Konica Minolta QMS 4060 Service Manual

®

QMS 4060 Print System Operation

1800463-001C

Trademarks

The following are trademarks or registe red tradem arks of their respective owners. Other

product names mentio ned in this manua l may also be trademar ks or re gistered

trademarks of their respective owners. Registered trademarks are registered in the

United States Patent and Trademark Office; some trademarks may also be registered in

other countries. QMS and the QMS logo are registered trademarks of QMS, Inc., and

Crown, the Crown seal, Q FORM, and PS Executive Seri es are trad emar ks of QM S, Inc .

PostScript is a trademark of Adobe Systems Incor porated for a page description

language and may be regist ered in cer tain jur isdictions. Th roughout this m anual,

“PostScript Level 2” is used to refer to a set of capabilities defined by Adobe Systems

for its PostScript Level 2 page description language. The se capab ilities, among others,

are implemented in thi s produc t throu gh a QM S-developed emulation that is comp atible

with Adobe's PostScript Level 2 language. Adobe/Adobe Systems Incor porated. 3Com ,

3+Open/3Com Cor poration. Aldus, Aldus PageMake r, Aldus FreeHand/Aldus

Corporation. Apple, App leTalk, EtherTalk, LaserWrite r, LocalTalk , Macintosh, TrueType/

Apple Computer, Inc. VINES/Banyan. CompuSer ve /H & R Block. DEC, DECnet, VMS /

Digital Equipment Cor poration. Phone NET/Farallon Computing, Inc. Hewlett-Packard,

HP, PCL, HP-GL, LaserJet/Hewlett-Packard Co. IBM PC, Token-Ring/International

Business Machines Corpora tion. Intel/Intel Corp oration. Microsoft, MS-DOS/Microso ft

Corporation. Novell and NetWare/Novell, Inc. QuarkXPress/Quark, Inc. TOPS/Sun

Microsystems, Inc. UNIX/UNIX Systems Laboratories.

Proprietary Statement

The digitally encoded software included with your CourageousCourageous Print System

is Copyrighted © 1998 by QMS, Inc. All Rights Re served. This software may not be

reproduced, modified, d isplayed, transferred, or copi ed in any for m or in any man ner or

on any media, in whole or in par t, withou t the express written per miss ion of QMS, Inc.

Copyright Notice

This manual is Copyrighted © 1998 by QMS, Inc., One Magnum Pass, Mobile, AL

36618. All Rights Reser ved. This manual may not be cop ied in whole or in part, no r

transferred to any other media or languag e, without the express written permission o f

QMS, Inc.

v

Contents

1 Introduction

Introduction .................................................................................. 1-2

About This Manual 1-2

Typographic Conventions 1-3

Orientation 1-4

Printer Basics ...............................................................................1-5

The QMS 4060 Print System 1-5

Printer Components 1-6

2 Consumables

Introduction .................................................................................. 2-2

Consumable Life Expectancies ..................................................2-2

Job Size and Consumable Life 2-2

Average Life Expectancies 2-5

Media ............................................................................................ 2-6

Preventing Media Jams 2-6

Loading Paper Requirements 2-6

Loading the Paper Tray 2-7

Labels: Special Considerations 2-14

Custom-Size Paper: Special Considerations 2-14

Transparencies: Special Considerations 2-15

Replacing Toner, Collector Bottle, and Cleaning Roller ........ 2-15

Toner Life 2-16

Toner Recycling 2-16

Toner Storage 2-17

Adding Toner 2-18

Replacing the Cleaning Roller and

Precharger 2-22

Replacing Developer ................................................................. 2-24

Replacing the Ozone Filter ....................................................... 2-33

Replacing the Drum Unit and Transfer Charger ..................... 2-35

Replacing the Fuser ................................................................. 2-43

Replacing the Pick Rollers ...................................................... 2-48

3 Printer Care

Introduction ................................... ...... ............. ............. ............. .. 3-2

Handling the Printer .................................................................... 3-2

Cleaning the Printer .................................................................... 3-3

Cleaning Toner Spills 3-3

Tools for Cleaning 3-4

Printer Cleaning Intervals 3-4

General Cleaning Guidelines 3-4

Cleaning the Transfer Assembly 3-5

Cleaning the Fuser Assembly 3-8

Cleaning the Reversing Unit 3-11

Cleaning the Outside of the Printer 3-12

QMS 4060 Print System Operationii

4 Printer Jams

Paper Jams ...................................................................................4-2

Paper Path 4-2

Automatic Jam Recovery 4-2

Clearing Paper Jams 4-2

Clearing Pick-Up Jams 4-5

Clearing LCIF Pick-Up Jams 4-6

4-9

4-9

Clearing a Feed Path Paper Loadi ng Jam 4-10

Clearing a Feed Path Jam in the Fuser Area 4-14

Clearing a Duplex Paper Path Jam 4-16

Clearing a Paper Ejection Jam 4-20

Clearing a Stacker Jam on the 2000-Sheet LCOS Stacker 4-20

Clearing a Paper Jam on the 3000-Sheet LCOS Stacker 4-23

Clearing CrownCopy ADF Paper Jams 4-27

5 Advanced Printing Features

Introduction .................................................................................. 5-2

High-Resolution Printing .............................................................5-2

Setting the Resolution 5-2

Printing Duplex .................................... ...... ....... ............................5-3

Automatic via a Paper Tray 5-3

Duplex Printing Tips 5-4

Tray Chaining ............ ...................................................................5-4

Setting Up Chaining Options 5-6

Collating Output ...........................................................................5-8

Chunk Collation 5-9

Advantages of Collation 5-10

Working with Status Pages .......................................................5-10

Identifying a Status Page Type 5-10

Cancelling/Ending Print Jobs ............ ...... ....... ...... ....................5-11

Cancelling a Print Job 5-12

Cancelling All Print Jobs 5-13

Ending a Print Job 5-14

Contents iii

6 Local and Remote Console

About This Chapter ..................................................................... 6-2

About Crown Consoles ............................................................... 6-2

Connecting Local Console ......................................................... 6-3

Setting Up Local Console 6-3

Starting a Remote Console Session .................................. ........ 6-4

Starting a Telnet Session 6-4

If You Cannot Start a Telnet Session 6-6

Starting a DECnet Session 6-7

Message Display and Console Modes ....................................... 6-9

Local and Remote Consoles 6-9

Message Display Mode 6-9

Console Mode 6-11

Using Remote Console ............................................................. 6-13

Console Commands .................................................................. 6 -14

User/Offline Mode Commands 6-14

Blocked Mode Commands 6-15

Admin Mode Commands 6-16

Print Job Status Information 6-17

System Information Commands 6-18

Listing Current Remote Console Sessions 6-23

Displaying the Active Jobs 6-23

Job Ordering Commands 6-25

Disk Operation Commands 6-30

System Setting Commands 6-38

System Console Mode Switching Commands 6-44

Session Termination Commands 6-47

7 Print Quality

Introduction ................................... ...... ............. ............. ............. .. 7-2

About Halftone Types ................................................................. 7-2

About Intensity ............................................................................ 7-3

About Print Density ..................................................................... 7-3

QMS 4060 Print System Operationiv

About Print Resolution ................................................................7-4

8 CrownView Printer Web

Page

CrownView Printer Web Page .....................................................8-2

Setting up the Printer Web Page 8-2

Printer Home Page 8-7

9 Troubleshooting Printer

Problems

Introduction .................................................................................. 9-2

Status Messages ..........................................................................9-2

Service Messages 9-11

HP-GL Error Codes and PCL Error Codes 9-19

Internal Hard Disk Problems .....................................................9-20

Hard disk Failure Messages 9-20

Reformatting the Drive and Reloading System Software 9-20

Testing PC Printer Communication ................................... ...... .9 -24

Creating the Test File 9-24

Sending the Test File 9-25

Miscellaneous Problems ...........................................................9-26

No Advanced Status Page’ 9-26

No Start-up Page 9-26

Paper Jam Message Stays On 9-27

Printer Resets 9-27

PostScript Errors 9-27

CrownNet Problems ............................ .......................................9-28

Windows Driver Problems .........................................................9-28

Printer Description Files 9-28

Output Problems ........................................................................9-29

Not All Pages Print 9-29

Contents v

Paper Jams Always Occur 9-29

Print Quality Problems .............................................................. 9-30

Enabling Toner Recycling Mode 9-31

Recovering From Toner Recyclin g Mode 9-31

Image Defects 9-32

Typical Page Sample 9-33

Background on the Page 9-34

Black or Dark Pages 9-36

Blank Pages 9-38

Blank Bands on the Page 9-40

Blurred Images or Characters on the Page 9-42

Dark Specks, Lines, or Dark Areas 9-44

Dark Lines on the Page 9-46

Fusing Problems on the Page 9-48

Light Print 9-50

Light Print with Background 9-52

Light Bands 9-54

Light Streaks 9-56

Overtoned Print 9-58

Residual Images on the Page 9-60

Voids or White Spots on the Page 9-62

Misregistration of the Page 9-64

Skewed Printing 9-66

Troubleshooting CrownCopy ................................................... 9-67

Placing a Service Call ............................................................... 9-68

A QMS Customer Support

Sources of Support ............... .............................................. ...... ..A-2

Your QMS Vendor A-2

Your Application Vendor A-2

Q-FAX A-2

CompuServe A-3

Internet A-3

QMS Customer Response Center (CRC) A-3

QMS World-wide Offices .............................................................A-5

QMS 4060 Print System Operationvi

B Configuration

Menu

Introduction ................................................................................. B-2

Menu Chart Conventions B-2

Installation Menu B-3

Operator Control Menu B-4

Administration Menu B-5

C Repacking the Printer

Introduction ................................................................................. C-2

Repacking Consumables ........................................................... C-2

Inserting Shipping Restraints .................................................. C-17

Reinstalling Shipping Restraints C-17

Final Repacking Steps C-20

Repacking the Options ............................................................. C-27

v

Contents vii

1

Introduction

In This Chapter . . .

n “Introduction” on page 1-2

n “Typographic Conventions” on page 1-3

n “Printer Basics” on page 1-5

n “The QMS 4060 Print System” on page 1-5

n “Printer Components” on page 1-6

Introduction

Introduction

This manual provides information on installing consumables such as

paper and toner. You’ll also find information on advanced printing features, printer care, print quality , and troubleshooting. Use this guide in

conjunction with your other QMS 4060 Print System documentation.

This chapter gives you a brief overview of this manual.

About This Manual

The information in this manual is divided into the following sections:

Introduction

1

Consumables

2

Printer Care

3

Printer Jams

4

Advanced

5

Printing Features

Local and

6

Remote Console

Print Quality

7

Provides an overview of this guide.

Describes the Paper that’s best suited

for your printer; how to load paper,

labels, transparencies; and how to

replace the toner, developer, fuser,

rollers, and print drum.

Describes how to handle and clean

the printer.

Provides you with detailed procedures

for clearing jams.

Explains how to print duplex, chain

trays, collate output, print a status

page, cancel a print job, and end a

print job.

Explains how to use the local console

port and remote console over a

network.

Gives information on how to improve

print quality through adjustments of

print density and printer resolution.

QMS 4060 Print System Operation1-2

Introduction

Crownview

8

Printer Webpage

Troubleshooting

9

Printer Problems

QMS Customer

A

Support

Configuration

B

Menu

Repacking the

C

Printer

Allows you to monitor printer

consumables, configure the printer to

send you email, and access

information that is norm al ly available

only by printing a status page.

Provides paper jam prevention tips,

explains how to locate and clear paper

jams, lists printer status messages,

outlines printer and print quality

problems and solutions, and describes

how to place a service call.

Provides product sales and support

telephone numbers and describes

how to communicate with QMS

through CompuServe, the Internet,

and Q-FAX

Provides you with a graphical

flowchart of the configuration menu.

Provides you with detailed procedures

for repacking the printer and options

for shipping.

.

Typographic Conventions

The following typographic conventions are used in this manual:

Mixed-Case

Courier

Mixed-Case

Italic

Courier

UPPERCASE

COURIER

lowercase bold PostScript operators and DOS commands

Introduction

Text you type, and messages and information

displayed on the screen

Variable text you type; replace the italicized

word(s) with information specific to your printer or

computer

Information displayed in the printer message

window

1-3

Introduction

lowercase italic

UPPERCASE File and utility names

↵ Press the Enter key (PC) or Return key

^ Press and hold down the Ctrl key (PC)

» Note:

Notes contain tips, extra information, or important information

Variable information in text

(Macintosh)

In Adobe Acrobat PDF versions of the manual,

click to play a QuickTime video clip of the

procedure described in the text

that deserves emphasis or reiteration.

▲ Caution:

Cautions present information that you need to know to avoid

equipment damage, process failure, or extreme annoyance.

M WARNING!

Warnings indicate the possibility of personal injury if a

specific procedure is not performed exactly as described in the

manual.

ACHTUNG!

Bitte halten Sie sich exakt an die im Handbuch

beschriebene Vorgehensweise, da sonst Verletzungsgefahr

bestehen könnte.

Orientation

All instructions in this and the other QMS manuals are referenced to

the front of the printer. F or e xample, if the installation instructions say

that the LCOS is on the left side of the printer, then it means you are

facing the front of the printer and the LCOS is on your left.

QMS 4060 Print System Operation1-4

Printer Basics

This section provides you with some basic introductory concepts on

the printer. These basic concepts will help you when you are trying

some of the more advanced procedures in the following chapters.

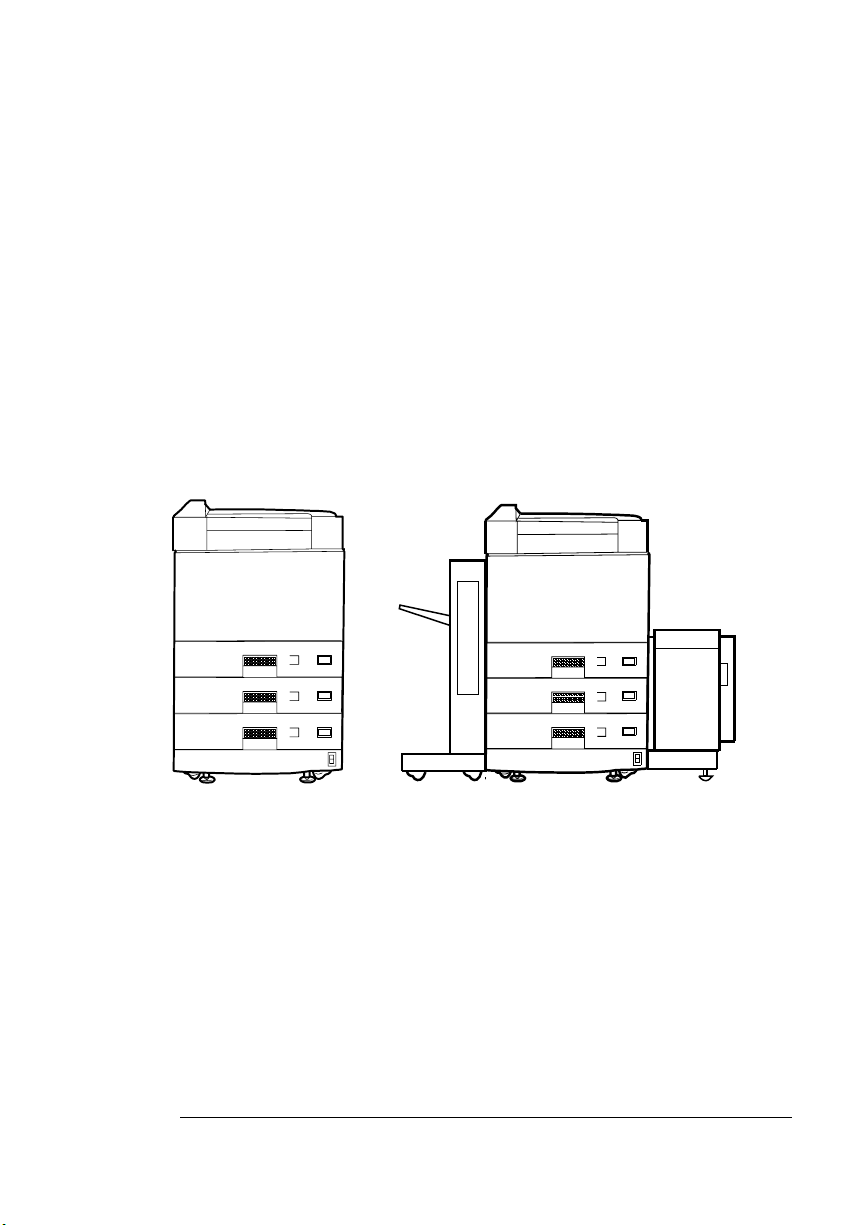

The QMS 4060 Print System

Your printer may or may not have installed the optional LCIF (largecapacity input feeder) or LCOS (large-capacity output stacker) paper

handling units. If you decide to order these units later, see the

manual for more information and installation instructions.

Printer Basics

Options

QMS 4060 QMS 4060

Some basic features of the printer are

n Paper input capacity of 1500 sheets, 4500 with the LCIF

n Paper stacking capacity of 500 sheets, 2500 with the 2K LCOS

n Paper stacking capacity of 500 sheets, 3500 with the 3K LCOS

n Consumable replacement by the operator

n Duplex printin g

Introduction

LCIFLCOS

1-5

Printer Basics

n Energy Star compliance

n Page recovery after printer jams

n Easy jam removal

n User friendly control panel

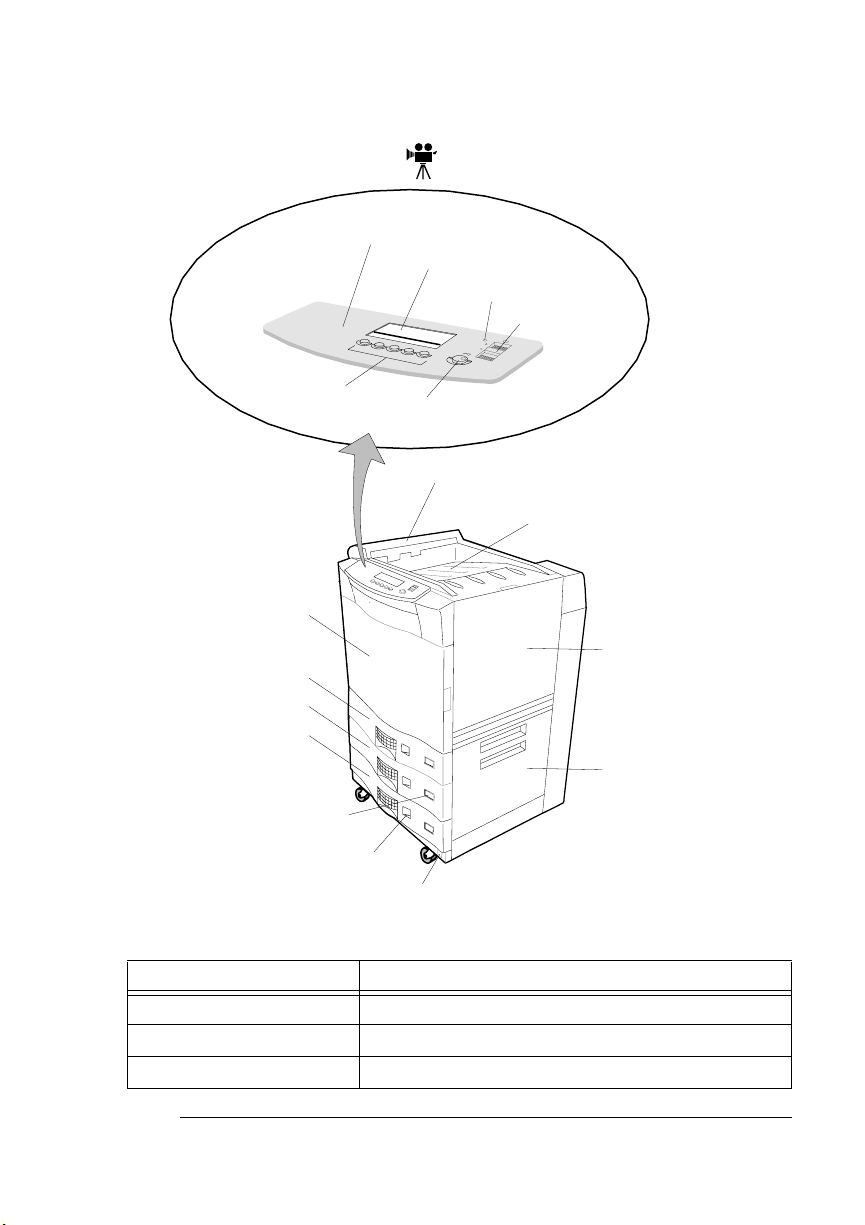

Printer Components

Refer to the illustrations and tables in this section when trying to find

your way around the printer.

QMS 4060 Print System Operation1-6

Right Frontal View

ControlControl

PanelPanel

Printer Basics

DisplayDisplay

Power IndicatorPower Indicator

On-Off SwitchOn-Off Switch

FunctionFunction

ButtonsButtons

Front Door

Upper Tray

Middle Tray

Lower Tray

Paper Size Indicator

Paper Level

Indicators

ContrastContrast

ControlControl

Ejection Unit

Output Tray

UpperRight

Cover

LowerRight

Cover

Main Power Switch

Printer Component Function

Control Panel The user interface to printer functions.

Contrast Control Controls the contrast of the LCD panel.

Function Buttons Five buttons for printer configuration.

Introduction

1-7

Printer Basics

Printer Component Function

Power Indicator Lights when the power is on.

On-Off Switch Turns the printer on or off.

Ejection Unit A door that ejects paper to the output tray.

Output Tray Holds 500 sheets of paper.

Upper-Right Cover Access for adding toner and deve lop er.

Lower-Right Cover Access for clearing feed jams.

Main Power Switch Main electrical power switch.

Paper Level Indicators Shows how much paper is left in tray.

Paper Size Indicator Shows what size paper tray is set to.

Lower Tray 500-sheet lower tray.

Middle Tray 500-sheet middle tray.

Upper Tray 500-sheet upper tray.

Front Door Access to internal components.

QMS 4060 Print System Operation1-8

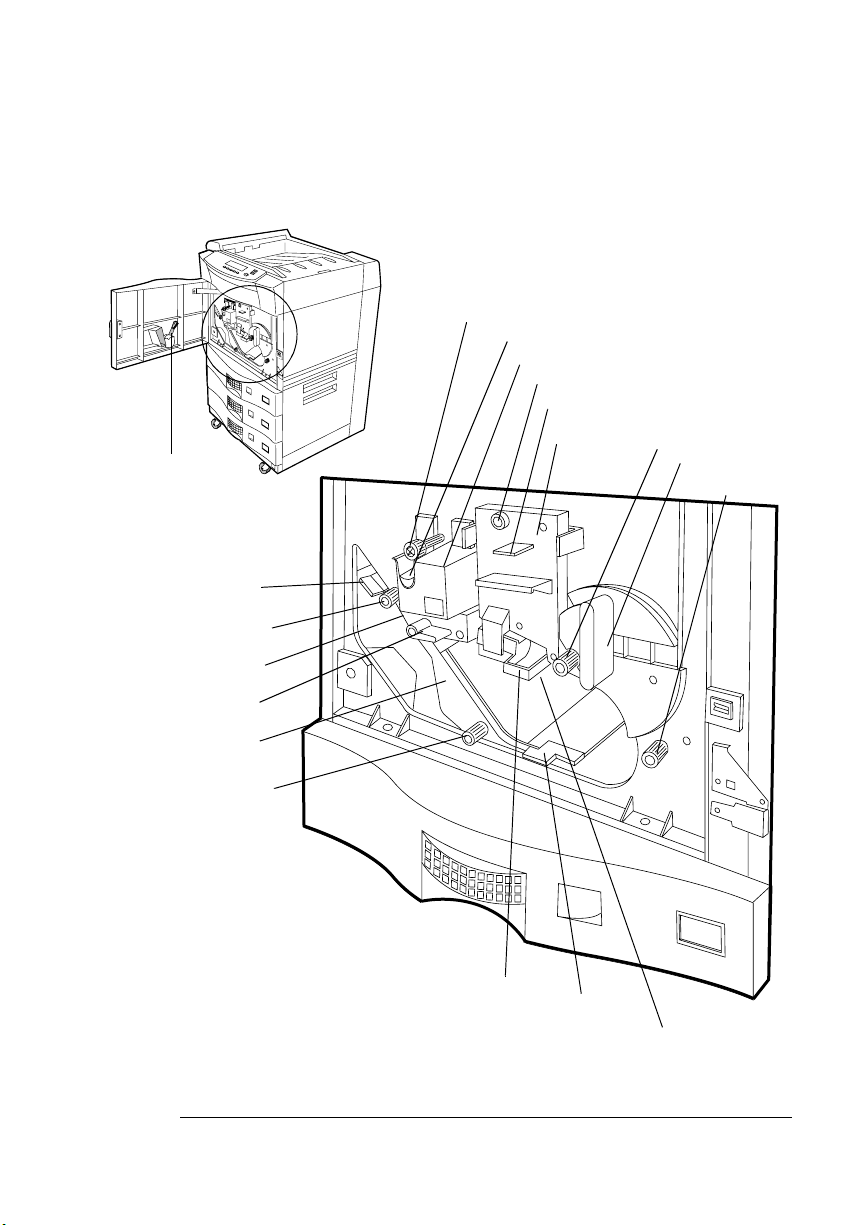

Inside the Front Door

....

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Cleaning Brush

Lever 5

Decurler Roller Knob

Fuser Lock Knob

Cleaning Roller

Fuser Unit

Drum Unit Lock Knob

Precharger Cleaner

Drum Unit

Printer Basics

Knob 2

Lever b1

Knob 1

Decurler Lever

Lever 4

Duplex Unit

Duplex Roller Knob

Introduction

Handle 3

LTR

Lever 6

Transfer Assembly Guide

1-9

Printer Basics

Printer Component Function

Fuser Lock Knob Locks the fuser unit in place.

Cleaning Roller Collects excess toner from the drum.

Fuser Unit Applies heat and pressure to melt the toner to

the paper.

Drum Unit Lock Knob Locks the drum unit in place.

Precharger Cleaner Used to clean the precharger for print quality.

Drum Unit Contains the precharger, cleaner, and

photosensitive drum.

Knob 2 Used for clearing jams as paper exits the paper

trays and enters the drum area.

Lever b1 Used to lock internal components in the paper

path.

Knob 1 Used for clearing jams as paper exits the paper

trays and enters the drum area.

Transfer Assembly Guide Transfers the print image from the drum to the

paper.

Lever 6 Used for clearing jams.

Handle 3 Used to hold the transfer assembly guide in

place.

Duplex Roller Knob Used to clear jams in the duplex area.

Duplex Unit For two-sided printing.

Lever 4 Releases tension on paper in the fuser area to

clear jams.

Decurler Lever Access to jammed paper in the decurler area.

Decurler Roller Knob Used to clear jams in the decurler area.

Lever 5 Access to jammed paper in the reverser area.

Cleaning Brush Used to clean the transfer assembly.

QMS 4060 Print System Operation1-10

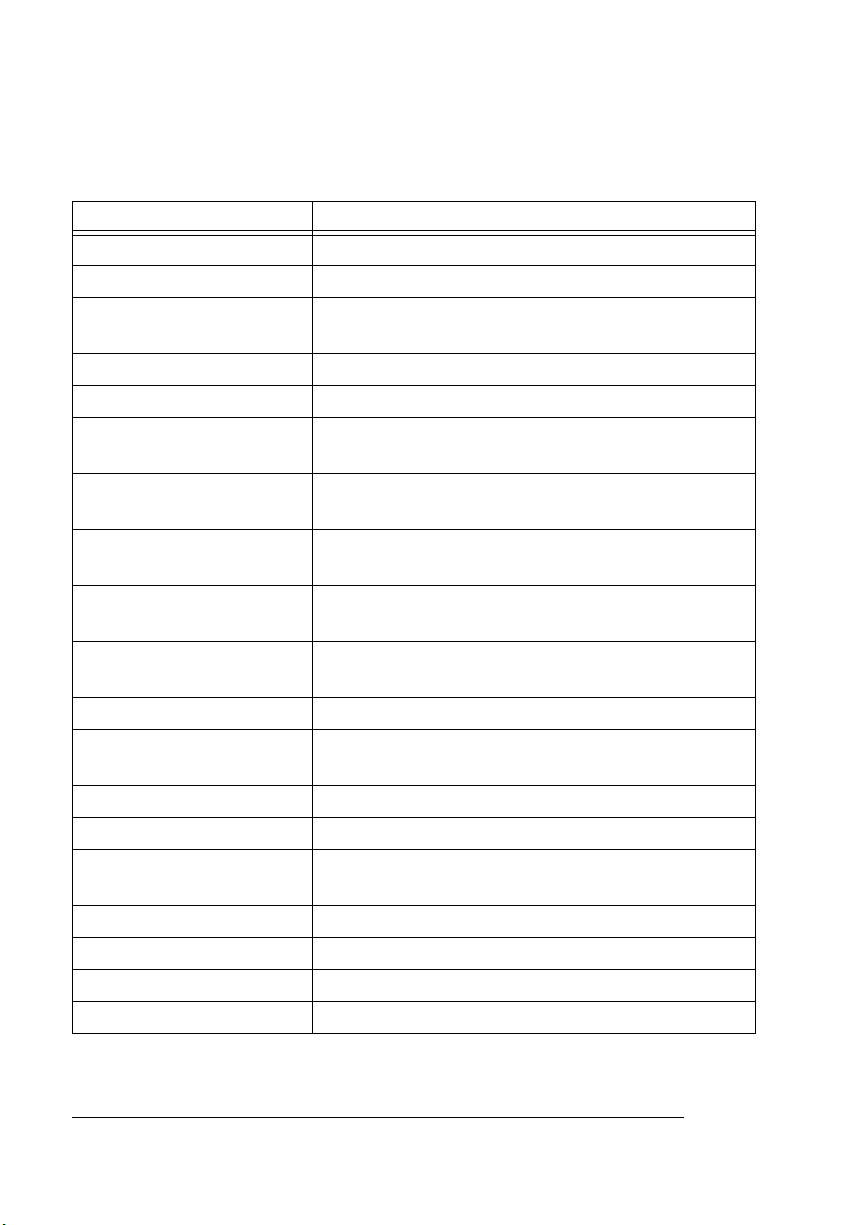

Under the Upper Right Cover

r

Toner Fill Lid

Printer Basics

Developer Fill Lid

Toner

Hopper

Developer

Unit

Printer Component Function

Toner Fill Lid Open to add toner.

Developer Fill Lid Open to add developer.

Toner Collector Bottle Used to collect waste toner.

Developer Collector

Bottle

Upper-Right Cover Access cover to toner and developer units.

Developer Unit Contains a supply of developer, when mixed with

Toner Hopper Contains a supply of toner. The control panel

Used to collect used developer.

toner, forms the image on the photosensitive

drum. The control pan el informs you when

developer is low or out.

informs you when toner is low or out.

Toner Collector Bottle

Developer Collecto

Bottle

Upper Right-Cover

Introduction

1-11

Printer Basics

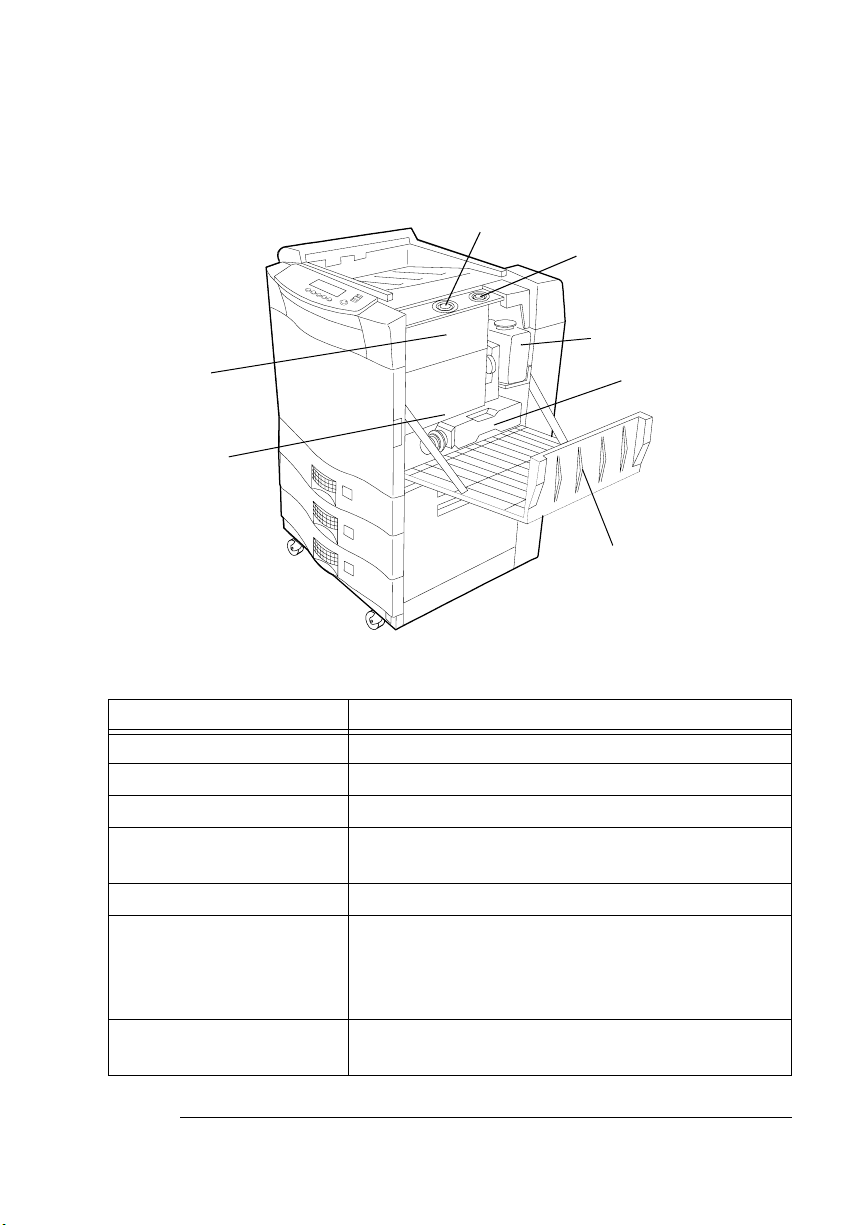

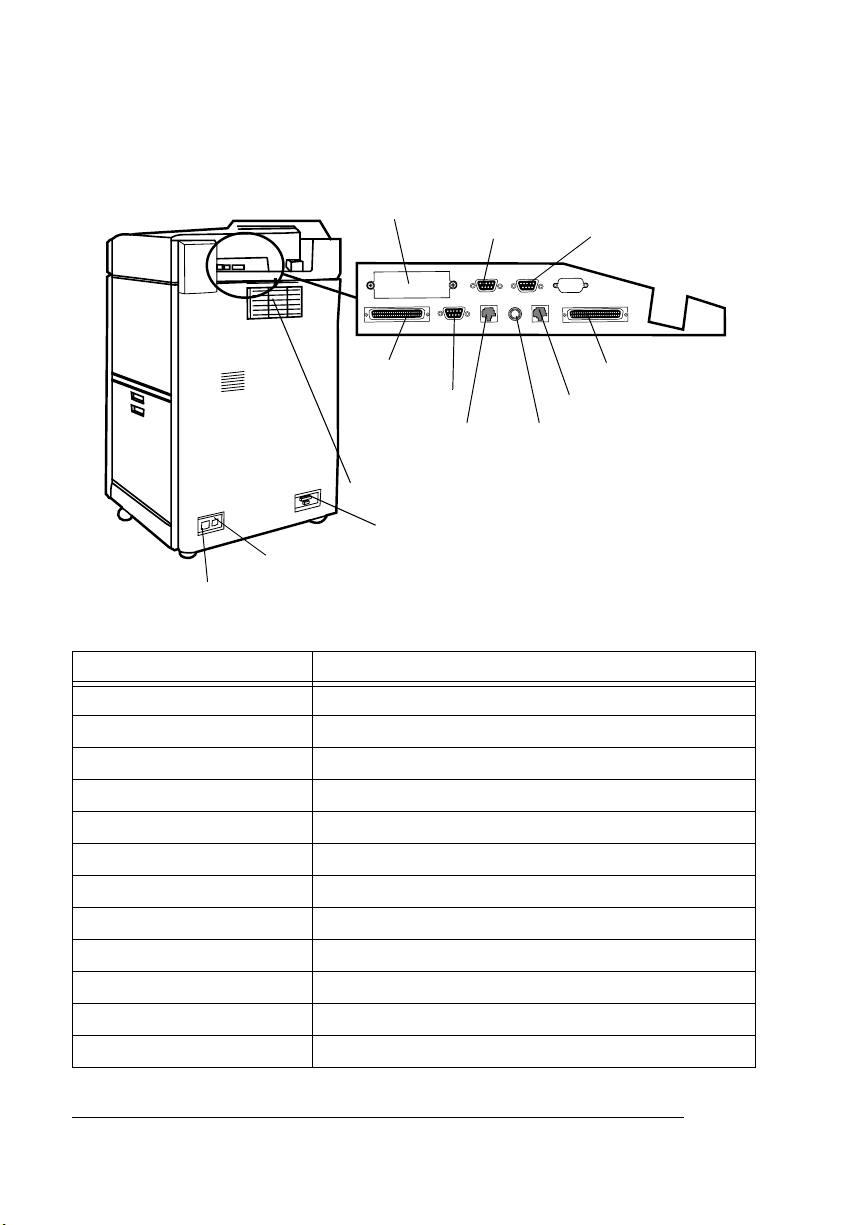

Rear of the Printer

Optional I/O

Optional

Serial Port

Local Console

Port

SCSI

Security Key

BuzzBox

Ozone Filter

LCOS Connector

AC Power Connector

LCIF Connector

Printer Component Function

Optional I/O Optional network port.

Optional Serial Port Optional serial interface.

Local Console Port Serial console port for printer configuration.

1284 Parallel Standard parallel port.

Ethernet RJ-45 10BaseT port.

Ethernet Coax 10Base2 port.

BuzzBox Audio alarm option.

SCSI For added disk drives or CrownCopy.

Ozone Filter Filters ozone produced in print process.

LCOS Connector Used for optional LCOS.

AC Power Connector Power input for printer.

LCIF Connector Used for optional LCIF.

Ethernet Coax

1284 Parallel

Ethernet RJ-45

QMS 4060 Print System Operation1-12

Printer Basics

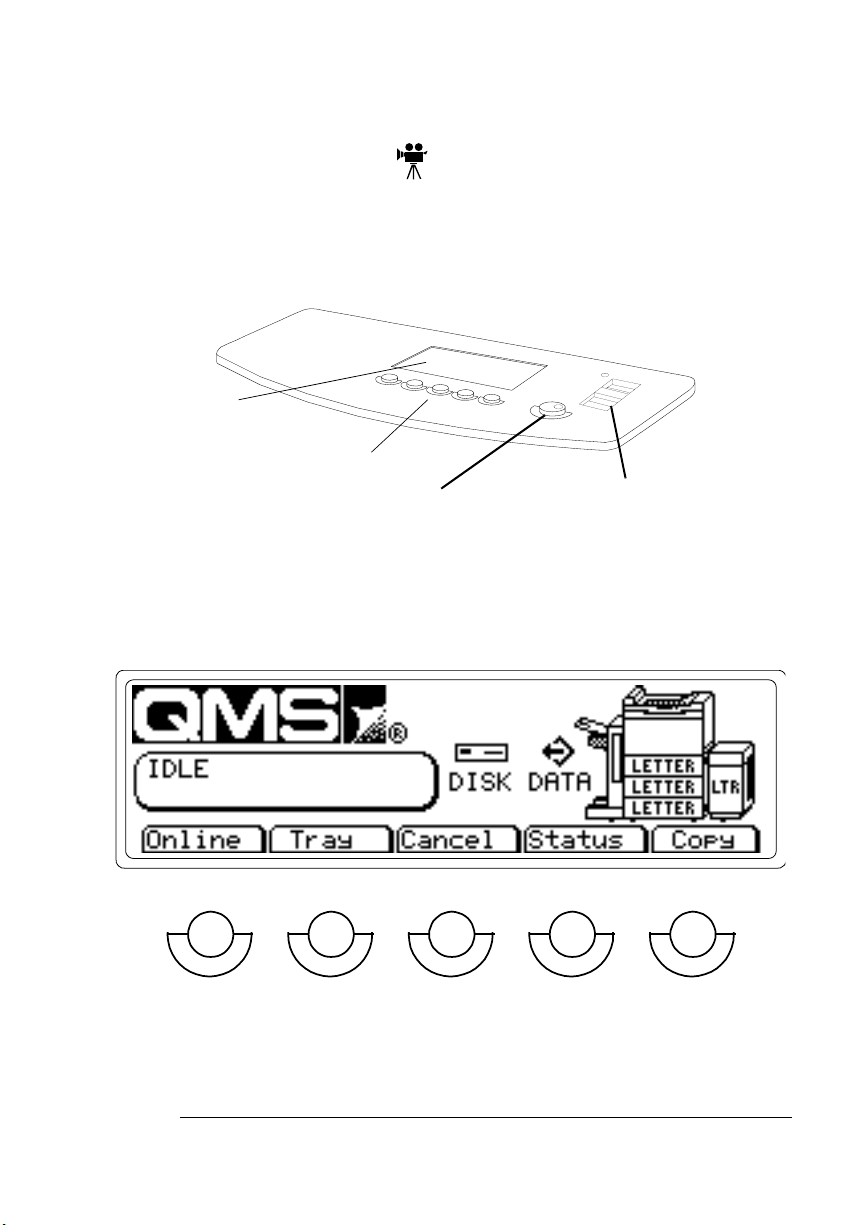

The Control Panel

The control panel for your QMS 4060 Print System consists of 5 control buttons and a backlit LCD display with a contrast control. The

LCD display contains graphical and textual information on printer status and control button functions.

LCD Display

Control Buttons

Contrast Control

The control buttons change function as you take the printer off line or

when you access menu selections. The following sections will help

you identify control panel elements and show you how to operate the

control panel.

On-Off Button

Introduction

1-13

Printer Basics

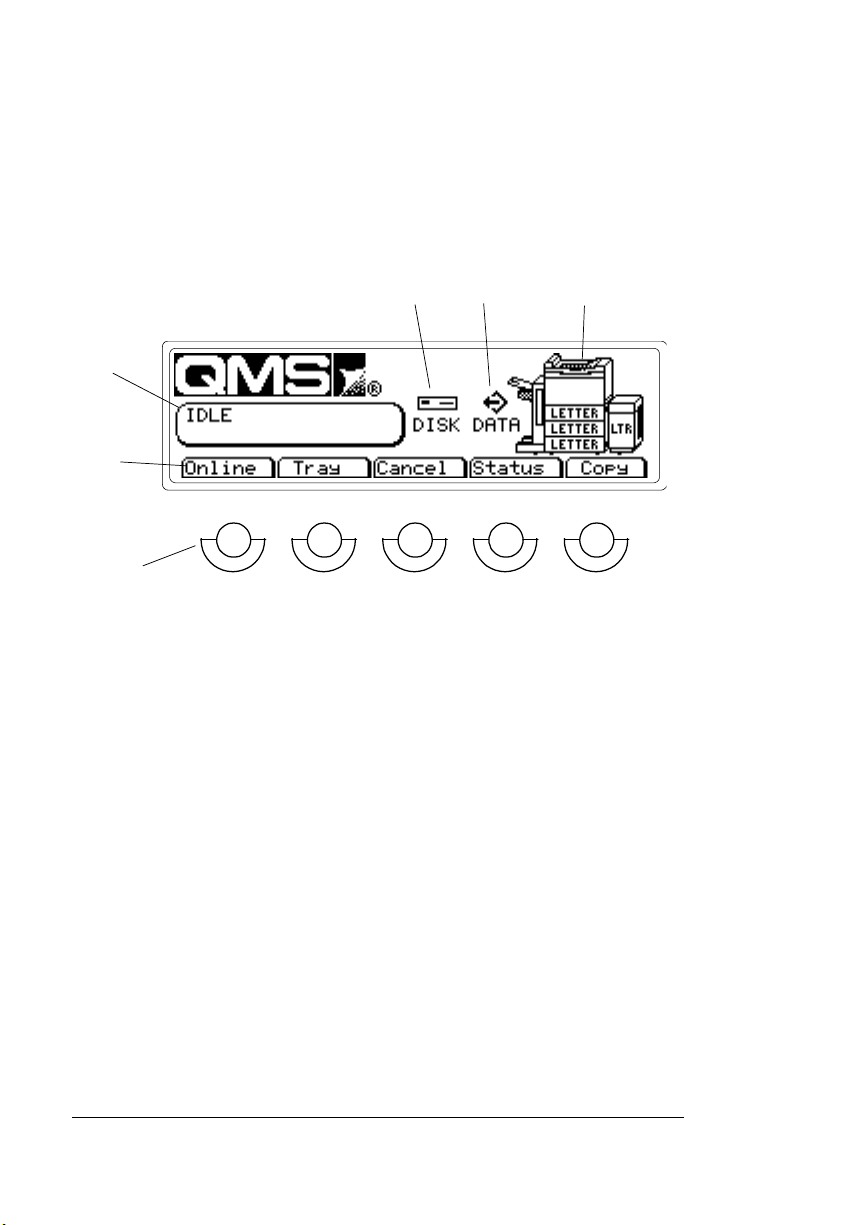

Control Panel Functions

This illustration shows the control panel with the elements numbered.

See the list below the illustration for an explanation of the element.

4

5

6

1

2

3

1 This is the printer message window. This provides status mes-

sages, error messages, and menu configuration information.

2 This indicates the present function of each control button below

the label.

3 These are the five control buttons.

4 The Disk symbol turns on whenever the printer is accessing the

internal hard disk. Otherwise this symbol will not appear.

5 The Data symbol flashes on and off periodically when the printer

is receiving data from the interfaces. Otherwise, this symbol will

not appear.

6 The printer graphic shows the type of paper set up for the three

input trays. The currently selected tray is highlighted. If the

optional high-capacity input bin or the outp ut stacker is installed,

then the graphic shows these units attached.

v

QMS 4060 Print System Operation1-14

2

Consumables

In This Chapter . . .

n “Consumable Life Expectancies” on page 2-2

n “Media” on page 2-6

n “Replacing Toner, Collector Bottle , and Cleaning Roller” on page 2-15

n “Replacing Developer” on page 2-24

n “Replacing the Ozone Filter” on page 2-33

n “Replacing the Drum Unit and Transfer Charger” on page 2-35

n “Replacing the Fuser” on page 2-43

n “Replacing the Pick Rollers” on page 2-48

Introduction

Introduction

This chapter covers information on the handling of printer consumables, such as paper, toner, developer, drum unit, fuser, and pick-up

rollers.

Consumable Life Expectancies

Job Size and Consumable Life

Your 4060 Print System is designed as a high-volume, network print

system that provides low cost-per-page printing and high-quality output. There are some factors that can directly affect the life of some

consumables and thus affect your cost per page.

This section explains these factors and gives you information to allow

you to customize your printing environment so that you can achieve

the lowest cost and longest life on your consumables.

Print Jobs

Your QMS 4060 Print System will actually work more efficiently when

continuously printing. The reason for this fact is that the printer has to

mechanically prepare itself for printing before and after every print

message it receives from the host computer. The amount of preparation before and after printing is the same for a 1-page job as for a 100page job. The efficiency improvement for the drum unit comparing

these two jobs would be from 12.5% for a 1-page job to 93% for a

100-page job. Use the following charts and tables to help you plan

your jobs and host printing environment.

» Note:

The units used in these charts are “faces.” Faces are counted

as the front and back of each page printed. For simplex printing, the

number of faces equals the number of pages. For duplex printing, the

number of faces is twice the number of pages printed.

QMS 4060 Print System Operation2-2

Consumable Life

Expectancies

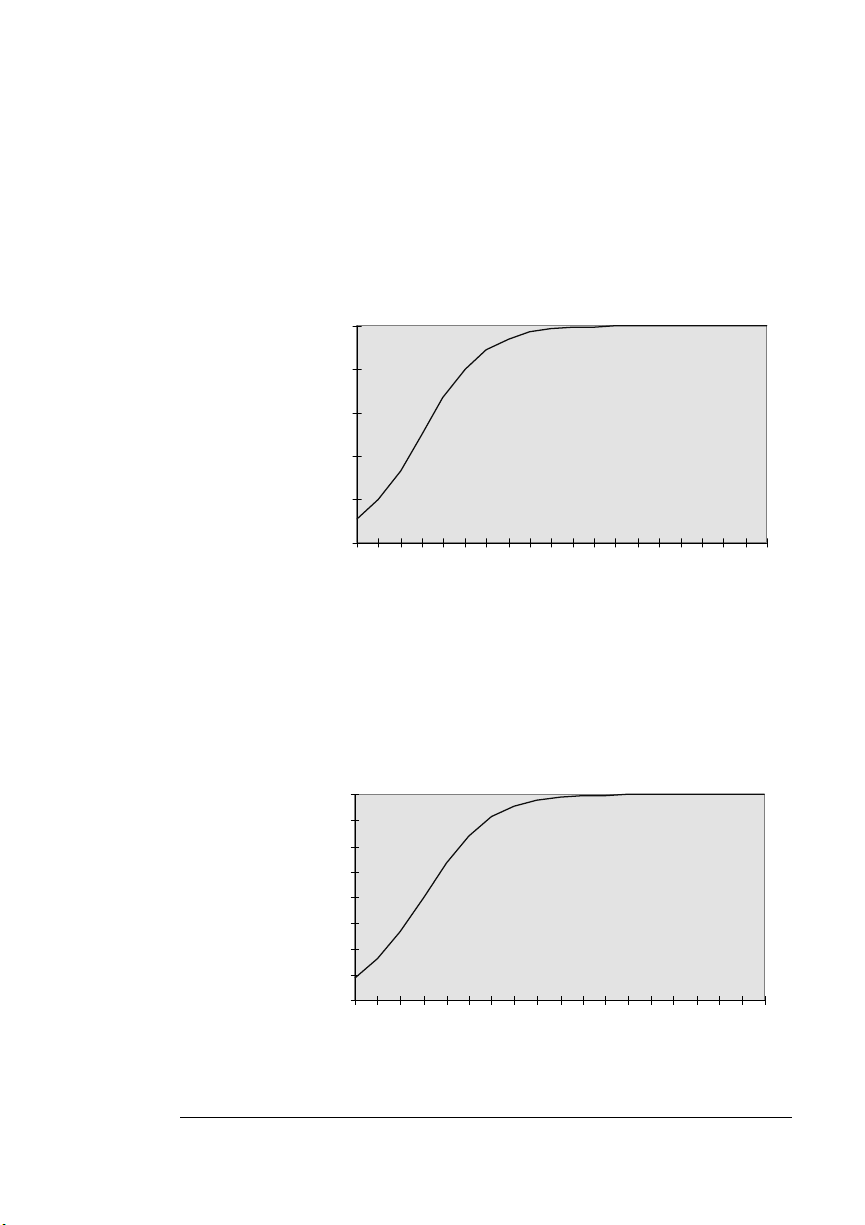

Drum Life

The drum unit rotates before and after each print operation to properly prepare itself for printing. Because of this, the drum unit will actually last longer if you continuously print jobs. The chart below

compares average printing output with drum unit life.

250000

200000

Drum

Life

Unit

150000

100000

(in faces)

50000

0

1

4

16

64

256

1024

4096

16384

Average Print Output (in faces)

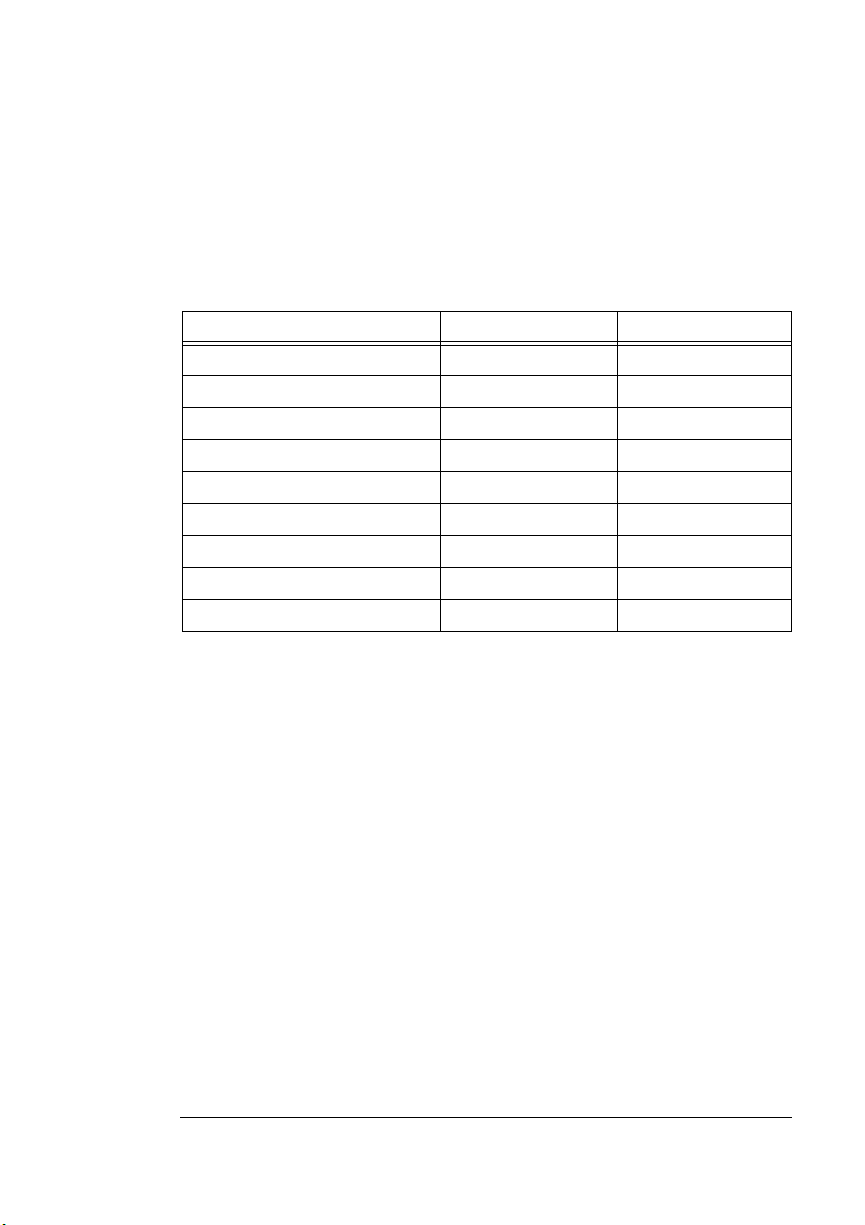

Developer Life

Since the developer is also used during these preparatory rotations of

the print drum, its life can also be affected by a v er age printing output.

The chart below compares average printing output with developer life.

160000

140000

Developer

Life

(in faces)

120000

100000

80000

60000

40000

20000

0

1

4

16

64

256

1024

4096

16384

Average Print Output (in faces)

65536

65536

160000

160000

Consumables

2-3

Consumable Life

Expectancies

Tips for Extending Consumable Life

As you check these charts, you can see that increasing the continuous printing output can greatly extend the life of the drum unit and

developer. For example, if your average printing output is 16 faces,

the charts show you that you can expect approximately 160,000 faces

printed for the drum unit and 105,000 faces printed for the developer.

Howev er, if you increase your average printing output to 32 faces, the

charts show you that you could expect approximately 190,000 faces

printed for the drum unit and 123,000 faces printed for the developer.

» Note:

The complexity of your print job can also affect the printer

speed and consumable life. Very complex graphics and fonts on the

page can slow down the printer controller and the printer speed.

Although the QMS 4060 uses a high performance controller with a

state of the art processor, even its performance can be affected by

very complex jobs.

Here’s a short list of tips for extending consumable life expectancies:

n Reduce the number of very small jobs.

n Fill the trays before printing large cycles.

n Use the optional LCIF and LCOS to prevent frequent reloading

and unloading of paper.

n If you print smaller jobs frequently from a network, set up your

host to queue several jobs and group them before sending them

to the printer.

n Manage you printing requirements to reduce the number of times

the printer starts and stops.

» Note:

The selected input tray can be reloaded when it runs out of

paper if the printer chains to one of the other trays. The printer will

continue feeding paper from the other tray while you are filling the

selected input tray and switch back to it after it is reloaded.

QMS 4060 Print System Operation2-4

Consumable Life

Expectancies

Average Life Expectancies

Use the following table as a guideline for life expectancies for each

consumable. Keep in mind that the life expectancy of each consumable depends on printing variables, such as page coverage, j ob size,

paper size, and printer operating condition.

Consumable Maximum Life Average Life

Toner (1 bottle) 20,000 faces 18,000 faces

Developer (1 bottle) 160,000 faces 114,000 faces

Drum Unit 250,000 faces 178,500 faces

Transfer Charger 250,000 faces 178,500 faces

Fuser 300,000 faces 300,000 faces

Cleaning Roller 40,000 faces 36,000 faces

Ozone Filter 320,000 faces 320,000 faces

Waste Toner Bottle 20,000 faces 18,000 faces

Pick Rollers 500,000 faces 500,000 faces

» Note:

All maximum life figures are based on continuous printing with

4% toner coverage on A4/Letter paper. Your figures will vary

depending on job size, toner coverage, and size of paper. “Faces”

includes printing duplex. Therefore, for 1 letter-size page that is

printed duplex, you would have 2 faces.

Consumables

2-5

Media

Media

Preventing Media Jams

There are several things you can do to reduce the occurrence of

media jams.

n Use paper, labels, and transparencies that match the printer

specifications. See appendix B, “Technical Specifications,” in the

Reference

n If you have problems with double feeding, remove the paper from

the tray or input bin and fan the edges. The sheets may be sticking together.

guide.

» Note:

n Print paper must be stored away from moisture and humidity.

n Refer to the table in the next section for loading paper

n If none of the above relieves paper jamming, notify your vendor.

Do not fan transparencies since this causes static.

Recommended storage temperature and humidity are 32°-95°F/

0°-35°C and 20%-80% RH for paper sealed in cartons. The recommended storage temperature and humidity for paper in

opened car tons are 59°-77°F/15°-25°C and 40%-50% RH.

requirements.

Loading Paper Requirements

When loading paper, you should note the direction of the arrow on the

manufacturer’s end-label. This arrow identifies the face side of the

paper.

Inspect the paper for indented or interlocked edges, bent corners,

wrinkled sheets and excess glue from the wrapper. Always discard

the top and bottom sheets in case glue from the wrapper has leaked

upon them.

QMS 4060 Print System Operation2-6

Loading...

Loading...