Page 1

SERVICE MANUAL

Models

ST-723/724

FEBRUARY 1999

CSM-ST723/724

KONICA BUSINESS TECHNOLOGIES, INC.

Page 2

Page 3

ST-723/724

SERVICE MANUAL

FEBRUARY 1999

Used on Konica Model

7823

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2001, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-1

2. PARTS IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-2

3. CROSS-SECTIONAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3

4. DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-4

5. ELECTRICAL COMPONENTS LAYOUT. . . . . . . . . . . . . . . . . . . . M-5

6. OUTLINE OF OPERATION IN EACH MODE

6-1. INITIAL OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-6

6-2. NON-SORT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-6

6-3. SORT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-7

6-4. GROUP MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-9

6-5. SORT STAPLE MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-10

6-6. MANUAL STAPLE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-11

6-7. BIN MOVEMENT AT END OF COPY CYCLE . . . . . . . . . . . . M-11

7. OPERATION OF EACH MECHANISM

7-1. PAPER TRANSPORT MECHANISM . . . . . . . . . . . . . . . . . . . M-12

7-2. PAPER ALIGNING MECHANISM. . . . . . . . . . . . . . . . . . . . . . M-13

7-3. BIN MOVING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . M-17

7-4. PAPER CLAMPING MECHANISM . . . . . . . . . . . . . . . . . . . . . M-21

7-5. PAPER DETECTION AT STAPLING MECHANISM . . . . . . . M-25

7-6. STAPLING MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-25

7-7. SORTER SET SWITCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-35

7-8. BIN EMPTY DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-36

8. OPERATION IN EACH MODE

8-1. NON-SORT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-37

8-2. SORT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-38

8-3. GROUP MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-40

8-4. SORT STAPLE MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-42

iii

Page 6

CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

TEST MODE

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY/REASSEMBLY

1-1. REMOVAL OF EXTERIOR COVERS. . . . . . . . . . . . . . . . . . . D-1

1-2. REMOVAL OF THE TRANSPORT GUIDE PLATE ASSY . . D-2

1-3. REMOVAL OF THE BIN MOVING MOTOR M1 UNIT . . . . . . D-3

1-4. REMOVAL OF PAPER CLAMP SOLENOID SL1 . . . . . . . . . D-4

1-5. REMOVAL OF THE STAPLE UNIT . . . . . . . . . . . . . . . . . . . . D-4

1-6. REMOVAL OF THE SORTER LOCK RELEASE LEVER . . . D-5

1-7. REMOVAL OF THE BINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

2. ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-9

TROUBLESHOOTING

1. MISFEED DETECTION/TROUBLESHOOTING

PROCEDURES

1-1. MISFEED DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-1

1-2. TROUBLESHOOTING PROCEDURES . . . . . . . . . . . . . . . . . T-1

2. MALFUNCTION DETECTION/TROUBLESHOOTING

PROCEDURES

2-1. MALFUNCTION DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . T-3

2-2. TROUBLESHOOTING PROCEDURES . . . . . . . . . . . . . . . . . T-5

◆ELECTRICAL WIRING DIAGRAM

◆ELECTRICAL CIRCUIT DIAGRAM

iv

Page 7

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward

machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal, it is conceivable that the combination of the

machine and the room air could present a hazardous

combination. This is because heat (such as from

fusing units) and electrical arcs (which can occur

inside switches) have the ability to ignite flammable

substances, including air.

When installing a machine, check to see if there

is anything nearby which suggests that a poten-

tial hazard might exist. For example, a laboratory

might use organic compounds which, when they

evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The

presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

effect may be caused by altering any aspect of the

machine’s design. Such changes have the potential

of degrading product performance and reducing

safety margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical size

differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace or

eliminate any fuse (including temperature fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion other

than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica copiers have gained a reputation for being

reliable products. This has been attained by a combination of outstanding design and a knowledgeable

service force.

The design of the copier is extremely important. It is

the design process that determines tolerances and

safety margins for mechanical, electrical, and electronic aspects. It is not reasonable to expect individuals not involved in product engineering to know what

General Safety Guidelines

This copier has been examined in accordance with

the laws pertaining to various product safety regulations prior to leaving the manufacturing facility to

protect the operators and service personnel from

injury. However, as with any operating device, components will break down through the wear-and-tear of

everyday use, as will additional safety discrepancies

be discovered. For this reason, it is important that the

technician periodically performs safety checks on the

copier to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the copier is

disconnected from its power source before continuing.

• Look for sharp edges, burrs, and damage on all

external covers and copier frame.

• Inspect all cover hinges for wear (loose or broken).

• Inspect cables for wear, frays, or pinched areas.

v

Page 8

SAFETY PRECAUTIONS

• Ensure that the power cord insulation is not damaged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND) of

the power cord to the frame of the copier -- ensure

continuity. An improperly grounded machine can

cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to any

electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

• Do not make any adjustments outside of the

specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to

clean parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that the

alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each copier

must be thoroughly inspected with respect to safety

considerations as part of every routine service call.

The operability of the copier, and more importantly,

the safety of those who operate or service the copier,

are directly dependent upon the conscientious effort

of each and every technician.

Remember...when performing service calls, use good

judgement (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the copier

as well as those who service the copier depend on it!

vi

Page 9

GENERAL,

MECHANICAL/

ELECTRICAL

Page 10

Page 11

SPECIFICATIONS

1

Type : 10-Moving-Bin Sorter (ST-723)

10-Moving-Bin Sorter with Automatic Stapler (ST-724)

Installation : Appendant to copier

No. of Bins : 11

Modes : Non-Sort

Sort

Group

Sort Staple ST-724 only

*1

*2

Manual Staple ST-724 only

*1: Not available for an ST-724 mounted together with

an DF-723.

*2: Available only for a system equipped also with an

DF-723.

In the Non-Sort Mode

Copy Medium : Recommended paper weighing 60 to 90 g/m

24 lbs., translucent paper, transparencies, heavy paper

(91 to 157 g/m

2

or 25 to 41 lbs.).

Size : A5 lengthwise to A3, and A3 Wide or 5-1/2"

× 17" and Full Bleed

Max. Capacity : Recommended paper : 1st Bin - 50

11"

(80 g/m

2

or 22 lb.) : 2nd to 10th Bin - 25/Bin

: Transparencies: 10 (max. size: A4 or 8-1/2"

: Other special paper: 10

2

or 16 to

× 8-1/2" to

× 11")

In the Sort/Group Mode

Copy Medium : Recommended paper weighing 60 to 80 g/m

2

or 16 to

22 lbs.

Size : A5 lengthwise to A3, 5-1/2"

Max. Capacity : 25 sheets of 80 g/m

In the Sort Staple Mode

Copy Medium : Recommended paper weighing 60 to 80 g/m

× 8-1/2" to 11" × 17"

2

or 22 lb. paper per Bin

2

or 16 to

22 lbs.

Size : A4 to A3, 8-1/2"

Max. Capacity : 25 sheets of 80 g/m

No. of Copies That Can

: 2 to 25 copies of 80 g/m

× 11" to 11" × 17"

2

or 22 lb. paper per Bin

2

or 22 lb. paper

be Stapled

Power Requirement : DC24V (supplied from copier)

Power Consumption : 72W or less

Dimensions : Width - 400 mm or 15-3/4"

Depth - 562 mm or 22-1/4"

Height - 404 mm or 16"

Weight : ST-723 - 15.8 kg or 34-3/4 lbs. (excl. Mounting Bracket)

ST-724 - 18.1 kg or 40 lbs. (excl. Mounting Bracket)

Environmental

: Same as copier

Requirements

M-1

Page 12

PARTS IDENTIFICATION

2

1

2

3

4

7

10

9

8

1. Sorter Lock Release Lever

2. Hookup Connector

3. Sorter Lock Lever

4. Drive Coupling Gear

5. Transport Guide Plates

6. Sorter Set Detector

7. Stapler Cover

(Cannot be opened on ST-723)

3

6

4428M060AA

11

4428M061AA

8. 1st to 10th Bins

9. Top Bin

10. Paper Aligning Bar

(ST-724 only)

11. Mounting Bracket

5

M-2

Page 13

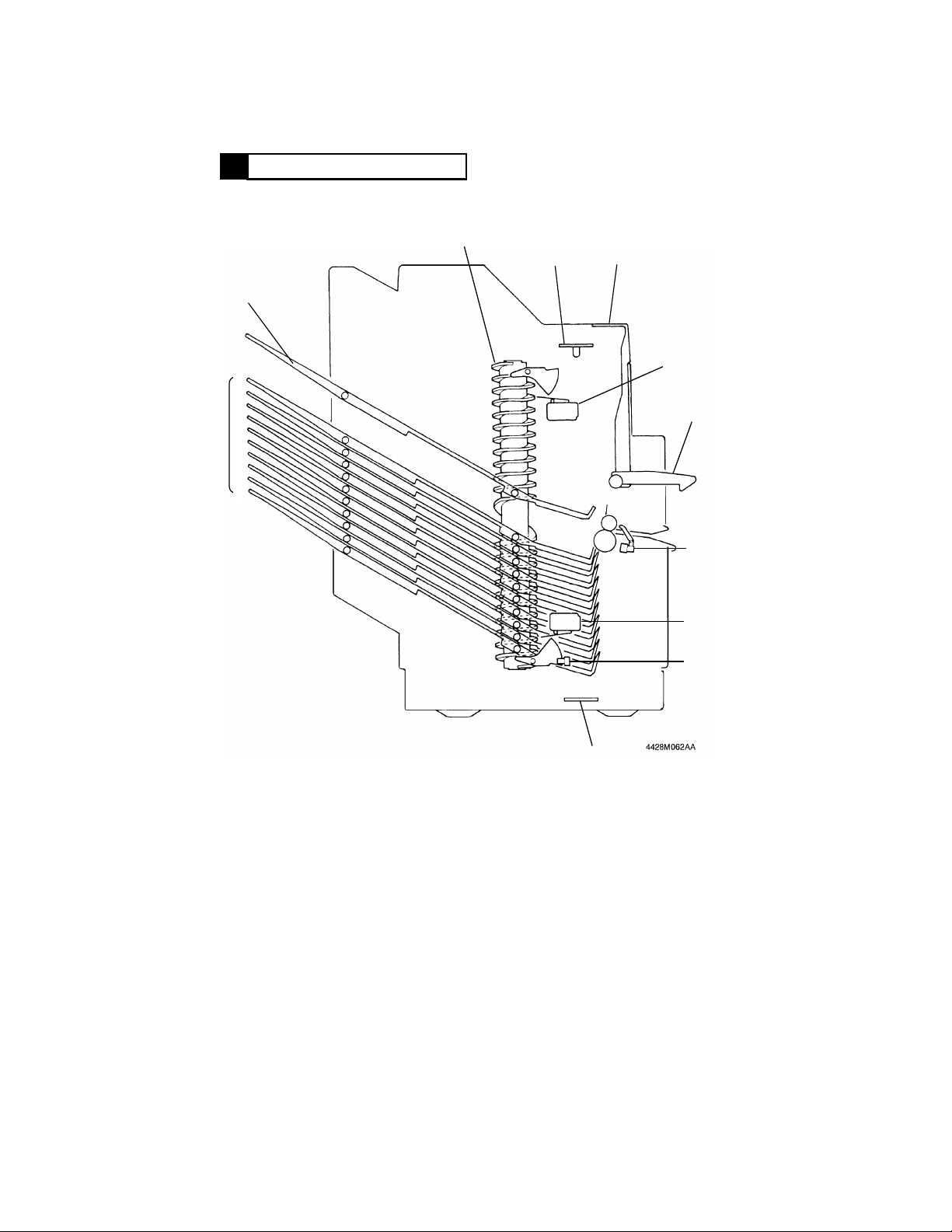

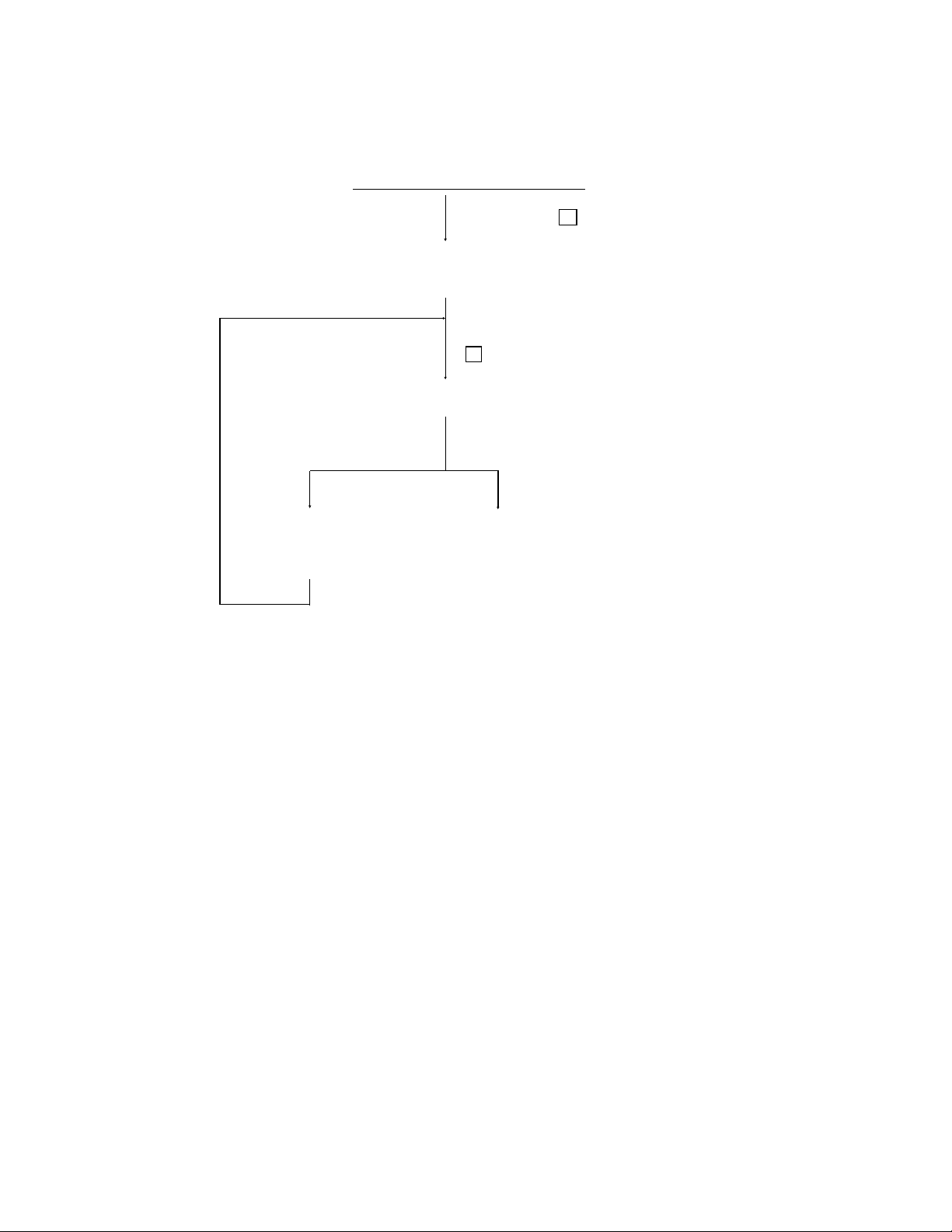

CROSS-SECTIONAL VIEW

3

3

4

2

1

5

6

7

8

9

10

1. 1st to 10th Bins

2. Top Bin

3. Spiral Cam

4. Bin Empty Sensor LED Board

PWB-B

5. Sorter Lock Release Lever

6. Bin Upper Limit Interlock

Switch S1

11

7. Sorter Lock Lever

8. Sorter Exit Sensor PC2

9. Bin Lower Limit Interlock

Switch S2

10. Bin Lower Limit Position

Sensor PC4

11. Bin Empty Sensor PQ Board

PWB-C

M-3

Page 14

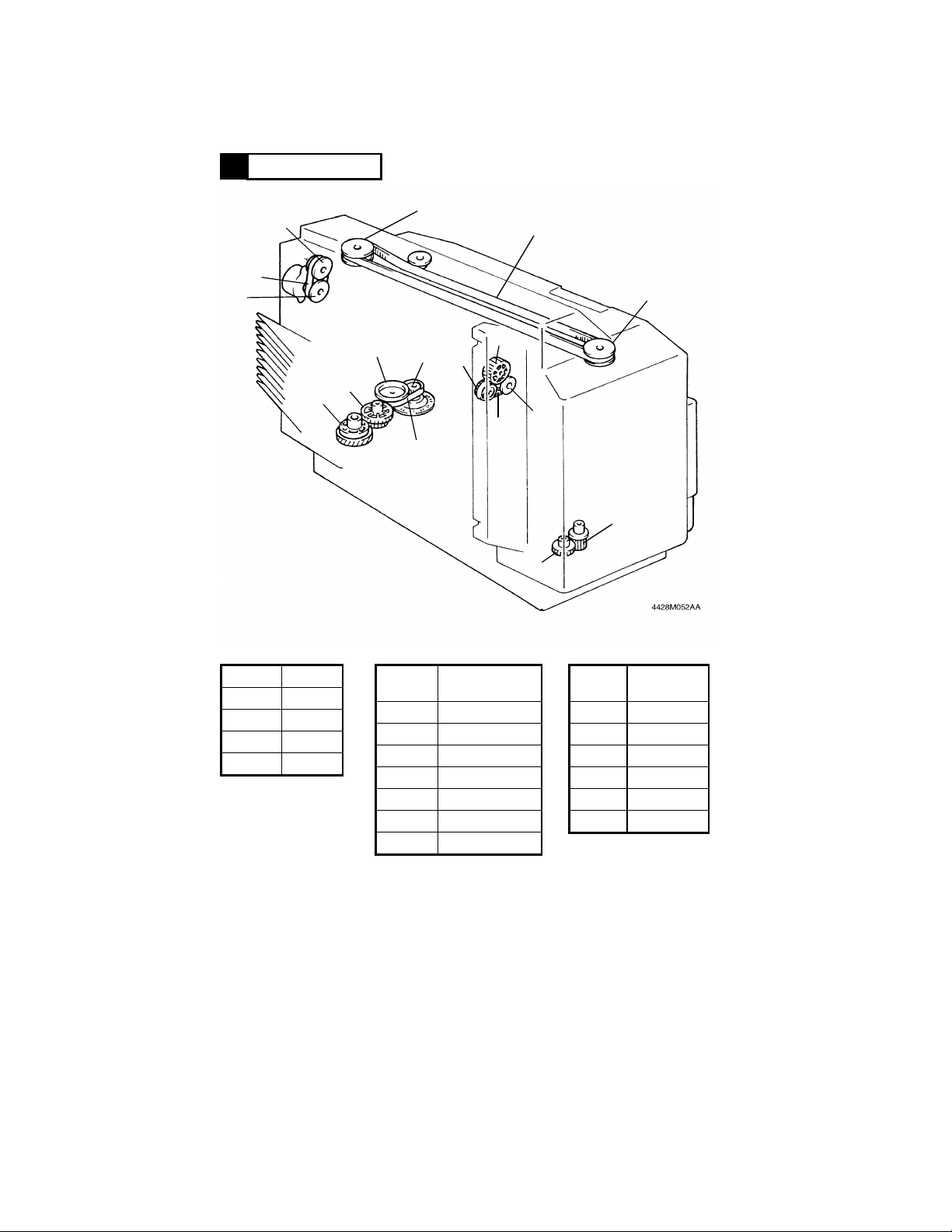

DRIVE SYSTEM

4

Belt 1

P1

P2

G3

G4

GP1

P5

Belt 3

P3

P6

G5

Belt 4

Belt 2

P4

GP2

G1

G2

Symbol Length

Belt 1 150 mm

Belt 2 918 mm

Belt 3 160 mm

Belt 4 150 mm

Symbol

G1 25/15

G2 36

G3 37

G4 34/16

G5 30

GP1 12/60

GP2 23/19

Gear/Pulley:

No. of Teeth

M-4

Symbol

Pulley: No.

of Teeth

P1 22

P2 22

P3 28

P4 28

P5 20

P6 20

Page 15

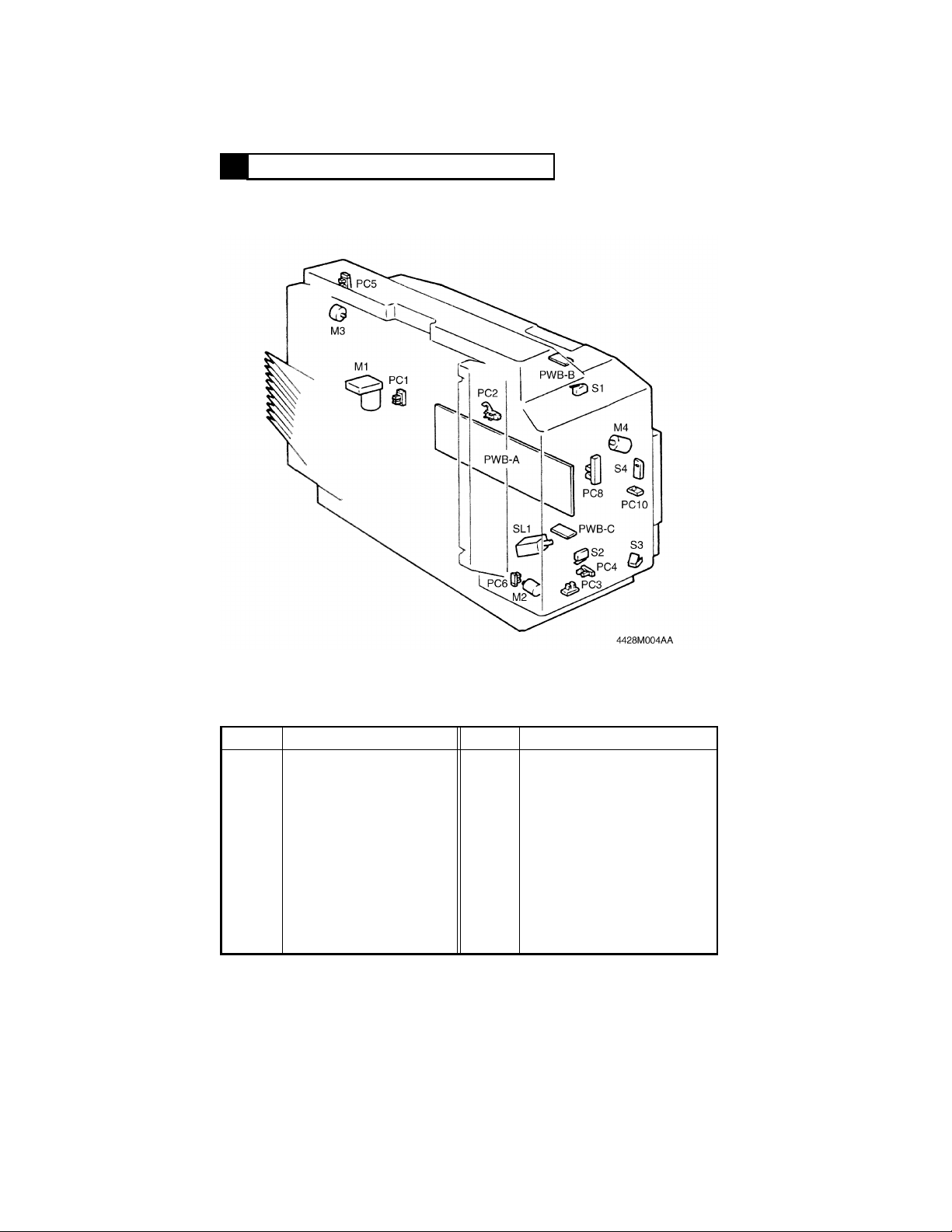

ELECTRICAL COMPONENTS LAYOUT

5

SYMBOL PARTS NAME SYMBOL PARTS NAME

PWB-A

PWB-B

PWB-C

M1

∗M2

∗M3

∗M4

∗SL1

PC1

PC2

PC3

PC4

∗ ... ST-724 Only

Control Board

Bin Empty Sensor LED

Board

Bin Empty Sensor PQ Board

Bin Moving Motor

Paper Clamp Motor

Paper Aligning Motor

Stapling Motor

Paper Clamp Solenoid

Bin Moving Pulse Sensor

Sorter Exit Sensor

Bin Positioning Sensor

Bin Lower Limit Position

Sensor

∗PC5

∗PC6

∗PC8

∗PC10

S1

S2

S3

∗S4

Paper Aligning Home Position

Sensor

Paper Clamp Home Position

Sensor

Paper Clamping Sensor

Staple Empty Detecting Sensor

Bin Upper Limit Interlock Switch

Bin Lower Limit Interlock Switch

Sorter Set Switch

Stapler Home Position

Detecting Switch

M-5

Page 16

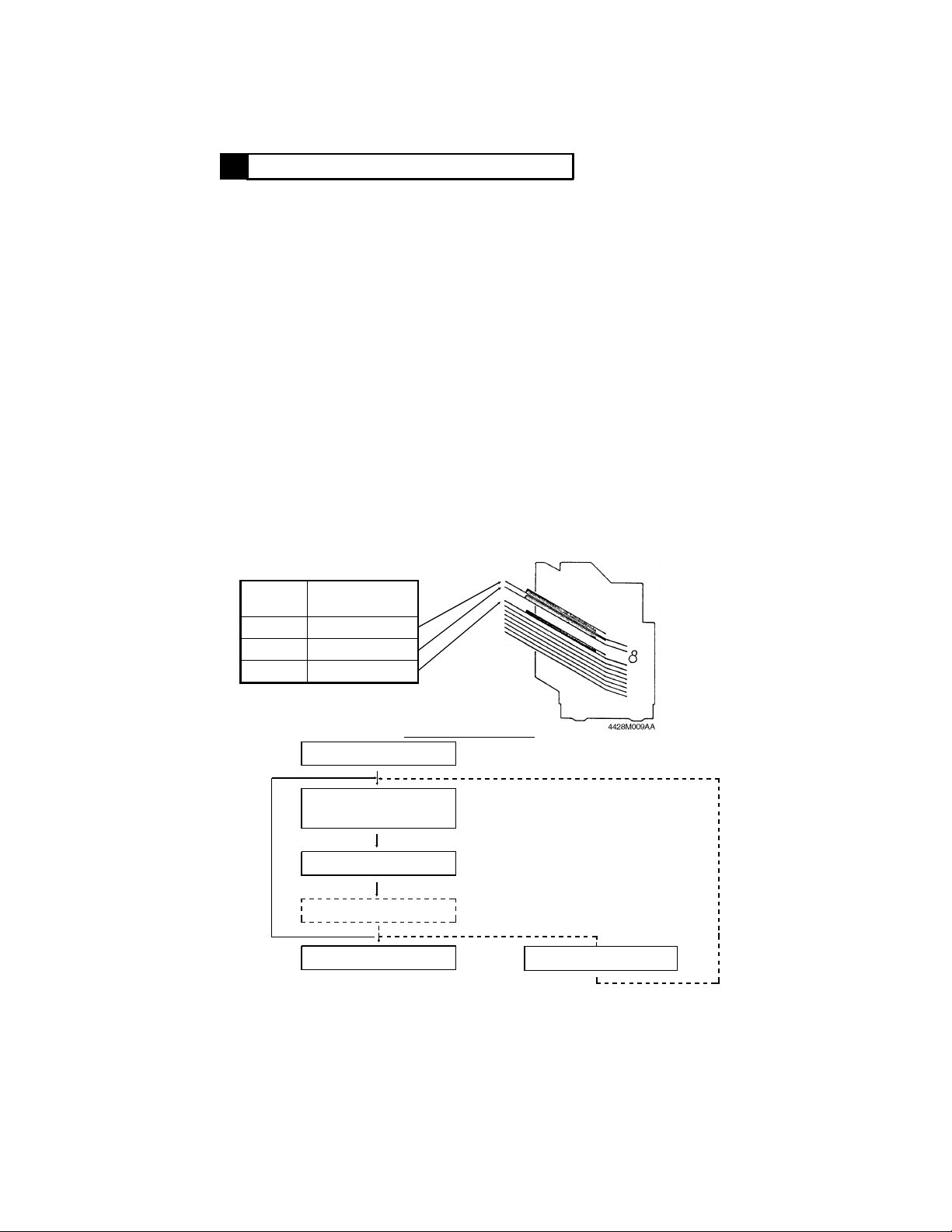

OUTLINE OF OPERATION IN EACH MODE

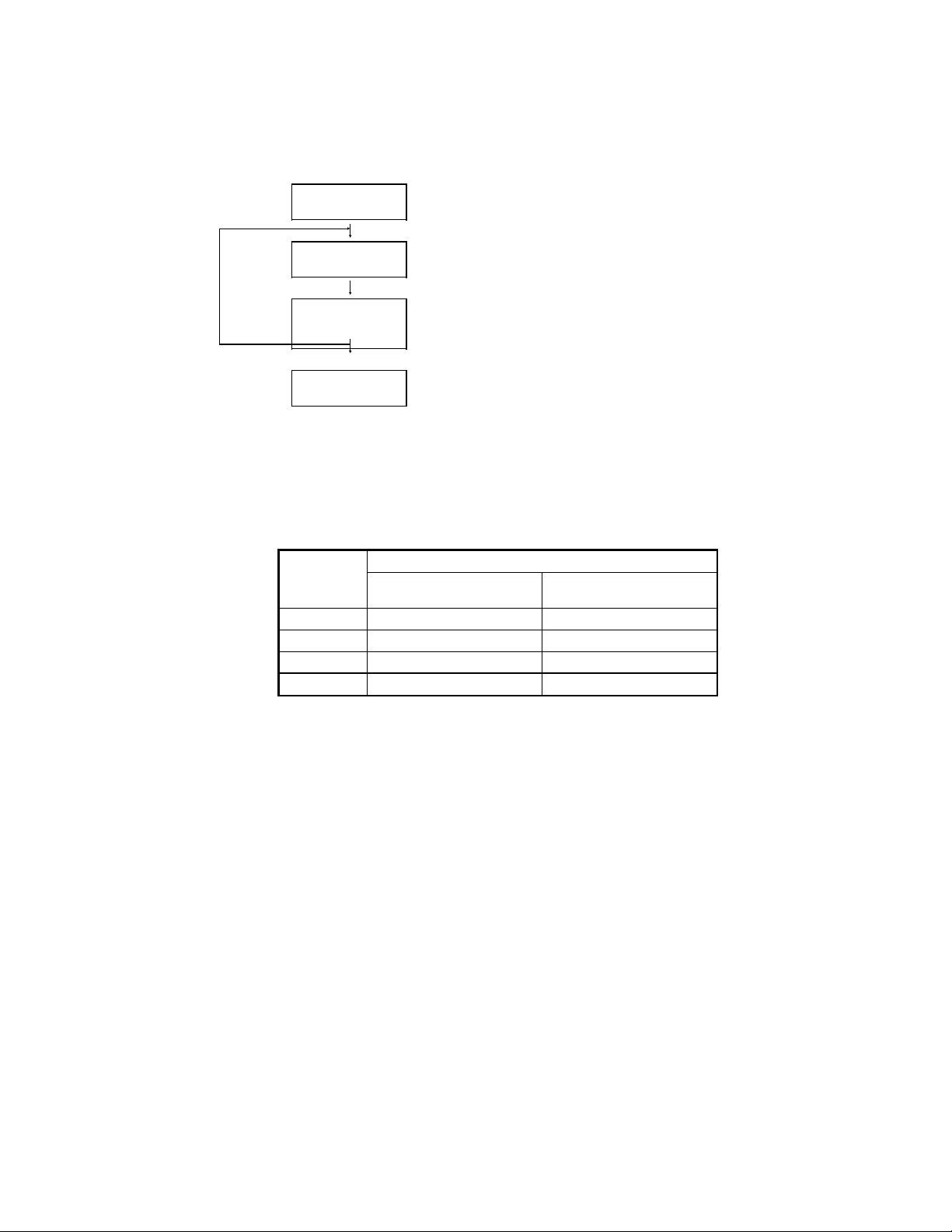

Repeats for the no. of

copies set to be made.

6

6-1. INITIAL OPERATION

The following operations are performed sequentially when Sorter Set Switch

S3 is first actuated after the Power Switch of the copier has been turned ON.

ST-723 performs step

➃ only.

➀ The Paper Aligning Bar is detected at its home position.

(For details, see p. M-14.)

➁ The Paper Clamp Unit is detected at its home position.

(For details, see p. M-22.)

➂ A check is made to ensure that the Stapler Arm is at its home

position.

* If not at the home position, the Stapler Arm is moved to the home

* position. (For details, see p. M-27.)

➃ The 1st Bin is detected at the reference position.

(For details, see p. M-19.)

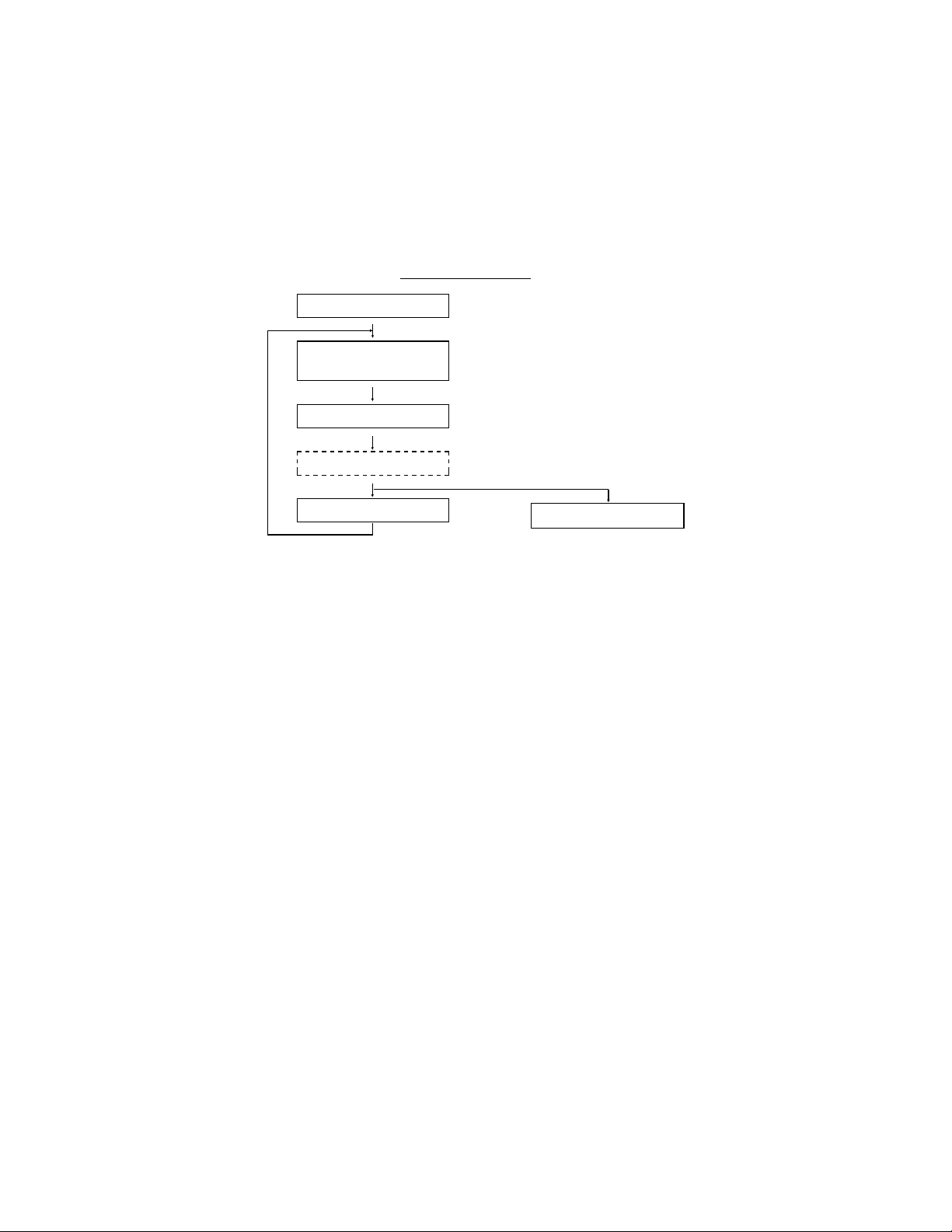

6-2. NON-SORT MODE

When in the Non-Sort Mode, the ST-724/ST-723 feeds all copies out onto

the 1st Bin. It feeds copies into the subsequent Bin as soon as the capacity

of the current Bin is exceeded. (As soon as 25 copies have been fed into the

10th Bin, the Remove Copies Indicator on the copier control panel lights up

and the copier inhibits the initiation of a new copy cycle.)

Example: Making 80 copies

No. of Copies

Bin

Fed In

1st 50

2nd 25

3rd 5

Outline of Operation

Out of Copier

Through

ST-724/ST-723

Fed into 1st Bin

Aligning

End of Operation

…ST-724 only

M-6

When the capacity of the

current Bin is exceeded

Bin Moving

Page 17

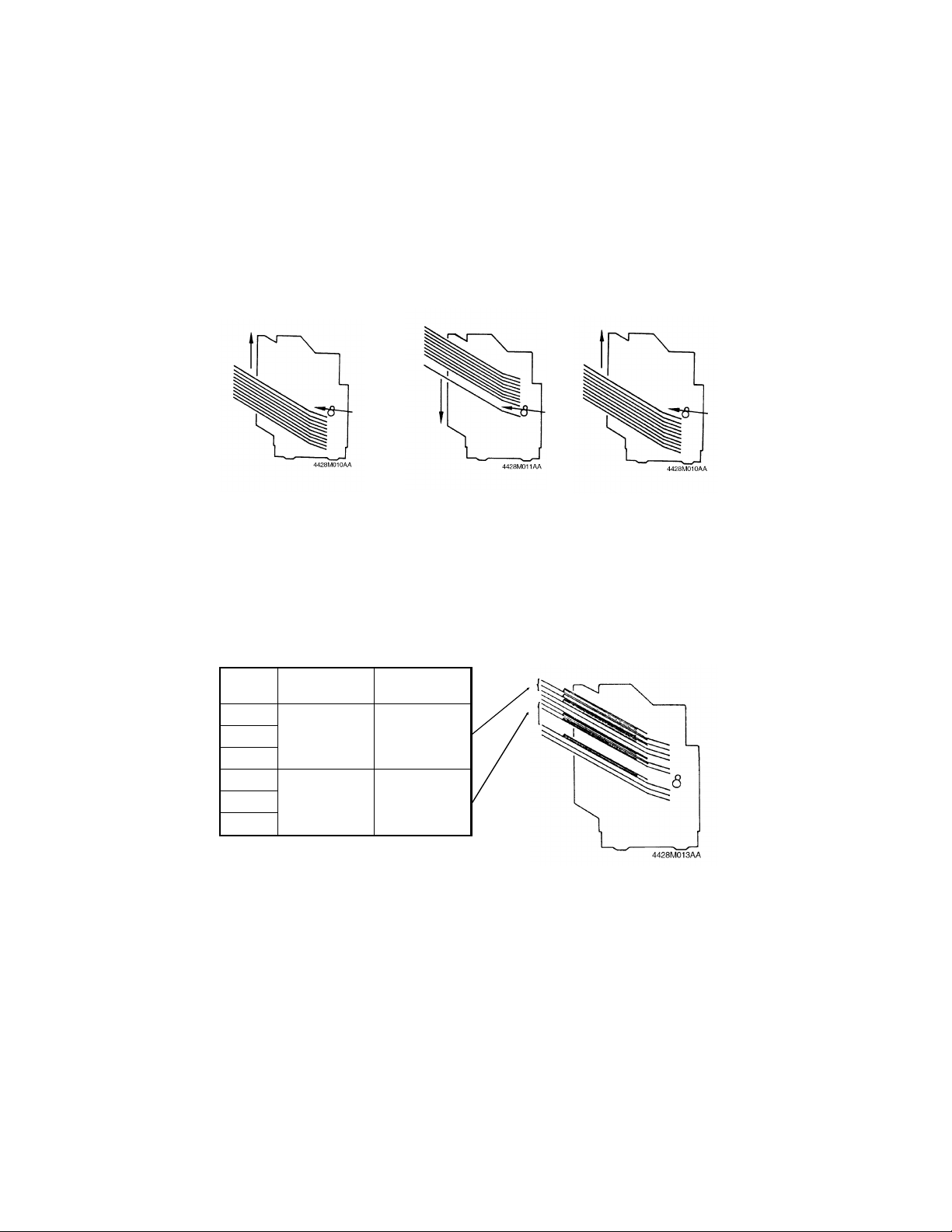

6-3. SORT MODE

● When in the Sort Mode, the ST-724/ST-723 sorts copies into complete

sets of originals, each set being fed out onto a Bin. Sorting is

bi-directional: the copies of the odd-numbered originals are sorted in the

sequence from the 1st Bin to 10th Bin (the Bins moving upward). Copies

of the even-numbered originals are sorted in the sequence from the 10th

Bin to 1st Bin (the Bins moving downward).

Example: Making 10 Copies Each from 3 Different Originals

Direction of Bin Moving for

Copies of 1st Original

Copy

Direction of Bin

Moving for

Copies of 2nd

Original

● When 25 copies have been fed out into the last Bin, the Remove Copies

Direction of Bin Moving for

Copies of 3rd Original

Indicator lights up on the copier control panel and the copier inhibits the

initiation of a new copy cycle. If, however, the 6th and subsequent Bins

are not used in the Sort Mode (i.e., the number of copies to be made has

been set to 5 or less), the Remove Copies Indicator does not light up.

Instead, the ST-724/ST-723 is automatically switched to the Auto Dual

Mode and copying continues using the 6th and subsequent Bins until the

Remove Copies Indicator lights up or the copy cycle is completed.

Example: Making 3 Copies Each from 30 Different Originals

Bin Original

1st

2nd

3rd

6th

7th

8th

1st to 25th 25

26th to 30th 5

No. of Copies

Fed Out

M-7

Page 18

● When the Start Key is pressed with 11 or more set for the number of

Repeats for the no. of

copies set to be made.

copies to be made, the number on the Multi-Copy Display is automatically

changed to 10 and the ST-724/ST-723 operates in the Sort Mode.

Outline of Operation

Out of Copier

Through

ST-724/ST-723

Fed into Bin

Aligning

Bin Moving

…ST-724 only

After the last copy

has been aligned

End of Operation

M-8

Page 19

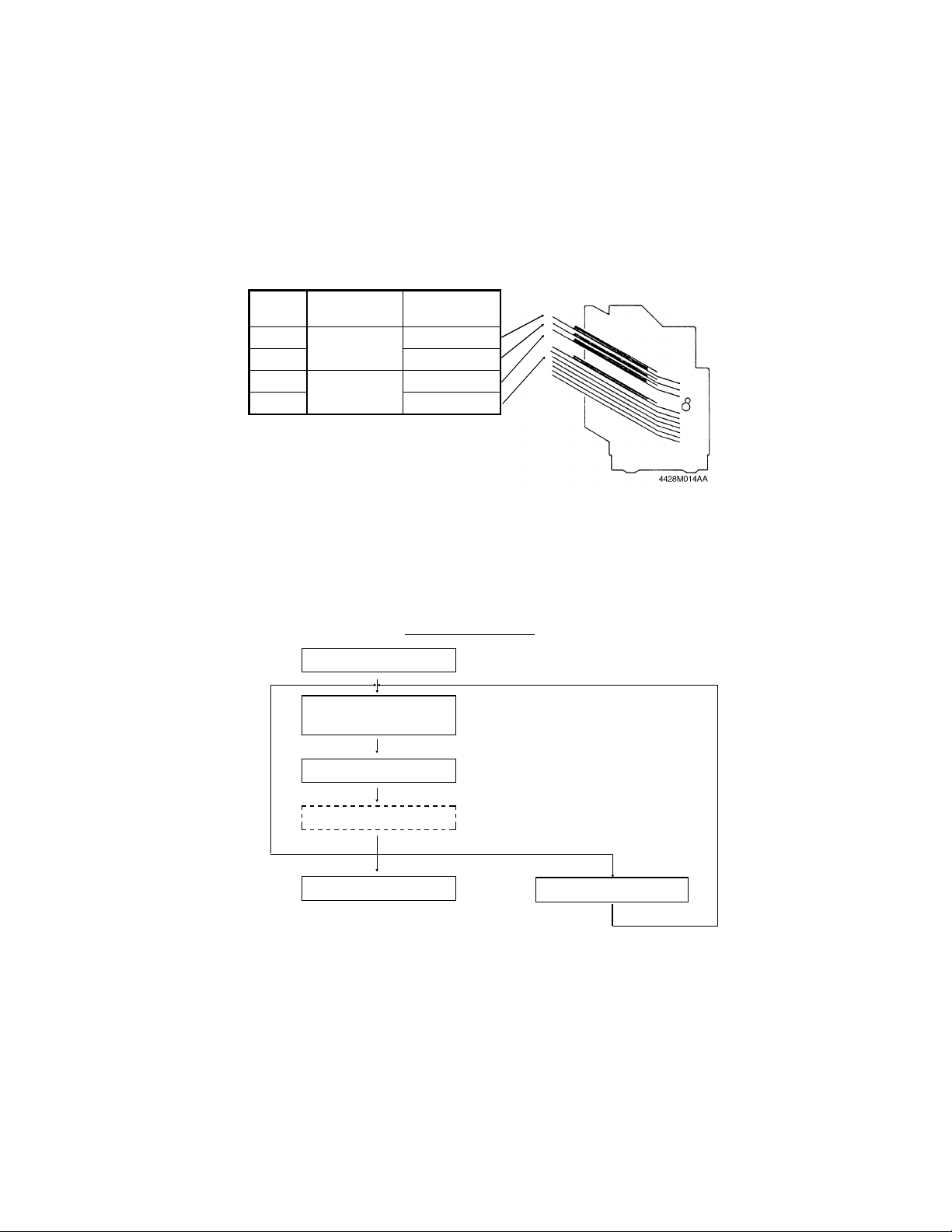

6-4. GROUP MODE

Repeats for the no. of

copies set to be made.

● When in the Group Mode, the ST-724/ST-723 separates copies made

from a single original into groups, each group containing the same, or a

different, number of copies.

Example: Making 25 Copies Each from 3 Different Originals

Bin Original

1st

2nd 5

3rd

4th 5

● If the settings on the copier control panel and other conditions require

1st

2nd

No. of Copies

Fed Out

25

25

more than 10 Bins, during execution of the copy job, the copier stops the

initiation of a new copy cycle and the Remove Copies Indicator lights up.

If space remains available in the 10th Bin, the Start Key can be pressed

again. All copies of the subsequent original or originals are now fed into

the 10th Bin. However, as soon as the capacity of the 10th Bin is

exceeded, the copier inhibits the initiation of the new copy cycle.

Outline of Operation

Out of Copier

Through

ST-724/ST-723

Fed into Bin

Aligning

End of Operation

…ST-724 only

At the end of the copy

cycle for one original

Bin Moving

M-9

Page 20

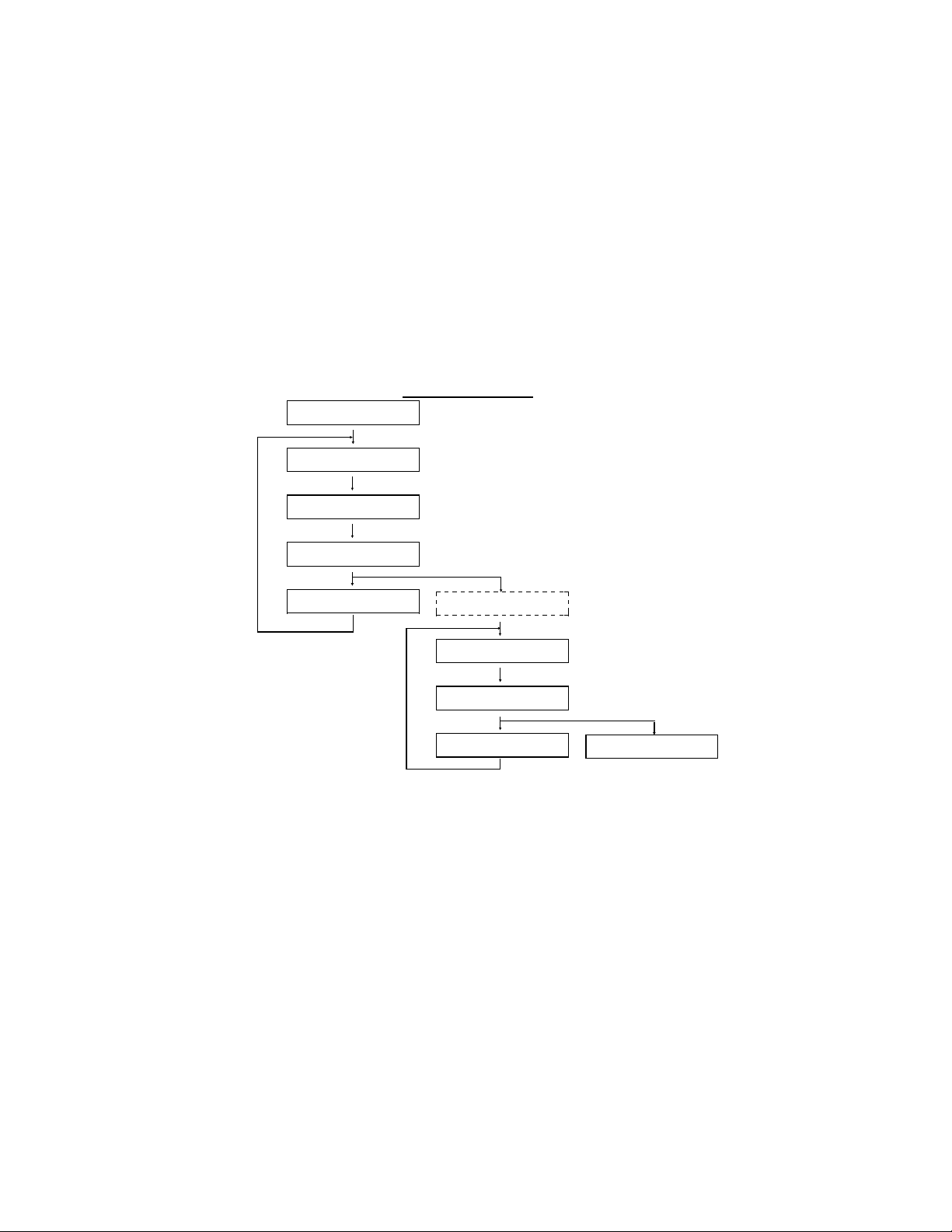

6-5. SORT STAPLE MODE (ST-724 ONLY)

Repeats for the no. of

copies set to be made.

● When in the Sort Staple Mode, the ST-724 automatically staples each of

the copy sets sorted into each Bin (the sorting operation is the same as in

the Sort Mode).

● Stapling action occurs starting with the lowest Bin in use. (For instance, if

1st to 4th Bins are in use, the copy sets are stapled starting with the 4th

Bin.)

● If copies are to be sorted only into the 1st Bin (i.e., when making one copy

each of two different originals), after both copies have been fed into the

1st Bin, the ST-724 moves the Bins to the 2nd Bin position and then back

to the 1st Bin position before initiating the stapling action.

● If the ST-724 is switched to the Auto Dual Mode during sorting, it cancels

the stapling action and sets the ST-724 into the Sort Mode.

Outline of Operation

Out of Copier

Through ST-724

Fed into Bin

Aligning

Bin Moving

● Stapling action is inhibited under any of the following conditions even if

the copy cycle has been initiated in the Sort Staple Mode:

After the last copy

has been aligned

Bin Moving

Clamping

Stapling

Bin Moving

…If the lowest Bin in

…use is not located to

…receive copies

End of Operation

➀ There is a copy or copies present in any of the Bins when the Power

Switch is turned ON and the copy cycle is initiated without having

removed it.

➁ The copy cycle is initiated with copies made in a preceding Non-Sort

cycle still in the Bins.

➂ The copy cycle is initiated with paper inserted into the Bin externally.

➃ There is only one copy in the Bin after sorting.

➄ Copies with different crosswise lengths are in the Bins.

➅ The copy set is not properly conveyed to the stapling position because of

a clamping or other failure (in which case, the ST-724 goes on to staple

the copy set in the next Bin).

M-10

Page 21

6-6. MANUAL STAPLE MODE (ST-724 ONLY)

The following two different operations are possible in the Manual Staple

Mode.

• When the Manual Staple Key on the copier control panel is pressed after

copies have been made in the Sort or Group Mode, the ST-724 staples

together two or more copies in a Bin. (The stapling action and stapling

inhibiting conditions are the same as those in the Sort Staple Mode.)

• When there are no copies in any of the Bins, the ST-724 can staple

together sheets of paper inserted into the 1st Bin by hand when the Manual

Staple Key on the copier control panel is pressed. At this time, the ST-724

performs no aligning action.

Operation

Press the Manual Staple Key.

Clamping

Stapling

End of Operation

No stapling action occurs if the sheets of paper have not properly been

conveyed to the stapling position because of a clamping or other failure.

6-7. BIN MOVEMENT AT END OF COPY CYCLE

If the 1st Bin is not located to receive copies at the end of a copy cycle, the

Bins are moved so that the 1st Bin will be located to receive copies 2 sec.

after copies have been removed from the Bins. This sets the ST-724/ST-723

M-11

Page 22

OPERATION OF EACH MECHANISM

7

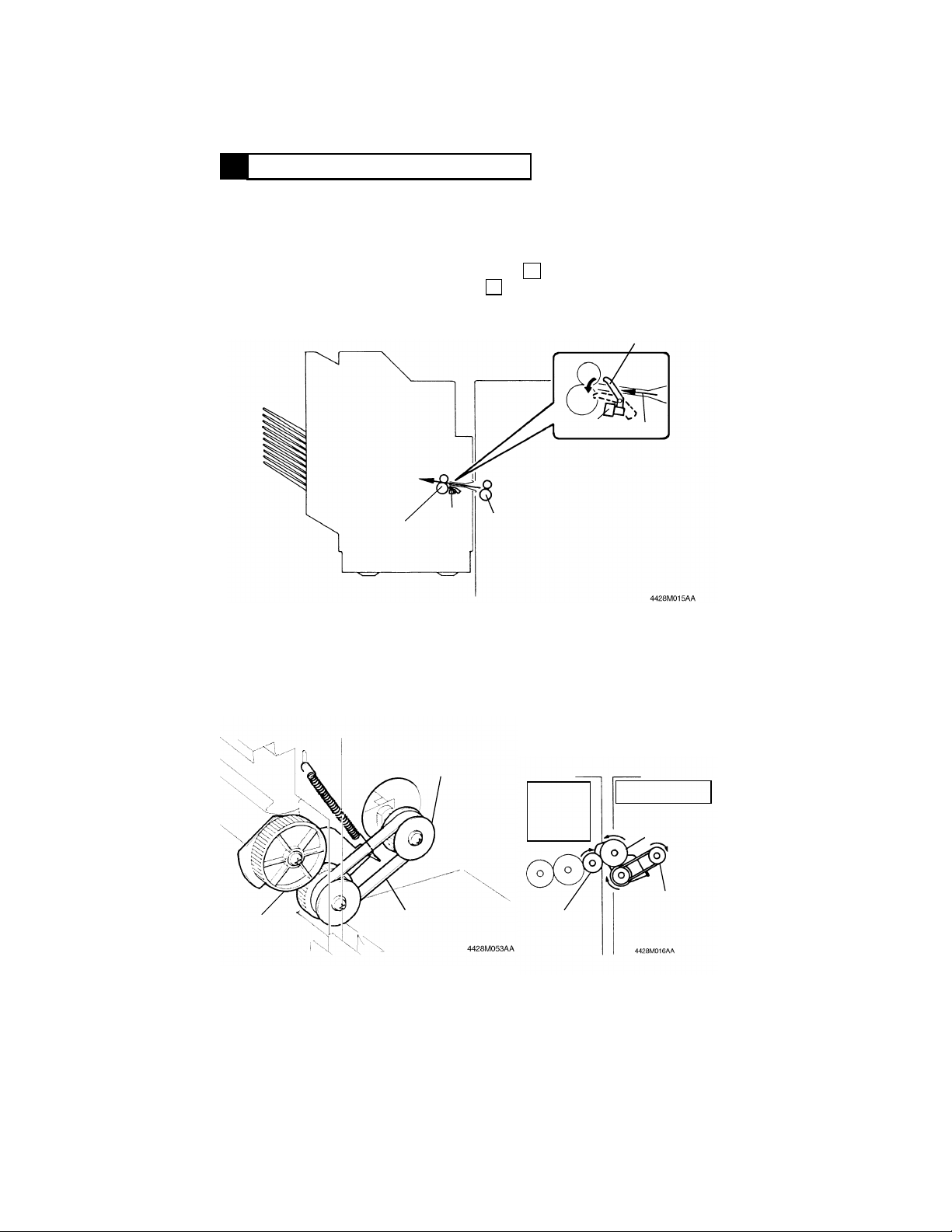

7-1. PAPER TRANSPORT MECHANISM

● Paper Path

The paper fed out of the Copier by the Exit Roller in the copier is fed

directly onto the Transport Roller in the ST-724/ST-723. The Transport

Roller turns to feed the paper almost straight into the Bin. During this

time, Sorter Exit Sensor PC2 is unblocked ( ) as the leading edge of

the paper moves past it and blocked ( ) as the trailing edge of the

H

L

paper moves past it. The paper path is constant, as shown below,

regardless of the operating mode selected for use.

Light Blocking Plate

Paper

PC2

Copier

Transport Roller

PC2

● Transport Roller Drive

Exit Roller in Copier

The Transport Roller is driven by the Drive Coupling Gear Assy which

receives drive from the Exit Roller Drive Gear inside the copier (or Duplex

Unit). This means that the Transport Roller turns in phase with the paper

take-up drive of the copier.

= Viewed from Rear of System =

Transport

Roller Pulley

Drive Coupling

Gear Assy

Timing Belt

Copier

or

Duplex

Unit

Exit Roller

Drive Gear

ST-724/ST-723

Drive Coupling

Gear Assy

Transport

Roller Pulley

M-12

Page 23

7-2. PAPER ALIGNING MECHANISM (ST-724 ONLY)

● The Paper Aligning Mechanism presses the copies fed into the Bins up

against the Aligning Reference Plate so that they can be aligned in the

crosswise direction. This mechanism will operate only with B5

Lengthwise, 8"

● The copies are aligned by the Paper Aligning Bar which is moved by

× 10" Lengthwise or greater size.

Paper Aligning Motor M3 turning forward or backward. The movement of

the Paper Aligning Bar differs depending on the paper size.

Paper Aligning Home

Position Sensor PC5

Spiral Shaft

M3

M3 Turning

Forward

Paper Aligning

Bar

● Paper Aligning Motor M3

M3 Turning

Backward

Aligning

Reference

Plate

Paper Aligning Motor M3 is a two-phase stepping motor. The output

pulses from pins 12 to 15 of IC1A are applied via IC6A and IC9A to M3 to

control the direction and distance of movement of the Paper Aligning Bar.

Each output pulse from IC1A turns M3 one angular increment, or a step,

which is 7.5°. This is equivalent in the movement of the Paper Aligning

Bar to approx. 0.3 mm. The number of output pulses from IC1A therefore

controls the distance of movement of the Paper Aligning Bar. The output

sequence of pulse signals (steps 1, 2, 3, and 4 or steps 4, 3, 2, and 1), on

the other hand, determines the direction of rotation of M3.

IC1A (Pin No.)

1 2 3 4

12 L L H H

13 H H L L

14 H L L H

15 L H H L

Step

Output Sequence M3 Turning Forward

M3 Turning Backward

M-13

Page 24

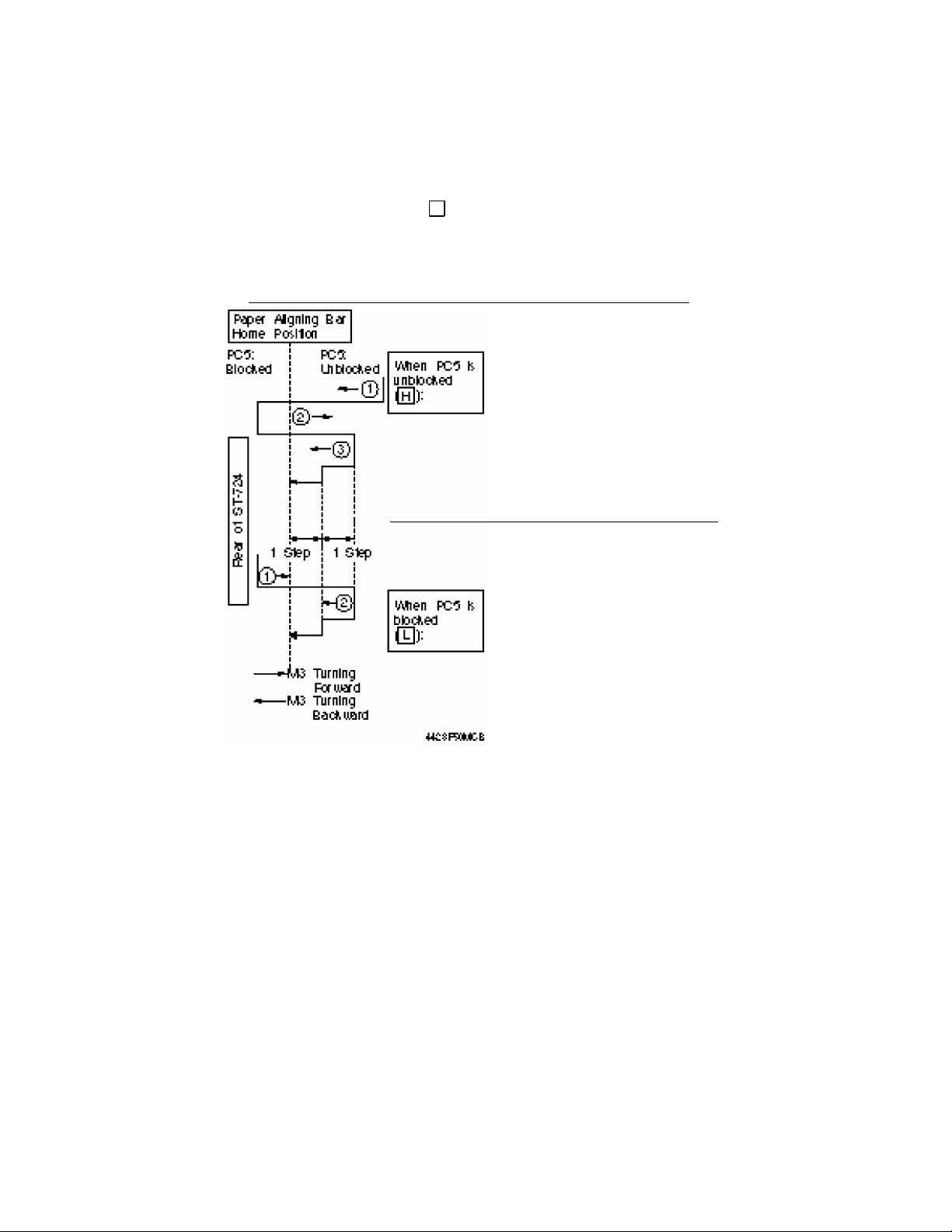

● Paper Aligning Bar Home Position Detection

The home position of the Paper Aligning Bar is where the Light Blocking

Plate fitted to the Paper Aligning Bar has just blocked Paper Aligning

Home Position Sensor PC5 ( ). This position serves as the reference

point, based on which the number of output pulses from IC1A is

calculated for different paper sizes.

Operation When Paper Aligning Bar is Detected at its Home Position

L

➀ M3 is turned backward until

PC5 is blocked.

➁ M3 is turned forward until

PC5 is unblocked.

➂ M3 is turned backward by one

pulse until PC5 is blocked, at

which time M3 is

deenergized. (See NOTE

below.)

➀ M3 is turned forward until

PC5 is unblocked.

➁ M3 is turned backward by one

pulse until PC5 is blocked, at

which time M3 is

deenergized. (See NOTE

below.)

NOTE: CPU checks whether PC5 is blocked or unblocked each time M3 is

The home position of the Paper Aligning Bar is detected under any of the

following timings:

energized for one pulse.

• When Sorter Set Switch S3 is turned ON.

• At the end of each mode (when the last copy has been aligned).

M-14

Page 25

● Outline of Paper Aligning Bar Operation

Home Position

…… The Bar is located near, but not in contact

with, the copy. (See NOTE below.)

…… The Bar presses the copy up against the

Aligning Reference Plate. (See NOTE

below.)

NOTE: Varies for different paper sizes.

➀

Standby Position

Aligning Position

➁

Home Position

➀ During a multi-copy cycle, the Paper Aligning Bar repeatedly

moves between the standby and aligning position until it

completes aligning the last copy.

➁ The Paper Aligning Bar returns to the home position when it

has completed aligning the last copy.

● Number of Pulses (Paper Aligning Bar Movement) for Different Paper

Sizes

Predetermined No. of Pulses

Paper Size

A3 0 51

× 17" 11 62

11"

8-1/2"

A4L 139 190

From Home to

Standby Position

× 11"L 137 188

From Standby to

Aligning Position

L: Lengthwise

M-15

Page 26

● Aligning Operation

Paper Aligning Bar at home position

60 msec. after Sorter Exit Sensor PC2 has

been unblocked ( ) as the leading edge

of the copy fed out of the copier reaches it

H

Paper Aligning Motor M3 turns forward for the predetermined number of

pulses corresponding to the paper size, thereby moving the Paper Aligning

Bar to the standby position.

270 msec. after PC2 has been blocked

( ) as the trailing edge of the copy

L

moves past it

M3 turns forward for the predetermined number of pulses, which moves the

Paper Aligning Bar to the aligning position to align the copy.

60 msec. later

In a multi-copy cycle

M3 turns backward for the

predetermined number of pulses

to return the Paper Aligning Bar to

In a single-copy cycle or at the end

of aligning the last copy

M3 turns backward and the Paper

Aligning Bar is detected at its home

position.

the standby position.

M-16

Page 27

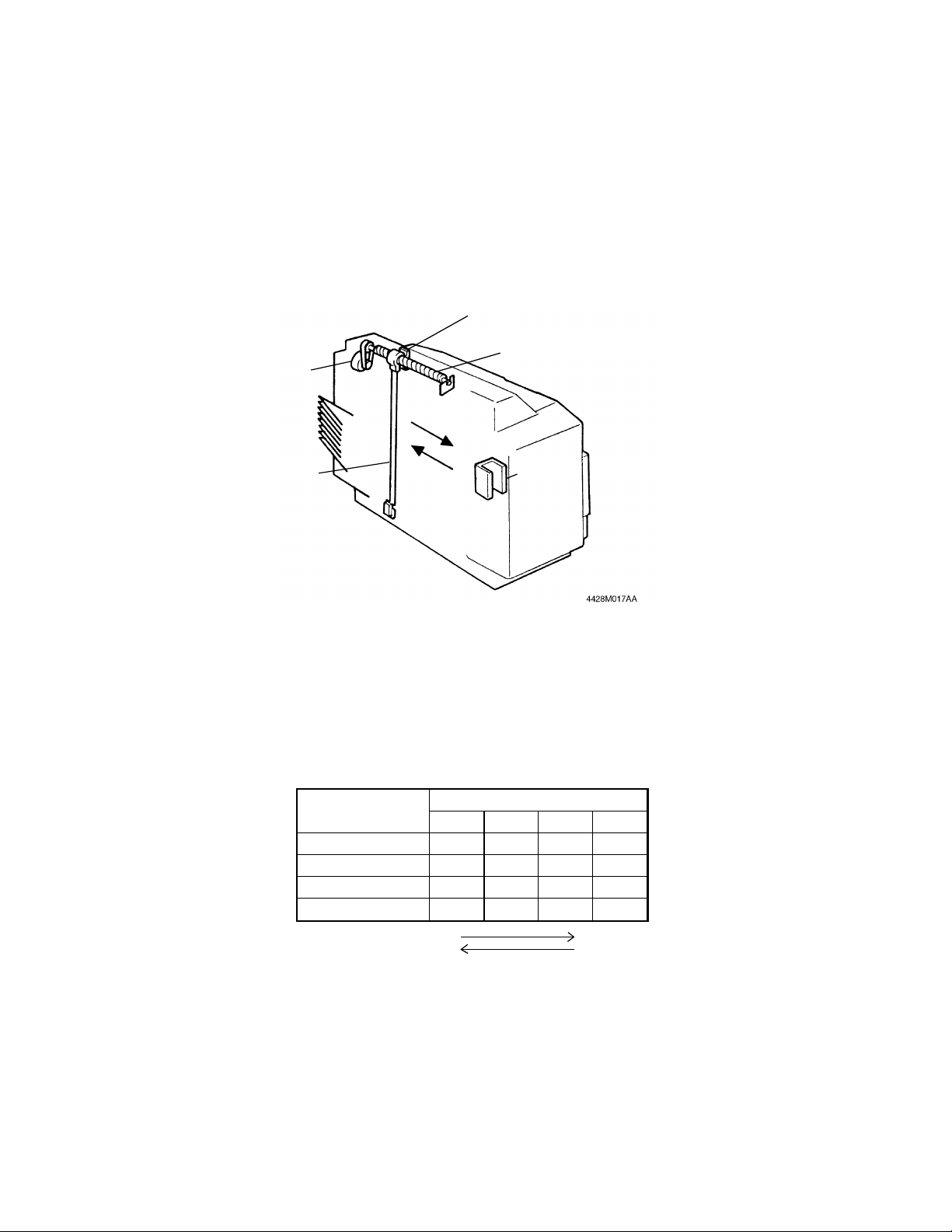

7-3. BIN MOVING MECHANISM

● The Top Bin and 1st to 10th Bin are all held in position by the grooves in

the Side Plate and those in the Spiral Cams. When the Spiral Cams are

turned one complete turn by Bin Moving Motor M1, all Bins and Top Bin

are at once moved up or down (depending on the turning direction of the

Spiral Cam) one Bin position along the grooves in the Spiral Cams.

Top Bin

Bin Upper Limit

Interlock Switch S1

1st to

10th Bin

Bin Lower Limit

Interlock Switch

S2

M1

Bin Moving Pulse

Sensor PC1

Bins Moving Up

Bins Moving Down

Spiral Cam

M1

PC1

Light Blocking Plate

M-17

4428M063AA

Bin Lower Limit Position

Sensor PC4

Pressure Roll

Drive Transmitting Belt

S1

S2

PC4

Bin Positioning

Sensor PC3

Page 28

● Bin Moving Motor M1

Bin Moving Motor M1 is a DC motor. The outputs from pins 5 and 6 of

IC1A are applied via IC7A and IC10A to M1. This energizes or

deenergizes M1 and controls the direction of M1 rotation.

IC1A-5 IC1A-6 Direction of M1 Rotation

L H Forward (Bins Moving Up)

H L Backward (Bins Moving Down)

H H Deenergized

If M1 is turned at its maximum speed, Bins vibrate heavily as they move,

resulting in a greater noise. M1 speed is controlled by pulse width

modulation, or PWM, which varies the width of pulses applied to M1,

thereby changing the average voltage applied to M1. The M1 shaft is

fitted with a Pulse Disk and Bin Moving Pulse Sensor PC1 is used to

convert the M1 shaft speed to pulse signals. The CPU knows the shaft

speed by means of the pulse frequency. Based on the output from PC1,

the M1 drive pulses are controlled, thereby minimizing vibration as it

occurs during Bin moving. This contributes to quieter operation.

Pulse Disk

M1

PC1

PC1

M-18

Page 29

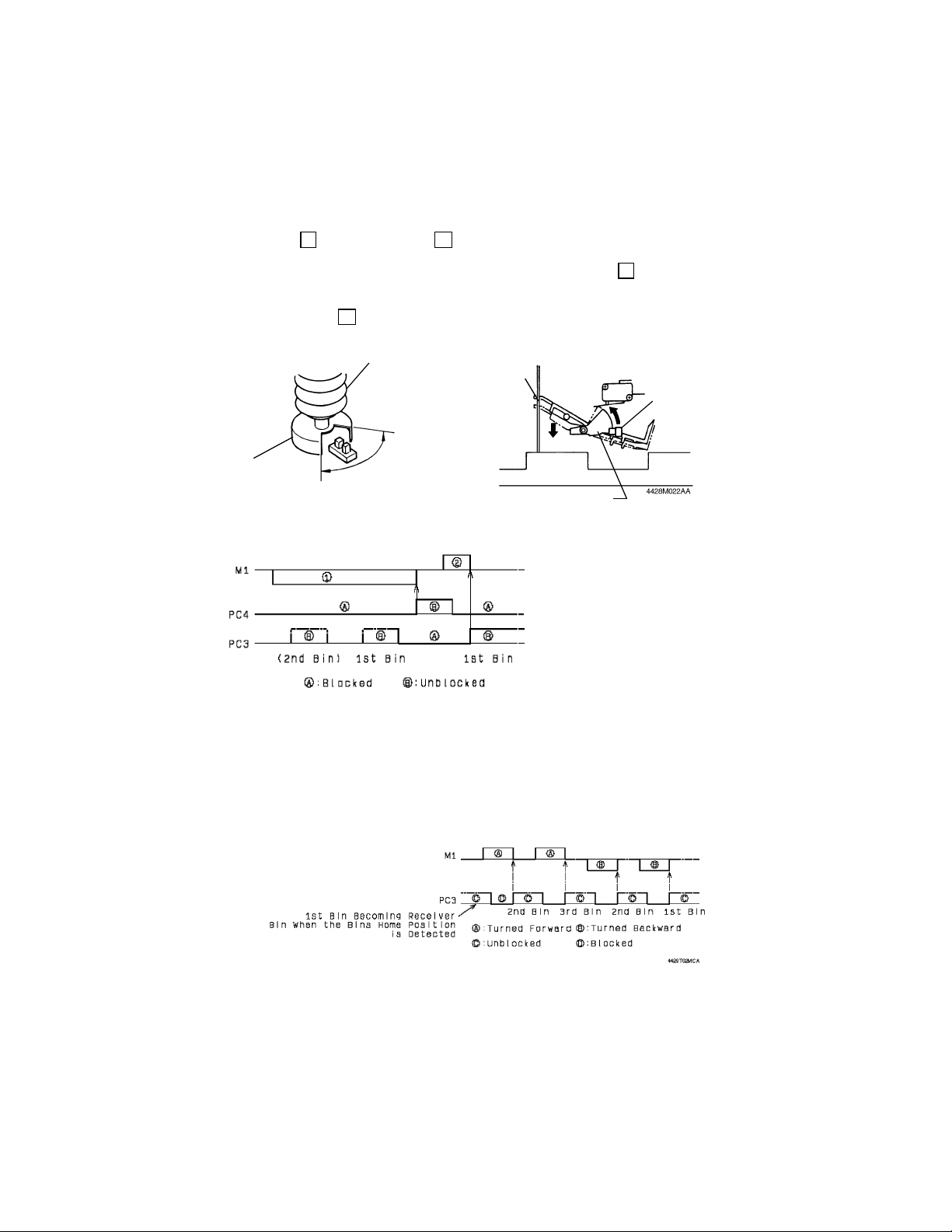

●

Bin Home Position Detection

The home position of the Bins is where the 1st Bin is located to receive

copies fed out of the copier. Movement of each Bin is controlled with this

position as the reference. The Bin home position is detected by Bin

Positioning Sensor PC3 and Bin Lower Limit Position Sensor PC4. PC3 is

blocked ( ) and unblocked ( ) by a Light Blocking Plate which turns

L

H

in phase with the Spiral Cam. It is unblocked when any of the Bins is

located to receive the copy. PC4 is normally kept blocked ( ) by a Light

L

Blocking Plate. However, when the 1st Bin is located lower than the level

to receive the copy, the 10th Bin pushes the Light Blocking Plate, which

unblocks PC4 ( ).

H

Spiral Cam

10th Bin

PC4

Light Blocking

Plate

PC3

Senses that any of

the Bins is located to

receive a copy.

4428M021AA

Light Blocking Plate

Operation at Bin Home Position Detection

➀ M1 is turned backward

until PC4 is unblocked.

➁ M1 is turned forward and

is deenergized as soon

as PC3 is unblocked.

(This is where the 1st Bin

4428T01MCA

The Bin home position is detected under the following timing:

• Sorter Set Switch S3 is turned ON for the first time after the Power

Switch of the copier has been turned ON.

● Bin Moving Control

After the Bin home position is detected, at which time the 1st Bin is

located to receive the copy, movement of the Bins is controlled by the

direction of M1 rotation and the number of times PC3 is blocked and

unblocked.

receives the copy.)

M-19

Page 30

● Bin Upper Limit Interlock Switch S1 and Bin Lower Limit Interlock Switch

S2

For a mechanical or electrical failure, Bin Moving Motor M1 can keep on

turning even when it should remain stationary. Bin Upper Limit Interlock

Switch S1 and Bin Lower Limit Interlock Switch S2 are installed to shut

down the DC24V power supply to M1, thereby bringing it to a stop if such

trouble occurs.

Bin Upper Limit Interlock Switch S1

If, during the upward motion of the Bins,

Actuator

Top Bin

the Bins continue moving upward above

the upper limit position (which is where

the 10th Bin is located to receive the

copy), the Actuator is swung by the Top

1st Bin

S1

Bin Lower Limit Interlock Switch S2

Bin as shown on the left, actuating S1 to

cut off the power supply to M1.

If, during the downward motion of the

Bins, the Bins continue moving

downward, having moved past the level

which unblocks Bin Lower Limit Position

10th Bin

S2

PC4

Sensor PC4, the Light Blocking Plate of

PC4 actuates S2 as shown on the left,

thus shutting down the power supply to

M1.

Light Blocking Plate

● Purpose of Installation of Top Bin

The paper this machine handles is mainly colored copies. Colored copies

tend to develop a slight face curl and, as a result, the copies fed out into

the1st Bin in the Sort mode can be misaligned with each other in the bin.

(With the 2nd Bin and lower, the copies fed into each bin are held by the

immediately upper bin and therefore the curl is minimized in the copies.)

The Top Bin in this machine therefore functions to keep the copies down

as they are fed into the 1st Bin.

M-20

Page 31

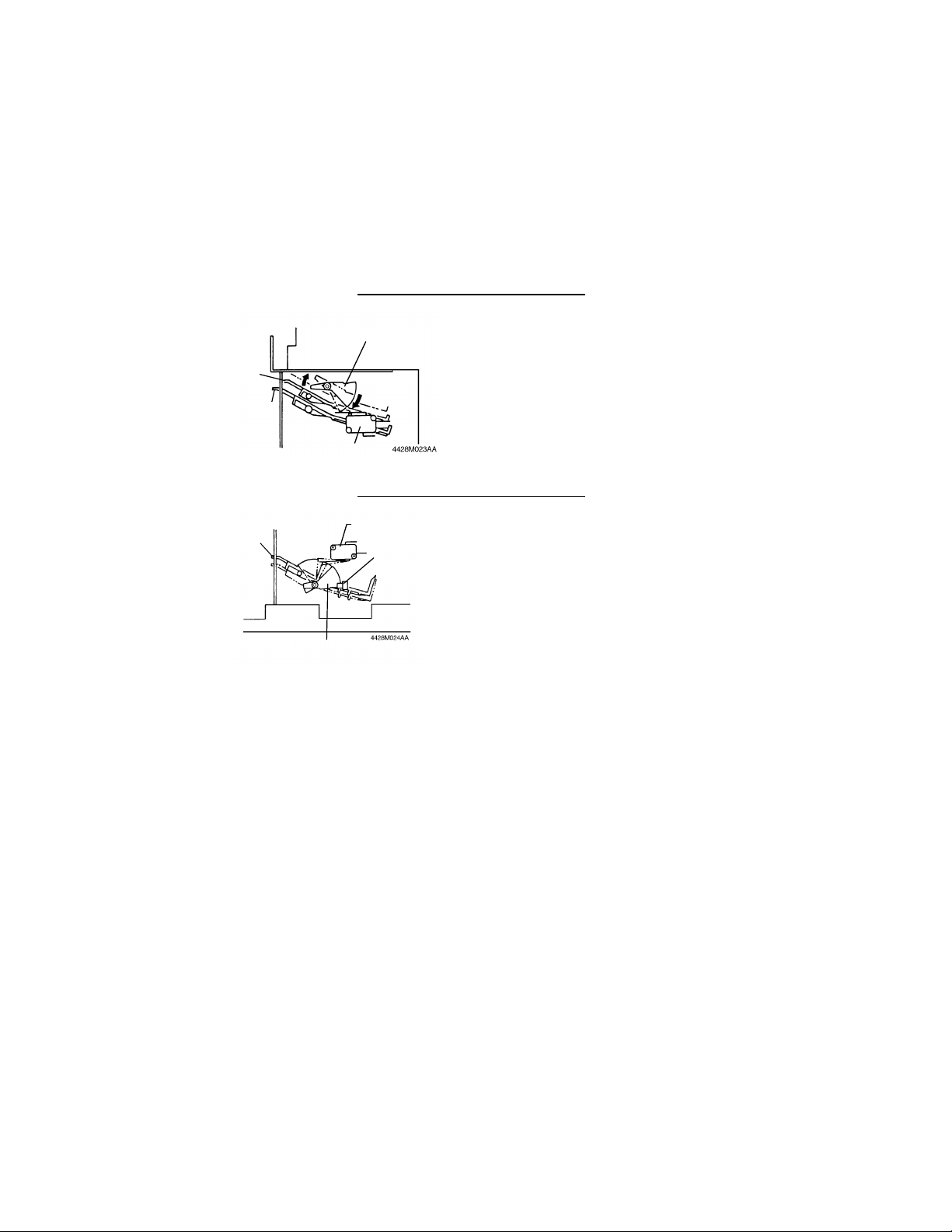

7-4. PAPER CLAMPING MECHANISM (ST-724 ONLY)

● The Paper Clamp Unit uses its jaws to clamp the copy set in the Bin and

moves it to the stapling position. After the copy set has been stapled

together, the jaws return it back to the Bin.

Jaws

Paper Clamp

Solenoid SL1

Paper Clamp

Motor M2

Paper Clamp Home

Position Sensor PC6

● The paper clamping operation consists of, (1) the Paper Clamp Unit being

moved between the home position (which is the stapling position) and the

clamping position by Paper Clamp Motor M2, and (2) the Jaws of the

Paper Clamp Unit clamping and unclamping the copy set as Paper Clamp

Solenoid SL1 is energized and deenergized.

● Paper Clamp Motor M2

A DC motor is used as Paper Clamp Motor M2. The output from pin 17 of

IC1A energizes or deenergizes M2 which turns in one direction only.

IC1A-17 M2

L Energized

H Deenergized

M-21

Page 32

● Moving Mechanism and Position Detection of Paper Clamp Unit

The Paper Clamp Unit is supported by four Rolls which run along the

Rails fitted to the Front Frame. Installed under the Paper Clamp Unit is a

Cam Slider, in which a Cam coupled to the drive shaft of M2 is fitted.

When M2 is energized to turn the Cam one turn, the Paper Clamp Unit

moves from home to the clamping position and then back to home

position.

Cam Slider

Cam

PC6

Cam Slider

Cam

Light Blocking

Plate

M2

Rail

Rolls

Rail

4428M026AA

Paper Clamp Home Position Sensor PC6 detects the Paper Clamp Unit at its

home (stapling) position and clamping position. PC6 is blocked ( ) and

unblocked ( ) by a semicircular Light Blocking Plate that turns in phase

H

L

with the Cam. The home position and clamping position are detected by the

Blocking Edge and Unblocking Edge of the Plate.

The Blocking Edge is where PC6 is just blocked, which is the home

position.

The Unblocking Edge is where PC6 is just unblocked, which is the

clamping position.

Paper Clamp Unit

Moving from Clamping

to Home Position

Home Position

Paper Clamp Unit

Moving from Home

to Clamping Position

Clamping Position

PC6

4428M028AA

Blocking Edge

4428M029AA

Being Blocked

4428M030AA

Unblocking Edge

Being Unblocked

4428M031AA

M2 is energized under the following timing to detect the home position of the

Paper Clamp Unit:

• Sorter Set Switch S3 is turned ON for the first time after the Power Switch

of the copier has been turned ON.

M-22

Page 33

● Paper Clamping Mechanism

As Paper Clamp Motor M2 turns, the Paper Clamp Unit moves to the

paper clamping position. Paper Clamp Solenoid SL1 is then energized.

When SL1 is energized, it moves the Lower Jaw upward by way of the

Lower Arm. At the same time, the Upper Arm which is in gear with the

Lower Arm pushes the Upper Jaw down. This results in the Upper and

Lower Jaws clamping the copy set. In addition, Pin A of the Lower Jaw

hooks catch B of the Aligning Reference Plate. This is done to move the

Aligning Reference Plate, together with the copy set, to the stapling

position.

SL1 is deenergized when the Paper Clamp Unit moves back again to the

clamping position after stapling. When SL1 is deenergized, the Jaws are

returned back to the original position via the Upper and Lower Arms by

the torsion spring fitted to the Lower Arm. (The Aligning Reference Plate

is returned to the original position by torsion springs C and D fitted to it,

as the Paper Clamp Unit moves to the paper clamping position.)

Home Position (Before Operation)

C

Upper Jaw

Aligning

Reference

Plate

Lower Jaw

D

Upper Arm

Gear

Coupling

Lower Arm

Torsion

Spring

SL1

At Clamping

A

B

M-23

Page 34

● Paper Clamping Operation

Paper Clamp Unit at home position

Paper Clamp Motor M2 is energized to move the Paper Clamp Unit

toward the clamping position.

M2 is deenergized as the Unblocking Edge of the Light Blocking Plate

reaches Paper Clamp Home Position Sensor PC6.

70 msec. later

Paper Clamp Solenoid SL1 is energized and the Jaws clamp the copy set.

70 msec. later

M2 is energized to move the Paper Clamp Unit toward the stapling

position.

M2 is deenergized as the Blocking Edge of the Light Blocking Plate

reaches PC6.

70 msec. later

(The copy set is stapled together. ... See 7-6. STAPLING MECHANISM.)

75 msec. later

M2 is energized to move the Paper Clamp Unit toward the clamping

position.

M2 is deenergized as the Unblocking Edge of the Light Blocking Plate

reaches PC6.

70 msec. later

SL1 is deenergized and the Jaws open to unclamp the stapled copy set.

70 msec. later

M2 remains energized until the Blocking Edge of the Light Blocking Plate

reaches PC6, allowing the Paper Clamp Unit to return to the home

position.

M-24

Page 35

7-5. PAPER DETECTION AT STAPLING MECHANISM (ST-724 ONLY)

In the beginning of a stapling sequence, the copy set in the Bin is moved to

the stapling position by the Paper Clamp Unit. Paper Clamping Sensor PC8

is used to check to see whether the copy set has been properly moved to

the stapling position before each stapling action occurs. If PC8 is not

blocked (

H ) by the copy set even when the Paper Clamp Unit has moved

to the stapling position because of a clamp failure or other reason, the

stapling action for that particular Bin is canceled and the sequence is started

for the stapling action for the next Bin.

PC8

Copy Set

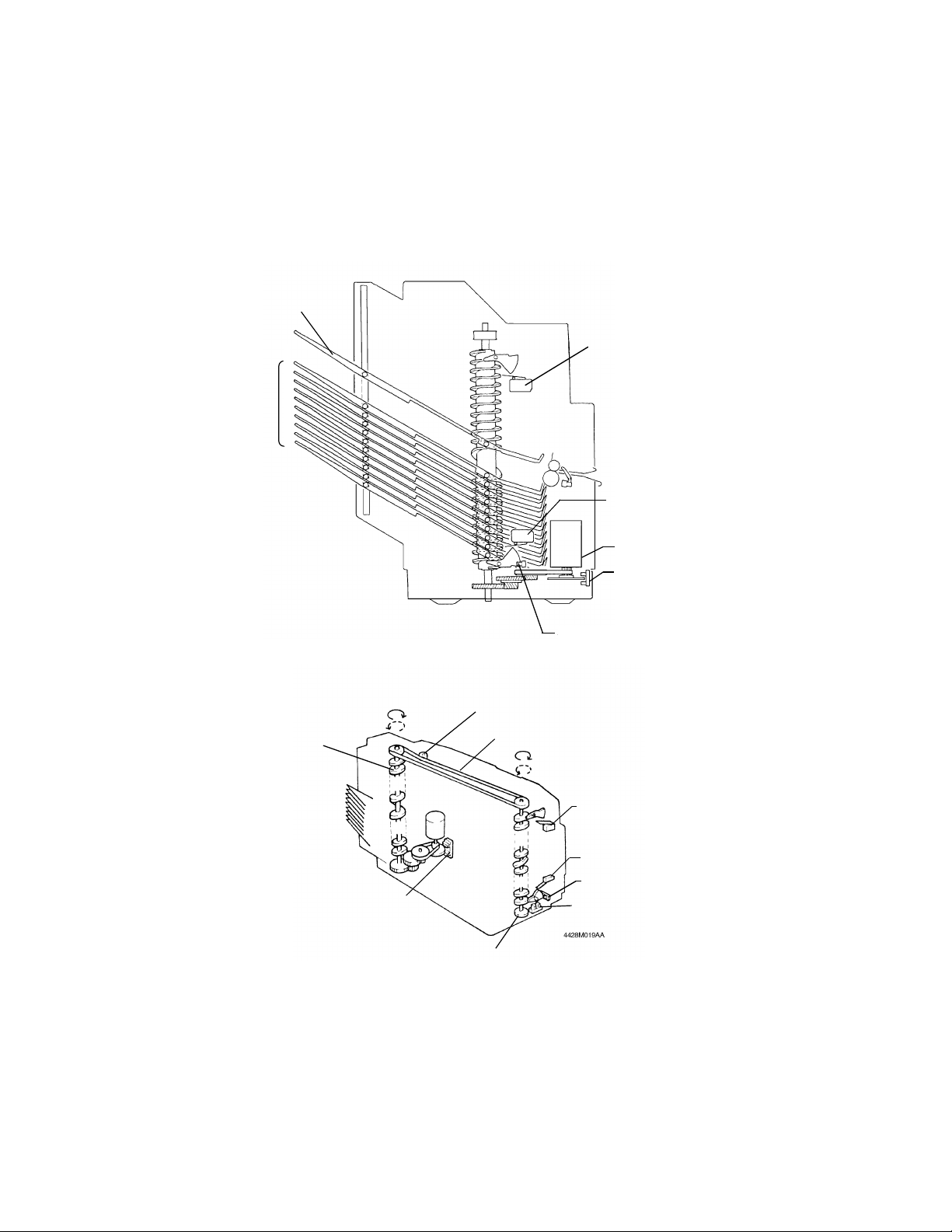

7-6. STAPLING MECHANISM (ST-724 ONLY)

● The Staple Unit has a Stapler Arm that is moved up and down by Stapling

Motor M4 to drive a staple into the copy set.

Stapler Home Position

Detecting Switch S4

Plunger Guide

Staple Forming

Mechanism

Stapling Table

M4

Knob

Stapler Arm

Paper Clamping Sensor

PC8

Staple Cartridge

Reverse Feed Check

4428M034AA

M-25

Page 36

● Stapling Motor M4

Stapling Motor M4, a DC motor, is energized or deenergized by the output

from pin 20 of IC1A. It turns in one direction only.

IC1A-20 M4

L Energized

H Deenergized

Stapler Arm Moving Mechanism

●

A cam slot is cut into the Stapler Arm, which the Roll on Gear D fits in.

When Stapling Motor M4 is energized to turn Gear D one complete turn

through a gear train of Gears A, B, and C, the Roll on Gear D causes the

Stapler Arm to move through the upper and lower limit positions once.

Upper Limit Position (Home Position)

Stapler Arm

M4

Roll

Cam slot

In Upward Stroke

Gear A

Gear B

Gear C

Gear D

In Downward Stroke

Lower Limit Position

M-26

Page 37

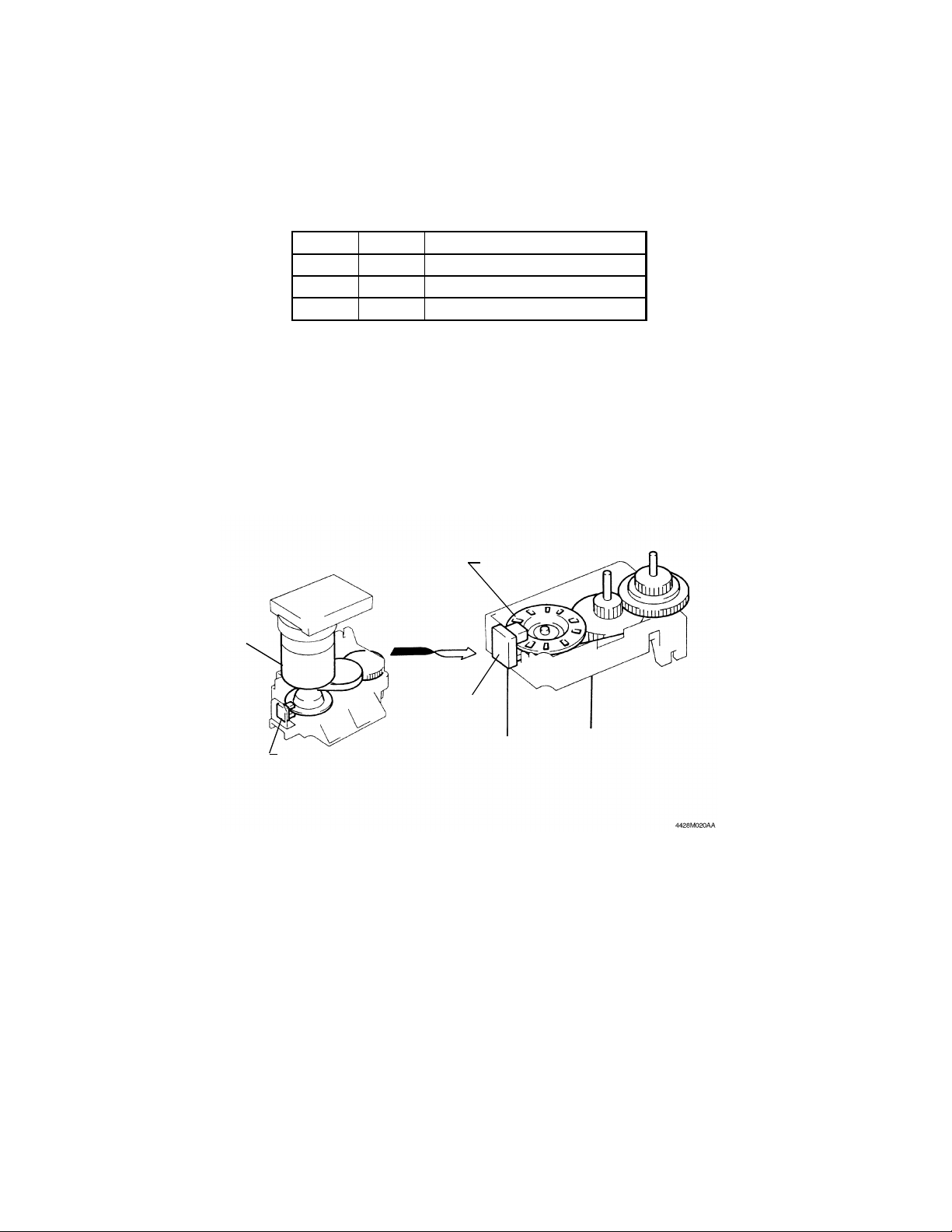

● Stapler Arm Home Position Detection

The home position of the Stapler Arm is detected by Stapler Home

Position Detecting Switch S4 which is actuated and deactuated by part A

of the Plunger Guide fitted to the Stapler Arm. The output from S4 is

applied to pin 1 of IC1A.

S4 IC1A-1

At Home Position ON L

When Arm Moves OFF H

At Home Position

Stapler Arm

S4

S4

A

Plunger Guide

Plunger

Guide

S4: ON

When Arm Moves

S4

Pushbutton

S4 Pushbutton

S4: OFF

A check is made to make sure if the Stapler Arm is at the home position

under the following timing. If the Stapler Arm is not detected at its home

position (S4 is deactuated), Stapling Motor M4 is energized and, when S4 is

actuated, is deenergized. (This is the sequence of operation to detect the

home position of the Stapler Arm.)

• Sorter Set Switch S3 is turned ON for the first time after the Power Switch

of the copier has been turned ON.

M-27

Page 38

● Staple Forming Mechanism

The staple forming mechanism consists of the Guide Plate, Former,

Driver, and Face Plate.

Guide Plate

(Front Sheath)

Former

Bending

Block

• The Guide Plate functions as a guide to hold the Former and Driver. The

A

Staple Sheet

Plunger Guide

Body

Driver

Face Plate

4428M037AA

Bending Block of the Guide Plate serves as a stopper for the staple sheet

being fed. The groove at A in the Bending Block holds the first, or front

staple of the staple sheet.

• The Former forms the front staple of the staple sheet held by the Bending

Block into an inverted-U shape.

• The Driver, fixed onto the Plunger Guide, separates the formed staple from

the staple sheet and drives it into the copy set.

• The Face Plate is fixed to the Body and presses the copy set down when

the staple is driven into it.

M-28

Page 39

● Operation of the Staple Forming Mechanism

1. As Stapling Motor M4 turns,

Body

Copy

Set

2. The Body reaches the copy set

the Stapler Arm moves

downward. At this time the

Body is pushed downward by

the Plunger Guide.

and stops moving. At this time,

the Face Plate presses the

copy set downward.

Driver

A

Former

Guide

Plate

Copy

Set

B

Bending

Block

Plunger Guide

Bending Block

Driver

A

Staple Sheet

Former

Former

4428M039AA

Driver

4428M040AA

Driver

Former

Stapling

Table

4428M041AA

3. As the Stapler Arm (i.e.

Plunger Guide) moves further

downward, the Former is

pushed by Claws A of the

Driver and moves downward to

form into an inverted-U the

first staple of the staple sheet

held in position by the Bending

Block.

4. Claws A of the Driver slide

along protrusions B of the

Guide Plate, slipping behind

the Former. The tip of the

Driver then reaches the first

staple of the staple sheet.

(At this time, the Bending

Block is pushed in the

direction of the arrow by the tip

of the Driver, releasing the first

staple.)

5. The Former reaches the copy

set and stops moving. The

Driver, on the other hand,

moves further downward to

separate the formed staple

from the staple sheet and

drives it into the copy set.

(The staple driven into the

copy set is bent by the

Stapling Table. This completes

the stapling action.)

M-29

Page 40

Former Moves

Upward As Driver

Does So.

Former

C

Driver

Plunger

Guide

6. The Stapler Arm (i.e. Plunger

Guide) moves upward from the

lower limit position. At this

time, the Driver moves upward.

7. Since the protrusion of the

Former fits into slot C in the

Driver, the Former is moved

upward as the Driver moves

upward.

Plunger Guide

Body Moves Upward As

Driver and Former Do So.

Face Plate

S4

8. Since the protrusion of the

Former fits into rectangular

hole D in the Face Plate, the

Body also moves upward.

D

Body

9. The Plunger Guide actuates

Stapler Home Position

Detecting Switch S4, which

deenergizes M4. This

completes the stapling action.

M-30

Page 41

● Moving Stapler Arm Pivot Axis

More Sheets of Paper

Less Sheets of Paper

The lower limit position of the Stapler Arm varies depending on the

number of sheets of paper to be stapled together. Since the Roll on Gear

D fits into the cam slot in the Stapler Arm, however, the Stapler Arm at its

cam slot end can move along only a given trajectory.

The pivot axis of the Arm is therefore made movable, thereby

compensating for the varying lower limit positions of the Arm depending

on the number of sheets of paper to be stapled together.

Pivot Axis

More Sheets of

Paper

Less

Sheets of

Paper

Stapler Arm

M-31

Page 42

● Staple Feed Mechanism

The staple sheet is fed one staple at a time onto the Bending Block by the

Feed Spring fitted to the Feeder.

Staple Feeding

When a Staple Cartridge is placed in position, tension is applied to the

Feeder in the direction of the arrow by the Cartridge, meaning that the

Feeder is pressed against the Driver.

Driver

Bending Block

Feeder

Cartridge

Staple Sheet

Feed Spring

When the Driver and Former move down as the Stapler Arm moves down,

the protrusion of the Former pushes the Feeder back in the direction of

the arrow, moving the Feed Spring one staple backward. (Because of the

Reverse Feed Check of the Staple Cartridge, the staple sheet is not

moved backward by the Feed Spring at this time.)

Former

Reverse Feed Check

When the Stapler Arm moves up after a staple has been driven into the

copy set, the Driver and Former move up. As a result, the Feeder is no

longer pushed by the protrusion of the Former and, instead, it is again

pushed toward the Driver. Since the Feed Spring moves in the direction of

the arrow at this time, the staple sheet is fed one staple to the Bending

Block.

M-32

Page 43

● Staple Sheet Empty Detection

Staple Empty Detecting Sensor PC10 is used to detect whether there is a

staple sheet or not in the Staple Cartridge. PC10 is a reflector-type

photosensor. When there is a staple sheet, the light from PC10 LED is

reflected by the staple sheet, turning ON the PC10 phototransistor. This

results in a LOW signal being input to pin 62 of IC1A. If there is no staple

sheet, the LED light is not reflected, which turns OFF the phototransistor.

At this time, a HIGH signal is input to pin 62 of IC1A and the Add Staple

Indicator lights up on the copier control panel.

Staple Sheet IC1A-62

Present L

Not Present H

Staple Sheet

Body

PC10

• A staple-sheet-empty condition is detected when there are about 60

staples remaining in the Staple Cartridge.

• If a staple-sheet-empty condition is detected during a stapling action, that

particular stapling sequence is continued until it is completed. After the

sequence has been completed, the Add Staple Indicator lights up.

• Immediately after a new Staple Cartridge has been installed, the Stapler is

operated to complete four consecutive stapling sequences (it is stopped

when Stapler Home Position Detecting Switch S4 is actuated a fourth

time). This is done to prevent a "dummy run" (an operation of the Stapler

without actually driving a staple into the paper) immediately following the

replacement of the Cartridge.

M-33

Page 44

● Stapling Operation Sequence

The Paper Clamp Unit moves the copy set in the Bin to the stapling

position.

Paper Clamping Sensor PC8 is blocked (

the stapling position.

A LOW signal is output from pin 20 of IC1A to energize Stapling Motor M4.

The Stapler Arm moves down and then up. (This completes the stapling of

the copy set.)

Stapler Home Position Detecting Switch S4 is actuated.

A HIGH signal is output from pin 20 of IC1A to deenergize M4.

The Paper Clamp Unit returns the stapled copy set back into the Bin.

L ) by the copy set moved into

M-34

Page 45

7-7. SORTER SET SWITCH

● Sorter Set Switch S3 is used to detect whether or not the ST-724/ST-723

is locked to the copier. When the ST-724/ST-723 is locked to the copier,

the protrusion of the mounting bracket actuates S3. The output from S3 is

detected by pin 2 of IC1A.

● When S3 is turned ON, the DC24V power of the copier is supplied to the

ST-724/ST-723.

S3 IC1A-2

When Connected ON L

S3

Protrusion of

Mounting Bracket

M-35

Page 46

7-8. BIN EMPTY DETECTION

● Bin Empty Sensor LED Board PWB-B and Bin Empty Sensor PQ Board

PWB-C work as a pair to detect a sheet of paper present in any of the

Bins. Depending on whether there is a sheet of paper present in the Bin,

PWB-B is blocked or unblocked, changing the output from pin 2 of IC1C

on PWB-C as follows.

● Pulses are output from pin 4 of IC1C on PWB-C and these pulses turn ON

and OFF LD1 on PWB-B repeatedly. IC1C on PWB-C determines if a

sheet of paper is present in the bin based on a light beam that strikes it in

synchronism with these pulses. This prevents erroneous detection of a

paper-empty condition caused by extraneous light.

Paper in Bin IC1C-2

Present H

Not Present L

PWB-B

M-36

PWB-C

Page 47

OPERATION IN EACH MODE

8

8-1. NON-SORT MODE

When the Fusing Motor begins in the copier, the Transport Roller is

turned by the Drive Coupling Gear Assy.

∗

... ST-724 Only.

Sorter Exit Sensor PC2 is unblocked (

copy moves past it.

60 msec. later

Paper Aligning Motor M3 turns forward for the specified number of pulses

(which varies depending on the paper size) to move the Paper Aligning

Bar to the standby position.

PC2 is blocked (

M3 turns forward for the specified

number of pulses, causing the Paper

Aligning Bar to align the copy fed into

the Bin.

M3 turns backward for the specified

number of pulses to move the Paper

Aligning Bar to the standby position.

PC2 is unblocked as the leading edge of the next copy moves past it.

PC2 is blocked as the trailing edge of the last copy moves past it.

M3 turns forward for the specified

number of pulses, causing the Paper

Aligning Bar to align the copy fed into

the Bin.

M3 turns backward, then the Paper

Aligning Bar is detected at its home

position.

L ) as the trailing edge of the copy moves past it.

270 msec. later

60 msec. later

270 msec. later

60 msec. later

H ) as the leading edge of the

When the capacity of

the current Bin is

exceeded: 480 msec.

later

Bin Moving Motor M1 is turned

forward until Bin Positioning

Sensor PC3 (in an unblocked

state,

H ) is blocked ( L ) and

then unblocked to move the Bins

so that the 2nd Bin, instead of the

previous 1st Bin, receives the

copy.

When the Fusing Motor stops

turning in the copier, the

Transport Roller stops turning.

M-37

Page 48

8-2. SORT MODE

Example: Making 2 copies each of 2 different originals in the Sort Mode

When the Fusing Motor begins in the copier, the Transport Roller is turned

by the Drive Coupling Gear Assy.

∗ ... ST-724 Only.

Sorter Exit Sensor PC2 is unblocked (

copy moves past it.

60 msec. later

Paper Aligning Motor M3 turns forward for the specified number of pulses

(which varies depending on the paper size) to move the Paper Aligning Bar

to the standby position.

PC2 is blocked (

M3 turns forward for the specified

number of pulses, causing the Paper

Aligning Bar to align the copy fed into

the Bin.

M3 turns backward for the specified

number of pulses to move the Paper

Aligning Bar to the standby position.

PC2 is unblocked as the leading edge of the second copy moves past it.

PC2 is blocked as the trailing edge of the second copy moves past it.

M3 turns forward for the specified number of pulses, causing the Paper

Aligning Bar to align the copy fed into the Bin.

M3 turns backward for the specified number of pulses to move the Paper

Aligning Bar to the standby position.

L ) as the trailing edge of the first copy moves past it.

270 msec. later

60 msec. later

270 msec. later

60 msec. later

H ) as the leading edge of the first

480 msec. later

Bin Moving Motor M1 is turned

forward until Bin Positioning

Sensor PC3 (in an unblocked

state,

H ) is blocked ( L ) and

then unblocked to move the

Bins so that the 2nd Bin,

instead of the previous 1st Bin,

receives the copy.

PC2 is unblocked as the leading edge of the first copy of the second original

moves past it.

PC2 is blocked as the trailing edge of the first copy of the second original

moves past it.

To ➀ on next page

To

➁ on next page

M-38

Page 49

➀

270 msec. later

M3 turns forward for the specified

number of pulses, causing the Paper

Aligning Bar to align the copy fed into

the Bin.

60 msec. later

M3 turns backward for the specified

number of pulses to move the Paper

Aligning Bar to the standby position.

PC2 is unblocked as the leading edge of the second copy of the second

original moves past it.

PC2 is blocked as the trailing edge of the second copy of the second original

moves past it.

270 msec. later

M3 turns forward for the specified

number of pulses, causing the Paper

Aligning Bar to align the copy fed into

the Bin.

60 msec. later

M3 turns backward, then the Paper

Aligning Bar is detected at its home

position.

M1 is turned backward until

PC3 (in an unblocked state,

H ) is blocked ( L ) and

then unblocked to move the

Bins so that the 1st Bin,

instead of the previous 2nd

Bin, receives the copy.

When the Fusing Motor stops

turning in the copier, the

Transport Roller stops turning.

➁

480 msec. later

M-39

Page 50

8-3. GROUP MODE

Example: Making 2 copies each of 2 different originals in the Group Mode

When the Fusing Motor begins in the copier, the Transport Roller is turned

by the Drive Coupling Gear Assy.

∗ ... ST-724 Only.

Sorter Exit Sensor PC2 is unblocked (

copy moves past it.

60 msec. later

Paper Aligning Motor M3 turns forward for the specified number of pulses

(which varies depending on the paper size) to move the Paper Aligning Bar

to the standby position.

PC2 is blocked (

M3 turns forward for the specified number of pulses, causing the Paper

Aligning Bar to align the copy fed into the Bin.

M3 turns backward for the specified number of pulses to move the Paper

Aligning Bar to the standby position.

PC2 is unblocked as the leading edge of the second copy moves past it.

PC2 is blocked as the trailing edge of the second copy moves past it.

M3 turns forward for the specified

number of pulses, causing the Paper

Aligning Bar to align the copy fed into

the Bin.

M3 turns backward for the specified

number of pulses to move the Paper

Aligning Bar to the standby position.

L ) as the trailing edge of the first copy moves past it.

270 msec. later

60 msec. later

270 msec. later

60 msec. later

H ) as the leading edge of the first

480 msec. later

Bin Moving Motor M1 is turned

forward until Bin Positioning

Sensor PC3 (in an unblocked

state,

H ) is blocked ( L ) and

then unblocked to move the

Bins so that the 2nd Bin,

instead of the previous 1st Bin,

receives the copy.

PC2 is unblocked as the leading edge of the first copy of the second original

moves past it.

PC2 is blocked as the trailing edge of the first copy of the second original

moves past it.

270 msec. later

M3 turns forward for the specified number of pulses, causing the Paper

Aligning Bar to align the copy fed into the Bin.

To

➀ on next page

M-40

Page 51

➀

60 msec. later

M3 turns backward for the specified number of pulses to move the Paper

Aligning Bar to the standby position.

PC2 is unblocked as the leading edge of the second copy of the second

original moves past it.

PC2 is blocked as the trailing edge of the second copy of the second original

moves past it.

M3 turns forward for the specified

270 msec. later

number of pulses, causing the Paper

Aligning Bar to align the copy fed into

the Bin.

60 msec. later

M3 turns backward, then the Paper

Aligning Bar is detected at its home

When the Fusing Motor stops

turning in the copier, the

Transport Roller stops turning.

M-41

Page 52

8-4. SORT STAPLE MODE (ST-724 ONLY)

Example: Making 2 copies each of 2 different originals in the Sort Staple

Mode

All copies have been fed out into the Bins and the Paper Aligning Bar

returns to the home position. (The operation to feed copies into the Bins

is the same as in the Sort Mode.)

480 msec. after Sorter Exit Sensor PC2 has been blocked as the

trailing edge of the last copy moves past it

Bin Moving Motor M1 is turned forward until Bin Positioning Sensor PC3 (in

an unblocked state,

H ) is blocked ( L ) and then unblocked to move the

Bins so that the 2nd Bin, instead of the previous 1st Bin, receives the copy.

85 msec. later

Paper Clamp Motor M2 is energized to move the Paper Clamp Unit toward

the paper clamp position. ............................................................................(A)

M2 is deenergized as the Unblocking Edge of the Light Blocking Plate

reaches Paper Clamp Home Position Sensor PC6.

70 msec. later

Paper Clamp Solenoid SL1 is energized and the Jaws clamp the copy set.

70 msec. later

M2 is energized to move the Paper Clamp Unit which holds the copy set

toward the stapling position.

When the copy set is

successfully clamped

M2 is deenergized as the Blocking Edge

of the Light Blocking Plate reaches PC6.

70 msec. later

Paper Clamping Sensor PC8 is

blocked.

Stapling Motor M4 is energized and the stapling sequence is started (only if

PC8 is blocked).

M4 is deenergized when Stapler Home Position Detecting Switch S4 (in the

ON position) is turned OFF and then turned ON, completing the stapling

sequence.

75 msec. later

M2 is energized to move the Paper Clamp Unit toward the clamping position

(to return the stapled copy set back into the Bin).

M2 is deenergized as the Unblocking Edge of the Light Blocking Plate

reaches PC6.

70 msec. later

SL1 is deenergized and the Jaws open to unclamp the stapled copy set.

To ➀ on next page

M-42

Page 53

➀

70 msec. later

M2 remains energized until the Blocking Edge of the Light Blocking Plate

reaches PC6, allowing the Paper Clamp Unit to return to the home

position. .........................................................................................................(B)

205 msec. later

M1 is turned backward until PC3 (in an unblocked state,

(

L ) and then unblocked to move the Bins so that the 1st Bin, instead of the

previous 2nd Bin, receives the copy.

85 msec. later

Steps are performed between (A) and (B) to complete the stapling of the

copy set in the 1st Bin.

H ) is blocked

M-43

Page 54

M-44

Page 55

TEST MODE

* The ST-724/ST-723 requires no Test Mode Jig for performing the Test Mode

operations.

Page 56

Page 57

The ST-724/ST-723 can be checked for different operations by using the Test Mode as detailed

below. It can be set into each Test Mode operation sequentially by switch operation.

Initial Display Shows the setting of the ST-724/ST-723.

↓

Input Check Shows the input level from each Sensor to PWB-A.

↓

Type Setting Make the necessary setting so that the subsequent operations can be run

↓

Initial Operation Performs the initial operation.

↓

Paper Size Setting Moves the Paper Aligning Bar to the aligning position for the paper size to be

↓

Sorting Moves the Bins in the Sort Mode (for bi-directional sorting). (The ST-724

↓

Stapling Performs the stapling sequence for all Bins. (The ST-723 skips this operation

↓

Bin Moving Moves the Bins up and down one Bin Position at a time so that each Bin will

↓

Paper Clamping Moves the Paper Clamp Unit between the home and paper clamp positions.

properly.

set. (The ST-723 skips this operation and moves onto the next one.)

also performs the paper aligning motion.)

and moves onto the next one.)

be located to receive the copy.

(The ST-723 skips this operation.)

S-1

Page 58

* Switches S1 to S3 on PWB-A are used to set the ST-724/ST-723 into the Test Mode and select

each Test Mode operation. Be also sure to turn ON Sorter Set Switch S3 to ensure that power is

supplied to each Motor of the ST-724/ST-723. (For this purpose, the Front Cover and Lower Right

Cover must be removed.

➭ See p. D-1.)

S2

LED1

S3

S1

LED6

Sorter Set Switch S3

LED5

* A particular Test Mode operation can be identified by LED1 through LED5 on PWB-A which may

be lit up, blinking, or off. In the text that follows, the following symbols are used to represent a lit,

blinking, and off LED.

LED4

LED5

On

LED3

LED2

LED1

Off

Blinking

* Where a particular LED gives a different indication between ST-724 and ST-723, that for ST-723 is

shown in ( ).

S-2

Page 59

Setting ST-724/ST-723 into Test Mode

• Holding down S1, press S3 (on PWB-A) once, and keep pressing S1 for about 5 sec.

• To exit from the Test Mode, press S3 (PWB-A).

Initial Display

LED5

Press S1.

Input Check

The LEDs look like

( )

LED1

Press S2 to check for the state of inputs from the following Sensors and

Switches.

"●" if Sorter Set Switch S3 is OFF.

To ensure correct operation in the subsequent Test Mode

operations, be sure to keep Sorter Set Switch S3 in the

ON position.

Indicates by a lit or off LED the state of the input from

each Sensor or Switch to PWB-A. The following shows the

states when the corresponding LED lights up. The

indication given in ( ) for ST-723 is for all times.

( )

Paper Aligning Home Position Sensor PC5: Blocked ( L )

Bin Lower Limit Position Sensor PC4: Unblocked (

Bin Upper Limit Interlock Switch S1: ON

Bin Positioning Sensor PC3: Unblocked (

Bin Moving Pulse Sensor PC1: Blocked (

Press S2 to check for the state of inputs from the following Sensors

and Switches.

Sorter Exit Sensor PC2: Unblocked (

Bin empty detection: Empty (

Staple Unit connection (CN5): Connected

Sorter Set Switch S3: ON

Stapler Home Position Detecting Switch S4: ON

Press S2 to check for the state of inputs from the following Sensors.

Off at all times

Staple Empty Detecting Sensor PC10: Empty (

Paper Clamping Sensor PC8: Blocked (

On at all times

Paper Clamp Home Position Sensor PC6: Blocked (

H )

L )

H )

H )

H )

L )

H )

L )

( )( )

( )( )( )

➀

➁

S-3

Page 60

➀

Press S1.

Type Setting

The LEDs look like

Press S1.

Initial Operation

The LEDs look like

➁

Not used with ST-724/ST-723

Press S2, and the LEDs look like .

Press S2 to check for the following.

Be sure to make the following setting to ensure that the

subsequent operations run properly.

Press S2, and the LEDs look like .

Press S2 four more times, and the LEDs look like the following:

The ST-724/ST-723 must perform the following initial

operations before it can go to the subsequent operation.

Press S2, and the Paper Clamp Unit, Staple Unit (only when the

Stapler Arm is not at its home position), Paper Aligning Bar, and

Bins perform the initial operations, in that order. (At the end of the

initial operations, the LEDs look like .)

Press S1.

Paper Size Setting

The LEDs look like

➂

The ST-723 skips this operation and moves onto the next

one.

Each time S2 is pressed, the LEDs look like as shown below and

the Paper Aligning Bar moves to the corresponding aligning

position. What is stored in memory is the last setting before the

Test Mode operation is switched to the next one.

A4 Crosswise

A4 Lengthwise

B5 Crosswise

B5 Lengthwise

Letter Crosswise

Letter Lengthwise

S-4

Page 61

➂

Press S1.

Sorting

The LEDs look like

Use S2 to enable or disable the ST-724/ST-723 for sorting

and use S1 to start or stop the sorting operation.

Press S2 to enable the ST-724/ST-723 for sorting

( ).

Press S1 to set the ST-724/S-723 to the standby state

( ).

In the ST-724, the Paper Aligning Bar moves at this time to the

standby position for the paper size set in "Paper Size Setting."

Each time Sorter Exit Sensor PC2 is blocked and unblocked by a

sheet of paper, the Bins are moved one Bin position to locate a new

Bin for receiving the copy, bi-directionally from 1st to 10th Bins, and

from 10th to 1st Bins. With the ST-724, it also performs the paper

aligning motion (the Paper Aligning Bar moving between the

standby and paper aligning position).

PC2

Press S1 to stop the sorting operation ( ).

In the ST-724, the Paper Aligning Bar returns at this time to the

home position.

Press S1.

Stapling

The LEDs look like

Off at all times

Off at all times

When PC8 detects a sheet of paper

On at all times

When the Paper Clamp Unit is at the home position

➃

➄

Press S2 to disable the ST-724/ST-723 for sorting

( ).

The ST-723 skips this operation and moves onto the next

one.

Press S2 and the Bins are moved to locate the 10th Bin for

receiving the copy. The ST-724 performs the stapling sequence

sequentially from the 10th Bin upward to the 1st Bin (at this time,

stapling occurs only if PC8 is blocked). Here are the indications

given by LEDs during this operation.

At the end of the operation

S-5

Page 62

➃

Press S1.

Bin Moving

The LEDs look like

Holding down S2, press S1.

Paper Clamping

The LEDs look like

Press S1, and the Paper Clamp Unit is detected at its home position

before the ST-724 returns to:

Initial Display

➄

Press S1, and the LEDs look like .

Each time S1 is pressed, the Bins are moved up one Bin to locate a

new Bin for receiving the copy. Each time S2 is pressed, the Bins

are moved downward one Bin to locate a new Bin for receiving the

copy.

The ST-723 skips this operation and goes back to "Initial

Display."

Each time S2 is pressed, the following operation is repeated.

1. (After the Bins are moved to locate the 1st Bin for receiving

the copy if they are located otherwise,)

The Paper Clamp Unit is moved to the paper clamp position.

2. The Paper Clamp Unit is moved to the home position.

S-6

Page 63

DIS/REASSEMBLY,

ADJUSTMENT

* The text contained herein is based on the ST-724. In the text, there may appear

some parts which you will not find in the ST-723.

* Precautions for Disassembly, Reassembly, and Adjustments

CAUTION

1. Before attempting to disassemble the ST-724/ST-723, always make sure that

no power is being supplied from the copier.

2. While power is being supplied to the ST-724/ST-723, do not attempt to

remove/install the print jacks from/to the PWBs or unplug/plug in the

connectors.

3. If the ST-724/ST-723 is run with its Covers removed, use care not to allow

your clothing to be caught in revolving parts such as the Timing Belt.

4. The basic rule is do not run the ST-724/ST-723 any time during

dis/reassembly.

Important

1. To reassemble the ST-724/ST-723, reverse the order of disassembly unless

otherwise specified.

2. Do not attempt to loosen or remove the screws to which red paint has been

Purpose of Applying Red Paint

Red paint is applied to those screws that cannot be readjusted or reinstalled

in the field.

Page 64

Page 65

DISASSEMBLY/REASSEMBLY

1

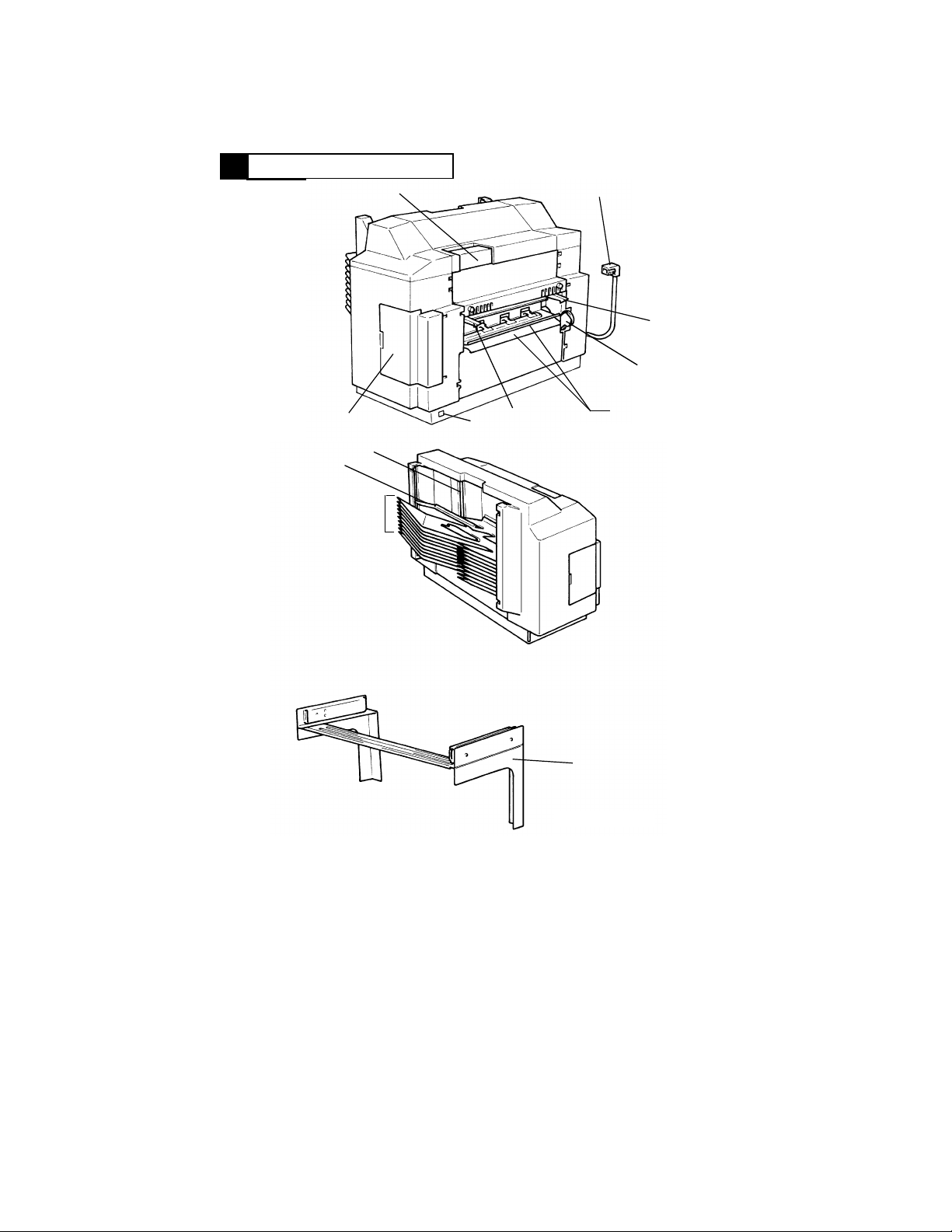

1-1. REMOVAL OF EXTERIOR COVERS

2

1

3

4

Front Cover: Remove four screws and slide the Cover to the front to remove it

1

Upper Cover: Remove the Front and Rear Covers and then lift the Upper Cover up

2

Rear cover: Remove four screws and slide the Cover to the rear to remove it

3

Lower Right Cover: Remove four screws and lift the Cover up to remove it from the main

4

from the main body.

to remove it from the main body.

from the main body.

body.

D-1

4428D001AA

Page 66

1-2. REMOVAL OF THE TRANSPORT GUIDE PLATE ASSY

1. Remove the Front, Rear, and Lower Right Covers.

Spring

PC2

PWB-A

2. Remove the spring for the Drive Coupling Gear Assy.

3. Remove two screws and the Gear Assy and Belt.

* At reinstallation, adjust the tension of the Belt. (See

p. D-9.)

4. Remove one screw and the Mounting Bracket for

Sorter Exit Sensor PC2.

(Front)

(Rear)

5. Remove two shoulder screws from the front of the unit

and two screws from the rear of the unit. Pull the

Transport Guide Plate Assy to the front as shown.

D-2

Page 67

1-3. REMOVAL OF THE BIN MOVING MOTOR M1 UNIT

1. Remove the Rear Cover.

2. Remove one screw and the Hookup Support.

3. Unplug PJ1 (M1) and remove three screws.

PJ1

4. Slide out the M1 Unit to the front and unplug PJ2

(PC1) to free the M1 Unit.

PJ2

M1 Unit

* At reinstallation, mate the two Pitch Rings with each

other as shown and, at the same time, tighten the

screws.

Pitch Ring

0

D-3

Page 68

1-4. REMOVAL OF PAPER CLAMP SOLENOID SL1 (ST-724 ONLY)

1. Remove the Front Cover.

2. Remove one screw and the Mounting Bracket for

Paper Clamp Home Position Sensor PC6.

3. Unplug CN1 and remove two screws to remove the

Paper Clamp Motor M2 Assy.

CN1

4. Unplug CN4 and slide the Paper Clamp Unit to the

front to remove it from the main body.

CN4

5. Remove two screws and SL1.

* At reinstallation, adjust the stroke of SL1. (See p.

D-9.)

1-5. REMOVAL OF THE STAPLE UNIT (ST-724 ONLY)

A

CN3

CN5

CN6

1. Remove the Front Cover.

2. Unplug CN3, CN5, and CN6.

3. Remove the CN3 Cord on the Staple Unit end from

Cord Clamps A.

D-4

Page 69

4. Remove two screws and the Staple Unit.

PC8

1-6. REMOVAL OF THE SORTER LOCK RELEASE LEVER

1. Remove the Front, Rear, and Upper Covers.

2. Remove four screws and the Upper Right Cover.

Lock Lever Spring Hook

3. Unhook the Lock Lever Spring in the rear of the unit

and snap off the E-ring from the Lock Lever Shaft.

4. Slide and remove the Lock Lever Shaft. Remove one

screw and one of the two Lock Levers.

5. Remove two screws and the Lock Release Lever.

* At reinstallation, press the screw up against the

cutout in the Lock Release Lever as shown at A on

the left.