KONICA MINOLTA EP6000 Service Manual

EP6000

GENERAL,

MECHANICAL/

ELECTRICAL

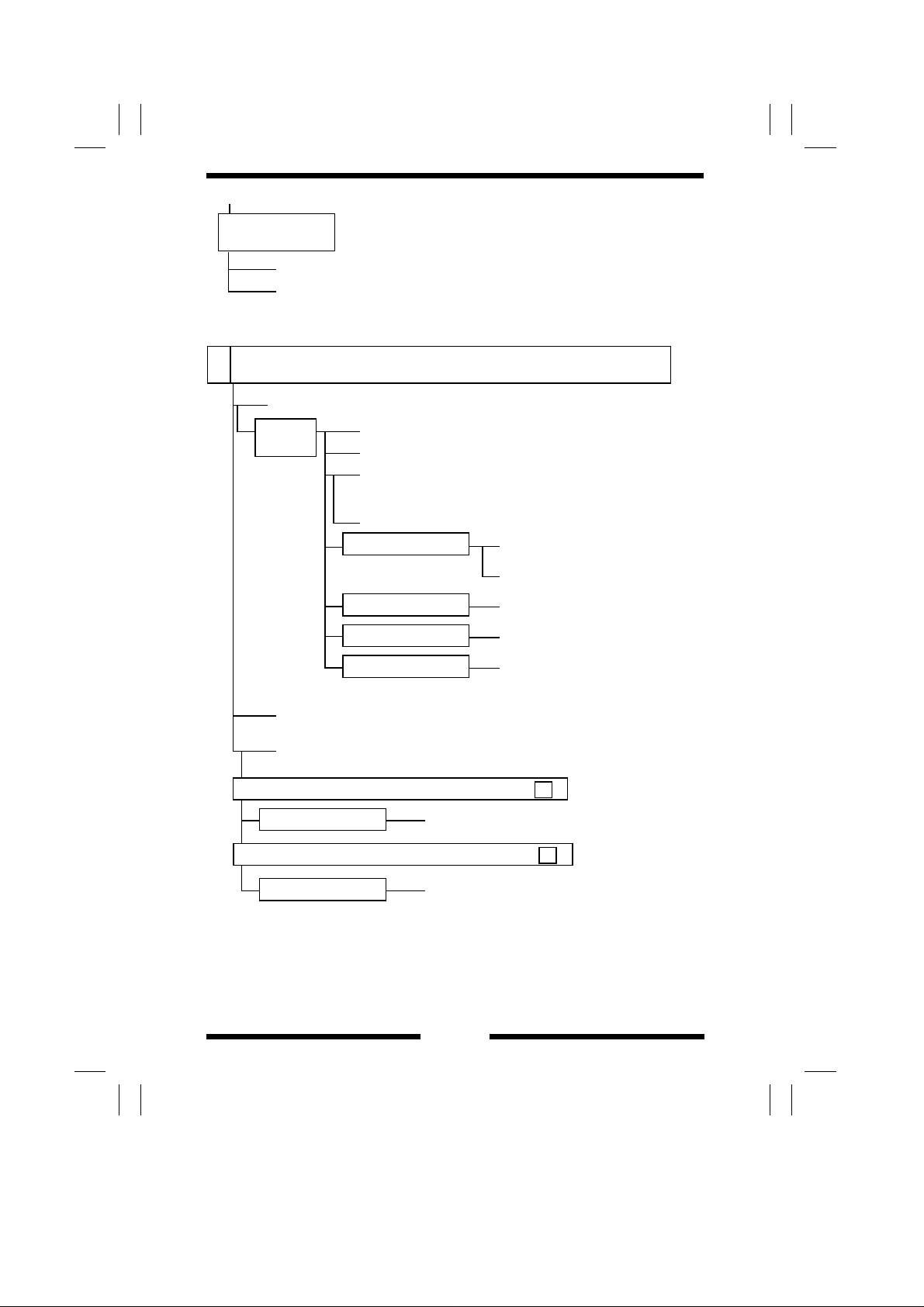

CONTENTS

GENERAL

1. SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

2. TECHNICAL HIGHLIGHTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

3. SPECIFICA TIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

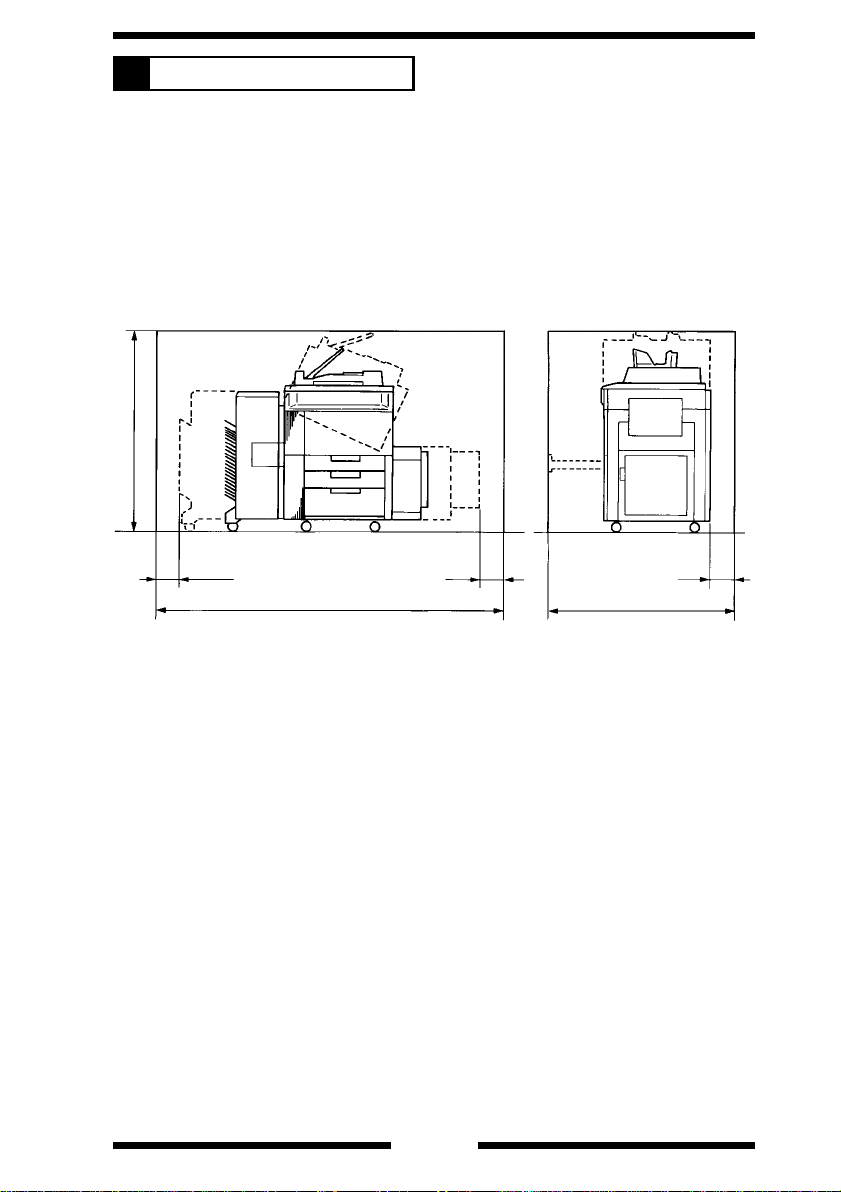

4. SPACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

5. PRECAUTIONS FOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . G-8

6. PRECAUTIONS FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-9

7. HANDLING OF THE CONSUMABLES . . . . . . . . . . . . . . . . . . . . . G-10

8. SYSTEM OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

9. PARTS IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-12

MECHANICAL/ELECTRICAL

1. CROSS-SECTIONAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-1

2. COPY PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3

3. DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-5

4. SEQUENTIAL EXPLANATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . M-7

5. WATCHDOG (CPU OVERRU N MONITOR) FUNCT ION . . . . . . . M-11

6. MALFUNCTION BYPA SS FUNCT ION. . . . . . . . . . . . . . . . . . . . . . M-14

7. IMAGE STABILIZATION SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . M-16

8. PC DRUM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-25

8-1. PC Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-25

8-2. PC Drum Drive Mechanism/Control . . . . . . . . . . . . . . . . . . . . M-25

8-3. Grounding of the PC Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . M-27

8-4. Drum Dry Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-27

9. DRUM CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-28

9-1. PC Drum Charge Corona . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-28

9-2. Control of the PC Drum Char ge Corona . . . . . . . . . . . . . . . . M- 30

9-3. PC Drum Charge Corona Wires Cleaning

Mechanism/Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-31

9-4. Ozone Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-33

i

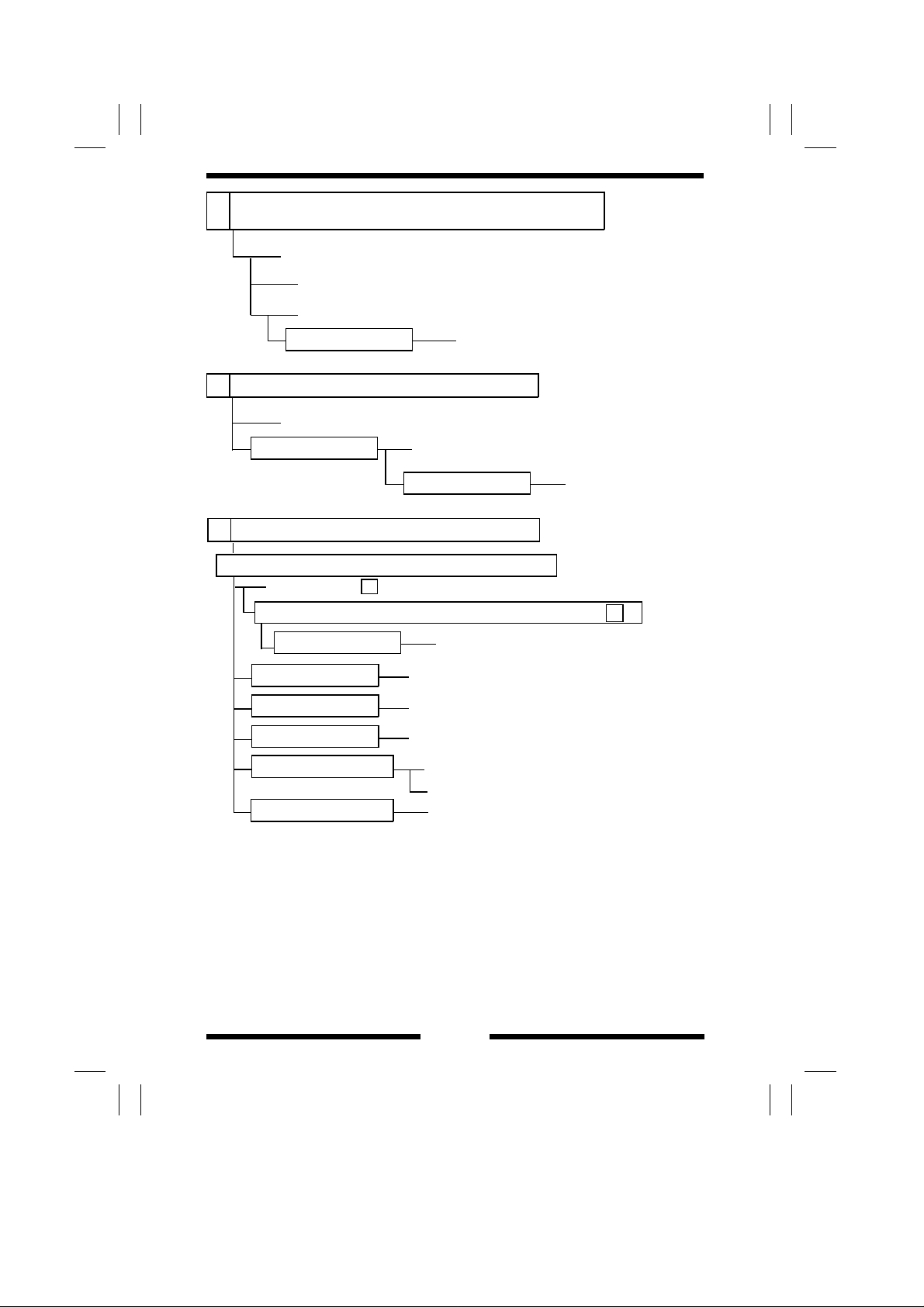

CONTENTS

10. OPTICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3 4

10-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-34

10-2. Function of Exposure Components . . . . . . . . . . . . . . . . . . . M-36

10-3. Exposure Lamp LA1 Control. . . . . . . . . . . . . . . . . . . . . . . . . M-37

10-4. Intensity Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-42

10-5. Scanner and Mirrors Carr iage Moving Mechanism. . . . . . . M-43

10-6. Scanner Motor M11 Control . . . . . . . . . . . . . . . . . . . . . . . . . M-45

10-7. Lens Drive Mechanism/Control. . . . . . . . . . . . . . . . . . . . . . . M-47

10-8. Optical Section Cooling Fan Motor . . . . . . . . . . . . . . . . . . . . M-53

11. ORIGINAL SIZE DETECTING SYSTEM. . . . . . . . . . . . . . . . . . . . M-54

11-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-54

11-2. Construction of the Original Size Detecting Sensor . . . . . . M-55

11-3. Original Detection Method. . . . . . . . . . . . . . . . . . . . . . . . . . . M-56

11-4. Sensor Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-58

11-5. Original Size Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-5 9

11-6. Original Size Detection Processing . . . . . . . . . . . . . . . . . . . M-60

12. IMAGE ERASE LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-62

12-1. Image Erase Lamp LA3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-62

12-2. Image Erase Lamp LA3 ON/OFF Control . . . . . . . . . . . . . . M-63

12-3. Control for Each Erase Function. . . . . . . . . . . . . . . . . . . . . . M-64

13. DEVELOPING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-69

13-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-69

13-2. Developing Unit Drive Mechanism . . . . . . . . . . . . . . . . . . . . M-70

13-3. Developer Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-71

13-4. Magnetic Pole Positioning. . . . . . . . . . . . . . . . . . . . . . . . . . . M-73

13-5. ATDC Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-75

13-6. Control for Abnormally Low T/C . . . . . . . . . . . . . . . . . . . . . . M-78

13-7. Sub Hopper Toner Replenishing Mechanism/Control. . . . . M-80

13-8. Sub Hopper Toner Empty Detecting Mechanism/Contro l. . M-82

13-9. Main Hopper Toner Replenishing Mechanism/Control . . . . M-85

13-10. Auxiliary Toner Replenishing . . . . . . . . . . . . . . . . . . . . . . . M-88

13-11. Developing Bias. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-90

13-12. Developing Unit Dehumidifying Heater . . . . . . . . . . . . . . . M-91

13-13. Toner Suction Fan Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . M-92

14. PRE-IMAGE TRANSFER ERASE LAMP. . . . . . . . . . . . . . . . . . . . M-93

14-1. Pre-Image Transfer Erase Lamp . . . . . . . . . . . . . . . . . . . . . M-93

14-2. Pre-Image Transfer Erase Lamp LA4 ON/OFF Control . . . M-93

ii

CONTENTS

15. PAPER TAKE-UP/F EED SECTION . . . . . . . . . . . . . . . . . . . . . . . . M-95

15-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-95

15-2. Drawer-in-Position Detection . . . . . . . . . . . . . . . . . . . . . . . . M-96

15-3. Paper Empty Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-97

15-4. Paper Lifting/Lowering Mechanism/Control. . . . . . . . . . . . . M-99

15-5. Paper Stack Lowering/Drawer Locking Mechanism/

Control (Inch Areas). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-103

15-6. Paper Level Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-105

15-7. 3rd-Drawer-in-Position Detection . . . . . . . . . . . . . . . . . . . . . M-107

15-8. 3rd Drawer Paper Empty Detection . . . . . . . . . . . . . . . . . . . M-1 08

15-9. Main Tray Paper Stack Lifting/Lowering Mechanism/

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-110

15-10. 3rd D r awer Pap er Level Detect ing Mechanism . . . . . . . . . M-114

15-11. Shifter Drive Mechanism/Control . . . . . . . . . . . . . . . . . . . . M-115

15-12. 3rd Drawer Lock/Release . . . . . . . . . . . . . . . . . . . . . . . . . . M-1 18

15-13. Paper Dehumidifying Heaters. . . . . . . . . . . . . . . . . . . . . . . M-119

15-14. Drawer Paper Take-Up Mechanism/Control . . . . . . . . . . . M-120

15-15. Vertical Transport Drive Mechanism . . . . . . . . . . . . . . . . . M-126

15-16. Multi Bypass Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-128

16. TRANSPORT/SYNCHRONIZING ROLLERS UNIT . . . . . . . . . . . M-136

16-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-136

16-2. Paper Dust Remover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-1 37

16-3. Transport Roller Drive Mechanism. . . . . . . . . . . . . . . . . . . . M-137

16-4. Transport Roller Drive Control . . . . . . . . . . . . . . . . . . . . . . . M-1 38

16-5. Synchronizing Roller Drive Mechanism . . . . . . . . . . . . . . . . M-139

16-6. Synchronizing Roller Drive Control. . . . . . . . . . . . . . . . . . . . M-140

16-7. Prevention of Low Image Density on Copy . . . . . . . . . . . . . M-142

17. IMAGE TRANSFE R/ PAP ER SEPARATOR CORONAS. . . . . . . . M-143

17-1. Image Transfer/Paper Separator Coronas. . . . . . . . . . . . . . M-143

17-2. Image Transfer/Paper Separator Coronas Control . . . . . . . M-144

17-3. Image Transfer/Paper Separator Corona Wires Cleaning

Mechanism/Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-145

17-4. Image Transfer/Paper Separator Coronas Assy Retracting

Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-148

17-5. Ozone Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-149

18. CLEANING UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-150

18-1. Construction of the Cleaning Unit. . . . . . . . . . . . . . . . . . . . . M-150

18-2. Cleaning Blade Moving Mechanism. . . . . . . . . . . . . . . . . . . M-151

iii

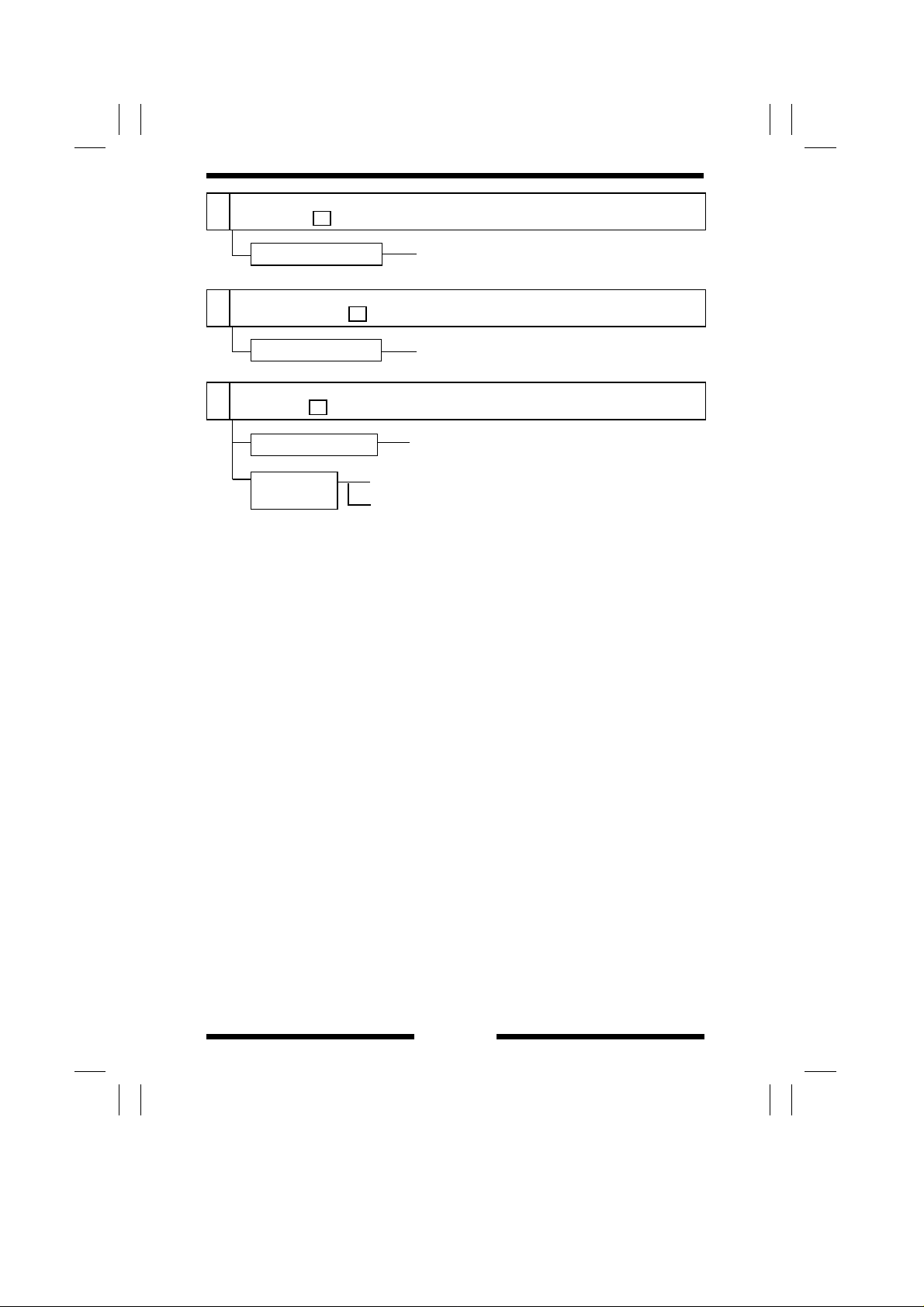

CONTENTS

18-3. Toner Conveying/Collecting Mechanism . . . . . . . . . . . . . . . M-152

18-4. Pre-Cleaning Erase Lamp LA5 ON/OFF Control. . . . . . . . . M-154

18-5. PC Drum Paper Se parator Fingers M oving Mechanism/

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-155

18-6. Cleaning Bias (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-159

19. MAIN ERASE LAMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-160

19-1. Main Erase Lamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-160

19-2. Main Erase Lamp LA2 ON/OFF Control. . . . . . . . . . . . . . . . M-160

20. TRANSPORT SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-162

20-1. Transport Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-162

20-2. Suction Fan Motor M18 Control . . . . . . . . . . . . . . . . . . . . . . M-163

21. FUSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-164

21-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-164

21-2. Fusing Rollers and Web Roller. . . . . . . . . . . . . . . . . . . . . . . M-166

21-3. Drive for the Fusing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-167

21-4. Fusing Rollers Pressure Mechanism . . . . . . . . . . . . . . . . . . M-169

21-5. Oil Application Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . M-1 69

21-6. Cleaning Web Take-Up Mechanism/Control . . . . . . . . . . . . M-170

21-7. Fusing Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . M-172

21-8. CPM Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-176

22. EXIT/DUPLEX SWITCHING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . M-178

22-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-178

22-2. Exit/Duplex Switching Mechanism/Control . . . . . . . . . . . . . M-179

23. DUPLEX UNIT TURNOVER MECHANISM . . . . . . . . . . . . . . . . . . M-181

23-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-181

23-2. Drive Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-182

23-3. Duplex Unit Turnover Mechanism . . . . . . . . . . . . . . . . . . . . M-183

24. DUPLEX UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-186

24-1. Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-186

24-2. Trailing Gate Unit Moving Mechanism/Control . . . . . . . . . . M-188

24-3. Gate Switching Mechanism/Control . . . . . . . . . . . . . . . . . . . M-189

24-4. Trailing Gate Unit Moving and Gate Switching

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-190

24-5. Front/Rear Edge Guide Plate Drive Mechanism/

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-191

24-6. Storing of Copies in Duplex Unit. . . . . . . . . . . . . . . . . . . . . . M-193

iv

CONTENTS

24-7. Leading Edge Guide Plate and Duplex Paper Take-Up

Drive Mechanism/Control . . . . . . . . . . . . . . . . . . . . . . . . . . . M-195

24-8. Duplex Paper Take-Up Operation . . . . . . . . . . . . . . . . . . . . M-197

25. POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-201

26. MEMORY BACKUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-204

v

SAFETY INFORMATION

1

(ALL Areas)

Danger of explosion if battery is incorrectly replaced.

(Denmark only)

Lithi umb at teri - Eksplosion sf a r e ved fej l a gt ig håndtering.

(Norway only)

(Sweden only)

CAUTION

Replace on l y wi th t he sa m e or eq ui v al e nt type

recommended by the manufacturer.

Dispose of used batteries according

to the manufacturer’s instructions.

ADVARSEL!

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér de t brugte bat t eri til bage til leverandøren.

ADVARSEL

Eksplo sjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende

type anbefalt av apparatfabrikanten.

Brukt e bat t erier ka sseres i henhold t i l f abrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekom m enderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(Finland only)

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

VAROITUS

tyyppiin. Hävitä Käytetty paristo valmistajan ohjeiden

mukaisesti.

G-1

TECHNICAL HIGHLIGHTS

2

This copier has the following mechanical features.

◆

The ori g i na l is a ligned at t he rear corner, while the copy paper i s fed

through the center of the copier.

◆

Three fusing heat er lamps are used, which enables the copier to

comple te wa r mi ng up i n less than 5 mi nu tes . (F or det a i ls, s ee p. M-164.)

◆

All or i ginal size de t ec ti ng se nsors ar e fix ed , en ha nc i ng mea suring

accuracy. (For details, see p. M-54.)

*

The copier becomes capable of detecting both the metric and inch

orig i na l si z es wh en eq ui p pe d wit h t he op ti on al o ri gi n al si ze de t ec t i ng

sensors.

◆

The paper take-up retry control minimizes the occurrence of paper

misfeeds. (For details, see p. M-124.)

The copier has the following control features.

◆

The watchdog (CPU overrun monitor) function monitors the operation of

the CPUs mounted in the copier and, if a CPU overrun is detected, it

automatically resets the faulty CPU, restarting the logic circuit and

mechanism. (For details, see p. M-11.)

◆

The malfunction bypass function minimizes downtime when the co pier

develops a malfunction. (For details, see p. M-14.)

◆

The image stabilization system stabilizes the copy image. (For details,

see p. M-16.)

G-2

SPECIFICATIONS

3

TYPE :Console

PLATEN : Stationary

PHOTOCONDUCTOR : Organic Photoconductor

COPYING SYSTEM : Electrostatic dry powdered image transfer to plain paper

PAPER FEEDING

SYSTEM

EXPOSURE SYSTEM : Mirror scanning, slit exposur e

DEVELOPING SYSTEM : New Micro-Toning syst em

CHARGING SYSTEM : Double-wire DC neg ative cor on a with S corotr on sy st em

IMAGE TRANSFER

SYSTEM

PAPER SEPARATING

SYSTEM

OZONE REMOVAL : By means of Ozone Filter

FUSING SYSTEM : Heat Roller

PAPER DISCHARGING

SYSTEM

TYPES OF ORIGINALS : Sheets, books, and other three-di mensional objects

MAXIMUM ORI GIN AL

SIZE

: 4-way system Multi Bypass Table: 50 sheets of

paper

1st and 2nd Drawer: Each h olding

up to 500 sheets of paper

3rd Drawer: Holding up to 2,500

sheets of paper

: Visible image transfer by means of a single-wire DC

negative corona with C or otro n system

: Single-wire AC corona with Corotron system (AC plus

DC positive bias vo lta ge) plus PC Drum Paper

Separator Fingers

: Charge Neutralizing Brush

weighing up to 3 kg or 6-1/2 lbs.

: A3 or 11" × 17" lengthwise

G-3

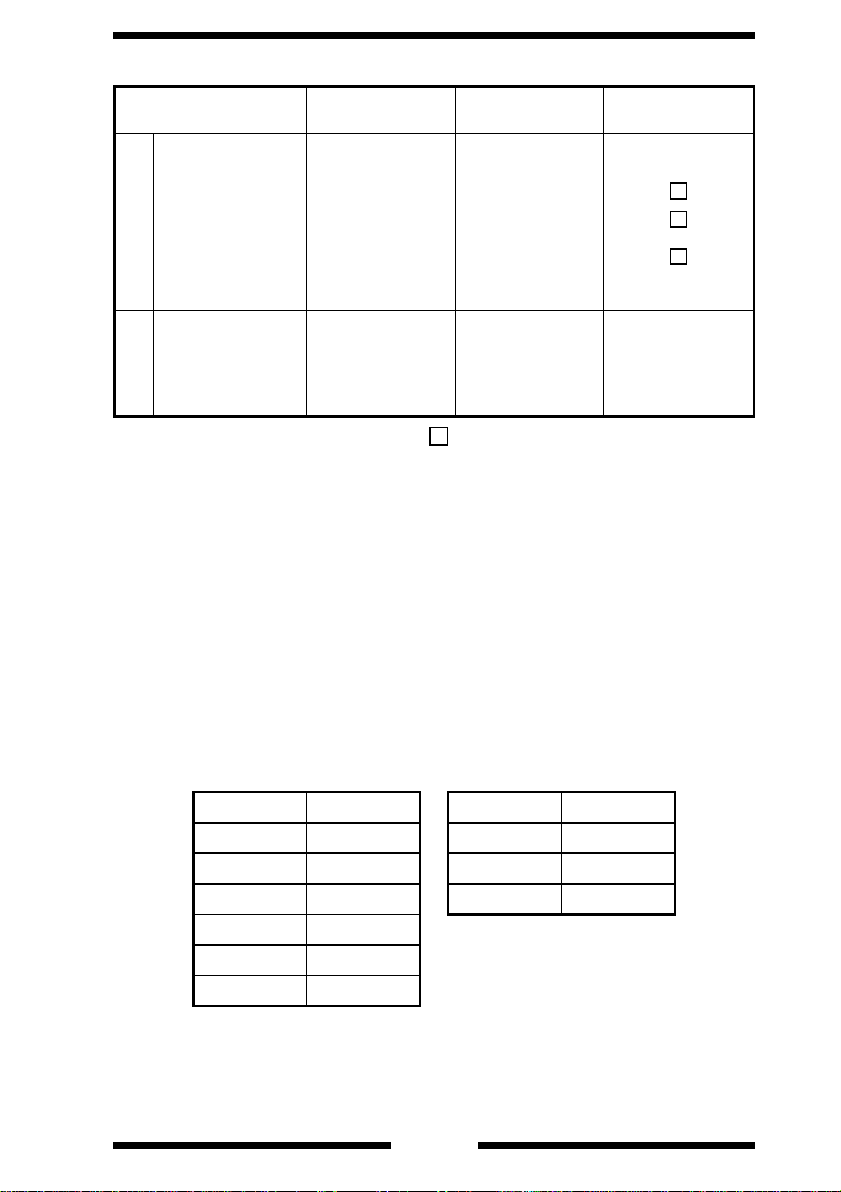

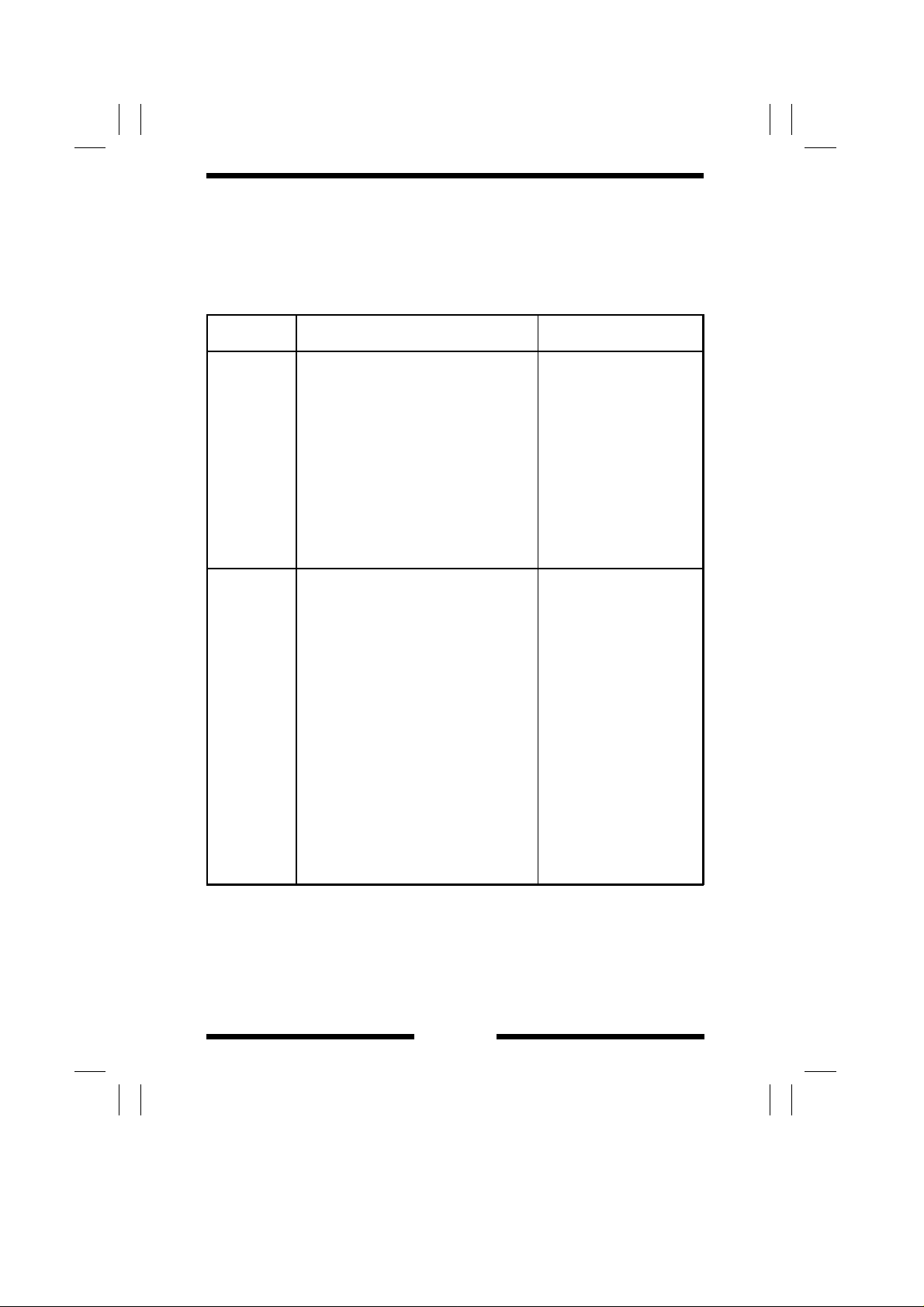

COPY MEDIUM :

Paper Source 1st to 2nd Drawer 3rd Drawer

Plain paper

(60 to 90 g/m

Translucent pap er — —

Transparencie s — —

MediumDimensions

Thick paper (90 to

157 g/m

Recycled paper O O O

Maximum

(Width × Length)

Minimum

(Width × Length)

2

)

2

)

OOO

——

297 × 432 mm A4C 297 × 432 mm

140 × 182 mm 8-1/2"×11"C 100 × 140 mm

Multi Bypass

Table

O: Permissible —: Not permissible : Conditionally permissible ... 20

sheets or less

L: Lengthwise, C: Crosswise

WARMING-UP TIME : 5 min. or less (with ambient temperature of 23°C or

WARMING-UP TIME

AFTER ENERGY

SAVER MODE

AUTO CLEAR TIME : Standard 1 mi n. (setting selectable from among 2 , 3,

FIRST COPY TIME : A4C or 8-1/2" × 11"C (Full s ize, fed from 1st Drawer ):

73°F and rated source voltage)

: 30 sec. or less (with ambient temperature of 23°C or

73°F and rated source voltage)

and 5 min.)

3.8 sec. or less

COPY SPEED : Full size

Metric Area Inch Area

Size copies/min. Size copies/min

A3L 31 11" × 17" 31

B4L 40 8-1/2" × 11"L 50

A4L 47 8-1/2" × 11"C 60

A4C 60

B5L 52

B5C 60

L: Lengthwise; C: Cro sswise

G-4

MULTIPLE COPIES : 1 to 999 cop ies ( coun t-do wn system)

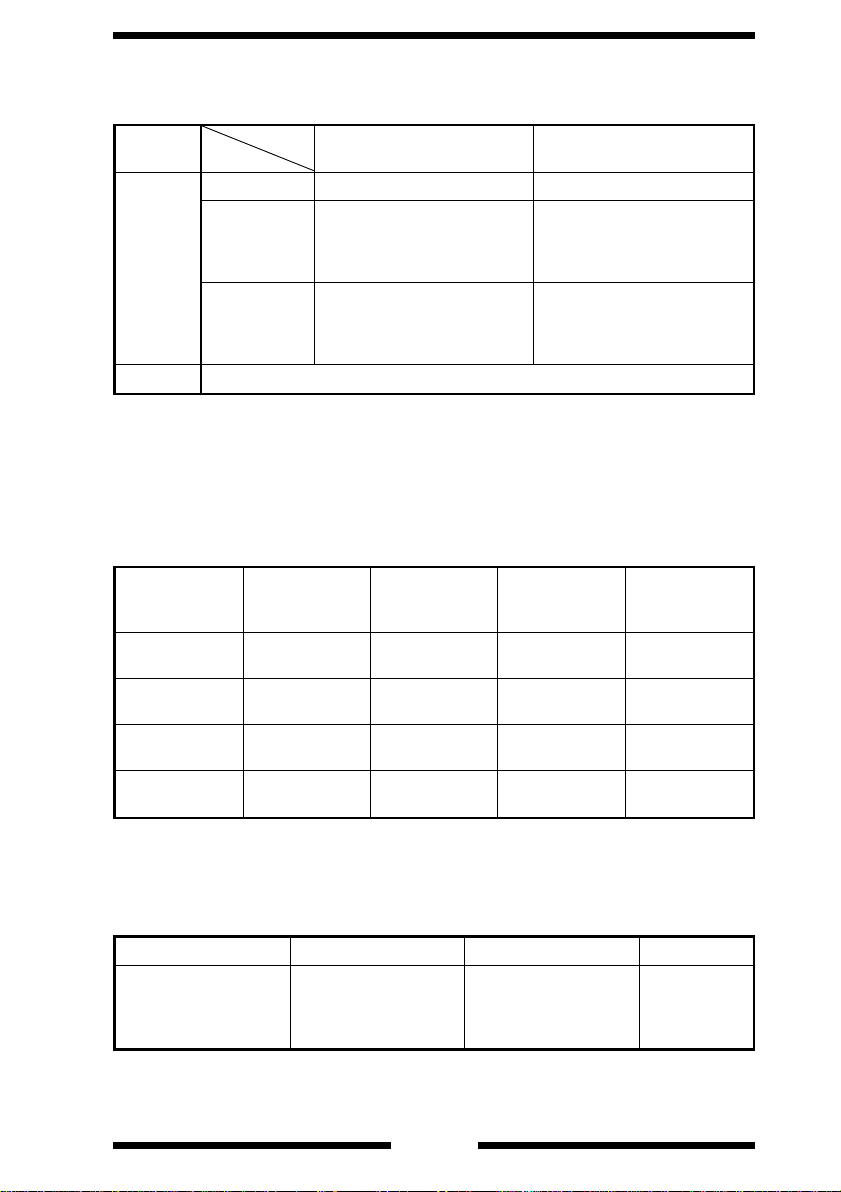

ZOOM RATIOS

Area

Mode

Full Size ×1.000 ×1.000

Reduction

Fixed

Enlargement

Variable ×0.50 0 to ×2.000 (in 0.001 increme nts)

LENS : Through Lens (F=5.6, f=215 mm)

LIGHT SOURCE : Halogen frost tube lamp

FUSING

TEMPERATURE

POWER/CURRENT

CONSUMPTION

Voltage

115 V

120,127 V

200~220 V

220~240 V

::190°C (in copy cycle and standby)

180°C (in Energy Saver mode)

: Copier with full set of options

Exposure

Lamp (Rating)

90 V

220 W

90 V

220 W

160 V

250 W

160 V

250 W

Metric Inch

×0.816

×0.707

×0.500

×2.000

×1.414

×1.154

Fusing Roller

Heater Lamp

(Rating)

115 V

900 W

120,127 V

900W

200/220 V

1040 W

200/220 V

1040 W

Max. Power

Consumption

1320 W 1070 W

1370 W 1070 W

1620~1790 W 133 0 W

1590~1740 W 133 0 W

×0.785

×0.733

×0.647

×0.500

×2.000

×1.545

×1.294

×1.214

Power

Consumption

in Standby

POWER

REQUIREMENTS

ENVIRONMENTAL CONDITIONS :

Temperature Humidity Ambient Illumination Levelness

10 to 35°C

(50 to 95°F) with a

fluctuation of 10°C or

less per hour

: 115V, 120V, 127V, 200V, 220V, 230V, 240V; 50/60 H z

15 to 85% RH with a

fluctuation of 20% RH

or less per hour

3,000 lux or less

G-5

1°

(1.75/100)

DIMENSIONS : Copier only

WEIGHT : 195 kg or 430 lbs.

STANDARD

ACCESSORIES

OPTIONS : Large Capacity Cassette C-302

Width .... 746 mm or 29-1/4"

Depth .... 720 mm or 28-1/4"

Height ... 969 mm or 38-1/4"

(including the Duplexin g Do cum ent Feeder and PC Drum)

: Duplexing Document Feeder AFR-9, Toner Collecting

Bottle, Operator’s Manual, Starter , PC Drum

Exit Tray

20-Bin Sorter S-206

Staple Sorter ST-207

Data Controller DT-103

Data Controller D-102

Plug-In C ounter

Bias Seal

Original Cover

G-6

SPACE REQUIREMENTS

4

To ensure easy copier operation, supply replacement, and service

mainte nance, adh ere to the r ec omm e nd ed sp ace requirements det a i led

below.

*

Be sur e to allow a clearance of 150 mm (6") or mor e at the back of the

copier as t he re i s a ve nt i la t i on du ct.

1335 mm or 52-1/2"

200 mm or 7-3 /4 "

2844 mm or 112"

300 mm or 11-3/4"

150 mm or 6"

1342 mm or 52-3/4"

1075O127CA

G-7

PRECAUTIONS FOR INSTALLATION

5

Installation Site

To ensu re saf e t y and utm o st performa nc e of t he co pi e r, th e cop i er s ho ul d

NOT be us ed i n a pl a ce :

●

Where it will be subjected to extremely high or low temperature or

humidity.

●

Which is exposed to direct sunlight.

●

Which is in the direct air stream of an air conditioner, heater or

ventilator.

●

Which puts the operator in the direct stream of exhaust from the copier.

●

Which has poor ventilation.

●

Where ammonia gas might be generated.

●

Which does not have a stable, level floor.

●

Where it will be subject to sudden fluctuations in either temperature or

humidity. If a cold room is quickly heated, condensation forms inside

the copier, resulting in blank spots in the copy.

●

Which is ne ar any ki nd of h ea ti ng de vi c e.

●

Where it may be splashed with water.

●

Which is dirty or where it will receive undue vibration.

●

Which is near volatile flammables or curtains.

Power Source

Use an outlet with a capacity of 115/120/127V, 12A or more, or

200/220/230/240V, 8.5A or more.

●

If any ot her electrical equipm ent is sou r ced from t he same power

outlet, make sure that the capacity of the outlet is not exceeded.

●

Use a power source with lit tle voltage fluctuation.

●

Never connect b y means of a mu ltiple socket any other appli ances or

machines to the outlet being used for the copier.

●

Make the following checks at frequent intervals:

•

Is the po w er p lug abnorm a l ly h ot?

•

Are the r e an y cracks or sc rap es i n th e cor d?

•

Has the power plug been inserted fully into the outlet?

•

Does something, including the copier itself, ride on the power cord?

●

Ensur e that the copier does not ride on the po wer cord or

communications cable of other electrical equipment, and that it does

not become wedged into or underneath the mechanism.

Grounding

To preve nt r ec ei v i ng el e ct ri cal shocks in the ca se of elec tr i c al l eakage,

alwa ys ground the copier.

●

Connect the grounding wire to:

•

The gr ou nd t er mi n al o f t he ou t let .

•

A grounding contact which complies with the local electrical standards.

●

Never connect the grounding wire to a gas pipe, the grounding wire for

a telephone, or a water pipe.

G-8

PRECAUTIONS FOR USE

6

To ensure that the copier is used in an optimum condition, observe the

following precautions.

●

Never place a heavy object on the copier or subject the copier to

shocks.

●

Insert the power plug all the way into the outlet.

●

Do not attempt to remove any panel or cover which is secured while the

copier is making copies.

●

Do not turn OFF the Power Switch while the copier is making copies.

●

Provi de go od ve nt i la t i on w he n maki n g a l arge number of c op i es

continuously.

●

Never use f l amm a ble sprays ne ar th e cop i er .

●

If the copier becomes inordinately hot or produces abnormal noise, turn

it OFF and unplug it.

●

Do not turn ON the Power Switch at the same time when you plug the

power cord into the outlet.

●

When unplugging the power cord, do not pull on the cord; hold the plug

and pull it out.

●

Do not bri ng an y magnetized ob j ec t ne ar the copier .

●

Do not place a vase or ve ssel containing wate r on the copier.

●

Be sure to turn OFF the Power Switch at the end of the workday or

upon po we r fa i l ure.

●

Use ca r e n ot to dr op paper clips, s t aples, or other small p ieces of m etal

into the copier.

Operating Environment

The operating environmental requirements of the copier are as follows.

•

Temperature: 10°C to 35°C (50 to 95°F) with a fluctuation of 10°C per

hour

•

Humidity: 15% to 85% RH with a fluctuation of 20% RH per hour

Power Requirements

The power source voltage requirements are as follows.

•

Voltage Fluctuation: AC115/120/127/200/220/230/240V

±10% (Copying performance assured)

−15% (Paper feeding performance

assured)

•

Frequency Fluctuation: 50/60 Hz ±0.3%

G-9

HANDLING OF THE CONSUMABLES

7

Before using any consumabl e s, always read the label on its container

carefully.

●

Use the r i gh t toner. The applicabl e co pi e r model na m e is i nd i ca t ed on

the Toner Bottle.

●

Paper is apt to be easily damaged by dampness. To prevent

absorpt ion of moisture, store paper, which has been re m oved from i ts

wrapper but not loaded into the Drawer, in a sealed plastic bag in a

cool, dark place.

●

Keep consumables out of the reach of children.

●

Do not touch the PC Drum with bare hands.

●

Store the pa per, tone r , an d ot he r c on su m ab l es i n a place free f ro m

direct sunlight and away from a ny heati ng apparatus.

●

The same sized paper is of two kind s, short grain and long grain. Short

grain paper should only be fed through the copier crosswise, long grain

paper sh ou ld onl y be f ed l en gth w i se .

●

If your hands become soiled with toner, wash them with soap and

water immediately.

●

Do not throw away any used consumables (PC Drum, starter, toner,

etc.). They are to be collected.

NOTE

Do not burn, bury in the ground, or throw into the water any

consumables (PC Drum, starter, toner, etc.).

G-10

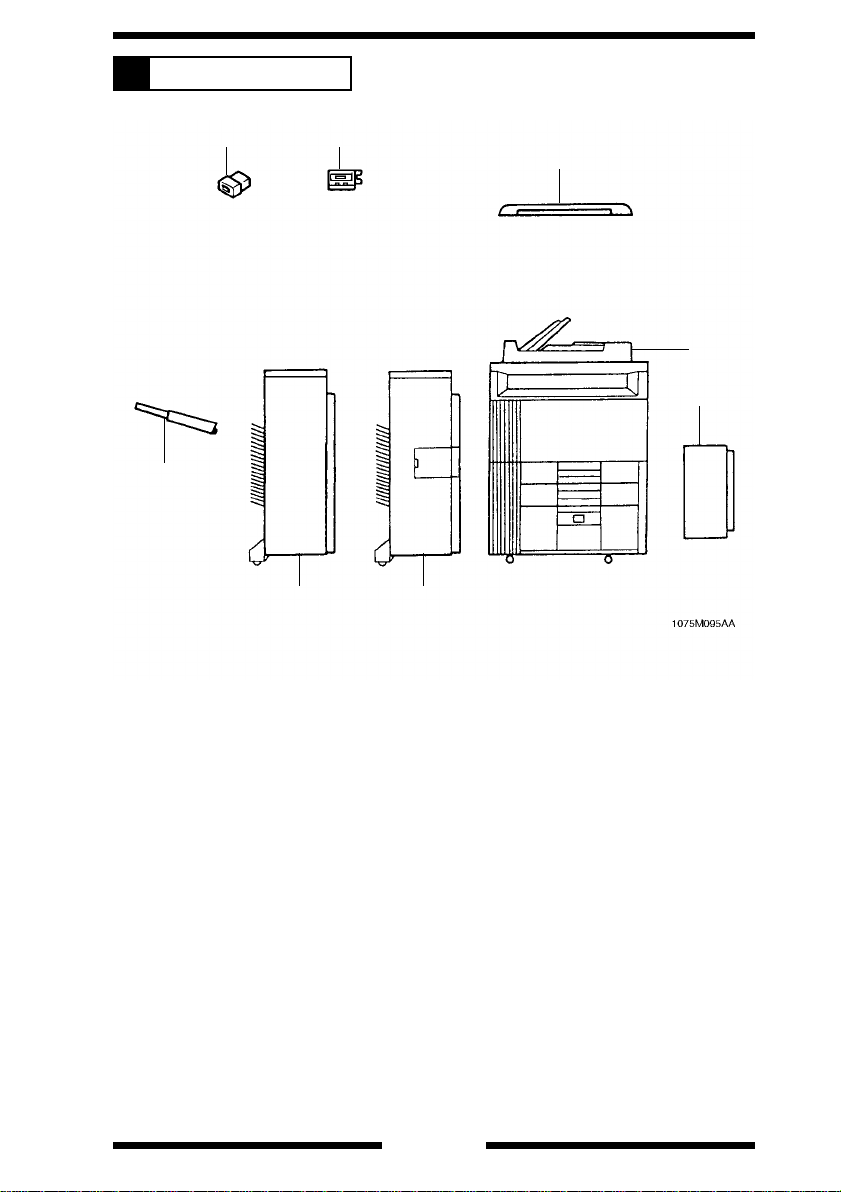

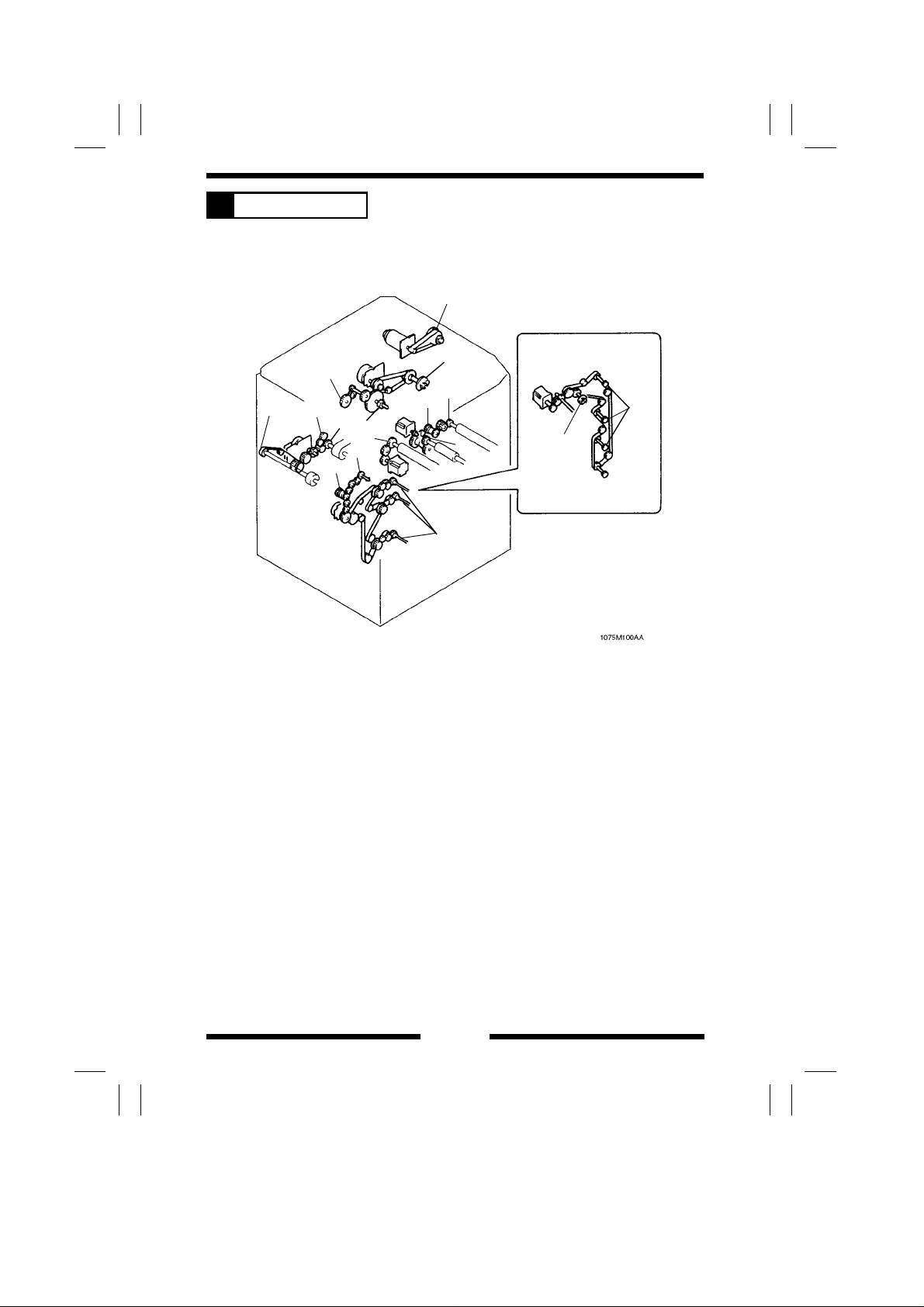

SYSTEM OPTIONS

8

1

8

1. Plug-In Counter

2. Data Controller D-102

3. Original Cover

4. Duplexing Document Feeder AFR-9 <Standard>

5. Large Capacity Cassette C-30 2

6. Staple Sorter ST-207

7. 20-Bin Sorter S-206

8. Exit Tray

2

76

3

4

5

G-11

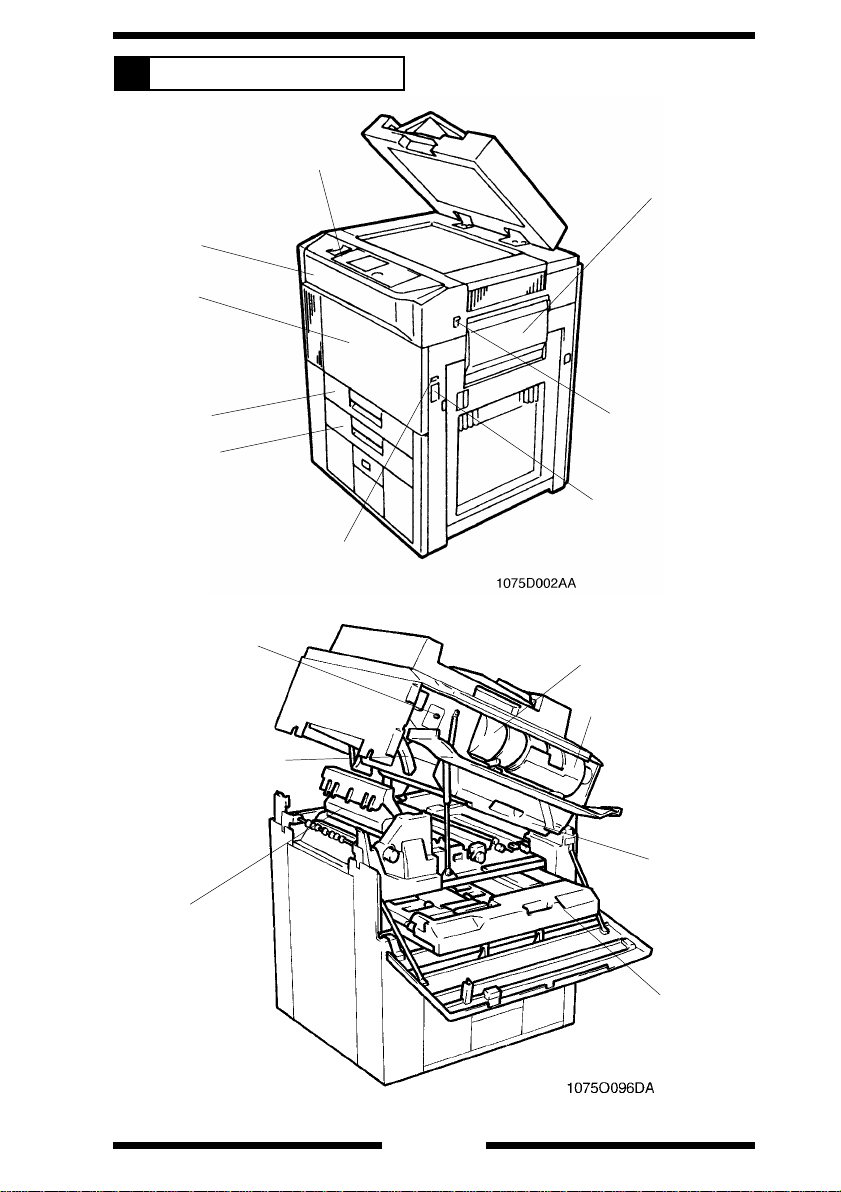

PARTS IDENTIFICATION

9

Control Panel

Upper Front Door

Lower Front Door

Manual Bypass Table

1st Drawer

2nd Drawer

Display Cont r ast

Control Knob

Lock Release Lever

Fusing Unit

Power Switch

Right Door Lock

Release Leve r

Total Counter

Toner Bottle

Toner Bottle Holder

PC Unit

G-12

Duplex Unit

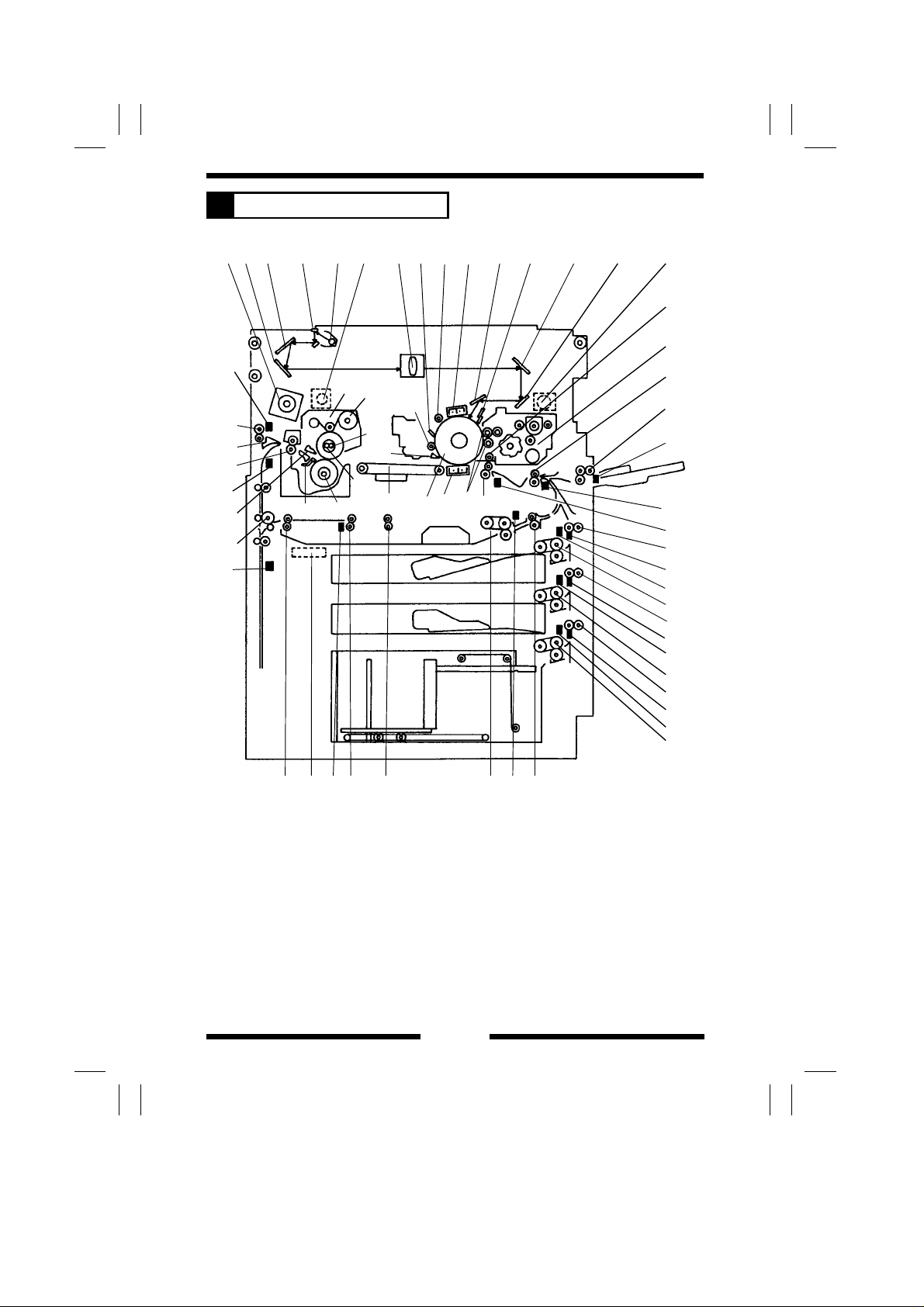

CROSS-SECTIONAL VIEW

1

36

35

34

E

33

37

F

32

56 7

27

28

29

25

30

31

26

10 11 12 1314

923 4 1615

8

22

23

24

20

21

17

19

18

A

B

C

44

I

J

45

46

K

L

47

48

M

N

49

1

D

G

4038 39 434241

H

1075M096AA

M-1

1. Optical Section Cooling Fan

Motor M17

2. 3rd Mirror

3. 2nd Mirror

4. 1st Mirror

5. Exposure Lamp LA1

6. Fusing Unit Ventilation Fan

Motor M8

7. Lens

8. Pre-Cleaning Erase Lamp LA5

9. Cleaning Blade

10. Main Erase Lamp LA2

11. PC Drum Charge Corona

12. 6th Mirror

13. 4th Mirror

14. Image Eras e Lamp LA 3

15. 5th Mirror

16. Toner Suction Fan Mot or M20

17. Developing Unit

18. Manual Bypass Take-Up Roll

19. Transport Roller

20. Synchroniz ing Roller

21. Pre-Image Transfer Erase

Lamp LA4

22. 1st and 2nd Sl eeve/Mag net

Rollers

23. Image Transfer/Paper

Separator Coronas

24. PC Drum

25. PC Drum Paper Separator

Finger

26. Suction Uni t

27. Fusing Unit

28. Web Roller

29. Upper Fusin g Rolle r Ma in

Heater La mp H1

30. Upper Fusin g Rolle r Sub

Heater La mp H2

31. Lower Fusing Roller Heater

Lamp H3

32. Lower Fusin g Paper Separator

Finger

33. Upper Fusin g Paper Se pa ra tor

Finger

34. Fusing Unit Transport Roller

35. Exit/Duplexing Switching Plate

36. Paper Exit Roller

37. Turnover/Paddles Roller

38. Turnover Drive Roller

39. Ventilation Fan Motor M19

40. Gate 2 Transport Roller

41. Gate 1 Transport Roller

42. Duplex Paper Take-Up Roll

43. Duplex Vertical Transport Roller

44. Vertical Transport Roller 1

45. 1st Drawer Paper Take-Up

Section

46. Vertical Transport Roller 2

47. 2nd Drawer Pa pe r Take-Up

Section

48. Vertical Transport Roller 3

49. 3 rd Drawer Pa per Take -Up

Section

- Misfeed Sensors -

A. Manual Feed P aper Empty

Sensor PC28

B. T ran spor t Roll er Sens or PC2 6

C. Paper Leading Edge Sensor

PC27

D. Paper Exit Sensor PC36

E. Transport Feed Sensor PC37

F. Duplex Unit Turnover Path

Sensor PC39

G. Duplex Unit Paper Entry

Sensor PC38

H. Duplex Unit Paper Take-Up

Sensor PC40

I. Vertical Transport Sensor 1

PC10

J. 1st Drawer Paper Take-Up

Sensor PC6

K. Vertical Transport Sensor 2

PC11

L. 2nd Drawer Paper Take-Up

Sensor PC7

M. Vertical Transport Sensor 3

PC12

N. 3 r d D r awer Pa per Take- Up

Sensor PC8

M-2

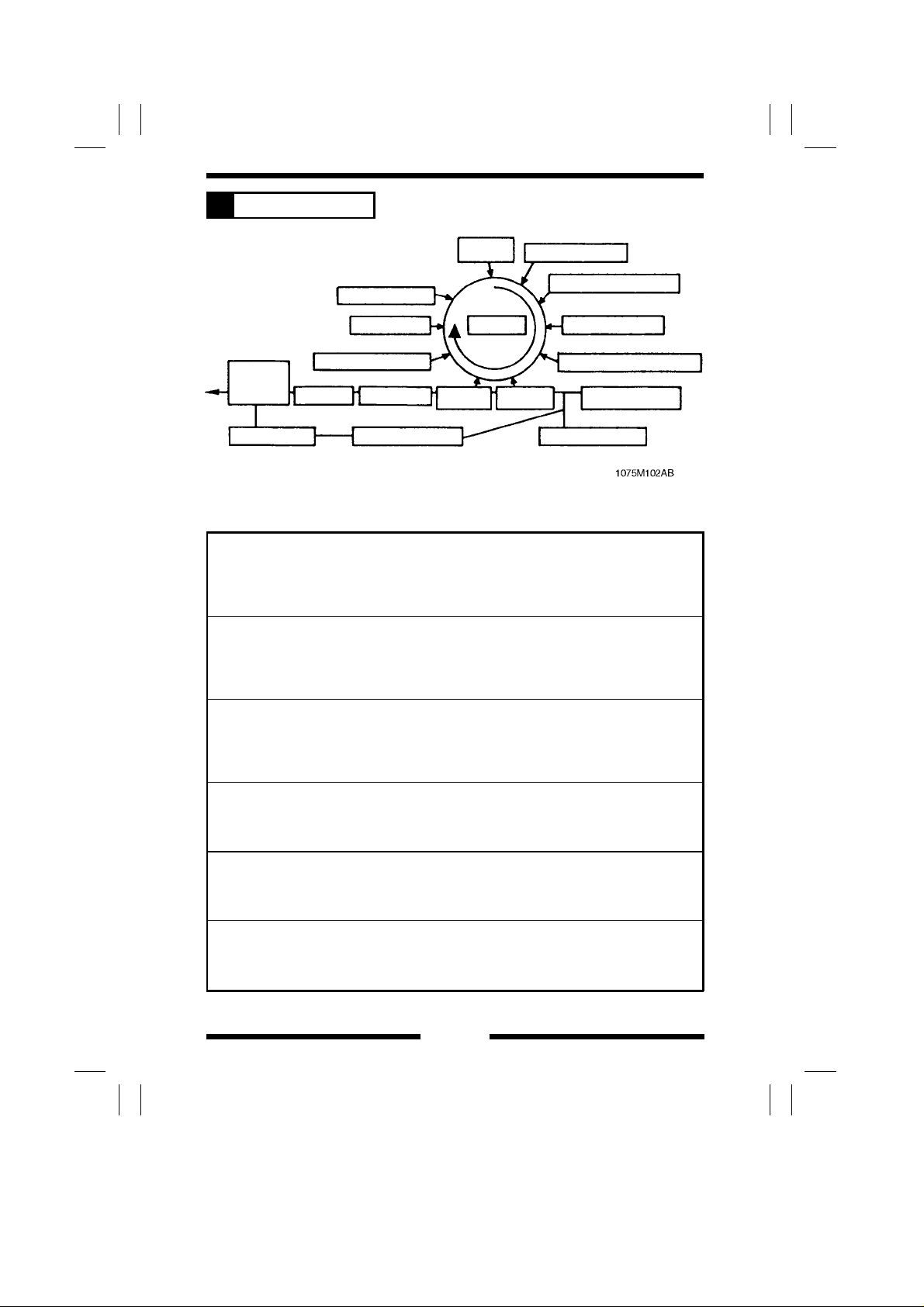

COPY PROCESS

2

15.

EXIT/DUPLEX

SWITCHING

16. TURNOVER

12. MAIN ERASE

11. CLEANING

10. PRE-CLE ANING ERASE

14. FUSING

13. TRANSPORT

17. DUPLEX UNIT

2. DRUM

CHARGING

1. PC DRUM

9. PAPER

SEPARATION

8. IMAGE

TRANSFER

3. EXPOSUR E

4. IMAGE ERASE

5. DEVELOPING

6. PRE-IMAGE TRANSFER ERASE

7. MULTI BYPASS

TABLE

7. PAPER FEEDING

1. PC Drum

The PC Drum is an aluminum cylinder coated with a photosensitive semiconductor.

It is used as the medium on which a visible developed image of the original is

formed.

(For more details, see p. M-25.)

2. Drum Charging

The PC Drum Charg e Co rona U nit is equipped with two corona wires a nd Scor otron

Grids to deposit a uniform negative charge across the entire surface of the PC

Drum.

(For more details, see p. M-28.)

3. Exposure

Light from the Exposure Lamp reflected off th e original is guided to the surface of

the PC Drum and reduce s the level of the negative charges, thereby forming an

electrostatic latent image.

(For more details, see p. M-34.)

4. Image Erase

Any areas of charge which are not to be developed are neutralized by lighting up

LEDs.

(For more details, see p. M-62.)

5. Developing

Toner positively charged in the Dev el oper Mixing Chamber is attracted ont o the

electrostatic latent image changing it to a visible, developed image.

(For more details, see p. M-69.)

6. Pre-Image Transfer Erase

Light from the Pre-Image Transfer Erase Lamp striking the surface of the PC Drum

improves image transfer and paper sep aration efficien cy.

(For more details, see p. M-93.)

M-3

7. Paper Feeding

Paper is fed from each drawer or Multi Bypas s Table.

(For more details, see p. M-95.)

8. Image Transf er

The single-wire Image Tr ans fer Corona Unit applies a DC negative corona e missio n

to the underside of the paper, thereby attracting toner onto the surface of the paper.

(For more details, see p. M-143.)

9. Paper Separation

The single-wire Paper Separator Corona Unit applies an AC corona emission [AC +

DC(+) bias voltage] to the underside of the paper to neutralize the paper.

(For more details, see p. M-143.)

In addition, mechanical paper separation is provided by the three PC Drum Paper

Separator Fingers.

(For more details, see p. M-155.)

10. Pr e-Cleani ng Erase

Light from the Pre-Cleaning Erase Lamp striking the surf ace of the PC D rum

reduces surface potential, thereby preventing toner accumulated on the back of the

Cleaning Blade fro m stickin g to the sur face of the PC Drum.

(For more details, see p. M-154.)

11. Cl eaning

Residual toner on the surface of the PC Drum is scraped off by the Cleaning Blade

and conveyed to the Tone r Collec ting Bottle.

(For more details, see p. M-150.)

12. Main Erase

Light from the Main Erase Lamp neutralizes any surface potential remaining on the

surface of the PC Drum after cleaning.

(For more details, see p. M-160.)

13. Tr ansport

The paper is fed to the Fusing Unit by the Suction Belts.

(For more details, see p. M-162.)

14. Fusi ng

The developed image is pe r manently fused to the paper by a combination of heat

and pressure applied by the Upper and Lower Fusing Rollers.

(For more details, see p. M-164.)

15. Exit/Duplex Switching

After the fusing process the paper is eit her fed out onto th e Exit Tray o r down into

the turnover mechanism of the Duplex Unit.

(For more details, see p. M-178.)

16. Tur nover

The 1-sided copy is turned over and fed into the Duplex Unit.

(For more details, see p. M-181.)

17. Dup l ex Unit

The 1-sided copies are stored and th en tak en up one by one for th e secon d copy

cycle.

(For more details, see p. M-186.)

M-4

DRIVE SYSTEM

3

7

C

B

4

1

2

A

3

12

13

F

D

5

11

6

G

8

9

10

E

14

16

15

M-5

A = Fusing Motor M6: Drives the Fusing Unit, Paper Exit Roller, and Suction

Belts.

1. Paper Exit Roller drive pulley

2. Fusing Unit drive gear

3. Suction Belt drive gear

B = PC Drum Drive Motor M5: Drives the PC Drum, Developing Unit, and

Toner Conveying Screw.

4. Toner Conv eying S cr ew driv e g ear

5. PC Drum drive coupling pawl A

6. Devel op i ng Un i t dr i ve co upling ge ar 2

C = Scanner Motor M1 1: Dr ives the S ca nner and 2n d / 3 r d M i rr or s Carriage.

7. Scanner dr ive pul ley

D = Tra nsport Mo t or M3: Drives the Transport Ro ller and Multi Bypass

Take-Up mechanism.

8. Mult i By pass Take-Up drive gear

9. Mult i Feed Pape r Take-Up Clutch CL5

10. Tr ansport Roller d r ive gear

E = Sync hronizi n g Mo t or M 4 : D r ives t he Synchronizing Roller

11. Synchronizing Roller drive gear

F = Paper Take-Up Motor M1: Drivers the Paper Take-Up mechanism and

the Duplex Take-Up mechanism.

12. Dup lex Take-Up mech anism drive gear

13. Duplex Unit Paper Take-Up Clutch CL6

14. Paper Take-Up Clut ch for dr awers CL1 to 3

G = Vert i cal Tran sport Motor M2 = D r ives the Vertical Transport Rollers and

Duplex Vertical Transport Rollers.

15. Vertical Transport Roller drive gear

16. Dup lex Vert ical Tr ansport Ro ller dr ive gear

M-6

SEQUENTIAL EXPLANATION

4

A The power cord is plugged into the outlet.

ON

B Power Switc h S 1 i s turned ON .

OFF

ON

ON

ON

Approx. 1 sec.

DC Power Supply 1 PU2 outputs DC24V for dehumidifiers.

ON

Drum Dry Heater H4, Lower Paper

Dehumidifying Heater H5, and Upper

Paper D ehumidi fying Heater H7

ON

Developing Unit Dehumidifying Heater

H6

H4, H5, H7, H6

PU2 outputs DC24V and DC5V.

ON

DC Power Supply Board PWB-C outp uts

DC24V. (DC24V line: ON)

ON

Master Bo ar d PWB-A outpu ts DC4. 7 V and DC12V .

Control panel display

Suction Fan Motor M18 turns at half speed.

ON

Upper Fusing Roller Main/Sub Heater Lamp H1/H2

The Lens is detected at the home position.

The Mirror is detected at the

home position.

The Scanner makes its initial motion.

The Lens is detected at the

full size position.

The Mirror is detected at

ON

Approx.

24 sec.

the full size position.

PC Drum Charge Wire Cleaning Motor / Image

Transf er/Pap er Separat or Charge Wire Cleanin g Motor

M21/M22

OFF

*

Only when Drum

Dehumi dif y i ng S wi tch

S9 and Pape r

Dehumi dif y i ng S wi tch

S10 are ON.

For details, see

OPTICAL SECTION.

M21, M22: Cleaner makes one round tr ip to

clean the wire and stops.

One-Shot Correction mode (For details, see

p. M-24.)

The surface temperature of the Upper Fusing Roller reaches 170°C.

ON

Fusing Motor M6 starts predrive.

➀

M-7

➀

After 85 se c. or

40 sec. or 5 sec.

OFF

M6

ON

Fusing Unit Ventilation Fan Motor M8

= The following sequence is when making a single copy in full size on A4

crosswise fed from the 1st Drawer. =

The Start Key is pressed .

C

(A4 crosswise pape r fed from 1st Drawer , full size, single copy cycle)

ON

M6

Approx.

5 sec.

ON

Paper Take-Up Motor / Vertical Transport Motor / Transport

Motor M1/M2/M3

ON

1st Draw er Paper Take-Up Clutch CL1

*

Timing depends on the surface temperature of the

Upper Fusing Ro ller and the diff erence in surface

temperature between the Upper and Lower Fusing

Rollers when S1 is turned ON.

(For details, see p. M-175.)

ON

PC Drum Drive Motor M5

ON

Developing Bias

ON

Optical Section Cooling Fan Motor / Ventilation Fan

Motor / Toner Suction Fan Motor / Power Supply

Unit Cooling Fan Motor M17/M19/M20/M29

Suction Fan Motor M18 turns at full speed.

Approx. 250 msec.

Approx. 350 msec.

Approx. 400 msec.

Approx. 450 msec.

ON

Image Transfer/Paper

Separator Coronas

Exposure Lamp / Image

Erase Lamp LA1/LA3

ON

Main Erase Lamp LA2

ON

PC Drum Charge Corona

ON

Pre-Image Transfer Erase

Lamp / Pre-Cleaning Erase

Lamp LA4/LA5

Vertical Transport Sensor 1 PC10 is blocked ( L ).

Approx. 60 msec.

Paper Leading Edge Sensor PC27 is bl ocked ( L ).

Approx. 50 msec.

OFF

OFF

CL1, M1

M2, M3

M-8

PWB-A outputs a LOW SCAN signal to Scanner Control

D

Processor Board PWB-J.

The Scanner starts a scan motion.

A LOW Image Leading Edge signal is input to PWB-A.

ON

LA3

Approx. 65 msec.

E PWB-J outputs a LOW TRON signal to PWB-A.

ON

M3/M4

Approx. 120 msec.

OFF

LA3 ... Leading edge erase

ON

Sepa r ator Finger Sol enoid SL6

Approx. 280 msec.

F PWB-J outputs a LOW SCEND signal to PWB-A.

Approx. 200 msec., the SCEND signal goes HIGH.

SCAN signal: H ... The Scanner stops and starts a return motion.

Scanner Reference Position Sensor PC1 is blocked ( L ).

Approx. 50 msec.

Approx. 80 msec.

Approx. 570 msec.

Approx. 690 msec.

Approx. 1,050 m sec.

OFF

LA1

OFF

PC Drum Charge Corona

OFF

Image Transfer/Paper Separator Coronas

OFF

LA4/LA5

OFF

LA2/LA3

M5

Approx. 1,350 msec.

OFF

Developing Bias

OFF

SL6

M-9

The trailing edge of the paper moves past Transport Roller Sensor PC26

G

(unblocked: H ).

Approx. 144 msec.

The trailing edge of the paper moves past Paper Leading Edge Sensor

H

PC27 (unblocked: H ).

Approx. 90 msec.

The trailing edge of the paper moves past Paper Exit Sensor PC36

I

(unblocked: H ).

Approx. 600 msec.

Approx.

4,600 msec.

OFF

M3

OFF

Synchronizing Motor M4

OFF

M6

OFF

M17/M19/M20/M29

M18 turns at half speed.

M-10

WATCHDOG (CPU OVERRUN MONITOR) FUNCT ION

5

5-1. Overview

The wat c hd og f un ct ion monitor s wh et h er a ny of t h e CPU s mo un ted i n th e

copier overrun. If this function detects that a CPU overruns, the copier

automatically resets the CPU, thereby restarting the logic circuit and

mechanism.

Even if a cop ier CP U oper a tes errati c al l y du e to electri ca l noi se , the r efo r e ,

the copier is able to recover from the faulty condition so that the number of

visits made by the Technical Representati ve for CPU overrun can be

minimized.

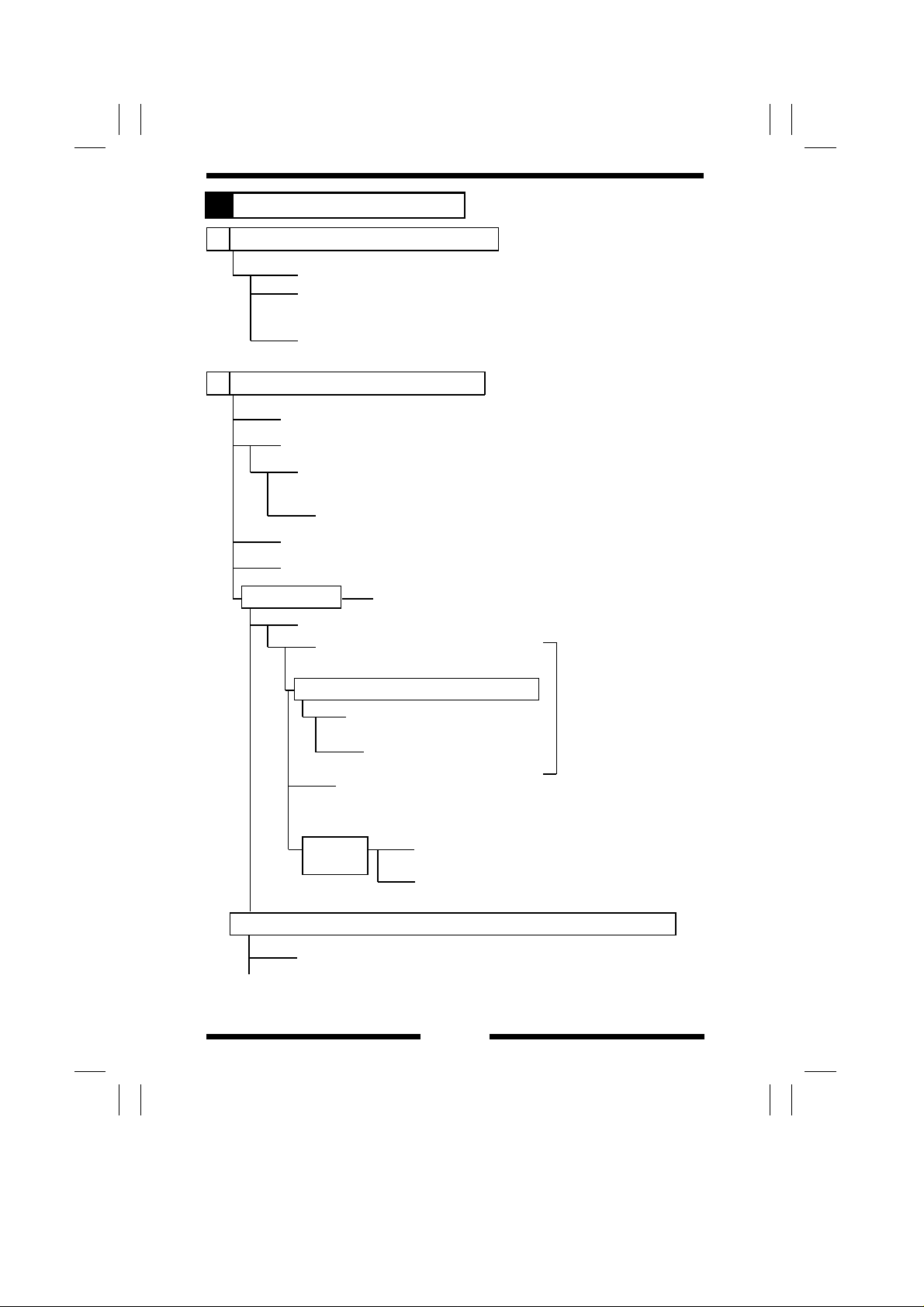

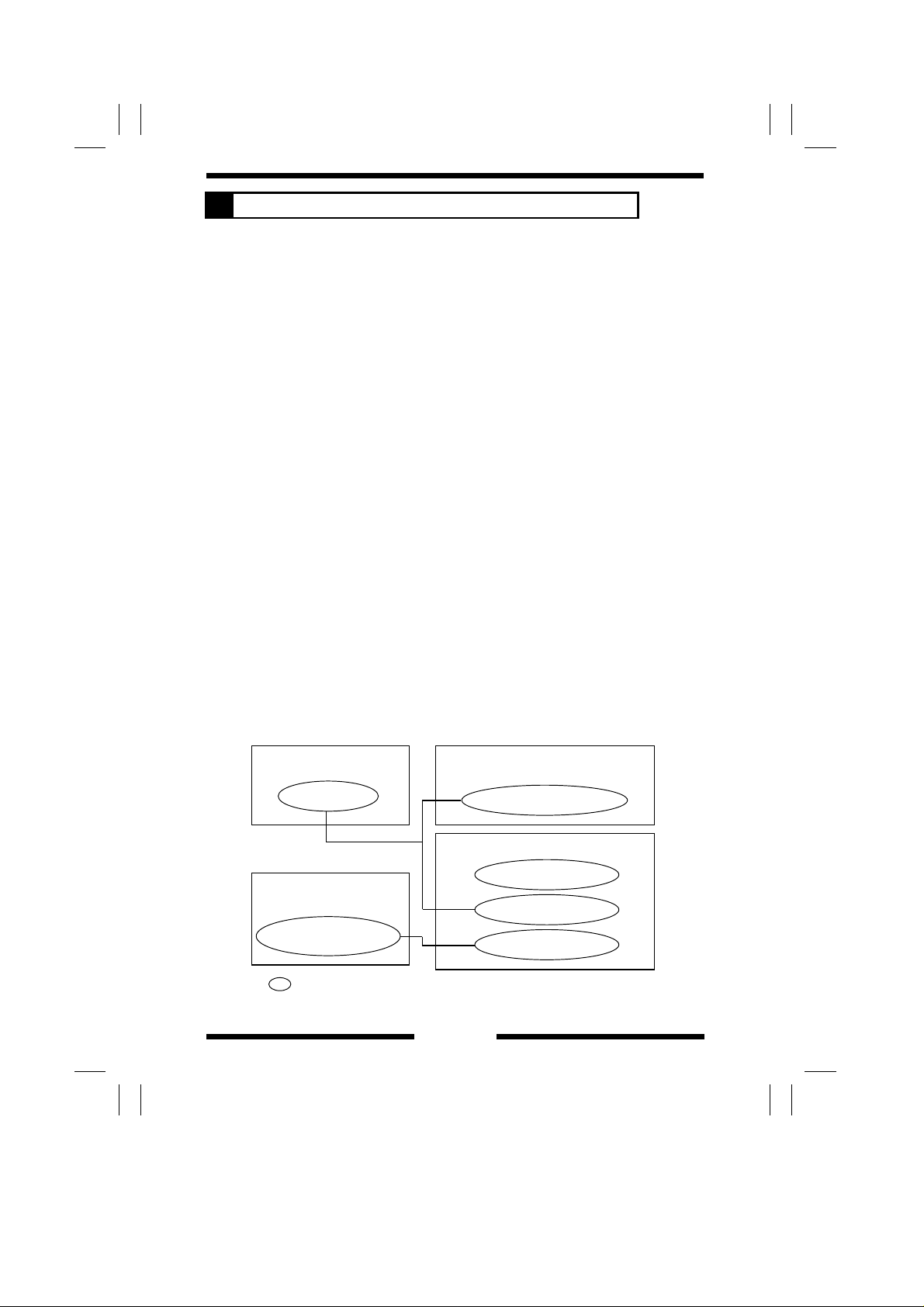

5-2. Configuration

The copier has three print ed-circuit boards each on which a CPU is mounted:

*

SCP (Scanner Control Processor) Board PWB-J that controls the optical

system;

*

MSC (Macro System Controller) Board PWB-B that controls the co ntr ol

panel and system ; and,

*

Master Bo ar d PWB-A .

In addition to these, each of the control boards for the Data Controller,

Duplexi ng Docum ent Feeder, and Sorter/Staple Sorter is equipped with a

CPU.

The watchdog functions are summarized as follows:

*

Each of t he copie r CPUs monitors whethe r or not i t overr uns.

*

The PWB-B monitors the communications conditions of the CPUs in the

Duplexing Document Feeder and Data Controller.

*

The PWB-A monitors the communications conditions of the CPUs in the

Sorter and Staple Sorter.

Data Controller

Control Board

Sorter, Staple Sorter

Control Board (PWB-A)

Board on which a

=

CPU is mounted

Duplexing

Document Feeder

Control Board (PWB-A)

Copier

SCP Board PWB-J

MSC Board PWB-B

Master Board PWB-A

M-11

5-3. Watchdog Funct i on Post-Processing

The following processing is performed if a faulty condition is detected in the

CPU. The Watchdog Counter available from the Tech. Rep. mode allows the

Techn i cal Represe ntati ve to check if any faulty condition has occurred in the

CPU. For details, see SWITCHES ON PWBs.

Faulty CPU Processing (in Standby)

Copier

Sorter,

Staple Sorter

1 : The CPU is autom atically r eset (i.e.,

shutting down power to all CPUs

including those in the op tio ns ) as

soon as a faulty CPU is detected.

1 : When the CPU malfun ct ions, t he

communication to Master Board

PWB-A of the copier is cut o ff or

faulty data is transmitted to the

PWB-A.

2 : The PWB-A detects that the CPU of

the Sorter or Staple Sorter is faulty.

3 : The PWB-A notifies MSC Board

PWB-B that the CPU of the Sorter or

Staple Sorter is faulty.

4 : As commanded by the PWB-B,

Option Relays RY3C and 4C are

turned OFF and ON t o rest art the

option.

5 : The communicat ion line fr om the

CPU of the Sorter or Staple Sorter to

PWB-A is recovered.

6 : PWB-A notifies PWB-B that the CPU

of the Sorter or Staple Sorter has

recovered from the faulty condition.

Processing

(during Copy Cycle)

1: Same as 1 on the left.

2: Since the paper is left

inside the copier, th e

copier detects a misfed

sheet of paper or two

when power is turned

ON again. If the MSC

CPU is faulty, however,

all paper in line f or the

exit will be ejecte d and

all paper headed to the

duplex will be stored,

before restarting the

CPU.

1 : Same as 1, 2, and 3 on

the left.

2 : The paper take-up

sequence is stopped.

3 : All sheets of paper

being fed through th e

copier are fed out of

the copier.

4 : Same as 4, 5, and 6 on

the left.

M-12

Loading...

Loading...