Page 1

» User Guide «

AM5500

Double, Mid-Size AMC

Dual 2.5" SATA Storage Carrier

Doc. ID: 1030-9305, Rev. 2.0

May 6, 2011

P R E L I M I N A R Y

If it’s embedded, it’s Kontron.

Page 2

Preface AM5500

Revision History

Publication Title:

Doc. ID: 1030-9305

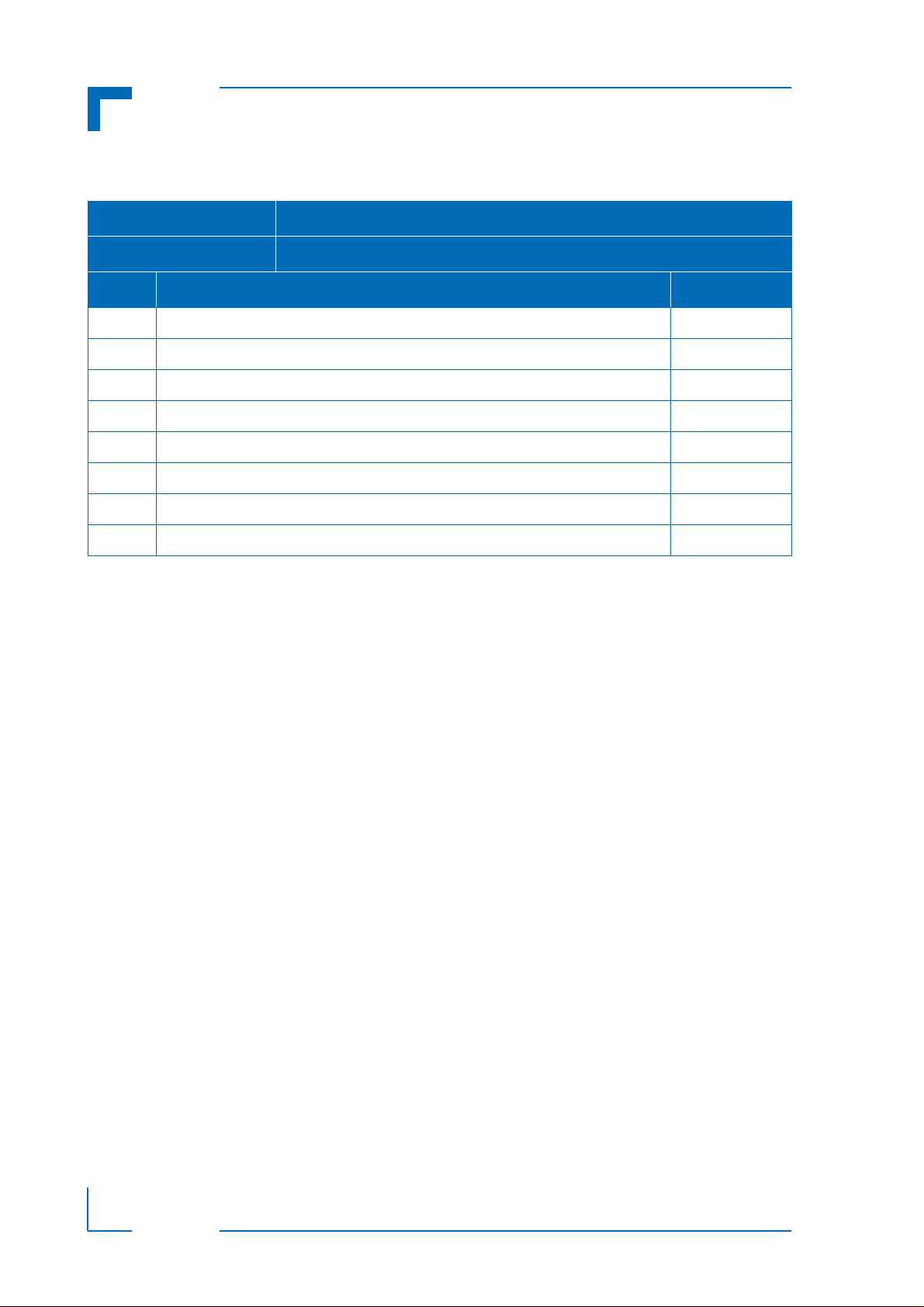

Rev. Brief Description of Changes Date of Issue

1.0 Initial issue 4-Jun-2009

2.0 General update 6-May-2011

AM5500: Double, Mid-Size AMC Dual 2.5" SATA Storage Carrier

Imprint

Kontron Modular Computers GmbH may be contacted via the following:

MAILING ADDRESS TELEPHONE AND E-MAIL

Kontron Modular Computers GmbH +49 (0) 800-SALESKONTRON

Sudetenstraße 7 sales@kontron.com

D - 87600 Kaufbeuren Germany

For further information about other Kontron products, please visit our Internet website:

P R E L I M I N A R Y

www.kontron.com.

Disclaimer

Copyright © 2009 Kontron AG. All right s reserved. All dat a is for information purposes only a nd

not guaranteed for legal purposes. Information has been carefully checked and is believed to

be accurate; however, no responsibility is assumed for inaccuracies. Kontron and the Kontron

logo and all other trademarks or registered trademarks are the property of their respective owners and are recognized. Specifications are subject to change without notice.

Page ii ID 1030-9305, Rev. 2.0

Page 3

AM5500 Preface

Table of Contents

Revision History .........................................................................................................ii

Imprint ........................................................................................................................ii

Disclaimer ..................................................................................................................ii

Table of Contents ......................................................................................................iii

List of Tables ..............................................................................................................v

List of Figures ..........................................................................................................vii

Proprietary Note .......................................................................................................vii

Trademarks ..............................................................................................................vii

Environmental Protection Statement ........................................................................vii

Explanation of Symbols ..........................................................................................viii

For Your Safety .........................................................................................................ix

High Voltage Safety Instructions ...........................................................................ix

Special Handling and Unpacking Instructions ......................................................ix

General Instructions on Usage ..............................................................................x

Two Year Warranty ....................................................................................................xi

1. Introduction ............................................................................. 1 - 3

1.1 Board Overview .......................................................................................1 - 3

1.2 System Relevant Information ..................................................................1 - 3

1.3 Board Diagrams ......................................................................................1 - 4

1.3.1 Functional Block Diagram ...............................................................1 - 4

1.3.2 Front Panel .....................................................................................1 - 5

1.3.3 Board Layout ..................................................................................1 - 6

1.4 Technical Specification ............................................................................1 - 7

1.5 Standards ................................................................................................1 - 8

1.6 Related Publications ...............................................................................1 - 9

2. Functional Description ........................................................... 2 - 3

2.1 Board Interfaces ......................................................................................2 - 3

2.1.1 Front Panel LEDs ...........................................................................2 - 3

2.1.2 Module Handle ................................................................................2 - 4

P R E L I M I N A R Y

2.1.3 Serial ATA Interface ........................................................................2 - 5

2.1.4 Programming Connector .................................................................2 - 6

ID 1030-9305, Rev. 2.0 Page iii

Page 4

Preface AM5500

2.1.5 AMC Card-edge Connector J2 ........................................................2 - 7

2.2 Module Management .............................................................................2 - 10

2.2.1 MMC Firmware Key Features .......................................................2 - 10

2.2.2 Sensors Implemented on the AM5500 ..........................................2 - 11

2.2.3 Firmware Code ..............................................................................2 - 13

2.2.4 Field Replaceable Unit (FRU) Information ....................................2 - 13

2.2.5 E-Keying ........................................................................................2 - 13

3. Installation ................................................................................3 - 3

3.1 Safety Requirements ...............................................................................3 - 3

3.2 Module Handle Positions .........................................................................3 - 4

3.3 Hot Swap Procedures ..............................................................................3 - 5

3.3.1 Hot Swap Insertion ..........................................................................3 - 5

3.3.2 Hot Swap Extraction ........................................................................3 - 7

3.4 Installation of Peripheral Devices ............................................................3 - 8

3.4.1 Installation of 2.5” HDD/SSD Devices .............................................3 - 8

4. Power Considerations .............................................................4 - 3

4.1 Voltage Ranges .......................................................................................4 - 3

4.2 Power Consumption ................................................................................4 - 4

4.2.1 Module Management Power Consumption .....................................4 - 4

4.2.2 Payload Power Consumption ..........................................................4 - 4

P R E L I M I N A R Y

4.2.3 IPMI FRU Payload Power Consumption .........................................4 - 4

Page iv ID 1030-9305, Rev. 2.0

Page 5

AM5500 Preface

List of Tables

1-1 System Relevant Information ................................................................... 1 - 3

1-2 AM5500 Main Specifications .................................................................... 1 - 7

1-3 Standards ................................................................................................. 1 - 8

1-4 Related Publications ................................................................................ 1 - 9

2-1 Module Management LED Function ........................................................ 2 - 3

2-2 Module Handle Positions ......................................................................... 2 - 4

2-3 SATA Connectors J3 and J5 Pinout ......................................................... 2 - 5

2-4 Programming Connector J4 Pinout .......................................................... 2 - 6

2-5 Pinout of AMC Card-edge Connector J2 ................................................. 2 - 7

2-6 Sensor List ............................................................................................. 2 - 12

2-7 OEM Event/Reading Types ................................................................... 2 - 13

4-1 DC Operational Input Voltage Ranges ..................................................... 4 - 3

4-2 Payload Power Consumption ................................................................... 4 - 4

4-3 IPMI FRU Payload Power Consumption .................................................. 4 - 4

List of Figures

1-1 AM5500 Functional Block Diagram .......................................................... 1 - 4

1-2 AM5500 Front Panel Versions ................................................................. 1 - 5

1-3 AM5500 Board Layout (Top View) ........................................................... 1 - 6

2-1 Front Panel LEDs .................................................................................... 2 - 3

2-2 Module Handle Positions ....................................................................... 2 - 4

2-3 SATA Connectors J3 and J5 .................................................................... 2 - 5

2-4 Programming Connector J4 ..................................................................... 2 - 6

3-1 Module Handle Positions ........................................................................ 3 - 4

3-2 Placement of the 2.5” SATA HDDs/SSDs on the AM5500 ....................... 3 - 8

P R E L I M I N A R Y

ID 1030-9305, Rev. 2.0 Page v

Page 6

Preface AM5500

This page has been intentionally left blank.

P R E L I M I N A R Y

Page vi ID 1030-9305, Rev. 2.0

Page 7

AM5500 Preface

Proprietary Note

This document contains information proprietary to Kontron. It may not be copied or transmitted by any means, disclosed to others, or stored in any retrieval system or media without the

prior written consent of Kontron or one of its authorized agents.

The information contained in this document is, to the best of our knowledge, entirely correct.

However , Kontro n cannot accept liab ility for any inaccuracies or the consequences thereof, or

for any liability arising from the use or application of any circuit, product, or example shown in

this document.

Kontron reserves the right to change, modify, or improve this document or the product

described herein, as seen fit by Kontron without further notice.

Trademarks

This document may include names, company logos and trademarks, which are registered

trademarks and, therefore, proprietary to their respective owners.

Environmental Protection Statement

This product has been manufactured to satisfy environmental protection requirements where

possible. Many of the components used (structural parts, printed circuit boards, connectors,

batteries, etc.) are capable of being recycled.

Final disposition of this product after its service life must be accomplished in accordance with

applicable country, state, or local laws or regulations.

P R E L I M I N A R Y

ID 1030-9305, Rev. 2.0 Page vii

Page 8

Preface AM5500

Explanation of Symbols

Caution, Electric Shock!

This symbol and title warn of hazards due to electrical shocks (> 60V)

when touching products or parts of them. Failure to observe the precautions indicated and/or prescribed by the law may endanger your

life/health and/or result in damage to your material.

Please refer also to the section “High Voltage Safety Instructions” on

the following page.

Warning, ESD Sensitive Device!

This symbol and title inform that electronic boards and their components are sensitive to static electricity. Therefore, care must be taken

during all handling operations and inspections of this product, in

order to ensure product integrity at all times.

Please read also the section “Special Handling and Unpacking

Instructions” on the following page.

Warning!

This symbol and title emphasize points which, if not fully understood

and taken into consideration by the reader, may endanger your health

and/or result in damage to your material.

Note ...

This symbol and title emphasize aspects the reader should read

through carefully for his or her own advantage.

P R E L I M I N A R Y

Page viii ID 1030-9305, Rev. 2.0

Page 9

AM5500 Preface

For Your Safety

Your new Kontron product was developed and tested carefully to provide all features necessary to ensure its compliance with electrical safety requirements. It was also designed for a

long fault-free life. However, the life expectancy of your product can be drastically reduced by

improper treatment during unpacking and installation. Therefore, in the interest of your own

safety and of the correct operation of your new Kontron product, you are requested to conform

with the following guidelines.

High Voltage Safety Instructions

Warning!

All operations on this device must be carried out by sufficiently skilled

personnel only.

Caution, Electric Shock!

Serious electrical shock hazards may exist during installation, repair

and maintenance operations with this product, for example when connecting or disconnecting external cabling with external voltages

applied. Therefore, the system integrator is responsible for ensuring

that no shock hazards exist during all operations.

Special Handling and Unpacking Instructions

ESD Sensitive Device!

Electronic boards and their components are sensitive to static electricity. Therefore, care must be taken during all handling operations

and inspections of this product, in order to ensure product integrity at

all times.

Warning!

This product has gold conductive fingers which are susceptible to contamination. Take care not to touch the gold conductive fingers of the

AMC Card-edge connector when handling the board.

Failure to comply with the instruction above may cause damage to the

board or result in improper system operation.

P R E L I M I N A R Y

Do not handle this product out of its protective enclosure while it is not used for operational purposes unless it is otherwise protected.

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations. Where

a safe work station is not guaranteed, it is important for the user to be electrically discharged

before touching the product with his/her hands or tools. This is most easily done by touching a

metal part of your system housing.

ID 1030-9305, Rev. 2.0 Page ix

Page 10

Preface AM5500

It is particularly important to observe standard anti-static precautions when changing piggybacks, ROM devices, jumper settings etc. If the product contains batteries for RTC or memo ry

backup, ensure that the board is not placed on conductive surfaces, including anti-static plastics or sponges. They can cause short circuits and damage the batteries or conductive circuits

on the board.

General Instructions on Usage

In order to maintain Kontron’s product warranty, this product must not be altered or modified in

any way. Changes or modifications to the device, which are not explicitly approved by Kontron

and described in this manual or received from Kontron’s Technical Support as a special handling instruction, will void your warranty.

This device should only be installed in or connected to systems that fulfill all necessary technical and specific environmental requirements. This applies also to the operational temperature

range of the specific board version, which must not be exceeded. If batteries are present, their

temperature restrictions must be taken into account.

In performing all necessary installation and application operations, please follow only the instructions supplied by the present manual.

Keep all the original packaging material for future storage or warranty shipment s. If it is necessary to store or ship the board, please re-pack it as nearly as possible in the manner in which

it was delivered.

Special care is necessary when handling or unp acking the product. Please co nsult the special

handling and unpacking instruction on the previous page of this manual.

P R E L I M I N A R Y

Page x ID 1030-9305, Rev. 2.0

Page 11

AM5500 Preface

Two Year Warranty

Kontron grants the original purchaser of Kontron’s products a TWO YEAR LIMITED HARDWARE

WARRANTY

implied by anyone on behalf of Kontron are valid unless the consumer has the expre ss written

consent of Kontron.

Kontron warrants their own products, excluding software, to be free from manufacturing and

material defects for a period of 24 consecutive months from the date of purchase. This warranty is not transferable nor extendible to cover any other users or long-term storage of the

product. It does not cover products which have been modified, altered or repaired by any

other party than Kontron or their authorized agents. Furthermore, any product which has

been, or is suspected of being damaged as a result of negligence, improper use, incorrect

handling, servicing or maintenance, or which has been damaged as a result of excessive current/voltage or temperature, or which has had its serial number(s), any other markings or

parts thereof altered, defaced or removed will also be excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in the event of any claim, he may

return the product at the earliest possible convenience to the original place of purchase,

together with a copy of the original document of purchase, a full description of the application

the product is used on and a description of the defect. Pack the product in such a way as to

ensure safe transportation (see our safety instructions).

as described in the following. However , no other warranties that may be granted or

Kontron provides for repair or replacement of any p art, assembly or su b-assembly at their own

discretion, or to refund the original cost of purchase, if appropriate. In the event of repair,

refunding or replacement of any part, the ownership of the removed or replaced parts reverts

to Kontron, and the remaining part of the original guarantee, or any new guarantee to cover

the repaired or replaced items, will be transferred to cover the new or repaired items. Any

extensions to the original guarantee are considered gestures of goodwill, and will be defined

in the “Repair Report” issued by Kontron with the repaired or replaced item.

Kontron will not accept liability for any further claims resulting directly or indirectly from any

warranty claim, other than the above specified repair, replacement or refunding. In particular,

all claims for damage to any system or process in which the product was employed, or any

loss incurred as a result of the product not functioning at any given time, are excluded. The

extent of Kontron liability to the customer shall not exceed the original purchase price of the

item for which the claim exists.

Kontron issues no warranty or representation, either explicit or implicit, with respect to its

products’ reliability, fitness, quality, marketability or ability to fulfil any particular application or

purpose. As a result, the products are sold “as is,” and the responsibility to ensure their suitability for any given task remains that of the purchaser. In no event will Kontron be liable for

direct, indirect or consequential damages resulting from the use of our hardware or software

products, or documentation, even if Kontron were advised of the possibility of such claims

prior to the purchase of the product or during any period since the date of its purchase.

Please remember that no Kontron employee, dealer or agent is authorized to make any modification or addition to the above specified terms, either verbally or in any other form, written or

electronically transmitted, without the company’s consent.

P R E L I M I N A R Y

ID 1030-9305, Rev. 2.0 Page xi

Page 12

Preface AM5500

This page has been intentionally left blank.

P R E L I M I N A R Y

Page xii ID 1030-9305, Rev. 2.0

Page 13

AM5500 Introduction

Chapter 1

1

Introduction

ID 1030-9305, Rev. 2.0 Page 1 - 1

P R E L I M I N A R Y

Page 14

Introduction AM5500

This page has been intentionally left blank.

P R E L I M I N A R Y

Page 1 - 2 ID 1030-9305, Rev. 2.0

Page 15

AM5500 Introduction

1. Introduction

1.1 Board Overview

The AM5500 is a dual 2.5” SATA storage carrier implemented as a Double, Mid-size AMC

module. There are two front panel versions that may be used with the AM5500, a standard front

panel and a front panel with retaining screws for mounting the module to the chassis.

The AM5500 has full hot swap capability, which enables the board to be replaced, monitored

and controlled without having to shut down the AMC-supporting carrier or the MicroTCA system. A dedicated Module Management Controller (MMC) is used to manage the board and support a defined subset of Intelligent Platform Management Interface (IPMI) commands and

PICMG (ATCA/AMC) command extensions, which enables operators to detect and eliminate

faults faster at module level. This includes monitoring onboard temperature conditions, board

voltages, managing hot swap operations, etc. All in all, IPMI enhances the board’s availability

and reliability while reducing the operating costs and the mean-time-to-repair.

The AM5500 operates with the Advanced Telecommunications Computing Architecture (AdvancedTCA® or A TCA) and the Micro Telecommunications Computing Architecture (MicroTCA

or µTCA) defined by the PCI Industrial Computer Manufacturers Group (PICMG).

1.2 System Relevant Information

The following system relevant information is general in nature but should still be considered

when developing applications using the AM5500.

Table 1-1: System Relevant Information

SUBJECT INFORMATION

Hardware Requirements The AM5500 can be installed on any AMC-supporting carrier board (with mechan-

ical restrictions) or MicroTCA backplane with the following AMC Card-edge connector port mapping:

• Common Options Region ports 2-3

• Two Serial ATA ports

P R E L I M I N A R Y

ID 1030-9305, Rev. 2.0 Page 1 - 3

Page 16

Introduction AM5500

Health

Hot Swap

Out-of-Service

IPMB-L

Hot Swap Switch

DC/DC

12 V -> 5 V

12 V payload

Com. Opt. Reg. Port 3

Com. Opt. Reg. Port 2

2.5" SATA

HDD/SSD

MMC

Module

Management

Controller

AMC Card-edge Con.Front Panel

SATA0

SATA1

2.5" SATA

HDD/SSD

Programming

Connector

RS-232

1.3 Board Diagrams

The following diagrams provide additional information concerning board functionality and

component layout.

1.3.1 Functional Block Diagram

Figure 1-1: AM5500 Functional Block Diagram

P R E L I M I N A R Y

Page 1 - 4 ID 1030-9305, Rev. 2.0

Page 17

AM5500 Introduction

AM5500 AM5500

Standard

Front Panel

Front Panel with

Retaining Screws

Module Management LEDs

• LED1 (red): Out-of-Service LED

• LED2 (red/green/amber): Health LED

• HS LED (blue): The hot swap indicator provides basic feedback to the

user on the hot swap state of the module. The HS LED

states are off, short blink, long blink, and on.

1.3.2 Front Panel

Figure 1-2: AM5500 Front Panel Versions

ID 1030-9305, Rev. 2.0 Page 1 - 5

P R E L I M I N A R Y

Page 18

Introduction AM5500

J3

SATA0

J5

SATA1

MMC

J1

1 (rear: 170)

85 (rear: 86)

J4

Temperature Sensor 2

P1

S1

P1

S1

109

12

Temper ature Sensor 1

1.3.3 Board Layout

Figure 1-3: AM5500 Board Layout (Top View)

P R E L I M I N A R Y

Page 1 - 6 ID 1030-9305, Rev. 2.0

Page 19

AM5500 Introduction

Note ...

When SATA HDDs/SSDs are installed, refer to their operational

specifications as this will influence the operational and storage

temperature of the AM5500.

1.4 Technical Specification

Table 1-2: AM5500 Main Specifications

FEATURES SPECIFICATIONS

Serial ATA Common Options Region ports 2-3

• Two Serial ATA ports

AMC Inter-

connection

Onboard Connectors • Two 22-pin SATA connectors, J3 and J5

• One 10-pin programming connector, J4, (RS-232 serial port)

AMC Card-edge

Connectors

Connector

Module Management

LEDs

LEDs

Module Management

Controller

IPMI

Hot Swap The AM5500 has full hot swap capability.

Thermal Management Two board temperature sensors

Power Consumption Management power: approx. 0.3 W

Temperature Range Operational: -5°C to +75°C

General

• One 170-pin AMC Card-edge connector

• LED1 (red): Out-of-Service LED

• LED2 (red/green/amber): Health LED

• HS LED (blue): Hot Swap LED

• The MMC carries out IPMI commands such as monitoring onboard tem-

perature conditions, board voltages and the power supply status, and

managing hot swap operations.

• The MMC is accessible via a local IPMB (IPMB-L).

Payload power: approx. 0.5 W (without HDD/SSD device)

Storage: -40°C to + 70°C

Mechanical Double, Mid-size AMC form factor

Dimensions 181.5 mm x 147.0 mm x 18.96 mm

Board Weight 140 grams (without HDD/SSD)

Software IPMI Module Management Controller Firmware providing the following features:

• Board supervision

• The MMC is accessible via IPMB-L

Software

ID 1030-9305, Rev. 2.0 Page 1 - 7

• The MMC Firmware can be updated in the field

P R E L I M I N A R Y

Page 20

Introduction AM5500

1.5 Standards

This Kontron AMC board complies with the requirements of the following standards.

Table 1-3: Standards

COMPLIANCE TYPE STANDARD REMARKS

CE Emission EN55022

EN61000-6-3

EN300386

Immission EN55024

EN61000-6-2

EN300386

Electrical Safety EN60950-1 -Mechanical Mechanical Dimensions IEEE 1101.10 -Environmental and

Health Aspects

Vibration (sinusoidal) TBD --

Vibration (sinusoidal,

transportation)

Shock (operating) TBD --

Climatic Humidity IEC60068-2-78 93% RH at 40°C, non-condensing

WEEE Directive 2002/96/EC Waste electrical and electronic equipment

RoHS Directive 2002/95/EC Restriction of the use of certain

TBD --

Note ...

For information relating to shock and vibration standards for the HDD/SSD

devices, refer to the respective manufacturer’s specification.

--

--

hazardous substances in electrical and

electronic equipment

Note ...

Kontron performs comprehensive environmental testing of its products in accor-

P R E L I M I N A R Y

dance with applicable standards.

Customers desiring to perform further environmental testing of Kontron prod-

ucts must contact Kontron for assistance prior to performing any such testing.

This is necessary, as it is possible that environmental testing can be destructive

when not performed in accordance with the applicable specifications.

In particular, for example, boards without conformal coating must not be

exposed to a change of temperature exceeding 1K/minute, averaged over a

period of not more than five minutes. Otherwise, condensation may cause irreversible damage, especially when the board is powered up again.

Kontron does not accept any responsibility for damage to products resulting

from destructive environmental testing.

Page 1 - 8 ID 1030-9305, Rev. 2.0

Page 21

AM5500 Introduction

1.6 Related Publications

The following publications contain information relating to this product.

Table 1-4: Related Publications

PRODUCT PUBLICATION

ATCA PICMG® 3.0 AdvancedTCA Base Specification R2.0, March 18, 2005

MicroTCA PICMG® MTCA.0 Micro Telecommunications Computing Architecture R1.0, July 6,

2006

PICMG® MTCA.1 Air-Cooled Rugged MicroTCA Specification R1.0, March 19,

2009

AMC PICMG® AMC.0, Advanced Mezzanine Card Specification R2.0

PICMG® AMC.3, Storage Interfaces R1.0

IPMI IPMI - Intelligent Platform Management Interface Specification, v1.5 Document

Revision 1.1, February 20, 2002

IPMI - Platform Management FRU Information Storage Definition, V1.0 Document

Revision 1.1, September 27, 1999

ID 1030-9305, Rev. 2.0 Page 1 - 9

P R E L I M I N A R Y

Page 22

Introduction AM5500

This page has been intentionally left blank.

P R E L I M I N A R Y

Page 1 - 10 ID 1030-9305, Rev. 2.0

Loading...

Loading...