Page 1

Service Manual

1

2

4

6

7

8

9

3

5

Contents

EN

REGIUS

Σ / Σ

II

Contents

Safety Warnings & Precautions

Before Repairing

Troubleshooting

Using a Service Tool to Confirm Behavior

Disassembly & Assembly

Adjustments

Maintenance & Inspection

Appendix

Revision History

1-1

Page 2

Blank Sheet

Page 3

Contents

Contents

Introduction.................................................................................... i

Cautions .............................................................................. i

Trademarks......................................................................... i

How to Read this Manual ............................................................. i

Structure of This Manual..................................................... i

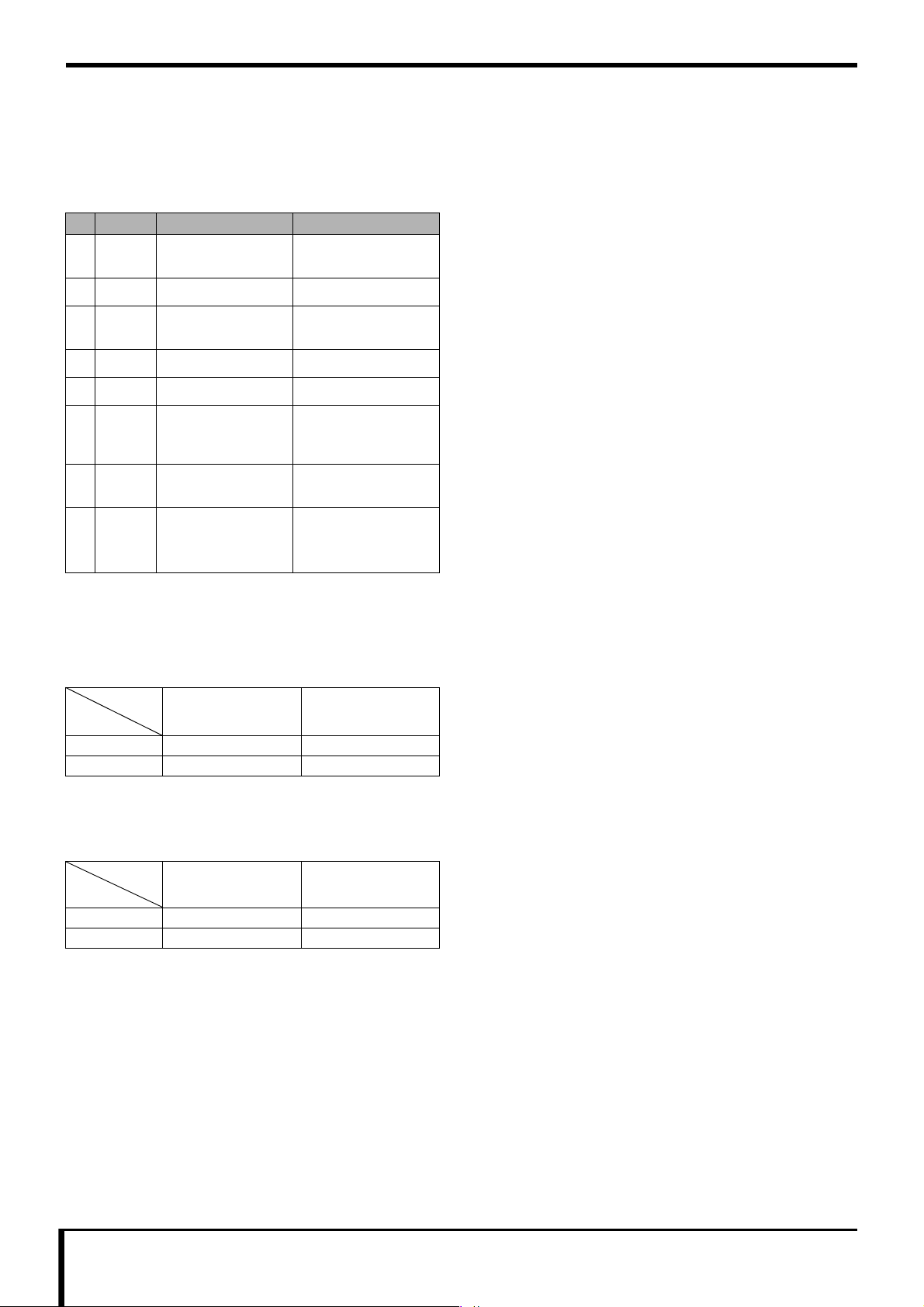

Difference between REGIUS and REGIUS II.......................ii

Parts changed.....................................................................ii

Board Compatibility.............................................................ii

Chapter 1 Safety Warnings & Precautions....... 1-1

1.1 Symbols relating to Safety ...........................................1-2

1.1.1 Safety Alert Symbol.............................................. 1-2

1.1.2 Warning Notice (Signal Words)........................... 1-2

1.1.3 Description of Graphic Symbols.......................... 1-2

1.2 Warning Labels.............................................................1-3

1.3 Safety Precautions .......................................................1-4

1.3.1 Precautions Necessary to Follow Legal and

Regulatory Requirements..................................... 1-4

1.3.2 General Precautions .............................................. 1-4

1.3.3 Handling Precautions............................................ 1-4

1.3.4 Precautions Relating to Handling

Cassettes/Plates...................................................... 1-4

1.3.5 Servicing Precautions............................................ 1-5

1.3.6 Disposal Cautions.................................................. 1-5

Chapter 2 Before Repairing............................... 2-1

2.1 Names of Parts.............................................................2-2

2.1.1 External View of the device.................................. 2-2

2.1.2 Status lamps........................................................... 2-3

2.2 Configuration ................................................................2-4

2.3 Main Specifications.......................................................2-5

2.3.1 Device Specifications............................................ 2-5

2.3.2 Image Reading & Erasing .................................... 2-5

2.3.3 Control Part Functions.......................................... 2-7

2.4 Block Diagram ..............................................................2-8

2.5 Main Part Locations .....................................................2-9

2.5.1 Frame...................................................................... 2-9

2.5.2 Upper Insertion Unit ...........................................2-10

2.5.3 Lower Insertion Unit........................................... 2-11

2.5.4 Sub-scan Unit ......................................................2-12

2.5.5 Exposure Unit...................................................... 2-13

2.5.6 Light Collection Unit .......................................... 2-13

2.5.7 Eraser Unit ........................................................... 2-14

2.6 Behavior Explained ....................................................2-15

2.6.1 State Transition Diagram.................................... 2-15

2.6.2 Normal Operation (Image Reading).................. 2-16

2.6.3 Initialization Operation ....................................... 2-19

2.6.4 Erase Operation ................................................... 2-21

2.7 Cassette/Plate Handling ............................................2-22

2.8 Tools, Instruments, Jigs, etc. Needed for Service ....2-22

Chapter 3 Troubleshooting ................................ 3-1

3.1 Work Flow.....................................................................3-2

3.2 Recovery Operation .....................................................3-2

3.3 How to Retrieve Logs...................................................3-3

3.4 Error Message Content & Countermeasures.............3-4

3.4.1 70xx: Initialization Errors......................................3-4

3.4.2 71xx: Sensor Errors............................................. 3-12

3.4.3 72xx: Single Unit Operation Initialization

Errors.................................................................... 3-29

3.4.4 73xx: Single Unit Operation Sensor Errors ...... 3-35

3.4.5 74xx: Image Read Related Errors...................... 3-52

3.4.6 76xx: Single Unit Operation Image Read

Related Errors...................................................... 3-55

3.4.7 77xx: FPGA, SDRAM Related Errors.............. 3-59

3.4.8 780x: Other.......................................................... 3-65

3.4.9 781x: Door status ................................................ 3-65

3.4.10 782x: Warnings ................................................... 3-66

3.4.11 7999: Reader Program Destroyed ..................... 3-66

3.4.12 14xxx: Sensitivity Correction Error................... 3-66

3.4.13 24xxx: JM Communication Errors.................... 3-67

3.4.14 25xxx: ImagePilot Connection Error ................ 3-67

3.4.15 26xxx: the service tool Error.............................. 3-68

3.4.16 27xxx: USB Related Errors................................ 3-68

3.5 Countermeasures for dealing with problems not

displayed as error messages.................................... 3-70

3.5.1 Device Sound ...................................................... 3-70

3.5.2 If power cannot be turned ON............................ 3-70

3.5.3 Plate related.......................................................... 3-70

3.5.4 Defective image .................................................. 3-70

Chapter 4 Using a Service Tool to Confirm

Behavior............................................. 4-1

4.1 Behavior Confirmation Summary ................................4-2

4.2 [Unit Test] (Check) Screen Display..............................4-2

4.2.1 The [Unit test] Screen & Function Summary......4-2

4.2.2 The [Unit Test] Screen & Function Summary.....4-3

4.3 Confirming behavior of a single device .......................4-3

4.4 Sensor status Check ....................................................4-5

4.4.1 Sensor status Confirmation Process .....................4-5

4.4.2 Cassette size & sensor status.................................4-5

4.4.3 Insertion site sensor status .....................................4-6

Chapter 5 Disassembly & Assembly.................5-1

5.1 Before Disassembly .....................................................5-2

5.1.1 Disassembly/Assembly Cautions .........................5-2

5.1.2 Checking & adjustments needed after

assembly..................................................................5-2

5.1.3 Problems that often occur after assembly ............5-3

5.2 Fundamental Steps ......................................................5-3

5.2.1 Power OFF/ON......................................................5-3

5.2.2 Removing the external panel & parts ...................5-4

5.2.3 Removing & attaching the upper cover assy .......5-5

5.2.4 Removing & attaching the upper insertion unit...5-6

5.2.5 Removing & attaching the left side panel ............5-7

Contents

Contents

REGIUS /II Service Manual 1

Page 4

Contents

Contents

Contents

5.2.6 Removing & attaching the right side panel......... 5-8

5.2.7 Removing & attaching the rear panel patch assy.5-9

5.2.8 Removing & attaching the lower insertion unit.. 5-9

5.2.9 Removing/attaching the front panel assy .......... 5-11

5.2.10 Removing & attaching the Sub-scan unit.......... 5-12

5.2.11 Removing and attaching the eraser unit ............ 5-17

5.2.12 Removing & attaching the exposure unit.......... 5-20

5.2.13 Removing & attaching light collection unit...... 5-21

5.2.14 Removing & attaching the upper door assy...... 5-23

5.3 Changing electrical parts............................................5-25

5.3.1 Changing the status LED board ......................... 5-25

5.3.2 Changing the LED drive2 board........................ 5-25

5.3.3 Changing the Eraser Unit Assy (Eraser LED).. 5-27

5.3.4 Changing the main board.................................... 5-28

5.3.5 Changing the SW power supply ........................5-30

5.3.6 Changing the power supply circuit breaker....... 5-31

5.3.7 Changing the Inlet-NF wiring Assy................... 5-32

5.3.8 Changing size detection sensors 1 and 2 ........... 5-33

5.3.9 Changing the cassette sensor.............................. 5-34

5.3.10 Changing the plate sensor (light receiving)....... 5-34

5.3.11 Changing the plate sensor (light emitting) ........5-35

5.3.12 Changing the V-SYNC sensor and V-SYNC

assembly............................................................... 5-37

5.3.13 Changing the entrance NIP sensor..................... 5-38

5.3.14 Changing the exit NIP sensor............................. 5-39

5.4 Changing mechanical parts.......................................5-40

5.4.1 Changing the loading/feeding motor ................. 5-40

5.4.2 Changing the sub-scan NIP motor and

sub-scan drive Assy............................................. 5-41

5.4.3 Changing the sub-scan feeding motor ............... 5-43

5.4.4 Changing the Eraser LED cooling fan............... 5-44

5.4.5 Changing the magnetic clutch............................ 5-45

5.4.6 Changing the upper door guide.......................... 5-46

5.4.7 Changing the link assemblies............................. 5-47

5.4.8 Changing the entrance guide.............................. 5-48

5.4.9 Changing the drive rollers................................... 5-49

5.5 Changing cassette parts ............................................5-51

5.5.1 Disassembling a cassette..................................... 5-51

8.2 Device Wiring Diagram ................................................8-9

8.2.1 REGIUS Device Wiring Diagram..............8-9

8.2.2 REGIUS II Device Wiring Diagram......... 8-10

Chapter 9 Revision History ................................ 9-1

9.1 Manual revision history.................................................9-2

Chapter 6 Adjustments ...................................... 6-1

6.1 Oblique adjustments ....................................................6-2

Chapter 7 Maintenance & Inspection................ 7-1

7.1 Maintenance/Inspection Schedule..............................7-2

7.2 Plate feeding path cleaning .........................................7-2

Chapter 8 Appendix ........................................... 8-1

8.1 Service Tool Screen (Unit test) ....................................8-2

8.1.1 [Unit test] Screen................................................... 8-2

8.1.2 [Unit Test] (Check) Screen................................... 8-3

8.1.3 [Error Hist] Screen ................................................ 8-7

8.1.4 [Warning setting] Screen....................................... 8-8

8.1.5 [Report of reader] Screen...................................... 8-8

2REGIUS /II Service Manual

Page 5

IMPORTANT

Introduction

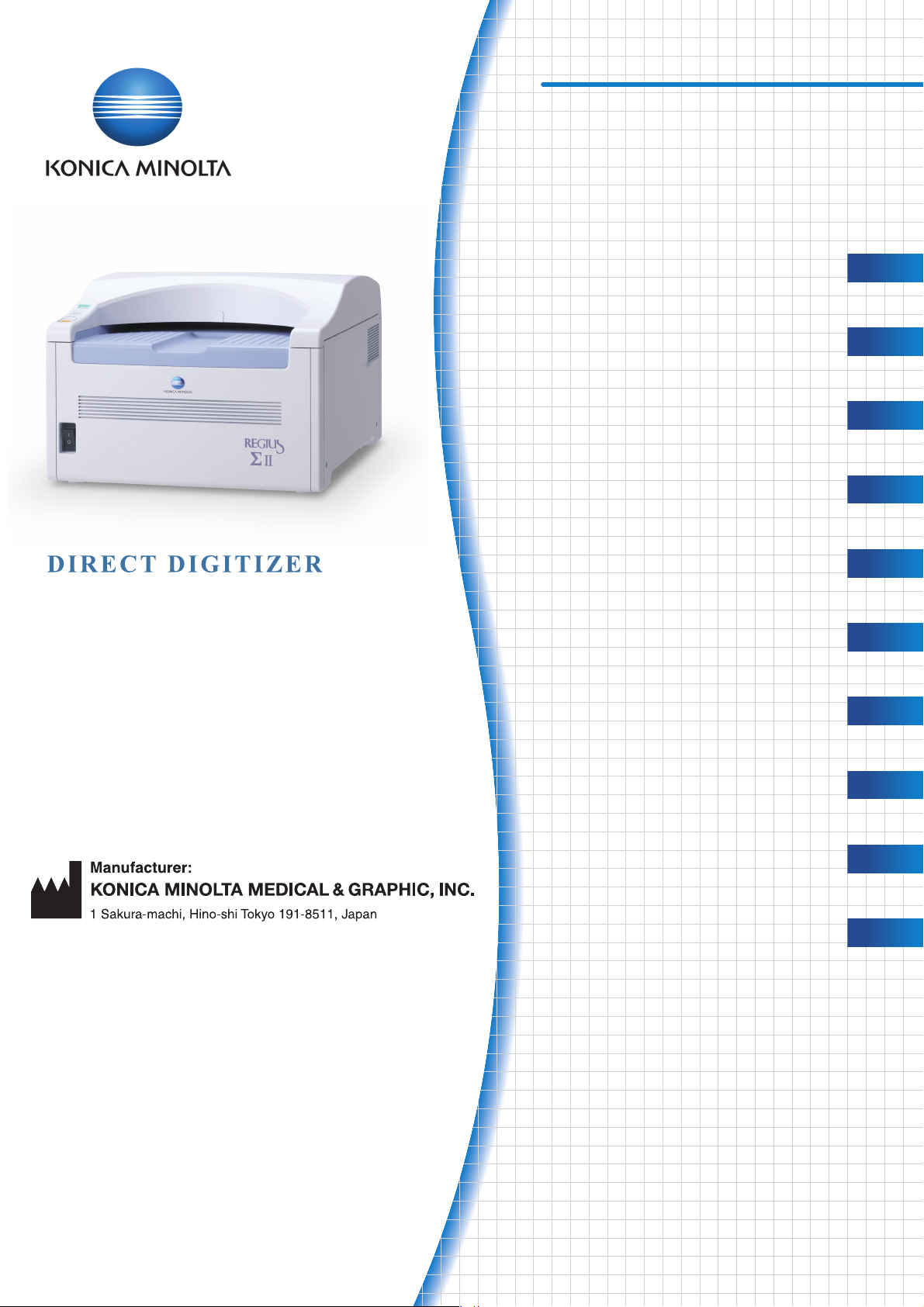

The Direct Digitizer REGIUS and/or REGIUS II (called the

"device" hereinafter) is an X-ray image cassette reading device that

uses photostimulable phosphor as an X-ray detector.

This manual states the cautions and steps for service engineers to

perform repair or maintenance of this device (or a system including

this device).

After reading through this manual, make sure it is readily

accessible for future reference.

How to Read this Manual

Structure of This Manual

This manual is divided into the following 9 chapters describing

device repair and maintenance methods, as well as safety

precautions and operation.

Chapter 1: Safety Warnings & Cautions

An explanation of the safety warnings and cautions to follow while

repairing or maintaining this device.

Chapter 2: Before Repairing

An explanation of device fundamentals that need to be understood

before attempting to repair or maintain this device.

Chapter 3: Troubleshooting

An explanation of the various methods for dealing with devicerelated troubles.

Chapter 4: Using a Service Tool to Confirm Behavior

An explanation of how to confirm device operation.

Chapter 5: Disassembly & Assembly

An explanation of the steps needed to disassemble and assemble

the device.

Cautions

1) Unauthorized reproduction of any part of this manual is

prohibited.

2) The contents of this manual are subject to change without

notice.

3) Any discrepancies, errors or omissions noted should be

communicated to the manufacturer.

4) Notwithstanding item 3) above, the manufacturer accepts no

responsibility whatsoever for any loss or decrease in profi ts

arising from usage of the product.

Chapter 6: Making Adjustments

An explanation of part adjustments necessary for repair and

maintenance.

Chapter 7: Maintenance & Inspection

An explanation of how to maintain and inspect the device.

Chapter 8: Appendix

A list of technical information for reference during device repair or

maintenance.

Chapter 9: Revision History

Settings and behavior confirmation of the device are

performed with the service tools of REGIUS ImagePilot

(hereinafter ImagePilot).Service tool operation details

can be found in the ImagePilot Installation & Service

Manual, so you are recommended to refer to it when

necessary.

Trademarks

Company names and product names in this manual are trademarks

or registered trademarks of their respective owners.

©, ® and ™, representing these ownerships, are omitted in the

following pages.

Copyright © 2011 Konica Minolta Medical & Graphic, Inc. All

Rights Reserved.

REGIUS /II Service Manual i

Page 6

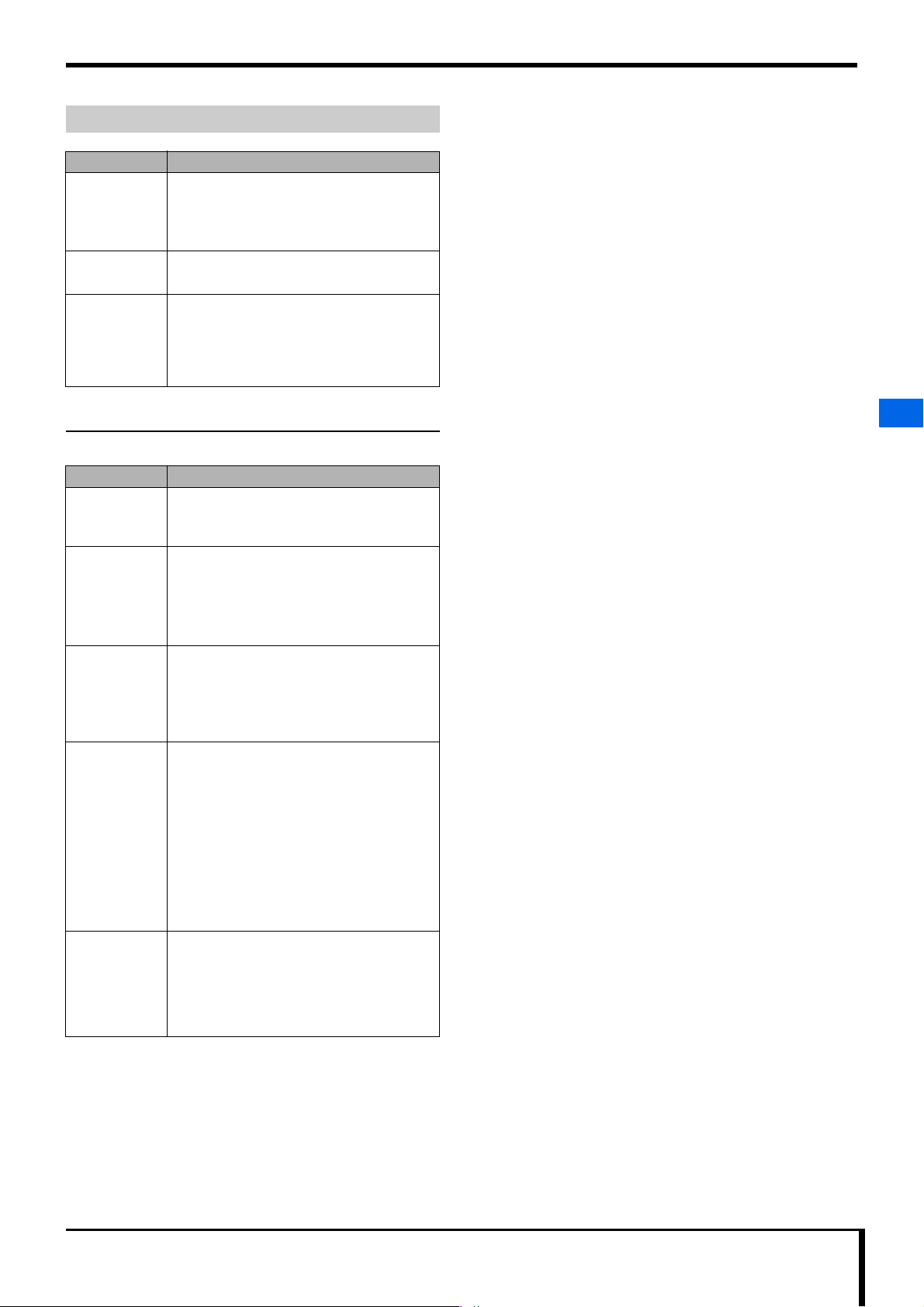

Difference between REGIUS and

REGIUS II

Parts changed

The following REGIUS parts are replaced in the REGIUS II.

Category Name Outline of the change

No.

1 Parts Front panel Logo (REGIUS II) is

2 Parts Rating plate -

printed

3 Parts Sensor on each

part_relay Assy

4 Parts LED_BOARD LED2_BOARD

5 Parts LED_DRIVE_BOARD LED_DRIVE2_BOARD

6 Parts FFC cable_Assy Number of pins,

7 Parts SW power supply -

MAIN_BOARD_Assy

8 Unit Eraser Unit

Pin-out

Connector connection

method

With a ferrite core

• LED2_BOARD

• LED_DRIVE2_BOARD

• FFC cable_Assy

Board Compatibility

Equipment and Board

• REGIUS can use both new and old boards.

• REGIUS is also be planned to be integrated in the new board.

Equipment

REGIUS

REGIUS II

Board

• LED_BOARD

• LED_DRIVE_BOARD

Old

• LED2_BOARD

• LED_DRIVE2_BOARD

New

LED and Drive Board

• The new and old boards are not compatible with each other when

combined.

Drive Board

LED

REGIUS

REGIUS II

ii REGIUS /II Service Manual

LED_DRIVE_BOARD LED_DRIVE2_BOARD

Page 7

1

Chapter

Chapter 1 Safety Warnings &

1

Precautions

An explanation of the safety warnings and cautions to follow while

repairing or maintaining this device.

1.1 Symbols relating to Safety ....................................................... 1-2

1.1.1 Safety Alert Symbol...................................................1-2

1.1.2 Warning Notice (Signal Words) ................................1-2

1.1.3 Description of Graphic Symbols ............................... 1-2

1.2 Warning Labels......................................................................... 1-3

1.3 Safety Precautions ................................................................... 1-4

1.3.1 Precautions Necessary to Follow Legal and

Regulatory Requirements ......................................... 1-4

1.3.2 General Precautions..................................................1-4

1.3.3 Handling Precautions................................................ 1-4

1.3.4 Precautions Relating to Handling

Cassettes/Plates........................................................1-4

1.3.5 Servicing Precautions................................................ 1-5

1.3.6 Disposal Cautions......................................................1-5

Safety Warnings & Precautions

Page 8

Chapter 1 Safety Warnings & Precautions

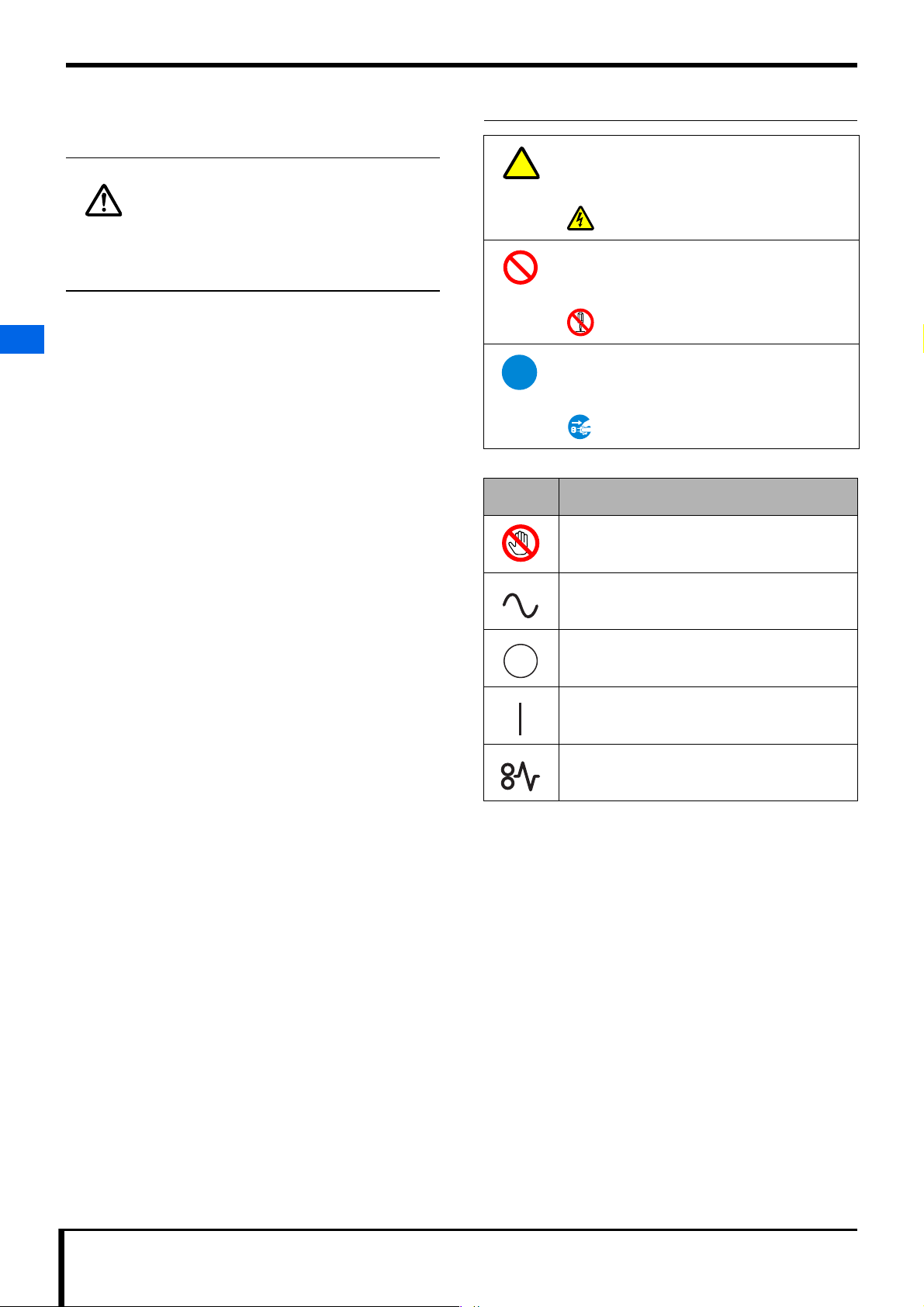

1.1 Symbols relating to Safety

1.1.1 Safety Alert Symbol

This is the "safety alert symbol." This symbol alerts

you to matters and/or operation potentially

hazardous to yourself and other people. Read these

messages and follow the instructions carefully.

1.1.2 Warning Notice (Signal Words)

Signal words indicate the degree of potential hazards in the use of

1

the product.

Signal words include the following three types, which are used

according to risk of damage caused by danger and the severity of

damage.

DANGER

Indicates a imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

1.1.3 Description of Graphic Symbols

A triangle indicates a danger against which you

should take precaution.

e.g.)

This symbol warns against "Danger of

Electrical Shocks".

A diagonal line indicates a prohibited course of

action.

e.g.)

This symbol indicates you "Do Not

Disassemble".

A solid circle indicates an imperative course of

action.

e.g.)

This symbol indicates you must "Remove

Plug from Power Outlet".

Graphic

symbols

Indicates items that cannnot be touched.

Explanation

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury. It may also be used to

1.1 Symbols relating to Safety

indicate hazardous situation where only physical damage is likely

to occur.

Indicates that AC power is being used.

Indicates the off position for the main power switch

of this device.

Indicates the on position for the main power switch

of this device.

Indicates that a plate is jammed inside the device.

1-2 REGIUS /II Service Manual

Page 9

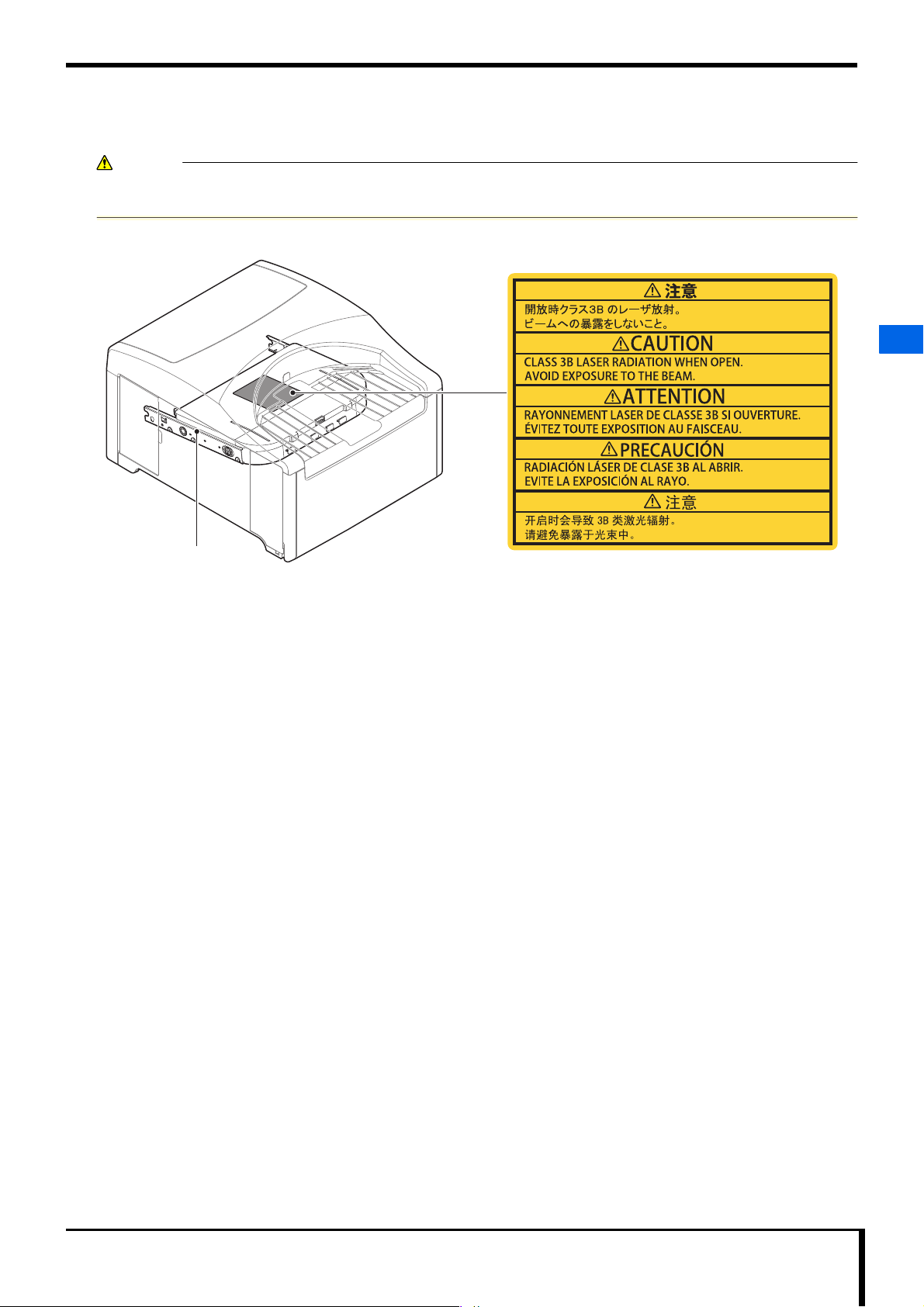

Chapter 1 Safety Warnings & Precautions

CAUTIONCAUTION

1.2 Warning Labels

Warning labels are attached to the following areas of the device.

Before performing maintenance such as installation or repair, make sure to fully understand the meaning of each warning

label, and how to handle each section they are located in.

Laser warning label

1

Exposure Unit

1.2 Warning Labels

REGIUS /II Service Manual 1-3

Page 10

Chapter 1 Safety Warnings & Precautions

1

1.3 Safety Precautions

1.3 Safety Precautions

Read all safety precautions thoroughly before using the device.

Be sure to observe the safety precautions described in this section.

1.3.1 Precautions Necessary to Follow Legal and Regulatory Requirements

CAUTION

Caution as to laser control

To prevent danger, make sure that only service engineers who

received proper formal training will remove the exterior cover or

touch the inside of the equipment.

Specifications of laser unit

Item Specifications

Class 3B

Medium Semiconductor laser

Wavelength 659 nm

Maximum output 130 mW

This device is a Class 1 laser product.

1.3.2 General Precautions

WARNING

Do not perform any work or operations that are not

•

described in this manual.

If you do accidentally conduct work not described in this

manual, you may suffer from burns or electric shock due to

touching a hot section or high voltage component of this

machine.

• Be sure to follow safety precautions for warning labels.

Be sure to follow the safety precautions contained in this

manual and shown on warning labels attached to this machine.

Failure to observe these precautions may result in personal

injury or damage to this machine.

• This device is equipped with a laser generator (class 3B).

Avoid exposing the eyes or skin to direct laser, as it could cause

a serious injury.

• Removing exterior covers

To prevent danger, make sure that only service engineers who

received proper formal training will remove the exterior cover

or touch the inside of the device.

1.3.3 Handling Precautions

WARNING

If unusual noises, odor, or smoke comes from this device,

•

stop operation.

If unusual noises, odor, or smoke coming from this device is

detected, immediately stop operation. If you continue to

operate it with the abnormal condition left as it is, it could

cause an electric shock, fire, or damage to the device.

• Be careful not to trip over or trample on the power cable.

If you continue to use the damaged cable, it could cause an

electric shock, heat generation or fire.

• Do not remove the power plug by pulling on the power

cable.

Doing so may cause the power cable to break, resulting in heat

generation or fire.

• Do not put drinks or foreign objects on the device.

Do not put drinks such as juice or foreign objects such as clips

and pins on this machine. If you use this device after liquids or

foreign objects such as metals have entered the machine, it can

cause a short in the internal circuit, resulting in fire.

CAUTION

Do not block air intakes or outlets of the device.

•

If air intakes or outlets of the device are blocked, it can cause

the device to fail or reduce the accuracy of image reading.

• Do not leave objects standing on the device or do not

step on it.

Doing so may lead to the risk of injury due to falling, or

damage the device.

• Do not use equipment such as mobile phones that emit

electromagnetic waves.

If you use equipment such as mobile phones that emit

electromagnetic waves near the device, it can have a negative

effect on the device.

1.3.4 Precautions Relating to Handling Cassettes/Plates

WARNING

Do not scratch the plate.

•

The photostimulable luminescent material used on the plate can

cause problems if it enters the human body. If the protective

layer on the plate surface has been severely damaged and the

photostimulable luminescent material is exposed, take the

following actions.

- If swallowed, consult a physician immediately.

- If the eyes are exposed to it, flush them with clean

water and consult a physician immediately.

- If the skin is exposed to it, rinse with clean water

immediately.

- Even if the photostimulable luminescent material does

not enter the human body, take preventive measures

against contact and dispose of the plate immediately in

accordance with the applicable standards.

1-4 REGIUS /II Service Manual

Page 11

1.3.5 Servicing Precautions

WARNING

Do not insert a piece of wire or metal.

•

Do not insert foreign objects such as metal strip or wire through

vent or gap in the main device. Doing so may result in electric

shock.

• Be sure to turn OFF when servicing.

Pulling the circuit board out of this machine or removing

connectors and cables while the power is turned on may result

in a serious accident. Make sure to turn off the power supply

circuit breaker before starting these operations.

CAUTION

When handling internal electronic components of the

•

device, wear a wristband.

When handling internal electronic components, wear an

antistatic wristband.

If you touch an electronic component such as circuit board with

an electrostaticallycharged hand, it can cause damage.

• Before cleaning, make sure to unplug the power supply,

or switch OFF the power supply circuit breaker.

Be sure to unplug or turn OFF the power switch before cleaning

this machine.

You could get your finger caught in sliding or rotating parts.

Chapter 1 Safety Warnings & Precautions

1

1.3 Safety Precautions

1.3.6 Disposal Cautions

CAUTION

Please follow the rules and regulations of your relevant

•

authorities in the disposal of this device, accessories,

options, consumables, media and their packing materials.

REGIUS /II Service Manual 1-5

Page 12

Blank Sheet

Page 13

Chapter

Chapter 2 Before Repairing

2

An explanation of device fundamentals that need to be understood before

attempting to repair or maintain this device.

2.1 Names of Parts......................................................................... 2-2

2.1.1 External View of the device....................................... 2-2

2.1.2 Status lamps............................................................... 2-3

2.2 Configuration............................................................................. 2-4

2.3 Main Specifications................................................................... 2-5

2.3.1 Device Specifications................................................. 2-5

2.3.2 Image Reading & Erasing......................................... 2-5

2.3.3 Control Part Functions...............................................2-7

2.4 Block Diagram ..........................................................................2-8

2.5 Main Part Locations.................................................................. 2-9

2.5.1 Frame......................................................................... 2-9

2.5.2 Upper Insertion Unit................................................. 2-10

2.5.3 Lower Insertion Unit................................................. 2-11

2.5.4 Sub-scan Unit ..........................................................2-12

2.5.5 Exposure Unit ..........................................................2-13

2.5.6 Light Collection Unit.................................................2-13

2.5.7 Eraser Unit ...............................................................2-14

2.6 Behavior Explained ................................................................2-15

2.6.1 State Transition Diagram.........................................2-15

2.6.2 Normal Operation (Image Reading).......................2-16

2.6.3 Initialization Operation.............................................2-19

2.6.4 Erase Operation.......................................................2-21

2.7 Cassette/Plate Handling ........................................................2-22

2.8 Tools, Instruments, Jigs, etc. Needed for Service ................2-22

2

Before Repairing

Page 14

Chapter 2 Before Repairing

3

2

6 7 98

12

1

11

10

5

4

15

16

13

8 14

1

1

17 18

FrontLeft

RearRight

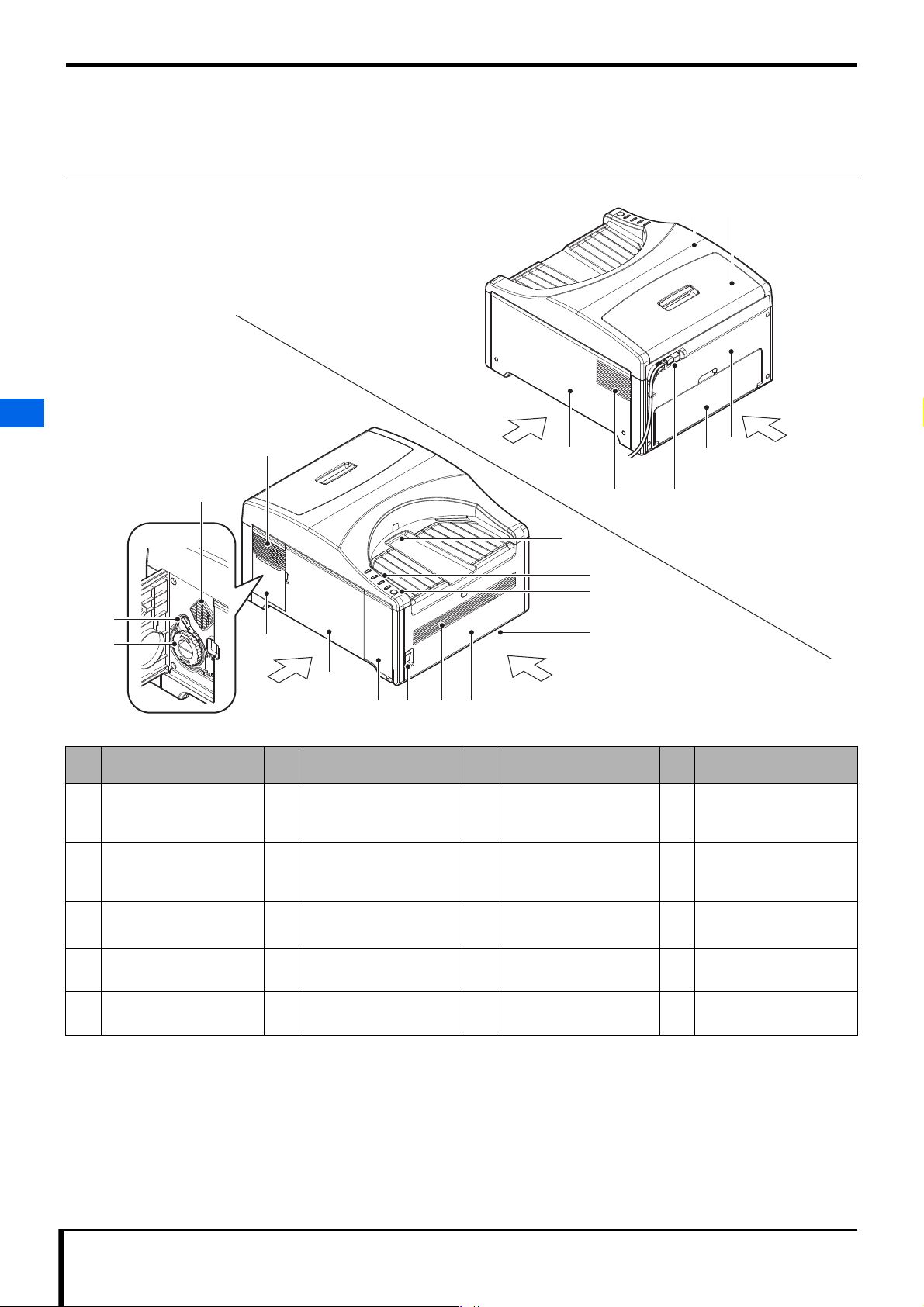

2.1 Names of Parts

Part names are indicated here that should be known in order to repair the device.

2.1.1 External View of the device

2

2.1 Names of Parts

No.

1 Intake vent 2 Light Collection Unit

5 Left side panel

9 Front panel

13 Right side panel

17 Upper cover

Common Name

(Part Name)

(Left side panel)

(Front panel Assy)

(Right side panel)

(Upper cover Assy)

No.

6 USB Cover

10 Cassette insertion slot 11 Status lamps

14 Power supply port

18 Upper Door

Common Name

(Part Name)

Cleaning Handle

(Handle)

(USB cover)

(Inlet-NF wiring Assy)

(Upper door Assy)

No.

3 Unjamming dial

7 Power supply circuit

Common Name

(Part Name)

(Handle)

breaker

(Circuit protector)

• Refer to Page 2-3.

15 Rear door

(Rear Assy)

No.

4 Left Door

8 Exhaust outlet

12 Erase button

16 Rear panel

Common Name

(Part Name)

(Left door Assy)

(Erase button)

(Rear panel patch Assy)

2-2 REGIUS /II Service Manual

Page 15

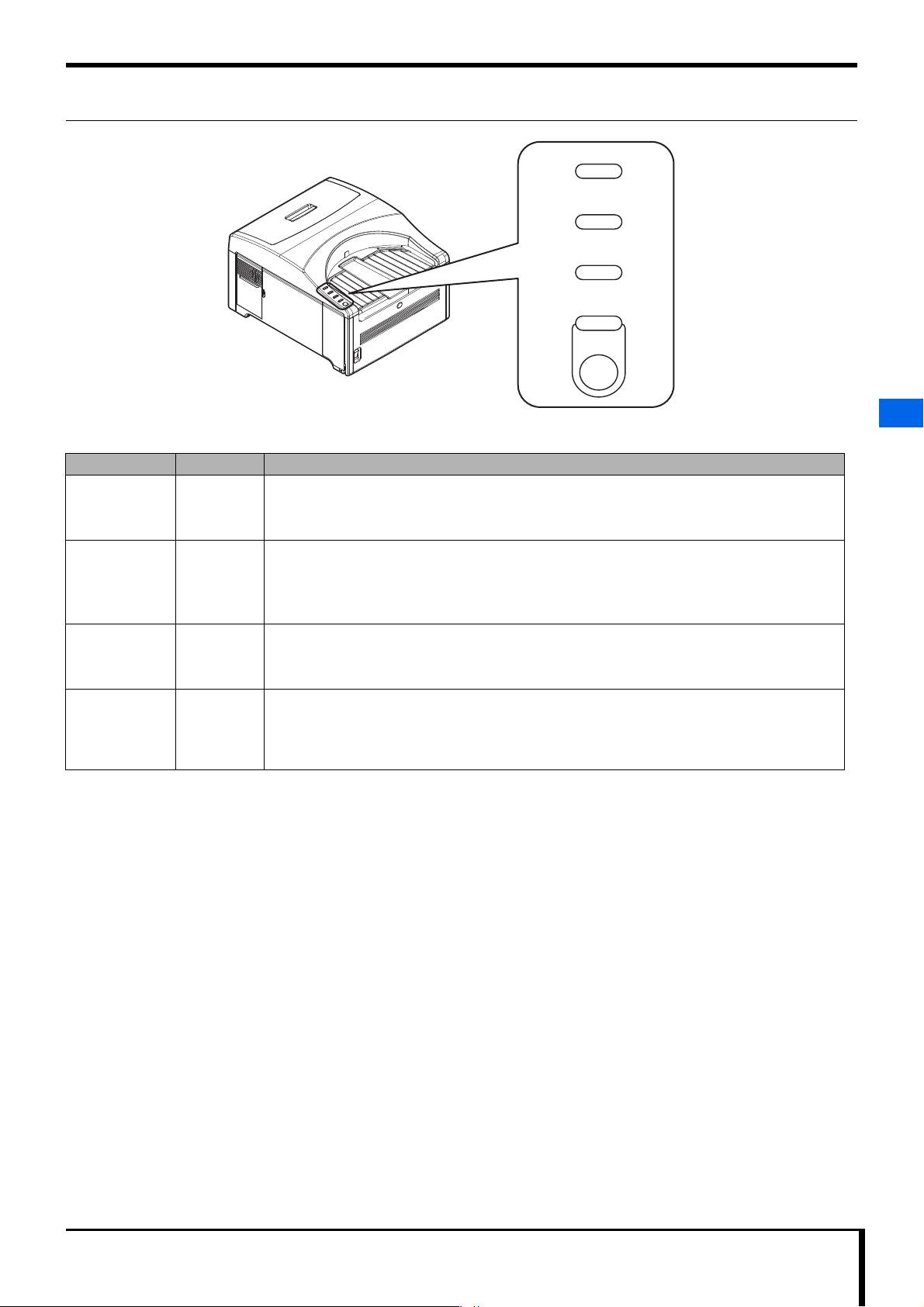

2.1.2 Status lamps

The 4 LEDs that indicate this device's current status are called "Status Lamps."

Name Color Function

Ready Lamp Green Indicates when a cassette is loaded or ejected.

• Lit: The cassette can be loaded.

• Blinking: The process has finished, and the cassette can be ejected.

Chapter 2 Before Repairing

Ready

Busy

Error

Erase

2

Busy Lamp Blue Indicates the process status.

• Lit: Process in progress.

• Blinking: Preparing to start process (inspection questions during image reading)

• Unlit: The process has stopped.

Error Lamp Yellow Indicates error and warning status.

• Lit: Warning status alert, or connection with ImagePilot not established.

• Blinking: Error status alert

Erase Lamp Orange Indicates Erase Mode status.

• Lit: Image erase in progress, or the Erase switch is being pressed.

• Blinking: Image erase mode is selected, and device is in standby mode for cassette loading (5

seconds).

2.1 Names of Parts

REGIUS /II Service Manual 2-3

Page 16

Chapter 2 Before Repairing

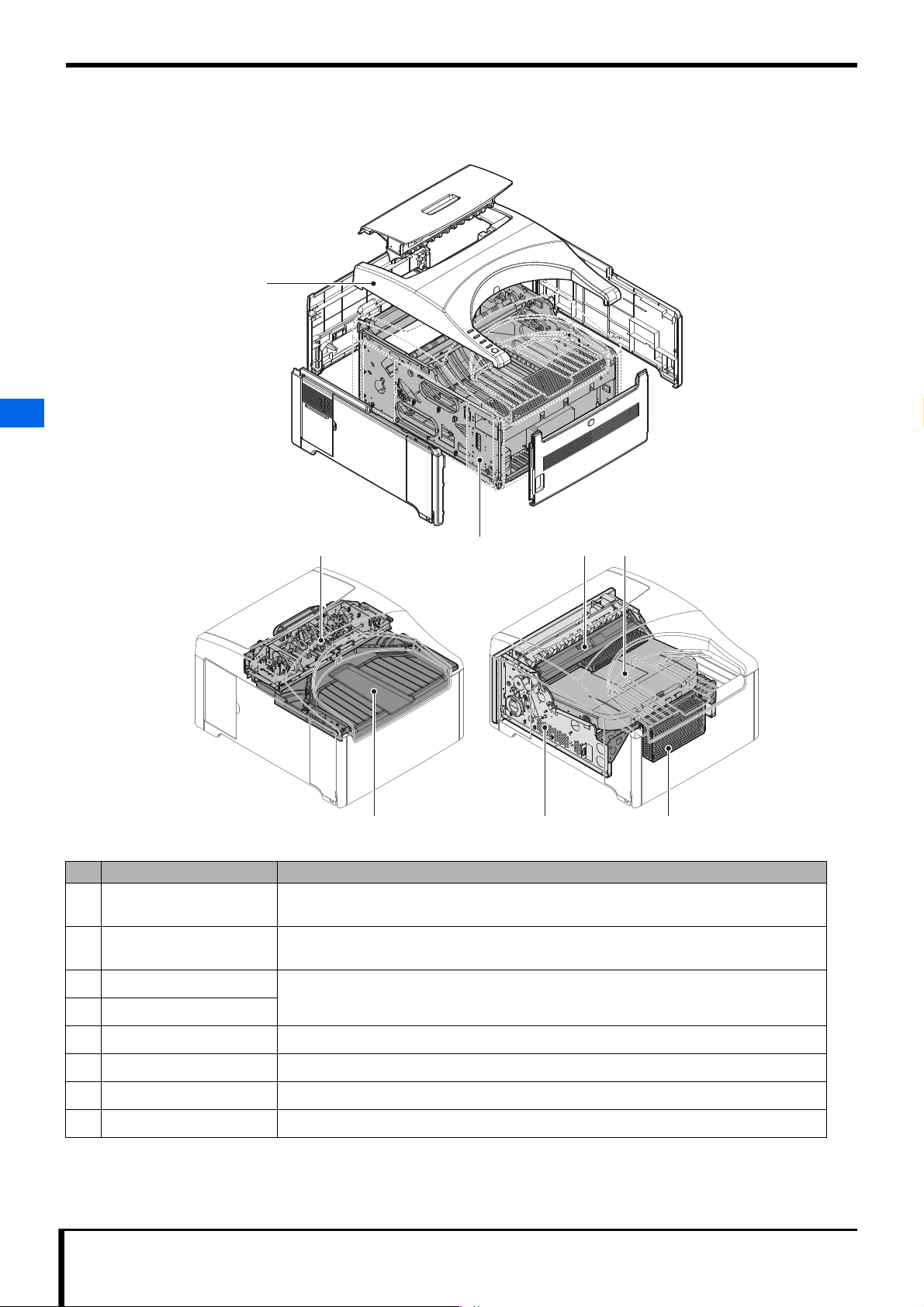

2.2 Configuration

A description of how the device is configured.

1

2

2.2 Configuration

3

4 85

No. Name Function

1 External Unit Protects the device's interior parts from light, vibration, and other outside influences.

2 Frame Make up the device's frame.

3 Upper Insertion Unit Has a mechanism to release the loaded cassette's lock, and to eject or return the plate to normal.

4 Lower Insertion Unit

It is made up of a upper panel, side panels, and a door for accessing interior parts of the device.

Control parts, an inlet for power supply, and power sources are also included.

Display and operational parts are also included.

2

76

5 Sub-scan Unit Feeds the plate (with sub scan).

6 Eraser Unit Erases any image information remaining on the plate.

7 Exposure Unit Scan excited laser light for the plate.

8 Light Collection Unit Gathers phosphor light generated from the plate and converts it into electric signals.

2-4 REGIUS /II Service Manual

Page 17

Chapter 2 Before Repairing

IMPORTANT

IMPORTANT

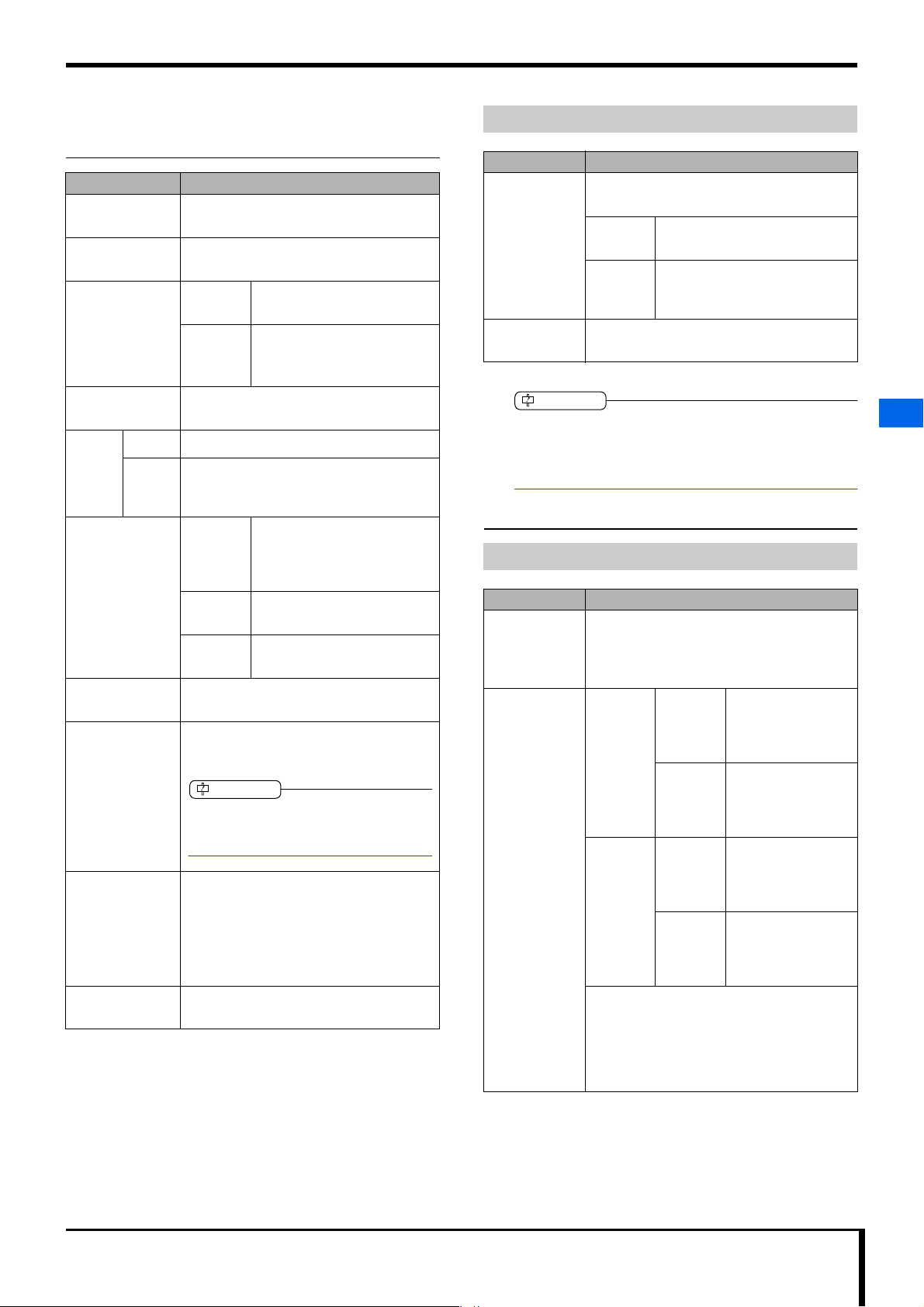

2.3 Main Specifications

2.3.1 Device Specifications

Item Content

External

dimensions

Mass Approximately 28 kg (excluding cassette

Noise level

(Excluding noise

originating from

user operation

(such as cassette

loading).)

Maximum power

consumption

Power

source

Hygrothermal

environment

External

connection

Service life 7 years (10 cassettes per day × 25 days per

Accessories • Power cable (length: 3 m)

Japan 100 V ± 10% (50/60 Hz)

Other

areas

510 (W) × 610 (D) × 355 (H) mm

and plate)

During

operation

During

standby

100 VA or less (100 V, 1 A or less)

115/120 V ± 10% (60 Hz)

110/220/230/240 V ± 10%(50/60 Hz)

200 V ± 10% (50 Hz)

Transport

packing

status

During

operation

When not

operating

USB 2.0 (Konica Minolta independent

communications specifications)

month × 12 months per year × 7 years =

21,000 cassettes)

User should consider service life 6 years. (A 6year service life is also mentioned in the

operation manual.)

Average = 53 dB or less

Maximum = 61 dB or less

Average = 25 dB or less

-20 to 60 ℃ / 90% RH or less

(no condensation)

0.7 to 1.0 atmospheric pressure

(= 709 to 1013 (hPa))

10 to 30 ℃ / 15 to 80% RH

(no condensation)

-10 to 40 ℃ / 90% RH or less

(no condensation)

• USB Cable

(length: 5 m, USB 2.0 High Speed

compatible)

• Operation manual

• Opening tools for cassette

Compatible Cassettes & Plates

Item Content

Readable

cassette

types

Readable plate

types

RC-300 cassettes with isolated open/close

structures and equivalent

Japan 14" × 17", 14" × 14", 11" × 14",

10" × 12", 8" × 10", 15cm × 30 cm

Other

areas

Regius Plate FP-1S or equivalent

14" × 17", 14" × 14", 11" × 14",

10" × 12", 8" × 10", 24cm × 30 cm,

18cm × 24 cm, 15cm × 30 cm

Cassettes/plates that can be used with this device are

device exclusive. Rigid type cassettes used with the

REGIUS MODEL 110, etc. cannot be used for this

device.

2.3.2 Image Reading & Erasing

Processing Ability

Item Content

Reading

resolution

Cycle time REGIUS Japan Up to 75 seconds

Normal read mode (175 µm)

High-definition read mode (87.5 µm)

• According to ImagePilot licensing. There

are no resolution settings for this unit.

per cassette

(14" × 14" / normal

read mode)

REGIUS

II

Other

areas

Japan Up to 54 seconds

Other

areas

Up to 80 seconds

per cassette

(14" × 17" / normal

read mode)

per cassette

(14" × 14" / normal

read mode)

Up to 60 seconds

per cassette

(14" × 17" / normal

read mode)

2

2.3 Main Specifications

Parts requiring

periodic change

None

• The fastest time from the cassette being

loaded and locked, to the end of the reading

process when the cassette is removed. The

fastest erase speed for standard dose

exposure. Cassette replacement time = 0

seconds.

REGIUS /II Service Manual 2-5

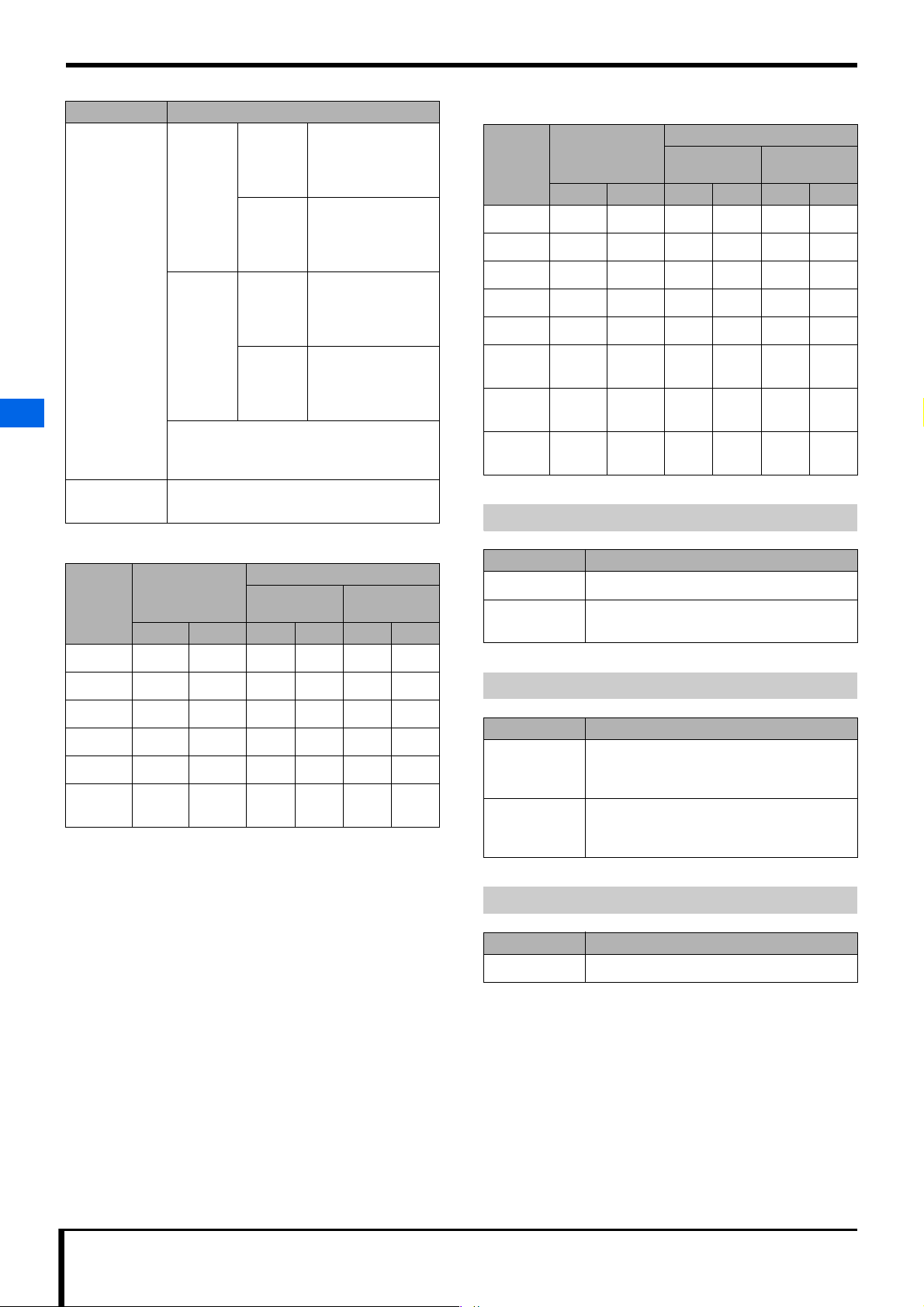

Page 18

Chapter 2 Before Repairing

Item Content

Processing

Ability

2

REGIUS Japan About 48 cassettes

Other

areas

REGIUS

II

Japan About 66 cassettes

Other

areas

per hour

(14" × 14" / normal

read mode)

About 45 cassettes

per hour

(14" × 17" / normal

read mode)

per hour

(14" × 14" / normal

read mode)

About 60 cassettes

per hour

(14" × 17" / normal

read mode)

• When continuous cassette loading, for the

number of cassettes going through the

process per hour.

Digital

gradation level

12-bit (4096 gradation)

Read image size (Other areas)

Cassette

type

14" 17" 365.75 442.05 2090 2526 4180 5052

14" 14" 365.75 365.75 2090 2090 4180 4180

11" 14" 289.10 365.75 1652 2090 3304 4180

10" 12" 264.25 315.35 1510 1802 3020 3604

8" 10" 213.50 264.25 1220 1510 2440 3020

24 cm

30 cm

18 cm

24 cm

15 cm

30 cm

Read capacity

(mm)

X way Y way X way Y way X way Y way

250.25 310.10 1430 1772 2860 3544

190.40 250.25 1088 1430 2176 2860

310.45 160.30 1774 916 3548 1832

Read pixel count

Normal read

mode

High-definition

read mode

Exposure Unit

Read image size (Japan)

Cassette

type

2.3 Main Specifications

14" 17" 365.75 442.05 2090 2526 4180 5052

X way Y way X way Y way X way Y way

Read capacity

(mm)

Read pixel count

Normal read

mode

High-definition

read mode

Item Content

Method Laser scanning by polygon mirror

Laser

wavelength

659 5 nm

14" 14" 365.75 365.75 2090 2090 4180 4180

11" 14" 289.10 365.75 1652 2090 3304 4180

10" 12" 264.25 315.35 1510 1802 3020 3604

8" 10" 213.50 264.25 1220 1510 2440 3020

15 cm

30 cm

310.45 160.30 1774 916 3548 1832

Light Collection Unit

Item Content

Method Light collecting mirror + reed-shaped light

guide + angled excitation light cut filter +

rounded photomultiplier tube (PMT)

Excitation light

elimination

An angled excitation light cut filter is placed in

the light guide window to eliminate excitation

light.

Eraser Unit

Item Content

Method Erasing done by white LED.

2-6 REGIUS /II Service Manual

Page 19

Sub-scan Unit

Item Content

Method Exposure unit fixed plate feed method

• Sub-scan (read/erase) of feeded

photostimulable phosphor plate by optical/

light collection unit.

Chapter 2 Before Repairing

Driving method The sheet-type plate roller feed method using

Operation

a 3-phase stepping motor.

• When reading:

reading is outward, erasing is out and back.

• When erasing:

reading is outward (max signal value

confirmation), erasing is out and back.

2.3.3 Control Part Functions

The main control part functions are as follows.

Function name Content

Image data

generation

function

Image data

revision/

calculation

function

Communication

function

• This function generates image data via laser

scanning.

• Moire elimination calculation

• Gain/offset revision calculation

• Shading irregularity correction, polygon

revision

• Erase speed calculation

• Command receiving function

• This function transmits read image data to a

console PC.

• This function provides a device status

notification.

2

2.3 Main Specifications

Control

function

Calibration

function

(during

maintenance/

shipment

settings)

• This function is triggered by cassette

loading, and performs a series of controls

including mechanical control, optical control,

signal processing control, communication

control, etc.

• This function performs the controls needed

to execute commands received via USB 2.0

interface communication.

• This function saves the base board serial

number to device memory which should

recognize the device's uniqueness.

Mainly the following functions are performed.

• Gain/offset function

• Irregularity calibration function

• Sensitivity calibration function

• Image position/size adjustment function

REGIUS /II Service Manual 2-7

Page 20

Chapter 2 Before Repairing

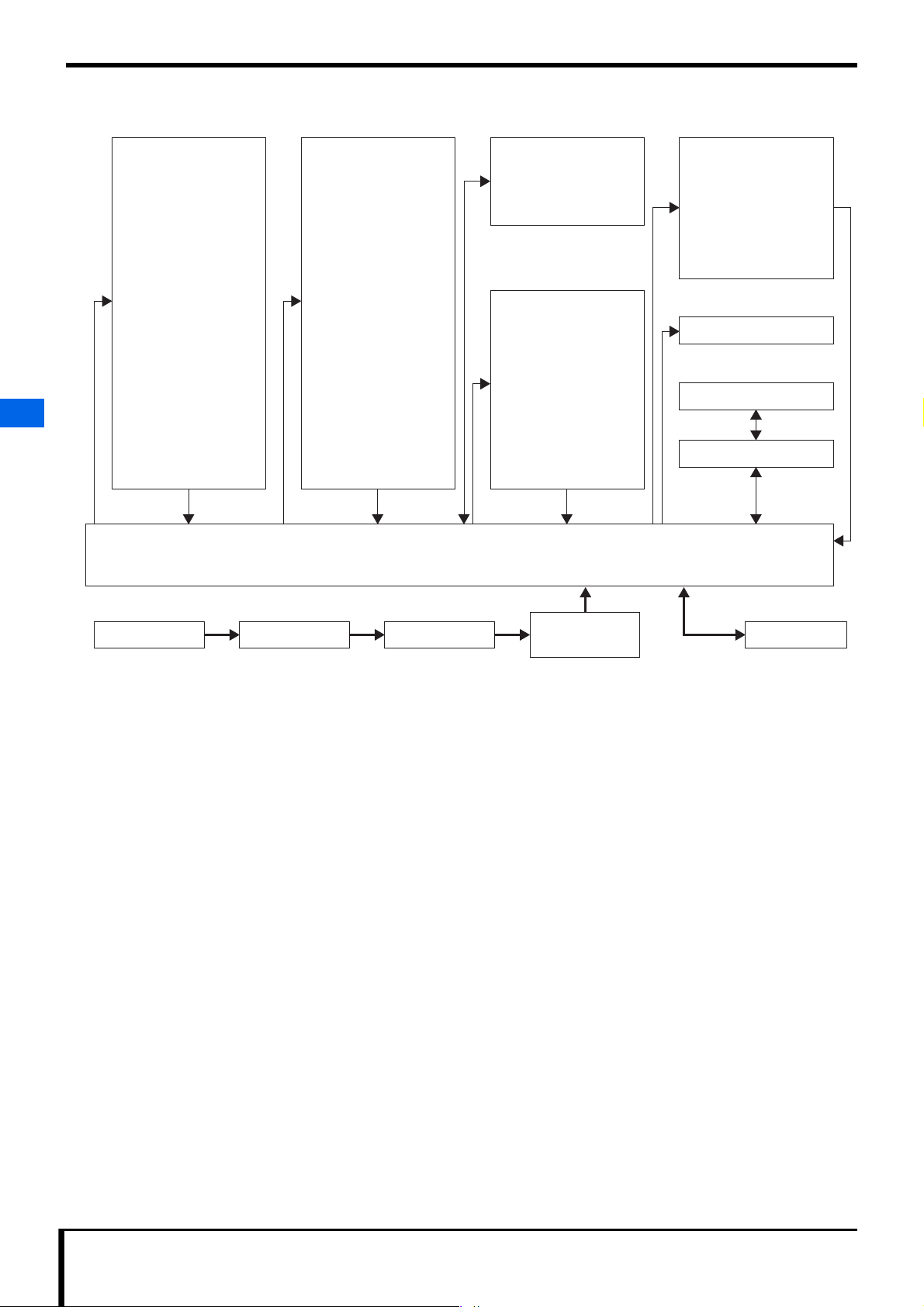

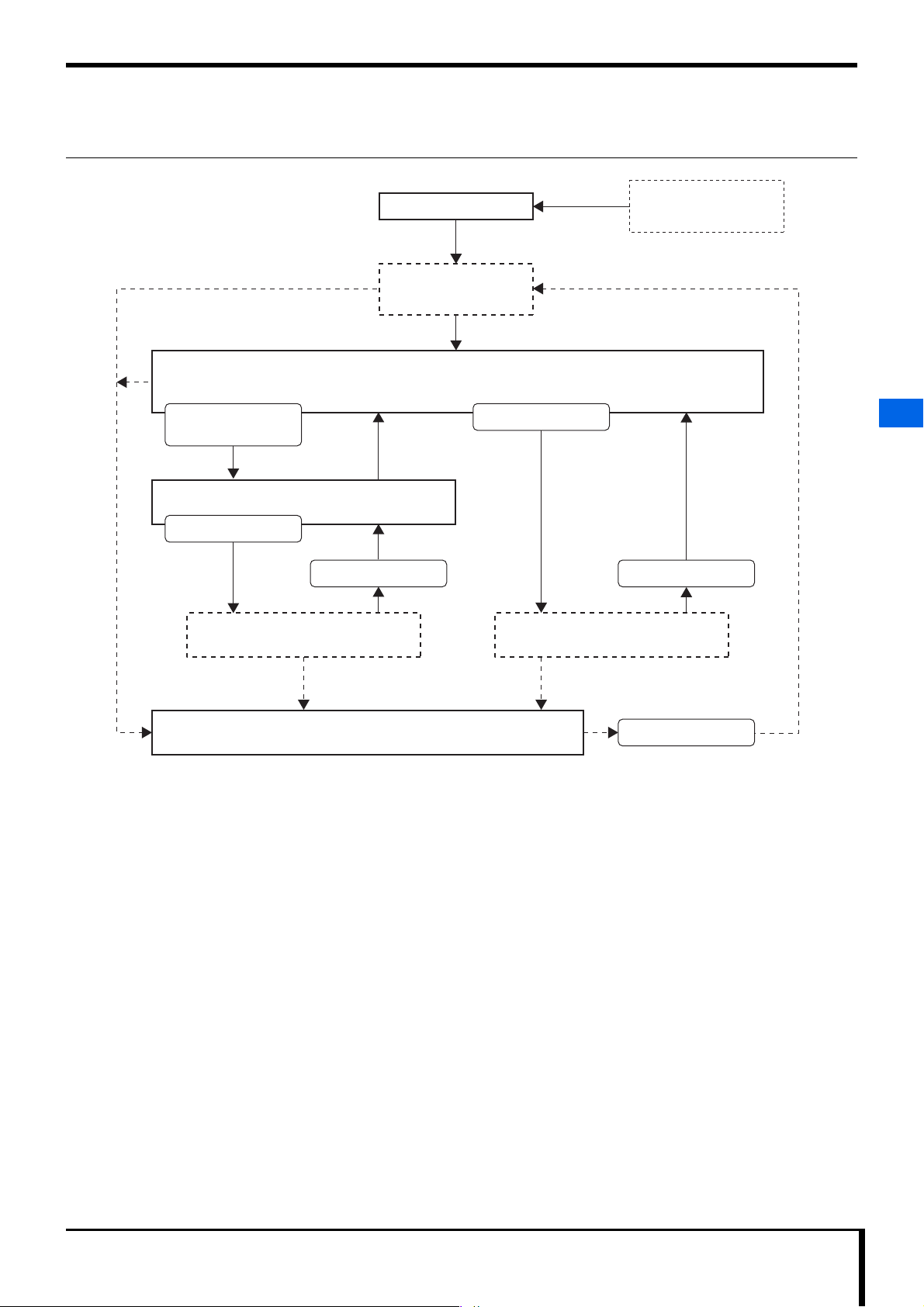

2.4 Block Diagram

2

2.4 Block Diagram

<Upper Insertion Unit>

Tray Moving Motor

Loading NIP Motor

Size Detecting Sensor 3

Size Detecting Sensor 4

Left Cassette Lock Sensor

Right Cassette Lock Sensor

Loading NIP HP Sensor

Loading NIP Open/Close Sensor

Tray Lock Release Sensor

Plate Sensor (light emitting)

Tray Sensor

Tray HP Sensor

Upper Door Interlock SW

AC100V to 240V

<Frame>

Eraser LED Cooling Fan

Magnetic Clutch

Loading/Feeding Motor

Left Door Open/Close Detection Sensor

Plate Sensor (light receiving)

Cassette Sensor

<Lower Insertion Unit>

Size Detecting Sensor 1

Size Detecting Sensor 2

MAIN_BOARD

LED_DRIVE2_BOARD

DC24/5V

Sub-scan NIP Motor

Sub-scan Feeding Motor

Entrance NIP Sensor

Rear Door Interlock SW

<Eraser Unit>

LED2_BOARD

<Sub-scan Unit>

V-SYNC Sensor

Exit NIP Sensor

SW power supply

<Exposure Unit>

LD_DRIVE_BOARD

LD_BOARD

H-SYNC_BOARD

Polygon

(DC24V)

STATUS_LED_BOARD

Photomultiplier Tube

ANALOG_BOARD

DC24V

External IF

USB24V

ImagePilot PCAC Power Source Inlet Noise Filter

Excluding what is listed in the diagram, motors are supplied 24V, and other devices are supplied 5V of electricity from the main board.

2-8 REGIUS /II Service Manual

Page 21

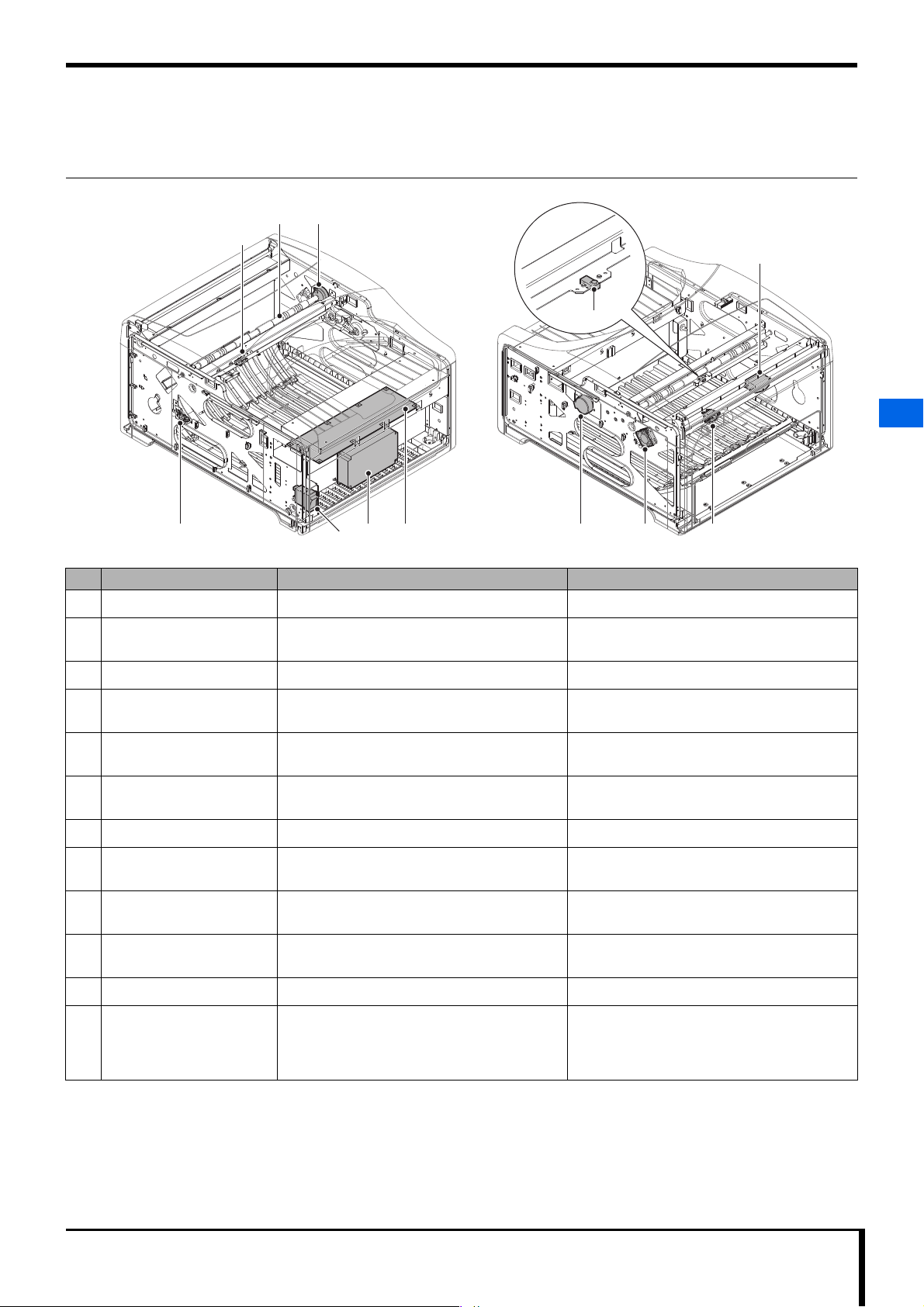

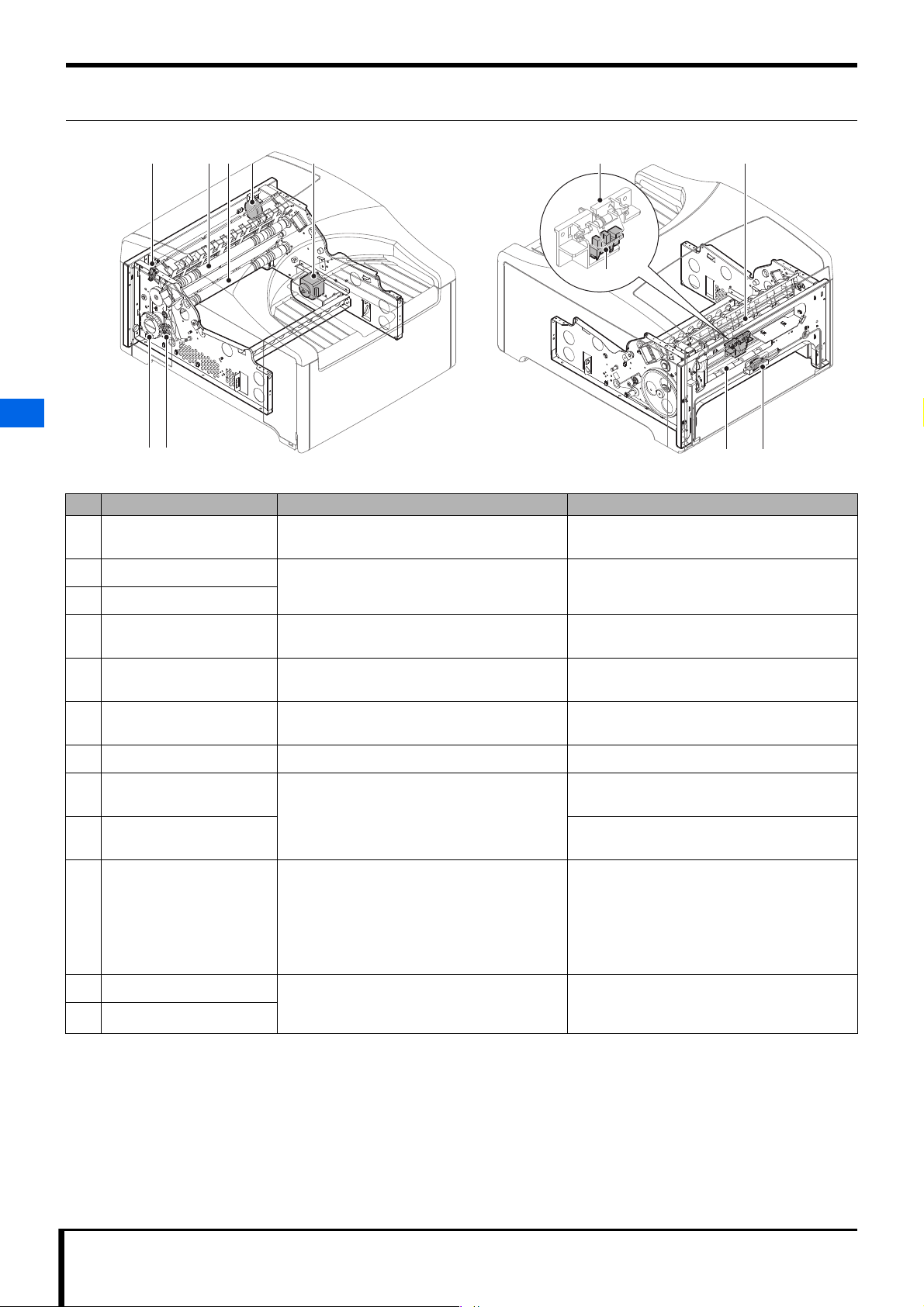

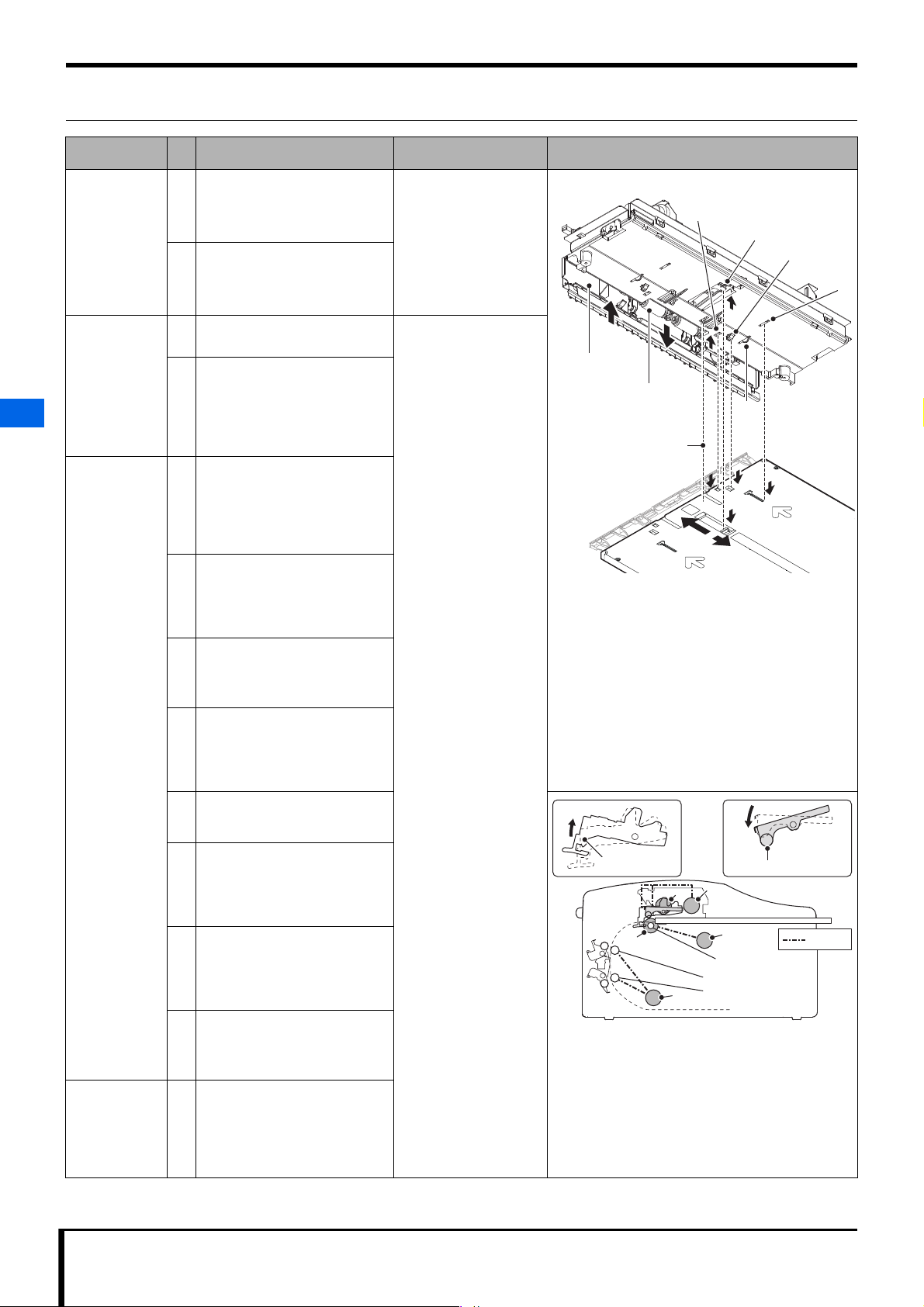

2.5 Main Part Locations

This is an explanation of where each device's main parts are positioned and how they function.

2.5.1 Frame

32

1

Chapter 2 Before Repairing

11

12

2

5 6 9 1084

No. Name Function Reference for how to change

1 Cassette Sensor Turned ON when the cassette is loaded. "5.3.9 Changing the cassette sensor (Page 5-34)"

2 Feeding Roller The loading/feeding motor operates to remove or

insert the plate from/into the cassette.

3 Magnetic Clutch Regulates power sent to feeding roller. "5.4.5 Changing the magnetic clutch (Page 5-45)"

4 Left Door Open/Close

Detection Sensor

5 Power supply circuit breaker Used to turn the device's power ON/OFF. "5.3.6 Changing the power supply circuit breaker

6 SW power supply - "5.3.5 Changing the SW power supply (Page 5-

7 MAIN_BOARD A base board that controls the device. "5.3.4 Changing the main board (Page 5-28)"

8 Insertion feed motor Removes or inserts the plate from/into the

9 Eraser LED Cooling Fan Takes in outside air to keep the eraser unit LED

10 Inlet-NF wiring Assy - "5.3.7 Changing the Inlet-NF wiring Assy (Page 5-

Turned ON when the left door is open. -

cassette.

cool.

7

"5.4.5 Changing the magnetic clutch (Page 5-45)"

(Page 5-31)"

30)"

"5.4.1 Changing the loading/feeding motor (Page

5-40)"

"5.4.4 Changing the Eraser LED cooling fan (Page

5-44)"

32)"

2.5 Main Part Locations

11 Noise filter - -

12 Plate Sensor (light receiving) Works together with the plate sensor (light

emitting) of the upper insertion unit to detect

whether a plate exists or not. Turns ON when a

plate exists.

"5.3.10 Changing the plate sensor (light receiving)

(Page 5-34)"

REGIUS /II Service Manual 2-9

Page 22

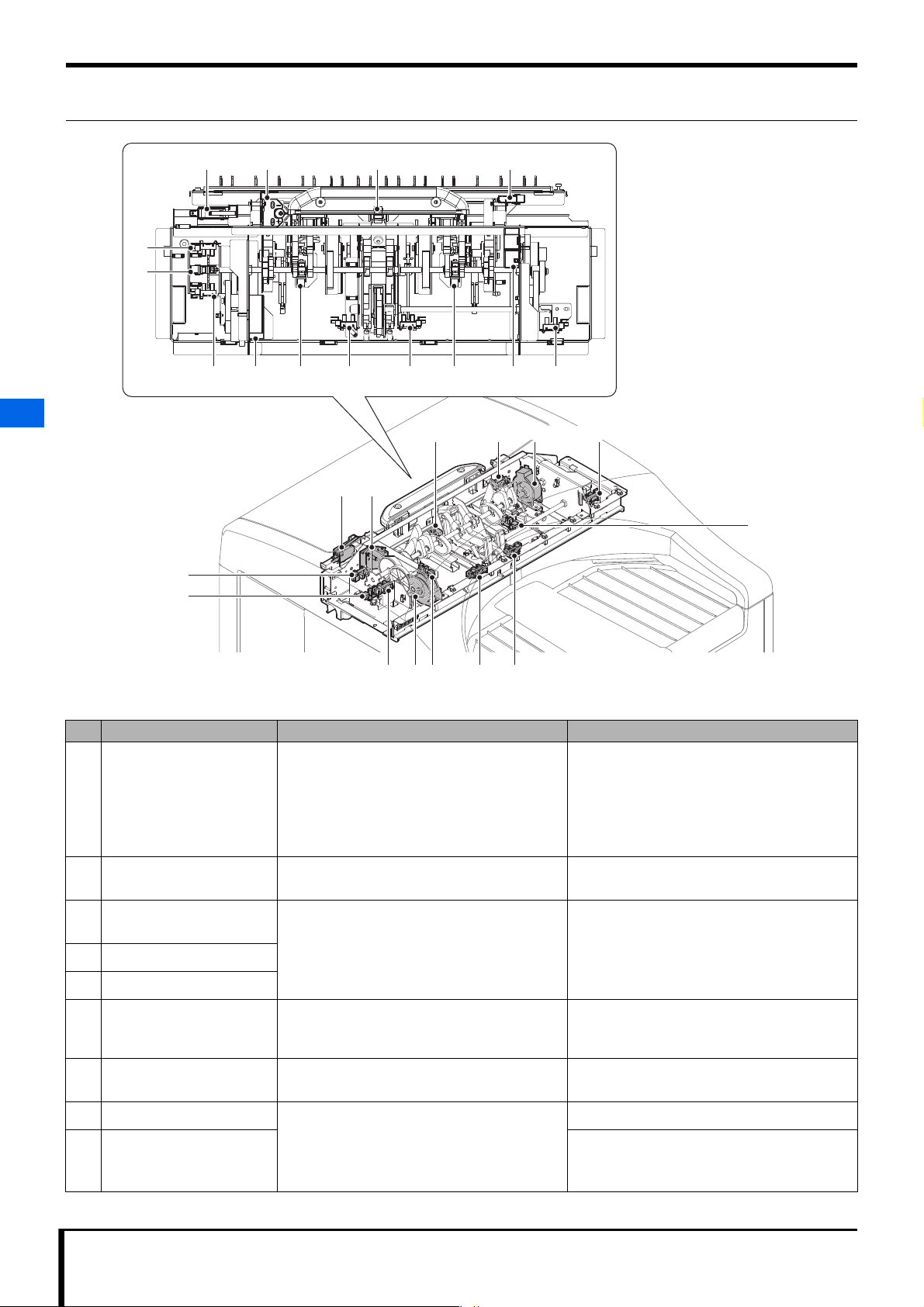

Chapter 2 Before Repairing

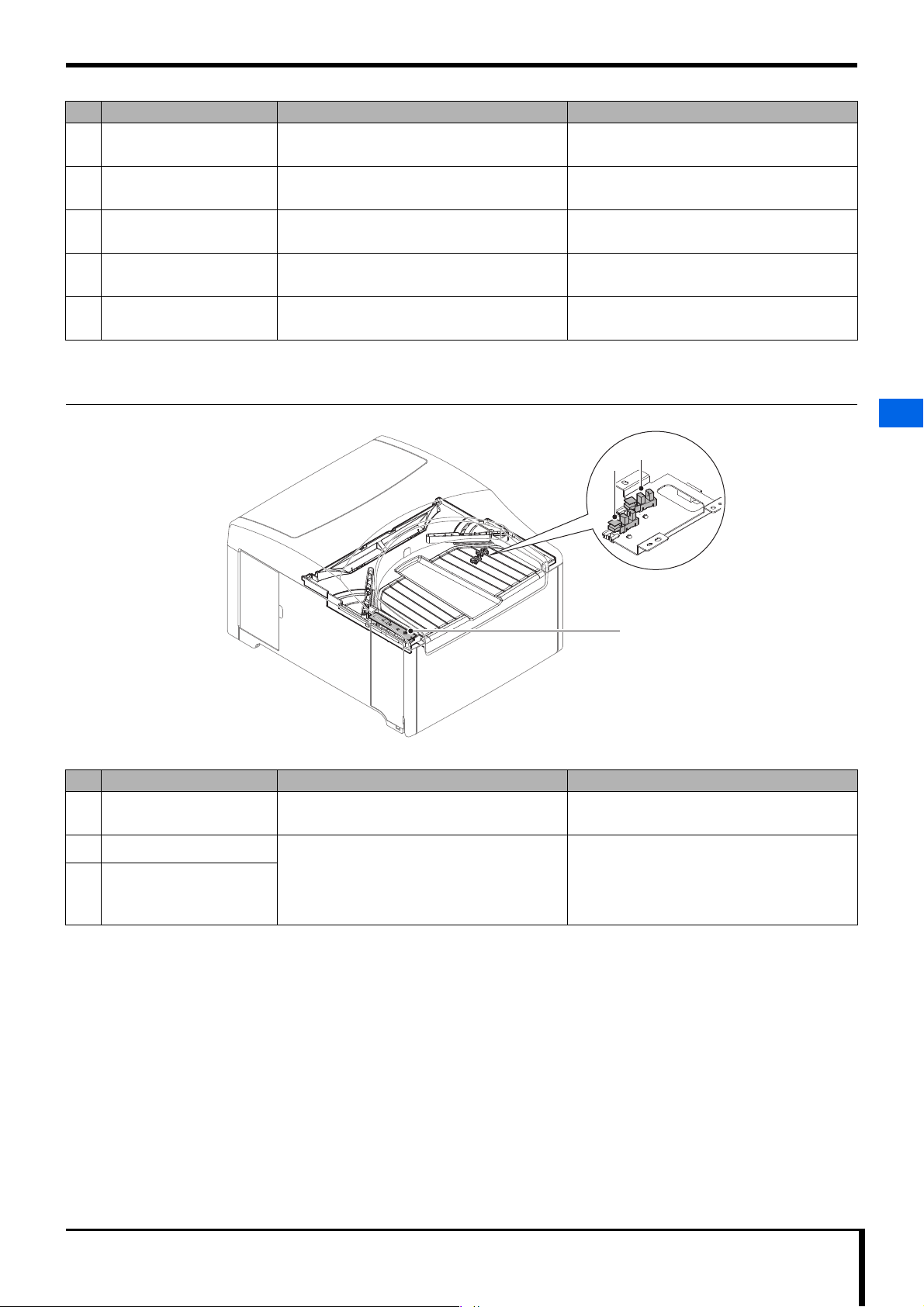

2.5.2 Upper Insertion Unit

1 2 10 11

3

4

5 7 13126 8 9 14

2

10

1 2

1311 14

2.5 Main Part Locations

12

3

4

65 9

No. Name Function Reference for how to change

1 Switch (interlock 1) Turned OFF when the upper door is open.

This is not a safety interlock, but when turned

OFF, power is disconnected from the following.

87

-

• Mechanical control power for motors, fans, etc.

• Eraser LED, power for high-voltage generation

• LD power

2 Adjusting cam, adjusting

board

3 Loading NIP Open/Close

Sensor

4 Tray Lock Release Sensor

5 Loading NIP HP Sensor

Used for oblique adjustments.

Refer to "6.1 Oblique adjustments (Page 6-2)".

Detects NIP status, the tray's lock status, etc.

when the plate is moving in and out of the

cassette.

Refer to "4.4.3 Insertion site sensor status (Page

4-6)".

Not changed as a single unit.

-

6 Insertion nip motor Performs NIP operation, or moves the tray's

abutment plate up and down when the image

plate is moving in and out of the cassette.

7 Left Cassette Lock Sensor Turned ON when the cassette is locked on the left

side.

8 Size Detection Sensor 4 Determines cassette size in a group of 4 sensors

9 Size Detection Sensor 3 Not changed as a single unit.

together with size detection sensors 1 and 2 of the

lower insertion unit.

Refer to "4.4.2 Cassette size & sensor status

(Page 4-5)".

Not changed as a single unit.

Not changed as a single unit.

Not changed as a single unit.

2-10 REGIUS /II Service Manual

Page 23

Chapter 2 Before Repairing

1

3

2

No. Name Function Reference for how to change

10 Plate Sensor (light emitting) Works together with the frame's plate sensor (light

receiving) to detect whether a plate exists or not.

"5.3.11 Changing the plate sensor (light emitting)

(Page 5-35)"

11 Tray Sensor Turned ON when the tray is outside of the

cassette.

12 Right Cassette Lock Sensor Turned ON when the cassette is locked on the

right side.

13 Casette tray move motor Moves the tray in and out, and corrects cassette

tilt.

14 Tray HP Sensor Turned ON when the notches used for moving the

tray in and out are in their home position.

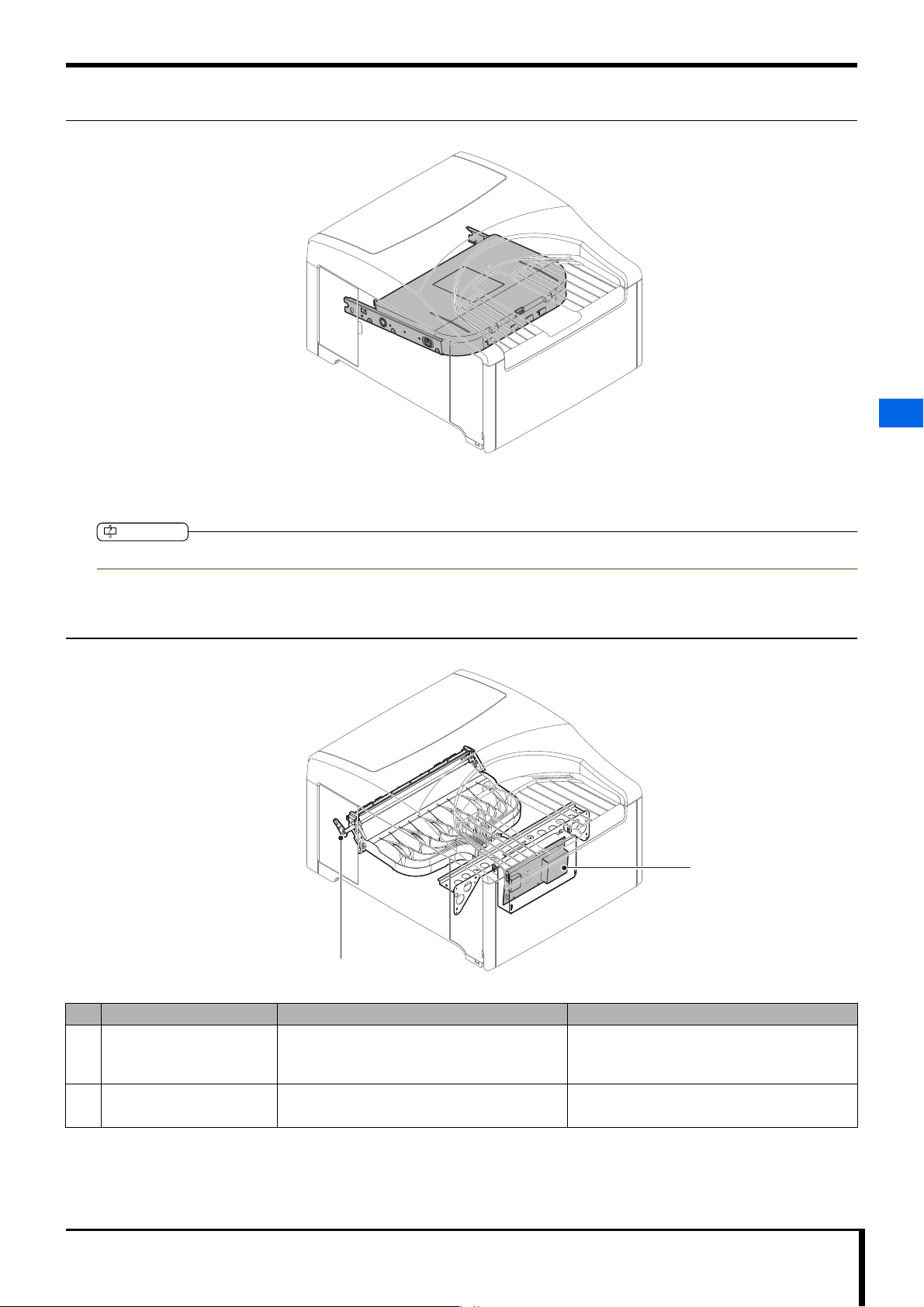

2.5.3 Lower Insertion Unit

Not changed as a single unit.

Not changed as a single unit.

Not changed as a single unit.

-

2

No. Name Function Reference for how to change

1 Status LED board A base board for status display (status lamps) and

operations (Erase switch).

2 Size Detection Sensor 1 Determines cassette size in a group of 4 sensors

3 Size Detection Sensor 2

together with size detection sensors 3 and 4 of the

upper insertion unit.

Refer to "4.4.2 Cassette size & sensor status

(Page 4-5)".

"5.3.1 Changing the status LED board (Page 5-

25)"

"5.3.8 Changing size detection sensors 1 and 2

(Page 5-33)"

2.5 Main Part Locations

REGIUS /II Service Manual 2-11

Page 24

Chapter 2 Before Repairing

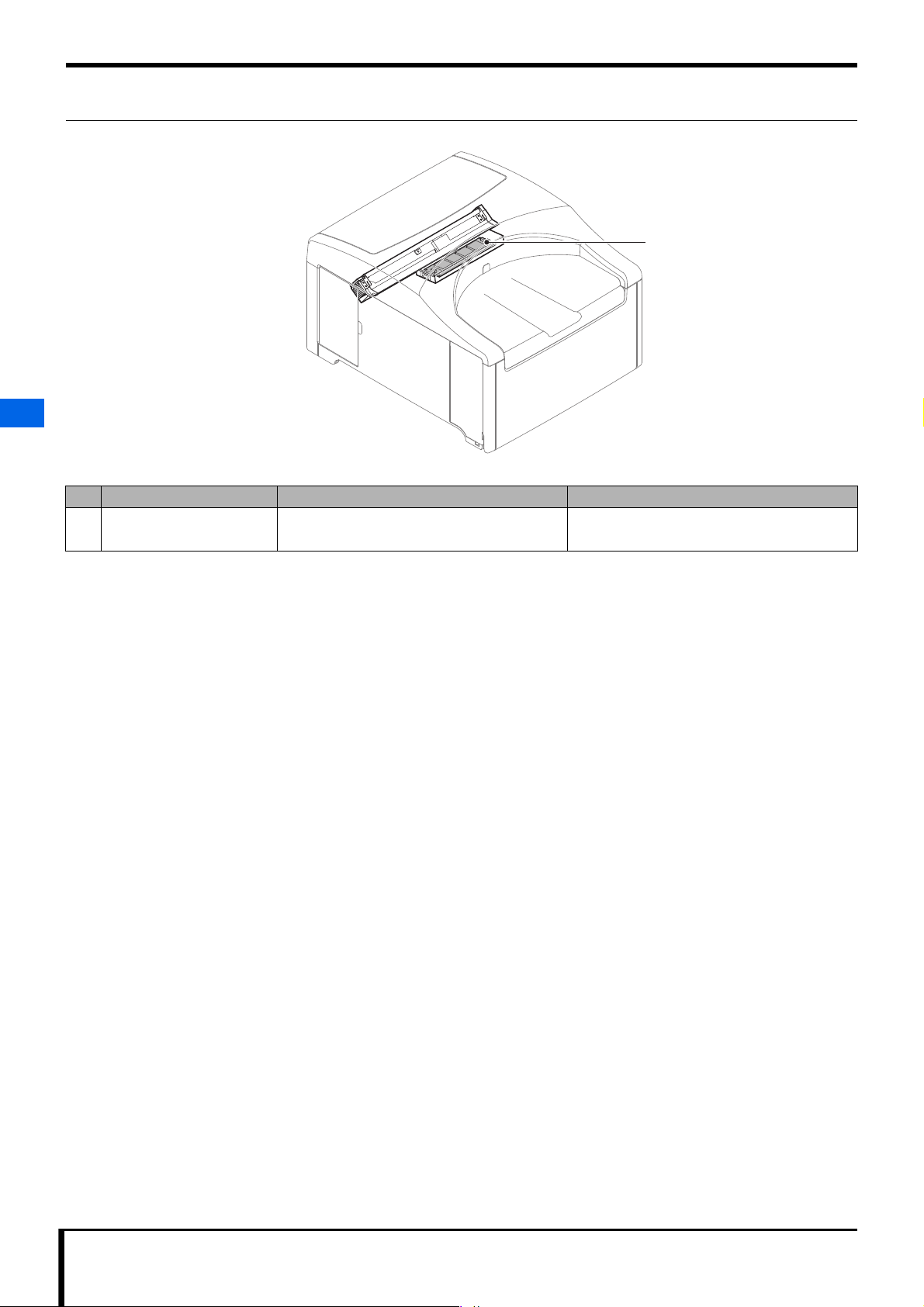

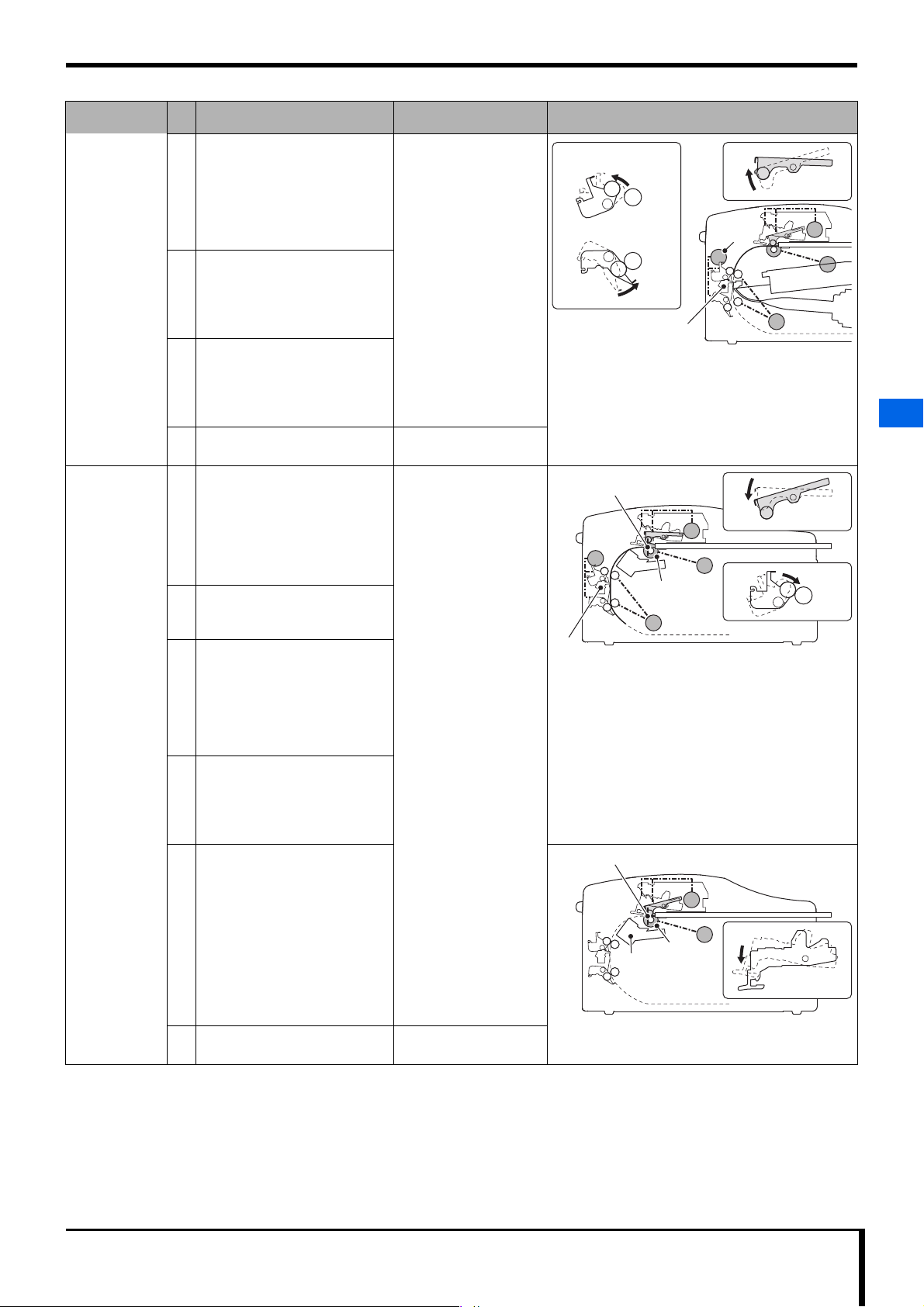

2.5.4 Sub-scan Unit

5 8111 2 3 4

12

2

2.5 Main Part Locations

76

No. Name Function Reference for how to change

1 Entrance NIP Sensor Turned ON when Drive Roller U is in NIP status. "5.3.13 Changing the entrance NIP sensor (Page

5-38)"

2 Drive Roller U Feeds the plate via a Sub-scan Feeding Motor. "5.4.9 Changing the drive rollers (Page 5-49)"

3 Drive Roller D

4 Sub-scan NIP Motor Performs NIP for Drive Roller U and Drive Roller D."5.4.2 Changing the sub-scan NIP motor and sub-

scan drive Assy (Page 5-41)"

5 Sub-scan Feeding Motor Feeds the plate. "5.4.3 Changing the sub-scan feeding motor

6 Handle

(Unjamming dial)

7 Exit NIP Sensor Turned ON when Drive Roller D is in NIP status. "5.3.14 Changing the exit NIP sensor (Page 5-39)"

8 Driven entrance assembly -

driven roller

9 Driven exit assembly - driven

roller

10 Switch (interlock 2) Turned OFF when the rear door is open.

Used to rotate Drive Rollers U and D when a plate

jam occurs.

Operates via Sub-scan NIP motor to perform NIP

for Drive Roller U and Drive Roller D.

This is not a safety interlock, but when turned

OFF, power is disconnected from the following.

(Page 5-43)"

9 10

-

-

-

-

• Mechanical control power for motors, fans, etc.

• Eraser LED, power for high-voltage generation

• LD power

11 V-SYNC assembly Detects when passage is available for the plate in

12 V-SYNC Sensor

a reading area.

Sensor is ON when a plate exists.

2-12 REGIUS /II Service Manual

"5.3.12 Changing the V-SYNC sensor and VSYNC assembly (Page 5-37)"

Page 25

Chapter 2 Before Repairing

IMPORTANT

2.5.5 Exposure Unit

Parts within the exposure unit cannot be changed individually. If a problem occurs within the exposure unit, the entire exposure unit must be

changed.

2

Do not disassemble the exposure unit.

2.5.6 Light Collection Unit

2.5 Main Part Locations

2

1

No. Name Function Reference for how to change

1 Handle

(Light Collection Unit

Cleaning Handle)

2 Analog board A base board that takes in analog signals from the

Activates a cleaning mechanism to keep the light

guide and laser scanning line of the light collection

unit free of dust.

photomultiplier tube and converts them.

REGIUS /II Service Manual 2-13

"5.2.10 Removing & attaching the Sub-scan unit

(Page 5-12)"

Not changed as a single unit.

Page 26

Chapter 2 Before Repairing

1

2.5.7 Eraser Unit

2

No. Name Function Reference for how to change

1 LED_DRIVE2_BOARD A base board that controls the Eraser LED. "5.3.2 Changing the LED drive2 board (Page 5-

25)"

2.5 Main Part Locations

2-14 REGIUS /II Service Manual

Page 27

2.6 Behavior Explained

Power Supply Circuit Breaker ON

Power Supply Circuit Breaker OFF

(Constant)

Cassette Ejected

Cassette Inserted

Erase Switch

pressed for 2 seconds

Cassette Inserted

Door Opened/Closed

Cassette Ejected

Routine Mode

Boot

Initialization Process

Erase Mode

Erase Process

Error Occurs

Image Reading

2.6.1 State Transition Diagram

Chapter 2 Before Repairing

2

No sleep mode as with REGIUS MODELS 110/210 is available. (No operation switch.)

2.6 Behavior Explained

REGIUS /II Service Manual 2-15

Page 28

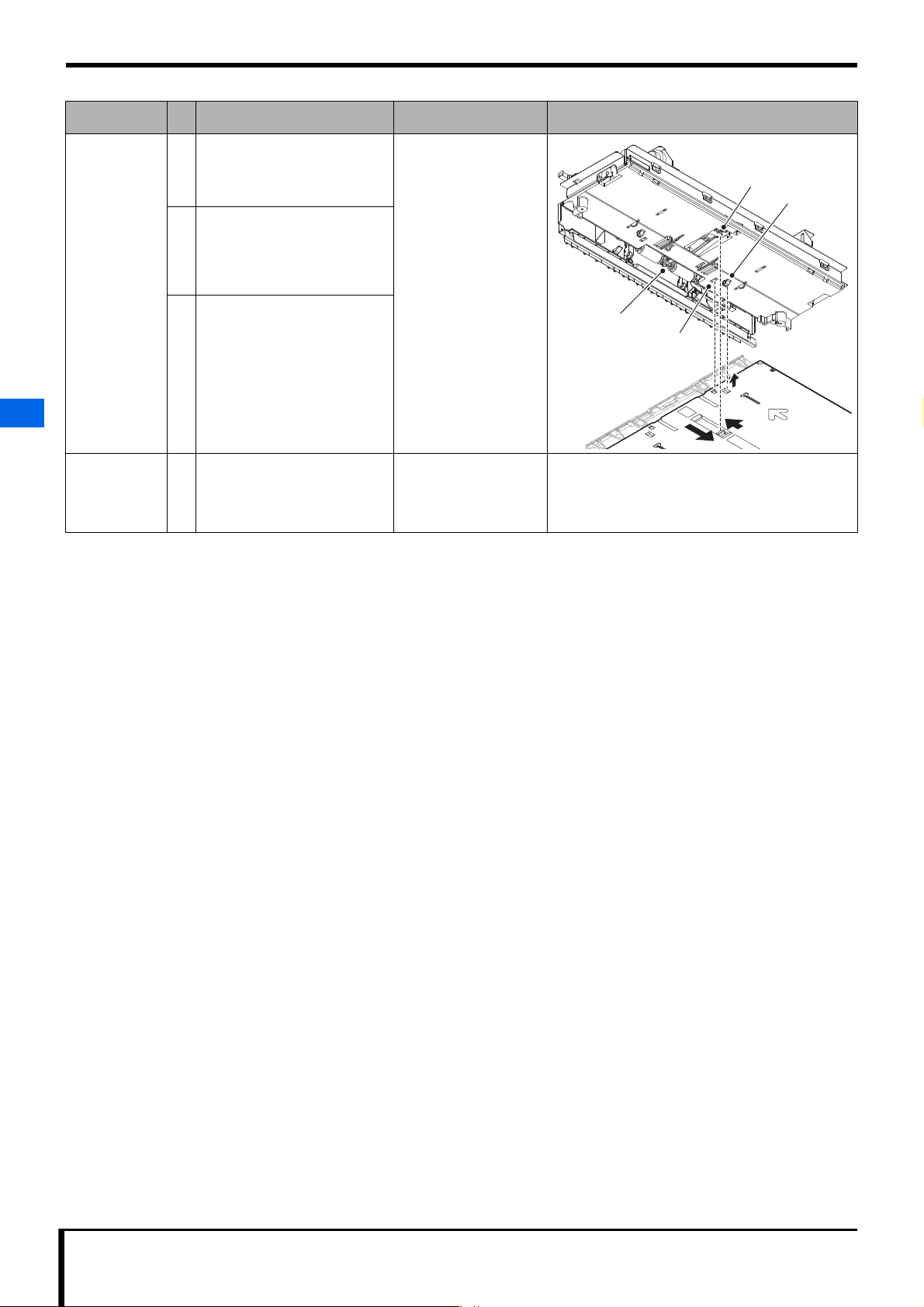

Chapter 2 Before Repairing

B

C

D

A

E

Upper Insertion Unit

Cassette

8

10

11

6

12

4

1

22

7

3

5

Abutment Plate

NIP Roller

Size Detection Sensor 3

9 ON

13 ON

13 ON

10

11

Feeding Roller

Drive Roller U

Drive Roller D

J

I

H

NIP Roller

Abutment Plate

F

G

Power

2.6.2 Normal Operation (Image Reading)

Operation/

Initialization

User loads

cassette

2

Plate is ejected

2.6 Behavior Explained

Plate is sent

(feed)

2-16 REGIUS /II Service Manual

control

No.

Feed (letters in parenthesis

correspond to the diagram)

1 Notch (A) for tray removal

retracts.

• Drive source: Tray moving

motor (F)

2 The tray's lock release Notch (B)

retracts.

• Drive source: Loading NIP

motor (G)

3 Notch (C) locks the cassette.

• No drive source

4 Notch (D) releases tray lock (bolt

mechanism). (For large

cassettes only)

• No drive sourcePart (E) is

pushed into operation by the

cassette.

5 Notch (A) is lowered, and

connects to the cassette's tray

ejection notch (cassette open/

close lever).

• Drive source: Loading NIP

motor (G)

6 Notch (A) moves in the tray's

return direction and corrects the

cassette's position.

• Drive source: Tray moving

motor (F)

7 Notch (B) is lowered, and the tray

lock is released.

• Drive source: Loading NIP

motor (G)

8 Notch (A) ejects the tray, and

bumps it against the abutment

plate.

• Drive source: Tray moving

motor (F)

9 Magnetic Clutch (H) is turned

ON. (Feeding roller connects to

drive source.)

10 The NIP roller is lowered, and

moves into NIP status with the

feeding roller.

• Drive source: Loading NIP

motor (G)

11 The abutment plate is raised with

the tray attached, and the image

plate is removed from the tray.

• Drive source: Loading NIP

motor (G)

12 Notch (A) slightly returns the tray

(to avoid tray and roller contact).

• Drive source: Tray moving

motor (F)

13 Loading/Feeding Motor (I) starts

the plate into send feed.

At the same time, Sub-scan

Feeding Motor (J) starts up.

• Drive source: Loading/

Feeding Motor (I)

Exposure / Optical /

Eraser

• Polygon starts to

rotate for cassette

detection.

• Seven seconds later,

the polygon lock is

confirmed, the laser

emits low level light,

and PMT high voltage

is turned ON. (PMT

voltage level rises until

V-SYNC detection)

Diagram (Numbers here correspond with the "No."

column)

Page 29

Chapter 2 Before Repairing

14

14 OFF

14 OFF

12 ON

12 ON

V-SYNC Detection

Driven Entrance Assembly

Driven Exit Assembly

K

14

16

15

19

18 ON18 ON18 ON

20 ON

20 ON

18 ON

21

18

20

Plate Detected

V-SYNC Detection

22 OFF

23 OFF

22

22

No Plate Detected

Operation/

control

(V-SYNC

detection)

Plate is returned

(feed)

(V-SYNC

detection)

(Plate

detected)

(No plate

detected)

No.

Feed (letters in parenthesis

correspond to the diagram)

14 Loading/Feeding Motor (I) stops.

Magnetic Clutch (H) is turned

OFF.

The feeding roller is released

from NIP status. (Otherwise the

plate will scrape against the

roller.)

15 Drive Roller D goes into NIP

status. (The timing is the same

regardless of cassette size.)

• Drive source: Sub-scan NIP

Motor (K)

16 Drive Roller U is released from

NIP status. (Timing differs

according to cassette size.)

• Drive source: Sub-scan NIP

Motor (K)

17 Send feed stops at 10 mm from

V-SYNC detection.

18 Sub-scan Feeding Motor (J)

begins the plate's return feed.

At the same time, an operation

begins in which Drive Roller U

moves into NIP status.

• Drive source: Sub-scan

Feeding Motor (J)

• From V-SYNC detection to 45

19

mm, feed speed gets faster,

then slows down.

20 When the plate sensor detects a

plate (at the front end of its return

direction), the Magnetic Clutch

turns ON, and the feeding roller

begins its return operation.

(Timing differs according to plate

size.)

21 The NIP roller is lowered, and

moves into NIP status with the

feeding roller.

• Drive source: Loading NIP

motor (G)

22 When the plate sensor does not

detect a plate (at the far end of its

return direction), the plate is

determined to be stored in the

cassette, and the tray's abutment

plate is lowered.

At the same time, Notch (B) is

enabled to release the tray lock

to take in tray storage.

• Drive source: Loading NIP

motor (G)

23 The Magnetic Clutch is turned

OFF.

Exposure / Optical /

Eraser

• When V-SYNC

detection has 42 line

counts (H-SYNC)

remaining, the laser

emits strong light, and

image reading begins.

• The Eraser LED lights

up.

• The Eraser LED shuts

down.

Diagram (Numbers here correspond with the "No."

column)

2

2.6 Behavior Explained

REGIUS /II Service Manual 2-17

Page 30

Chapter 2 Before Repairing

B

A

C

24

25

26

Plate Sensor

(light emitting)

Operation/

control

Plate storage

No.

Feed (letters in parenthesis

correspond to the diagram)

24 Notch (A) returns the tray to the

cassette. (Max send: Abutment)

Exposure / Optical /

Eraser

Diagram (Numbers here correspond with the "No."

column)

• Drive source: Tray moving

motor (F)

25 Notch (A) moves slightly in the

extraction direction. (To relieve

the tray of push stress.)

• Drive source: Tray moving

motor (F)

26 Notch (C) releases the cassette

lock.

• Drive source: Loading NIP

motor (G)

2

User ejects the

cassette

(and

initialization

begins).

27 Moves into standby mode to

prepare for the next image

reading.

2.6 Behavior Explained

2-18 REGIUS /II Service Manual

Page 31

Chapter 2 Before Repairing

Power ON/When door is closed

Initialization Operation

Normal Shutdown Abnormal Shutdown

Error Detection

Gain Offset Calculated

Eraser LED / Cooling Fan

Disconnection Check

Motor HP Eject Operation

Plate Residue Check

Sensor Check

Error Detection

Error Detection

Error Detection

Error Detection

Optic Device

Operation Check

2.6.3 Initialization Operation

By switching the power supply circuit breaker to ON, device operation will begin, starting with the initialization process.

After starting up, firmware initialization content is as follows.

1) CPU Initialization Process

2) OS Initialization Process

3) FPGA Configuration & Initialization

4) Generation of all resources, such as each firmware task, etc.

5) Kernel runs

Each task operation will begin from this point, and the device will start up. USB communication initialization, mechanical and optical

initialization etc. will also be performed simultaneously.

Mechanical Initialization Operation

Summary

Sensor Check

All sensors are checked, then checks are made of whether or not

there is a cassette in the Cassette Insertion Slot, and whether or not a

plate is inside the device. If one is detected, error notification is

provided.

For details, refer to " Sensor Check Flow (Page 2-20)".

Plate Residue Check

The Sub-scan Feeding Motor is rotated for a certain amount of

time, and if the V-SYNC sensor is turned ON (plate detected) at

that time, the following operation is performed.

1. After the Sub-scan Feeding Motor has stopped, it will turn a

determined number of revolutions, and the plate is sent to an area

where it can easily be ejected from the upper Door (unjamming

send process).

2. An error message is displayed.

Motor HP Eject Operation

The Tray Moving Motor, Loading NIP Motor, and Sub-scan NIP

Motor HP eject operation is performed. During each operation,

changes to the sensors attached to each motor are confirmed to

make sure that no errors have occurred in the sensors.

Tray Moving Motor: Tray HP Sensor

Loading NIP Motor: Lock Release Sensor

Sub-scan NIP Motor: Entrance NIP Sensor

Eraser LED/Cooling Fan Disconnection Check

The Eraser LED and Eraser LED Cooling Fan are turned ON for a

certain time, and if an Eraser LED error signal or Erase Fan error

signal is detected during that time, error notification is given.

For details, refer to " Moving into Eraser LED/Cooling Fan

Disconnection Check Status (Page 2-21)".

Optic Device Operation Check

Polygon is rotated, and confirmation is made that polygon lock

signal detection can be performed.

Laser is activated to emit light, while HSYNC updates and PID

(Polygon-ID) detection are confirmed. If HSYNC updates and PID

detection cannot be confirmed, error notification is provided.

For details, refer to " Moving into Optical Device Operation Check

Status (Page 2-20)".

Gain Offset Calculated

Pixel values are entered with two reference current source types,

and the gain offset is calculated from each average.

• Motor HP Eject Operation and Eraser LED/Cooling Fan Disconnection

Check will be performed in parallel.

Loading NIP HP Sensor

Loading NIP Open/Close Sensor

Exit NIP Sensor

2

2.6 Behavior Explained

REGIUS /II Service Manual 2-19

Page 32

Chapter 2 Before Repairing

Sensor Check

Normal Shutdown

Abnormal Shutdown

Error Notification to Status Management Task

(Error Code = E7413)

OFF

(High Voltage OFF)

High Voltage SW

Error Notification to Status Management Task

(Error Code = E7000)

ON

(Tray Ejection)

Tray Sensor

Error Notification to Status Management Task

(Error Code = E7001)

OFF

(Plate Attached)

Plate Sensor

Error Notification to Status Management Task

(Error Code = E7002)

Error Notification to Status Management Task

(Error Code = E7003)

ON

(Plate Attached)

ON

(Cassette Attached)

V-SYNC Sensor

Cassette Sensor

Cassette Status Monitor

notified that Cassette

Insertion Monitoring will

begin

Sensor Check Flow

2

2.6 Behavior Explained

Moving into Optical Device Operation Check Status

Polygon Rotation Begins

Polygon Rotation Stability Standby Timer Begins

Polygon Rotation

Check in Progress

Timeout

Polygon Lock Detected

Polygon Rotation Stability Standby Timer Stops

Laser ON (half size 87.5 μm setting)

PID Signal Detection

Standby

PID Signal Detection OK

Laser OFF

Polygon stopped

PID Signal Detection Failure

Laser OFF

Polygon stopped

2-20 REGIUS /II Service Manual

Page 33

Chapter 2 Before Repairing

Timeout

Eraser LED Error Detection

Error Signal Monitoring

Erase Fan Error Detection

Eraser LED ON

Eraser LED Cooling Fan ON

Error Monitor Timer Begins

Eraser LED OFF

Eraser LED Cooling Fan OFF

Eraser LED OFF

Eraser LED Cooling Fan OFF

Eraser LED OFF

Eraser LED Cooling Fan OFF

Moving into Eraser LED/Cooling Fan Disconnection Check Status

2.6.4 Erase Operation

When the device's status is READY, holding down the Erase switch for at least 2 seconds will put it into Erase Mode status. Loading a cassette

while the Erase Lamp is blinking will start the Erase operation.

The Erase operation adjusts to the plate status to perform at the optimal speed.

2

2.6 Behavior Explained

REGIUS /II Service Manual 2-21

Page 34

Chapter 2 Before Repairing

IMPORTANT

2.7 Cassette/Plate Handling

Carefully adhere to the following instructions when handling a

cassette or plate.

Maintaining image quality

Always make sure the plate's reading surface has not

•

been scratched or contaminated with foreign objects.

• If you find any foreign objects on the plate's reading

surface, immediately clean it off.

• When handling a plate, wear the proper type of gloves

according to film handling.

2

2.7 Cassette/Plate Handling

• Keep the plate away from sunlight.

• If the plate is exposed to fluorescent light during cleaning,

etc. make sure to complete the task as quickly as

possible and immediately load the plate into the cassette

when finished.

• Do not let the cassette get scratched or dirty.

Transport & storage

Follow the specifications below in regards to temperature

•

and humidity.

- Temperature: 10 to 30 °C

- Humidity: 15 to 80% RH (with no condensation)

• Do not expose it to X-rays, rays or any other sort of

radiation.

• A plate which has been unsealed must be loaded and

stored in the cassette.

• Do not drop or bump the cassette.

• Stand the cassette in a rack for storage during operation.

Things to confirm before insertion

To prevent trouble during feed of the plate, insert the cassette only

after confirming the following points.

• Make sure the cassette has not been altered in form or

damaged.If the cassette is found to have a problem, do

not insert it into the device.

• Confirm that no memo clips, paper, or other such objects

are caught inside.

• Confirm that the cassette is locked.

Disposal

Refer to "1.3.6 Disposal Cautions (Page 1-5)"

•

Only cassettes and plates exclusively produced for this

device can be used with it. Rigid cassettes that are

used with REGIUS MODEL 110 etc. cannot be used.

2.8 Tools, Instruments, Jigs, etc. Needed for Service

The following tools, instruments, jigs are needed to service this

device.

Jig / Tool Comment

Standard Tools

• Phillips-head screwdriver

(#1 bit): for cassette

• Phillips-head screwdriver

(#2 bit): for device

• Flathead screwdriver

• Hex wrench

• Wrench

• Nippers

• Tray

A static electricity

countermeasure type wristband

(for grounding)

Laser safety glasses Capable of protecting against

Te st e r

Gloves

Portable vacuum cleaner Used to clean the plate's

Cloth Used to clean the device's

Plastic sheet Use to cover light collection

Cloth, cardboard, etc.

Maintenance PC

USB Cable Used to connect a

A 14" × 17" size cassette and

plate

Supplies

Jig / Tool Comment

Alcohol

Zip ties

Snap bands

The tray is used to store

loose screws and parts.

659 nm laser wavelength

feeding path.

external parts after servicing.

unit when removing them to

keep dust out.

maintenance PC to the

device.

Used when performing

oblique light adjustment. (If

not possessed by the user)

2-22 REGIUS /II Service Manual

Page 35

Chapter

Chapter 3 Troubleshooting

3

An explanation of the various methods for dealing with device-related

troubles.

3

3.1 Work Flow................................................................................. 3-2

3.2 Recovery Operation ................................................................. 3-2

3.3 How to Retrieve Logs............................................................... 3-3

3.4 Error Message Content & Countermeasures.........................3-4

3.5 Countermeasures for dealing with problems not displayed

as error messages.................................................................. 3-70

Troubleshooting

Page 36

Chapter 3 Troubleshooting

CAUTIONCAUTION

HINT

3

3.1 Work Flow

The following flow provides countermeasures to various issues

that may occur with the device.

Problem Countermeasure Flow

1. If the plate is still inside the device,

remove it.

2. Restart the device.

- Refer to "3.2 Recovery

Operation (Page 3-2)".

3. Check if the error occurs again.

An error message is displayed

on the ImagePilot for this

problem.

An error message is not

displayed on the ImagePilot for

this problem.

3.1 Work Flow

Contact Information

When contacting our service window regarding a problem, provide

the following information with as much detail as possible.

Item Content

Log, etc.

Facility connection

format

Recovery information

System Information

Image Data If a defective image is created, make a backup of

Other Details

4. Refer to "3.4 Error Message

Content & Countermeasures (Page

3-4)" and perform the appropriate

countermeasure.

If unable to perform the

countermeasure.

Contact our service window with a

detailed explanation of the problem

(refer to " Contact Information").

Refer to "3.5 Countermeasures for

dealing with problems not displayed

as error messages (Page 3-70)" and

perform the appropriate

countermeasure.

If the plate is still inside the device,

remove it before doing anything else.

If unable to perform the

countermeasure.

Contact our service window with a

detailed explanation of the problem

(refer to " Contact Information").

• When trouble occurs with the device, extract a

device log etc. from the ImagePilot.

(refer to "3.3 How to Retrieve Logs")

• If a defective image is created, compile the

following log from the ImagePilot.

- App Log

- System Log

- Reader Log

- JM Log

• Did the device recover with the door opened/

closed?

• Did the breaker have to be switched OFF/

ON?

the defective image from the ImagePilot.

3.2 Recovery Operation

When an error occurs, restart this device and check if the error

occurs again. The following is an explanation on how to restart.

If the plate is still inside the device, remove it before

performing a recovery operation.

For details on how to eject a plate, refer to the operation

manual.

1. Open and close the upper door.

Opening and closing the upper Door triggers the device's

initialization process.

Opening/closing any other door on the device will also work.

The initialization process will be triggered in the same

fashion.

If a sensor, etc. has gone bad, the initialization process will be

halted, and the error will occur again.

Dealing with a Service Call Error

If a V-SYNC error occurs during the image read process, or a basic

operation failure occurs in the base board (RAM/ROM cannot be

accessed), the reader will be in Service Call Error status. Opening/

closing the door or turning the power OFF/ON will not correct the

error in this case.

If a Service Call Error (Error code 7118, 7125, 7318, etc.) occurs,

repair/replace the part that caused the error, then have a service

engineer perform the following steps for recovery.

1. Start up the Reader Settings Service Tool on an

ImagePilot connected to this device.

The [Service Tool] screen will be displayed for reader

settings.

2. Select [Reader Settings], then click the [Settings]

button for [Unit test].

3-2 REGIUS /II Service Manual

Page 37

Chapter 3 Troubleshooting

IMPORTANT

The [Unit test] screen is displayed.

3. Click the [Clear Service Call error] button.

The error will be cleared.

4. Turn the device power OFF and ON.

3.3 How to Retrieve Logs

This section describes how to retrieve logs.

Retrieve logs before powering ON/OFF.

1. Launch the reader setting service tool using Image

Pilot with this device connected.

The [Service Tool] screen for reader setting is displayed.

2. Select [Reader Setting] and click on the [Setting]

button of [Reader log].

The [Reader log] screen is displayed.

3. Click the [Get reader log] button.

The behavior depends on the Image Pilot version.

• For V1.50/1.51

The log is stored in the following location:

C:¥Konicaminolta¥kim¥Server¥ReaderSetting¥Prog¥

Pegasus¥ ~ Board Number ~ ¥Log¥

Board number example r170-0001_A1P5H1010-00050

• V1.52 or higher

Select the save destination folder from the [Browse for

Folder] screen, and click the [OK] button.

3

The log is saved in the selected folder.

3.3 How to Retrieve Logs

REGIUS /II Service Manual 3-3

Page 38

Chapter 3 Troubleshooting

3.4 Error Message Content & Countermeasures

3.4.1 70xx: Initialization Errors

Possible causes if solutions

Error

code

7000

Error Name/Description

Tray ejection detected during

initialization

When sensors are checked

upon initialization:

• Tray Sensor is OFF. (tray

ejection)

7001

3

Plate detection during

initialization

When sensors are checked

upon initialization:

• Plate Sensor is OFF.

(There is a plate.)

provided in Operation Manual

do not resolve the issue

(including reoccurrence)

• Sensor malfunction

• Deformation of detector

• Cassette not removed

• Foreign object

• No solid connection

• Disconnection

• MAIN_BOARD

malfunction

• Sensor malfunction

• Plate not removed

• Foreign object

• No solid connection

• Disconnection

• MAIN_BOARD

malfunction

(Please take the following steps to diagnose and the problem.)

1. Use the service tool to confim that the Tray Sensor is detecting the

tray.

If not, take the following steps and replace parts as required:

- Confirm that all connectors are secure, there is no deformation of

the detector, and that the spring is loaded.

Confirm that the Tray Sensor (JP26)-(JP28-1)(JP28-2)-(JP30-1)

(JP30-2)-(MCN6) is working.

- Confirm that all wires are firmly connected.

- Replace the upper insertion unit.(Sensors do not require

replacing)

2. Change the main board.

3. Replace the upper insertion unit.

1. Use the service tool to confirm that the Plate Sensor detects a plate.

If not, take the following steps and replace parts as required:

- Confirm that all connectors are secure.

Confirm that the Plate Sensor (light receiving) (JP12)-(JP11-1)

(JP11-2)-(MCN7) is working.

Confirm that the Plate Sensor (light emitting) (JP27)-(JP29-1)

(JP29-2)-(JP30-1)(JP30-2)-(MCN6) is working.

Confirm that all wires are firmly connected.

- Change the sensor.

2. Change the main board.

7002

Plate detection via V-SYNC

during initialization

When sensors are checked

upon initialization:

• V-SYNC Sensor is ON.

(There is a plate.)

• Sensor malfunction

• Deformation of detector

• Detector not securely

attached

• Plate not removed

• Foreign object

• No solid connection

• Disconnection

• MAIN_BOARD

malfunction

1. Use the service tool to confirm that the V-SYNC Sensor is working.

If not, take the following steps and replace parts as required:

- Confirm that all connectors are secure, there is no deformation of

detector, the spring is loaded, and the detector is securely

attached.

Confirm that the V-SYNC Sensor (JP32)-(JP31-1)(JP31-2)(JP36-1)(JP36-2)-(MCN5) is working.

Confirm that all wires are firmly connected.

- Change the sensor.

2. Change the main board.

Countermeasure

3.4 Error Message Content & Countermeasures

3-4 REGIUS /II Service Manual

Page 39

Error

code

7003

Error Name/Description

Cassette L/R lock detection

during initialization

When sensors are checked

upon initialization:

• Size Detection Sensors 1

to 4 are in any status other

than "no cassette

detected."

• Cassette Sensor is ON.

(There is a cassette.)

Possible causes if solutions

provided in Operation Manual

do not resolve the issue

(including reoccurrence)

• Sensor malfunction

• Deformation of detector

• Plate not removed

• Foreign object

• No solid connection

• Disconnection

• MAIN_BOARD

malfunction

Chapter 3 Troubleshooting

Countermeasure

(Please take the following steps to diagnose and the problem.)

1. Use the service tool to confirm that Size Detection Sensor 1 to 4,

Cassette Sensor and Right/Left Cassette Lock Sensor are working.

If any are not working, take the following steps and replace parts as

required:

- Confirm that all connectors are secure, there is no deformation of

the detector, and that the spring is loaded.

Confirm that Size Detection Sensor 1(JP14)-(JP16-1)(JP16-2)(MCN7) is working.

Confirm that Size Detection Sensor 2(JP15)-(JP16-1)(JP16-2)(MCN7) is working.

Confirm that Size Detection Sensor 3 (JP23)-(JP30-1)(JP30-2)(MCN6) is working.

Confirm that Size Detection Sensor 4(JP17)-(JP30-1)(JP30-2)(MCN6) is working.

Confirm that Right Cassette Lock Sensor (JP25)-(JP30-1)

(JP30-2)-(MCN6) is working.

Confirm that Left Cassette Lock Sensor (JP21)-(JP30-1)(JP30-2)(MCN6) is working.

Confirm that Cassette Sensor (JP10)-(MCN7) is working.

- Confirm that all wires are firmly connected.

- If Size Detection Sensor 1/2 is malfunctioning, replace the

sensor.

- If Size Detection Sensor 3/4, Cassette Sensor or Right/Left

Cassette Lock Sensor is malfunctioning, replace the upper

insertion unit.(Sensors do not require replacing)

2. Use the service tool to confirm that Loading NIP Motor is working.