Page 1

QMS® 1660E

Print System

Operation

1800383-001B

Page 2

Trademarks

The following are tradema rks or registered trademarks of their respective ow ners.

Those listed as registered a re register ed in the United S tates Patent and Trademark

Office. Some trademarks are also reg istered in other countries. Other pr oduct nam es

mentioned in this man ual may be tradem arks o r registered tradem arks of the ir

respective owners. QMS, the QMS logo, Crow n, the Crown sea l, PS Executive Series,

imPRESS/QMS, Inc. Adobe is a register ed trademar k of Adobe System s Incorp orated,

registered in the United States Patent and Trademark Office. PostScript is a trademark

of Adobe Systems Inco rp orated for a pag e description language and may be registered

in certain jurisdictions. T hroughout this m anual, “PostSc ript Level 2” is used to refer to

a set of capabilities defin ed by Adobe S ystems for its Pos tScript Leve l 2 page

description language. Th ese capabilitie s, among other s, are implem ented in this

product through a QMS-developed emulation that is compatible with Adobe's PostScript

Level 2 language. Apple, App leTalk, ImageWriter, LaserWriter, Macintosh, EtherTalk,

and LocalTalk/Apple Computer, Inc. DEC, DECnet, VMS/Digital Equipment Corporation.

Hewlett-Packard, HP, PCL, HP-GL, LaserJet/Hewlett-Packard Co. IBM PC, AT, PC/XT,

Token-Ring/International Bus iness Mach ines Corporatio n.ITC Avant Garde Gothic, IT C

Zapf Chancery, ITC Bookman, ITC Zapf Dingbats/International Typeface Corpor ation.

Helvetica, Palatino, Times/Linotype- Hell AG and/or its subs idiaries. Nov ell, NetWare/

Novell, Inc. UNIX/UNIX System s Labor atories, Inc. Ethern et and Xerox/Xe rox

Corporation. The ENER GY STAR logo is a trademark of the United States

Environmental Protection Agency. The ENERGY STAR emblem does not represent EPA

endorsement of any pr oduct or ser vice.

Proprietary Statement

The digitally encoded software included w ith your QMS 166 0E Print System is

Copyrighted © 1994 by QM S, Inc. All Rights R eserved. This software may not be

reproduced, modified, d isplay ed, tr ans ferred, or cop ied in any form or in any manner or

on any media, in whole or in par t, without the express written permiss ion of QMS, Inc.

Copyright Notice

This manual is Copyrighted © 1994 by QM S, Inc., One Mag num Pass, Mob ile, AL

36618. All Rights Reserve d. This manual m ay not be copie d in whole or in pa rt, nor

transferred to any other me dia or language, w ithout the express written permiss ion of

QMS, Inc.

Page 3

ContentsContents

1 Introduction

Introduction .................................................................................. 1-2

About This Manual .......................................................................1-2

Typographic Conventions 1-3

2 Consumables

Introduction .................................................................................. 2-2

Preventing Print Media Jam s ............................... ....... ............ ....2 -2

Loading the 250-Sh eet Pa per Casse tte ... ..... ....... ....... ....... ..... ....2 -3

Loading the Multipurpose Tray ...................................................2-6

Envelopes: Special Considerations 2-10

Labels: Special Considerations 2-10

Letterhead and Memo Paper: Special Considerations 2-11

Transparencies: Special Considerations 2-11

Page 4

Using Toner Cartrid ges .. ....... ....... ....... ....... ....... ......... ....... ....... . 2-12

Toner Cartridge Life 2-12

Toner Cartridge Storage 2-12

Refilled Toner Cartridges 2-13

Extending Toner Cartridge Life 2-13

Replacing a Toner Cartridge 2-14

3 Advanced Printing Features

Introduction . . .... ... ..... ...... . ....... .... ... ..... ...... . ....... ..... .. ..... ...... ... ..... .. 3-2

High-Resolutio n Printin g ..................................... .............. ....... .. 3-2

Memory Requirements for High-Resolution Printing 3-2

Dou b le-S i d e d Prin ti ng ... ..... ............ ..... ............ ..... ................ ..... .. 3-4

Cassette Chaining ....................................................................... 3 -4

Chaining Cassettes 3-5

Collating Output .................... ........ ..... ...... ............. ...... ........ ........ 3-6

Advantages of Collation 3-6

Working with Chunk Collation 3-6

Improving Collation Performa nce 3-7

A Note About Collating PCL 5 Files 3-8

Working wi th Sta tus Pa ges ...... ... ..... ...... ... ..... .... ..... ... ...... ... ..... .. 3-9

Identifying a Status Page Type 3-9

Cancelling/Ending Print Jobs ................................................... 3-10

Cancelling a Print Job 3-10

Ending a Print Job 3-11

4 Printer Care

Introduction . . .... ... ..... ...... . ....... .... ... ..... ...... . ....... ..... .. ..... ...... ... ..... .. 4-2

Handling the Printer .................................................................... 4-2

Conserving Energy ...................................................................... 4-3

Cleaning the Printer .................................................................. .. 4-4

Cleaning Guidelines 4-4

Cleaning the Film on the Metal Feed Roller 4-4

QMS 1660 Print System Op e rati o nii

Page 5

Cleaning the Outside of the Printer 4-5

5 Print Quality

Introduction .................................................................................. 5-2

About Print Resolution ................................................................5-2

About Print Den sity .. ...... ... ..... ..... ....... ....... .... ..... ..... ..... ....... ..... ....5-3

About Gamma Cor recti on ..................... ....... ........ ....... ....... ..... ....5 -4

About Halftone Types ........................ ............ ....... .............. ....... ..5-5

6 Troubleshooting

Introduction .................................................................................. 6-2

Automatic Jam Reco very ...... ............ ....... ............ ....... ............ ....6 -2

Clearing Media Jams ............. ..... .... ... .... ... ..... .... ... .... ... .... ... ..... ....6-2

Locating Print Media Jams 6-2

Clearing Front Inside Area Jams 6-4

Clearing Paper Cassette Area Jams 6-6

Clearing Front Upper Door Area Jams 6-7

Clearing Multipurp ose Tray Area Jams 6-8

Status Messages ......................... .................................................6-9

Service Messages ......................................................................6-11

HP-GL and PCL Error Codes .....................................................6-12

HP-GL Error Codes 6-12

PCL Error Codes 6-13

Testing PC-Printer Communication .........................................6-13

Creating the Test File 6-13

Sending the Test File 6-14

Printer Problem Checklist .......... .............. ................... ............ ..6-18

IBM PC and Compatible Computer Checklist 6-20

Apple Macintosh Checklist 6-21

Control Panel Problems ............................................................6-22

Data Indicator Stays Lit 6-22

Contents iii

Page 6

Paper Jam Message Stays On 6-22

Paper Size Mismatch 6-22

Toner Out Message Displays 6-23

Driver Prob lems .. ..... .... ... ....... .... ... ..... ...... ... ..... .... ..... ... ...... ... ..... 6-23

LaserWriter 8.x Driver Printing Problems 6-23

QMS Windows Driver Printing Problems 6-24

Emulation Probl ems .......................... ....... ....... ..... ....... ......... ..... 6-24

Emulation Error 6-24

PostScript Pri nt Job Doesn't Print 6-24

PostScript Level 1 Problems 6-24

Fon t Pr oble m s ...... ............ ..... ............ ......... ............ ..... .............. 6-2 5

Can't Access Downloaded Fonts 6-25

Can't Download Fonts 6-25

Intellifonts Not Available 6-26

Hard Disk Problems .................................................................. 6-26

IDE Internal Hard Disk Not On Line 6-26

External SCSI Hard Disk Not On Line 6-27

Output P r o blem s ..... ......... ............ ..... ................ ..... ............ ....... 6-2 7

600x600, 1200x600, or 1200x1200 dpi Printing Unavailable 6-27

Binary Data Printing Problem 6-28

Blank Pages 6-28

End-of-Document (EOD) Command Probl em s 6-29

Multiple Pages Problem 6-29

NetWare Banner Page Job Doesn't Print 6-30

Not All Pages Print 6-30

Orientation Problem 6-30

PostScript Error with Error Handler Enabled 6-30

Start-up Page Doesn't Print 6-31

Status Page Problems 6-31

Printer Reset Problems ............................................................. 6 -32

General Print Qu ality Pr oblem s ....... ...... ..... ..... ..... ..... ....... ...... . 6-32

Specific Pri nt Qual i ty Pro blem s ......... ..... .... ... ..... ...... ... ..... ...... . 6-33

Black Image (Entire Page) 6-33

Blurred Background 6-33

Dark Image (Entire Page) 6-33

Light Image (Entire Page) 6-34

Stain Along the Edge of the Page 6-34

Stains on the Back of the Page 6- 34

QMS 166 0 Pri nt System Operati o niv

Page 7

Toner Smudges 6-34

Uneven Print Density 6-34

White or Light Lines 6-35

Placing a Service Call ................................................................6-35

A QMS Customer Support

Sources of Supp ort ......... ....... ..... ...... ... ..... ..... ....... ....... .... ..... ..... . A-2

Your QMS Vendor A-2

Your Application Vendor A-2

Q-FAX A-2

The QMS Corporate Bulletin Board System A-3

CompuServe A-3

Internet A-3

QMS Customer Response Center (CRC) A-4

QMS National Service A-4

QMS World-wide Offices ............................................................ A-5

Index

Contents v

Page 8

Page 9

1

Introduction

In This Chapter...

n

About this manual

n

Typographic conventions

Page 10

Introduction

Introduction

This manual provides information you may need only once in a while.

Use it in conjunction with your other QMS 1660E Print System documentation.

This chapter gives you a brief overview of this manual.

About This Manual

The informati on in thi s manual is divided into the foll owing secti ons :

Introduction

1

Consumables

2

Advanced Printing

3

Features

Printer Care

4

Print Quality

5

Provides an overview of the manual.

Describes how to load paper in the

250-sheet cassette and multipurpose

tray, how to load labels and

transparencies, and how to replace

the toner cartridge.

Explains how to use the printer’s

three resolutions, print on both sides

of a sheet of paper, chain cassettes,

collate output, print a status page,

cancel a print job, and end a print job.

Describes how to handle and clean

the printer.

Shows how to improve print quali ty

through a discussion of print

resolution, print density, and gamma

correction.

QMS 166 0 E Print System Oper atio n1-2

Page 11

About This

Manual

Troubleshooting

6

QMS Customer

A

Support

Provides media jam prevention tips,

explains how to locate and clear

media jams, lists printer status

messages, outlines printer and print

quality problems and solutions, and

describes how to place a service call.

Provides world-wide product sales

and support telephone numbers and

describes how to communicate with

QMS through the QMS Bulletin

Board, CompuServe, the Internet and

Q-FAX.

Index

Typographic Conventions

The following typographic conve ntions are used in this manual:

Mixed-Case

Courier

Mixed-Case

Ital ic

Cour ier

UPPERCASE

COUR IER

lowercase bold PostScript operators and DOS commands

lowercase italic

UPPERCASE File and utility names

↵ Press the Enter key (PC) or Return key (Macintosh)

^ Press and hold down the Ctrl key (PC)

Text you type, and messages and information displayed

on the screen

Variable text you type; replace the italicized word(s) with

information specific to your printer or computer

Information displayed in the printer message window

Variable information in text

» Note:

▲ Caution

Notes contain tips, extra informati on, or important inform ation

that deserves emphasis or reiteration.

:

Cautions present information that you need to know to avoid

equipment damage, proce ss failure, or extreme annoya nce.

Introduction

1-3

Page 12

About This

Manual

M

WARNING

specific procedure is not performed exactly as des cribed in the

manual.

!

Warnings indicate the possibility of personal injury if a

ACHTUNG!

beschriebene Vorgehensweise, da sonst Verletzungsgefahr

bestehen könnte.

Bitte halten Sie sich exakt an die im Handbuch

v

QMS 166 0 E Print System Oper atio n1-4

Page 13

2

Consumables

In This Chapter . . .

n

Loading paper in the 250-sheet paper cassette

n

Loading paper in the multipurpose t ra y

n

Loading labels

n

Loading transparencies

n

Replacing the toner cartridge

Page 14

Introduction

Introduction

This chapter describes how to pre vent media jam s, how to load the

250-sheet media cassette and the multipurpose tray, how to load

transparencies and labels, and how to replace the toner cartridge in

the printer.

Preventing Print Media Jams

Many printer problems are caused by improper handling of media.

There are several things you can do to reduce the chance of media

jamming in your printer:

n

Use print media that meets the guidelines set for the printer. (See

the “Consumable Supplies” section of appendix B, “Technical

Specifications,” in the

n

Make sure print media is not folded or wrinkled.

Reference

, for more complete inform at ion. )

n

Do not overfill the multip u rpose t ray or the p aper cassettes. The

multipurpose tray holds about 100 sheets of paper, 50 transparencies, or 40 labels; the standard cassettes hold about 250

sheets of paper. An optional 500-sheet pape r cassette is also

available.

n

If you have problems with multiple sheets of paper or transp arencies feeding through the printer, remove the paper or transparencies from the tray or cassette and fan the edges. The sheets may

be sticking together.

n

Store media away from moisture and hum idit y. They may cause

media to turn up at the edges or wrinkles to occur. The recommended relative humidit y duri ng operation is 20% -80% .

n

Load media printing side down. The printing side of paper is indicated on the paper wrapping.

QMS 166 0 E Print System Oper atio n2-2

Page 15

Loading the

250-Sheet

Paper Cassette

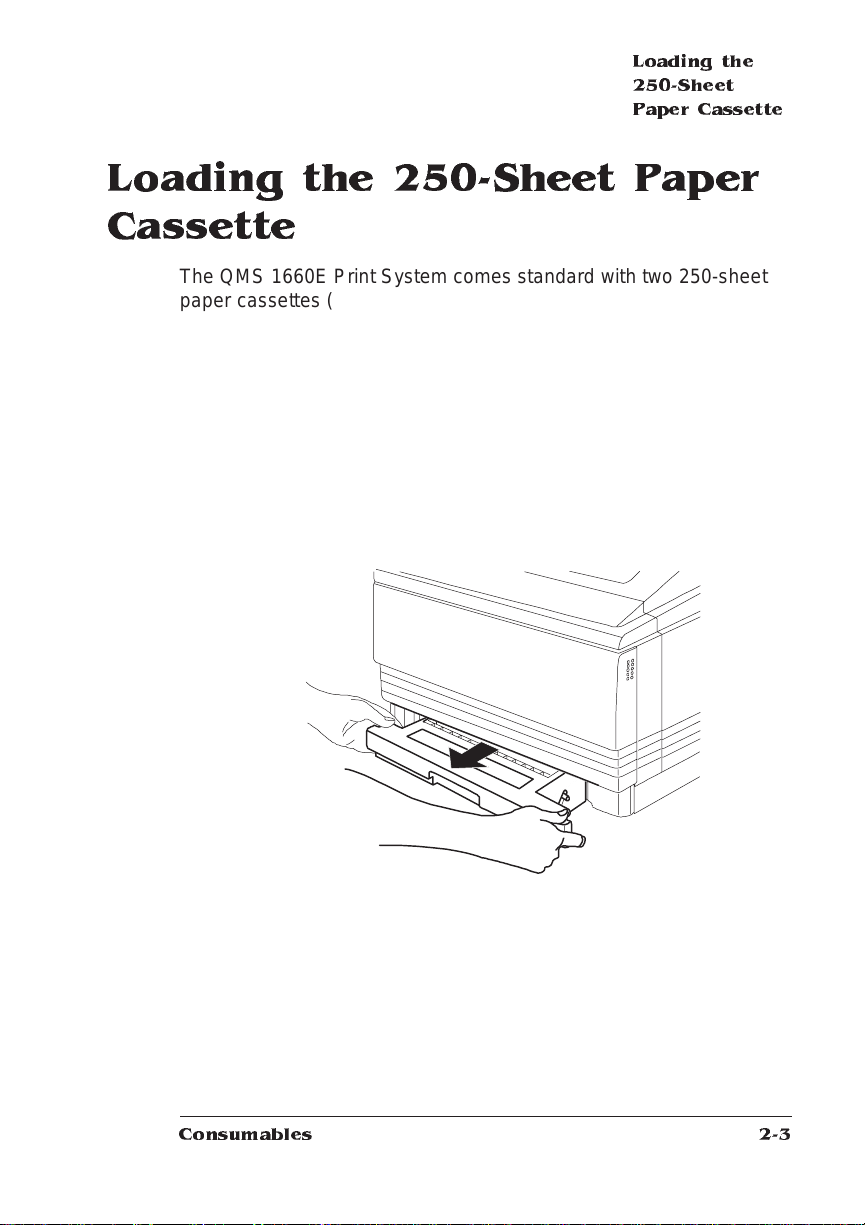

Loading the 250-Sheet Paper Cassette

The QMS 1660E Print System comes standard wit h two 250-sheet

paper cassettes (letter/A4 and 11"x17"/A3). The printer aut oma tical ly

pulls paper from the cassette.

» Note:

The paper size must match the paper cassette size. Since the

paper cassette sends a paper size signal to the printer controlle r,

using the wrong size paper will cause your image to be positioned

incorrectly on the page or clipped. You may purchase additional

cassettes from your QMS vendor.

Load paper in either 250-sheet cassette as follows:

1 Remove the paper cassette from the printer.

2 Align the pap er stack on a flat surfa ce.

Consumables

2-3

Page 16

Loading the

250-Sheet

Paper Cassette

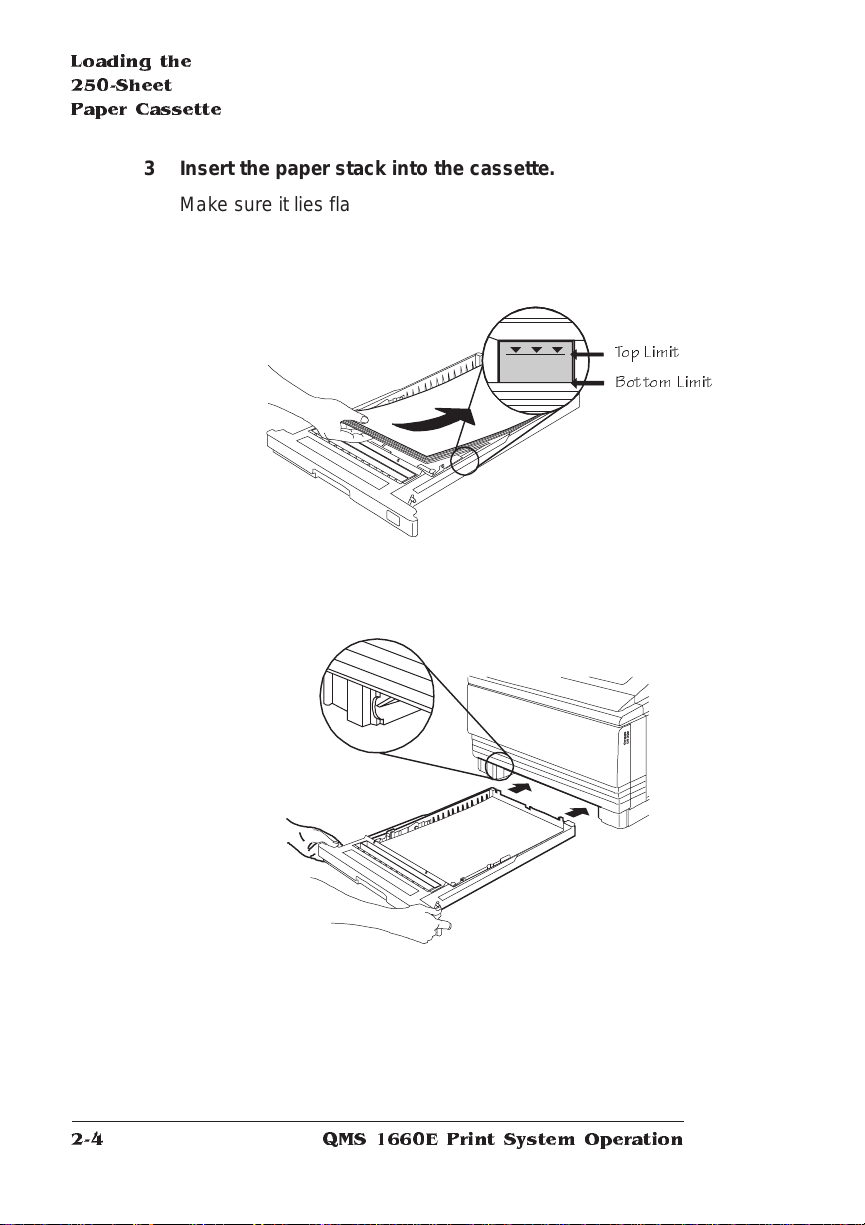

3 Insert the paper stack into the cassette.

Make sure it lies flat, does not exceed the top limit mark, and

rests under the retaining clips. The cassette holds about 250

sheets of 20 lb (75 g/m

4 Insert the paper cassette into the cass et te installatio n slot.

2

) paper.

Top Limit

Bottom Lim it

QMS 166 0 E Print System Oper atio n2-4

Page 17

Loading the

250-Sheet

Paper Cassette

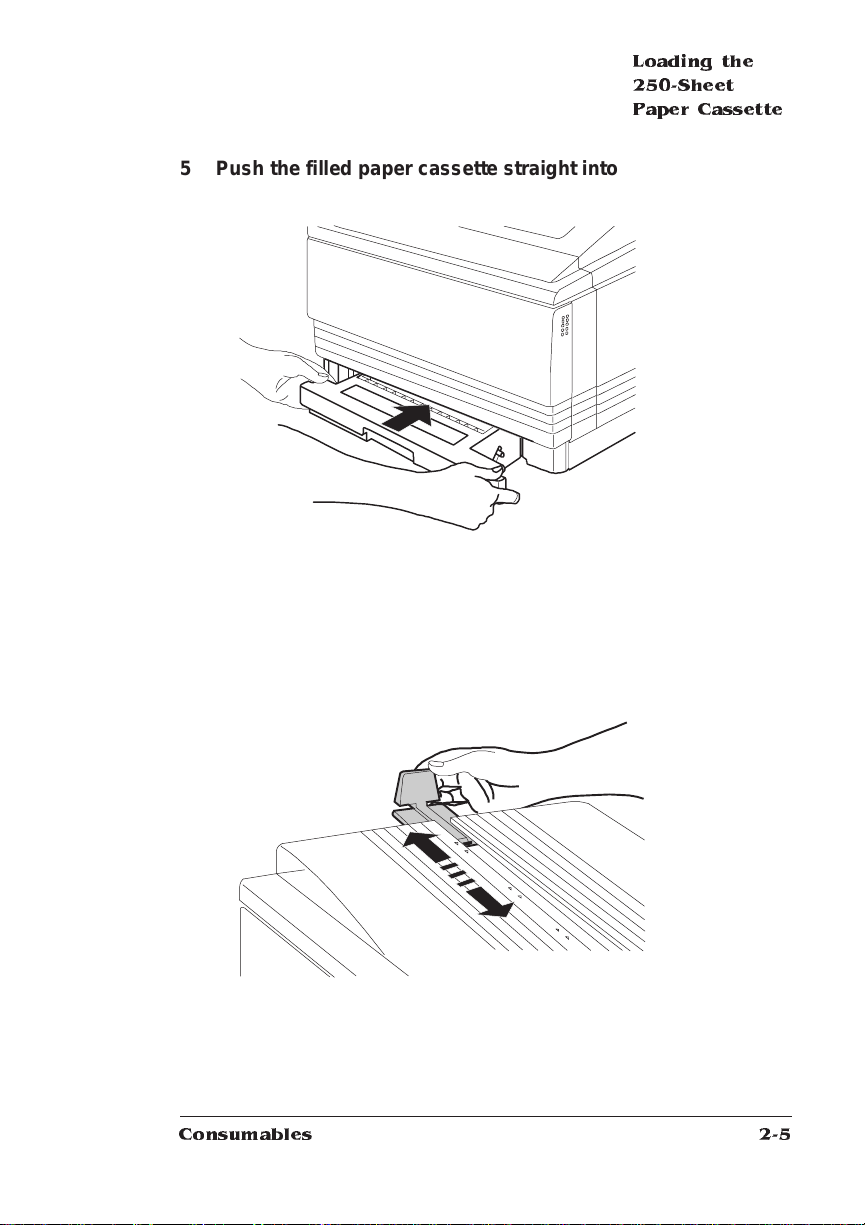

5 Push the filled paper casse tte straight into the installatio n

slot until it is firmly seated.

6 Adjust the media stop to fit the paper size.

The printer delivers your output print-side down to the output tray

at the top of the printer. The media stop keeps the output positioned in the tray.

Consumables

2-5

Page 18

Loading the

Multipurpose

Tray

7 If necessary, install the cassette rear cover(s).

If you’re using one or more 11" x 17"/A3 or legal/B4 paper cassettes and the cassette rear covers aren’t installed, install them

now.

Loading the Multipurpose Tray

Use the multipurpose tray to print on label stock, odd-sized paper,

and transparencies. The multipurp ose tray is also especially useful if

you want to print on a single sheet of letterhead or colored paper without changing the paper in the paper cassette.

This section explains how to load print media in the multipurpose tray.

For tips on how to get the best possible printing result s from media

other than paper, see “Envelopes: Special Considerati ons,” “Label s:

Special Considerations,” “Letterhead and Memo Paper: S pecial Considerations,” and “Transparencies: Special Considerations,” at the

end of this section.

» Note:

A PAPER SIZE MISMATCH error can be caused if the media in

the multipurpose tray is not the media size selected for the

multipurpose tray (inputbin 1). If the printer supports the media size

you want, insert the correct size media in the multipurpose tray. If the

printer does not support the media size you want, select the universal

media size to clear the error. See “Media Size” in chapter 4, “Printer

Configuration,” of the Reference for more informat ion on

multipurpose size.

QMS 166 0 E Print System Oper atio n2-6

Page 19

Loading the

Multipurpose

Tray

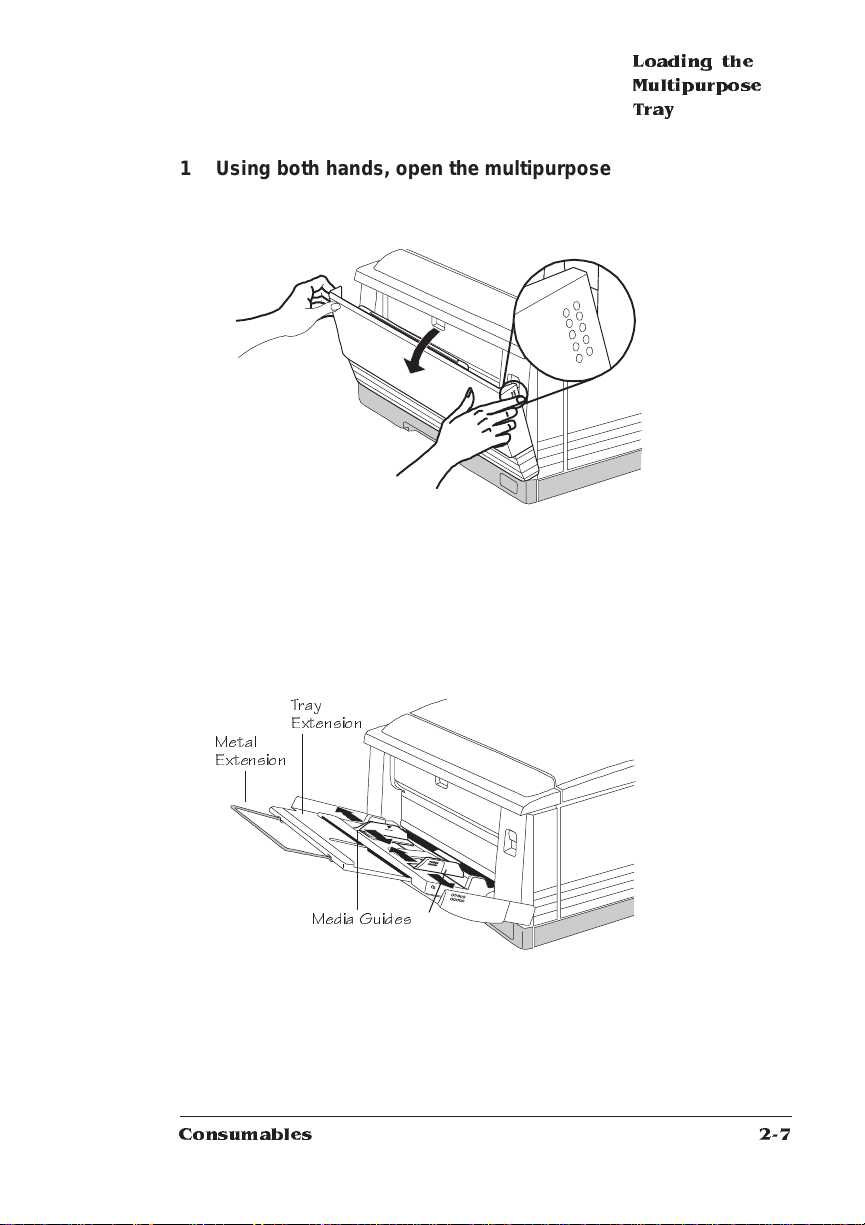

1 Using both hands, open the mul tip urp ose tray.

The tray opens to about a 65° angle.

2 Adjust the multip urp os e tray exte nsi on to fit the media siz e.

You may also need to pull out the metal extension.

3 Adjust the med ia guid es to the size of the medi a.

Tray

Extension

Metal

Extension

Media Guides

Consumables

2-7

Page 20

Loading the

Multipurpose

Tray

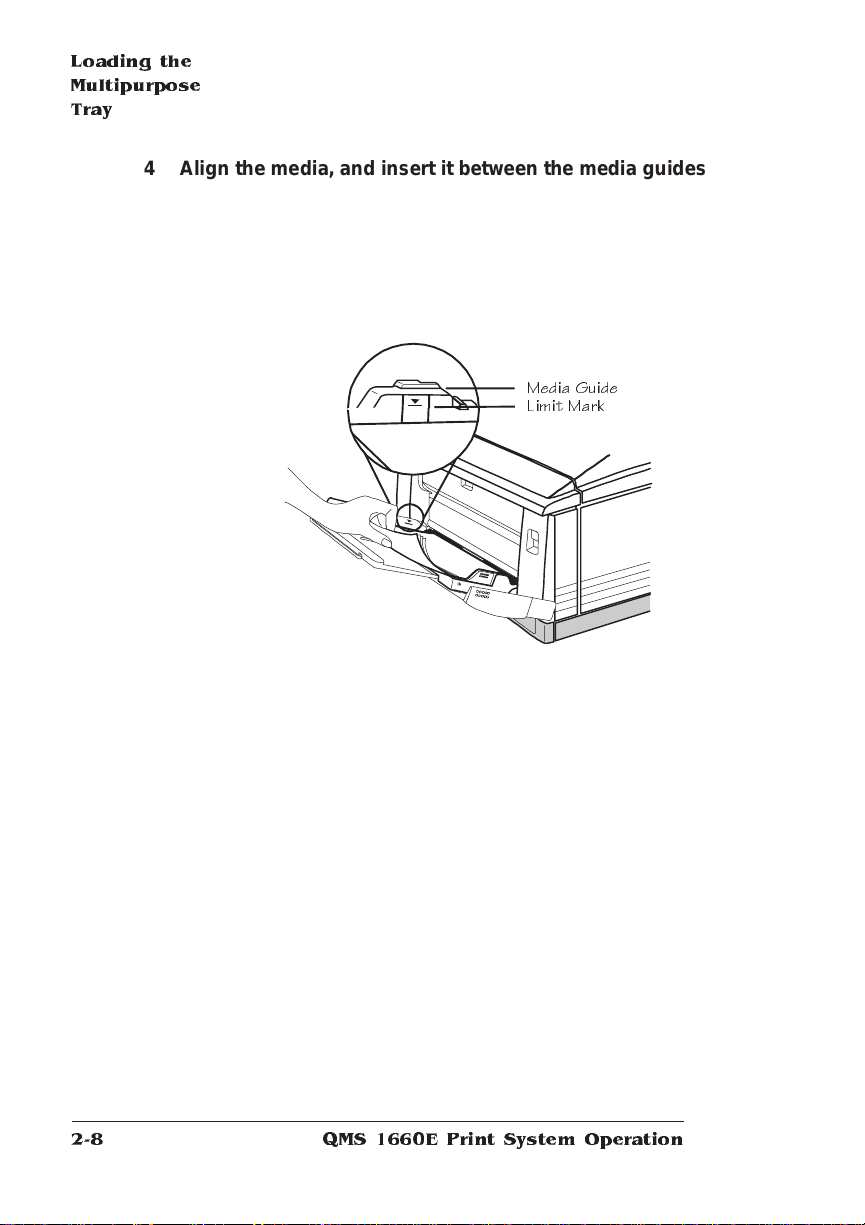

4 Align the media, and insert it betwe en the medi a guid es as

far as possible into the printe r, making sure it doesn’t

exceed the limit mark on the media gui de.

The multipurpose tray holds about 100 sheets of 20 lb (75 g/m

paper, 50 transparencies, or 40 labels. Load 8.5" x 11"/A4 media

lengthwise (long edge first).

Media Guide

Limit Mark

2

)

QMS 166 0 E Print System Oper atio n2-8

Page 21

Loading the

Multipurpose

Tray

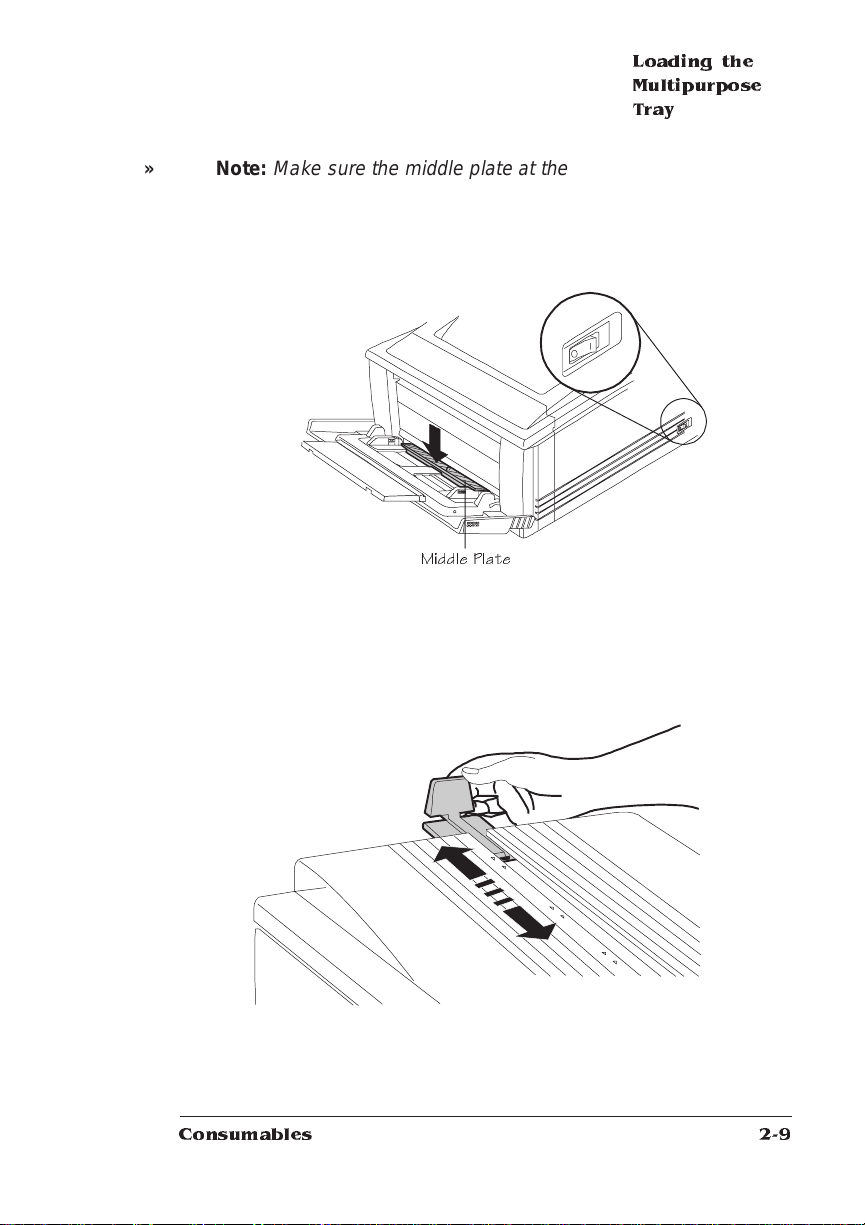

» Note:

Make sure the middle plat e at the mult ipurpose t ra y’s

media entrance is lowere d before insert ing the medi a. If the

middle plate is raised, turn the power off and back on again

before inserting the media.

Middle Plate

5 Check the media guides to make sure they touch the sides of

the print media.

6 Adjust the med ia stop to the correc t media siz e.

Consumables

2-9

Page 22

Loading the

Multipurpose

Tray

Envelopes: Special Considerations

The QMS 1660E Print System is not specifically designed to support

envelope printing. But if you want to test print a standard envelope to

see if the print quality is suitable for your needs, keep in mind the fo llowing considerations:

n

Use landscape orientation to create the envelope text in your

application short-edge first.

n

Set the multipurpose tray to universal paper size.

n

Feed the envelope in the multipurpose tray short-edge first.

See chapter 4, “Printer Configurat ion, ” of the

information on multipurpose tray size.

n

Open the envelope flap as soon as the envelope is deposited in

the output tray. This prevents the flap from sealing shut due to the

heat involved in the printing process. After inserting your document in the envelope, you can seal the flap as usual.

Reference

Labels: Special Considerations

Labels are printed from the mult ipurpose t ray. Keep in mind the following considerations:

n

Use only labels recommended for laser printers, such as Avery

5260 or Canon label stock.

n

Load up to 40 labels at a time in the multipurpose tray.

n

Format the label inform ation in your ap plicat ion. Try printing the

formatted inform at ion on a plain sheet of paper first to check

placement. (See your applicat ion docum ent ation for specifi c

information on formatting and printing labels.)

for more

QMS 166 0 E Print System Oper atio n2-10

Page 23

Loading the

Multipurpose

Tray

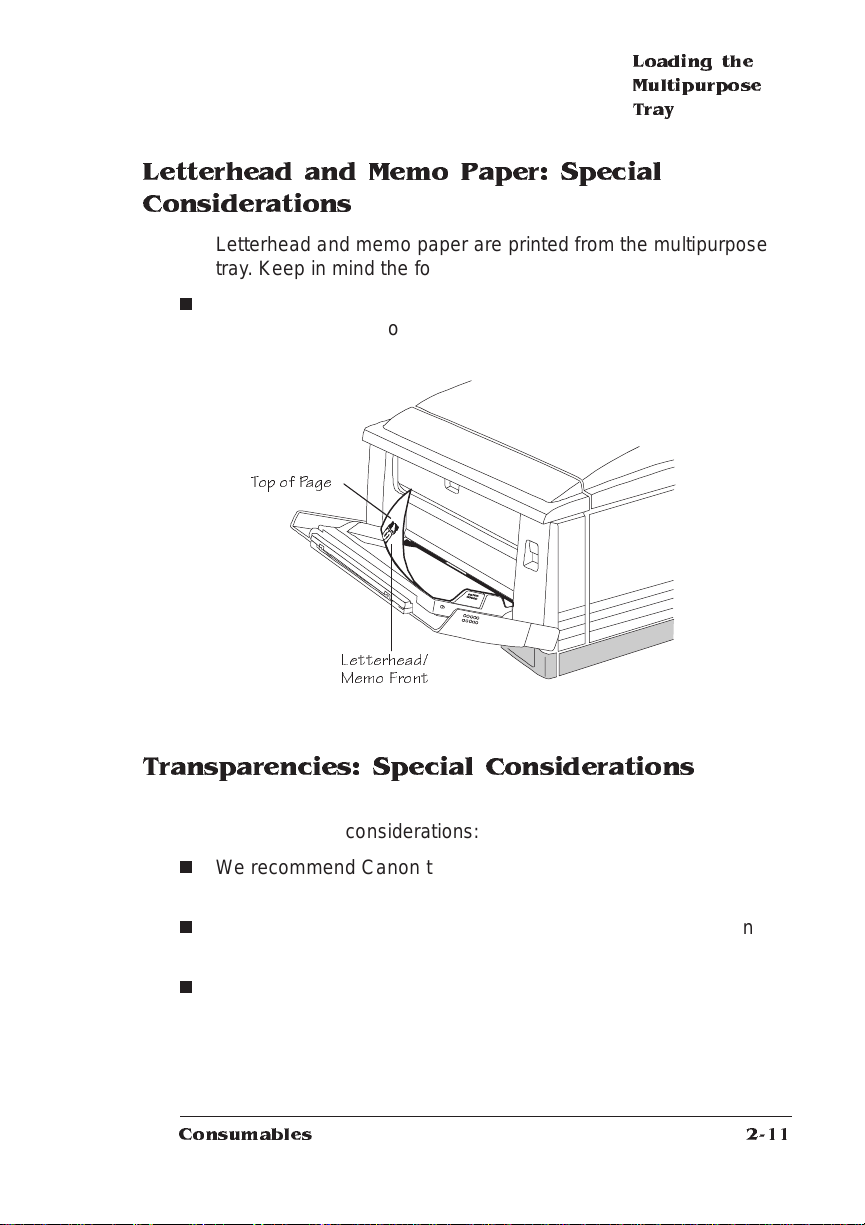

Letterhead and Memo Paper: Special Considerations

Letterhead and memo paper are print ed from the multipurpose

tray. Keep in mind the following:

n

Load the paper lengthwise (long edge first), face down, and with

the top of the page on the left side of the tray.

Top of P age

Letterhead/

Memo Front

Transparencies: Special Considerations

Transparencies are to be printed in the multipurpose tray. Keep in

mind the following co nsiderations:

n

We recommend Canon type D or 3M type PP2500 transparencies.

n

Slightly fan the stack of transparencies before loading them in the

multipurpose tray to prevent a jam.

n

Load transparencies printing side down. The correct print side is

usually marked on the transparen c y package.

Consumables

2-11

Page 24

Using Toner

Cartridge s

n

Load up 50 transparencies at a time in the multipurpose tray.

Loading a larger number of transparencies at a time may cause

static buildup.

n

Keep the media path clean. Transparencies are especially sensitive to a dirty path. If there are shadows on either the top or the

bottom of the sheets, refer to chapter 4, “Print er Care,” of the

Operation

n

Remove each transparency from the output tray before the next

sheet is printed to prevent jams or misfeeds.

manual for instructions on how to clean the path.

Using Toner Cartridges

Characters and images are created in your laser printer through a

process that applies toner (made of carbon particles) to the page in

the printer ’s fusing unit. When an image is formed, a positive electrical charge is applied to transfer the image to the page. The toner cartridge contains the toner and the photosensitive drum neede d to

operate the laser printer.

Toner Cartridge Life

In normal printing mode, a toner cartridge lasts for approximately

7,500 letter/ A4 -size pages at normal (5%) page coverage. If the

printer is run entirely in Conserve T oner mode (Administration/Engine/

Conserve Toner menu), a toner cartridge lasts for over 23,00 0 letter/

A4-size pages at normal (5% page) coverage.

The shelf life of an unopened toner cartridge is approximately one

year.

Toner Cartridge Storage

Toner cartridges

n

Are sensitive to bright light. Do not remove the toner cartridge

from its protective bag until you’re ready to install it.

QMS 166 0 E Print System Oper atio n2-12

Page 25

Using Toner

Cartridg es

n

Should be kept level during storage. Do not stand or store the

cartridge on its end.

n

Should be kept away from monitors, disk drives, and floppy disks.

The magnets in the cartridge can damage stored data.

The shelf life of an unopened toner cartridge is approximately one

year.

Refilled To ner Cartridges

QMS does not recommend using ref ille d toner cartridges on this

printer. Refilled toner cartridges may produce variations in toner quality and reliability and may reduce the print quality of your documents.

In addition, toner leaks affect your warranty.

Extending Ton er Cartridge Life

Redistributing T one r

When the toner supply is low, TONER OUT displays in the printer’s

message window, and parts of the page usually start printing lighter

than normal.

Sometimes, you can increase the life of the toner cartridge by taking it

out of the printer and redistributi ng the t oner—hold th e cartridge wit h

both hands and then gently rock it from side-to-side (as you do for a

new cartridge) five or six times. If the TONER OUT message remains

in the message window, you must replace the toner cartridge, as

described later in this chapter.

Conserving Toner

To help you lower your printing costs, your printer provides an option

called Conserve Toner, which simulates draft-quality printing. T he

printer reduces the amount of toner used during printing by screening

the black dots in a 1:4.5 ratio. In other words, 1 black dot is printed for

every 4.5 black dots that would print in normal printing mode.

The Conserve Toner option can be enabled through your printer

driver or through the Administration/En gine/ Conserve Toner menu.

Consumables

2-13

Page 26

Using Toner

Cartridge s

» Note:

The Conserve Toner option is designed for draft printing only.

Turn off Conserve Toner when printing proof or final copies of

documents to avoid any possible distortion of patterns, halftone, and

images.

Replacing a Toner Cartridge

You may purchase additional cartridges from your QMS vendor. See

the “Print Engine Specification s” section of appendix B, “Technical

Specifications,” in the

tridges.

M

WARNING!

become extremely hot when the printer is used. Personal injury could

result if you touch those areas when opening the front cover or

removing the toner cartridge .

ACHTUNG!

heiß, wenn der Drucker in Betrieb ist. Es besteht daher

Verletzungsgef ahr, wenn Sie die Abdeckklappe öf fne n oder die

Tonerkartusche auswechseln wollen!

The fixing assembly and print delivery guide areas

Die Fixiereinheit und die Papierführung werden sehr

Reference

Removing the Empty Toner Cartridge

Remove the empty toner cartridge as foll ow s:

for more informat ion on to ner car-

1 Using both hands, open the mul tip urp ose tray.

2 Push up on the release button, and open the front cover.

QMS 166 0 E Print System Oper atio n2-14

Page 27

Using Toner

Cartridg es

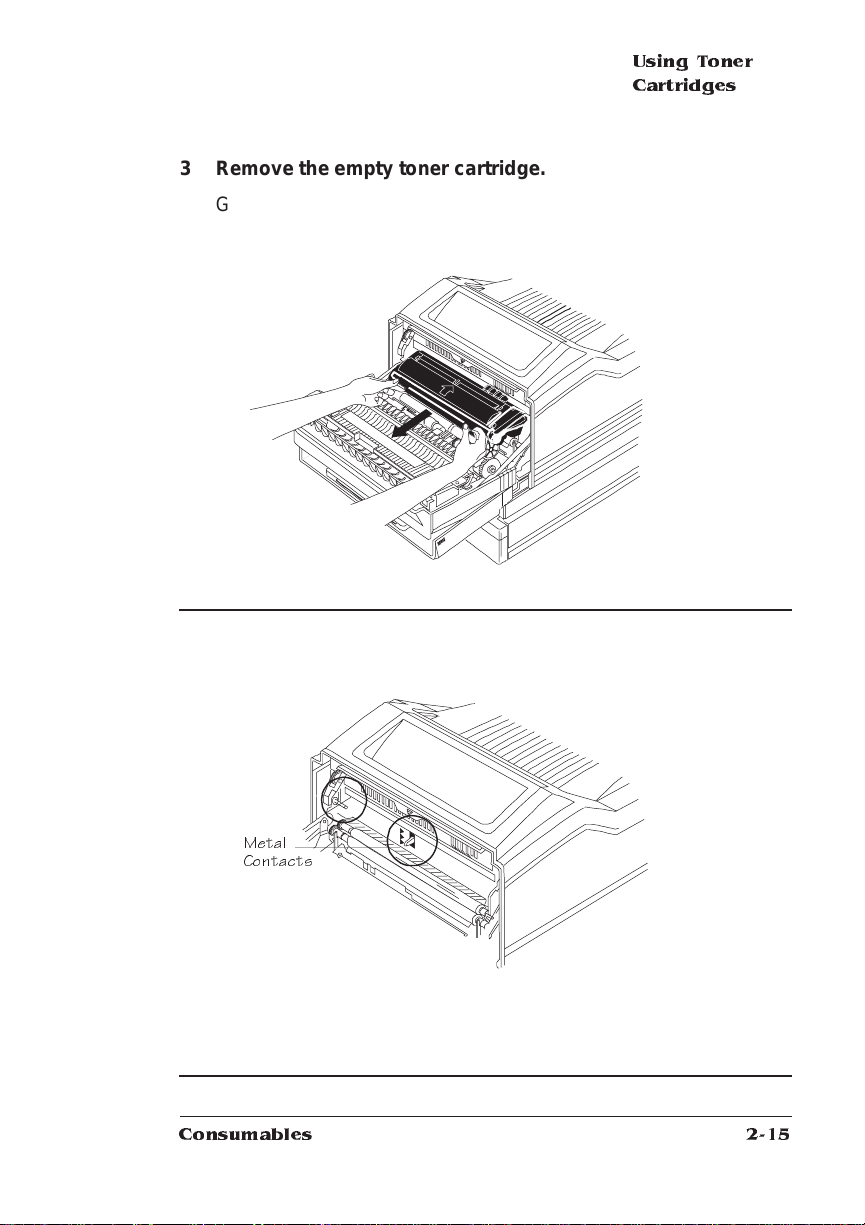

3 Remove the empty toner cartridge.

Grasping the green tabs of the empty toner cartridge with both

hands, remove the cartridge by pulling it toward you.

▲ Caution :

Do not touch or insert anything in the meta l contact s or the

opening circled in the following illustration. Corrosion or obstruction in

this area could cause the printer to malfunction.

Metal

Contacts

Put the old toner cartridge in a trash receptacle. Do not dispose of it

by burning.

Consumables

2-15

Page 28

Using Toner

Cartridge s

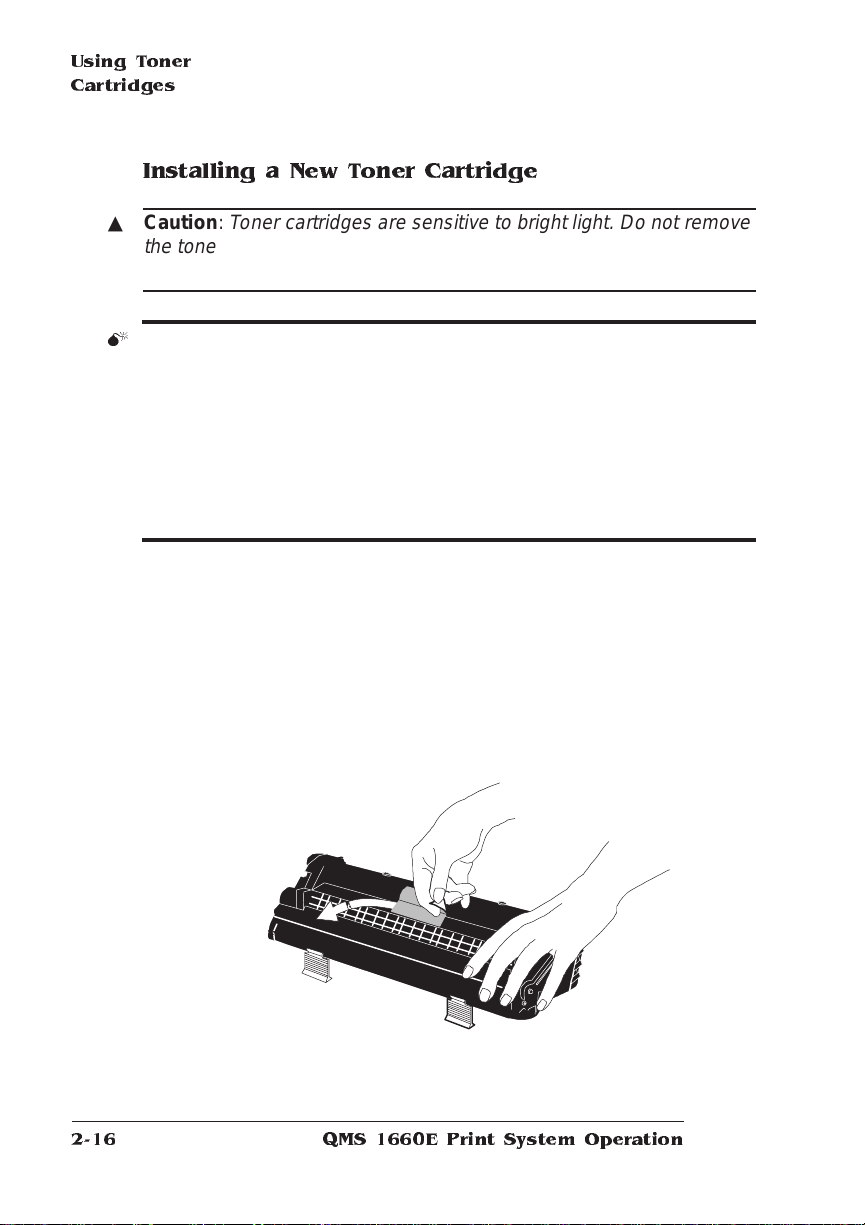

Installing a New Toner Cartridge

▲ Caution:

Toner cartridges are sensitive to bright light. Do not remove

the toner cartridge from its protective bag until you’re ready for

installation.

M

WARNING!

The fixing assembly and print delivery guide areas

become extremely hot when the printer is used. Personal injury could

result if you touch those areas when opening the front cover or

installing the toner cartridge.

ACHTUNG!

Sowohl die Fixiereinheit als auch die Papierführung

werden im Druckbetrieb extrem heiß. Um Verletzungen zu

vermeiden, sollten diese Druckerpartien, z.B. wenn Sie eine neue

Tonerkartusche einlegen, nicht berührt werden!

Use the following proce dure to install a new tone r cartrid ge:

1 Lift the toner cartri dg e out of its sh ippi ng carto n, ope n the

aluminum pr otecti ve bag , and remove the cartrid ge.

2 Remove the black pro tective sh eet, an d discard it.

Place the cartridge on a stable, flat surface to get a good grip on

the protective sheet tab.

QMS 166 0 E Print System Oper atio n2-16

Page 29

Using Toner

Cartridg es

3 Distribute the toner in the cartridge.

Hold the cartridge with both hands, and gently rock it from side to

side five or six times to distribute the toner.

Consumables

2-17

Page 30

Using Toner

Cartridge s

4 Remove the tape seal.

Hold the cartridge in place with one hand and, using your other

hand, grasp the orange tab on the right side of the tape seal.

Keeping the toner cartridge parallel to the flat surface, pull the

orange tab straight out (26.4"/67 cm). Discard the orange tab and

tape seal.

Tape Seal

▲ Caution:

Once the toner cartridge is installed, each time the front

cover of the printer is opened, the drum protective shutters open and

the drum surface is exposed to light. This may deteriorat e the drum

and reduce print quality.

QMS 166 0 E Print System Oper atio n2-18

Page 31

Using Toner

Cartridg es

5 Slide the toner cartridg e into the printer.

Grasp the green tabs on the toner cartridge, and place the cartridge on the rails inside the printer. Then, slightly lifting the green

tabs, slide the cartridge straight back into the printer un til it is

firmly seated.

6 Close the front cover, and then close the multipur pos e tray

(if it’s not being used).

v

Consumables

2-19

Page 32

Page 33

3

Advanced Printing Features

In This Chapter . . .

n

High-resolution printing

n

Double-sided printing

n

Chaining cassettes

n

Collating output

n

Printing a status page

n

Canceling a print job

n

Ending a print job

Page 34

Introduction

Introduction

This chapter describes how to change print resolution, print on both

sides of a sheet of paper, chain cassettes, collat e output, print a status page, cancel a print job, and end a print job.

High-Resolution Printing

The QMS 1660E Print System supports three print resoluti ons:

300x300 and 600x600 dpi (dots per inch), and either 1200x600 or

1200x1200 dpi.

» Note:

If you purchased a printer with 12 MB or 24 MB of RAM, you

can print at 1200x1200 dpi by installing an optional 1200x1200 dpi

resolution daughterboard. (You will also need to add more memory;

see the following section for detail s.) If you purchased a printer with

48 MB of RAM, the 1200x1200 dpi resolution daug hterb oard is

already installed. In either case, the 1200x1200 dpi capability

replaces the 1200x600 dpi capability; they are not available

simultaneously.

Menu Administration/Engine/Def Resolution

Choices 300 dpi—300x300 dpi resolution

600 dpi—600x600 dpi resolution

or

1200 dpi—1200x600

Default 600 dpi

1200x1200 dpi resolution

Memory Requirements for High-Resolution Printing

The amount of memory you need to print at each resolution depends

on the size media you are using.

The following table lists the mini mum memory requirem ent s for each

resolution/media comb inat ion.

QMS 166 0 E Print System Oper atio n3-2

Page 35

High-

Resolution

Printing

» Note:

If a certain resolution is chosen and the minimum amoun t of

memory is not installed in the printer, the file is printed using the next

lower resolution. For example, if you choose 1200x1200 dpi

resolution and 11x17 media, but the printer has only 24 MB of RAM

instead the required 40 MB mini mum , the file print s at 600x600 dpi.

Media Minimum RAM (in MB)

300x300 dpi 600x600 dpi 1200x600 dpi* 1200x1200 dpi*

11x17

12x19

A3

A4

A5

A6/Postc a rd

B4

B5

B6

Executive 12 12 12 20

Full Ledger 12 16 24 40

Legal

Letter

Postcard/A 6 12 12 12 12

Universal 12 16 24 40

*1200x600 dpi resolution is not available on printers in which a 1200x1200 dp i

resolution daughterboard is installed.

12

12

12

12

12

12

12

12

12

12

12

12

16

16

12

12

12

12

12

12

12

12

20

24

24

12

12

12

16

12

12

16

12

40

48

40

20

12

12

32

16

12

24

20

Advanced Printing Feature s

3-3

Page 36

Double-Sided

Printing

Double-Sided Printing

You can print on both sides of a sheet of paper using the multipurpose

tray. After printing one side, insert the paper in the tray with the side

you want to print next facing down.

▲ Caution :

curling can cause print media jams and wrinkles on the printed page.

Straighten the front of the paper if it’s curled because

Top of

Page

Cassette Chaining

The QMS 1660E Print System comes standard wit h two 250-sheet

cassettes: letter/A4 and 11" x 17"/A3. You can insert only one of these

cassettes at a time in the printer unless you purchase an optional

paper feeder. The optional paper feeder allow s you to install another

250-sheet cassette, increasing paper feed capacity to 500 sheets, or

600 sheets including the 100-sheet multipurpose tray.

Printed

Side of Page

Attaching an optional cassette supporter to the paper feeder allows

you to install an optional 500 -she et cas sette, increasing paper feed

QMS 166 0 E Print System Oper atio n3-4

Page 37

Cassette

Chaining

capacity from 250 to 750 sheets, or 850 sheets counting the multipurpose tray.

You may choose to have the printer automatically draw from the

optional cassette when the standard 250-sheet cassette is empty.

There are three ways to do this:

n

Use your application if it includes a procedure for using a dualcassette printer. Check your documentation.

n

Use the PS Executive Series Utilities to configure the print er's

paper source.

n

Configure your printer for cassette chaining through the printer's

control panel. The following section conta ins more inform ati on.

Chaining Cassettes

The Chain Inputbins option in the Operat or Control menu allows you

to “chain” inputbins (tray and cassettes) so that when the first inputbin

empties, the printer aut oma tical ly draw s paper from another inputbin .

Menu Operator Control/Chain Inputbins

Choices Off—Doesn’t switch inputbins; uses only the default inputbin.

On—Switches to the next inputbin with the same size and type

of media when the default inputbin is empty.

On Any—Switches to the next inputbin, regardless of the size

and type of media installed, when the default inputbin is

empty.

Default On

Notes Use the Operator Control/Inputbin menu to set the default

inputbin.

Advanced Printing Feature s

3-5

Page 38

Collating Output

Collating Output

Collation is the printing of multiple copies of a document in numeric

order. The QMS 1660E Print System is collation capable . It can

deliver multiple copies of your document in collated or uncollate d

order to the output tray.

Menu Operator Control/Collation

Choices On—Enable collation.

Off—Disable collation.

Default On

The following figure show s collated and uncollat ed stacking for two

copies of a four-page file.

4

3

2

1

4

3

2

1

Collated Uncollated

1

3

2

2

1

4

4

3

Advantages of Collation

The main advantages of collation are convenience and the t ime savings derived from not having to separate and sort individual copies of

a document. Each copy of the document exists as a whole unless

chunk collation has occurred.

Working with Chunk Collation

To collate a multiple-copy document, the printer must have enoug h

display list memory to hold the display list (R1) blocks for all p ages in

the collation range. (See the “Mem or y” section of chapter 5, “Addi tional Technical Information,” in the

Reference

for more information

QMS 166 0 E Print System Oper atio n3-6

Page 39

Collating

Output

display list compressed blocks.) If there is not enough memory, chunk

collation occurs.

Chunk collation breaks a print job into several smaller collation

sequences. For example, in the following figure, copies a and b of

each collation sequence must be manuall y combined to create one

collated print job.

8

7

Copy 1(a) Copy 2(a) Copy 3(a) Copy 4(a)

4

3

Copy 1(b) Copy 2(b) Copy 3(b) Copy 4(b)

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

8

7

6

5

2

1

6

5

4

3

2

1

If chunk collation does occur, it may be best to use a header and/or

trailer page to determine the beginnin g and end of each collat ion

sequence. (See chapter 4, “Printer Configuration ,” of the

Reference

for more information on using head er and trailer pages.

Improving Collation Performance

To improve collation performance greatly, which allows you to collate

longer and more complex print jobs, do one of the following:

n

Add more memory (SIMMs), which automat ically increases the

size of the Display List memory client. See chapte r 6, “Printer

Options,” of the

tional memory.

Reference

for information on how to insta ll addi-

n

Add any memory, if available and not being used by other clients,

to the Display List memory client (Administration/Memory/K Mem

Display menu). See chapter 5, “Additional T echnical Information,”

Advanced Printing Feature s

3-7

Page 40

Collating

Output

of the

Reference

system’s memory.

for more information on configuring your print

▲ Caution:

This option should be used only by individuals who are

familiar with adjusting memory client s’ values. Incorrect use of

this option could cause your system to operate incorrectly.

n

If the print system has an optional hard disk (internal or external),

turn on Enable Disk Swapping (Adm inist rati on/M em ory/E nab le

Disk Swap menu). The extra memory is distributed to all memory

clients.

n

Collate through your application.

» Note:

Collating through your application is more time consuming

than collating through the print e r. The application sends the

complete job the requested number of times rather than sending

it once and holding data in printer memor y.

A Note About Collating PCL 5 Files

PCL 5 allows you to set the number of copies you want to print per

page rather than per file. When collation is turned off, the printer

prints the requested number of copies for each page. However, when

collation is turned on, the printer looks at the number of copies

requested for the first page of the file and prints that many copies of

each page.

Example— You have a 3-page PC L 5 file and specify 3 copies of

page 1, 1 copy of page 2, and 2 copies of page 3.

n

With collation t urned off, the pages print in the following orde r:

1, 1, 1, 2, 3, 3.

n

With collation t urned on, the pages print in the following order:

1, 2, 3, 1, 2, 3, 1, 2, 3.

QMS 166 0 E Print System Oper atio n3-8

Page 41

Working with

Status Pages

Working with Status Pages

Printing a status page is a two-step procedure: Identify the type of

status page you want to print, and then print it.

Identifying a Status Page Type

Two types of status pages are available:

n

Standard— This one-page document provides printer identification information (printer type and nam e, firmware version and

release, and number of sheets printed), printer sett ings (Po stScript level, start-up options, paper handling inf ormatio n, resolution, and gamma correction), current memory con figurati on,

timeouts, comm unicat ion sett ing s and input buffer sizes for all

standard and optional network interf aces, and hard disk status

(address, size, and free space). In addition, an angle bar prints in

the lower-left corner for image alignment.

n

Advanced—This docum ent , which can be five or more pages

long, contains the same informat ion as the stand ard statu s page

as well as configuration menu setting s and a full list of fonts and

downloaded emulations.

Menu Administration/Special Pages/Status Page Type

Choices Standard, Advanced

Default Standard

Printing a Status Pa ge

After you have identified the type of status page to print, send it to the

printer in one of the following ways.

» Note:

If you choose an advanced status page but only a standard

status page prints, the printer has run out of RAM. Either reall ocate

memory among the mem o ry clients (see chapter 5, “Addit ional

Technical I nformat ion, ” in the

printer (see chapter 6, “Printer Options, ” in the

n

Press the Status Page key on the printer control panel.

Advanced Printing Feature s

Reference

) or add more memory to the

Reference

).

3-9

Page 42

Cancelling/

Ending Print

Jobs

n

Use the PS Executive Series Utilities (see the PS Executive online help for instructions).

» Note:

Only standard status pages can be printed from PS

Executive. Advanced status pages are not available.

Cancelling/Ending Print Jobs

The Cancel key has two functions:

n

It cancels all print jobs that are currently printing, interpreting,

spooling, or terminating .

n

It allows you to send an end-of-job indicator to a currently compiling print job that is waiting for incoming dat a.

You don’ t have to press the Online/Offl ine key to take th e printer off

line before using the Cancel key. There are no equivalent functions in

the configuration menu.

» Note:

Cancelling a Print Job

If you need to cancel the cancel job or end job procedure,

press the Menu key.

Press the control panel keys in the order shown in the followi ng

instructions to cancel a print job.

Press this

key ...

Cancel Access the Cancelling Job menu. You

to... The message window

are prompted for co nfirmation that you

want to cancel the print job.

QMS 166 0 E Print System Oper atio n3-10

reads...

CANCELLING JO B?

YES

Page 43

Cancelling/

Ending Print

Jobs

Cancel or

Select

Select Yes. YES

IS SE LECTED

Cancel all print jobs in the queue that

are currently printing, interpreting,

spooling, or terminating. The

CANCELLING JO B me ssage displays

until the print job is completely removed

from the printer.

CANCELLING JO B

Ending a Print Job

If the first print job in the queue is waiting for, but not receiving, the

data it needs to finish printing, the message window displa ys

WAITING FOR INPUT

END JOB?

Use the following procedure to end all print jobs in t he queue that are

waiting for incoming data.

» Note:

This procedure does not end a print job that is still receiving

data. Its only purpose is to provide an end-of-job indicat or for a print

job that does not have one. You can identify an end-of-job indicator in

the Administrati on/ Com mun icati ons/P arall el/En d Job Mode and

Administration /Com m unicat ions/ Serial/ E nd Job Mode menus. (S ee

chapter 4, “Printer Configuration,” in the

Reference

for more

information). Also see chapter 5, “Additional Technical Information,” in

the Reference for a complete discussion of End Job Mode.

Press this

key ...

Cancel Access the Cancelling Job menu. CANCELLING JO B?

Next Advance to the End Job option. CANCELLING JO B?

Cancel or

Select

to... The message window

reads...

YES

END JO B

Select End Job. END JO B

IS SE LECTED

v

Advanced Printing Feature s

3-11

Page 44

Page 45

4

Printer Care

In This Chapter...

n

Handling the printer

n

Cleaning the printer

Page 46

Introduction

Introduction

Blurred or splotchy prints and paper jams can result from dusty printer

parts. Regular cleaning takes only a few minute s and helps ensure

print quality.

This chapter describes how to handle and clean the printer.

Handling the Printer

Handle the printer with care to preserve its appearance and to ensure

maximum performan ce. Abuse may ca use damage. Keep the following guidelines in mind:

n

Do not place anything on the top of the printer.

n

Do not place anything on the multipurpose tray except the media

being used for printing.

n

Do not leave the printer open for any length of time, esp ecially in

well-lit places; light may damage the toner cartridge.

n

Wait until the printer has cooled down before covering it with a

dust cover.

n

Lift the printer from the bottom only. Make sure two people are

available to lift the printer when moving it.

n

Keep media in the output tray at minim um level. If media st acks

too high, media may j am or curl .

n

Do not attempt to lubricate or disassemble the printer.

n

Store the printer under the following conditions when it’s not

going to be used for an extended period:

- Unplug the printer .

- See the “Environmental Requirem ent s” section of appendix

B, “Technical Specificati ons,” in the

specifications.

QMS 166 0 E Print System Oper atio n4-2

Reference

, for storage

Page 47

- Remove the toner cartridge from inside the printe r. After

removing the cartridge from the printe r, return it to the aluminum bag in which it was originally packaged or wrap it in a

thick cloth to prot ect it from direct sunlight or any other bright

light.

Conserving Energy

Your print er is compliant with US Environmental Protection Agency (EPA) Energy

Star regulations. The EPA Energy Star

Computers program promo tes the use of

energy-efficient personal computers, m onitors, and pri nters and the reduction of air

pollution caused by power generation.

The Energy Star option (Admini strat ion/ Engine/ E nergy Star men u)

specifies whether t he printer changes to a low-power state (the

engine remains on, but the fuser turns off) after a period of inactivit y.

When a print job is received, the printer returns to normal power

within 90 secon ds.

Conserving Energy

Printer Care

4-3

Page 48

Cleaning the

Printer

Cleaning the Printer

Your print er requires little cleaning. You need to clean only the following:

n

The film on the metal feed roller

n

The outside of the printer

Cleaning Guidelines

M

WARNING!

printer.

Unplug the printer’s power cord before cleaning the

ACHTUNG!

Sie den Drucker reinigen.

In addition to unplugging the printer, follow these guidelines when

cleaning the printer:

n

Use only water. Never use neutral detergents or other cleaning

solutions.

n

Do not leave moisture inside the printer. After cleaning, allow all

parts to dry thoroughly before closing the printer co ver.

n

Use a soft, lint-free cloth.

Ziehen Sie den Netzstecker aus der Steckdose bevor

Cleaning the Film on the Metal Feed Roller

To mainta in clea r, crisp print quality, clean the film on the metal fe ed

roller at the following times:

n

Every time the toner cartridge is changed.

n

Whenever print quality becomes unsatisfactory.

QMS 166 0 E Print System Oper atio n4-4

Page 49

Cleaning the

Printer

Procedure

1 Remove the toner cartridge.

This procedure is described in chapter 2, “Consumables,” of this

manual.

2 Clean the film on the metal feed roller.

Use a soft, water-dampened cloth. Wipe the area dry with

another soft cloth.

Film

Metal Feed

Rubber Fee d

Roller

Roller

Cleaning the Outside of the Printer

To protect and maintai n the appearance of your printer, wipe the

entire outside of the printer wit h a soft, slight ly damp clot h.

v

Printer Care

4-5

Page 50

Page 51

5

Print Quality

In This Chapter . . .

n

Selecting different resolutions

n

Adjusting the print quali ty

n

Changing the gamma correction

Page 52

Introduction

Introduction

Your print er provides the fl exibil ity to control seve ral print qualit y factors, including print resolution, print density, and gamma correction.

This chapter guides you in achieving maximu m print quality. For a

more detailed explanat ion of all of the factors that affect your printed

output, refer to chapter 5, “Additional Techn ical Inform ati on, ” in the

Reference

.

About Print R esolution

The QMS 1660E Print System supports three print resolutions:

or

300x300, 600x600, and either 1200x600

daughterboard is installed, 1200x1200 dpi (dots per inch). This choice

of resolutions allows you to customize the quality of your output

according to its use.

Menu Administration/Engine/Def Resolution

Choices 300 dpi—300x300 dpi resolution.

, if a 1200x1200 dpi

600 dpi—600x600 dpi resolution.

1200 dpi—1200x600 or 1200x1200 dpi resolution.

Default 600 dpi

» Note:

Printing at 600x600, 1200x600, and 1200x1200 dpi resolution

on certain media sizes requires additional memor y. See the “HighResolution Printing” section in chapter 3, “Advanced Prin ting

Features,” of the

Options,” of the

1200x1200 dpi daughterboard.

Operation

Reference

QMS 1660E Print System Oper atio n5-2

manual for details. See chapter 6, “Printer

manual for more informat ion on the

Page 53

About Print Density

Print density is the amount of toner placed on the page, making the

print appear lighter or darker. The higher the density, the darker the

print looks and the higher the contrast is on the page.

About Print

Density

» Note:

» Note:

If the print density is too light, make sure that the Administ ration/Engine/ Conserve Toner option is turned off before making any

adjustments. The Conserve Toner option saves toner by simulating

draft-quality print ing. (See chapter 4, “P rinte r Configura tion ,” of the

Reference

To adjust the print density use the followi ng procedure.

1 Open the multip urpose tray, push up on the front cover

2 Locate the density ad justm ent di al that is inside the printer

3 Adjust the dial to the desired setti ng.

for more information. )

release button, and open the front cover.

on the right side.

The scale on the density adjustm ent dia l shows the densit y setting; the dark marking identifies increased densit y, and the light

marking identifies reduced density.

To increase density (darken the print on the page), use your left

thumb to rotate the dial up. To decrease density (lighten the print),

rotate the dial down. The dial clicks at the center setting.

You may want to increase density as the toner cartridge

depletes.

To Darken

To Lighten

Print Quality

Density Adjustment Dial

5-3

Page 54

About Gamma

Correction

About Gamma Correction

Gamma correction is the compression or expansion of the ranges of

dark or light shades in a printed image to provide the best copy of

scanned images. Through manipulation of shading levels, your

printer can be set to improve the print quality of a scanned image

automaticall y. For detailed information of this procedure, se e chapter

5, “Additional Te ch nical Inform at ion,” in the

Reference

The main benefit of gamma correction is that it improves the print

quality of a scanned image by improving halftoning at a given resolution. To get the best gray-scale PostS cript image at any resolution,

gamma correction should be turne d on.

You can set gamma correction throu gh PS Execut ive or through the

Administration /Em ulat ions/Po stS c ript/Gamm a Correction menu .

Menu Administration/Emulations/PostScript/Gamma Correcti o n

Choices No—Disables gamma correction

Yes—Enables gamma correction

Default No

Notes Gamma correction is automatically adjusted when printer

resolution is changed. However, gamma correction has no

effect on files printed at 1200x1200 dpi resolution.

Gamma correction applies only to PostScript images.

.

If turning on gamma correction doesn’t yield a suitable grayscale image for your needs, set a specific gamma correction

value through your drawing application or through the

PostScript sett ransfer operator. (See your drawing application

documentation and the

Manual

for more information.)

PostScript Language Reference

QMS 1660E Print System Oper atio n5-4

Page 55

About Halftone Types

Your print er provides two diffe re nt types of halftone s—basic and

advanced. These two options allow you to customize the smoothness

of the printed image according to the number of grayscales it uses.

Menu Administration/Emulations/PostScript/Half tone Type

Choices Basic—Regular dot placement at 53 lpi for 300x300 res o lu tion

or 71 dpi for 600x600 resolution.

Advanced—Variable dot placement according to the grayscale

within the image. Generally, this option provides smoother

transitions between grayscales within the image.

Default Advanced

Notes When the advanced halftone type is chosen, gamma

correction (Administration/Emulati ons/PostScript/G amma

Correction menu) has no effect on the image.

The basic halftone type provides the same result as the

advanced halftone type at 1200x1200 dpi resolution.

About H alftone

Types

v

Print Quality

5-5

Page 56

Page 57

6

Troubleshooting

In This Chapter . . .

n

Preventing media jams

n

Removing media jams

n

Responding to status messages

n

Problem checklist

n

Print quality problems

n

Placing a service call

Page 58

Introduction

Introduction

This chapter offers media jam prevention tips, explains how to remove

media jams, lists and explains many control panel messages, outlines

possible printer and print-quality problems and solutions, and explains

how to place a service call.

Automatic Jam Recovery

With most printers, if a jam occurs, you must remove the jam med

media and then reprint the job. Howeve r, the QMS 1660E Print System provides automatic jam recovery (when enabled throug h the

Administration /Engin e/Page Recovery menu). If a media jam occurs,

remove the jammed media, and the printing auto maticall y resumes

from the page the printer stopped at when the jam o ccurre d .

» Note:

For automatic jam recovery to work, it i s necessary to leave the

printer turned on when you remove the jamme d media. After the jam

is cleared, open and close the front cover once before printing.

Printing will not resume unt il you do this.

Clearing Media Jams

Locating Print Media Jams

When print media jams occur , a PAPER JAM message displays in the

message window. Frequent jams in any area indicate that the area

should be checked, repaired, or cleaned. Repeated jam s may also

happen if you are using t he wrong weight print media. (See the “Print

Media” section of appendix B, “Technical Specifications,” in the

, for print media specifications.)

ence

QMS 1660E Print System Oper atio n6-2

Refer-

Page 59

Clearing Me di a

Jams

Print media jams can occur in any of the followi ng areas.

Fixing

Assembly

Area

Upper Cassette

Pick-up Roller

Lower Cassette

Pick-up Roller

Front Upper Door

Multipurpose

Tray Pick-up Roller

Check each of the indicated locations, and remove any jam me d print

media. Jams can occur in more than one location at a time, so be

sure to check all the indicated locations. After clearin g the jam,

always open and close the front cover once before printing. Printin g

will not resume until you do this.

When printing from a cassette, check for the media jam in the following order:

n

Check the front inside area.

n

Check the paper cassette area.

n

Check the front upper door area.

When printing from the multipurpose tray, check for the media jam

in the following order:

n

Check the multipurpose tray area.

n

Check the front inside area.

n

Check the front upper door area.

Troubleshooting

6-3

Page 60

Clearing Medi a

Jams

Clearing Front Inside Area Jams

M

WARNING!

extremely hot when the printer is used. Personal injury could result if

you touch those areas.

The fixing assembly and print delivery guide become

ACHTUNG!

Die Fixiereinheit und die Papierführung werden sehr

heiß, wenn der Drucker in Betrieb ist; bei Berühru ng dieser Part ien

besteht Verletzungsgefahr!

1 Using both hands, open the mul tip urp ose tray.

2 Push up on the release button, and open the front cover.

3 Remove the jam from the fixi ng assembly area.

n

Pull the jammed media away from the printe r.

n

Pull the jammed m edia in the opposit e directio n (toward the

printer) only if the end of the paper has passed completely

through the fixing assembly.

» Note:

If print media is pulled toward the inside of the printer

before it has passed completely through the fixing assembly

area, infused toner may adhere to the inside of the printer

and stain the backs of the following printed pages.

Print Delive ry

Guide

Fixing

Assembly

QMS 1660E Print System Oper atio n6-4

Page 61

Clearing Me di a

Jams

4 Check the output tray.

If the print media has passed through to the output tray, pull the

print media in the direction of the arrow.

After checking all print media paths in the fixing assembly area,

close the front cover and the multipurpose tray. If the jam has

been cleared, printing will restart. If the jam remains, che ck the

paper cassette area, as described in the next section of this

chapter.

Output Tray

Troubleshooting

6-5

Page 62

Clearing Medi a

Jams

Clearing Paper Cassette Area Jams

1 Determine which paper cassette is currently being used and

remove it.

2 Check the paper cassette pick-up roller area and remove any

jammed print m edi a by pu lling in the di recti on of the arrow.

3 After replacing the paper cassette, op en and close the

printer’s front cover.

If the jam has been cleared, printing will restart. If the jam

remains, check the front upper door area, as described in the

next section of this chapter.

QMS 1660E Print System Oper atio n6-6

Page 63

Clearing Me di a

Jams

Clearing Front Upper Door Area Jams

M

WARNING:

hot when the printer is used. Personal injury could result if you touch

that area.

The inside of the front upper door becomes extremely

ACHTUNG!

Die Innenseite der oberen Abdeckklappe wird im Betrieb

sehr heiß; bei Berührung dieser Partien besteht Verletzungsgefahr!

1 Open the front upp er doo r and rem ove the j am by pull ing in

the direction of the arrow.

Front Upper Door

2 After removing the jamm ed print medi a, close the front

upper door.

If the jam has been cleared, printing will restart.

If you can’t easily remove the print media from the front upper

door area, remove the jam from the fro nt inside area, as

described earlier in the “Clearing Front Inside Area Jams” section

of this chapter.

Troubleshooting

6-7

Page 64

Clearing Medi a

Jams

Clearing Multipurpose Tray Area Jams

» Note:

Leaving print media in the multipurpose tray can cause the

print media position to shift during removal of the jam. This may result

in a media feed failure and another jam when printing is restarte d.

1 Using both hands, open the mul tip urp ose tray.

2 Remove all print medi a rem ain ing in the m ultipu rp ose tray

and close th e tray extension.

3 Push up on the front cover release button , and open the

front cover.

4 Remove the print medi a from the paper pick-up area by pull-

ing in the direction of the arrow.

5 If the jam has been cleared, close the front door and printing

will restart.

If you are unable to locate the jam in the multipurpose tray area,

check the areas for locating jams when using a paper cassette,

described earlier in this chapter.

QMS 1660E Print System Oper atio n6-8

Page 65

Status Messages

Status messages in the message window provide information about

your printer and help you locate many problems. They are displayed

in order of importance. If a message is only one line long, it can be

displayed along with anothe r message (with the highest priorit y message on the top line). However, if either message is two lines long, only

the highest priority message is displayed. When the condition associated with a displayed message h as changed, the message is cleared

from the window, and the next highest priority message is displayed.

Status

Messages

» Note:

Status messages are not displayed while the printer is off line.

The following status messages may appear in the message windo w:

This me ss a ge. .. means... Do this...

x

ACTIVE JO BS The prin te r is on line. x

identifi es the numbe r o f j ob s i n

proces s.

ADJUST

CANCELLING JOB The Cancel key has been

CLOSE ENGINE

DOOR(S)

IDLE The prin te r is o n line, but n o

INPUT I DLE

PRINTING

INITIALIZ IN G The p rin ter is get tin g rea dy to

PAPER JAM Media has jammed w h il e b eing

INPUTBIN

BIN A cassette is not inserted

correctly.

the cassette.

presse d, an d t he oldest j ob in

the print queue is being

cancelled.

The fron t c ov e r of the pri nte r is

open.

jobs ar e i n pr o ce s s.

The prin te r is o n lin e an d

printing jo b s a lre a dy in th e

queue. No new jobs are arriving

at the communication

interfaces.

go on l in e.

pulled fro m a casset te or tra y,

passing through the printer, or

exiting i nto th e output tray.

INPUTBI N

identif ie s

Adjust the cassette.

Close the front

cover completel y.

Troubleshooting

6-9

Page 66

Status

Messages

This me ss a ge. .. means... Do this...

PAPER S IZE

MISMATCH

PRINTIN G STATU S A status p ag e is printing.

SIZE

SIZE

PAPER IN

PAPER IN

BIN

PUT

ANY BIN

PUT

INPUTBIN

TEST PR INT A test p rin t p ag e i s be in g

TONER ABSENT The t oner ca rtridg e is no t

TONER OUT The toner cartridge is empty. Replace the toner

WAITING FOR IDL E A job is in p roc e ss. A cces s to

The media size selected for the

multipurpose tray is not the size

currentl y in th e tray.

The Operator Control/Chain

Inputbins menu is set to On and

the chained cassettes are

empty.

The Operator Control/Chain

Inputbins menu is set to Off and

a media c assette (or the

multipu rpose tray ) i s empty.

SIZE

is the media size the

cassette is c ur ren tly c on fi gu red

for.

INPUTBIN

cassette or m ultipurpos e tra y.

printed.

installed.

the menu is n ot allowed un ti l

the job is finished.

is the e m pty

If the pr inter supports th e m e di a

size you w ant,

insert it in the multipurpose tray. If the

printer doesn’t support the media size

you wan t, s e le ct

univers a l a s the

media si ze . S ee

“Media Size” in

chapter 4, “ Printer

Configuration,” o f

Reference

the

more information.

Refill an e mp ty

cassette wit h the

specif ie d s iz e

media.

Refill th e cassette

or multipurpose tray

with the sp ec if ie d

size med i a.

cartridge. Refer to

chapter 2, “C o nsumables,” for

instructions.

Wait until t he jo b is

finished and the

printer g oe s id le to

access the configuration men u .

for

QMS 1660E Print System Oper atio n6-10

Page 67

This me ss a ge. .. means... Do this...

WAITING ON IN PUT

END JOB?

WARMING U P The prin te r is w a rm in g u p. Wait unti l the IDLE

The compiler is w ai tin g on

incomi ng dat a for the first job in

the queue. The job may not

have an end-of-job indicator

and the refore can ’t en d. Th e

message clears if more input

arrives fro m the p or t or if you

press the Cancel key. No other

jobs can be printed until this job

has ended.

Service M essages

The following service messages may appear in the message window.

Service

Messages

Cancel or end the

print job.

message displays

before p rin ti ng.

» Note:

A service message sometimes occurs as a result of an unusual

combination of events, not because of an actual problem. Whe n the

printer stops and a service message displays in the message window,

turn the printer off and then back on. This often clears the service

message indicato r, and printer operation resumes. Always try this

before making a service call.

Service calls should be placed to the vendor from whom you purchased the printer. If you can’t get service from your vendor, see

appendix A, “QMS Customer Su pport,” for mo re inform ation.

Troubleshooting

6-11

Page 68

HP-GL and PCL

Error Codes

This message... indicates... Do this...

CALL FOR SERVICE

ENGINE ERROR 1

CALL FOR SERVICE

ENGINE ERROR 10

CALL FOR SERVICE

ENGINE ERROR 11

CALL FOR SERVICE

ENGINE ERROR 12

CALL FOR SERVICE

ENGINE ERROR 20

CALL FOR SERVICE

ENGINE ERROR 21

A fuser unit error. Contact your QMS

vendor.

A main motor error.

A scanner motor error.

A fan motor error.

A beam detect error.

The controller failed to respond

to a VSYNC request.

HP-GL and PCL Error Codes

HP-GL Error Codes

This code... indicates...

0 Not enough memory for the print job.

1 Too many transformation.

2 Math error.

3 Job aborted.

4 Instruction not recognized.

5 Wrong number of parameters.

6 Out of range parameter or illegal character.

7 Not used.

8 Unknown character set.

9 Position overflow.

10 Buffer overflow.

QMS 1660E Print System Oper atio n6-12

Page 69

PCL Error Codes

This code... indicates...

0 Not enough memory for the print job.

1 State lost.

2 Math error.

3 Job aborted.

4 Out of memory for macros.

5 Disk full. Cannot store fonts.

6-13 Internal error 1-8.

Testing PC-Printer Comm u n ication

To test communicati on betwee n your printer and your PC, first create

a short file that ejects a page from the printer. Then send the file to

the printer.

Testing PC-

Printer

Communication

Creating the Test File

To create the test file, type the following comm an d s at the DOS

prompt (you can use either uppercase or lowercase letters; however,

you must type the PostScript show pag e operat or in lowercase l etters). The ↵ symbol means to press the Enter key. To produce the ^D

and ^Z, press and hold down the Ct rl key while you type the appropriate letters (d and z). These characters signify the end of the file and

must always be included.

copy con printest.ps↵

showpage↵

^D^Z↵

Troubleshooting

6-13

Page 70

Testing PC-

Printer

Communica tion

Sending the Test File

Parallel Communication

1 To send the PRINTEST.PS file you just created to the printer,

type

print printest.ps↵

2 If you’re prompted for the na m e of the list device, type

lpt1↵

or type the name of the PC’s parallel port to which the printer is

connected (for example, lpt2 or lpt3).

» Note:

If the PC has more than one parallel port, they’re probably

labeled. If not, check the PC’s documentation for the LPT port

names.

3 If the printer and PC are communicating, a blank page ejects

from the printer. Skip ahead to “PC Printing Software ” to finish connecting the printer.

If a blank page doesn’t eject and you typed the file correctly, you

may want to check your AUTOEXEC.BAT file to see if LPT1 (the

parallel port) is being directed to COM1 (the serial port):

a If the AUTOEXEC. B AT file contains the line

MODE LPT1:=COM1:

delete it.

b Then type

MODE LPT1:,,P↵

The “P” tells the PC to continue sending print jobs until the

printer accepts them .

c Reboot the P C and try the communi cati on test again.

See chapter 6, “Troubleshooting,” of the

and refer to your DOS documentation for more informatio n.

Operation

manual

QMS 1660E Print System Oper atio n6-14

Page 71

Testing PC-

Printer

Communication

Serial Communication

1 To send the PRINTEST.PS file you just created to the printer,

type

print printest.ps↵

2 If you’re prompted for the na m e of the list device, type

com1↵

or type the name of the PC’s serial port to which the printer is

connected (for example, com2 or com3).

» Note:

If the PC has more than one serial port, they’re probably

labeled. If not, check the PC’s documentation for the COM port

names.

3 If the printer and PC are communicating, a blank page ejects

from the printer. Skip ahead to “PC Printing Softwar e ” to finish connecting the printer.

If a blank page doesn’t eject and you typed the file correctly, you

may want to check your AUTOEXEC.BAT file in DOS to make

sure that the printer's serial port settings match tho se of the PC.

a Look for a command line like this in your AUTOE X EC. BAT

file:

MODE COM1: 9600,N,8,1,P

In this example, the serial port setting s are 9600 for baud

rate, N (no) parity, 8 data bits, and 1 stop bit. The P stands for

infinite retry.

» Note:

If the mode statement isn’t in yo ur A UTOEXEC.BAT

file, you can temporarily set the mode parameters at the

DOS prompt to continue this test by typing the command line

as shown above. To make this setti ng perma nent you must

add the mode statement to your AUTOEX EC. BAT file, and

then reboot the PC for your change to take effect.

b Check the start-up page, which prints when you turn on th e

printer (unless you disabled it). This tells you the current

serial port settings for the printer.

Troubleshooting

6-15

Page 72

Testing PC-

Printer

Communica tion

Changing Serial Port Settings

Since your printer is configured at the factory for the most typical

printing environments, the serial settings in your AUTOEXEC.BAT file

and on the start-up page may be the same. However, if they differ,

you must configure the printer to u se the serial settings specif ied in

the AUTOEXEC.BAT file.

The following table exp lains how to use the printer cont rol panel to

configure the printer’s serial settings.

n

If the serial settings (baud rate, parity, data bits, and stop

bits) shown on the start-up page match those in your

AUTOEXEC.BAT file, you need make no further

changes.

n

If the printer’s serial port sett ing s are different fro m your

PC’s settings, use the printer control panel, as described

in the following section, “Changing Serial Port Settings, ”

to make them match.

Step Pre ss this

key...

1 Online/Offline take the printer off line (the

2 Menu enter the configuration menu. CONFIGURATION

3 Next access the Administration

4 Select enter the Administration menu. ADMINISTRAT IO N

5 Select enter the Communications

6 Next access the Serial menu. COMMUNICATIONS

7 Select enter the Serial menu. SERIAL

8 Next access the Baud Rate menu. SERIAL

to... The message

window reads...

IDLE

Online/Offline indicator goes

out).

OPERATOR CONTROL

CONFIGURATION

menu.

menu.

ADMINISTRATION

COMMUNICATI ONS

COMMUNICATIONS

TIMEOUTS

SERIAL

MODE

BAUD RATE

QMS 1660E Print System Oper atio n6-16

Page 73

Testing PC-

Printer

Communication

9 Select enter the Baud Rate menu. BAUD RATE

*960 0 BA UD

10 Next (one or

more times)

11 Select select the displayed baud rate.

12 If you need to change other settings, press the Nex t key t o access the

appropriate menu, then repeat steps 9-11 to find and select the new

settings.

13 O n line/Offline Access the Save Changes

14 Next Access the Yes option. SAVE CHANGES?

15 Select Save your changes. IDLE

16 Online/Offline Put the printer back on line

* Baud rates of 19200 and 38400 require that both RTS an d CTS

hardware flow control ((Administration/Communications/Serial/Hdwe

Flow Ctl menu) be selected. These baud rates do not support XON/

XOFF software flow control )Rcv Sw Flow Ctl).

display the correct baud rate.* BAUD RATE

# BAUD

#

IS SE LECTED

SERIAL

BAUD RATE

SAVE CHANGES?

menu.

(the Online/Offline indicator

lights).

NO

YES

IDLE

Verifying the Serial Port Setting Changes

1 Reboot the printer.

2 Compare the seri al port settin gs listed on the start-up page

to those in you r A UTO EXE C. B AT file.

3 Try the communication test again.

If a blank page ejects from the printer, the printer and the PC are

communicating. Skip ahead to “PC Printing Software ,” below, to

finish connecting the printer. If a blank page does not eject and