Page 1

®

QMS 1725E Print System Operation

1800386-001B

Page 2

Trademarks

The following are tradema rks or registered trademarks of their respective ow ners.

Other product names m entioned in this m anual may a lso be trade marks or reg istered

trademarks of their resp ective owners. Re gistered trademar ks are register ed in the

United States Patent and Trademark Office; some trademarks ma y also be re gistered in

other countries. QMS and the QMS logo are r egistered tradema rks of QMS, Inc., and

Crown, the Crown sea l, and PS Execu tive Series are trademarks of QMS, Inc.

PostScript is a trademark of Adobe Sys tems Incor porated for a pa ge description

language and may b e registered in cer tain jurisdiction s. Througho ut this manual,

“PostScript Level 2” is use d to refer to a set of capabilitie s define d by Adobe System s

for its PostScript Level 2 p age description la nguag e. Thes e c apabili ti es, a mong others,

are implemented in this produ ct thr ough a Q MS-dev eloped emulation that is compatib le

with Adobe's PostScript Level 2 la nguag e. Adobe/Adobe Systems Inc or porated. 3C om,

3+Open/3Com Corpora tion. Aldus, Aldu s PageMaker, Aldus FreeHand/A ldus

Corporation. Apple, AppleTalk, EtherTalk, LaserWriter, LocalTalk, Macintosh, TrueType/

Apple Computer, Inc. VINES/Banyan. CompuSe rve /H & R Block. DEC, DEC net, VMS/

Digital Equipment Corporation. P honeNE T/Farallon Comp uting, Inc. Hewlett-P ackard,

HP, PCL, HP-GL, LaserJet/Hewlett-Packar d Co. IBM PC, Token-Ring/International

Business Machines Corporation. Intel/Intel Co rporation. Microsoft, MS-DOS/Mi crosoft

Corporation. Novell and N etWare/Novell, Inc. QuarkXPr ess/Quark, Inc. TOPS/Sun

Microsystems, Inc . UNIX/UNIX System s Labor atories.

Proprietary Statement

The digitally encoded software included w ith your QMS 172 5E Print System is

Copyrighted © 1995 by QM S, Inc. All Rights R eserved. This software may not be

reproduced, modified, d isplay ed, tr ans ferred, or cop ied in any form or in any manner or

on any media, in whole or in par t, without the express written permiss ion of QMS, Inc.

Copyright Notice

This manual is Copyrighted © 1995 by QM S, Inc., One Mag num Pass, Mob ile, AL

36618. All Rights Reserve d. This manual m ay not be copie d in whole or in pa rt, nor

transferred to any other me dia or language, w ithout the express written permiss ion of

QMS, Inc.

Page 3

Contents

1 Introduction

Introduction ......................................... ..........................................1-2

Abo u t Th is Guide ... ..................... . ....................................... . ......... 1-2

Typographic Conventions 1-3

2 Consumables

Introduction ......................................... ..........................................2-2

Preventing Media Jams ...............................................................2-2

About Paper .... ... .... ... ...... . ...... ... ... .... ... ...... . ..... .... ... .... ... ...... ... ... ....2-3

Paper Sizes 2-3

Paper Storage 2-4

Paper Feeding .......... ....... ...... ..... ..... ... ....... ..... ....... ...... ... ..... ..... ....2-5

Page 4

Face-up Output Bin ........................... .............. ..... .............. ....... .. 2-6

Manual Feed ................................................................................. 2-7

Printing Tran spa renc ies .................. ..... ..... ..... ..... ....... ...... ..... ... .. 2-8

Printing La b e l s ... ............................... . ................................ . ......... 2- 9

Printing Envelopes ...................................................................... 2-9

Formatting Data for Envelopes 2-10

Printing a Single Envelope 2-10

The Optional Envelope Cassette 2-11

Using Toner Cartrid ges .. ....... ....... ....... ....... ....... ......... ....... ....... . 2-11

When to Replace the To ner Cartridge 2-11

Handling the Toner Cartridge 2-12

Installing the Toner Cartridge .................................................. 2-13

3 Advanced Printing Features

Introduction................................................................................... 3-2

High-Resolutio n Printin g ............................... ...... .............. ....... .. 3-2

High-Resolution Printing and Duplexing 3-2

Cassette Chaining ....................................................................... 3-3

Collating Ou tput .................................................... ......................3-4

Working with S tatus Pa ges . ..... ..... ..... ..... ....... ..... ...... ..... ... ....... .. 3-5

Identifying a Status Page Type 3-5

Printing a Status Page 3-6

Cancelling/Ending Print Jobs ..................................................... 3-6

Cancelling a Print Job 3-7

Ending a Print Job 3-8

4 Printer Care

Introduction................................................................................... 4-2

Handling the Printer .................................................................... 4-2

QMS 1725E Print System Op e rati o nii

Page 5

Keeping the Printer Clean ........................ ............ ................... ....4 -3

Cleaning the Anti-Static Teeth 4-3

Cleaning the Transfer-Guide Lock-Tray and Strip 4-5

Cleaning the Media-Feed-Guide Area 4-6

5 Print Quality

Introduction ...................................................................................5-2

About Print Density . ..... ......... ...... ....... ....... ..... ....... ....... ....... ....... ..5 -2

About Gamma Cor recti on .......... ....... ......... ....... ....... ......... ...... ....5-3

Changing Print Resolution ..........................................................5-4

Setting Default Resolution 5-5

6 Troubleshooting Printer

Problems

Introduction ..................... ........ ..... ....... ....... ......... ......... ........ ..... ....6-2

Status Messages ...... .................................................... ................6 -2

Service Messages 6-4

HP-GL and PCL Error Codes 6-5

PostScript Er rors ............ ....... ..... ...... ..... ..... ..... ..... ....... ...... ..... .....6-5

Printer Problem Checklist .......... .............. ................... ............ ....6 -6

Media Jams ...................................................................................6- 8

Locations 6-8

Clearing an Input Bin Media Jam 6-9

Clearing an Image-Transfer Area Media Jam 6-11

Clearing a Fuser Assembly Area Media Jam 6-12

Clearing an Output Bin Media Jam 6-14

Clearing a Duplexer Media Jam 6-15

Problem Descriptions ................................................................6-16

Paper Jam Message Stays On 6-16

Data Indicator Stays Lit 6-16

No Advanced Status Page 6-17

iii

Page 6

No Start-up Page 6-17

Printer Resets 6-17

Blank Pages 6-18

Not All Pages Print 6-18

Printer Will Not Duplex 6-19

Print Quality Problems ................................. ............................. 6-19

Printer Will Not Print 600 dpi 6-20

Image Defects ............................................................................ 6-20

White or Light Lines 6-20

Light Image (Entire Page) 6-20

Dark Image (Entire Page) 6-21

Stain Along the Edge of the Page 6-21

Stains on the Back of the Page 6- 21

Image Easily Smears when Rubbed 6-21

Placing a Service Call ............................................................... 6-22

A QMS Customer Support

Sources of Supp ort ............... ....... ..... ...... ... ..... ..... ....... ....... .... .....A -2

Your QMS Vendor A-2

Your Application Vendor A-2

Q-FAX A-2

The QMS Corporate Bulletin Board System A-3

CompuServe A-3

Internet A-3

QMS Customer Technical Assurance (CTA) A-4

QMS National Service A-5

QMS World-wide Offices .............................................................A-6

Index

v

QMS 1725E Print System Op e rati o niv

Page 7

1

Introduction

In This Chapter . . .

n

About this guide

n

Typographic convent ions

Page 8

Introduction

Introduction

This guide will lead you through procedures for installing consumables such as media and toner cartridges. You’ll also find information

on advanced printing feature s, printer care, print quality, and a troubleshooting section in case something goes wrong. Use this guide in

conjunction with your other QMS 1725E Print System documentation.

This chapter gives you a brief overview of this manual.

About This Guide

The informati on in thi s manual is divided into the foll owing secti on s:

n

Chapter 1—Intr oductio n

Provides an overview of this guide.

n

Chapter 2—Consumab les

Describes the paper stocks best suited for your printer; how to

load paper, labels, t ransparencies, envelopes; and how to

replace the toner cartridge.

n

Chapter 3—Advanced P rintin g Features

Explains how to print duplex, chain cassettes, collate output, print

a status page, cancel a print job, and end a print job.

n

Chapter 4—Printer Care

Describes how to handle and clean the printer.

n

Chapter 5—Print Qu ality

Gives information on how to improve print quality through adjustments of print density, gamma correction and printer resolution.

n

Chapter 6—Troubleshootin g

Provides media jam prevention tips, explai ns how to locate and

clear media jams, lists printer status messages, outlines printer

QMS 1725E Print System Op e rati o n1-2

Page 9

About This

Guide

and print quality problems and solution s, and describes how to

place a service call.

n

Appendix A—QM S Custom er Suppo rt

Provides world-wide product sales and support telephone numbers and describes how to communicate with QMS through the

QMS Bulletin Board, Comp uS e rve , the Internet, and Q-FAX.

Typograph ic Conventions

The following typographic conve ntions are used throughout this manual:

Mixed-Case

Courier

Mixed-Case

Italic

Text you type, and messages and information

displayed on the screen

V ariable text you type; replace the italicized word(s)

with information specif ic to your printer or comput er

Courier

UPPERCASE

COURIER

lowercase

bold

lowercase

Information displayed in the printer message

window

PostScript operators and DOS comm ands

Variable inform ation in text and P ostS cript variables

italic

UPPERCASE File and utility names

↵ Press the Enter key (PC) or Return key (Macintosh)

^ Press and hold down the Ctrl key (PC)

» Note: Notes contain tips, extra inform ation, or important information that

deserves emphasi s or reiteration.

O

Caution:

equipment dam age, process fail ure, or extreme annoyance.

Cautions present information that you nee d to know to a void

Introduction

1-3

Page 10

About This

Guide

M

WARNING!

procedure is not performed ex a ctly as described in the manual.

ACHTUNG! Bitte halten Sie s ich ex akt a n die im Handbuch beschriebene

Vorgehensweise, da sonst Verletzungsgefahr beste hen könnte.

v

Warnings indicate the possibility of personal injury if a specific

QMS 1725E Print System Op e rati o n1-4

Page 11

2

Consumables

In This Chapter . . .

n

Preventing media jams

n

About paper

n

Loading paper, transparencies, label s, and envelopes

n

Toner cartridges

Page 12

Introduction

Introduction

This chapter covers basic printer operation using various kinds of

paper and print media; loading paper, transparencies, labels, and

envelopes; and toner cartridge handling and replacem ent .

Preventing Media Jams

There are several things you can do to reduce the occurrence of

media jams.

n

Your paper, labels, and overhead transparencies must meet the

guidelines set for the printer. See appendix B, “Technical Specifications,” in your

n

If you have problems with double feeding, remove the media from

the cassette or input bin and fan the edges. The sheets may be

sticking together. However, do not fan transparencies since this

causes static electricity.

Reference

guide.

n

Print media must be stored away from moi sture and humidi ty.

n

Many manufacture rs place an arrow on the end of the wrapper

that indicates which side of the media should be used for printing.

If you have problems and cannot determine which side of the

paper should be printed, remove the paper from the cassette,

rotate the stack a half-turn, turn the stack over, and then place it

back in the cassette.

n

If none of the above relieves media jamming, notif y your vendor.

QMS 1725E Print Sytem Ope rati o n2-2

Page 13

About Paper

Your print quality depends in large part on the quality of the pape r.

You can get sharper contrast on printed pages by using special laser

printer paper, which is available from a variety of paper manufacturers. This paper is thicker, smoother, and whiter than copier paper and

gives your page a more professional appearance.

The printer accommodat es paper from 16 to 24 pounds (60 to 90 g/

2

) with cassette feed and 16 to 36 pounds (60 to 135 g/m2) with

m

manual feed. Conventional copier paper is adequate for most applications. Copier paper has a smooth, clean surface, controlled elect rical

properties, and heat stability. This assures good image tra nsfer wit hout excessive curling of the paper.

You can use special paper, such as bond paper, often used for stationery, for special applications. However, textured paper may result in

uneven toner placement and print quality may vary . You may want to

do a test run before printing a large quantity. Colored paper may also

be used, but not paper with a colored coating applied . Appendi x B,

“Technical Specifications,” in your

tional paper specifications.

Reference

About Paper

guide contains addi-

Paper Sizes

Your printer supports four different paper sizes. It autom ati cally

detects which size paper cassette is installed and jud ges the paper

size accordingly; letter-size paper in a legal-size cassette does not

work. Be sure to match the paper size to the appropriate paper cassette. You may purchase additional paper cassettes from your QMS

vendor.

Consumables

2-3

Page 14

About Paper

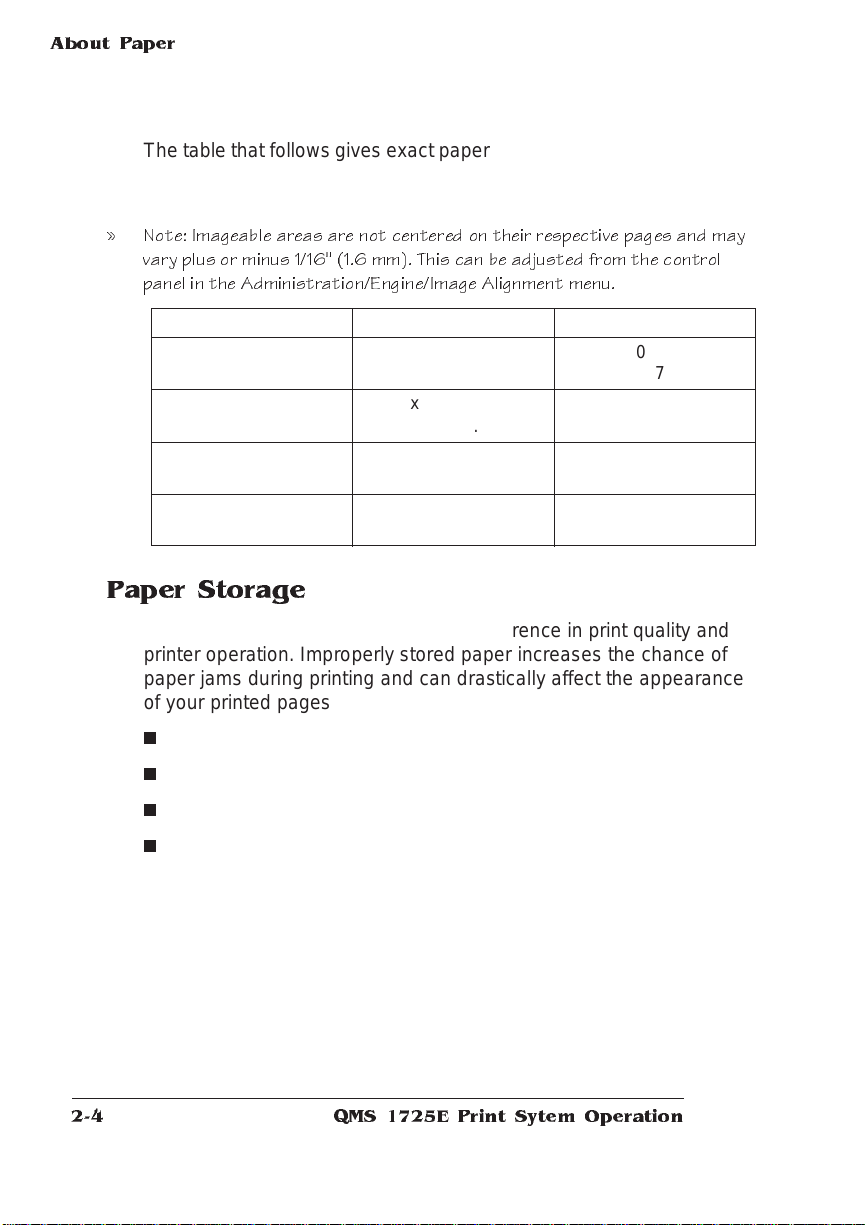

The table that follows gives exact paper sizes your printer supports as

well as the imageable area. This imageable area is smaller than the

size of the paper.

» Note: Imageable areas are not cente red on t heir respect ive page s and may

vary plus or minus 1/1 6" ( 1.6 mm). This can be adjusted from the control

panel in the Administration/E ngine/Ima ge Al ignment menu.

Type Size Imageable Area

Letter 8.50" x 11.00"

(215.90 x 279.40mm)

Legal 8.50" x 14.00"

(215.90 x 355.60mm)

Executive 7.25" x 10.50"

(184.15 x 266.70mm)

A4 8.27" x 11.69"

(210.00 x 297.00mm)

8.20" x 10.66"

(208.28 x 270.76mm)

8.20" x 13.66"

(208.28 x 346.96mm)

6.95" x 10.16"

(176.53 x 258.06mm)

7.97" x 11.36"

(202.50 x 288.50mm)

Paper Storage

How you store paper can make a big difference in print quality and

printer operation. Improperly stored paper increases the chance of

paper jams during printing and can dra stically affect the appearance

of your printed pages. Keep paper in good condition by storing it

n

In its wrapper

n

On a flat surface

n

In a closed cabinet

n

In a cool, dry area

Do not leave paper unwrapped or in a place where heat and humidity

can damage it.

QMS 1725E Print Sytem Ope rati o n2-4

Page 15

Paper Feeding

There are two ways of feeding paper through your printer:

n

Cassette feed (automat ically)

n

Manual feed (by hand)

Cassette feed automatically pull s paper from one of the cassettes at

the front of the printer. The cassettes handle paper as light as 16

pounds (60 g/m

mum loading depth is 1.97 inches (50 mm).

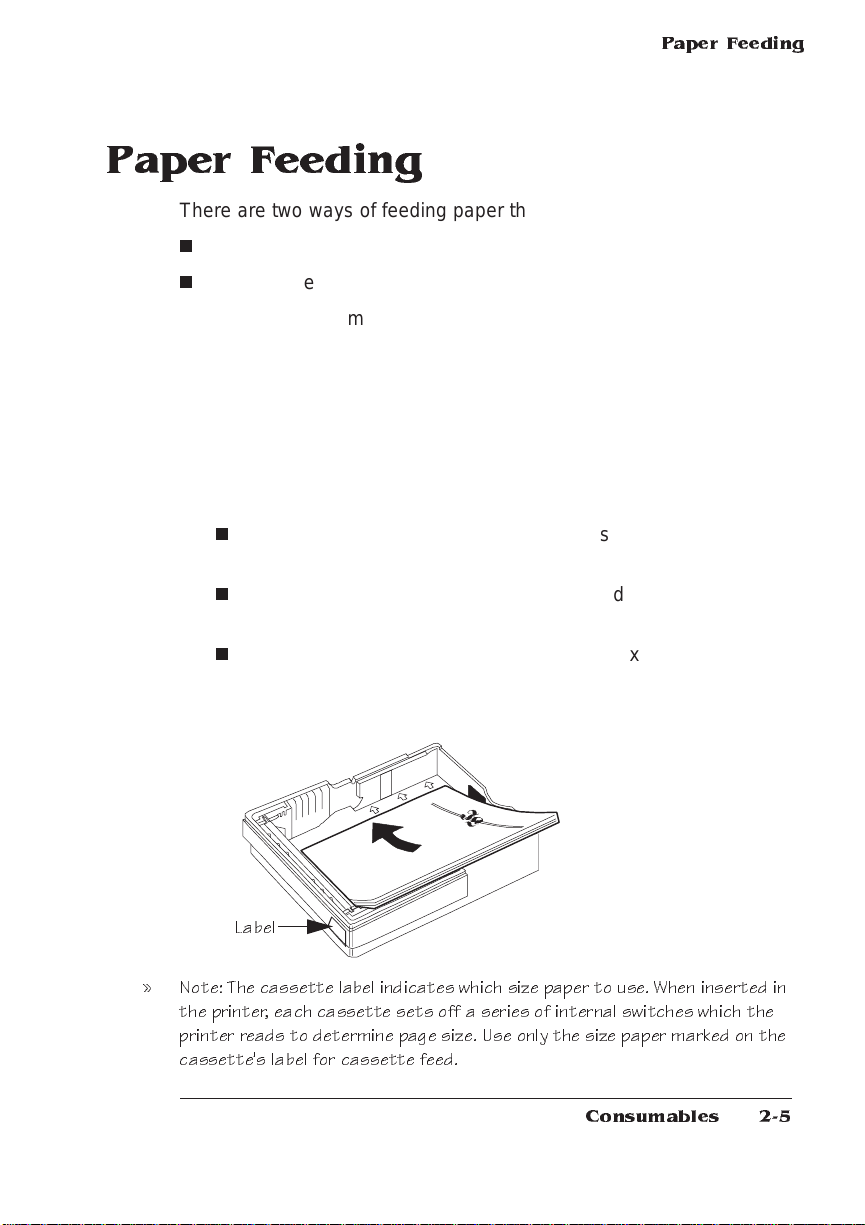

Use the following instructions to install a casset te:

1 Fill the cassettes with paper.

If you’re using

n

Letterhead and printing simp lex (single sided), be sure to

place the paper face up, top edge inserted first.

n

Letterhead and printing duplex (doubl e sided), place the

paper face down, bottom edge inserted first.

2

) or as heavy as 24 pounds (90 g/m2), and the maxi-

Paper Feeding

n

Letterhead and printing combination simplex and duplex jobs,

refer to the Letterhead option in the Engine submenu covered

in chapter 4, “Printer Configuration,” of your

Label

» Note: T he cas s e tte label indicates which size pape r to use. When inse r ted in

the printer, each casse tte sets off a seri e s of i nterna l s wi tches which the

printer reads to determine page size. Use only the size paper marked on the

cassette's label f or cassette feed.

Reference

Consumables

guide.

2-5

Page 16

Face-up

Output Bin

2 Place the covers on the cassettes.

3 Slide the filled cassettes into the pr op er ope nings in the

front of the printer.

Face-up Output Bin

After being printed, paper normall y stacks face down in the recessed

area on the top of the printer. The face-down output bin holds up to

500 sheets of paper. For face-up output, you must attach the face-up

output bin to the rear of the printer and configure the printer to access

this bin. This output bin holds up to 50 sheets of paper. Use the following instructions to attach the face-up output bin:

1 Insert the two end tabs of the face-up output bin into the slot

on the back of the printer.

2 Allow the extended par t of the bin to lean back into its nor-

mal positio n.

1

2

QMS 1725E Print Sytem Ope rati o n2-6

Page 17

Manual Feed

Manual Feed

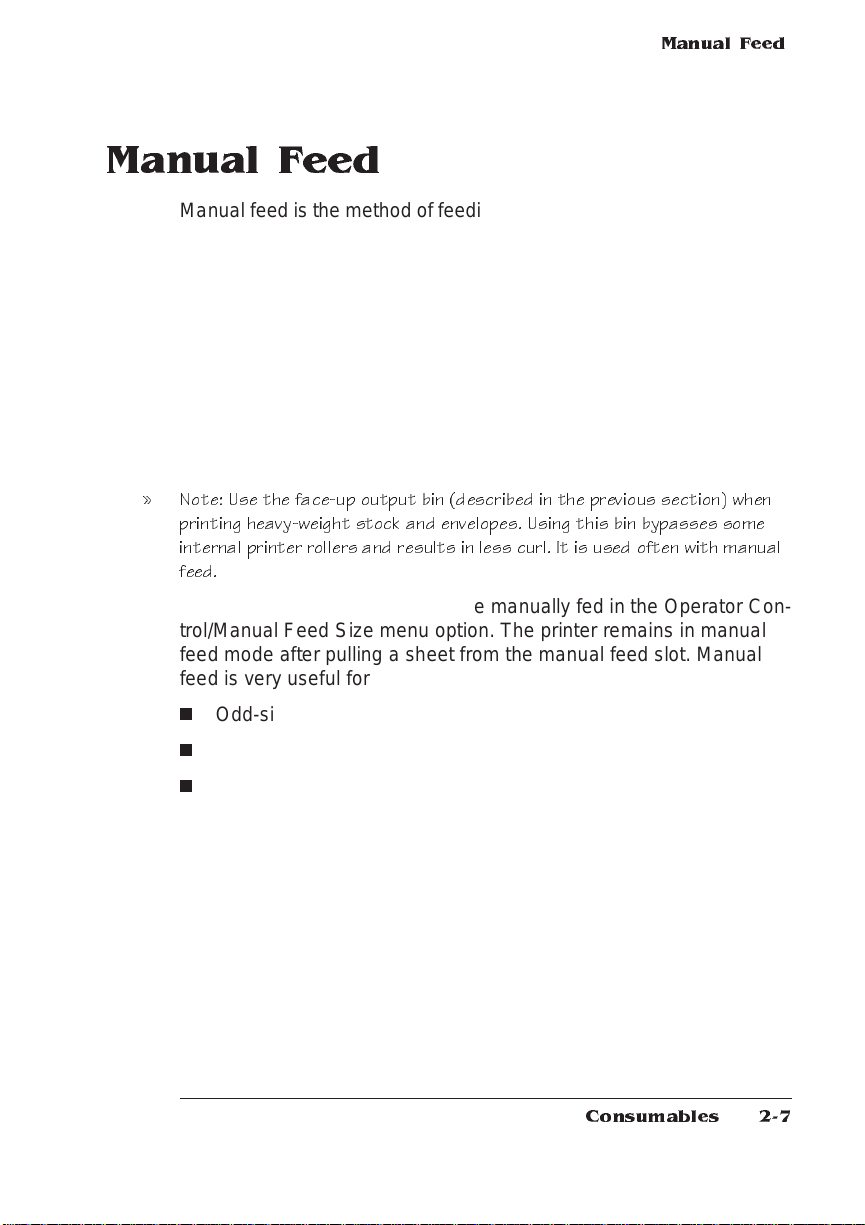

Manual feed is the method of feeding media by hand. Y ou can use the

manual feed slot with the adjustabl e feed guide on top of the paper

cassettes for a single manual-feed job. Single-sheet manual feed

makes it possible to feed individual sheet s of paper or other material

(such as envelopes, label stock, and transparencies) into your printer.

Paper weight can range from 16 to 36 pounds (60 to 135 g/m

Envelopes can be fed from the manual feed slot of the upper cassette

or with the optional envelope feeder (see chapter 6, “Printer Options,”

in the Reference guide for more informa tion). Cut sheets, labe ls, and

transparencies can be fed from the manual feed slot of either cassette.

» Note: Use the face-up output bin (de scribed in the previous section) when

printing heavy-weight stock and envelopes. Us ing this bin bypas ses some

internal printer rollers and r esults in less curl. It is us ed ofte n with m anual

feed.

Specify the size of the media to be manually fed in the Operator Control/Manual Feed Size menu option. The printer remai ns in manua l

feed mode after pulling a sheet from the manu al feed slot. Manual

feed is very useful for

2

).

n

Odd-sized paper (cut sheets)

n

Transparencies

n

Heavy-weight labels and envelopes

Use the following instructions to feed med ia by hand.

Consumables

2-7

Page 18

Printing

Transparencies

1 After selecting manu al feed in the Operator Contro l menu,

adjust the manual feed guide s on the upper or lower paper

cassette to match the width of media you are using.

Manual feed guide

(

left

2 Insert the media alo ng the guides as far as it goes.

The media is automa tical ly fed into the print er, and the printed

media is forwarded to the selected output bin.

)

Manual feed guide

(right)

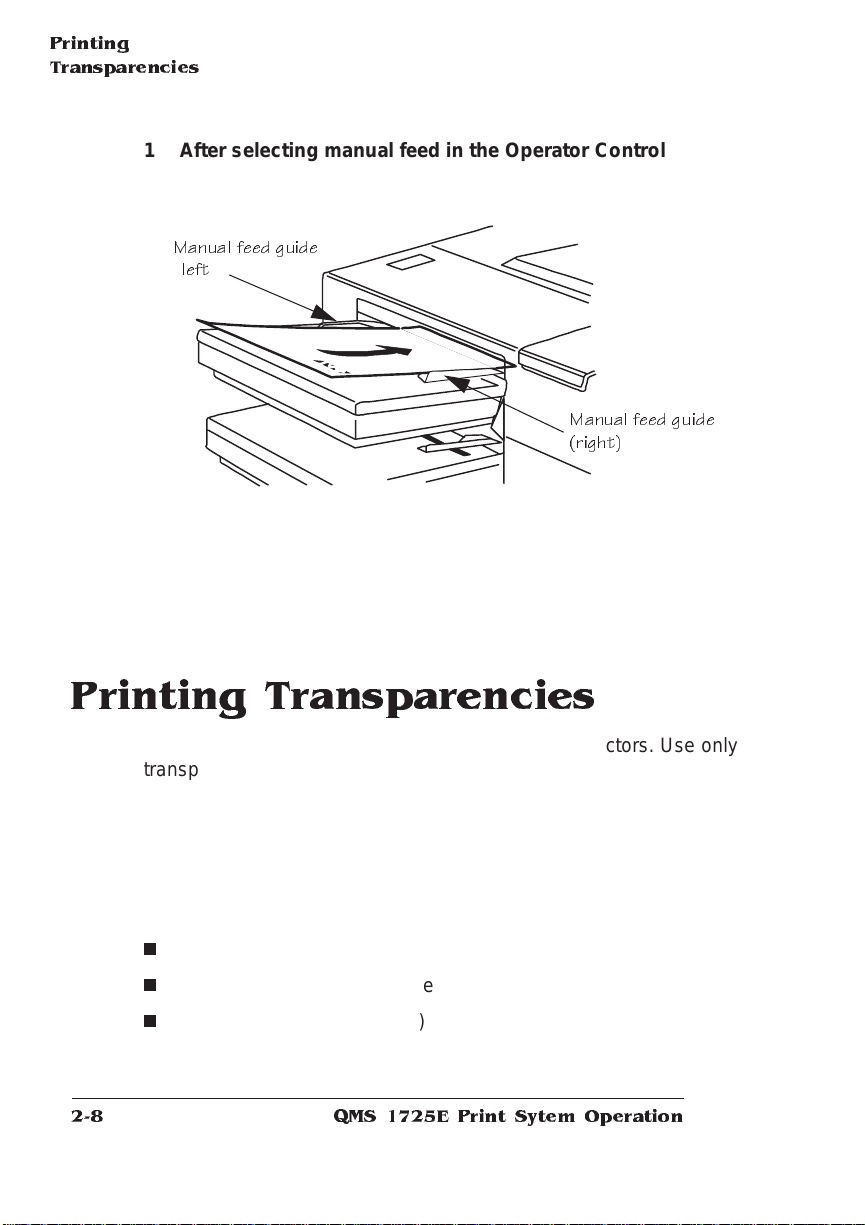

Printing Transparencies

You can also print transparencies for overhead projectors. Use only

transparencies recommended for laser printers, such as Canon brand

type D and 3M type PP2500. Always use manual feed from either the

upper or lower paper cassette, and the face-up output bin at the back

of the printer. Remove each transparen cy from the face-up bin after

printing to avoid jams. Transparencies must withstand temperatures

up to 356° F (180° C). Other specifications on overhead transpa rencies are

n

Thickness: 0.111 to 0.113 mm (4.37 to 4.45 mils)

n

Cutting Dimen sion Tolerance: +/-0. 7 mm (0.03 1")

n

Cutting Angle: 90° (+/- 0.2°)

QMS 1725E Print Sytem Ope rati o n2-8

Page 19

Transparencies are especially sensitive to a dirty paper path. If there

are shadows either on the top or the bottom of the sheet s, see chap ter 4, “Printer Care,” of this manual for instructions on how to clean

the media path.

Printing Labels

Adhesive label stock has pressure-sensitive (peel and stick) adhesive

backing. The procedure for feeding labels is almost the same as for

regular paper; however, you must use the face-up output bin.

Recommended labels have the following specif icat ions:

n

Type: Use only labels recommend ed for laser printers, such

as Avery 5260. Adhesive label stock should have pressuresensitive (peel-and-stick) adhesive backing.

n

Weight: The printer supports 17-34 lb (64-128 g/m

when using manual feed.

Printing Labels

2

) labels

» Note: Label data should be formatted within your application. Try printing

your dat a on a plain shee t of paper first to check pl acement. This reduces

the number of label sheets you use.

Printing Envelopes

Envelopes may be printed in two ways:

n

From the manual feed slot on the upper cassette (single en velopes)

n

From the optional envelope tray (up to 100 envelopes)

Non-standard-size envelopes are acceptable using manual feed as

long as they fall into the following size ranges:

n

Minimum size: 3.5" x 7" (86 mm x 178 mm)

n

Maximum size: 7.4" x 10.5" (188 mm x 267 mm)

Consumables

2-9

Page 20

Printing

Envelopes

Formatting Data for Envelopes

Your printer receives the necessary instructions to print on envelopes

from your software. Read the printing section of your application manual to find out how your software supports envelope printing. The

printer should be in landscape mode for most application s. Usually,

this is accomplished through the application.

When formatting data for envelopes, leave a 0.6" (15 mm) margin

from the edges of the envelope. Print on only one side. Rememb e r,

some parts of an envelope consist of three layers of paper the front,

back, and flap. Print in these layered regions may be faded.

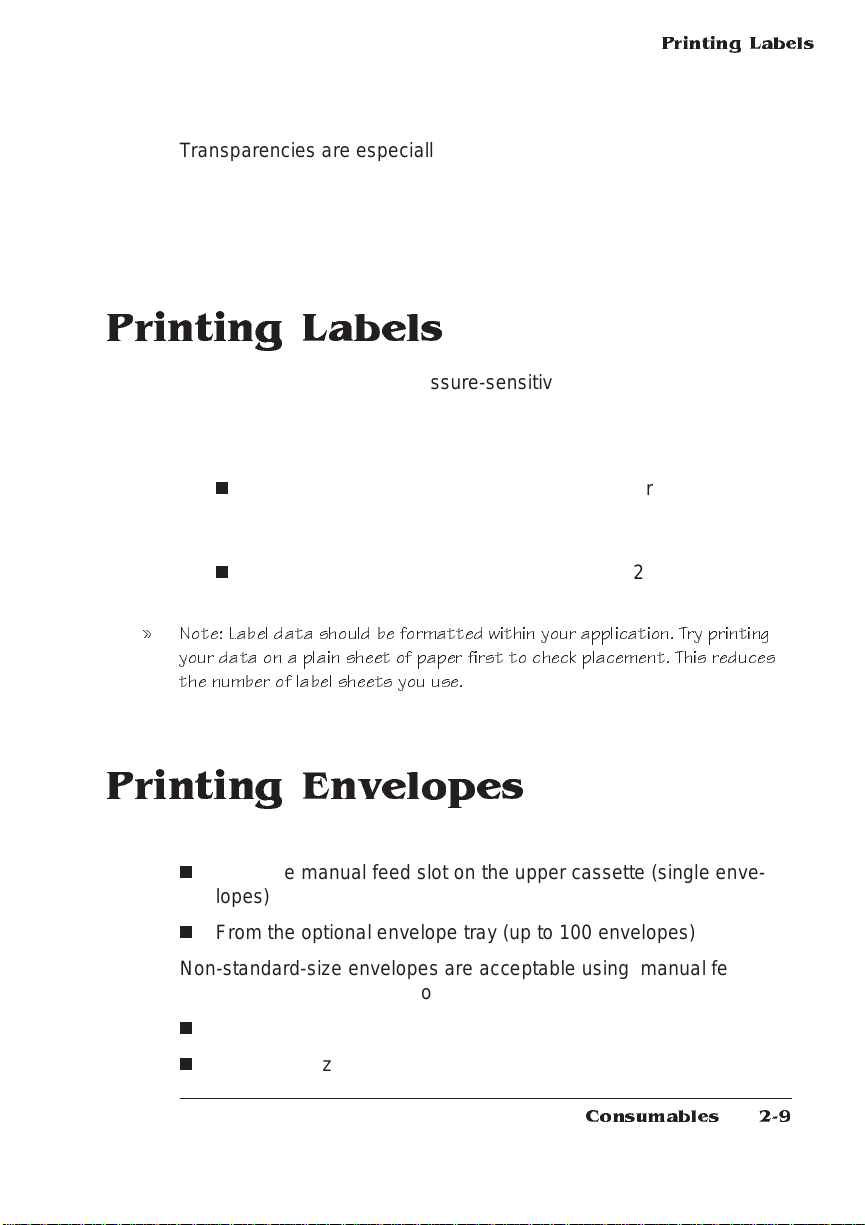

Printing a Single Envelope

Adjust the manual fee d guides on top of the casset te to the correct

size of the envelope. Insert a single envelope into the manual feed

slot as shown in the following illustration, with the face up and the flap

side toward the left manual feed guide.

Manual feed guide s

Because envelopes pass through hea ted roll er s, the gumm ed area

on the flap may seal. Open the flap immedia tely after it passes

through the printer, before the seal cools. You may then reseal in the

QMS 1725E Print Sytem Ope rati o n2-10

Page 21

Using Toner

Cartridg es

normal manner. The use of envelopes with emulsion-based glue

avoids this problem.

» Note: Before printing envelopes, disab le the dupl exer if it is i nstalled a nd

check the manual feed guide s to make sure t heyre not too tight and

buckling the envelopes. Also, make sure envelope size and type meet

specifications listed in appendix B, Technical Specifications, of your

Reference

the rear of the printer.

guide. If envelopes curl excessively, use the face-up output bi n at

The Optional Envelope Cassette

To load up to 100 envelopes at a time, use the optional envelope cassette. Instructions for installat ion and use are in chapt er 6, “Printer

Options,” in your

information on the optional envelope ca ssett e.

Reference

guide. See your QMS vend or for m ore

Using Toner Cartridges

Quality printing requi res uni form tone r application and a clean paper

path. This chapter explains basic maintenance to keep your printer

running smoothly. It includes instal ling a toner cartridge, cleaning

printer parts, and general print er care.

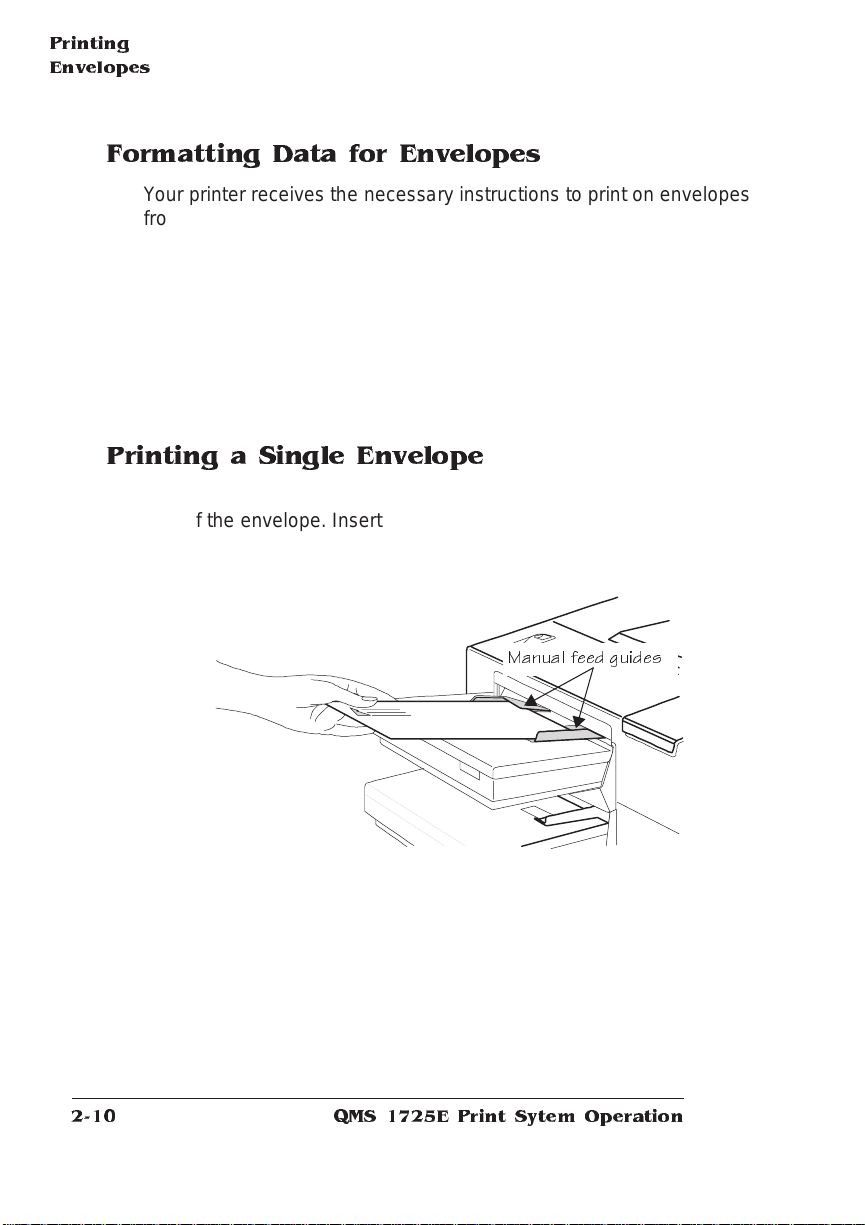

When to Replace the Toner Cartridge

The toner cartridge lasts for approximately 8,000 print s at 5% coverage. (For example, a one-page letter with no graphics.) When the cartridge toner supply runs low, the printer message TONER OUT

displays. Usually, parts of the page print lighte r. It is your option

whether or not to continue printing when the engine senses it is out of

toner.

When toner is low, it is sometimes helpfu l to take the cartridge out of

the printer and redistribute the ton er. This is done by gently rocking

the cartridge side to side. Then reinstall the cartridge . If the TONER

OUT message rem ains in the display panel after redistributing toner,

Consumables

2-11

Page 22

Using Toner

Cartridge s

the cartridge must be replaced.

Handling the Toner Cartridge

The cartridge contains the ton er and laser-sensitive drum needed to

operate the laser printer. The cartridge

n

Is sensitive to light; do not expose it to direct sunlight after op ening

n

Should be installed immedia tely af ter openi ng

n

Should be kept level for storage; do not stand or store the cartridge on its end

n

Contains a magnet; keep the cartridge away from CRTs, disk

drives, and floppy disks since damage may occur to stored data

Additional toner cartridges may be purchased from your QMS vendor.

Toner specifications are in appendix B, “Technical Specificati ons,” of

your

Reference

manual.

QMS 1725E Print Sytem Ope rati o n2-12

Page 23

Installing the

Toner Cartridge

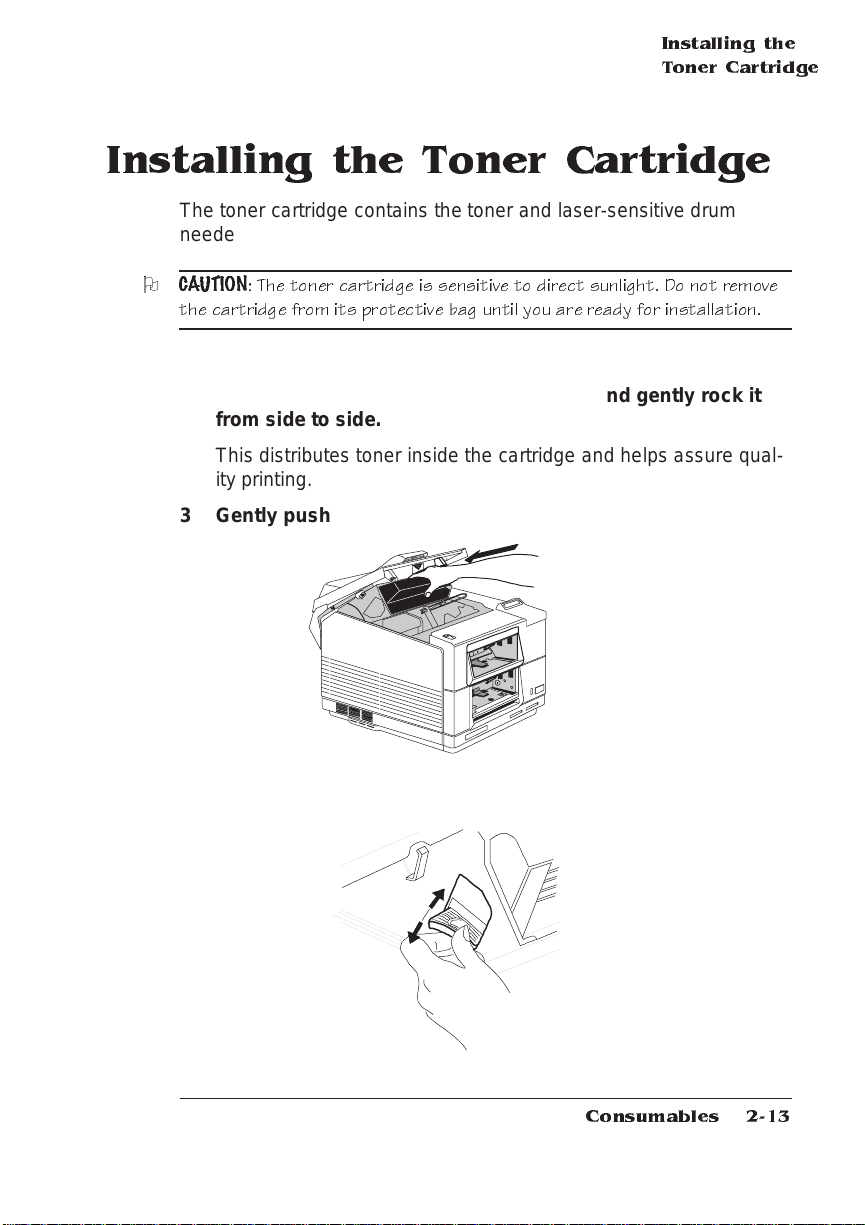

Installing the Toner Cartridge

The toner cartridge contains the toner and laser-sensitive drum

needed to operate the laser printer.

O

CAUTION

the cartridge from its protective b ag until you are ready for installation.

1 Open the printer top cover.

2 Hold the new cartridg e with both han ds and gently ro ck it

3 Gently push the ca r trid ge into the pri nter unti l it fits firml y.

: The toner cartridge is sensitive to direct sunlight. Do not remove

from side to sid e.

This distributes toner inside the cartridge and helps assure quality printing.

4 Grasp the tab protrudin g from the le ft side of the cartrid ge

and flex it to break it loose.

Consumables

2-13

Page 24

Installing the

Toner Cartridge

5 Pull the tab straight out. Pul l the attached 22 inches (55 cm)

of tape comple te ly out of the cartrid ge. Disc ard the tab an d

tape.

6 Close the printer top cover.

The toner cartridge is now ready for use.

v

QMS 1725E Print Sytem Ope rati o n2-14

Page 25

3

Advanced Printing Features

In This Chapter . . .

n

High-resolution printing

n

Chaining cassettes

n

Collating output

n

Working with status pages

n

Cancelling a print job

n

Ending a print job

Page 26

Introduction

Introduction

This chapter describes changing print resolution, using high-resolution while duplexing, chaining pape r cassettes, collating outpu t, printing a status page, cancelling a print job, and ending a print job.

High-Resolution Printing

The QMS 1725E Print System supports two print resolutions: 300 and

600 dpi (dots per inch). Printing at 300 dpi, your printer requires less

processing time compared to 600 dpi, since it has fewer dots per inch

to map, therefore reducing the time it takes to print. Printing at 300 dpi

also reduces the amount of toner used compared to pages printed at

600 dpi. For pages that contain gre at detail, such as graphics with

multiple levels of shading, or for document s requiring the best pos sible character detail, you should set your printer to 600 dpi resolution.

QMS 1725E Print System

Your

(megabytes) of memory, more than enough to handle both 300 or 600

dpi during simplex printing.

comes from t he f act o r y with 8 MB

You can set the default resolution of your printer through the Administration/Engine/Def Resolution m e nu.

Menu Administration/Engine/Def Resolution

Choices 300 dpi—300x300 dpi resolution.

600 dpi—600x600 dpi resolution.

Default 600 dpi

High-Resolution Printing and Duplexing

If you purchased a printer with the duplex option installed, you may

print on any of the media sizes at 300x300 dpi. However, printing

duplex at 600x600 dpi will require additional mem or y. The foll owing

QMS 1725E Print Sytem Ope rati o n3-2

Page 27

table lists the minimum amount of memory necessary for each resolution/media size combination :

Media Minimum RAM (in MB)

300x300 dpi 600x600 dpi

Simplex Duplex Simplex Duplex

Letter 4 MB 6 MB 8 MB 12 MB

Legal 4 MB 6 MB 8 MB 16 MB

Executive 4 MB 6 MB 8 MB 12 MB

A4 4 MB 6 MB 8 MB 12 MB

Cassette Chain ing

This printer has two cassettes (also known as trays or input bins) for a

total media capacity of approximately 1000 sh eets bef ore a reload is

necessary. You may choose to have the printer automatically draw

from the alternate cassette when the current cassette empties. There

are three ways to do this:

Cassette Chaining

n

Your application may include a specific procedure for using a

dual-cassette printer. Check your document ation.

n

The PS Executive Series Utilities offer a menu-driven program for

paper tray selection in the paper source section. If you have this

program installed, you can use it to help you configure the

printer's paper source.

n

The most convenient way to configure the printer is through its

control panel.

Use the following table to help you configure cassette chaining

through the control panel.

» Note: Make sure that the two paper ca ssette s instal led in your printer use

the same size paper.

Advanced Printing Feature s

3-3

Page 28

Menu Operator Control/Chain Inputbins

Choices On—turns on tray chaining.

Off—turns off tray chaining.

Default On

Notes Use the Operator Control/Inputbin menu to set the

default input bin.

Collating Output

With sufficient memory (12MB minim um ) or a hard disk installed, th e

QMS 1725E Print System can deliver multiple copies of your files in

collated order to the face-down output bin without havin g to send the

file repeatedly. This feature dramatically reduces your data transmis sion and improves performance. The illustration below shows collated

and uncollated stacking for two copies of a three-page file.

2

1

3

2

1

3

2

2

1

1

3

3

Collated Uncollated

The face-down output bin has an offset stacking fea ture that when

enabled, offsets the mult iple copies of a print job. With a hard disk

installed, collation performance is greatly improved because the file is

stored in QMS-compressed format for repeated printing. When disk

space is consumed during a print job, the printer begins chunk collating. Chunk collation breaks a job into sections and perform s collation

on each of those sections. The next diagram shows the printing

QMS 1725E Print Sytem Ope rati o n3-4

Page 29

Working with

Status Pages

order of three copies of a large document when chunk collation is

used. Several factors control the point when chunk collati on occurs.

Copy

1

Pages 101-200 Pages 101-200 Pages 101-200

Copy Copy Copy

Pages 1-100 Pages 1-100 Pages 1-100

The maximum collation sequence is 100 sheets. See the “Collation”

section in chapter 4, “Printer Configu ratio n,” in your

for more informat ion on collat ion .

Copy

2

Copy

3

321

Reference

Working with Status Pages

Printing a status page is a two-step procedure: Identify the type of

status page you want to print, and then print it.

guide

Identifying a S tatus Pag e Type

Two types of status pages are available:

n

Standard— This one-page document provides printer identification information (printer type and nam e, firmware version and

release, and number of sheets printed), printer sett ings (Po stScript level, start-up options, paper handling inf ormatio n, resolution, and gamma correction sett ing ), current memory

configuration, time-outs, communication settings and input buffer

sizes for all standard and optional interfaces, and hard disk status

Advanced Printing Feature s

3-5

Page 30

Cancelling/

Ending Print

Jobs

(address, size, and free space). In addition, an angle bar prints in

the lower-left corner for image alignment.

n

Advanced—This docum ent , which can be five or more pages

long, contains the same informat ion as the stand ard statu s page

as well as configuration menu setting s and a full list of fonts and

downloaded emulations.

Menu Administration/Special Pages/Status Page Type

Choices Standard, Advanced

Default Standard

Printing a Status Page

After you have identified the type of status page to print, send it to the

printer in one of the following ways:

n

Use the PS Executive Series Utilities (see the PS Executive online help for instructions).

n

Use the control panel keys to select “Yes” in the Print Status

menu option.

Menu Administration/Special Pages/Print Status

Choices Yes, No

Default Yes

» Note: Only standard status pages can be printed from PS Executive.

Advanced status pages are not available.

Cancelling/Ending Print Jobs

The Cancel key has two functions:

n

It cancels all print jobs that are currently printing, interpreting, or

spooling.

n

It allows you to send an end-of-job indicator to a currently compiling print job that is waiting for incoming dat a.

QMS 1725E Print Sytem Ope rati o n3-6

Page 31

Cancelling/

Ending Print

Jobs

Once the print jobs are canceled or ended, the printer resumes printing other jobs in the queue.

You don’t have to press the Online/Offline key to take th e printer off

line before using the Cancel key. There are no equivalent functions in

the configuration menu.

» Note: If you nee d to cancel the cancel job or end job procedure, press the

Menu key.

Cancelling a Print Job

Press the control panel keys in the order shown in the followi ng

instructions to cancel a print job.

Press

this key

Cancel Access the Cancelling Job menu. You

Cancel

or Select

to... The message window

are prompted for confirmation that you

want to cancel the print job.

Select Yes. YES

Cancel all print jobs in the queue that

are currently printing, interpreting, or

terminating. The CANC ELLING JO B

message displays until the print job is

completely removed from the printer.

reads...

CANCELLING JOB?

YES

IS SE LECTED

CANCELLING JOB

Advanced Printing Feature s

3-7

Page 32

Cancelling/

Ending Print

Jobs

Ending a Print Job

If the first print job in the queue is waiting for, but not receiving the

data it needs to finish printing, the message window displa ys

WAITING FOR INPUT

END JOB?

Use the following procedure to end all print jobs in the queue that are

waiting for incoming data.

» Note: T his procedure does not end a print job that is st ill receiving data. Its

only purpose is to provide an e nd-of-job indicator for a print job that does

not have one. You can identify an end-of-job ind icat or in the Administration/

Communications/Parallel and Administration/Communications/ Serial menu.

(See chapter 4, Printer Configuration, in the

information). Also see chapter 5, Additional Technical Information, in the

Reference

guide for a complete d iscussi on of End Job Mode.

Reference

guide for more

Press this

key

Cancel Access the Cancelling Job menu. CANCELLING JO B?

Next Advance to the End Job option. CANCELLING JO B?

Cancel

or Select

to... The message window

reads...

YES

END JO B

Select End Job. END JO B

IS SE LECTED

v

QMS 1725E Print Sytem Ope rati o n3-8

Page 33

4

Printer Care

In This Chapter . . .

n

Handling the printer

n

Cleaning the printer

Page 34

Introduction

Introduction

This chapter describes the proper handling and cleanin g procedures

used during routine maintenance. Keeping your printer clean will help

maintain the professional appearance of your documents.

Handling the Printer

Handle the printer with care to preserve its life. Abuse may cause

damage.

n

Do not place anything on the top of the printer.

n

Two or more people are required to move the printer. Never carry

or move the printer by lifting from the paper cassette slot. Lift the

printer from the bottom only.

n

Keep the output bin at minim um level. If paper stacks too high,

you may experience paper jams and excessive paper curl.

n

Do not leave the printer open for any length of time, esp ecially in

well-lit places. Light may damage the toner cartridge.

n

Remove the toner cartridge before moving the printer . Never ship

printer with a toner cartridge installed.

n

If you are not going to use the printer for an extended length of

time

n

Unplug the power cord from the power source outlet

n

Leave the cartridge inside the printer

QMS 1725E Print System Op e rati o n4-2

Page 35

Keeping the

Printer Clean

Keeping the Printer Clean

To maintain sharp print quality, clean the inside of the printer at the

following times:

n

Every time the toner cartridge is changed

n

After printing 8,000 single-sided pages

n

Whenever print quality becomes unsatisfactory

The inside of the printer must be wiped clean of any toner residue and

paper dust. The areas requiring regular cleaning are

n

The anti-static te eth

n

The transfer-guide lock-tray (green with handle)

n

The transfer-guide strip (silver metal)

n

The media-feed-guide area (black steel)

M

WARNING!

Unplug the printers power cord before cleaning the printer.

ACHTUNG!

Drucker reinigen.

Ziehen Sie den Netzs tecker aus der Steckdose bevor Sie den

Cleaning the Anti-Static T eeth

The anti-static teeth decrease the static charge placed on each sheet

of media as it passes through the printer. This allows the media to pull

toner from the toner cartridge drum. If the anti-static teeth are dirty, too

much of the static charge remains on the media and can cause light or

missing print on pages (especially in duplex operation).

Printer Care

4-3

Page 36

Keeping the

Printer Clean

To clean the anti-static teeth

1 Open the printer top cover to the uprigh t posi tio n and

2 Use the cleaning brush to wipe clea n the anti-static teeth.

remove the clea ning brush from its position guides lo cated

directly behin d the con trol panel on the inside of the printe r.

Anti-static

teeth

Transfer

charging

roller

O

Caution:

Be careful not to t ouch the transfer charging roller when cleaning

the anti-static tee th. Finger oil, scratches, or other contaminants on the

roller may reduce print q uality

.

QMS 1725E Print System Op e rati o n4-4

Page 37

Keeping the

Printer Clean

Cleaning the Transfer-Guide Lock-Tray and Strip

The transfer-guide area controls the path of the media as it passes

through the printer. Dust can accumulate over time on these guides

and affect the appearance of your print. T o clean the transfer-guide area

1 Make sure the prin ter’s power cord is unpl ugg ed an d open

the printer top section.

2 With a water-dampened, soft cloth, gen tly wipe off any dust

that may have accumulated on the transfer-gu id e lock-tray

and the transfer-guide strip.

Transfer

charging

roller

O

Caution:

moistened cloth. Finger oil, scratches , and other contaminants may re duce

the print quality

3 Using a dry, soft cloth, wipe the cleane d area to remov e

Be careful not to touch the trans fer charging roller with the water-

.

moisture.

Transfer-

guide lock-

Printer Care

tray

4-5

Page 38

Keeping the

Printer Clean

Cleaning the Media-Feed-Guide Area

The media feed guide area provides the media path bet ween t he

transfer guide area and the fuser assembly.

M

WARNING

: Be careful; the a rea around the fuser ass em bly is h ot.

ACHTUNG!

Fixiereinheit heib.

1 Make sure the prin ter’s power cord is unpl ugg ed an d open

the printer top section.

2 With a water-dampened, soft cloth, wipe off any accumulated

dust from the media feed guide area.

Fuser

assembly

3 Using a dry, soft cloth, wipe the cleane d area to remov e

moisture.

Verletzungsgefahr! Bei B etrieb wird die Umgebung der

Media

feed

guide

v

QMS 1725E Print System Op e rati o n4-6

Page 39

5

Print Quality

In This Chapter . . .

n

About print quality

n

About gamma correction

n

Changing print resolution

Page 40

Introduction

Introduction

Density, gamm a correction, and print resolu tion are some of the factors that affect print quality. High-resolution technol o gy, while more

complex, gives you more flexibility to control the print quality fact ors.

This chapter will aid you in setting your printer up for maximum performance. For a more detailed explanat ion of factors that affect your

printer ’s output, refer to chapte r 5, “Additional Technical Information, ”

in your

Reference

guide.

About Print Density

Changing the print reso lut ion sett ing fro m 300 to 600 dpi de crea ses

the spacing between dots of toner put on the page. Print density is the

amount of toner placed on each dot, making the print appear lighte r

or darker. The higher the density, the darker the print looks and the

higher the contrast is on the page. To adjust the print density

1 Open the printer top cover.

2 Locate the density ad justm ent dial that is insi de the printer

on the left side.

The scale on the density adjustm ent dia l shows the densit y setting; the dark marking identifies increased densit y, and the light

marking identifies reduced density.

QMS 1725E Print System Op e rati o n5-2

Page 41

About Gamma

Correction

3 Adjust the dial to the desired setti ng.

To increase density (darken print on the page), slide the dial

toward the rear of the printer. To decrease density (lighten print

on the page), slide the dial toward the front of the printer. The dial

clicks at the center setting.

» Note: You may want to increase dens ity as the toner cartridge

depletes.

About Gamma Correction

Gamma correction is an adjustm ent of the ranges of shading in a

printed image to provide the best copy of scanned images. Through

manipulation of shading levels, your printer can be se t to improve the

print quality of a scanned image automat ically. For detailed information on the steps taken during the automated process, see chapter 5,

“Additional Technical Informatio n,” in your

The main benefit of gamma correction is that it improves the print

quality of a scanned image by improving contrasts at a given resolution. To get the best gray-scale PostSc ript image at any resolution ,

gamma correction should be turne d on.

Print Quality

Reference

guide.

5-3

Page 42

Changing Print

Resolution

You can se t gamma correction throu gh PS Exec or through the

Administration /Engin e/G am ma Correction me nu.

Menu Administration/Engine/Gamma Correction

Choices On, off

Default Off

Notes When gamma correction is set to “on,” gamma correction is

automatically adjusted when printer resolution is changed.

Gamma correction applies only to PostScript images.

If turning on gamma correction doesn’t yield a suitable gray-

scale image for your needs, set a specific gamma correction

value through your drawing application or through the

PostScript settransfer operator. (See your drawing application

documentation, the

and the

information.)

PostScript Language Reference Manual

QMS Crown Technical Reference Manual

for more

,

Changing Print Resolution

Another way to sharpen the images printed on your pages is through

setting the print resolution. Y our printer is capable of printing at 300 or

600 dpi. For pages requiring the best quality your printer can provide,

set the printer resolution to 600 dpi.

QMS 1725E Print System Op e rati o n5-4

Page 43

Changing Print

Resolution

Setting Default Resolution

This option sets the print engine’s default resoluti on.

Menu Administration/Engine/Def Resolution

Choices 300 dpi—300x300 dpi resolution.

600 dpi—600x600 dpi resolution.

Default 600 dpi

Notes Printing duplex using 600x600 re solution with lega l size media

requires 16 MB of printer memory.

v

Print Quality

5-5

Page 44

Page 45

6

Troubleshooting Printer Problems

In This Chapter . . .

n

Status messages

n

Printer problem checklist

n

Media jams

n

Problem descriptions

n

Print quality problems

n

Image defects

n

Placing a service call

Page 46

Introduction

Introduction

This chapter provides information to aid you in resolving printer problems you may encounter, or at least guide you to the proper sources

of help. Y ou’ll find in this chapter tables of common status messages,

a problem checklist, and actions you should ta ke when a specific

problem occurs. There are step-by-step instruction for rem oving

media jams from the ke y locations alon g the media path, as well as

descriptions of common print quality problems with corresponding

solutions. You’ll also find what informat ion you’l l need to have before

placing a service call if one becomes necessary.

Status Messages

Printer control panel mes sages help you locate many pro blem s.

When the printer needs operator assistance, the message window

displays one of the following messages:

Status message Explanation

x

ACTIVE JOBS The printer is on line. x identifies the

number of jobs in process.

ADJUST

INPU TBIN

CANCELLING JO B The Cancel k ey h as bee n pressed, and

CLOS E ENG IN E DOOR(S ) One or more of the front or side covers

DUPLEXER ABSE NT The optional duplexer unit is not

DUPLEXER JAM Media has jammed while passing

INPUTBIN

BIN JA M Media has jammed while being pulled

BIN The specified input bin (cassette) isn’t

inserted correctly, or the cover is open.

from the specified input bin.

the oldest job in the print queue is

being cancelled.

is open and must be closed.

installed.

through the duplexer.

QMS 1725E Print System Op e rati o n6-2

Page 47

Status

Messages

IDLE The printer is on line, but no jobs are in

process.

ILLE GA L DUP LEX PRIN TING The optional envelope feeder was

selected as the input bin and the

duplexer as the output bin. The printer

does not support duplexing envelopes.

ILLE GA L MAN UAL FEED

PRIN TI NG

INITIALIZING The printer is getting ready to go on

Media has been inserted in the manual

feed slot before the paper tray lifting

mechanism is in the ready position.

line.

INPUT IDLE

PRIN TI NG

OUTPUTBIN

OUTPUTBIN

PRINTING STAT US A status page is printing

SIZE

PUT

BIN

TEST PRINT A test print page is printing.

TONER ABSENT The toner cartridge is not installed.

TONE R OUT The engine’s toner cartridge is empty.

TRANSPORT JAM Media has jammed while passing

WAI TING FOR IDLE A job is in process. Acce ss to the menu

OUTPUTBIN

OUTPUTBIN

PAPER I N

FULL T he specified output bin is full.

JAM Media has jammed between the printer

INPUTBIN

The printer is on line and printing jobs

already in the queue. No new jobs are

arriving at the communication

interfaces.

engine and the specified output bin

(tray).

The selected input b in (cass ette) needs

paper of the specified size.

through the engine.

is not allowed until the job is finished.

Troubleshooting Printer Problem s

6-3

Page 48

Status

Messages

WAITING ON INPUT

END JOB?

WARMING UP The printer is warming up.

The compiler is waiting on incoming

data for the first job in the queue. The

job may not have an end-of-job

indicator and therefore cann ot end. The

message clears if more input arrives

from the port or if you press the Cancel

key. No other jobs can be printed until

this job has ended.

Service Messages

When the printer requires service, operation stops and the message

window displays CALL FOR SERVICE followed by the location of the

problem and error number. Have this inform ation availabl e when yo u

call for service.

» Note: A service me ssage someti mes occurs as a result of an unusual

combination of events, not beca use of an actual problem. When the printer

stops and a service message displays i n the message window, turn the

printer off and back on. This ofte n clears the serv ice mes sage indicator and

printer operation resumes. Al ways try this b efore making a se rvice call .

Service calls should be placed to the vendor from whom you purchased the printer. If you cannot get service from your vendor, see

appendix A, “QMS Customer Support.”

QMS 1725E Print System Op e rati o n6-4

Page 49

PostScript Errors

HP-GL Error Codes and PCL Error Codes

The following tables list error codes that could appear on the printer

message window when running HPG L or PCL emulation s.

HP-

GL

Error

Code

0 Not enough memory for

1 Too many

2 Math error. 2 Math error.

3 Job aborted. 3 Job aborted.

4 Instruction not

5 Wrong number of

6 Out of range parameter,

7 Not used.

8 Unknown character set.

9 Position overflow.

10 Buffer overflow.

Explanation

job.

transformations.

recognized.

parameters.

or illegal character.

PCL

Error

Codes

0 Not enough memory for

1 State lost.

4 Out of memory for

5 Disk full. Cannot store

6 - 13 Internal error 1 - 8.

Explanation

job.

macros.

fonts.

PostScript Errors

If your printer is having trouble printing when using PostS cript emulation, you should turn on the Error Handler in the control panel menu.

Error Handler is a diagnostic tool that identifies PostScrip t errors

encountered during a print job.

Troubleshooting Printer Problem s

6-5

Page 50

Printer Problem

Checklist

Menu Administration/Startup Options/Do Error Handler

Choices Yes—Load the Error Handler.

No—Don’t load the Error Handler.

Default No

Notes Refer to the

Systems Incorporated, Reading, PA: Addison-Wesley, 1990,

ISBN 0-201-18127-4) for information on PostScript errors.

PostScript Language Reference Manual

Printer Problem Checklist

This section contains a list of possible printer problems and solutions.

If you have just installed your printer, be sure you have followed the

steps in chapter 2, “Setting Up Your Printer,” in the

guide.

If there is no display message, use the following steps to identify the

source of your problem and to learn of possible solutions:

(Adobe

Getting Start ed

1 Does the printer power ligh t come on ?

YES - Go to number 2.

NO - Check the following:

n

Is the power cord plugged into both the power outlet and

the printer?

n

Are both printer power switches in the On position (|)?

n

Is the power outlet working?

n

Does the line voltage from the power outlet m atch the

printer's power requirements? See appendi x B, “Technical Specifications,” in your

QMS 1725E Print System Op e rati o n6-6

Reference

guide.

Page 51

Printer Probl e m

Checklist

2 Can you print a status page?

YES - Go to question 3.

NO - Check the following:

n

Is the printer off line before you try to ent er the Ad mi nistration/Special Pages/P rint Sta tus me nu? It should be.

n

Does the cassette have paper? If it is out of paper, the

PAPER OUT message displays and the Error indicator

lights.

n

Is the method of tray delivery configured correctly? See

chapter 4, “Printer Configuration,” in your

guide.

n

Are all the printer covers closed securely?

n

Is there a media jam? If a paper jam message displays

and the Error indicator lights, go to one of the following

sections in this chapter on clearing a media jam.

3 Is the printer receiving data from the compu ter? If the Data

indicator blinks after a file is sent, the printer is receiving the

data. If not, check the foll owi ng :

Reference

n

Is the printer on line? The online/off line in d icato r should

be on and the message window should display IDLE.

n

Has the emulation been chang ed from ESP to an emulation that doesn’t match the file you are sending. S ee

chapter 4, “Printer Configuration,” in the

guide.

n

Print a status page from the control panel. If you are

using the serial interface, is the baud rate (speed of data

transmission) of the printer, the computer, and your software application the same? See chapter 4, “Printer C onfiguration,” in the

n

If you still cannot identify the problem, contact your QMS

vendor.

Troubleshooting Printer Problem s

Reference

guide.

Reference

6-7

Page 52

Media Jams

4 Is the printer printing codes o r not printi ng at all when in

5 If nothing prints at all, do an engine test print.

ESP mode?

n

Reconfigure the port to the specific printer emul ati on of

the file you are trying to print. See chapter 4, “Printer

Configuration,” in the

use the PS Executive Series Utilities to change modes.

n

If a PostScript file prints PostScript emulation statements

while in ESP mode, increase the ESP timeout. See chapter 4, “Printer Confi gurati on, ” in your

change it from the control panel, or use the PS Executive

Series Utilities.

n

If you continue t o have problems with the ESP mode

selecting the appropriate printer emulation, contact you r

QMS vendor.

On the front of the printer below the control panel and above the

power switch is a line indentation with an opening. Insert a pen or

end of a paper clip into the opening until you hear a slight click.

This should produce a page with vertical lines from one end to the

other. If the test print sh ows any patte rn other than this, contact

your QMS vendor.

Reference

guide for instructions, or

Reference

guide to

Media Ja ms

Locations

When a media jam occurs, the media path graphic on the printer's

control panel lights in the area closest to the location of the jam and a

paper jam message displays in the message window. Frequent jams

in any area indicate that area should be checked, repaired, or

QMS 1725E Print System Op e rati o n6-8

Page 53

Media Jams

cleaned. Repeated jams may also happen if you are using the wrong

weight paper. Jams can occur in the following areas:

n

Upper input bin

n

Lower input bin

n

Image transfer area

n

Fuser assembly area

n

Output are a

n

Duplexing unit

After checking for and removing media from the areas indicated,

open and close the printer cover to clear the jam signal. If all the

jammed media has been removed, printing automatically restarts

when the cover is closed. If printing does not restart or if the printer

jams again, make sure that no pieces of media remain in the printer.

Clearing an Input Bin Media Jam

Follow these instructions to clear a media jam from the upper or lower

input bin:

1 Open the printer top cover and locate the transfer-gu id e

lock-tray.

M

WARNING

hot.

ACHTUNG!

Papierführung heiß.

: Be careful; the area around t he trans fer-guide and roller is

Verletzungsgefahr! Bei B etrieb wird die Umbegung der

Troubleshooting Printer Problem s

6-9

Page 54

Media Jams

2 Gently open the tran sfer-guid e lock-tray and remove an y

media.

If necessary, remove the cassettes from the print er first.

Transfer

lock-tray

-guide

3 If you experien ce diffi cul ty in removi ng the me dia, or i f

media isn’t visib le under the transfer-g ui de lock-tray, lift the

green lever on the inner metal plate to check for jammed

media under the metal pla te. Remov e the medi a.

Transfer-

guide lock-tray

Green lever

QMS 1725E Print System Op e rati o n6-10

Page 55

Media Jams

4 Restore the inner metal plate to its or igin al posi tio n and

close the transfer-guide lock -tray.

Both must be properly in place before closi ng the print er or the

printer may be damaged.

5 Close the printer ’s top cover.

Clearing an Imag e-Transfer Area Media Jam

To clear a media jam from the image-t ransfe r area, fol low these

steps:

1 Open the printer top cover and locate the transfer-gu id e

lock-tray.

M

WARNING

hot.

ACHTUNG!

Papierführung heiß

: Be careful; the area around t he trans fer-guide and roller is

Verletzungsgefahr! Bei B etrieb wird die Umbegung der

.

Troubleshooting Printer Problem s

6-11

Page 56

Media Jams

2 Gently open the tran sfer-guid e lock-tray and remove an y

3 After removing the media, close the transfer-gui de lock-tray.

O

media by rolling it toward you.

Avoid touching the transfer roller. Be careful not to get the paper

near any clothing. It may contain som e unfused toner.

Transfer

roller

Caution: Make sure the tra nsfer-gui de lock-tray i s properly in place

before closing the printer or the printer may be d amaged .

Transfer-guide

lock-tray

4 Close the printer top cover.

Clearing a Fuser Assem bly Area Media Jam

Use this procedure to clear a paper jam from the fuser assembly

area:

1 Open the printer top cover and locate the fuser assem bly.

M

WARNING

ACHTUNG!

Fixiereinheit heiß .

: Be careful; the area around the f user as sembl y is hot.

Verletzungsgefahr! Bei B etrieb wird die Umgebung der

QMS 1725E Print System Op e rati o n6-12

Page 57

Media Jams

2 If the jam is at the front of the fuser assembly, remove the

media by using the green plas tic kno b at the left of the fuser

and rolling it away from you.

Be careful not to get the media near any clothing . It may contain

some unfused toner.

Green

knob

Fuser

assembly

3 If the media is stuck in the rear of the fuser assemb ly, open

the green fuser assembly rear do or.

Remove the media by turning the green plastic knob at the left of

the fuser to feed the media through the fuser assembl y.

M

WARNING

ACHTUNG!

Fixiereinheit heiß .

: Be careful; the a rea around the fuser ass em bly is h ot.

Verletzungsgefahr! Bei B etrieb wird die Umgebung der

Fuser

assembly

rear door

Troubleshooting Printer Problem s

6-13

Page 58

Media Jams

4 After removing the media, close the fuser assem b ly rear

door and make sure it is properly in place before closing the

printer or the printer may be damaged .

5 Close the printer top cover.

Clearing an O utp ut Bin Media Jam

Follow these steps to clear a jam from the output are a:

1 Open the printer top cover and locate the fuser assem bly.

M

WARNING

: B e ca reful; the area around t he fuser as semb ly is hot.

ACHTUNG!

Fixiereinheit heiß .

2 If the media is jammed inside the fuser assembl y, grasp the

edge of the media and remove it.

3 If the jammed media has pa ssed com pletel y throu gh the

fuser assembly and is partially visib le in the upper ou tpu t

Verletzungsgefahr! Bei B etrieb wird die Umgebung der

QMS 1725E Print System Op e rati o n6-14

Page 59

Media Jams

bin, close the printer top cover, and then lift the media guide

arm and pull out the media slowly.

After removing the media, lower the media guide arm.

Media

guide arm

Clearing a Du plexer Med ia Jam

To clear a jam from the duplexing unit , follow these instructions:

1 Press lightly on the upper edge of the duplex access door on

the lower-left side of the printer.

2 The door clicks and springs open.

1

2

Troubleshooting Printer Problem s

6-15

Page 60

Problem

Descriptions

3 Carefully remove any jammed medi a. Then close the duplex

access door.

Problem Descriptions

Paper Jam Message Stays On

If a PAPER JAM message stays on, open the printer and clear the

jam. If the message is still there, try opening and closing the top of the

printer again. See the prece ding secti on on clearing me dia jam s for

more information.

Data Indicator Stays Lit

If the printer has warmed up and the Data indicator stays on, two

problems may exist. If you are downloading additional typ efaces, too

many can overload the printer’s memo ry, causing the printer to reset

and lose information previously downloaded to RAM. Make sure you

have enough printer memory.

On an LocalTa lk network, Macintosh comput ers sometim es interf ere

with each other. If this happen s often, reinstall th e LaserWriter and

Laser Prep files, which reset the printer. If neither of these is the problem, place a service call to your QMS vendor.

QMS 1725E Print System Op e rati o n6-16

Page 61

Problem

Descriptions

No Advanced Status Page

If your printer prints a standard status page even though you’ve configured the printer in the Adm inist rati on/ Spe cial Pa ges/S t atu s Page

Type menu to print an advanced status page, your printer probably

doesn’t have enough free memory available. To print an advanced

status page you may need to reduce the amount of memory assigned

to one or more of the memory clients or add more memory (see the

“Memory” section in chapter 5,”Additiona l Technical Inform at ion, ” of

Reference

the

guide for information abo ut memo ry clients ).

No Start-up Page

If the Ready indicator is on, but no start-up page prints, check the following:

1 Has the start-up page been disabled?

Use the PS Executive Series Utilities or the control panel to make

sure the start-up page is on.

2 Turn the printer off. From a cold start, the printer takes

approximatel y 1 to 2 minutes to warm up.

Be sure you wait long enough for a start-up page before suspecting a problem.

3 Check to be sure the paper casset tes are loaded with paper,

in place and secure.

4 Open the top cover of the printer and check for a medi a jam.

5 Make sure a toner cartridge is install ed.

If you still have not solved the problem, you need to call your QMS

vendor for help. Go to the last section of this chapter, “Pla cing a Service Call.”

Printer Resets

Occasionally, Macintosh appli cations interf ere with each other. Applications send a printer prep file to the printer at the beginning of each

document. Other prep files cannot be sen t without resetting the

Troubleshooting Printer Problem s

6-17

Page 62

Problem

Descriptions

printer. Monitor your activities to see if there is a correlation between

your use of a certain application and the printer resetting. If so, contact the application developer.

Downloading too many typefaces can ove rload the printer memory

and cause the printer to reset to default. Additional m emo ry (RAM),

which can be used for font storage, is available and easily installed.

Contact your QMS vendor for information on RAM upgrades. See

chapter 6, “Printer Options,” in your

If the printer resets in other circumstances, you should call your QMS

vendor for service.

Blank Pages

If a blank start-up page ejects or blank pages come out during a printing job, try the followin g:

1 Check the to ner cartridge.

2 Be sure you have broken the tab on the side of the toner car-

Reference

The image does not print if the cartridge is empty.

tridge and removed the seal ing tape .

guide.

3 If the toner cartridge is not emp ty, the sealing tape has been

removed, and blank page s are ejec ting , take the cartridge

out, roll it from side to side, and rein stal l the cartridg e in the

printer.

4 If these solutions do not work, contact your QMS vendor to

purchase another toner cartridge.

Not All Pages Print

If the printer stops printing in the middle of your file, try the followi ng:

1 Check your cable.

You could have th e wrong kind of cable, or your printer may not

be configured for the correct cable and port.

2 Make sure no one pressed the Cancel key while your job was

printing.

QMS 1725E Print System Op e rati o n6-18

Page 63

3 Check the message window to see if the cassette you are

using need s mo re m edi a.

Printer Will Not Dup lex

If the error message DUPLEXER ABSENT appears in the message

window, make sure you have the optional duplexing assembly c orrectly installed by referring to chapter 6, “Printer Options,” in your

erence

configured the printer from the front panel to duplex (Operator Control/Def.Duplex), but the printer conti nues print ing simp lex, you may

need additional memory allocat ed to the fra me buffe r. See chapter 3,

“Advanced Printer Feat ures, ” in this guide for additional inf ormatio n

on memory required for duplexing.

guide. If you have correctly installed the duplexing unit and

Print Quality Problems

Print quality problems are those related to the appearance of the

pages you print. Print quality problems include white lines on the

page, uneven blacks, and other print distortions.

Print Quality

Problems

Ref-

First, refer to the appendix B, “Techn ical Specifi ca tions,” in your

erence

mended media and continue to have problems with the quality of your

printed pages, try this quick-check procedure:

1 Check the print density con trol leve r on the inside of the

2 If the TONER OUT message is on, remove the toner cartridge

3 If the message remains on , replac e the toner cartrid ge.

guide for recommended media type s. If you are using recom-

printer.

Change the setting and try printing another page. See chapter 5,

“Print Quality,” for inform ati on on sett ing the prin t density.

and gently rock it from side to side.

The toner can settle, and this procedure redistributes th e toner.

Reinsert the cartridge and try printing again.

Troubleshooting Printer Problem s

Ref-

6-19

Page 64

Image Defects

4 Place a service call to your QM S vendo r.

Printer Will Not Print 60 0 dpi

If you have configured the printer from the front panel to print at 600

dpi resolution but the printer continues printing 300 dpi, you may need

additional memory allocat ed to the fram e buffer. See the “Memory”

section in chapter 5, “Additional Technical Inform ati on, ” in your

guide for additional informati on on memory config urati on.

ence

Image Defects

The following list includes several image defects with possible solutions. Try the solutions in the sequence given. If the solutions listed

don’t solve the problem, place a service call to your QMS vendor. See

the next section in this chapter, “Placing a Service Call.”

Refer-

White or L ight Lines

1 Remove the toner car trid ge and gently rock it from side to

side as you would before instal ling a new cartridg e.

This redistributes toner inside the cartridg e. Reinstall t he cartridge.

2 If step 1 does not solve the probl em, insta ll a new tone r car-

tridge.

Light Image (Entire Page)

1 Make sure you pu lled the tab from the toner cartri dg e.

2 Increase the print density by ad ju sting the print den si ty con-

trol lever inside the printer to the thick end of the wedge shaped scale.

QMS 1725E Print System Op e rati o n6-20

Page 65

Image Defects

3 Remove the toner car trid ge and gently rock it from side to

side as you would when i nstal ling a new cartri dg e.

This redistributes toner inside the cartridg e. Then, reinstall t he

cartridge.

4 If steps 1, 2, and 3 do not solve the problem, install a new

cartridge.

Dark Image (Entire Page)

1 Decrease print density by adjusting the print density control

lever inside the printer to the thi n end of the wedg e-sha ped

scale.

2 Remove the toner car trid ge and gently rock it from side to

side as you would when i nstal ling a new cartri dg e.

This redistributes toner inside the cartridg e. Then, reinstall t he

cartridge.

3 If steps 1 and 2 do not solve the problem, install a new toner

cartridge.

Stain Along the Edge of the Page

Install a new toner cartridge.

Stains on the Back of th e Page

The media path may be dirty. Clean the media path area. See chapter

4, “Printer Care,” for more information.

Image Easily Sm ears when Rub bed

Place a service call.

Troubleshooting Printer Problem s

6-21

Page 66

Placing a

Service Call

Placing a Service C all

If you have a problem you cannot resolve, contact your QMS vendor.

Your QM S vendor is best equipped to immedia tely handle any problem you may e ncounter.

If you have technical questions your vendor is unable to answer, you

can call or fax questions to QMS Customer Technical Assurance (See

Appendix A, “QMS Customer Suppo rt” for informa tio n on contacti ng

QMS Customer Technical Assurance). If you’ve determined your

printer needs to be examined by a QMS service technician, contact

QMS National Service for work inside the US, or one of the QMS

international offices for work outside of the US. (National and int er national contacts are listed in appendix A, “QMS Customer S upport .”)

Before calling, be sure you have the answers to these questions

handy to help our technicians serve you more quickly:

1 What is your printer model an d serial num ber ?

2 What kind of host comp uter do you h ave?

3 What operating system do you have and wh at versio n?

4 What interface are you using? If serial, what protocol?

5 What application are you using?

6 What is the emulation of the file you'r e trying to print? I n

what emulation mode is the port?

7 What is the firmw are revi sio n num ber for your prin ter? (It is

listed on both the status and start-up pages. )

8 If you can print, have a status page available.

Your service representative needs to know these things prior to helping you.

v

QMS 1725E Print System Op e rati o n6-22

Page 67

A

QMS Customer Support

In This Chapter . . .

n

Sources of customer support

n

QMS world-wide offices

Page 68

Sources of Support

Sources of Support

Several sources of help and information are availa ble, dependin g on

the type of help you need:

Your QMS Vendor

Your local vendor (the one from whom you bought the printer) may be

best equipped to help you. Your vendor has specially trained service

technicians available to answer questions, and the equipment to analyze your printer problems.

Your Application Vendor

Often, “printing” problems ha ve more to do with the application being

used than with the printer. In this case, the app lication ma nufa cturer

is the best source of help.

Q-FAX

Q-FAX, a QMS informa tion retrieval service, provides applicati on

notes, technical support notes on comm on print ing proble ms, and

information about printer sp ecifi catio ns, opt ions, accessories, consumables, and prices.

In the United States and Canada, call (800) 633-7213 to reach QFAX. In all other countries, call (205) 633-3850. Have your fax num ber handy when you call (or place the call from your fax machine's

handset).

» Note: The 205 area code will change to 334 on January 15 , 1995.

You can choose to have either a directory (a list of currently available

documents on a particular topic) or a specific docum ent sent to you.

The first time you call, request the directory (press 2 on your phone or

fax keypad when prompted). Then call back to request sp ecific documents. You can order up to three documents per call.

QMS 1725E Print System Op e rati o nA-2

Page 69

Sources of

Support

The QMS Corporate Bulletin Board System

The QMS Corporate Bulletin Board Sy stem (BBS ) contains te chnical

support notes, application not es, drivers, pat ches, and ut ilities. T echnical questions not requiring an immed iate respon se can be left on

electronic mail for the Sysop (System Operato r).

The bulletin board [(205) 633-3632] operates at 1200, 2400, 9600,

and 14400 baud, 8 data bits, no parity, 1 stop bit, with XMODEM,

YMODEM, and ZMODEM capabilities. Contact QMS Customer Technical Assurance for more inform ation about the bulletin board.

» Note: The 205 area code will change to 334 on January 15 , 1995.

CompuServe