deactivation by disabling ekey governed links, the IPMC then turns OFF the payload

+12V power. When it is safe to remove the RTM blade from the slot, the IPMC turns the Blue / Hot Swap LED

ON. Front Blade IPMC turns OFF the management power only when there is no RTM detected. (RTM806X

removed from the slot)

1.6.2 Advanced Mezzanine Card

The AT8060 has one AMC bay. Using a mezzanine allows to add storage or I/O not provided on board.

1.6.2.1 AMC Expansion

The AMC slot provides an AMC.1 type 4, AMC.3 SATA. This means that the following signaling are supported:

• PCI-Express Gen2 X8 on AMC ports 4-11

6 AT8060

Page 22

www.kontron.com

• PCI-Express clock on FCLKA

• SATA on AMC port

Product Description

7 AT8060

Page 23

Chapter 2

Board Features

www.kontron.com

2.1 Block Diagram .................................................. 9

2.2 System Core ..................................................... 10

2.3 USB 2.0 Interfaces............................................. 10

2.4 USB Flash Module.............................................. 11

2.5 Serial ATA/Serial Attached SCSI............................ 11

2.6 Redundant BIOS Flash........................................ 12

2.7 Ethernet Interfaces............................................ 12

2.8 Serial Interfaces................................................ 14

2.9 AMC Mezzanine ................................................. 14

2.10 FPGA............................................................... 15

2.11 Redundant IPMC Firmware & BootBlock.................. 16

2.12 LEDs Description ............................................... 16

Page 24

www.kontron.com

2. Board Features

2.1 Block Diagram

Figure 2-1:Block Diagram

9 AT8060

Page 25

www.kontron.com

2.2 System Core

2.2.1 Processors (SandyBridge-EP Series)

• Built on 32 nanometer process technology.

• Six/Eight cores processor in 2011-land FCLGA.

• 32KB L1/core

• 256KB L2 / core

• Up to 20MB L3: Up to 2.5MB per core.

• Streaming SIMD Extension 4.1 and 4.2

• Integrated 4-channel DDR3 controller, DDR3-1600 memory with ECC

• Intel QuickPath interconnect links, 8.0/7.2 GT/s in each direction

• Intel 64 Bit Architecture

• Enhanced Intel SpeedStep Technology

• Intel Virtualization Technology (VT)

• Intel Hyper-Threading Technology (HT)

2.2.2 Intel Patsburg PCH

• Direct Media Interface (DMI) x4 lanes for communicating with CPU0

• SATA Gen3 up to 6Gbps, SAS Gen2 up to 3Gbps, USB

2.3 USB 2.0 Interfaces

The board embeds a USB controller in the PCH. This controller is compliant to USB 2.0. It provides two USB

ports on the face plate, two on the RTM and two ports are reserved for the eUSB SSD. Those ports can be used

for external storage and for booting.

USB supports Plug and Play and hot-swapping operations (OS level). These features allow USB devices to be

automatically attached, configured and detached, without reboot or running setup.

Signal Path:

- 2 USB 2.0 on front panel (J12, J13)

- 2 USB 2.0 on the RTM front panel

- 2 USB 2.0 onboard for the eUSB SSD

10 AT8060

Page 26

www.kontron.com

BIOS Settings:

Advanced -> USB Configuration

Chipset -> South Bridge -> USB Configuration

2.4 USB Flash Module

The AT8060 supports up to two Solid State Drives. It is a NAND flash disk module with a USB 2.0 interface. The

modules are socketed on two 2x5 headers attached to the AT8060. They are available in many sizes and

accessible only when removing the top cover. By default the USB devices are used as booting devices.

Signal Path:

USB Flash Module Connector are available on J10 and J11. See section 3.4 for more details.

BIOS Settings:

Advanced --> USB Configuration

Boot --> BBS

Note:

During the installation of an OS on a HDD, the USB Flash Module must be deactivated. If the USB

Flash Module remains active, the Master Boot Record will be installed on it by default. This can not

be avoided and will cause the OS to be unable to boot from the HDD.

2.5 Serial ATA/Serial Attached SCSI

2.5.1 Serial Attached SCSI

The PCH's SAS ports 0-3 are available in the RTM connector. It supports SATA GEN1 (1.5Gb/s), GEN2 (3Gb/s),

GEN3 (6Gb/s) and SAS 3Gb/s on the RTM storage interfaces.

2.5.2 Serial ATA (PCH)

The PCH SATA port 0 is connected to the AMC Port 2. It supports SATA GEN1 (1.5Gb/s), GEN2 (3Gb/s) and

GEN3 (6Gb/s) on the AMC storage interface.

11 AT8060

Page 27

www.kontron.com

2.6 Redundant BIOS Flash

Two redundant 64MBits, SPI EEPROMs are connected to PCH for the BIOS. Only one EEPROM at a time is

available for the PCH. If for some reason a BIOS update corrupts an EEPROM which prevents the CPU from

completing the boot sequence, the IPMC will swap the active SPI EEPROM and force a reboot.

2.7 Ethernet Interfaces

2.7.1 Fabric Interface

The fabric interface can be either 10GbE or 1GbE.

The AT8060 has boot from LAN capability (PXE) or iSCSI support on these ports. You can enable the option

from the BIOS Setup Program. Please refer to Section 5.1, AMI UEFI Setup Program.

The AT8060 has one dual port 10GbE controller (i82599EB) connected to the Fabric Interface. This controller

can also be used as a dual 1Gb. The controller auto-negociates between 10G-BASE-KX4 and 1G-BASE-KX.

Features high performance with TCP/IP and UDP/IP checksum offloading for IPv4 and IPv6, packet filtering,

and jumbo frame up to 15.5K.

See http://www.intel.com

Signal Path:

The two ports are available on the Fabric Interface.

BIOS Settings:

Advanced --> Legacy Expansion ROM Configuration -> FI: XE OpROM, Port 1 and 2

for additional details on the i82599EB.

2.7.2 Base Interface

An i82576EB dual port 1Gb Ethernet controller is connected on the Base Interface.

Boot from LAN capability (PXE) is supported on these ports. Enable the option from the BIOS Setup Program.

Please refer to Section 5.1, AMI UEFI Setup Program.

Features high performance with TCP/IP and UDP/IP checksum offloading for IPv4 and IPv6, packet filtering,

and jumbo frame up to 16K.

See http://www.intel.com

for additional details on the i82576EB.

12 AT8060

Page 28

www.kontron.com

Signal Path:

The two ports are available on the Base Interface.

BIOS Settings:

Advanced --> Legacy Expansion ROM Configuration -> BI: GE OpROM, Port 1 and 2

2.7.3 SFP

A Powerville quad 1000 Base-T / SerDes controller is installed onboard. Two ports are routed to the RTM and

two are routed to the front panel SFP connectors. The front SFP cages support multi-rate fiber SFP modules.

The SFP interfaces feature the following connectivity:

• front panel with a dual SFP cage

• two connections through the RTM connector

Signal Path:

The front panel and on the RTM.

BIOS Settings:

Advanced --> Legacy Expansion ROM Configuration -> FP: GE OpROM, Port 1 and 2 (front panel)->

RTM:

CAUTION LASER LIGHT!

Do not look into the laser beam!

The SFP module is fitted with a class 1 or 1M laser. To avoid possible exposure to

hazardous levels of invisible laser radiation, do not exceed maximum ratings.

The SFP port has a bi-color green/amber LED with the following signification:

Table 2-1: SFP LED Significations

LED Signification

Green on Link 1Gbit

Green blink Activity 1Gbit

Amber on Link 10/100Mbit

Amber blink Activity 10/100Mbit

13 AT8060

Page 29

www.kontron.com

2.8 Serial Interfaces

The AT8060 uses serial interfaces to manage the CPU, the only way to get visual information from the board

when used without a RTM806X. Serial ports are provided on the faceplate and on the RTM faceplate for

asynchronous serial communications. They are 16C550 high-speed UART compatible and support 16-byte

FIFO buffers for transfer rates from 9,6Kbps to 115,2Kbps.

Table 2-2:Serial Interface connector Pinout

Pin Signal

1 RTS

2 DTR

3 TX#

4 GND

5 GND

6 RX#

7 DSR

8 CTS

Note:

Standard product uses a RJ-45 8 pins connector. RI (ring indicator) and DCD (data carrier detect)

signals are not available.

The pinout is a custom one, not the same as RS-232D TIA/EIA-561.

Signal Path:

COM1 is routed to a RJ45 on the frontplate or to the IPMC for SOL.

COM2 is routed to the RTM serial interface.

BIOS Settings:

Advanced -> Serial Port Console Redirection -> Console Redirection Settings (COM0 and COM1)

2.9 AMC Mezzanine

The AMC slot supports AMC.1 (PCIe) and AMC.3 (SAS/SATA) in addition to the AMC.0 base specification. The

AMC is hot swappable according to PICMG 3.0 Rev. 2.0 and supports mid-size AMC units.

One AMC site is available. Characteristics of the AMC are as follow:

•Type B+

•Supports mid-size single width mechanical format

•PCI-Express X8 (GEN2 2.5GTs or 5.0GTs) with reference clock on AMC FCLKA

•Fully compliant PCI-Express hot plug support

14 AT8060

Page 30

www.kontron.com

•SATA link to the PCH

•Compliant to AMC.0, AMC.1 and AMC.3

•50W maximum power budget

Note:

The thermal solution needs to be validated by the integrator when AMC Thermal Design power

exceeds 20W.

As per AMC.1 R2.0, the carrier board is required to provide PCIe 100MHz reference clock to the AMC on FCLKA.

However, modules are not required to use it. Kontron recommends using AMC modules that use the reference

clock on FCLKA. If the module makes its own reference clock, then the spread spectrum of PCI-Express clock

synthetizer will be disabled by e-keying; otherwise the behavior of the PCI-Express link will be erratic.

Note:

All electromagnetic compatibility testing has been done with spread spectrum. Disabling the spread

spectrum can complicate EMC.

The SATA interface on port 2 allows to use a SATA AMC storage mezzanine on the AT8060. AMC SATA electrical

path is properly designed for Hot Swap operation but special care must be taken to ensure proper un-mount

sequence within the operating system.

BIOS Settings:

Advanced --> SATA Configuration

Advanced --> Legacy Expansion ROM Configuration -> AMC Slot OpROM(s)

Chipset -> IOH Configuration -> AMC Port Link Speed

Server Mgmt -> Managed FRU Deactivate Policies

Software Usage:

AMC serial port is available on port 15.

AMC serial port GUID : 471C5D14-2AE7-42B9-A9B0-0628546B42CC

Note:

The maximum power budget is 50W for an Advanced Mezzanine Card.

2.10 FPGA

The FPGA has many functions. One of them is to act as a companion chip to the IPMC. The states of all the

critical signals controlled by the IPMC are memorized in the FPGA and are preserved while the IPMC firmware

is being updated.

The FPGA is a RAM-based chip that is preloaded from a separate flash memory at power-up. Two such flash

memory devices are provided; one that can only be programmed in factory and the other one that can be

updated in the field. The factory flash is selected by inserting jumper JP2 pins 3-4. Field updates require to

cycle the power of the board. The IPMI LED2 will blink amber if the factory flash is being used to signal a fail

safe configuration.

The FPGA update complies to PICMG HPM.1 specification and is remotely updatable via any IPMC channel.

15 AT8060

Page 31

www.kontron.com

2.11 Redundant IPMC Firmware & BootBlock

The IPMC runs a firmware from SPI flash memory. The IPMC Boot Block saves the last two copies of the IPMC

firmware image in the same as it's boot block SPI flash memory. The Boot Block manages the IPMC

reprogrammation and can rollback to the previous firmware image in the IPMC internal flash in case of update

problem.

Note:

The IPMC has an external hardware watchdog.

2.12 LEDs Description

The following table lists the LED on the faceplate (excluding the SFP Ethernet LEDs).

Table 2-3:Faceplate LEDs

LED Name Color Controlled by Description

HDD activity Green Chipset/FPGA AMC & RTM HDD activity status

ATC A0 Blue IPMC Blade Hot Swap status

ATC A1 Amber/Red IPMC Blade OOS (out-of-service)

ATC A2 Amber/Green IPMC Healthy status

ATC A3 Amber/Green IPMC/CPU Application specific

B.I. 1 Amber/Green FPGA Base Interface Channel 1 Status

B.I. 2 Amber/Green FPGA Base Interface Channel 2 Status

F.I. 1 Amber/Green FPGA Fabric Interface Channel 1 Status

F.I. 2 Amber/Green FPGA Fabric Interface Channel 2 Status

RTM 1 Amber/Green FPGA

RTM 2 Amber/Green FPGA

FRONT 1 Amber/Green FPGA

FRONT 2 Amber/Green FPGA

Management LAN RTM Interface Channel

1 status

Management LAN RTM Interface Channel

2 status

Management LAN SFP Interface Channel

1 status

Management LAN SFP Interface Channel

2 status

2.12.1 Hot Swap LED (LED0)

The Blue / Hot Swap LED indicates the hot swap status of the unit. The LED is ON when it is safe to remove the

unit from the slot. During normal operation, this LED is OFF.

16 AT8060

Page 32

www.kontron.com

2.12.2 Out Of Service (LED1)

The AdvancedTCA LED1 is red or amber and indicates an Out-of-Service (OOS) condition. During normal

operation, the OOS LED is OFF. This LED is ON during firmware upgrade and is user configurable if needed by a

customer application.

2.12.3 Healthy LED (LED2)

The AdvancedTCA LED2 is green or amber and indicates a healthy condition. The healthy LED indicates if the

blade is powered up and all voltages and temperatures are within specifications. During normal operation,

this LED is ON (green). This LED is also ON (amber) when one of the RTM806X voltage or temperature fails.

17 AT8060

Page 33

www.kontron.com

Figure 2-2:Faceplate LEDs

Hot Swap (Blue)

Solid On (100 % on): FRU Inactive

Long Blink ( 90 % on): FRU Activation Request

Solid Off ( 0 % on): FRU Activation In Progress / FRU Active

Short Blink ( 10 % on): FRU Deactivation Request / FRU Deactivation In Progress

Out of service (Red/Amber) [ default : Red ]

Solid On : MMC in reset

Fast Blink (~50 % on) : MMC upgrade/rollback in progress

Application Defined : May be controlled by application using PICMG API

Health Led (Amber/Green) [ default : Green ]

Off : Payload power down

Green : Health Ok

Amber : Health Error (Critical)

Application Defined : May be controlled by application using PICMG API

Hard Disk Activity Led (Green)

Blink : Hard Disk Activity

FI Led (Green/Amber)

Green On : Link 10Gbit

Green Blink : Activity 10Gbit

Amber On : Link 1Gbit

Amber Blink : Activity 1Gbit

BI Led (Green/Amber)

Green On : Link 1Gbit

Green Blink : Activity 1Gbit

Amber On : Link 10-100Mbit

Amber Blink : Activity 10-100Mbit

SFP RTM Led (Green/Amber)

Green On : Link 1Gbit

Green Blink : Activity 1Gbit

Amber On : Link 10-100Mbit

Amber Blink : Activity 10-100Mbit

SFP Front Led (Green/Amber)

Green On : Link 1Gbit

Green Blink : Activity 1Gbit

Amber On : Link 10-100Mbit

Amber Blink : Activity 10-100Mbit

18 AT8060

Page 34

Chapter 3

Installing the Board

www.kontron.com

3.1 Setting Jumpers................................................ 20

3.2 Processor......................................................... 21

3.3 Memory........................................................... 21

3.4 Onboard Connectors and Headers ......................... 24

3.5 Board Hot Swap and Installation .......................... 25

Page 35

www.kontron.com

3. Installing the Board

3.1 Setting Jumpers

3.1.1 Jumper Description

Table 3-1:Jumper Description

Name Description Jumper

Reserved Reserved JP2 (1-2)

FPGA PROM Selection When On, it selects the factory prom JP2 (3-4)

Clear BIOS setup in flash When On, it clears the BIOS Setup JP2 (5-6)

Reserved Reserved JP2 (7-8)

Reserved Reserved JP2 (9-10)

Reserved Reserved JP2 (11-12)

Onboard video enable When On, it enables onboard video controller. JP2 (13-14)

Watchdogs When On, it disables the watchdogs JP1 (1-2)

Reserved Reserved JP1 (3-4)

Reserved Reserved JP1 (5-6)

AMC & RTM Activation When On, it overrides the AMC & RTM activation JP1 (7-8)

AMC PCIe Override When On, drives AMC/RTM PCIe clocks JP1 (9-10)

Reserved Reserved JP1 (11-12)

Reserved Reserved JP1 (13-14)

20 AT8060

Page 36

www.kontron.com

3.1.2 Jumper Setting & Locations

Watchdogs Disabled

Watchdogs Enabled

JP1 (1-2) Watchdogs

IN

OUT

Reserved

Normal

JP1 (3-4) Reserved

IN

OUT

Override (FPGA turn-on table)

Normal

JP1 (5-6) IPMI Override

IN

OUT

Override (turn-on FRUs)

Normal

JP1 (7-8) FRU Override

IN

OUT

Default Configuration

Override (drive FRUs clocks)

Normal

JP1 (9-10) FRU PCIe Override

IN

OUT

Factory Mode

Operation

JP1 (11-12) Factory Mode

IN

OUT

Reserved

Normal Normal Operation

JP1 (13-14) Reserved

IN

OUT

J1 J2 J3

J4 J5

J6

J7

J8

JP2

JP1

1

13

2

14

1

13

2

14

J30

J31

Reserved

Normal Operation

JP2 (1-2) Spare

IN

OUT

Factory Prom (Fail-Safe)

Normal (Auto)

JP2 (3-4) FPGA PROM Selection

IN

OUT

Reserved

Normal Operation

JP2 (5-6) Clear BIOS Setup In Flash

IN

OUT

Reserved

Normal Operation

JP2 (7-8) FPGA Reserved #0

IN

OUT

Reserved

Normal Operation

JP2 (9-10) FPGA Reserved #1

IN

OUT

Reserved

Normal Operation

JP2 (11-12) Reserved

IN

OUT

Reserved

Normal Operation

JP2 (13-14) IPMC Reserved

IN

OUT

Default Configuration

Figure 3-1:Jumper Settings and Locations

Note:

More details about the jumper settings can be found on the Quick Reference Sheet.

3.2 Processor

This product can be shipped with the CPUs and a thermal solution installed. The thermal solution is custom

and critical for passive cooling. Cooling performance can greatly be affected if heat sink is not handled

properly. Do not attempt any heat sink removal after installation.

3.3 Memory

The AT8060 has 4 memory channels connected to each CPU. There is one DIMM per memory channel for a total

of 4 per CPU. The AT8060 accepts DDR3, VLP(very low-profile) (0.72 inch; 18.29mm), 1.5V or 1.35V modules,

registered, ECC, x4 or x8 memory with up to 4 ranks per DIMM. The DDR3 memory channels run at 1333MHz or

1600MHz. The maximum DDR3 SDRAM size is 16GBytes per DIMM for a populated 128GBytes maximum.

Memory modules shall have a validated thermal solution (heatsink) and may necessitate a certain class of

chassis. It is recommended that modules have thermal sensors for accurate temperature monitoring and to

21 AT8060

Page 37

www.kontron.com

throttle the memory interface in case of overheating. Memory can perform double refresh rate to get higher

maximum operating temperature.

Kontron recommends the use of validated memory with this product. Thermal issues or other problems may

arise if you don’t use recommended modules. At the time of publication of this user guide, the following

memories memory list has been have been qualified and approved. As the memory market is volatile, this list

is subject to change, please consult your local technical support for an up to date list.

3.3.1 Memory List and Characteristics

Table 3-2:Approved Memory List

Manufacturer Part Number Description Company

M392B5273CH0-CK0 4GB VLP 1600 MHz RDIMM Samsung

M392B1K70CM0-CK0 8GB VLP 1600 MHz RDIMM Samsung

M392B5273CH0-YH904 8GB VLP 1333 MHz LV-RDIMM Samsung

VL33B5263E-K9S 4GB VLP 1333 MHz UDIMM Virtium

M392B2G70BM0-YK0 16GB VLP 1600 MHz RDIMM Samsung

SGU04G72H1BC2SA-BBRT 4GB VLP 1333 MHz UDIMM Swissbit

MT18JDF1G72PDZ-1G6 8GB VLP 1600 MHz RDIMM Micron

Memory should have the following characteristics:

• DDR3 1333 or DDR3 1600

• 1.35V or 1,5V

• Single or dual-rank modules are supported

• x4 or x8 memory with up to 4 ranks per DIMM

• Registered & ECC

• Only very low profiles (VLP) 0.72inches maximum heights (18.3mm)

WARNING

Because static electricity can cause damage to electronic devices, take the following

precautions:

Keep the board in its anti-static package, until you are ready to install memory.

Wear a grounding wrist strap before removing the board from its package; this will

discharge any static electricity that may have built up in your body.

Handle the board by the faceplate or its edges.

22 AT8060

Page 38

www.kontron.com

3.3.2 Installing Memory

On an anti-

static plane, place the board so that you

are facing the front plate connectors

Remove the memory protection top cover.

Insert the memory module into any available

socket, aligning the notches on the module with the

socket’s key inserts.

1- Insert the memory module in the connector

using

your thumbs.

2- Eject partially the memory module, using the

connector latches while applying some pressure on

the top to avoid the full removal of the modules.

3- Fully Reseat the modules in the connector

using

your thumbs.

4- Repeat steps 2 and 3 a second time.

5- Push down the memory module until the

retaining clips lock on each side.

Repeat these steps to populate the other socket.

To remove a memory module from a socket, push

sideway the retaining clips on each side of the

socket, to release the module. Pull out the memory

from the socket.

23 AT8060

Page 39

www.kontron.com

3.4 Onboard Connectors and Headers

P10

J1 J2 J3

J4 J5

J6

J7

J8

J10 J11

J12

J13

J15

J17

J19

JP2

JP1

1

13

2

14

1

13

2

14

J30

J31

J23

A

B

C

D

G

H

E

F

Table 3-3:Onboard Connectors and Headers

Description Connector Comments

Memory Sockets J1 -J8 DDR3 1333MHz or DDR3 1600 MHz Memory Sockets

USB Flash Connectors J10 & J11 USB Connectors for the USB SSD Modules

USB Connectors J12 Dual USB Connector

Management Console Port J13 RJ-45 Serial Port Connector

SFP Connectors J15 & J17 Faceplate SFP Connectors

AMC connector J19 AMC Connector

Base & Fabric Interface Connector J23 Base & Fabric Interface Connector

RTM Connectors J30 & J31 RTM Connectors

Power & IPMB P10 Power & IPMB

Figure 3-2:Onboard Connectors and Headers Locations

24 AT8060

Page 40

www.kontron.com

3.5 Board Hot Swap and Installation

Because of the high-density pinout of the hard-metric connector, some precautions must be taken when

connecting or disconnecting a board to/from a backplane:

1 Rail guides must be installed on the enclosure to slide the board to the backplane.

2 Do not force the board if there is mechanical resistance while inserting the board.

3 Screw the frontplate to the enclosure to firmly attach the board to its enclosure.

4 Use ejector handles to disconnect and extract the board from its enclosure.

WARNING

Always use a grounding wrist wrap before installing or removing the board from a

chassis.

3.5.1 Installing the Board in the Chassis

To install a board in a chassis:

1 Remove the filler panel of the slot or see "Removing the Board" below.

2 Ensure the board is configured properly.

3 Carefully align the PCB edges in the bottom and top card guide.

4 Insert the board in the system until it makes contact with the backplane connectors.

5 Using both ejector handles, engage the board in the backplane connectors until both ejectors are locked.

6 Fasten screws at the top and bottom of the faceplate.

3.5.2 Removing the Board

If you would like to remove a card from your chassis please follow carefully these steps:

1 Unscrew the top and the bottom screw of the front panel.

2 Unlock the lower handle latch, depending on the software step; this may initiate a clean shutdown of the

operating system.

3 Wait until the blue LED is fully ON, this mean that the hot swap sequence is ready for board removal.

4 Use both ejectors to disengage the board from the backplane.

5 Pull the board out of the chassis.

25 AT8060

Page 41

www.kontron.com

3.5.3 Installing an AMC

To install an AMC:

1 Remove the AMC filler panel.